Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

258 results about "Wear out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear out (third-person singular simple present wears out, present participle wearing out, simple past wore out, past participle worn out) To cause (something) to become damaged, useless, or ineffective through continued use, especially hard, heavy, or careless use. You're going to wear out that game if you keep playing so rough with it.

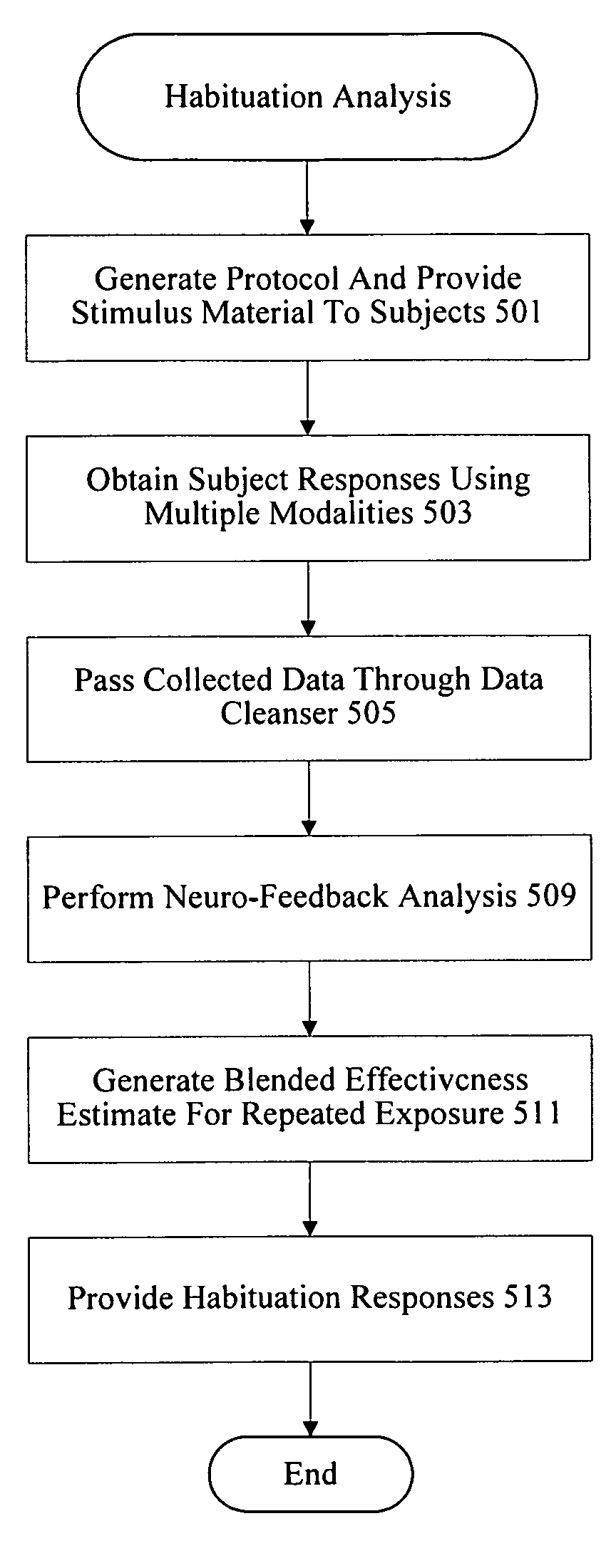

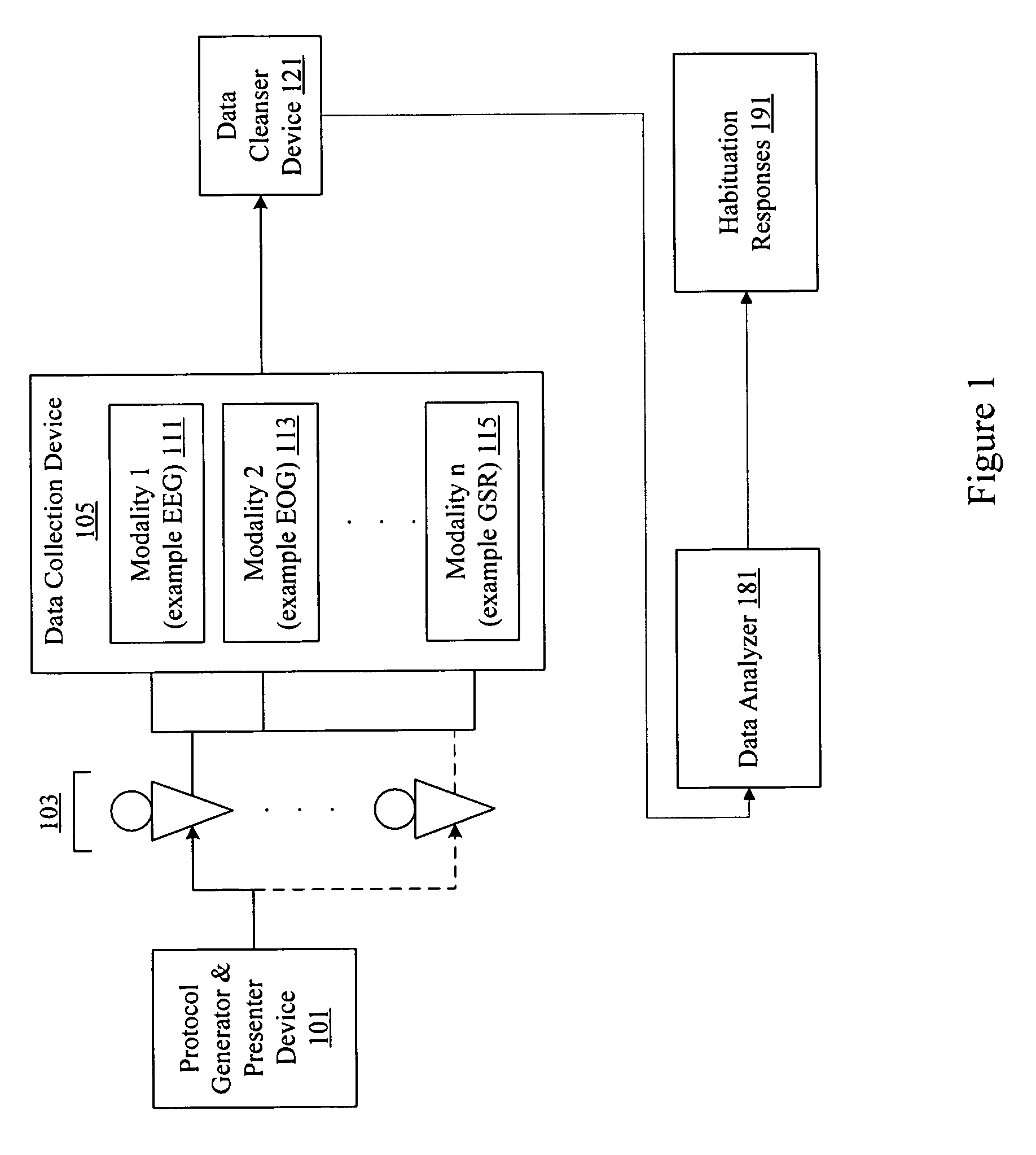

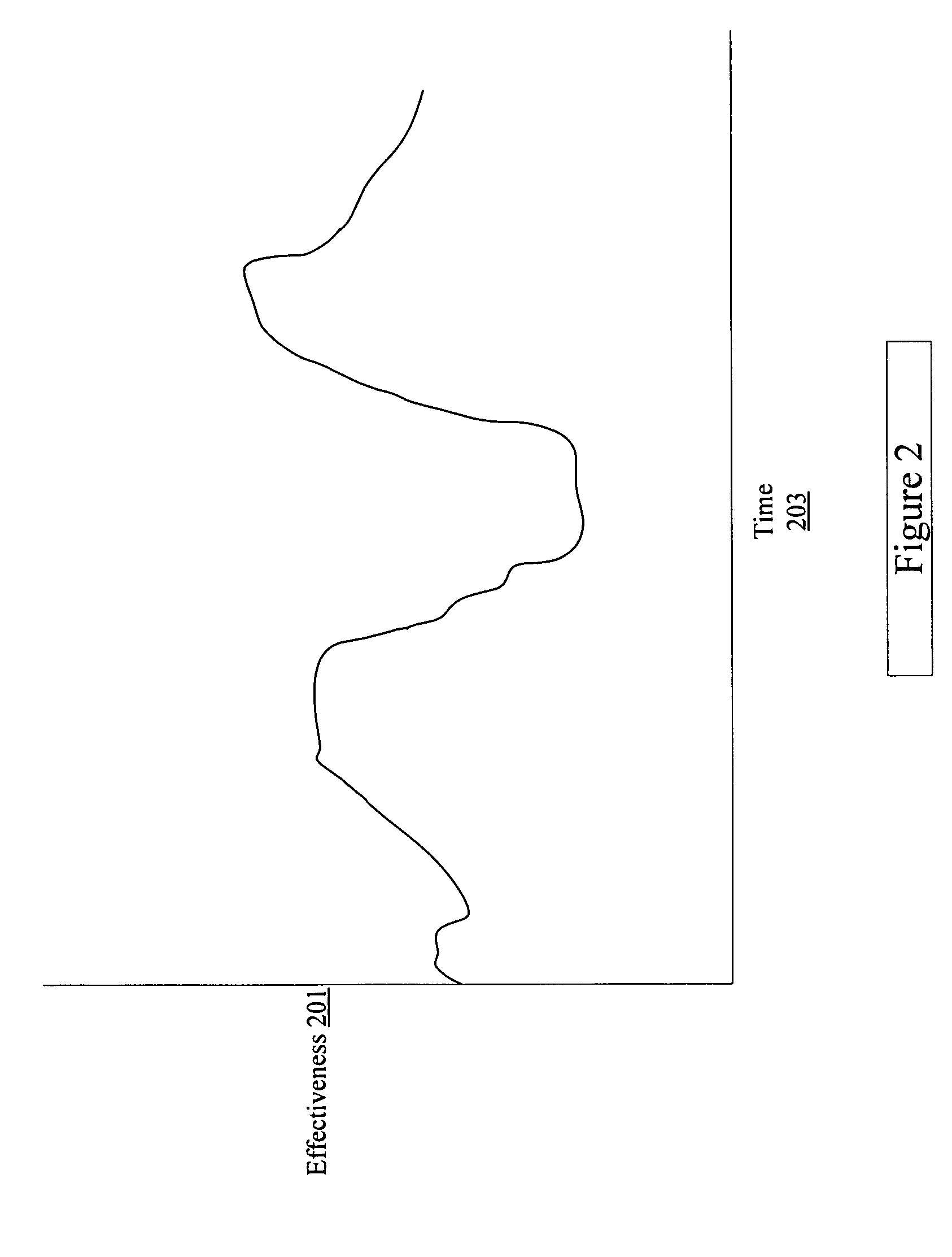

Habituation analyzer device utilizing central nervous system, autonomic nervous system and effector system measurements

A system performs habituation analysis using central nervous system, autonomic nervous system, and effector data. Subjects are repeatedly exposed to stimulus material and data is collected using mechanisms such as Electroencephalography (EEG), Galvanic Skin Response (GSR), Electrocardiograms (EKG), Electrooculography (EOG), eye tracking, and facial emotion encoding. Data collected is analyzed to determine habituation and associated wear-out profiles for stimulus material.

Owner:THE NIELSEN CO (US) LLC

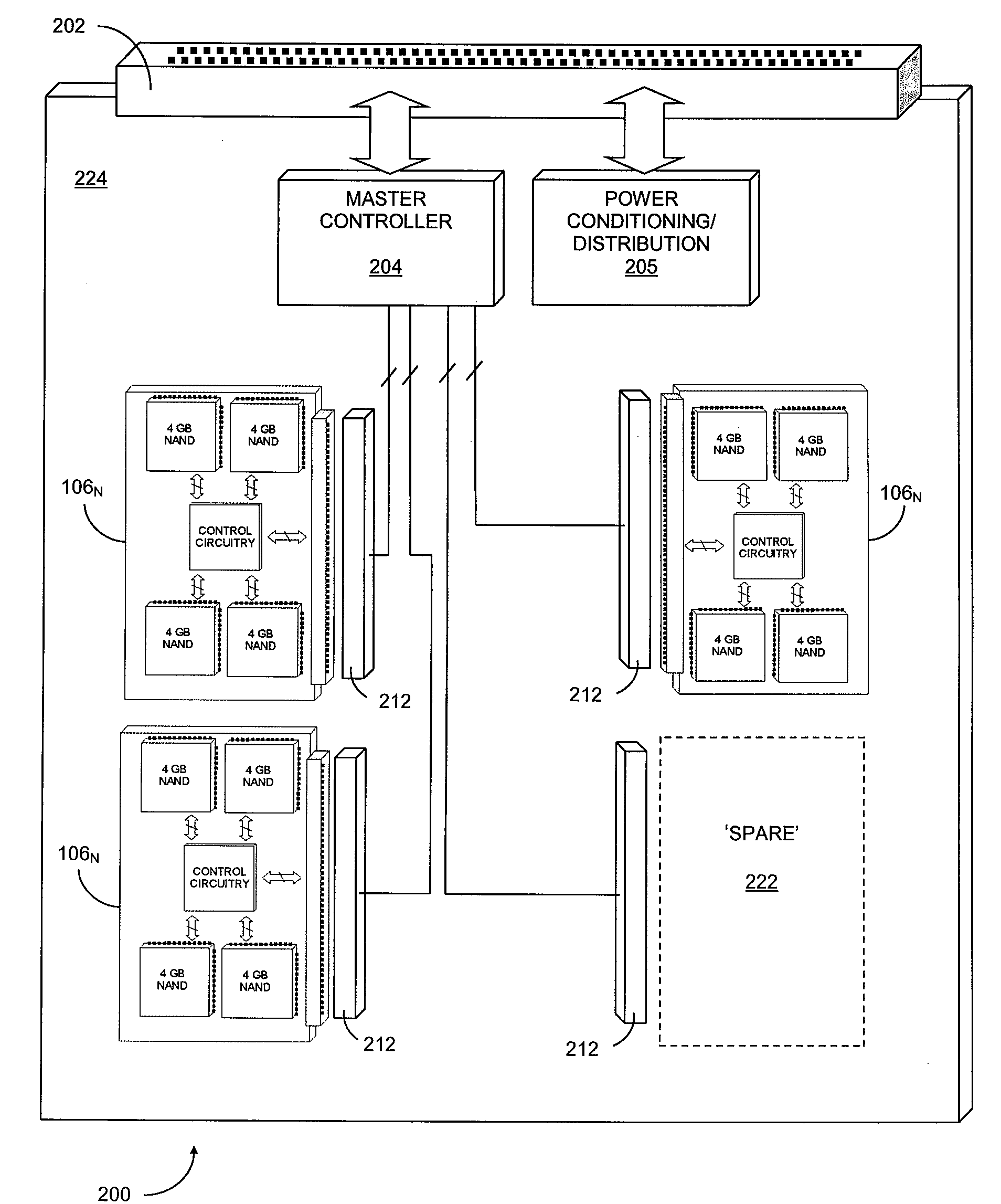

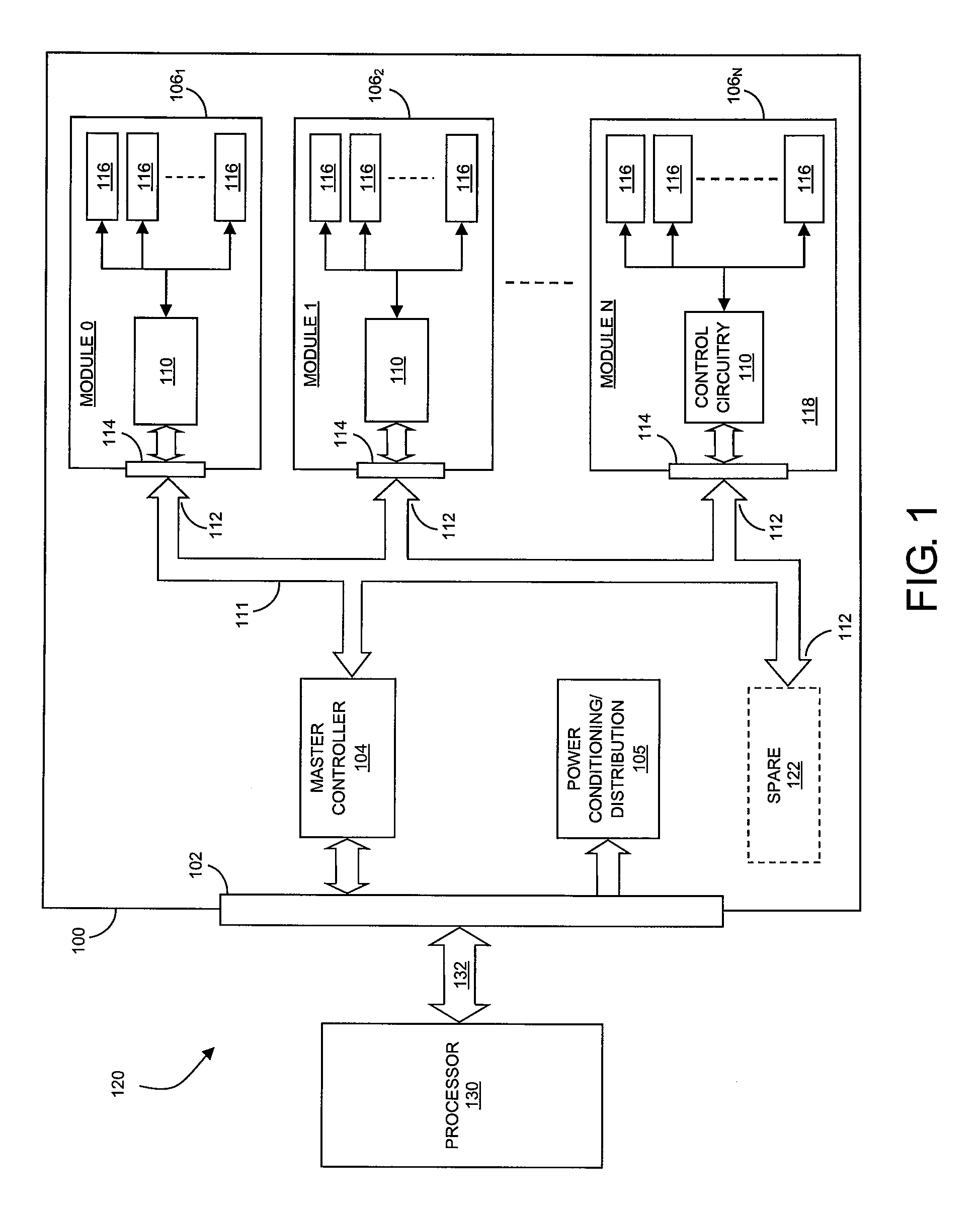

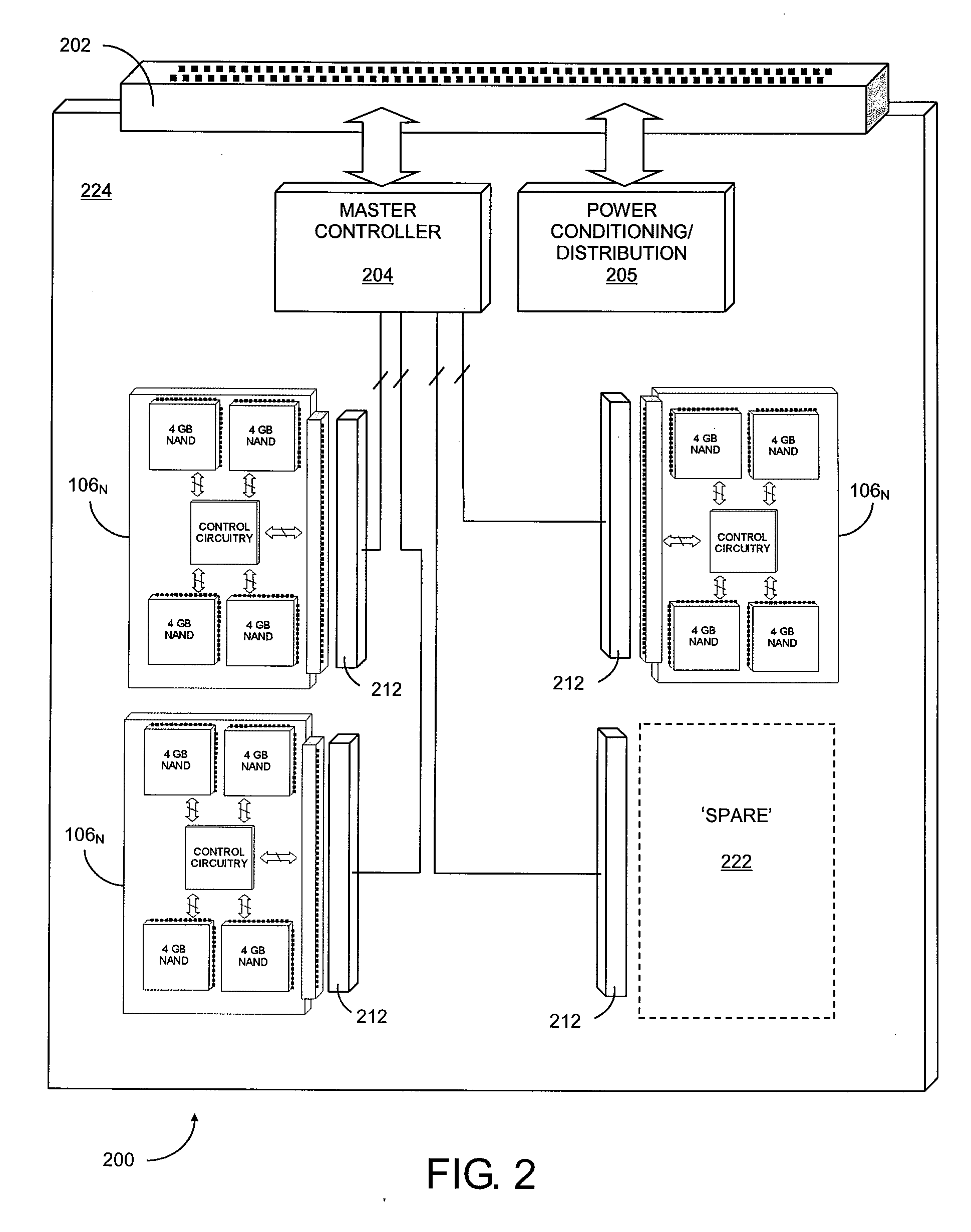

Scaleable and maintainable solid state drive

InactiveUS20090063895A1Memory adressing/allocation/relocationRedundant hardware error correctionInternal memoryEngineering

Methods and apparatus for maintaining a solid state disk drive facilitate expansion of storage capacity and maintenance of internal memory storage media, for example, are disclosed. Memory modules are adapted for removable installation in a solid state drive allowing for expansion of drive storage capacity and servicing of failed or worn out memory storage media. Data can be managed to mitigate loss during expansion, maintenance and servicing of the solid state drive.

Owner:MICRON TECH INC

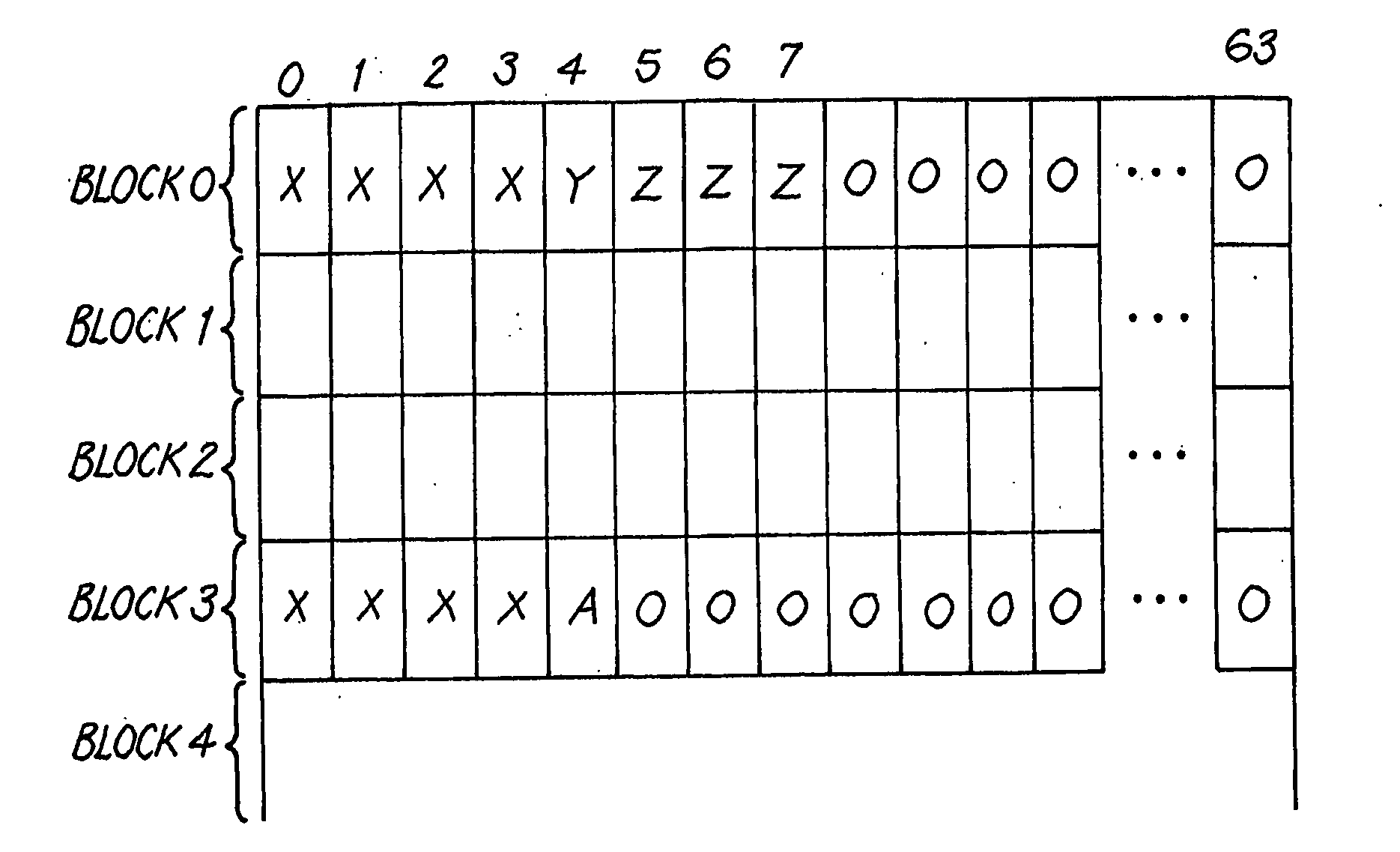

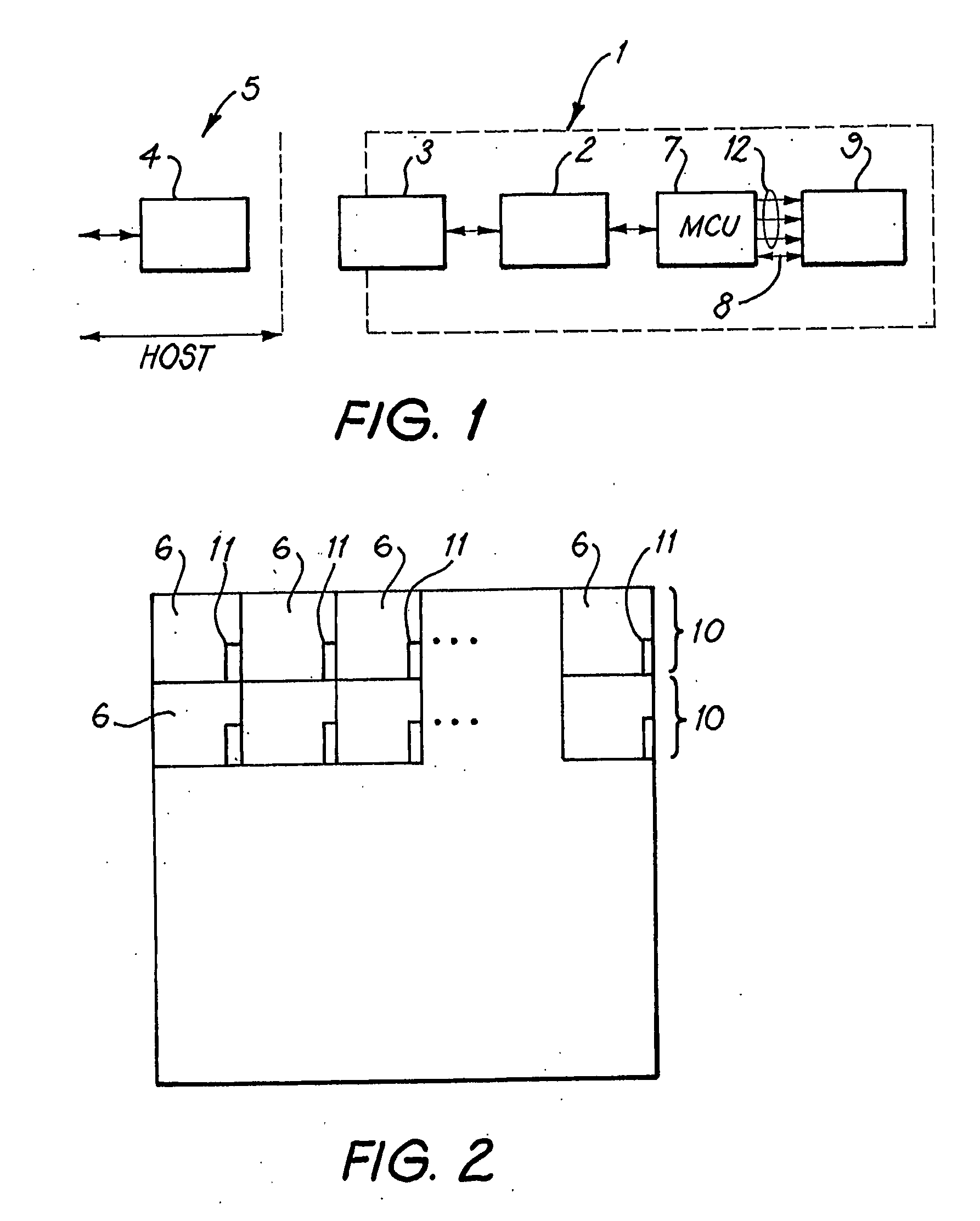

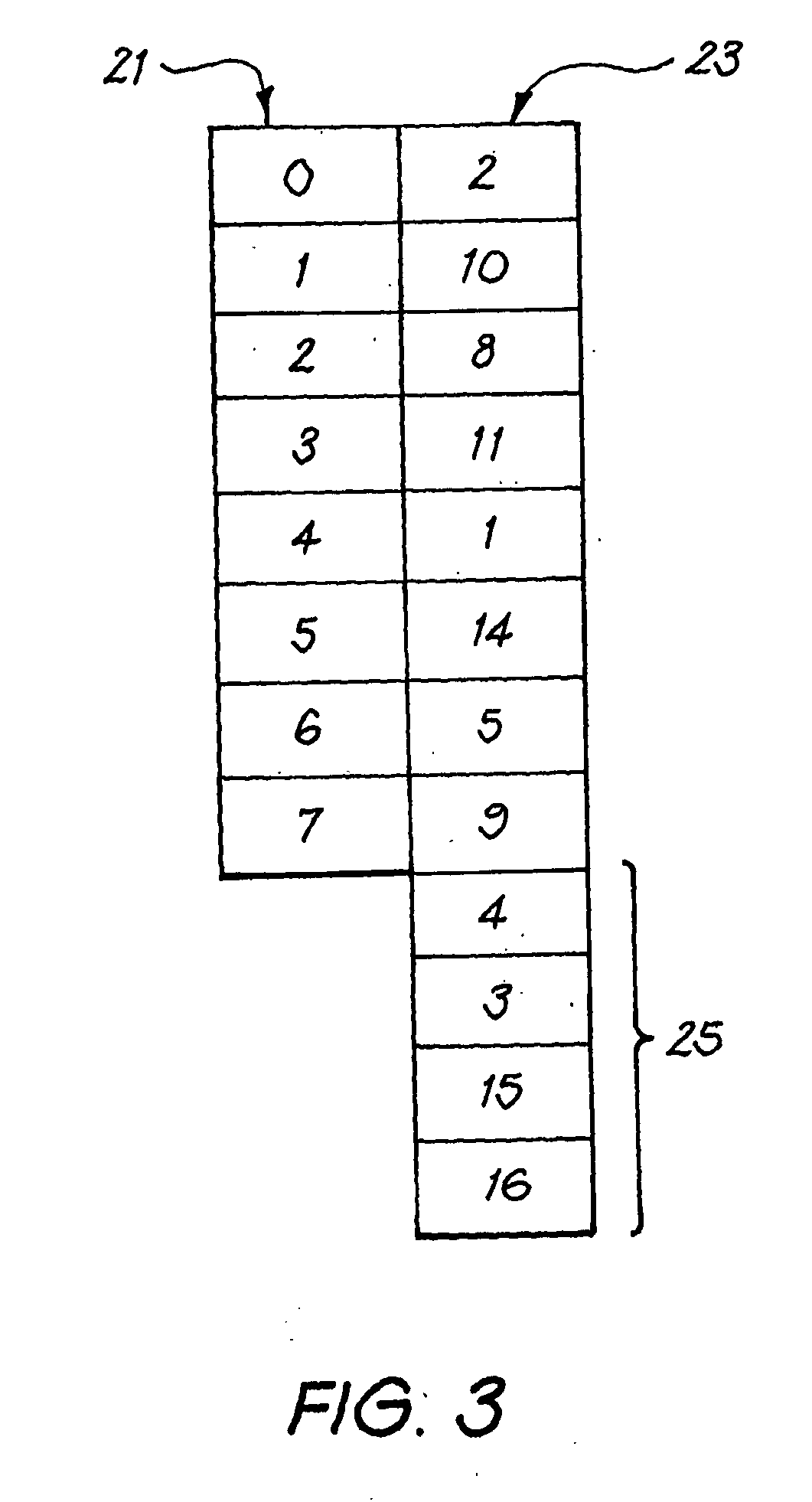

Portable Data Storage Device Using a Memory Address Mapping Table

InactiveUS20080228995A1Reduce in quantityFast operationMemory architecture accessing/allocationCombination recordingMemory addressUSB

A portable data storage device includes a USB controller, a master control unit and a NAND flash memory device. The master control unit receives data to be written to logical addresses, and instructions to read data from logical addresses. It uses a memory address mapping table to associate the logical addresses with the physical addresses in the memory device, and writes data to or reads data from the physical address corresponding to the logical address. The mapping is changed at intervals, so that different ones of the physical address regions are associated at different times with the logical addresses. This increases the speed of the device, and also means that no physical addresses are rapidly worn out by being permanently associated with logical addresses to which data is written relatively often.

Owner:TREK TECH SINGAPORE PTE

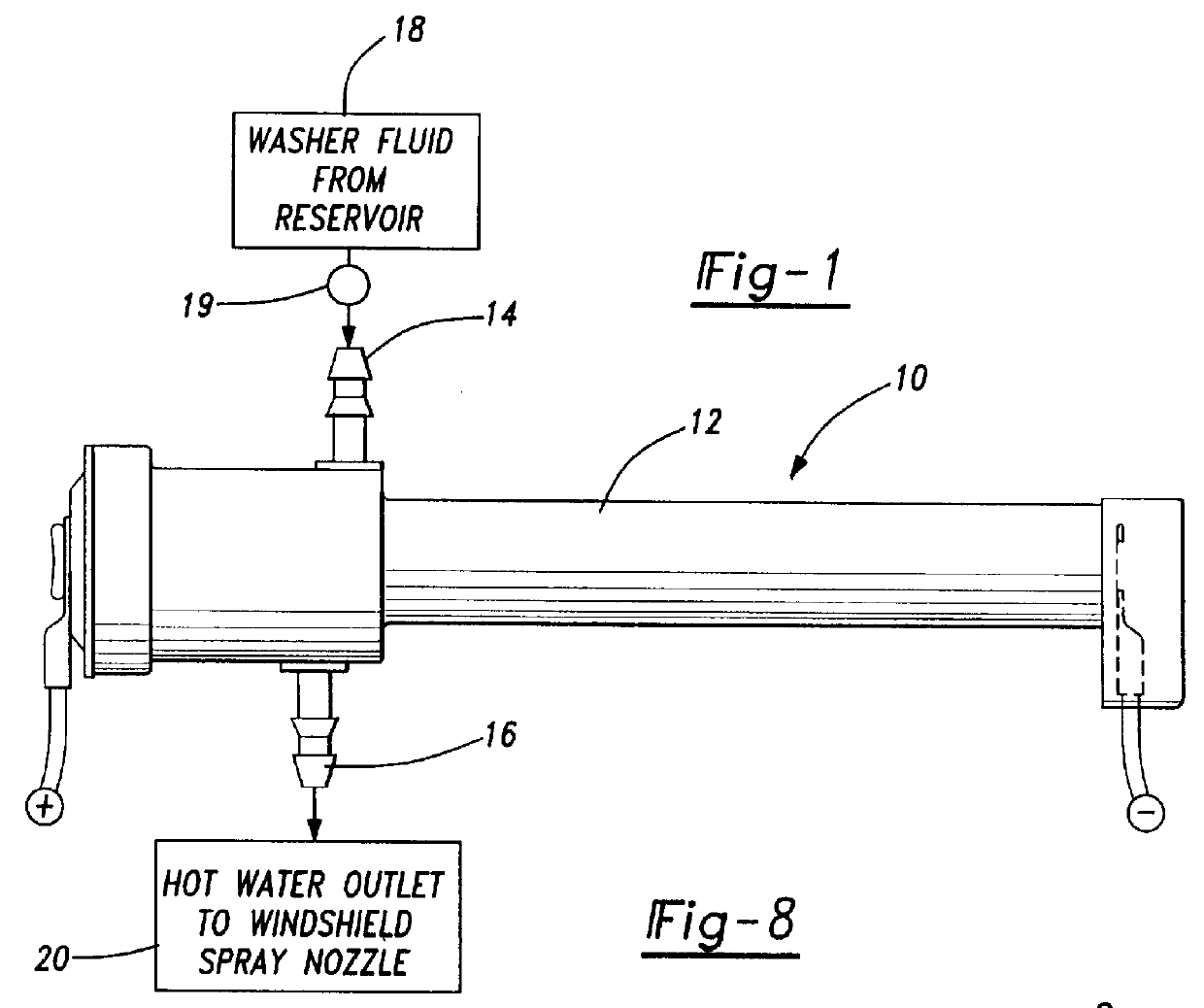

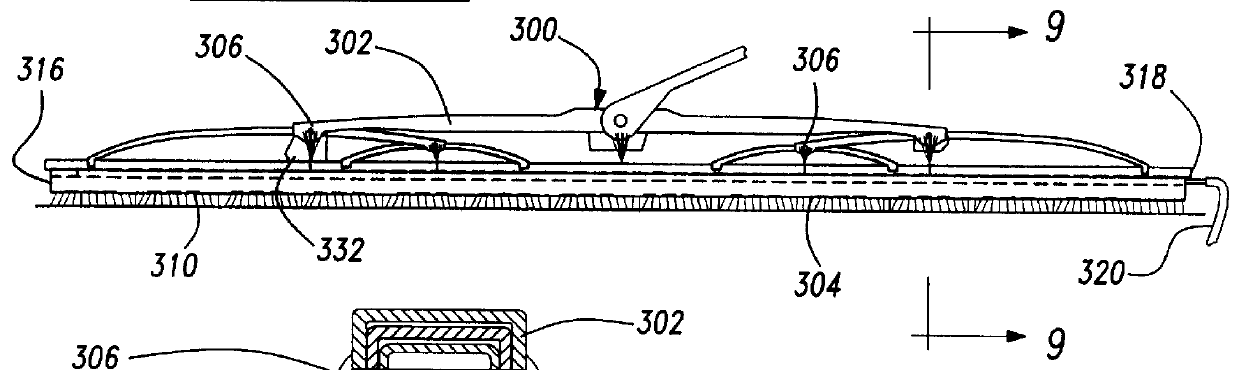

Windshield heated wiping system

InactiveUS6032324AEffectively doubling clean wiping life of the rubber bladeSpray nozzlesWindow cleanersCounter flowEngineering

A windshield wiper system for an automotive vehicle is disclosed in which the windshield wiper washer fluid is heated and delivered to the windshield through the rubber wiping element. In one embodiment, the windshield wiper fluid is heated to a substantial level of temperature and pressure within a sealed reservoir by the heat from the engine coolant system. In another embodiment, a tubular electrical high intensity heating element with turbulent counter flow is used to instantly heat the windshield wiper fluid, and the heating element is automatically electrically energized in response to fluid flow through the tubular heating element. In another embodiment electrical direct current vehicle power or selectively alternating current external power is used to heat fluid to a substantial level of temperature and pressure within a sealed insulated reservoir. A novel windshield wiper blade is also disclosed in which the wiper blade has a longitudinally elongated fluid chamber formed along its length. The fluid chamber is closed at one end and connected to the source of the washer fluid at its other end. A plurality of longitudinally aligned slits is formed through the wiper blade to the outlet edge to uniformly dispense the heated washing fluid downstream of wipe direction, and onto the vehicle windshield while one or more openings are also formed in the wiper blade to direct a portion of the heated washing fluid to the joints in the wiper support frame to remove ice binding the wiper frame flex joints. Additionally, the dual configuration of the blade edge is such that the second edge pair wears out sequentially to the first edge pair effectively doubling the clean wiping life of the blade.

Owner:LANSINGER JERE RASK

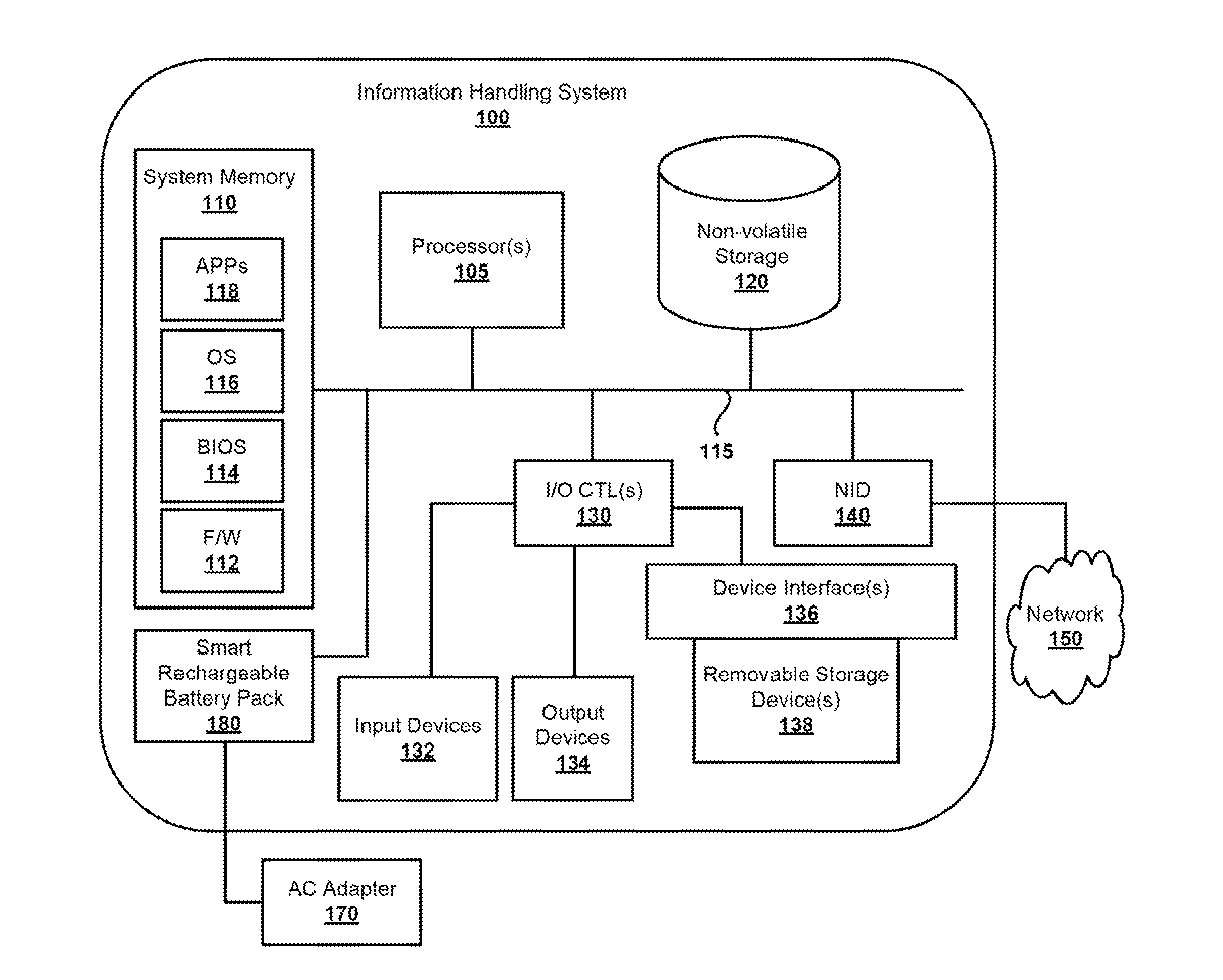

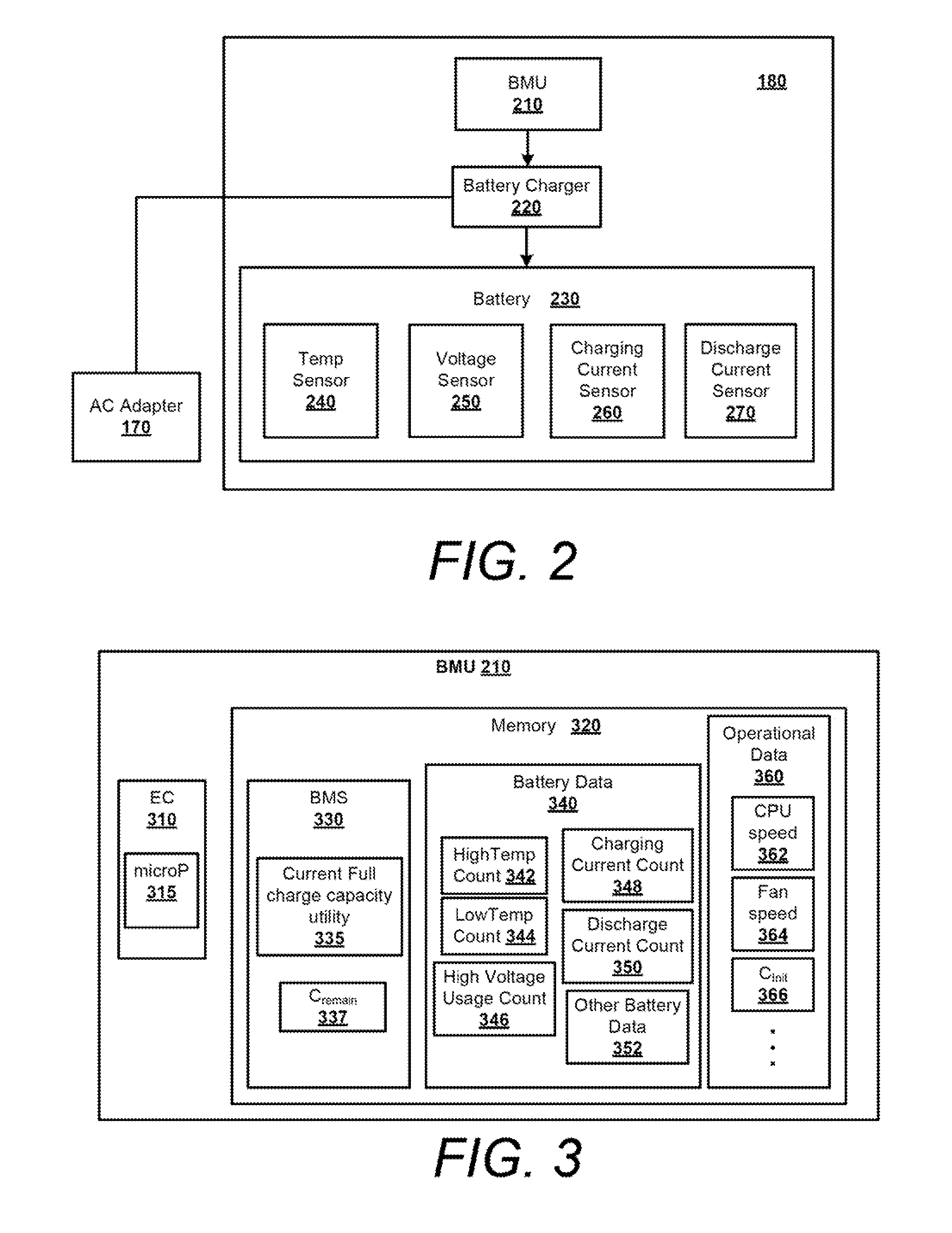

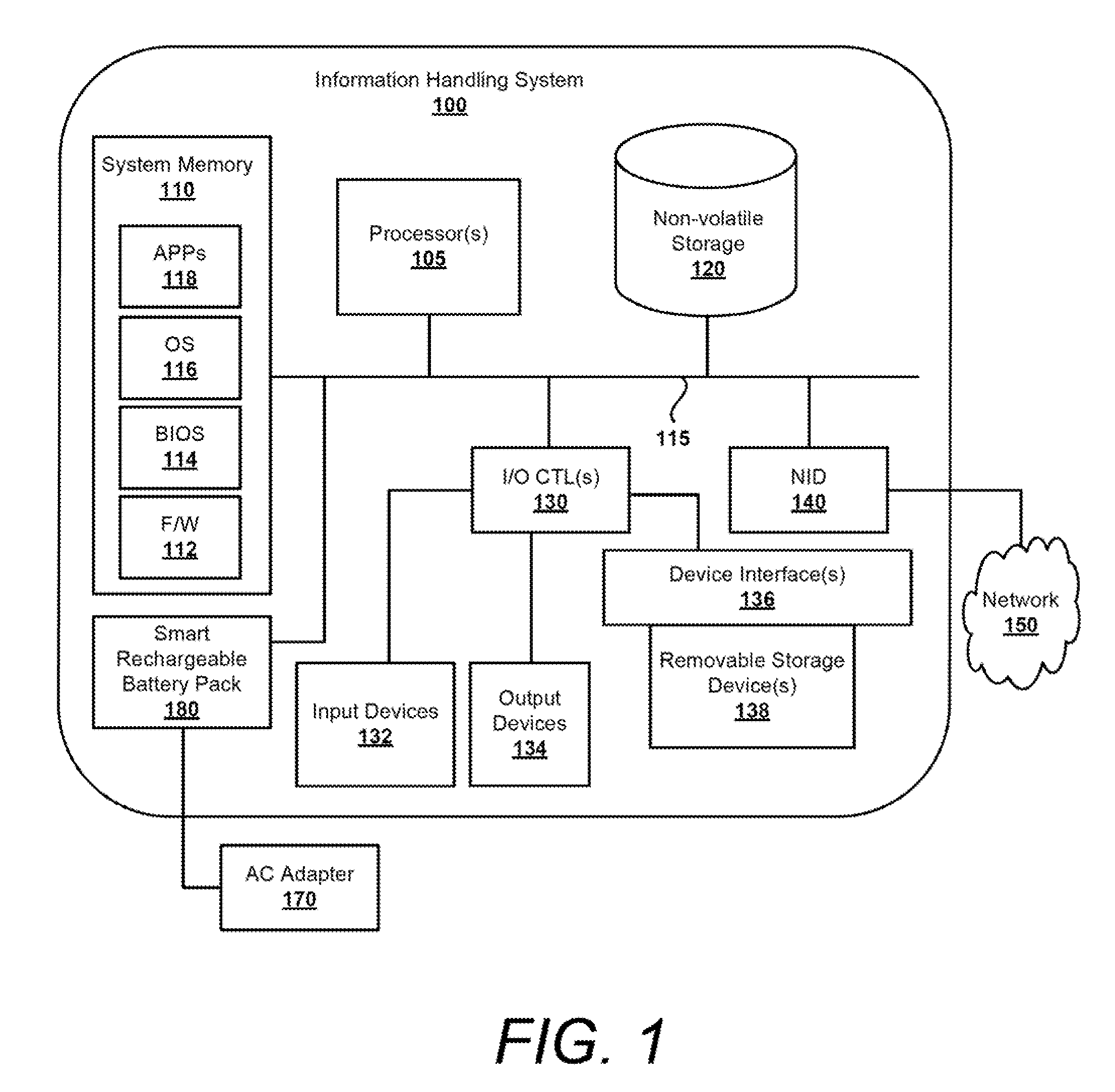

Mitigating premature wear out of a rechargeable battery

ActiveUS20140217958A1Rate of decrease in fullReduce degradation rateElectrical testingElectric powerRechargeable cellInformation handling system

A computer-implemented method and information handling system manage a rate of decreasing full capacity of a rechargeable battery by using a projected / target rate of decreasing charge capacity for the battery. The method includes determining an actual rate of decreasing charge capacity of the battery, comparing the actual rate of decreasing charge capacity to the projected / target rate of decreasing charge capacity to determine whether the actual rate of decreasing charge capacity is greater than the projected rate of decreasing charge capacity, and if the actual rate of decreasing charge capacity is greater than the projected / target rate of decreasing charge capacity, modifying one or more variable parameters to slow down the actual rate of decreasing charge capacity of the battery such that the actual rate of decreasing charge capacity remains within a range of the projected / target rate of decreasing charge capacity, and charging and discharging the battery using the modified parameters.

Owner:DELL PROD LP

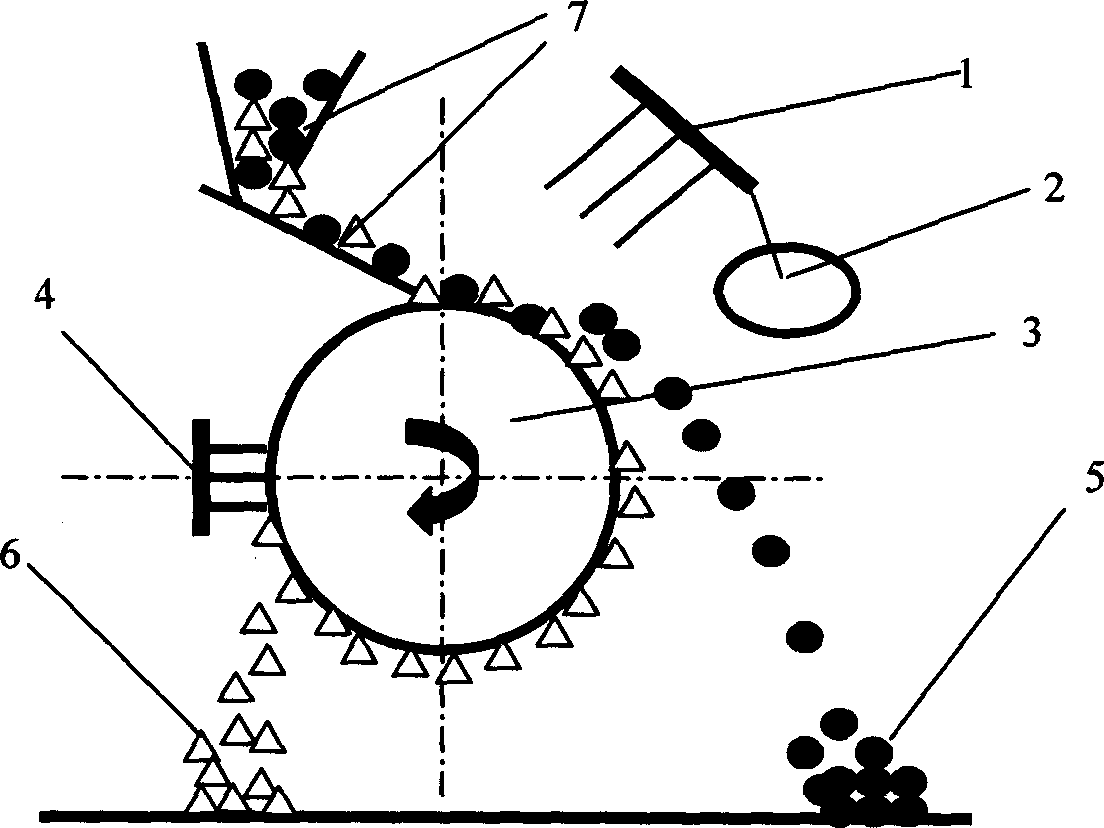

Breaking and high tension electrostatic separating method for worn-out printed circuit board

InactiveCN1654124ANo pollution in the processReduce pollutionElectrostatic separationGrain treatmentsElectrostatic separationEngineering

The crushing and high voltage electrostatic separation process of waste printed circuit board includes first crushing waste printed circuit board into 5-20 mm fragments, then pulverized into 0.06-0.5 mm grains and final separating metal grains from non-metal grains. The pulverized grains are fed to separating roller in high voltage electrostatic separating apparatus homogeneously and bombarded with negative ions the corona electrode generates to be charged. The metal grains are discharged fast in the earthing roller and electrostatically attracted with the static charge the electrostatic electrode generates to separate from the separating roller and fall into the metal collecting area, while the negatively charged non-metal grains are repelled electrically by the electrode to maintain on the surface of the metal roller before being brushed with a brush to fall into the non-metal collecting area. Thus, non-metal grains are separated from the metal grains in low cost, high efficiency and no pollution.

Owner:SHANGHAI JIAO TONG UNIV

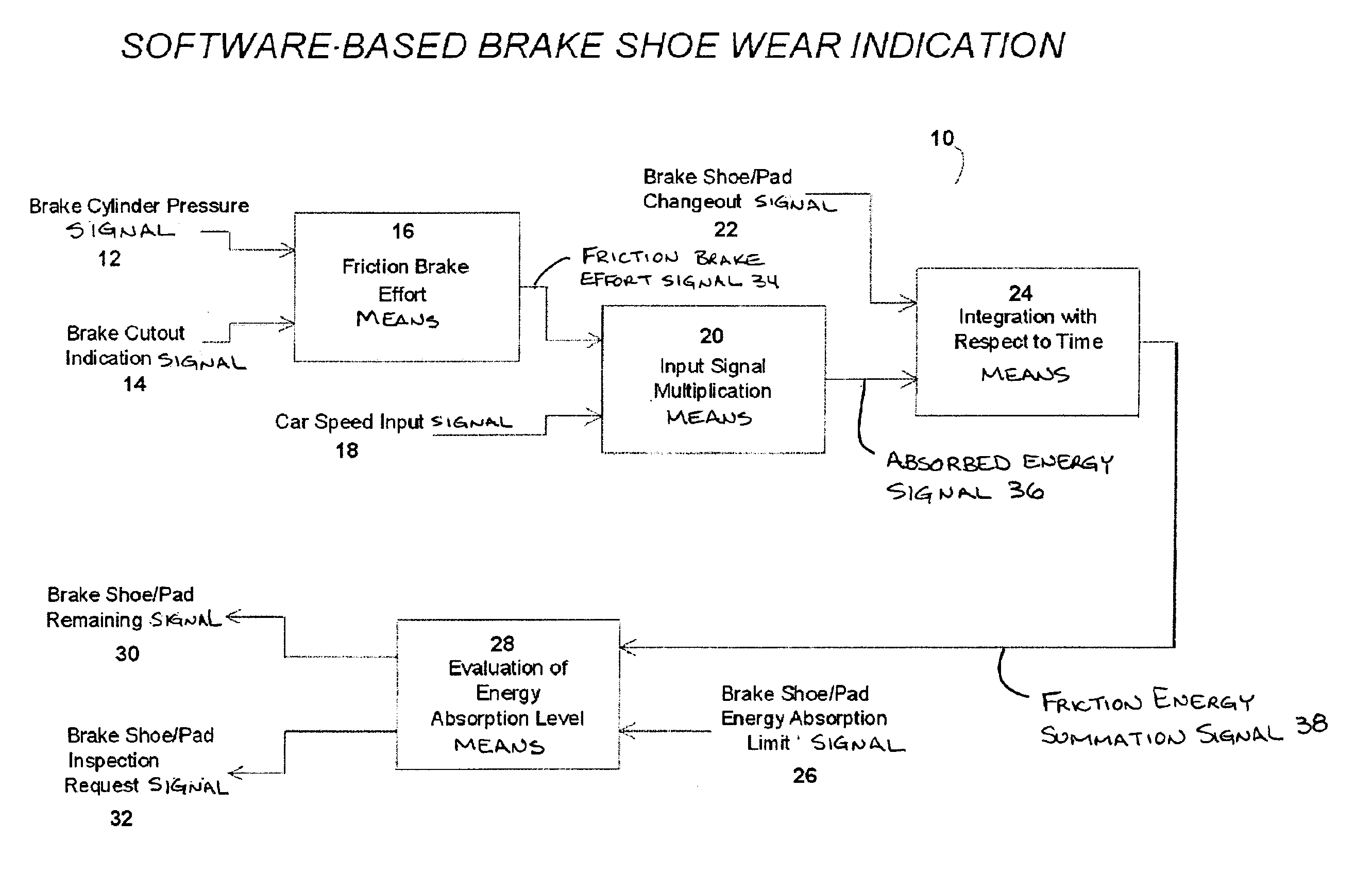

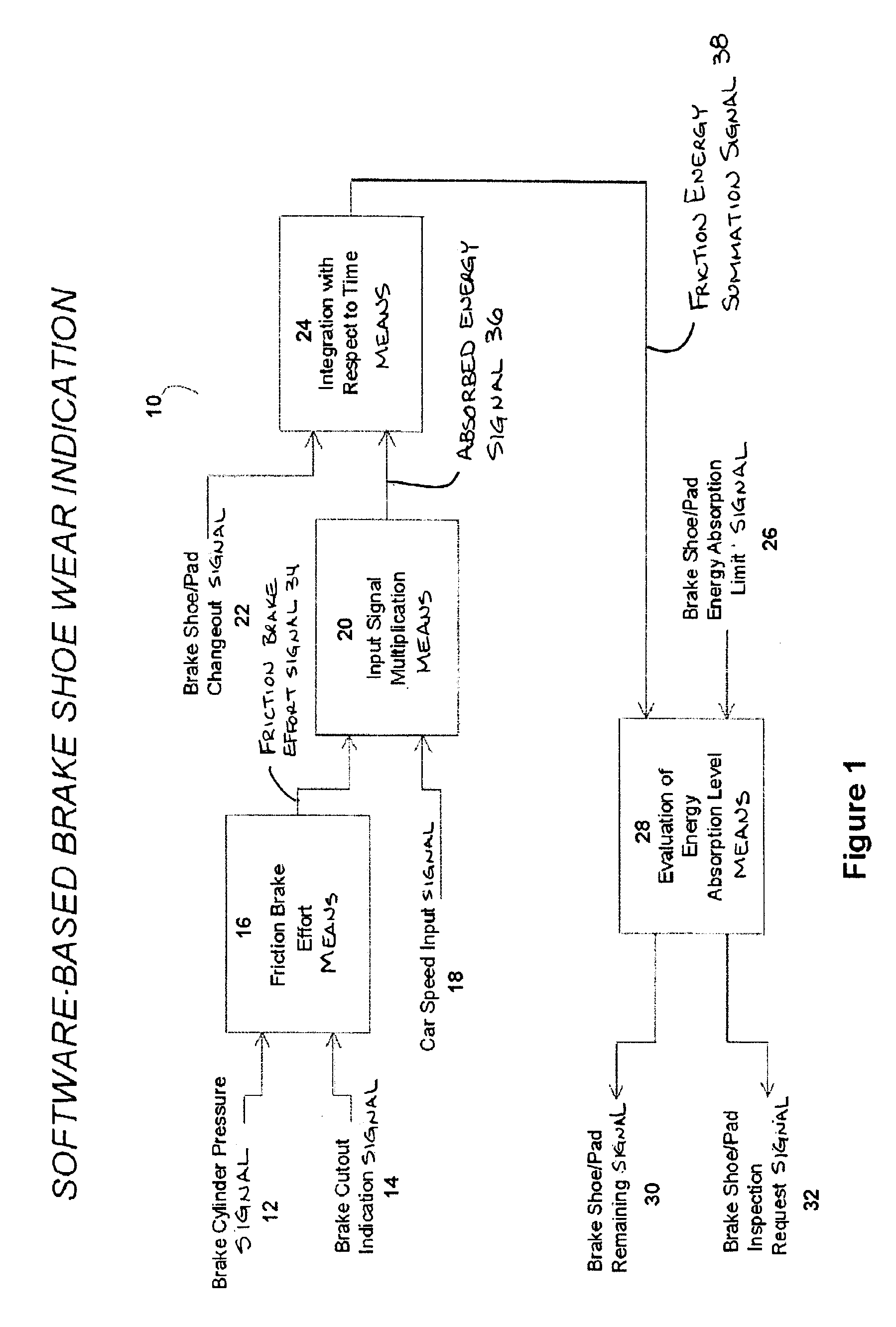

Software based brake shoe wear determination

InactiveUS6847869B2Reduce harmReduce amount of friction brake effort suppliedVehicle testingRegistering/indicating working of vehiclesEngineeringEnergy supply

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

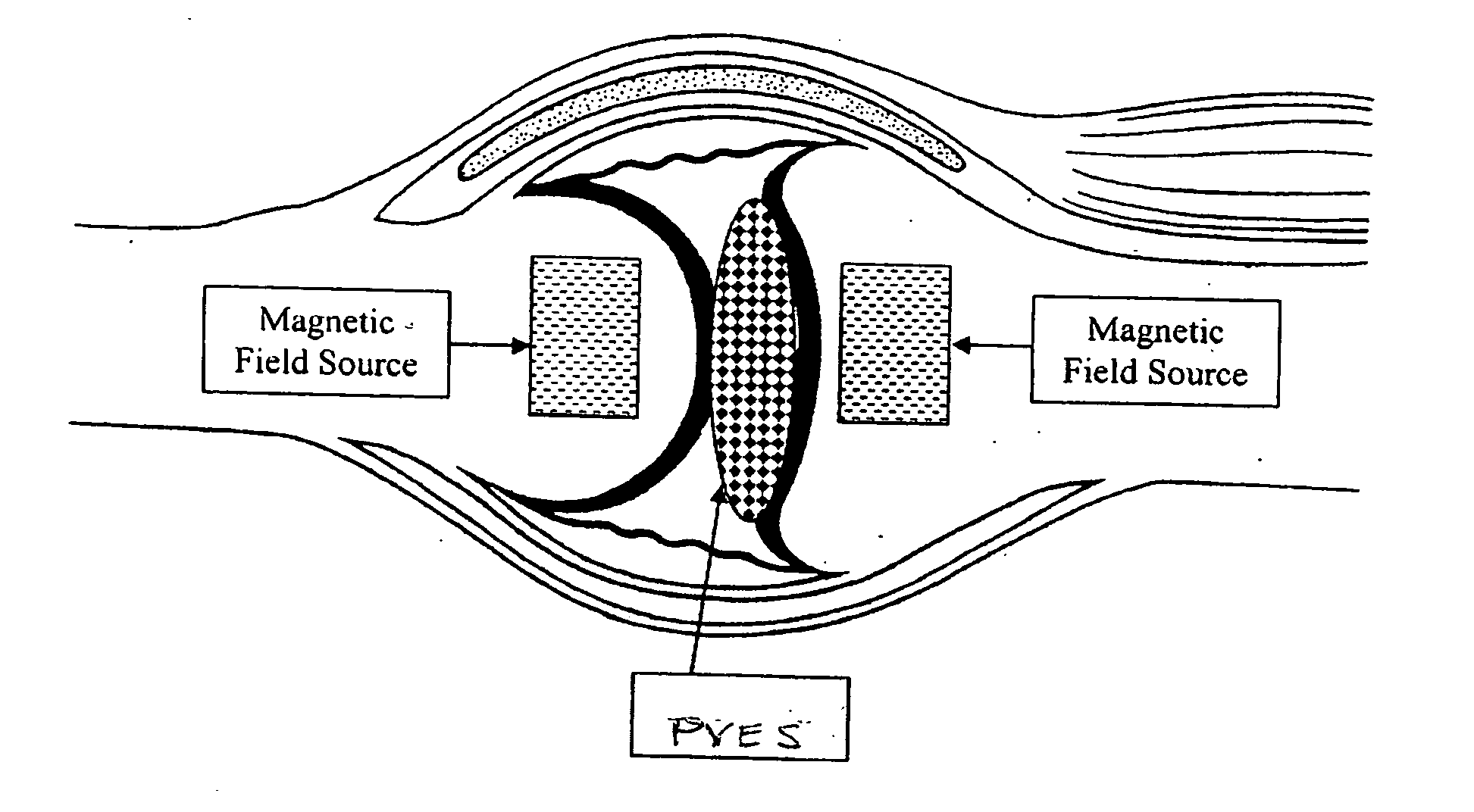

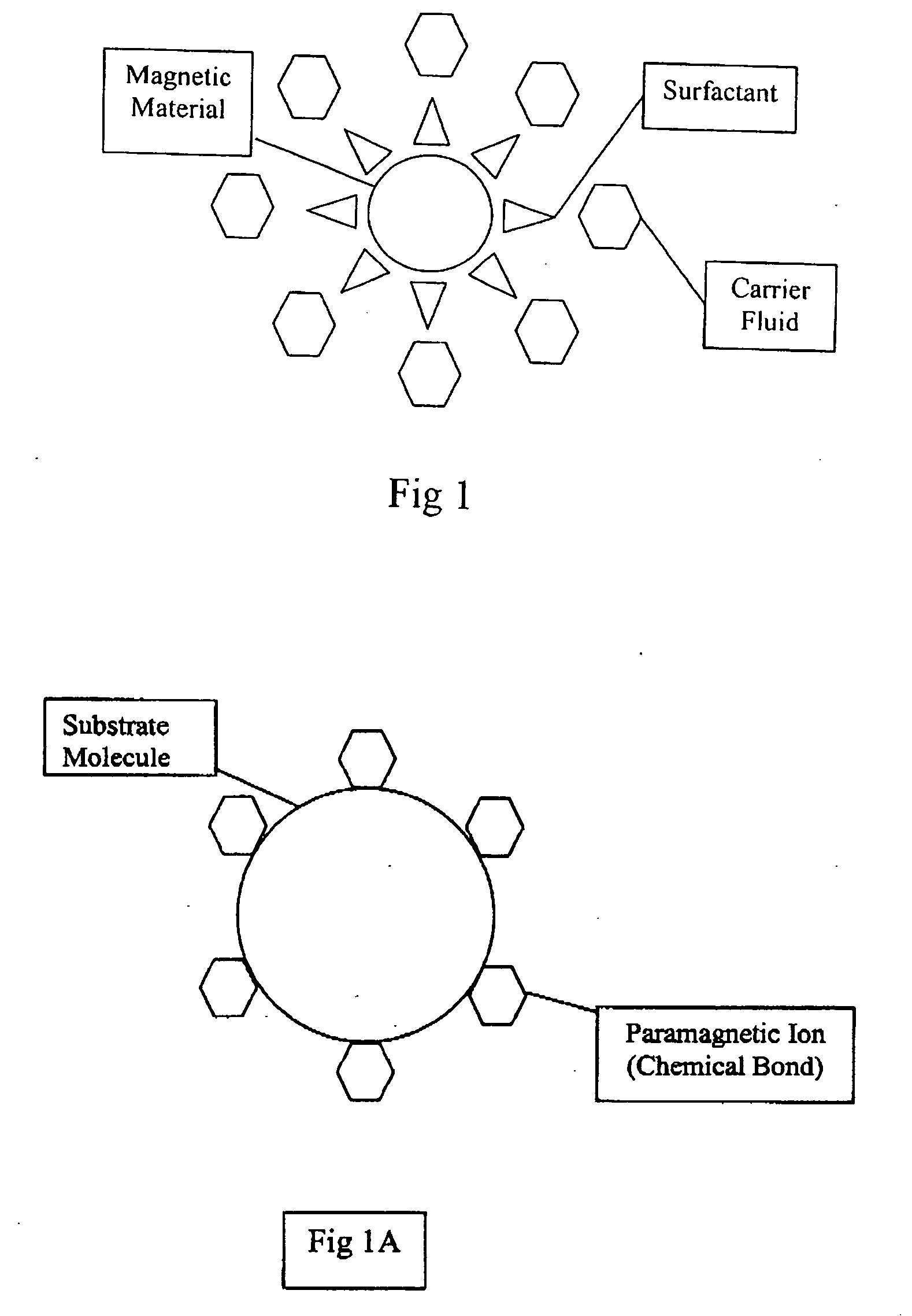

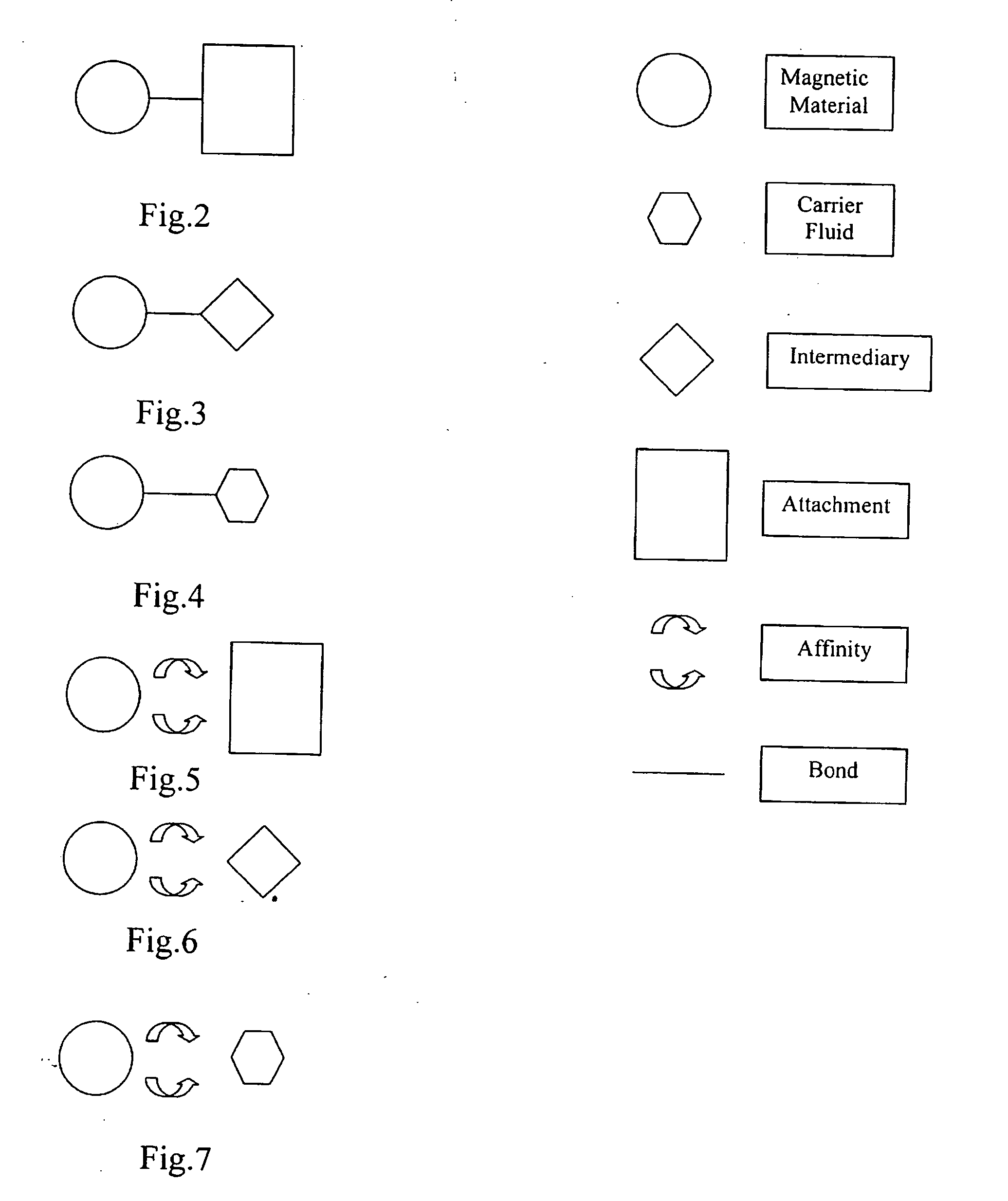

Paramagnetic liquid interface

InactiveUS20070100457A1Improve rheologyExtended durationFinger jointsWrist jointsArticular surfacesEngineering

Natural joint interfaces wear out and / or are damaged causing pain and disability. They can be currently replaced by artificial surfaces made of materials or in the near future by magnetic fields. They would benefit from a PVES (paramagnetic visco-viscoelastic supplement) that can replace or augment natural joint interfaces or augment total joint replacements. Joint replacement components can be modular and would benefit from a PVES to decrease wear and damp impact between modular parts of a single component. The PVES is a dynamic interface allowing components to be less rigid. Energy transmission is reduced. PVES can act as an interface between natural damaged joint surfaces obviating the need for classic total joint replacement or between the surfaces of artificial joint components to improve or supplement their function. These PVES can be controlled by magnetic fields with respect to their location, physical properties, loads, etc. PVES are typically made of paramagnetic ions and a substrate molecule. One such PVES can be made of gadolinium ions and hyaluronic acid to form gadolinium hyaluronate.

Owner:HYDE EDWARD R JR

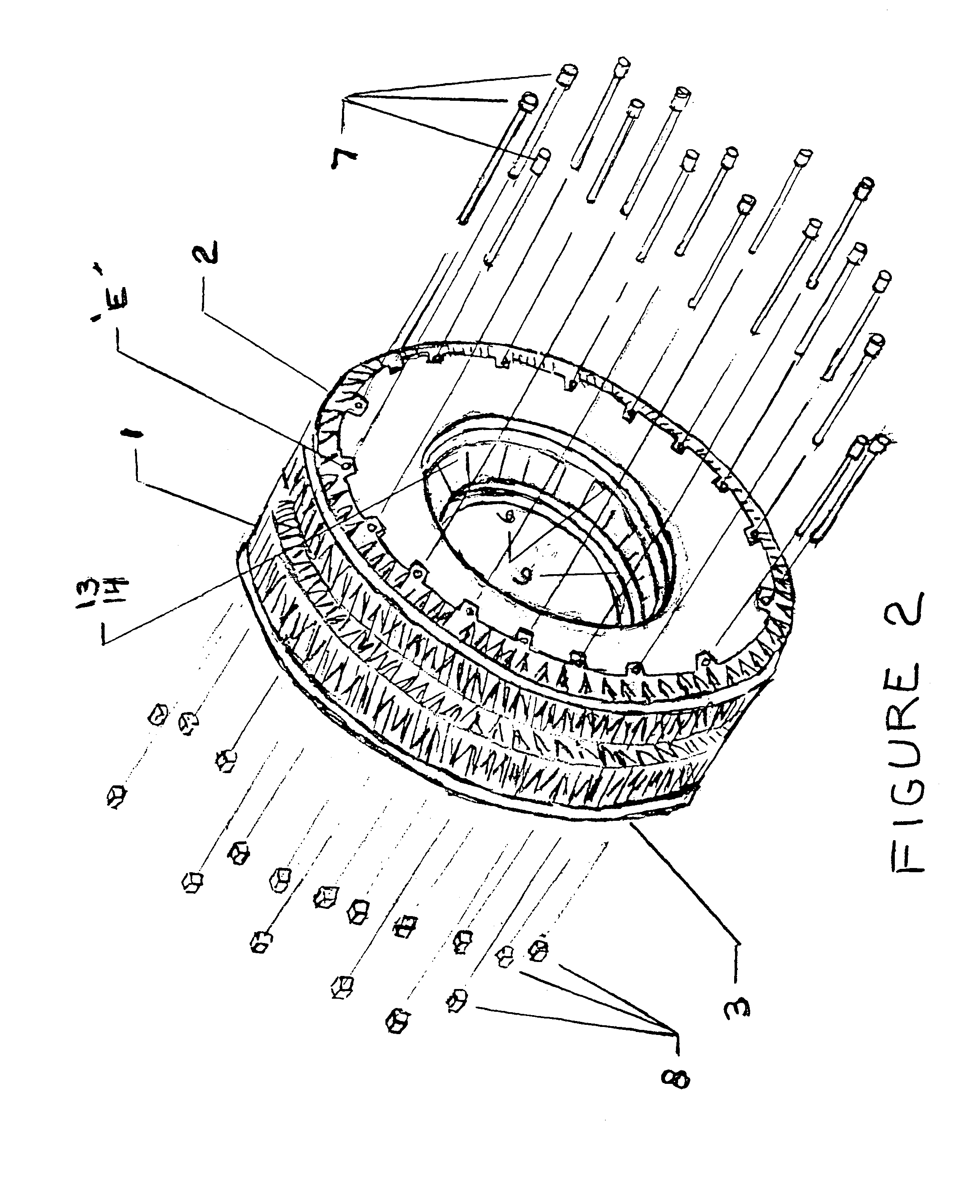

Modular tire

InactiveUS7316252B1Less expensiveWith separate inflatable insertsWith multiple inflatable chambersModularityFlat tire

A device for serving as a wheel for motor vehicles, where the wheel has its tire tread replaceable when it is worn out via unique rims and molded tire features. An alternate internal structure prevents the tire from “going flat” or “blowing out” when it is punctured or cut. In one variation the tire can be used with existing rims and can be retro-fitted into existing tire by mating the tires with this invention's “Non-Flat Tire” internal element and special rim. A variation of the “Non-Flat Tire” system uses spring-like materials for its tire core that is shaped similar to a tire's inner tube, and functions like an “air-filled” tire, but the absence of the use of air in this unique configuration gives it the “Flat Tire Prevention” effect.

Owner:HEARD NATHANIEL

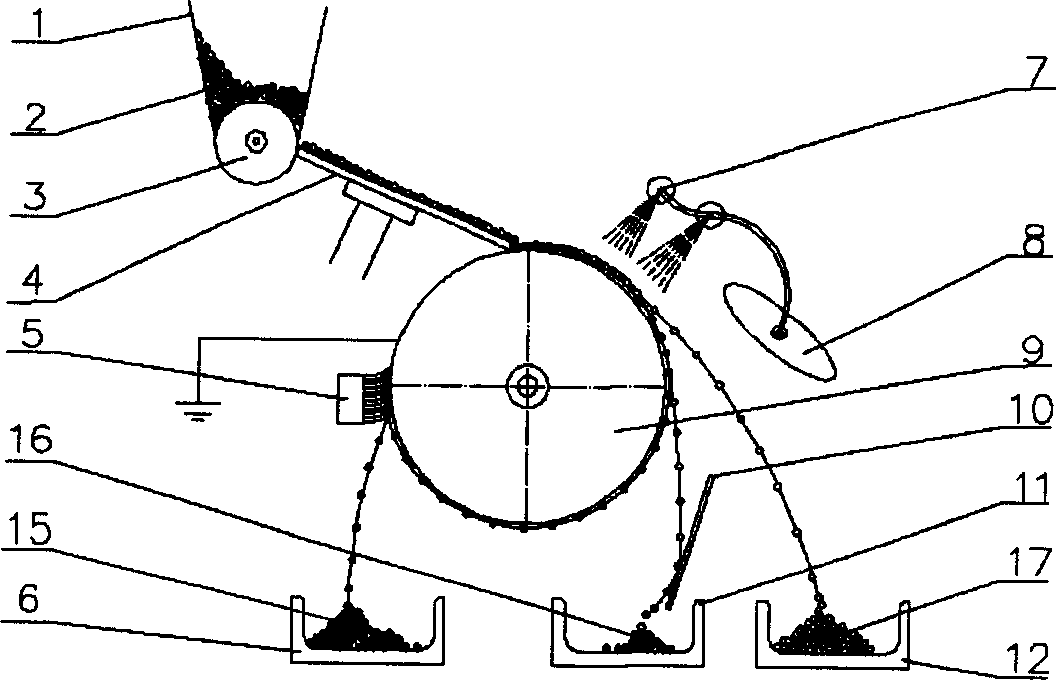

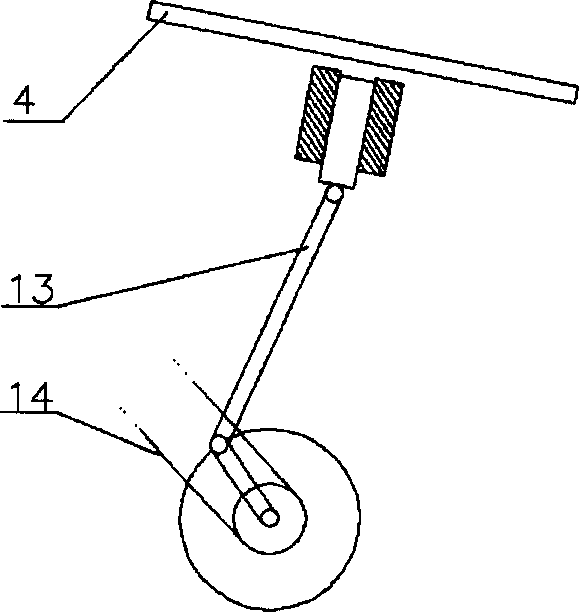

Friction-loss and vibration analog experimental equipment for main motion components of IC engine

InactiveCN1940523AMonitor temperature in real timeReal-time monitoring of abrasive compositionInternal-combustion engine testingInvestigating abrasion/wear resistancePiston ringFriction loss

A tester used for simulating wear-out and vibration of main movable parts on internal combustion engine consists of master driving system formed by air cylinder, piston ring, piston, crankshaft, inlet and outlet of high pressure air; state monitoring system formed by pressure transducer and vibration transducer on bearing base, oil monitoring transducer and temperature transducer as well as vibration transducer on machine rack, and dynamic transducer on crankshaft. It is featured as utilizing high pressure air to simulate explosion pressure in air cylinder and to simulate operation condition causing wear-out and vibration of cylinder sleeve and piston ring pair in said engine.

Owner:WUHAN UNIV OF TECH

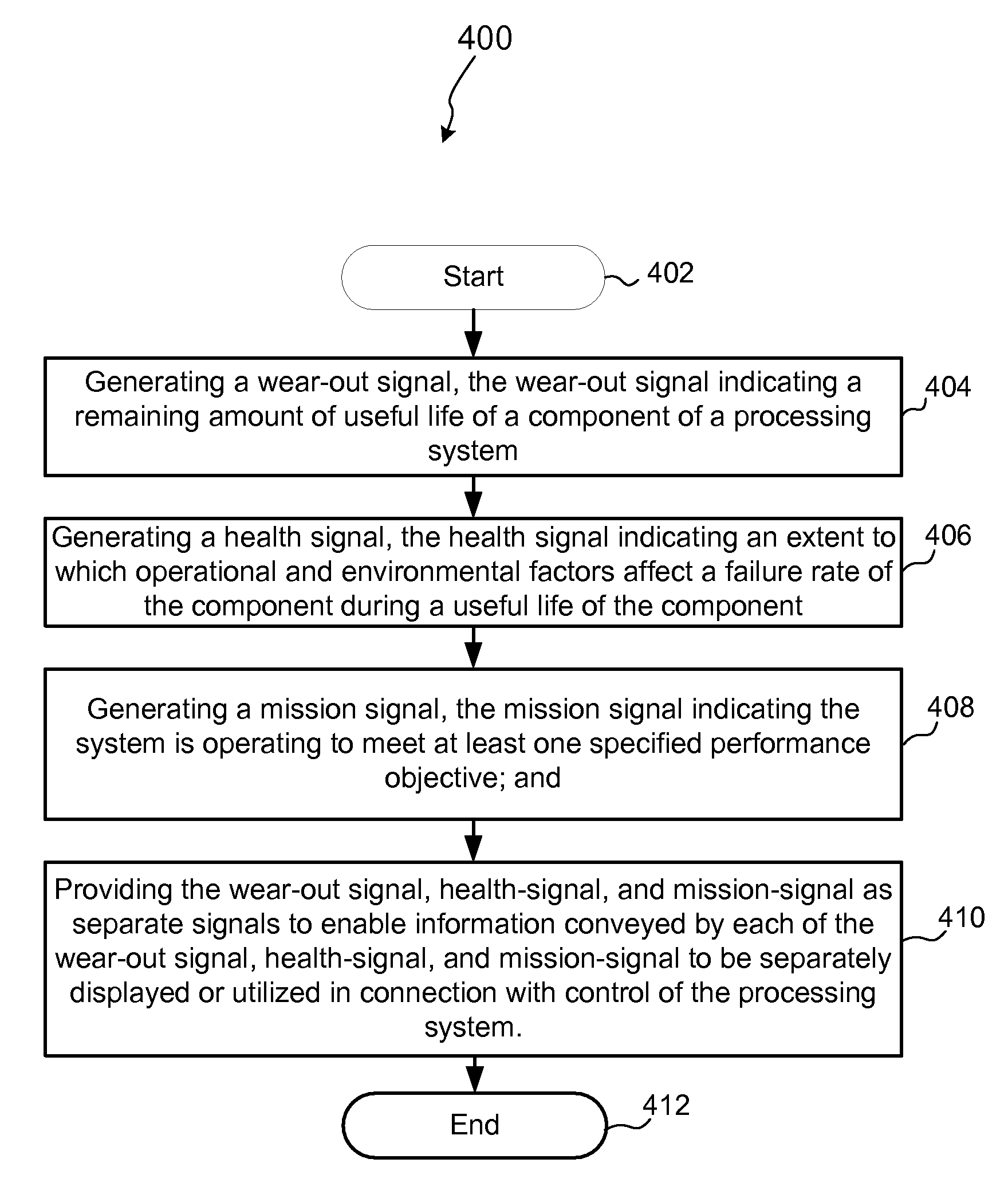

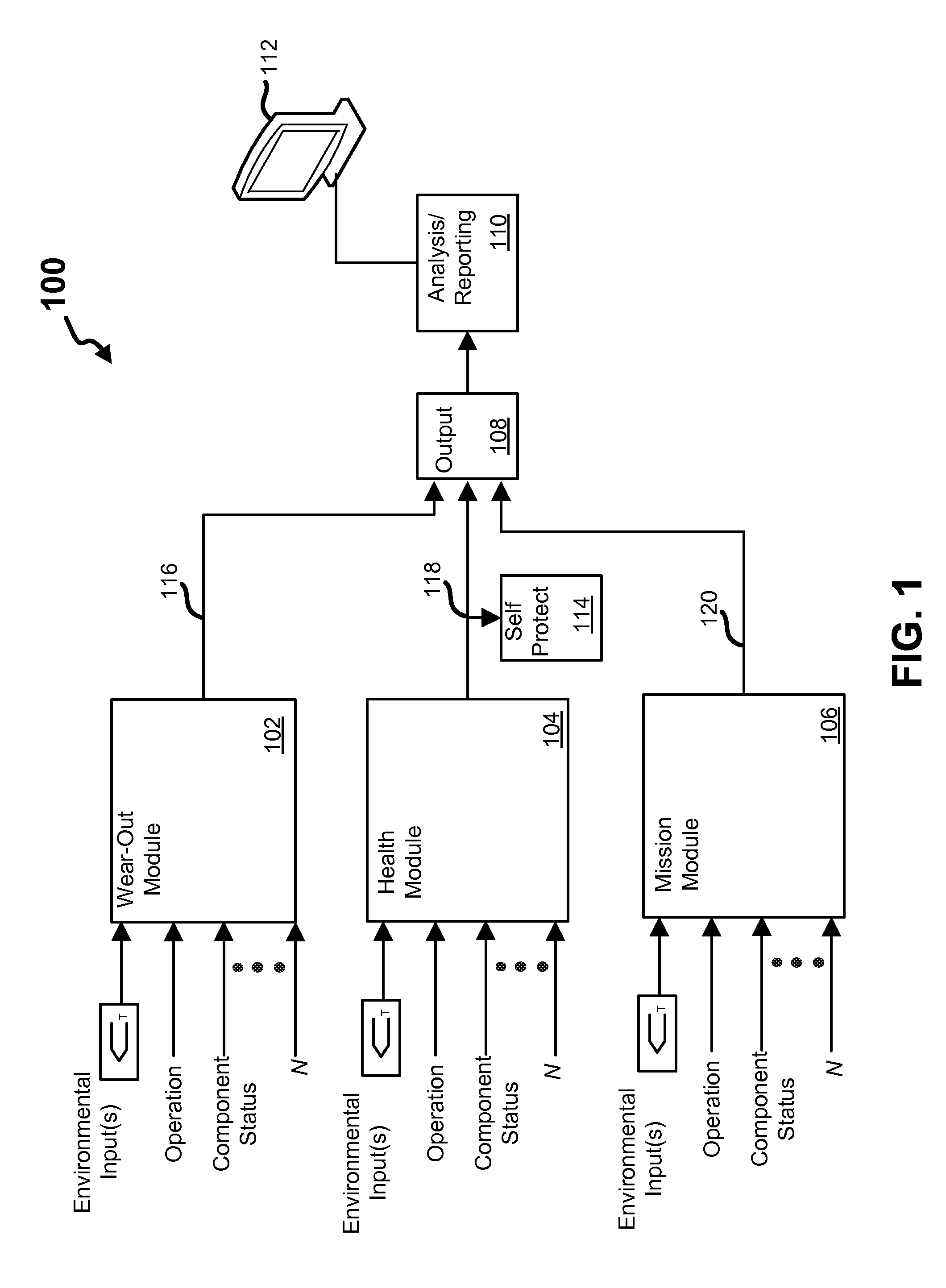

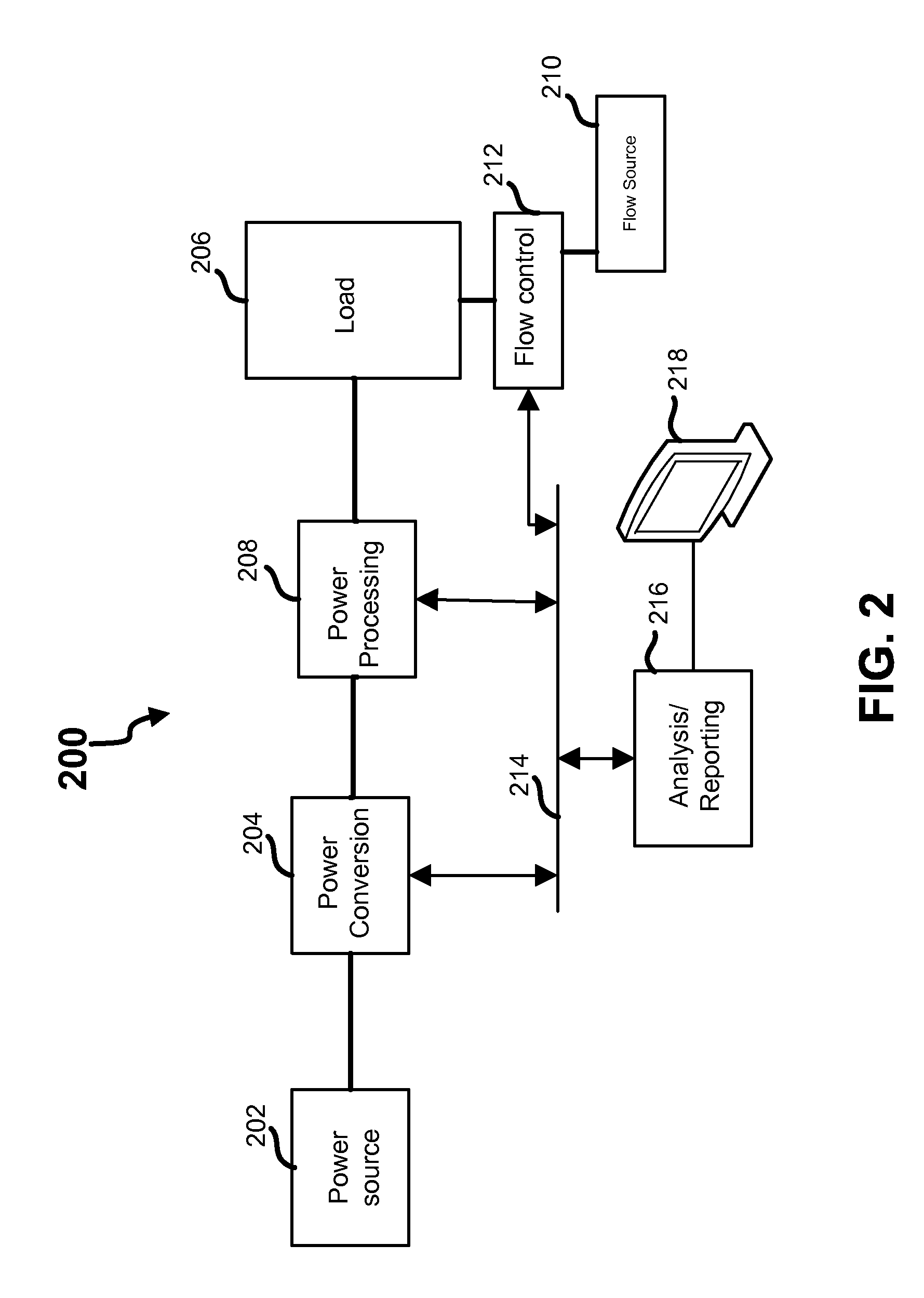

Predictive diagnostics system, apparatus, and method for improved reliability

InactiveUS20090249128A1Programme controlTesting/monitoring control systemsFailure rateHandling system

A system for managing a processing system and / or a processing system component is described. The system may include a wear-out module configured to provide a wear-out signal, the wear-out signal indicating a remaining amount of useful life of the component; a health module configured to provide a health signal, the health signal indicating an extent to which operational and environmental factors affect a failure rate of the component during a useful life of the component; and a mission module configured to provide a mission signal, the mission signal indicative of whether an operating condition is approaching a threshold that would adversely affect the system's ability to meet at least one performance objective.

Owner:ADVANCED ENERGY IND INC

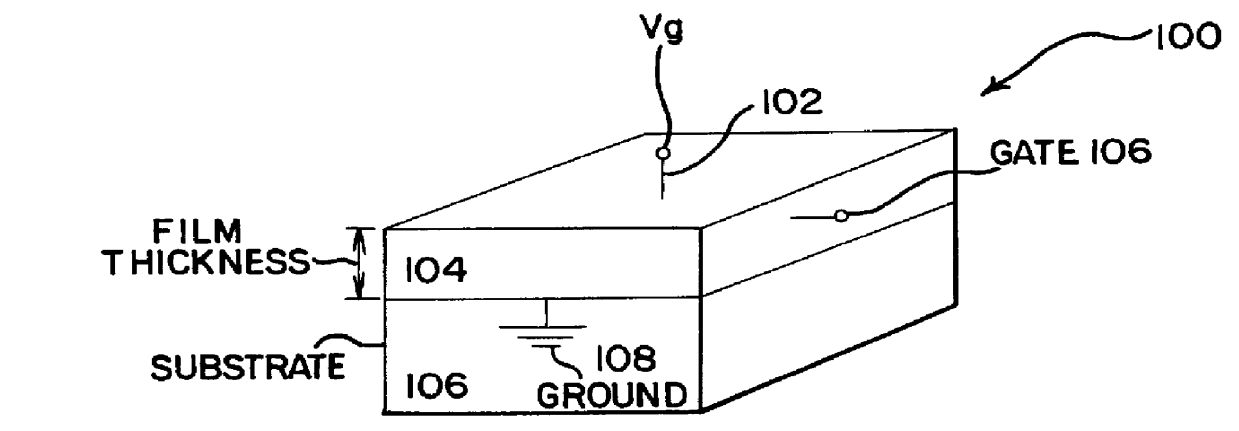

Method for quantifying ultra-thin dielectric reliability: time dependent dielectric wear-out

An ultra-thin dielectric film is subject to a dynamic electrical bias. During a first phase, the ultra-thin dielectric film is under a high field bias generated by the application of a high voltage. The duration of the high electrical stress is dependent on the intrinsic properties of the ultra-thin dielectric material. In a second phase, the ultra-thin dielectric film is subjected to an operating field bias generated by the application of an operating voltage. The change in the field bias exposes the dielectric to a similar dynamic stress that microelectronic devices ordinarily experience. At the operating field stage, a gate current is measured and compared to a predetermined range. Once the gate current exceeds that range the test concludes. Otherwise, the test cycles between the above-mentioned phases for a predetermined number of iterations based on prior experimental correlation. In a destructive testing mode, the process is continuous and does not conclude until the gate current exceeds a predetermined range. The ultra-thin dielectric gate current may also be measured as the ultra-thin dielectric is heated so that the transport properties or reliability of the ultra-thin dielectric is more clearly understood.

Owner:ADVANCED MICRO DEVICES INC

Liquid crystal display panel resource processing method

InactiveCN1900770ARealize harmless treatmentAchieve sustainable useNon-linear opticsEpoxyLiquid-crystal display

The method includes following steps: using manual work or dipping LCD faceplate in solvent to remove polarized light film; using cutting method or dipping faceplate in acid liquor to remove sealing epoxy resin to open up two pieces of base plate of LCD faceplate in glass; dipping faceplate in organic solvent to remove liquid crystal; after cleaning glass base plate, and dipping the base plate to acid leach liquor to remove metallized plating film so as to obtain clean glass base plate; picking up and refining indium from acid leach liquor. The invention carries out innocent treatment for worn-out LCD faceplates, and recovers resources.

Owner:NANJING UNIV

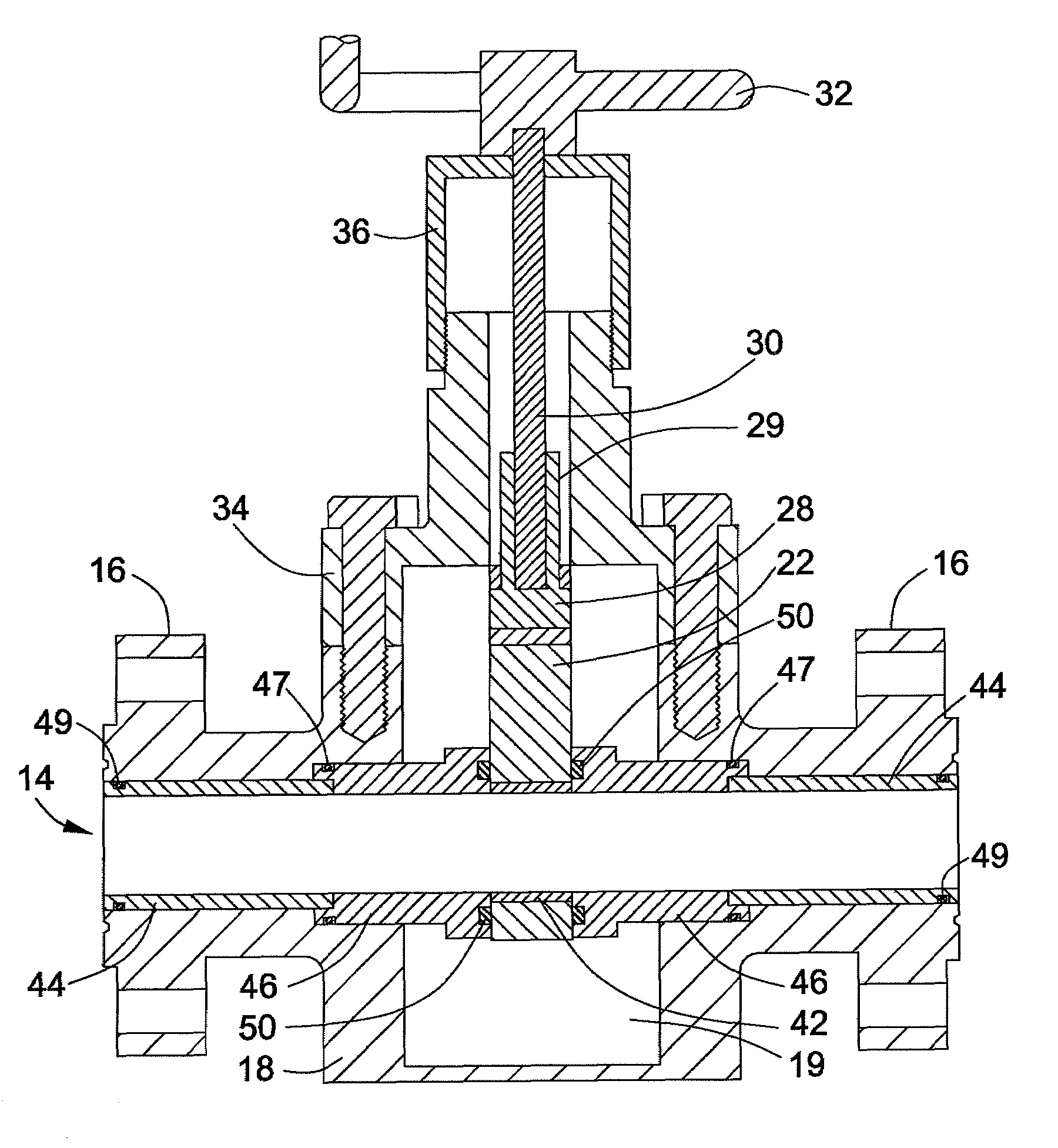

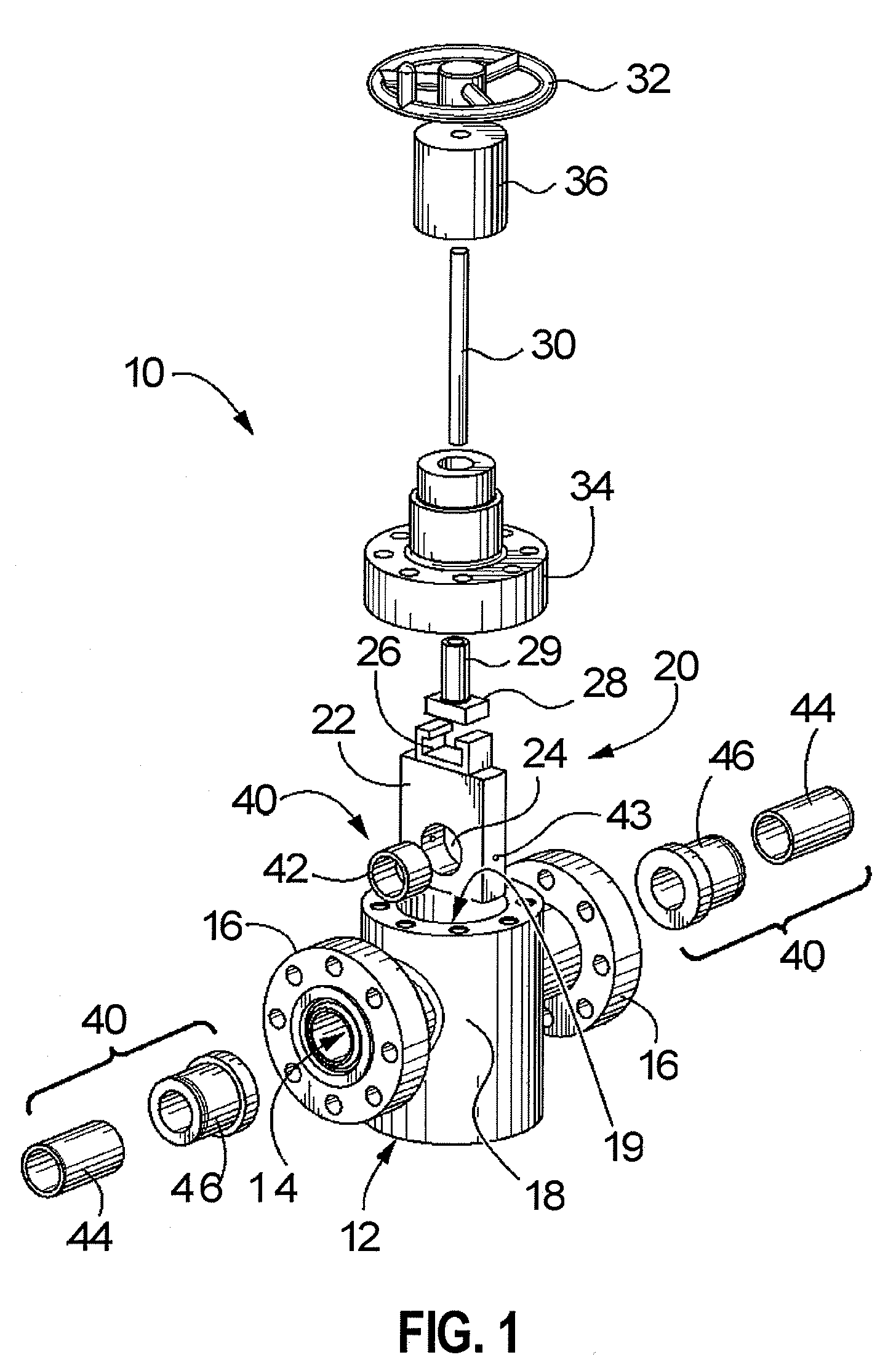

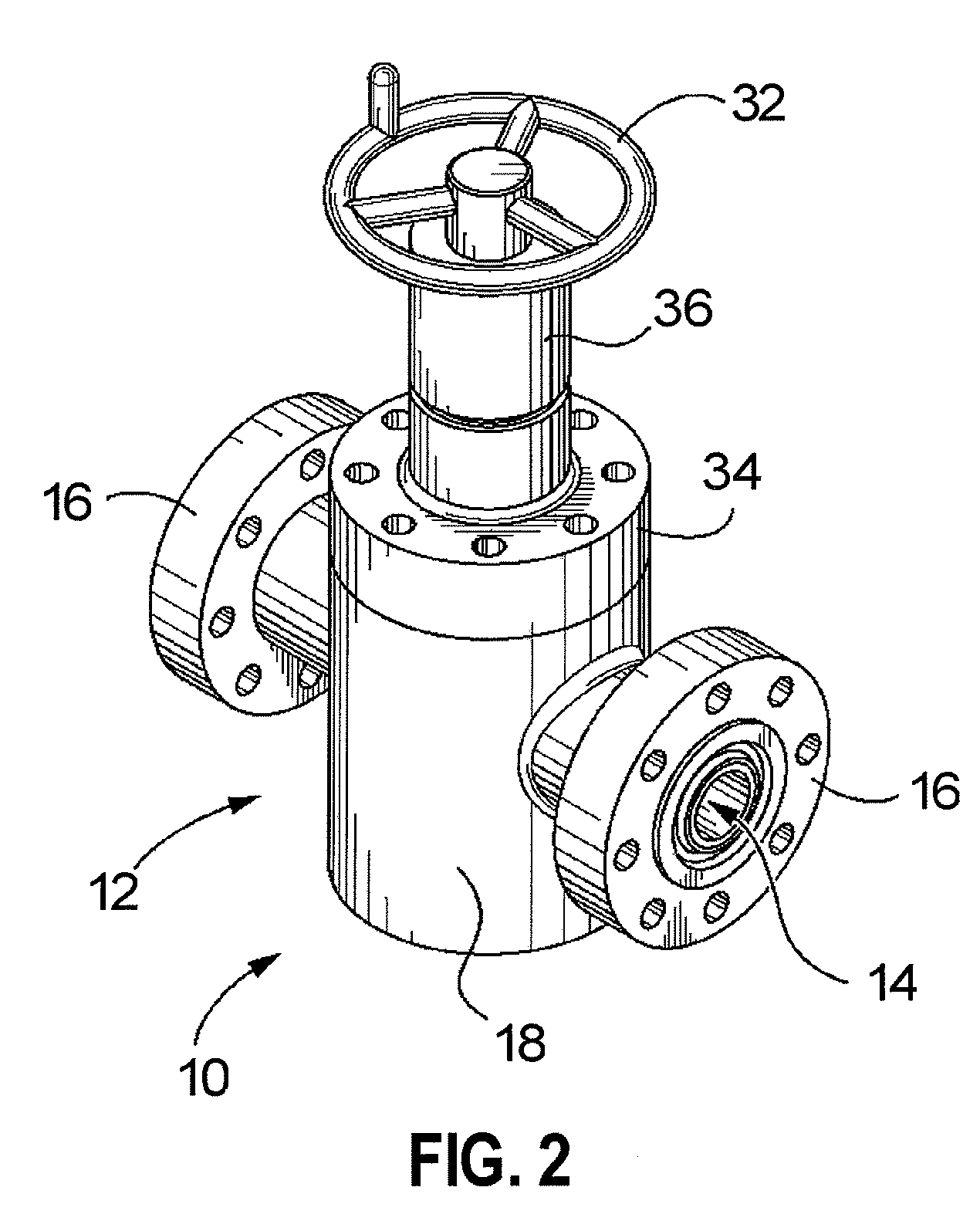

Gate valve with replaceable inserts and method of refurbishing same

ActiveUS20060091347A1Improve wear resistanceQuickly and easily refurbishedPipe supportsPlug valvesWear resistantEngineering

A gate valve includes a valve body having a cylindrical passage defining a flow path through the valve, a gate for controlling fluid flow through the valve and a replaceable wear-resistant flow-path liner for in the flow path. The flow-path liner includes a plurality of replaceable wear-resistant inserts, including wear sleeves lining ports of the valve body, valve seats and a gate insert for a flow path bore through the gate. Each replaceable valve seat has a wiper ring for cleaning the gate when it opens and closes. By regularly inspecting and replacing worn-out inserts, the service life of the gate valve can be prolonged and the expense associated with replacing or rebuilding the valve body is avoided.

Owner:WELLS FARGO BANK NAT ASSOC +1

Gate valve with replaceable inserts

ActiveUS7481239B2Improve wear resistanceQuickly and easily refurbishedPlug valvesPipe supportsWear resistantKnife blades

A gate valve includes a valve body having a cylindrical passage defining a flow path through the valve, a gate for controlling fluid flow through the valve and a replaceable wear-resistant flow-path liner for in the flow path. The flow-path liner includes a plurality of replaceable wear-resistant inserts, including wear sleeves lining ports of the valve body, valve seats and a gate insert for a flow path bore through the gate. Each replaceable valve seat has a wiper ring for cleaning the gate when it opens and closes. By regularly inspecting and replacing worn-out inserts, the service life of the gate valve can be prolonged and the expense associated with replacing or rebuilding the valve body is avoided.

Owner:WELLS FARGO BANK NAT ASSOC +1

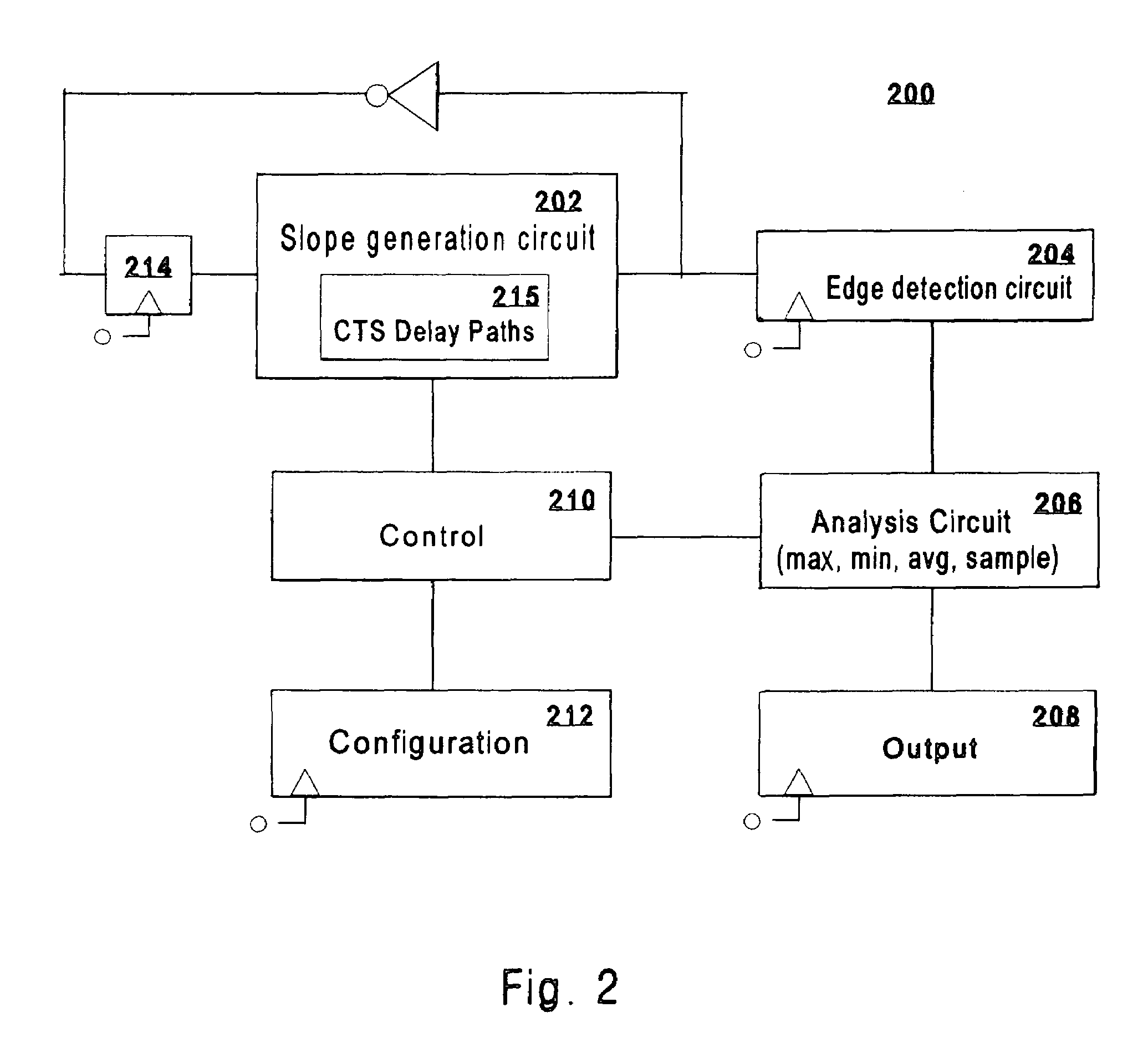

Circuit for dynamic circuit timing synthesis and monitoring of critical paths and environmental conditions of an integrated circuit

InactiveUS7576569B2Multiple input and output pulse circuitsPulse characteristics measurementsEngineeringCritical path method

A circuit for dynamically monitoring the operation of an integrated circuit under differing temperature, frequency, and voltage (including localized noise and droop), and for detecting early life wear-out mechanisms (e.g., NBTI, hot electrons).

Owner:INT BUSINESS MASCH CORP

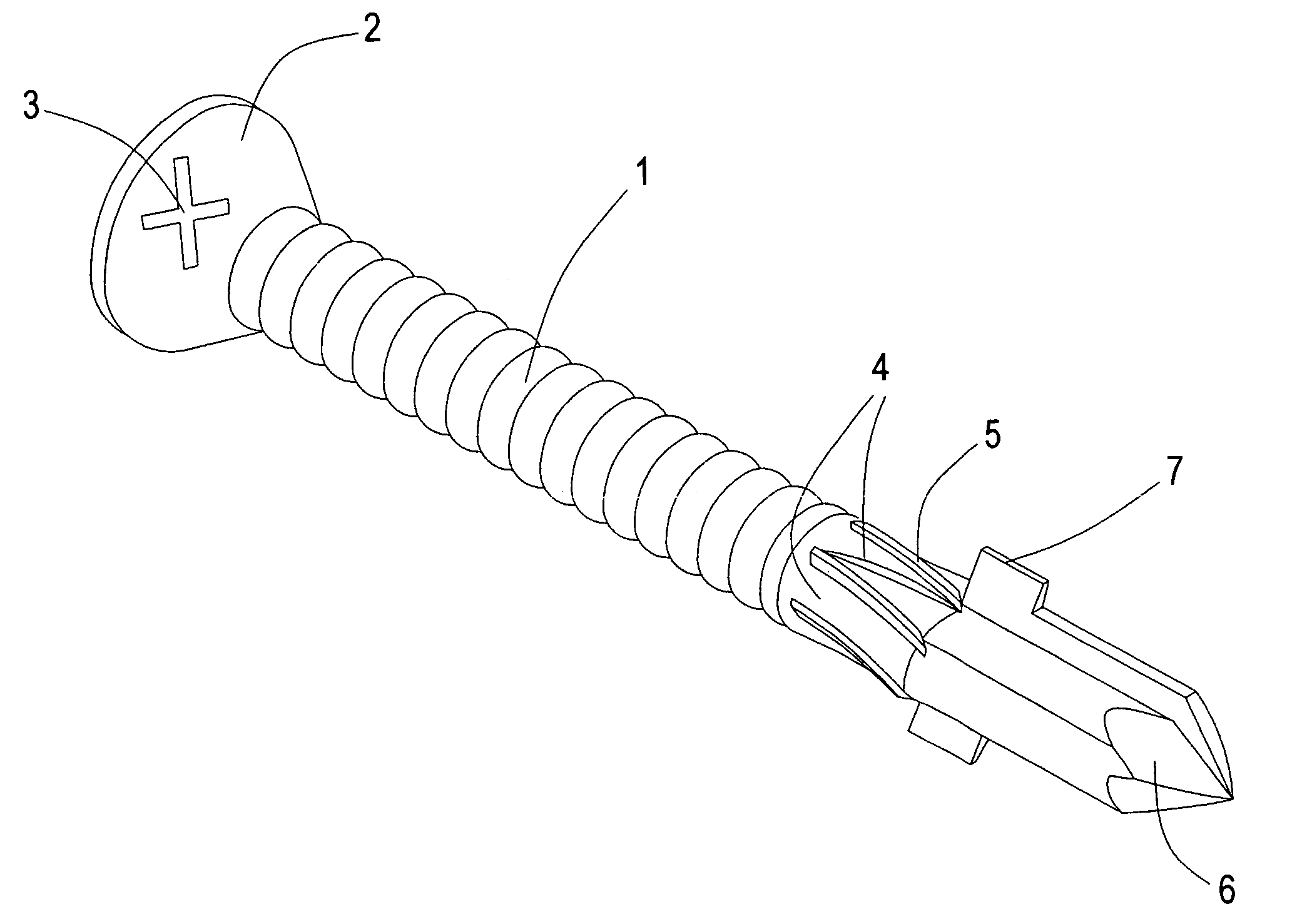

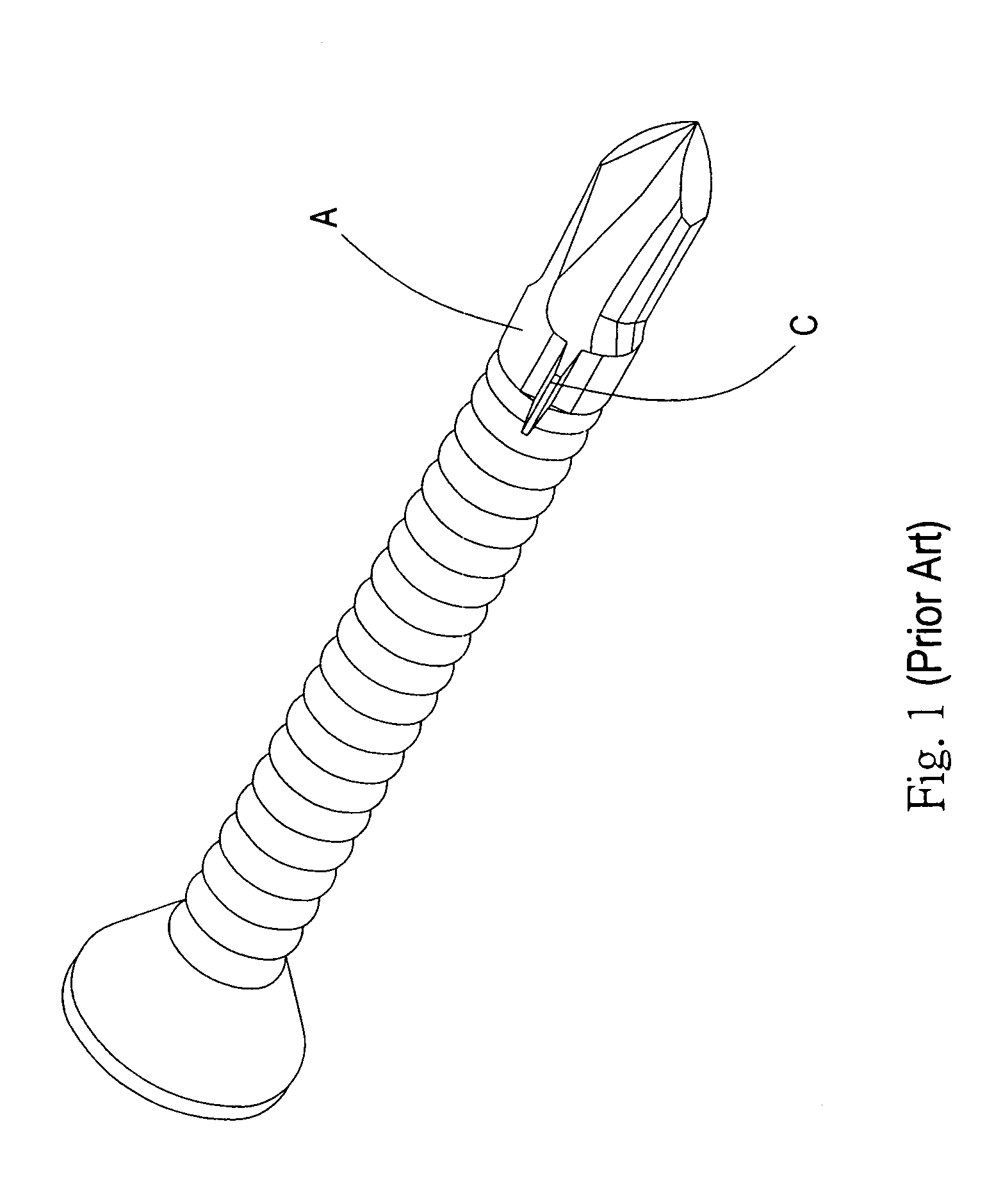

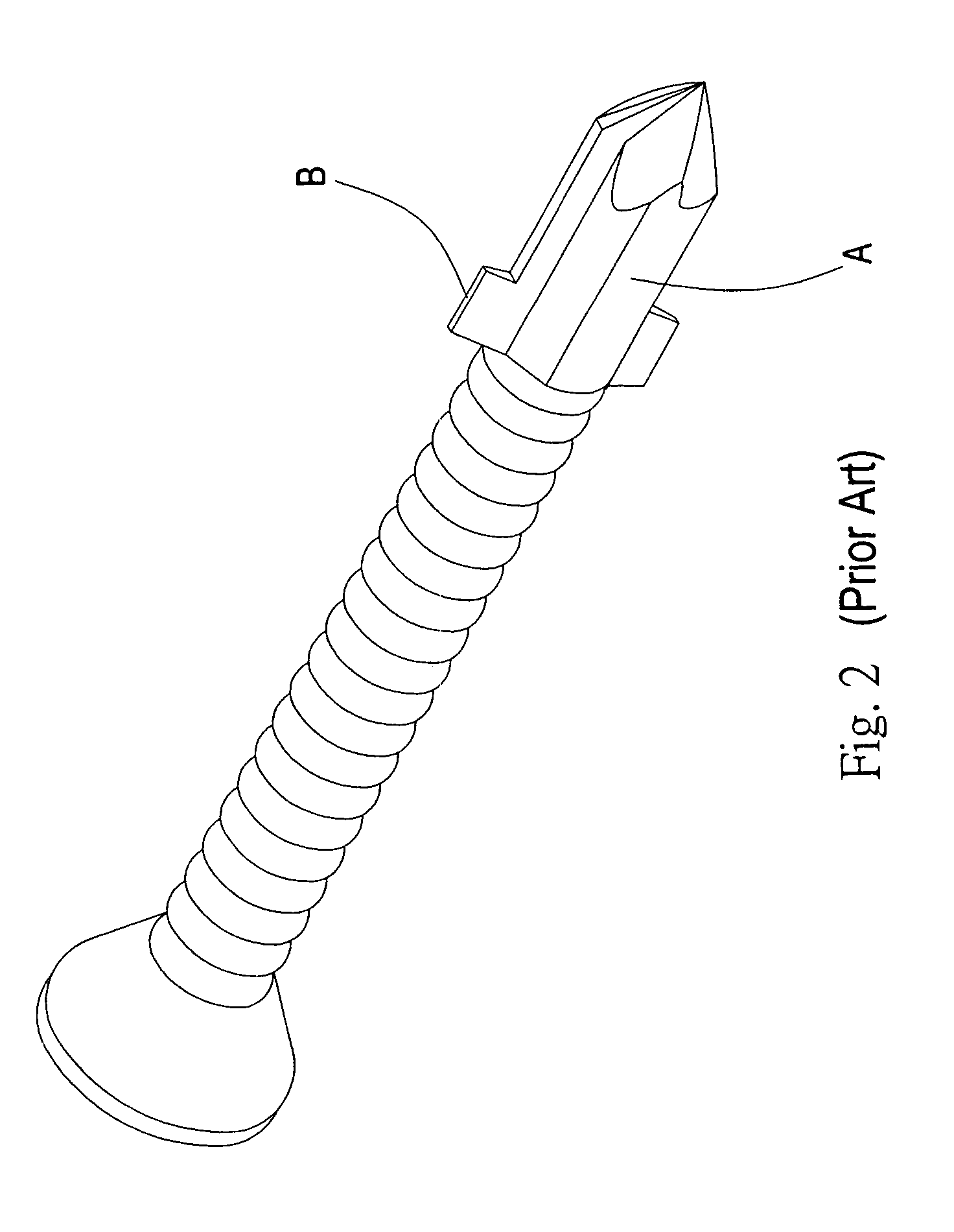

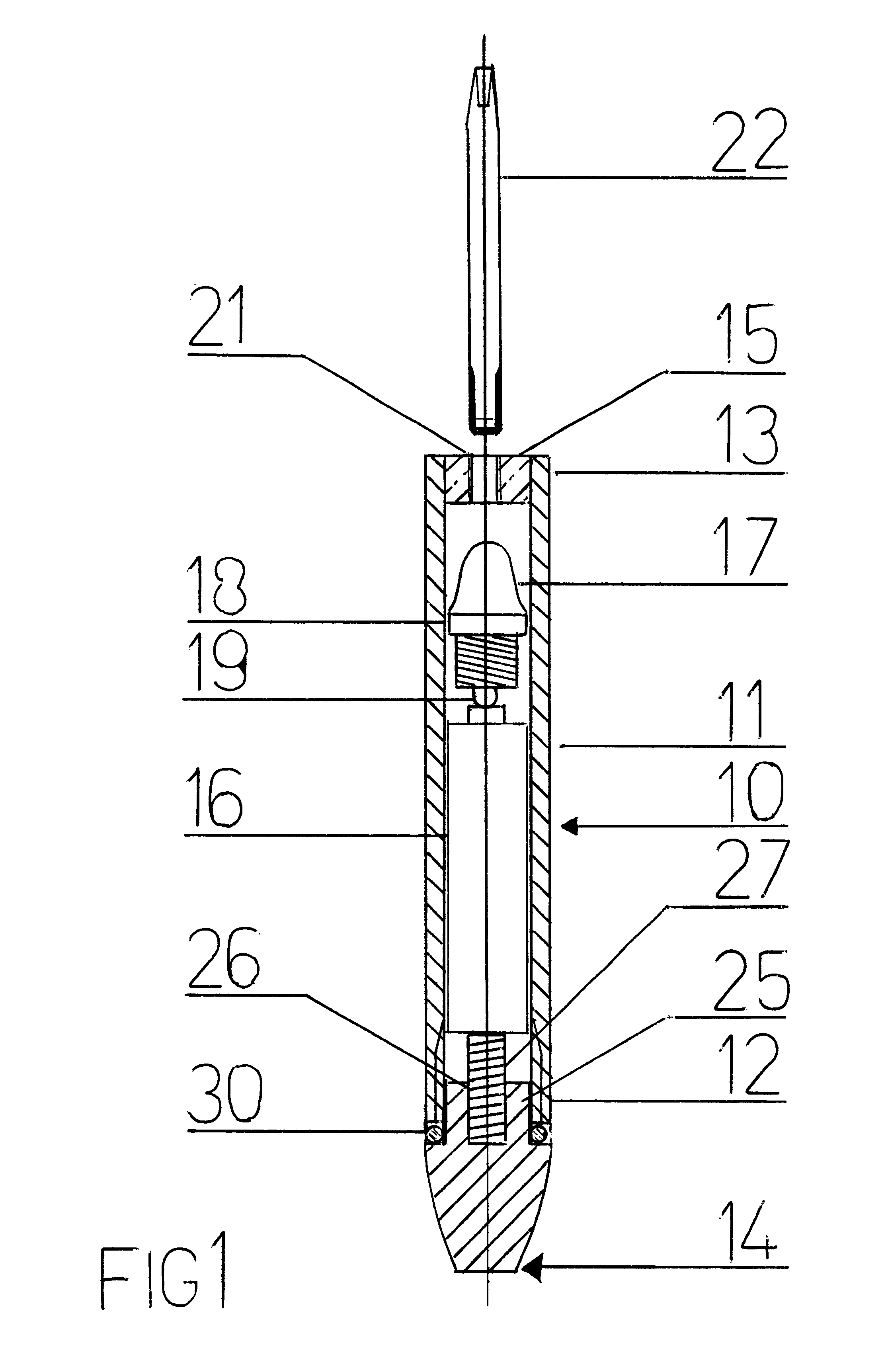

Screw with protruding sheets on head portion

A screw with protruding sheets on a head portion comprises a thread portion; a screw tail at one end of the thread portion, a slot formed on the screw tail; a plurality of screwing sheets formed at another end of the thread portion; a plurality of recesses formed between the plurality of screwing sheets for removing undesired pieces; a drilling head being formed at front ends of the screwing sheets; the drilling head formed with a plurality of protruding sheets made of soft metal. By screwing the screw by rotating from the slot, the screw will rotate so as to drill a hole and enter into a wood plate. Then the protruding sheets enlarge the hole. The undesired wood pieces are removed from the recesses. When the screw further drills into a metal plate, the protruding sheet will be worn out because the protruding sheet is made of soft metal.

Owner:TOP GREEN CORP

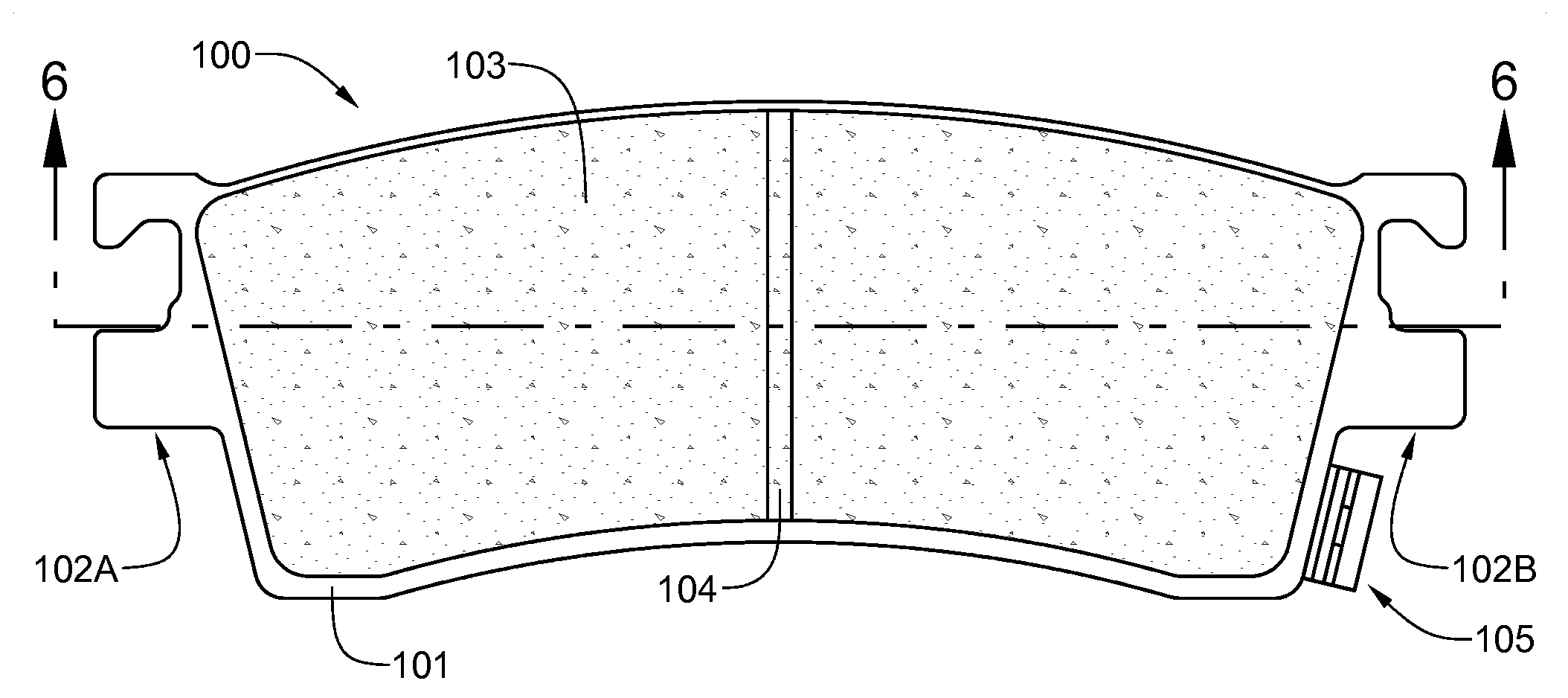

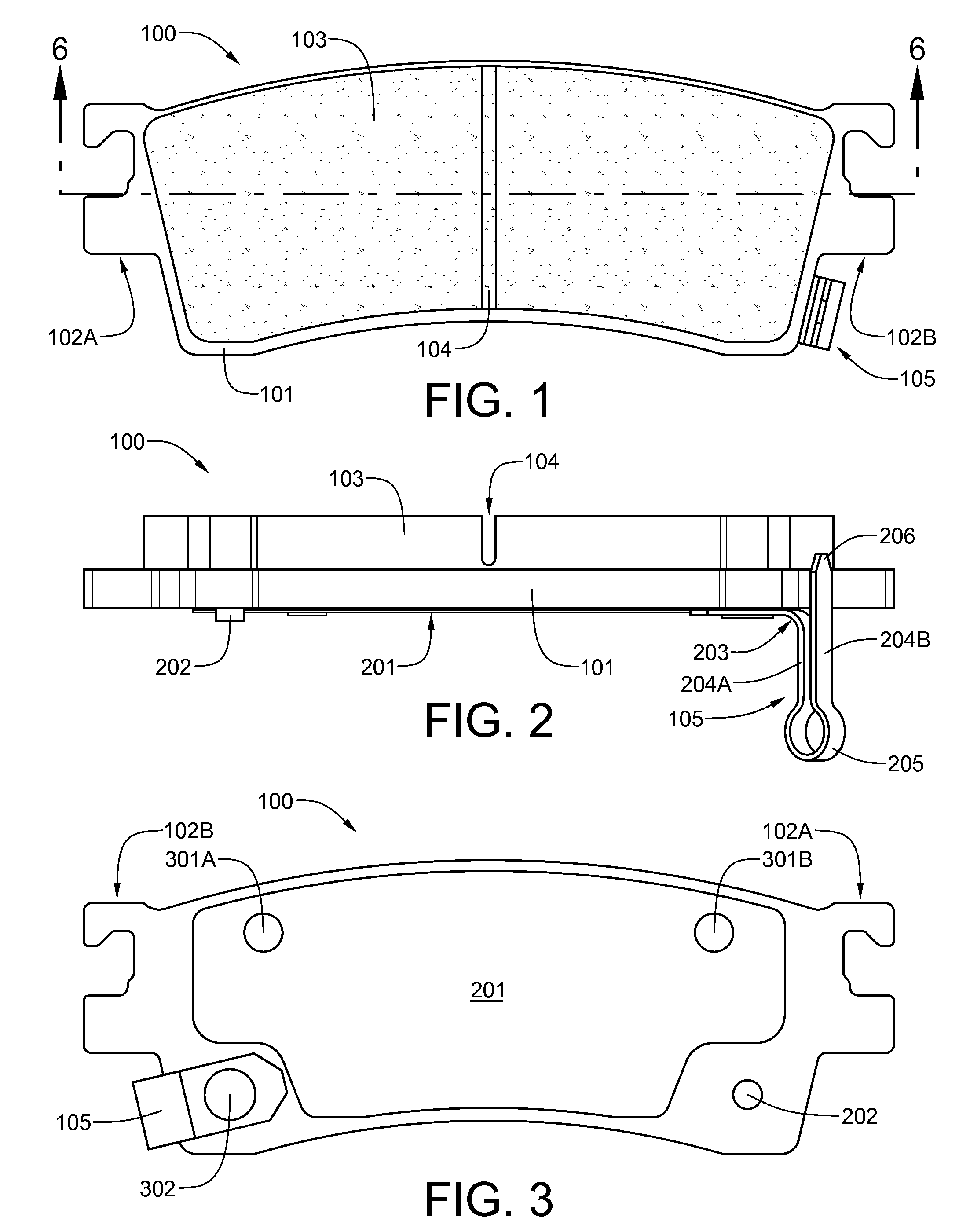

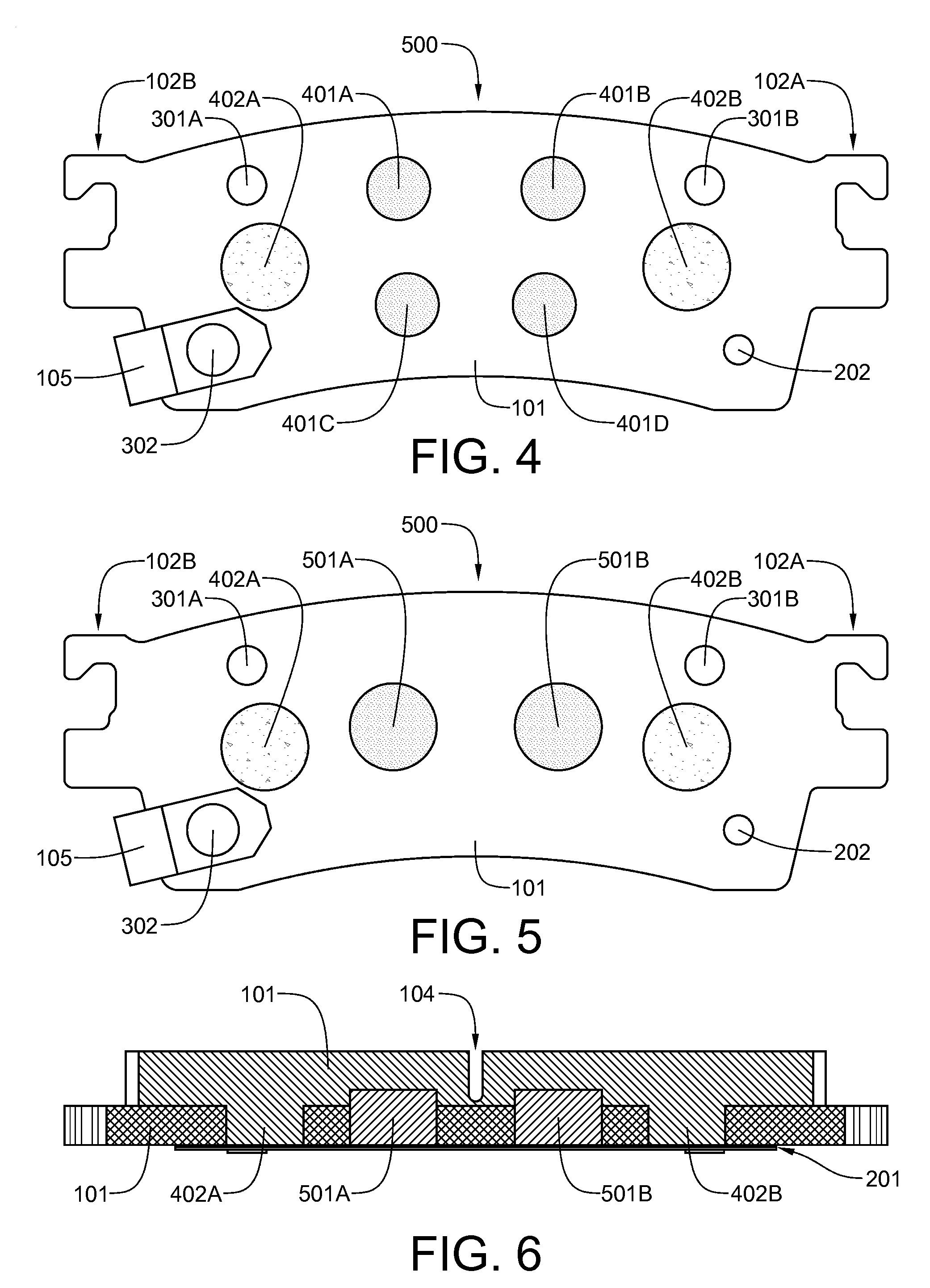

Disc brake pads having a visual wear indicator which signals the need for pad replacement

A new method and apparatus signals to an inspector on a cursory exterior examination of a vehicle that brake pads have reached the limit of safe wear. Brake pads are designed to release a material that has a color other than the browns and grays of conventional brake pad dust when they reach the limit of safe wear. The colored material distributes itself on the wheel of the vehicle, thereby offering telltale evidence of worn-out brake pads. A first embodiment brake pad employs a colored powdered material enclosed in at least one pocket beneath the normal wear range of the friction lining. A third embodiment brake pad employs a heat-stable, colored liquid or slurry in metal capsule. The capsule is breached by rubbing against the brake rotor when the wear limit is reached. Inorganic pigments are used for powder, slurry and friction lining colorants.

Owner:LUNDSKOG DAVID A

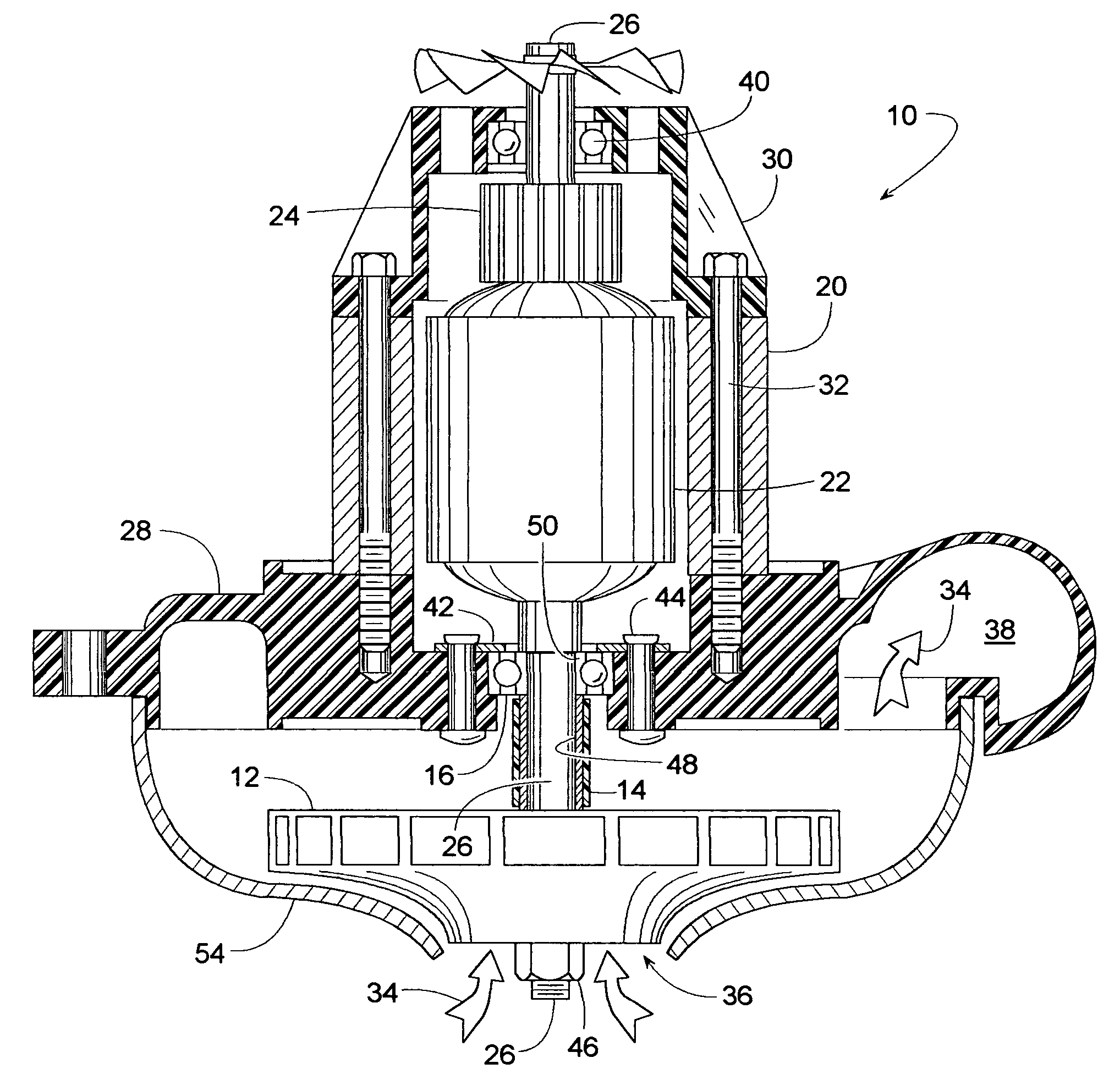

Water repellent motor sleeve

A high-speed universal motor running at over 10,000 or even over 20,000 rpm includes a non-rubbing water repellent sleeve that protects the bearings from moisture damage. Rather than having a sliding contact seal that can quickly wear out under such high speeds, the sleeve is made of material having a low solid surface energy so that the seal material itself repels waters on its own. TEFLON is the preferred material, which is relatively soft, so to prevent the compressibility of the seal from affecting the axial positioning of parts on the motor shaft, the seal is installed such that the seal does not contribute to the critically precise positioning of the shaft and the parts mounted to it. In some embodiments, for example, the relatively soft seal simply overlies a much stiffer, accurately machined metal spacer.

Owner:ELECTRO MOTOR

Systemic cabinet

InactiveUS7967401B2Convenient and quick constructionDifferent orientation-positioning efficiencyFolding cabinetsSectional furnitureOn boardEngineering

Owner:HSU LI CHUNG

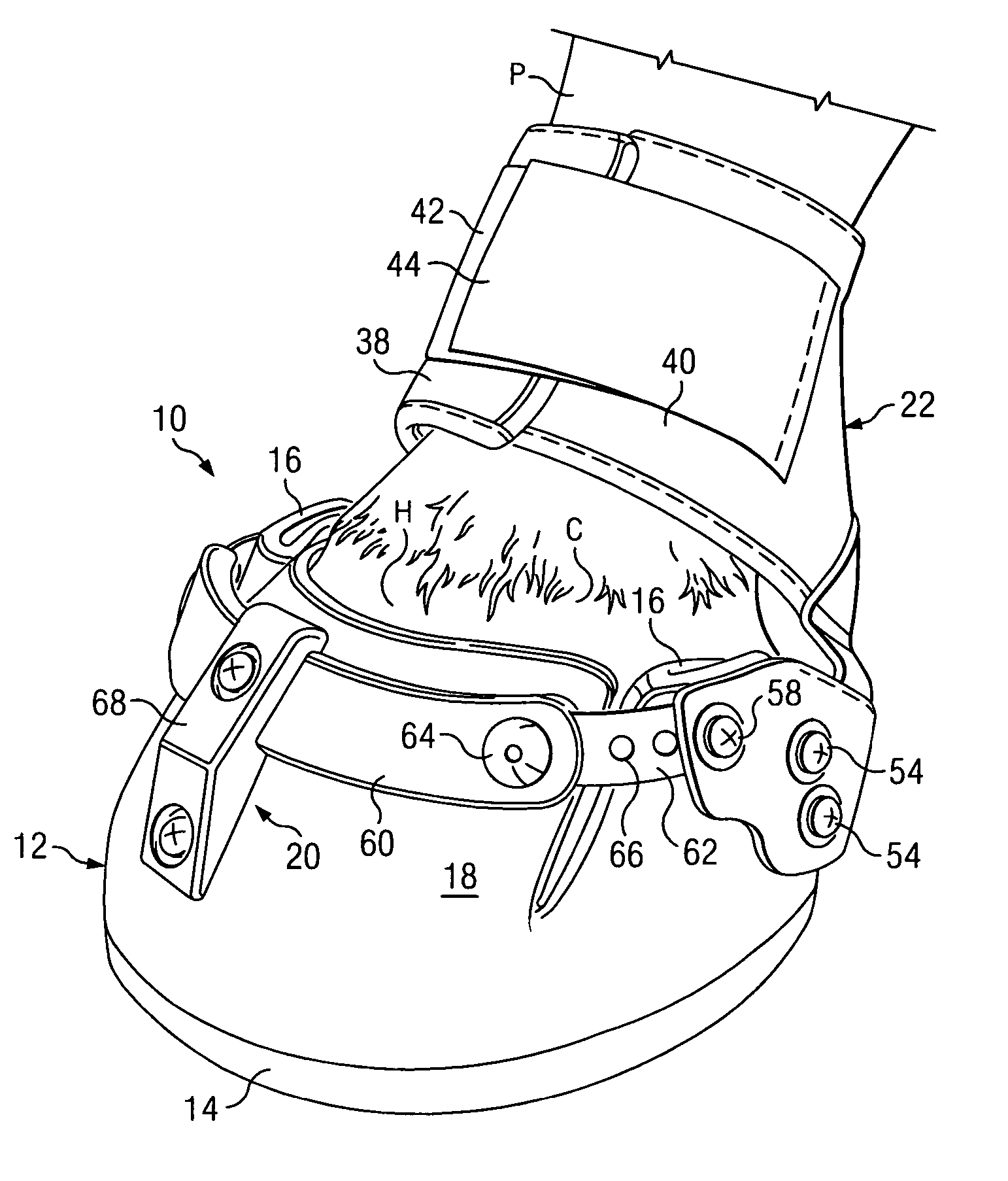

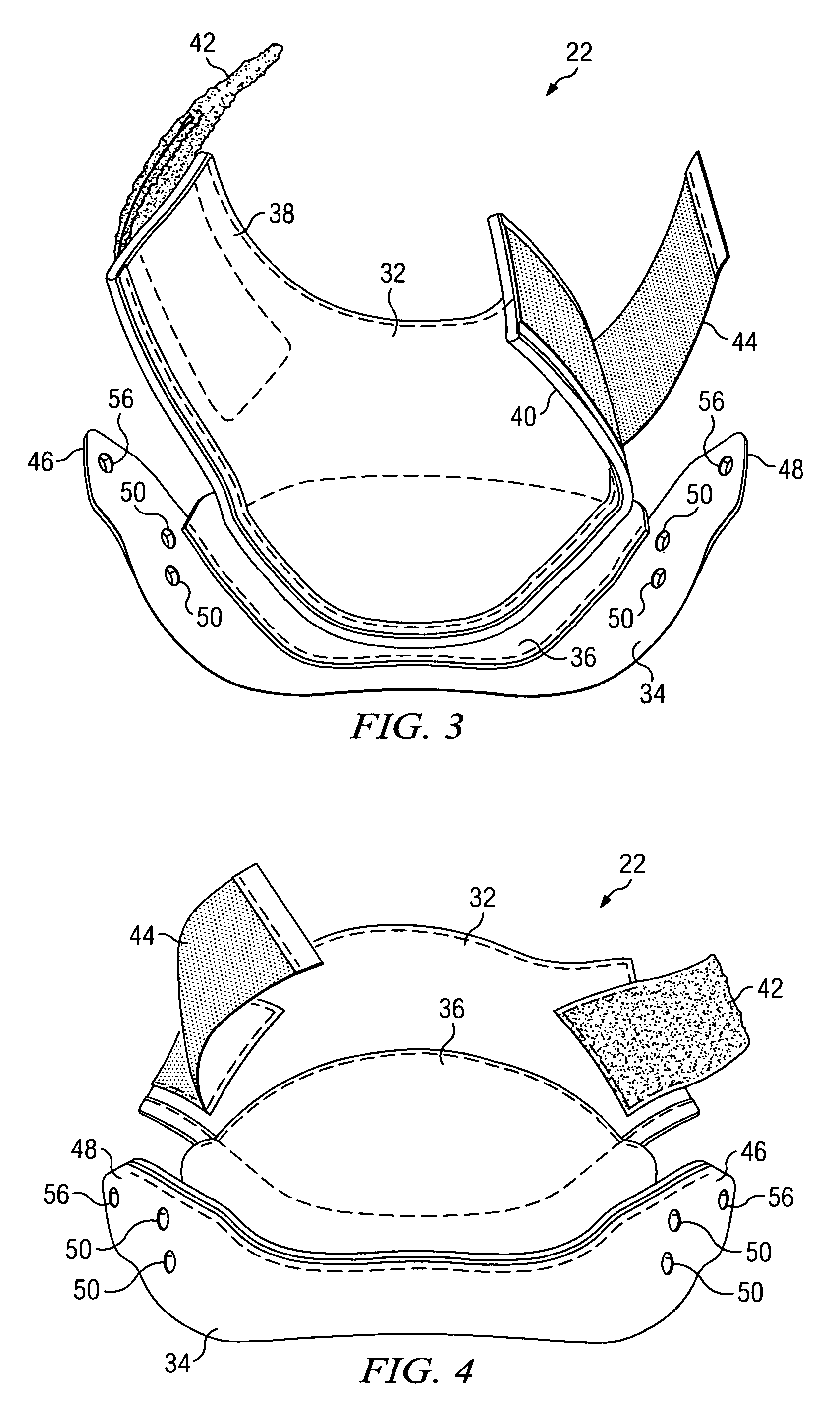

Slip-on horse boot with replaceable pastern gaiter

InactiveUS20060064950A1High retention rateNeutralize its gripping effectProtection coversGrooming devicesEngineeringPastern joint

A horse boot (10) includes a shell (12) for a hoof and a gaiter (22) for the pastern. The shell has a sole (14), an upper (16), a tongue (18), and an elastic strap (60) for tightening the upper and the tongue around the hoof of a horse. The gaiter (22) is releasably attached to the upper so as to extend around the rear of the shell and can be wrapped around the pastern (P) of the horse immediately above the hoof's hairline (C) and below the fetlock to function as a barrier against the entry of debris into the shell. The gaiter provides an additional anchor to retain the shell in place under extreme conditions of use. The releasable connection to the shell (12) allows replacement of the gaiter (22) when worn out.

Owner:EASYCARE

High tension electrostatic separating apparatus and method for worn-out broken printed circuit board granules

InactiveCN1654129ALow costReduce energy consumptionElectrostatic separationElectrostatic separationEngineering

The present invention is high voltage electrostatic separation apparatus and method of crushed waste printed circuit board grains. The mixed metal and non-metal material grains fed with the composite feeding system to fall onto the surface of the main roller homogeneously via the feeding roller and the feeding vibration board are charged in the high voltage electrostatic field applied with the corona electrodes. Metal grains are attracted electrostatically by the static electrode to deviate from the main roller and fall into the metal collecting area, and the non-metal grains are repelled by the electrode to maintain on the surface of the main roller and to be brushed into the non-metal collecting area, while small amount of semiconductor grains fall in the way to the middle product collecting area. Compared with airflow separation method and water separation method, the present invention has the features of low cost, high efficiency, simple structure, no pollution and other advantages.

Owner:SHANGHAI JIAO TONG UNIV

Mitigating premature wear out of a rechargeable battery

ActiveUS9263912B2Reduce degradation rateEnd of lifeElectrical testingElectric powerElectrical batteryRechargeable cell

Owner:DELL PROD LP

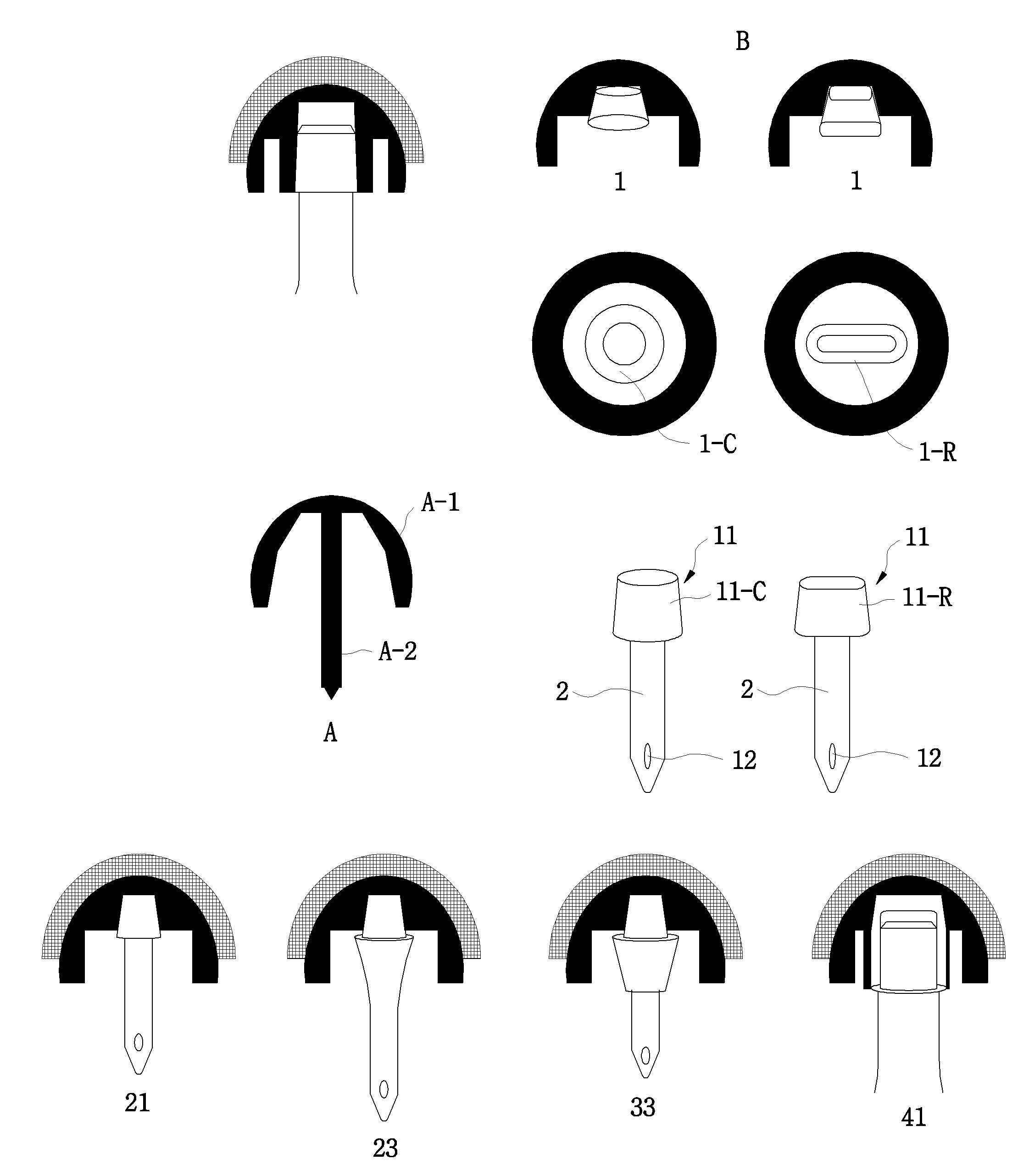

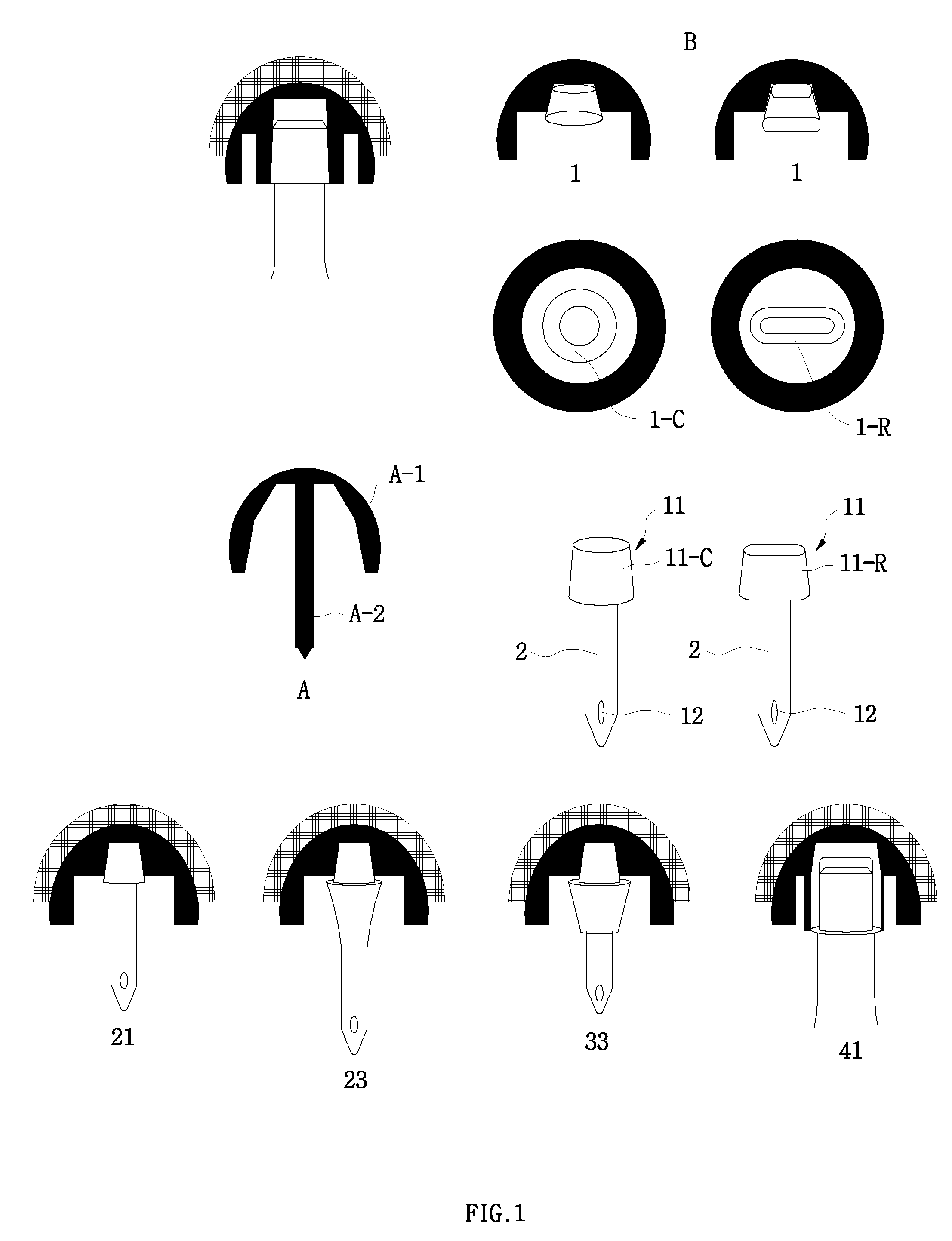

Modular Femoral Head Surface Replacement, Modular Femoral Neck Stem, and Related Sleeve, Adapter, and Osteoconducting Rod

InactiveUS20090043397A1Relief the painRestore stabilityInternal osteosythesisBone implantEtiologyBody of femur

Disclosed therein is a big femoral head and femoral head surface replacement, which are used for hip osteoarthritis and vascular necrosis of femoral head. As a person get older and aged, the weight bearing hip joint is indispensably changed to osteoarthritis and sometimes showed avascular necrosis of the femoral head with unknown etiology. The deformed femoral head and hip joint should be replaced with the THA. Till now, the total hip replacement is performed in such a way that the necrosed femoral head and a healthy femoral neck are all removed and a femoral stem is inserted into the marrow cavity, and in this case, a small femoral head causes a reduction of a range of motion and dislocation of the hip joint occasionally, and osteolysis due to abrasion of plastic acetabular liner. In case of a conventional femoral head surface replacement (hereinafter, called “conventional FHSR”), a complication of femoral neck fracture and could not combined use with conventional THA. Recently, hard bearing system such as metal on metal THA or ceramic on ceramic THA without using plastic has been introduced to solve the problem of osteolysis due to abraded plastic particles generated when the THA is worn out as time goes. But there also have many problems as a limited range of motion, resected normal femoral neck and difficulties of rereplacement of the femoral stem. Because of the big femoral head or the FHSR can increase the range of motion and lower dislocation rate these devices are gradually widespread in young active person and Asian peoples. This invented design of the modularity gives the convenience to the surgeon and economically lower burden to patients to use of the FHSR and big femoral head system. The related accessory showed initial stability of the FHSR during operation and prevent from femoral neck fracture in follow-up periods.

Owner:PARK HYUNG BAE

Simple, mechanism-free device, and method to produce vortex ring bubbles in liquids

An apparatus and method are described that allows for the production of vortex-ring bubbles in a host liquid. A simple embodiment of the device consists of an inverted cup with a short nozzle protruding into it through the center of its end face. Circular plates are fixed to both open ends of the nozzle tube, which itself is positioned such that its lower end is at a higher level than the open end of the inverted cup. When cup is immersed in a liquid, open end down, and the inside of the cup is pressurized with an inflow of gas, a confined volume of gas will form inside the cup, and the liquid level in the cup will fall, and peel away from the nozzle lower end plate. The gas is exposed to the open lower end face of the nozzle, but does not enter the nozzle until the pressure has built up within the cup sufficiently to break the surface tension meniscus at the nozzle inlet. The gas then self accelerates up through the nozzle and rapidly exits at the upper end of the nozzle tube. The confined liquid level in the cup rises back up in response and enters the nozzle in a unique self-siphoning action shutting off further gas flow out the nozzle. The exiting gas bubble self organizes into a gas-filled, vortex ring. Alternatively, the exiting flow of gas can be captured in a second conical nozzle and buoyantly directed to the throat of the nozzle where it undergoes the same self acceleration and self siphoning to form a vortex ring at the throat exit. Other different embodiments of the device that all operate under the same method of intermittent breaking of surface tension forces followed by self acceleration and self siphoning to generate a vortex ring bubble are described. The advantages of the device are that it is mechanically simple, easy to manufacture, has no moving parts, will not wear out, and does not require any operator intervention in order to function.

Owner:THOMAS ANDREW SYDNEY WITHIEL

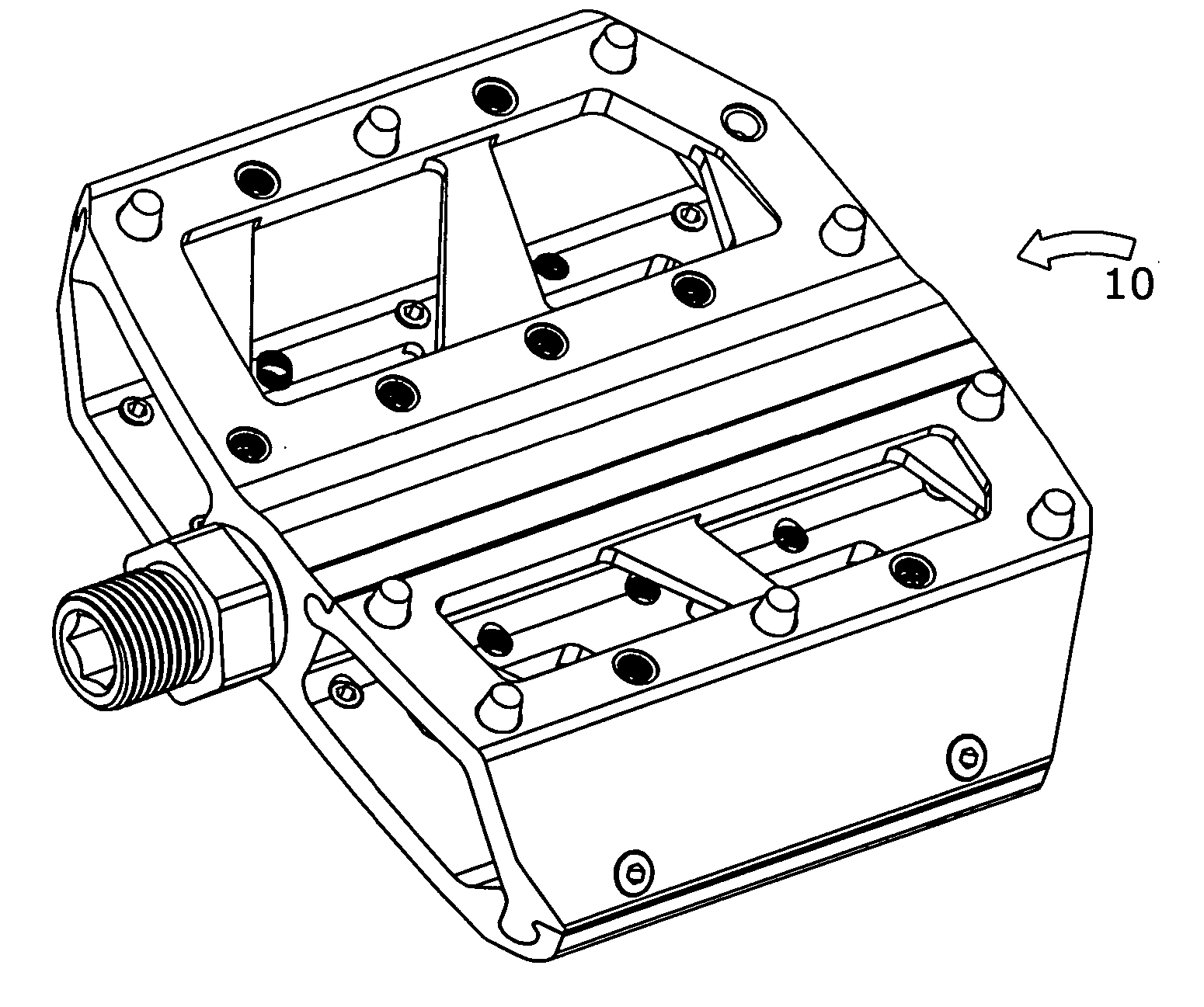

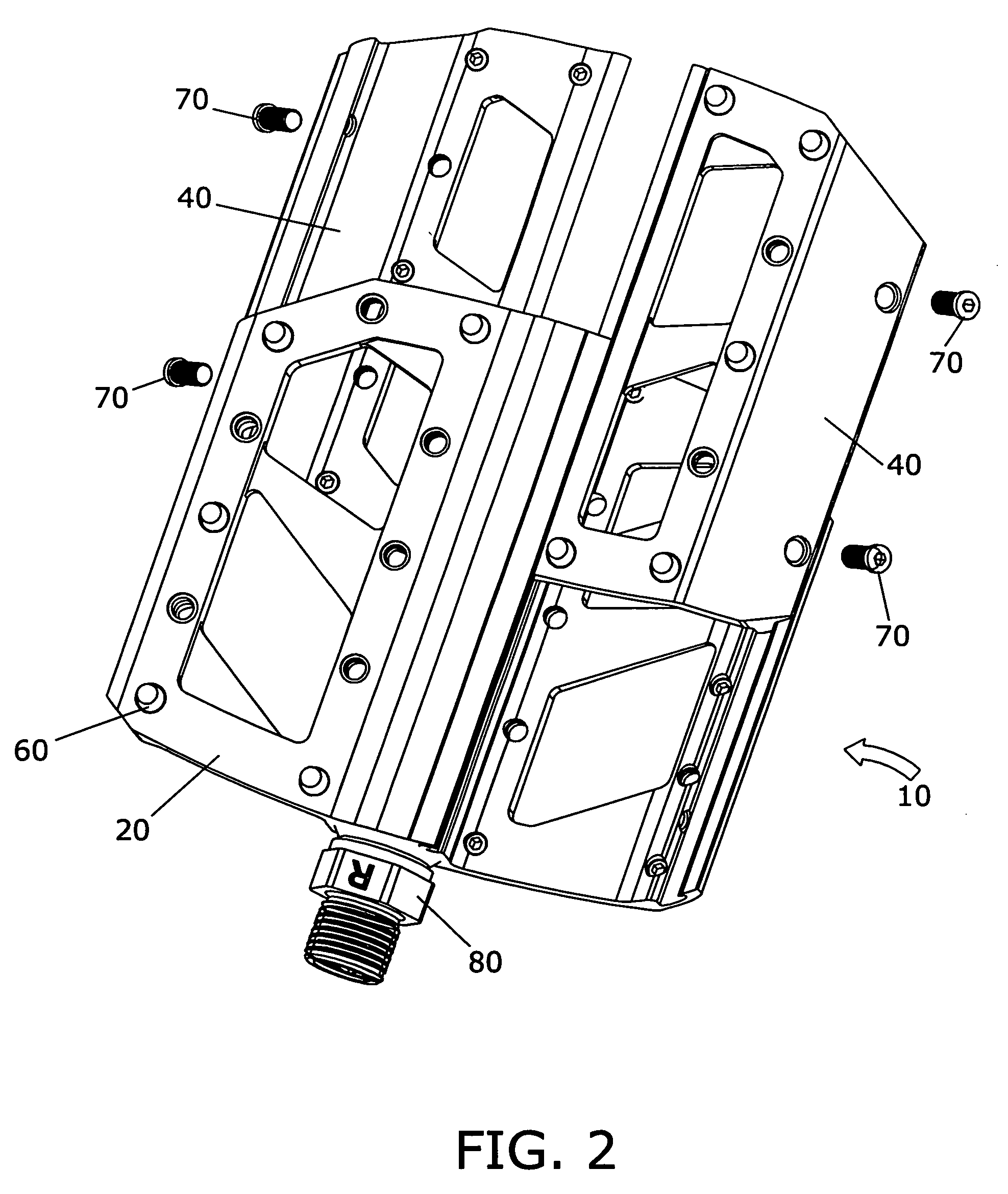

Bicycle pedal

ActiveUS20060266154A1Improve the immunityCheap replacementControlling membersMechanical apparatusEngineeringWear out

A pedal with a body that has two plates that can be easily removed or displaced to access the inner surfaces of the pedal and the backside of traction pins. In this way, traction pins can be replaced even after the pins have been worn out or broken. Also, the plates can be made out of a harder, more durable, more expensive material than the material of the body, because the plates are typically subjected to the most impact and abrasion because of the shape and location of the plates. Alternatively, the plates can be made of a relatively inexpensive material because the plates are easy to replace if worn or damaged. Also disclosed is a system for re-greasing the inside of the pedal including a screw-in end cap that can be removed, and a slot down the inside of the body that allows grease to flow around a sealed bearing.

Owner:CRANK BROS INC

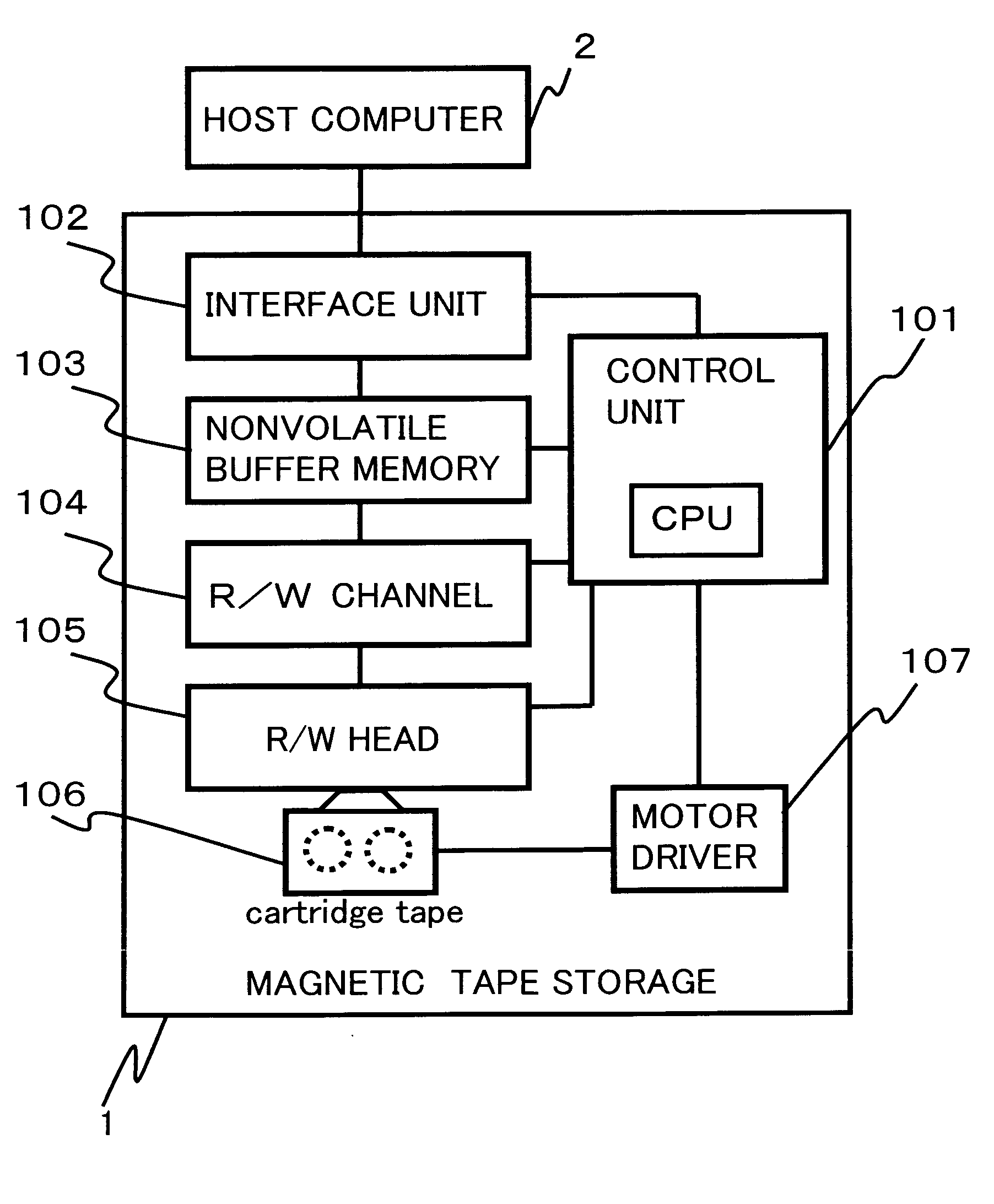

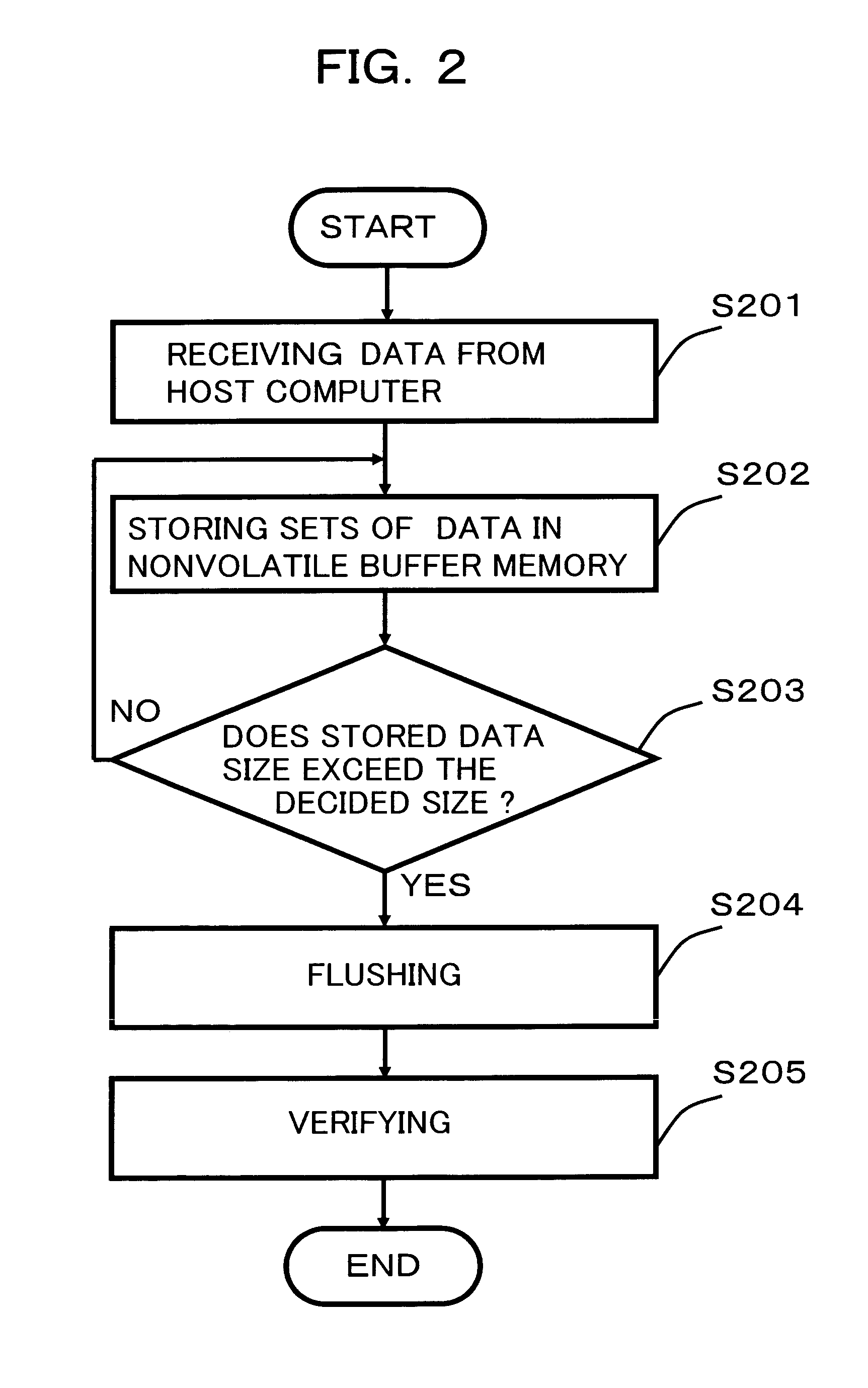

Magnetic tape storage, method for writing data to magnetic tape, and medium for writing data program

InactiveUS20080007856A1Reduce frequencySimple methodRecording carrier detailsRecord information storageData setMagnetic tape

In a magnetic tape storage including a nonvolatile buffer memory, the buffer memory memorizing sets of data sent from a host computer, a set of data including a pair of one file and one tape mark, the tape mark showing the end of the file, sets of data are continuously stored in the buffer memory until the total data amount of the sets of data comes up to a predetermined data amount, and the sets of data stored in the buffer memory are wrote to a magnetic tape (called flushing) when the total data amount of the sets of data in the buffer memory exceeds the predetermined data amount. The frequency of the flushing and tape reposition according to the flushing can be greatly decreased. The wear-out of the magnetic tape and mechanical section relating to the magnetic tape running in the storage can be reduced.

Owner:FUJITSU LTD

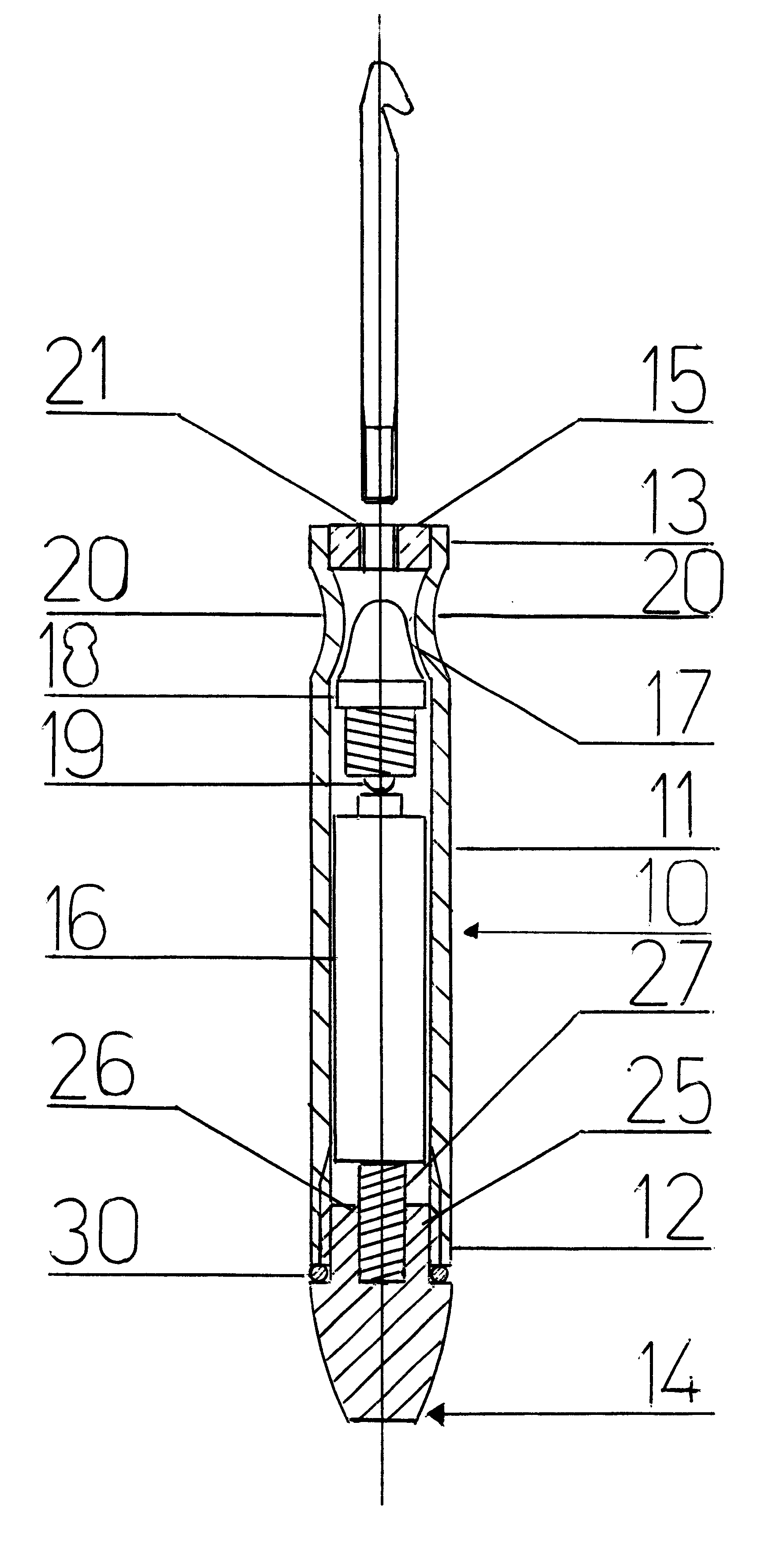

Hand held device providing effective site illumination

InactiveUS6325522B1Easy to operateElectric circuit arrangementsLighting elementsHand heldHand held devices

A hand held device providing effective illumination of a site being worked on has a metal tube serving as a handle, at one end of which a switch is threaded therein, and at the other end of which a window is secured. Located within the handle are a battery, which communicates with the switch by means of a spring, and a light bulb, which faces the window. Interchangeable implements, including tools and instruments, are individually releasably secured within an orifice in the window. The switch operates simply, facilely, and positively, with no parts which will wear out.

Owner:WALIAN HARALD

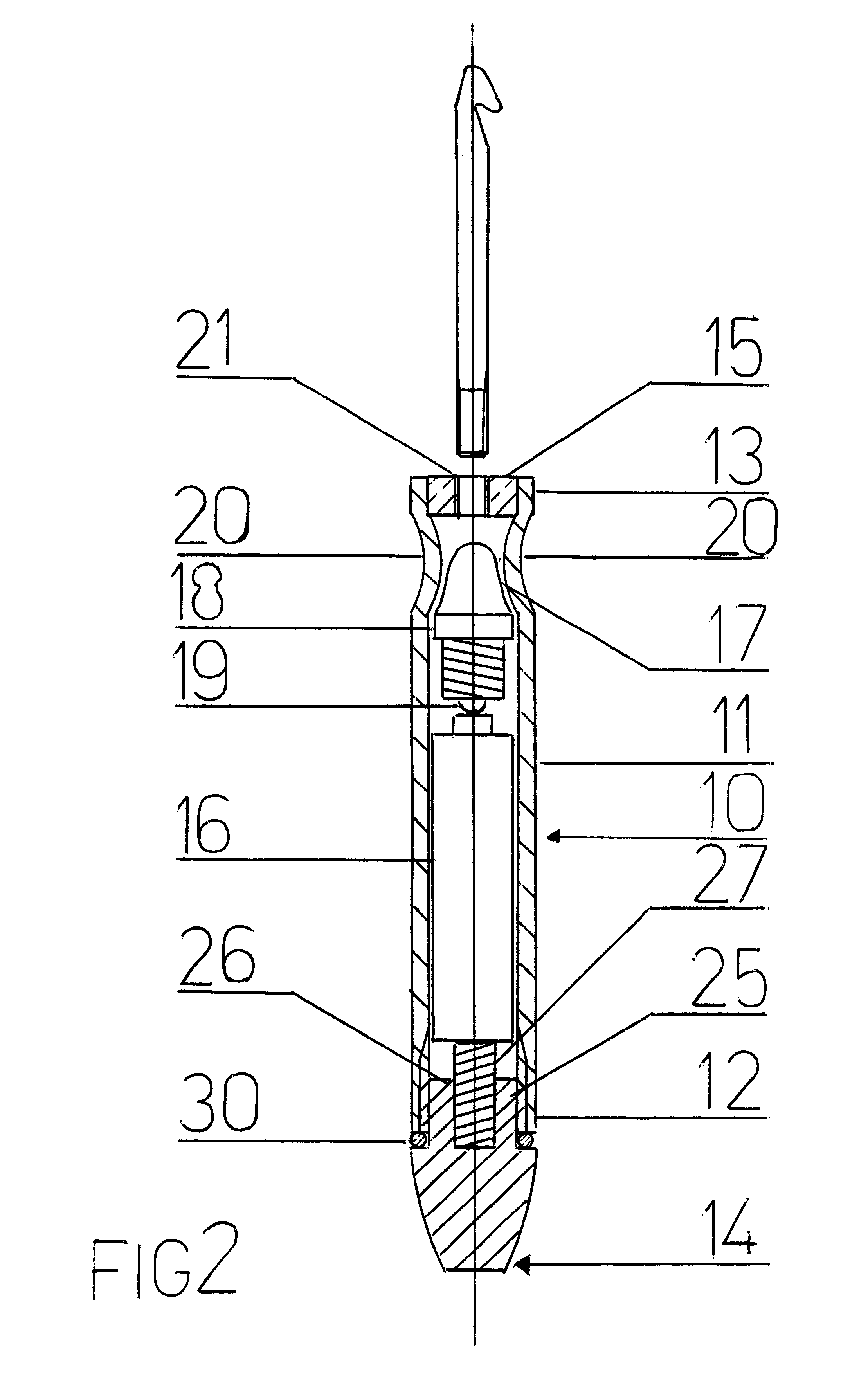

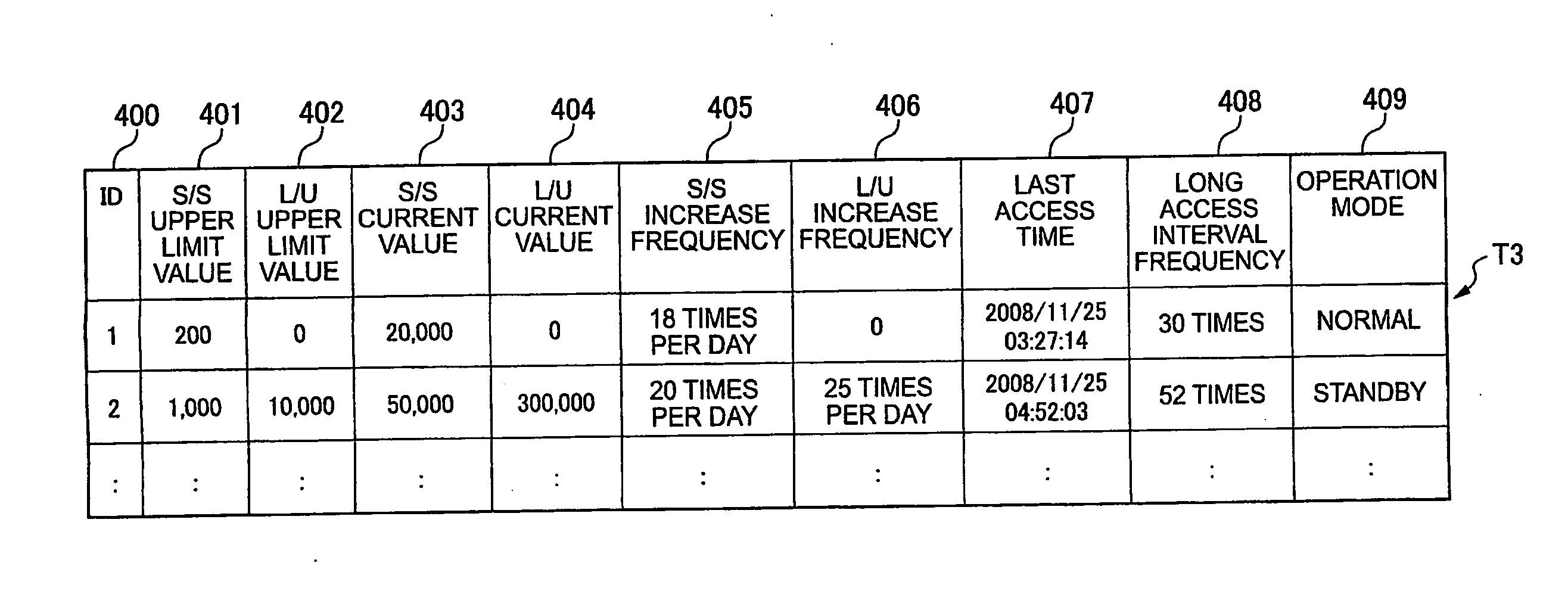

Storage system

InactiveUS20110264854A1Improve storage reliabilityImprove reliabilityEnergy efficient ICTError detection/correctionLow speedOperation mode

To maintain reliability even when the repetition of the power saving control for storage systems occurs frequently due to the access from the host computer. During the course of controlling the operation mode of the drives, the controller measures the start / stop cycle count and the load / unload cycle count, calculates the S / S wear-out rate showing the ratio of the measured value of the start / stop cycle count to the first upper limit value and the L / U wear-out rate showing the ratio of the measured value of the load / unload cycle count to the second upper limit value, and for the drives in the idle operation mode, selects the low-speed rotation operation mode if the S / S wear-out rate is greater than the L / U wear-out rate, or selects the standby operation mode if the S / S wear-out rate is less than the L / U wear-out rate.

Owner:HITACHI LTD

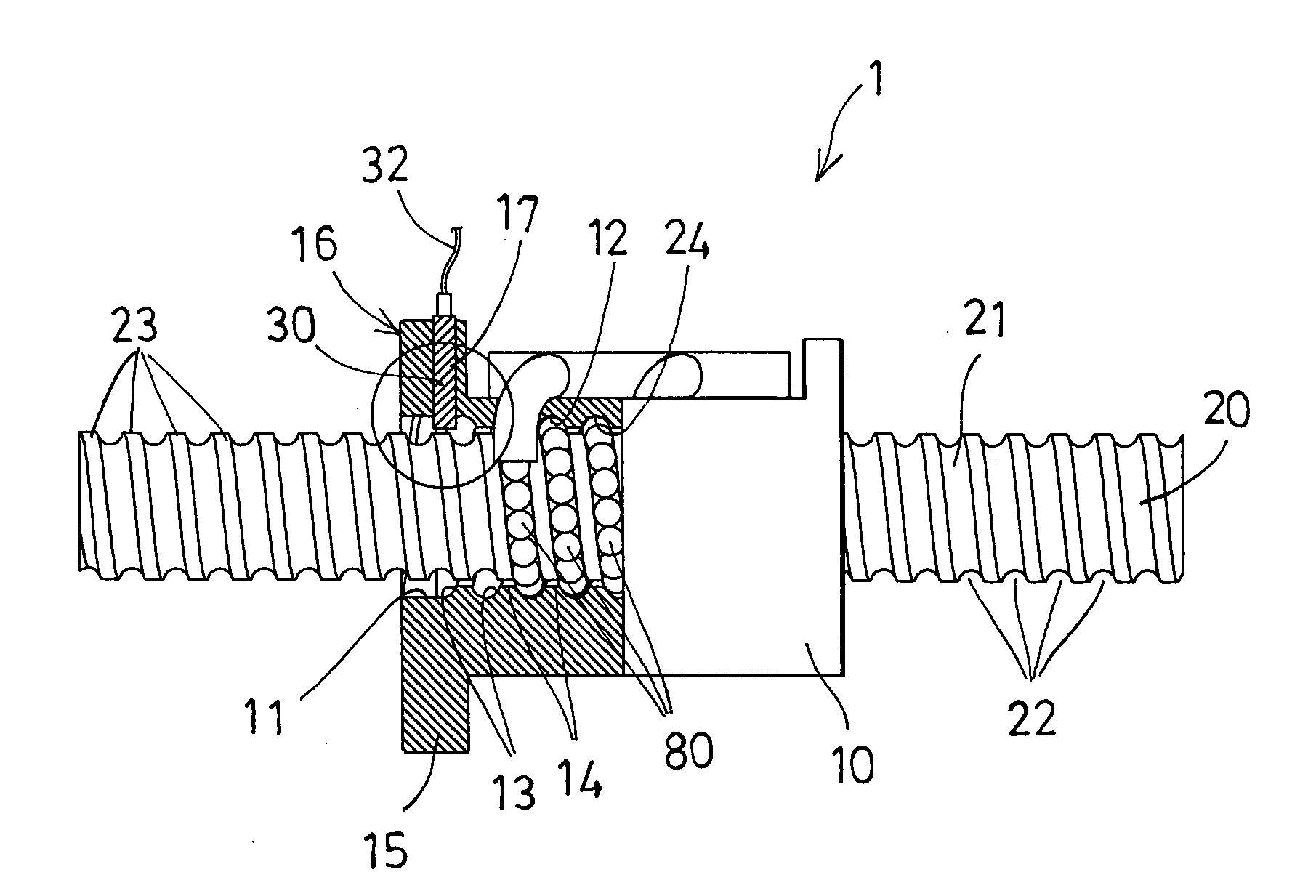

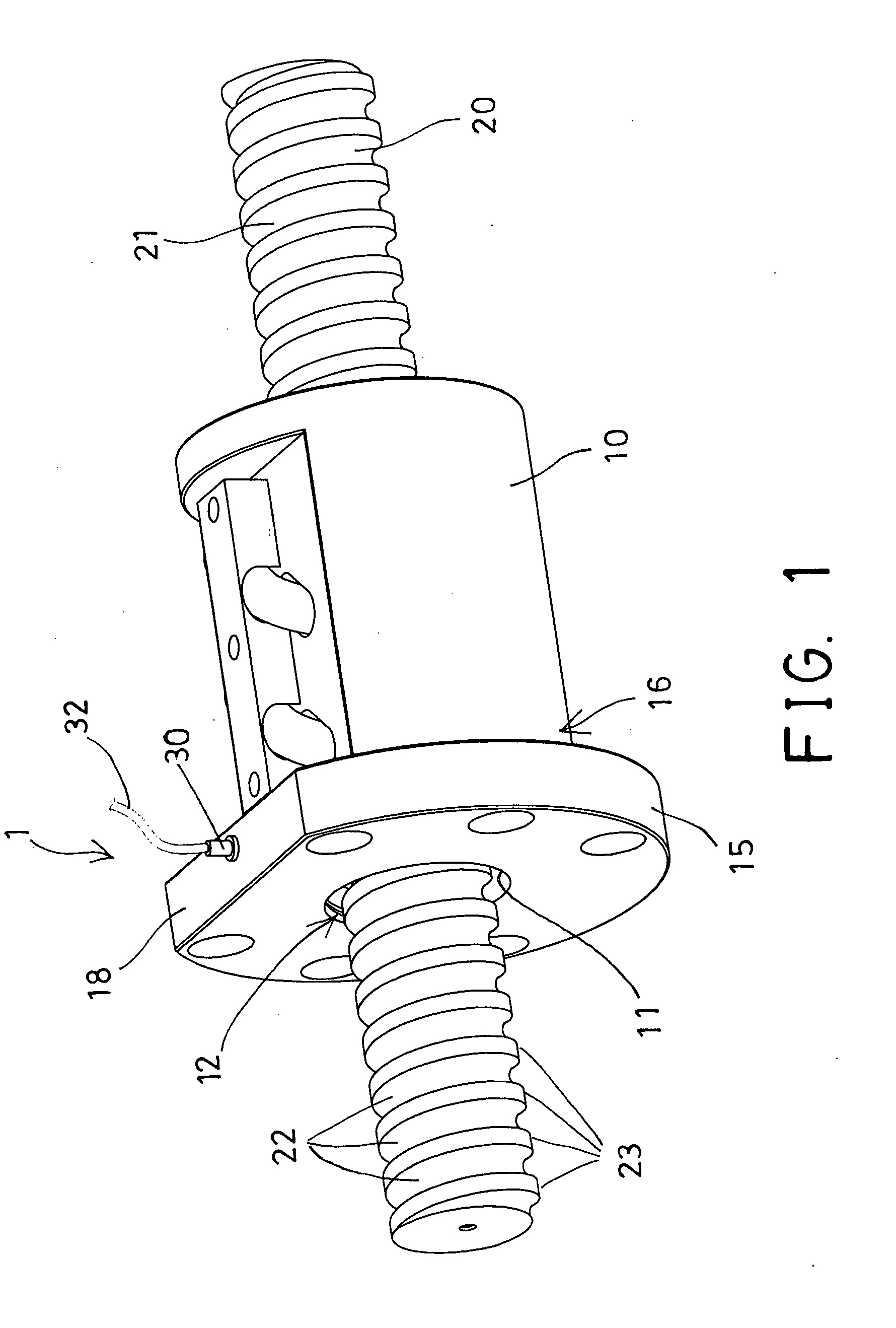

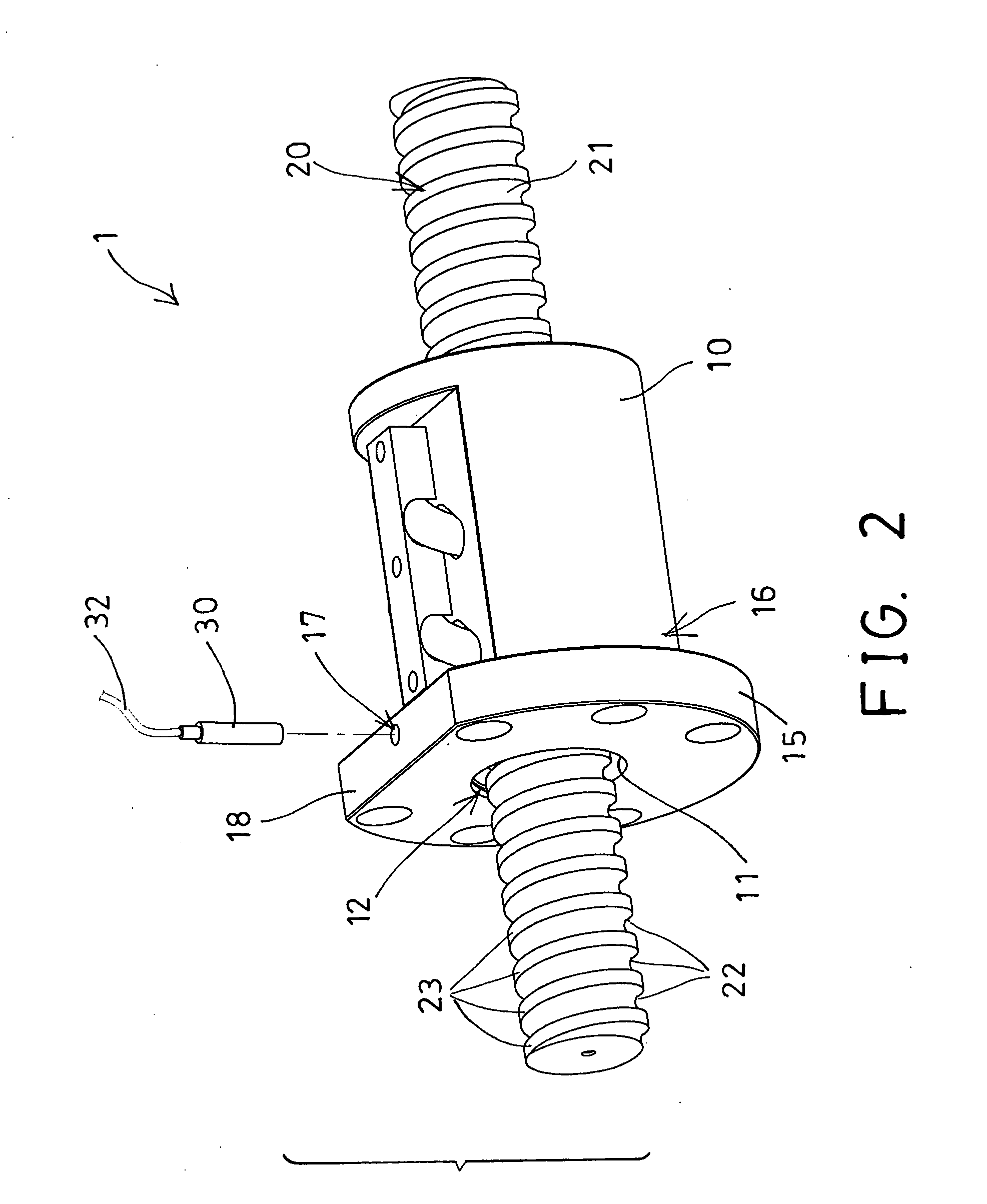

Ball screw device having image sensor

A ball screw device includes a number of bearing members received between a ball nut and a screw shaft, and an image device engaged into the bore of the ball nut, and directed toward the screw shaft but spaced from the screw shaft for taking an image of the screw shaft and for viewing a changing of the inner thread of the screw shaft and for allowing the users to change or to replace the worn out ball nut and / or the worn out screw shaft and / or the worn out bearing members right away or at the best time. A processor device may be coupled to the image device for processing the images taken by the image device. A displayer may display the images, and a warning device may generate a warning signal when the screw shaft has been worn out.

Owner:HIWIN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com