Welding machine and welding processing method thereof

A welding machine and solder technology, used in metal processing, welding equipment, metal processing equipment, etc., can solve the problems of low welding processing efficiency, virtual welding, and the inability to meet the production requirements of safety, low cost, high efficiency and high quality. , to achieve the effect of simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

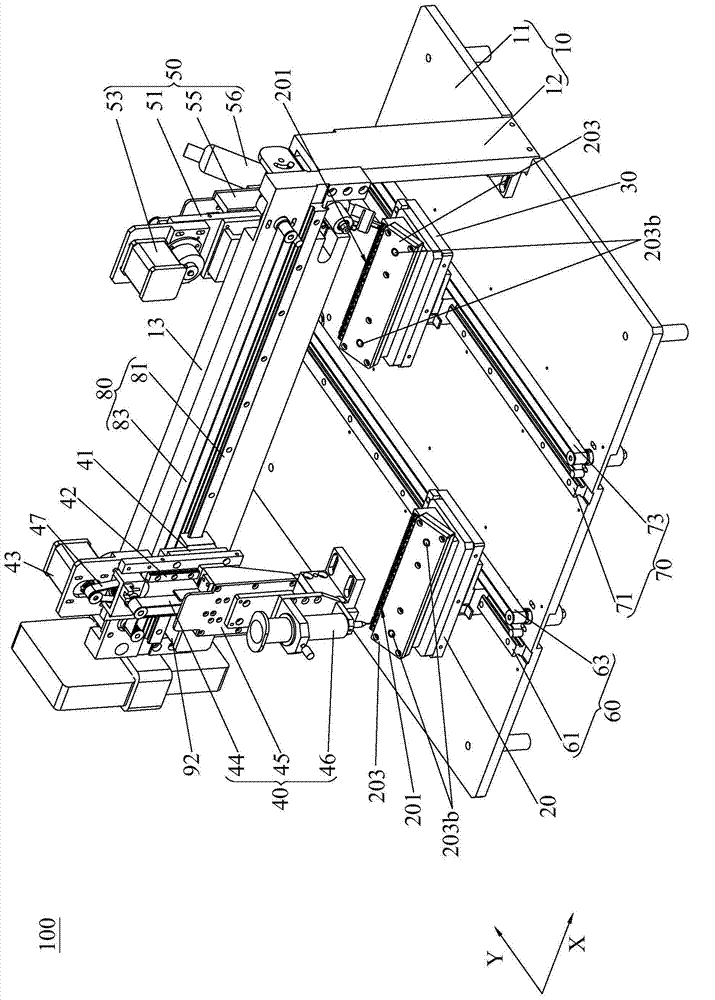

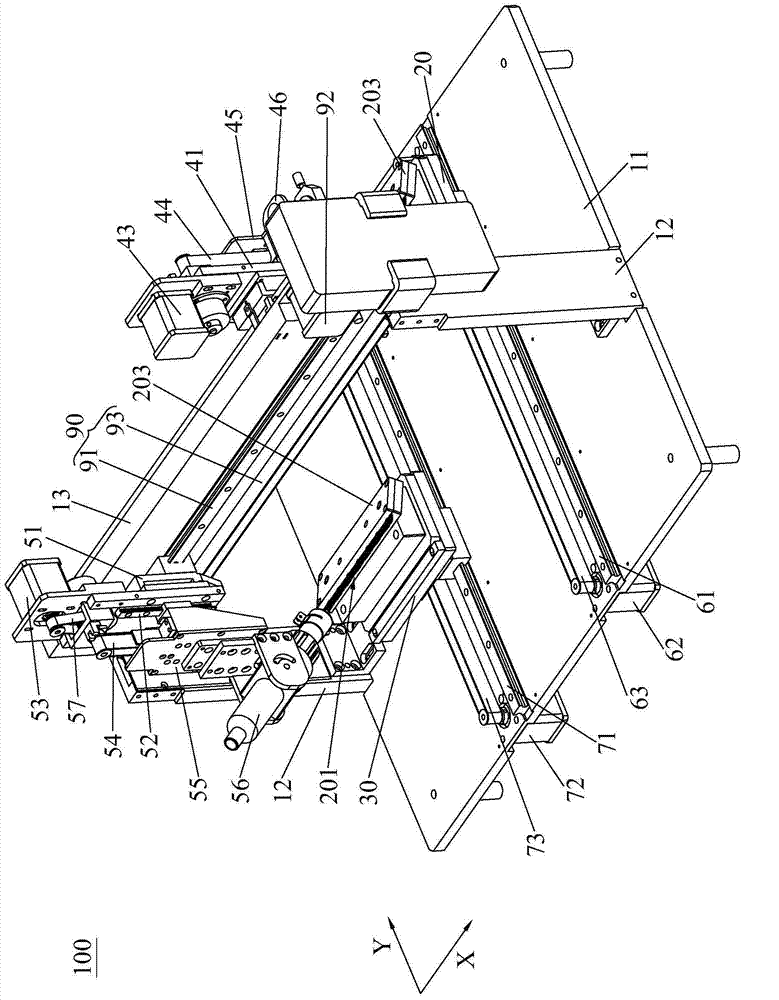

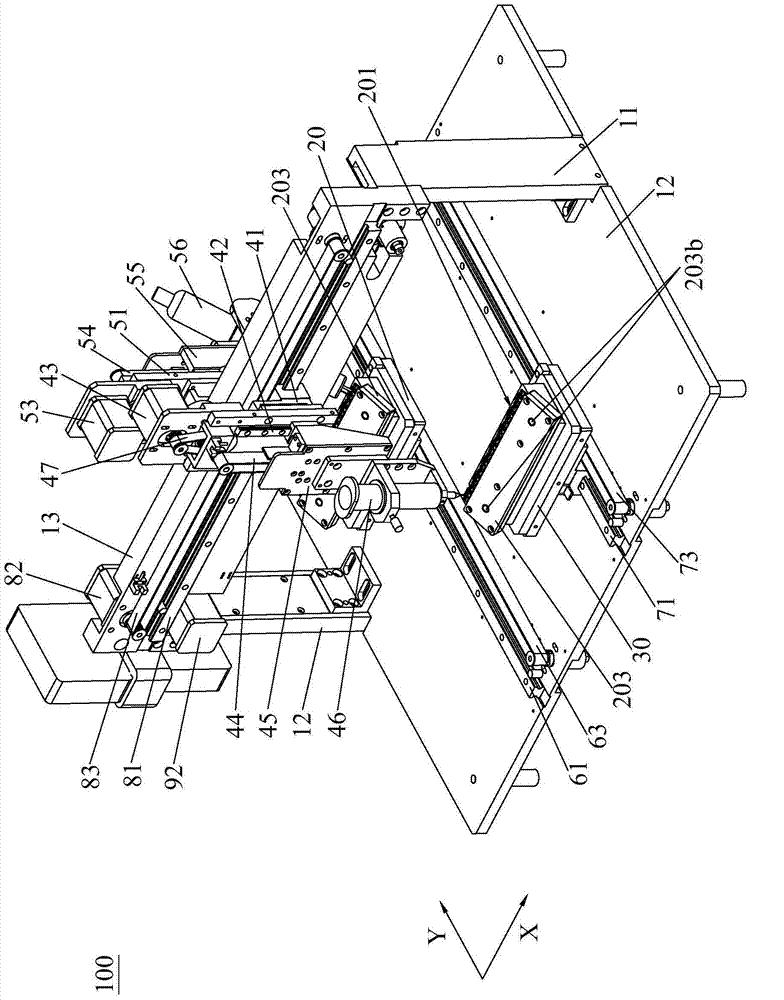

[0045] see Figure 1 to Figure 3 The welding machine 100 of the first embodiment of the present invention includes a frame 10, a first carrier 20, a solder feeding device 40, a solder curing device 50, and a first transfer device 60 and a material transfer device 80 that are all arranged on the frame 10. And curing transfer device 90, the first carrier 20 is used to load the product 201 to be welded, wherein, the welding process of product 201 can be between the contact terminal (not marked in the figure) and the connector (not marked in the figure) Welding processing, but not limited thereto, will not be repeated here. The frame 10 has a soldering station and a curing station distributed along a Y axis, the first carrier 20 is arranged on the first transfer dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com