Two-axis multipoint automatic spot welding device and using method

An automatic spot welding, multi-point technology, applied in welding equipment, resistance welding equipment, electrode characteristics and other directions, can solve the problems of unstable welding quality, high labor intensity, and high equipment cost, achieve excellent product quality, reduce labor intensity, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

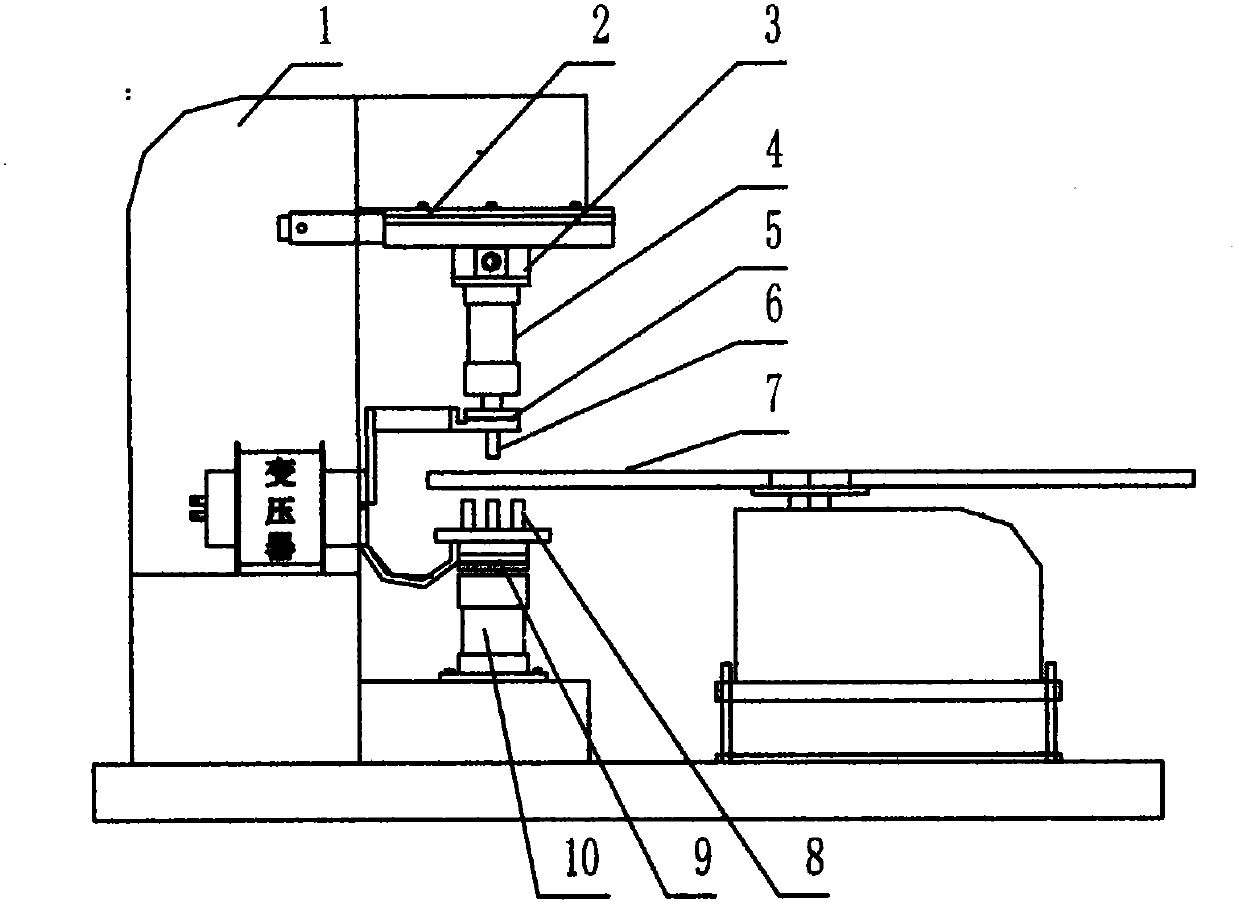

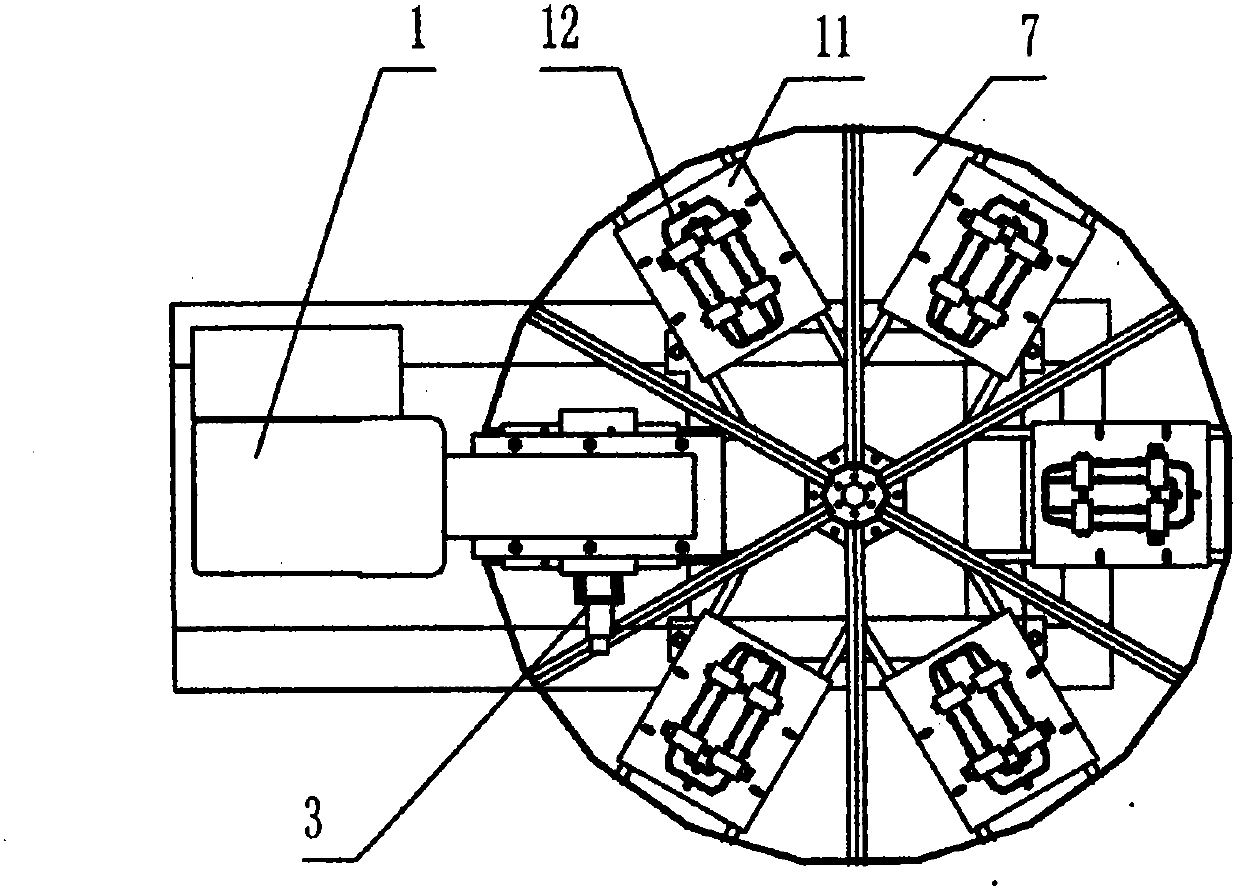

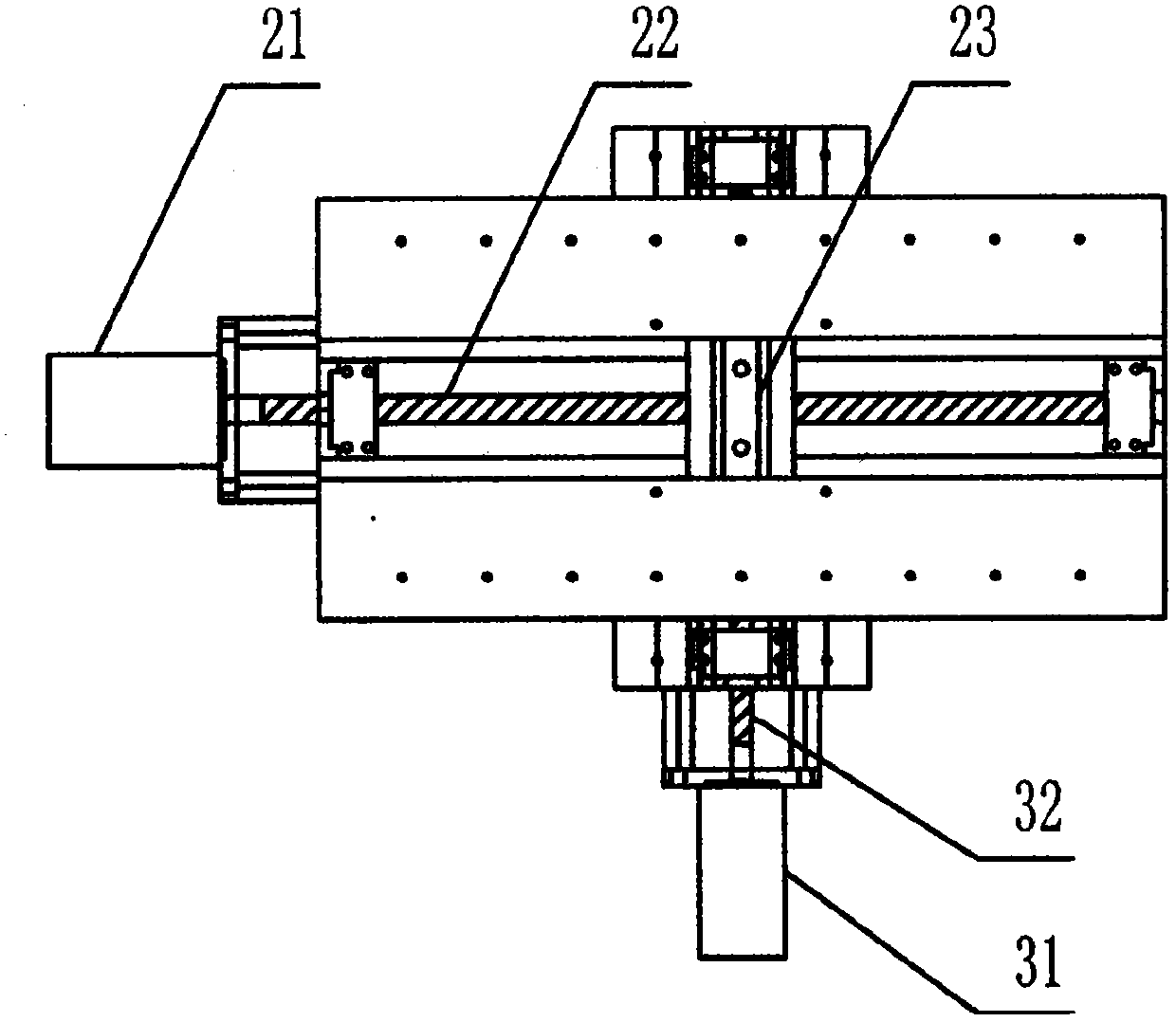

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is described further: embodiment: referring to accompanying drawing, two-axis multi-point automatic spot welding device, this device is provided with spot welding machine, rotating workpiece table 7, workpiece tire mold 11, support 1 and a transformer, the spot welding machine is provided with an upper spot welding arm and a lower spot welding arm, and the upper spot welding arm is provided with an upper cylinder 4, an upper electrode holder 5, and an upper electrode 6 connected sequentially from top to bottom; The following spot welding arm is provided with a lower cylinder 10, a lower electrode seat 9, and a lower electrode 8 connected sequentially from bottom to top; A disc-shaped table top is provided with several workpiece tire molds 12 on the disc-shaped table top, and the rotary table is arranged in the middle of the upper and lower spot welding arms; it is characterized in that: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com