Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Improve welding process efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

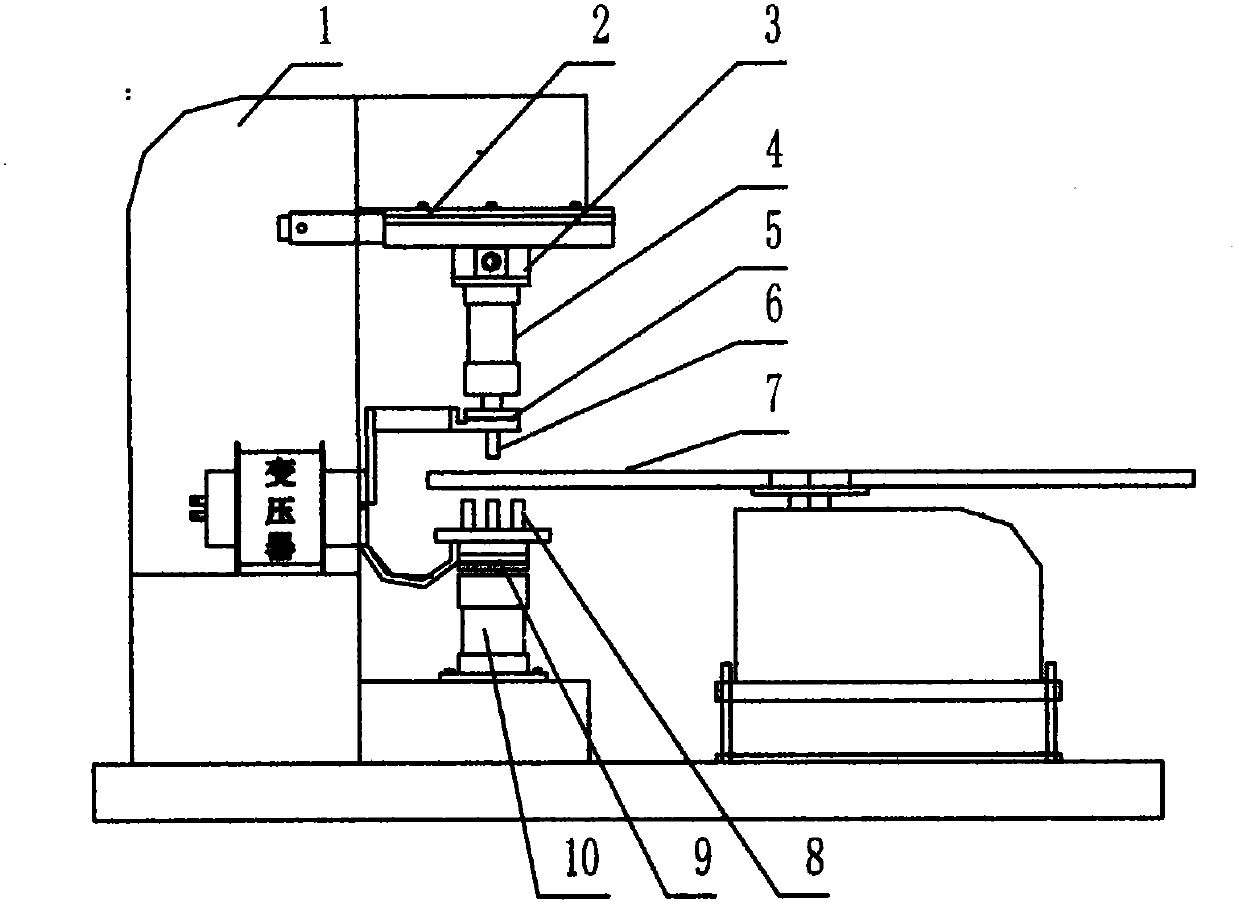

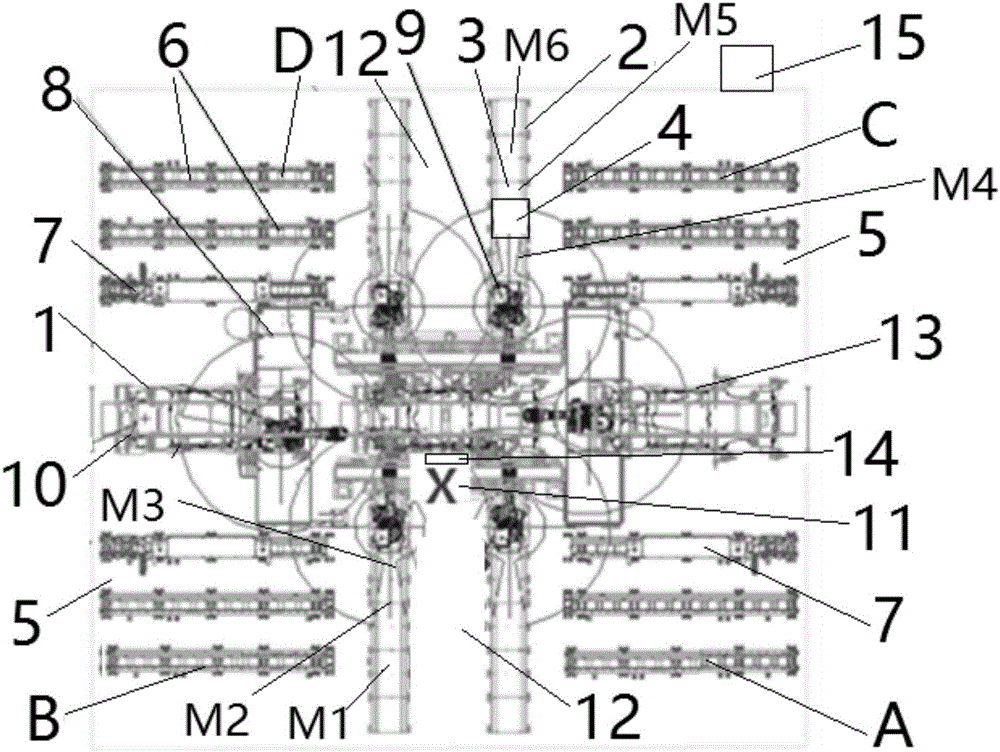

Two-axis multipoint automatic spot welding device and using method

InactiveCN103273181AImprove welding process efficiencyGuarantee welding qualityElectrode featuresDrive motorControl mode

The invention discloses a two-axis multipoint automatic spot welding device and a using method. The two-axis multipoint automatic spot welding device comprises a spot welding machine, a rotary working platform, workpiece forming dies, a machine base and a transformer. The spot welding machine is a two-axis spot welding machine, an X-axis linear module and a Y-axis linear module are arranged on the upper portion of an upper spot welding arm, the upper spot welding arm is installed on a transverse sliding block of the Y-axis linear module, the Y-axis linear module and a longitudinal sliding block of the X-axis linear module are fixed together through a two-axis connecting plate, a plurality of lower electrodes are arranged on a lower electrode holder of a lower spot welding arm, and a programmable controller is further arranged, and is connected with a driving motor in a control mode. The using method includes the steps of (1) manufacturing the workpiece forming dies, (2) manufacturing an upper electrode, (3) manufacturing the lower electrodes, (4) producing welding point coordinate information, inputting the welding point coordinate information to a numerical control system in the digital programmable controller, (5) setting the control state of the digital programmable controller to the rotary working platform, and (6) carrying out machine starting and operation. The two-axis multipoint automatic spot welding device is applicable to multipoint welding operation, complete in structure and high in degree of automation, work and labor are saved, energy is saved, and efficiency is high.

Owner:窦川忠

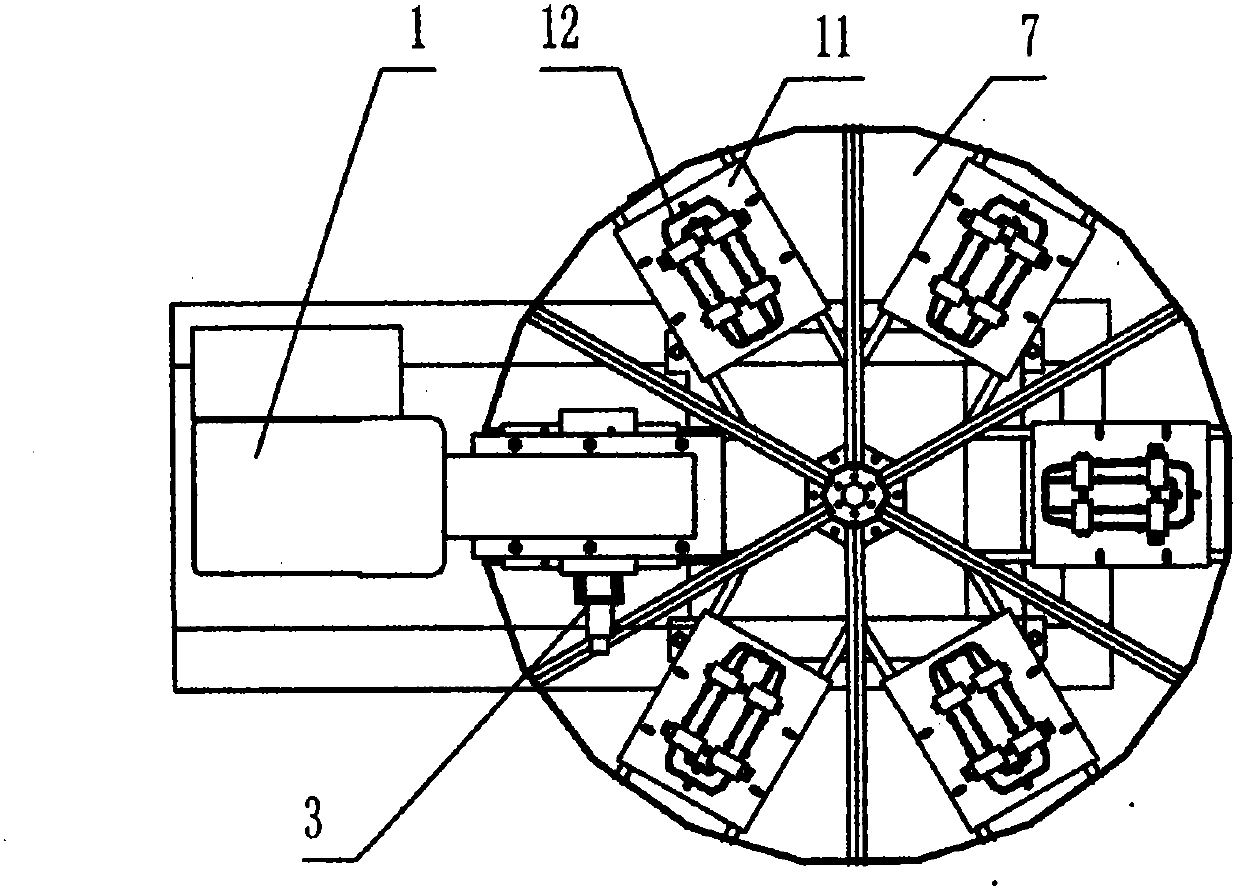

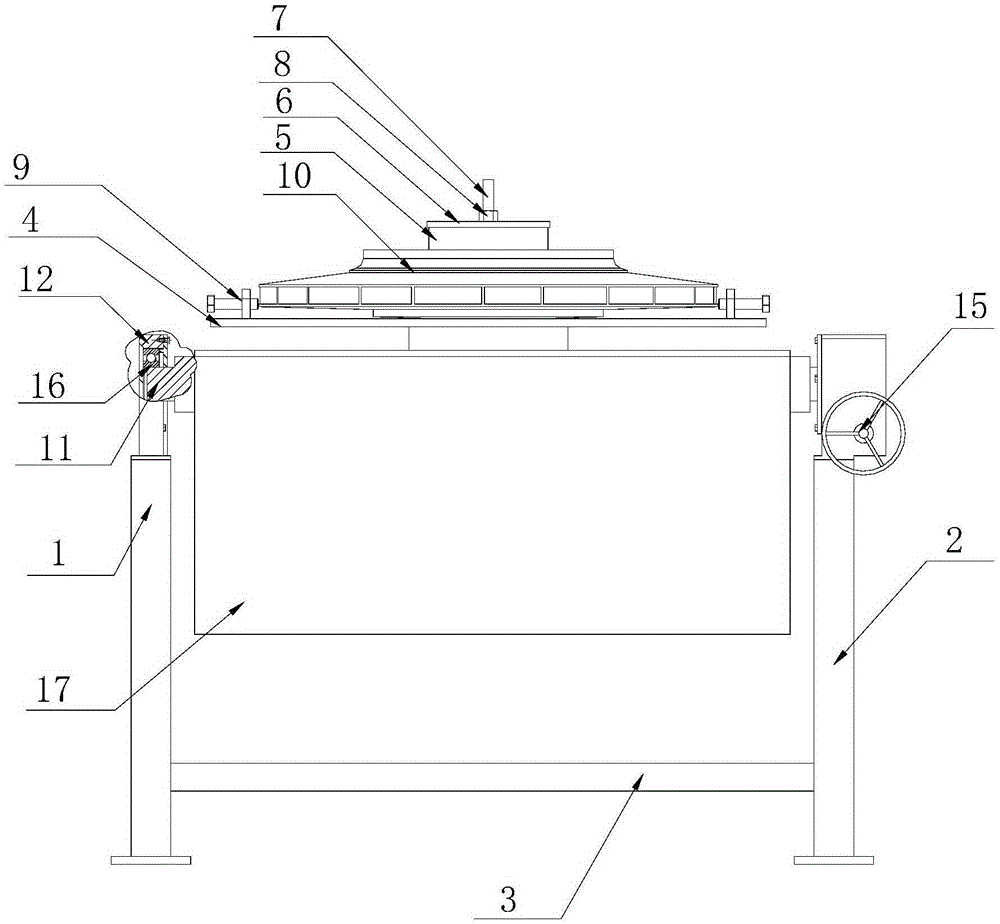

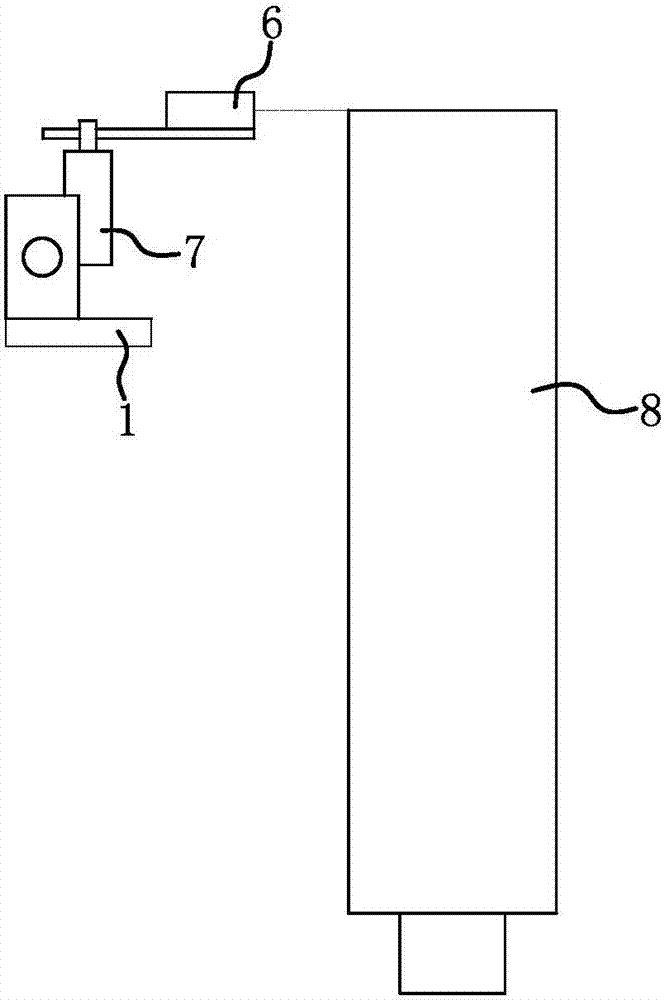

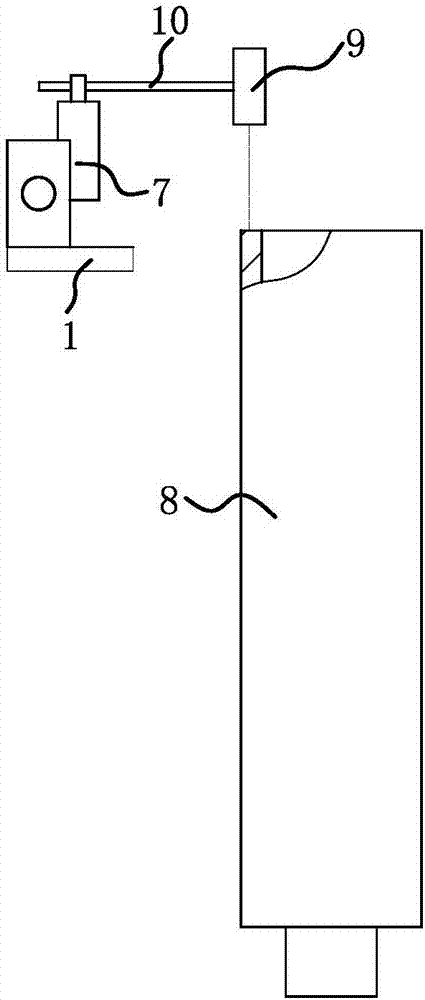

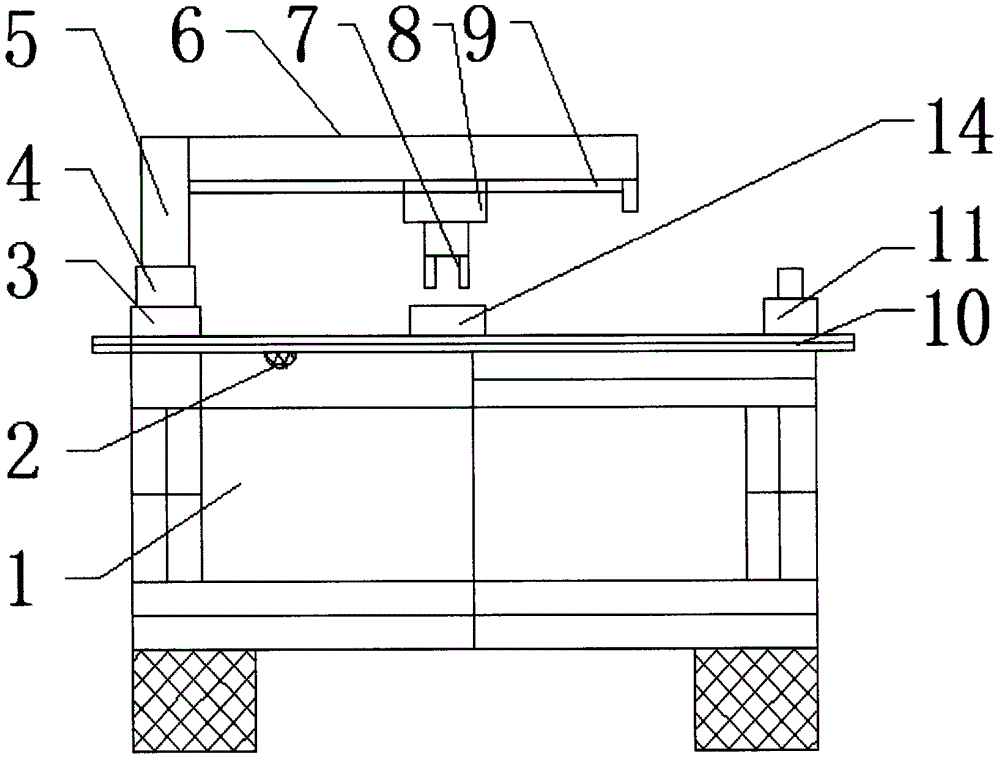

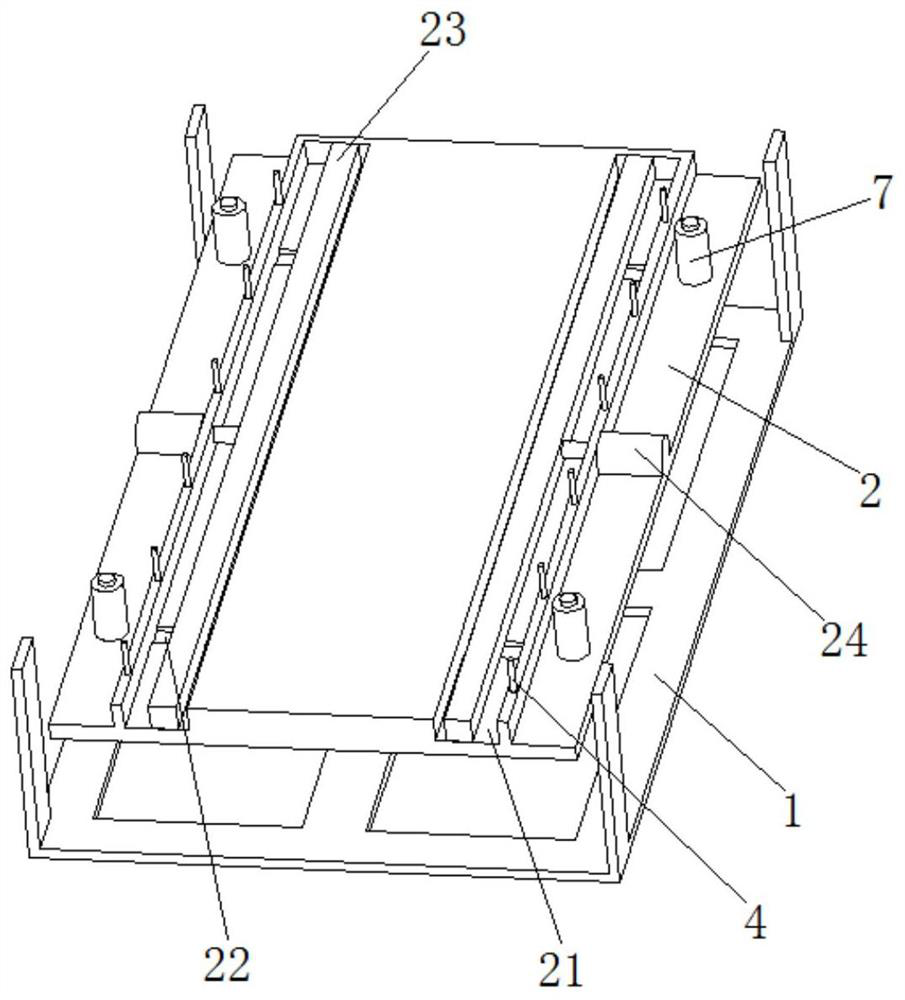

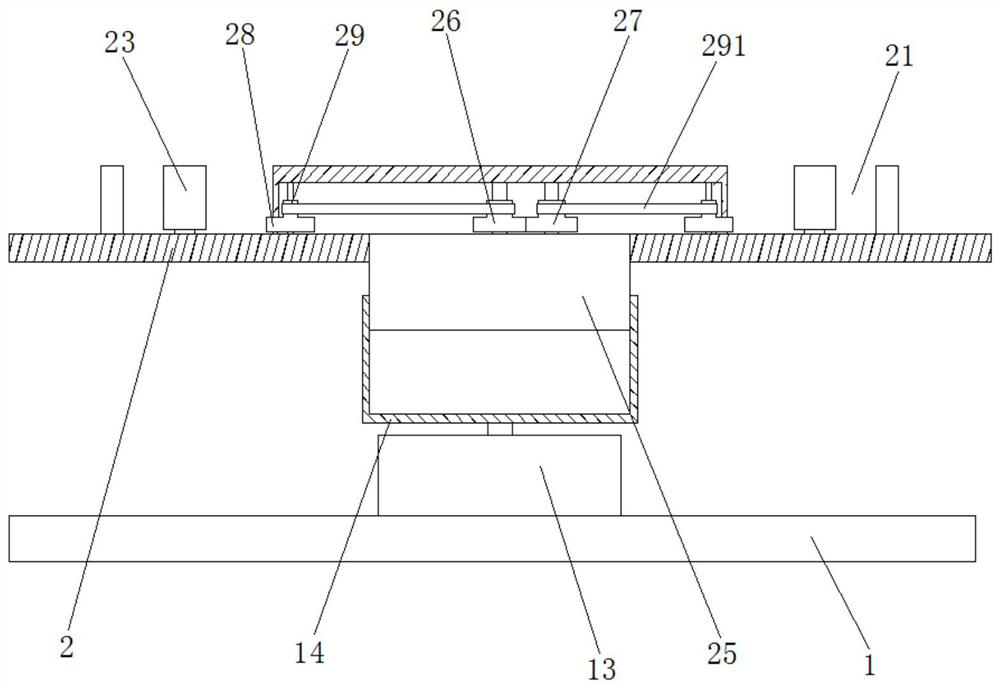

Welding rotatable work fixture for automobile front bumper beam sub assembly

InactiveCN103801878AImprove welding process efficiencyImprove efficiencyWelding/cutting auxillary devicesAuxillary welding devicesUltimate tensile strengthMachining

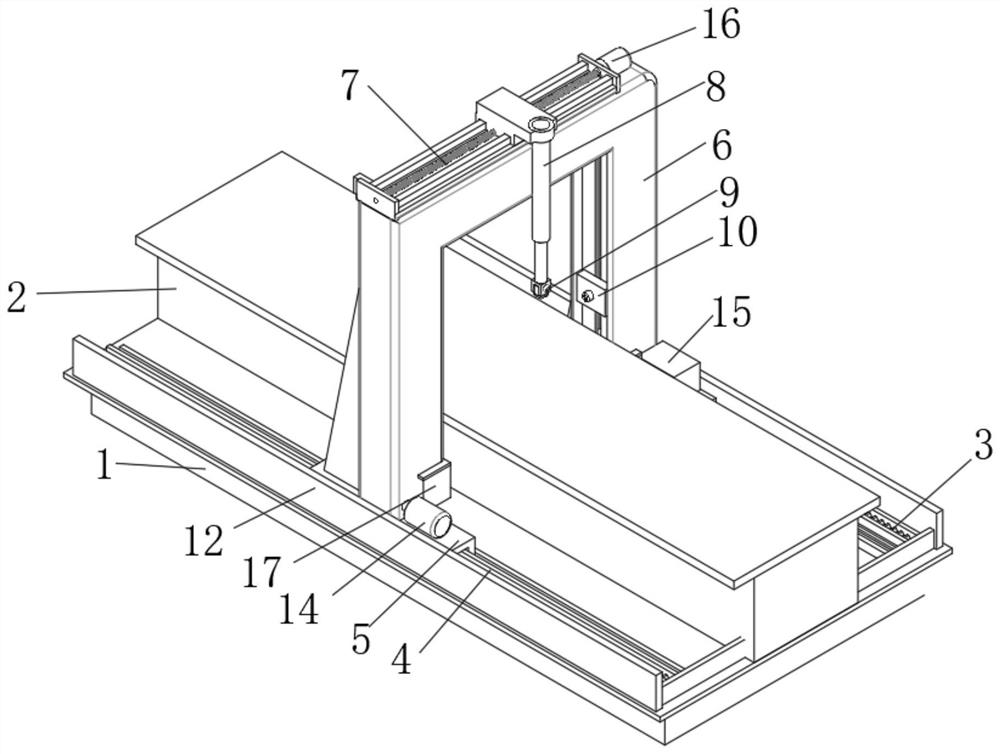

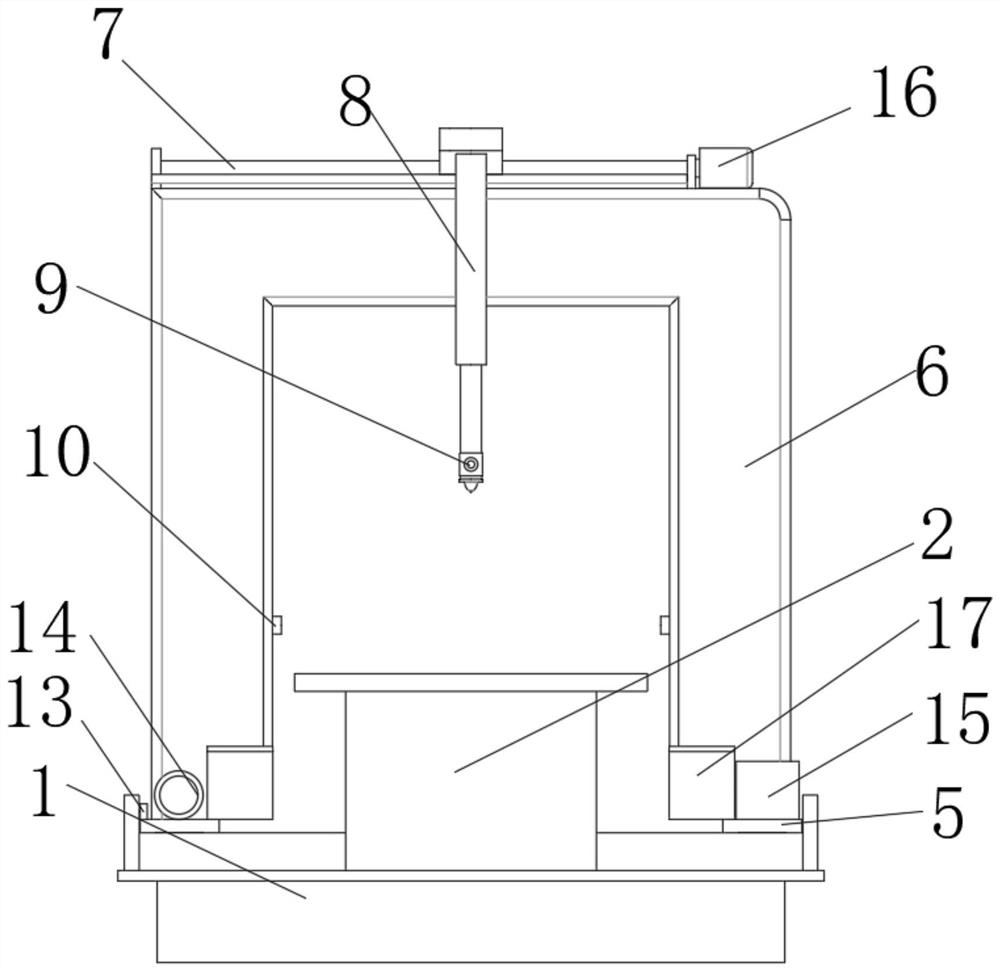

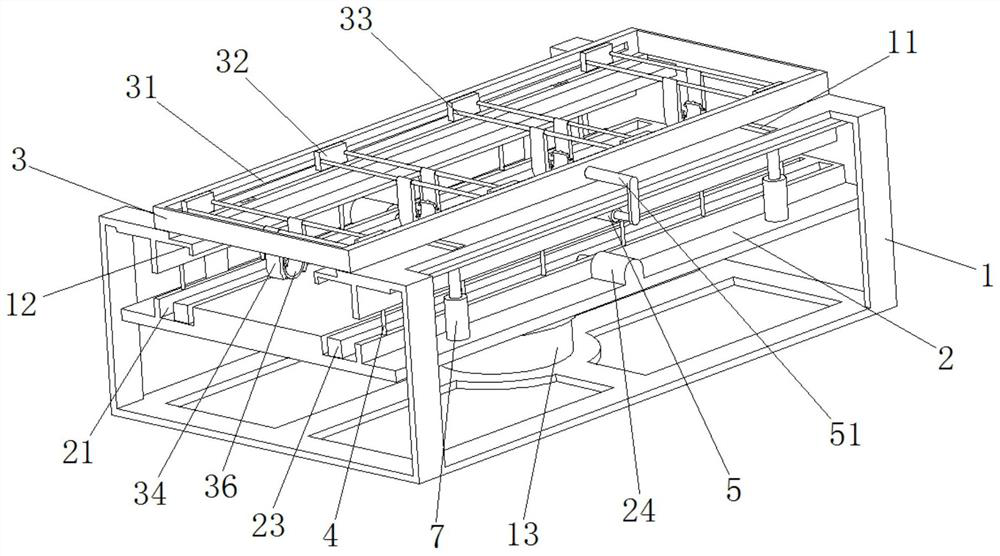

A welding rotatable work fixture for an automobile front bumper beam sub assembly comprises a base (1). The right side of the base (1) is provided with a tilt motor (2) and a speed reducing case (15), and the left side of the base (1) is provided with a turnover board assembly (4). The welding rotatable work fixture is characterized in that a six-directional adjusting main positioning mechanism (5), a left side face compression air cylinder mechanism (6), a six-directional adjusting auxiliary positioning mechanism (7), a right side face compression air cylinder mechanism (8), a front face compression air cylinder mechanism (9), compression pliers (11) and a material supporting air cylinder mechanism (12) are inflated with air and tightly press the automobile front bumper beam sub assembly, a foot switch (3) controls the tilt motor (2) to rotate, the turnover board assembly (4) rotates by 0-270 degrees according to the welding position, and the welding position is carried out. By means of the welding rotatable work fixture, the machining efficiency can be improved manyfold, the speed is high, the benefits are high, the labor intensity is reduced, and the quality of machined products is good.

Owner:JIANGSU CHANGTONG VEHICLE DEV

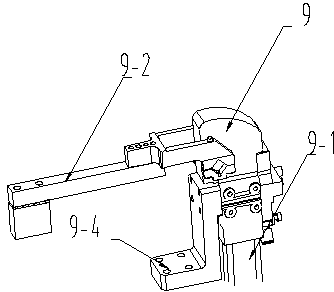

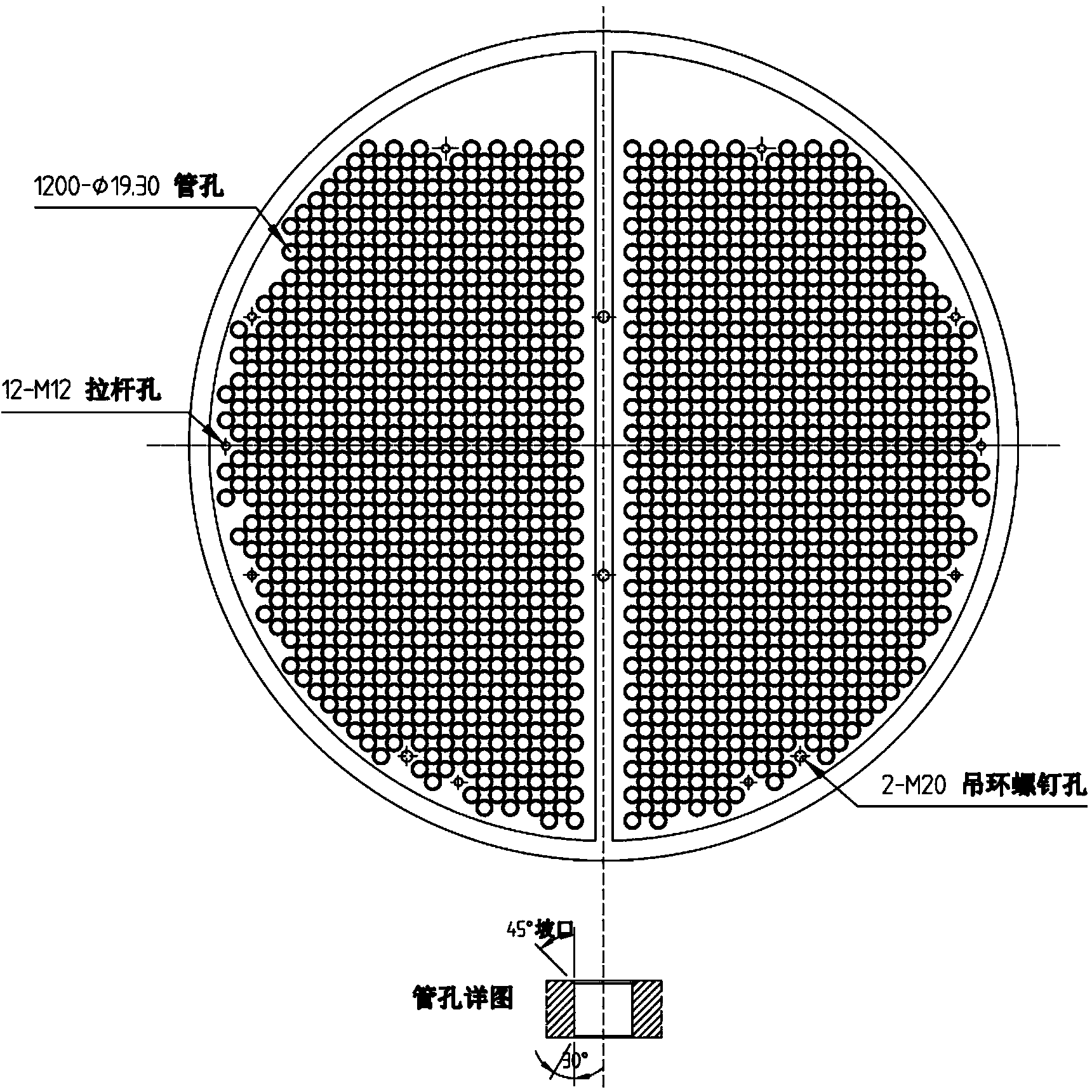

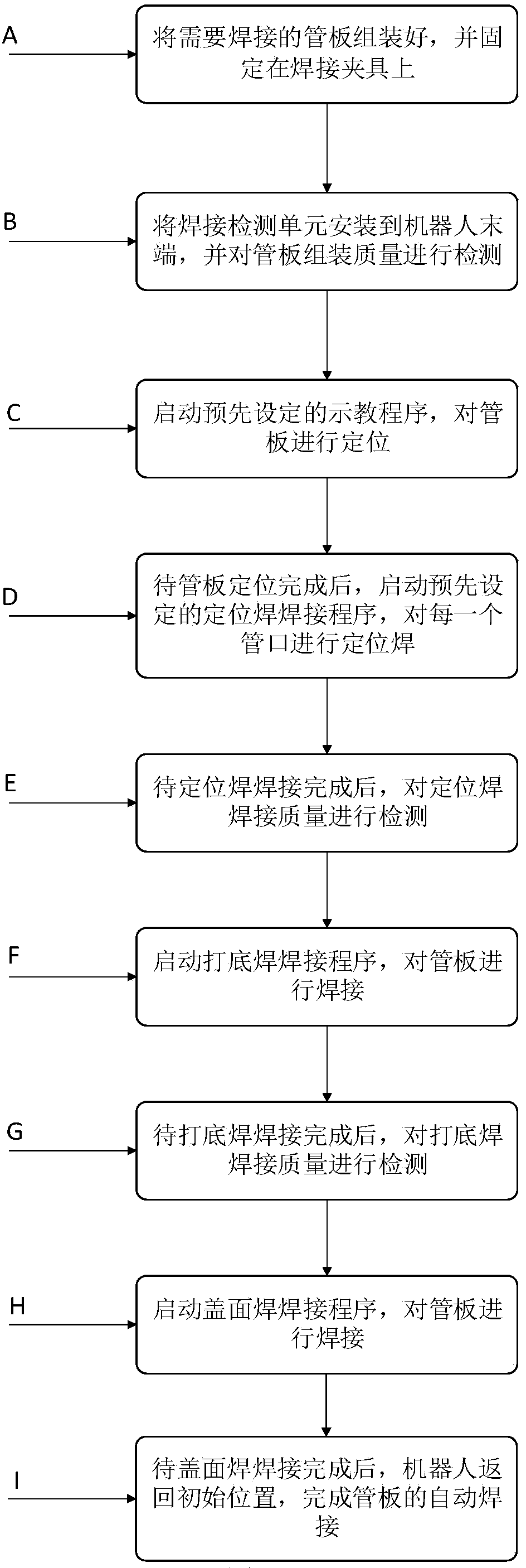

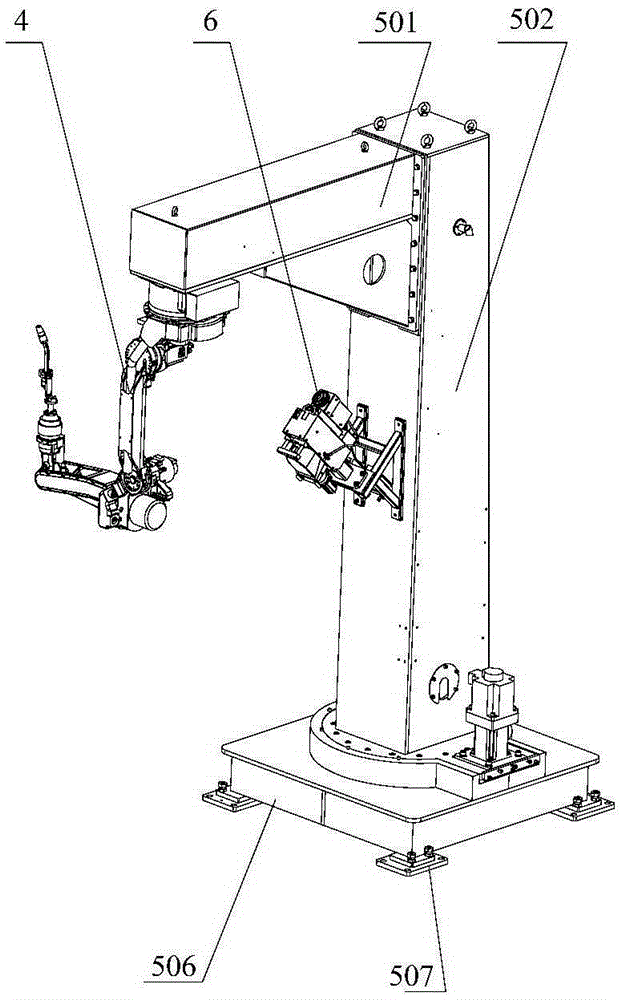

Welding method for tube plate of robot

InactiveCN104384763AImprove welding process efficiencyHigh degree of intelligenceWelding/cutting auxillary devicesAuxillary welding devicesThree dimensional modelEngineering

The invention relates to a welding method for a tube plate of a robot. The robot is applied to the field of the welding for the tube plate of a pressure vessel. The welding method comprises the following steps: integrally mounting a tube plate welding head and a detecting unit at the tail end of the robot; planning a welding path and writing a welding program on the basis of a to-be-welded tube plate three-dimensional model according to a tube plate welding technical demand, thereby realizing automatic welding; adopting a visual detecting method for detecting the welding quality. According to the invention, a welding detecting unit is combined with the robot, so that the welding processing efficiency is increased, the intelligent degree of the welding method is high, workpieces in various sizes can be processed, and the welding quality of the products is ensured.

Owner:JIANGNAN UNIV

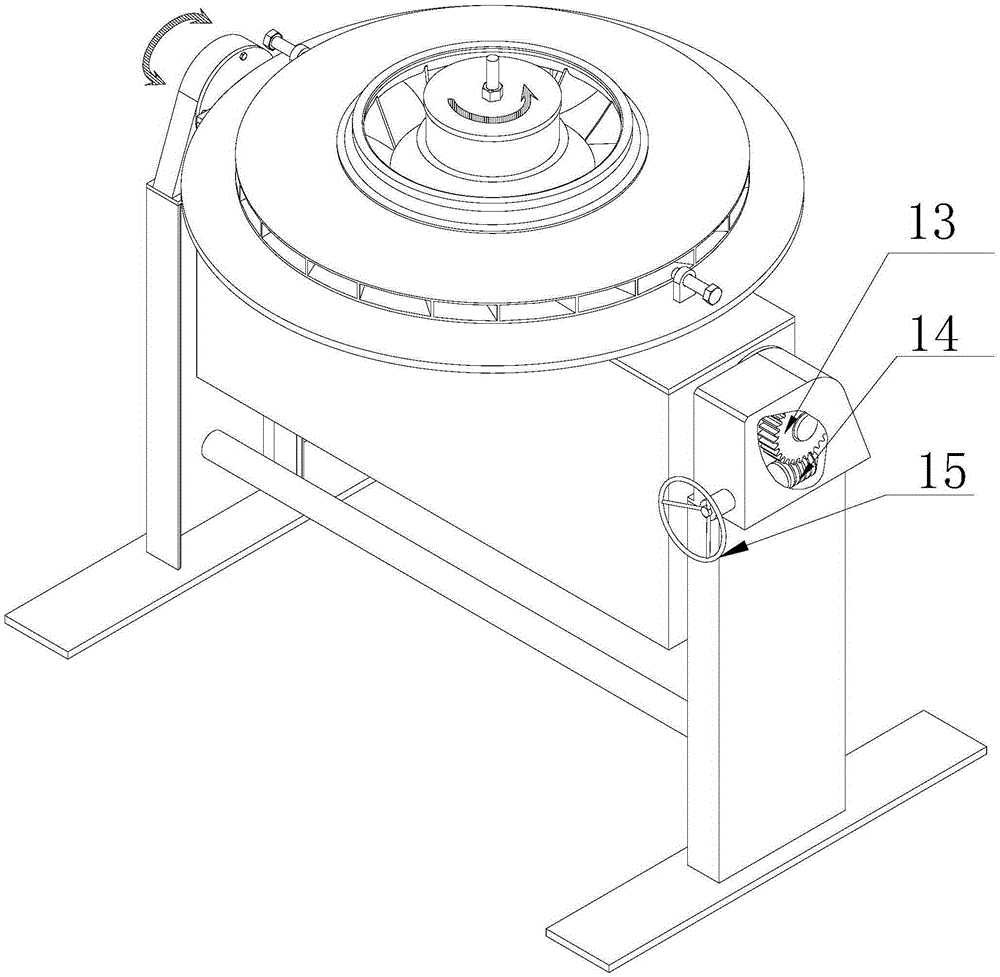

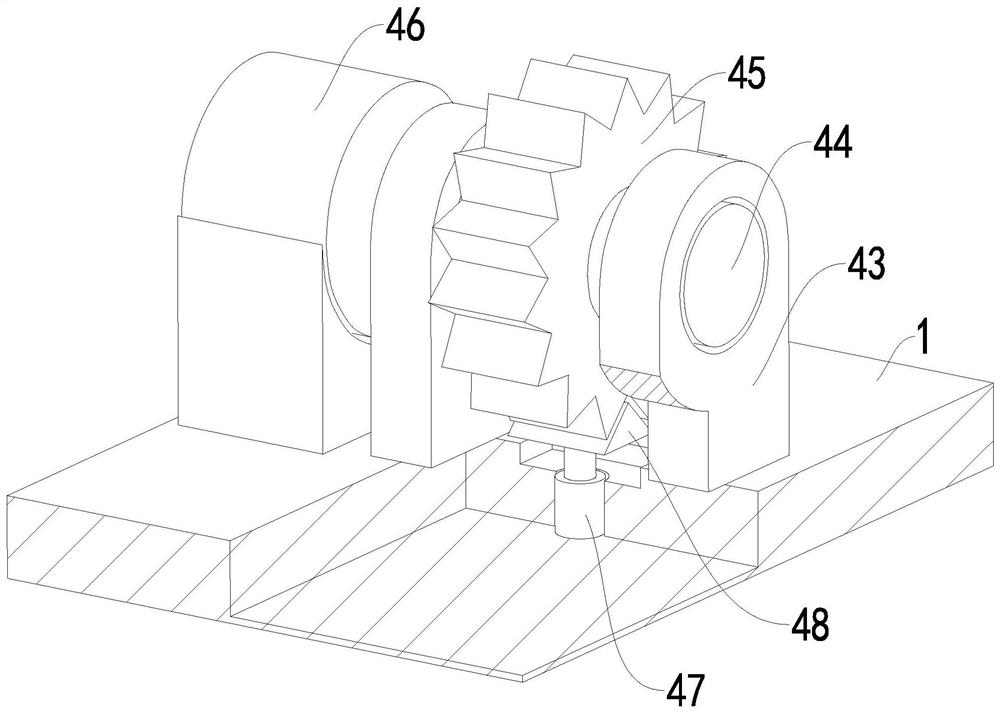

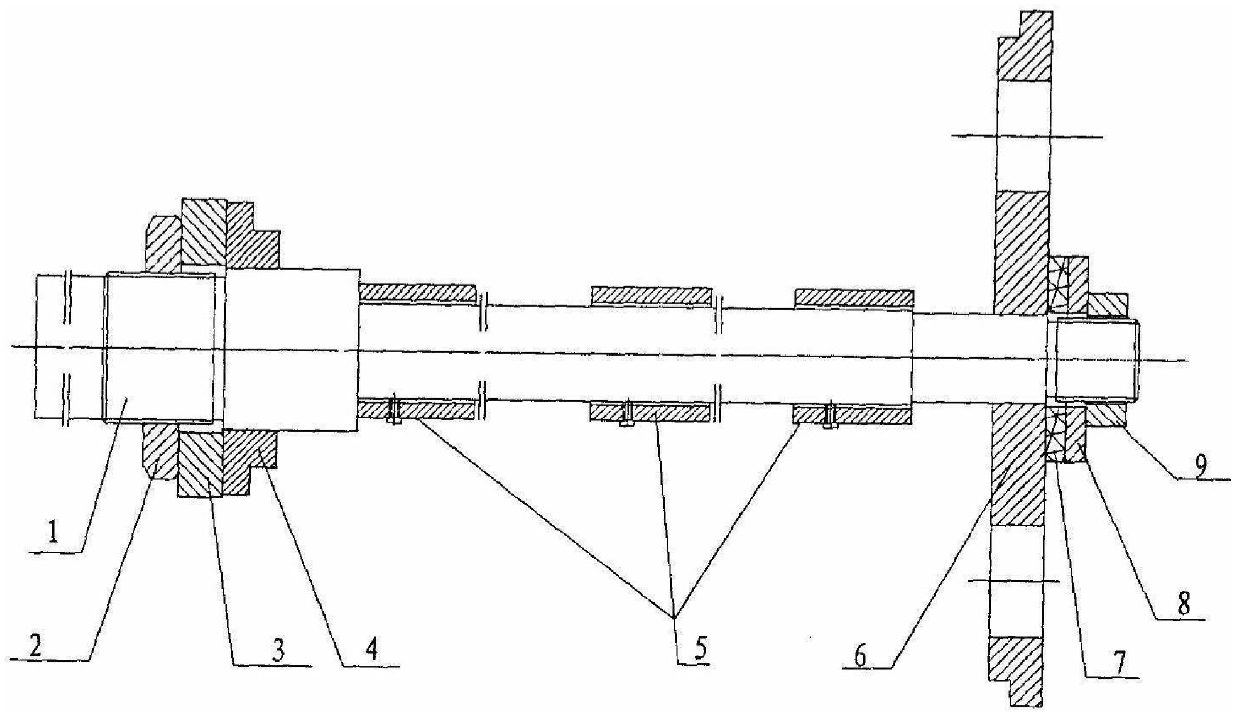

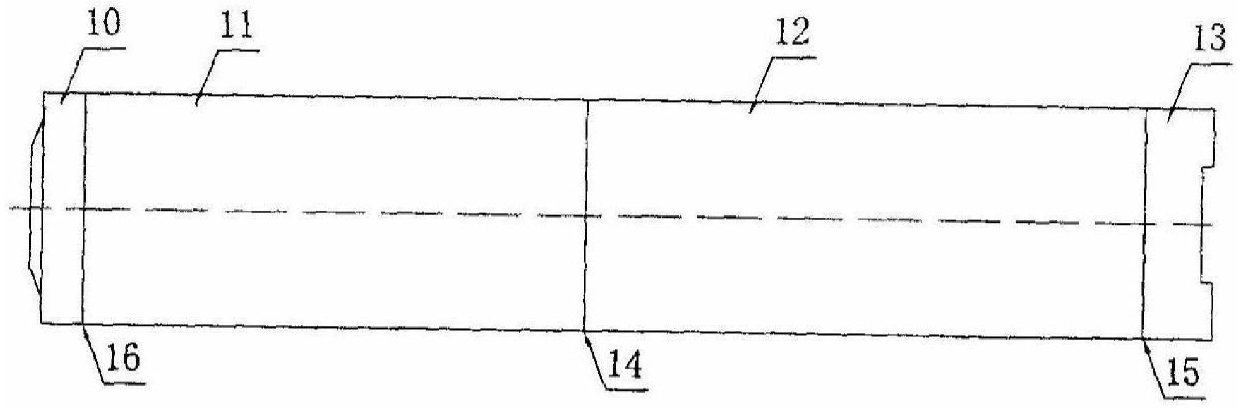

Tool for welding impeller of centrifugal blower

InactiveCN105345351AGuarantee welding qualityImprove welding process efficiencyTurbinesWelding/cutting auxillary devicesImpellerEngineering

The invention discloses a tool for welding an impeller of a centrifugal blower. The tool comprises a rack, a rotation mechanism and an overturning mechanism. By adopting the tool for welding the impeller of the centrifugal blower disclosed by the invention, the welding quality of the impeller can meet the welding technology requirement; the welding processing efficiency of the impeller is improved; the time which a worker spends on polishing a welding joint is reduced; the labor cost for manufacturing the impeller is reduced; and industrial large-scale production of the tool is facilitated.

Owner:安徽虎渡科达流体机械有限公司

Bridge steel structure prefabricated part manufacturing and machining machine and machining method

InactiveCN113020888AReduce the effect of weldingLow efficiencyWelding/cutting auxillary devicesAuxillary welding devicesSteel platesManufacturing engineering

The invention relates to a bridge steel structure prefabricated part manufacturing and machining machine and machining method. The bridge steel structure prefabricated part manufacturing and machining machine comprises a base, clamping mechanisms, a material lifting mechanism, a rotating mechanism and a bearing mechanism, wherein the clamping mechanisms are arranged in the middle of the upper end face of the base in a bilateral symmetry manner, and the material lifting mechanism is arranged on the upper end face of the base and located at the left side of the clamping mechanism at the left side; and the clamping mechanisms are connected through the rotating mechanism, and the bearing mechanism is arranged at the right side of the clamping mechanism at the right side. The bridge steel structure prefabricated part manufacturing and machining machine and machining method solve the problems that in the prior art, in the process of splicing and welding bridge steel structure prefabricated parts on the ground in a manual manner: after welding of the upper ends of the bridge steel structure prefabricated parts is completed, the bridge steel structure prefabricated parts are difficult to turn over, and the back faces of the bridge steel structure prefabricated parts are difficult to weld; and small steel plate assemblies are held and fixed in a manual manner, the angle between the steel plate assemblies and the size accuracy degree are difficult to control in the process, and the welding machining effect on the bridge steel structure prefabricated parts is reduced.

Owner:高黎明

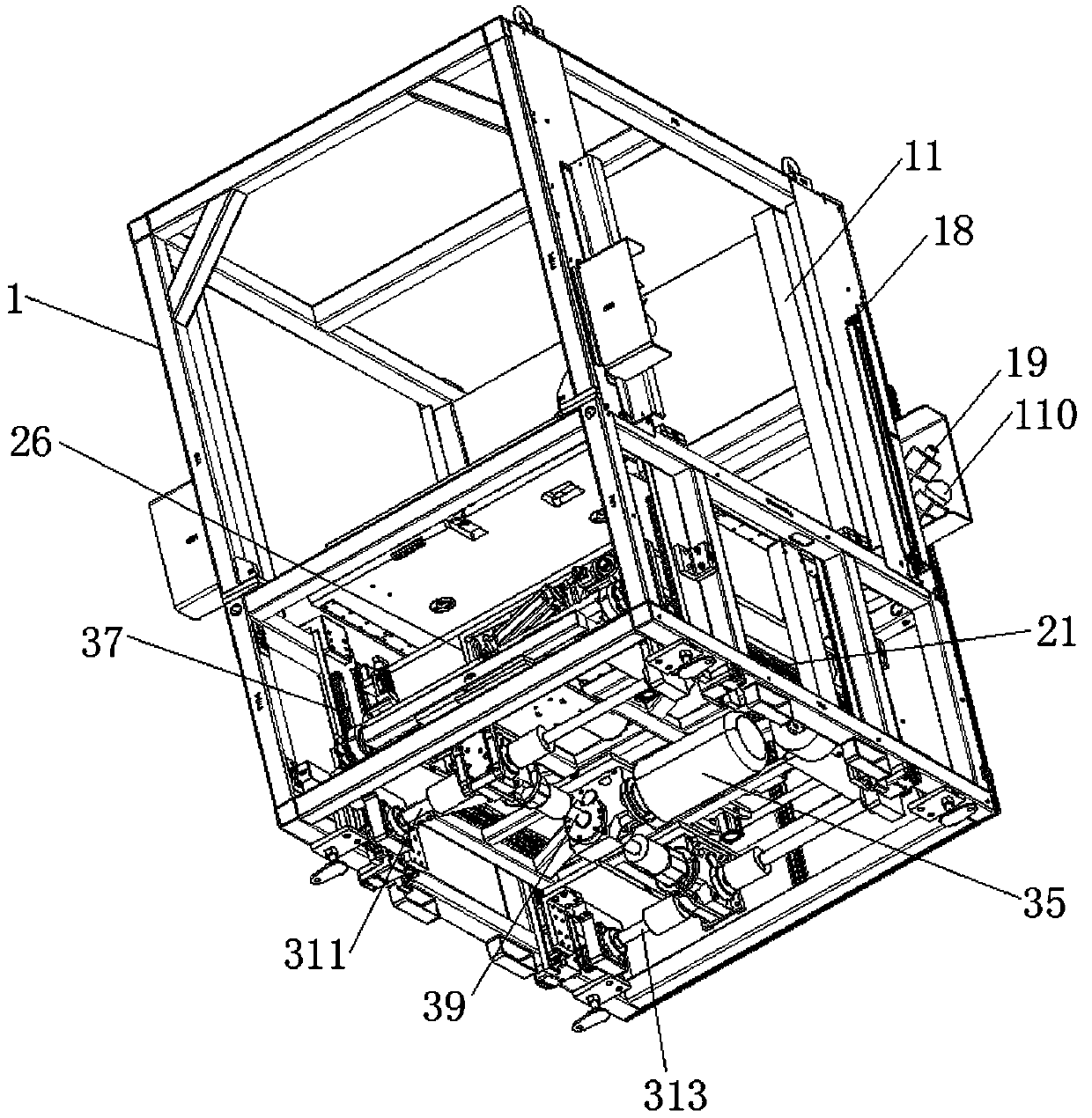

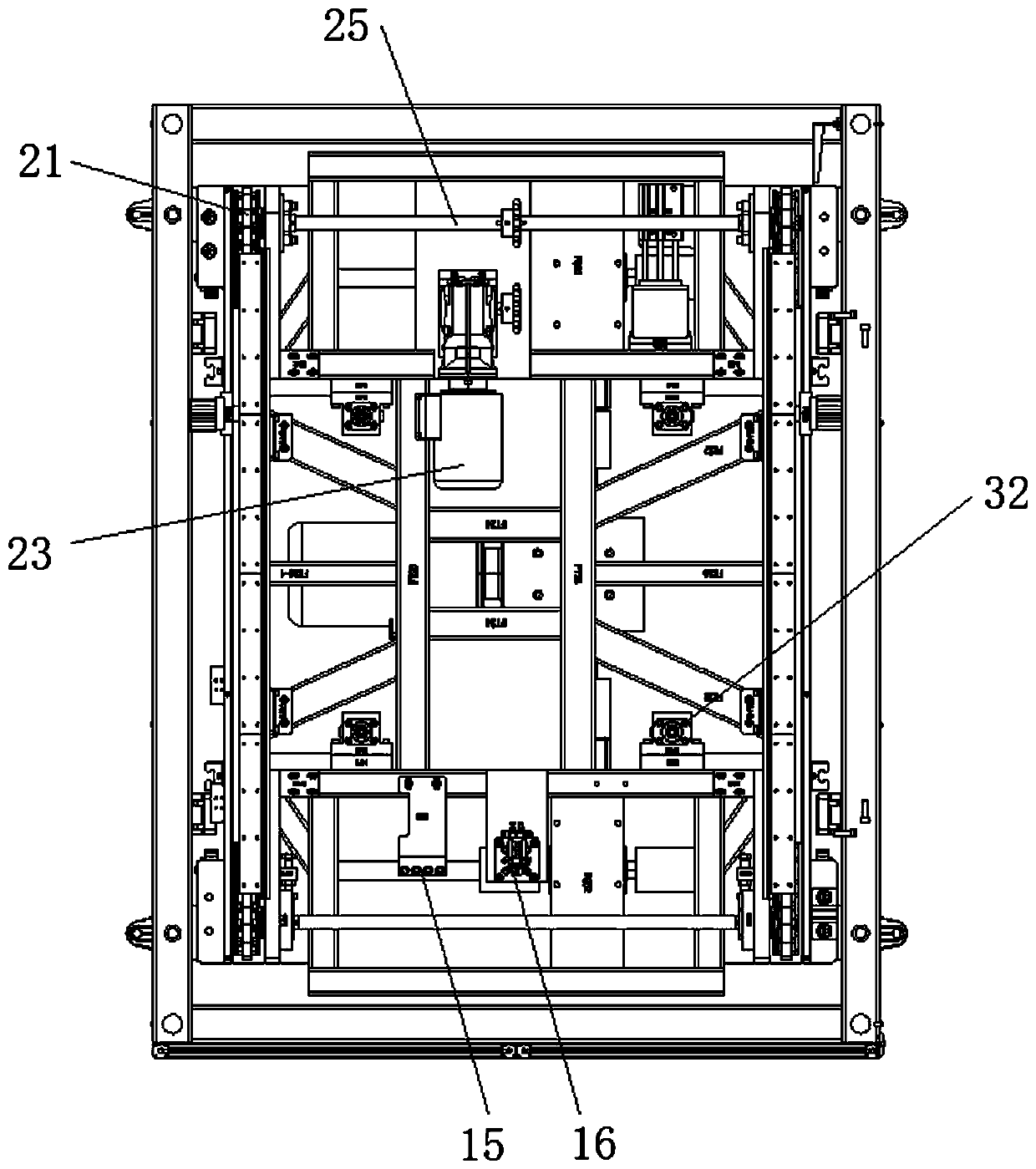

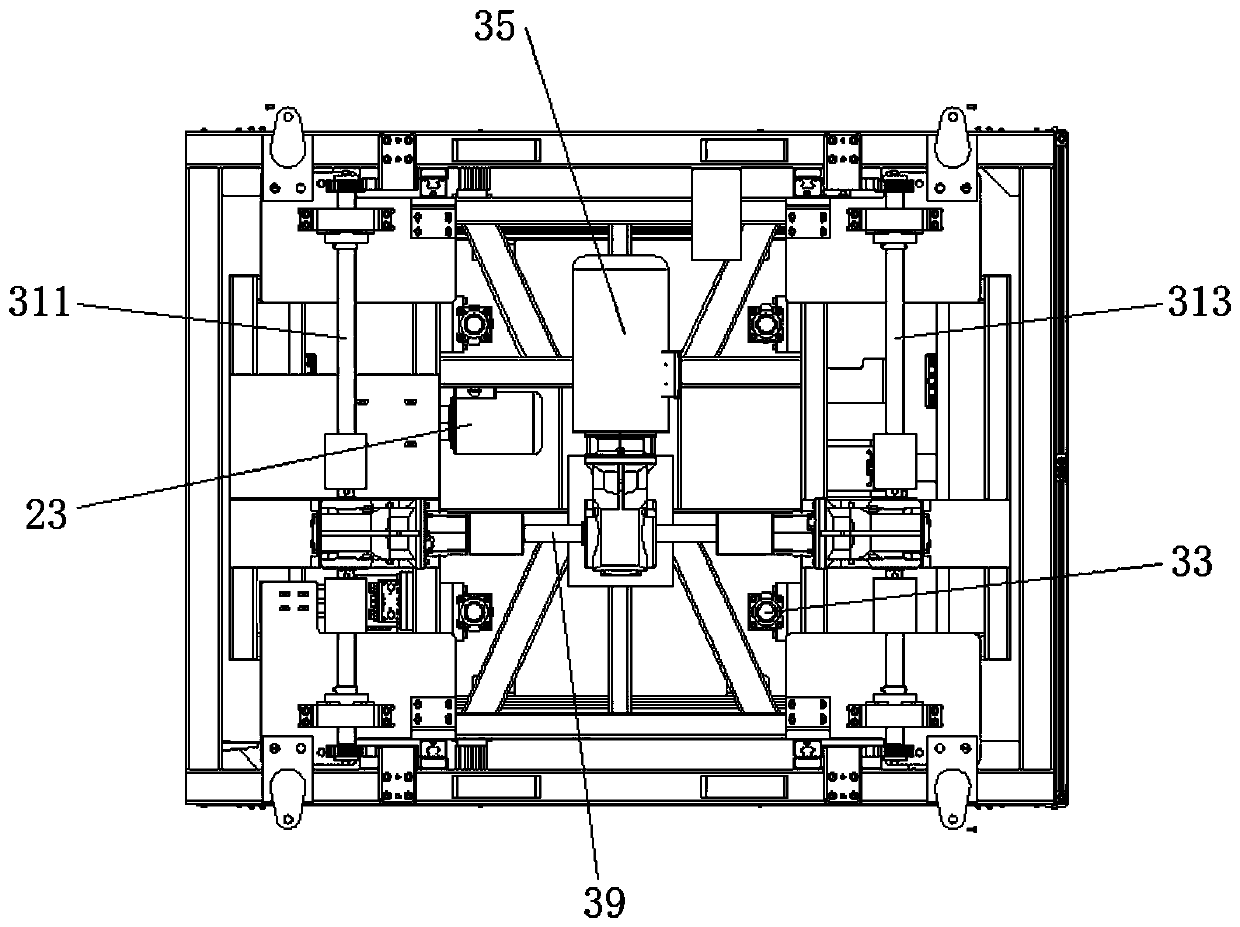

Robot-based box welding system

InactiveCN105290663AQuick clampingQuick loading and unloadingWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlEngineering

Owner:CHANGSHA CTR ROBOTICS

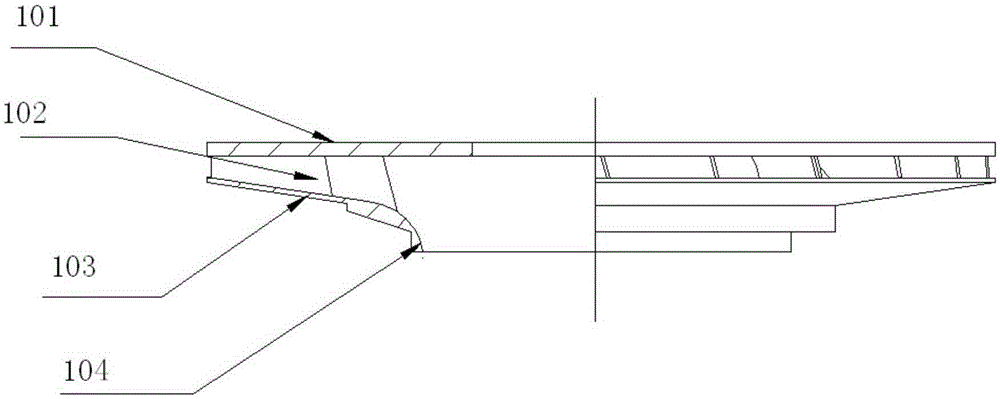

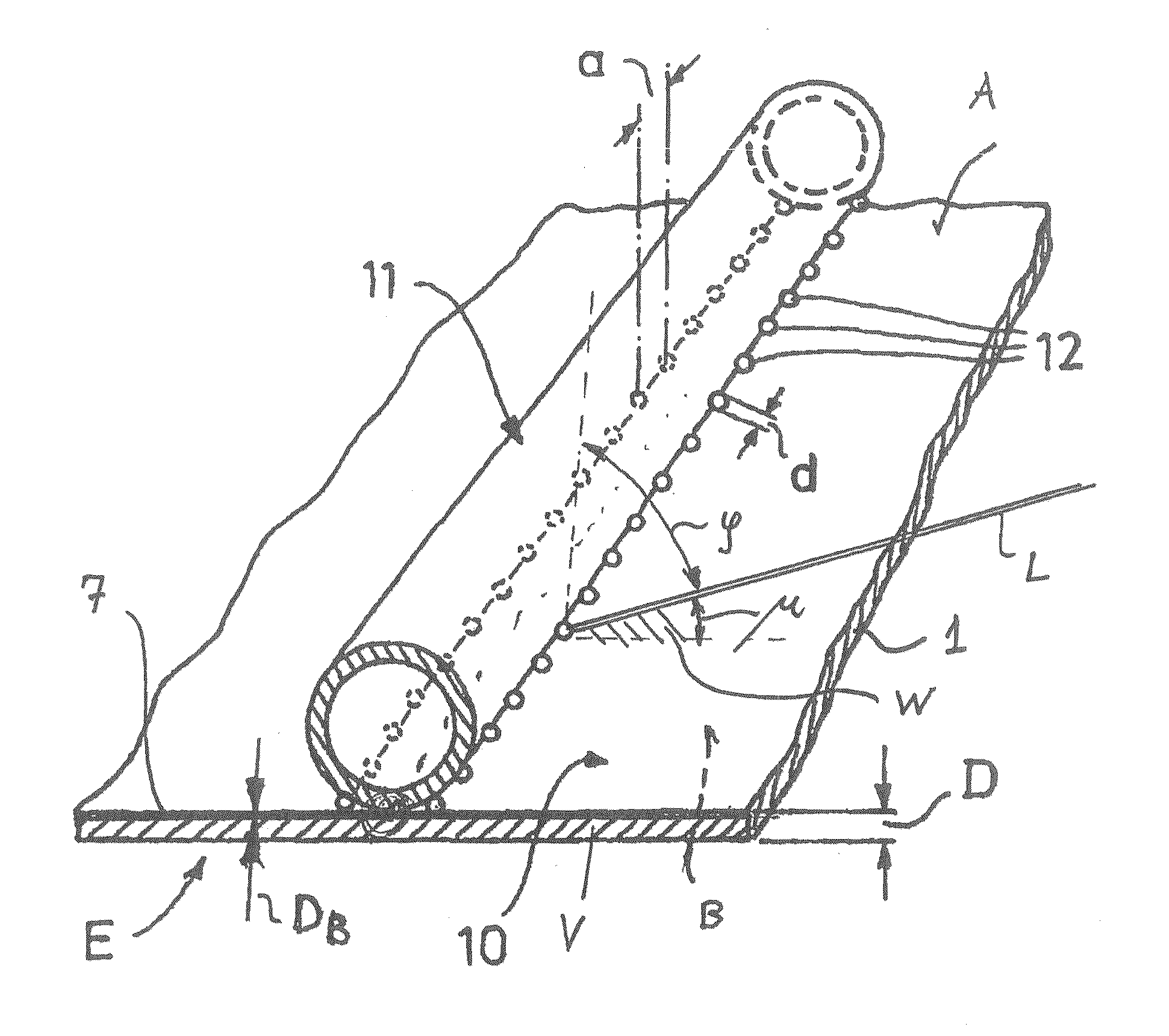

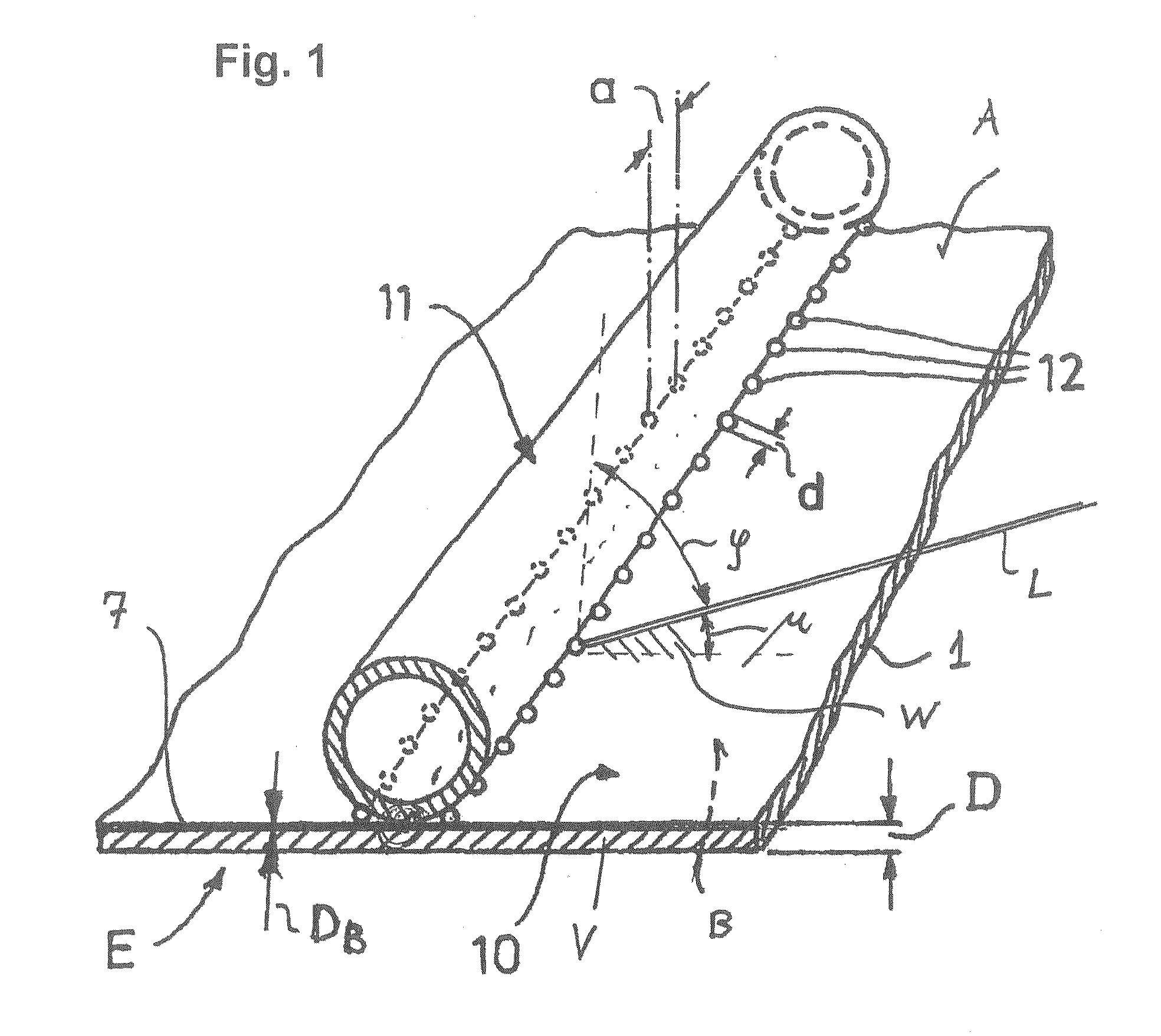

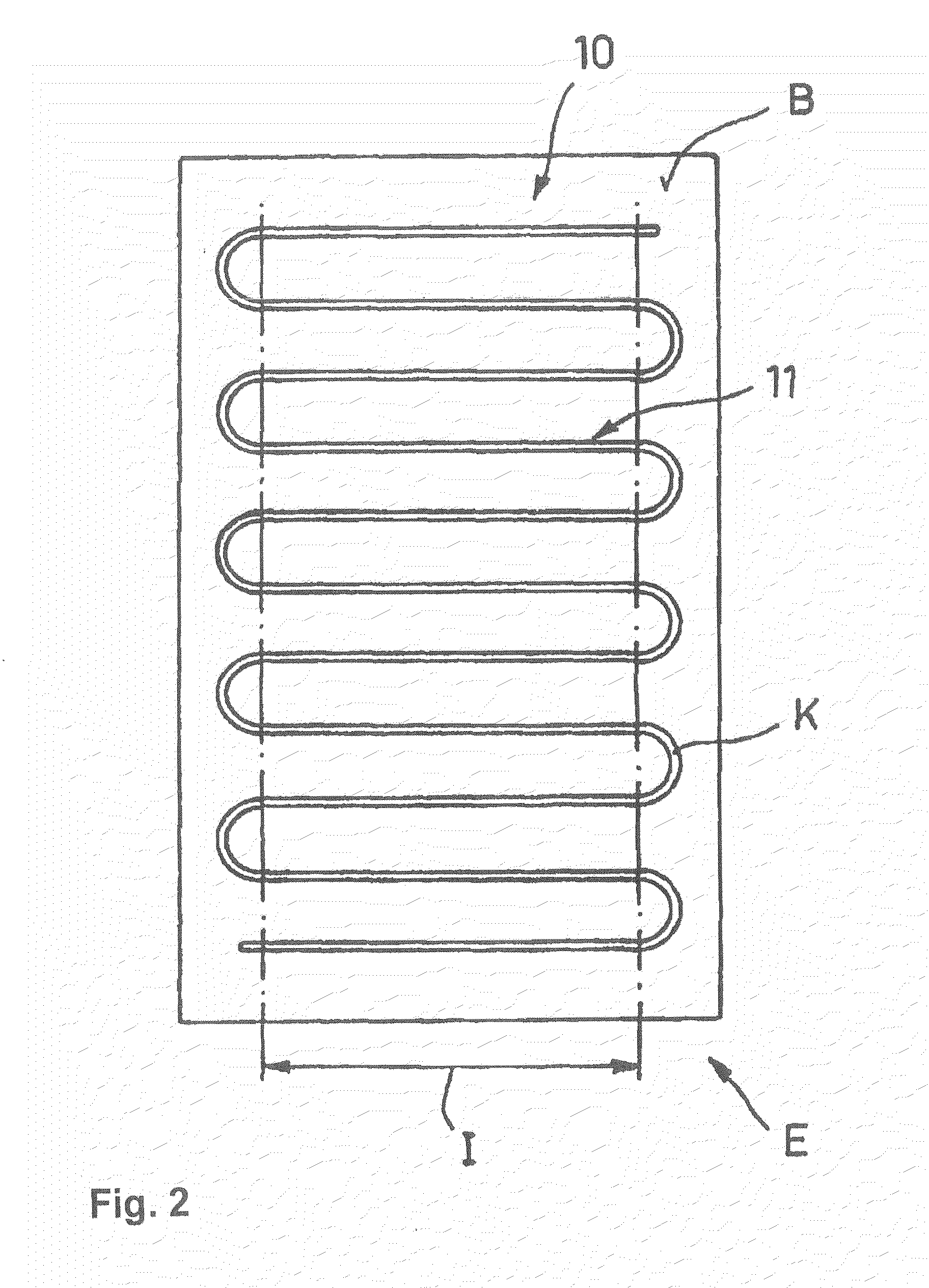

Method for the laser welding of a composite material to a component, and laser-weldable composite material for such a method

ActiveUS20100261011A1Increase efficiencyHigh functionalitySolar heating energySolar heat devicesWeld seamHigh reflectivity

The invention relates to a method for the laser welding of a composite material (V) to a component (11) in particular for the production of a solar collector element (E), wherein the composite material (V) comprises a strip-shaped substrate (1) composed of a metal having high reflectivity to laser radiation, said substrate having a first side (A) and a second side (B), wherein a dielectric coating (7) is situated at least on the first side (A), and wherein, in order to produce a weld seam, a laser beam (L) is projected at an acute orientation angle (μ) at least onto the first side (A) of the substrate (1) provided with the dielectric coating (7). In order to improve the energy efficiency of the laser radiation used, it is proposed that the dielectric coating (7) has a thickness (DB) in the range of 140 nm to 210 nm and the laser beam (L) is radiated in at an orientation angle (μ), in particular in focused fashion, in such a way that the radiated-in energy of the laser beam (L) is absorbed to the extent of at least 15 percent.

Owner:ALANOD GMBH

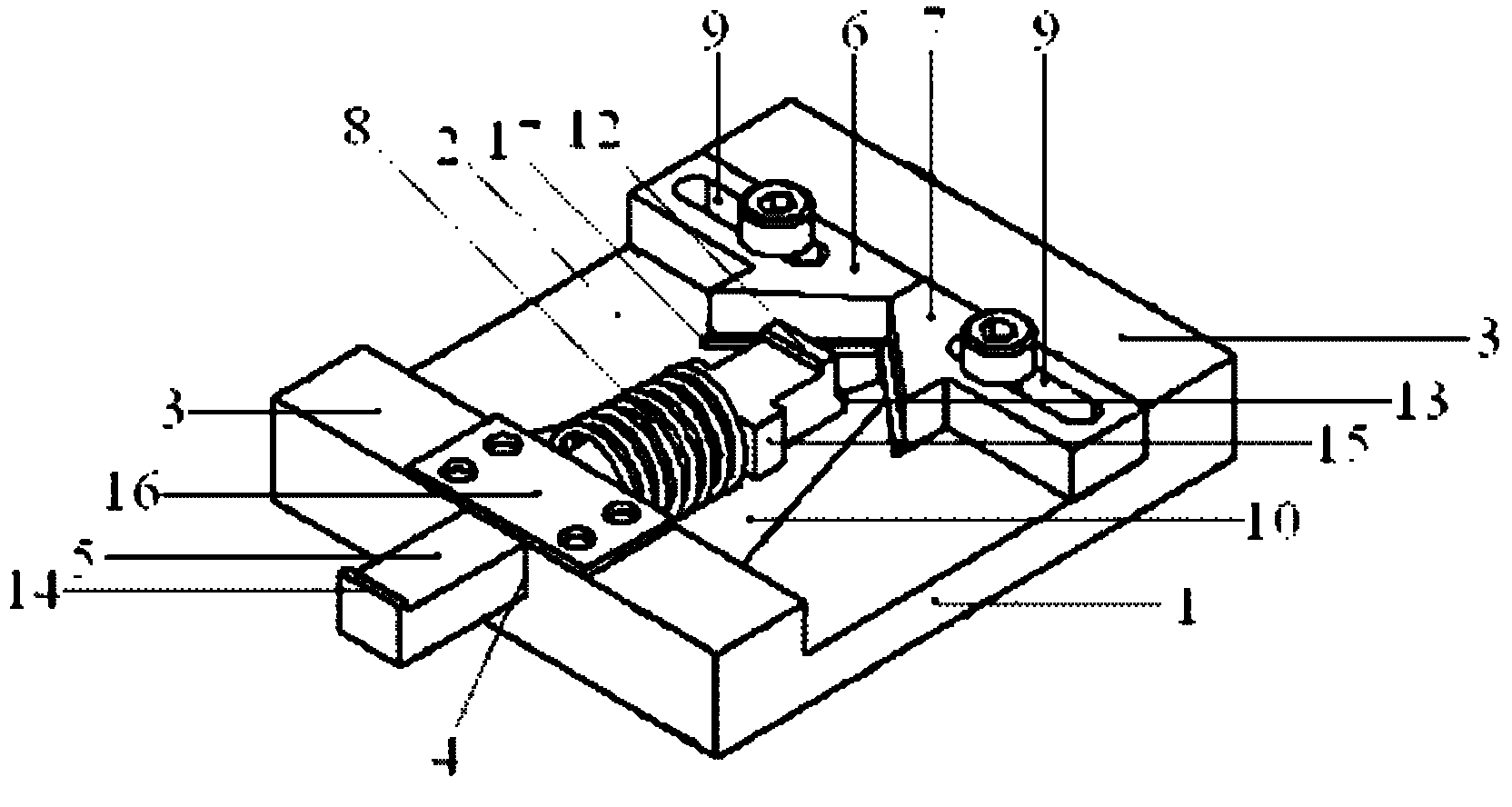

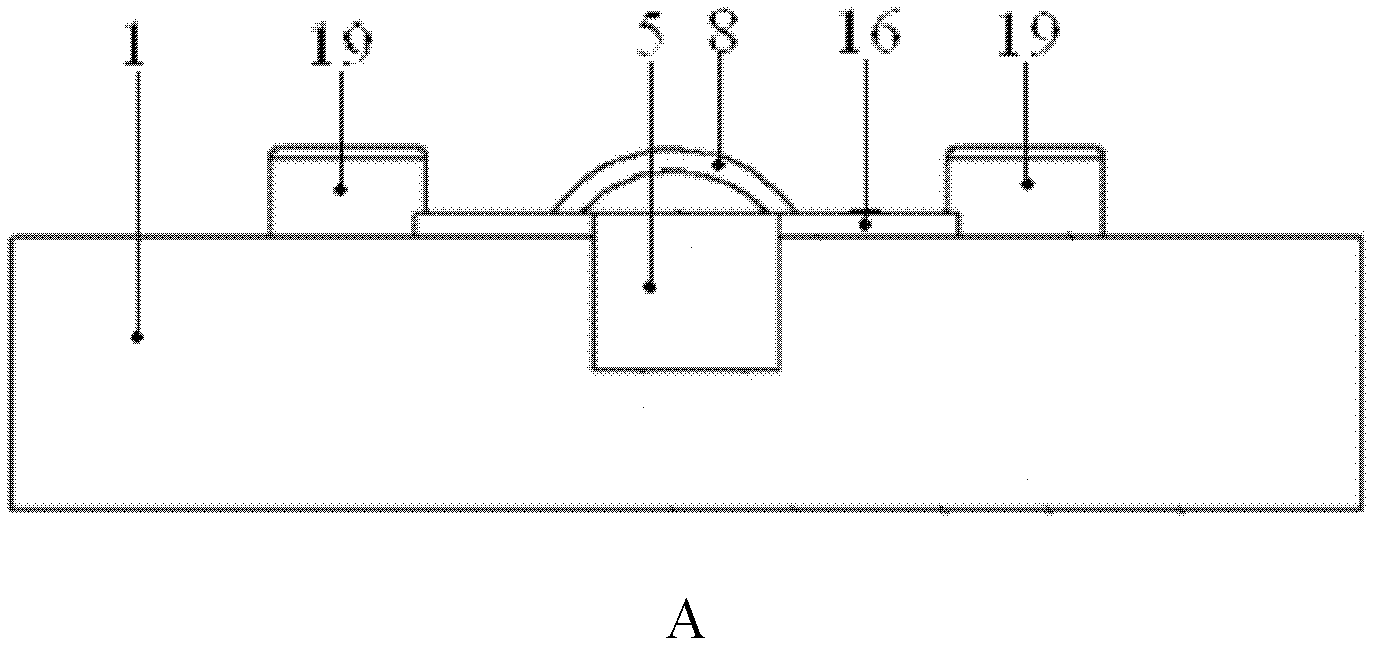

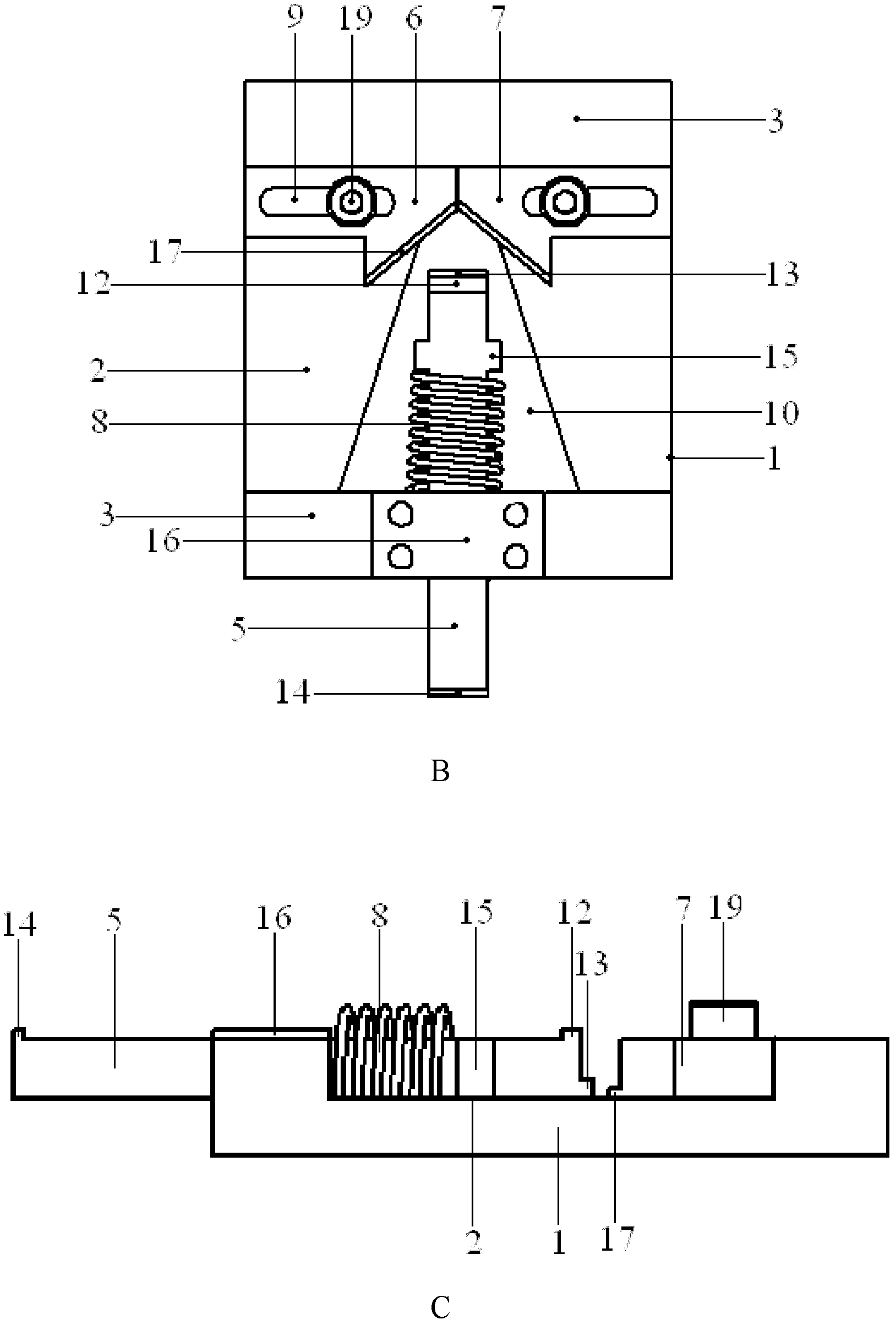

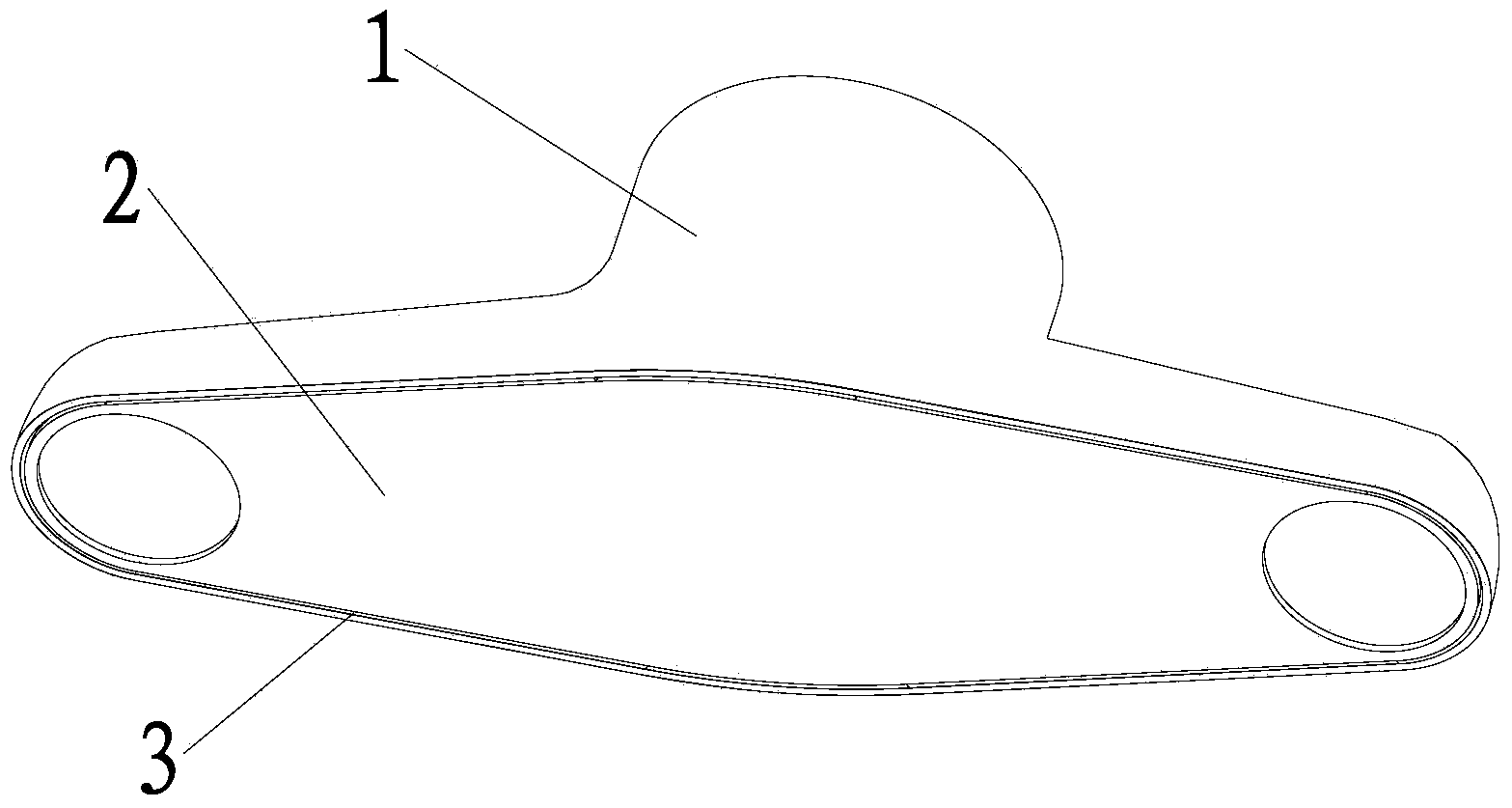

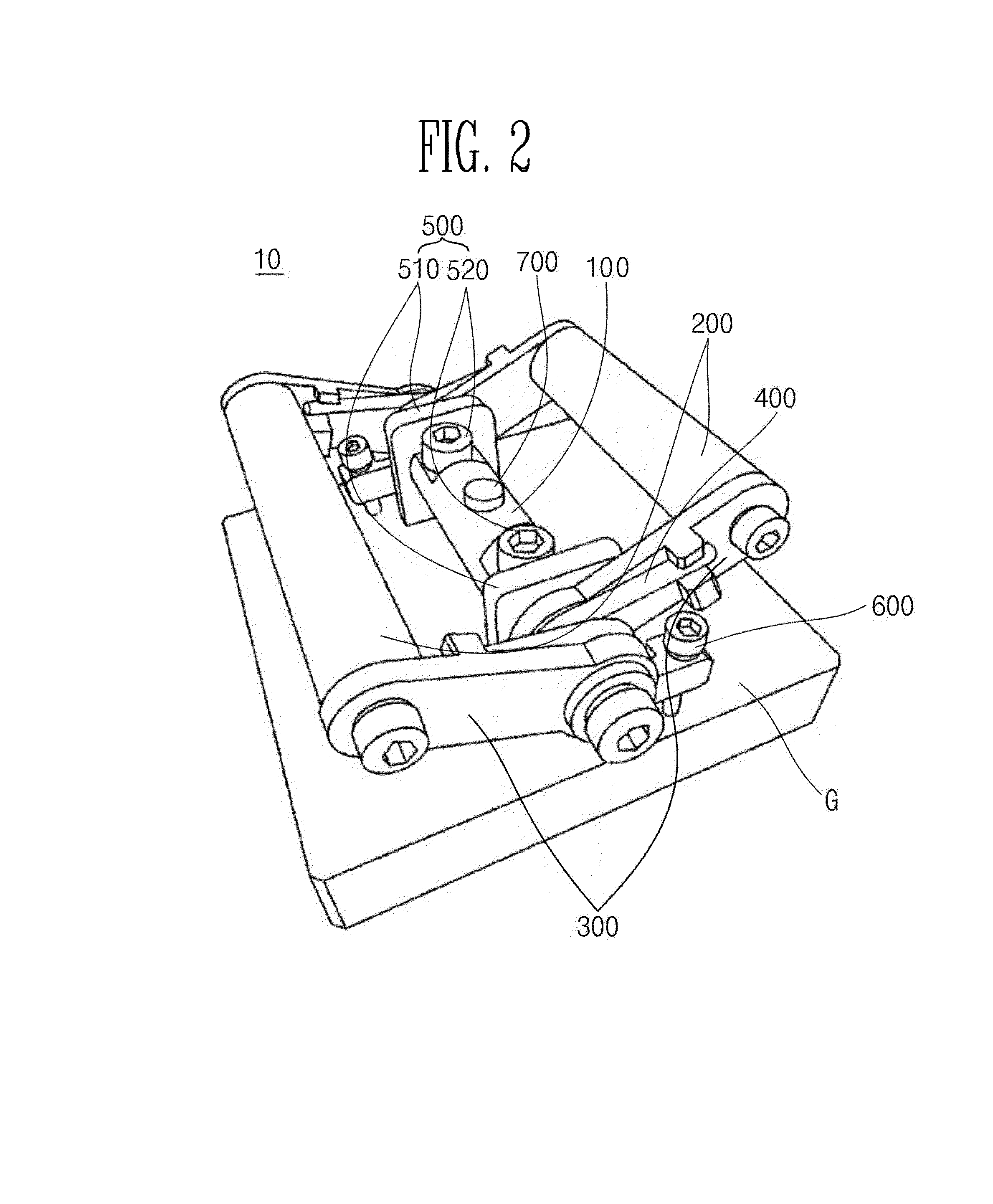

Surface emitting laser packaging fixture

InactiveCN102658447ASimple structureEasy to moveWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSemiconductor

The invention discloses a surface emitting laser packaging fixture, relates to the technical field of semi-conductor optoelectronics, solves the problem that a packaging machine for packaging a surface emitting laser is high in welding cost, poor in mobility, and infirm in fixing and has deviation easily. The surface emitting laser packaging fixture comprises a fixture main body; the middle of the fixture main body is provided with a rectangular sinking structure, and two ends of the fixture main body are provided with bulge structures in the same width; the middle of a bulge structure at one end is provided with a sliding groove; the fixture also comprises an ejector rod, a left fastening part and a right fastening part; the ejector rod penetrates through the sliding groove and is movably connected with the fixture main body; a spring is sleeved in the ejector rod; the left fastening part and the right fastening part are respectively provided with a length adjusting groove; and the left fastening part and the right fastening part are fixed with the fixture main body through adjusting screws in the length adjusting grooves. The surface emitting laser packaging fixture is simple in structure, high in mobility, small in deviation and easy and convenient to operate, and improves the efficiency of a welding process.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

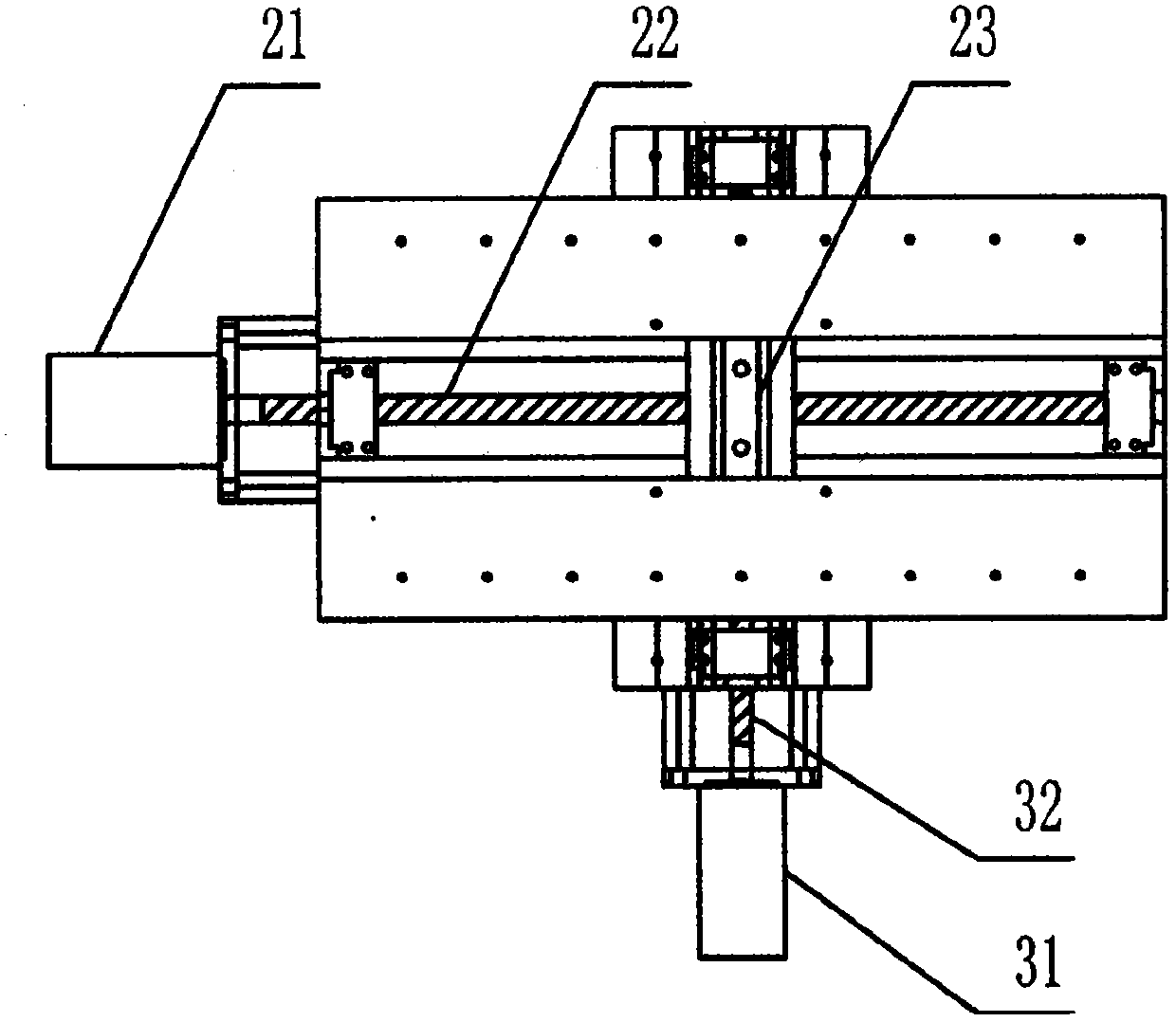

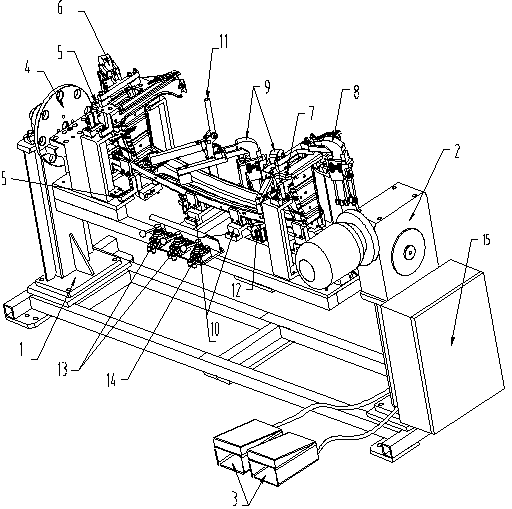

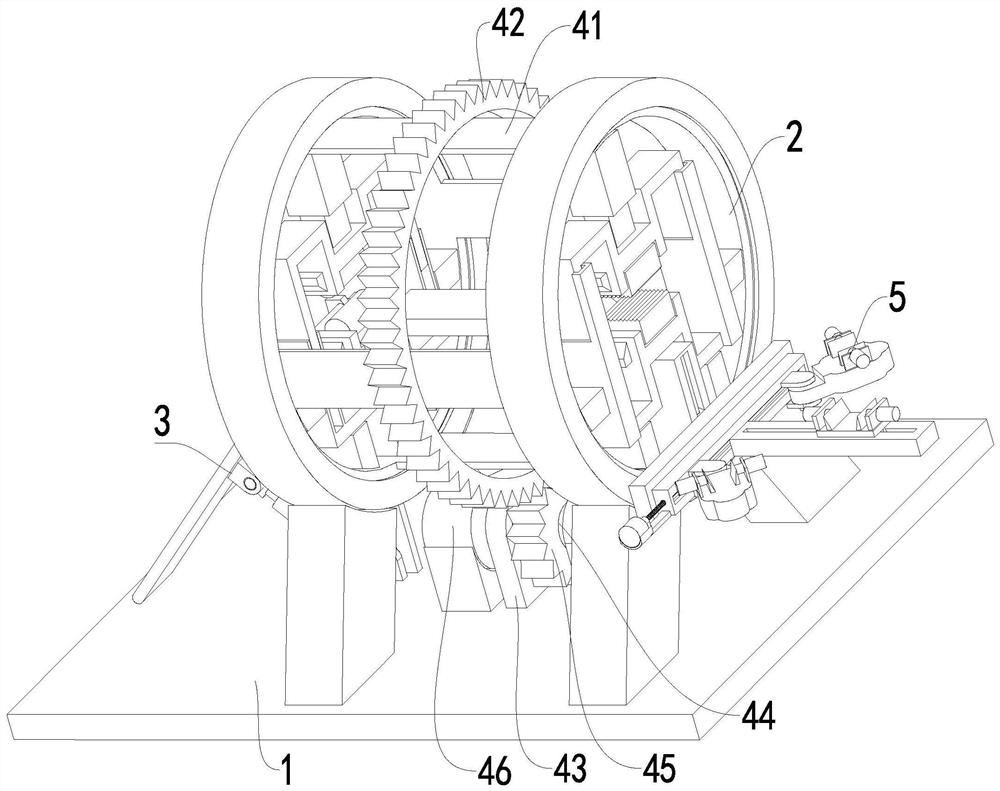

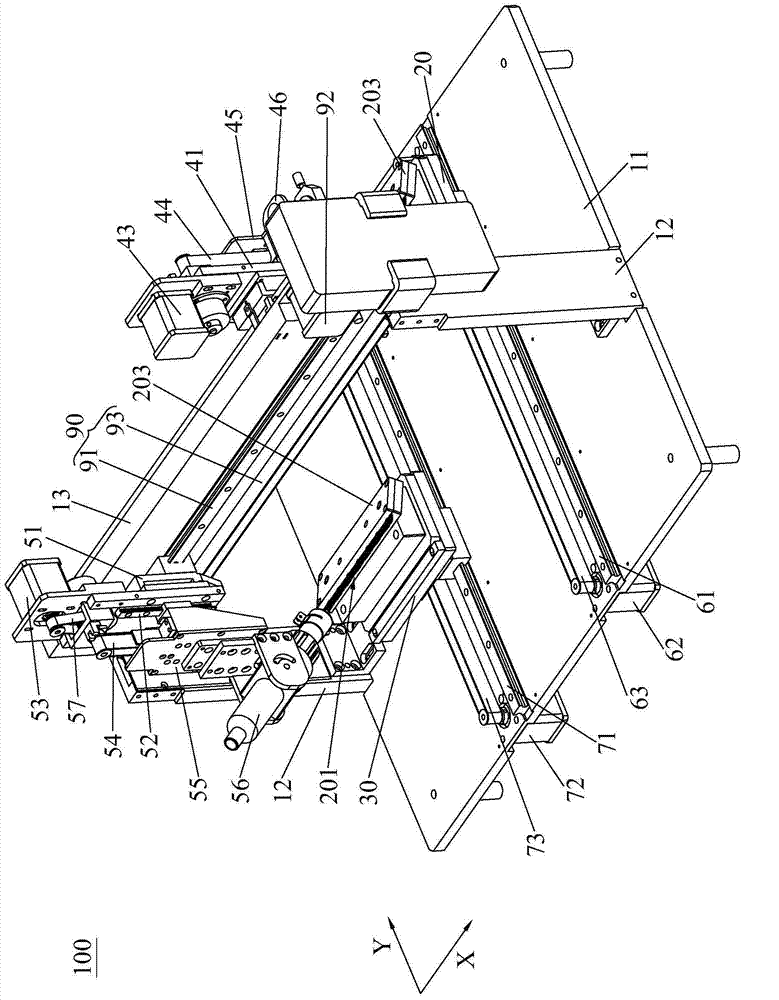

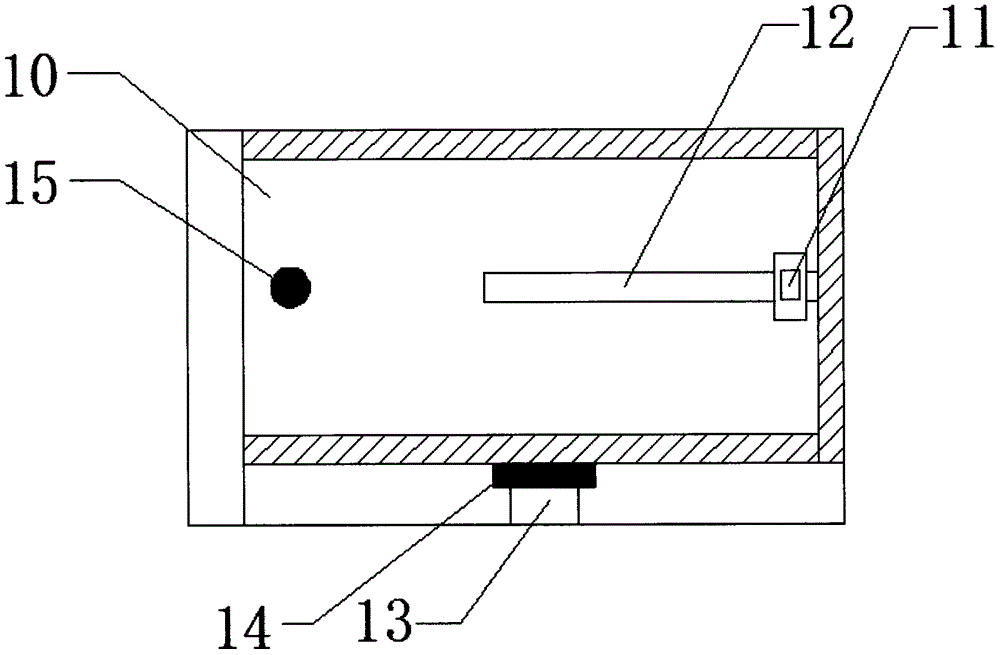

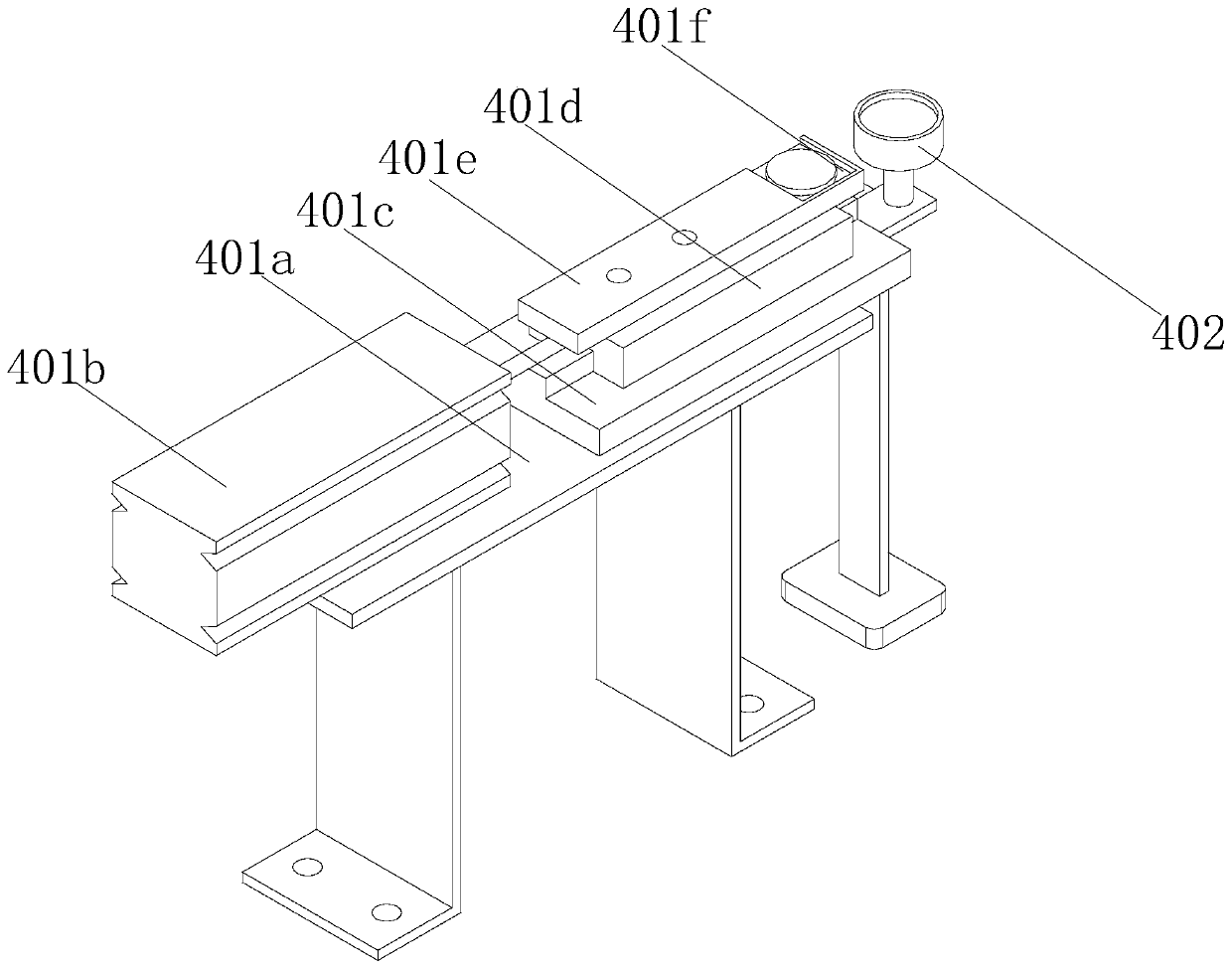

Diamond cutting tool welding machine and matrix position control method

ActiveCN106862814AAutomatically adjust the positionImprove welding process efficiencyWelding/cutting auxillary devicesOther manufacturing equipments/toolsDiamond cuttingElectricity

The invention provides a diamond cutting tool welding machine and a matrix position control method, and belongs to the technical field of machine tools. The diamond cutting tool welding machine and the matrix position control method solve the problems that the position of a j matrix of a diamond cutting tool needs to be adjusted once every time an existing diamond cutting tool welding machine machines one diamond cutting tool, and consequently the machining efficiency is influenced. The diamond cutting tool welding machine comprises a rack and a lifting plate. An electronic sensing element used for monitoring whether a to-be-welded point of a matrix is located at a set welding position or not is further mounted on the rack. The diamond cutting tool welding machine further comprises a control circuit, and the electronic sensing element and a motor are both electrically connected with the control circuit. When a diamond cutting tool is welded, the actual position of the to-be-welded point of the matrix is located below the set welding position, the control circuit controls a spindle of the motor to continuously rotate till the electronic sensing element monitors that the position of the to-be-welded point of the matrix is consistent with the set welding position, and the control circuit controls the motor to stop rotating according to a monitor signal of the electronic sensing element.

Owner:项俊俊

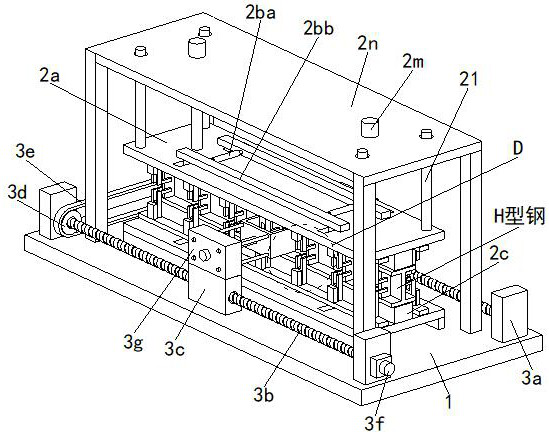

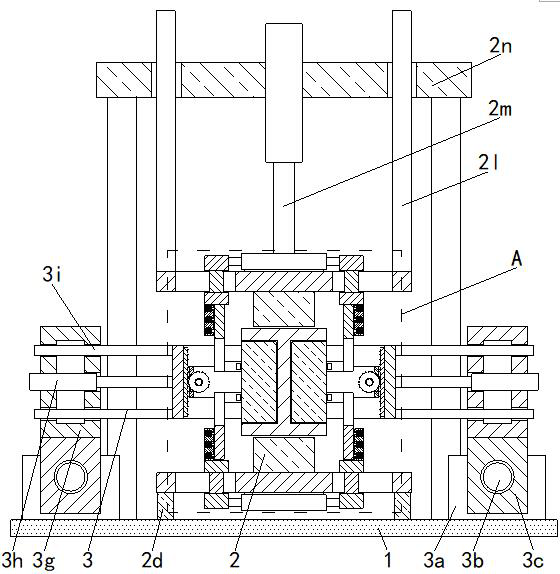

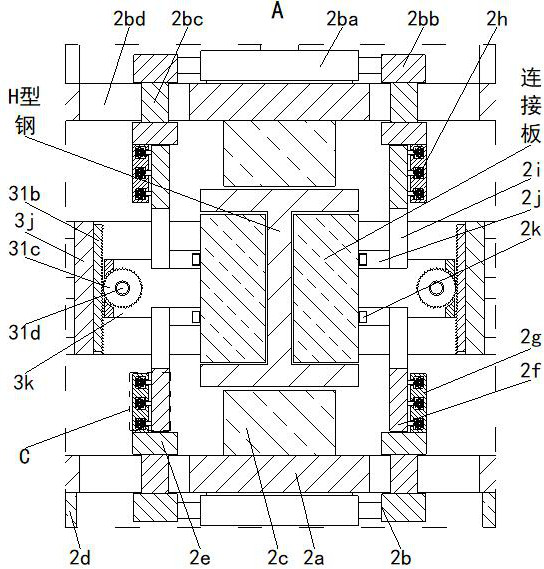

Building steel structure manufacturing, welding and machining integrated equipment

ActiveCN113385849AFirmly connectedHigh compressive strengthWelding/cutting auxillary devicesAuxillary welding devicesConstruction engineeringCompressive strength

The invention provides building steel structure manufacturing, welding and machining integrated equipment. The building steel structure manufacturing, welding and machining integrated equipment comprises a workbench, a clamping device and a welding device. According to the building steel structure manufacturing, welding and machining integrated equipment, H-shaped steel is involved in the using process of a building steel structure, connecting plates are welded to the H-shaped steel in the actual using process to enhance the compressive strength of the H-shaped steel and provide convenience for the H-shaped steel to be connected with other steel structures through the connecting plates, and in the process of welding the connecting plates on the H-shaped steel, the following problems that before welding, the connecting plates need to be uniformly mounted on the H-shaped steel manually and are symmetrically distributed on the two sides, the manual operation has uncertainty and cannot ensure that the adjacent connecting plates are uniformly distributed, so that the compressive strength of each part of the H-shaped steel is non-uniform, meanwhile, symmetrical arrangement of the connecting plates on the two sides cannot be guaranteed, and connection between the H-shaped steel and other steel structures through the connecting plates is affected are solved.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

A vacuum electron beam welding method for solid rocket motor combustion chamber shell

ActiveCN107182225BShorten the production cycleReduce labor intensityElectron beam welding apparatusRocket engine plantsPorosityCombustion chamber

The invention discloses a vacuum electron beam welding method for a combustion chamber shell of a solid rocket motor, which comprises the following steps: determining a component assembly scheme and designing technical equipment; formulating a welding process scheme and technical regulations. Compared with the prior art, the method adopted by the present invention has the advantages and beneficial effects as follows: the quality of the weld seam is good, and the X-ray inspection confirms that there are no defects such as excessive air holes, unfused, cracks, etc.; the welding processing efficiency is high, the processing cost is low, and the single The production cycle is shortened and the labor intensity is reduced.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

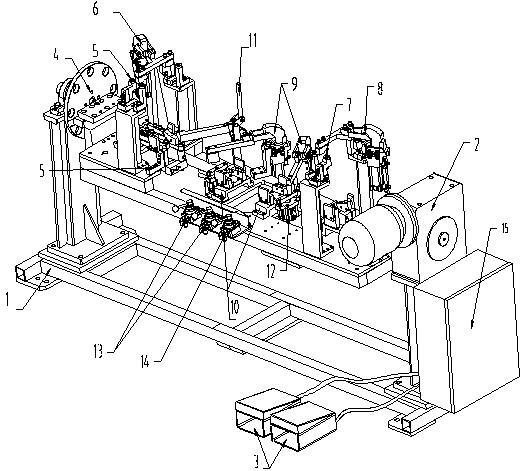

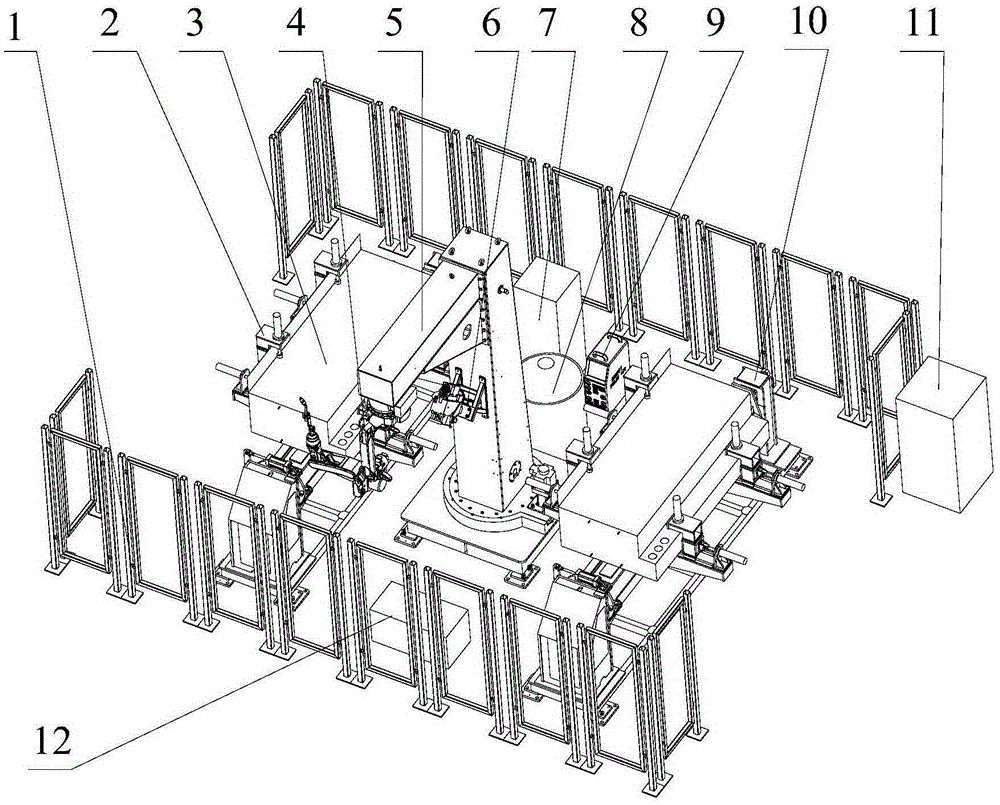

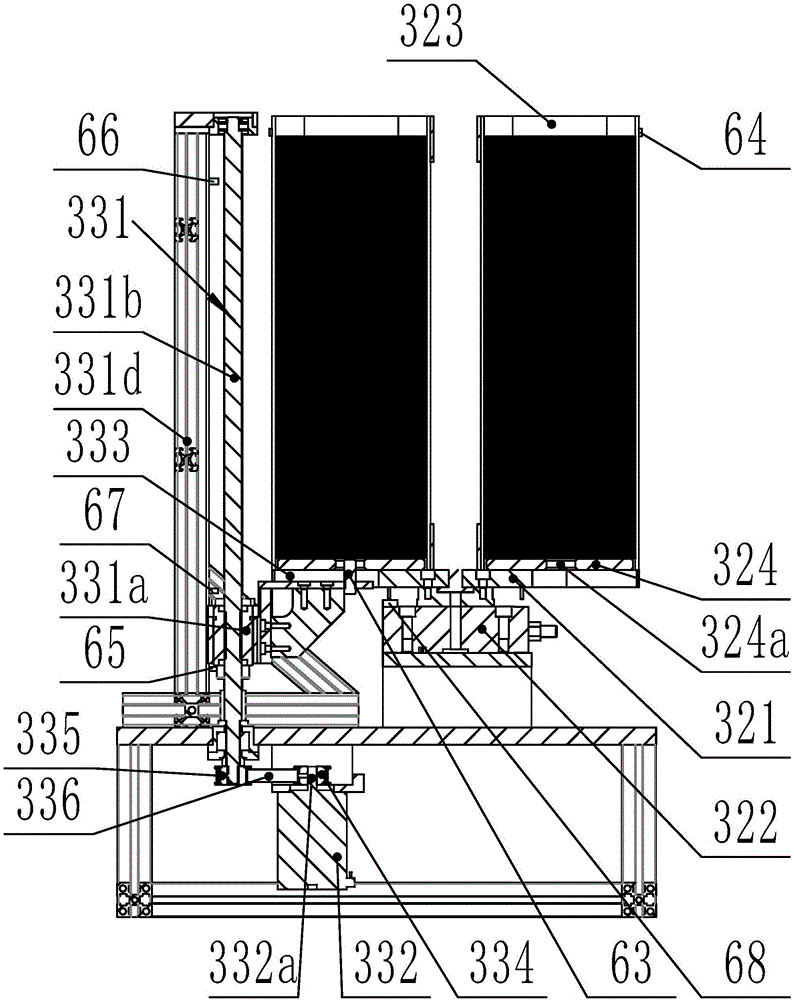

Welding production line suitable for switching of various vehicles

InactiveCN106583970AQuick switchEasy to storeWelding/cutting auxillary devicesAuxillary welding devicesProduction lineControl theory

The invention provides a welding production line suitable for switching of various vehicles and belongs to the technical field of automotive part welding and machining equipment. A servo translating track (3) of a servo translating component (2) of the welding production line suitable for switching of various vehicles is perpendicular to a vehicle body conveying track (1), a servo trailer wagon (4) is arranged on the servo translating track (3), a plurality of storage regions (5) are arranged on two sides of the servo translating track (3), and each storage region (5) is a structure in which a machining clamp (6) can be stored. The welding production line suitable for switching of various vehicles is simple in structure and low in cost; production clamps are stored conveniently; the production clamps suitable for different vehicles are arranged simultaneously, switching of the different production clamps can be realized conveniently and rapidly when parts of the different vehicles are welded, therefore, the welding and machining efficiency of the parts of the different vehicles is improved effectively, the investment of equipment of the production line is reduced, and the occupied area of the production line is also reduced.

Owner:ANHUI RUIXIANG IND

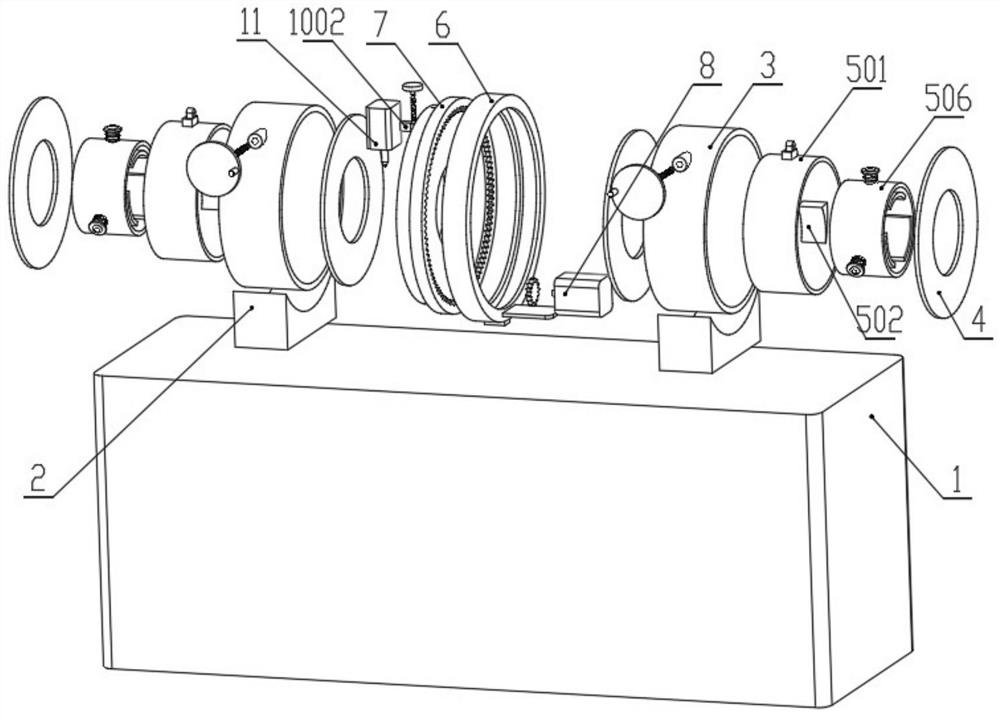

Automatic welding device and method for pipeline butt-joint machining

InactiveCN114029693AGuaranteed accuracy and stabilityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeManufacturing engineering

The invention discloses an automatic welding device and method for pipeline butt-joint machining. The automatic welding device comprises a workbench, fixing seats, clamping frame bodies, side cover plates and clamping adjusting mechanisms, wherein the fixing seats are connected to the left side and the right side of the upper end face of the workbench; the clamping frame body is fixedly connected to the position of the upper side of the fixing seat; the side cover plates are connected to the left side and the right side of the clamping frame body; and the clamping adjusting mechanism is arranged in the clamping frame body. According to the automatic welding device for pipeline butt-joint machining, steel pipes can be conveniently, rapidly and stably clamped and fixed, so that the butt-joint precision and stability of the steel pipes can be effectively guaranteed, the welding quality of the steel pipes is improved, the steel pipes can be conveniently, automatically and uniformly welded, the welding machining efficiency of the steel pipes is improved, the steel pipes with different diameters can be conveniently welded through adjustment of a distance adjusting mechanism, and the applicability of the welding device is improved.

Owner:NANJING NIEBO INTERNET OF THINGS TECH CO LTD

Welding machine and welding processing method thereof

ActiveCN104722876ASimple structureSimple and convenient welding operationHeating appliancesMetal working apparatusEngineeringMechanical engineering

The invention discloses a welding machine. The welding machine comprises a rack, a first carrier, a welding flux feeding device, a welding flux solidifying device, a first transporting device, a feeding transporting device and a solidifying transporting device, wherein the first transporting device, the feeding transporting device and the solidifying transporting device are arranged on the rack. The rack is provided with a welding flux containing station, a solidifying station and a first processing route, wherein the welding flux containing station and the solidifying station are distributed along the Y axis, and the first processing route is distributed along the X axis which staggers the Y axis. The first transporting device drives the first carrier to carry out reciprocating movement between the welding flux containing station and the solidifying station along the Y axis. The welding flux feeding device is opposite to the welding flux containing station. The feeding transporting device can drive the welding flux feeding device to carry out reciprocating movement in the first processing route, so that welding flux feeding is carried out on a product loaded by the first carrier which moves to the welding flux containing station by the welding flux feeding device. The welding flux solidifying device is opposite to the solidifying station. The solidifying transporting device can drive the welding flux solidifying device to carry out reciprocating movement in the first processing route, so that heating and solidifying are carried out on the product loaded by the first carrier which moves to the solidifying station by the welding flux solidifying device.

Owner:DONGGUAN SANXIN PRECISION MACHINERY

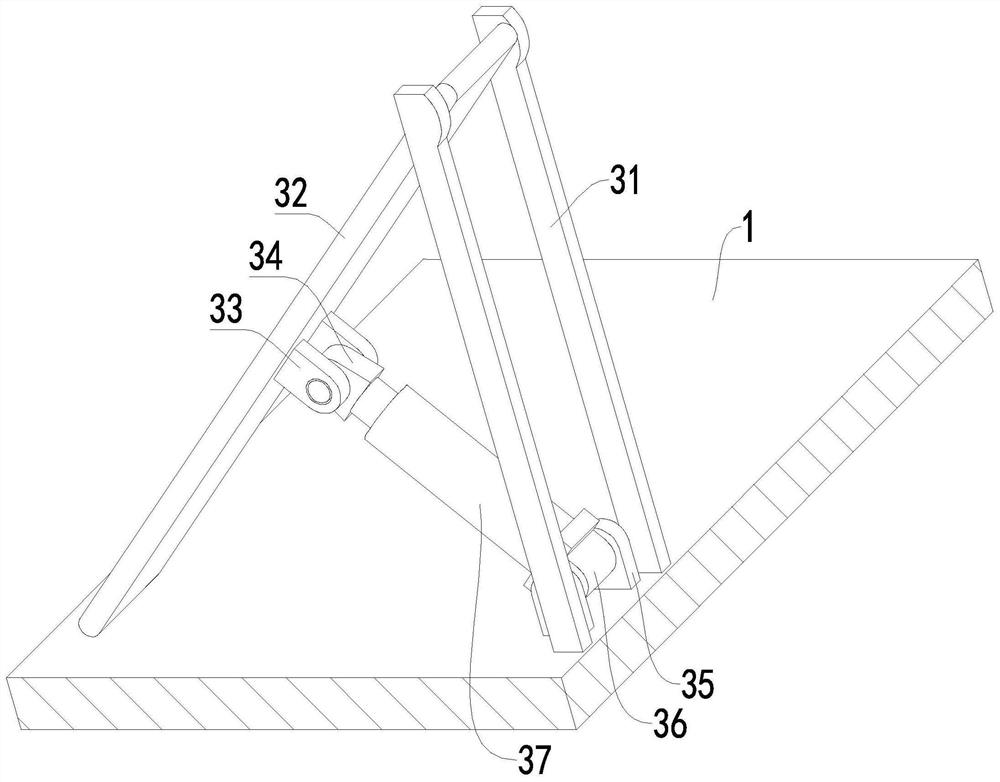

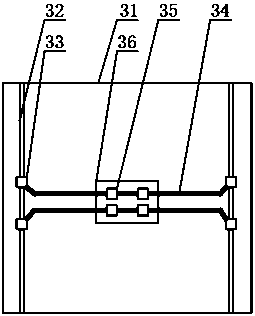

I-steel overturning welding device

InactiveCN108620799ARealize automatic flipImprove turnover efficiencyWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

An I-steel overturning welding device comprises a base on which a door frame is arranged, wherein a motor is arranged at one side of the base; one end of a telescoping rod is fixed to a motor; a sliding seat is arranged on the other side of the base, and the sliding seat can slide on the base in the direction toward the motor; a supporting seat is arranged on the sliding seat, and a first hydraulic cylinder is fixed to the supporting seat; a welding gun fixing seat is arranged on a pushing rod of the first hydraulic cylinder, and a first welding gun is arranged on the welding gun fixing seat and is horizontally positioned in the motor direction; a second hydraulic cylinder is arranged on the door frame, and a pushing rod of the second hydraulic cylinder is vertically downward; a second welding gun is arranged on the pushing rod; a working plate is arranged on the sliding seat; on end of the working plate is hinged with the top surface of the sliding seat; and one end, far away from themotor, of a telescoping rod is hinged with the bottom surface of the working plate. According to the device adopting the abovementioned structure, an I-steel can be automatically welded during welding processing, and moreover, the accuracy of a welding position is ensured, so that the welding efficiency is improved, and meanwhile, the welding quality is ensured.

Owner:宜昌众友机械有限公司

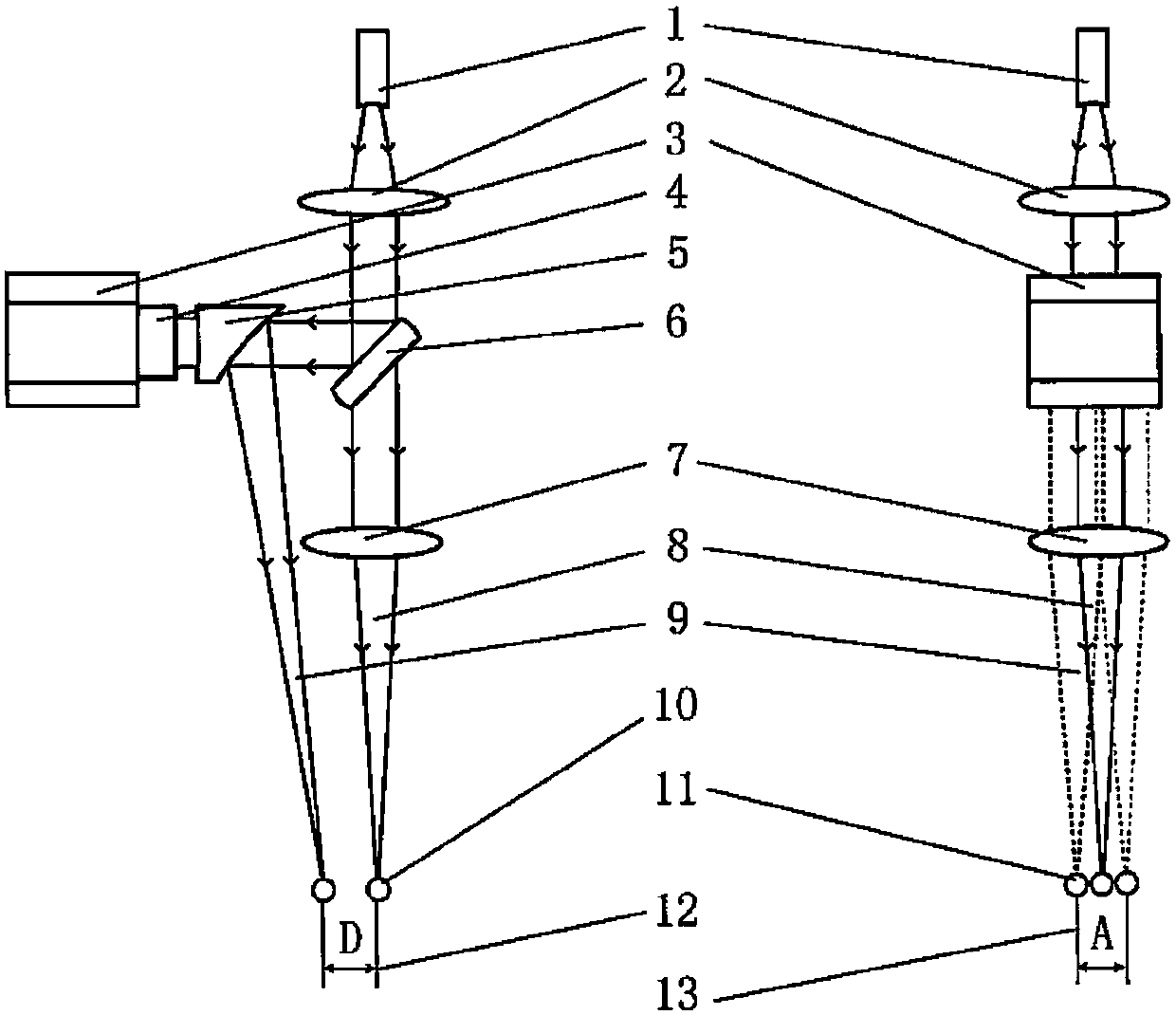

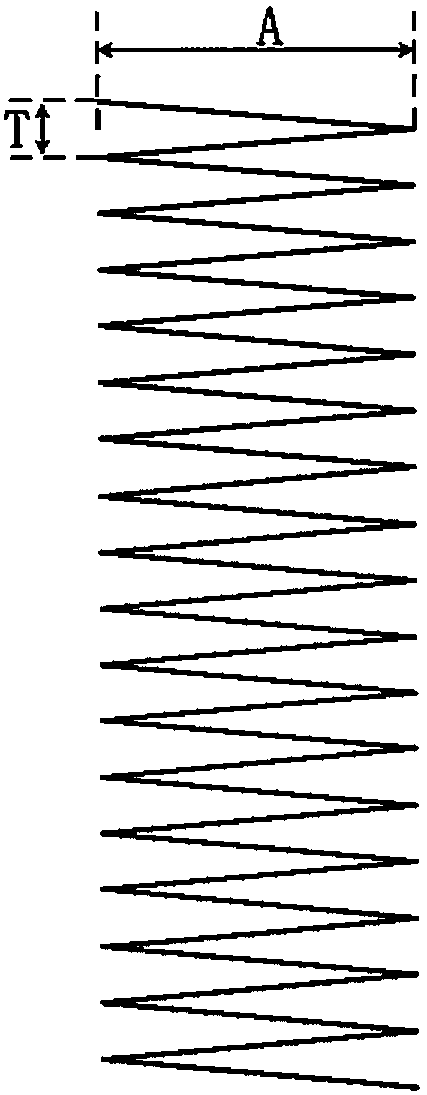

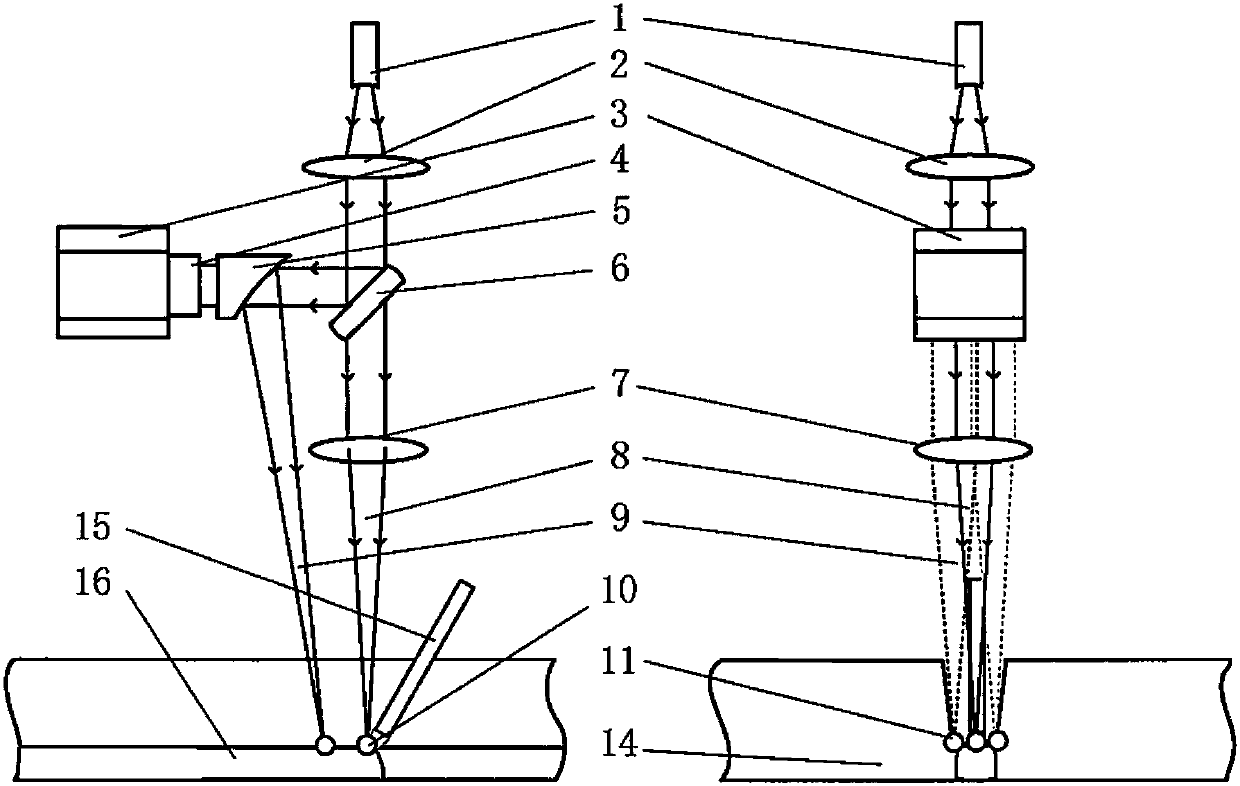

Laser double beam welding equipment and method

ActiveCN105772939BSolve the problem of non-fusionImprove welding qualityLaser beam welding apparatusBeam splitterLight beam

The invention discloses a laser double-beam welding device and method. The laser double-beam welding device comprises a beam splitter and a laser scanning device. The beam splitter is used for splitting an initial laser beam transmitted to the beam splitter into a first beam and a second beam, wherein the first beam is used for acting on welding flux. The laser scanning device is used for scanning the input second beam into a swinging light beam, wherein the swinging light beam is emitted in the direction roughly parallel to the spreading direction of the first beam and swings in the preset swinging direction in the emitting direction, and the swinging beam is used for acting on an area to be welded. According to the laser double-beam welding device and method, the problem that the area to be welded is not fused can be effectively solved, the welding quality is improved, and the stability in the welding process can be guaranteed as well. Meanwhile, repeatability in the welding process can be improved, and the welding efficiency can be better improved.

Owner:COMAC +1

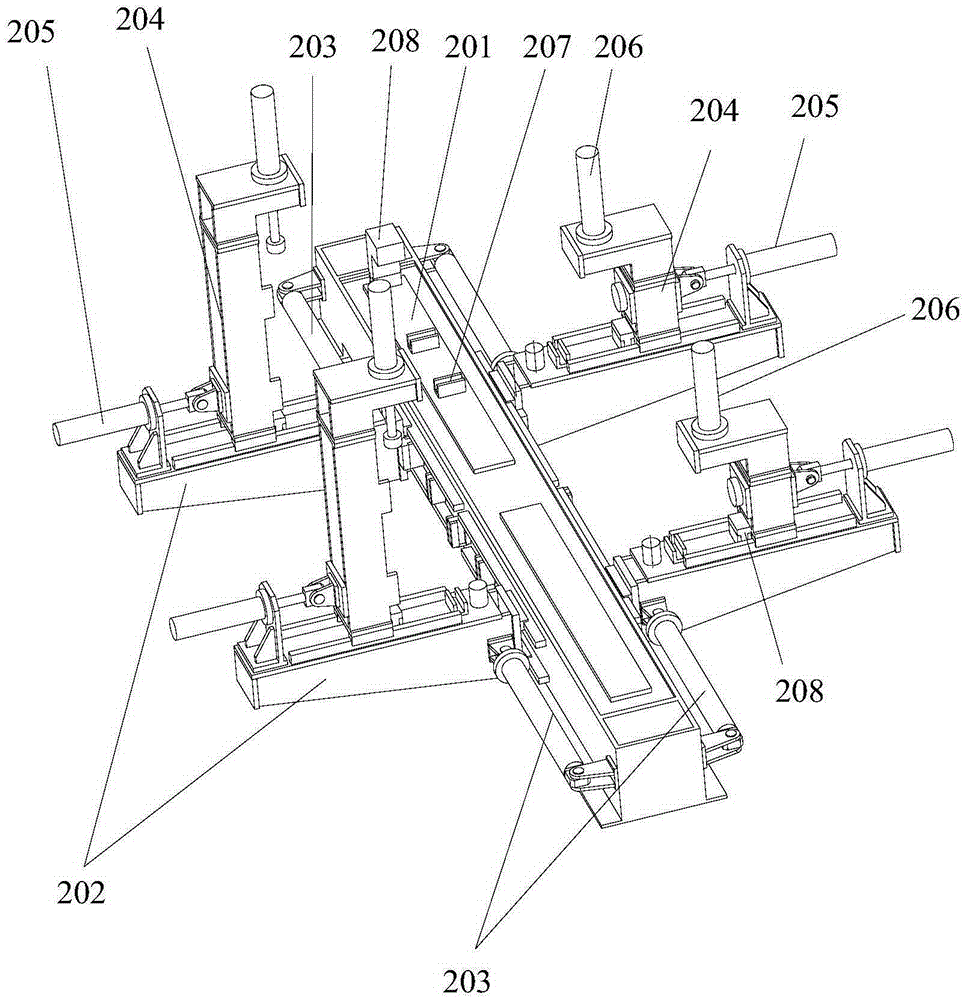

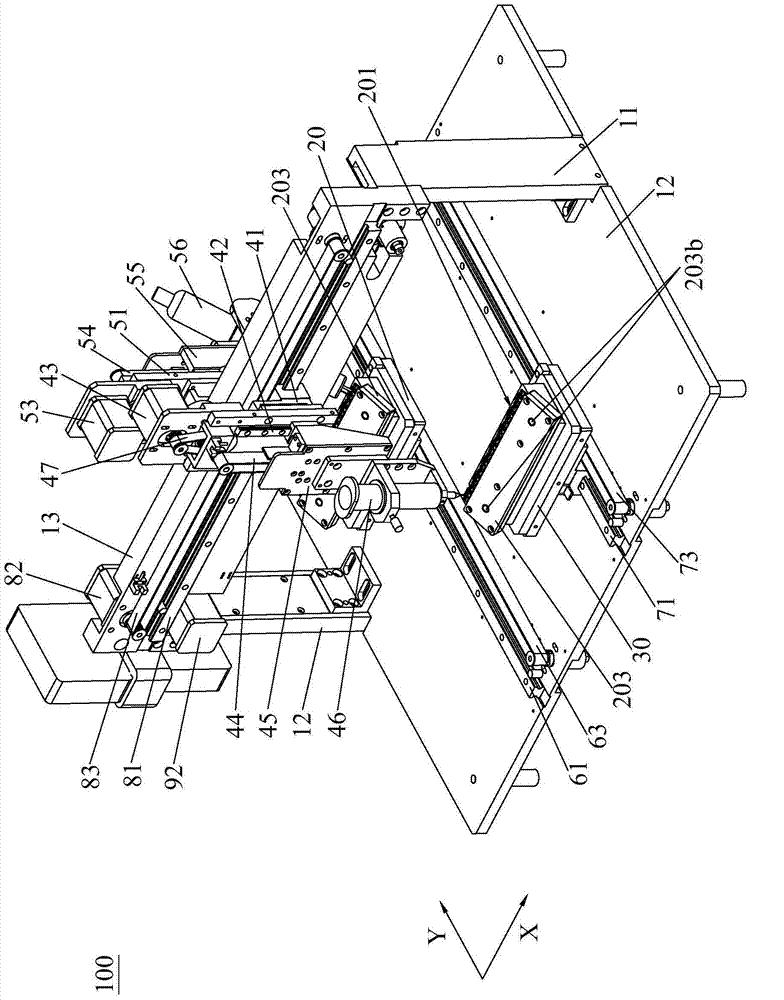

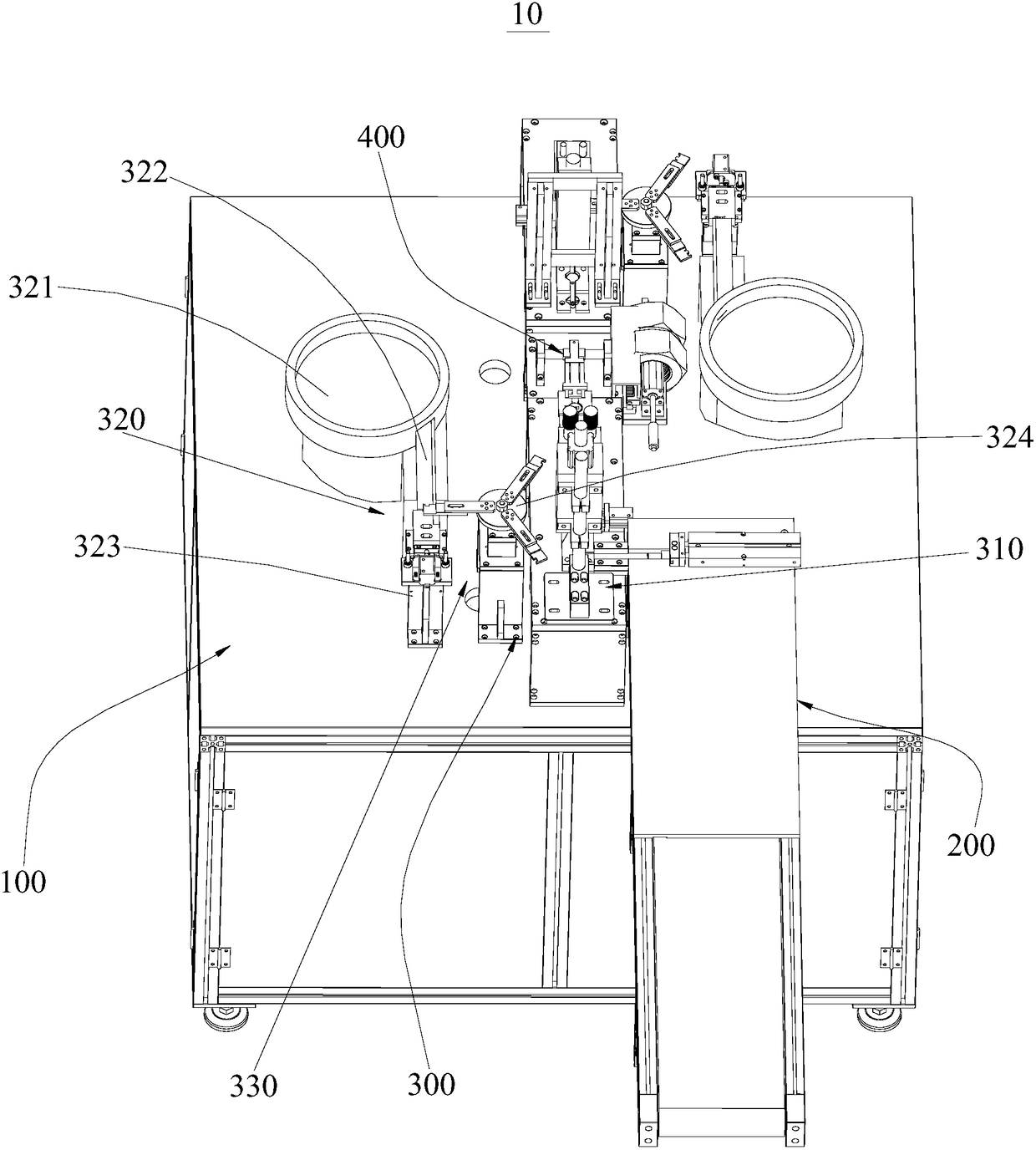

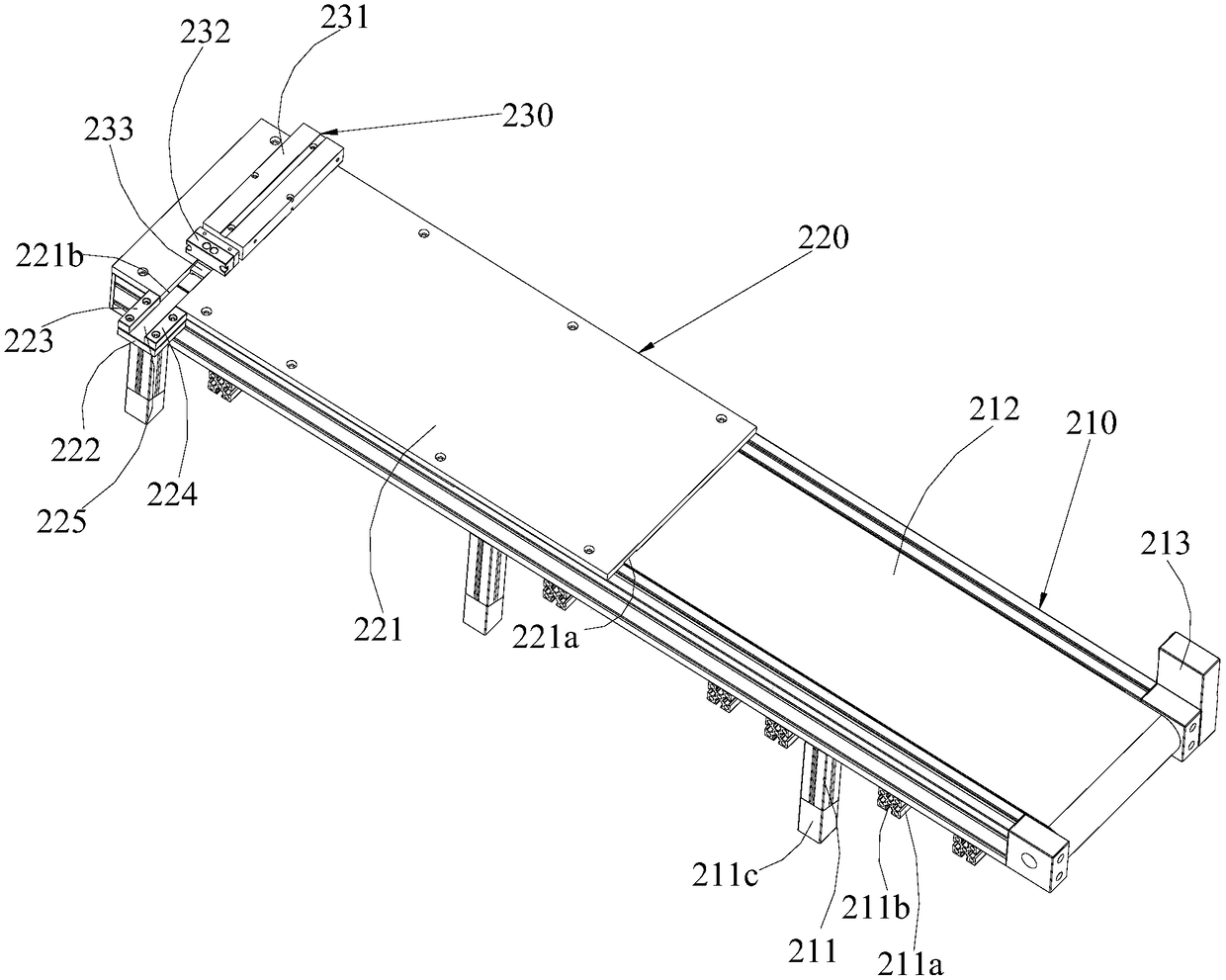

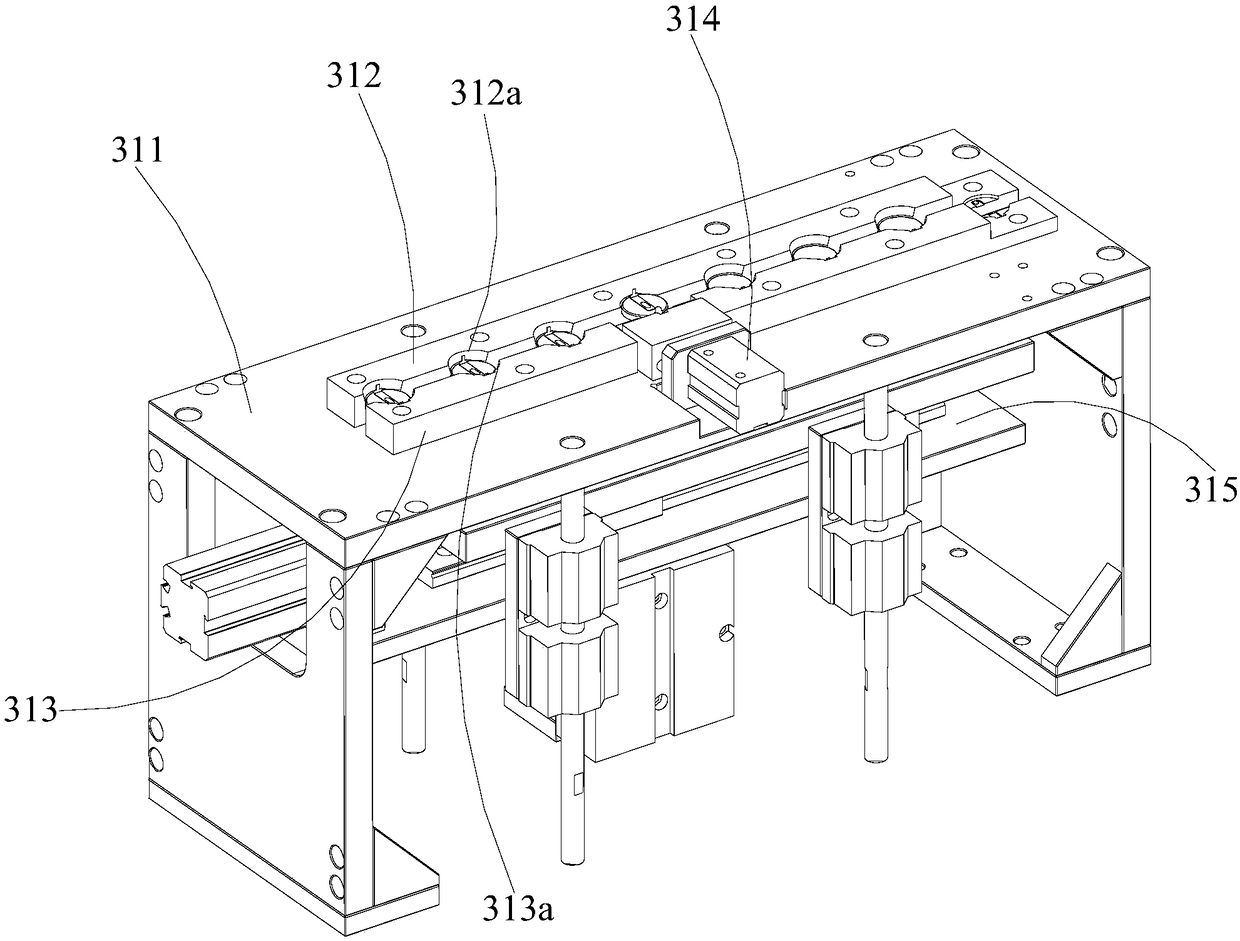

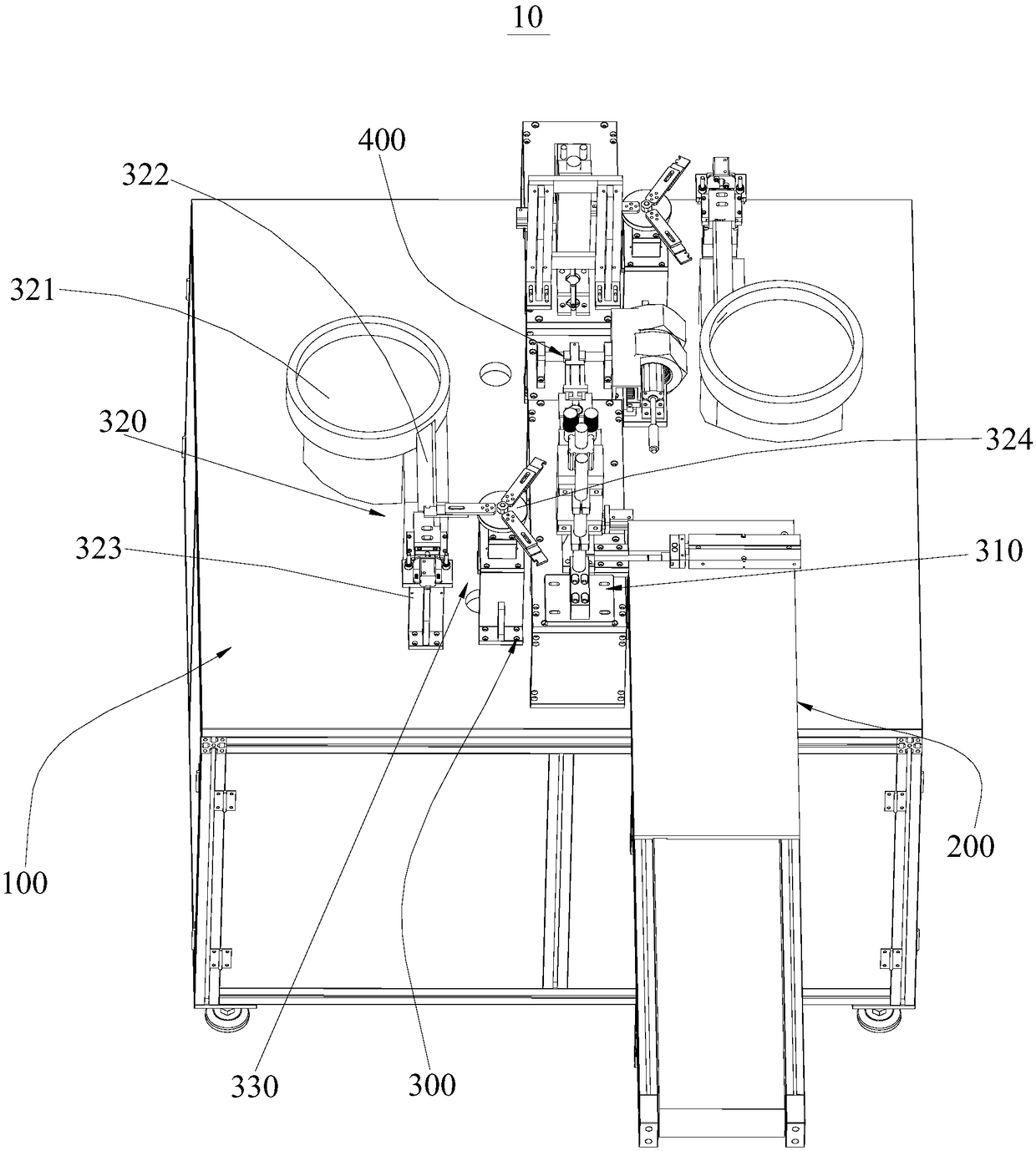

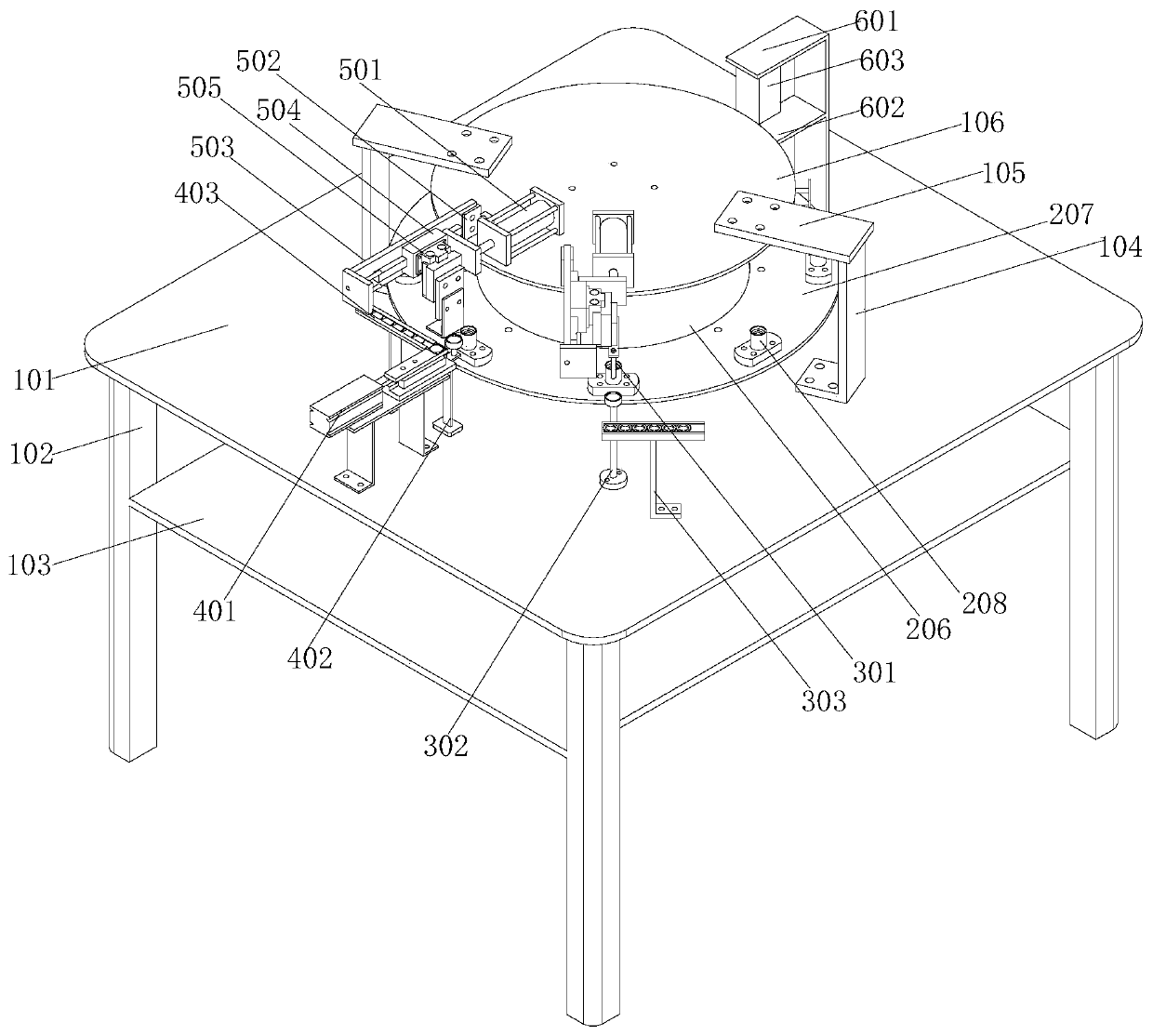

Chip transferring and spot-welding mechanisms and thermistor chip welding equipment with same

PendingCN108608128APrecise Welding OperationAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingThermistor

The invention provides chip transferring and spot-welding mechanisms and thermistor chip welding equipment with the chip transferring and spot-welding mechanisms. Each chip transferring and spot-welding mechanism comprises a chip welding and positioning device, a welded part feeding device and a chip welding device. Each welded part feeding device is installed on one side of the corresponding chipwelding and positioning device, each chip welding device is installed on the corresponding chip welding and positioning device, each chip welding and positioning device is used for performing weldingand positioning and transferring on chips, and each welded part feeding device is used for feeding welded parts to the corresponding chip welding and positioning device. The chip transferring and spot-welding mechanisms are provided with the chip welding and positioning devices, the welded part feeding devices and the chip welding devices, and thus feeding operation of the chips and the welded parts are completed; and meanwhile, the chips can be subjected to precise welding operation through the chip welding devices, the welding machining efficiency can be improved, the welding machining precision can also be improved, and damages to the chips due to the excessively high welding temperature are prevented.

Owner:惠州嘉科实业有限公司

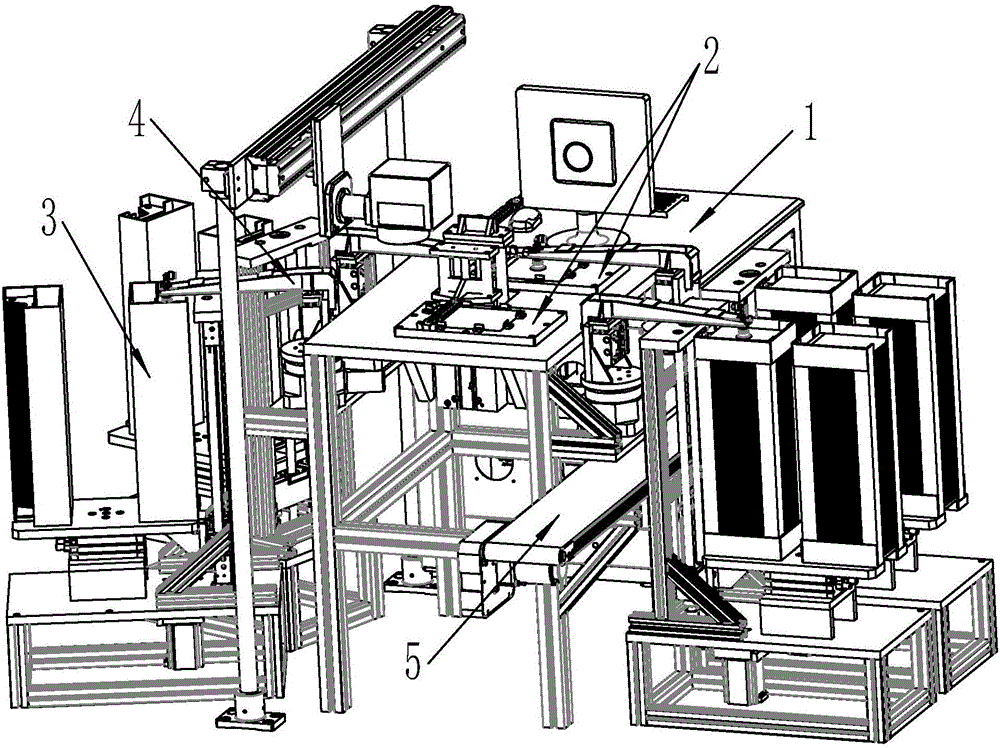

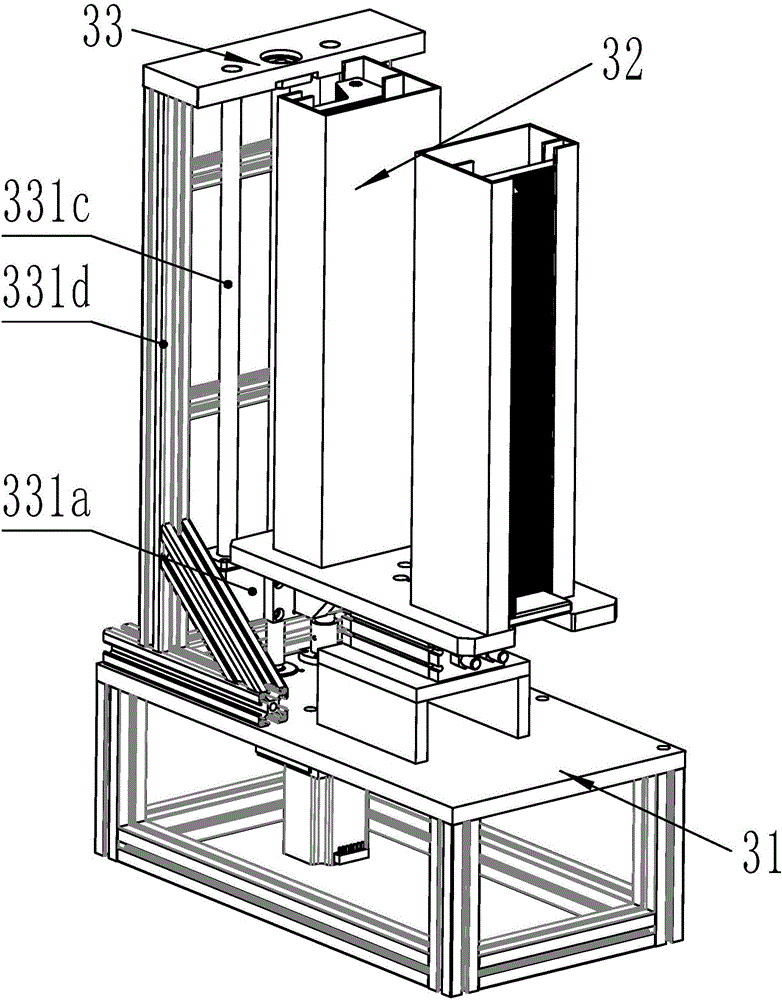

Laser welding auxiliary system

ActiveCN106271266ANovel structureEasy to implementWelding/cutting auxillary devicesAuxillary welding devicesWaste productSystem structure

The invention discloses a laser welding auxiliary system. The laser welding auxiliary system comprises a working platform, wherein at least one welding pressing table is arranged on the working platform; each welding pressing table is equipped with at least two material storing devices; each material storing device is equipped with a mechanical arm assembly; the mechanical arm assembly is used for grabbing a workpiece to be welded in the material storing device and putting the workpiece to be welded onto the welding pressing table. By adoption of the structure, the laser welding auxiliary system grabs the workpiece to be welded in the material storing device and puts the workpiece to be welded onto the welding pressing table through the mechanical arm assembly, and presses and positions the workpiece to be welded through the welding pressing table; the whole laser welding auxiliary system is novel in structure, greatly improves the degree of automation of laser welding, reduces the labor intensity of workers, improves the welding efficiency, effectively improves the welding quality, ensures the stability of the quality of a finished product, significantly reduces the occurrence rate of a waste product and thus reduces the production cost; therefore, the laser welding auxiliary system has extremely high practicality.

Owner:重庆金樾光电科技有限公司

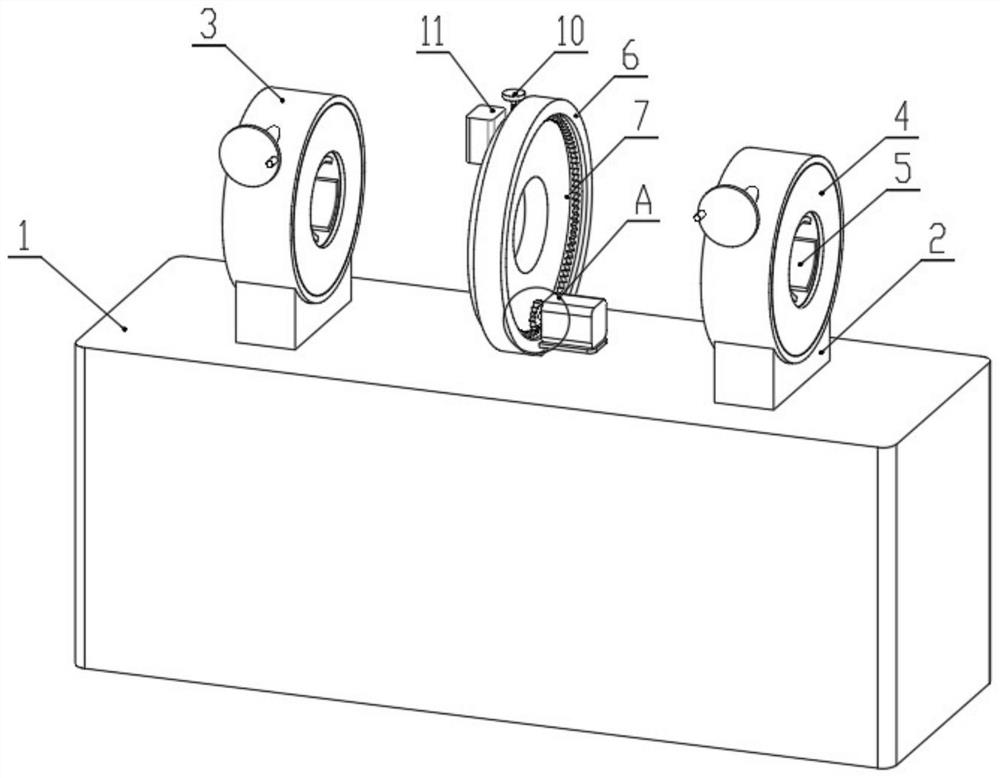

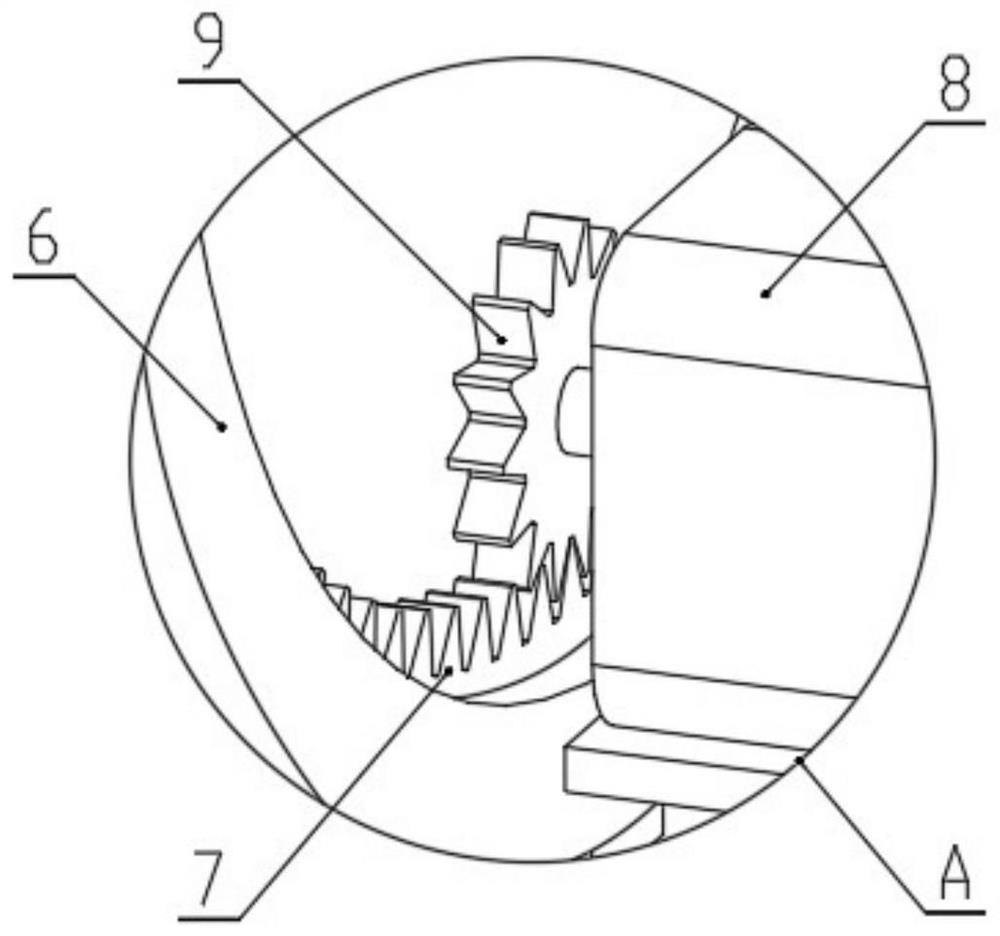

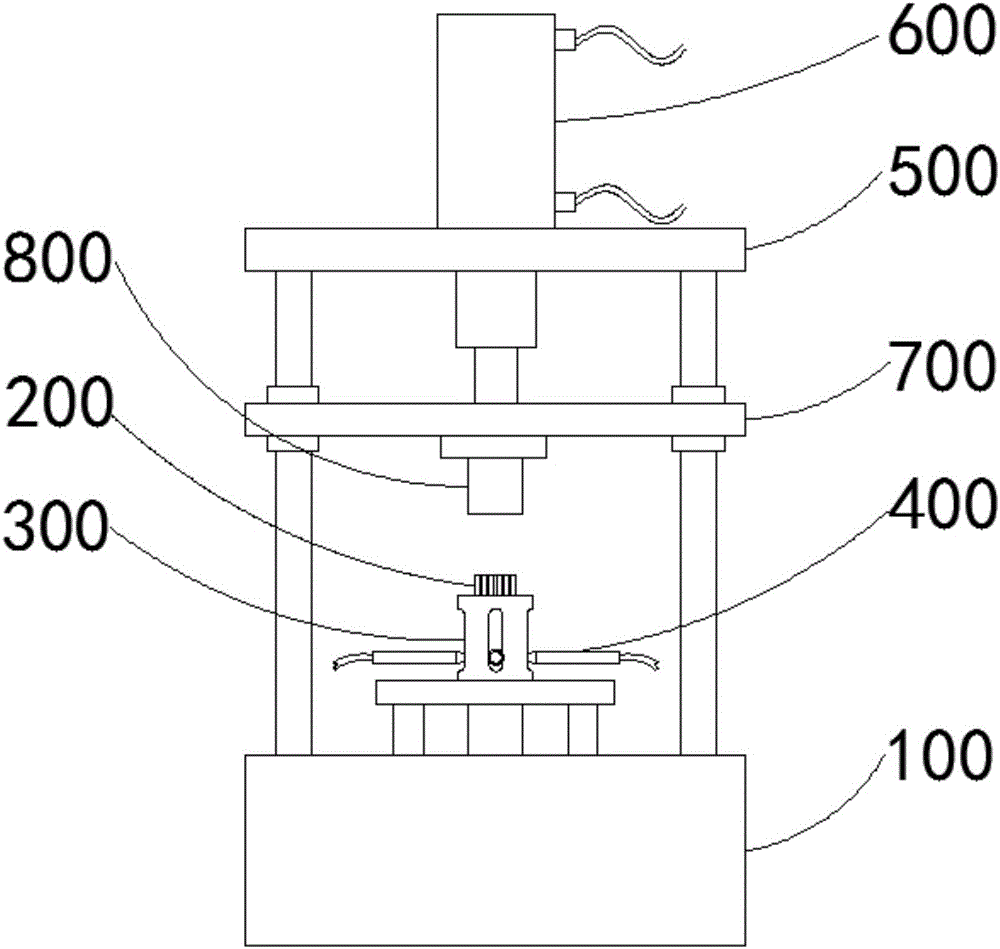

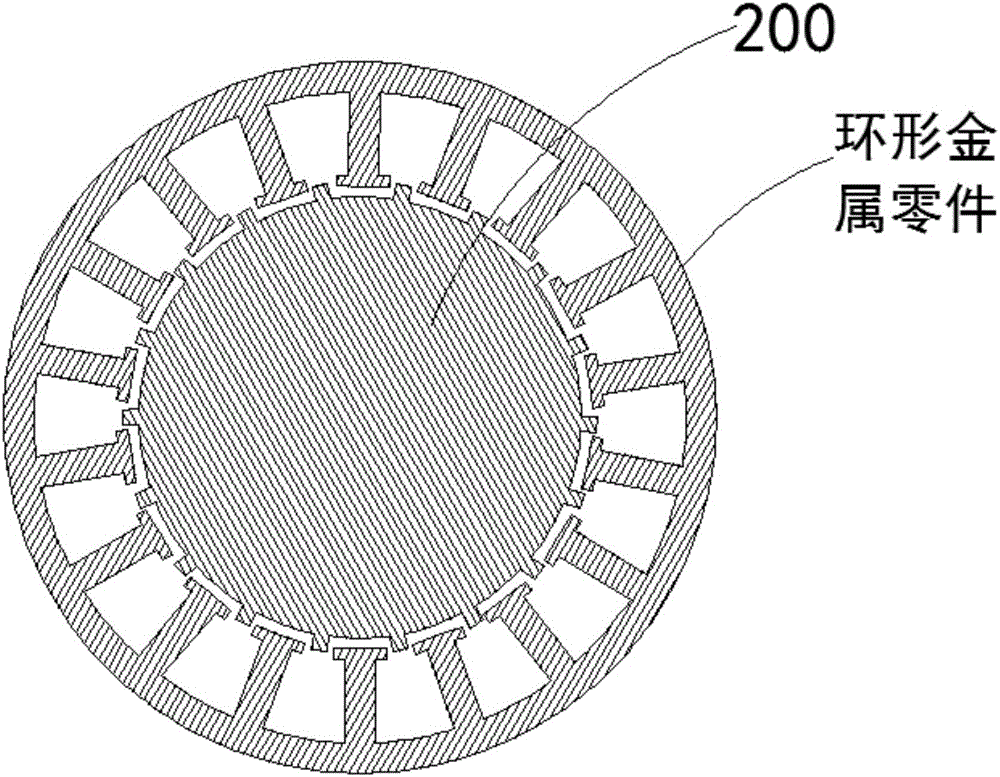

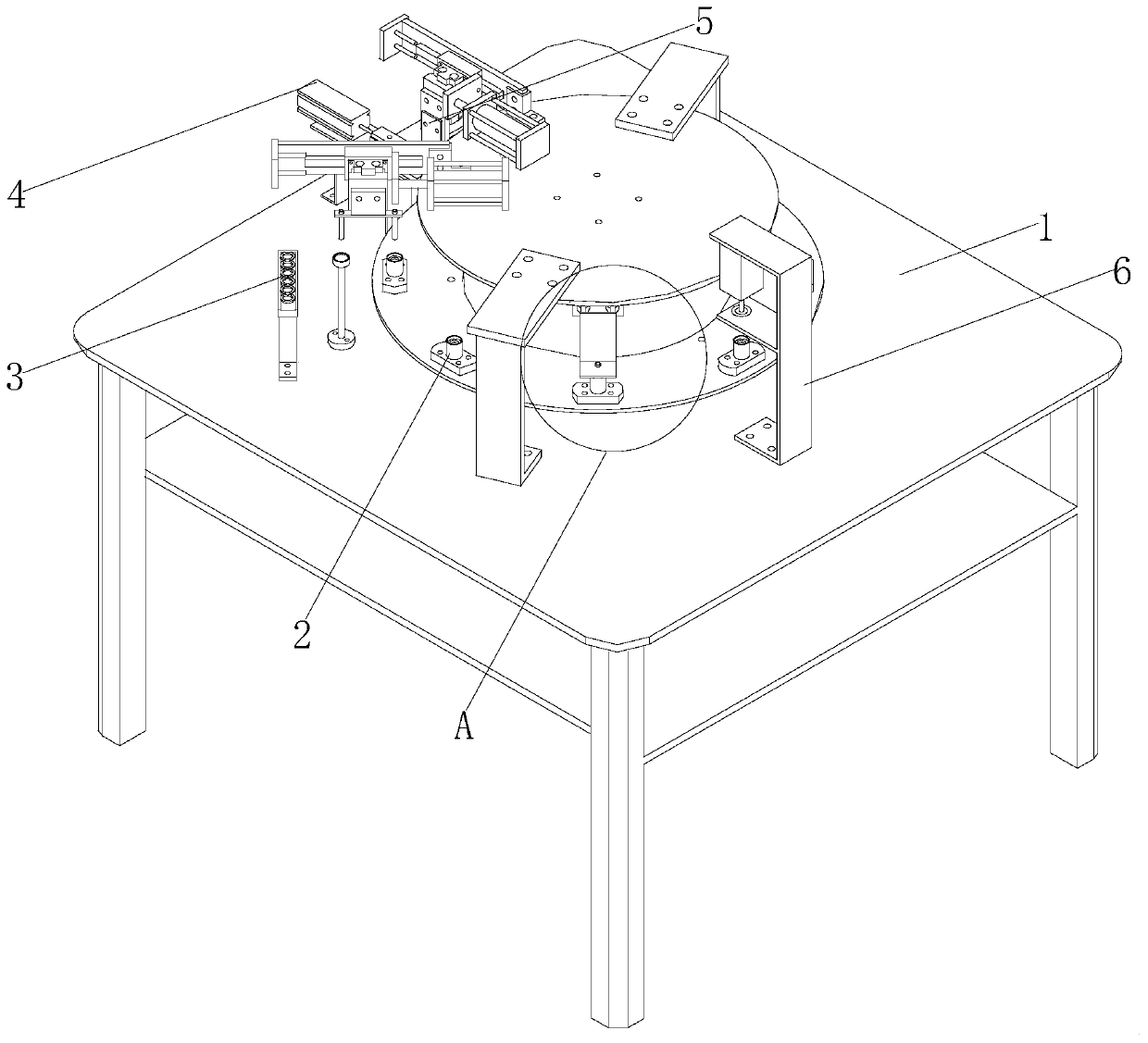

Welding equipment for ring-shaped metal parts

InactiveCN104999206AReduce labor intensityImprove welding process efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMetal

The invention provides welding equipment for ring-shaped metal parts and belongs to the technical field of part processing. The welding equipment comprises a machine station, wherein a clamping device and a welding device are arranged on the machine station; the clamping device comprises a vertically arranged clamping upright column adopting a cylindrical shape, and a plurality of clamping strips are arranged on the outer wall of the clamping upright column, uniformly arranged in the circumferential direction of the clamping upright column at intervals, and matched with clamping grooves in the inner wall of a ring-shaped metal part; the welding device comprises a plurality of welding guns arranged in the radial direction of the clamping upright column and are uniformly arranged in the circumferential direction of the clamping upright column at intervals, and welding nozzles of the welding guns right face the outer wall of the clamping upright column. The welding equipment for the ring-shaped metal parts adopts the plurality of welding guns for simultaneous welding processing, so that not only can the labor intensity of an operator be reduced effectively and the welding processing efficiency be improved, but also the welding effect can be improved greatly and defects in the prior art can be overcome.

Owner:CHONGQING FENGYANG ELECTROMECHANICAL

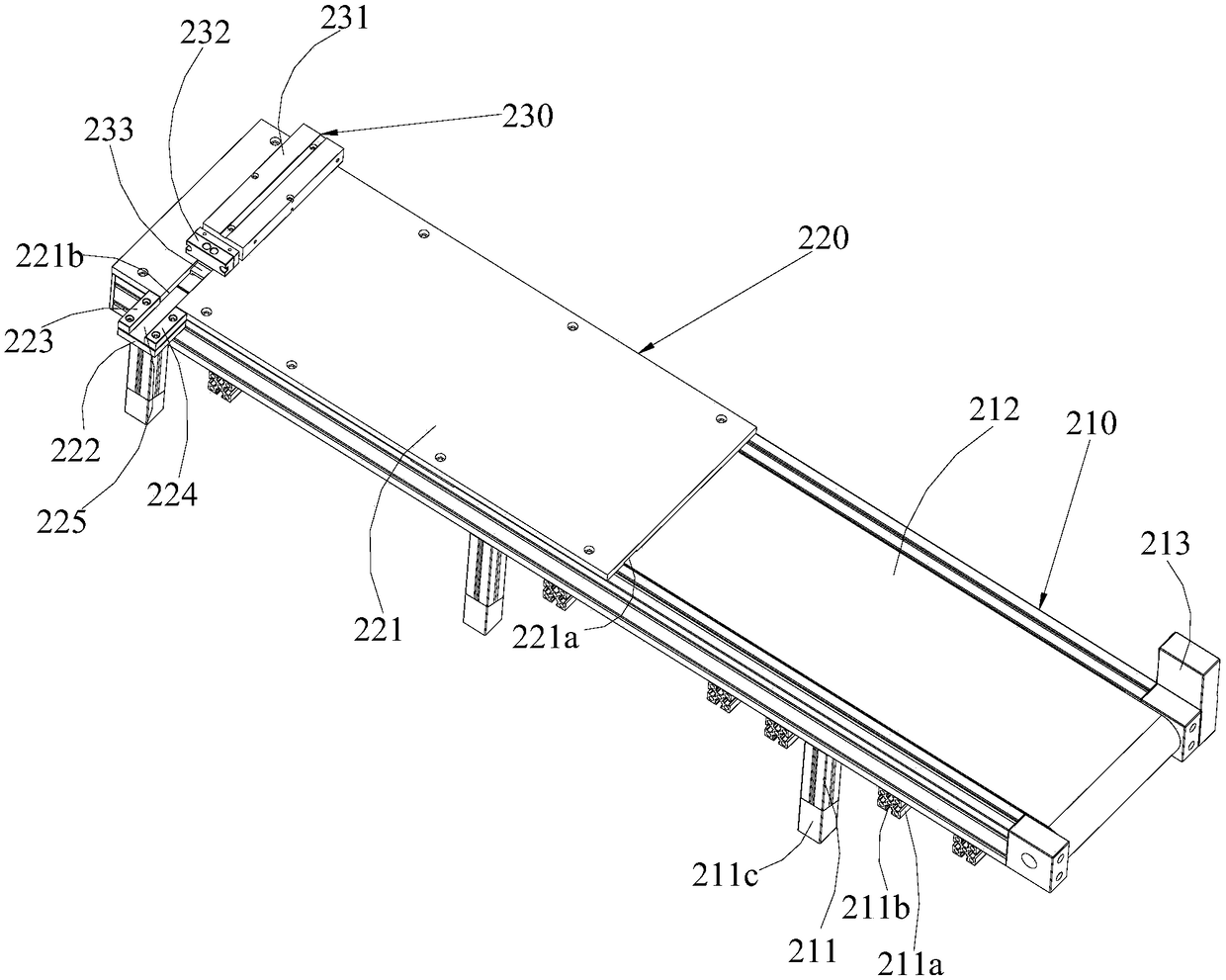

Multi-layer station lifting and transmission equipment

PendingCN111112825ASave human effortImprove efficiencyVehicle componentsMetal working apparatusElectric machineryMotor drive

The invention discloses multi-layer station lifting and transmission equipment, which comprises a rack body, a horizontal transmission mechanism and a vertical transmission mechanism. The horizontal transmission mechanism and the vertical transmission mechanism are both mounted in the rack body, and the rack body is provided with a part taking and placing operation station and a die change station. The horizontal transmission mechanism is provided with a speed chain for transmission of a tire film, auto parts to be welded and machined are placed on the tire film, a first motor is arranged to be connected with and drive the speed chain through a shaft rod, and the two sides of the speed chain are provided with sensors for detecting the position of the tire film in the transmission process.The vertical transmission mechanism comprises a tire film bottom plate supporting frame, a lifting mounting plate and a second motor, the lifting mounting plate is provided with a guiding rail and a rack which are perpendicular to the tire film bottom plate supporting frame, and guiding sliding blocks in fit embedding with the guiding rail are arranged at the two side edges of the tire film bottomplate supporting frame. A shaft rod connected with the second motor is provided with a gear in occlusion transmission with the rack, and the second motor drives the tire film bottom plate supportingframe to vertically ascend and descend.

Owner:佛山派阁汽车塑料技术有限公司

Computer motherboard welding operation device

InactiveCN108856951AEasy to weldImprove efficiencyHeating appliancesSoldering auxillary devicesElectric heatingPeripheral

The invention provides a computer motherboard welding operation device which comprises a base. Side frames are arranged on two sides of the base, and clamping seats are arranged at the locations of inward surfaces of the lower portions of the side frames and are mounted on the base; an adjusting mechanism is arranged between the tops of the side frames, a hydraulic cylinder is arranged on the lower portion of the adjusting mechanism, a piston rod is vertically arranged on the lower portion of the hydraulic cylinder, a positioning mechanism is arranged on a side wall of the lower end of the piston rod, and an electric heating needle is arranged at the tip of the lower end of the piston rod; the adjusting mechanism comprises a frame, first guide shafts are arranged on two sides of the frame,first slide pipes sleeve the outer peripheral surface of each first guide shaft, a second guide shaft is arranged between the first slide pipes, second slide pipes sleeve the outer peripheral surfaceof the second guide shaft, a movable plate is arranged between the second slide pipes, and the upper portion of the hydraulic cylinder is mounted on the movable plate. The computer motherboard welding operation device has the advantages that the electric heating needle can bring convenience for welding computer motherboards, and accordingly the welding processing efficiency can be greatly improved.

Owner:XUZHOU COLLEGE OF INDAL TECH

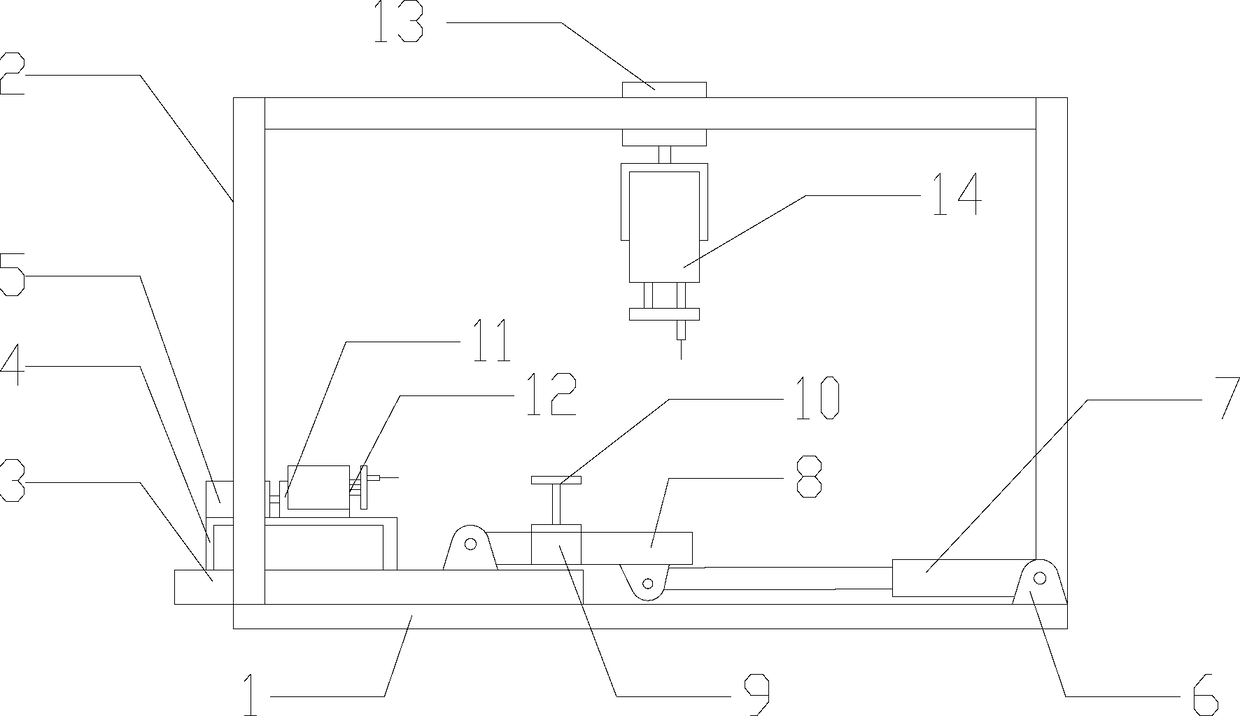

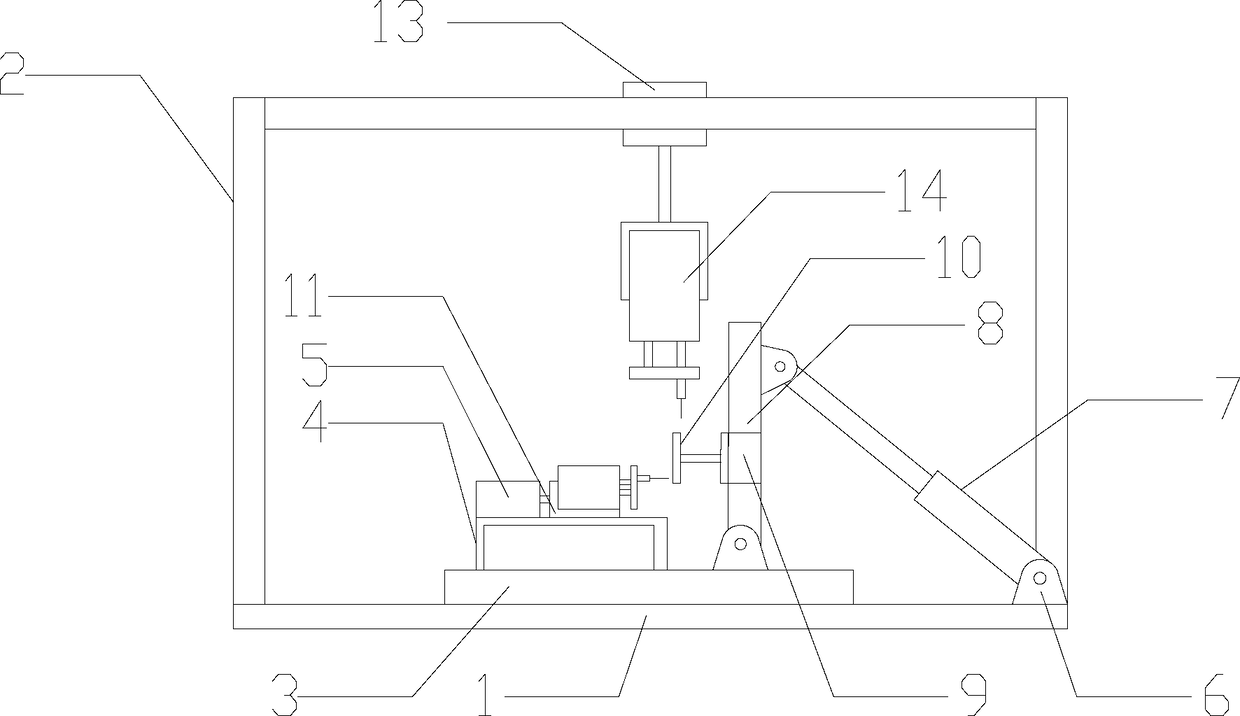

Chip turnover mechanism and thermistor chip welding equipment thereof

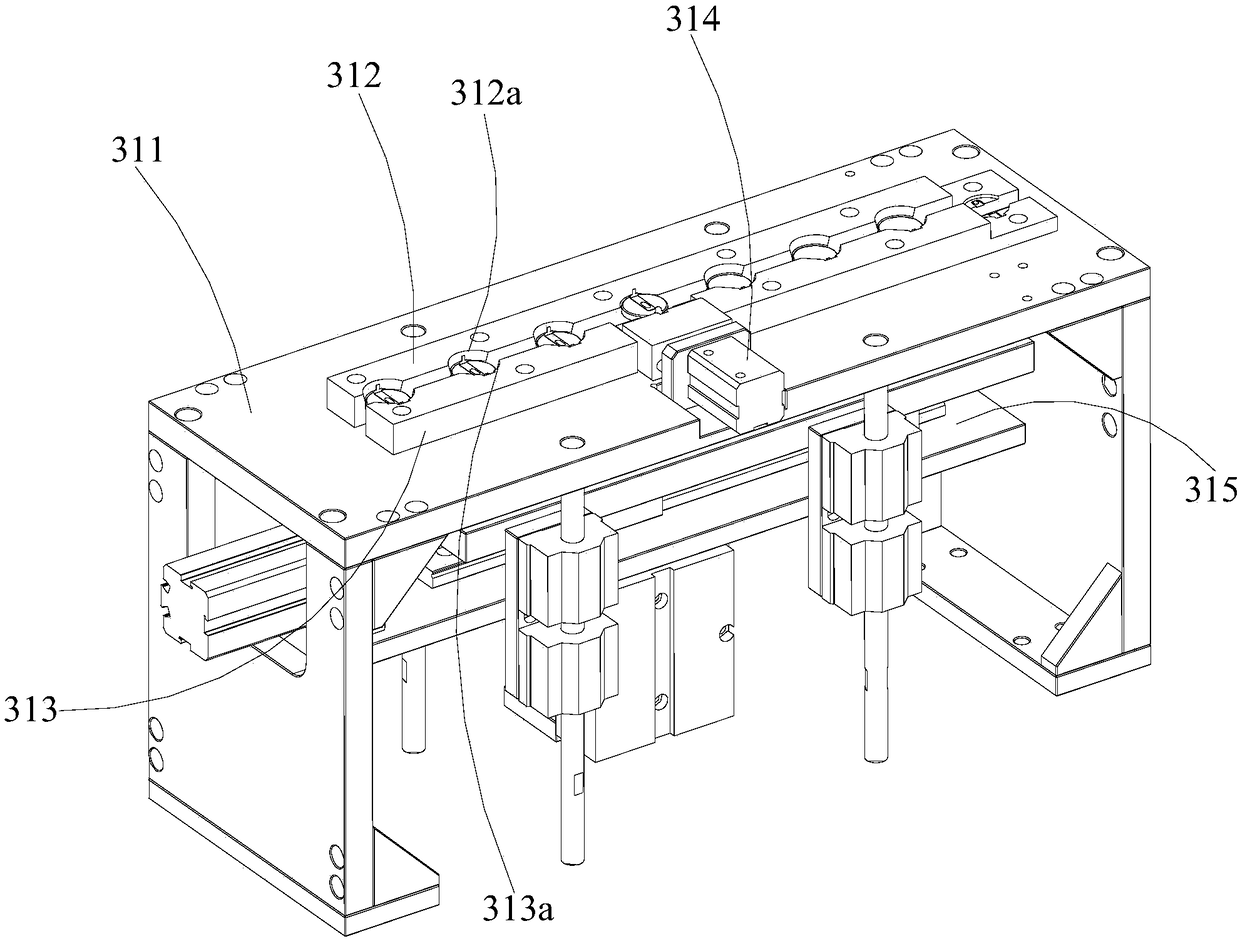

PendingCN108526799AImprove welding process efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThermistor

The invention discloses a chip turnover mechanism and thermistor chip welding equipment thereof. The chip turnover mechanism comprises a turnover fixing base, a turnover driving device, a turnover guide device and a turnover conveying device; the turnover driving device, the turnover guide device and the turnover conveying device are arranged on the turnover fixing base; the turnover driving device is connected to the turnover guide device; and the turnover conveying device is arranged on the turnover guide device. The chip turnover mechanism has the advantages that through the turnover fixingbase, the turnover driving device, the turnover guide device and the turnover conveying device, the operation of overturning a chip can be realized, so that the chip can be subjected to the welding operation of the front and back sides, welding points on the welding surface cannot be touched, and therefore the welding efficiency and the welding quality of the chip can be improved.

Owner:惠州嘉科实业有限公司

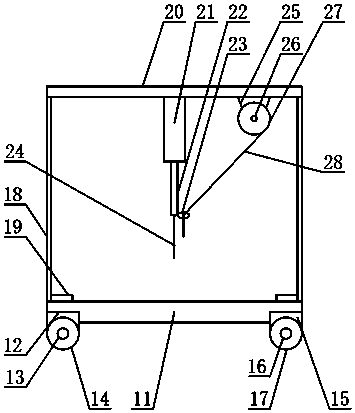

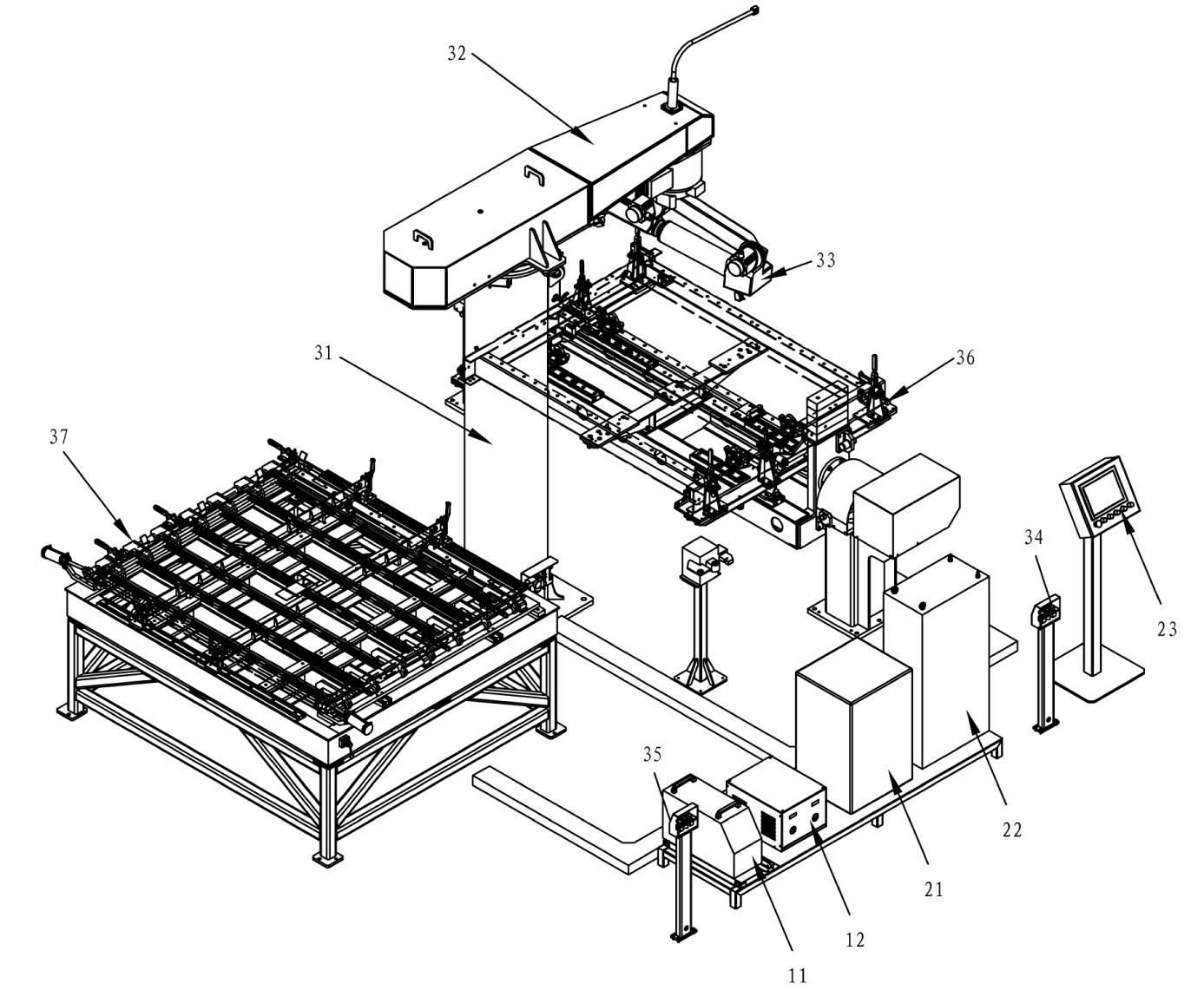

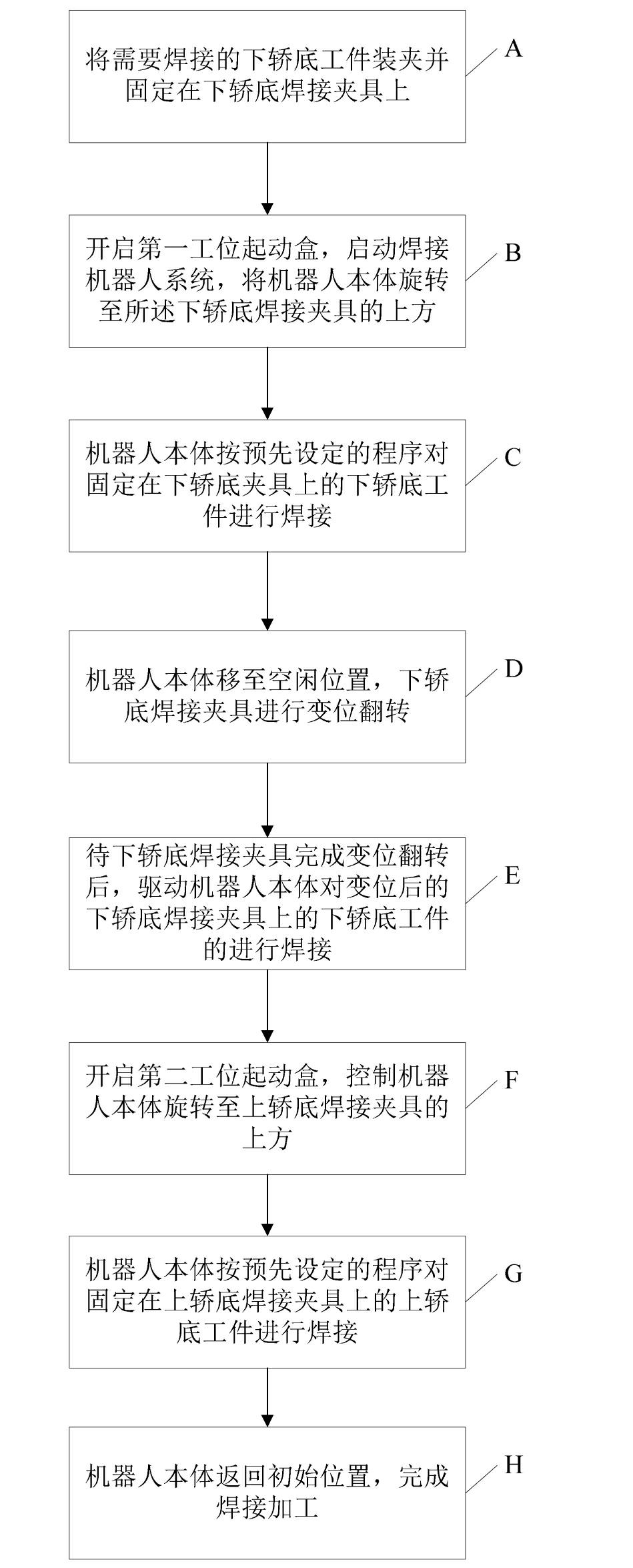

Welding method for car bottom of elevator based on welding robot

InactiveCN102601535AHigh degree of intelligenceImprove welding process efficiencyWelding/cutting auxillary devicesAuxillary welding devicesAutomotive engineeringWelding

The invention discloses a welding method for a car bottom of an elevator based on a welding robot, wherein the welding robot is applied in the field of welding the car bottom of the elevator. The welding method specifically comprises the following steps that: one surface of a lower car bottom workpiece fixed on a lower car bottom welding fixture is welded at a first welding station; deflection overturning is carried out on the lower car bottom welding fixture; the other surface of the lower car bottom workpiece is welded; and an upper car bottom workpiece is welded at a second welding station. According to the welding method for the car bottom of the elevator based on the welding robot, the upper car bottom workpiece and the lower car bottom workpiece are respectively clamped on an upper car bottom welding fixture and the lower car bottom welding fixture and are welded by adopting the welding robot through the two welding stations, thereby improving the welding efficiency; the welding method is high in intelligence degree, so that the workpieces in various dimensions can be processed by the specially-used welding fixtures, thereby ensuring the welding quality of a product.

Owner:GUANGZHOU YONGRI ELEVATOR

Stainless steel water faucet shell welding technology

ActiveCN104043901AImprove welding strengthDense weldWelding/soldering/cutting articlesLaser beam welding apparatusWeld strengthFusion welding

The invention relates to a water faucet shell production technology, in particular to a stainless steel water faucet shell welding technology. The stainless steel water faucet shell welding technology comprises the following steps of material selection, part preparation, cleaning before welding, part clamping, part welding and post-welding checking. In the part clamping process, a welding clamp needs to be adjusted so that a welding position of a base plate can be embedded in a welding position of a body. A laser penetration fusion welding method is adopted for part welding. Due to the facts that the welding position of the base plate is embedded in the welding position of the body, and the body and the base plate are welded together through the laser penetration fusion welding method which is highly centralized in energy density, weld strength of weld joints is high, and the weld joints are compact and beautiful in appearance.

Owner:HUAQIAO UNIVERSITY

Welding locating device of sheet metal parts

InactiveCN105798522AReasonable structural designEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a welding locating device of sheet metal parts. The welding locating device comprises a locating device body, wherein a first sliding groove is horizontally formed in the surface of a locating plate; a second sliding groove vertical to the first sliding groove is formed in the surface of the locating plate; a rotating base is mounted above the left end of the locating plate; a driving device is arranged above the rotating base; an adjusting rod is arranged above the right side of a supporting rod; a slide rail is arranged below the adjusting rod; a sliding block is mounted below the slide rail; a fixture is arranged below the sliding block; a first clamping block is mounted above the right end of the locating plate; the first clamping block is connected with the first sliding groove in a sliding manner; and a second clamping block is mounted above the second sliding groove in a sliding manner. The welding locating device of sheet metal parts has the advantages that the structure design is reasonable, the operation is simple, the safety and practicability are achieved, and the like, the welding efficiency can be greatly improved, and the device can be universally popularized and utilized.

Owner:XINCHANG QIXING STREET CHUNQIANG MACHINERY FACTORY

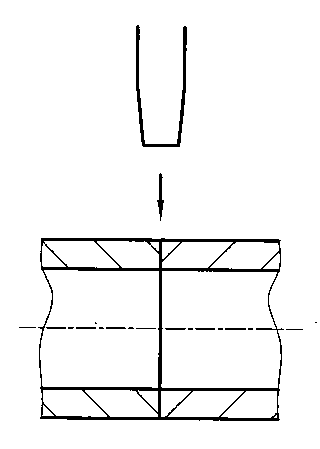

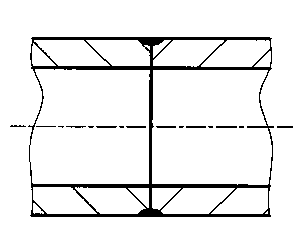

Stainless steel thin-wall pore-free laser welding method

InactiveCN103084735AEasy to processGood workmanshipWorkpiece edge portionsLaser beam welding apparatusWeld lineLaser soldering

The invention discloses a stainless steel thin-wall pore-free laser welding method. The method is characterized in that the stainless steel wall thickness delta is more than or equal to 0.5 mm and less than or equal to 3mm; the welding process parameters are that the pulse width is 1 to 3ms, the frequency is 40 to 50 Hz, the single-point energy is 5 to 7J, the power is 2.5 to 3.5kW, and the speed is 5 to 12mm / s; a groove is V-shaped or slot-shaped; and the groove angle theta is 15 to 20 degrees, or the slot width alpha of the groove is 0.1 to 0.2mm, and the depth h is 0.5 to 2mm. By the method, filling material-free self-fluxing laser welding can be realized, a through pore can be avoided in a welding line, and a welding process is high in efficiency; and the laser welding method can adapt to large-scale production, and can be used in small-scale production.

Owner:DANDONG TOP ELECTRONICS INSTR GRP

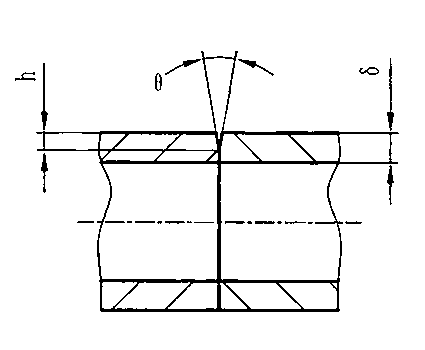

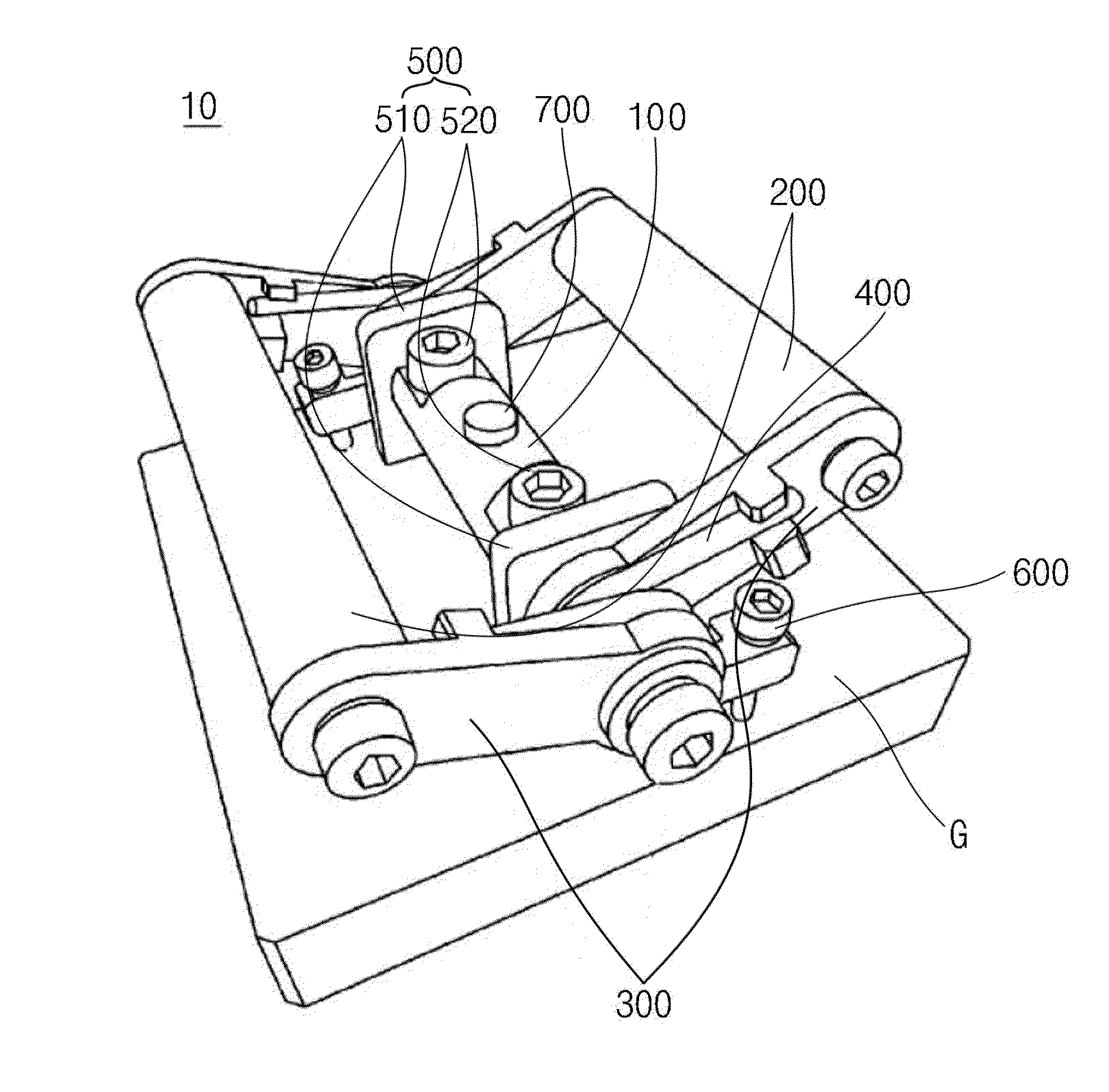

Guide frame support device

ActiveUS9409260B2Easy to adjustIncrease elasticityWelding/cutting auxillary devicesPipeline systemsEngineeringTorsion spring

Provided is a guide frame support device for a pipe welding device, the guide frame support device, which supports a guide frame provided on an outer circumferential surface of a pipe to be welded, including: a hinge bar connected to an inner circumferential surface of the guide frame; a pair of support bars which rotates around the hinge bar at a predetermined angle; hinge links, one side of each of which is hinge-connected to both ends of the hinge bar and the other side of each of which is connected to both ends of the pair of support bars; and a torsion spring provided between the pair of support bars and for providing elastic force to enable the support bars to rotate around the hinge bar at a predetermined angle.

Owner:HYUNDAI HEAVY IND CO LTD

Lithium battery cap linear laser welding device and welding method thereof

InactiveCN110640318ARealize automatic mechanized loading workImprove feeding efficiencyLaser beam welding apparatusEngineeringSmall footprint

The invention belongs to the technical field of lithium battery cap welding equipment, and particularly relates to a lithium battery cap linear laser welding device. The device comprises a rack, wherein the rack comprises a workbench; four supporting legs are fixedly mounted at the bottom of the workbench; supporting plates are fixedly mounted on the inner sides of the four supporting legs; two vertical blocks are fixedly mounted at the top of the workbench; fixing blocks are fixedly mounted at the tops of the two vertical blocks; and top plates are fixedly mounted at the bottoms of the two fixing blocks. Through cooperation of an orifice plate feeding mechanism, an explosion-proof diaphragm feeding mechanism and two displacement mechanisms, automatic mechanized feeding of orifice plates and explosion-proof diaphragms can be achieved, manual feeding operation is not needed, the feeding efficiency is improved, the labor cost is reduced, and the machining efficiency is improved. By meansof a rotary plate mode, compared with adoption of a conveying belt, the overall occupied area of the device is small, and installation and placement are convenient.

Owner:江苏志瑞能源科技有限公司

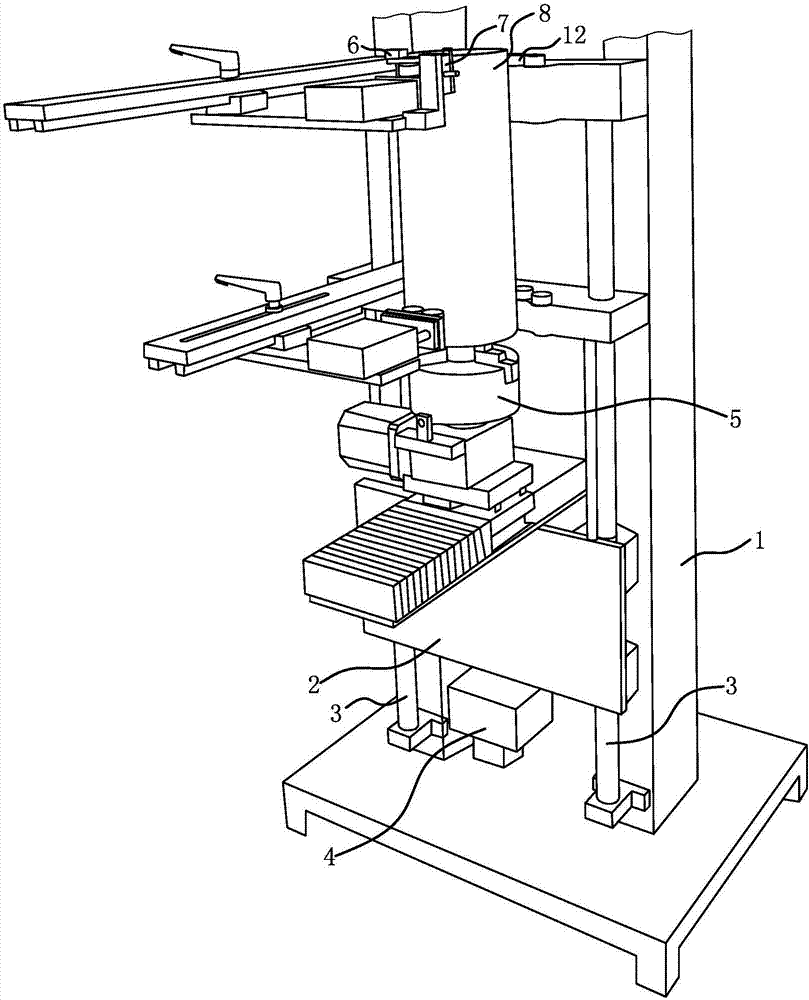

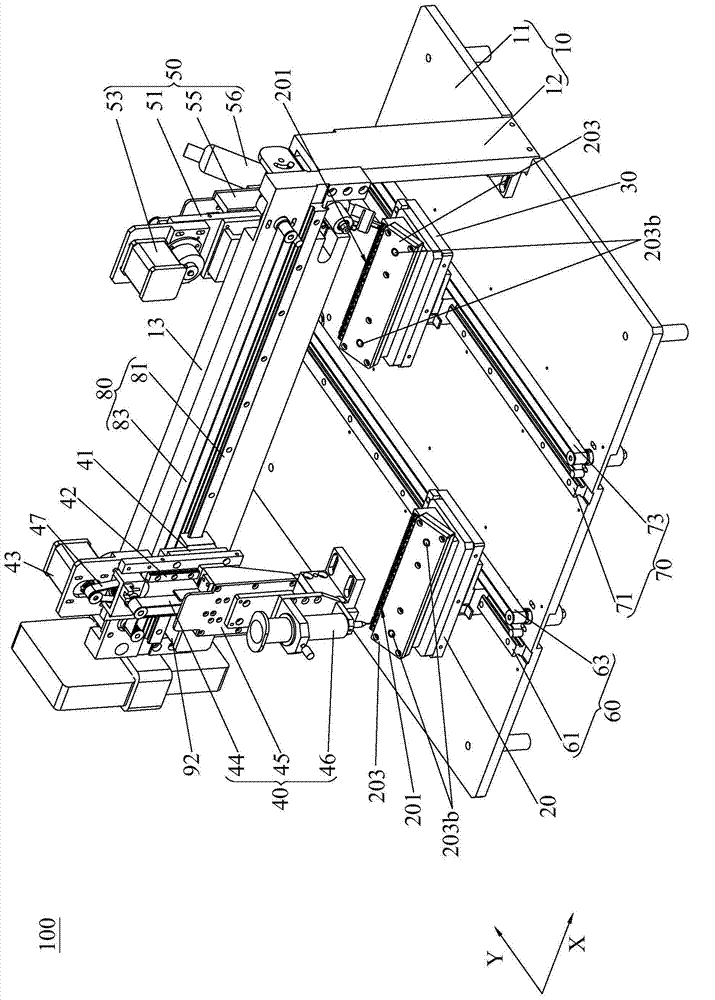

Portal type intelligent welding robot based on visual and three-dimensional model recognition

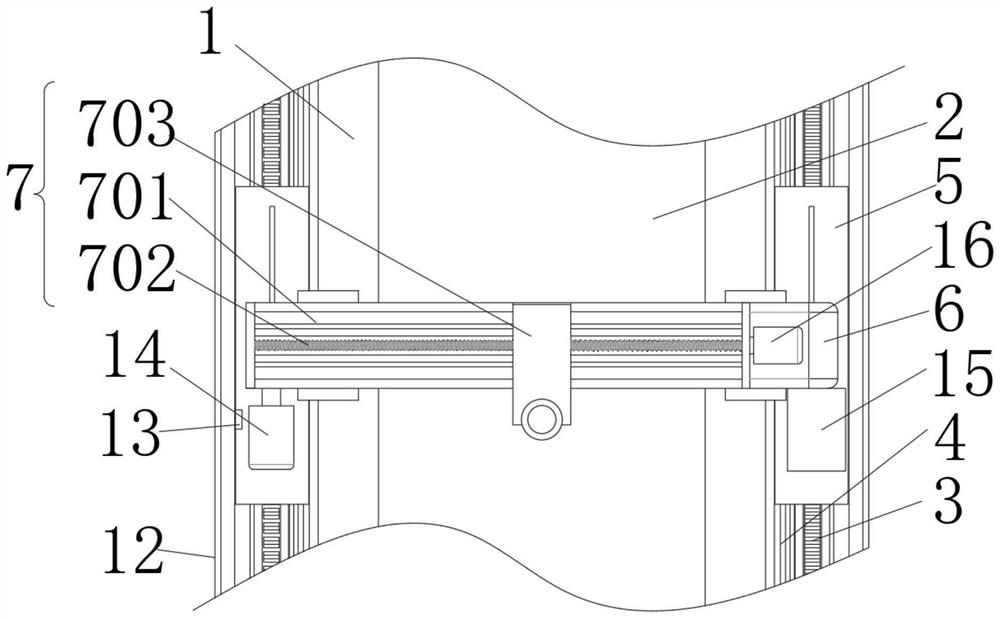

PendingCN112122841AImprove welding process efficiencyImprove accuracyProgramme-controlled manipulatorWelding/cutting auxillary devicesImaging processingImage manipulation

The invention provides a portal type intelligent welding robot based on visual and three-dimensional model recognition, and relates to the technical field of welding equipment. The portal type intelligent welding robot based on visual and three-dimensional model recognition comprises a base, a welding table and a working method, wherein the welding table is fixedly connected to the middle of the upper portion of the base; the two upper sides of the base are each fixedly connected with a fixed sliding rail; the upper portions, located at the middle parts of the two fixed sliding rails, are eachfixedly connected with a gear rack; sliding bases are slidably connected to the upper portions of the two fixed sliding rails correspondingly; and a portal frame is fixedly connected to the middle parts of the upper portions of the two sliding bases. The portal type intelligent welding robot provided by the invention is provided with two horizontal-axis cameras and two longitudinal-axis cameras by which three-dimensional information of a workpiece can be quickly obtained through an image processing algorithm; three-dimensional modeling is conducted and then path planning and programming can be automatically conducted through a three-dimensional digital-analog processing system, so that an engineer does not need to write a welding program after conducting actual measurement and three-dimensional modeling, and thus the welding efficiency is greatly improved.

Owner:安徽工布智造工业科技有限公司

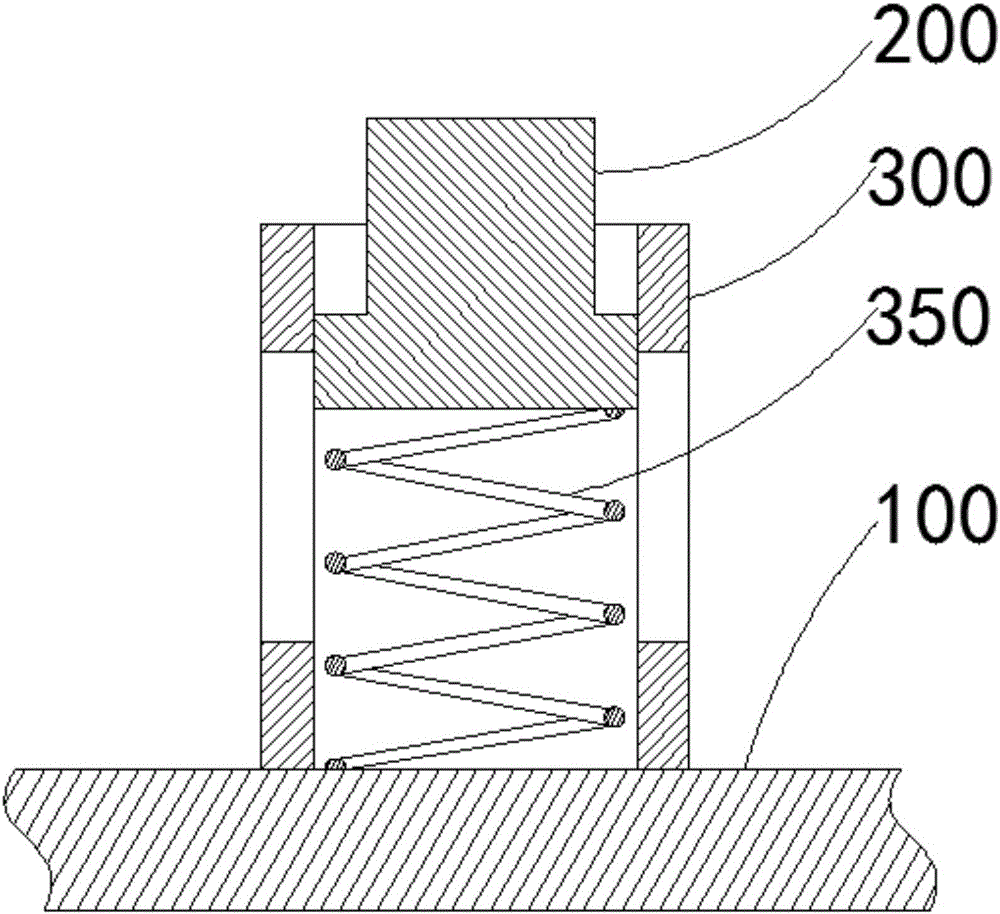

Automobile exhaust connecting pipe welding, clamping, fixing and displacing tool

ActiveCN111618517AGuaranteed docking accuracyEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderStructural engineering

The invention relates to the field of auto spare parts processing, in particular to an automobile exhaust connecting pipe welding, clamping, fixing and displacing tool which comprises a fixed machinetool; a lifting table is inserted in the fixed machine tool; a plurality of spring telescopic rods are symmetrically and fixedly connected onto the lifting table; first sliding chutes are symmetrically formed in the top of the fixed machine tool; a movable frame is arranged on the top of the fixed machine tool; the bottom of the movable frame is inserted in the first sliding chutes; fixed groovesare symmetrically formed in the lifting table; clamping grooves are symmetrically formed above the fixed grooves in the fixed machine tool; second sliding chutes are symmetrically formed in the fixedgrooves; adjusting clamping strips are arranged in the fixed grooves; a first hydraulic cylinder is symmetrically and fixedly connected with the two sides of the lifting table; and the output end of the first hydraulic cylinder penetrates through the fixed grooves to be fixedly connected with one side of the adjusting clamping strips. The automobile exhaust connecting pipe welding, clamping, fixing and displacing tool is simple in structure, can simultaneously clamp and fix a plurality of exhaust connecting pipes precisely, ensures welding precision and is suitable for popularization.

Owner:徐州凯密斯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com