Welding method for car bottom of elevator based on welding robot

A welding robot, welding method technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of welding deformation, low welding efficiency, affecting product quality, etc., to improve efficiency, ensure welding quality, intelligent high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention applies the welding robot to the processing field of the elevator car bottom, which improves the welding efficiency and processing quality of the car bottom. The welding robot system of the present invention and the welding method of the elevator car bottom are introduced below in conjunction with the embodiments:

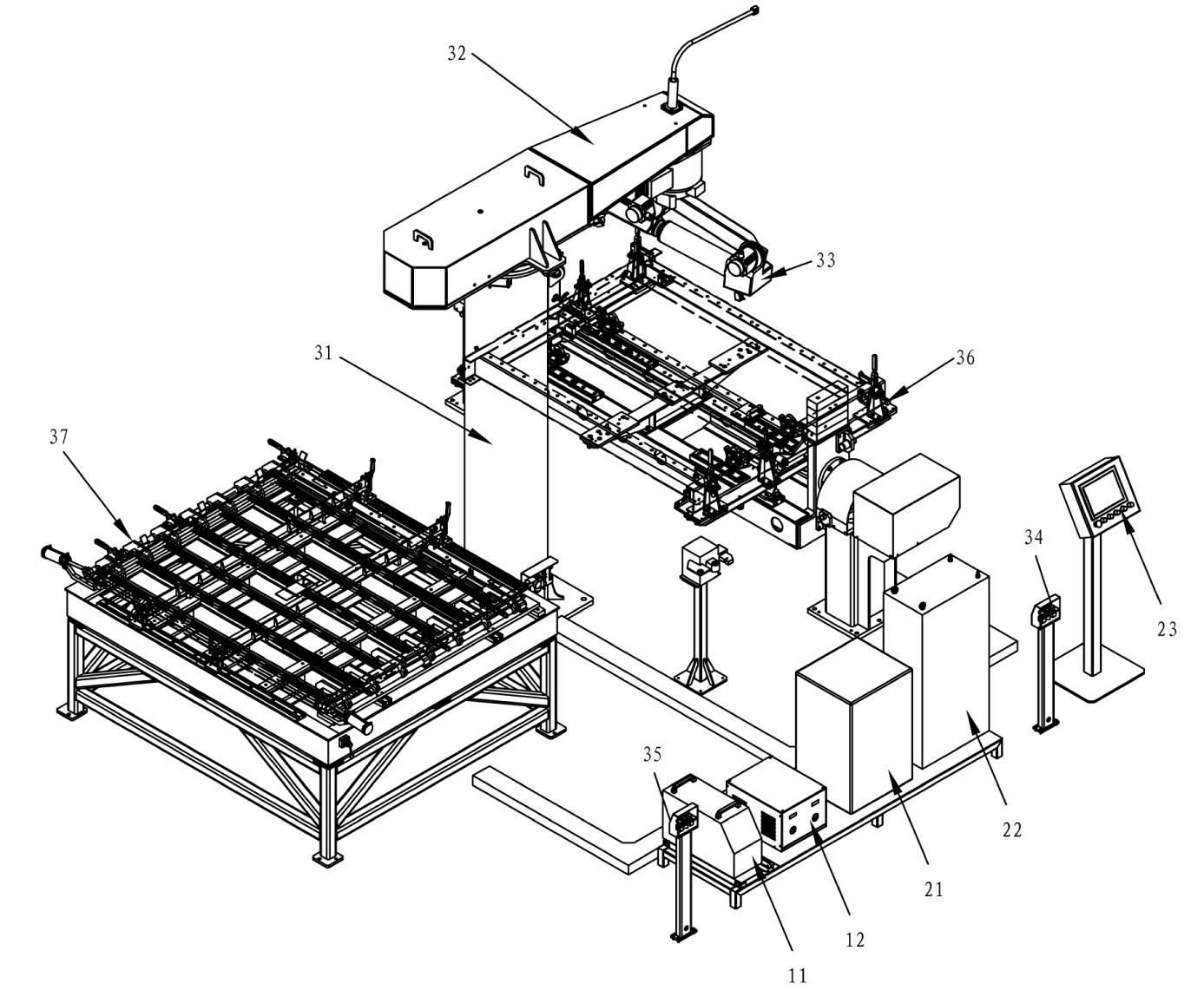

[0024] refer to figure 1 The welding robot system includes a power supply system, a control system and an execution system. The power supply system provides power for the entire system, including a welding power supply 11 and a transformer 12; the control system is used to control the robot body, the upper car bottom welding fixture and the lower car The operation of the bottom welding fixture includes a robot control center 21, which is connected with a peripheral signal control panel 22 and a man-machine interface 23 through a data port; the execution system includes a rotating arm column 31, a rotating arm 32 and a robot body 33. One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com