Breaking and high tension electrostatic separating method for worn-out printed circuit board

A technology of printed circuit boards and waste circuit boards, which is applied in the field of industrial waste treatment and recycling, and can solve the problems of low sorting efficiency of airflow sorter, inability to effectively sort materials, and great influence of material shape, etc., and achieve structural Simple, low cost, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

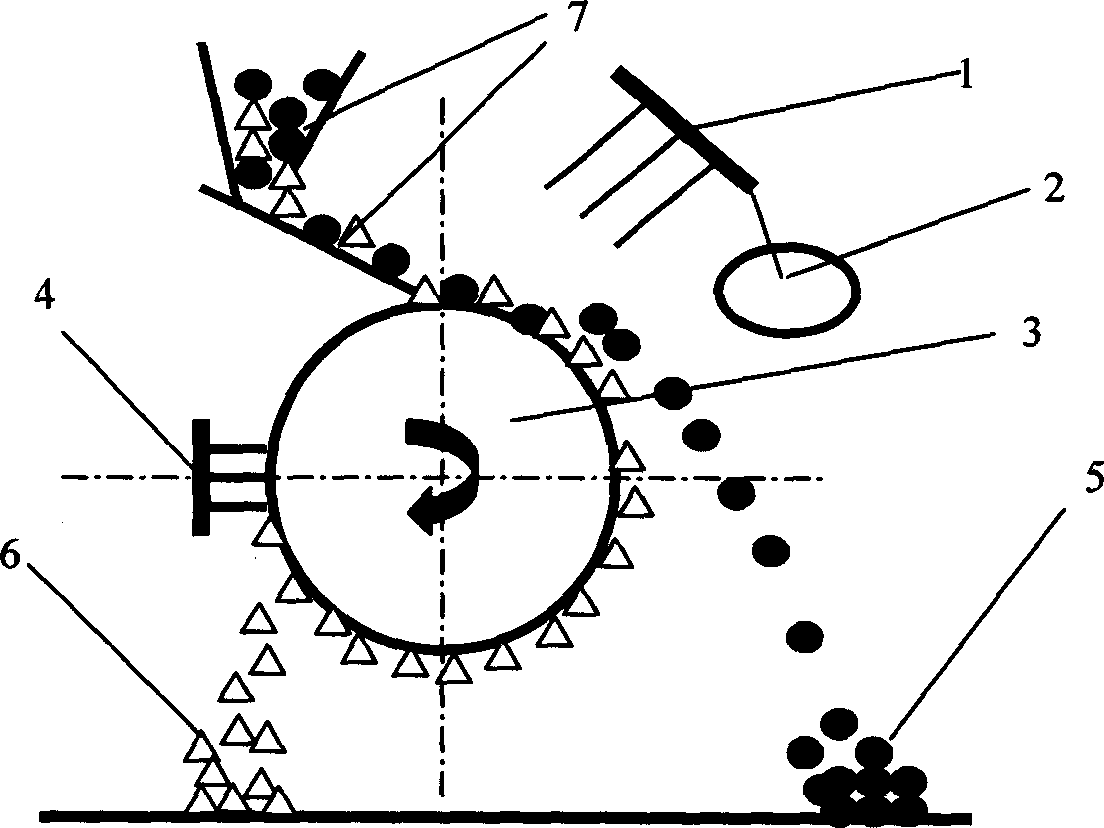

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] The flow process of the inventive method is as figure 1 As shown, it includes three processes: crushing waste printed circuit boards, further pulverizing the crushed particles, and conducting high-voltage electrostatic separation of metal and non-metal particles. First, use the conveyor belt to transport the waste circuit boards to the double-toothed roller crusher, crush the waste circuit boards into fragments with a particle size of 5mm to 20mm, and then use the conveyor belt to transport the waste circuit board fragments with a particle size of 5mm to 20mm to the high-speed impact crusher , and further crush the waste printed circuit boards into particles of 0.06mm to 0.5mm. Then the pulverized particles are sent to high-voltage electrostatic separation equipment, and the metal substances and non-metal substances in the mixed materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com