Welding equipment for ring-shaped metal parts

A technology for metal parts and welding equipment, applied in the field of parts processing, can solve the problems of high labor intensity of operators and low welding efficiency, and achieve the effect of making up for defects, improving efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

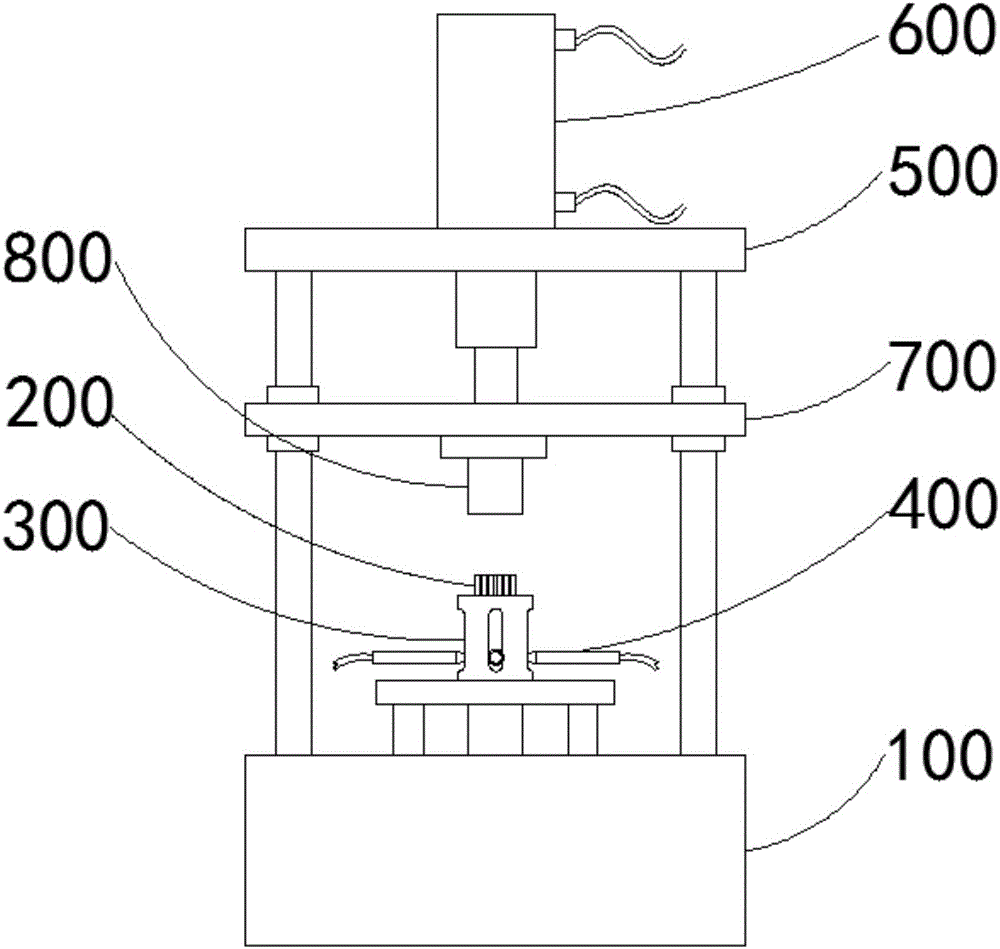

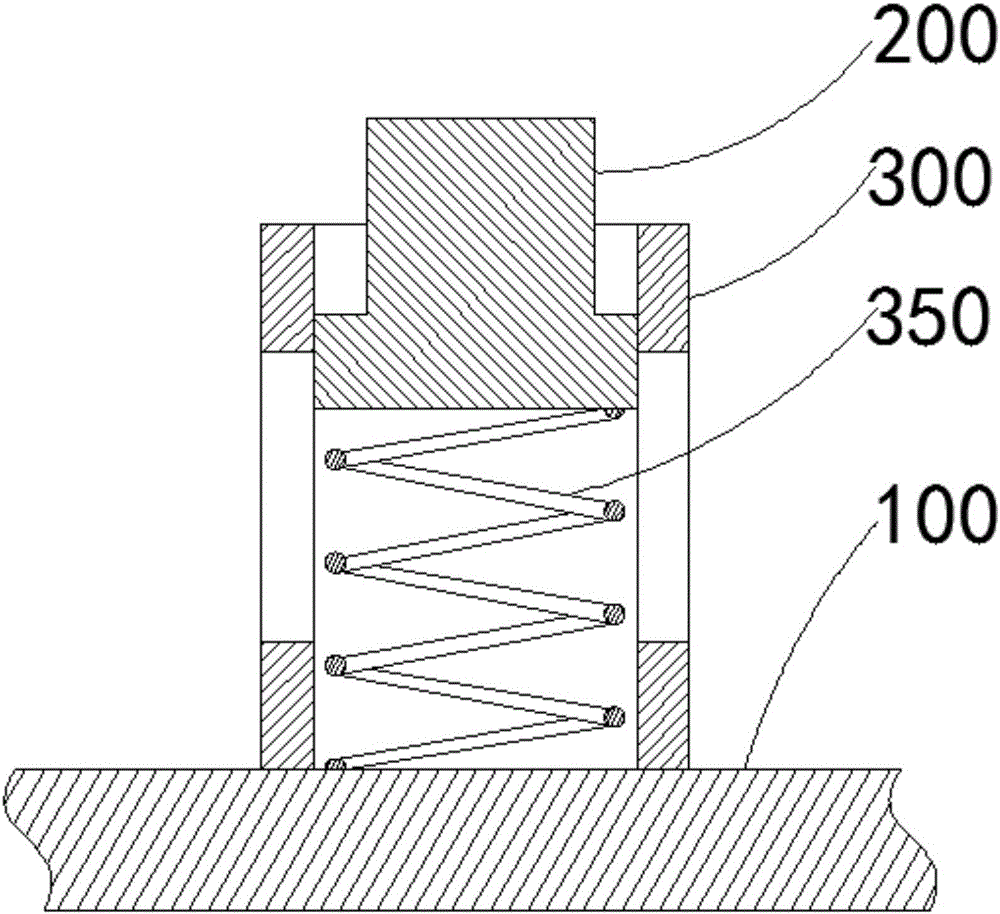

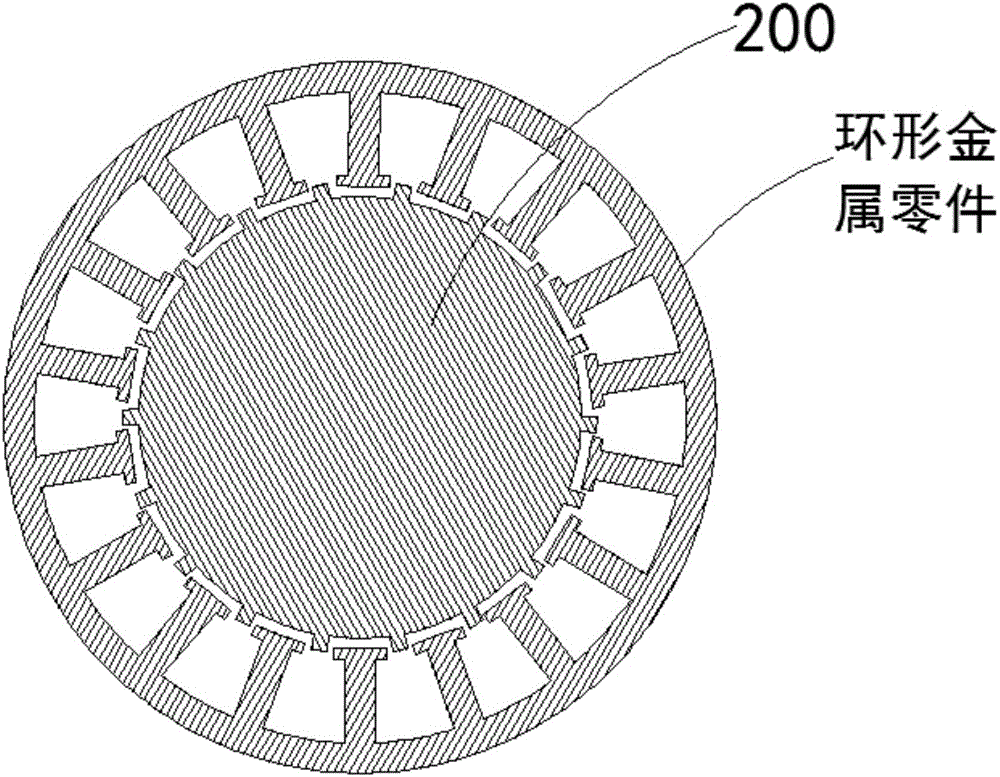

[0037] For the first embodiment, refer to Figure 1-3 , the ring-shaped metal parts welding equipment includes a machine platform 100, the machine platform 100 is provided with a clamping device and a welding device, the clamping device includes a vertically arranged clamping column 200, and the clamping column 200 is cylindrical Shaped and the outer wall is provided with a plurality of clamping strips, a plurality of clamping strips are evenly spaced along the circumferential direction of the clamping column 200, the clamping strips are matched with the clamping grooves on the inner wall of the ring metal part, and the welding device includes multiple Welding torches 400 arranged at uniform intervals along the circumferential direction of the clamping column 200, the length direction of each welding torch 400 is the same as the radial direction of the clamping column 200, and the welding tip of each welding torch 400 is facing the clamping The outer wall of the column 200 . ...

no. 2 example

[0062] The second embodiment, the device provided by the embodiment of the present invention, its realization principle and the technical effect produced are the same as those of the previous embodiment. For brief description, for the parts not mentioned in the device embodiment, please refer to the corresponding content in the previous embodiment .

[0063] In this embodiment, a limit sliding bar is provided on the outer wall of the guide column, and a limit slide groove is provided on the inner wall of the sleeve 300 , and the limit slide bar and the limit slide groove match each other.

[0064] Wherein, there are a plurality of limit slide bars, which are evenly spaced along the circumferential direction of the guide column; the number and position of the limit slide grooves correspond to the limit slide bars.

[0065] The purpose of such setting is to prevent the guide column from rotating during the lifting process, thereby improving the stability of its movement.

no. 3 example

[0066] The third embodiment, the implementation principle and technical effect of the device provided by the embodiment of the present invention are the same as those of the previous embodiment. For a brief description, for the parts not mentioned in the device embodiment, please refer to the corresponding content in the previous embodiment .

[0067] In this embodiment, the sleeve 300 is provided with a limit block for placing the guide column to slide out of the sleeve 300 , and the limit block is detachably connected to the top of the sleeve 300 .

[0068] Wherein, the limiting block is in the shape of a cuboid, which is connected to the top of the sleeve 300 by bolts, and part of it blocks the movement path of the guide post, but does not block the movement path of the clamping column 200 and the ring metal part.

[0069] The purpose of setting the limit block is to effectively prevent the clamping column 200 and the guide column from completely detaching from the sleeve 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com