Preparation methods of microcrystal graphite cathode electrode plate and button lithium battery

A microcrystalline graphite and negative electrode technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, battery electrodes, etc., can solve the problems of poor electrical properties of natural microcrystalline graphite, achieve good stability, reduce usage, increase The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment provides a method for preparing microcrystalline graphite for negative electrode materials of lithium batteries, comprising the following steps:

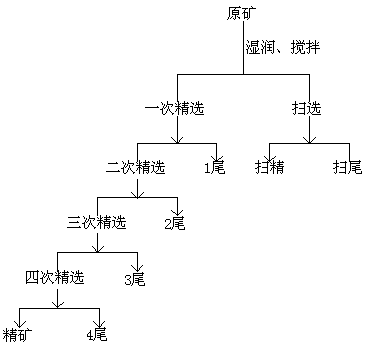

[0056] S1. Raw ore treatment: crush Lutang aphanitic graphite, and then conduct deep grinding on the microcrystalline graphite raw ore, and obtain materials with a fineness of -0.074mm through grinding, and increase the content of materials with a fineness of -0.074mm 90% of the raw ore samples are subjected to flotation, specifically as figure 1 As shown, a roughing process is adopted for four times of selection and one sweeping process, followed by drying and magnetic separation to obtain microcrystalline graphite with a fixed carbon content of 90%;

[0057] Wherein, the properties of the Lutang aphanitic graphite described in step S1 are as follows: moisture 2.4%, volatile matter 2.99%, ash content 18.37%, carbon content 78.64%, specific surface area 12.8 m2 / g.

[0058] S2. acid leaching purification: the ...

Embodiment 2

[0062] The implementation is basically the same as in Example 1, except that the process conditions are different in step S2, as follows:

[0063] S2. acid leaching purification: the microcrystalline graphite obtained in step S1 is mixed with a mixed acid, the mixed acid is a mixed acid of HF and HCL, the liquid-solid ratio of the mixed acid to graphite is 2ml / g, the volume content of HF is 30%, and that of HCL The volume content is 10%, and then carry out acid leaching under normal pressure under the conditions of temperature 60°C and reaction time 1h. The leaching residue is washed with distilled water or deionized water until the graphite precipitates when the washing solution is neutral, and then filtered. Dry at ~150°C for 2-3 hours to obtain purified microcrystalline graphite with a fixed carbon content of 99.12%.

Embodiment 3

[0065] The implementation is basically the same as in Example 1, except that the process conditions are different in step S2, as follows:

[0066] S2. acid leaching purification: the microcrystalline graphite obtained in step S1 is mixed with a mixed acid, the mixed acid is a mixed acid of HF and HCL, the liquid-solid ratio of the mixed acid to graphite is 3.5ml / g, the volume content of HF is 60%, and the HCL The volume content is 20%, and then carry out normal pressure acid leaching at a temperature of 80°C and a reaction time of 4 hours. The leaching residue is washed with distilled water or deionized water until the graphite precipitates when the washing solution is neutral, and then filtered, and heated at a temperature of Dry at 80-150° C. for 2-3 hours to obtain purified microcrystalline graphite with a fixed carbon content of 99.56%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible specific capacity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com