Nitrogen oxide phosphor powder and synthesis method thereof

A technology of nitrogen oxides and synthesis methods, which is applied in chemical instruments and methods, luminescent materials, sustainable buildings, etc., can solve the problems of reducing the luminous brightness of phosphors for LEDs, poor morphology of synthesized products, and low crystal phase purity of products. , to achieve smooth and improved crystallinity, reduce sintering temperature, and optimize crystal morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

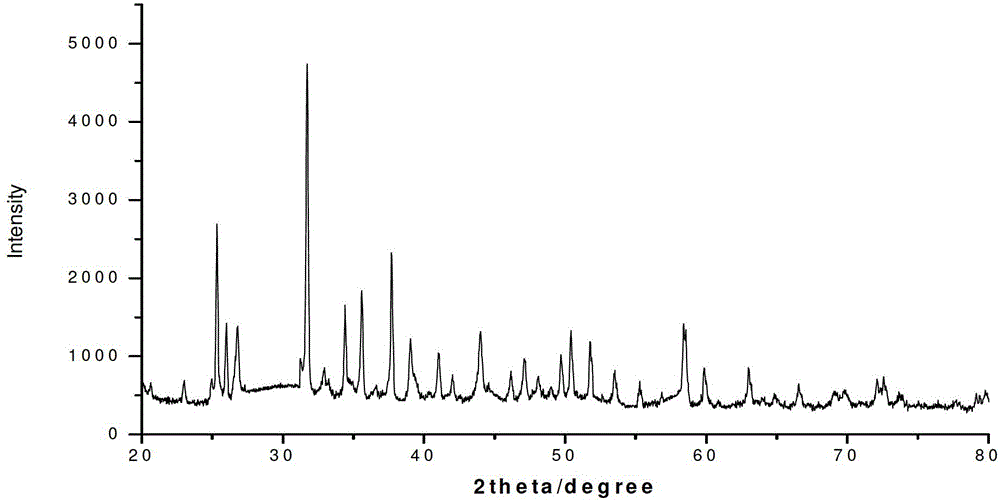

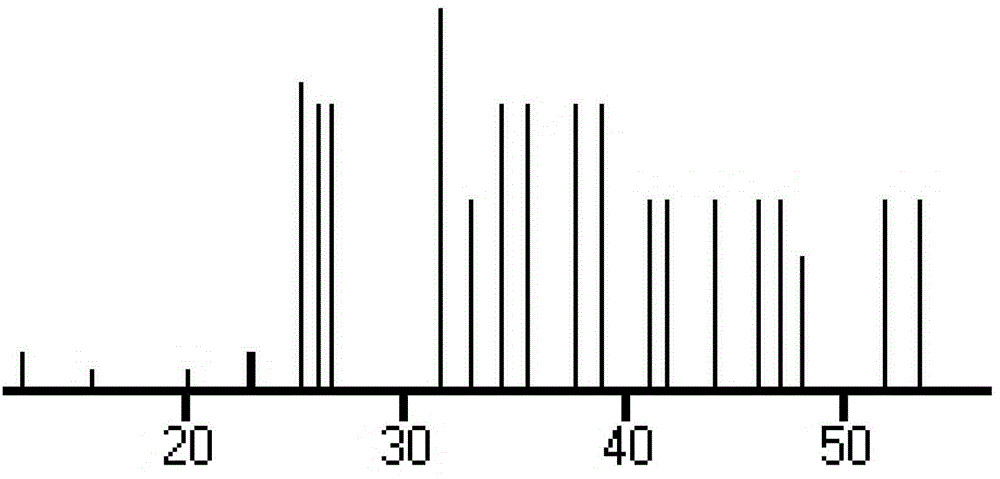

Embodiment 1

[0029] The first step to synthesize the precursor Si of nitrogen oxide phosphor 2 N 2 O: Weigh SiO according to the stoichiometric ratio 2 60.1g, Si 3 N 4 140.31g, 3wt% flux ammonium chloride (NH 4 Cl) is mixed and fully ground (requires uniform mixing, the grinding time is 50min), then placed in an alumina crucible, placed in a tube furnace, sintered at 1500°C for 3 hours in a protective gas, and then naturally cooled to obtain Si 2 N 2 O, the protective gas is nitrogen, and the gas flow rate is 15ml / min.

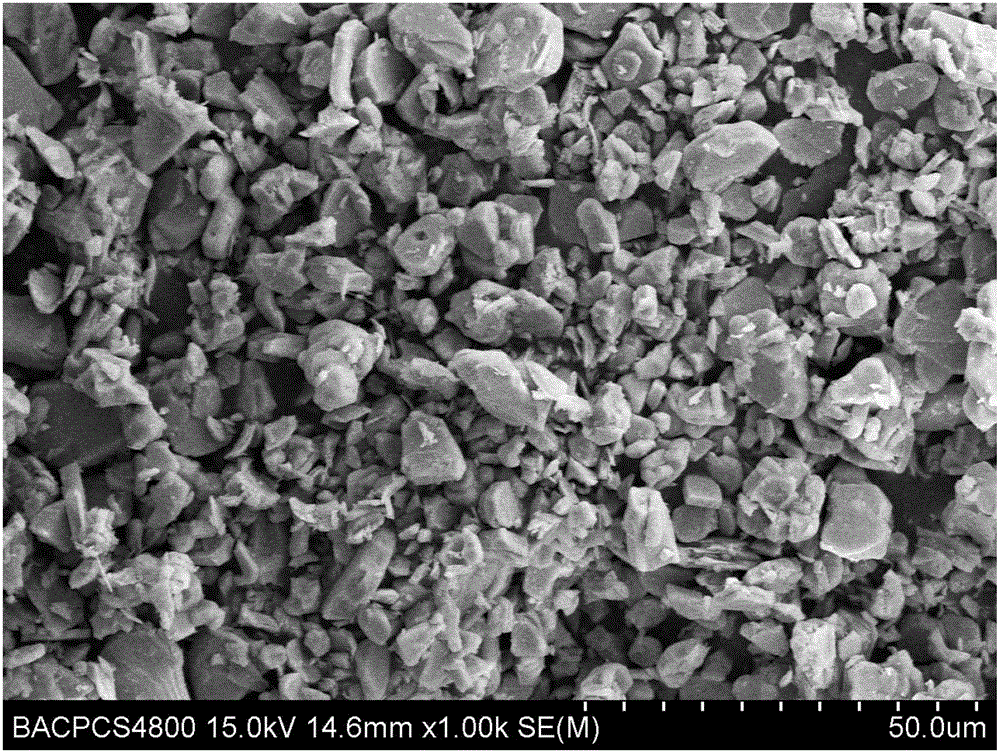

[0030] The second step is in the front body Si 2 N 2 The matrix structure provided by O is doped with Sr and Eu elements to synthesize the oxynitride phosphor material Sr 0.96 Si 2 N 2 o 2 :0.04Eu: According to Sr 0.96 Si 2 N 2 o 2 : The stoichiometric ratio of 0.04Eu element will result in Si 2 N 2 After O is ground and sieved (150 mesh sieve), weigh 5g, then weigh SrCO 3 7.07g and Eu 2 o 3 0.351g, finally add 5wt% SrF2 Flux, the above-mentioned compo...

Embodiment 2

[0035] In order to show the advantages of preparing the nitrogen oxide phosphor material of the present invention, the first step of Example 2 is consistent with that of Example 1, and the parameters of the second step are mainly changed to compare with the examples.

[0036] The second step is in the front body Si 2 N 2 The matrix structure provided by O is doped with Ba, Sr and Eu elements to synthesize the oxynitride phosphor material Sr 0.4 Ba 0.58 Si 2 N 2 o 2 :0.02Eu: According to Sr 0.4 Ba 0.58 Si 2 N 2 o 2 : The stoichiometric ratio of 0.02Eu element will result in Si 2 N 2 After O is ground and sieved, weigh 5g, and then weigh BaCO 3 5.72g, SrCO 3 2.95g and Eu 2 o 3 0.176g, finally add 5wt% BaF 2 Flux, put the above ingredients into molybdenum crucible after grinding, move the crucible into high temperature tube furnace, 2 :H 2 =9:1 sintering at 1480°C for 4 hours with a gas flow rate of 25ml / min, then naturally cooled to room temperature and taken o...

Embodiment 3

[0039] The first step of embodiment 3 is consistent with that of embodiment 1, and the parameters of the second step are changed emphatically to contrast with each embodiment.

[0040] The second step is in the front body Si 2 N 2 The matrix structure provided by O is doped with Ca, Sr element and Eu element to synthesize the oxynitride phosphor material Ca 0.8 Sr 0.18 Si 2 N 2 o 2 :0.02Eu: According to Ca 0.8 Sr 0.18 Si 2 N 2 o 2 : The stoichiometric ratio of 0.02Eu element will result in Si 2 N 2 After O is ground and sieved, weigh 5g, and then weigh CaCO 3 4g, SrCO 3 1.33g and Eu 2 o 3 0.176g, finally add 5wt% SrF 2 Flux, put the above ingredients into molybdenum crucible after grinding, move the crucible into high temperature tube furnace, 2 :H 2 =9:1 sintering at 1480°C for 4 hours with a gas flow rate of 25ml / min, then cooled to room temperature and taken out.

[0041] Grind and sieve as required, wash and dry with dilute hydrochloric acid to obtain ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com