Method and apparatus for separating plastic

A sorting device and plastic technology, applied in plastic recycling, chemical instruments and methods, solid separation, etc., can solve problems such as insufficient sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

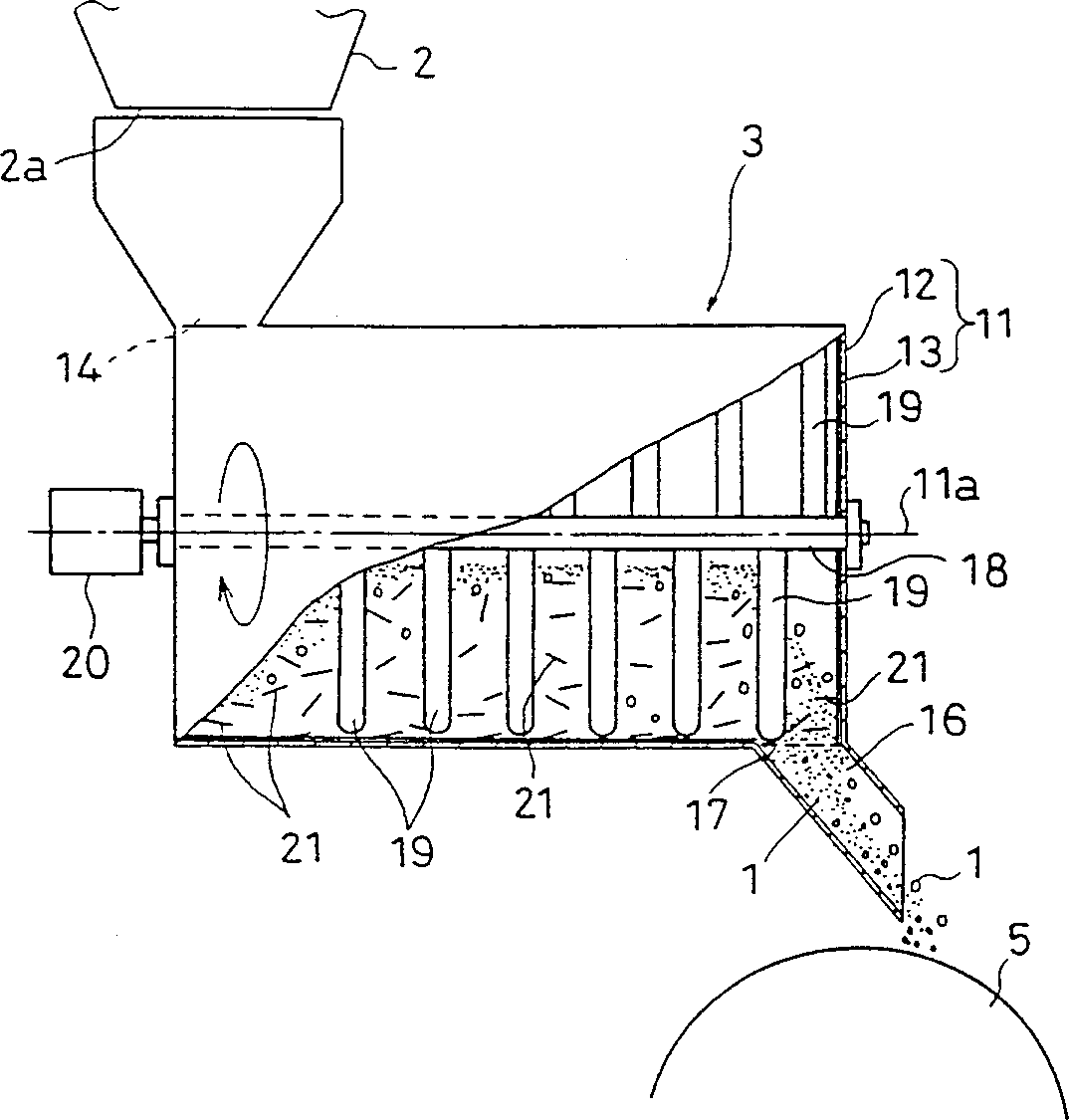

[0023] Hereinafter, embodiments of the present invention will be described based on the drawings. First, the first embodiment of the present invention will be described. The plastic sorting device S includes a hopper 2, a friction charging device 3, an electrostatic separation part G, a first separation container 8 and a second separation container 9. The hopper 2 is used to put plastic pieces (sorted and crushed garbage) 1 of different resins in a mixed state of a plurality of types. The frictional charging device 3 described above is arranged on the side of the outlet 2a of the hopper 2 and is used for frictionally charging each plastic sheet 1 by stirring. The electrostatic separation part G is arranged below the frictional charging device 3 and is used to electrostatically separate a plurality of types of frictionally charged plastic sheets 1. The first separation container 8 and the second separation container 9 described above collect the plastic sheet 1 electrostatically se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com