Preparation method of wheat bran aleurone

A technology for wheat bran aleurone and wheat bran, which is applied in the field of preparing aleurone from wheat bran, a by-product of wheat processing, can solve the problems of reducing the nutritional value of aleurone finished products, loss of water-soluble nutrients, etc., and achieves low production cost and avoidance of loss. , to ensure the effect of nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

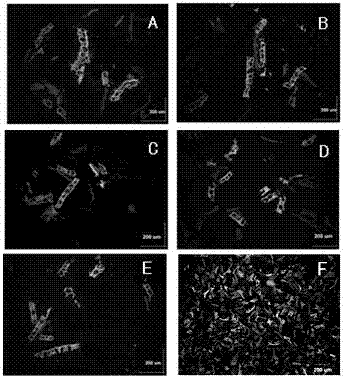

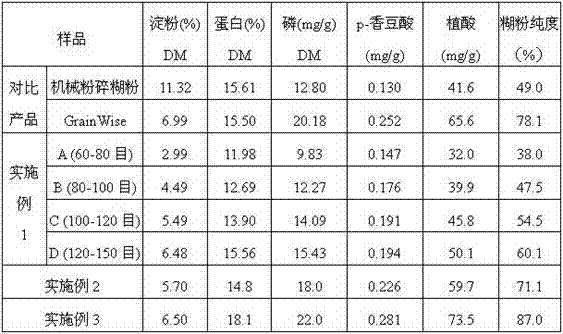

[0037] Take 2kg of wheat bran and place it in a 20-mesh rotary vibrating sieve (product of Xinxiang Gaofu Screening Machinery Co., Ltd., model: S49-400) for vibratory sieving for 20 minutes to remove residues on the inner surface. Starch, take the sieve; use a blade mill (product of Shanghai Bingdu Electric Co., Ltd., model: Q-500B3) to crush the above-mentioned sieve obtained after impurity removal to a particle size of 400 μm, pass through a 20-mesh standard sieve, and take the sieve Undercuts; the pre-crushed undersizes were dried in an oven at 40°C for 30 minutes until their moisture content was 9%; turbine pulverizers (products of Jiangyin Longchang Machinery Manufacturing Co., Ltd., model: DWFJ-5) were used to The dried wheat bran is crushed at low temperature, the gas intake temperature of the crushing chamber of the turbo mill is set to -15°C, the temperature at the material outlet is 10°C, and the working frequency of the millstone is set to 40Hz; the particle size aft...

Embodiment 2

[0039] Take 2kg of wheat bran, place it in a 20-mesh rotary vibrating sieve (same as above) and carry out vibratory screening for 25 minutes to remove the residual starch on the inner surface, and take the sieved material; use a blade grinder (same as above) Crush the above-mentioned oversize obtained after impurity removal to a particle size of 600 μm, pass through a 20-mesh standard sieve, and take the undersize; seal the above-mentioned pre-crushed oversize and place it in a -18°C environment for pre-cooling for 30 minutes; use a turbine The type pulverizer (same as above) crushes the frozen wheat bran at a low temperature. The air inlet temperature of the pulverization chamber of the turbo pulverizer is set at -15°C, the temperature at the material outlet is set at 10°C, and the working frequency of the grinding disc is set at 45Hz; Repeat the above low-temperature grinding operation for wheat bran particles with a particle size greater than 250 μm after low-temperature gri...

Embodiment 3

[0041] Take 2kg of wheat bran, place it in a 20-mesh rotary vibrating sieve (same as above) for vibration sieving, and sieve for 30 minutes to remove the residual starch on the inner surface, and take the sieved material; use a blade grinder (same as above) Crush the above-mentioned oversize after removing impurities to a particle size of 800 μm, pass through a 20-mesh standard sieve, and take the oversize; place the above-mentioned pre-crushed oversize in an oven at 40°C for 30 minutes to dry until its moisture content is 10% ; The frozen wheat bran is crushed at low temperature using a turbine pulverizer (same as above). The gas intake temperature of the pulverization chamber of the turbo pulverizer is set at -15°C, and the temperature at the material outlet is set at 10°C. The frequency is set to 50Hz; the wheat bran particles with a particle size greater than 250 μm after low-temperature grinding are repeatedly subjected to the above-mentioned low-temperature grinding opera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com