Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Smooth particle surface" patented technology

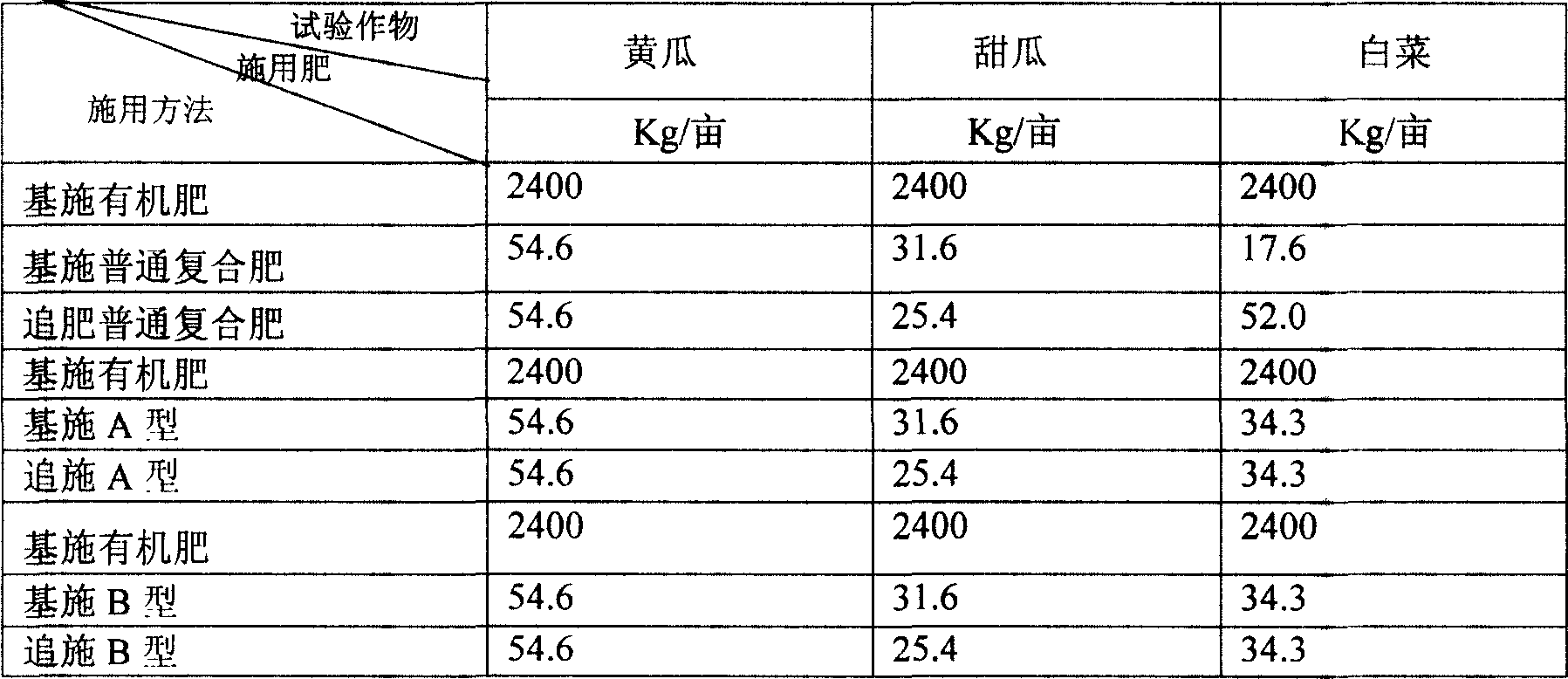

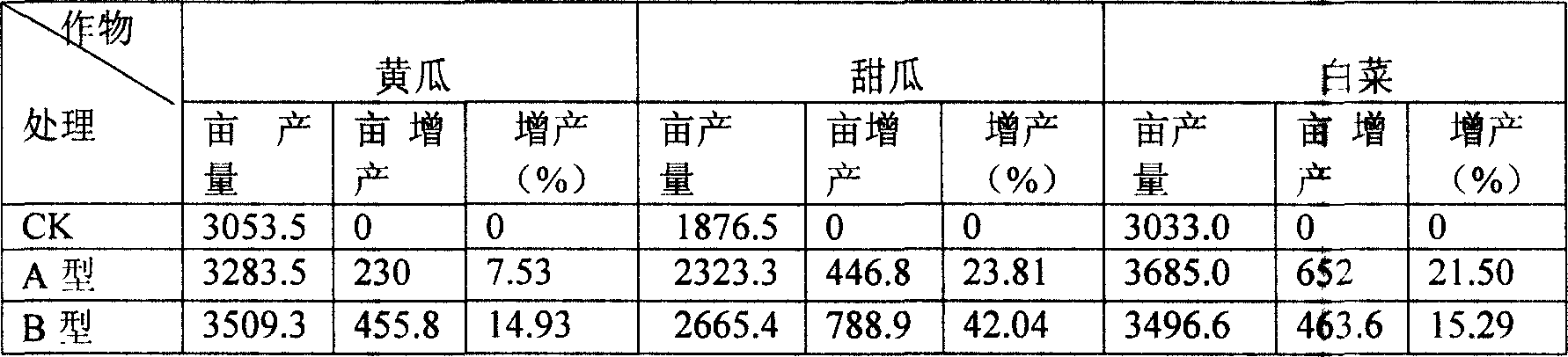

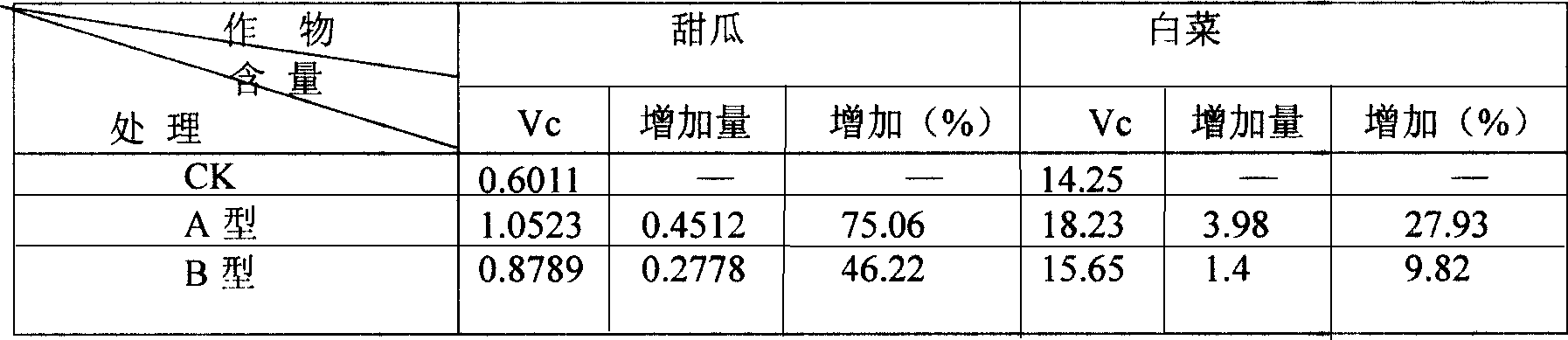

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Humic acid composite material and preparation method thereof

InactiveCN101041600APromote absorptionGood water solubilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorNitrogen

The invention discloses a particle-typed composite fertilizer of humic acid and manufacturing method, which consists of dressing and karyosome, wherein the dressing contains nitrogen, phosphor and potassium. The manufacturing method comprises the following steps: graining humic acid; cladding; graining; solidifying fused fertilizer on the particle of humic acid; making the composite fertilizer dissolved into water without falling; fitting for large scale of agricultural product.

Owner:阴高鹏

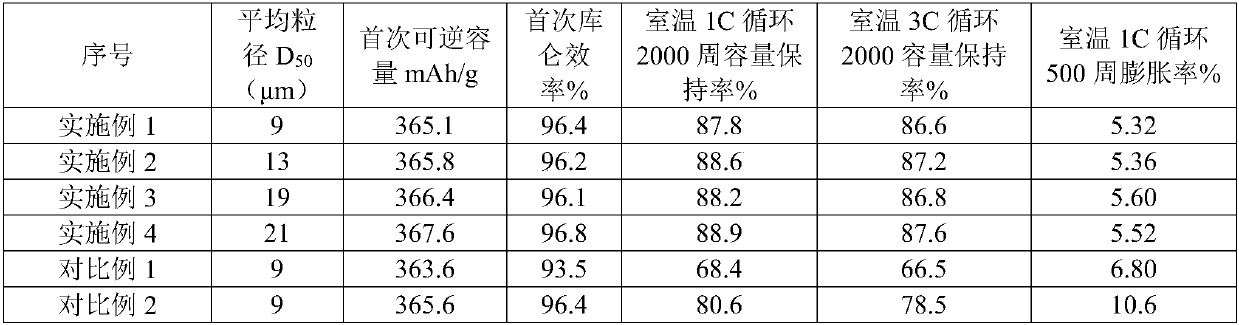

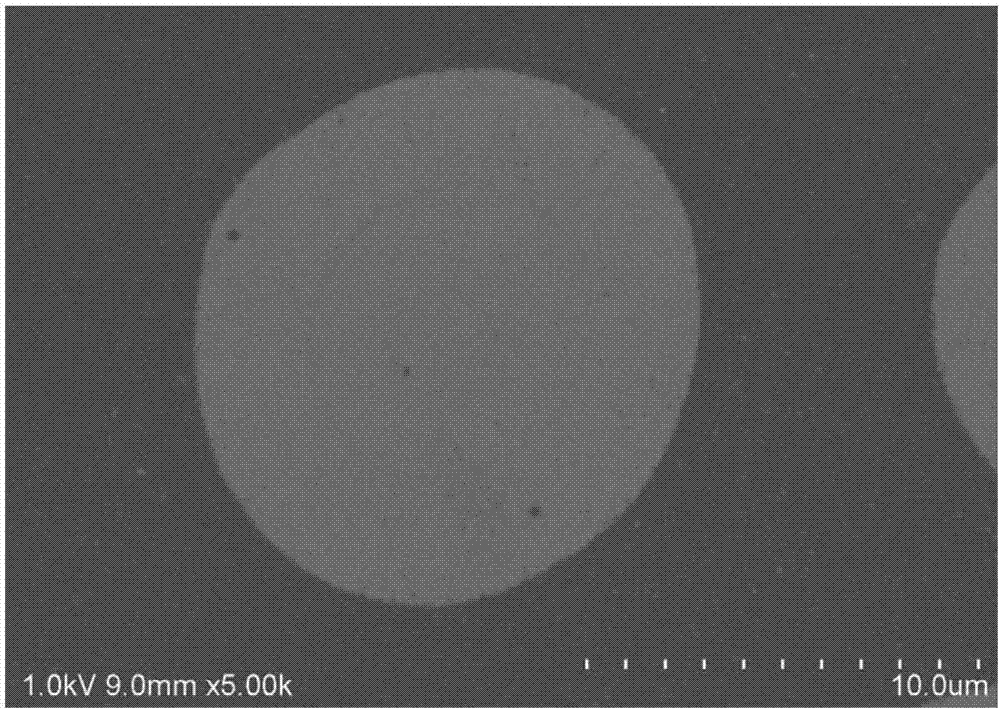

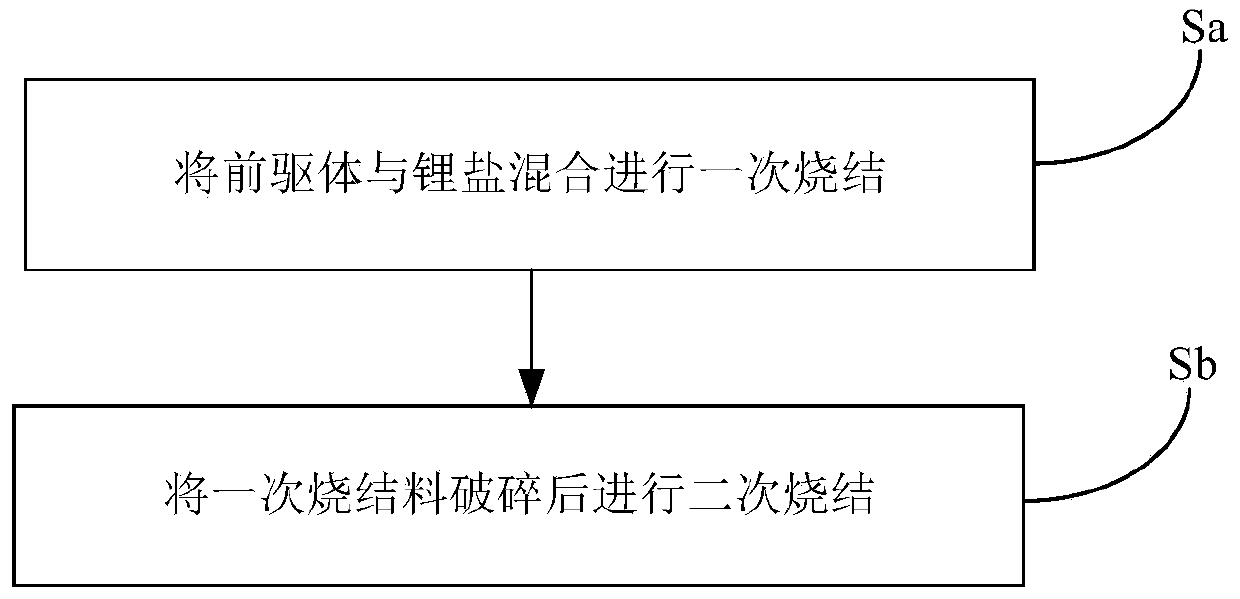

High-nickel ternary positive electrode material with single crystal morphology and preparation method of high-nickel ternary positive electrode material

InactiveCN111463411AIncrease productionImprove product qualitySecondary cellsPositive electrodesDopantPhysical chemistry

The invention discloses a high-nickel ternary positive electrode material with single crystal morphology and a preparation method of the high-nickel ternary positive electrode material. The positive electrode material is formed by a base material and a coating layer, wherein the base material is prepared from a high-nickel ternary precursor, a lithium source and a doping agent; the doping agent comprises a doping element, the doping element is a metal element, the coating layer is formed by a coating material, the coating material comprises a coating element, and the coating element is a metalelement and / or a non-metal element. The positive electrode material is obtained by mixing the high-nickel ternary precursor, the lithium source and the doping agent, performing primary sintering, then mixing with the coating material, and performing secondary sintering. The high-nickel ternary positive electrode material disclosed by the invention has the advantages of single crystal morphology,smooth surface, small specific surface area and high compaction density, and the single crystallization of the high-nickel ternary positive electrode material improves the specific capacity and cycleperformance of the positive electrode material and prolongs the service life of the positive electrode material. The preparation method is simple in process, easy to implement and beneficial to industrial large-scale production.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

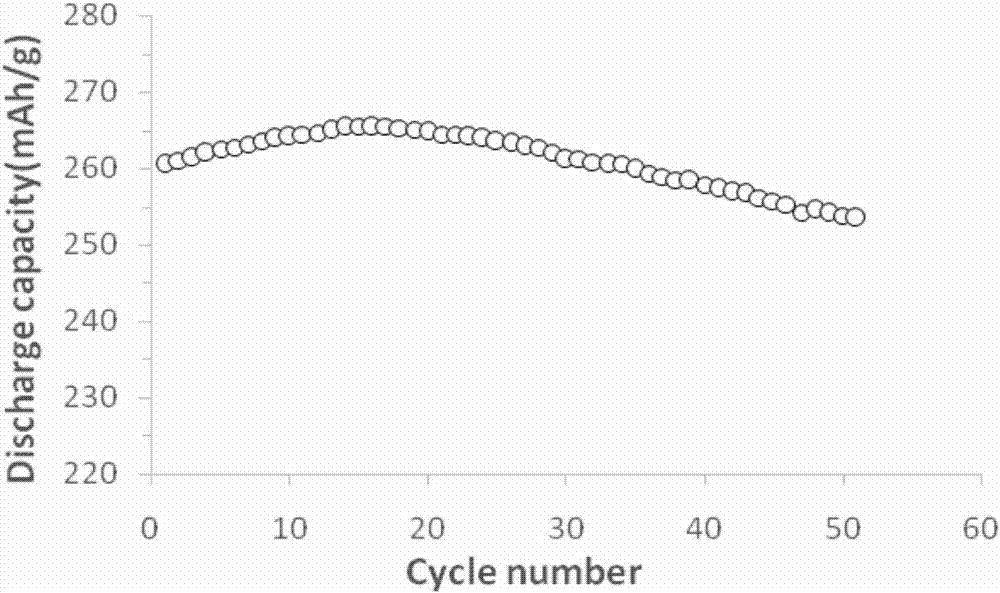

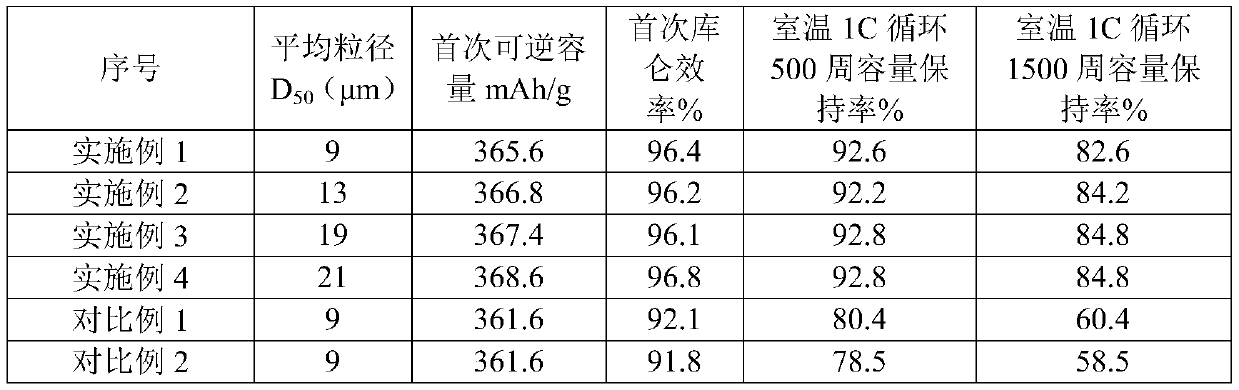

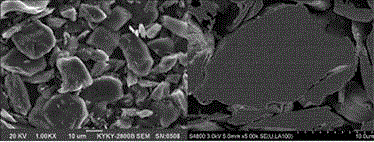

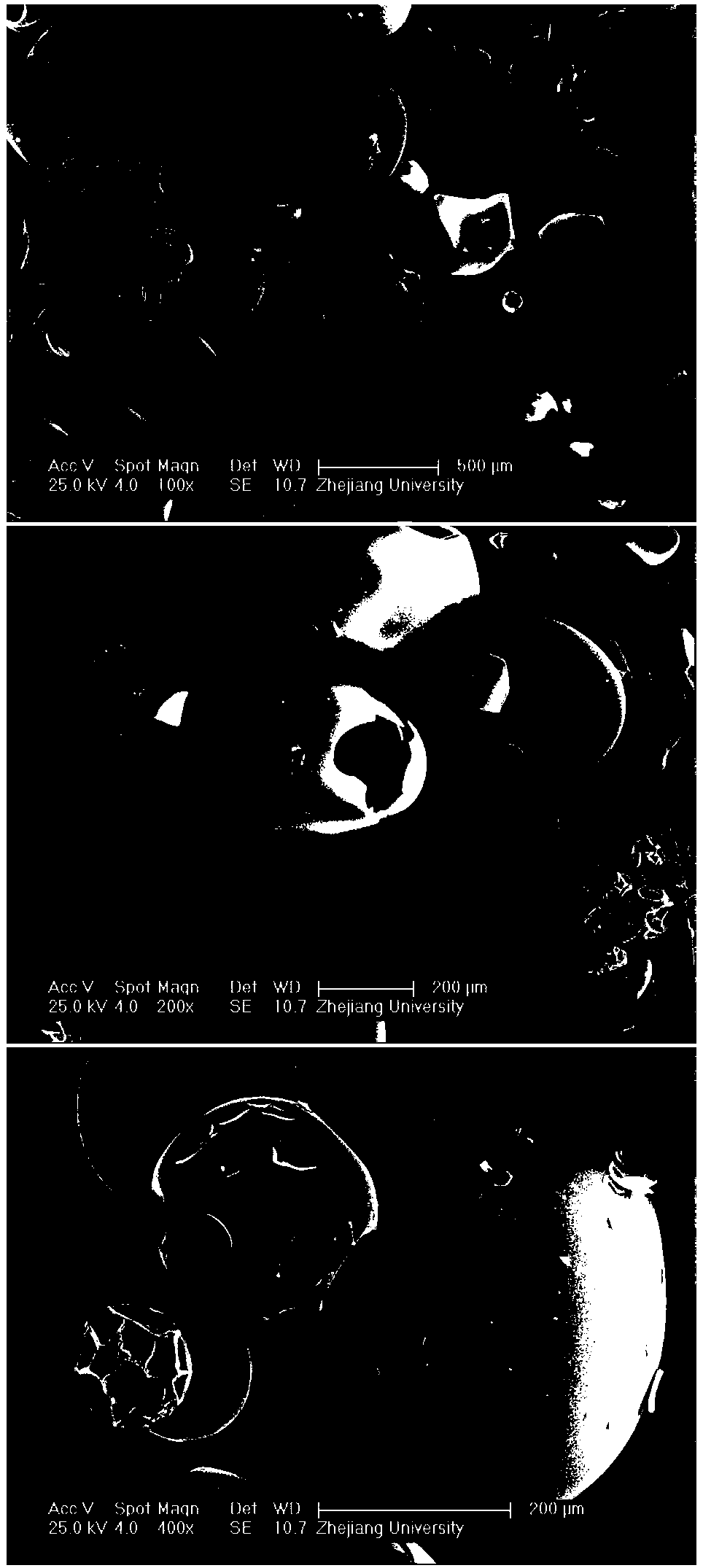

Long-life modified natural graphite cathode material as well as preparation method and use thereof

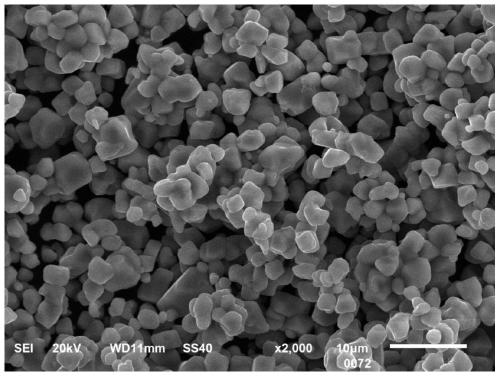

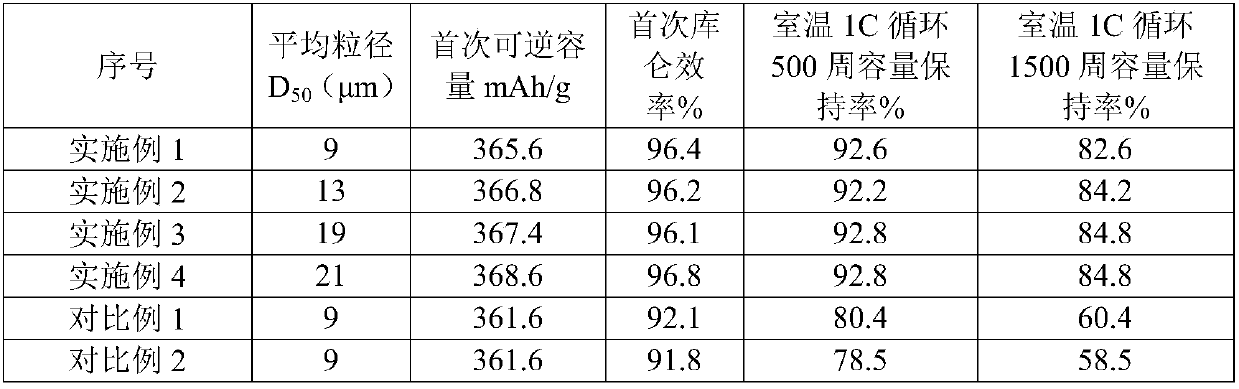

ActiveCN107814382AHigh sphericitySmooth particle surfaceCarbon compoundsCell electrodesFilling rateHigh pressure

The invention discloses a long-life modified natural graphite cathode material as well as a preparation method and use thereof. According to the preparation method, natural graphite powder and asphaltare dipped by virtue of a hot isostatic pressure machine, so that holes in graphite particles can be completely filled with asphalt at high temperature and high pressure conditions; and meanwhile, anasphalt coating layer is formed on the surface of the natural graphite powder, and graphitization is carried out so as to obtain the modified natural graphite cathode material with a core-shell structure, wherein synthetic graphite is embedded into the inside and surface of the natural graphite in situ, the filling rate of the synthetic graphite in the holes of the natural graphite is more than or equal to 94%, the surfaces of the particles are smooth, and the spheroidization degrees of the particles are high. According to the preparation method, the primary coulombic efficiency of the modified natural graphite cathode material is more than or equal to 96%, and the capacity retention ratio of the material after being circulated at a room temperature 1C for 1500 cycles is more than or equal to 80%, so that the prepared material is high in primary coulombic efficiency, long in service life and can be used for replacing synthetic graphite for producing powder battery cathode materials, and the cost is greatly lowered. The preparation method is simple in preparation process and low in cost and has relatively high practicability.

Owner:GUANGDONG DONGDAO NEW ENERGY +1

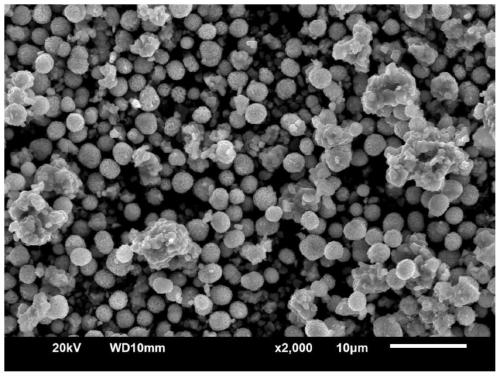

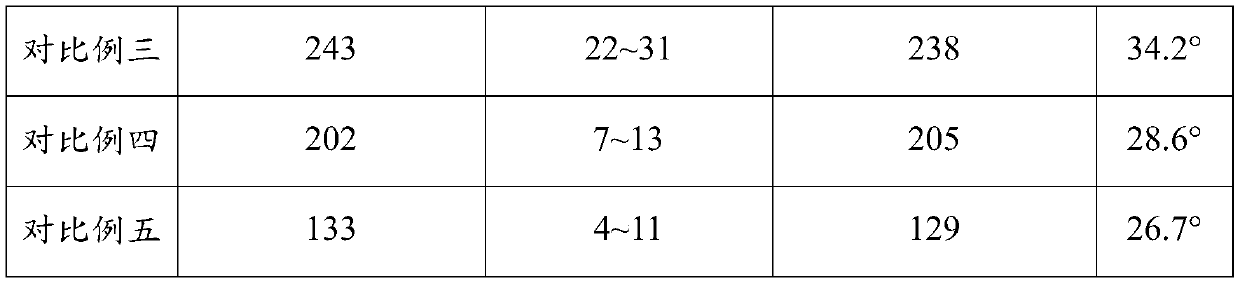

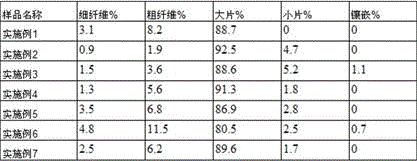

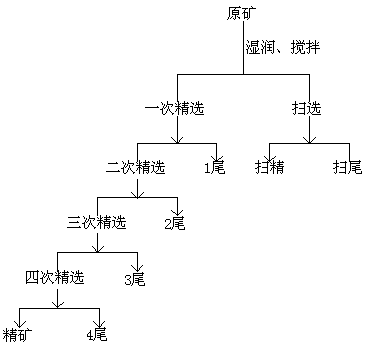

Modified microcrystal graphite cathode material of lithium ion battery as well as preparation method and application thereof

ActiveCN107814383APreserve structural propertiesHigh sphericityGraphiteCell electrodesSodium-ion batteryLithium-ion battery

The invention relates to the technical field of lithium ion battery carbon cathode materials and in particular to a modified microcrystal graphite cathode material of a lithium ion battery as well asa preparation method and application thereof. The material has the advantages that (1) a modified core-shell structured natural graphite cathode material with artificial graphite embedded into and onthe surface of natural graphite in situ is prepared, the overall structural properties of natural microcrystal graphite are maintained, pores of the natural microcrystal graphite is filled with the artificial graphite, and the outer surface of the natural microcrystal graphite is wrapped by the artificial graphite; (2) compared with a conventional cathode material, the cathode material prepared byusing the method provided by the invention is good in isotropy, is capable of inhibiting and absorbing expansion of electrodes in the charge and discharge process, is high in primary coulombic efficiency, long in service life and good in high-magnification charge and discharge performance and is capable of replacing artificial graphite to manufacture cathode materials of power batteries, so as tolower the cost greatly; and (3) the method is simple in preparation process, low in cost and relatively high in practicability.

Owner:GUANGDONG DONGDAO NEW ENERGY +1

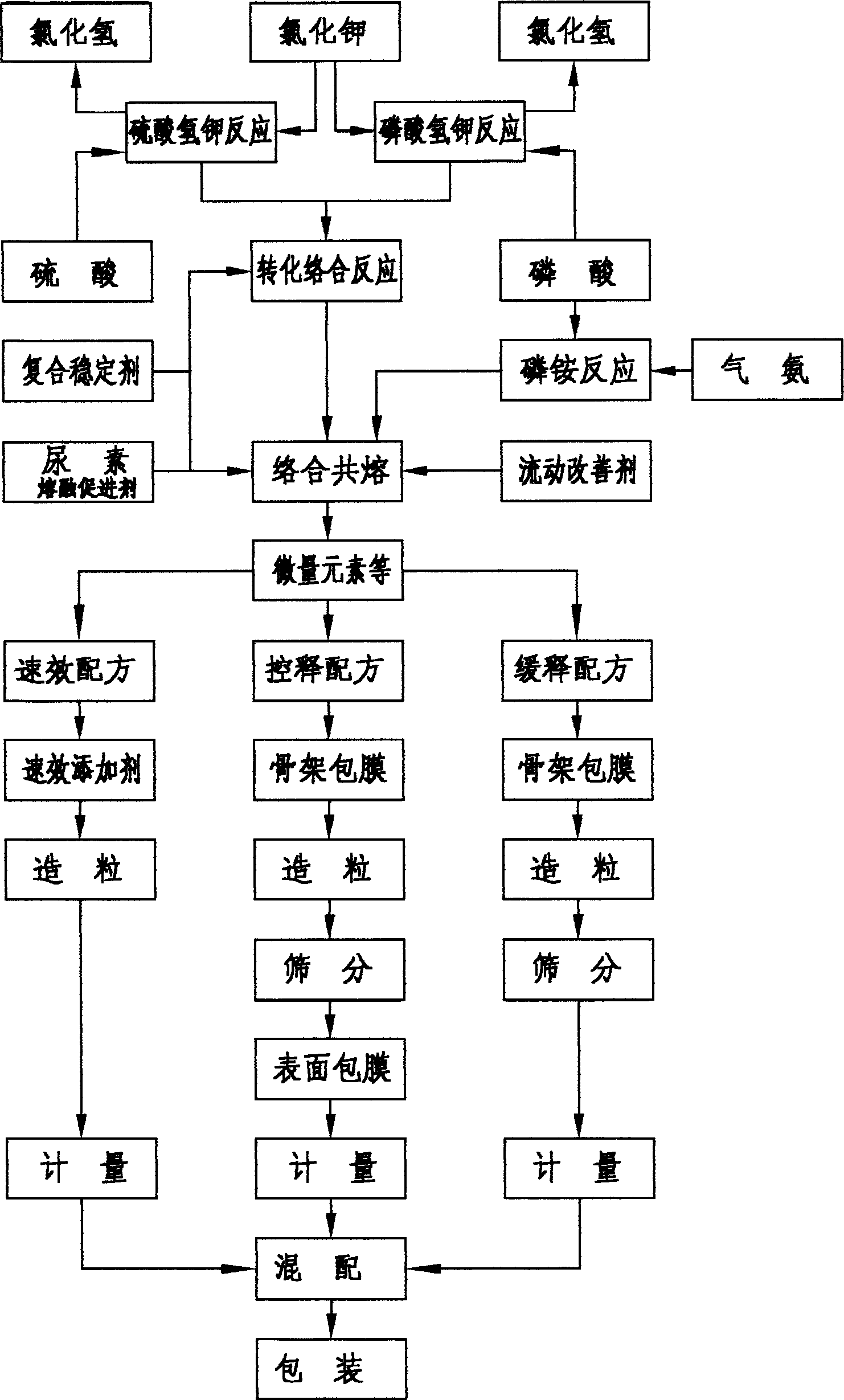

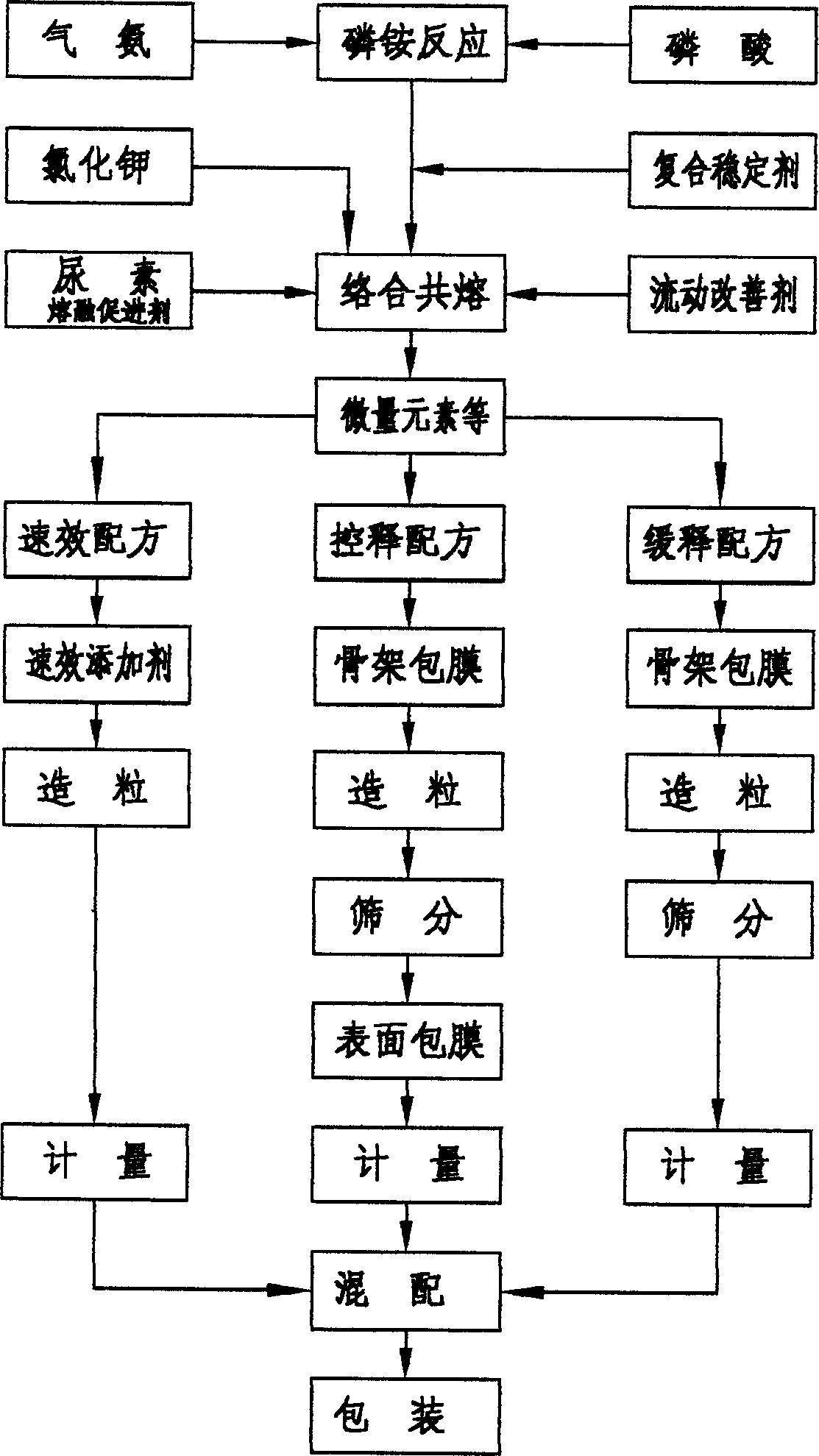

Nutrient released modle of compound controlled releasing and production thereof

InactiveCN1644568AWide range of choicesAdjustable release rateFertilizer mixturesPhosphoric acidSlurry

A controlling and releasing composite fertilizer nutrient releasing model and production are disclosed. The production is carried out by potassium chloride reacting with phosphoric acid and concentrated sulfuric acid, recovering hydrogen chloride, two products reacting, adding urine to obtain mixed slurry of potassium sulfate and urea phosphate, adding stabilizer and flowing-performance improver, reacting with urea to obtain ammonium phosphate mixing melt in melting boiler, regulating NPK proportion, adding functional additive, combing releasing mechanism with instant releasing, frame slow releasing and surface controllable releasing, granulating, coating, computing fertilizer proportion, and obtaining controllable releasing composite fertilizer. Its advantages include low cost, regulating releasing period and no environmental pollution.

Owner:周端午

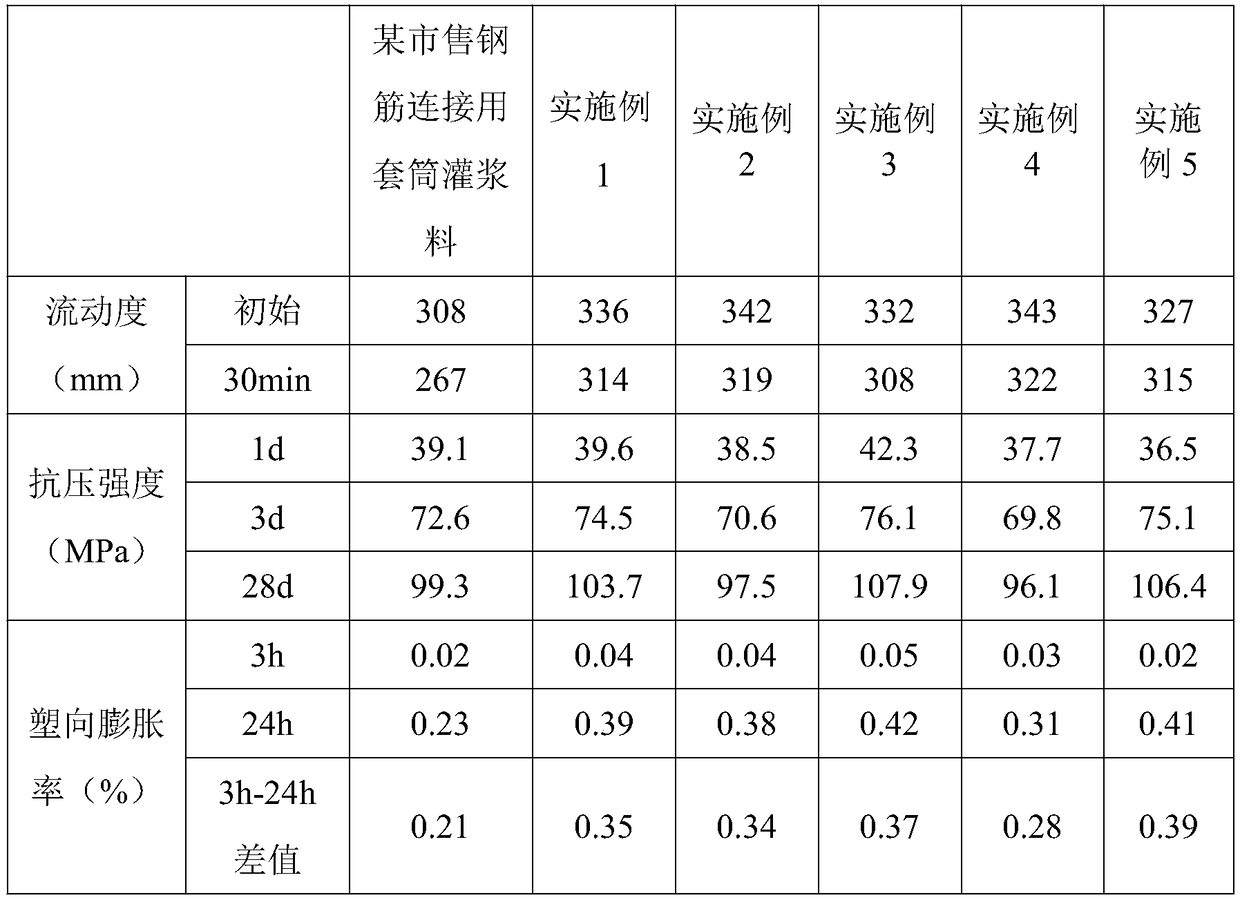

High-fluidity sleeve grouting slurry for rebar connection and preparation method thereof

The invention belongs to the field of building materials and particularly discloses a high-fluidity sleeve grouting slurry for rebar connection and a preparation method thereof. The grouting slurry isprepared from the following materials in parts by weight: 390-410 parts of cement, 90-110 parts of admixture, 460-500 parts of sand, 0.05-0.07 part of a water-retaining agent, 1.4-1.6 parts of a de-foaming agent, 6-8 parts of a compound water reducer, 40-50 parts of compound retarder, 35-40 parts of a compound expanding agent, 7-10 parts of a compound early strength agent and 135-145 parts of water. The preparation method for the grouting slurry comprises the steps of proportionally weighting the raw materials and uniformly stirring in a certain stirring manner. The sleeve grouting slurry forrebar connection prepared according to the invention is high in fluidity and can solve the problems of more insufficient initial fluidity or lower surplus initial fluidity and poorer fluidity holdingability than those of standard slurry of the present sleeve grouting slurry for rebar connection in practical engineering application.

Owner:成都宏基建材股份有限公司

Production method of granule type composite microbial agent and product thereof

InactiveCN101274862ASuitable for fertilizationHigh strengthAmmonium salt fertilisersOrganic fertilisersChemical reactionMicrobial agent

The invention provides a production method for a granular composite microbial inoculant, which comprises the following steps: 65 to 80 weight percent of powdery composite microbial inoculant, 5 to 30 weight percent of an adhesive and 5 to 15 weight percent of carbamide or mixture of carbamide and ammonium hydrogen carbonate are weighed; the materials are then mixed, granulized by adding with water, dried, cooled and sieved to be made into the granular composite microbial inoculant. As the granular composite microbial inoculant obtained by adopting the production method of the invention does not bond or react with various fertilizers when in mixing, the granular composite microbial inoculant is suitable for mechanical fertilizing.

Owner:北京世纪阿姆斯生物技术有限公司

PEPSET resin moulding and sand cyclic utilization clean casting technology

ActiveCN103934411AFast and uniform curingLower regenerationFoundry mouldsMould handling/dressing devicesProcess engineeringRaw material

The invention relates to a PEPSET resin moulding and sand cyclic utilization clean casting technology. The technology comprises the following steps: using raw materials to carry out PEPSET resin sand moulding: putting a sand core into a mould cavity, closing the mould cavity by using an automatic mould closer, then casting with molten iron; shaking out the sands after the moulding of product; transferring the old sands into a waste sand regeneration processing system; wherein the regenerated sands can be applied to a cold box core blower to manufacture sand cores, thus the addition amount of new sands is reduced, and the cyclic utilization of old sands is achieved.

Owner:LAIZHOU XINZHONGYAO MACHINERY

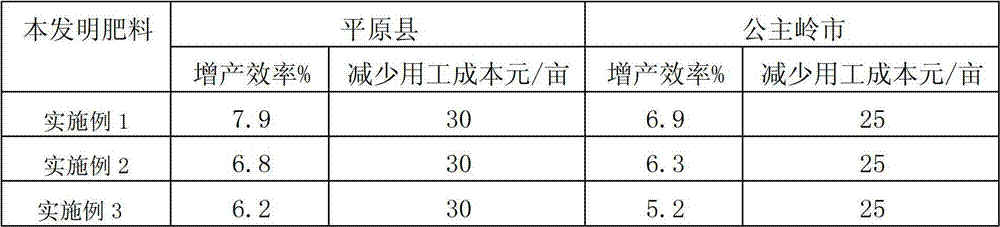

Preparation method of mechanically fertilized controlled-release fertilizer special for winter wheat

The invention relates to a preparation method of mechanically fertilized controlled-release fertilizer special for winter wheat. The preparation method comprises the following steps: taking urea, monoammonium phosphate, potassium chloride and zinc sulfate according to the proportion, granulating by a high tower to obtain granular core fertilizer; spraying urea solution onto the core fertilizer to form a urea film to obtain urea-coated fertilizer; taking epoxy resin and polyurethane, and adding curing agent T31, diluting agent benzyl glycidyl ether and talcum powder, mixing uniformly to obtain an outer film coating agent; spraying the outer film coating agent onto the urea-coated fertilizer to obtain three double-layer coated controlled-release fertilizer varieties I, II and III with the dosage of the outer film coating agent respectively occupying 3%, 5% and 7% of the urea-coated fertilizer; and further compounding according to the proportion to obtain the controlled-release fertilizer. The preparation method provided by the invention prepares the core fertilizer special for the wheat according to absorption requirements of the winter wheat on nutrition such as nitrogen, phosphorus, potassium and zinc; and then the double-layer coating is adopted, wherein an inner film improves surface characteristics of the fertilizer granules, and an outer film controls the nutrition release, so that controlled-release fertilizer is suitable for the nutrition absorption of the winter wheat and is suitable for mechanical fertilization.

Owner:菏泽金正大生态工程有限公司

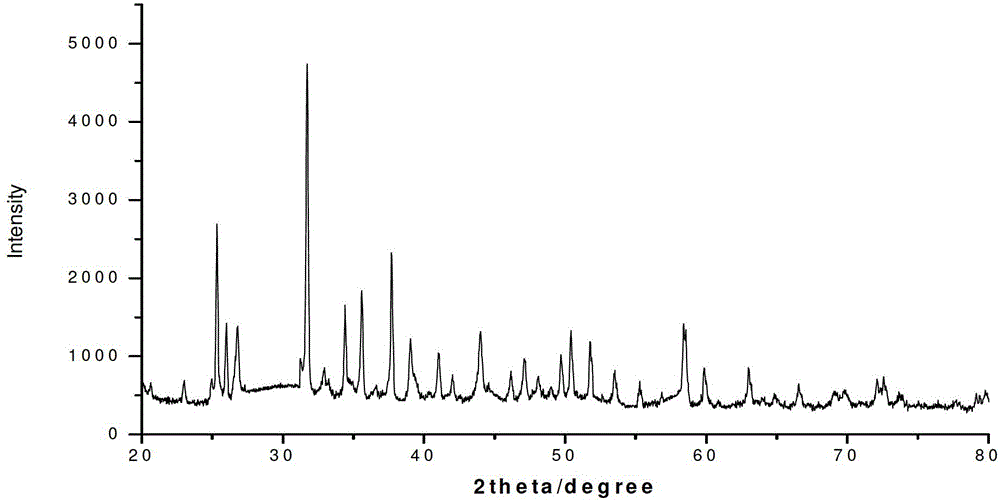

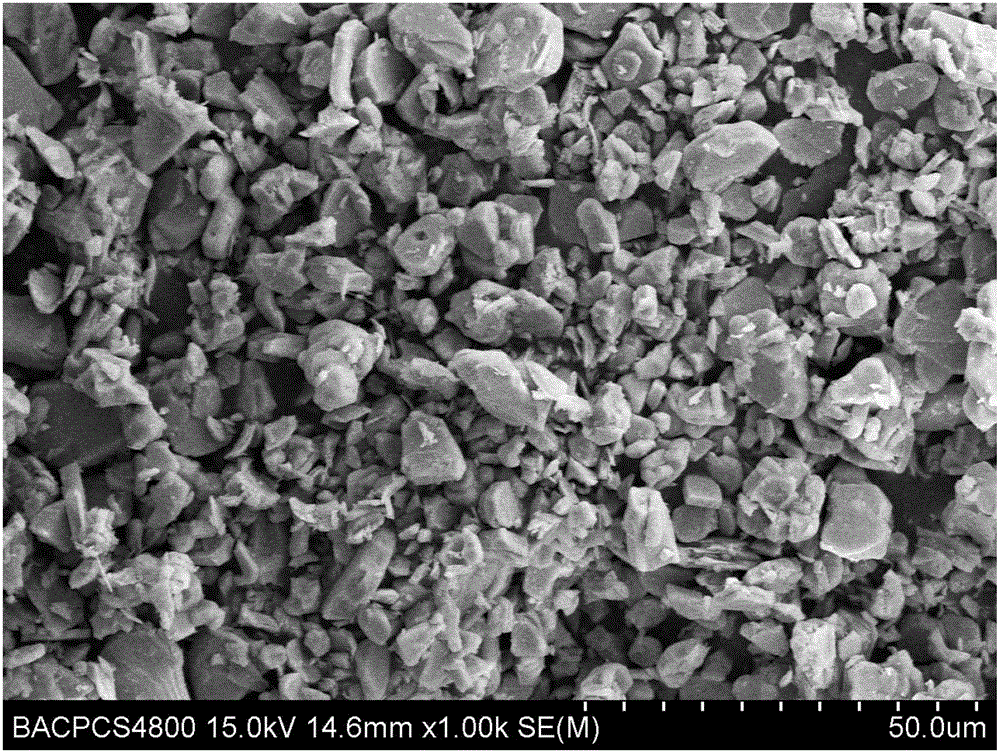

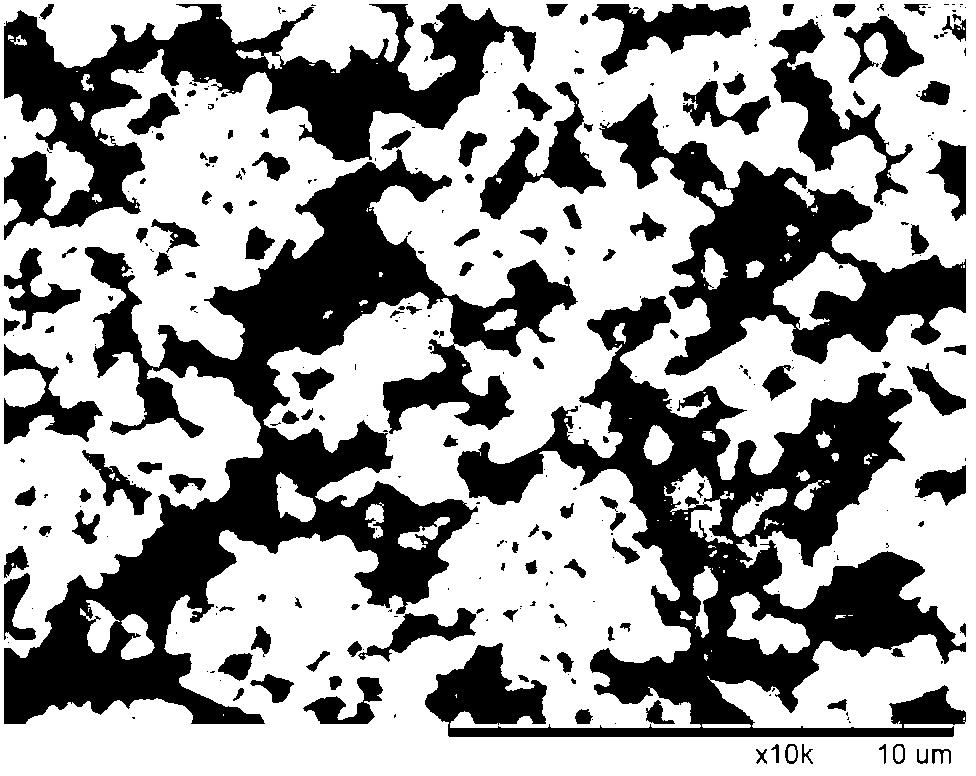

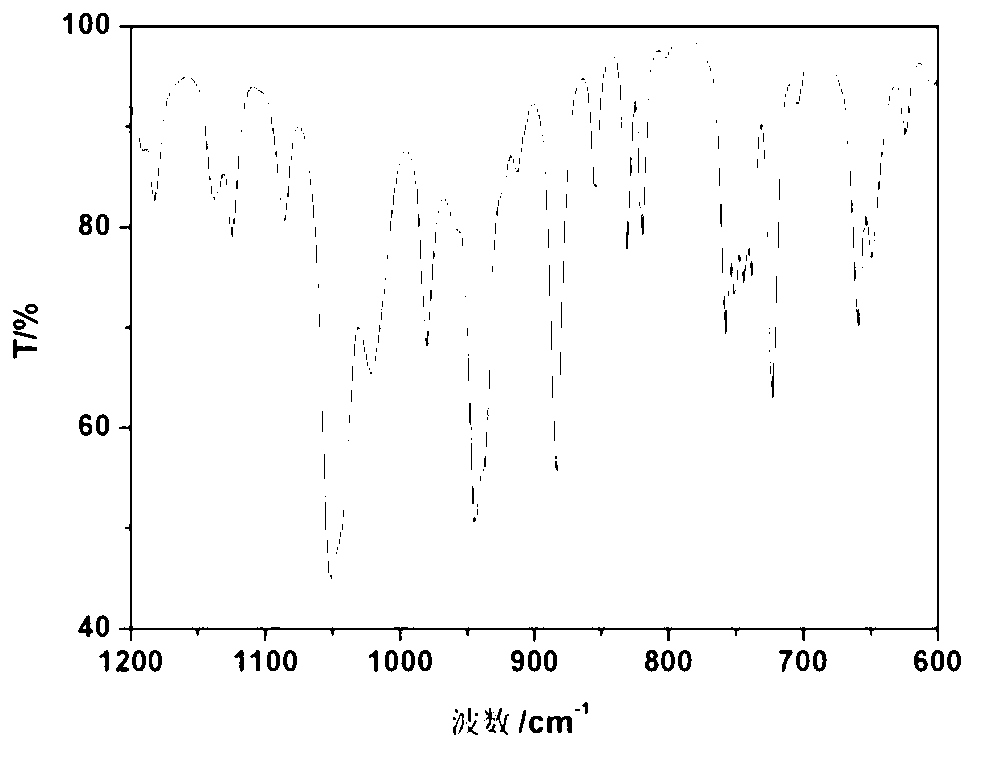

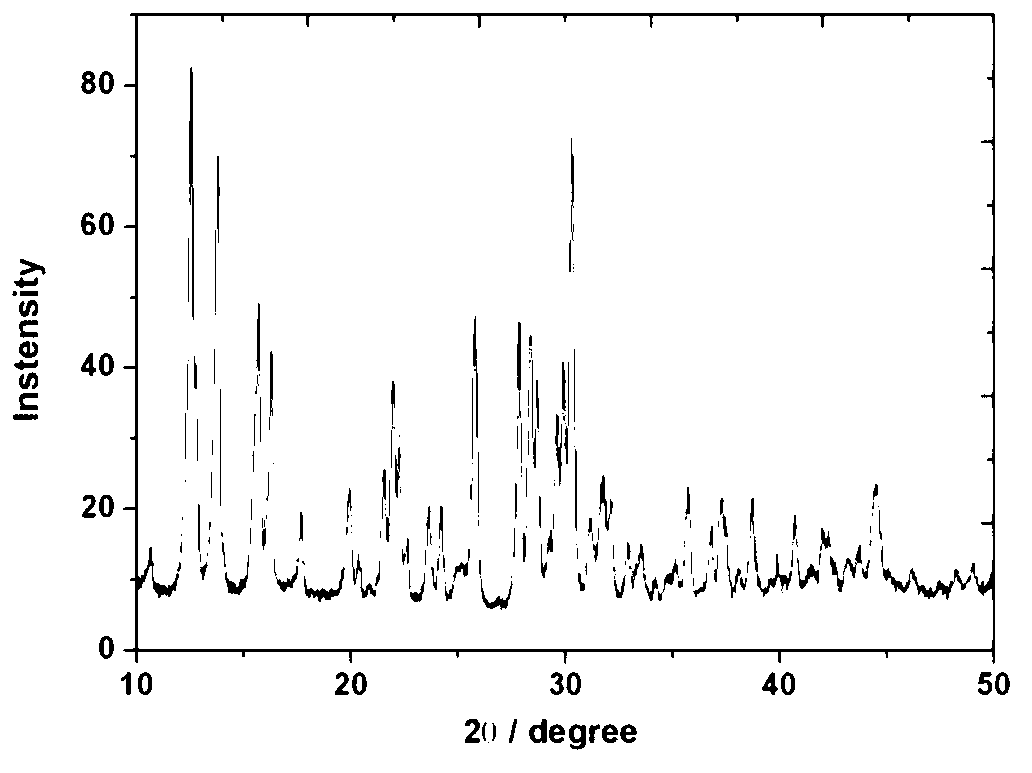

Nitrogen oxide phosphor powder and synthesis method thereof

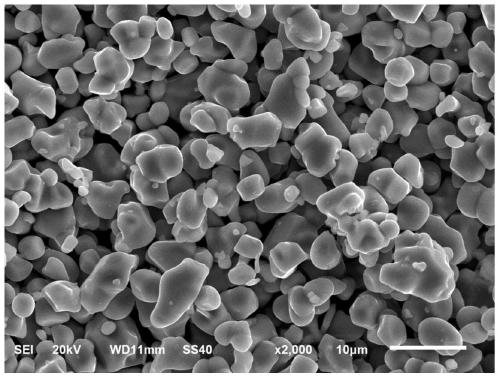

InactiveCN102911659ALarge particle sizeSmooth particle surfaceGas discharge lamp usageLuminescent compositionsCrystal morphologySynthesis methods

The invention relates to a nitrogen oxide phosphor powder and a synthesis method thereof. The nitrogen oxide phosphor powder is characterized in that the general chemical formula of the nitrogen oxide phosphor powder is Al-xByOzN2 / 3+4 / 3y-2 / 3z: xRE, wherein X is lager than or equal to 0 and smaller than 1.0, Y is larger than or equal to 1.0 and smaller than or equal to 3, Z is lager than 0 and smaller than or equal to 2.0; A represents at least one element of Be, Mg, Ca, Sr, Ba and Zn; B represents the element Si; and RE represents at least one element of Eu, Ce, Dy and Mn. The invention provides the novel method for preparing the nitrogen oxide phosphor powder for a light emitting diode (LED) by utilizing a two-step synthesis method. By using the novel method, the purity of the nitrogen oxide phosphor powder is increased to a large extent, the sintering temperature of the nitrogen oxide phosphor powder is further improved, crystal morphology of the nitrogen oxide phosphor powder is optimized, a particle surface of the nitrogen oxide phosphor powder is smooth, and the crystallinity is improved, so that the light emitting intensity of the nitrogen oxide phosphor powder is improved.

Owner:IRICO

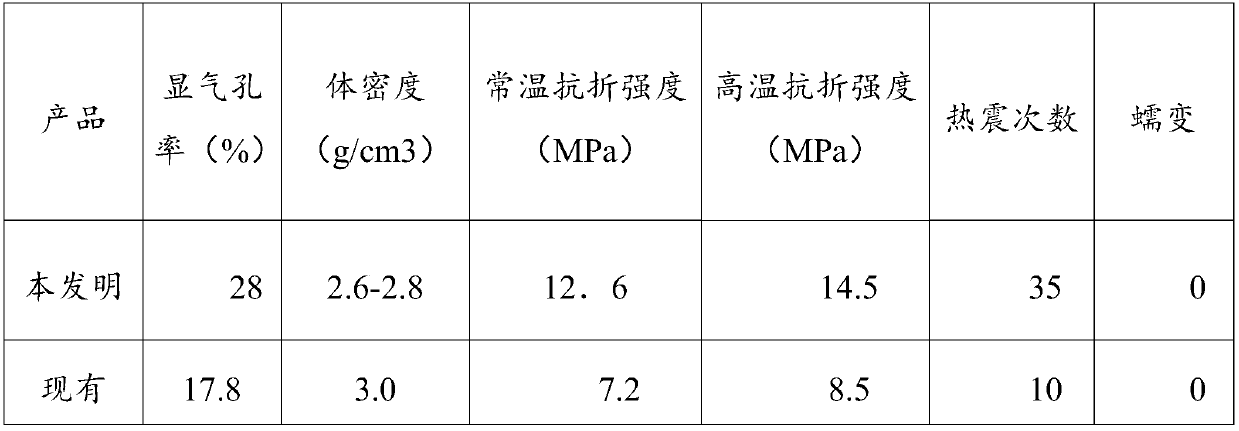

Sagger used for high-temperature firing and preparation method of sagger

The invention relates to a sagger used for high-temperature firing and a preparation method of the sagger. The sagger used for high-temperature firing is formed by performing mixing forming by using aluminum oxide powder, kaolin powder, clay powder, white corundum, quartz and mullite as raw materials and performing high-temperature firing. The sagger used for high-temperature firing provided by the invention has a good thermal shock effect, low costs and long service life, and can maintain the crack resistance, uniformity and quality stability of a product during mass production, and is suitable for use in environments with larger temperature differences; the sagger used for high-temperature firing provided by the invention is produced during high-temperature firing, and compared with a sagger formed by synthesizing quartz and mullite in advance and performing mixing forming on the market, the sagger provided by the invention has a more uniform finished-product phase, better color andthermal shock stability, and a small phase thermal expansion coefficient, thereby having extremely high thermal shock stability; and the quartz is added, so that the thermal shock performance can be improved.

Owner:山东莱科陶瓷材料有限公司

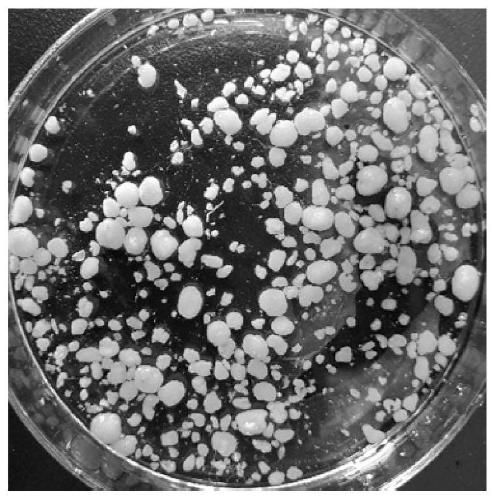

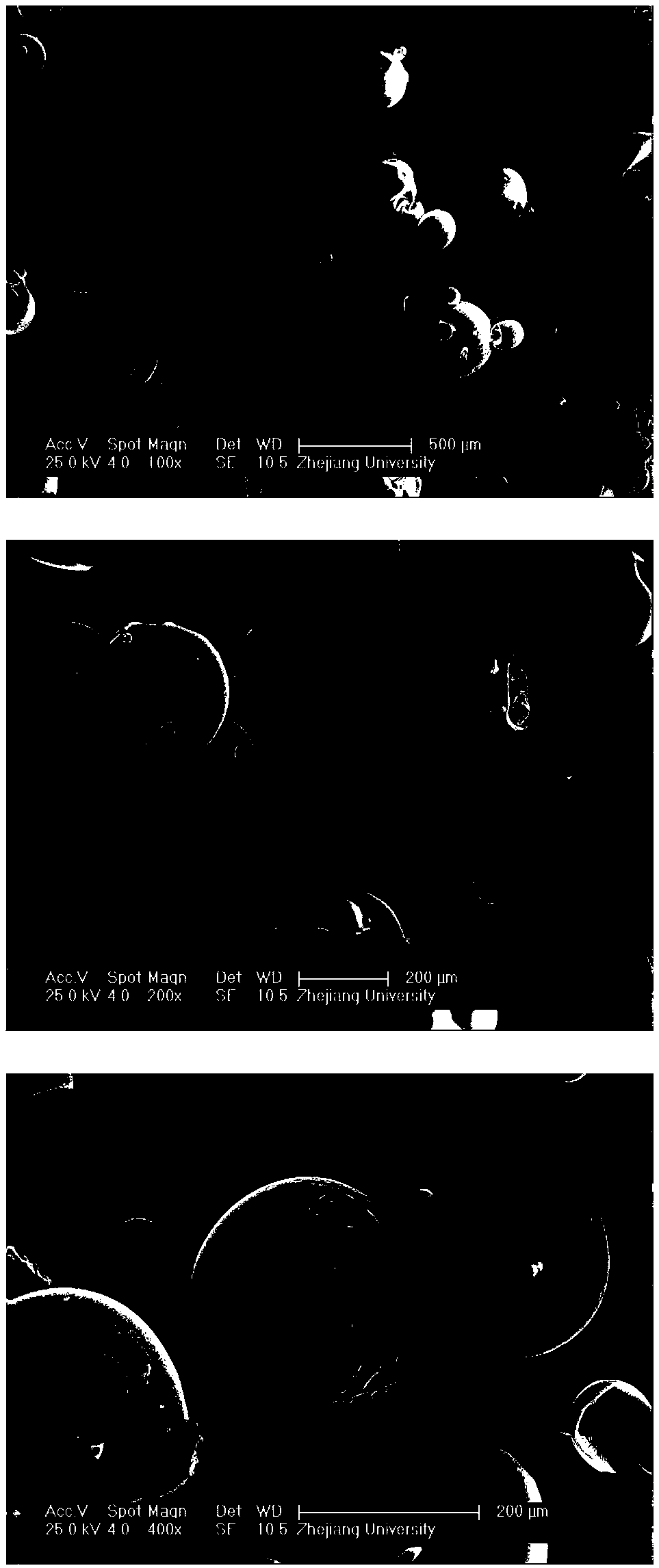

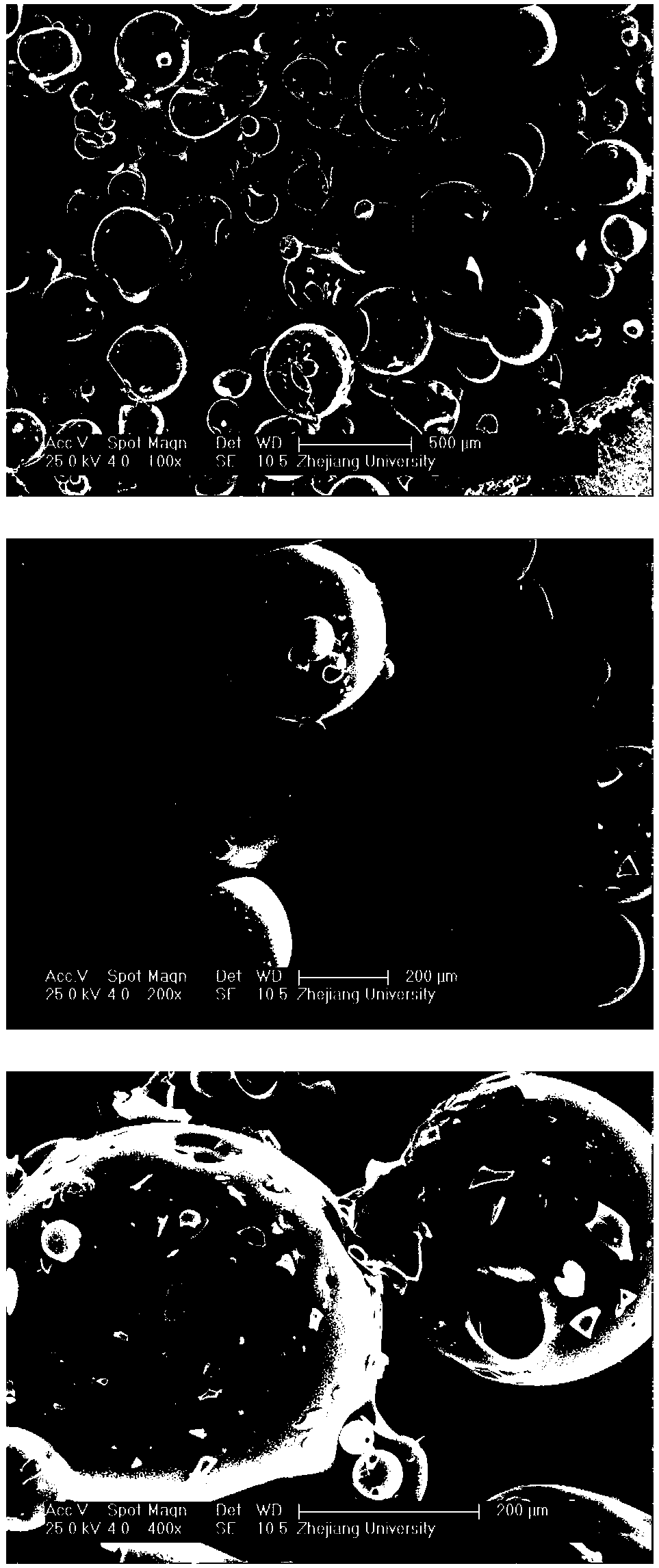

Preparation method for spherical aluminum oxide powder

InactiveCN107117635AEvenly distributedGood shape rateAluminium oxide/hydroxide preparationWater basedEmulsion polymerization

The invention discloses a preparation method for nano-scale and micro-scale spherical aluminum oxide powder. According to the invention, the manner of combining a sol-gel technology with an emulsion method is utilized to prepare the spherical aluminum oxide; a water-based aluminum sol is used as a main raw material; an organic reagent is used as a dispersion medium; the spherical aluminum oxide is compounded in the manner of water-in-oil emulsion polymerization; the interfacial tension between an oil phase and a water phase is utilized to manufacture a tiny spherical droplet; and the formation of a water-phase sol particle and the gel is limited in the tiny droplet. The raw material components of the spherical aluminum oxide according to the technology are convenient for design; the particle size of the powder is within the scope of 0.5-100mu m and is adjustable; the spheroidization rate is high; the liquidity is excellent; and the dispersion is easy.

Owner:SUZHOU NANODISPERSIONS

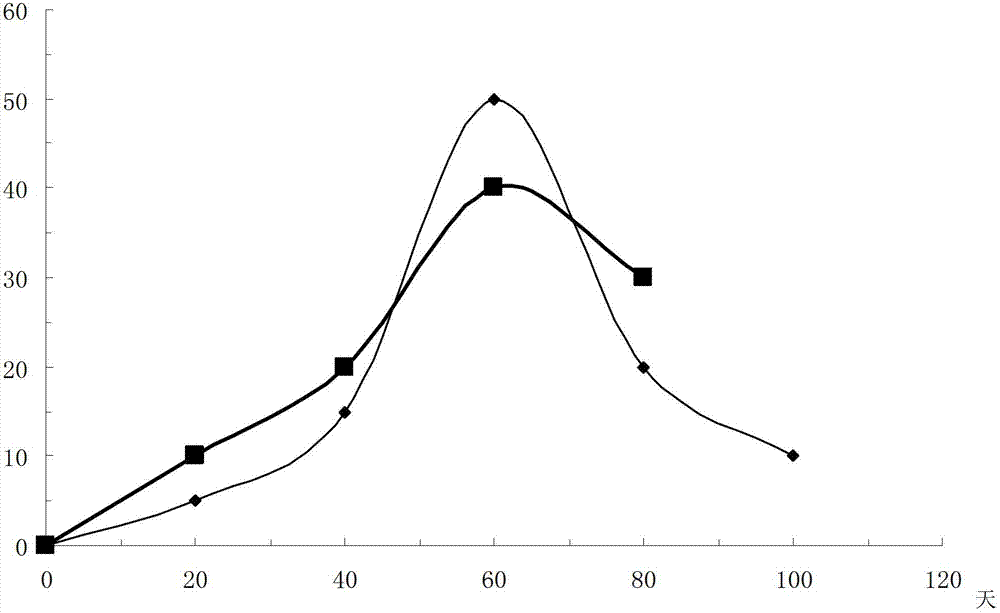

Method for using signal molecules for accelerating repair of disintegrated aerobic granular sludge

PendingCN109987698AImprove hydrophobicityAccelerated structural repairWater treatment parameter controlSustainable biological treatmentSignalling moleculesSludge

The invention relates to a method for using signal molecules for accelerating repair of disintegrated aerobic granular sludge. According to the method for using the signal molecules for accelerating repair of the disintegrated aerobic granular sludge, by adding the exogenous AHLs signal molecules to repair the disintegrated the aerobic granular sludge, in a process of repairing structures of the disintegrated aerobic granular sludge, regranulation of the crushed granular sludge is accelerated, after 20-30 days, the disintegrated aerobic granular sludge is basically and completely repaired, therepaired aerobic granular sludge is smooth in particle surface, regular in shape and compact in structure, and has good settling performance, after adding of the exogenous AHLs is stopped, the granular sludge structures are still intact, and the settling performance and the granule density remain at high levels. According to the method for using the signal molecules for accelerating repair of thedisintegrated aerobic granular sludge, by adding the exogenous AHLs temporarily, an excellent repairing effect on the disintegrated aerobic granular sludge is achieved, the repaired granular sludge is intact in structure and good in settling performance, moreover, operation is simple, and practical application is easy.

Owner:SHANDONG UNIV

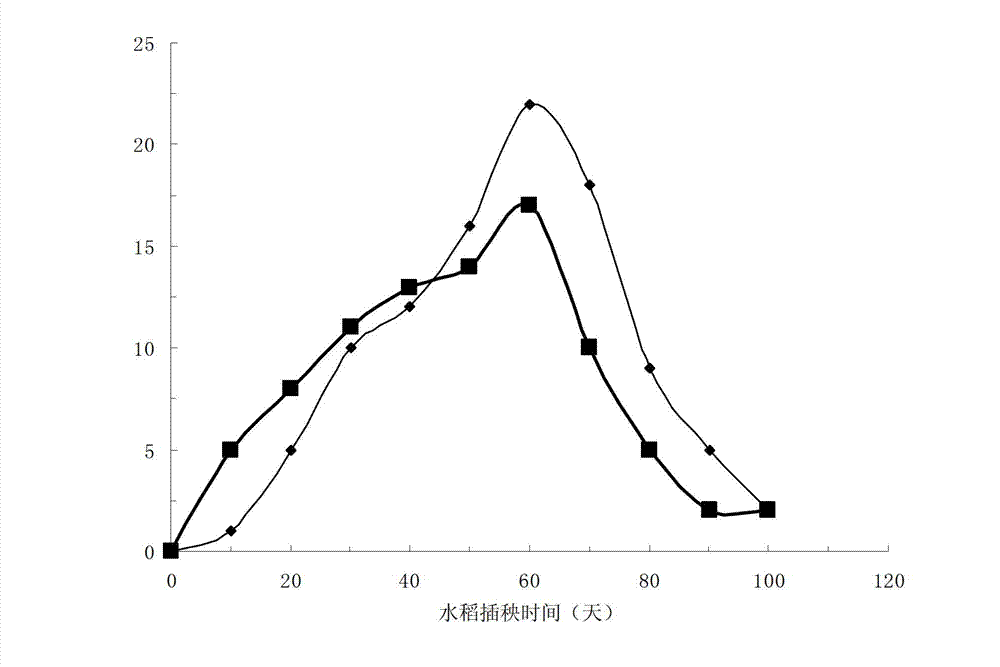

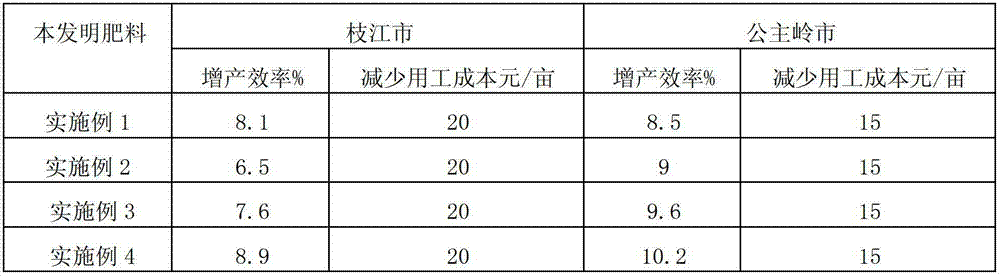

Preparation method for controlled-release fertilizer special for mechanically applied rice

The invention relates to a preparation method for controlled-release fertilizer special for mechanically applied rice. The preparation method comprises the following steps: performing double-layer coating by using high tower pelleting compound fertilizer as core fertilizer to obtain the corresponding double-layer coating controlled-release fertilizer I, double-layer coating controlled-release fertilizer II and double-layer coating controlled-release fertilizer III, wherein the bottom layer urea coating accounts for 4 to 6 weight percent of the core fertilizer, and the outer layer film coating agent accounts for 2 weight percent, 4 weight percent and 6 weight percent of the urea coated fertilizer respectively based on the total weight of the reclaimed polyethylene film resin and the reclaimed polystyrene foam resin; and mixing the double-layer coating controlled-release fertilizer I, the double-layer coating controlled-release fertilizer II and the double-layer coating controlled-release fertilizer III according to the mass ratio of 1:(1-3):(1-2) to obtain the controlled-release fertilizer special for mechanically applied rice. The controlled-release fertilizer special for mechanically applied rice meets the absorption requirements of the rice on nitrogen, phosphorus and potassium nutrients in the growth stage, is difficult to crush and is suitable for mechanical fertilizer application.

Owner:菏泽金正大生态工程有限公司

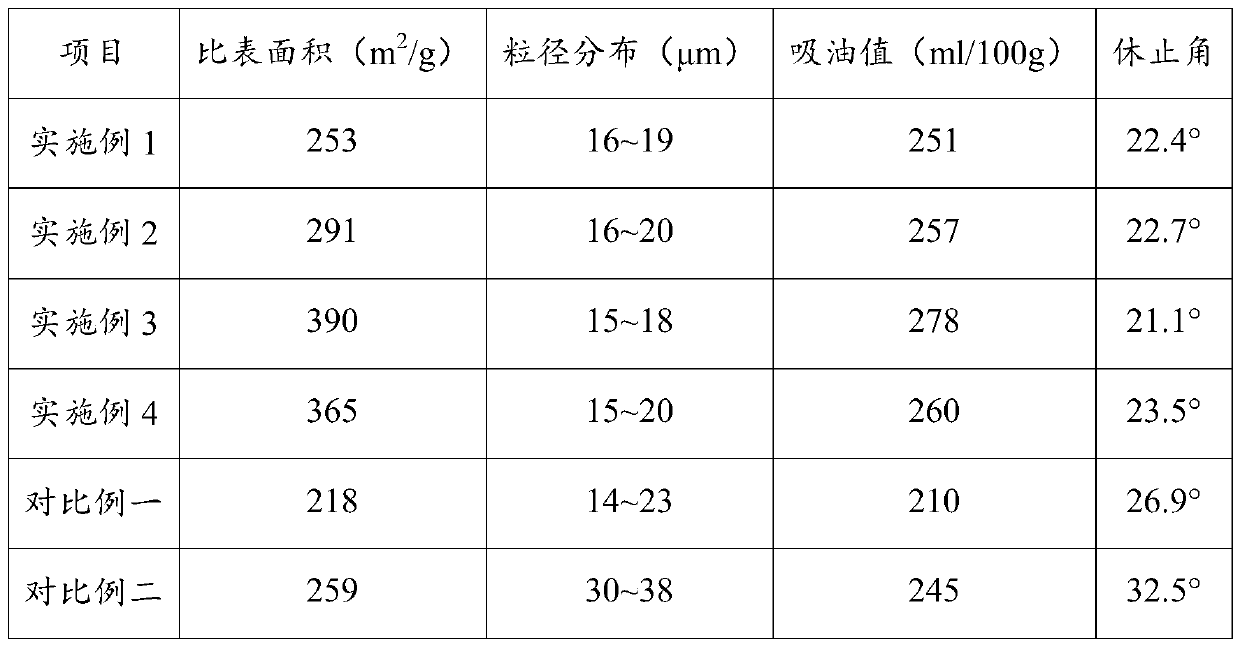

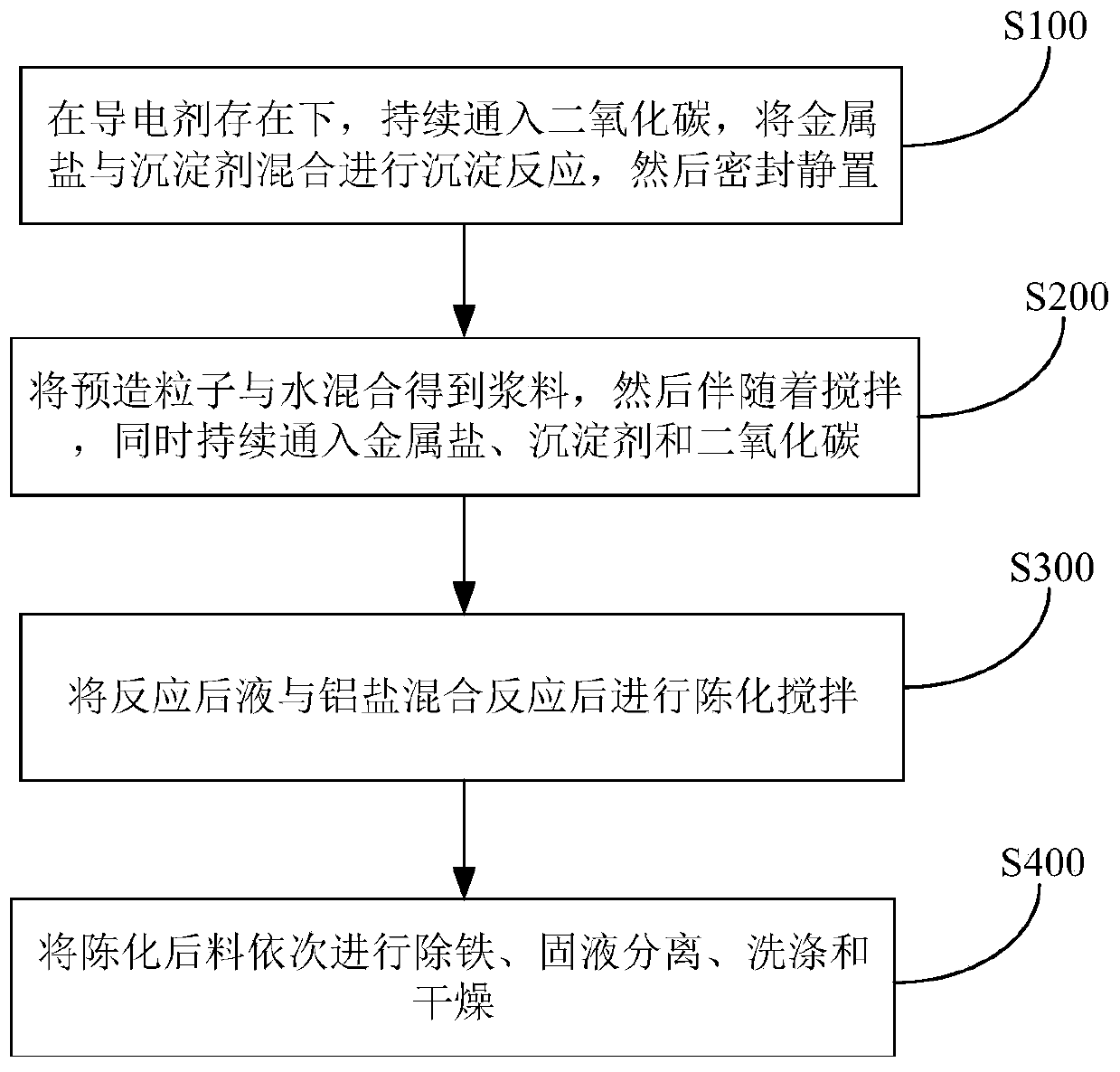

Silica with high fluidity and high oil absorption value for washing powder and preparation method thereof

ActiveCN110395740AHigh oil absorption valueUniform particle sizeInorganic/elemental detergent compounding agentsSilicaFiltrationSODIUM SILICATE SOLN

The invention belongs to the technical field of silica preparation, and particularly relates to silica with high fluidity and high oil absorption value for washing powder and a preparation method thereof. The preparation method of silica comprises the following steps: S1, adding water into a reaction kettle, adding a sulfuric acid solution under stirring, performing heating, dropwise adding a sodium silicate solution until a pH value is 3.5-4.5, then simultaneously dropwise adding the sodium silicate solution and the sulfuric acid solution to carry out a cocurrent neutralization reaction, controlling a pH value to be 3.0-5.0, simultaneously stopping addition of the sulfuric acid solution when drop addition of the sodium silicate solution is completed, and further performing stirring; S2, continuously adding the sodium silicate solution, stopping drop addition of the sodium silicate solution when a pH value is 7.0-8.0, and performing maturing; and S3, performing pressure filtration andwashing on the formed silica, and performing spray drying treatment to obtain the silica. The silica has uniform particle size distribution, large specific surface area, high oil absorption value andhigh fluidity, and has good application prospects in washing powder.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

Spray pelleting process of compound fertilizer

InactiveCN1834070AReduce manufacturing costSmooth particle surfaceAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAmmonium sulfateAqueous solution

This invention relates to a method for spray granulation of composite fertilizers, that is, potassium chloride and oil of vitriol react with each other to produce potassium hydrosulphate solution. The potassium hydrosulphate solution is homogeneously mixed with ammonium dihydrophosphate and reacts with ammonia to produce neutralization paste containing ammonium sulphate, potassium sulphate and diammonium hydrophosphate. The neutralization paste is then granulated, dried, cooled and screened to obtain composite fertilizers. This spray granulation of composite fertilizers has the advantages of low production cost and smooth particle surfaces.

Owner:潍坊昌大肥料有限公司

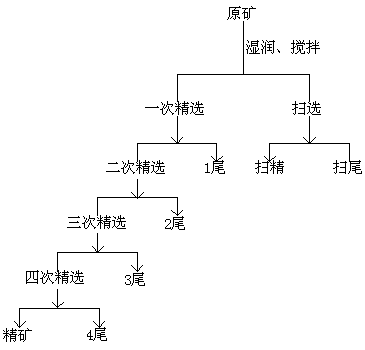

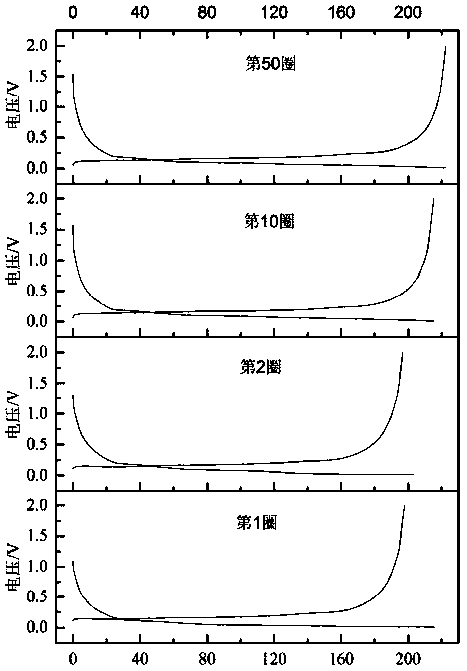

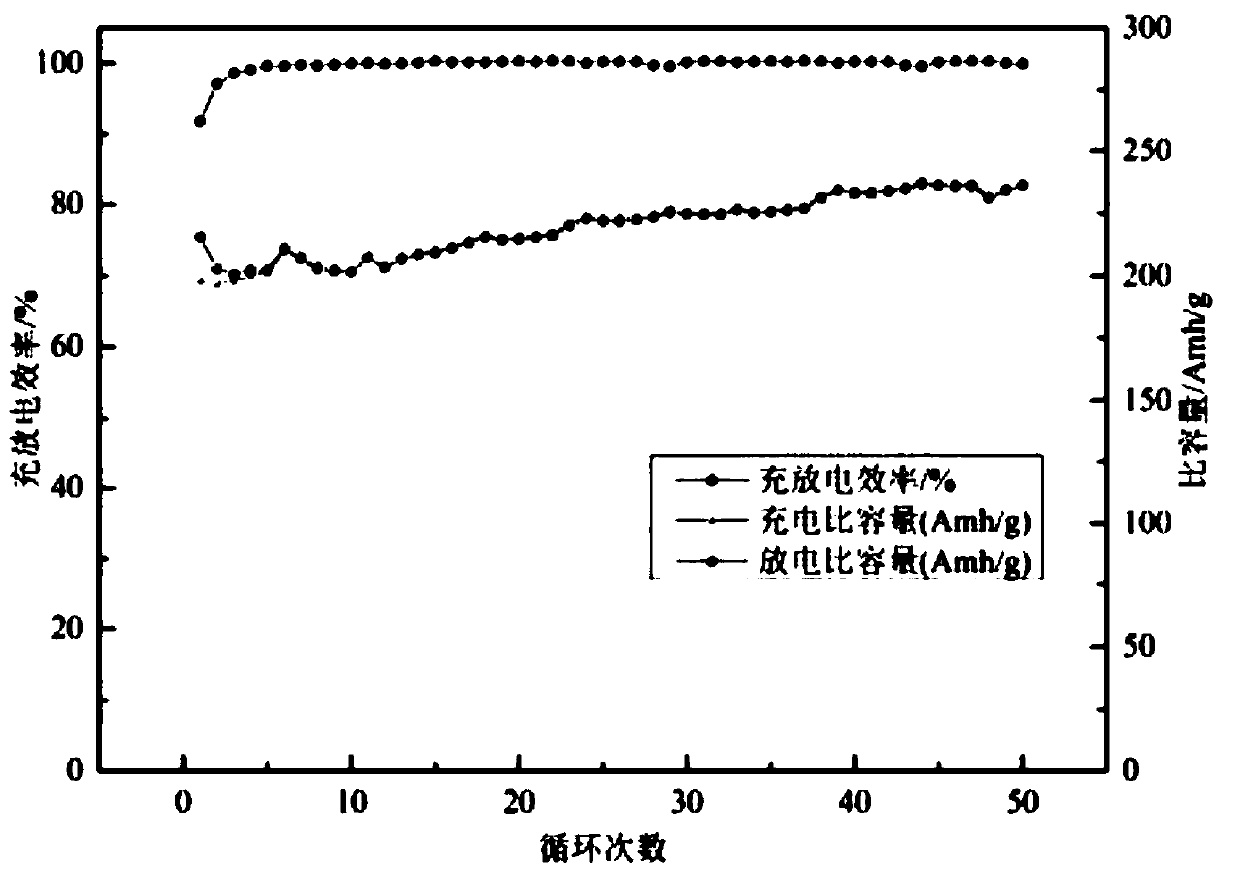

Microcrystal graphite used for negative electrode material of lithium battery, and preparation method of microcrystal graphite

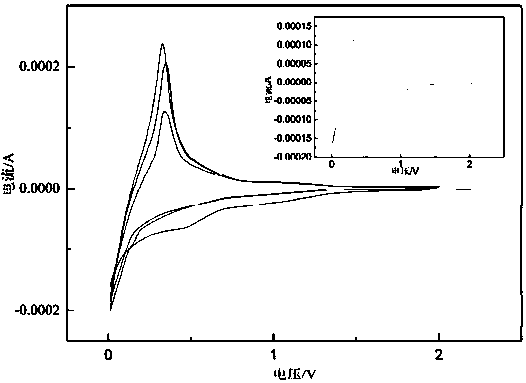

InactiveCN107799770AHigh puritySmall particle sizeHybrid capacitor electrodesCell electrodesPower flowCharge discharge

The invention relates to the technical field of a negative electrode material of a lithium battery, and discloses microcrystal graphite used for a negative electrode material of a lithium battery, anda preparation method of the microcrystal graphite. The cyclic specific capacity of the microcrystal graphite material at the current density of 100 mA / g can reach 224 mAh / g; the initial efficiency isrelatively high and can reach greater than 90%, and high stability is achieved; in a high rate condition, the cyclic specific capacity of the material is relatively low, and the reversible specific capacity is about 50 mAh / g; however, the material is excellent in high-rate cycle performance, particularly, in different charging-discharging rate conversion conditions, relatively high cycle stability still can be kept; and therefore, the microcrystal graphite negative electrode material disclosed in the invention can be applied to the field of a supercapacitor which has not high requirement on the cycle capacity and has extremely high requirement on the high-rate cycle stability.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

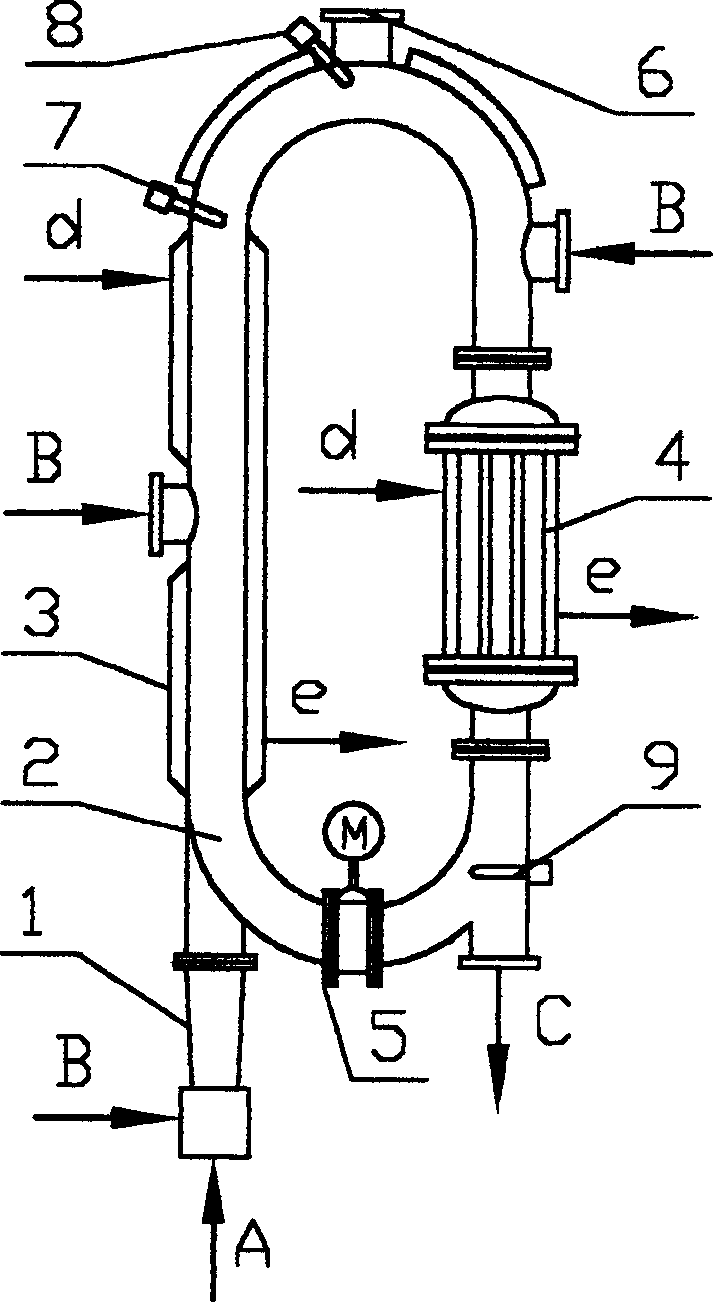

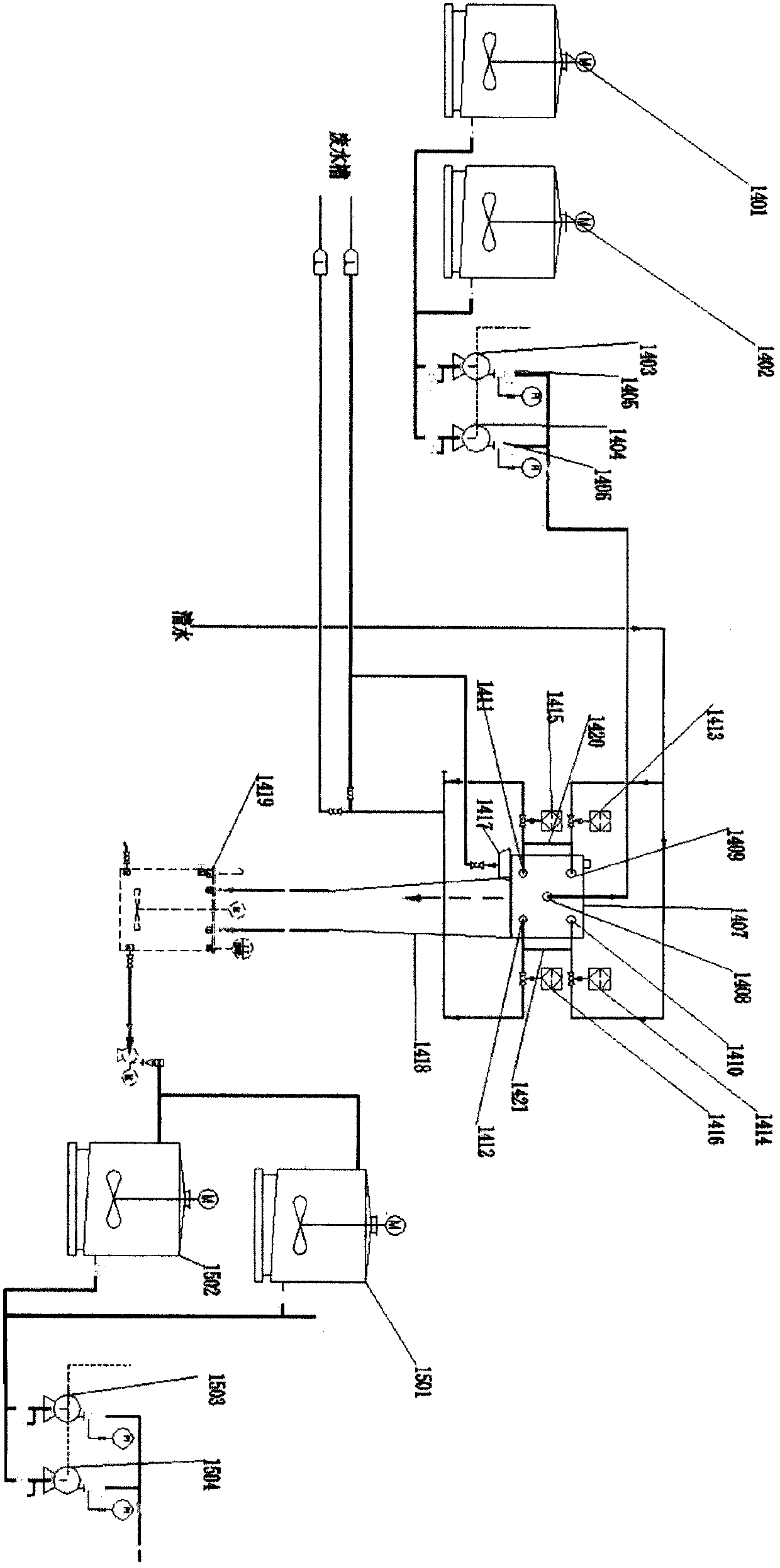

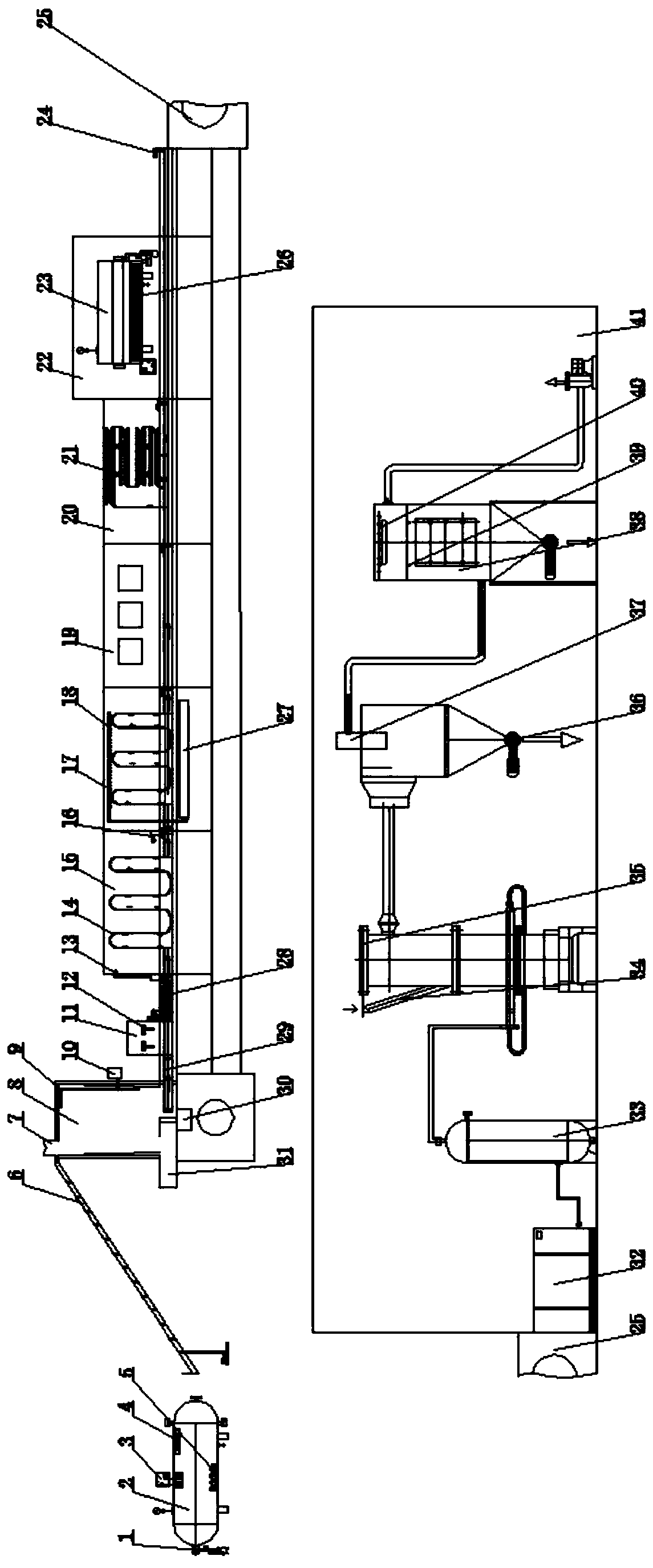

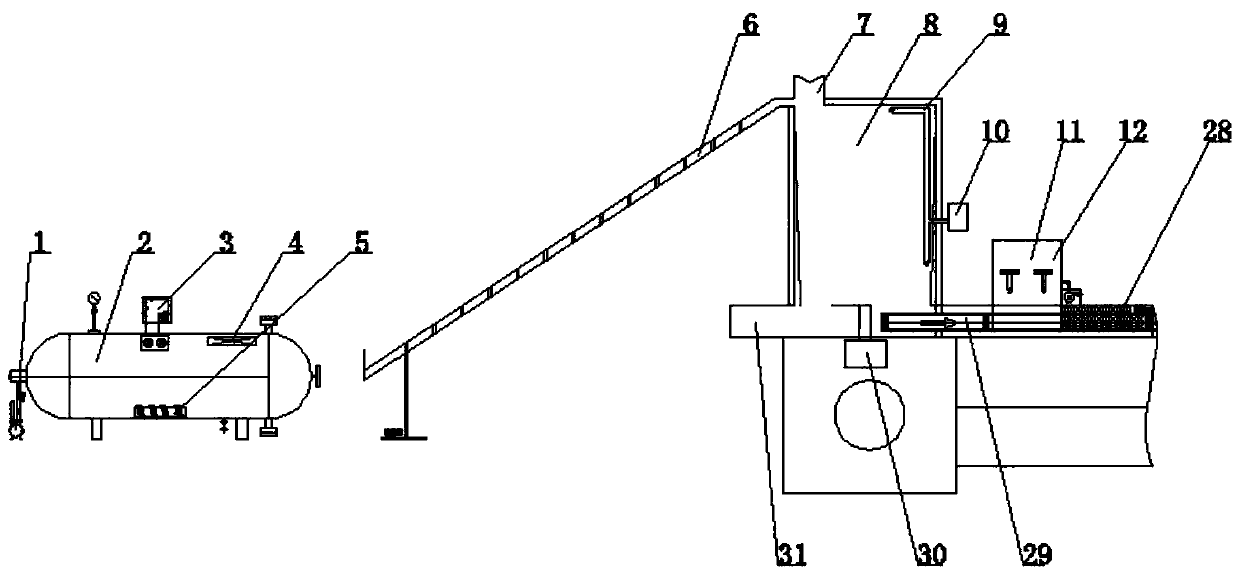

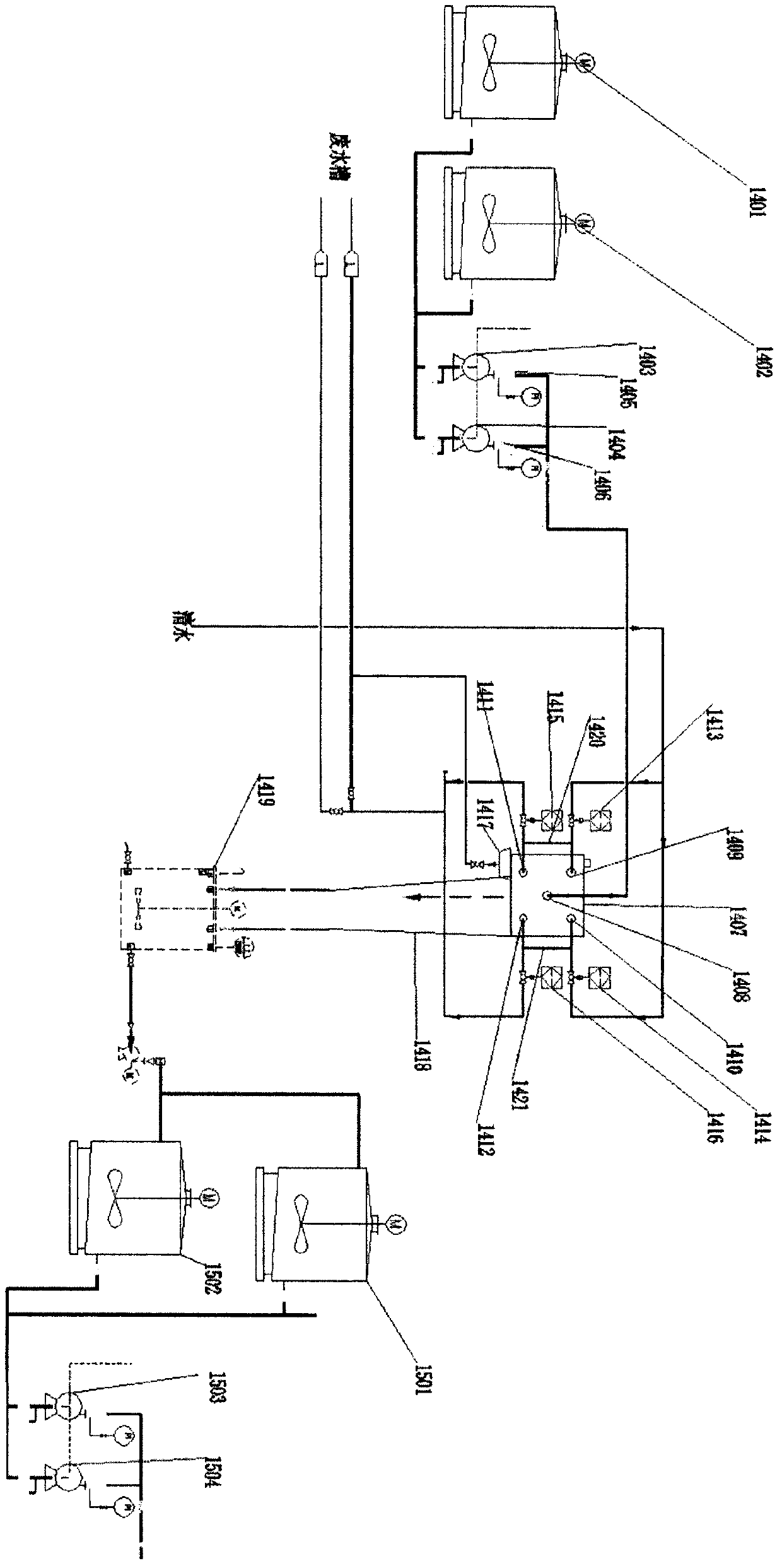

Special nano-lithium titanate composite material preparation system for lithium battery

The invention relates to a special nano-lithium titanate composite material preparation system for a lithium battery. The special nano-lithium titanate composite material preparation system is characterized by comprising the following steps: mixing titanium dioxide, aluminum salt, a carbon source, lithium salt and magnesium salt, firstly pulping the titanium dioxide, dissolving the aluminum salt,the magnesium salt and the lithium salt and putting the titanium dioxide, the aluminum salt, the magnesium salt and the lithium salt in a dispersing agent for mixing; performing vacuum drying to obtain a precursor, wherein the molar ratio of titanium to aluminum to magnesium to lithium to carton elements is 5:(0.05-0.3):(0.1-0.4):(4.95-4.7):(2-20); putting the precursor in an inert gas heating furnace for high-temperature calcination, wherein the temperature is 800-1000 DEG C, and the time exceeds 8 hours; then reducing a calcined product to a room temperature to obtain a carbon-coated lithiumtitanate composite material.

Owner:GUANGXI JINMAO TITANIUM

Preparation method of submicron hexanitrohexaazaisowurtzitane in batch

InactiveCN103342618AUniform particle sizeSmooth particle surfaceExplosive working-up apparatusOrganic solventEngineering

The invention discloses a preparation method of submicron hexanitrohexaazaisowurtzitane in batch. The method comprises: adding a surfactant into water to prepare a surfactant solution, grading by using grinding ball mediums with different diameters, adding CL-20, the surfactant solution and the grinding ball mediums into grinding tanks, cooling, symmetrically putting the grinding tanks, fixing the grinding tanks onto a planet grinder for planet grinding, separating a grinded explosive suspension and the grinding ball mediums, performing solid-liquid separation for the explosive suspension, and drying to obtain the submicron CL-20. According to the preparation method provided by the invention, the CL-20 explosive, the surfactant solvent and the grinding ball mediums with different diameters are graded, and the planet grinder is used for repeated grinding. The prepared epsilon-CL-20 is uniform in powder particle size, smooth in particle surface, and regulatable in average particle size; during a preparation process, no organic solvent impurities are introduced, a post treatment is reduced , a total grinding time is 1-10 hours, and a grinding time is short. The method is suitable for production in batch.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Yacon fruit flake and whole powder multielement joint processing production system

PendingCN109832585AWith cavitation effectWith mechanical shear effectFruits/vegetable preservation by irradiation/electric treatmentFood shapingFreeze-dryingCyclonic separation

The invention belongs to the technical field of agricultural product processing devices, relates to a pulverizing device, and in particular relates to a yacon fruit flake and whole powder multielementjoint processing production system. A pretreatment unit, a peeling and slicing unit, an anti-browning unit, an anti-caking treatment unit and a high-speed nitrogen flow pulverizing unit are mounted sequentially from the upstream side to the downstream side of the working procedure, wherein the pretreatment unit comprises an airtight decompression tank; an ultrasonic generation device and a magnetic field generation device are arranged in the airtight decompression tank; the peeling unit comprises a centrifugal peeling device and a slicing device; the centrifugal peeling device and the slicingdevice are sequentially mounted; the anti-browning unit comprises an anti-browning induction treatment device, an anti-metal ion induction treatment device and an anti-caramelization browning treatment device; the anti-caking treatment unit comprises a microwave drying device, an anti-caking polarity remover spray device and a freeze drying device; the high-speed nitrogen flow pulverizing unit comprises a nitrogen generating device, a nitrogen tank, a nitrogen pulverizer and a cyclone separator; and the cyclone separator is provided with a multi-stage discharge port.

Owner:SDIC ZHONGLU FRUIT JUICE

Nano TiO2-containing cellulose-based low-temperature phase change energy storage microcapsule and preparation method thereof

ActiveCN105754554AImprove thermal conductivityPrevent leakageHeat-exchange elementsMicroballoon preparationCelluloseHeat conducting

The invention discloses a nano TiO2-containing cellulose-based low-temperature phase change energy storage microcapsule and a preparation method thereof; the low-temperature phase change energy storage microcapsule comprises a capsule core and a capsule wall, wherein the capsule core is a core-shell structure composite phase change material formed by wrapping the surface of paraffin with ethylene glycol, and the capsule wall is formed by a carboxymethyl cellulose membrane doped with nano TiO2 particles; the preparation method comprises the steps of firstly, preparing a composite phase change material by using an aqueous phase ethylene glycol solution and oil phase liquid paraffin through a micro-emulsion method; then, preparing the capsule wall by using a carboxymethyl cellulose water solution containing tetrabutyl titanate and a silane coupling agent through a sol-gel reaction to obtain the microcapsule; the microcapsule has average particle size of 3-10 microns, phase-transition temperature of minus 12 to 5 DEG C and an enthalpy value of 170-200J / g; furthermore, the microcapsule also has good heat-conducting property; the microcapsule is simple in preparation technology and easy in large-scale production, and products of the preparation method do not contain inorganic salt and an organic solvent which can easily corrode a container, so that the preparation method is green and environment-friendly.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

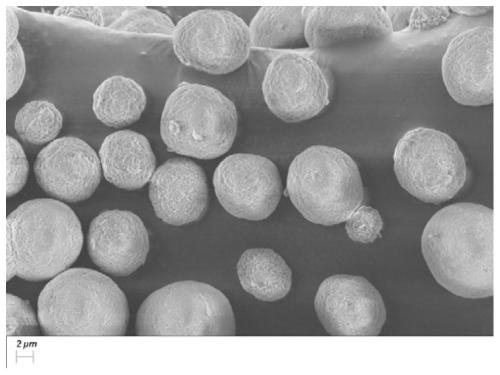

Lithium-rich manganese-based solid solution positive electrode material for lithium ion battery and preparation method of lithium-rich manganese-based solid solution positive electrode material

ActiveCN107221656AGood particle sphericityIncrease capacityCell electrodesSecondary cellsLithium electrodeParticle-size distribution

The invention discloses a lithium-rich manganese-based solid solution positive electrode material for a lithium ion battery and a preparation method of the lithium-rich manganese-based solid solution positive electrode material. The chemical general formula of the lithium-rich manganese-based solid solution positive electrode material is xLi2MnO3.(1-x)LiNiCoMn<c>O2, wherein x is more than or equal to 0.2 but less than or equal to 0.7, (a+b+c) is equal to 1, a is more than or equal to 0.2 but less than or equal to 0.8, c is more than or equal to 0.1 but less than or equal to 0.5, the lithium-rich manganese-based solid solution positive electrode material is dense in particles, no hollow phenomenon exists, the tap density TD is larger than 2.0g / cm<3>, the particle size distribution coefficient K90 is 0.6-0.9, and K90=(D90-D10) / D50. The lithium-rich manganese-based solid solution positive electrode material has the advantages of good sphericity, dense particles and narrow particle size distribution, the capacity and the electrochemical performance of the lithium-rich manganese-based solid solution positive electrode material can be remarkably improved, and the cycle lifetime of the lithium-rich manganese-based solid solution positive electrode material can be remarkably prolonged; and moreover, according to the preparation method, a complexing agent does not need to use, and the preparation process is simple, is easy and stable to control, is low in production cost, is environmental-friendly, has no pollution and is suitable for industrial production on a large scale.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Preparation method of special disposable mechanically-applied fertilizer for corn

The invention relates to a preparation method of a special disposable mechanically-applied fertilizer for corn. According to the invention, urea, monoammonium phosphate, potassium chloride and zinc sulfate are compounded, a high-tower granulated compound fertilizer is used as the core fertilizer, and double film layers are coated, wherein the inner layer film is a urea film and used for improving the surface characteristic of the fertilizer granules, and the outer layer film is a thermoplastic resin coating and a thermosetting coating and is used for controlling the release of the nutrients. The special mechanically-applied fertilizer for corn has more smooth and harder surface, and is suitable for mechanical application. The fertilizer satisfies the requirements of corn for absorbing nitrogen, phosphorus, potassium, zinc and other nutrients; and the large-scale field test proves that the fertilizer has favorable yield increase effect.

Owner:菏泽金正大生态工程有限公司

Low-temperature melt process of producing granulated azophoska

InactiveCN1398826AEliminate the heating processLow investment costGranulation by liquid drop formationFertiliser formsTrace elementPotassium

The present invention is a low-temperature melt process for producing granulated azophoska. Melt material is first produced through mixing semi-finished product solid urea with sodium nitrate or potassium chloride or heating solid urea and sodium nitrate or potassium chloride, then it is mixed with solid ammonium phosphate to produce suspension melt slurry. The mixed melt slurry is dispersed into small liquid drops through a prilling granulator, and the small liquid drops are cooled, solidified in an oil cooling tank and separated to obtain the product. The said process may be also used in producing trace element fertilizer or color fertilizer. The said process has greatly lowered melt material temperature, no need of heating solid ammonium phosphate, simple production process, low cost, and no environmental pollution.

Owner:俞政

Aluminum-coated precursor as well as preparation method and application thereof

ActiveCN111434617AGranularity controllableUniform particle size distributionSecondary cellsPositive electrodesPhysical chemistryManganese

The invention discloses an aluminum-coated precursor and a preparation method thereof. The chemical formula of the aluminum-coated precursor is xMCO3(1-x)Al(OH)3, M is at least one of nickel, cobalt and manganese, and x is 0.995-0.999. The aluminum-coated precursor has the advantages of controllable particle size, uniform particle size distribution, high degree of sphericity, smooth particle surface, high tap density, low possibility of breakage and excellent electrochemical performance and energy density, and meanwhile, a positive electrode material prepared from the precursor has relativelyhigh specific capacity and excellent cycle performance and electrochemical discharge performance.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

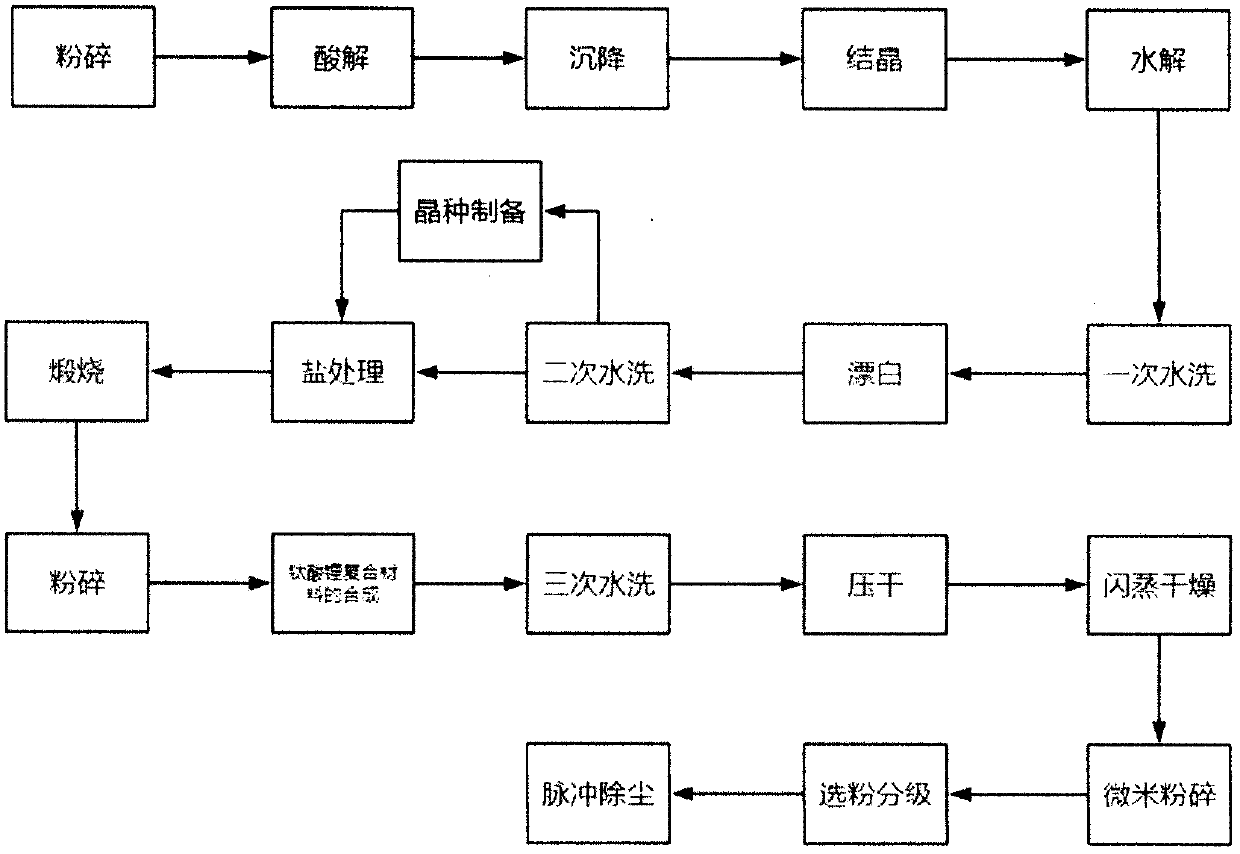

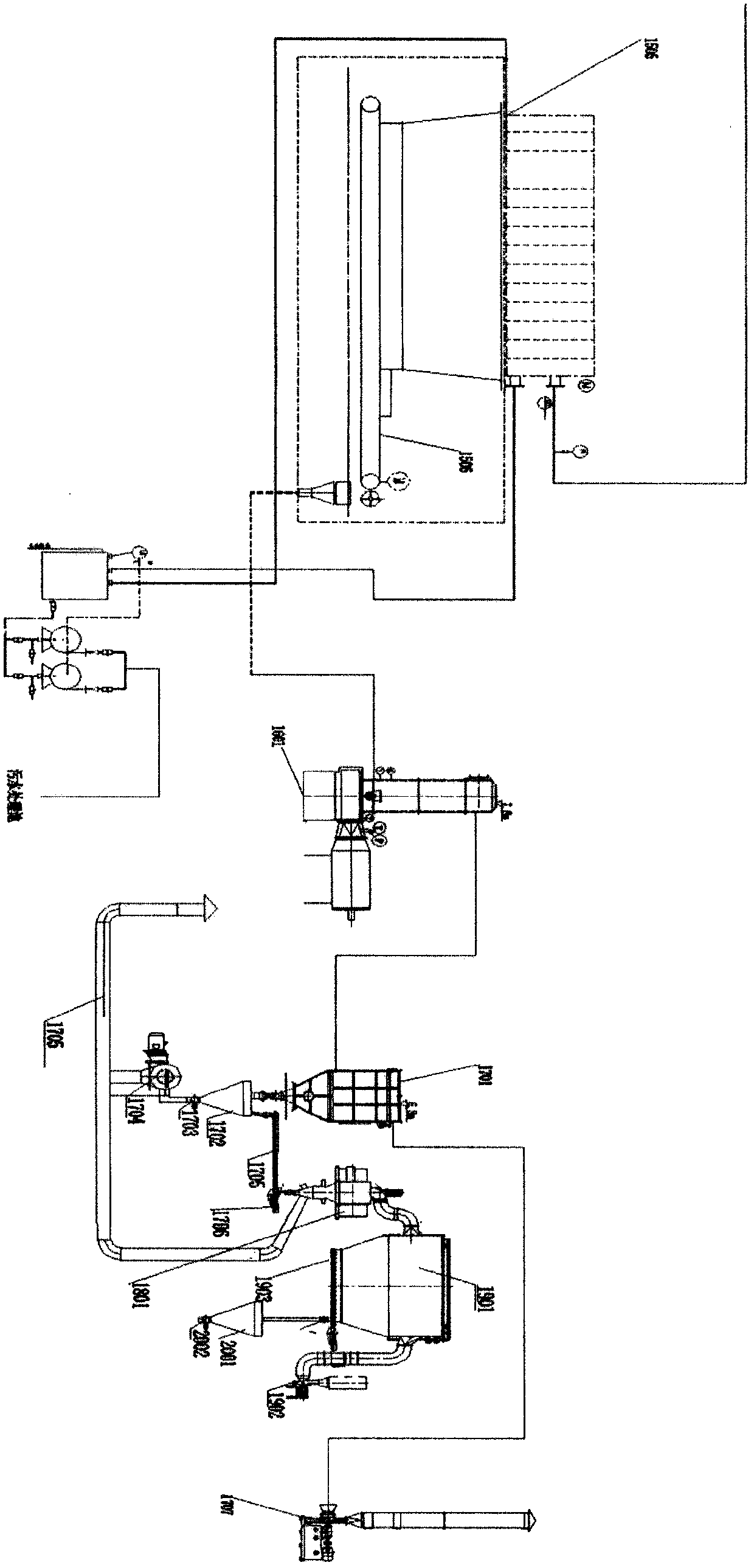

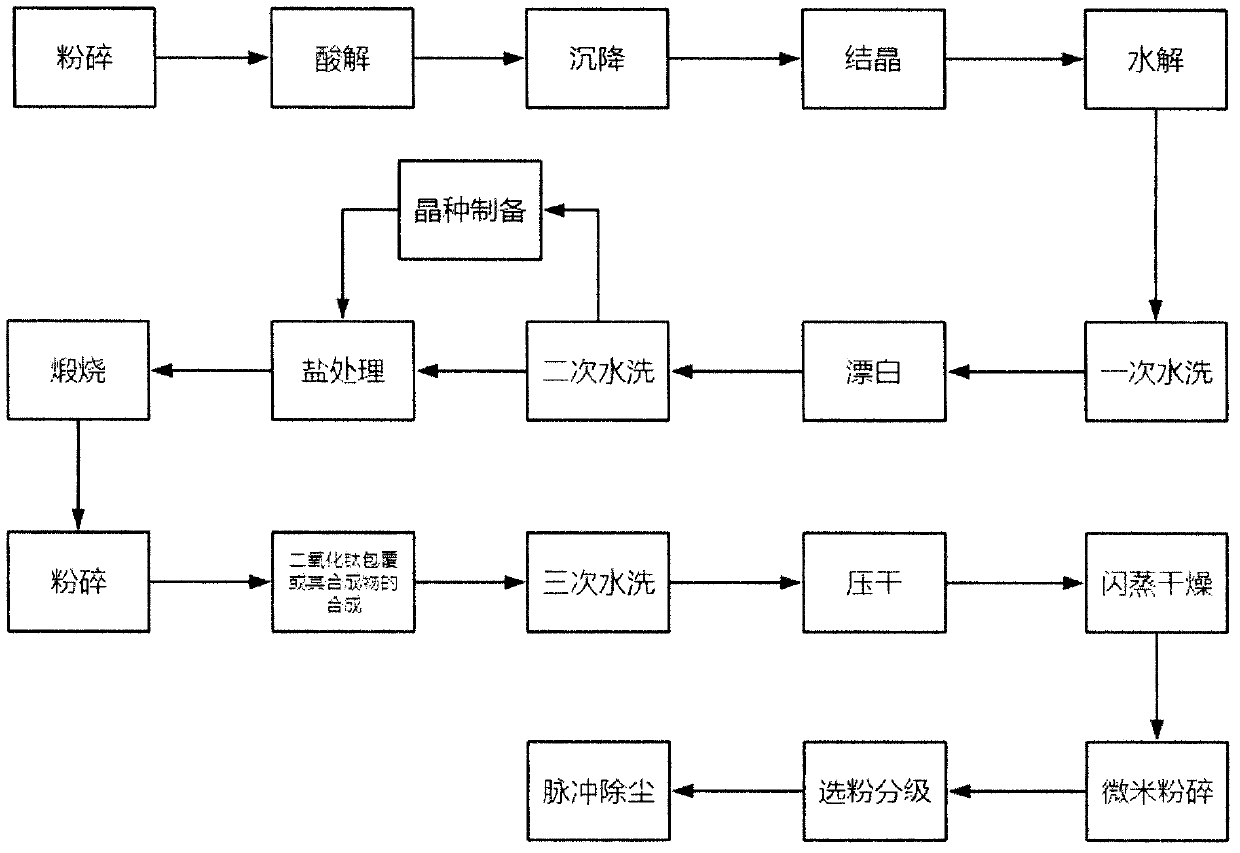

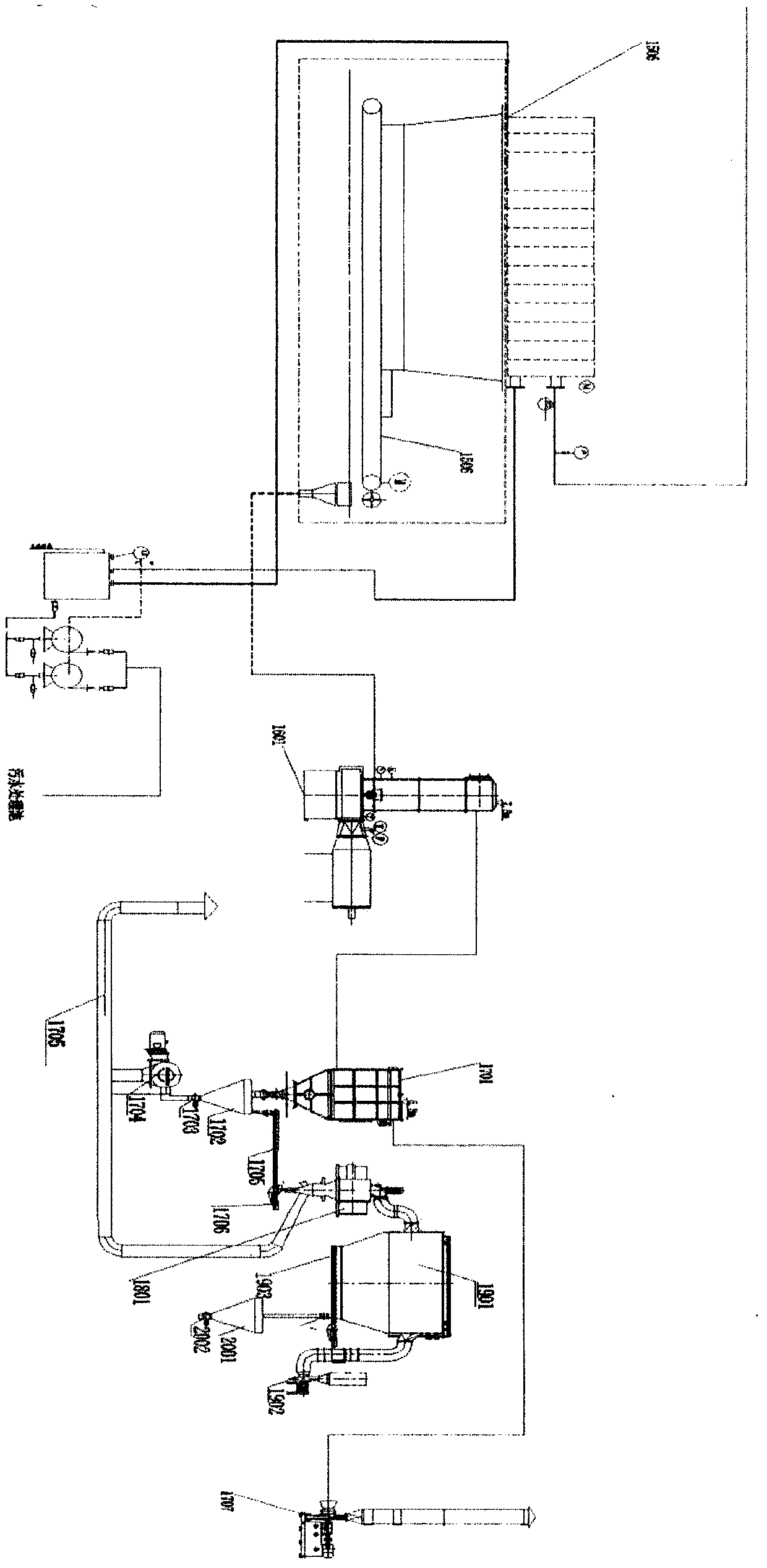

Preparation process of nanometer titanium dioxide or synthetic compound thereof

InactiveCN109911930ASmooth particle surfaceUniform shapeTitanium dioxideFilter pressFlash evaporation

The invention relates to a preparation process of nanometer titanium dioxide or a synthetic compound thereof. According to the present invention, treatment is performed through three-washing filter press treating, pressing drying, flash evaporation drying, micro-crushing and other processes; the particles of the prepared titanium dioxide or the synthetic compound thereof have characteristics of smooth surface, uniform shape and controllable particle size; and the method has characteristics of simple and feasible process and low cost, and is suitable for industrial mass production.

A long-life modified natural graphite negative electrode material and its preparation method and application

ActiveCN107814382BHigh sphericitySmooth particle surfaceCarbon compoundsCell electrodesPower batteryGraphite particle

The invention discloses a long-life modified natural graphite cathode material as well as a preparation method and use thereof. According to the preparation method, natural graphite powder and asphaltare dipped by virtue of a hot isostatic pressure machine, so that holes in graphite particles can be completely filled with asphalt at high temperature and high pressure conditions; and meanwhile, anasphalt coating layer is formed on the surface of the natural graphite powder, and graphitization is carried out so as to obtain the modified natural graphite cathode material with a core-shell structure, wherein synthetic graphite is embedded into the inside and surface of the natural graphite in situ, the filling rate of the synthetic graphite in the holes of the natural graphite is more than or equal to 94%, the surfaces of the particles are smooth, and the spheroidization degrees of the particles are high. According to the preparation method, the primary coulombic efficiency of the modified natural graphite cathode material is more than or equal to 96%, and the capacity retention ratio of the material after being circulated at a room temperature 1C for 1500 cycles is more than or equal to 80%, so that the prepared material is high in primary coulombic efficiency, long in service life and can be used for replacing synthetic graphite for producing powder battery cathode materials, and the cost is greatly lowered. The preparation method is simple in preparation process and low in cost and has relatively high practicability.

Owner:GUANGDONG DONGDAO NEW ENERGY +1

Process for producing negative electrode material coke by taking supercritical extraction oil slurry as raw material and application of process

ActiveCN106635102AQuality improvementRound appearanceCell electrodesCoking carbonaceous materialsSlurryTower

The invention belongs to the technical field of production of negative electrode materials and in particular relates to a process for producing negative electrode material coke by taking supercritical extraction oil slurry as a raw material and application of the process. Before aromatic hydrocarbon-enriched oil is coked, fractional distillation of a fractional distillation tower and a light component removing process are combined; produced raw coke is subjected to drying treatment so that the water content of the raw coke is less than one percent; the process is used for producing the negative electrode material coke; the graphitization degree of a lithium-ion battery prepared by a negative electrode material for preparing the lithium-ion battery reaches 95 percent or more and the capacity reaches 360mAh / g.

Owner:SHANDONG YIDA NEW MATERIAL

Preparation methods of microcrystal graphite cathode electrode plate and button lithium battery

InactiveCN107732152ALarge specific surface areaReduce usageFinal product manufactureCell electrodesCapacitancePower flow

The invention relates to the technical field of cathode materials for lithium batteries, and discloses a microcrystal graphite cathode electrode plate and a button lithium battery. The cycling specific capacitance of microcrystal graphite is up to 224 mAh / g at the electric current density of 100 mA / g, the first efficiency is relatively high and is more than 90%, and the stability is good. The cycling specific capacitance of the material is relatively low under the condition of high rate, the reversible specific capacity is 50 mAh / g; but the high-rate cycling performance is excellent, the higher cycling stability is still kept particularly under the condition of conversion of different charge-discharge rates, and the microcrystal graphite cathode material can be applied to the field of supercapacitors having no strict requirement on the cycling capacity but a quite high requirement on high-rate cycling stability.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

Instant tea granules and preparation method thereof

The invention discloses instant tea granules and a preparation method thereof. The method includes the steps of raw material extraction, filtration, centrifugation, concentration and drying granulation, wherein the raw materials of tea are extracted by using hot water, filtered and centrifuged, pass through a light scraping flat-sheet membrane and a reverse osmosis membrane, and then are concentrated by adopting a centrifugal thin film evaporator to obtain a concentrated solution; maltodextrin is added into the concentrated solution to prepare a mixed material, material temperature is adjusted, an inert gas hollow granulation technology is adopted, an inert gas is added and fully mixed with the material, and then spray drying is conducted to obtain the instant tea granules. The prepared instant tea is in a hollow granule shape, the granules are smooth in surface, even in size, large in mean diameter, good in liquidity and instant solubility and better in integrated quality, and can beused as cold solubility instant-tea, and the product safety is high; the preparation process is simple, the production cost is low, and the method has high operability.

Owner:HANGZHOU TEA RES INST CHINA COOP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com