A long-life modified natural graphite negative electrode material and its preparation method and application

A technology of natural graphite and negative electrode materials, applied in chemical instruments and methods, battery electrodes, carbon compounds, etc., can solve problems such as poor cycle performance and poor safety, achieve improved cycle life, high degree of spheroidization, and increase preparation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

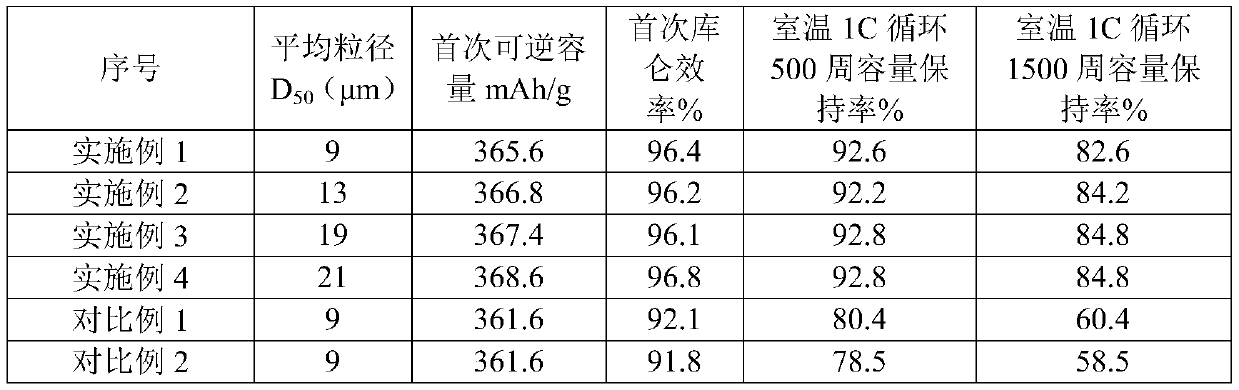

Examples

Embodiment 1

[0054] (1) the spherical natural graphite with an average particle diameter of 8 μm and the coal tar pitch (0.5% quinoline insoluble matter content) with an average particle diameter of 15 μm are mixed uniformly by mass ratio 100:40, and sealed in the aluminum skin;

[0055] (2) Place the aluminum skin of step (1) in a hot isostatic press, raise the temperature to 300°C at 100MPa, keep the temperature and hold the pressure for 1 hour, turn off the power and cool to room temperature with the furnace;

[0056] (3) the material that step (2) obtains is broken into 3mm coarse powder in Raymond machine;

[0057] (4) Put the material obtained in step (3) into kerosene at 60°C, stir at a speed of 300r / min for 3 hours, filter, wash the filtrate once again, and dry at 160°C under vacuum;

[0058] (5) Under the protection of nitrogen, the material obtained in step (4) is first heated to 900° C. at a heating rate of 3° C. / min, and kept for 30 minutes; then heated to 1300° C. at a heating...

Embodiment 2

[0061] (1) The spherical natural graphite with an average particle diameter of 12 μm and the impregnated asphalt (0.6% quinoline insoluble matter content) with an average particle diameter of 20 μm are mixed uniformly by mass ratio 100:35, and sealed in a rubber bag;

[0062] (2) Place the rubber bag of step (1) in a hot isostatic press, raise the temperature to 350°C at 120MPa, keep the temperature and hold the pressure for 2 hours, then turn off the power and cool to room temperature with the furnace;

[0063] (3) the material obtained in step (2) is broken into 2mm coarse powder in a turbine pulverizer;

[0064] (4) Put the material obtained in step (3) into washing oil at 100°C, stir at a speed of 400r / min for 2 hours, filter, wash the filtrate once again, and dry at 200°C under vacuum;

[0065] (5) Under the protection of nitrogen, the material obtained in step (4) is first heated to 900° C. at a heating rate of 5° C. / min, and kept for 40 minutes; then heated to 1300° C. ...

Embodiment 3

[0067] (1) The spherical natural graphite with an average particle diameter of 18 μm and the impregnated pitch (0.4% quinoline insoluble matter content) with an average particle diameter of 20 μm are mixed uniformly by mass ratio 100:40, and sealed in the aluminum skin;

[0068] (2) Place the aluminum skin of step (1) in a hot isostatic press, raise the temperature to 320°C at 80MPa, keep the temperature and hold the pressure for 3 hours, turn off the power and cool to room temperature with the furnace;

[0069] (3) the material obtained in step (2) is broken into 1mm coarse powder in the Raymond machine;

[0070] (4) Put the material obtained in step (3) into xylene at 120° C., stir at a speed of 500 r / min for 2 hours, filter, rewash the filtrate twice, and dry at 200° C. under vacuum;

[0071] (5) Under the protection of nitrogen, the material obtained in step (4) is first heated to 900° C. at a heating rate of 4° C. / min, and kept for 50 minutes; then heated to 1300° C. at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com