Preparation method for nickel-base superalloy powder for laser forming

A nickel-based superalloy, laser forming technology, applied in metal processing equipment, transportation and packaging, additive processing, etc., can solve the problems of reducing the quality and performance of formed samples, increasing the production cost of laser forming, complex physical and chemical changes, etc. , to achieve the effects of stable forming performance, low oxygen content, and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

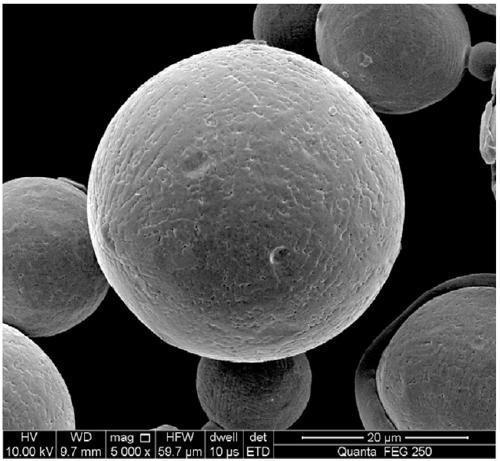

Image

Examples

Embodiment 1

[0049] (1) Alloy smelting: Put 20kg of nickel-based superalloy raw materials into the vacuum induction melting furnace, and put Ti and Zr into the feeding bin (Ti: 0.82kg, Zr: 0.02kg). Close the hatch, vacuumize and reduce the furnace pressure to 10 -1 MPa, for alloy smelting, when heated to 1570 ° C, Ti and Zr are added through the feeding bin. The nickel-based superalloy raw material includes the following components in terms of mass percentage: Ni: 9.97kg, Co: 4.15kg, Cr: 2.7kg, Mo: 0.765kg, W: 0.418kg, Al: 0.72kg, Ti: 0.82 kg, Ta: 0.488kg, Nb: 0.182kg, Zr: 0.02kg, B: 0.06kg, C: 0.008kg.

[0050] (2) Vacuum degassing: After the alloy is completely melted, perform vacuum degassing at 1580°C for 10 minutes.

[0051] (3) Atomized powder making: The completely melted alloy raw material is introduced into the atomizing furnace through the guide tube at a flow rate of 3.5kg / min, the atomization temperature is controlled at 1650°C, the pressure of the powder making furnace is 0....

Embodiment 2

[0068] (1) Alloy smelting: Put 20kg of nickel-based superalloy raw materials into the vacuum induction melting furnace, and put Ti and Zr into the feeding bin (Ti: 0.82kg, Zr: 0.02kg). Close the hatch, vacuumize and reduce the furnace pressure to 10 -1 MPa, heating starts to carry out alloy smelting, when heating to 1570°C, Ti and Zr are added through the feeding bin. The nickel-based superalloy raw material includes the following components in terms of mass percentage: Ni: 9.96kg, Co: 4.13kg, Cr: 2.7kg, Mo: 0.758kg, W: 0.413kg, Al: 0.727kg, Ti: 0.82 kg, Ta: 0.486kg, Nb: 0.182kg, Zr: 0.02kg, B: 0.06kg, C: 0.008kg.

[0069] (2) Vacuum degassing: After the alloy is completely melted, perform vacuum degassing at 1610°C for 5 minutes.

[0070] (3) Atomized pulverization: The completely melted alloy raw material is introduced into the atomization furnace through the guide tube at a flow rate of 4kg / min, the atomization temperature is controlled at 1670°C, the pulverization furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com