Diamond cutting tool welding machine and matrix position control method

A diamond cutting and welding machine technology, applied in diamond cutting tool welding machine, diamond cutting tool welding machine substrate position control, welding field, can solve the problems that affect the processing efficiency, take up a lot of time, can not guarantee the quality of brazing, etc., to achieve The effect of ensuring the consistency of welding quality and improving the efficiency of welding processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

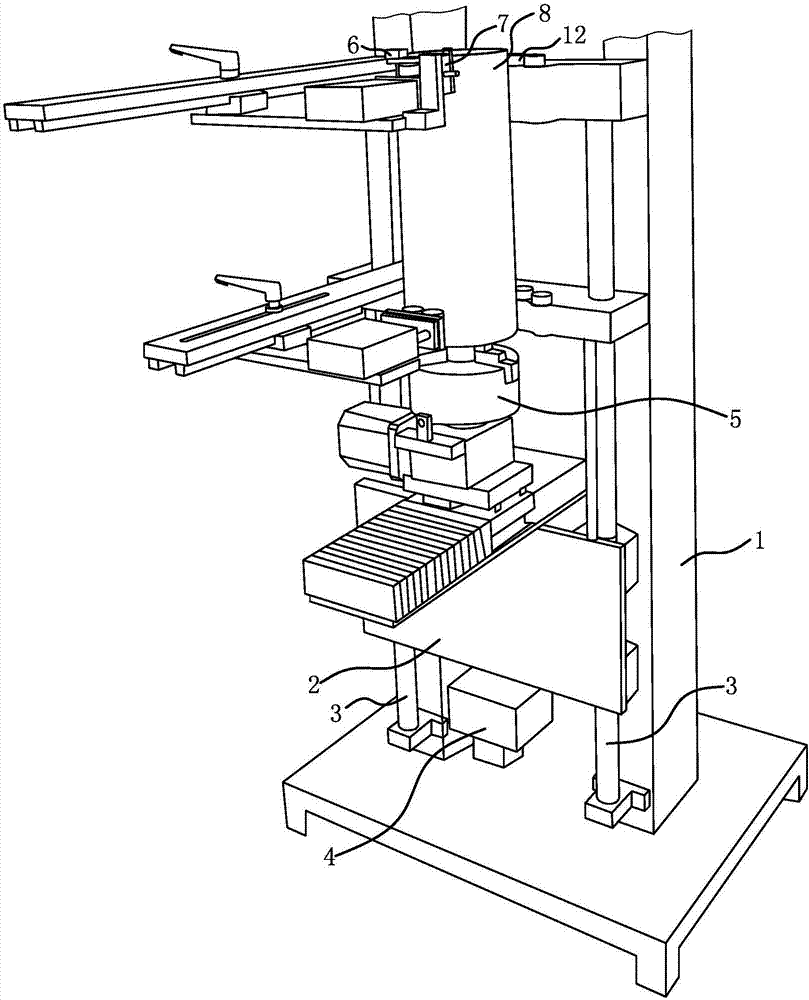

[0023] The diamond cutting tool welding machine comprises a frame 1, a lifting plate 2, a clamping mechanism 12 at the top of a substrate and a control circuit.

[0024] The lifting plate 2 and the frame 1 are connected through the vertical guide rail 3, the motor 4 is installed on the frame 1, and the mechanical transmission structure that can make the lifting plate 2 move along the vertical guide rail 3 is passed between the motor 4 and the lifting plate 2 Connected; the mechanical transmission structure includes a screw mandrel connected with the rotating shaft of the motor 4 and a screw nut fixedly connected with the lifting plate 2, the screw mandrel and the screw nut are threaded, that is, the rotation of the main shaft of the motor 4 can force the lifting plate 2 to move up and down.

[0025] A base body positioning structure 5 is installed on the lifting plate 2; the base body positioning structure 5 is determined according to the type of the diamond cutting tool. The ...

Embodiment 2

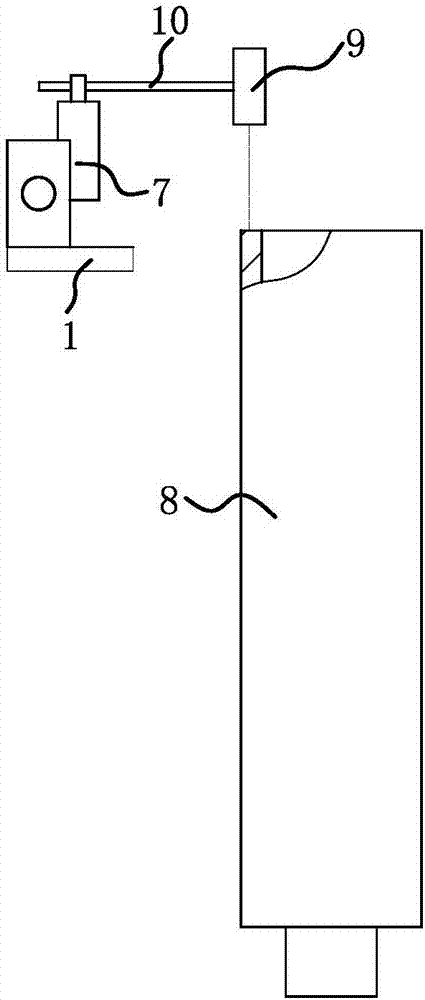

[0031] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: image 3 As shown, the electronic sensing element is a distance measuring sensor 9, and the distance measuring sensor 9 is connected to the frame 1 through a height-adjustable sliding table 7 and a swing rod 10, and the base of the height-adjustable sliding table 7 is fixed to the frame 1 Connect, fork 10 is arranged horizontally, and one end of fork 10 is rotatably connected with the lifting slide table of height-adjustable slide table 7, and the other end of fork 10 is fixedly connected with distance measuring sensor 9. In this way, the height of the distance measuring sensor 9 can be flexibly adjusted according to the position of the heating tube of the high-frequency machine, and the horizontal position of the distance measuring senso...

Embodiment 3

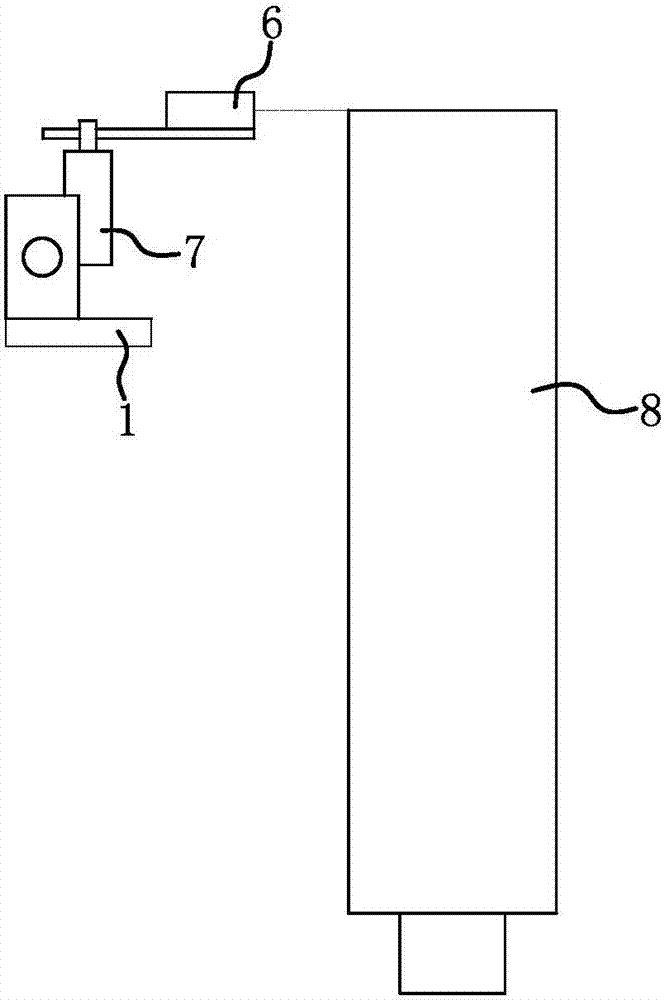

[0034] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 4 As shown, the diamond cutting tool welding machine is used for welding the diamond segment circular saw blade, the high frequency welding machine is located on one side of the substrate of the diamond segment circular saw blade, and the photoelectric sensor 6 is located on the other side of the diamond segment circular saw blade substrate 11 . The point to be welded on the diamond segment circular saw blade base 11 is the apex of the base, then the position of the light emitted by the photoelectric sensor 6 is perpendicular to the plate surface of the diamond segment circular saw blade base 11 and is at the top of the diamond segment circular saw blade base 11. Corresponding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com