Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

302 results about "Electrostatic separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Breaking and high tension electrostatic separating method for worn-out printed circuit board

InactiveCN1654124ANo pollution in the processReduce pollutionElectrostatic separationGrain treatmentsElectrostatic separationEngineering

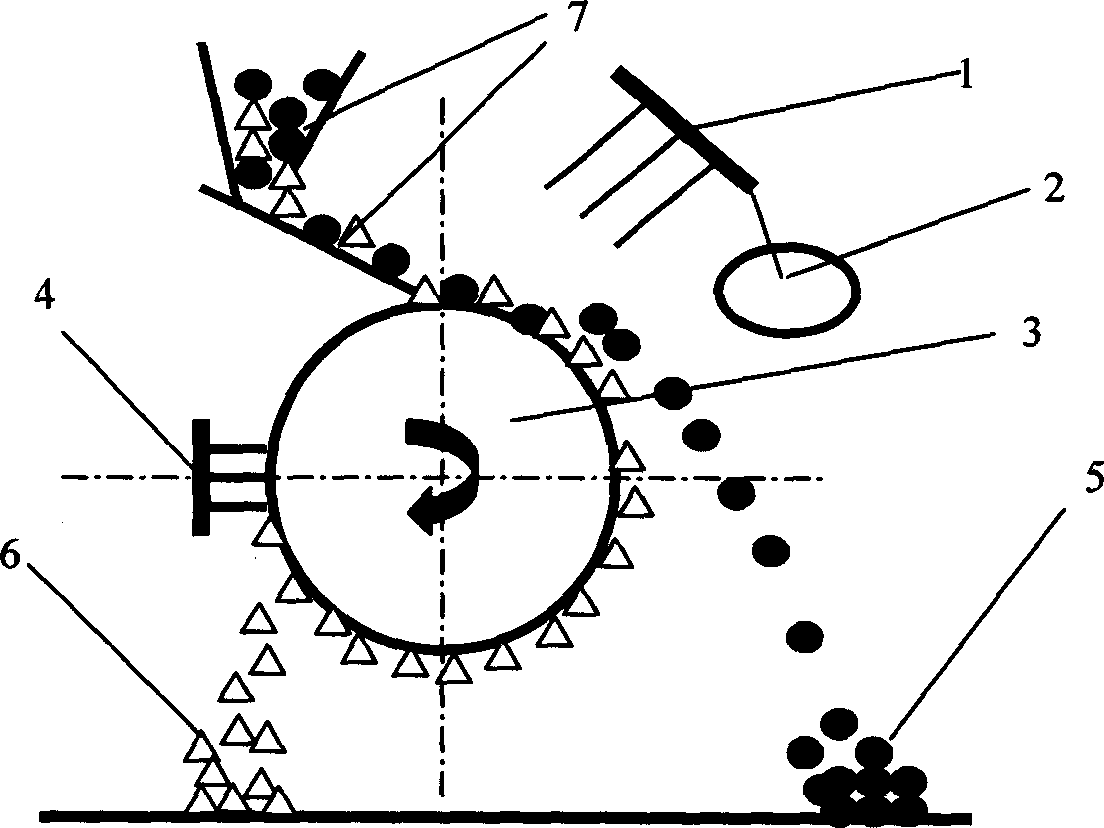

The crushing and high voltage electrostatic separation process of waste printed circuit board includes first crushing waste printed circuit board into 5-20 mm fragments, then pulverized into 0.06-0.5 mm grains and final separating metal grains from non-metal grains. The pulverized grains are fed to separating roller in high voltage electrostatic separating apparatus homogeneously and bombarded with negative ions the corona electrode generates to be charged. The metal grains are discharged fast in the earthing roller and electrostatically attracted with the static charge the electrostatic electrode generates to separate from the separating roller and fall into the metal collecting area, while the negatively charged non-metal grains are repelled electrically by the electrode to maintain on the surface of the metal roller before being brushed with a brush to fall into the non-metal collecting area. Thus, non-metal grains are separated from the metal grains in low cost, high efficiency and no pollution.

Owner:SHANGHAI JIAO TONG UNIV

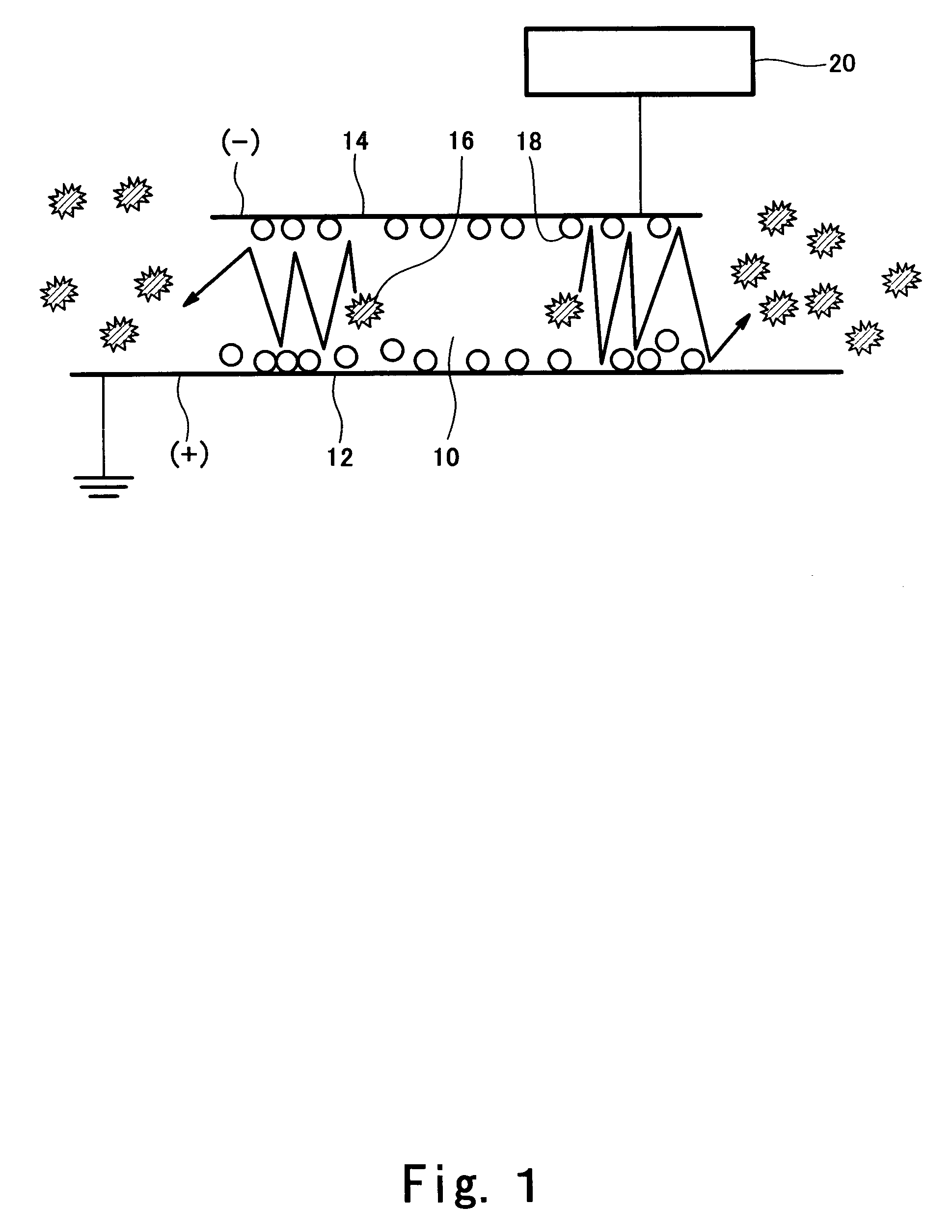

Electrostatic separation system for removal of fine metal from plastic

InactiveUS20070084757A1Separation efficiency can be improvedEasy to separateElectrostatic separationElectrostatic separationEngineering

An electrostatic separation system for separating fine metal and plastics is disclosed. An electrostatic separation system according to the present invention comprises a negative electrostatic induction plate and positive metal net made of special materials, which have appropriate dimensions and an appropriate space between them to improve separation efficiency, and a separating plate which is appropriately positioned to improve separation efficiency. The electrostatic separation system has processing capacity more than 5 times in comparison to conventional electrostatic selection systems and is able to separate fine particles of 0.1 mm in size. In addition, the electrostatic separation system has wide application in recycling other useful recourses as well as separating the mixture of fine particle metal and non-metal materials.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

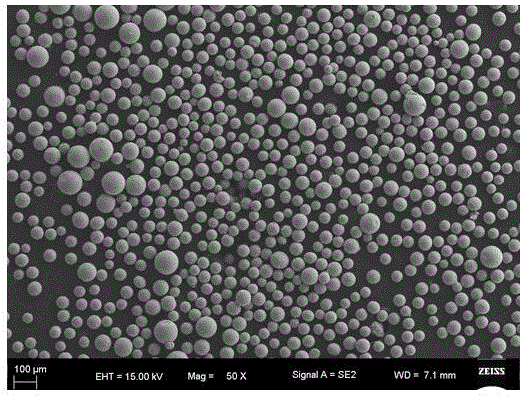

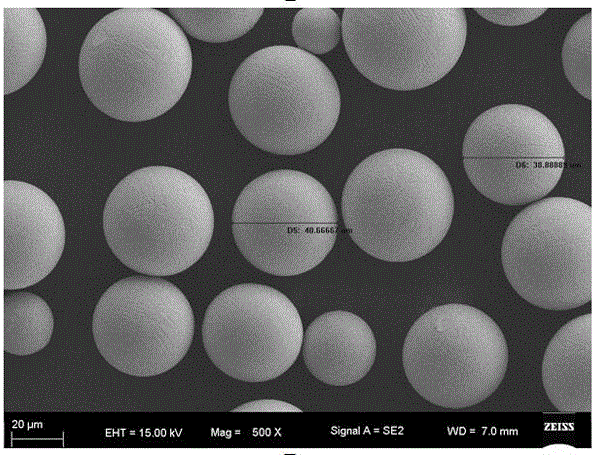

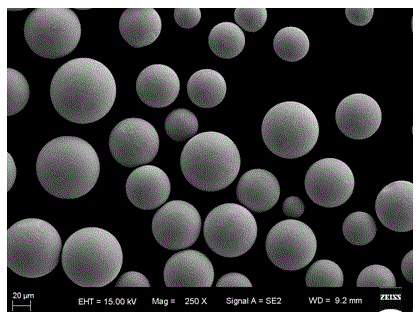

Preparation method of IN718 alloy spherical powder

InactiveCN104308167AReduce oxygen contentReduce contentElectrostatic separationNon-metallic inclusions

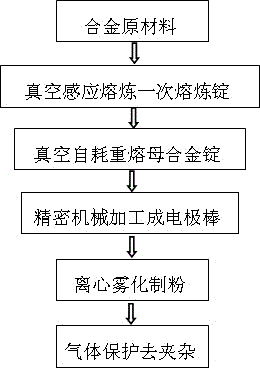

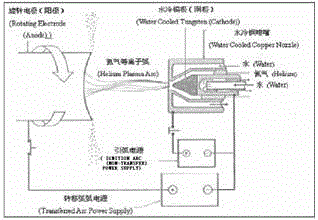

The invention discloses a preparation method of IN718 alloy spherical powder. The method comprises the following steps of step 1, smelting an IN718 alloy master ingot; step 2, processing the IN718 alloy master ingot into an IN718 alloy electrode bar with the diameter of 50 to 90mm and the length of 600 to 800mm, wherein the straightness of the electrode bar is controlled to be smaller than or equal to 0.1mm / m; step 3, placing the IN718 alloy electrode bar in a sealed furnace chamber protected by inert gas, rotating the IN718 alloy electrode bar at high speed, and heating the end part of the electrode bar by using a plasma gun to melt the electrode bar; step 4, atomizing the melted metal under the action of centrifugal force to enable melted metal to fly to form fine liquid droplets, wherein the liquid droplets are quickly cooled in inert gas to form spherical particles, and the spherical particles fall into a collector at the bottom of the furnace chamber to form the IN718 alloy spherical powder; step 5, under the protection of the inert gas, performing electrostatic separation processing on the prepared IN718 alloy spherical powder to remove non-metal impurities from the powder to obtain the pure IN718 alloy spherical powder. The method has the characteristics of good sphericity degree, fine particle size, low oxygen content and few impurities.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Process for preparing ultrahigh pure quartz sand through silica raw material

The invention discloses a process for preparing ultrahigh pure quartz sand through a silica raw material. The silica raw material is treated in such procedures to produce ultrahigh pure quartz sand with SiO2 content larger than 99.995% as manual sorting, calcining, water quenching, crushing, magnetic separation, electrostatic separation, ultrasonic pickling, flotation, ultrasonic alkali washing, drying, secondary magnetic separation, high temperature chlorination, dehydroxylation treatment and the like, and organic alkali washing, electrostatic separation, secondary magnetic separation, dehydroxylation treatment and high temperature chlorination are particularly added. The process for purifying quartz sand provided by the invention is obvious in effect, high in product purity, low in production cost increase and capable of meeting the requirements of such industrial production on raw materials as quartz glass, etc.

Owner:南京工业大学东海先进硅基材料研究院 +1

Treatment method for waste printed circuit board

ActiveCN102191383ASimple componentsFast stripping speedProcess efficiency improvementElectrostatic separationEngineering

The invention provides a treatment method for a waste printed circuit board, which comprises the following steps of: wet sealing-off treatment, separation of lead and tin, rough crushing, magnetic separation of iron, vortex separation, fine crushing and separation of fine nonmetal powder, electrostatic separation of metal and nonmetal in coarse mixture, recovery of heat energy through fire burning and harmless treatment of harmful tail gas. The invention combines wet sealing-off, decomposing classification and fire burning to reasonably recover usable resources, and is environment-friendly.

Owner:JIANGXI GREEN ECO MFG RESOURCE CYCLE

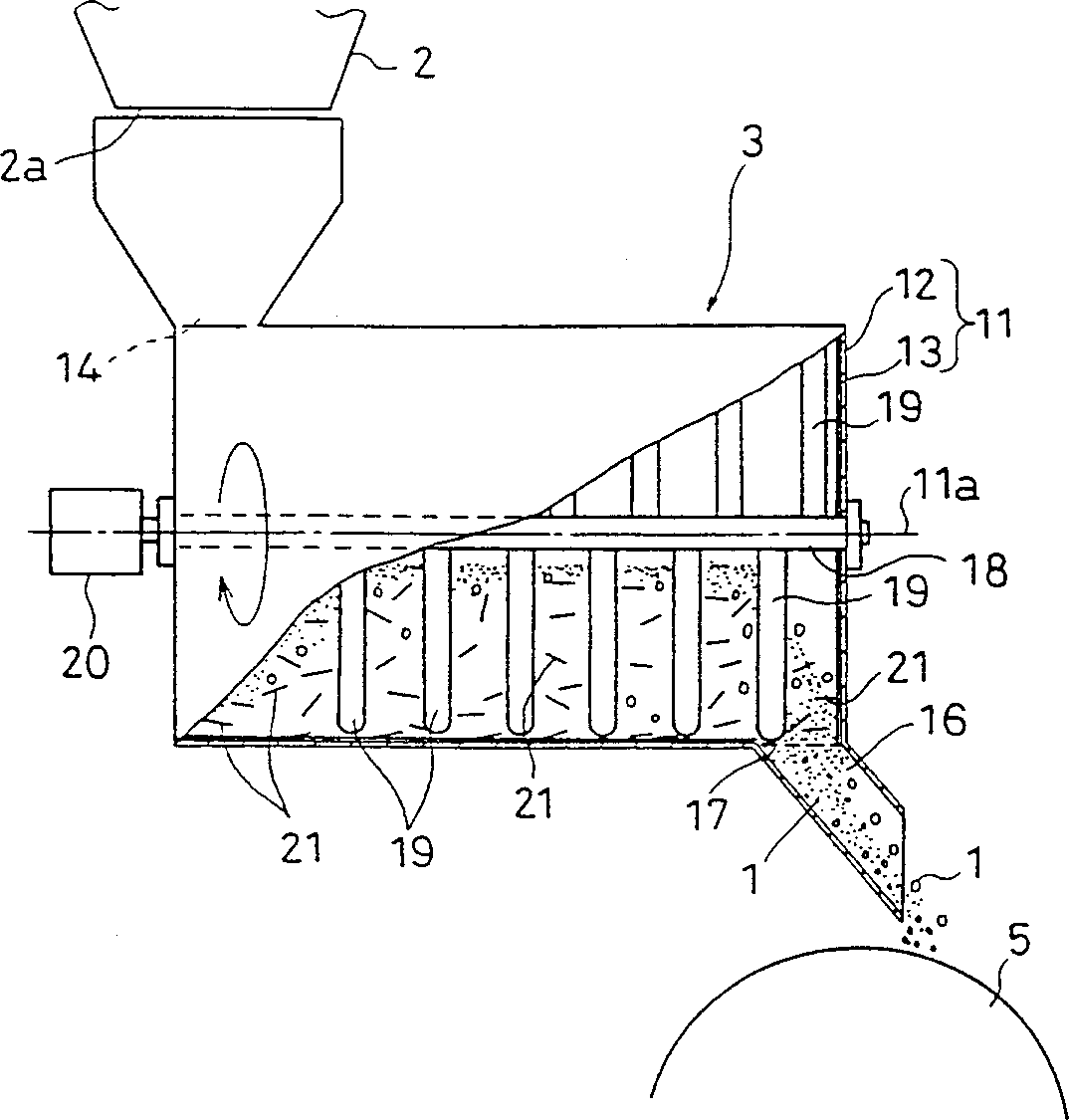

Method and facility for sorting and separating waste plastic

InactiveCN102574304AEfficient implementation of recyclingReliable removalElectrostatic separationPlastic recyclingElectrostatic separationCrusher

Disclosed is a facility for precisely sorting, by material, waste plastic that includes many types of material. Said facility is provided with: a crusher (11) that pulverizes a waste plastic feedstock into waste plastic fragments having a prescribed size; a steam-cleaning device (13) that is disposed downstream from the crusher and that cleans the waste plastic fragments; a primary wet specific-gravity sorter (14) and a secondary wet specific-gravity sorter (15) that are disposed downstream from the steam-cleaning device and that use separation liquids, which have specific gravities in the middle of the specific gravities of the materials included in the waste plastic fragments, to separate out at most three types of floating or sinking specific-gravity-sorted fragments; and first through third electrostatic separation devices (16A-16C), each of which is disposed downstream of the primary and secondary wet specific-gravity sorters and has a frictional charging device, which frictionally charges the specific-gravity-sorted fragments, and an electrostatic sorter that puts the frictionally-charged specific-gravity-sorted fragments in an electrostatic field between a rotating drum electrode to which a high voltage is applied and an opposing electrode, thereby changing the direction the fragments fall and separating said fragments by material.

Owner:HITACHI ZOSEN CORP +1

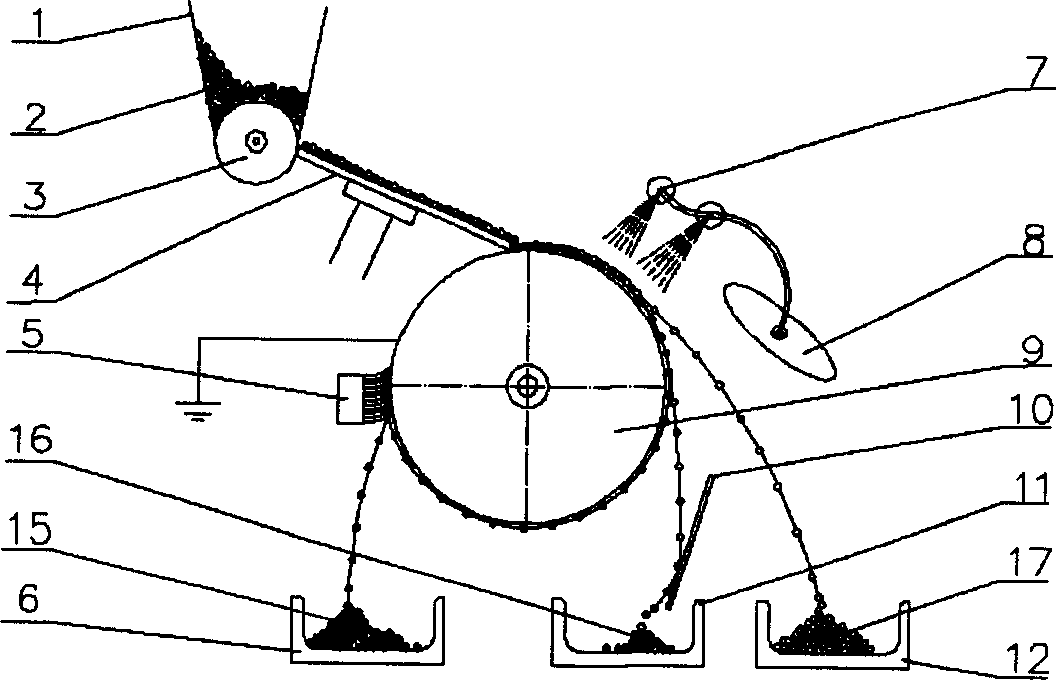

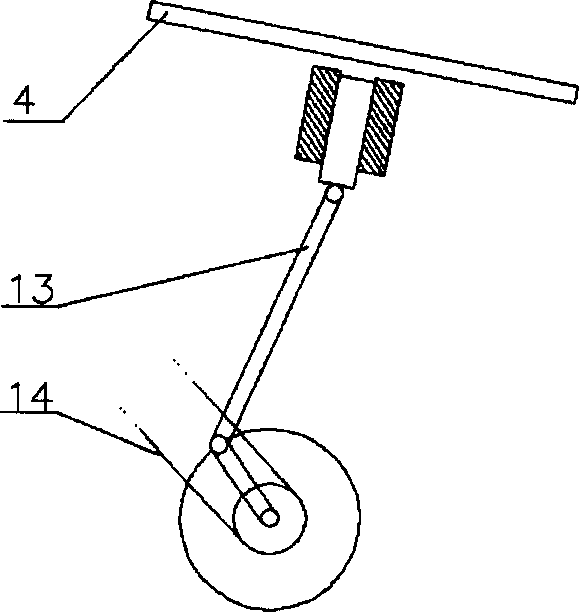

High tension electrostatic separating apparatus and method for worn-out broken printed circuit board granules

InactiveCN1654129ALow costReduce energy consumptionElectrostatic separationElectrostatic separationEngineering

The present invention is high voltage electrostatic separation apparatus and method of crushed waste printed circuit board grains. The mixed metal and non-metal material grains fed with the composite feeding system to fall onto the surface of the main roller homogeneously via the feeding roller and the feeding vibration board are charged in the high voltage electrostatic field applied with the corona electrodes. Metal grains are attracted electrostatically by the static electrode to deviate from the main roller and fall into the metal collecting area, and the non-metal grains are repelled by the electrode to maintain on the surface of the main roller and to be brushed into the non-metal collecting area, while small amount of semiconductor grains fall in the way to the middle product collecting area. Compared with airflow separation method and water separation method, the present invention has the features of low cost, high efficiency, simple structure, no pollution and other advantages.

Owner:SHANGHAI JIAO TONG UNIV

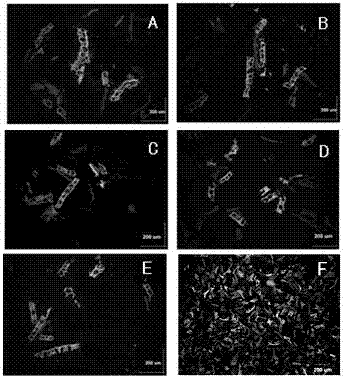

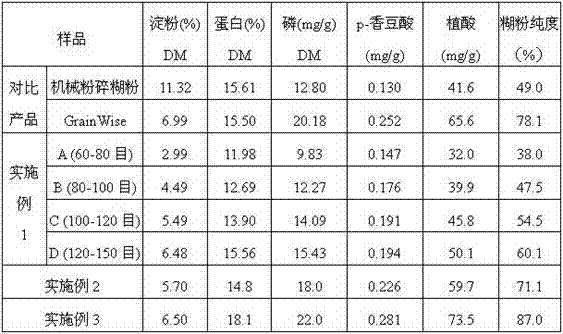

Preparation method of wheat bran aleurone

ActiveCN102894262AAchieve FeaturedAchieve enrichmentFood preservationGrain treatmentsBiotechnologyElectrostatic separation

The invention provides a preparation method of wheat bran aleurone which is prepared by taking wheat bran as raw material. The preparation method comprises the following steps of: removing impurities, precrushing, predrying / prefreezing, crushing at low temperature, enriching, carrying out air classification and grading or high-voltage electrostatic separation, sterilizing and packaging to obtain an aleurone finished product, wherein the operations of removing impurities and enriching are carried out in a spin-vibration screen, the operation of crushing at low temperature is carried out through a turbo type crusher at the crushing temperature ranging from 15 DEG C below zero to 10 DEG C, and the operation of high-voltage electrostatic separation is carried out in a high-voltage direct-current electrostatic field. As a dry method for machining and treating, the method provided by the invention can be used for remaining the nutritional ingredients of the aleurone to the maximum extent and is good in separation effect for an aleurone layer, high in purity of the prepared aleurone finished product, simple in process flow and low in production cost.

Owner:JIANGNAN UNIV

Method and device for dehulling separation of flax seed

InactiveCN1883808AReduce processing timeThorough peelingSievingGrain huskingDecortication procedureMoisture

Disclosed is a method for flax seeds decortication and separation, comprising dehydrading flax seeds to a moisture percentage of 2-4%; feeding same into a rotary centrifugal decortication machine continuously, decorticating the flax seeds to form a mixture of shells and kernels; and separating the shells and kernels mixture through an electrostatic field. An apparatus realizing said method comprises a centrifugal decortication machine, screen means mounted on the discharge side of the centrifugal decortication machine, a convey belt mounted on the discharge side of the screen, and electrostatic absorption means mounted over the discharge terminal of the convey belt front part. The method is provided with continuously industrialization production for large amounts of product, complete seperation of shells and kernels, and high production efficiency to shorten the art time from the flax seeds feeding, decorticating to discharging by 80%, decrease full cost by 50%, and produce no environmental waste materials.

Owner:大同市宏致亚麻科技股份有限公司

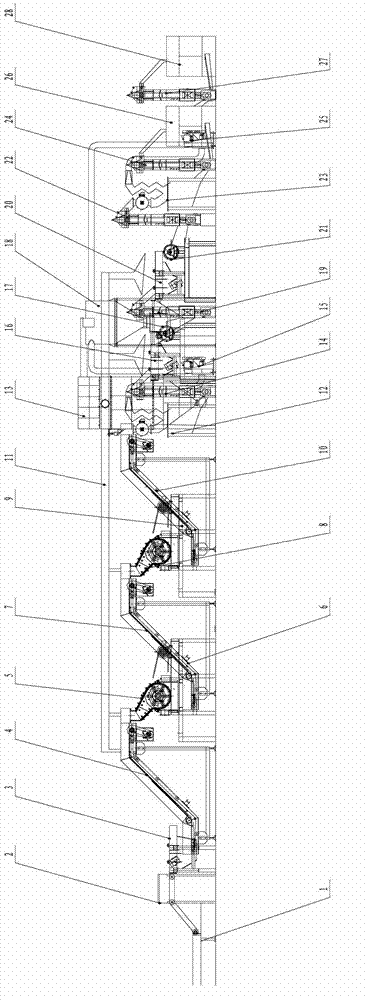

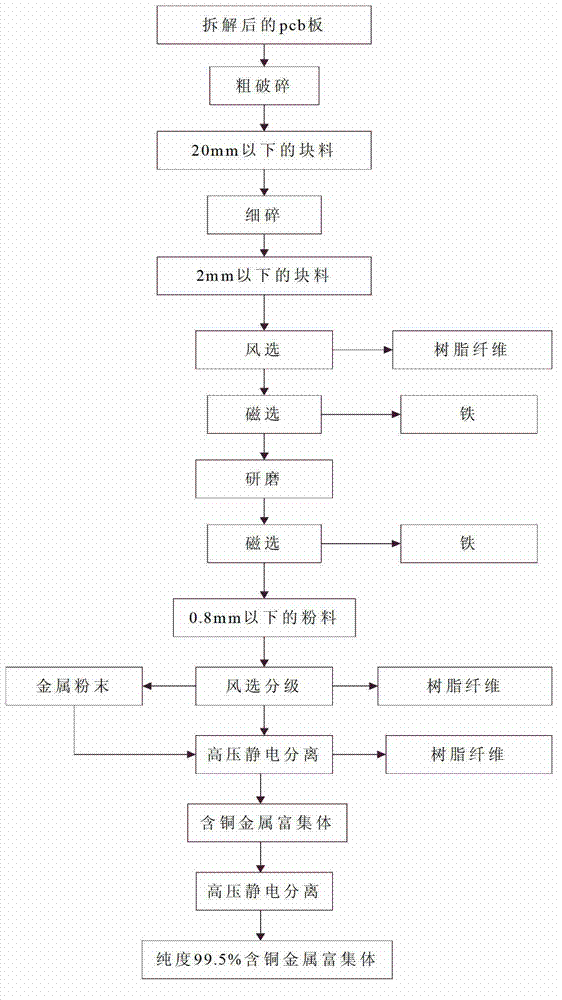

Waste PCB (printed circuit board) crushing and sorting system

ActiveCN102962244AEfficient recyclingAvoid pollutionSolid waste disposalElectronic waste recyclingElectrostatic separationExhaust fumes

The invention discloses a waste PCB (printed circuit board) crushing and sorting system. The waste PCB crushing and sorting system comprises a disassembling unit, a crushing unit, a primary air classification unit, a deferrization unit, a grinding unit, a fine deferrization unit, an air classification separating unit, a high-voltage electrostatic separation unit, a dust and waste gas disposition unit and a central control unit, wherein a circuit board is disassembled and crushed, and then is subjected to procedures such as primary air classification, primary deferrization, grinding, secondary deferrization, air classification separating and high-voltage electrostatic separation, and a copper-containing metal concentration with the purity of 99.5% is obtained. The waste PCB crushing and sorting system provided by the invention is used for recovering available resources in a waste PCB plate treating process, treating the waste PCBs in scales, efficiently recovers resources, and avoids the environment pollution.

Owner:启迪再生资源科技发展有限公司

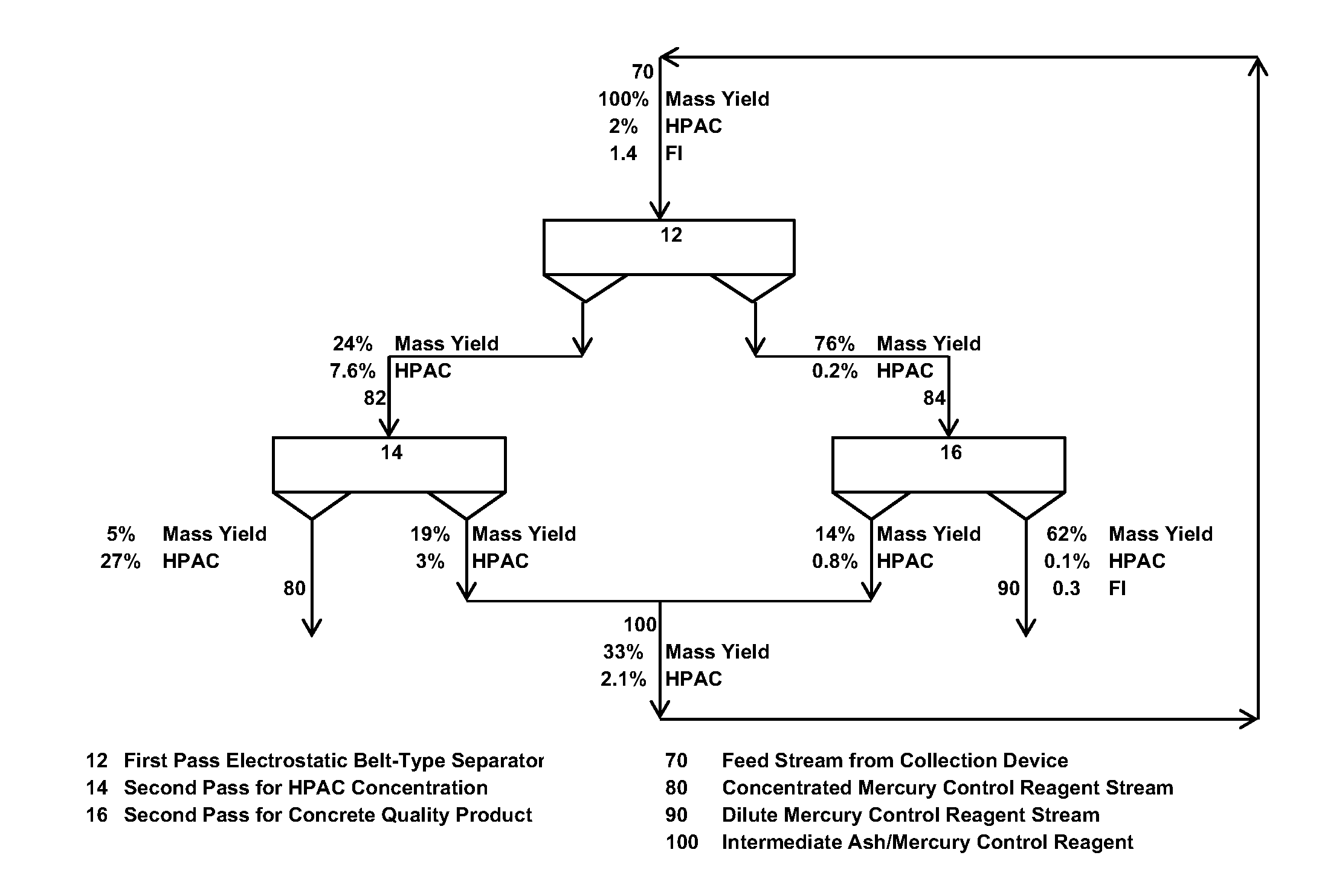

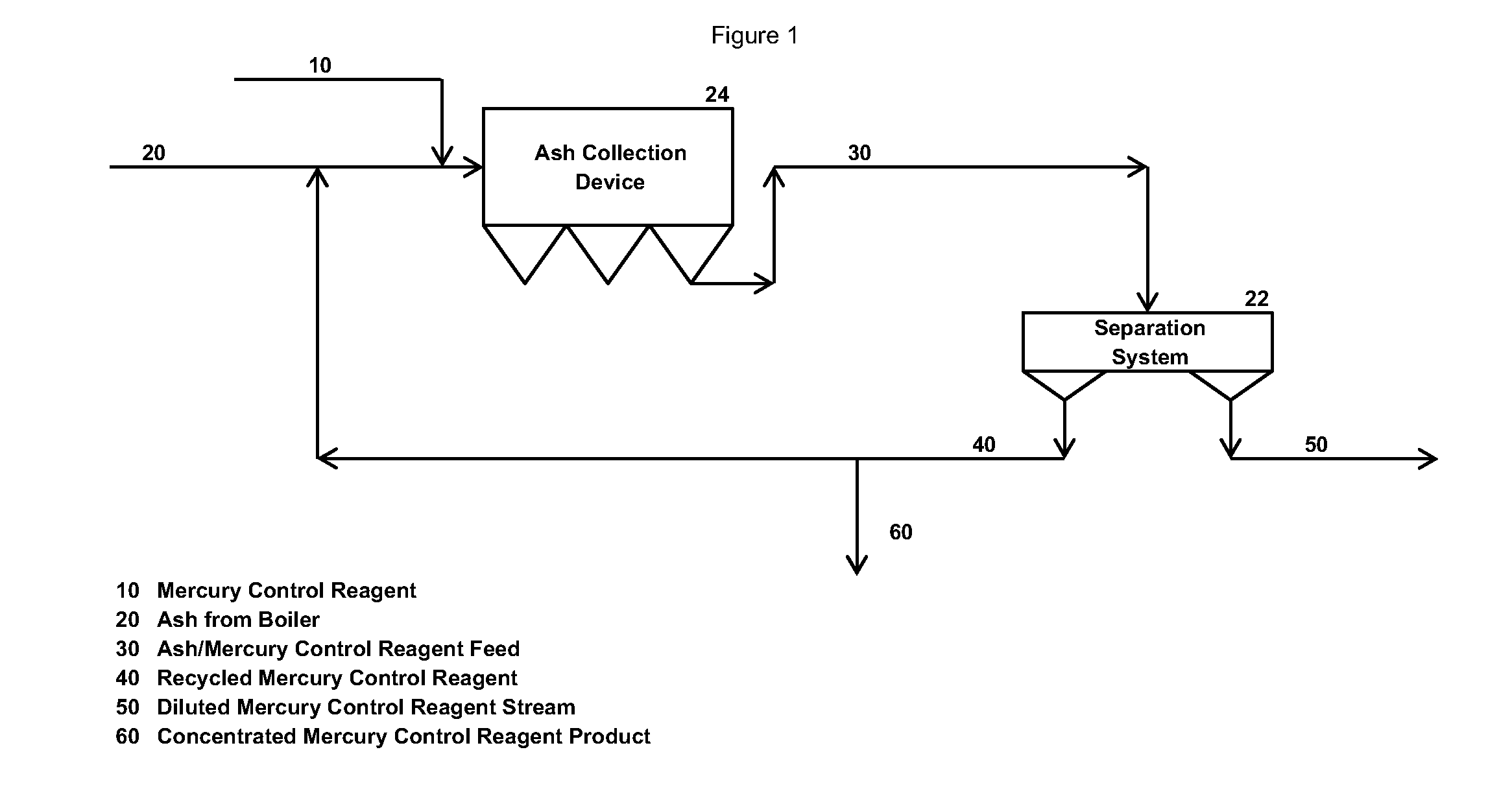

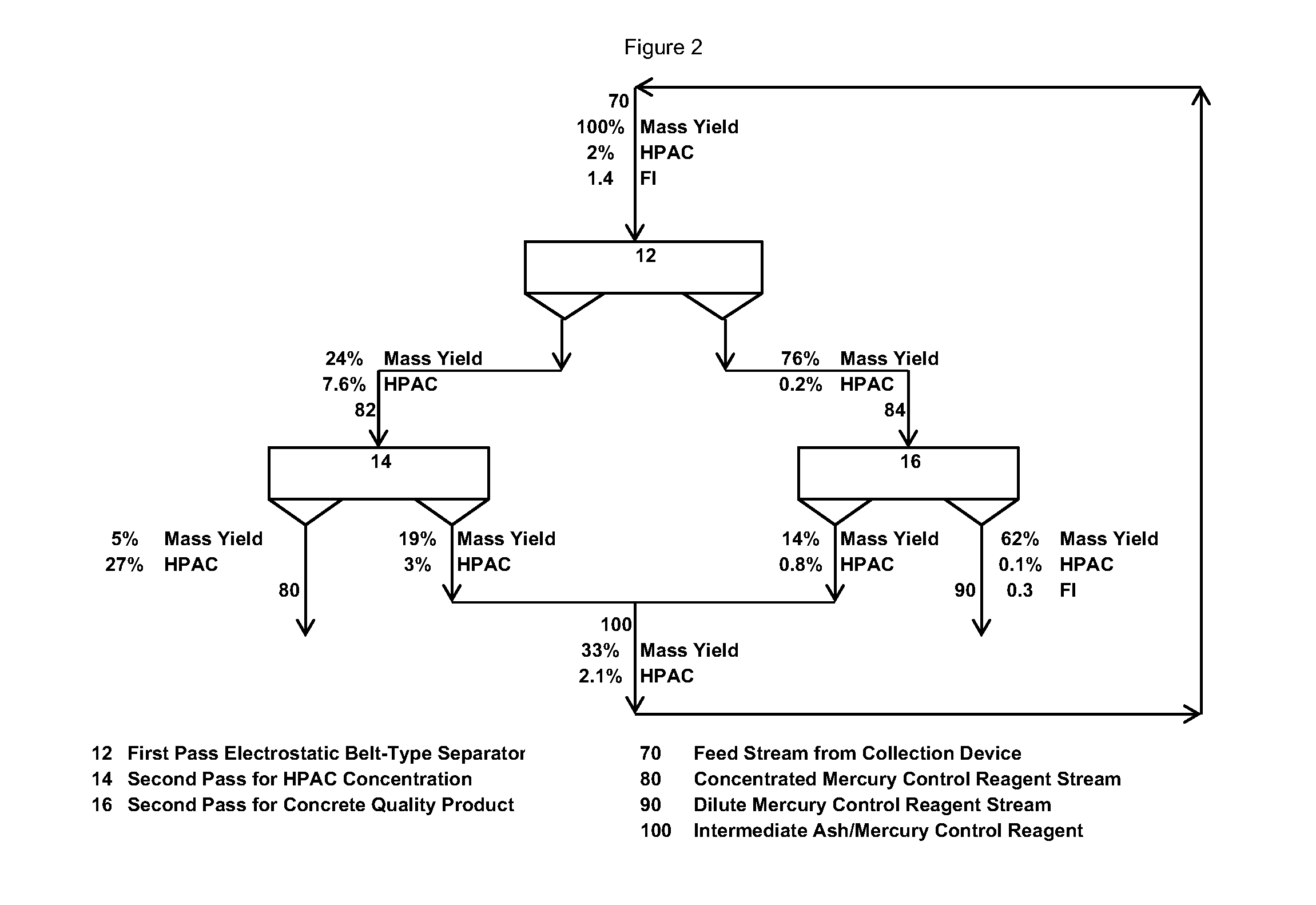

Recovery of mercury control reagents by tribo-electric separation

InactiveUS20110289923A1Reduce the amount requiredImprove recycling efficiencyGas treatmentElectrostatic separationParticulatesElectricity

A method and apparatus for recovering mercury control reagents from particulate materials is disclosed. The particulate materials include fly ash mixed with mercury control reagents collected from boiler flue gases. The particulate materials are provided to an electrostatic separation system, which is operated under predetermined conditions so as to produce a concentrated stream of the mercury control reagent and a diluted stream containing minimal mercury control reagent.

Owner:SEPARATIONS TECH

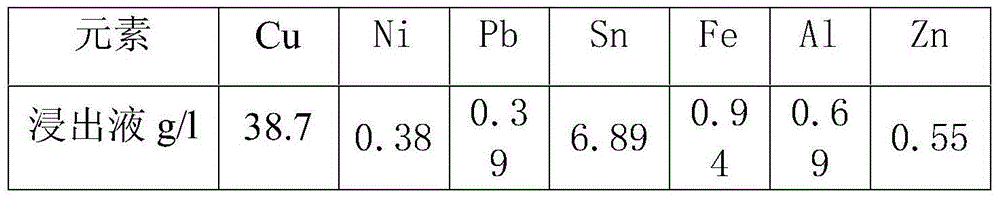

Resourceful comprehensive utilization method of waste printed circuit boards

ActiveCN104532005ARealize resource utilizationSolve problems such as pollutionProcess efficiency improvementElectrostatic separationSlag

The invention discloses a resourceful comprehensive utilization method of waste printed circuit boards. The method comprises the following steps: crushing waste printed circuit boards and carrying out magnetic separation to obtain ferrous raw materials and non-ferrous raw materials; carrying out high-voltage electrostatic separation on the non-ferrous raw materials to obtain metallic materials and non-metallic materials; and separating such metals as copper, gold and silver from the metallic materials. By adopting the method disclosed by the invention, such valuable metals as copper, tin, aluminum, iron, lead, gold and silver and metal slag containing nickel and zinc in the waste printed circuit boards can be recovered and the materials such as non-metallic resin can also be recovered. By adopting the resourceful comprehensive utilization method, the problems of environmental pollution caused by the waste printed circuit boards and the like are solved and the resourceful comprehensive utilization of the waste printed circuit boards is achieved. The method is simple in process and is economical and practical and industrialization is easy to implement.

Owner:清远市东江环保技术有限公司

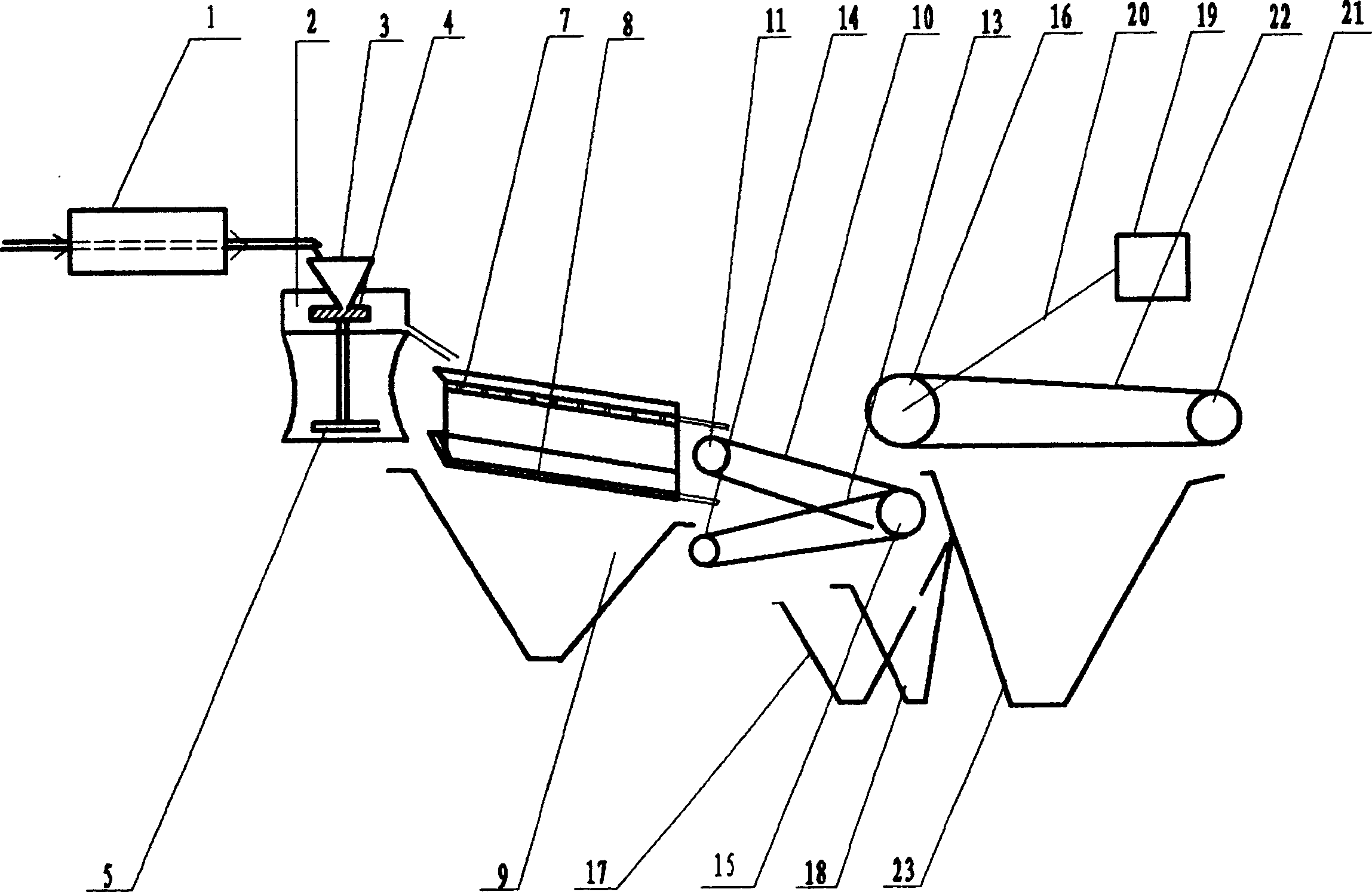

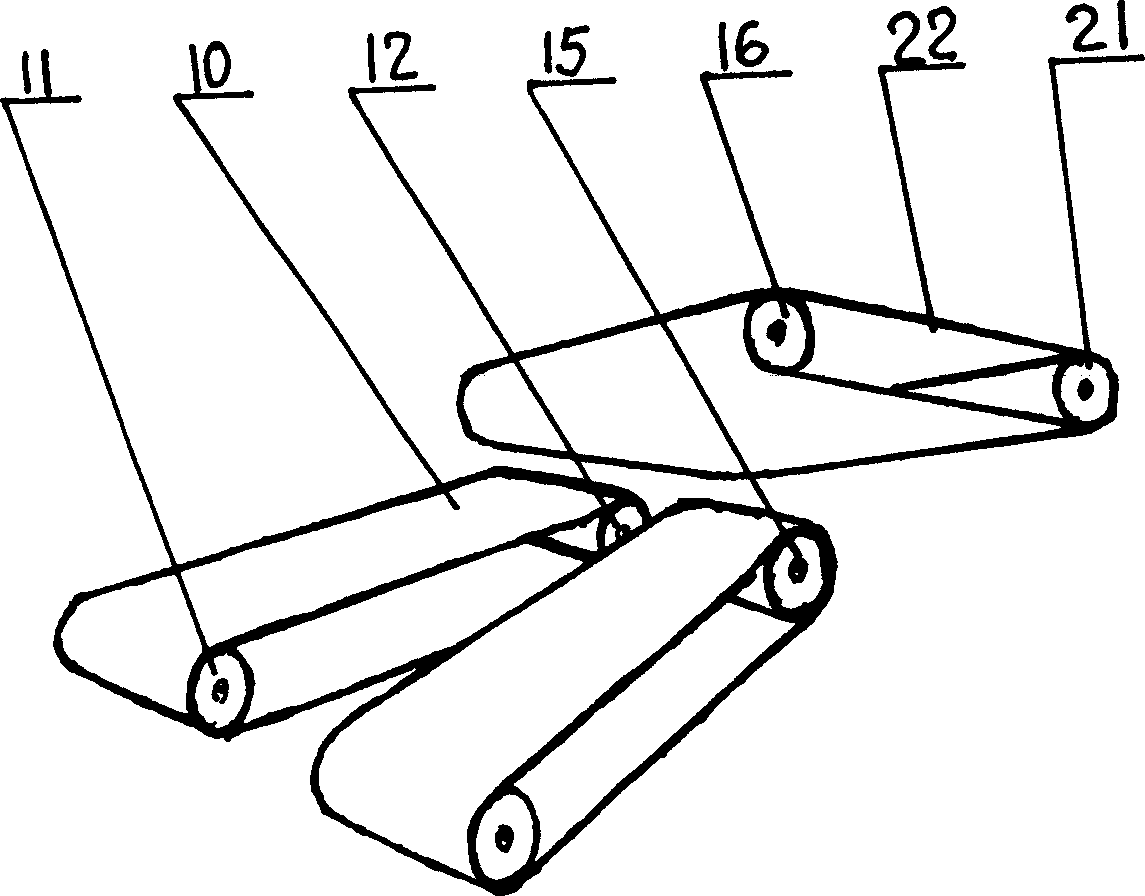

Grinding recovery treatment technology of waste electron wiring board and its equipment

InactiveCN1786222AGood dissociationEasy to separateSolid waste disposalProcess efficiency improvementBrute forceElectrostatic separation

The invention relates to a worn-out electronic circuit plate mechanical disintegration and electrostatic separation recovery processing technique and its using equipment. The processing steps include the following steps: crushing worn-out electronic circuit plate; intermediate crushing after removing iron; fine crushing; dividing part nonmetal matter by ultra-micro classifier; sending to high voltage electrostatic separator to from finished product. The equipment includes brute force crusher, magnetic separator, intermediate crusher, fine crusher, ultra-micro classifier, and high voltage electrostatic separator. Its advantages are good crushing dissociation, good reclaiming effect, low energy consumption, long using life and no secondary pollution.

Owner:浙江丰利粉碎设备有限公司

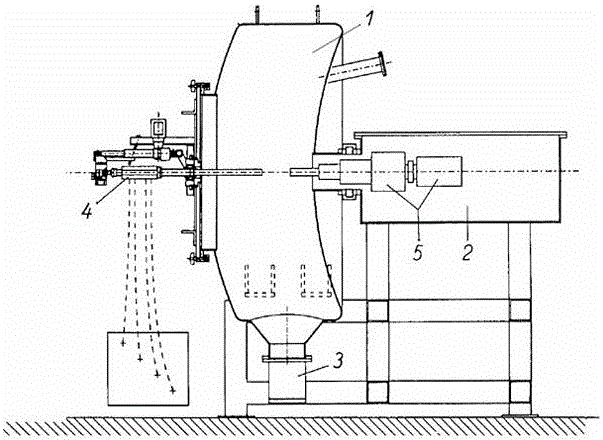

Preparation method of Waspalloy spherical powder for additive manufacturing

InactiveCN106623959AFast pure meltingReduce the introductionAdditive manufacturing apparatusTransportation and packagingVacuum pumpingElectrostatic separation

A preparation method of Waspalloy spherical powder for additive manufacturing includes the steps of conducting alloy component compounding according to AMS 5706 standards and subjecting master ingots to vacuum melting twice; producing the master ingots into alloy electrode bars by means of forging and machining; subjecting an atomizing unit to pre-vacuum-pumping treatment, and feeding the atomizing unit with mixed inert protective gas; feeding the electrode bars into an atomizing chamber by a feeding system, heating electrode bar end faces by a plasma torch, preparing metal liquid droplets under the centrifugal action of a rotating electrode, and making the metal liquid droplets form spherical metal powder by flash setting; using a powder collecting device comprising an electrostatic separation component for removing inclusions of the spherical metal powder and collecting purified powder. The preparation method has the advantages of high production efficiency, high batch stability and high -270-mesh powder yield and can be used for easily preparing the Waspalloy spherical powder high in purity, sphericity and fluidity.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

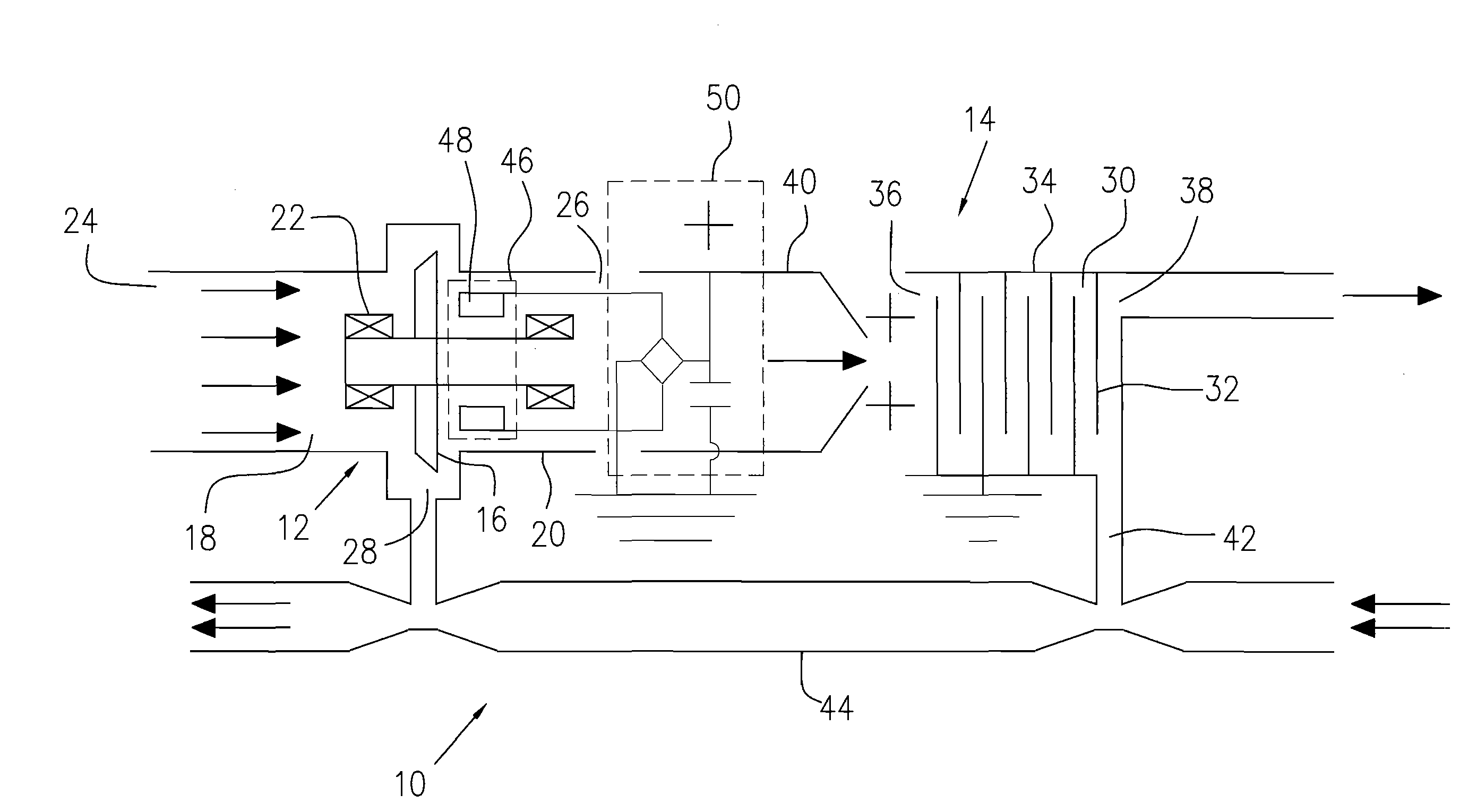

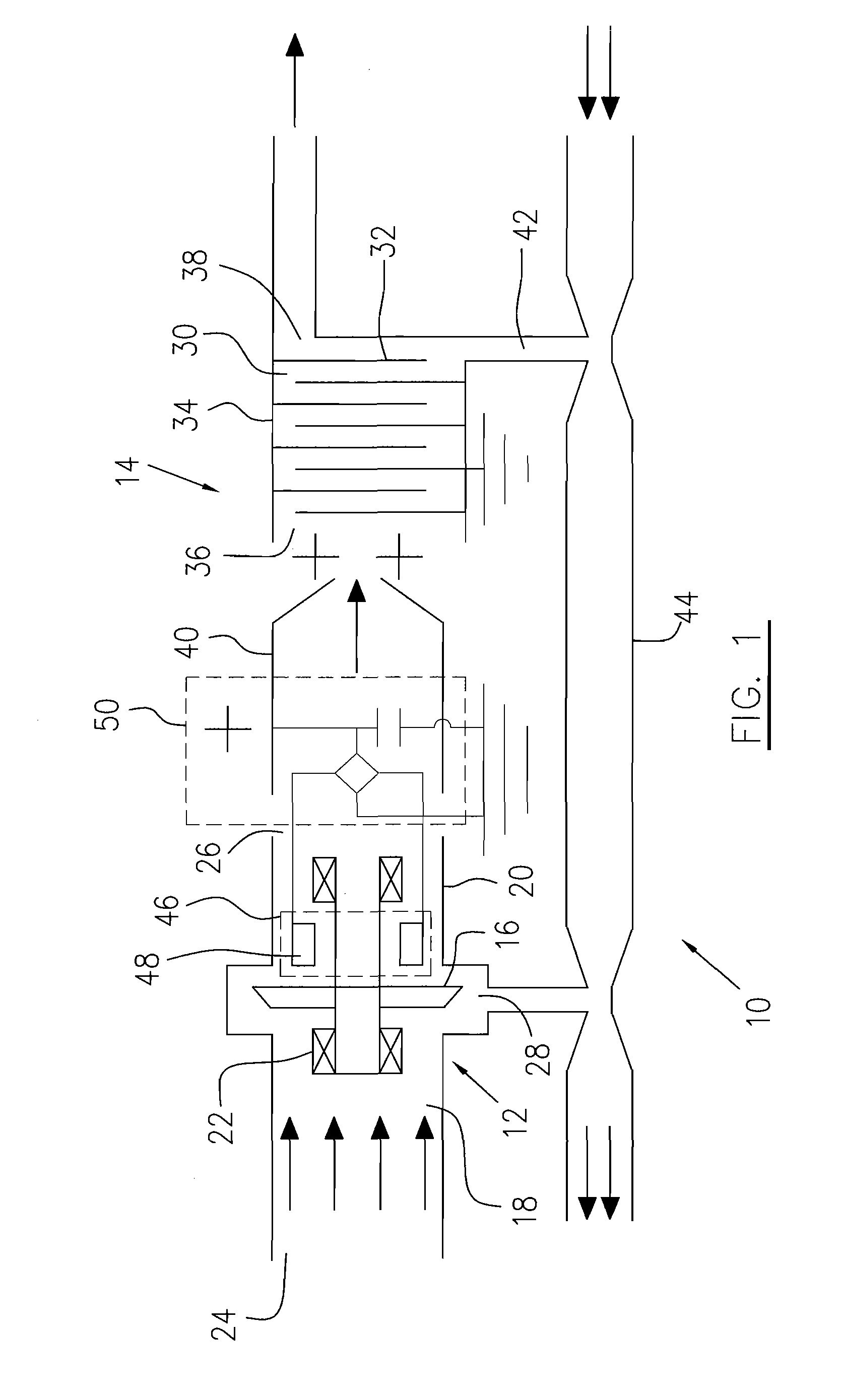

Self-contained electrostatic air/oil separator for aircraft engine

InactiveUS20080078291A1Dispersed particle filtrationAircraft accessoriesElectrostatic separationGas turbines

An air / oil separator for use in a gas turbine engine comprises a centrifugal separation stage in fluid communication with a downstream electrostatic separation stage. The centrifugal separation stage rotationally drives an electric generator to power the electrostatic separation stage.

Owner:PRATT & WHITNEY CANADA CORP

Processes for preparing and purifying quartz sand and quartz powder and products thereof

The invention discloses processes for preparing and purifying quartz sand and quartz powder and products thereof. The process for preparing and purifying quartz sand comprises the following steps: carrying out rough concentration on vein quartz green ores, crushing, roasting, quenching with water, grinding and grading, carrying out high-gradient magnetic separation, carrying out a complex reaction by using drugs, carrying out floatation, carrying out electrostatic separation, washing with deionized water, and drying to obtain the product. The process for preparing and purifying quartz powder comprises the following steps: carrying out rough concentration on vein quartz green ores, crushing, roasting, quenching with water, grinding and grading, carrying out high-gradient magnetic separation, carrying out a complex reaction by using drugs, treating with microwaves, carrying out electrostatic separation, washing with deionized water, and drying to obtain the product. The quartz sand and the quartz powder produced by using the processes provided by the invention do not bubble in the production process of glass and chips, optical fibers and cables can not break, and the glass does not have water grains. The quartz sand and the quartz powder have widened the application fields, and are applicable to the fields of monocrystalline silicon, polycrystalline silicon, optical fibers and cables, war industry, fine chemical industry and micro-electronics.

Owner:刘少云

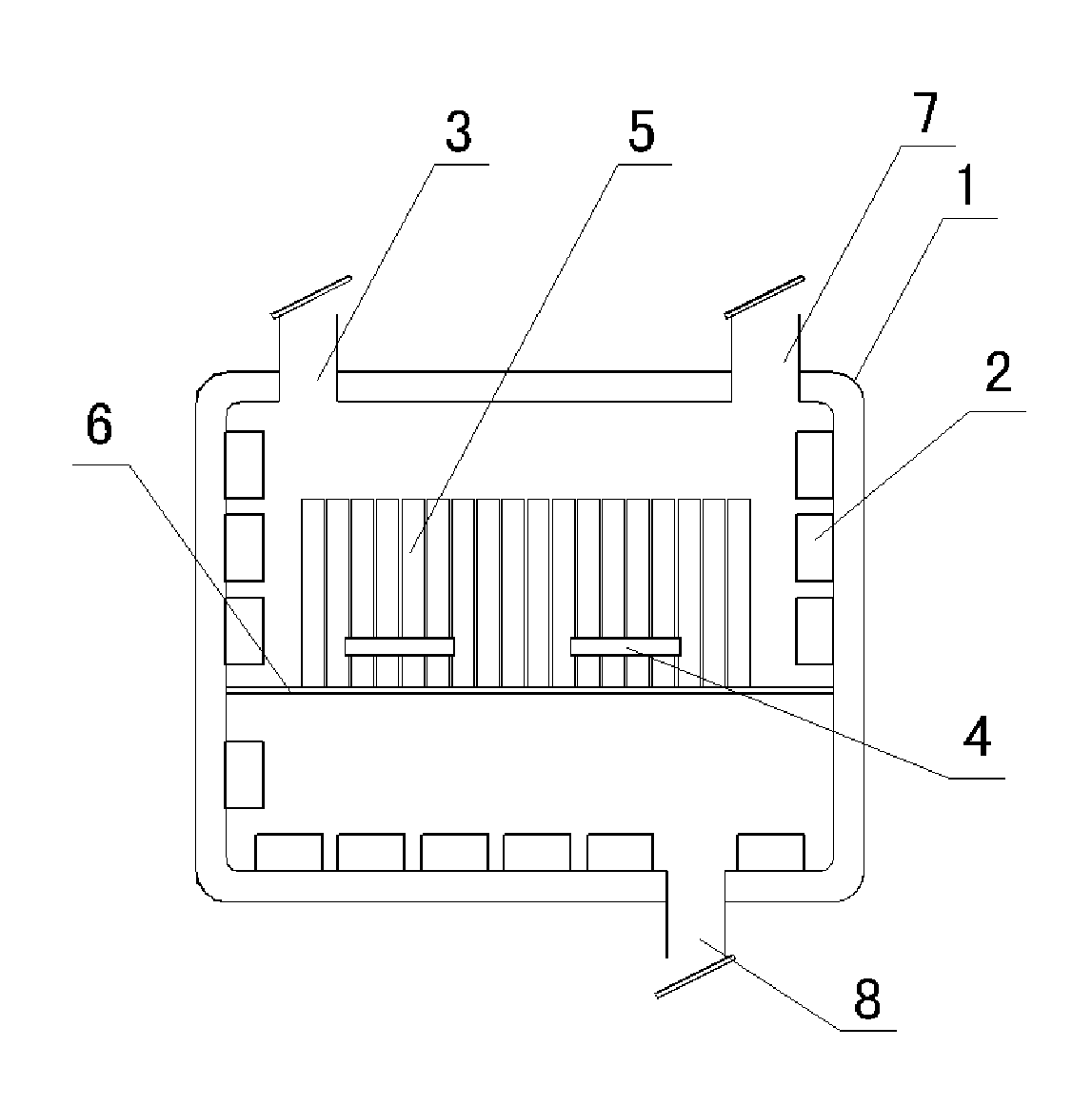

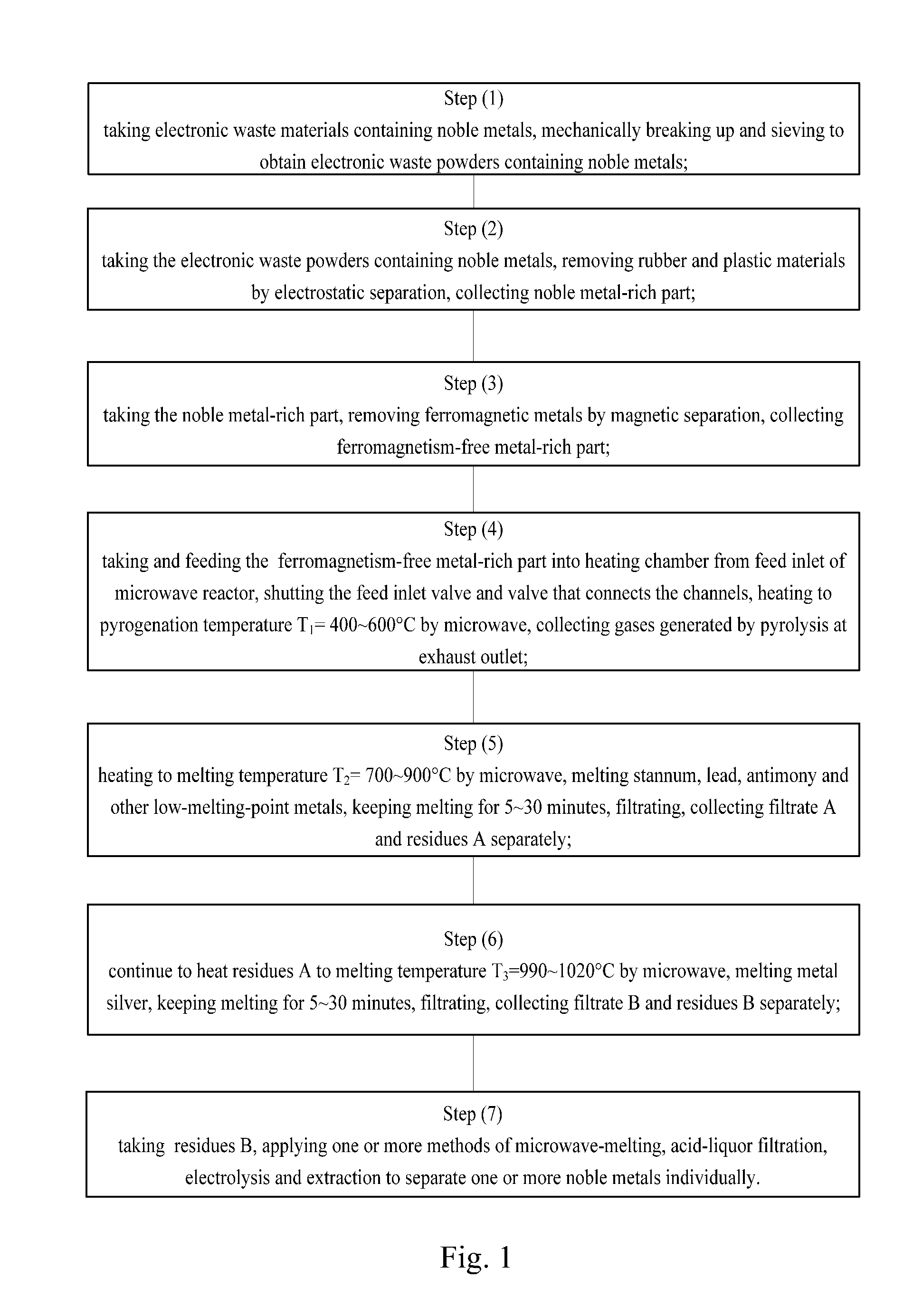

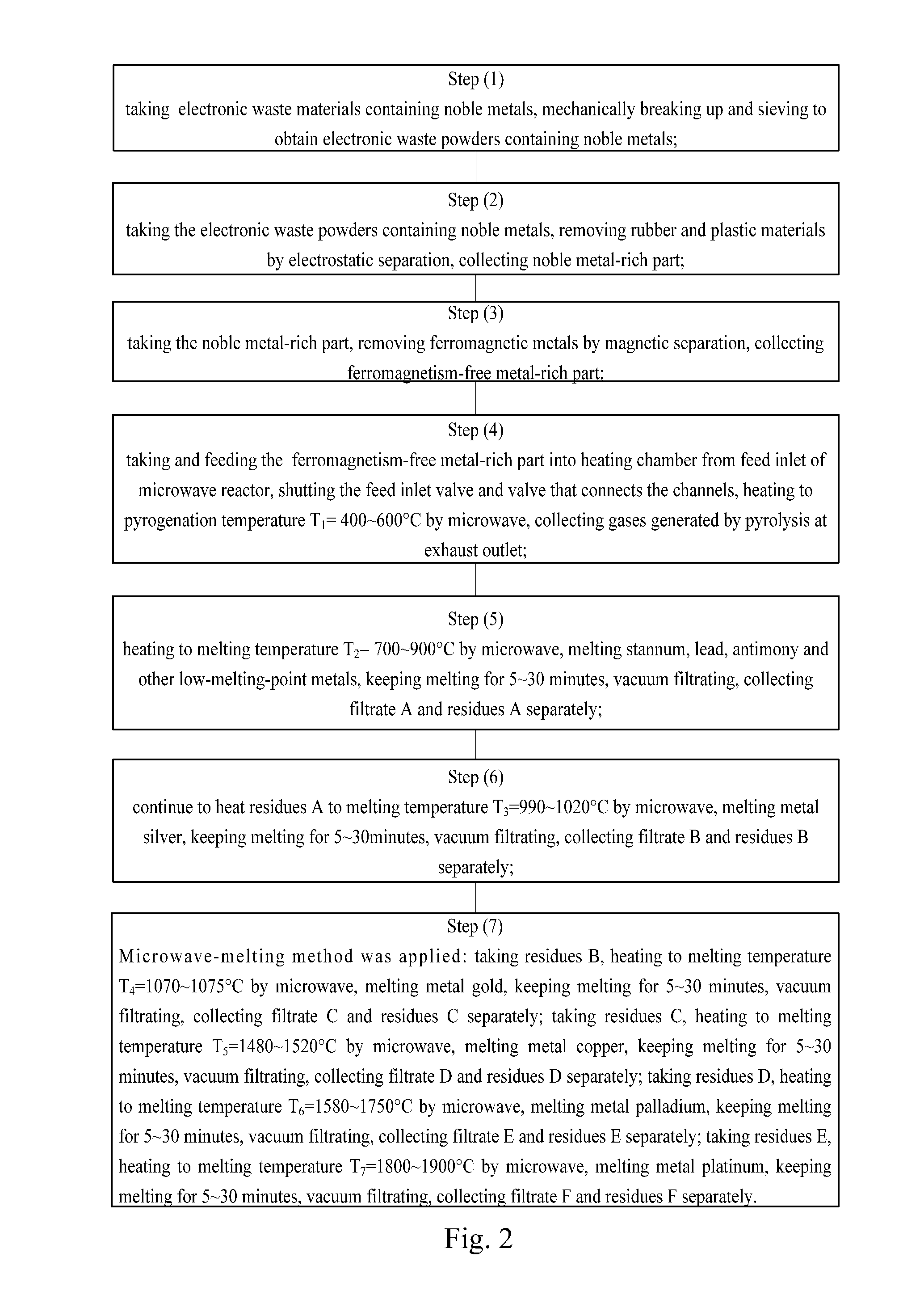

Method for recycling noble metal from electronic waste material and apparatus thereof

ActiveUS20130174694A1Heating up fastEasy to controlFrom normal temperature solutionsLiquid separation by electricityElectrostatic separationMicrowave pyrolysis

A method for recycling noble metals from electronic waste materials and apparatus thereof. The method comprises the following steps: mechanically breaking up the electronic waste materials; removing rubber and plastic materials by electrostatic separation; removing ferromagnetic metals by magnetic separation; removing residual rubber and plastic materials by microwave pyrolysis; removing low-melting-point metals by indirectly heating using microwave; separating the noble metals from one another in turn from low-melting-point metal to high-melting-point metal for recycle. The apparatus includes a microwave housing. A filtering screen is positioned on the inside wall of the housing horizontally, and vertically-arranged and open-ended heating pipes are positioned over the filtering screen. The method and apparatus can adequately recycle resources in the electronic waste materials.

Owner:GEM CO LTD

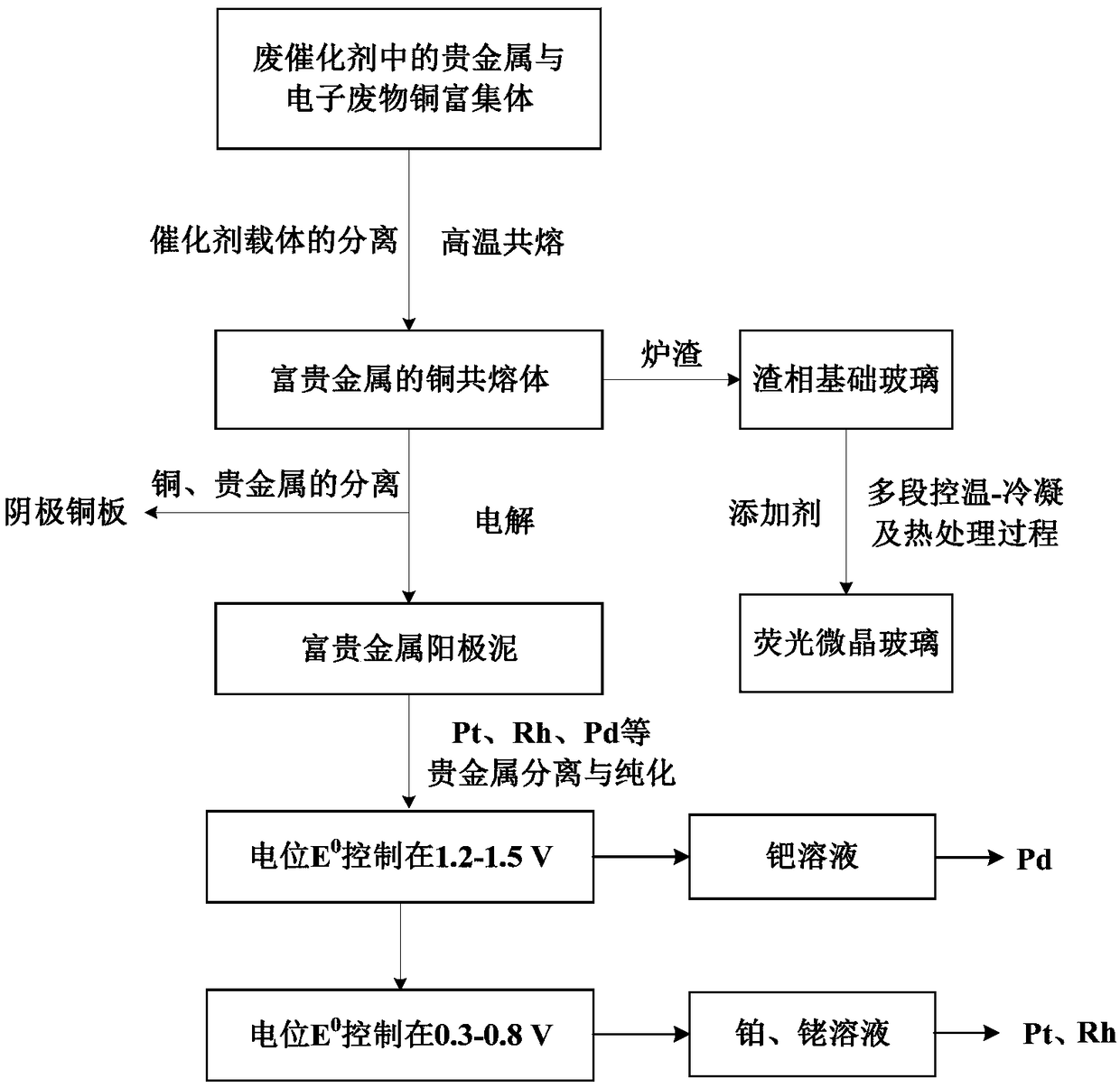

Method for collaborative resource between waste circuit board and automobile tail gas waste catalyst

ActiveCN109136532AEasy to separateEnable co-processingProcess efficiency improvementElectrostatic separationEngineering

The invention discloses a method for collaborative resource between a waste circuit board and an automobile tail gas waste catalyst. The method comprises the following steps: firstly, obtaining a copper-rich collective through performing crushing, magnetic separation and high voltage electrostatic separation on the waste circuit board; crushing the automobile tail gas waste catalyst to obtain waste catalyst powder; mixing the copper-rich collective and the waste catalyst powder to obtain mixed powder; adding a reagent in a certain amount of mixed powder in proportion, placing in a high-temperature muffle furnace for reaction and cooling to a room temperature after the completion of the reaction to obtain a product of which an upper layer is a glass layer, and a lower layer is a copper layer; separating the copper layer from the glass layer, taking out, crushing, then placing the glass layer in the muffle furnace for heat treatment; after the completion of the treatment, pouring microcrystalline glass liquid into a mold while the microcrystalline glass liquid is still hot, reducing the temperature and forming; after a room temperature is lowered, preparing out fluorescent microcrystalline glass. In the process, the recovery rate of precious metals exceeds 98 percent, the precious metals are enriched for 20 times or more, and the obtained fluorescent microcrystalline glass can betaken as an LED fluorescent lamp and other materials. To sum up, the method has the characteristics of being efficient, environmentally friendly and high in resource degree and is suitable for large-scale industrial application.

Owner:SHANGHAI JIAO TONG UNIV

Burning-free non-cyaniding method for treating waste printed circuit board

ActiveCN102676822ACompletely separate and recycleHigh recovery rateFinal product manufactureTransportation and packagingPlatinumElectrostatic separation

The invention provides a burning-free non-cyaniding method for treating a waste printed circuit board. The method comprises the following steps of: sealing-off, lead and tin separation, crushing and electrostatic separation, and respective extraction of antimony, aluminum, copper, nickel, silver, gold, platinum and palladium. By the method disclosed by the invention, the maximization of valued metal resource recycling is realized, metallic lead and tin can be thoroughly separated and recovered, and at the same time the recovery rate of metallic palladium is improved.

Owner:JIANGXI GEM RESOURCES RECYCLING CO LTD

Preparation method of superfine high-grade spherical EP741NP alloy powder

The invention relates to a preparation method of superfine high-grade spherical EP741NP alloy powder. The method comprises the following steps: 1) proportionally preparing materials according to the EP741NP alloy composition, and smelting to obtain an EP741NP alloy bar; 2) processing the smelted EP741NP alloy bar into an electrode bar; 3) installing the electrode bar into a reaction chamber, vacuumizing the reaction chamber, and proportionally charging inert gas into the reaction chamber; 4) heating the end of an electrode bar to uniformly melt the end, throwing atomized liquid drops from the end of the electrode bar so that the liquid drops are quickly cooled into spherical particles in an inert gas atmosphere and fall into a collector, wherein a plasma torch comprises a tungsten cathode and a copper anode, and the electrode bar is not used as an electrode; and 5) carrying out electrostatic separation on the prepared EP741NP alloy powder in an inert gas protective atmosphere, screening, sampling and packaging. The EP741NP alloy powder prepared by the method is superfine, and has the characteristics of high purity, high-grade sphericity and no hollow powder or satellite powder.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

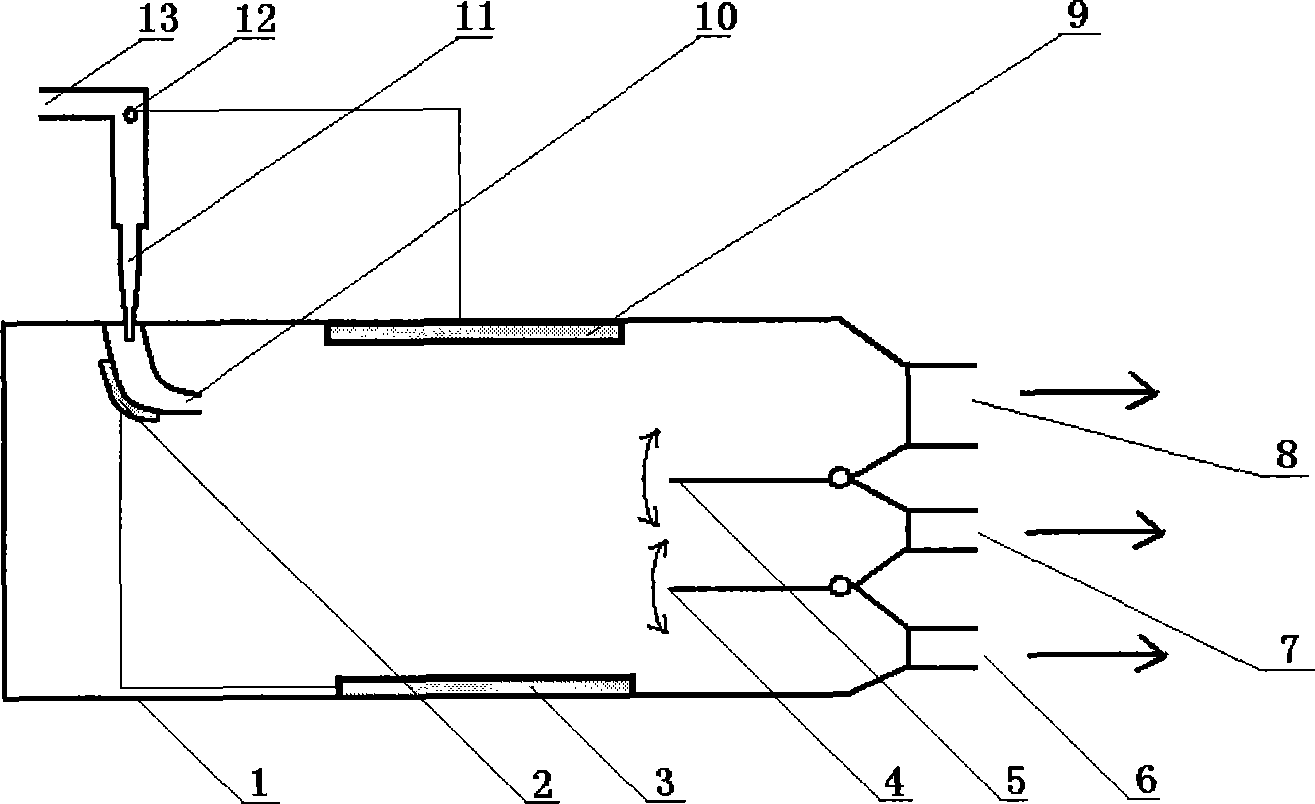

Injection type electrostatic sorting method and apparatus

InactiveCN101462094ASolve the World Puzzle of SortingNo pollution in the processElectrostatic separationElectrostatic separationElectrical conductor

The invention relates to a method and a device for injection electrostatic separation, which are used for separating superfine materials which consist of conductor particles and nonconductor particles. The device mainly comprises a high-pressure electrostatic generator, a high-pressure draught fan, a suspension mixing cavity, a corona cavity, a gas-liquid nozzle, a discharge polar plate, a separation cavity, a separation electrode, a material receiver, a frame, an insulating plate, a metal protective net and the like. The principle of the method and the device is to suspend powder into gas phase flow and solid phase flow, to make solid particles have saturated charge through a corona electric field, to inject the solid particles to the discharge polar plate through the gas-solid nozzle, to achieve the effect that the conductor particles completely discharge but the nonconductor particles almost do not discharge, and to finally complete separation according to the difference of the charge of the particles. The device has definite principle, a simple structure, convenient use and good separation effect, completely solves the worldwide problem of separation of the superfine particles (such as rutile), has the advantages of small fixed investment, low operation cost, small resource consumption and no generation of environmental pollution, and can be widely used in the fields of ore dressing, milling, coal preparation, resource recovery and utilization and the like.

Owner:杨卫华

Grid type electrostatic separator/collector and method of using same

InactiveUS20090071328A1Easy to chargeImprove agglomerationParticle charging/ionising stationsMagnetic separationParticulatesControl system

In one embodiment, apparatuses and methods for collecting particulates use an aperture air flow control system and an inline series of alternating discharge and grid type electrodes each with a separate electrical circuit centrally located between either parallel grid electrodes or plate electrodes. In another embodiment, an external enclosed pre-discharger design and physical arrangement improves agglomeration of sub-micron particles. In yet another embodiment, an external opposing dual channel discharger design also improves agglomeration of particles. In another embodiment, two or more separate electrode arrangements are used within a collecting chamber to improve the operation and collection efficiency of the apparatus. The present invention also preferably increases the frequency of recharging the particles, to increase collection efficiency. In one embodiment, the collection chamber includes both a recharging zone and a high voltage zone followed by a series of fields separated by agglomerating recharging units.

Owner:DUNN JOHN P

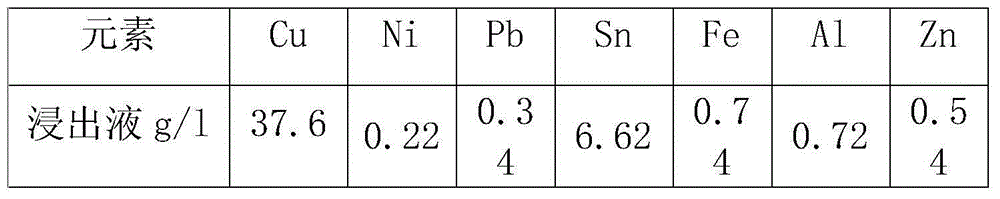

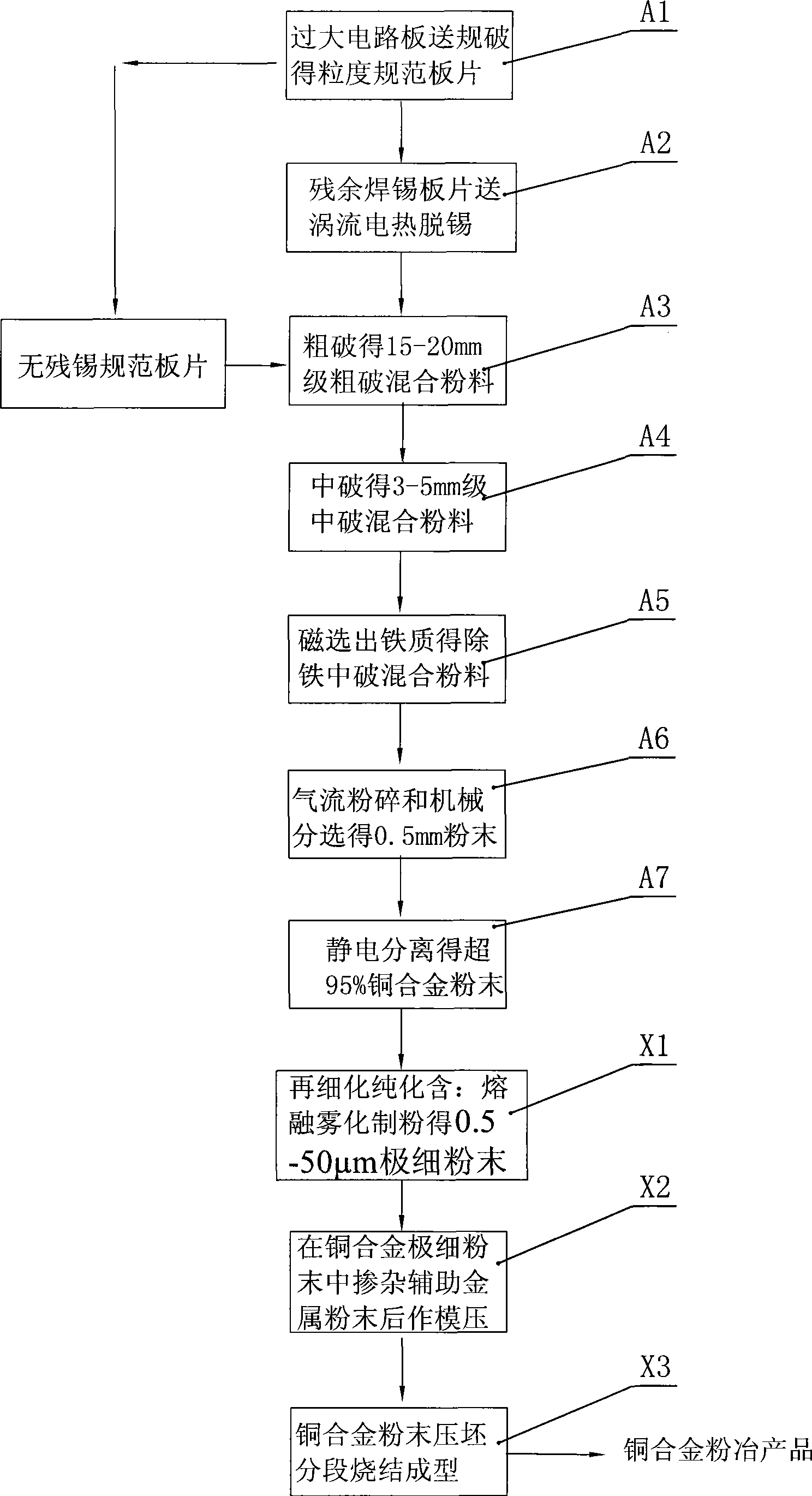

Method for recycle of copper alloy from waste circuit board and cyclic reconstruction of powder metallurgical product as well as device system thereof

ActiveCN101474675AMeet the requirements of deep processingQuality improvementSolid waste disposalSoldering apparatusElectrostatic separationPre treatment

The invention relates to a method for recovering a copper alloy from a waste circuit board to reproduce a sintered metal product circularly and a device system thereof. In the method, the waste circuit board on electronic equipment is subject to breaking, magnetic separation, crushing, mechanical separation and electrostatic separation to separate the waste circuit board into copper alloy powder and plastic glass powder. The method further comprises the following steps: X1) further purifying and refining the obtained copper alloy powder to prepare more purified and finer superfine copper alloy powder; X2) filling the superfine copper alloy powder into a product die for die pressing; and X3) stepwise sintering a pressed compact obtained by die pressing to obtain a powder metallurgy finished product. The method and the device system can perform pre-treatment on the waste circuit board to obtain the copper alloy powder by separation, and can perform effective subsequent treatment on the copper alloy powder obtained by separation to make a marketable product, and the treatment process is environment-friendly, economical and efficient.

Owner:JIANGXI GREEN ECO MFG RESOURCE CYCLE

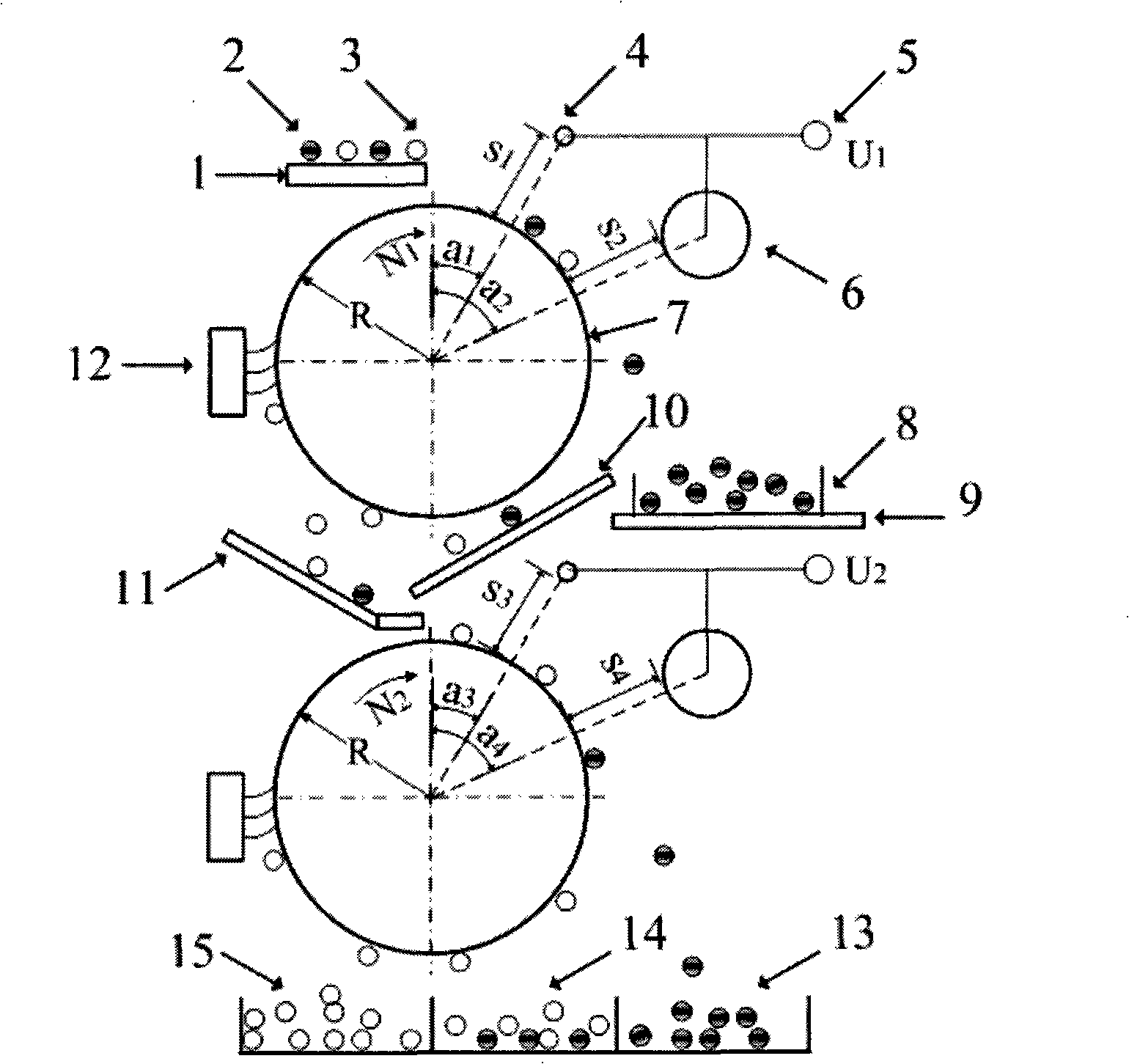

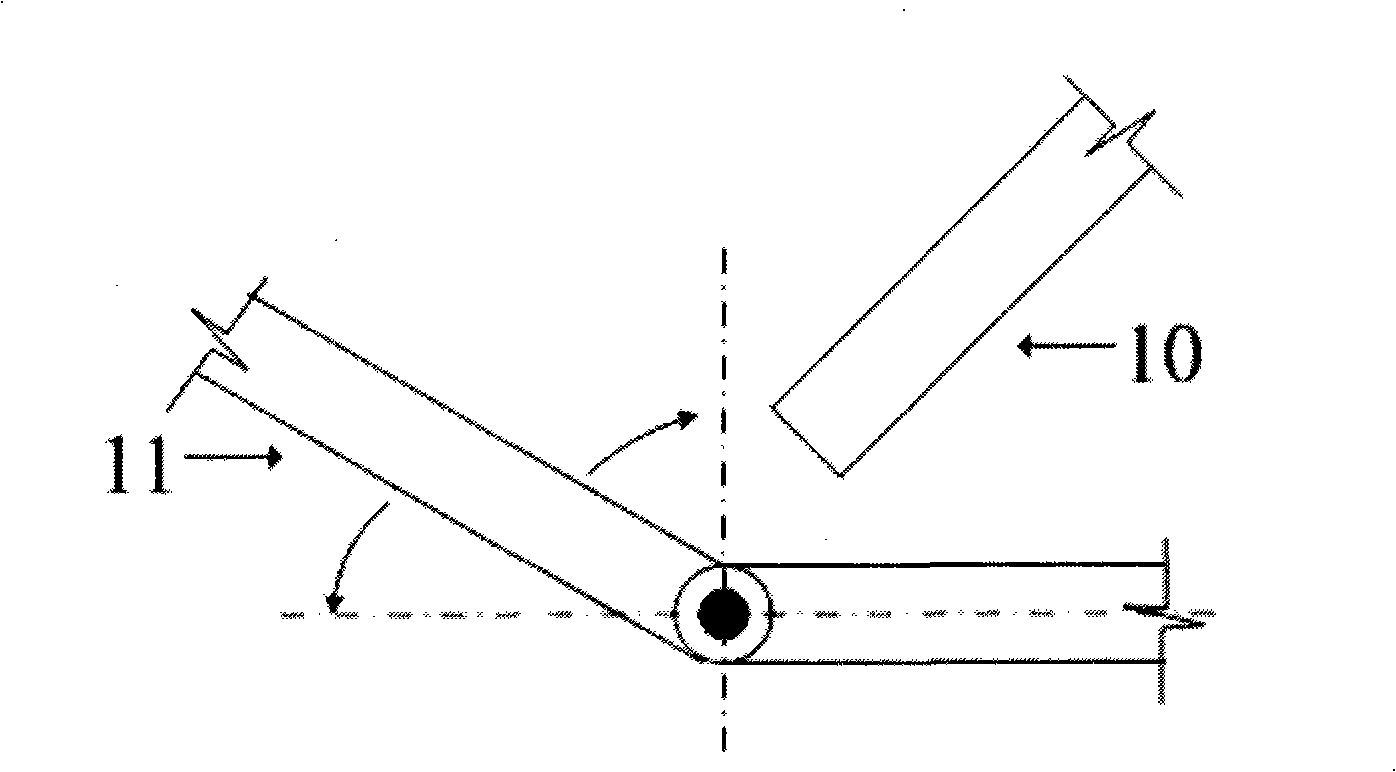

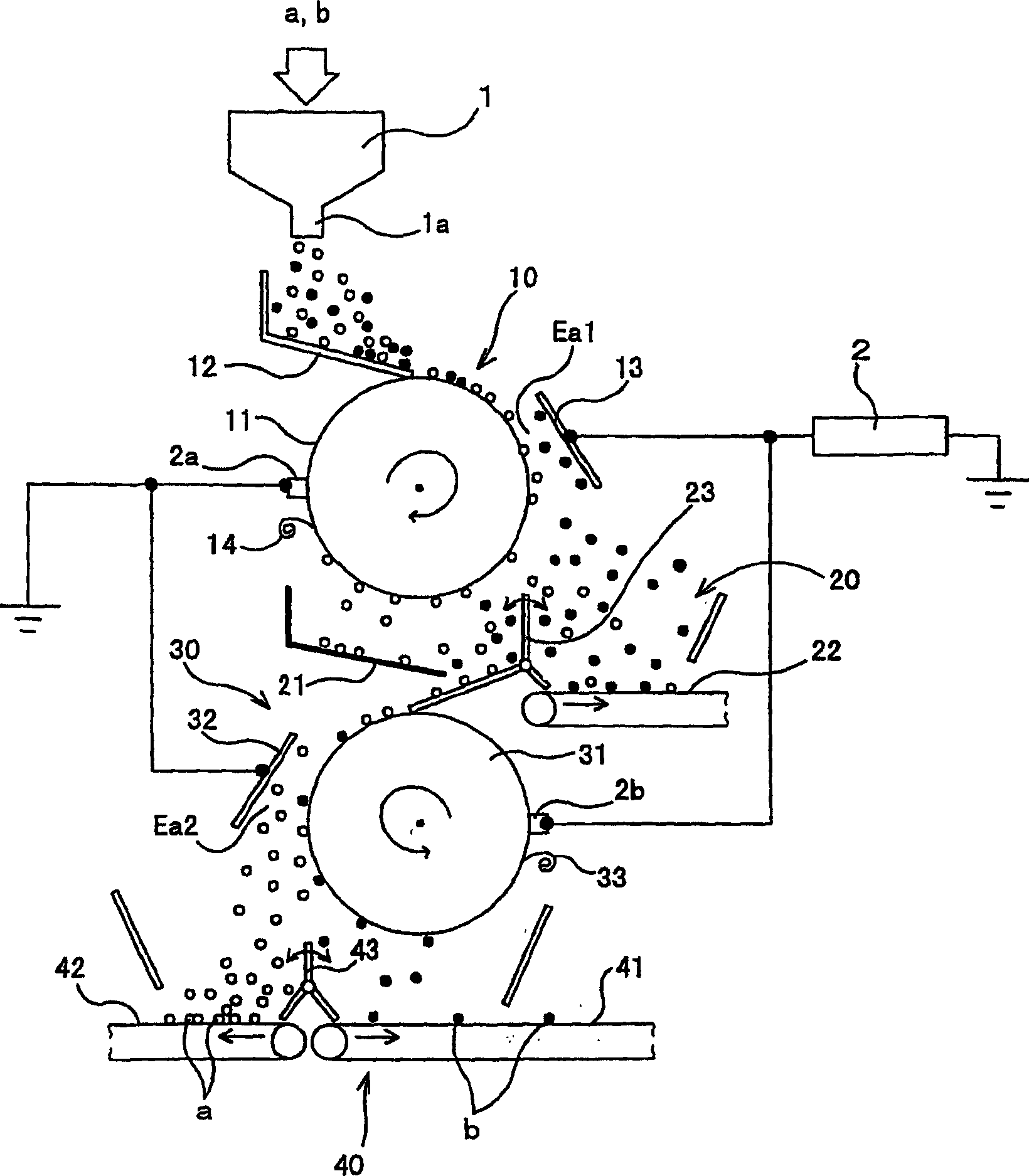

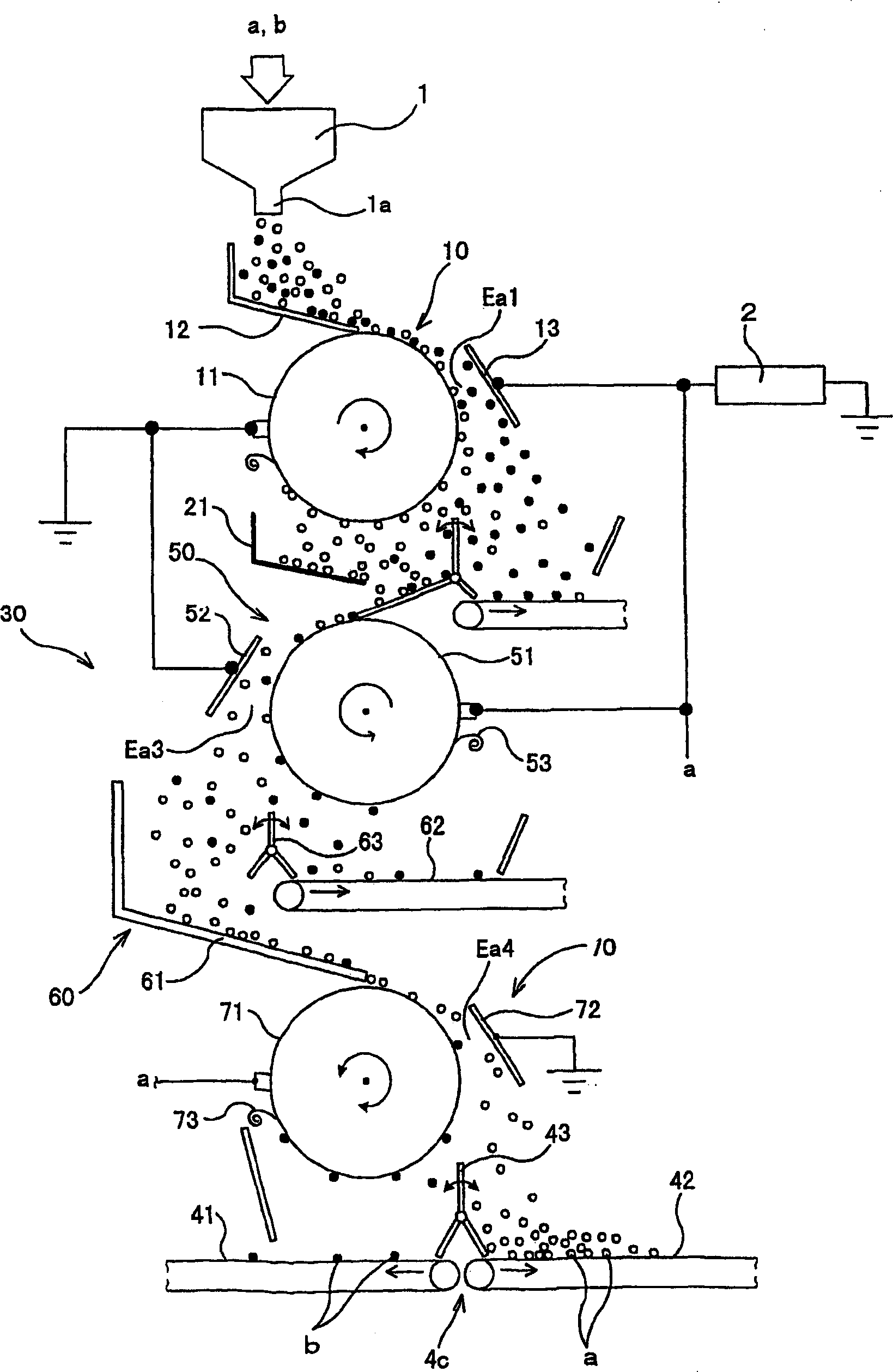

Multiple-roller type high-pressure electrostatic separation method for recovering waste and old printed circuit boards

InactiveCN101406861AHigh recovery rateStabilizationElectrostatic separationElectrostatic separationEngineering

The invention relates to a method in multi-roll type high-voltage electrostatic separation for recycling a worn-out printed circuit board, which belongs to the technical field of environmental protection. The method comprises the following steps: at least two roll type separation devices with the same structure are arranged in the vertical direction to form an array; materials are fed into a primary separation device to carry out primary separation; an intermediate product and the like which are generated after separation are collected and transported to a secondary separation device to carry out secondary separation; and then products can enter a tertiary separation device, a quaternary separation device and the like in sequence according to requirement, until the recycling of the worn-out printed circuit board is completed. The problems of intermediate products, stability and treatment capacity can be solved by multistep separation, so as to realize optimization to electrostatic separation. Compared with the prior roll type high-voltage electrostatic separator, the method has higher recovery ratio of metal and non metal and more stable processing process, and greatly improves the processing efficiency.

Owner:SHANGHAI JIAO TONG UNIV

Method and apparatus for separating plastic

InactiveCN1312738ARecycling doesHigh recovery rateElectrostatic separationPlastic recyclingElectrostatic separationElectrical polarity

The invention provides a plastic sorting method and apparatus, which, when plastic pieces comprising a plurality of types of resin plastics are agitated and frictionally charged, are able to impart the plastic pieces a necessary amount of charge or polarity for the thorough separation even if the difference in the amount of the different types of plastic pieces is large and to increase the recovery rate. If the amount of a specified type plastic pieces(1)to be recovered is small, the agitation and the electrostatic separation is carried out after adding the specified type plastic pieces(1)as auxiliary frictional charging material(21)into the frictional charging device(3), and the auxiliary frictional charging material(21)remains in the frictional charging device(3)and is used repeatedly.

Owner:HITACHI ZOSEN CORP

Method for electrostatically separating particles, apparatus for electrostatically separating particles, and processing system

InactiveUS7119298B2Easy to separateLess impuritiesGas current separationThreshersElectrostatic separationEngineering

An electrostatic separation apparatus for conductive particles and insulating particles with reduced separation time and improved separating capability, comprises a substantially flat-plate shaped bottom electrode (26) provided on lower side, a substantially flat-plate shaped mesh electrode (22) provided above the bottom electrode (26) as spaced a predetermined distance apart from the bottom electrode (26) and having a number of openings (24) to allow particles to pass therethrough, a direct current power supply connected to at least one of the mesh electrode (22) and the bottom electrode (24), and a voltage is applied across the bottom electrode (22) and the mesh electrode (24), thereby forming a separation zone (10) between the electrodes.

Owner:KAWASAKI HEAVY IND LTD

Crushing machine for separating crushed material

InactiveCN104741196AReduce wearReduce pollutionPlastic recyclingDrying gas arrangementsMicrocomputerElectrostatic separation

The invention discloses a crushing machine for separating crushed materials. The crushing machine comprises a machine body, wherein the machine body is internally provided with a crushing chamber and a separation chamber; a feeding hole is connected with the crushing chamber through a feeding channel; a heating device is arranged inside the feeding channel; the crushing chamber is internally provided with a stirring and crushing device; the stirring and crushing device comprises a fixed screw rod and a crushing screw rod; a motor is connected to one end of the crushing screw rod; spiral cutters A are arranged on the fixed screw rod; spiral cutters B are arranged on the crushing screw rod; a filtering net is arranged at the opening of the lower end of the crushing chamber; the separation chamber comprises a centrifugal pump, a separation cylinder and a separation device; the separation cylinder is electrified; the separation device comprises a material discharge groove, a positive electrode plate, a negative electrode plate and a microcomputer controller; an electrostatic separation space consisting of the positive electrode plate and the negative electrode plate is arranged below the material discharge groove. According to the crushing machine for separating crushed materials, plastic can be molten by using hot air, so that abrasion to the crushing cutters can be reduced, and the processing efficiency and the processing quality can be improved; as different crushed materials are separated by using high-pressure static electricity, the crushing machine has the characteristics of low cost, high efficiency, no pollution, and the like.

Owner:宁波海洲机械有限公司

Coarse fraction ilmenite titanium selecting art

ActiveCN101564706AGuaranteed qualityGuaranteed RecoveryWet separationElectrostatic separationMaterials science

The invention relates to a coarse fraction ilmenite titanium selecting art, belonging to the ore sieving field. The method comprises following steps: A. concentrating the magnetic tailings, entering into a spiral chute, obtaining a spiral ore concentrate and a helical mine tailing; B. sieving the helical ore concentrate, collecting the part with the graininess of 0.6-0.074 mm, drying, enriching the titanium middling, performing dry type strong magnetic separation, obtaining titanium ore concentrate and ferrotitanium middling. The invention for sieving titanium ore concentrate not only ensures the quality, but also the recovery rate of the titanium ore concentrate. The product quality and the recovery rate are better than the helix as well as shaking table art and the cost is smaller than the helix as well as electrostatic separation art.

Owner:四川安宁铁钛股份有限公司

Apparatus for separating plastic chips

InactiveCN1454119AHigh recovery rateHigh purityElectrostatic separationPlastic recyclingElectrostatic separationEngineering

Under the charging friction device, from top to bottom, respectively arrange the first electrostatic separation part and the second electrostatic separation part of the separation electrostatic field formed between the drum electrode and the counter electrode, and the first electrostatic separation Part of the plastic sheets separated by the electrostatic field for separation are put into the electrostatic field for separation of the second electrostatic separation part for separation again, so as to improve the separation purity and recovery rate of the plastic sheets.

Owner:HITACHI ZOSEN CORP

Comprehensive treatment method for waste liquid crystal display

ActiveCN103157646AAvoid conversionAvoid separationSolid waste disposalProcess efficiency improvementTin dioxideIndium

The invention provides a comprehensive treatment method for a waste liquid crystal display, and the method comprises the steps of: (1) simply dismantling; (2) removing polarizers; (3) separating liquid crystal: using an organic solvent to dissolve the liquid crystal to separate the liquid crystal away from a glass substrate, and collecting the liquid crystal after distillation; (4) separating a glass sheet from a coating, wherein the glass sheet is made to be glass-ceramics after being washed; (5) recovering indium from the coating: mixing the scraped oxide coating with ferric sulfate, calcining in an oxidation atmosphere at a temperature of 500-600 DEG C, and then soaking in water to obtain a solution containing indium sulfate; after replacement, filtering to obtain indium with a purity of more than 95.6%, and returning filtrate B to water soaking; and dissolving residue A in sulfuric acid, filtering to obtain tin oxide in residue C, and filtrate C can be concentrated for crystallization to obtain ferric sulfate for calcination; (6) sorting plastic; and (7) sorting metal and nonmetal components by using electrostatic separation. According to the present invention, indium in liquid crystal displays can be completely recycled, and therefore integrated treatment and recycling of a waste liquid crystal display are obtained.

Owner:JIANGXI GREEN ECO MFG RESOURCE CYCLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com