Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

551results about "Electrode features" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

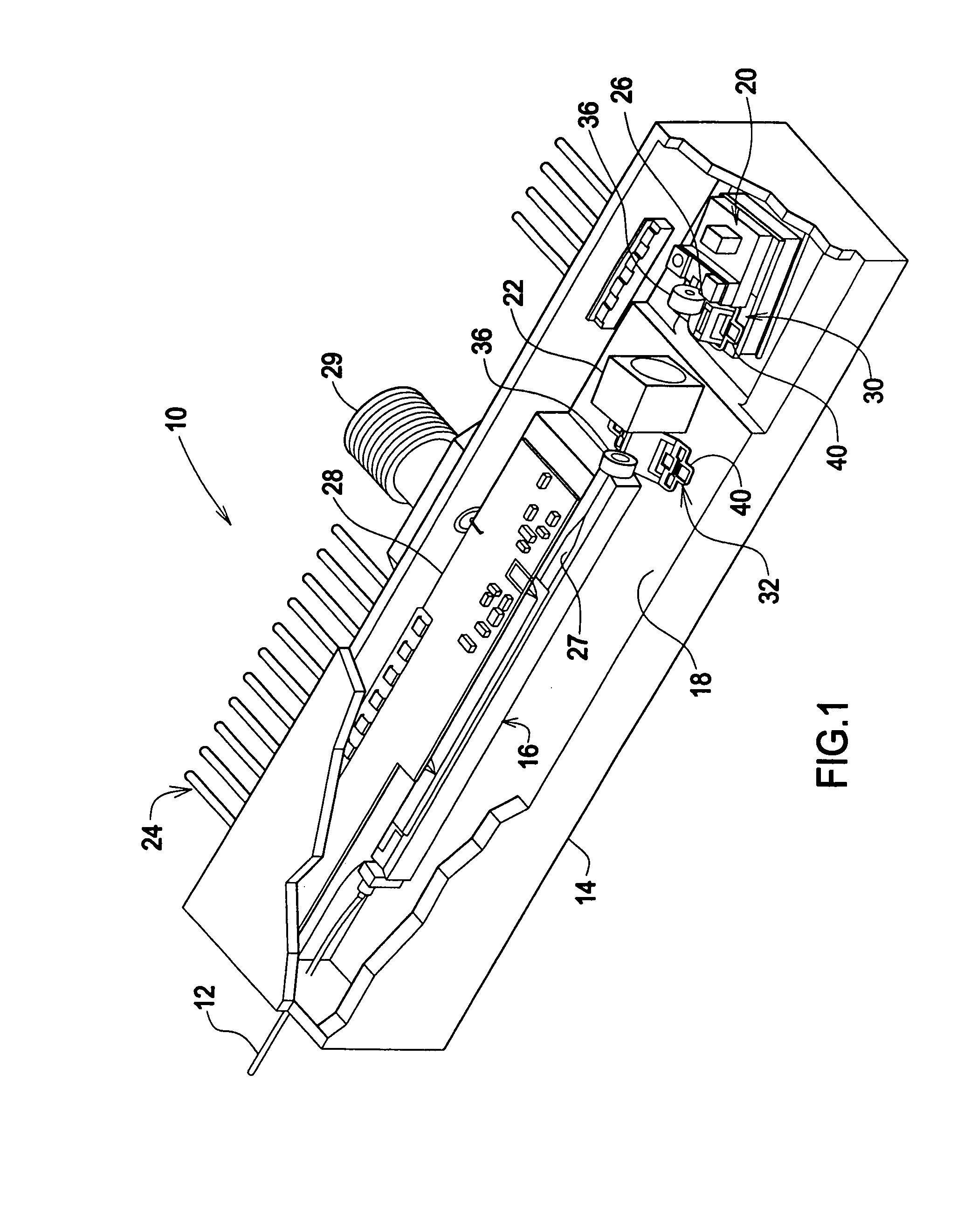

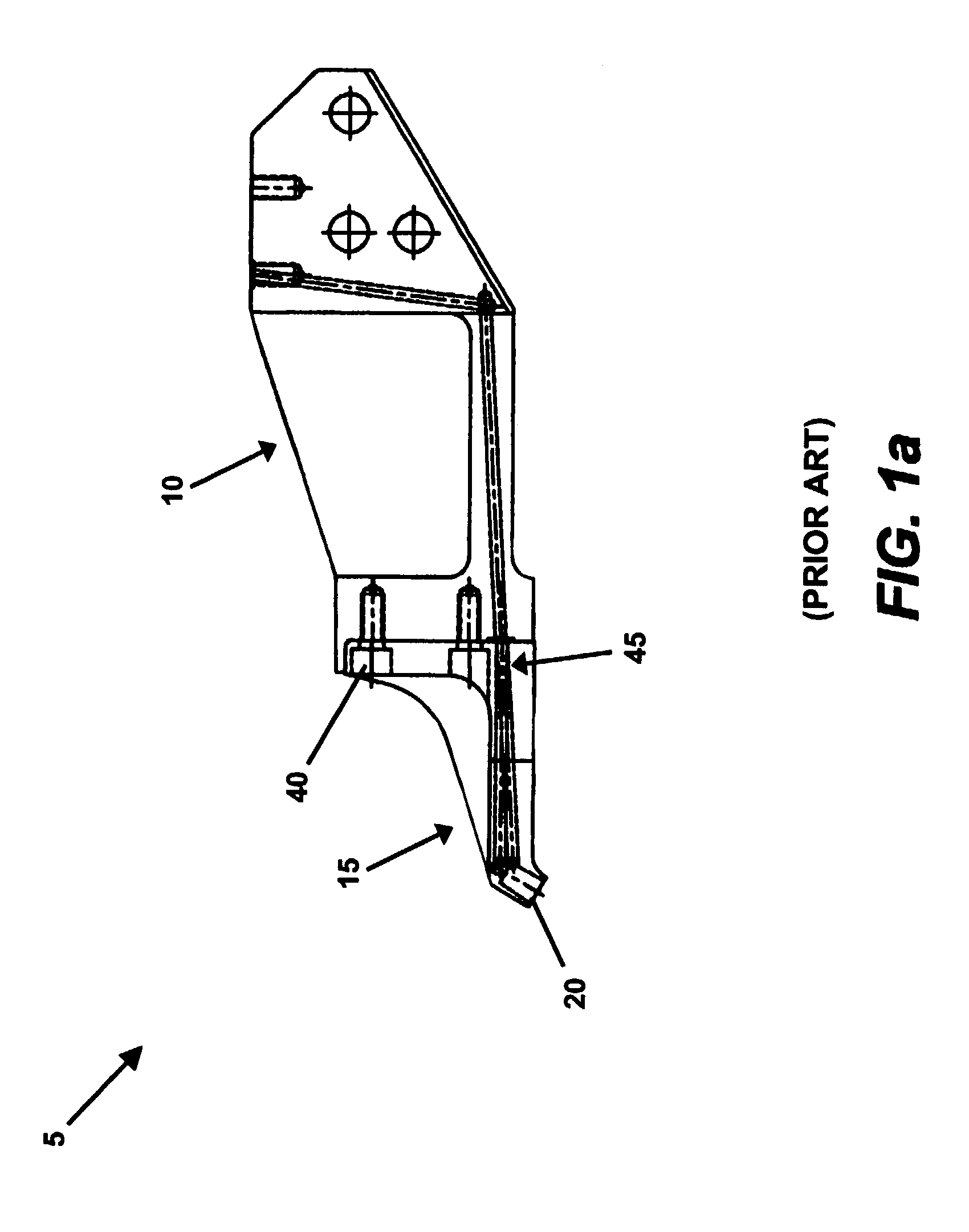

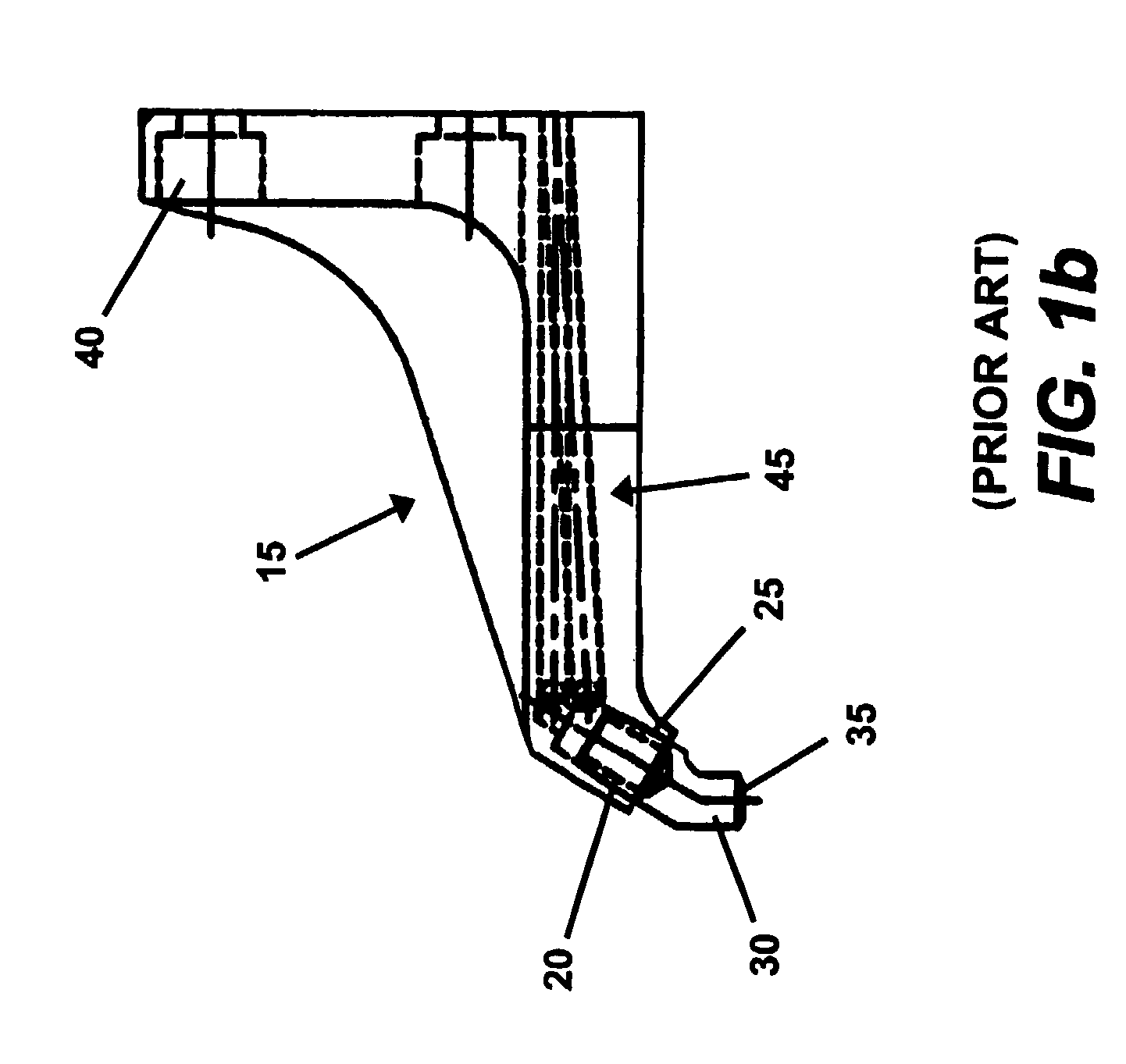

Sub-micron adjustable mount for supporting a component and method

InactiveUS7126078B2Control deformationOhmic-resistance electrodesElectrode featuresEngineeringLateral movement

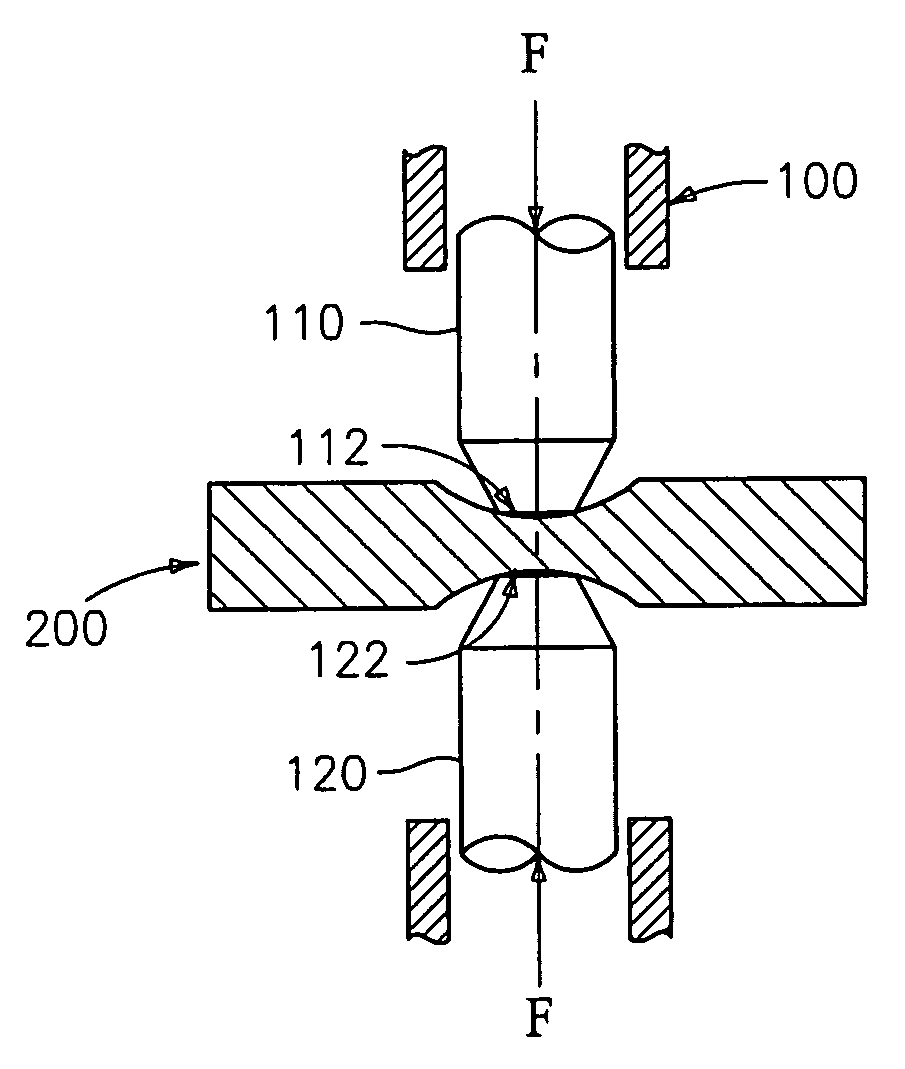

An arrangement is provided including an electrode extending to an electrode tip for contacting a workpiece. A welding configuration of the electrode tip is established by exposing the electrode tip to a selected welding environment for use in forming a weld having a target set of weld parameters. An electrode passage is defined in a biasing force arrangement supporting at least a portion of the length of an elongated, flexible electrode and to limit lateral movement sufficient to transfer at least a portion of a resilient force to the electrode tip so that the tip resiliently contacts the weld region. The electrode passage limits induced lateral flexing to an extent which transfers an amount of the resilient force to the first end portion of the electrode that is sufficient to provide for formation of a weld between the support arrangement and the workpiece.

Owner:DEMERS JOSEPH R

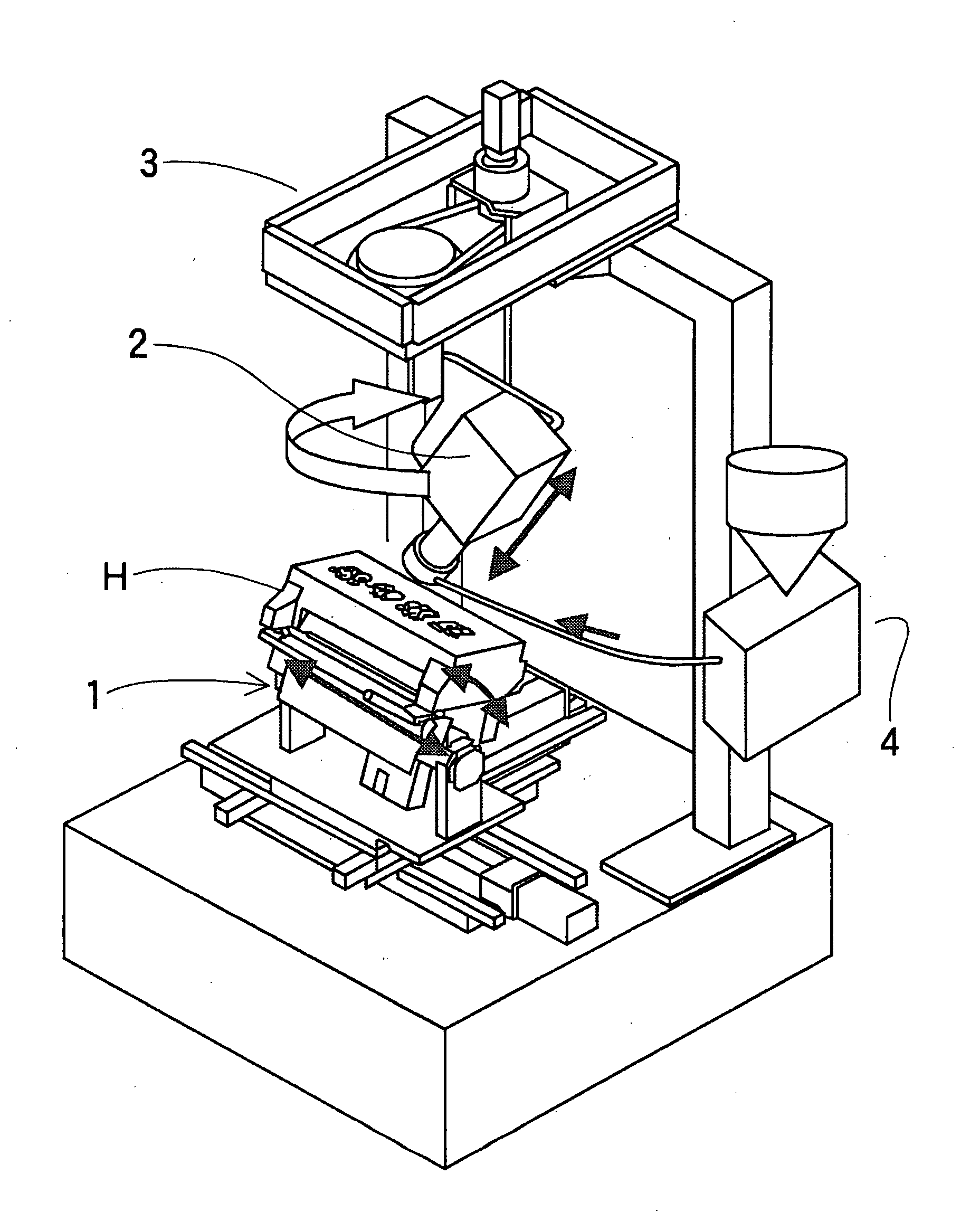

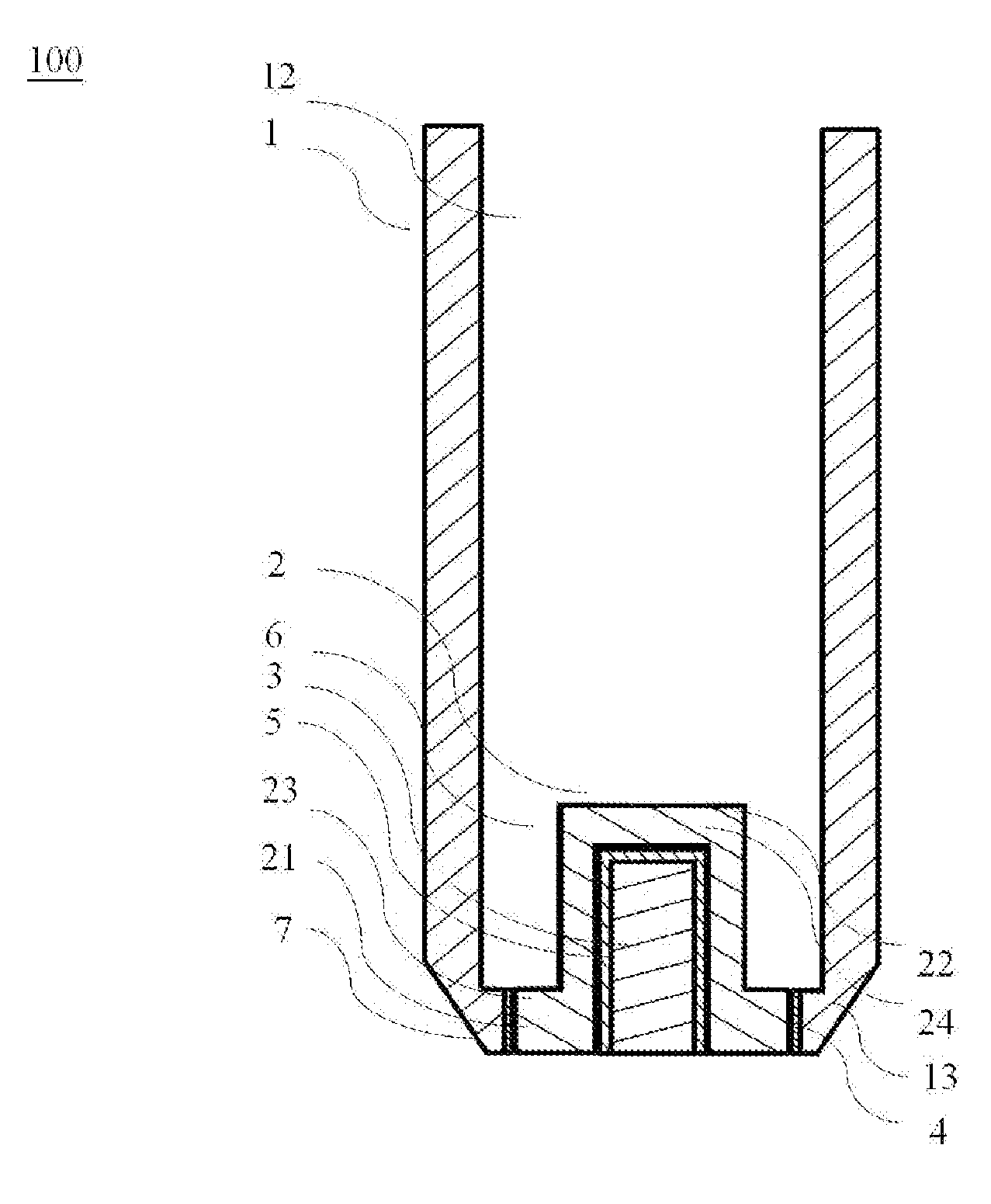

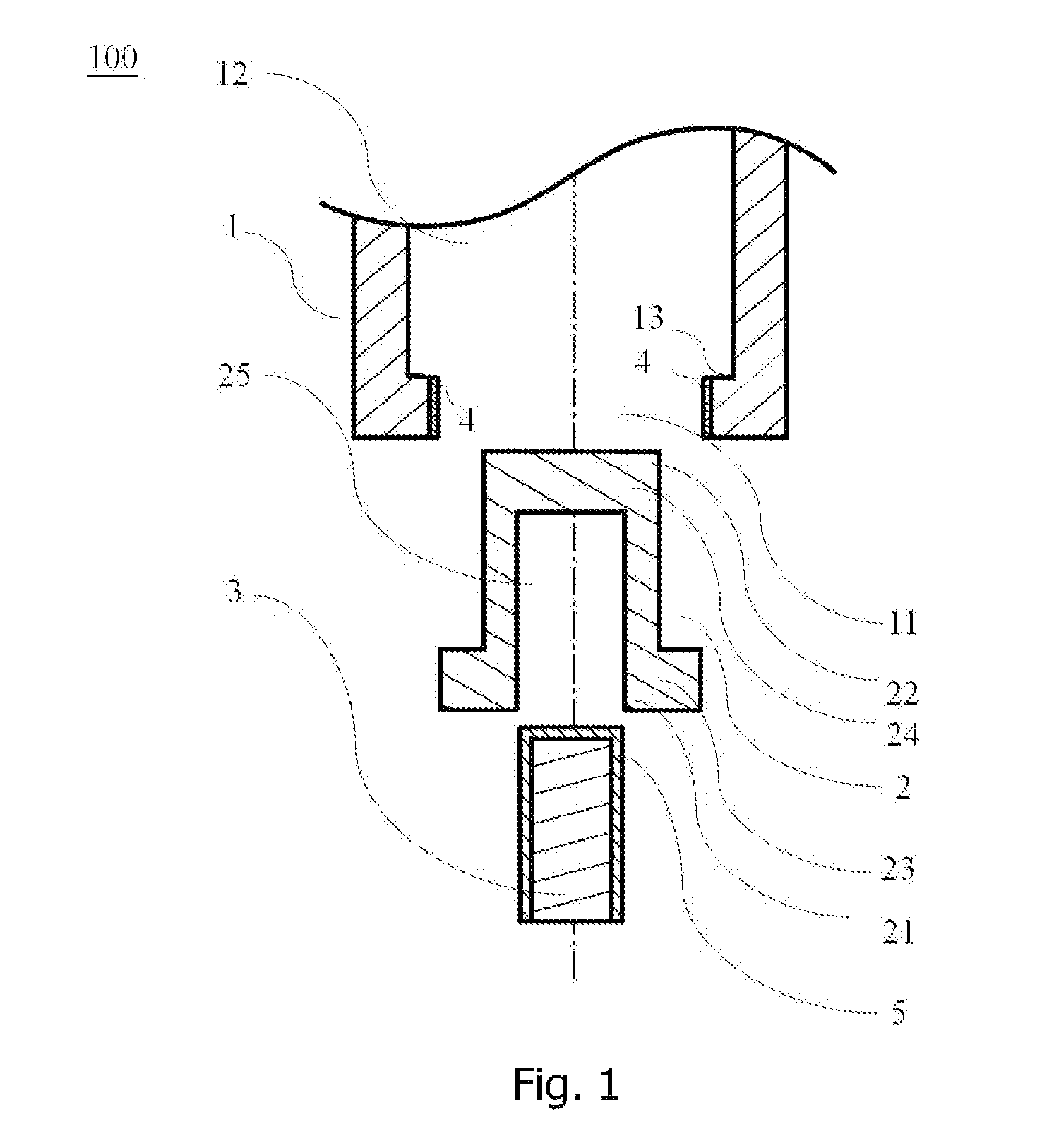

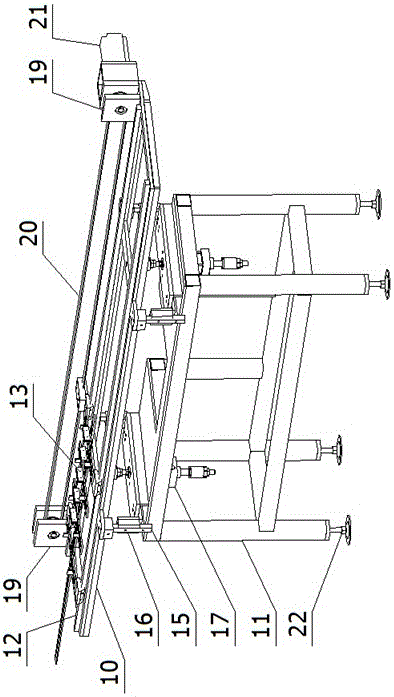

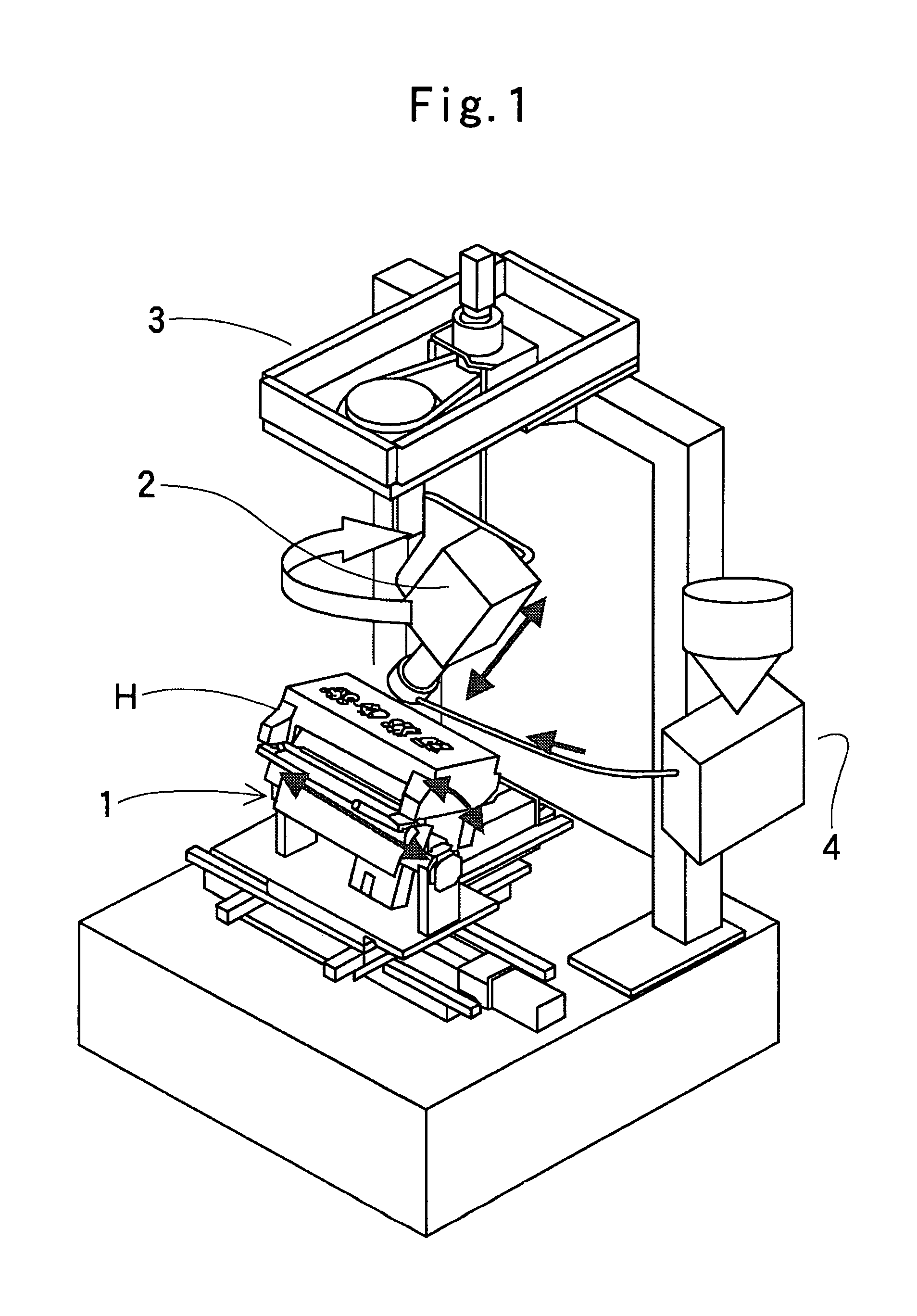

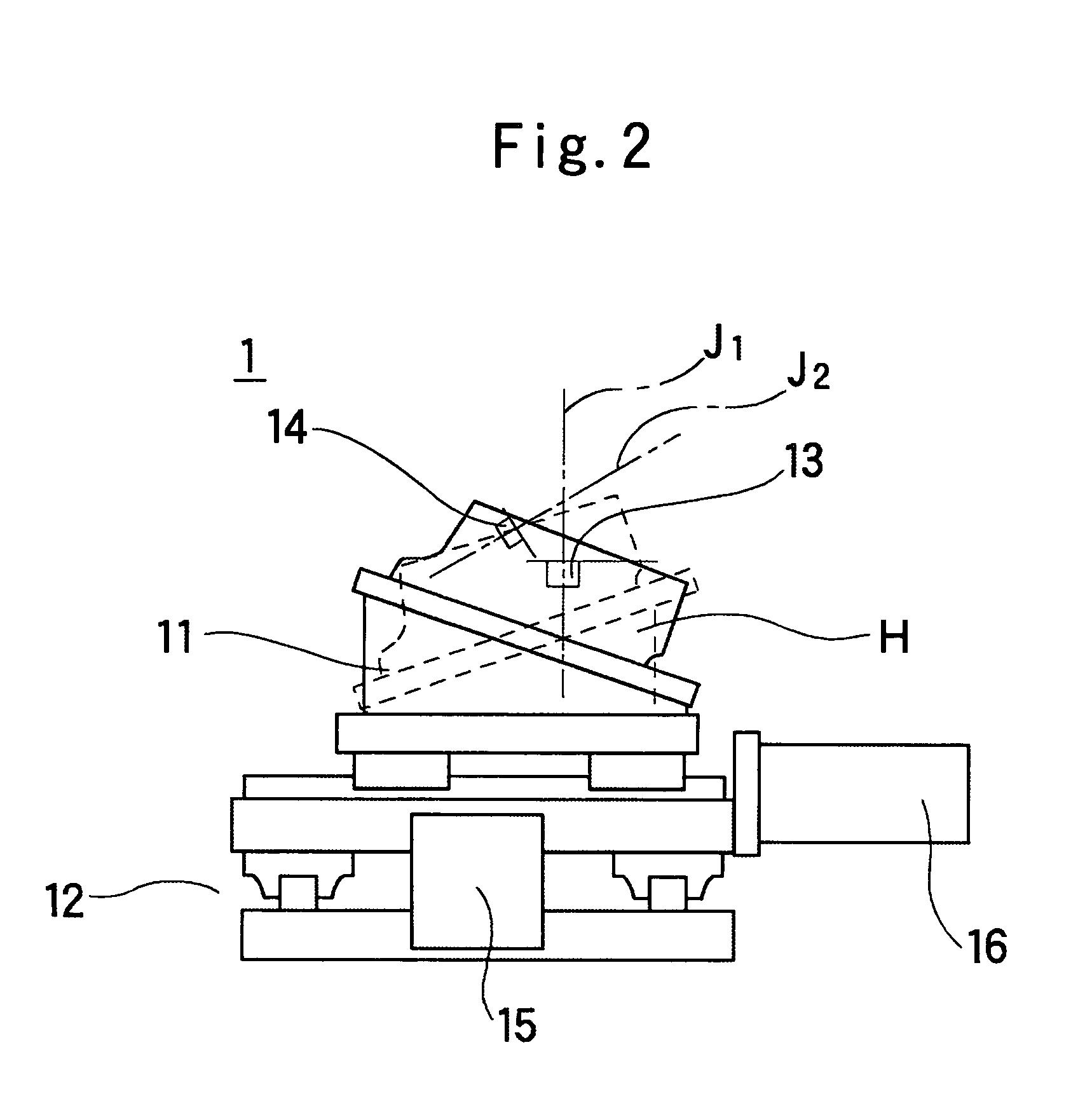

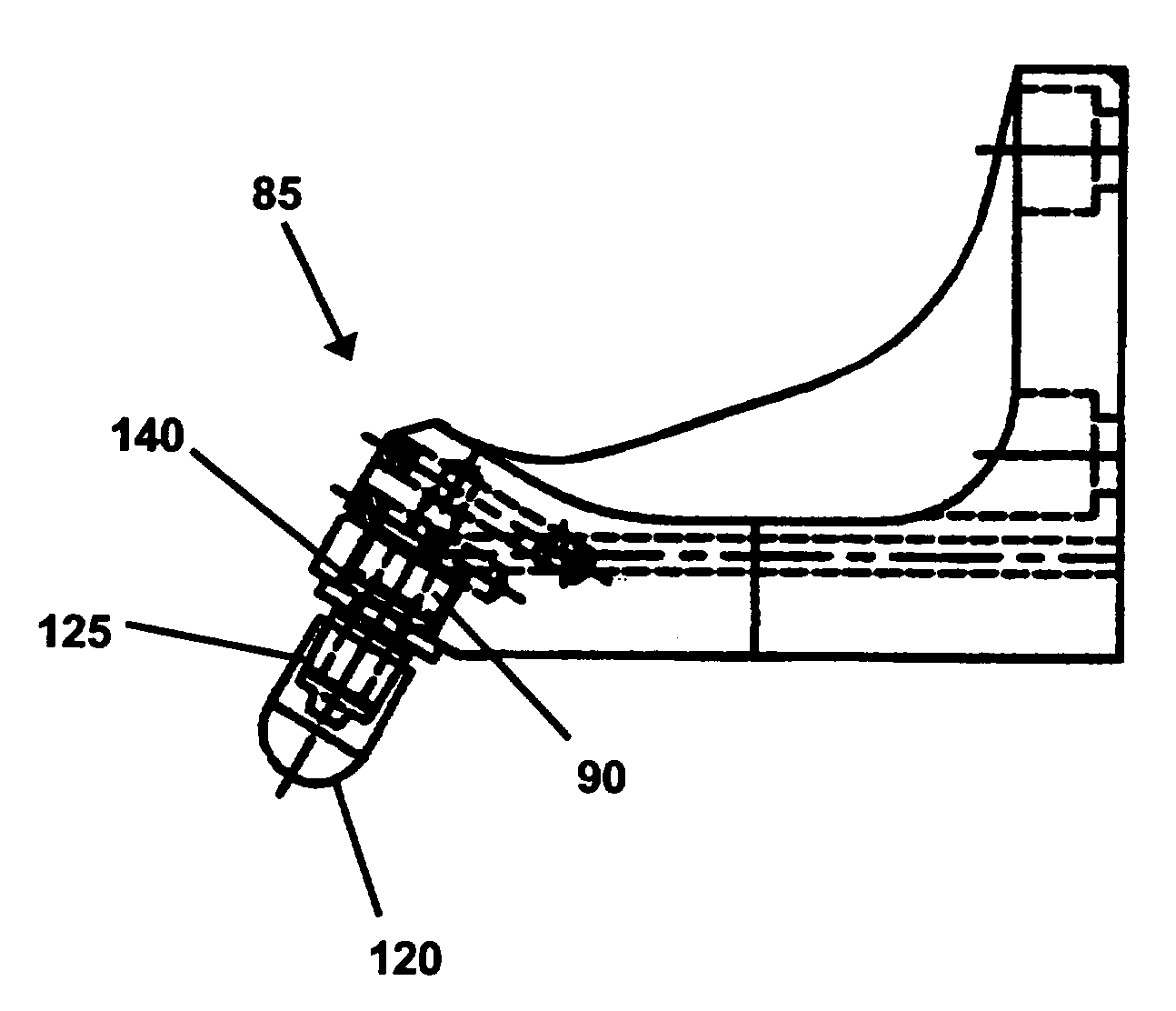

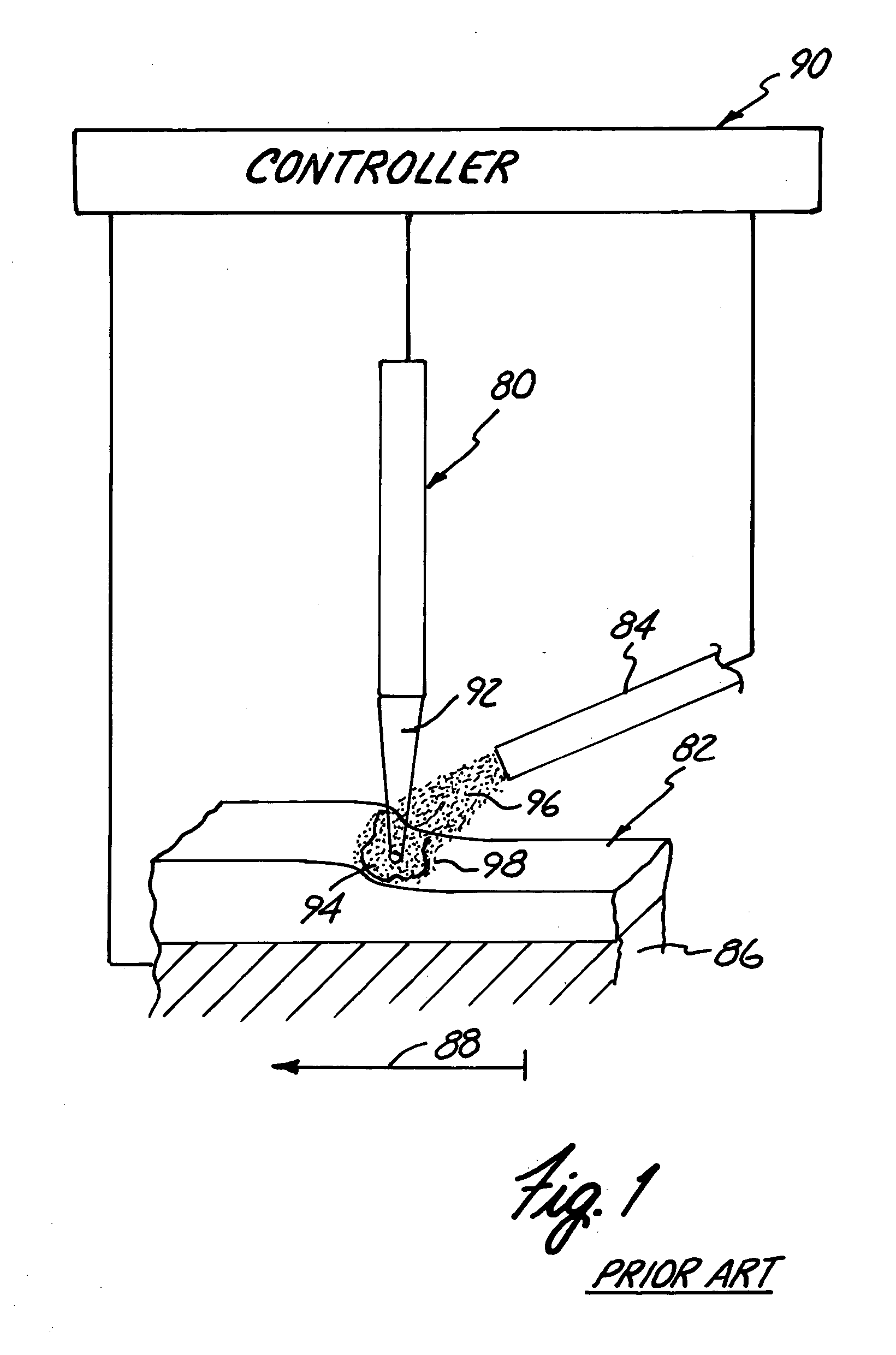

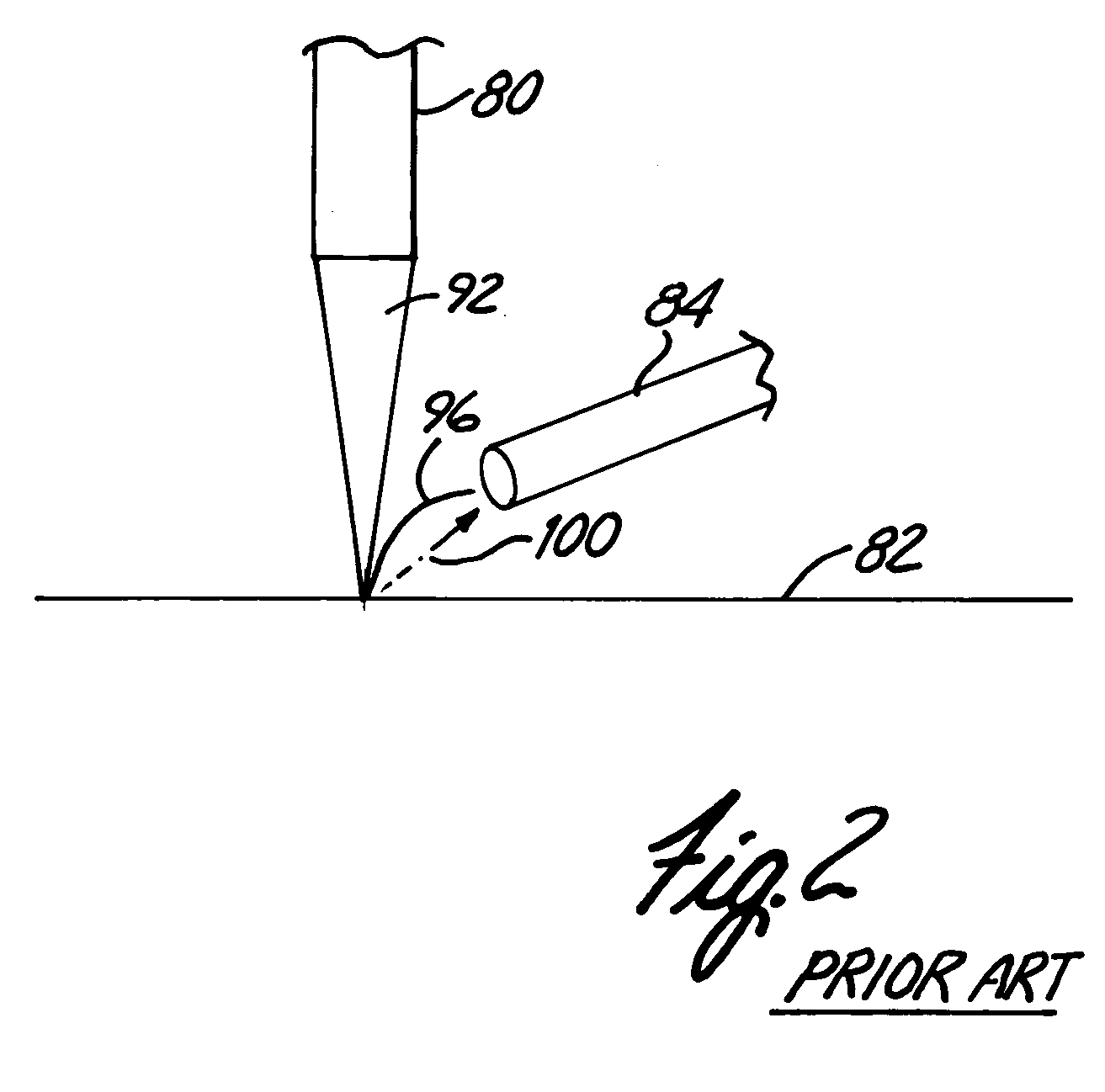

Laser cladding apparatus and method

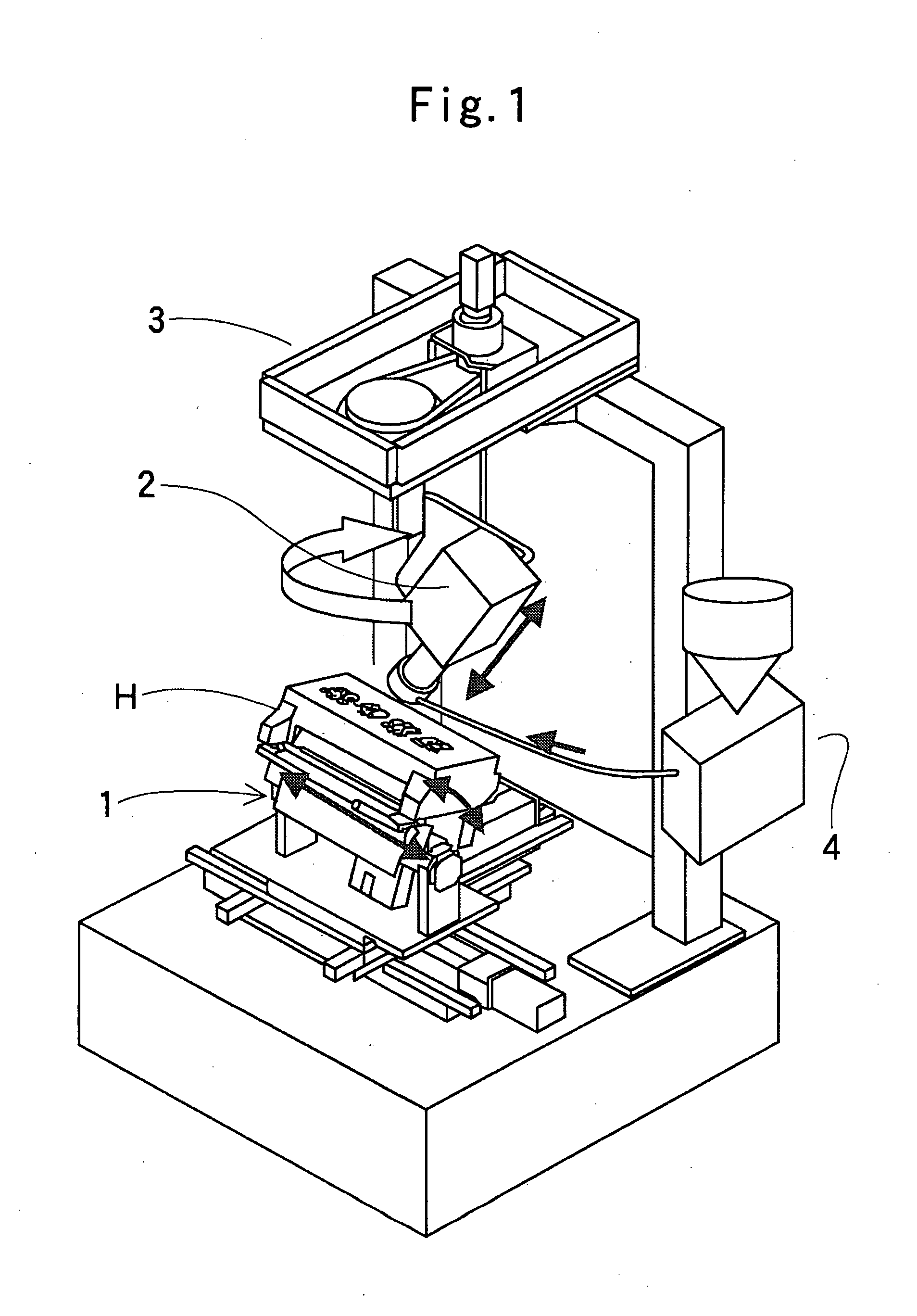

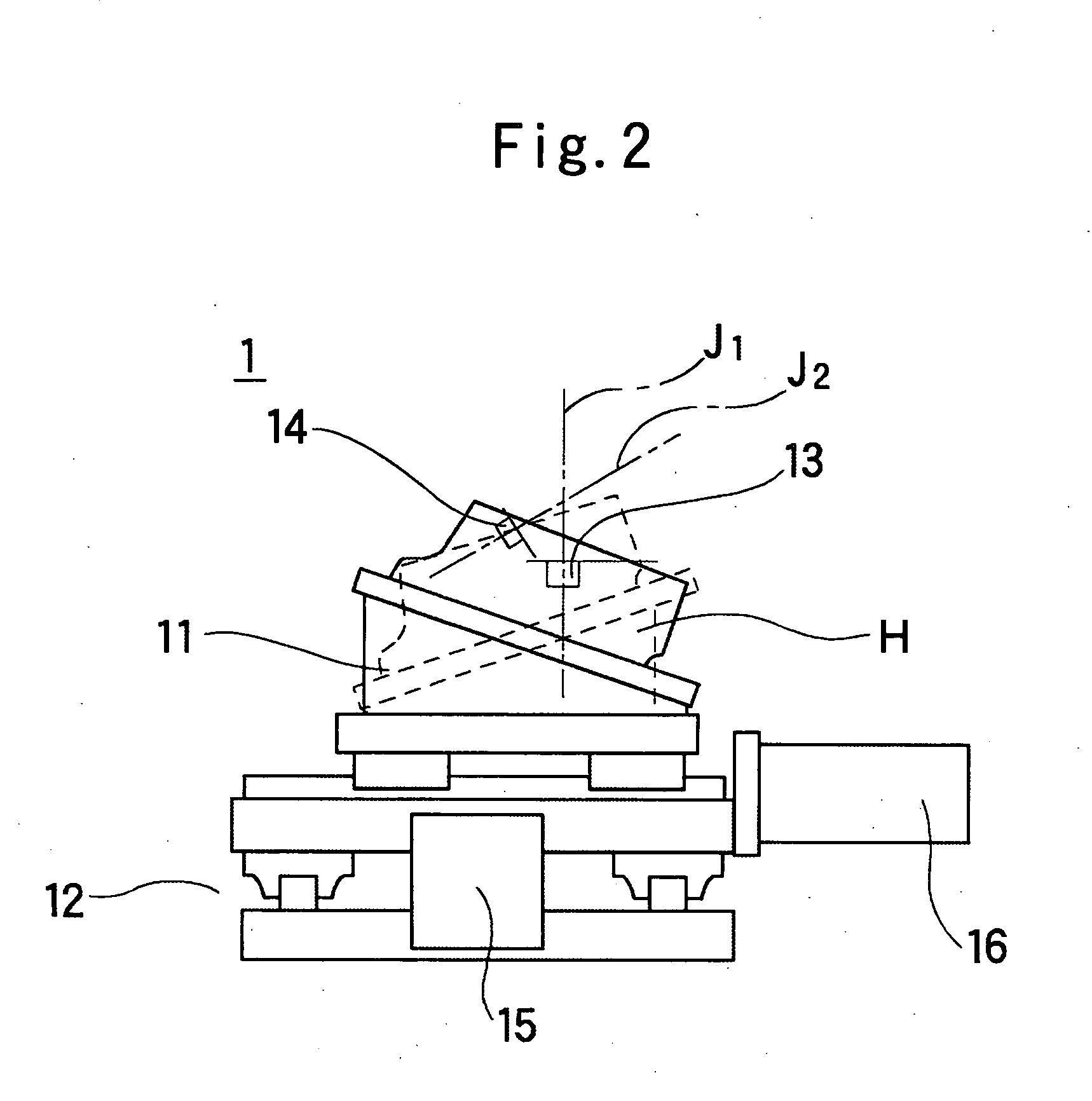

ActiveUS20060169679A1Simplify constituent elementReduce facility costsCylinder headsElectrode featuresLaser processingCylinder head

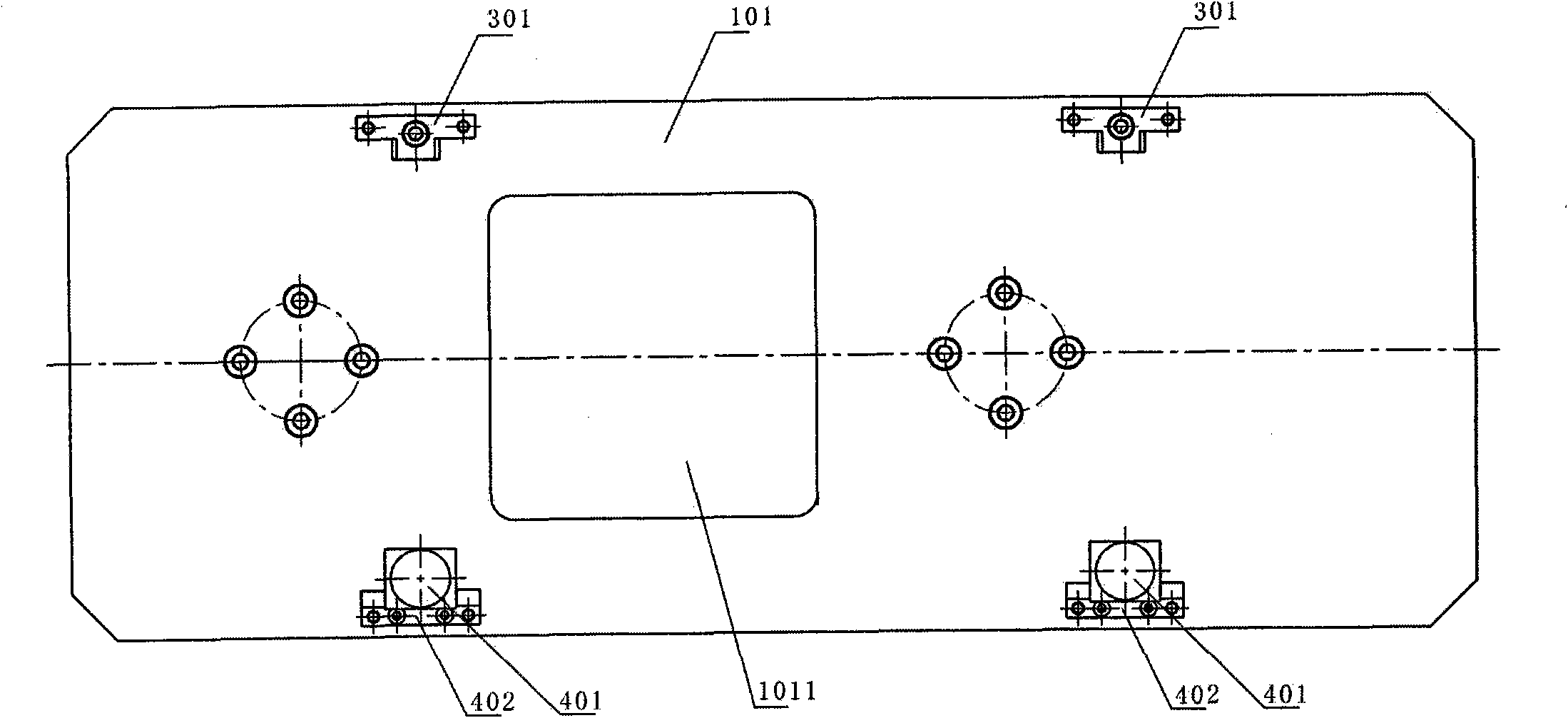

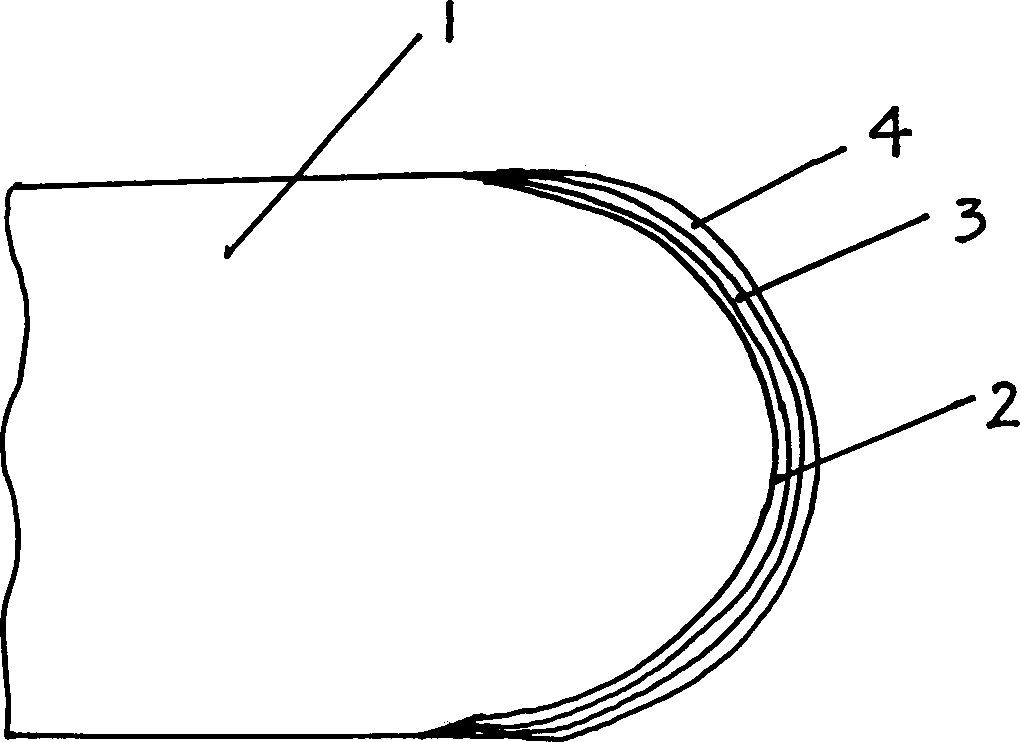

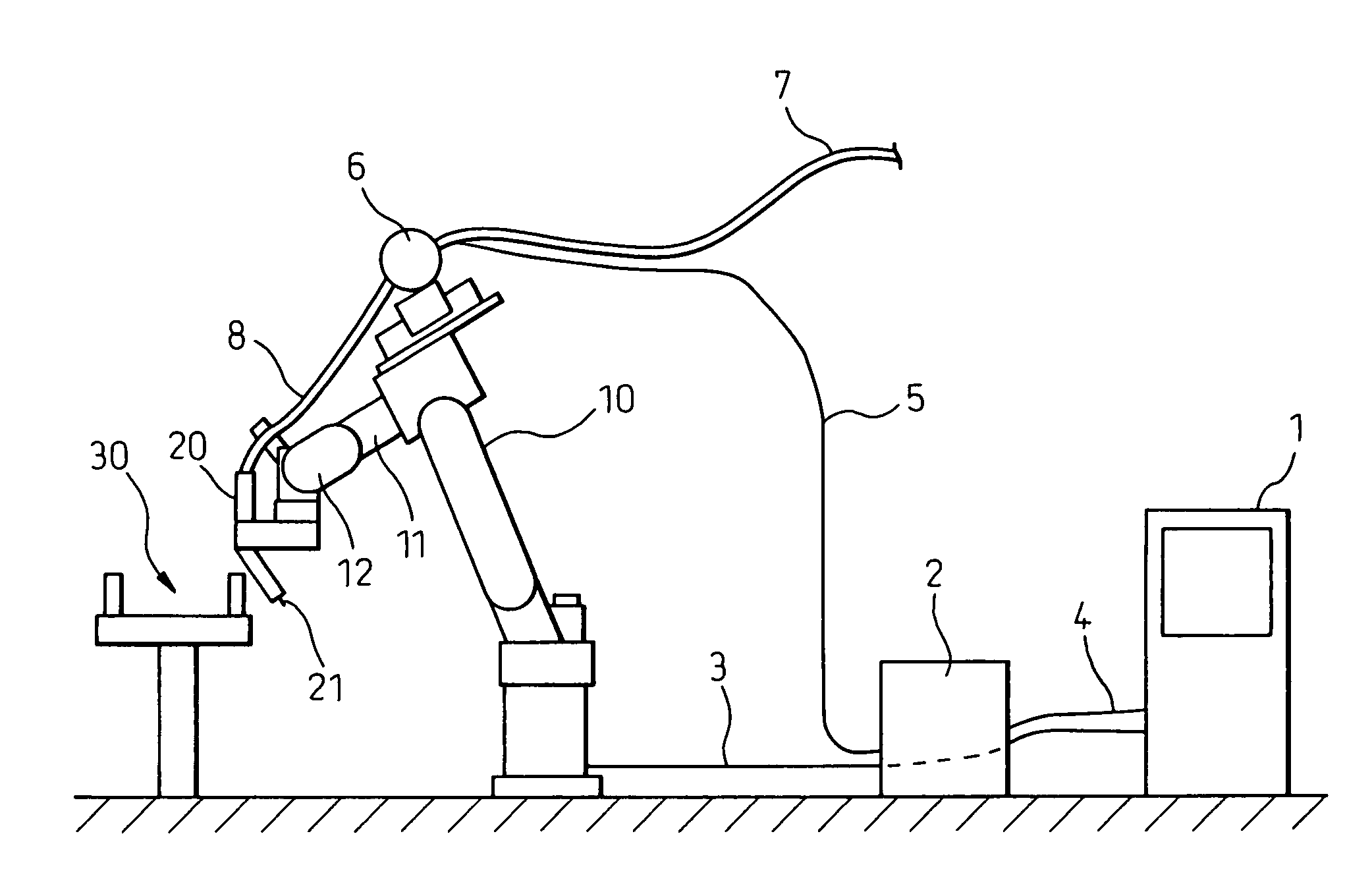

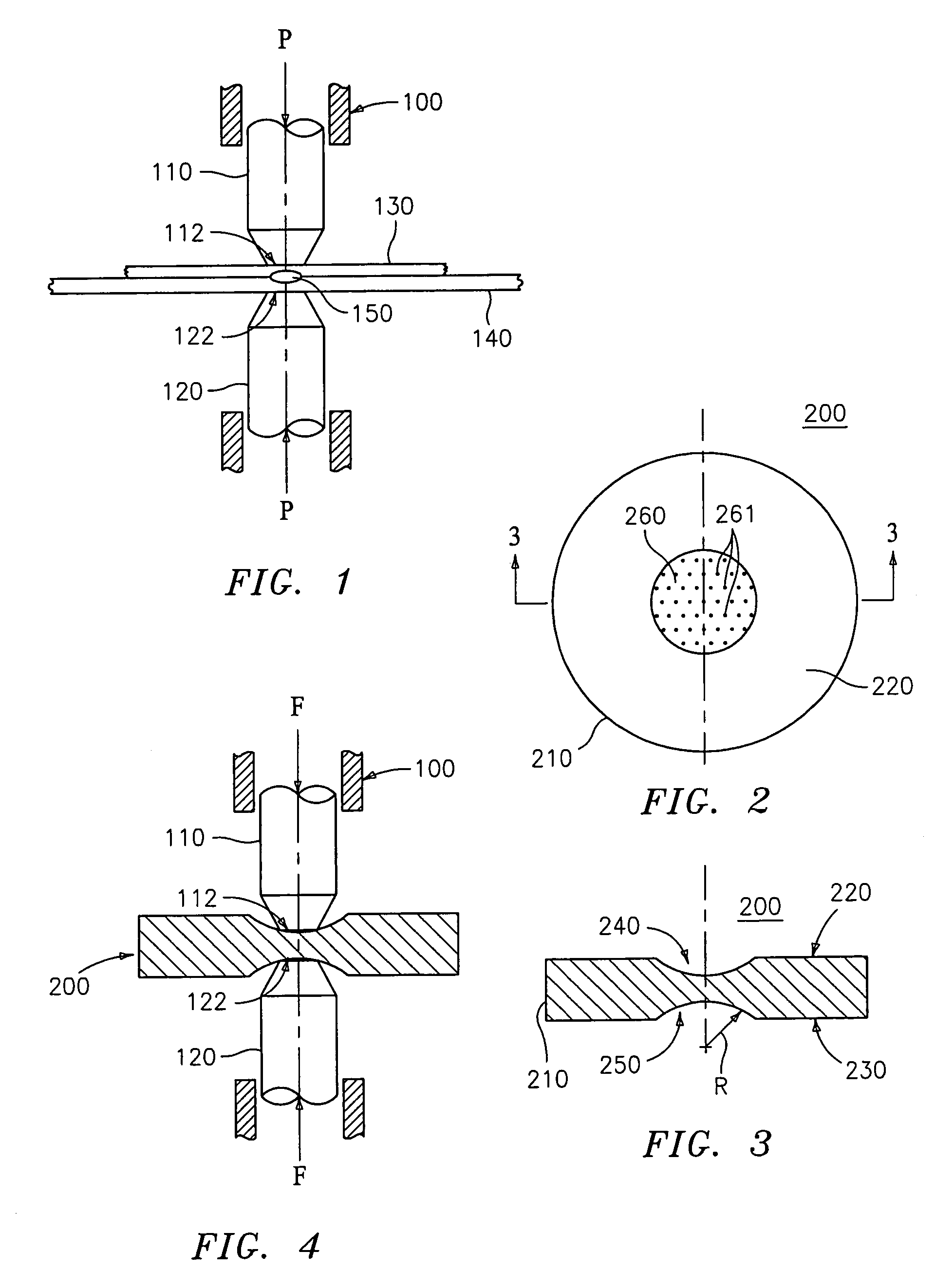

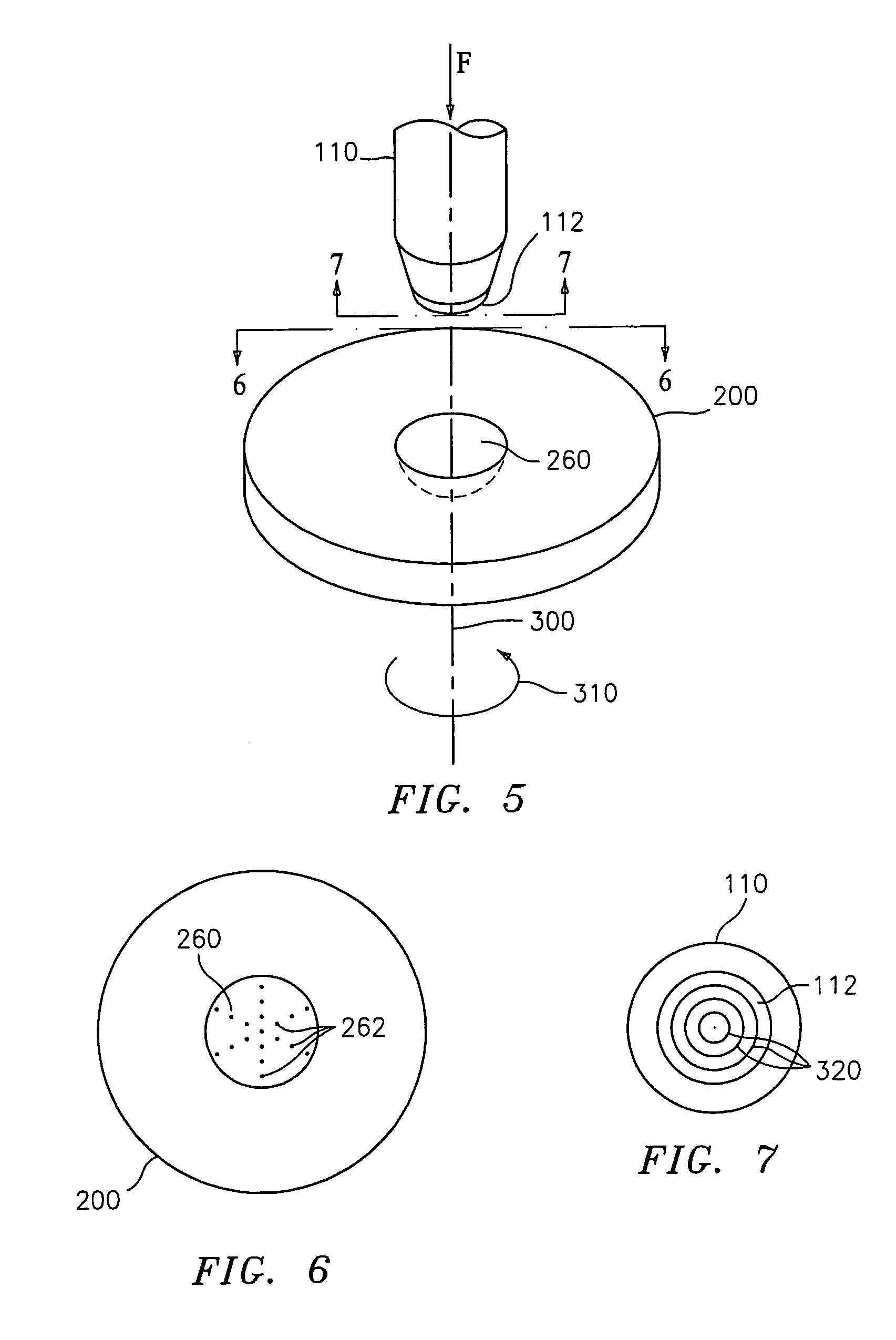

A laser-clad processing apparatus of the present invention is one which is for carrying out laser-clad processing onto a valve-seat portion of a cylinder head, and is characterized in that it comprises cylinder-head holding means (1) for holding a cylinder head (H) in an inclining manner so that the central axial line of a valve seat becomes the vertical direction, a laser-processing head (2) for irradiating a laser beam onto a process part of the valve seat and at the same time discharging a powdery material to this process part, rotary means (3) which rotates around the central axial line of the valve seat in such a state that the laser-processing head is inclined with respect to the vertical direction, and powdery-material supply means (4) for supplying the powdery material to the laser-processing head. Moreover, a laser-clad processing method of the present invention is characterized in that it fixes the cylinder head (H), and forms a clad layer while rotating the laser-processing head (2), which emits the laser beam with respect to the valve-seat portion of the cylinder head and discharges the powdery material, around the axial center line of the valve seat.

Owner:TOYOTA JIDOSHA KK

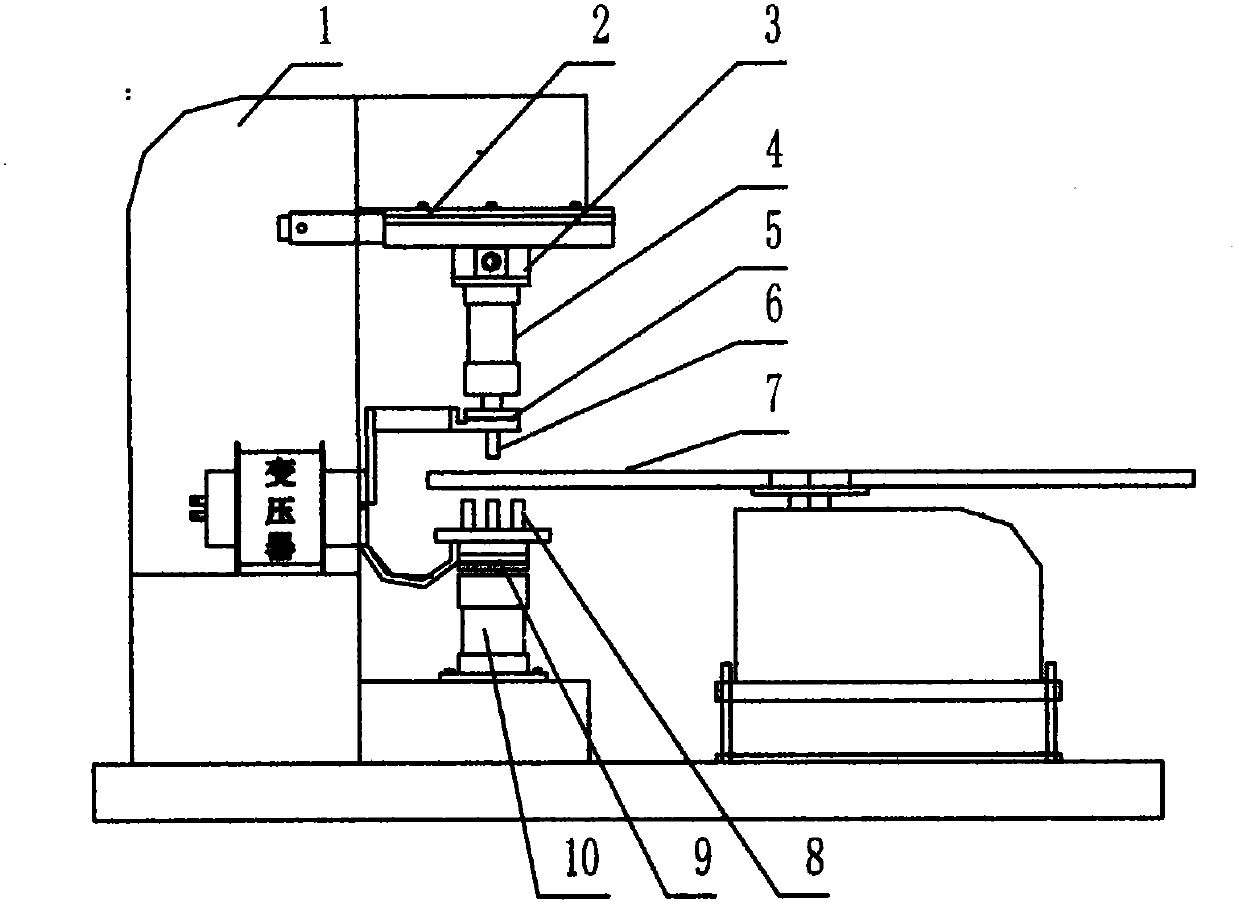

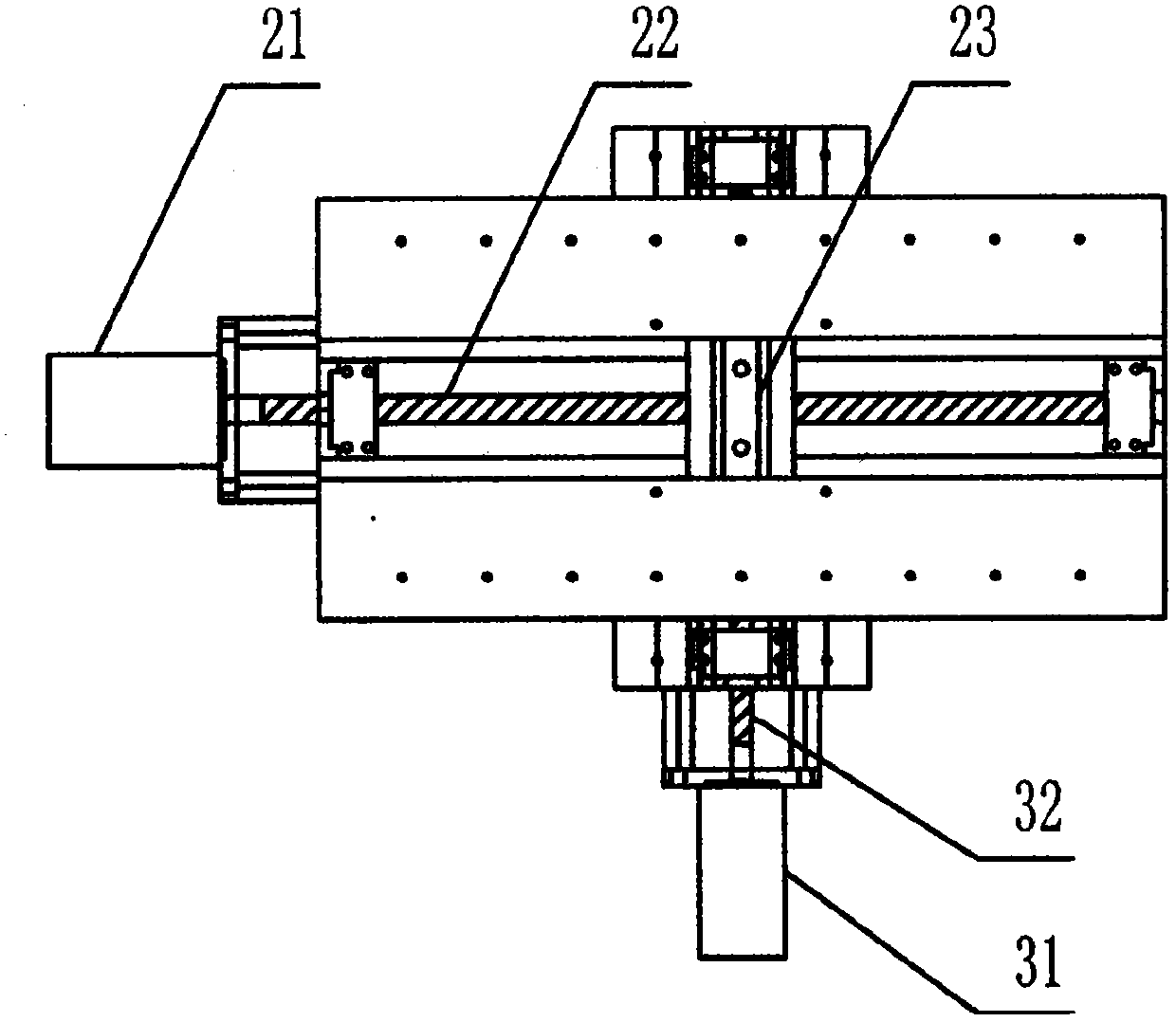

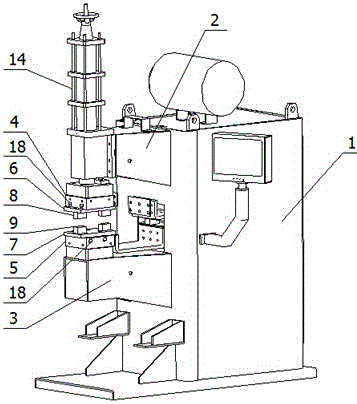

Two-axis multipoint automatic spot welding device and using method

InactiveCN103273181AImprove welding process efficiencyGuarantee welding qualityElectrode featuresDrive motorControl mode

The invention discloses a two-axis multipoint automatic spot welding device and a using method. The two-axis multipoint automatic spot welding device comprises a spot welding machine, a rotary working platform, workpiece forming dies, a machine base and a transformer. The spot welding machine is a two-axis spot welding machine, an X-axis linear module and a Y-axis linear module are arranged on the upper portion of an upper spot welding arm, the upper spot welding arm is installed on a transverse sliding block of the Y-axis linear module, the Y-axis linear module and a longitudinal sliding block of the X-axis linear module are fixed together through a two-axis connecting plate, a plurality of lower electrodes are arranged on a lower electrode holder of a lower spot welding arm, and a programmable controller is further arranged, and is connected with a driving motor in a control mode. The using method includes the steps of (1) manufacturing the workpiece forming dies, (2) manufacturing an upper electrode, (3) manufacturing the lower electrodes, (4) producing welding point coordinate information, inputting the welding point coordinate information to a numerical control system in the digital programmable controller, (5) setting the control state of the digital programmable controller to the rotary working platform, and (6) carrying out machine starting and operation. The two-axis multipoint automatic spot welding device is applicable to multipoint welding operation, complete in structure and high in degree of automation, work and labor are saved, energy is saved, and efficiency is high.

Owner:窦川忠

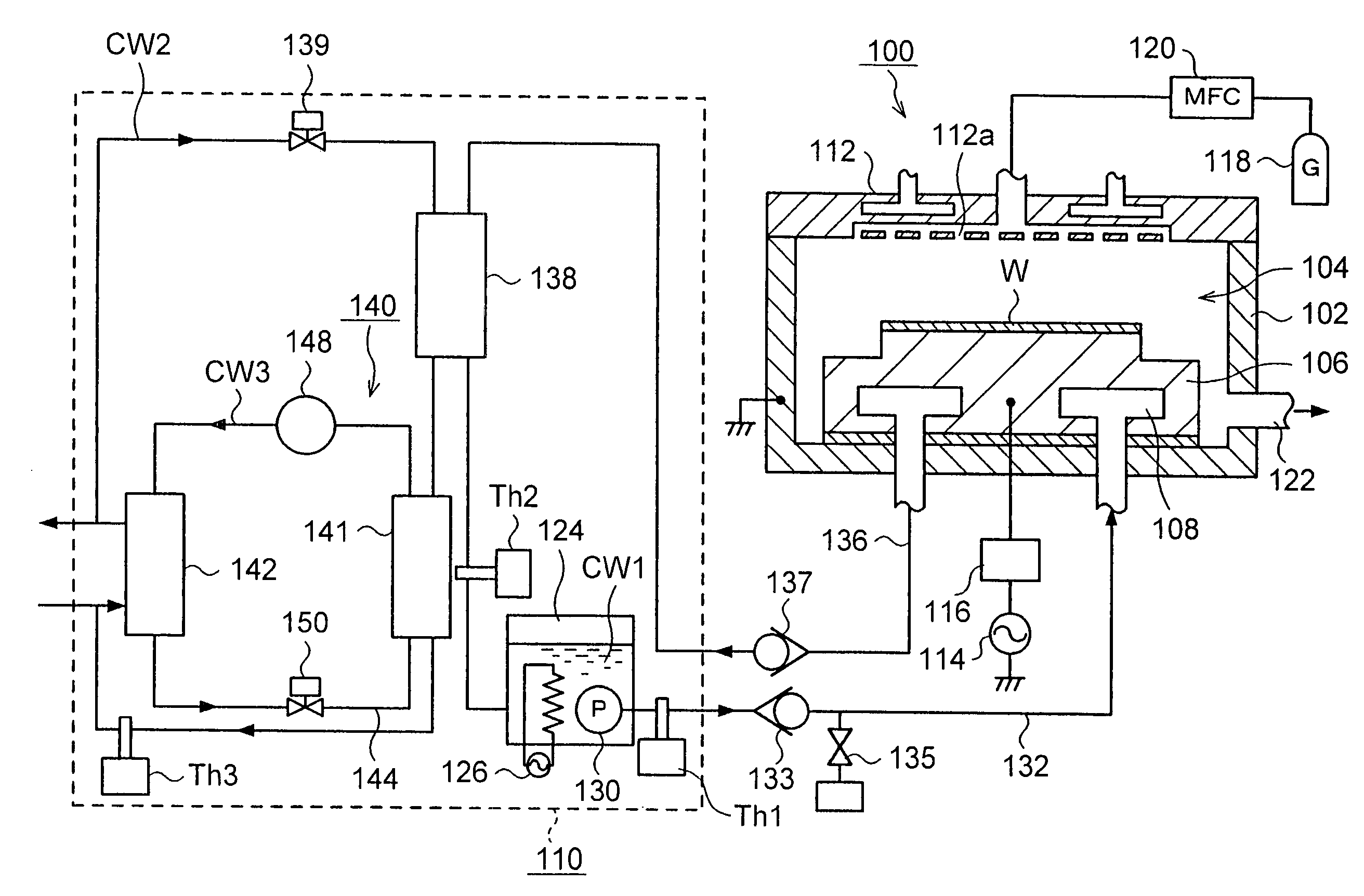

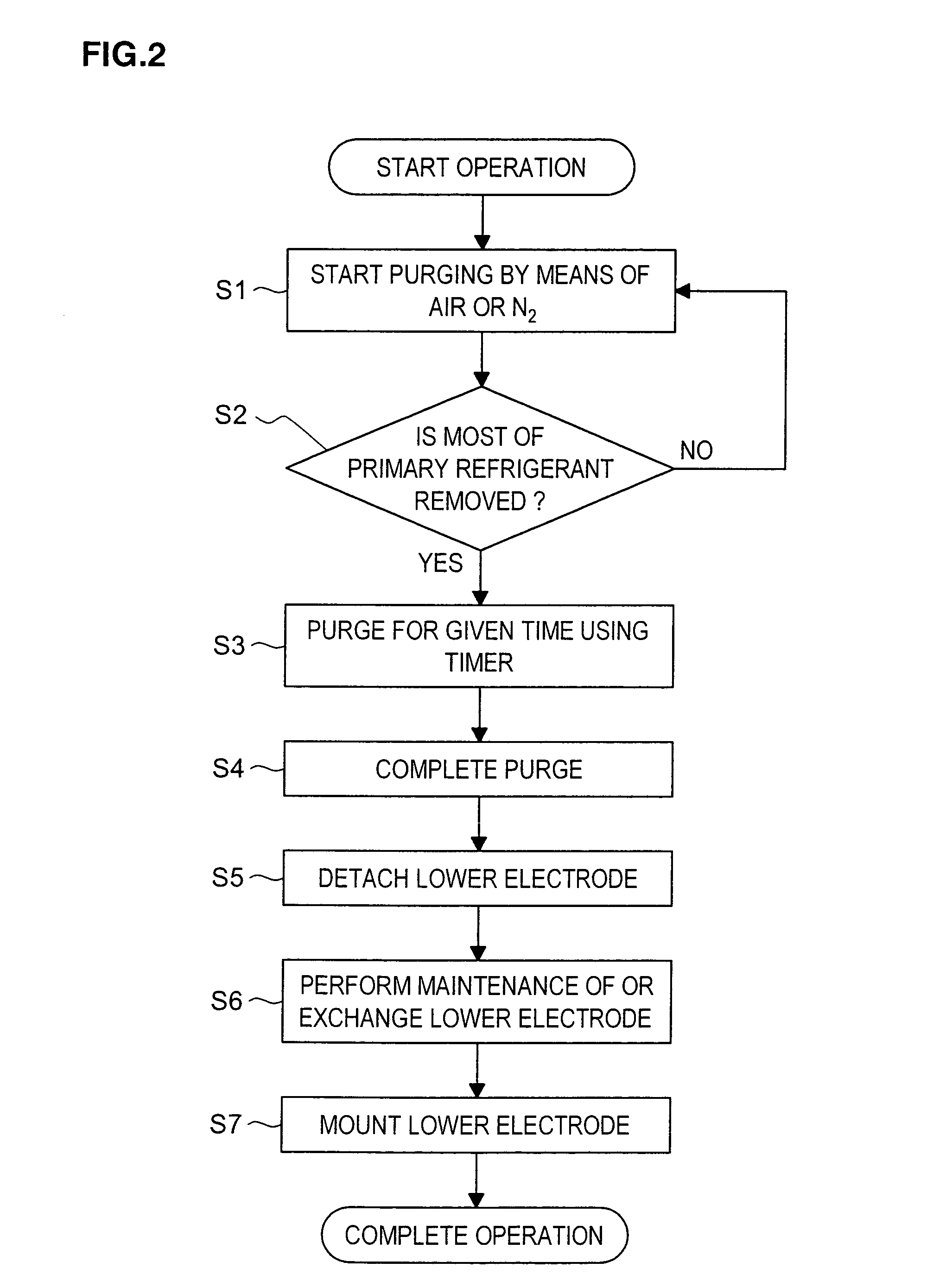

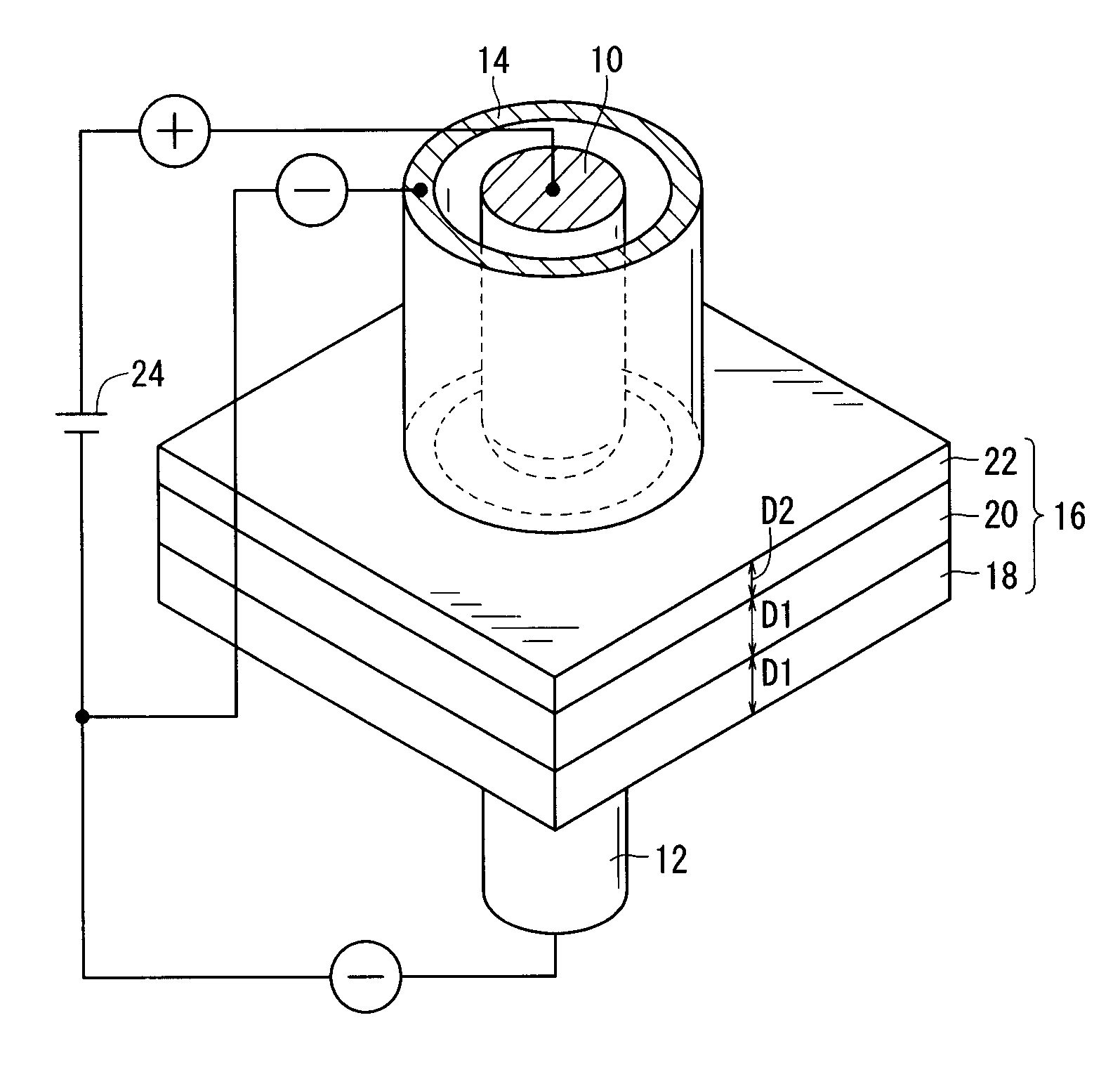

Cooling apparatus and plasma processing apparatus having cooling apparatus

InactiveUS7000416B2Save energyManagement moreSemiconductor/solid-state device manufacturingIndirect heat exchangersEngineeringRefrigerant

a cooling apparatus 110 comprises a primary refrigerant circulating circuit which allows a primary refrigerant CW1 whose temperature is adjusted by a heat exchanger 138 to circulate through an electrode to adjust a temperature of the electrode, a secondary refrigerant circulating circuit which supplies a secondary refrigerant CW2 to the heat exchanger to adjust the temperature of the primary refrigerant, and a freezing circuit 140 which has a first heat exchanger 141 interposed in the secondary refrigerant circulating circuit and which adjust a temperature of the secondary refrigerant by a tertiary refrigerant. The temperature of the primary refrigerant is adjusted by the secondary refrigerant without adjusting the temperature using the freezing circuit. When a temperature of the primary refrigerant is set higher than that of the secondary refrigerant, the temperature of the primary refrigerant can be adjusted only by the secondary refrigerant. Only when the temperature of the primary refrigerant is set lower than that of the secondary refrigerant, the temperature of the secondary refrigerant is adjusted by the freezing circuit and thus, it is possible to save energy.

Owner:TOKYO ELECTRON LTD

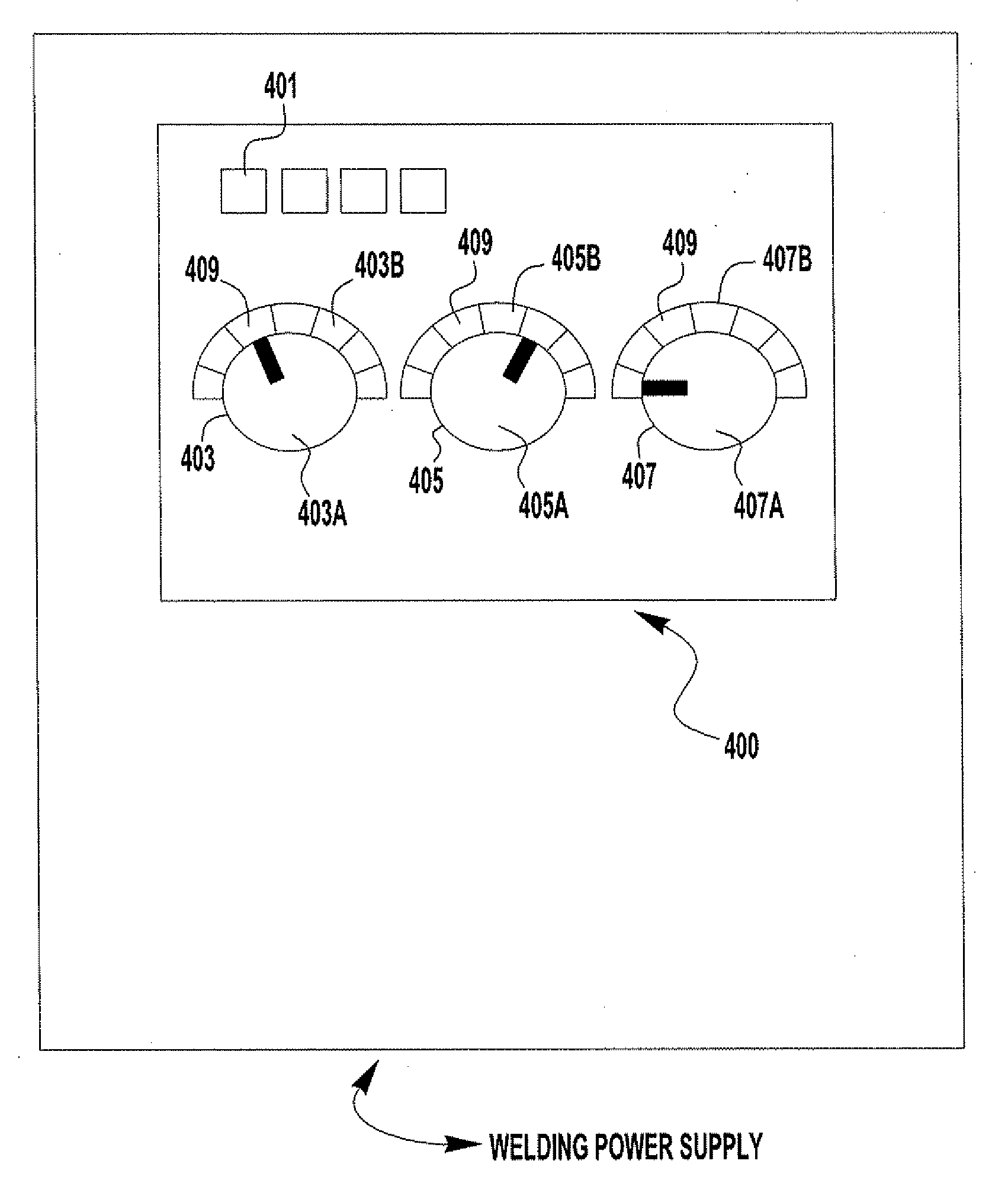

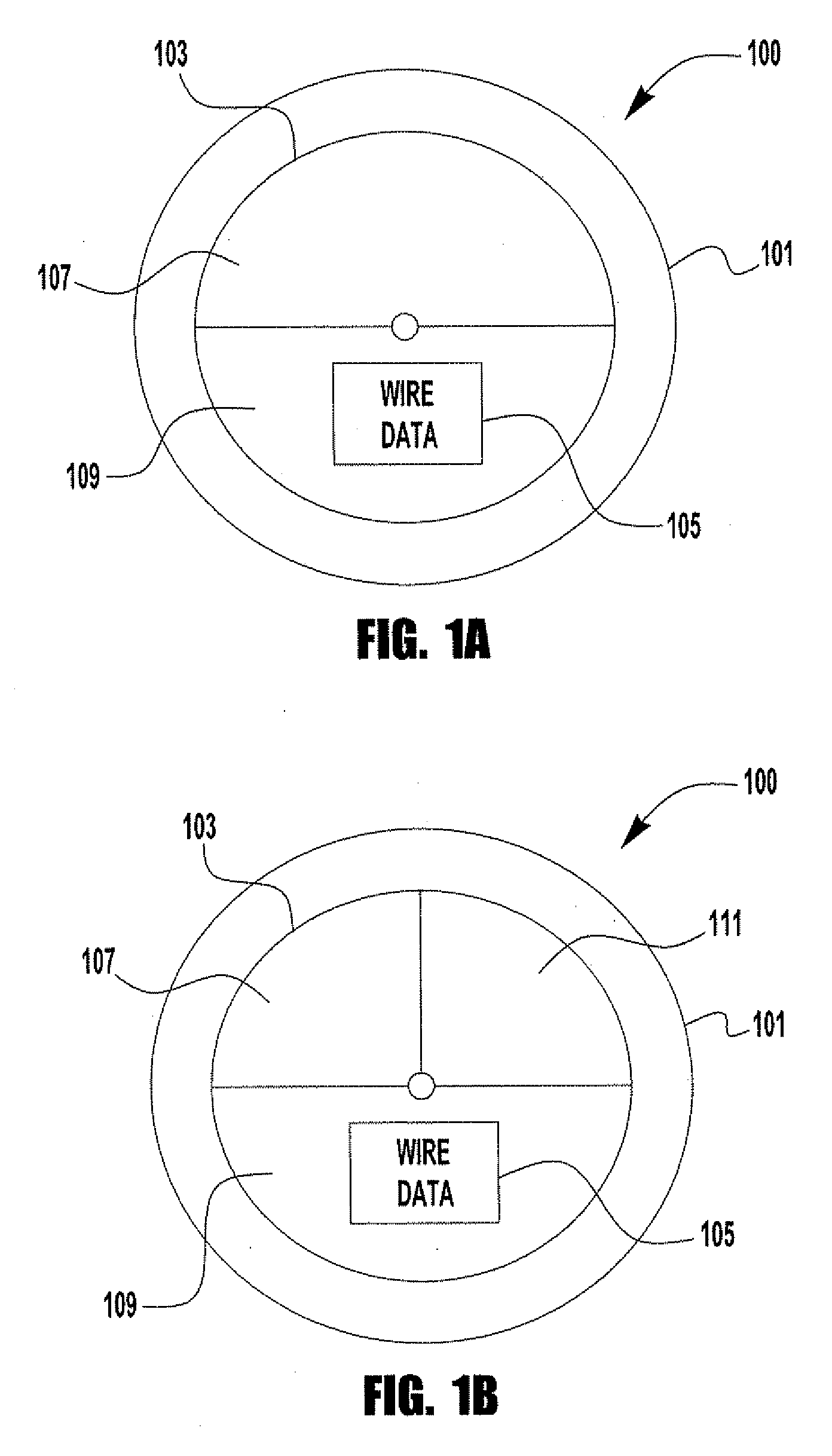

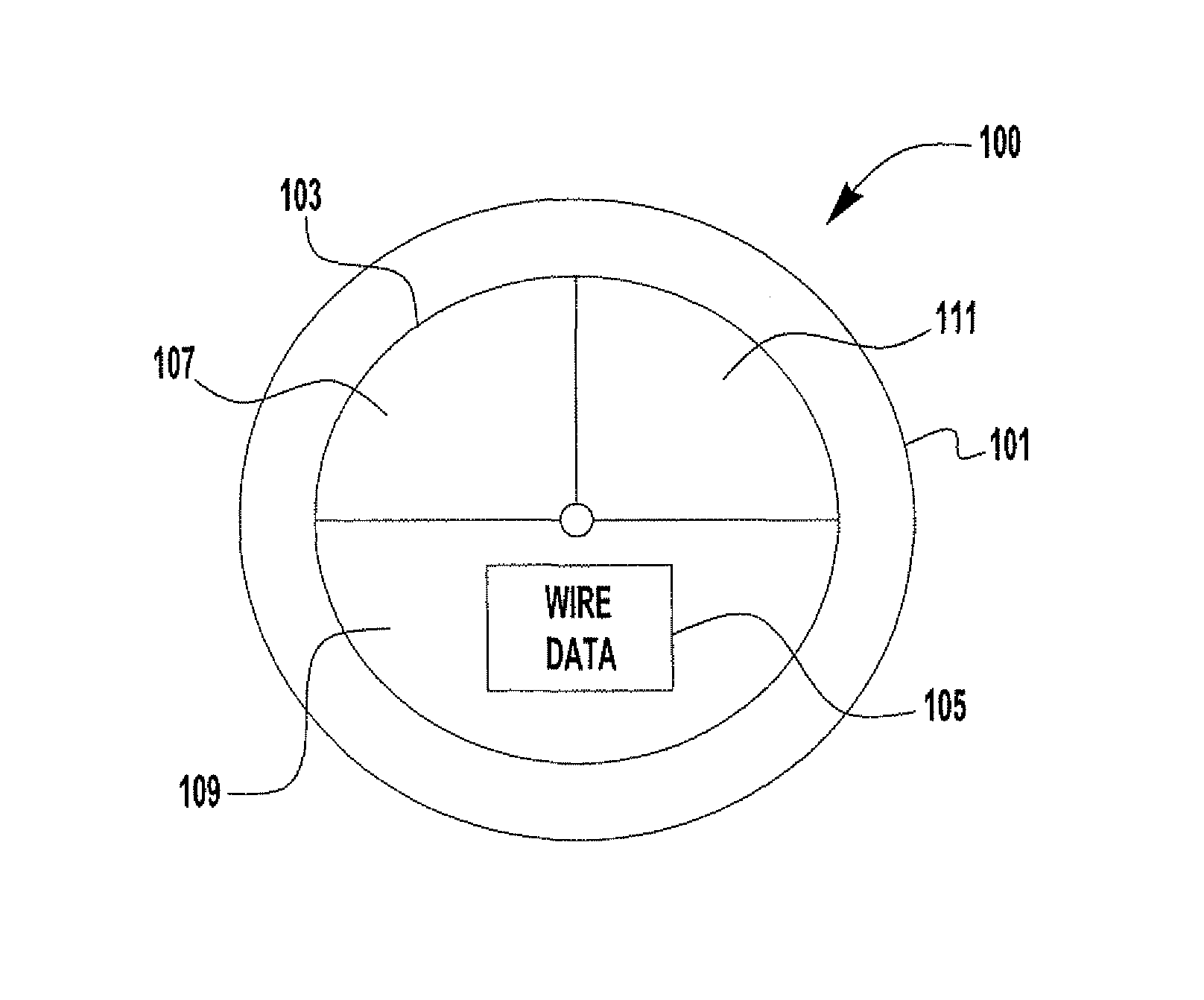

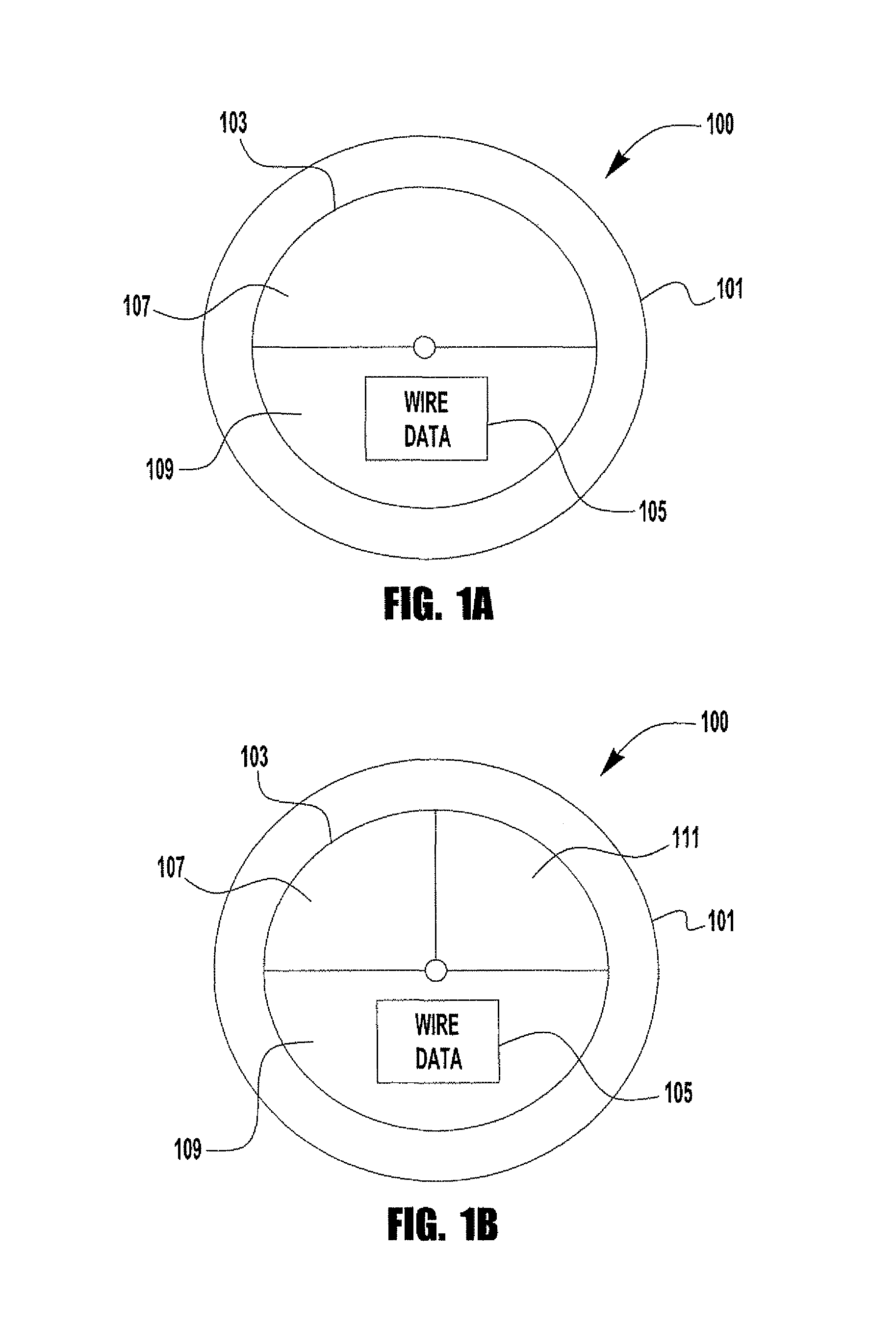

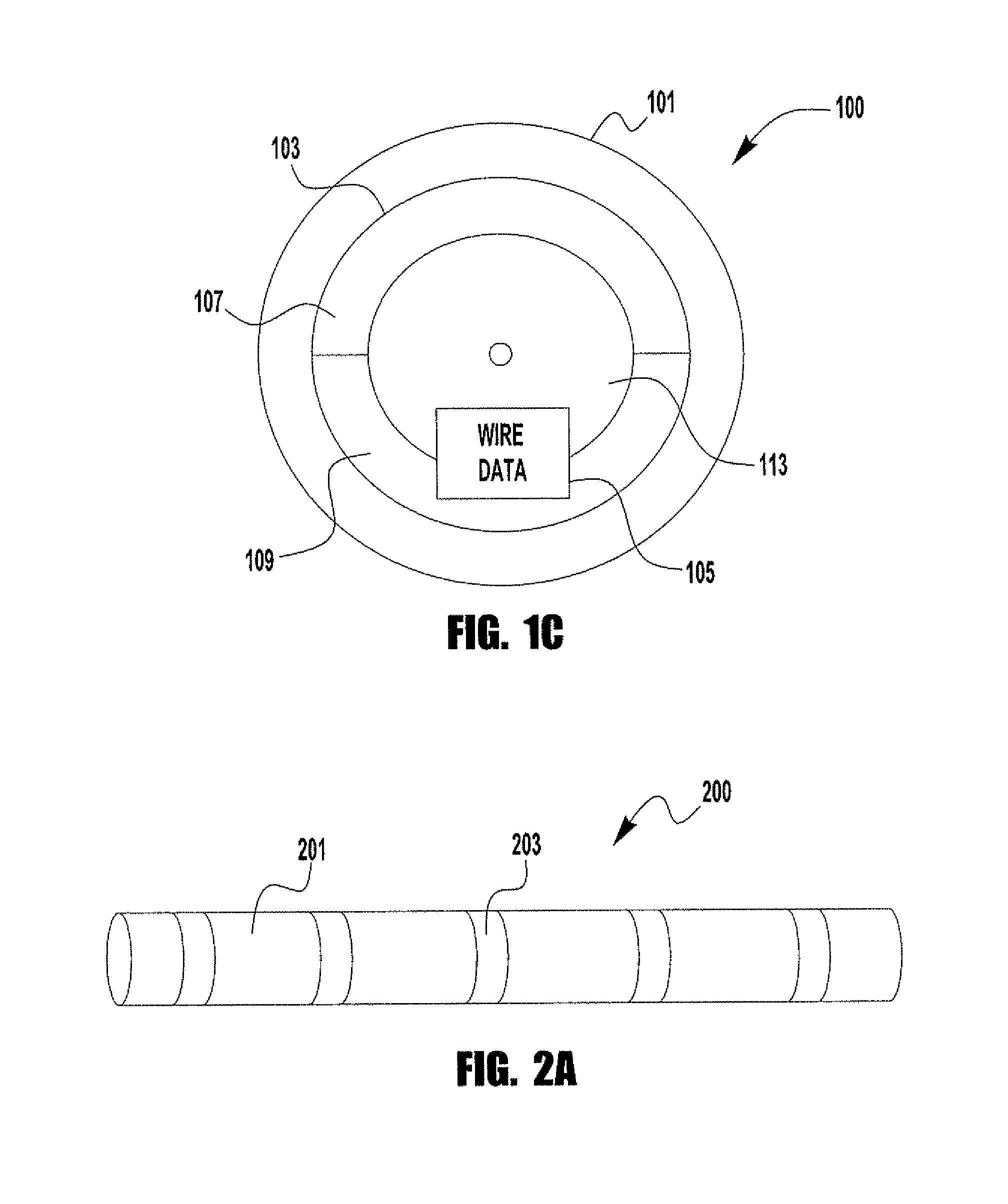

Synergistic welding and electrode selection and identification method

ActiveUS20110000893A1Improve welding qualityImprove efficiencyOhmic-resistance electrodesWelding electric supplyEngineeringElectrical and Electronics engineering

A method of identifying and selecting welding electrodes and welding output parameters on a welding power source is provided. The method includes identifying electrodes and / or electrode packaging with distinct colors and / or patterns which correspond to properties of the electrode. The method also may include employing distinguishable identifying markings on a power supply which correspond to the electrodes to be used to allow for easy setting of output parameters.

Owner:LINCOLN GLOBAL INC

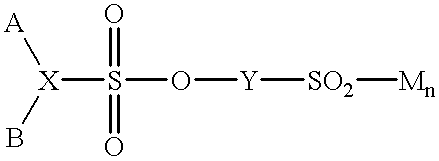

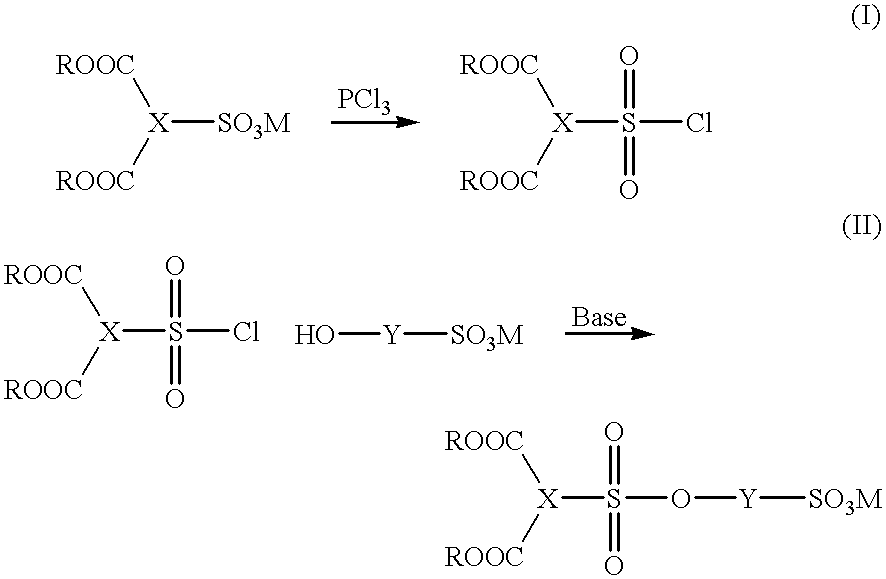

Apparatus for RF active compositions used in adhesion, bonding, and coating

InactiveUS20010035406A1Reduce total usageDielectric heatingSoldering apparatusThermal energySusceptor

A susceptor composition that can bond two or more layers or substrates to one another and that can be used to coat or cut a substrate. The susceptor composition is activated in the presence of radio frequency (RF) energy. In one embodiment, the susceptor composition of the present invention comprises a susceptor and a carrier. The carrier and susceptor are blended with one another and form a mixture, preferably a uniform mixture. The susceptor is present in an amount effective to allow the susceptor composition to be heated by RF energy. In a preferred embodiment, the susceptor also functions as an adhesive. The susceptor is an ionic or polar compound and acts as either a charge-carrying or an oscillating / vibrating component of the susceptor composition. The susceptor generates thermal energy in the presence of an RF electromagnetic or electrical field (hereafter RF field).

Owner:AMBRELL CORP

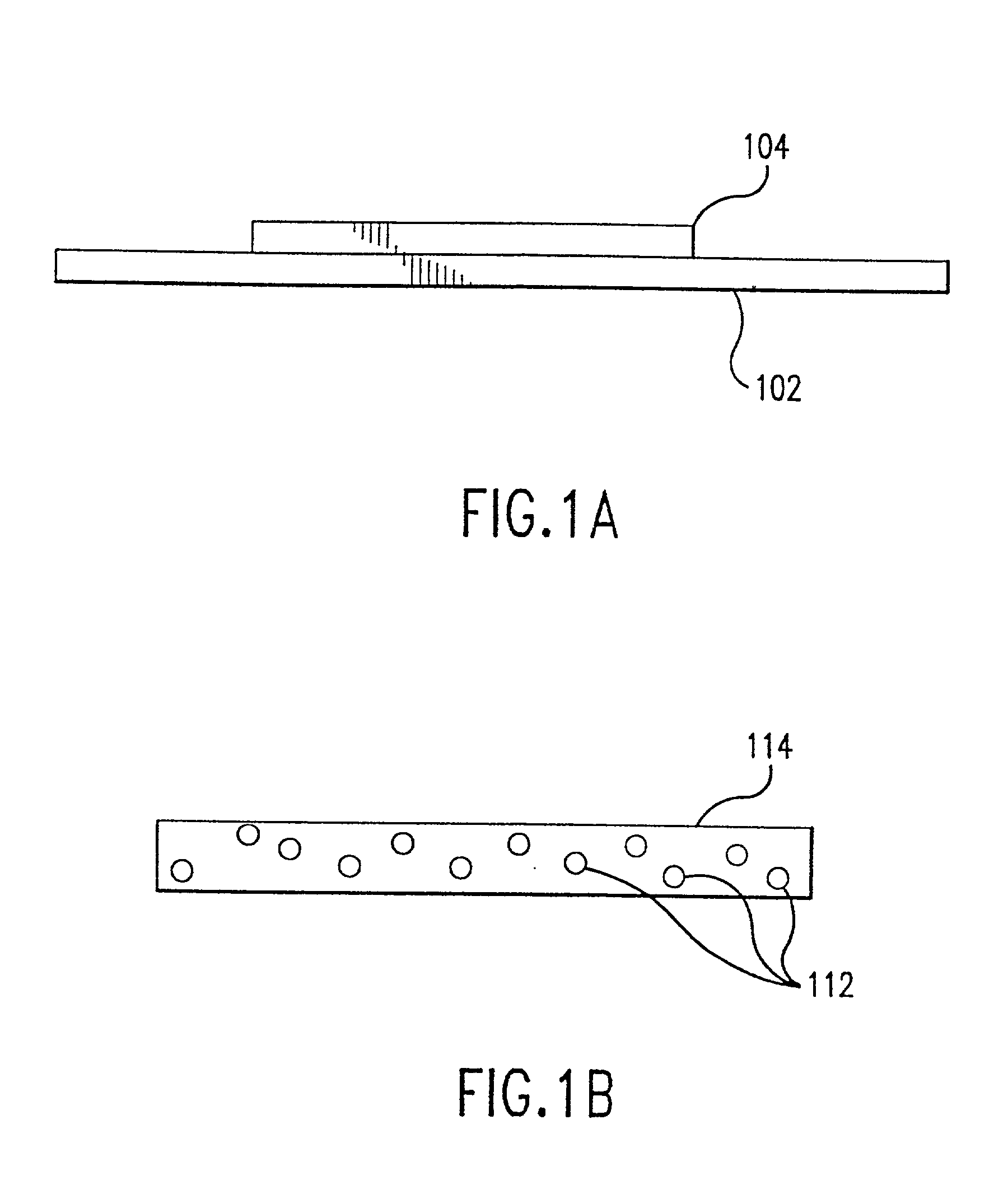

Electrode texturing tool and method of use thereof

An article for texturing an electrode having a tip hardness and a tip contour is disclosed. The article includes a plate having an upper surface and a lower surface, and an indentation in at least one of the upper and the lower surface. The indentation includes a textured surface having a plurality of asperities. The textured surface has a hardness greater than the tip hardness of the electrode. The texture of the textured surface is imprinted into the tip of the electrode in response to the tip of the electrode and the textured surface being pressed against each other.

Owner:GM GLOBAL TECH OPERATIONS LLC

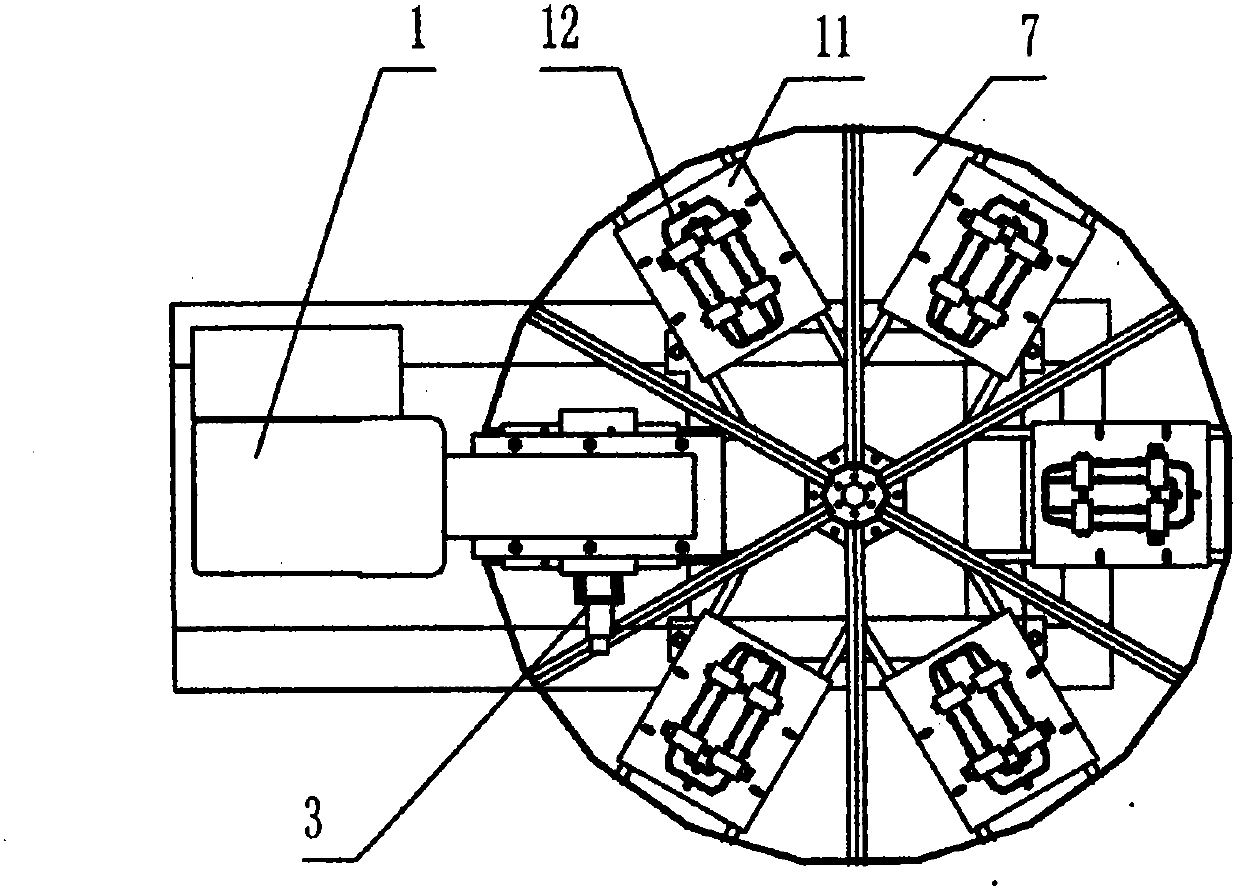

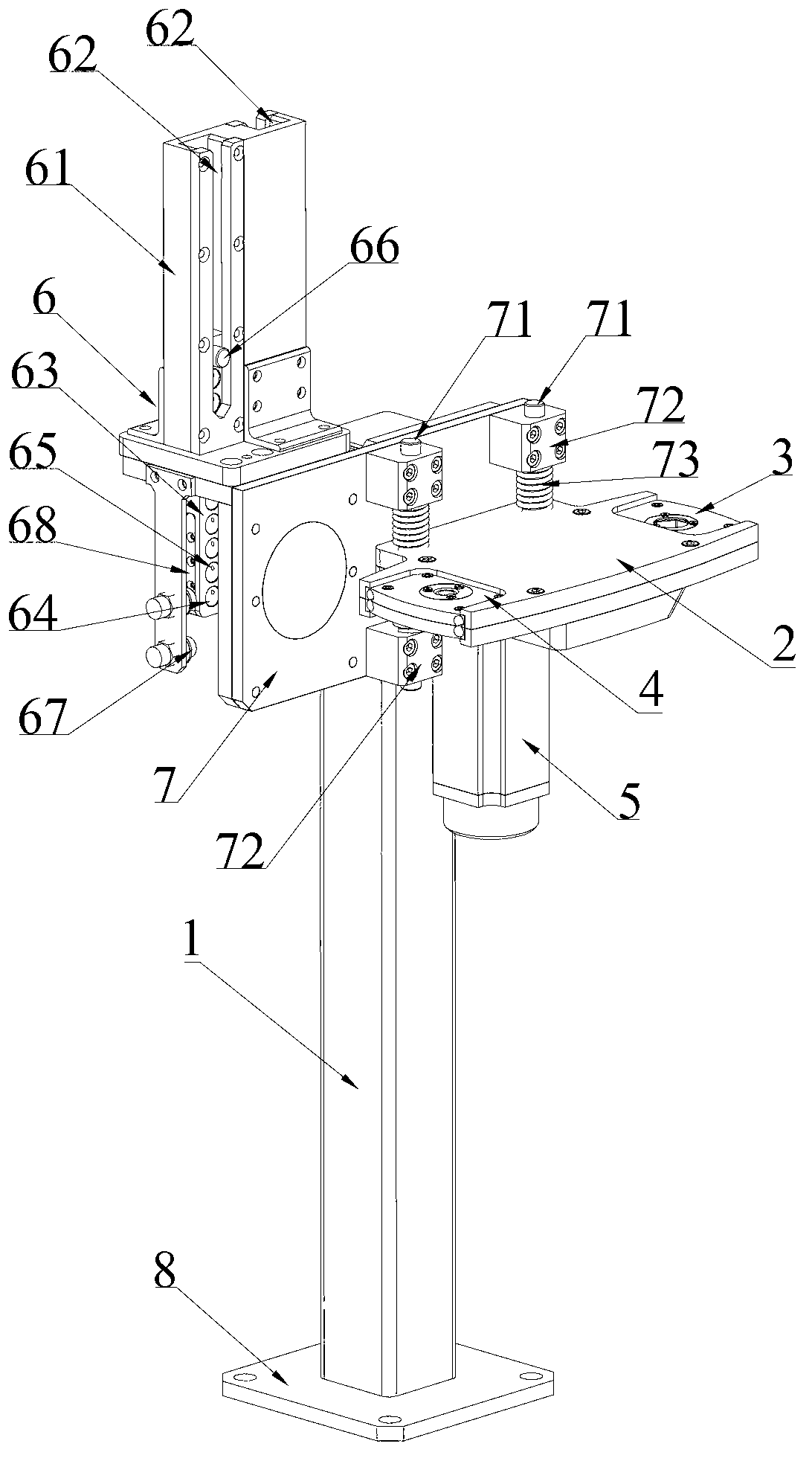

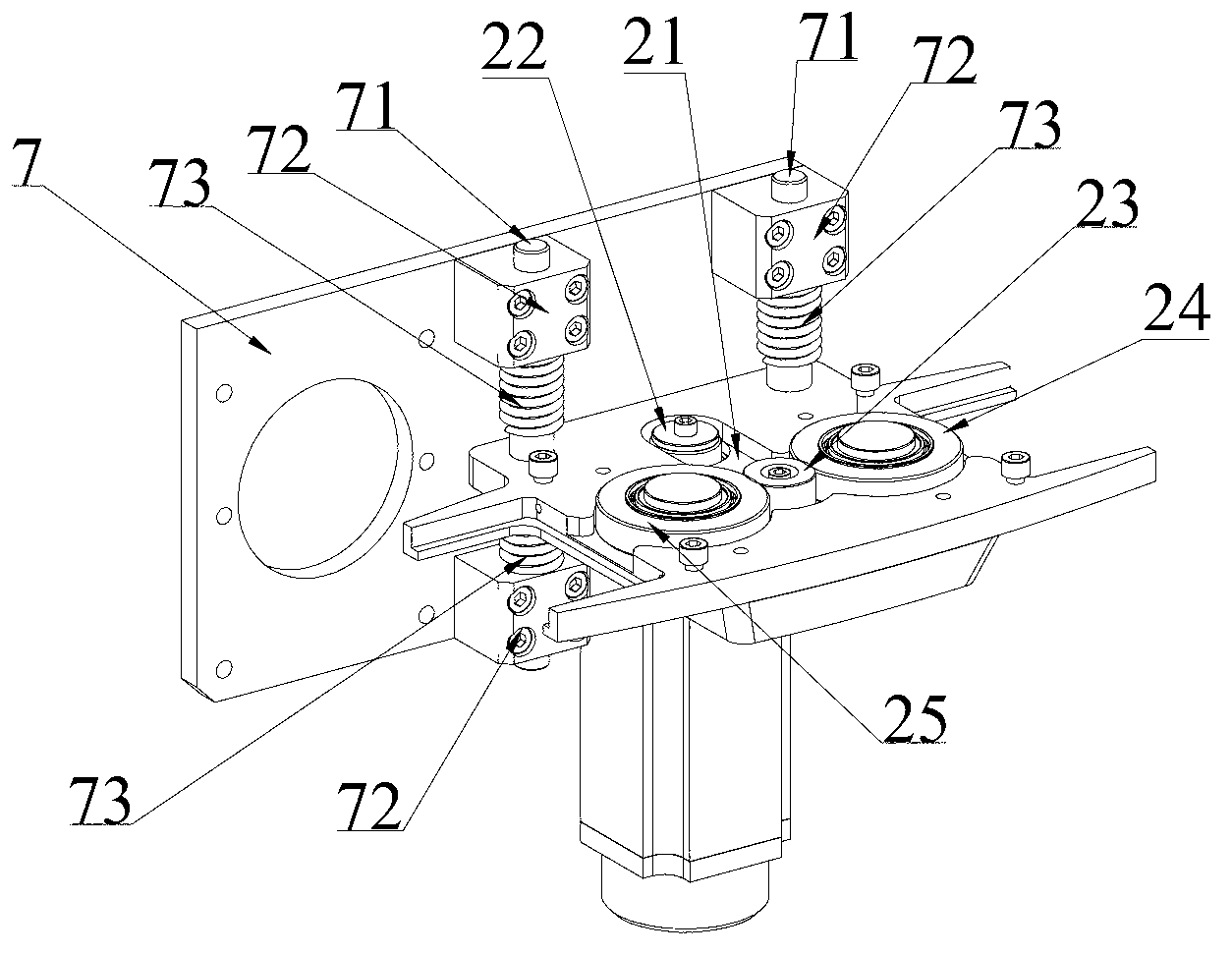

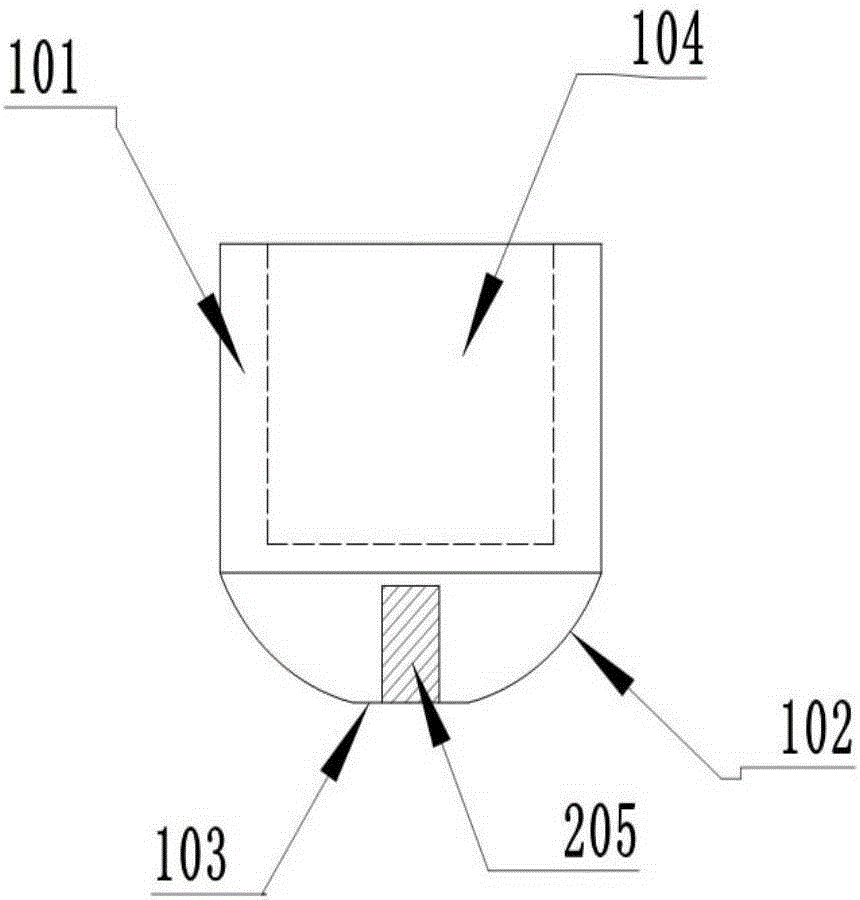

Electrode coping and replacing all-in-one machine

ActiveCN103170720ASolve the technical problem of stopping the line and changing the capHigh degree of automationElectrode featuresProduction lineEngineering

The invention discloses an electrode coping and replacing all-in-one machine which is used in the field of electrode coping and replacement in an automobile automatic welding production line. The electrode coping and replacing all-in-one machine comprises a machine frame, a drive machine head arranged on the machine frame, an electrode coping unit and an electrode cap replacing unit, wherein the electrode coping unit and the electrode cap replacing unit are arranged on the drive machine head. The drive machine head is provided with a servo motor used for driving the electrode coping unit and the electrode cap replacing unit. According to the electrode coping and replacing all-in-one machine, the electrode coping unit and the electrode cap replacing unit on the drive machine head are driven through the servo motor, coping of an electrode and replacement of an electrode cap can be completed and automation and integration of the coping and the replacement of the electrode cap can be achieved. Meanwhile, due to integration of device functions, the technical problem that the automobile automatic welding production line is stopped for electrode cap replacement is solved and automatic degree of the automobile automatic welding production line and production capacity of automobiles are improved.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD +1

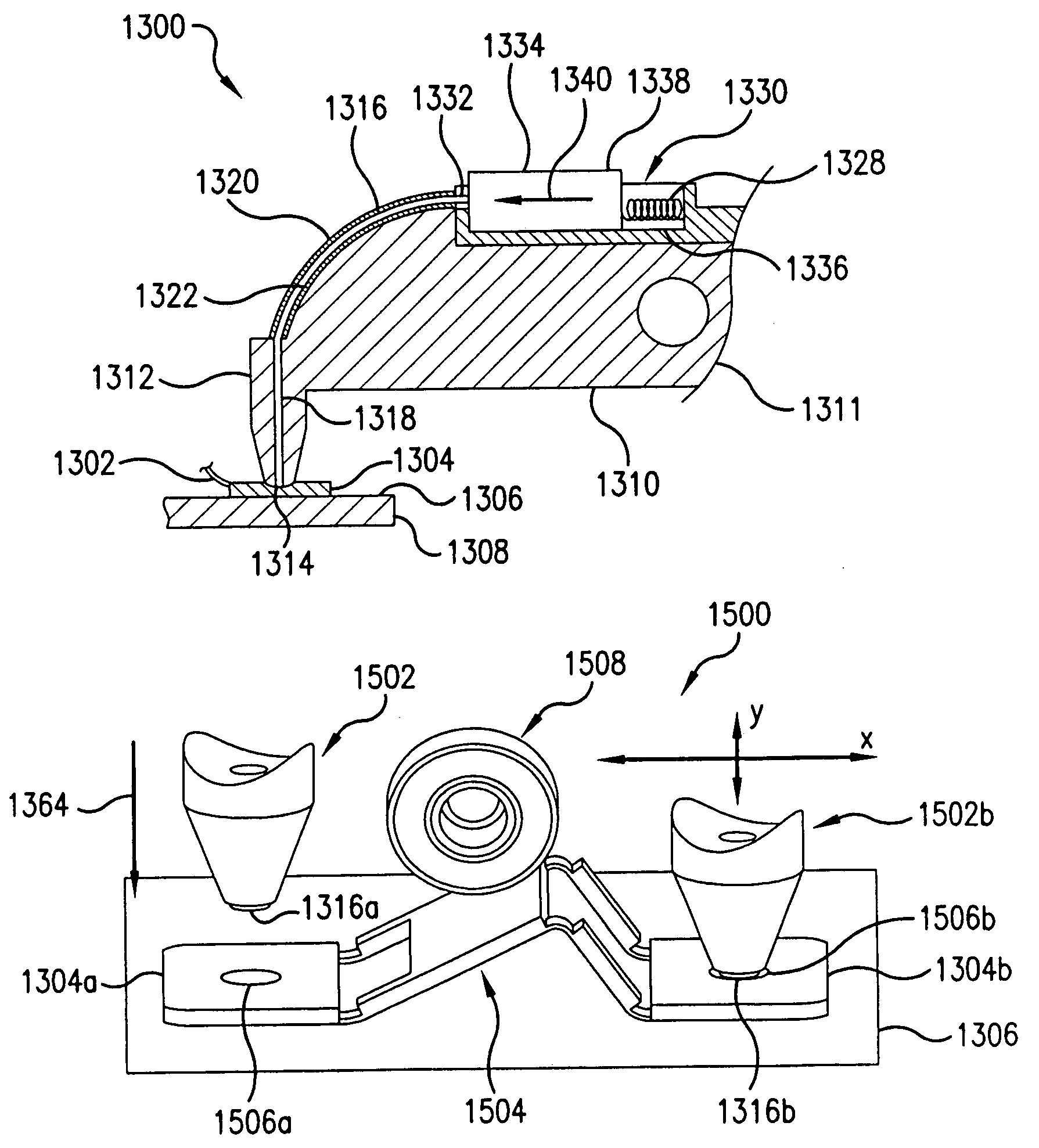

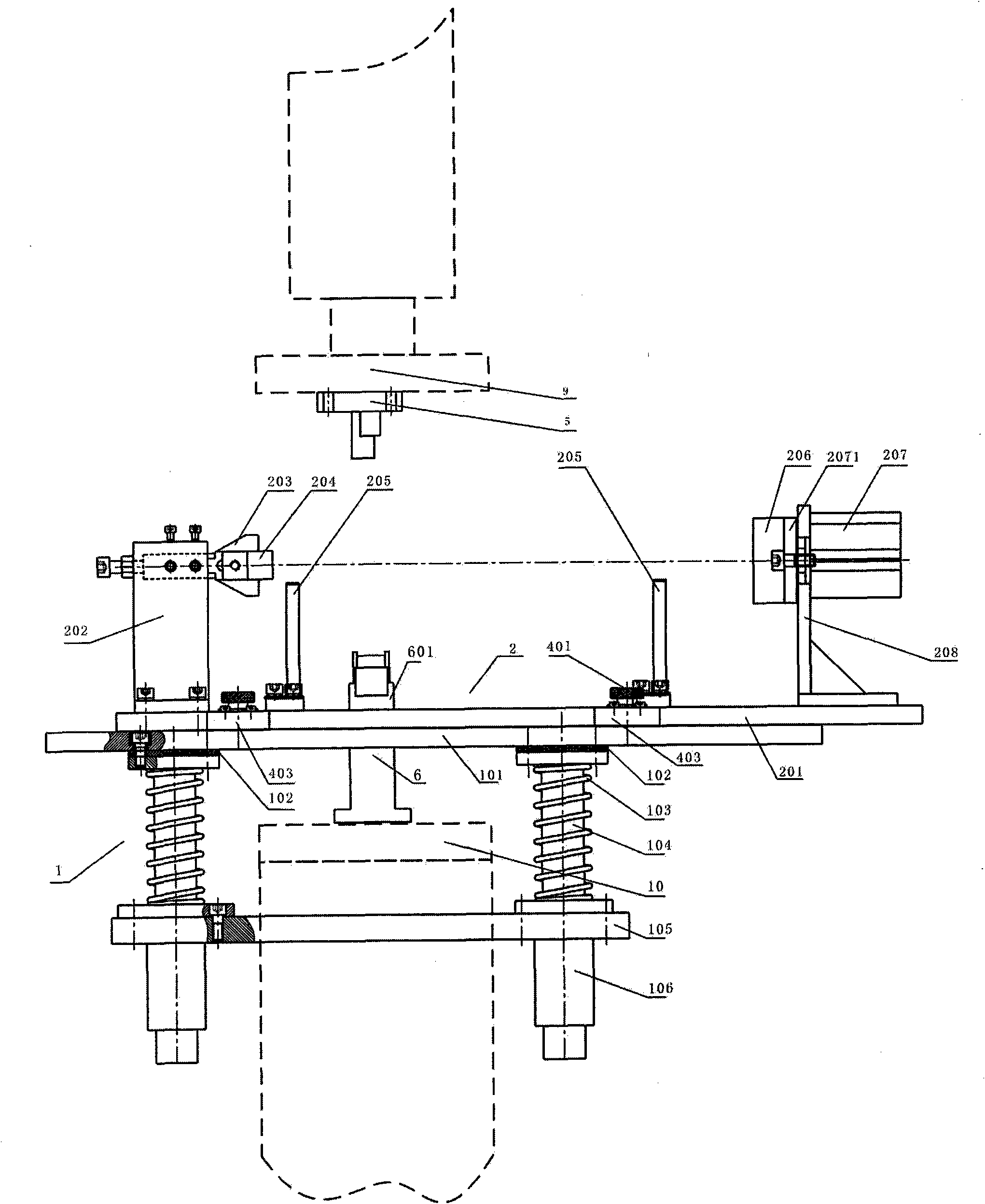

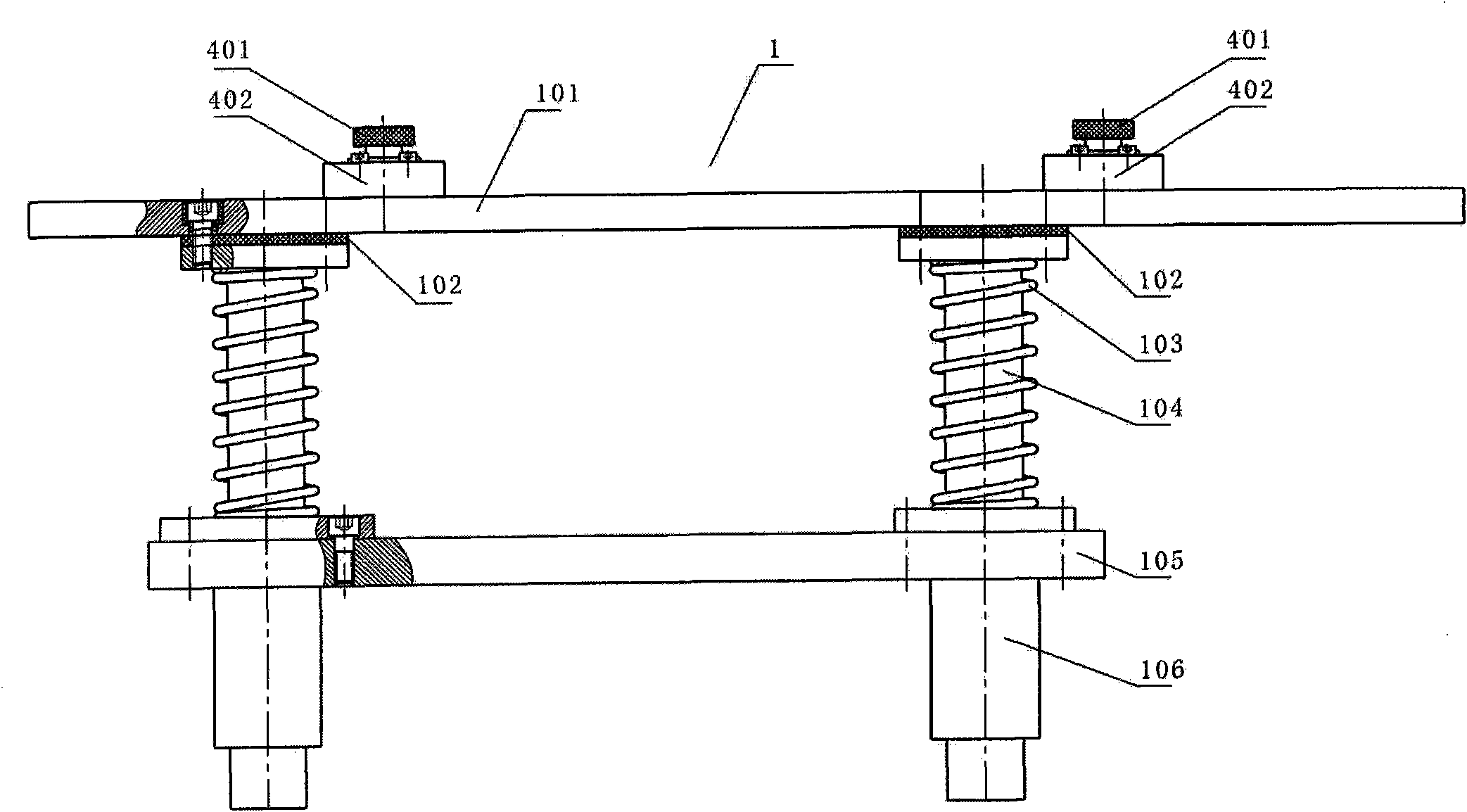

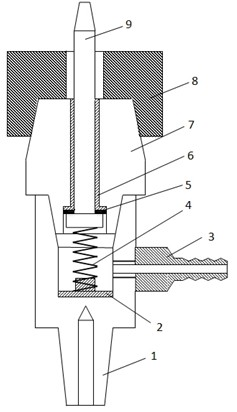

Automobile shock absorber support projection welding floating tool

The invention discloses an automobile shock absorber support frame projection welding floating tool, which relates to spot welding equipment and consists of a projection welding floating universal base, a replaceable automobile shock absorber support positioning frame, a replaceable positioning frame positioning mechanism, a wedge-shaped pressing mechanism, an upper electrode seat and a lower electrode seat, wherein the replaceable automobile shock absorber support positioning frame is arranged on the projection welding floating universal base through the replaceable positioning frame positioning mechanism and the wedge-shaped pressing mechanism, the projection welding floating universal base is arranged on a casing of a projection welder, the upper electrode seat is arranged under an upper electrode plate of the projection welder, and a lower electrode is arranged on a lower electrode plate of the projection welder. A spring is used for buffering in welding contact moment, thus the tool is stable and reliable, the salient point plastic deformation can not be caused, the salient point size is prevented from being changed by the upper electrode cylinder impact, and the welding strength stability is good.

Owner:浙江鼎信航天科技有限公司

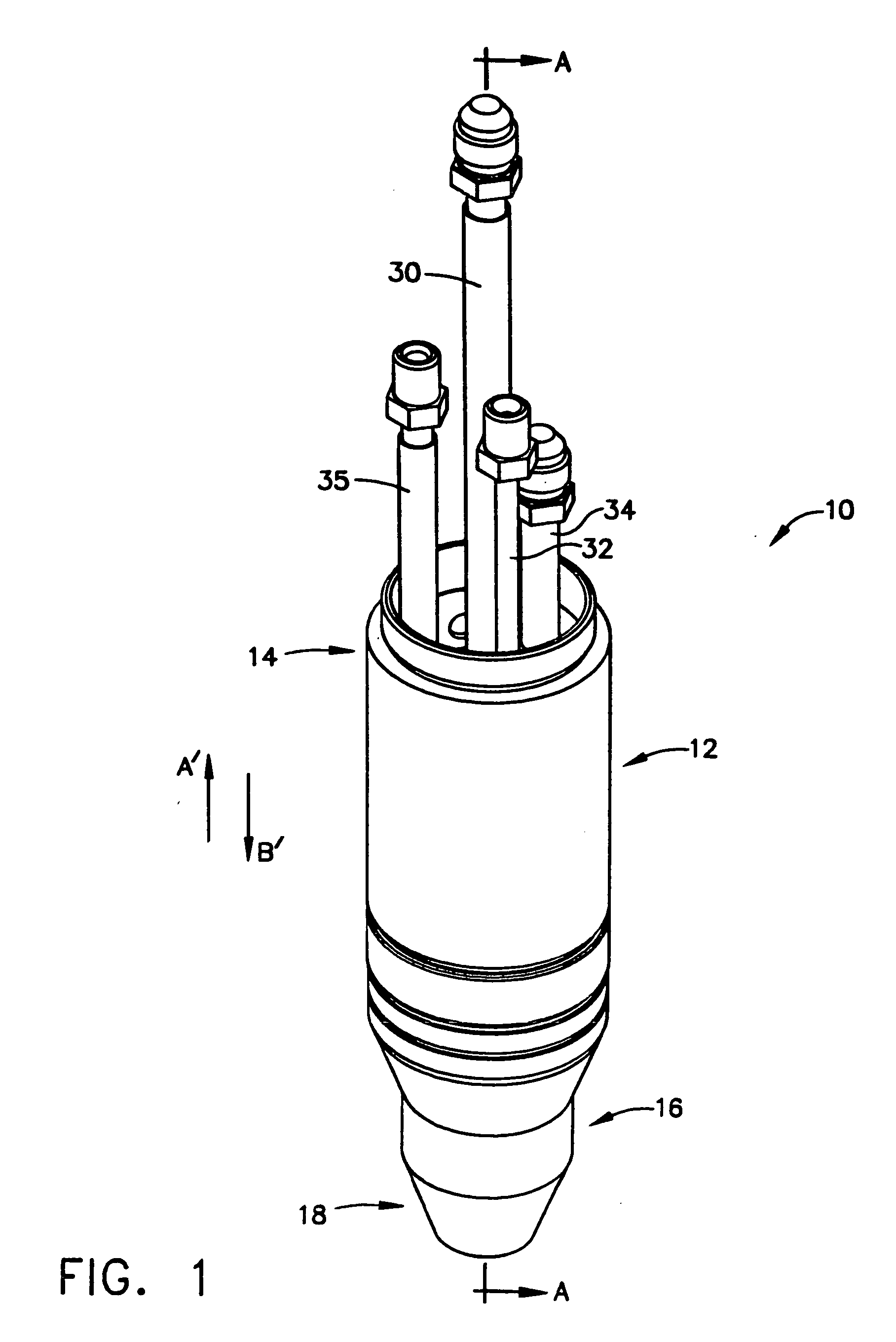

Electrode for plasma torch with novel assembly method and enhanced heat transfer

ActiveUS8633417B2Long electrode lifeReduce manufacturing costOhmic-resistance electrodesElectrode featuresEnhanced heat transferEngineering

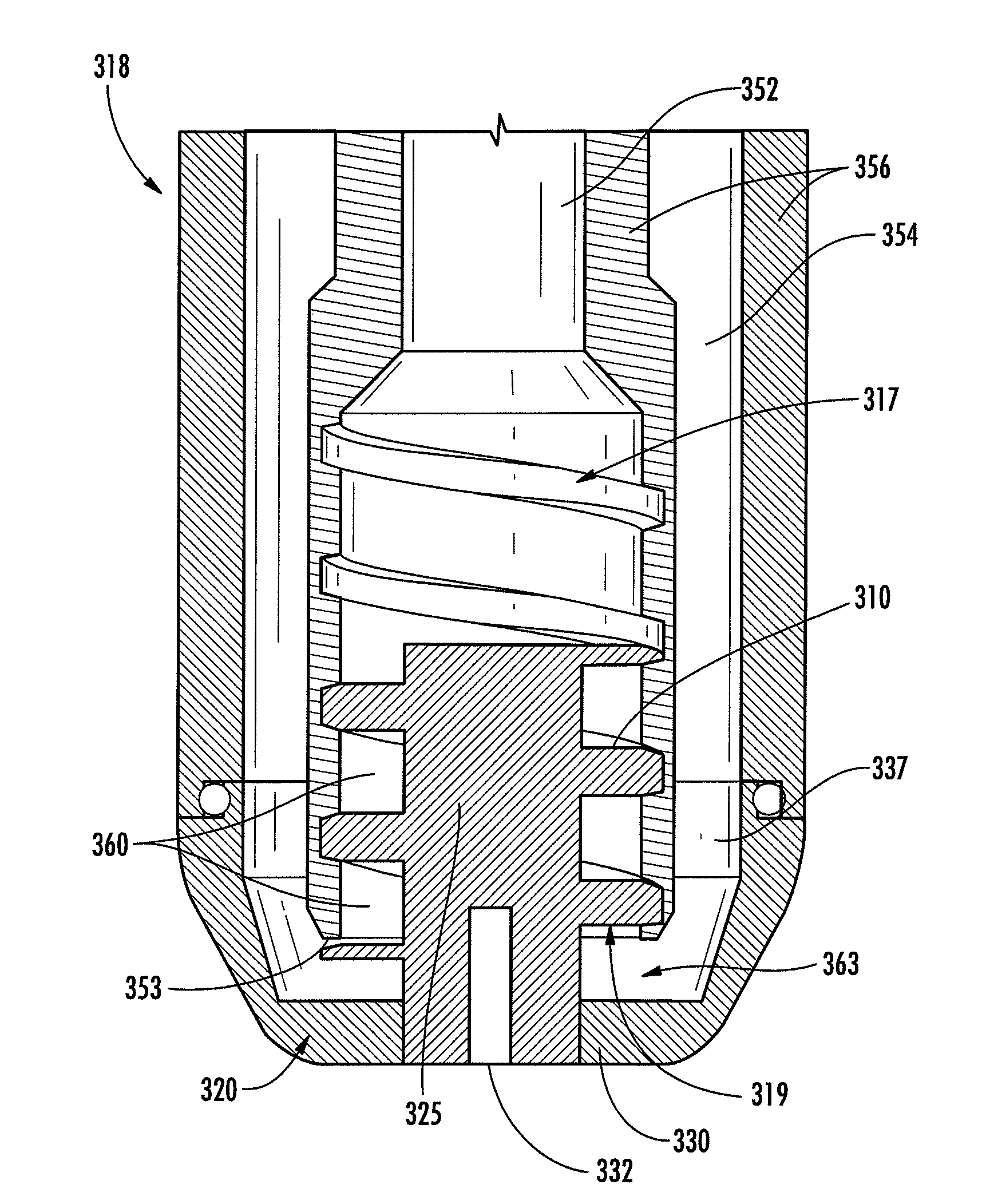

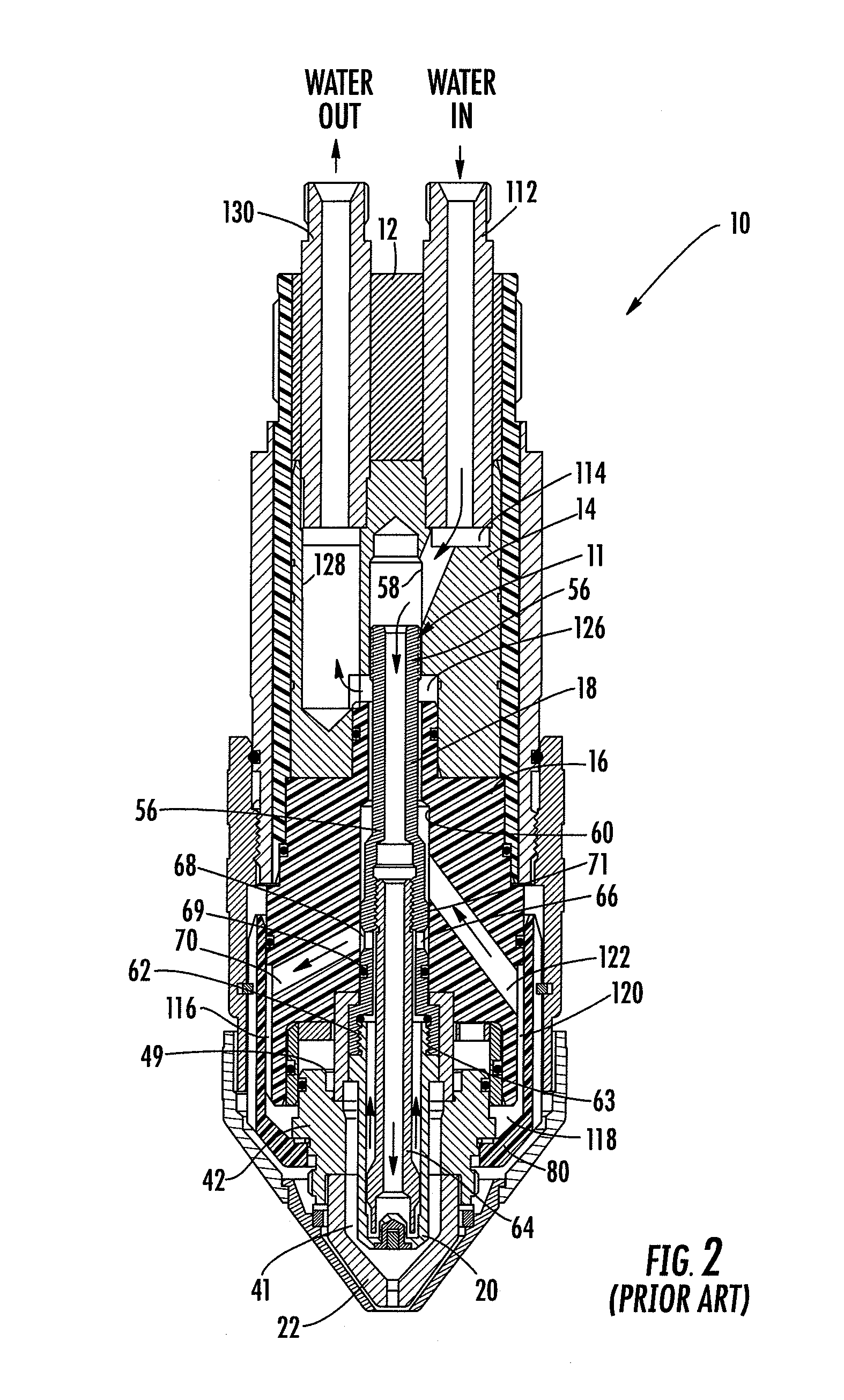

Embodiments of the present invention are related to an electrode for a plasma arc torch, the electrode comprising a generally tubular outer wall, an end wall, and a protrusion. The end wall is joined to a distal end of the outer wall and supports an emissive element in a generally central region. The protrusion extends from the generally central region of the end wall and is configured to connect with an electrode holder by a releasable connection, wherein the protrusion is configured such that at least one coolant passage forms between the protrusion and the electrode holder when the electrode is connected with the electrode holder. In some embodiments, the releasable connection comprises a threaded connection, wherein the protrusion is threaded to releasably connect to a threaded coolant tube of the electrode holder. In other embodiments, at least one coolant passage is defined by the threaded connection.

Owner:THE ESAB GROUP

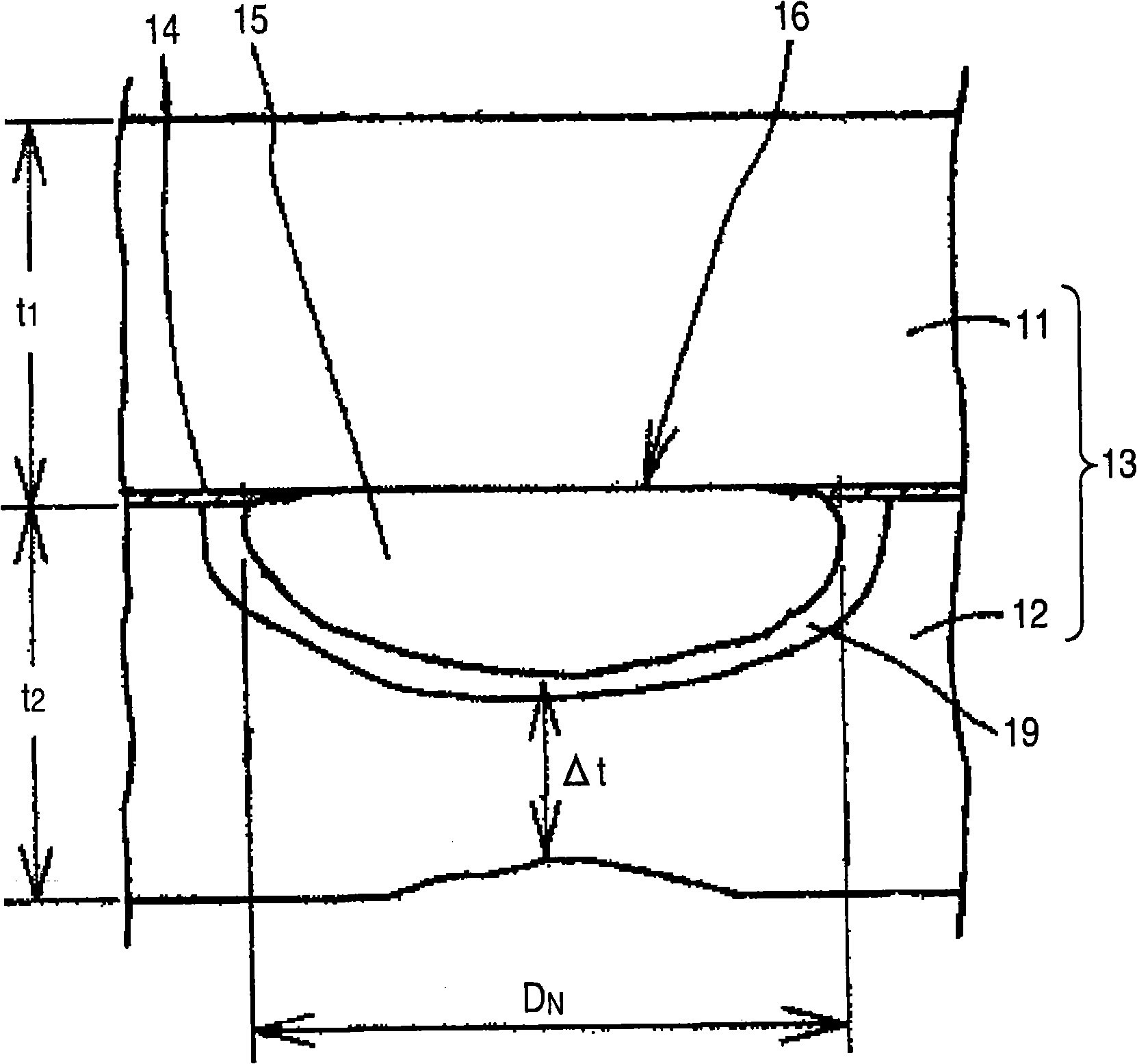

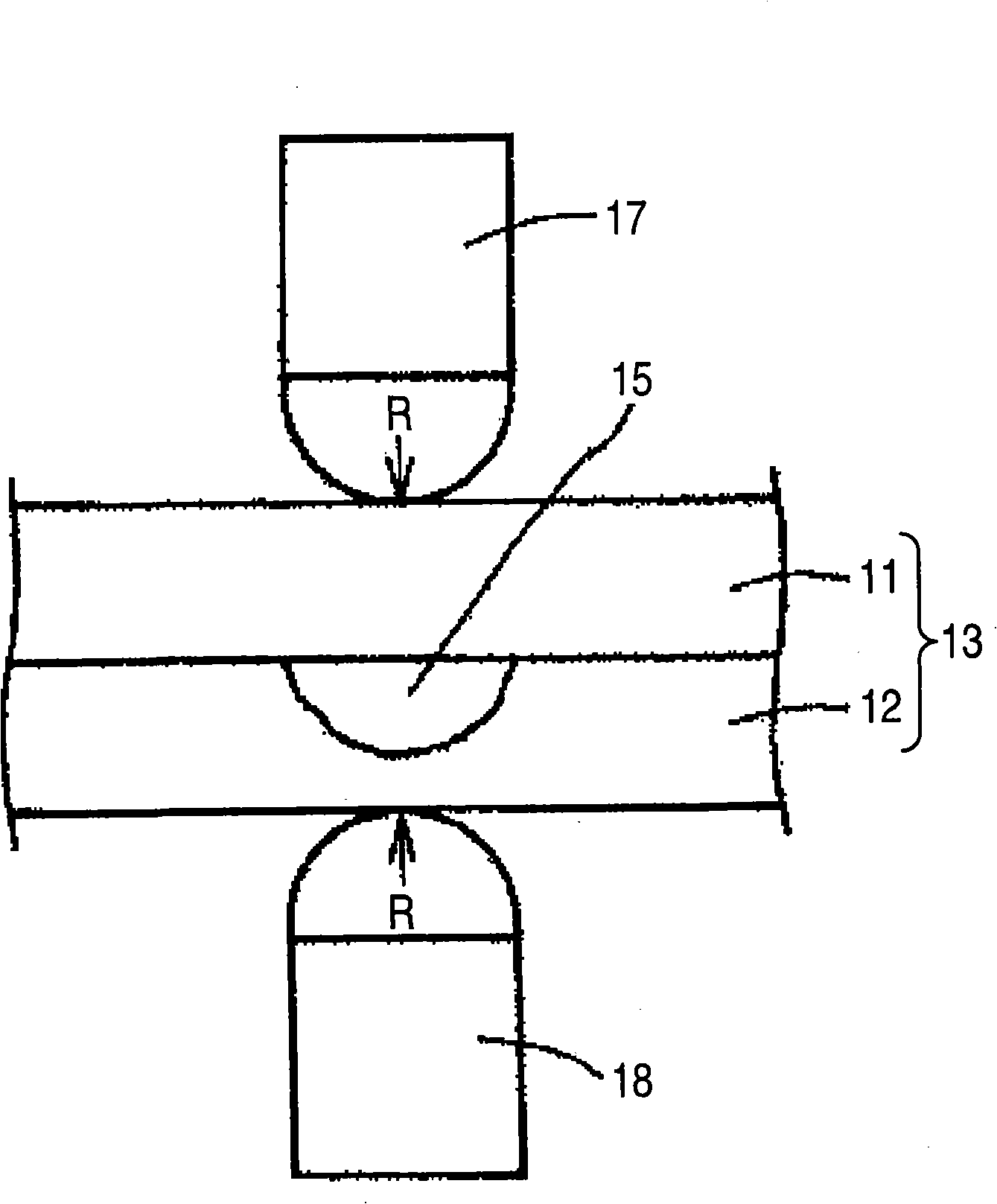

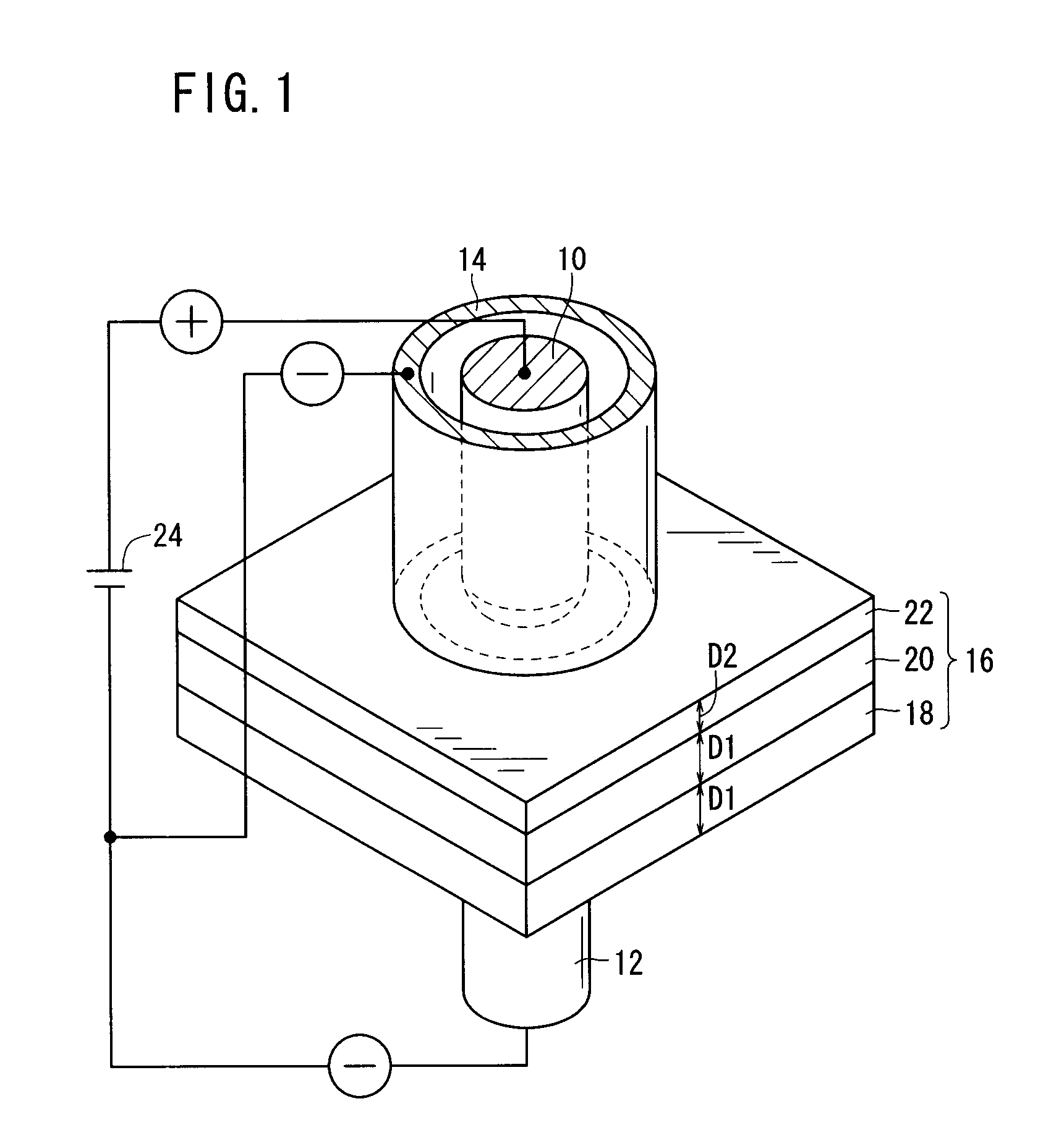

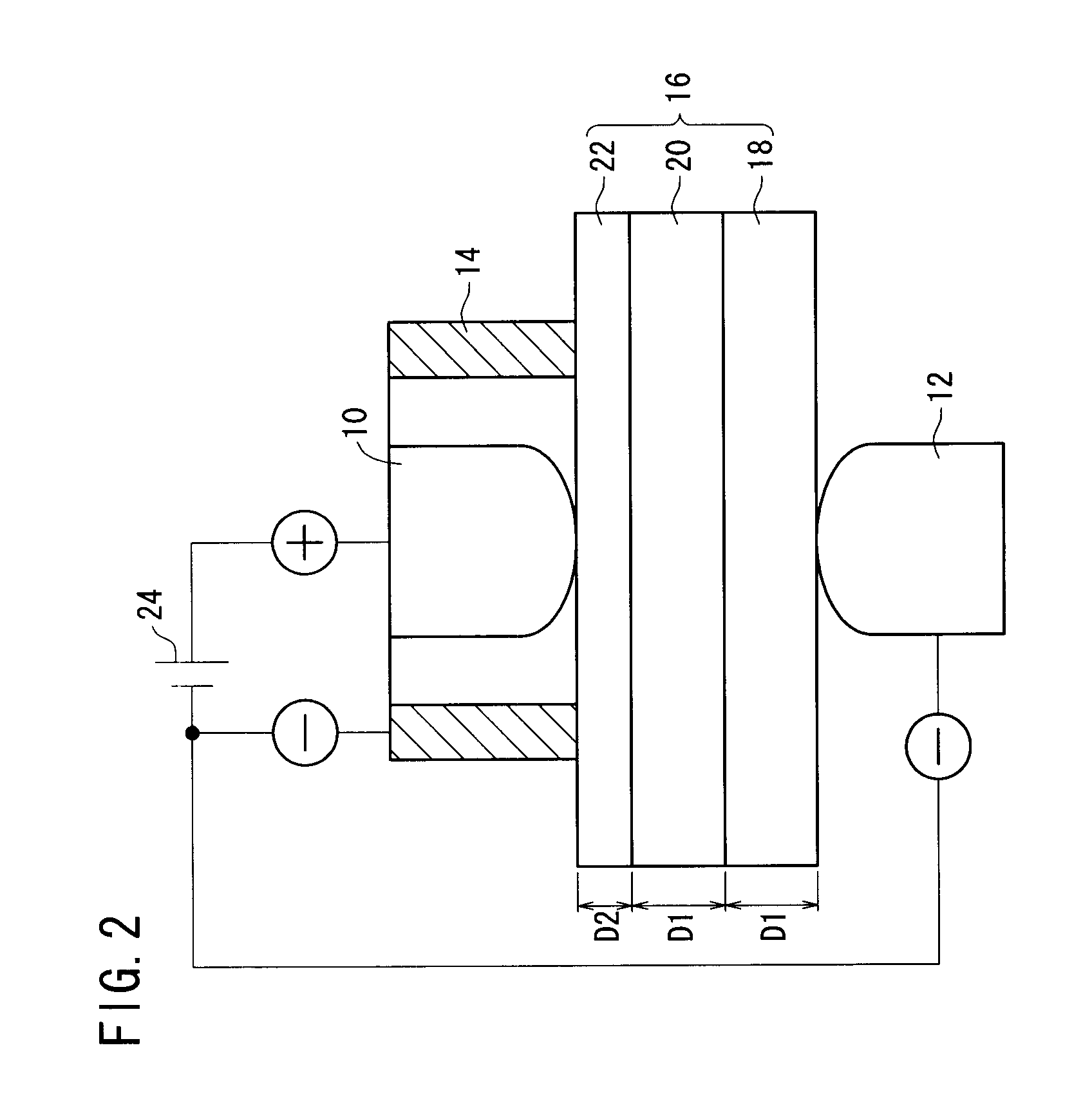

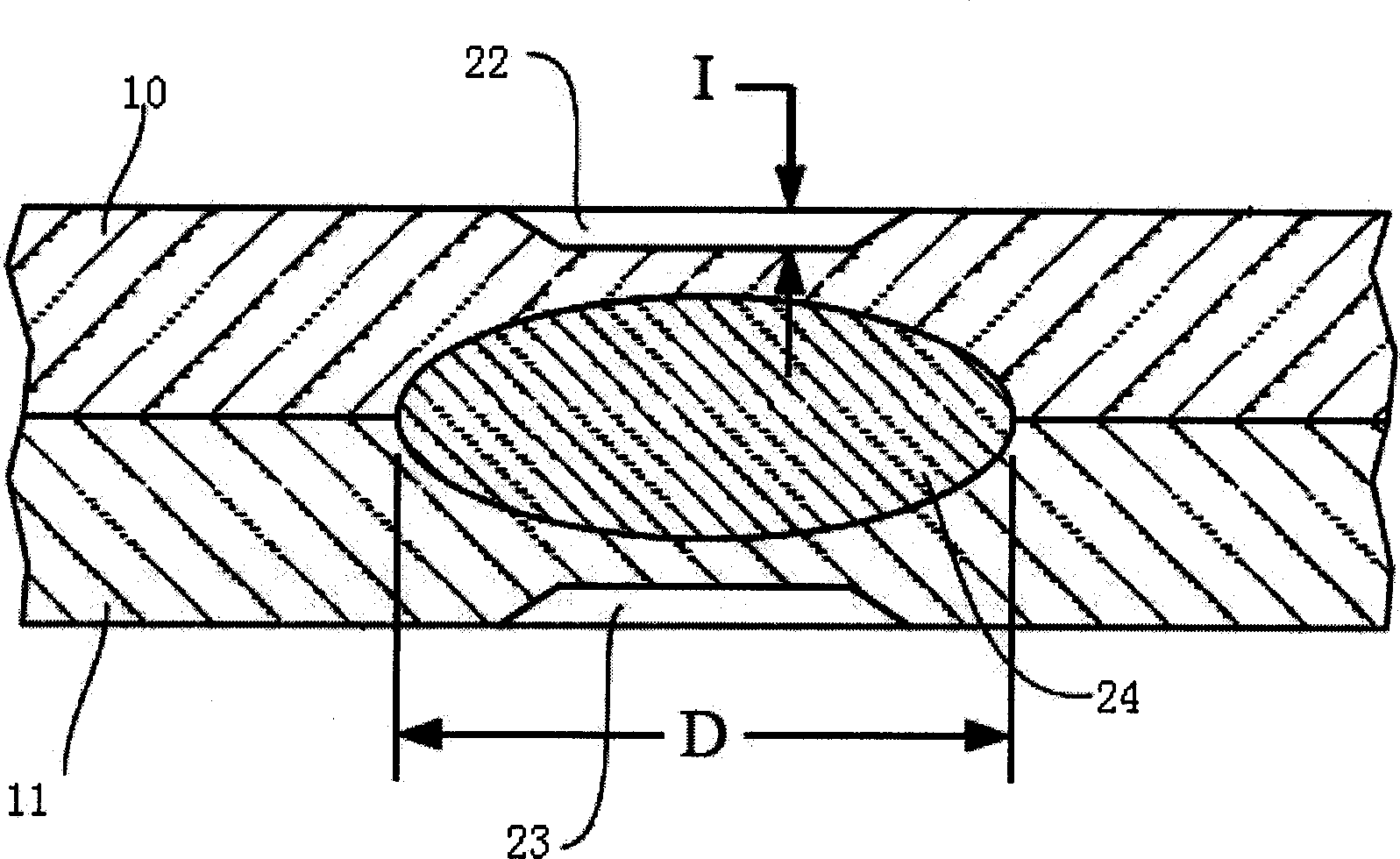

Joint product between steel product and aluminum material, spot welding method for the joint product, and electrode chip for use in the joint product

InactiveCN101405105AImprove joint strengthElectrode featuresWelding/soldering/cutting articlesReaction layerSpot welding

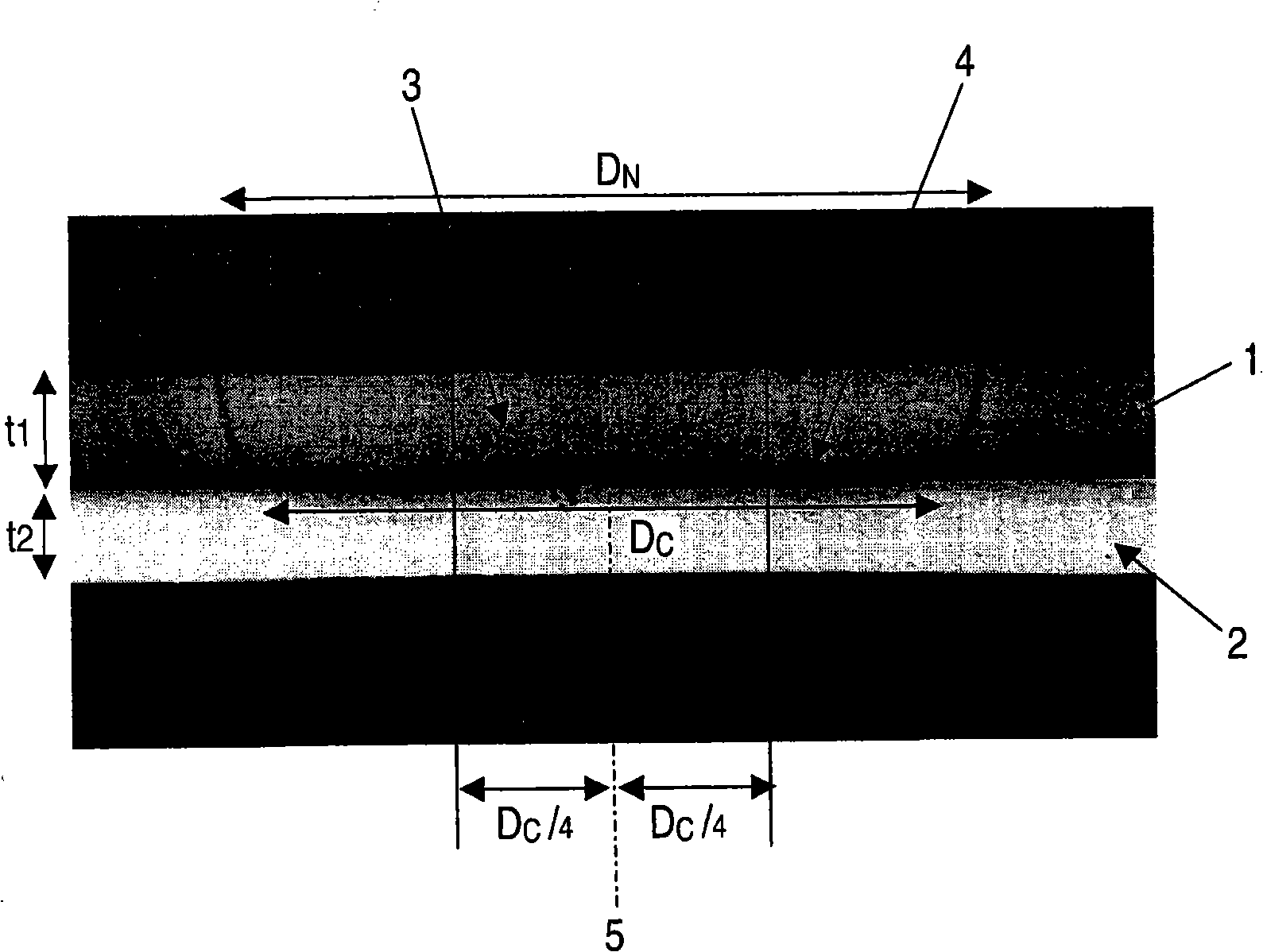

The present invention provides a joint product of a steel product and an aluminum material, and a spot welding method for the joint product, ensuring that spot welding with high bonding strength can be performed. In one embodiment, a steel product 1 having a sheet thickness t 1 of 0.3 to 3.0 mm and an aluminum material 2 having a sheet thickness t 2 of 0.5 to 4.0 mm are joined together by spot welding to form a joint product of a steel product and an aluminum produce. In this joint product, the nugget area in the joint part is from 20 t 2 0.5 to 100 t 2 0.5 mm 2 , the area of a portion where the thickness of the interface reaction layer is from 0.5 to 3 [mu]m is 10 t 2 0.5 mm 2 or more, and the difference between the interface, reaction layer thickness at the joint part center and the interface reaction layer thickness at a point distant from the joint part center by a distance of one-fourth of the joint diameter D c is 5 [mu]m or less. According to this construction, there can be provided a dissimilar material joint product with excellent bonding strength, which can be formed by an existing spot welding apparatus at a low cost without newly using other materials such as clad material or without newly adding a separate step, and a spot welding method for the dissimilar material joint product.

Owner:KOBE STEEL LTD

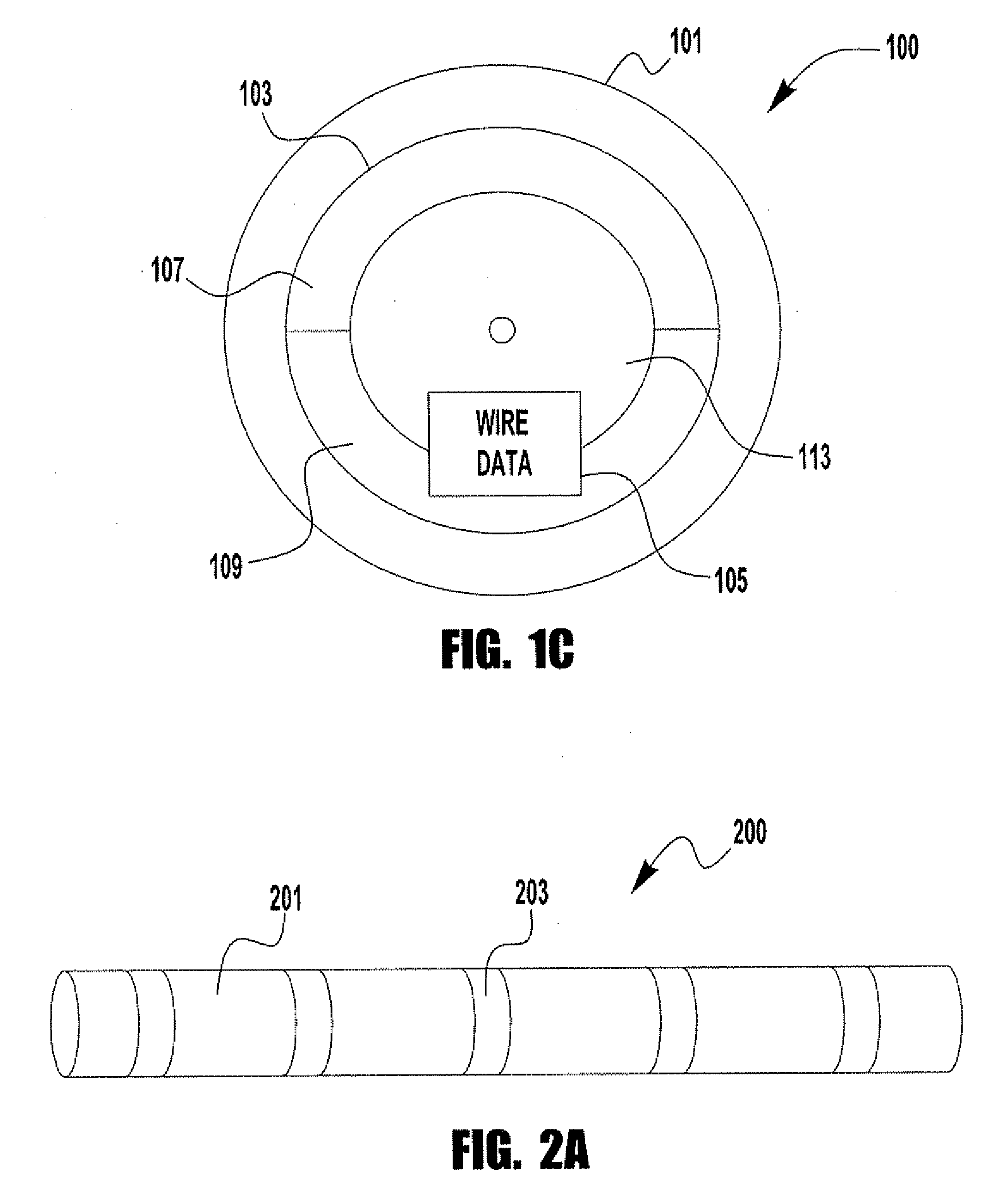

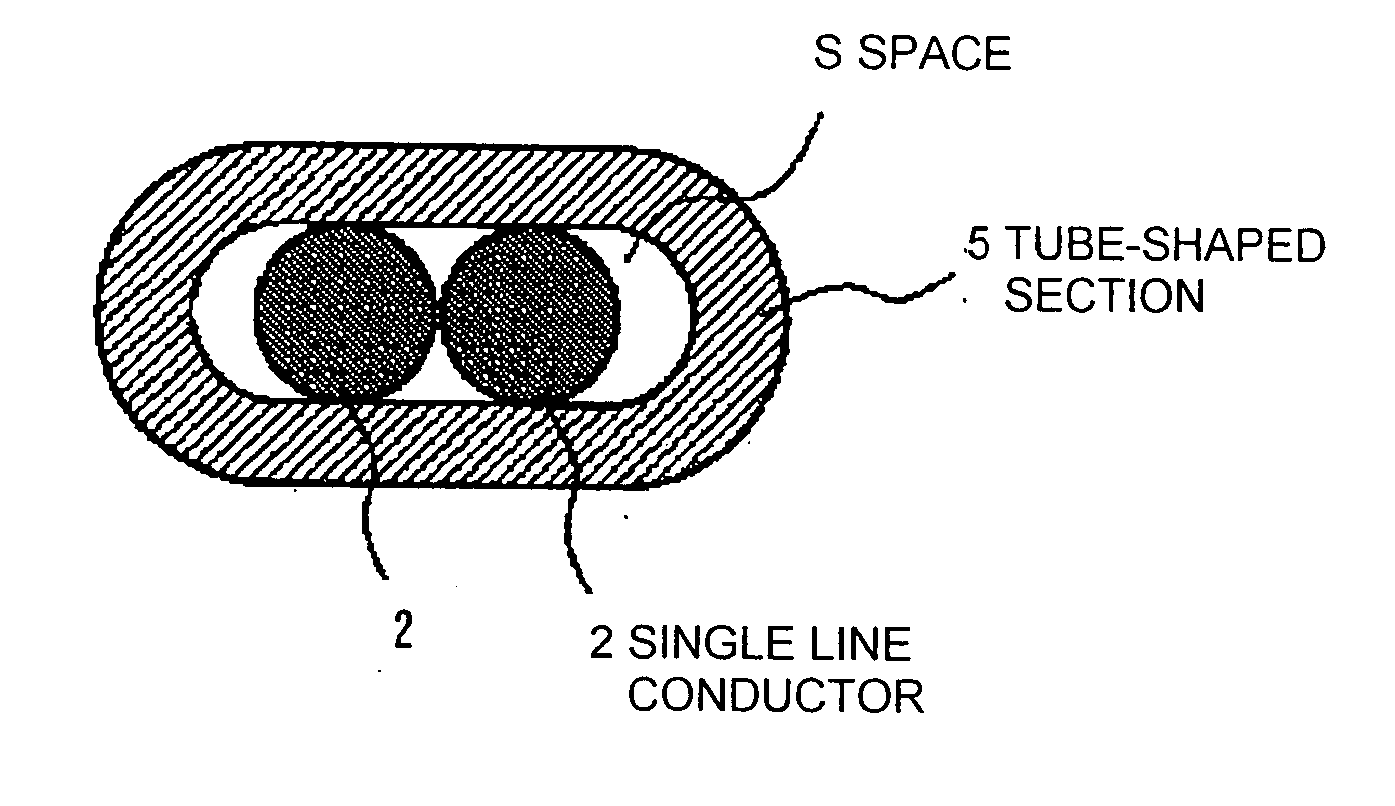

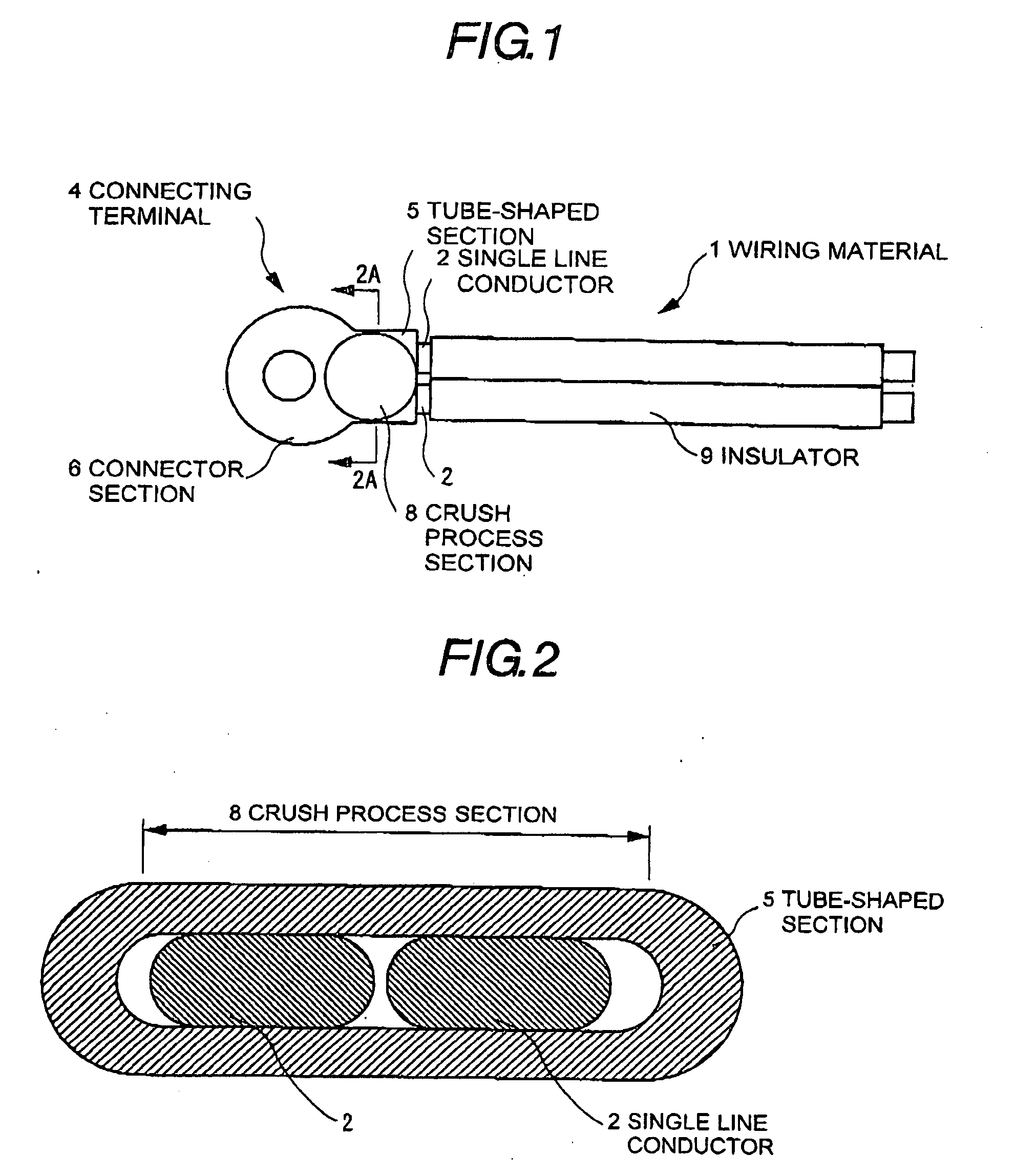

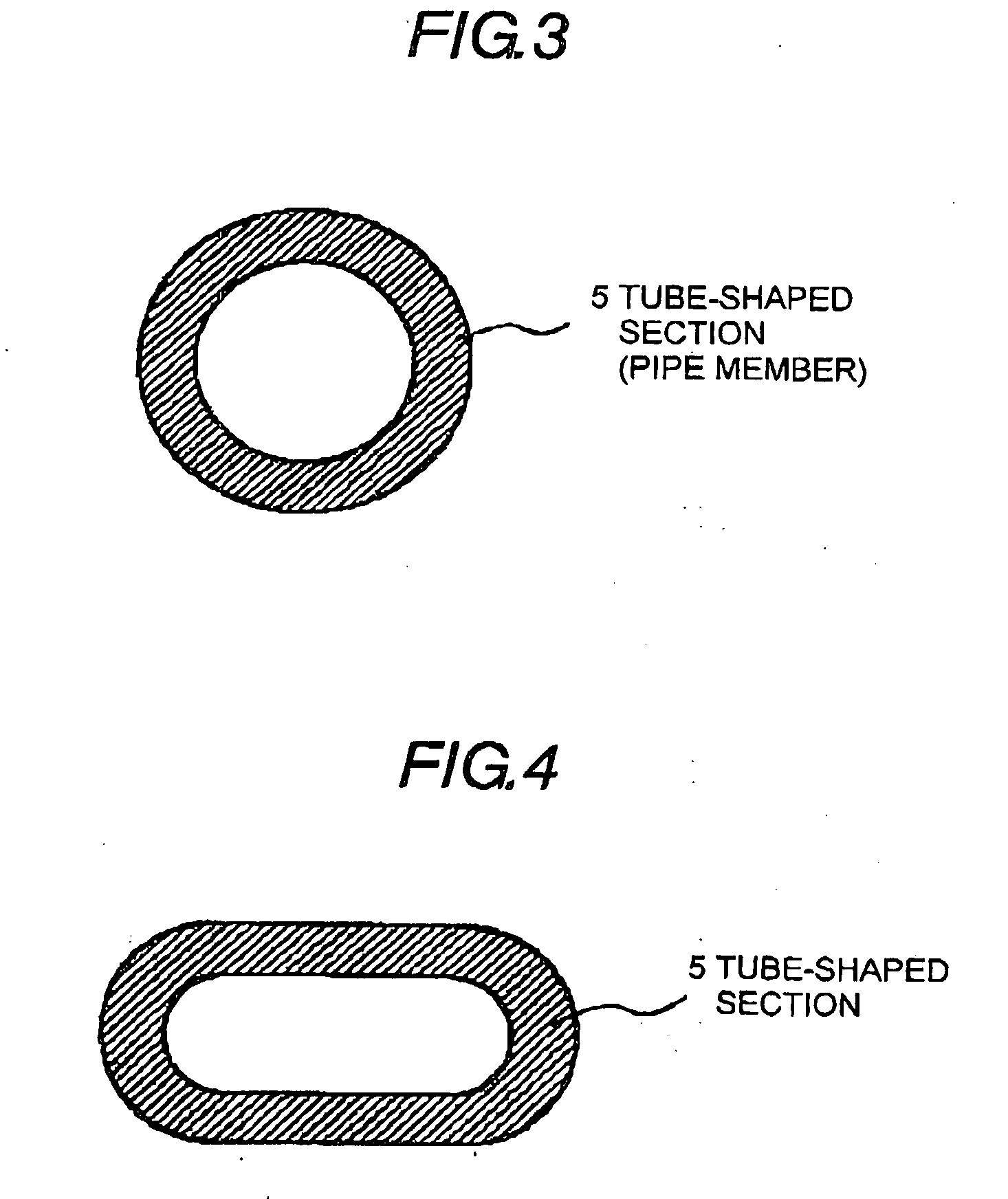

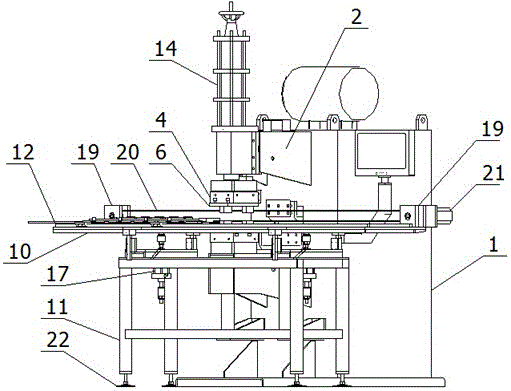

Wiring Material, Method for Manufacturing Such Wiring Material and Resistance Welding Apparatus Used in Such Manufacturing Method

ActiveUS20080081499A1Improve connection reliabilitySoldering apparatusElectrode featuresElectrical resistance and conductanceElectricity

A wiring material is provided by electrically connecting a connecting terminal with two single line conductors arranged in parallel. The connecting terminal is provided with a tube-shaped section for storing two single line conductors, the two single line conductors are inserted into the tube-shaped section, resistance welding is performed by carrying electricity from the external of the tube-shaped section in a status where the tube-shaped section and the single line conductors are mutually brought into contact, and the connecting terminal is electrically connected with the two single line conductors.

Owner:HITACHI CABLE

Plasma arc torch electrode

InactiveUS7132619B2Improve cooling effectEfficiently attachedOhmic-resistance electrodesElectrode featuresElectricityTorch

A variety of electrodes for use in a plasma arc torch are provided that improve cooling between the electrode and an adjacent cathodic element such as a cathode. At least one passageway is formed between the electrode and the cathode for the flow of a fluid, e.g. cooling fluid, wherein the flow of the fluid is proximate, or through an adjacent vicinity of, electrical contact between the cathode and the electrode. The passageway is formed through the electrode, through the cathode, between the electrode and the cathode, and through a third element in the various forms of the present invention. Further, methods of operating a plasma arc torch using the electrodes according to the various forms of the invention are also provided.

Owner:VICTOR EQUIP

Resistance welding method and resistance welding apparatus

ActiveUS20100243616A1Easy to controlOhmic-resistance electrodesElectrode featuresElectrical resistance and conductanceEngineering

A resistance welding apparatus includes a welding gun having a first electrode tip serving as a first welding electrode, a second electrode tip serving as a second welding electrode, and a current branching electrode. The current branching electrode has an annular shape and is disposed in surrounding relation to the first electrode tip. The first electrode tip and the current branching electrode abut against a thinnest workpiece disposed on an outermost side of a stacked assembly that is resistance-welded by the resistance welding apparatus, and have opposite polarities to each other. When an electric current is passed from the first electrode tip to the second electrode tip and through the stacked assembly, a branched electric current flows from the first electrode tip to the current branching electrode.

Owner:HONDA MOTOR CO LTD

Electrode head of the plasma cutting machine

InactiveUS8455786B2Easy to compressLess defective and deformedOhmic-resistance electrodesElectrode featuresPlasma cuttingPhysics

An electrode head of the plasma cutting machine is provided. The electrode head comprises a sheath, a bearing means, an electrode core, a first brazing means and a second brazing means. The sheath has a first end and a second end. A first flange extends radially inward from the first end. The bearing means has a third end and a fourth end. A second flange extending from the third end is fixed to the first flange of the sheath via the first brazing means. A protrusion portion is provided axially from the interior of the fourth end. A recess portion is extending from the third end into the interior of the protrusion portion. The electrode core is fixed in the recess portion via the second brazing means.

Owner:FANG WEN YI

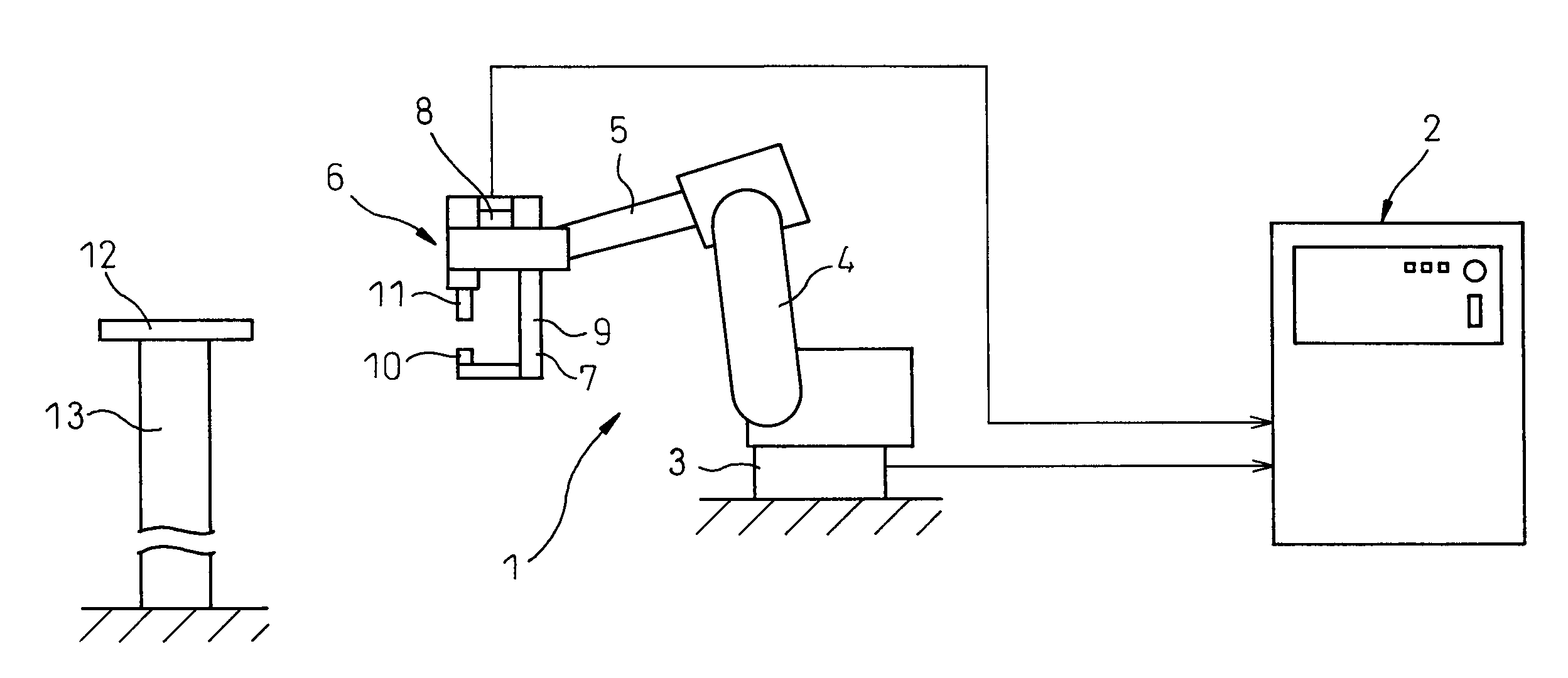

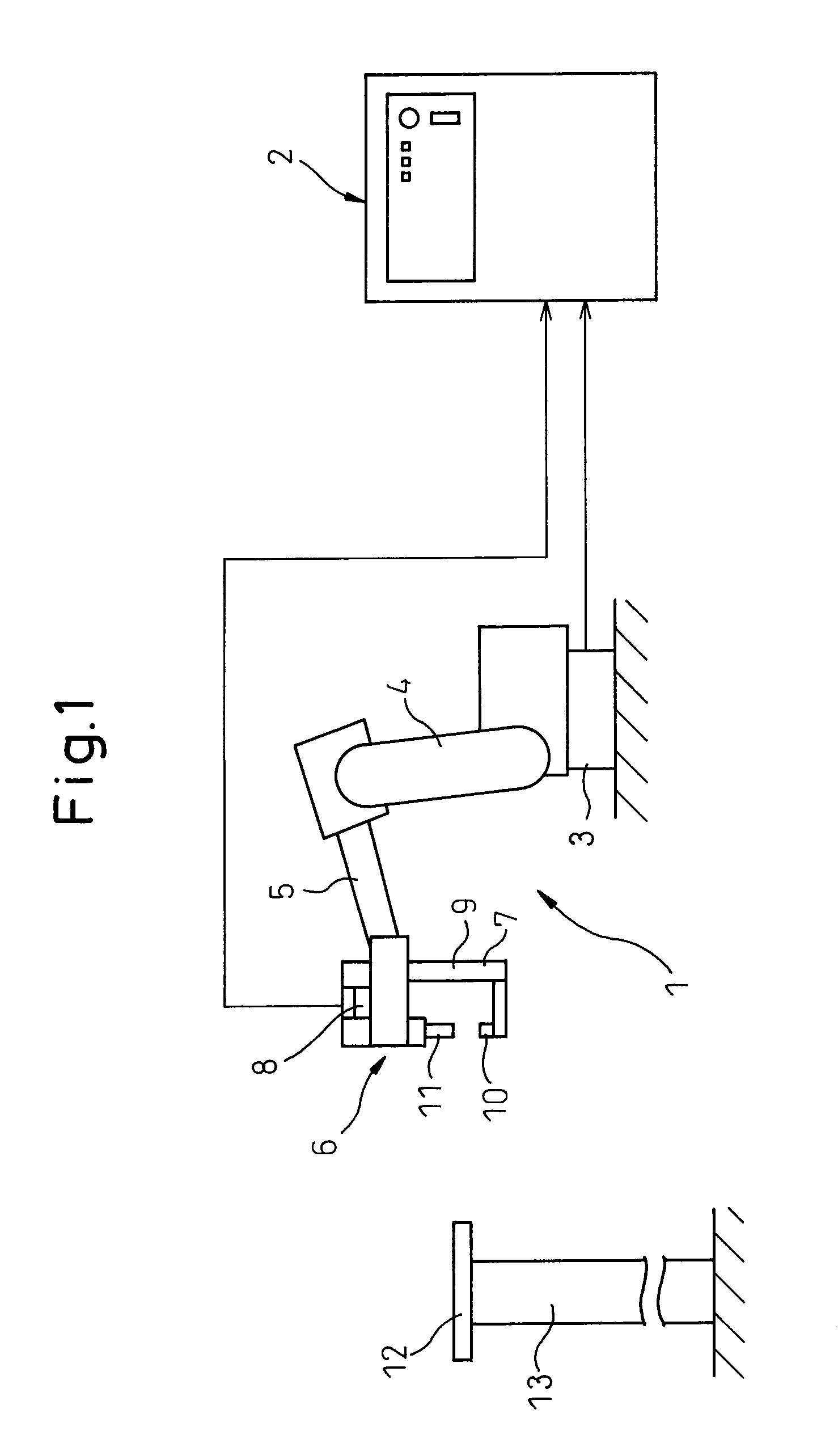

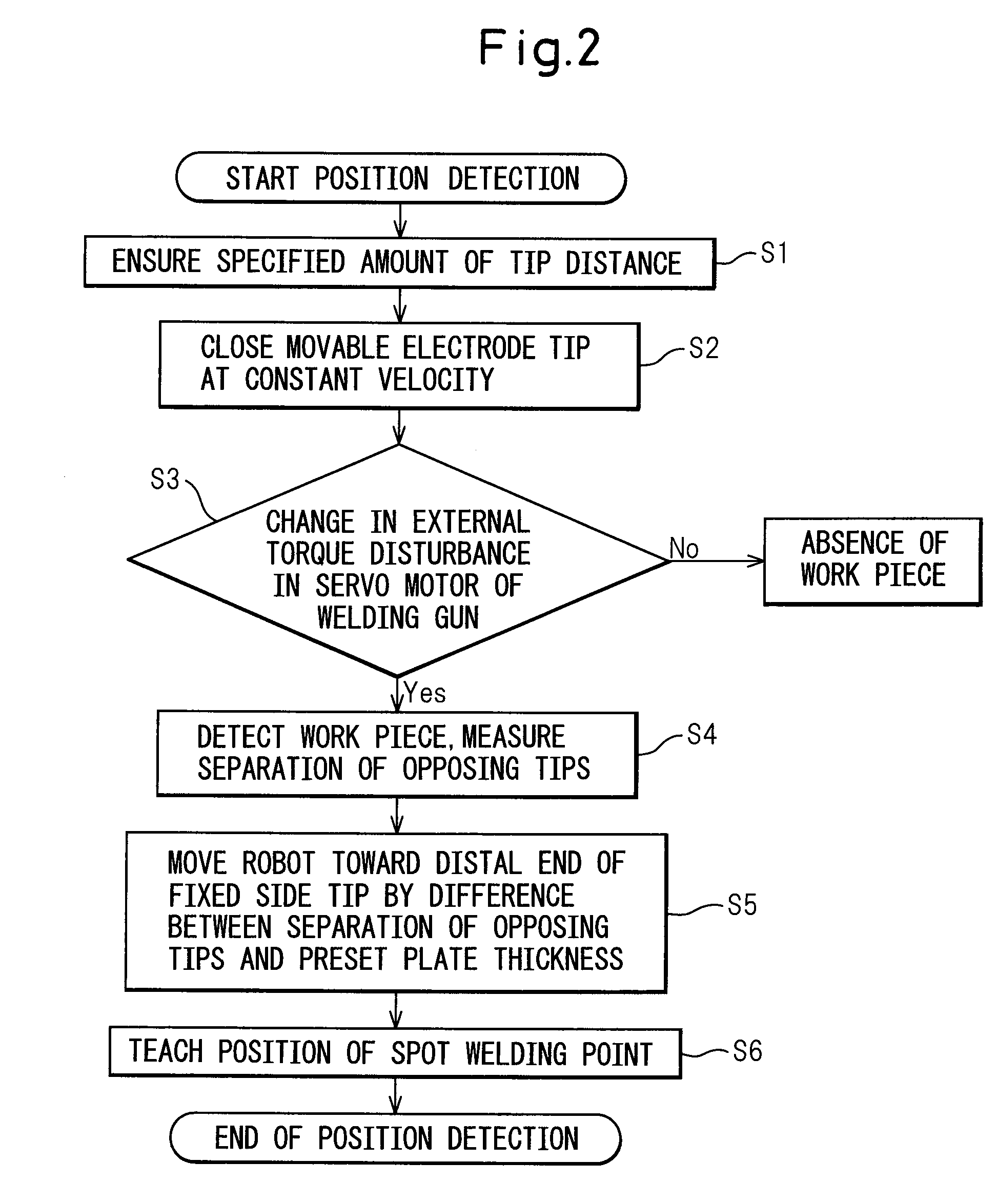

Positioning method of spot welding robot

ActiveUS20090001056A1Shorten the timeImprove workabilityWelding/cutting auxillary devicesElectrode featuresMotor driveEngineering

A positioning method of spot welding robot having: (A) moving a welding gun with a separation between an opposition electrode tip and a movable electrode tip kept open and larger than a preset plate thickness of a work piece so as to position the opposition electrode tip and the movable electrode tip on both sides of the work piece in a plate-thickness direction of the work piece, respectively, and temporarily positioning the opposition electrode tip at a stand-by position; (B) moving the movable electrode tip in a direction approaching toward the opposition electrode tip, monitoring the current value of the servo motor driving the movable electrode tip, and when the current value exceeds a prescribed value, determining that a distal end of the movable electrode tip has been brought into contact with the work piece, stopping a movement of the movable electrode tip and measuring an open separation of two opposing tips between the movable electrode tip and the opposition electrode tip that has been temporarily positioned at the stand-by position; and (C) determining the difference value by subtracting the preset value for the work piece from the open separation of two opposing tips, and moving the opposition electrode tip in the direction approaching toward the movable electrode tip from the stand-by position to the position of a spot welding point to finally position the opposition electrode tip, by using the difference value as the amount of movement of the opposition electrode tip.

Owner:FANUC LTD

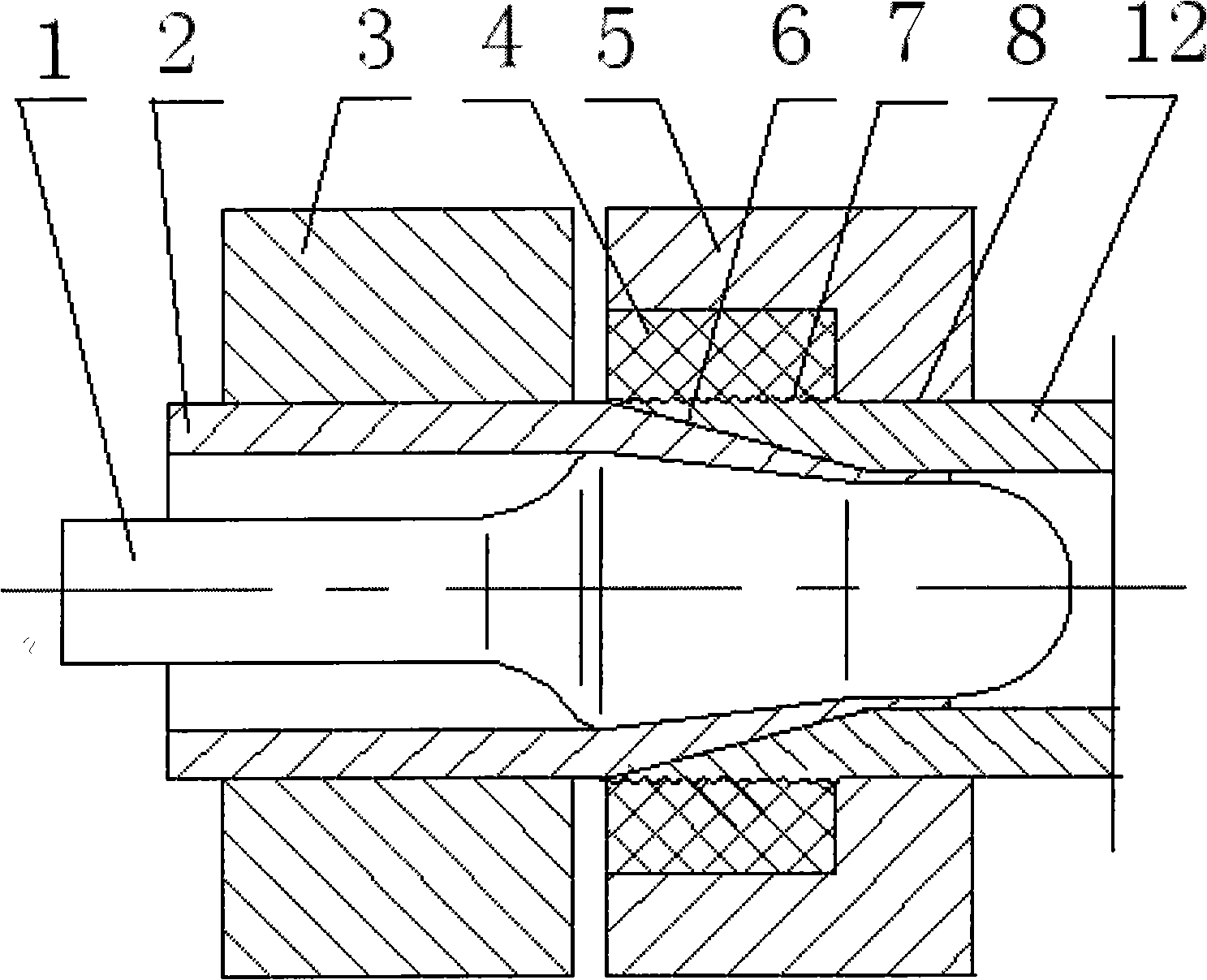

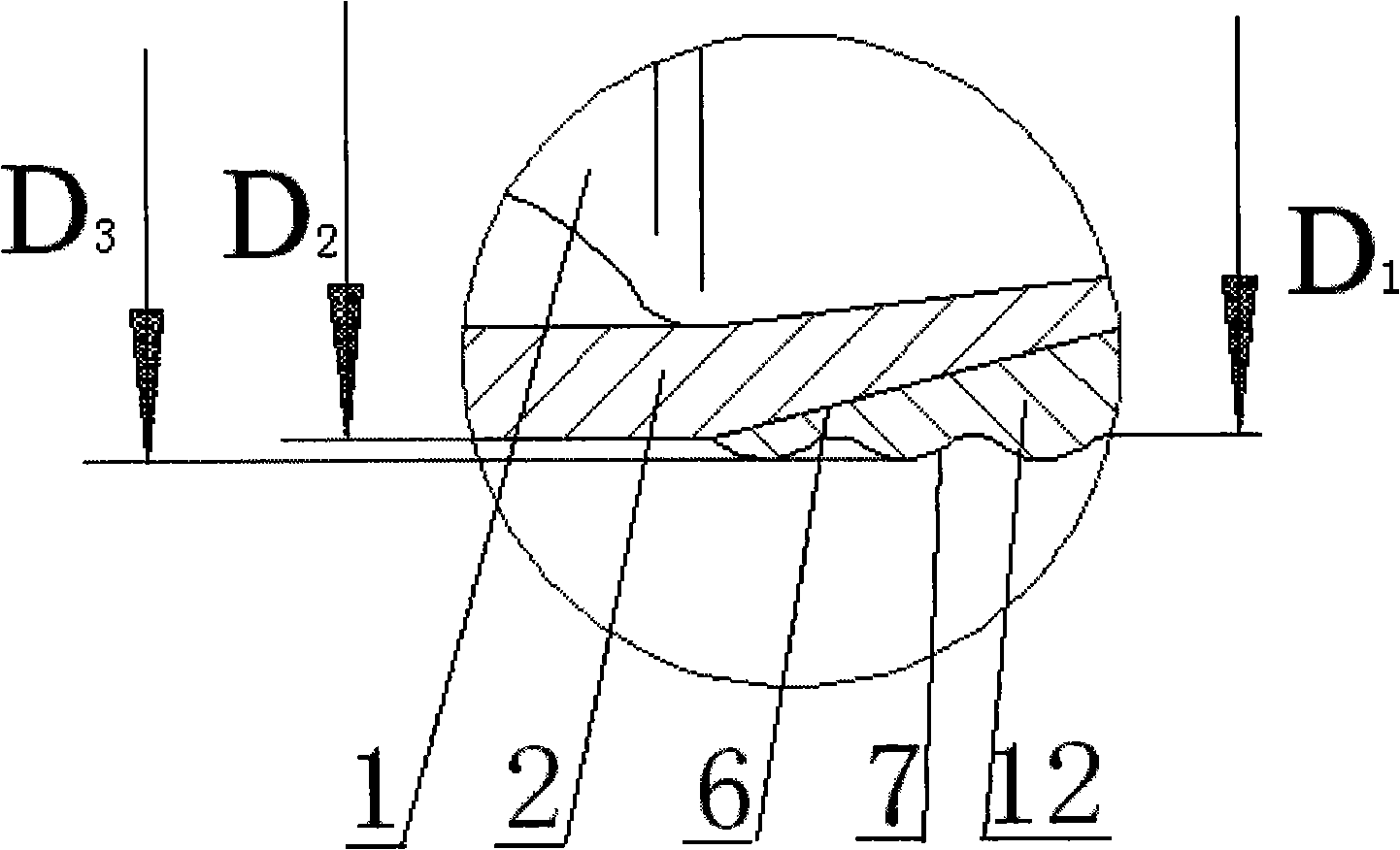

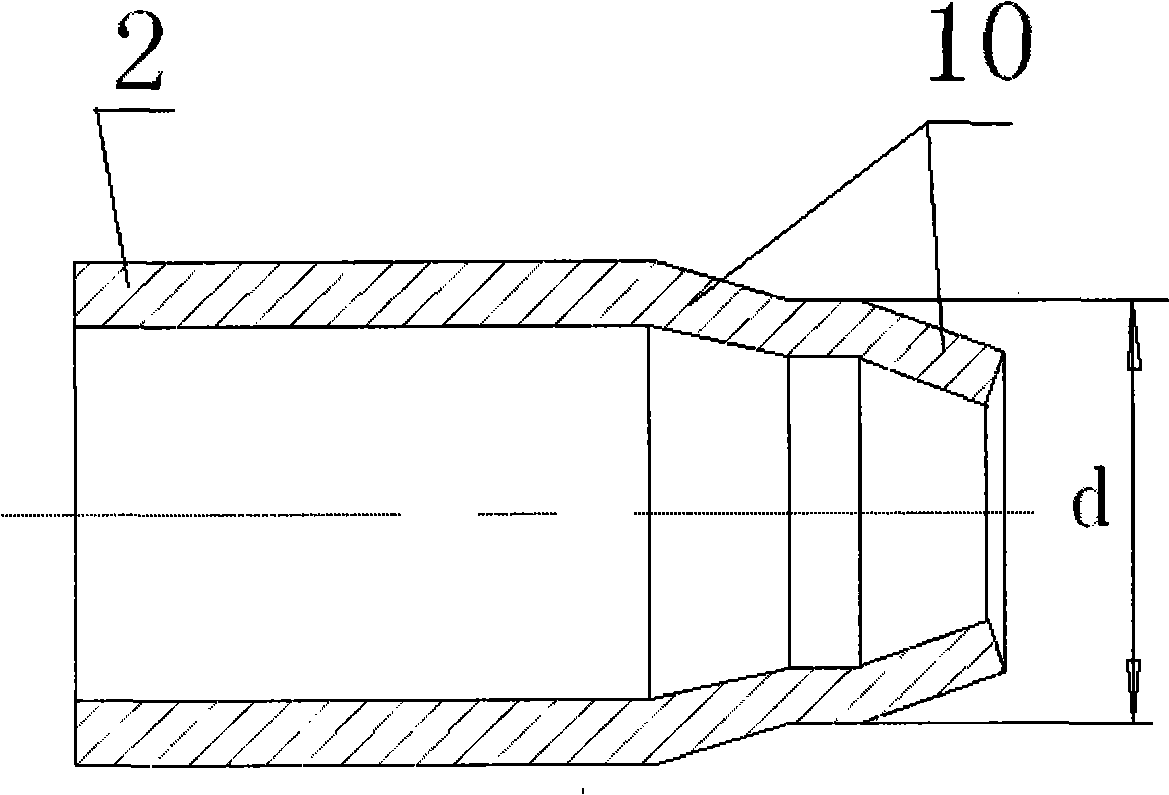

Plug-in type copper aluminum pipe welded joint and method of producing the same

InactiveCN101319741ASame outer diameterNot easy to fall offElectrode featuresNon-disconnectible pipe-jointsMaterials scienceCopper tubing

The invention relates to an inserting copper-aluminum pipe welded joint and a method of fabrication thereof. A taper face of weld is arranged at the joint welding position of a copper pipe, and raised grains are arranged on the outer wall of an aluminum pipe. During welding, a mosaic block is arranged at the welding position of the fixed electrode; a groove is arranged in the mosaic block, and raised grains are prepared on the groove; and the nominal diameter of the groove which bears raised grains is identical with the outer diameter of the aluminum pipe. The aluminum fluid melted during welding can be filled in the raised grains of the groove of the mosaic block, so that the deformation of the aluminum pipe is avoided, and the quality and strength of the product are improved. By such welding method, the aluminum pipe can be clamped to avoid breaking off; in addition, the outer diameter of the welding position of the copper-aluminum pipe joint is kept identical with the outer diameter of the aluminum pipe.

Owner:左铁军 +1

Synergistic welding and electrode selection and identification method

ActiveUS8766132B2Improve welding qualityImprove efficiencyFilament handlingWelding electric supplyWelding power supplyEngineering

Owner:LINCOLN GLOBAL INC

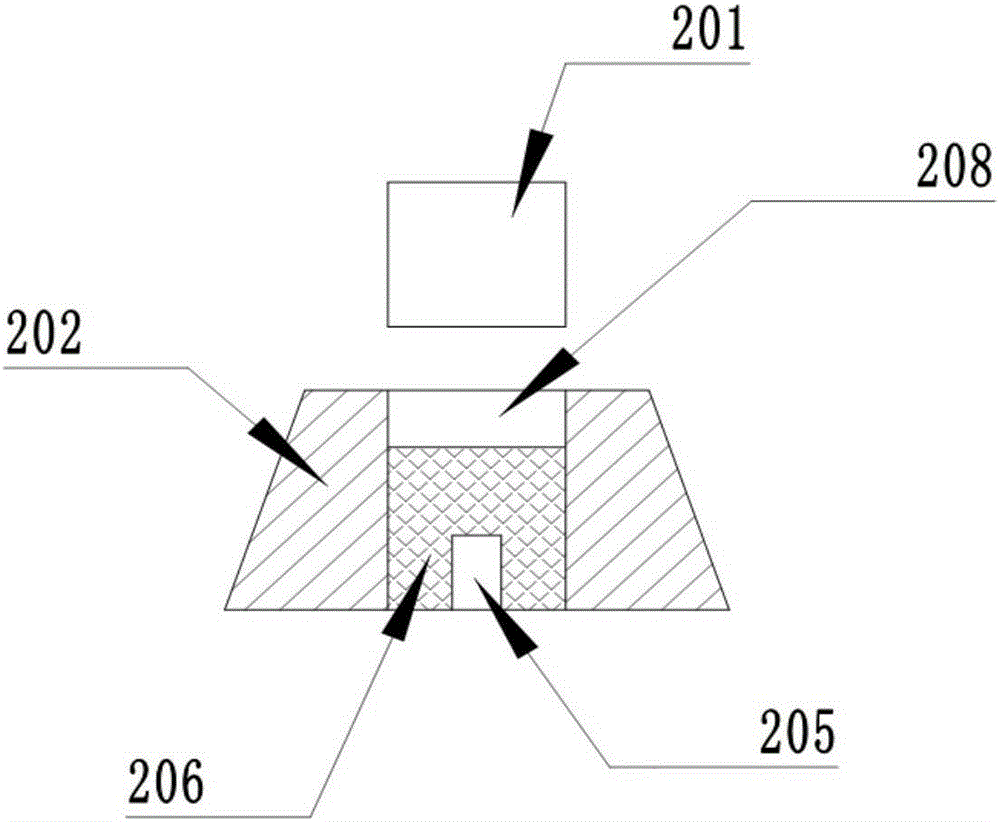

Multi-leg rectangular stirrup welding device

ActiveCN105729029AHigh speedEasy to operateWelding/cutting auxillary devicesElectrode featuresReciprocating motionEngineering

The invention discloses a multi-leg rectangular stirrup welding device. The multi-leg rectangular stirrup welding device comprises a double-electrode welding device and a stirrup fixing device, wherein the double-electrode welding device comprises an engine base; the engine base is provided with an upper bracket and a lower bracket; an upper electrode base and a lower electrode base are arranged between the upper bracket and the lower bracket; an upper conductive board and a lower conductive board are arranged between the upper electrode base and the lower electrode base; the upper conductive board is connected with two upper welding electrodes which are arranged in parallel; the lower conductive board is connected with two lower welding electrodes which are arranged in parallel; the upper bracket is connected with a retracting mechanism capable of driving the upper electrode base to do reciprocating motion in the direction toward the lower electrode base; the stirrup fixing device comprises a rail frame and a rack; the rail frame is provided with two slide rails which are arranged in parallel; a stirrup fixing mold frame is arranged between the two slide rails. The multi-leg rectangular stirrup welding device is simple to operate; only steel bars need to be arranged on the stirrup fixing mold frame and then are conveyed into a welding working station to finish welding, so that the labor cost is reduced; meanwhile, the welding speed is increased and the machining efficiency is improved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Copper alloy electrode for resistance weld and its manufacturing method

InactiveCN1775453AExtend working lifeHigh working reliabilityElectrode featuresWelding/cutting media/materialsElectrical resistance and conductanceMetal alloy

The present invention relates to a resistance welding copper alloy electrode and its production method. It is characterized by that in said electrode, on the matrix of electrode end portion at least three layers of materials are distributed, they are metal alloy layer contacted with said matrix, intermediate metal alloy composite material layer and external surface metal alloy layer. Besides, said invention also provides the concrete steps of its production method. Said copper alloy electrode has high working reliability and long working life.

Owner:陈铮 +1

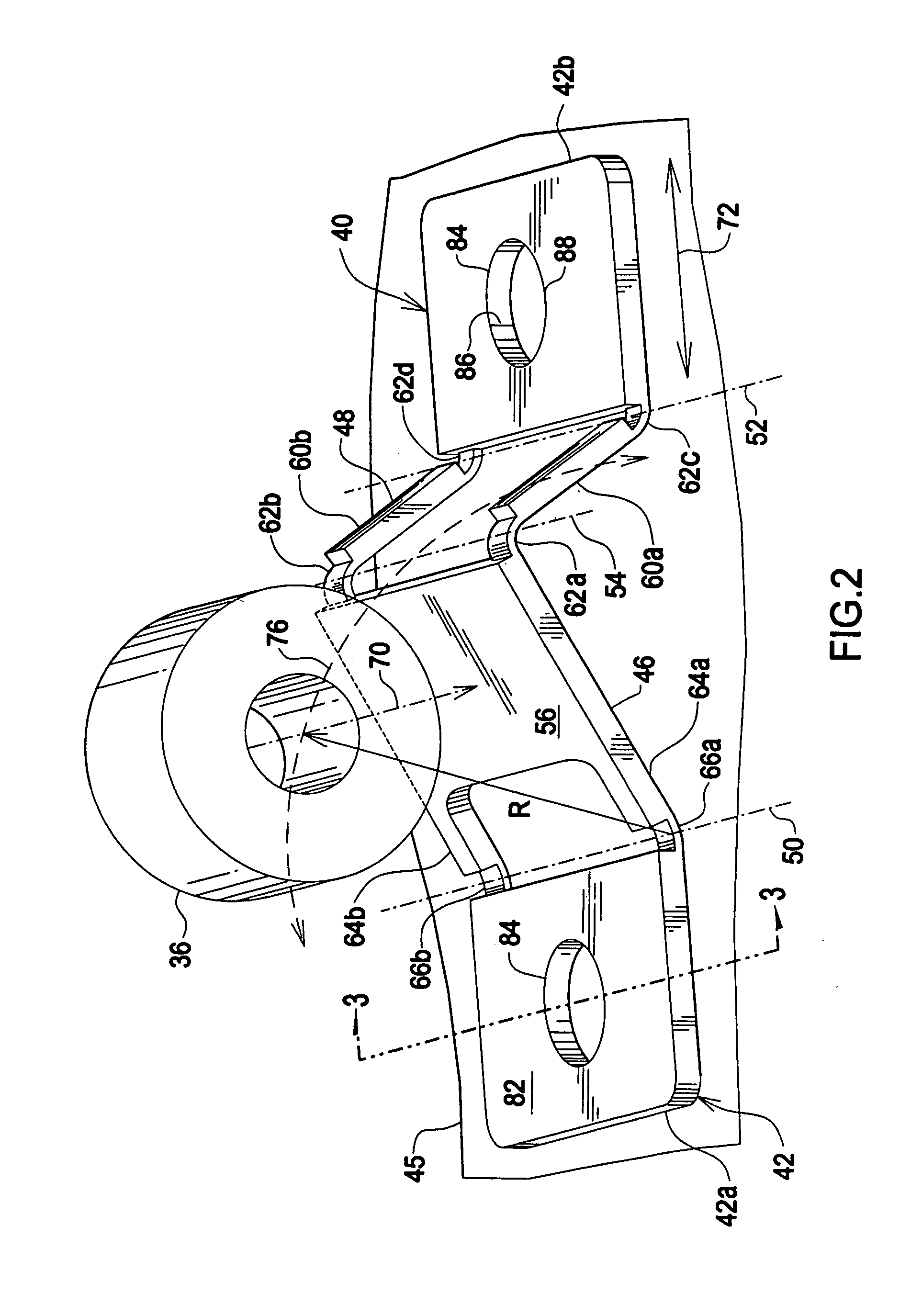

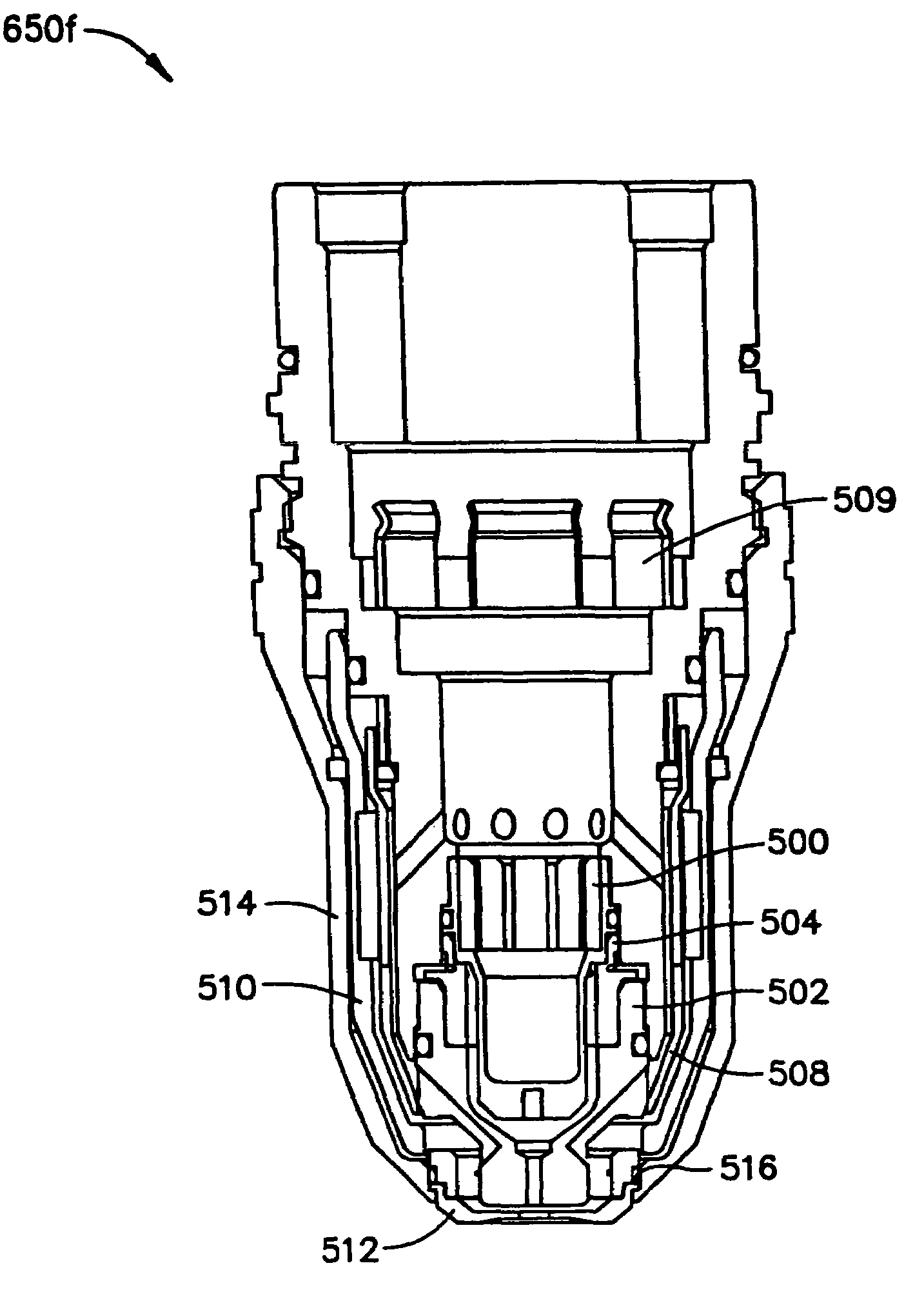

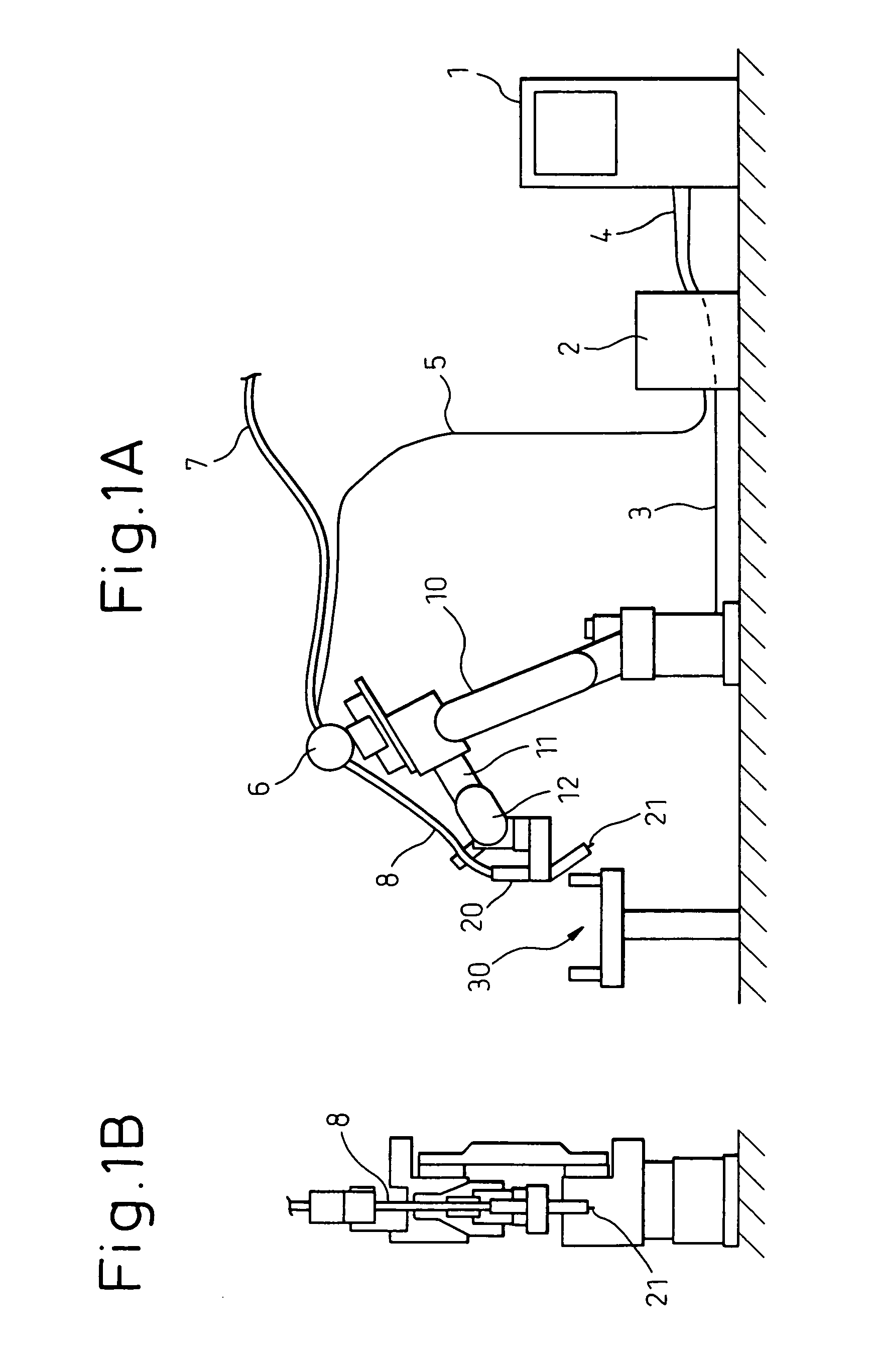

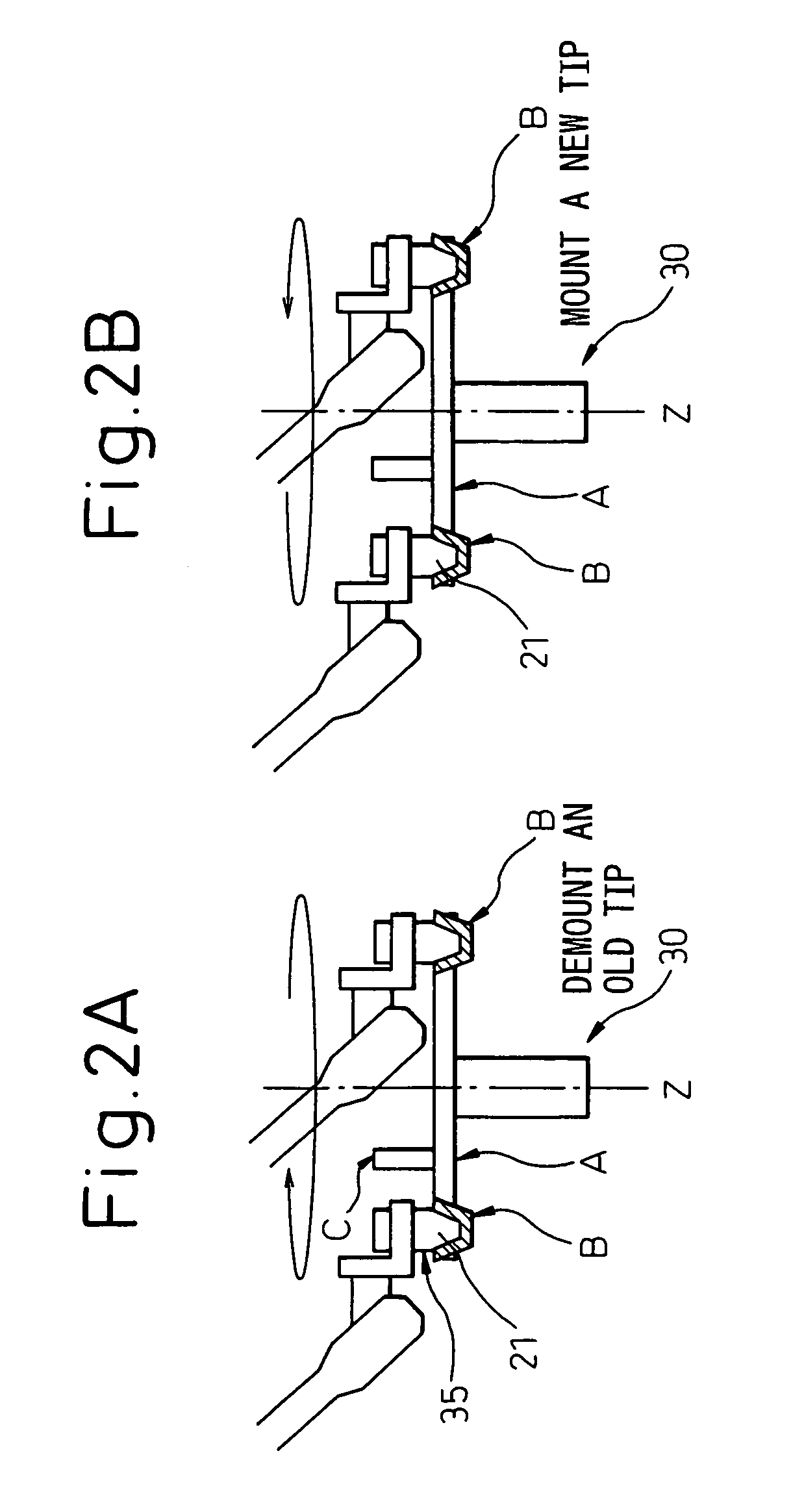

Apparatus for automatically changing a robot tool tip member

ActiveUS7204792B2Simple structureFew stepsPrecision positioning equipmentWeld torches cleaningEngineeringMechanical engineering

An apparatus for automatically changing a tool tip member for a robot includes a tip member changing jig disposed in an operational area of the robot. The tip member changing jig includes a base member, a rotating member supported by the base member so as to be rotatable about a rotation axis, and tip member holding means disposed at positions that are offset from the rotation axis of the rotating member. The tip member holding means holds the tool tip member so that a central axis of relative rotation, for threadedly mounting or demounting the tool tip member on or from the tool body, extends substantially parallel to the rotation axis of the rotating member and so that rotation of the tool tip member, with respect to the rotating member, is locked.

Owner:FANUC LTD

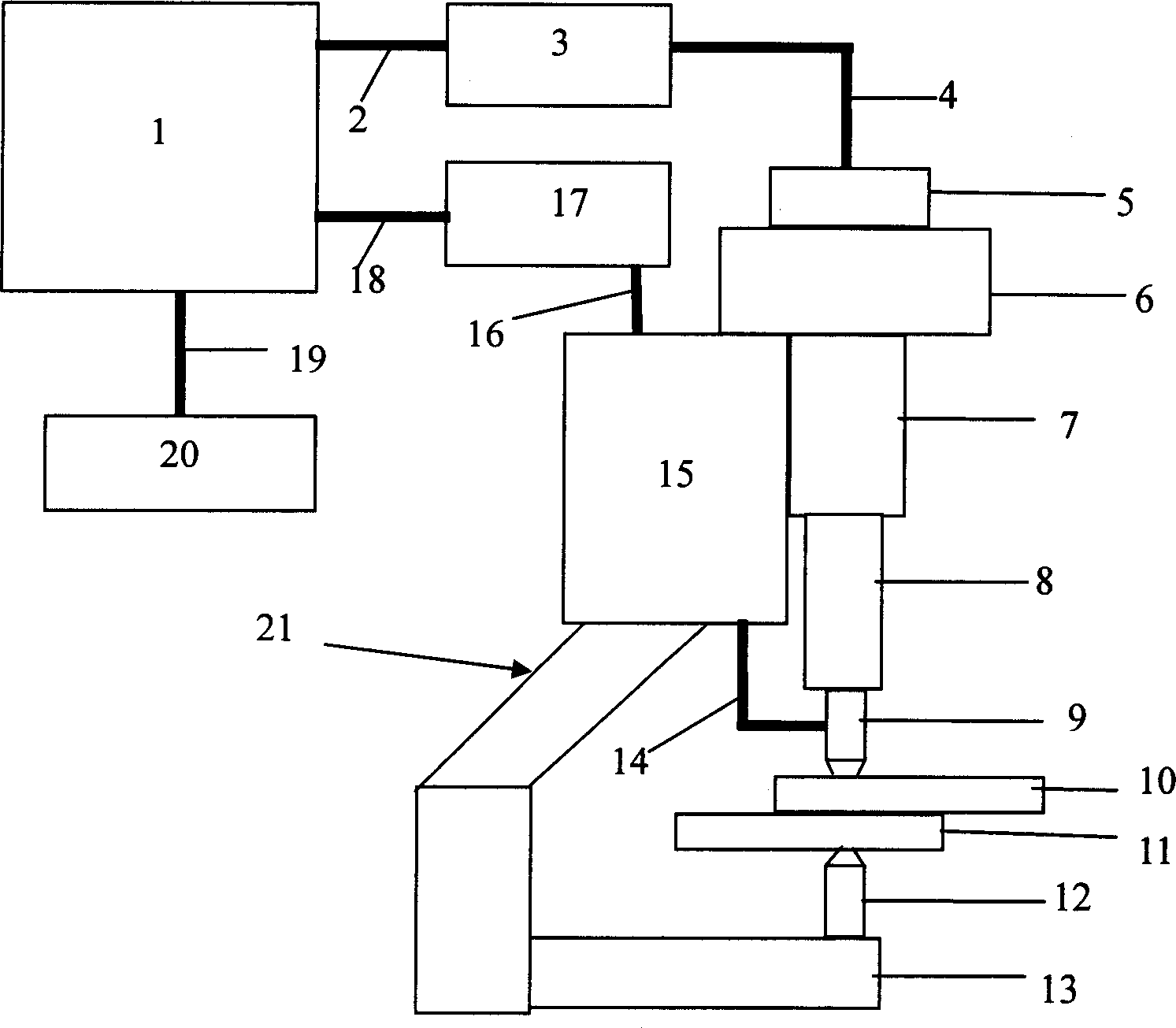

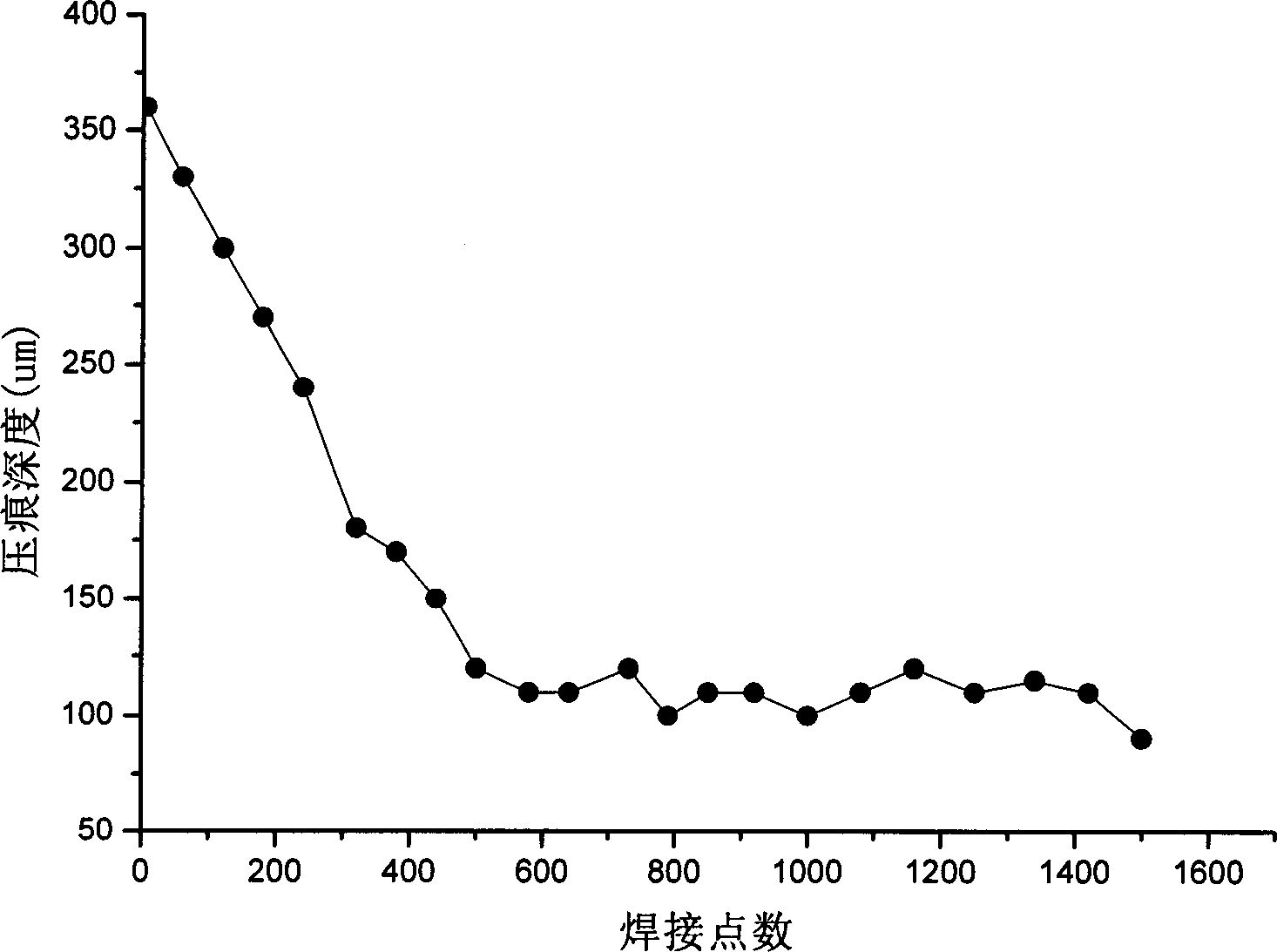

Electrode dressing on-line distinguishing method based on spot-welding of servo torch

The invention relates to an online check method of electrode abrasion, based on the point weld of servo weld gun, belonging to the weld technique. The invention uses the servo weld gun to online obtain the depth of impression, to realize the online extraction of impression depth at each electrode abrasion step in the point weld process; according to the change rule of impression depth with the electrode abrasion, at the initial weld step, the impression depth is deeper, and with the increase of electrode abrasion, the electrode end area increase, to reduce the current density and electrode pressure at the end surface of electrode, to reduce the depth of impression, to realize the online check of electrode abrasion via the impression depth, to check if the electrode should be repaired. The invention compares and analyzes the change character of impression depth at different electrode abrasion steps, via extracting the impression depth information to realize the online check, and reduce the effect of unconfirmed electrode abrasion on the quality of weld point.

Owner:SHANGHAI JIAO TONG UNIV

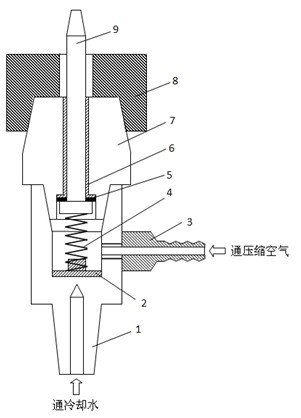

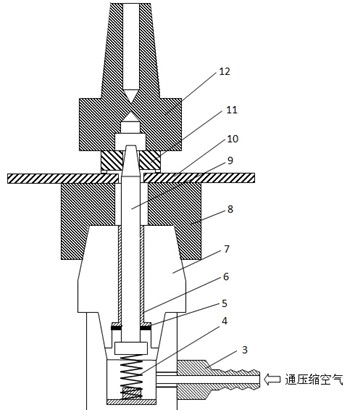

Compulsive air-cooling lower electrode specially used for resistance projection welding of annular nut

The invention discloses a compulsive air-cooling lower electrode specially used for resistance projection welding of an annular nut, which comprises three parts consisting of a lower body of a lower electrode holder, an upper body of the lower electrode holder, and an electrode cap. The lower body of the lower electrode holder adopts a combined cooling way of water cooling and compulsive air-cooling; and the upper body of the lower electrode holder and the electrode cap adopt the compulsive air-cooling. The way of compulsive air-cooling through compressed air is adopted to prevent splashes in the nut from damaging threads during welding, improve the service life of the electrode, and reduce the adherence of the splashes. A locating pin is automatically reset through the pressure generated by the compressed air and a spring. A conical locating pin is adopted to improve the locating precision of the nut, and improve the generality of the locating pin when nuts of different diameters are welded. The compulsive air-cooling lower electrode specially used for the resistance projection welding of the annular nut has a simple structure, is convenient to operate, is easy to obtain stable welding quality during welding, and has more ideal engineering practicability.

Owner:重庆平伟科技(集团)有限公司

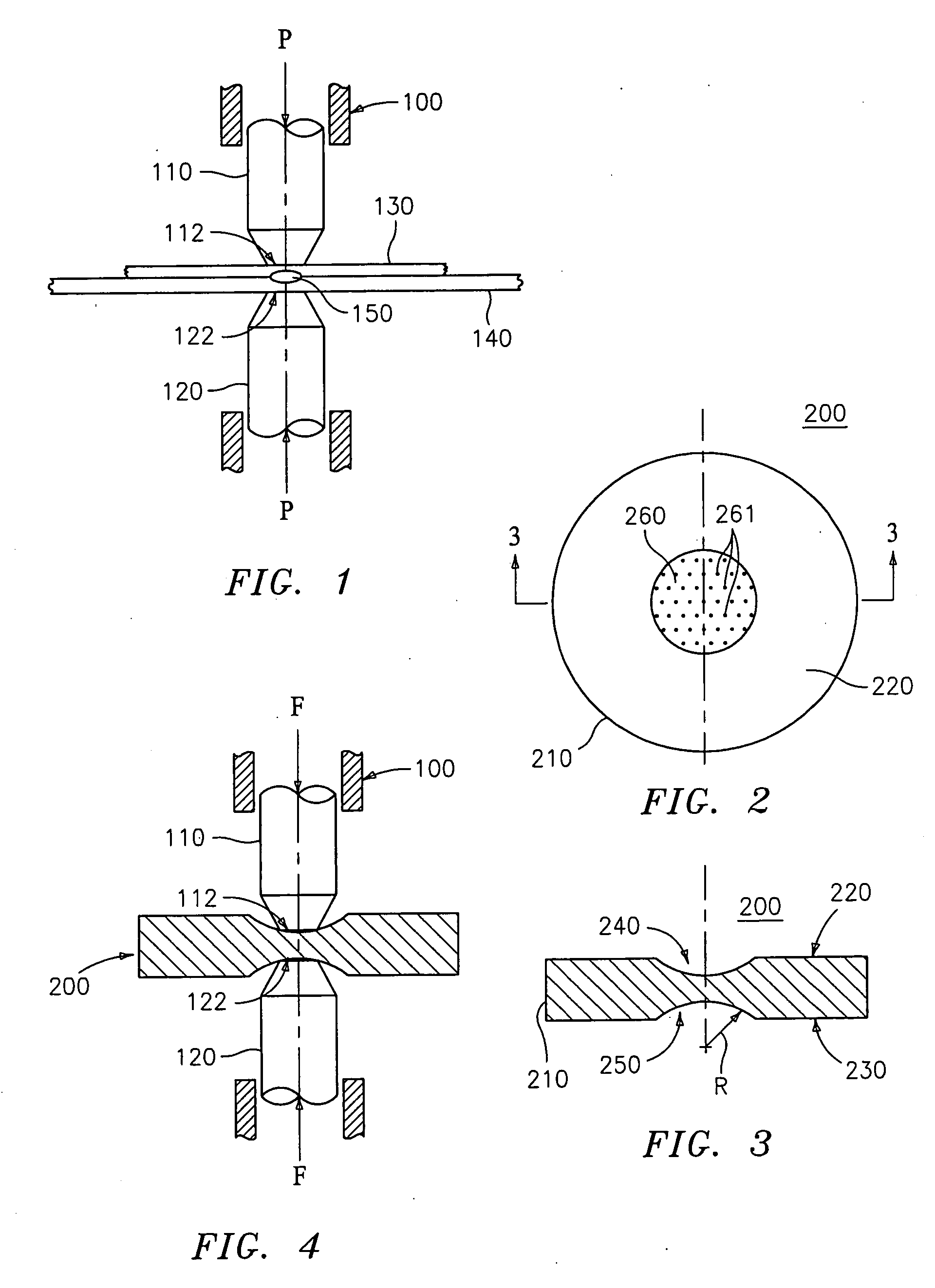

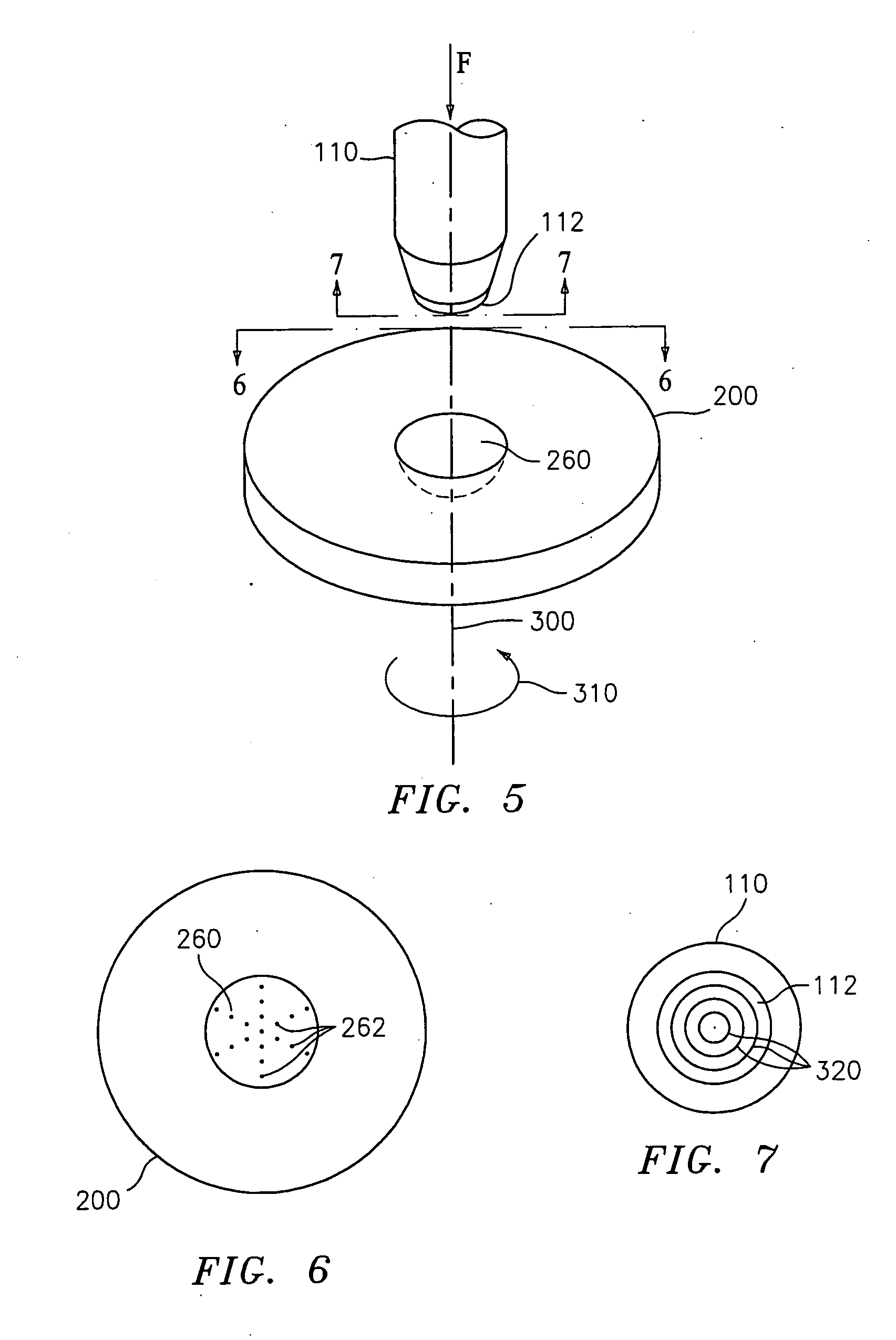

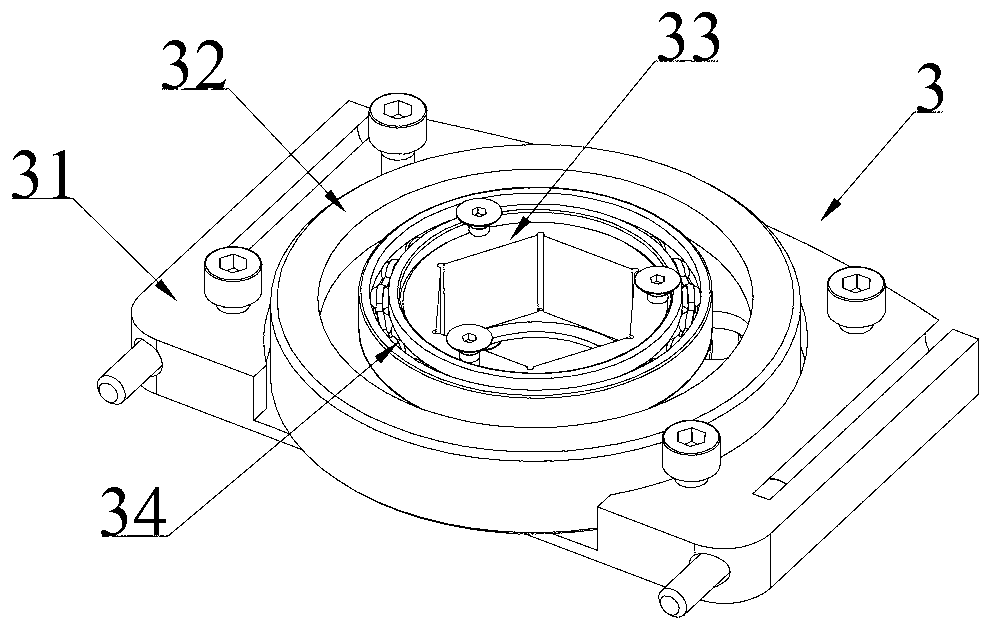

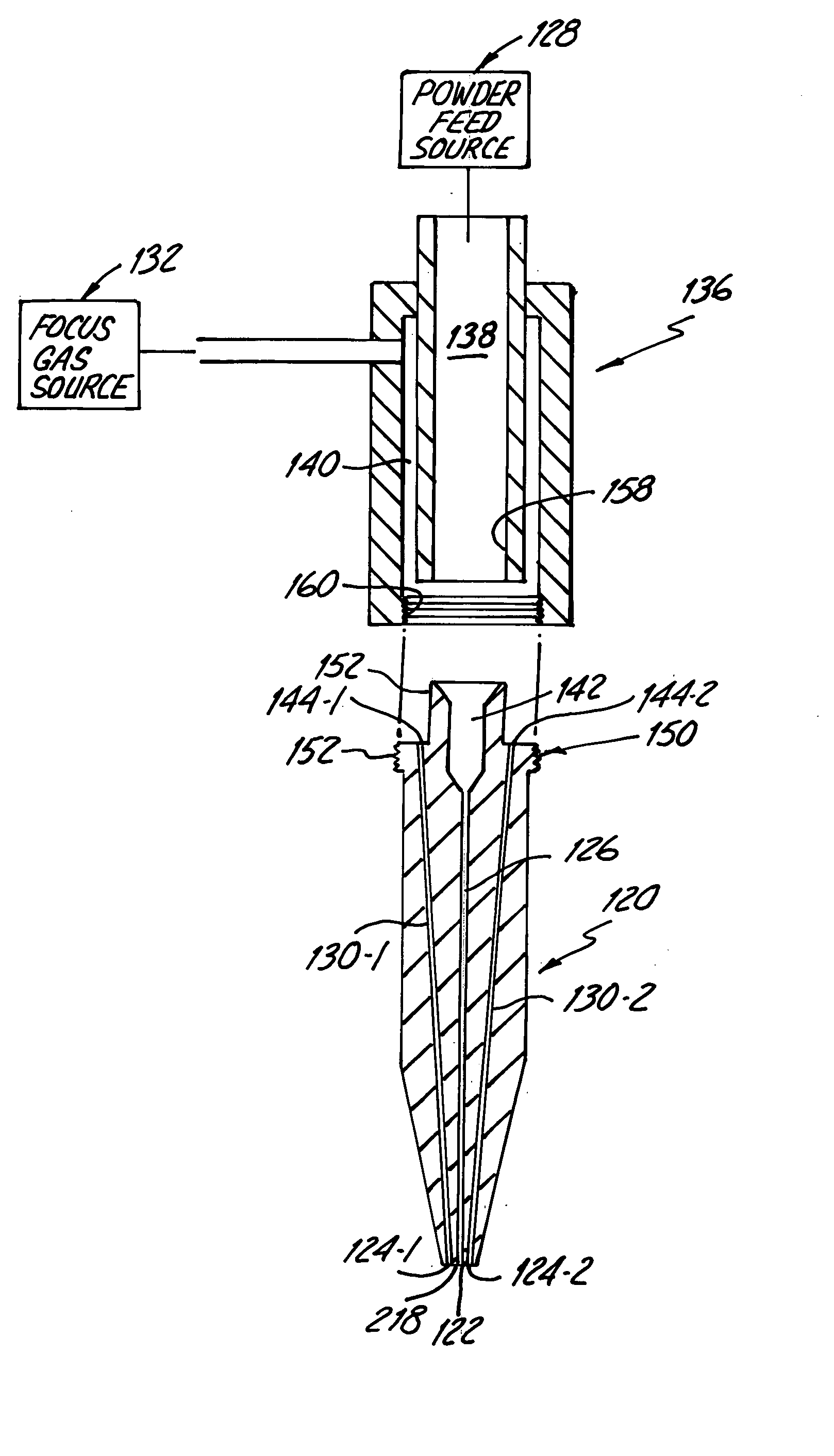

Laser cladding apparatus and method

A laser-clad processing apparatus of the present invention is one which is for carrying out laser-clad processing onto a valve-seat portion of a cylinder head, and is characterized in that it comprises cylinder-head holding means (1) for holding a cylinder head (H) in an inclining manner so that the central axial line of a valve seat becomes the vertical direction, a laser-processing head (2) for irradiating a laser beam onto a process part of the valve seat and at the same time discharging a powdery material to this process part, rotary means (3) which rotates around the central axial line of the valve seat in such a state that the laser-processing head is inclined with respect to the vertical direction, and powdery-material supply means (4) for supplying the powdery material to the laser-processing head.Moreover, a laser-clad processing method of the present invention is characterized in that it fixes the cylinder head (H), and forms a clad layer while rotating the laser-processing head (2), which emits the laser beam with respect to the valve-seat portion of the cylinder head and discharges the powdery material, around the axial center line of the valve seat.

Owner:TOYOTA JIDOSHA KK

Electrode texturing tool and method of use thereof

An article for texturing an electrode having a tip hardness and a tip contour is disclosed. The article includes a plate having an upper surface and a lower surface, and an indentation in at least one of the upper and the lower surface. The indentation includes a textured surface having a plurality of asperities. The textured surface has a hardness greater than the tip hardness of the electrode. The texture of the textured surface is imprinted into the tip of the electrode in response to the tip of the electrode and the textured surface being pressed against each other.

Owner:GM GLOBAL TECH OPERATIONS LLC

Resistance spot welding electrode and manufacturing method thereof

ActiveCN105234544ASolve thin and discontinuous problemsImprove connection strengthElectrode featuresWelding/soldering/cutting articlesElectrical resistance and conductanceElectrical conductor

The invention relates to a resistance spot welding electrode and a manufacturing method thereof, and belongs to the technical field of resistance spot welding. The resistance spot welding electrode comprises a first conductor and a second conductor. A groove matched with the second conductor in appearance is formed in the lower end face of the first conductor. The second conductor is inlaid in the groove. The lower end face of the second conductor is flush with the lower end face of the first conductor. The electrical resistivity of the second conductor is larger than the electrical resistivity of the first conductor. A cooling groove is formed in the upper end face of the first conductor. When the resistance spot welding electrode is used for welding, the connection strength between metal plates can be improved; the manufacturing method is simple and convenient, and the manufactured resistance spot welding electrode is firm in combination, good in performance and high in strength.

Owner:HENAN UNIV OF SCI & TECH

Connecting adapter for weld electrode

InactiveUS7022934B1Low cost replacementFirmly connectedEngine sealsOhmic-resistance electrodesCooling fluidBiomedical engineering

An electrically and thermally conductive adapter for connecting a weld electrode to a tip holder portion of a welding device. The adapter has a first, threaded end, for removable engagement with a like-threaded receiving cavity in the tip holder. The threads may be of parallel configuration to minimize damage to the receiving cavity. The adapter has a second, preferably tapered end, for receiving a removable weld electrode. A passageway is preferably provided through the adapter for transporting cooling fluid to the electrode. An o-ring may be retained on the adapter and designed to engage with a groove in the receiving cavity in order to prevent leakage of cooling fluid from around the threads. The adapter is economical to manufacture and may be quickly and easily removed or installed to the tip holder. The adapter reduces damage to the tip holder commonly caused by the repeated changing of electrodes.

Owner:HONDA GIKEN KOYGO KUBUSHIKI KIASHA

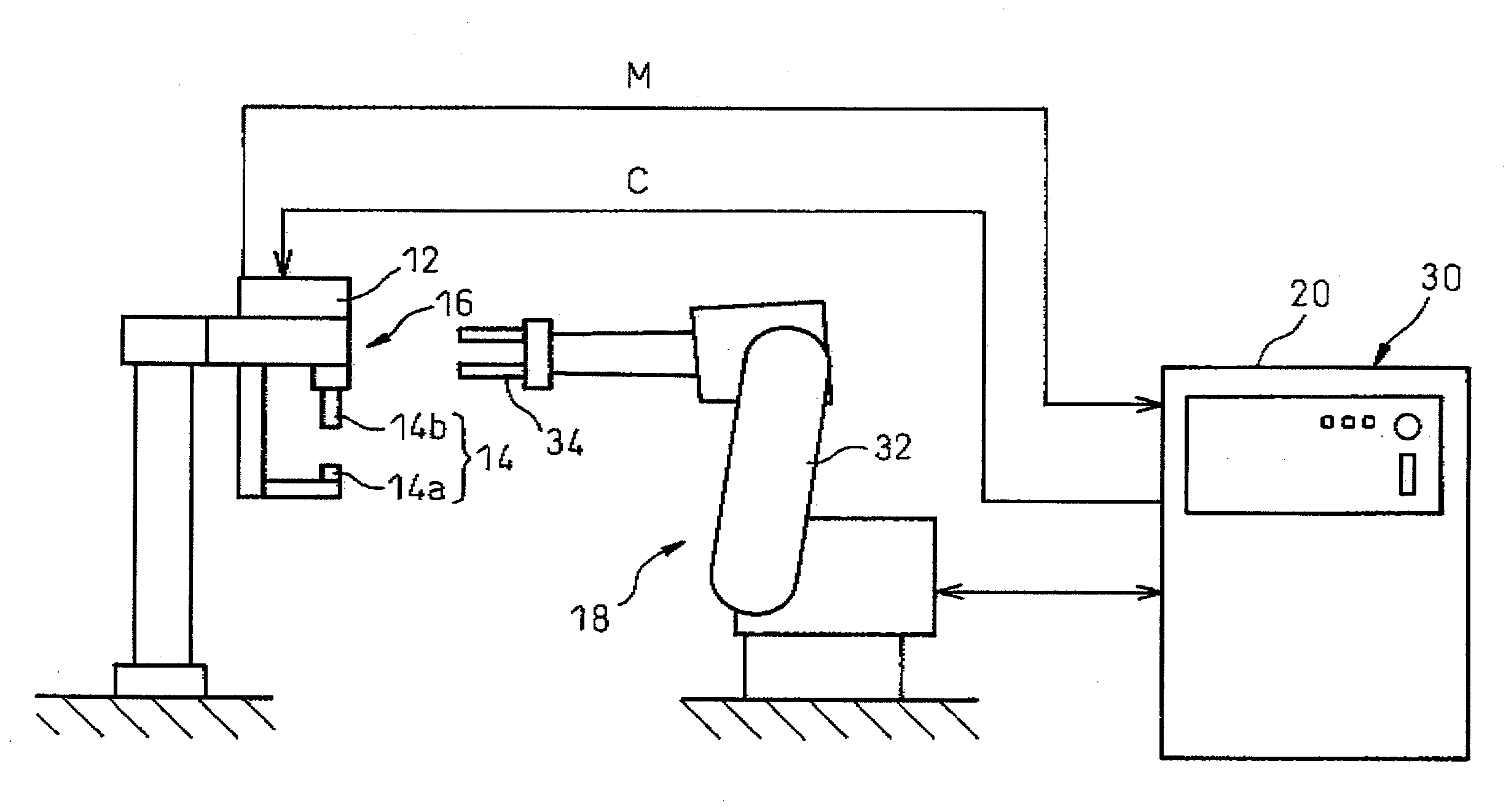

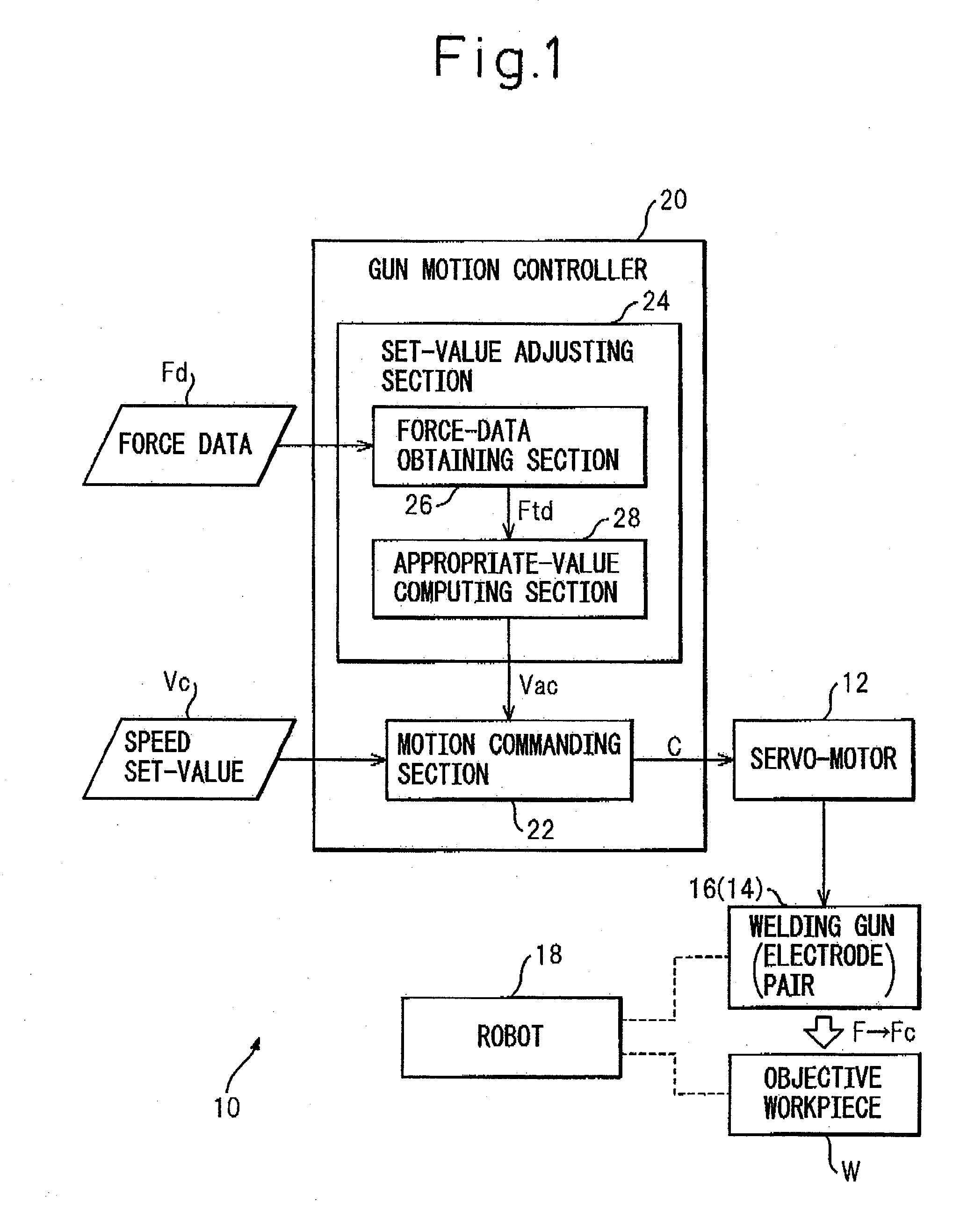

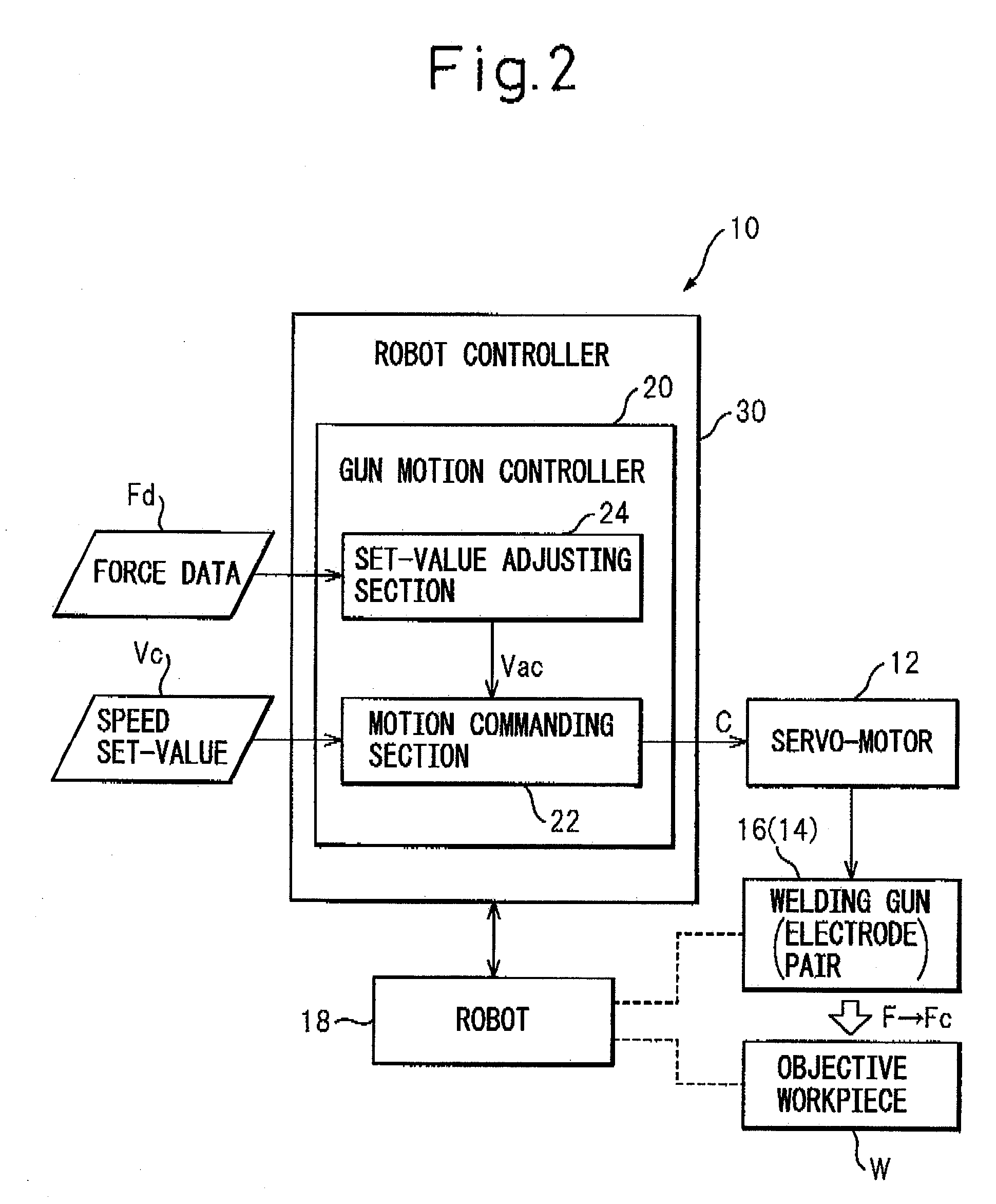

Spot welding system and method for adjusting welding-gun closing speed

ActiveUS20080308533A1Improve welding qualityShorten cycle timeOhmic-resistance electrodesWelding/cutting auxillary devicesProperty valueEngineering

A spot welding system including a welding gun with an electrode pair actuated by a servo-motor, a robot carrying the welding gun or objective workpieces and operating to change the relative positions and orientations of the welding gun and the workpieces, and a gun motion controller controlling the servo-motor to actuate the electrode pair to open or close. The gun motion controller includes a motion commanding section outputting a motion command to the servo-motor in accordance with a speed set-value designating a closing speed of the electrode pair, and a set-value adjusting section automatically adjusting the speed set-value to an appropriate value. The set-value adjusting section includes a force-data obtaining section obtaining force data representing, in a time-series manner, the pressurizing force generated in the electrode pair when the servo-motor actuates the electrode pair to close in accordance with the motion command, and an appropriate-value computing section determining the appropriate value of the speed set-value based on pre-convergence transient data in the force data.

Owner:FANUC LTD

Powder feed nozzle for laser welding

A powder feed nozzle for laser welding applications including a multiple outlet nozzle tip for focusing a discharged powder stream. The multiple outlet nozzle tip disperses multiple outlet streams and includes a powder discharge outlet and at least one focus gas discharge outlet, radially spaced from the powder discharge outlet, for dispersing a powder stream and a gas stream. Powder flows from a powder source through a powder channel to discharge a powder stream. Focus gas flows through a focus gas channel angled relative to the powder channel to discharge a focus gas stream.

Owner:MTS SYSTEMS CORPORATION

Method for cryogenic treatment of galvanized steel sheet resistance spot welding electrode

InactiveCN1435505AExtend working lifeLow cryogenic processing costsElectrode featuresWelding/cutting media/materialsOperating lifeMaterials science

A process for deep cold treatment of the spot-welding electrode for the galvanized steel plate in order to elongate its service life includes putting the Cu-alloy electrodes in a container full of deep cold medium in a deep cold treater layer by layer, setting parameters, deep cold treating, and naturally raising their temp to ordinary temp. Its advantages are long service life elongated by 4 times, no splash on welding, and high welding quality.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com