Graphene oxide/titanium dioxide-active carbon three-dimensional composite material and preparation method thereof

A composite material and titanium dioxide technology, which is applied in the field of air purification, can solve the problems of easy recombination collision probability of electron holes, slow catalytic reaction rate of composite materials, hindering electron conduction, etc., so as to reduce the risk of secondary pollution, reduce the phenomenon of agglomeration, Reduce the effect of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

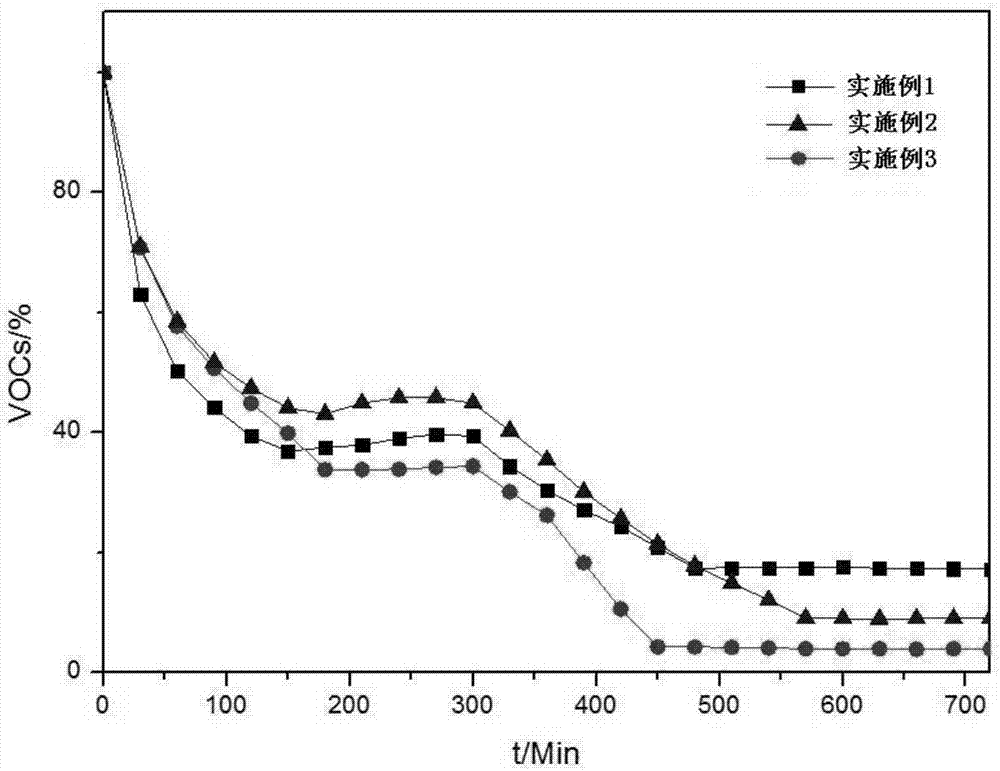

Embodiment 1

[0025] Preparation of graphene oxide / titanium dioxide-activated carbon three-dimensional composite material, the steps are as follows:

[0026] Weighing 12 mg of graphene oxide was slowly added to a stirred solution of 100 mL of water and 20 mL of ethanol, ultrasonically treated for half an hour, and then stirred for half an hour to fully mix to obtain a graphene oxide dispersion.

[0027] Slowly add 1.2g of mixed crystal titanium dioxide with a particle size of 5nm to the above-mentioned graphene oxide dispersion in a stirred state, stir for 1 hour and then perform ultrasonication for 1 hour. This process is repeated twice to obtain a uniformly dispersed mixture. liquid; pour the resulting mixed solution into a high-pressure reactor containing tetrafluoroethylene lining, put it into an environment of 100 ° C for 1 hour, take it out, and naturally cool it to room temperature to obtain a graphene oxide / titanium dioxide composite material. Suspension, ready to use.

[0028] Cut...

Embodiment 2

[0031] Preparation of graphene oxide / titanium dioxide-activated carbon three-dimensional composite material, the steps are as follows:

[0032] Weigh 100 mg of graphene oxide and slowly add it to a solution of 20 mL of water and 100 mL of ethanol under stirring, ultrasonically treat it at a frequency of 100 Hz for half an hour, and then stir for half an hour to fully mix it to obtain graphene oxide Dispersions.

[0033] Slowly add 10g of mixed crystal titanium dioxide with a particle size of about 50nm into the graphene oxide dispersion under stirring, stir for half an hour and then ultrasonicate for half an hour. Repeat this process twice to obtain a uniformly dispersed mixed solution Pour the resulting mixed solution into a high-pressure reactor containing tetrafluoroethylene lining, put it into a 200°C environment for 8 hours, take it out, and cool it to room temperature naturally to obtain a suspension containing graphene oxide / titanium dioxide composite material. Turbid ...

Embodiment 3

[0037] Preparation of graphene oxide / titanium dioxide-activated carbon three-dimensional composite material, the steps are as follows:

[0038] Weigh 30mg of graphene oxide and slowly add it to a solution of 60mL of water and 20mL of ethanol in a stirring state, ultrasonically treat it at a frequency of 100Hz for half an hour, and then stir for half an hour to make it fully mixed to obtain a graphene oxide dispersion. liquid.

[0039]Slowly add 1.6g of mixed crystal titanium dioxide with a particle size of about 21nm to the above-mentioned graphene oxide dispersion in a stirred state, stir for half an hour and then ultrasonicate for half an hour. Repeat this process twice to obtain a uniformly dispersed Mixed solution: Pour the obtained mixed solution into a high-pressure reactor with a tetrafluoroethylene liner, put it in an environment of 150 ° C for 5 hours, take it out, and naturally cool it to room temperature to obtain a graphene oxide / titanium dioxide composite material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com