Copper alloy electrode for resistance weld and its manufacturing method

An electrode manufacturing and copper alloy technology, applied in the direction of electrode features, manufacturing tools, welding medium, etc., can solve the problems of reducing the toughness of cermets, coating cracking, and the thermal expansion coefficient is very different, reducing the friction coefficient and improving the working life. , the effect of reducing the bonding phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

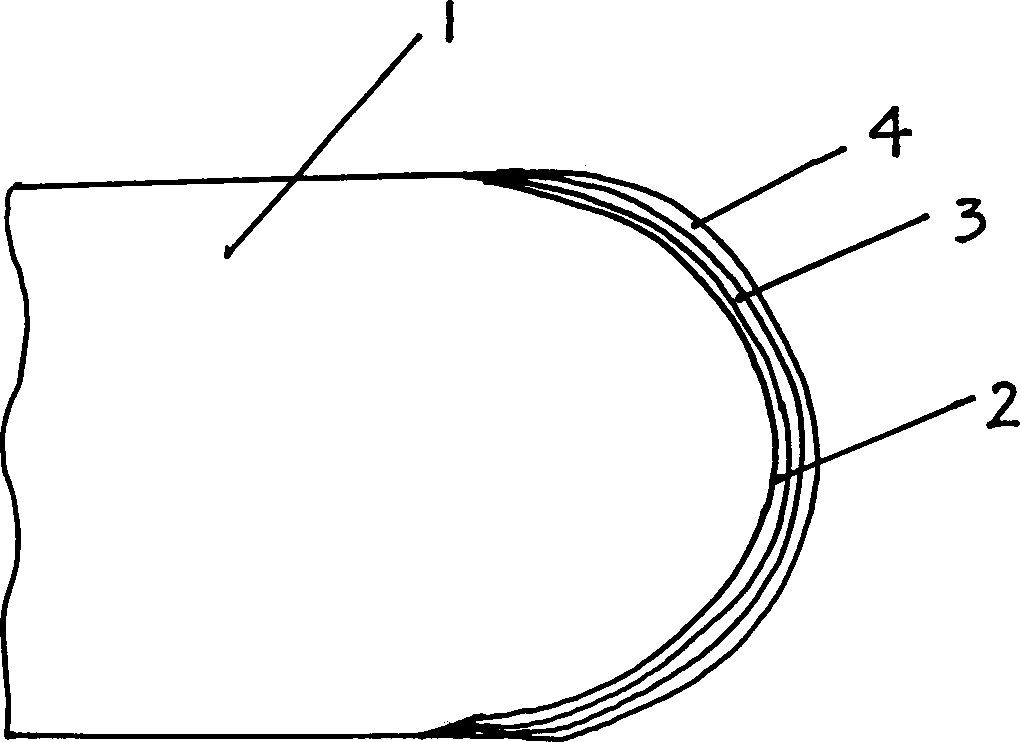

[0032]In the resistance welding copper alloy electrode provided by the present invention, three layers of materials are first distributed on the substrate 1 at the end of the electrode, the metal alloy layer 2 is in contact with the substrate, the metal alloy composite material layer 3 is in the middle, and the outermost surface is a metal alloy layer 4. The thickness of the metal alloy layer in contact with the substrate is 10-40 microns, and the thickness of the metal alloy composite material layer in the middle is 20-50 microns. In order to better prevent the adhesion of electrodes, a layer of dense metal alloy layer formed by chemical vapor deposition method or physical vapor deposition method or high-speed cold gas flow spraying WS2 method is used outside the metal alloy layer on the outermost surface. The thickness is about 0.5 microns.

[0033] The composition of the above-mentioned first three layers of materials: the metal alloy layer in contact with the substrate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com