High tension electrostatic separating apparatus and method for worn-out broken printed circuit board granules

A printed circuit board and high-voltage electrostatic technology is applied in the field of high-voltage electrostatic separation devices, which can solve the problems of low sorting efficiency of airflow sorting machines, inability to achieve effective sorting, and large influence of material shape, and achieve simple structure, low cost, and high efficiency. The effect of less equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

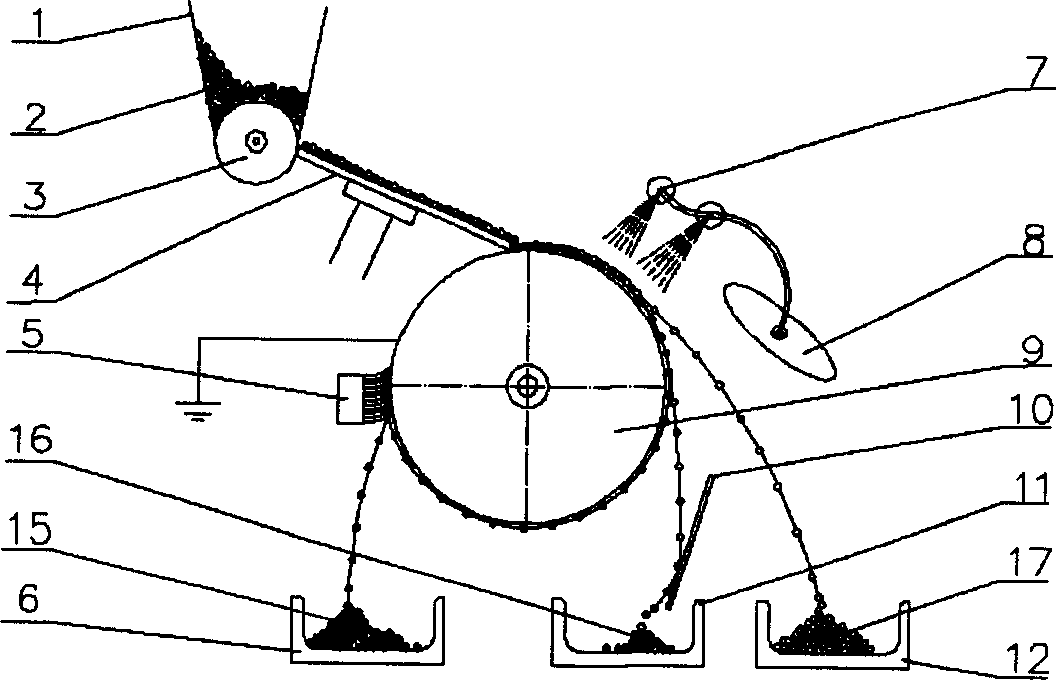

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

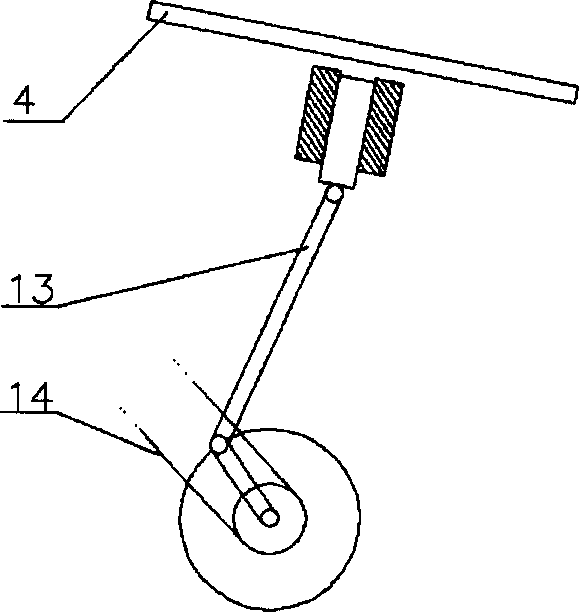

[0021] The structure of the high-voltage electrostatic separation device designed for the broken particles of waste printed circuit boards in the present invention is as follows: figure 1 As shown, the feeding drum 3 with a groove is arranged at the bottom of the feeding hopper 1, the bottom of the feeding hopper 1 is connected with the vibrating feeding plate 4, the feeding vibration mechanism is arranged at the lower part of the vibrating feeding plate 4, and the vibrating feeding plate 4 is connected to the upper surface of the main drum 9 A corona electrode 7 and a static electrode 8 are arranged on the upper right side of the clockwise rotation direction of the main roller 9, a brush 5 is arranged on the left side of the main roller 9, and a non-metallic particle collection area 6 is arranged on the bottom of the main roller 9 from left to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com