Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134 results about "Universal motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

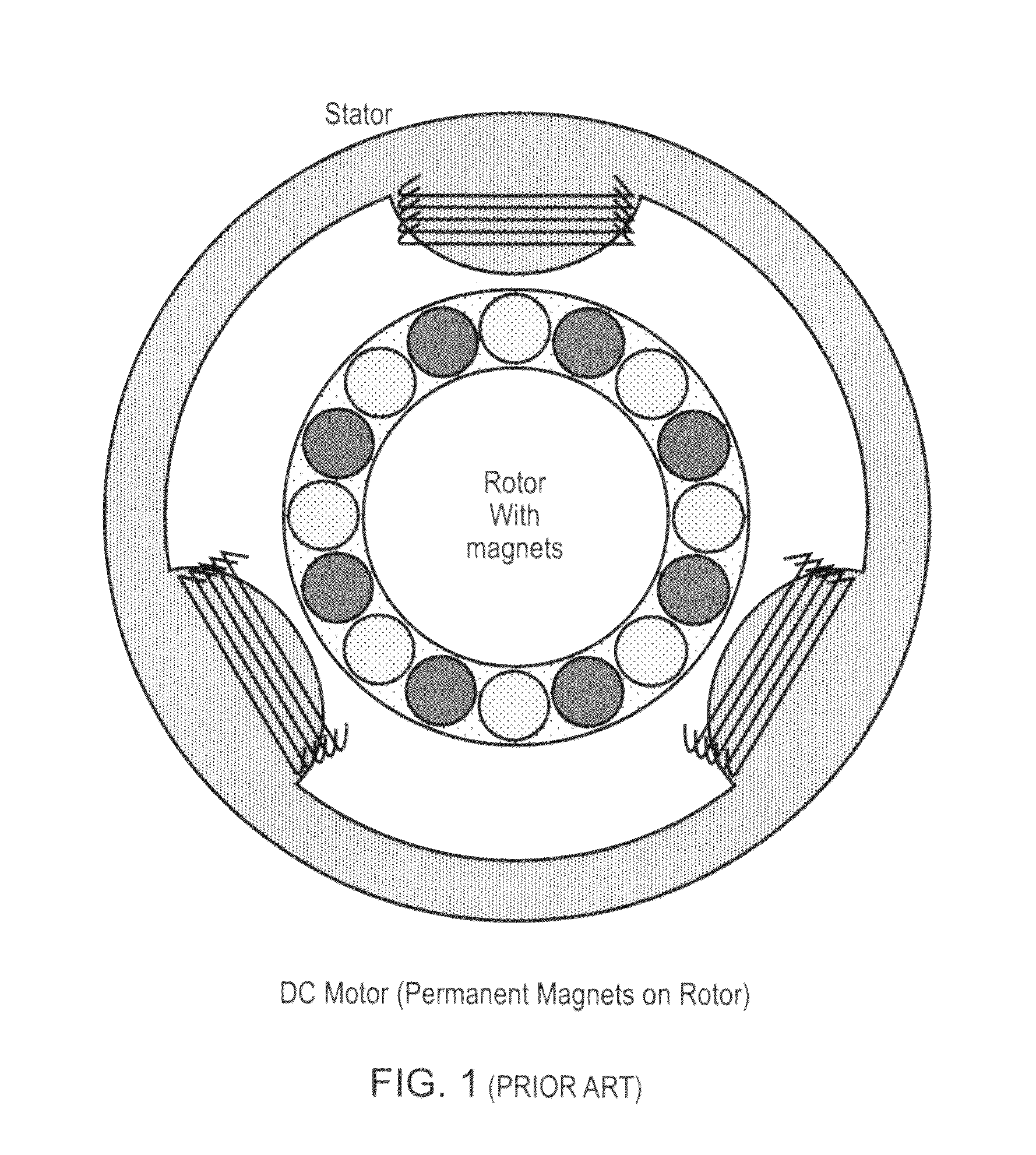

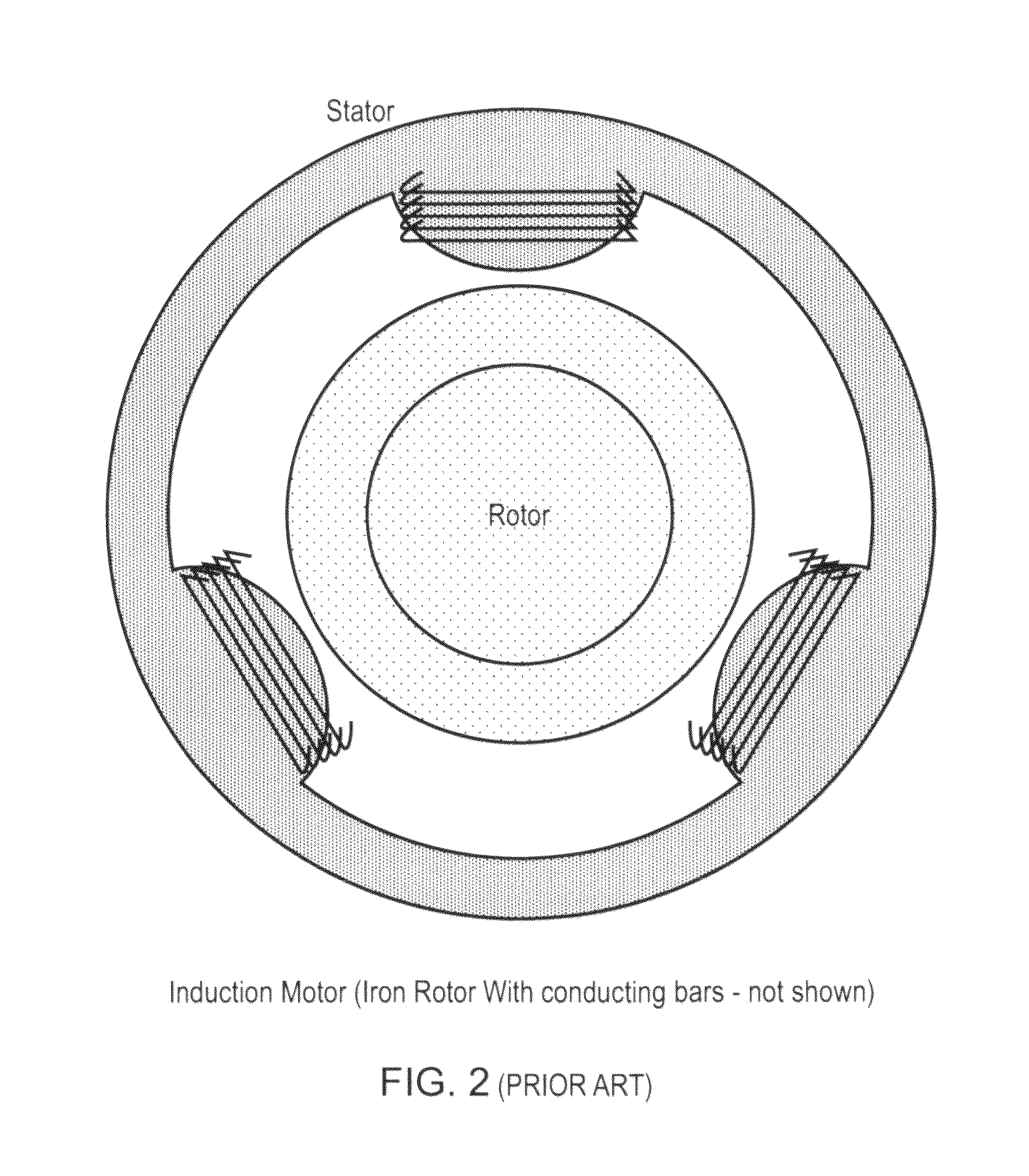

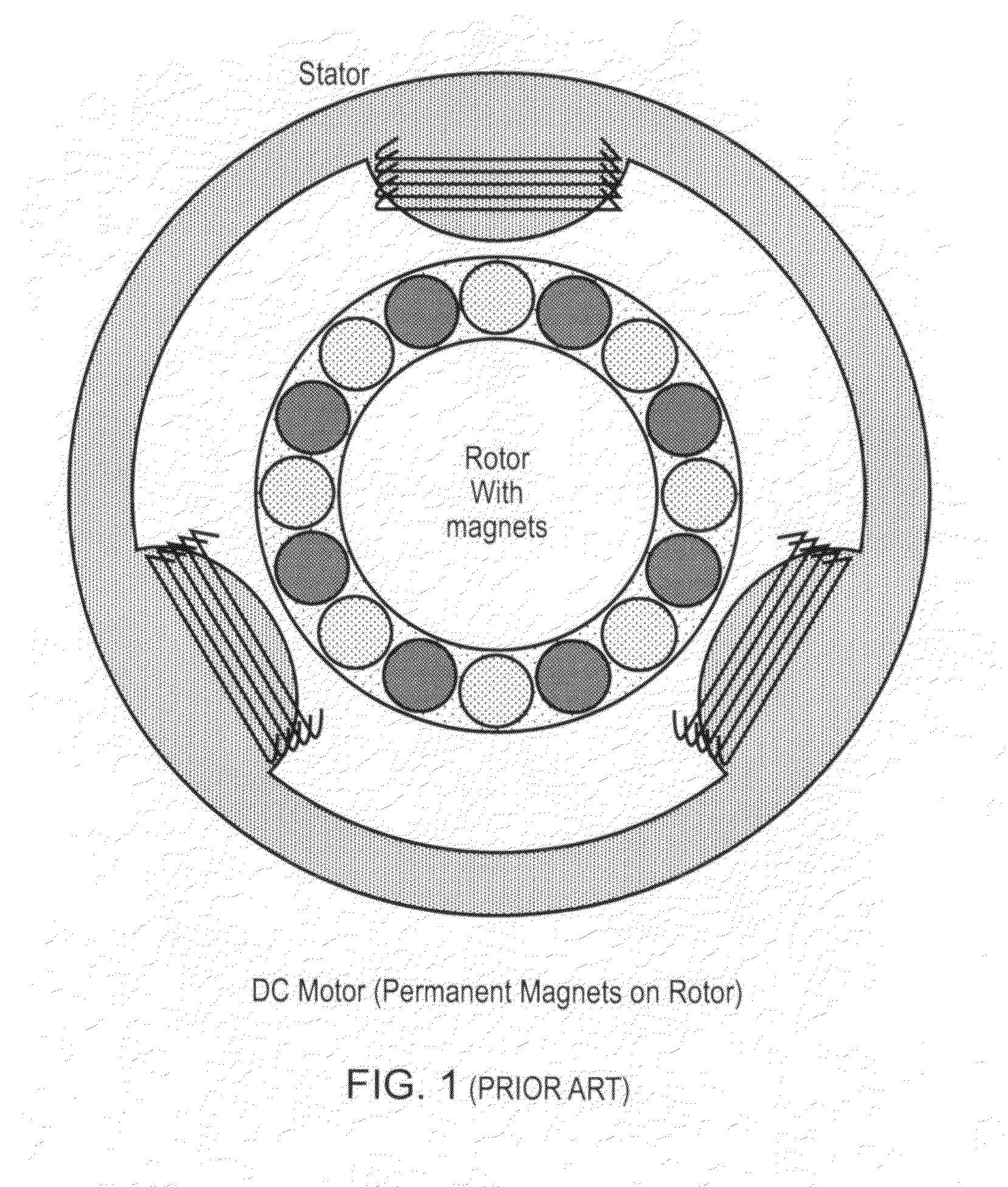

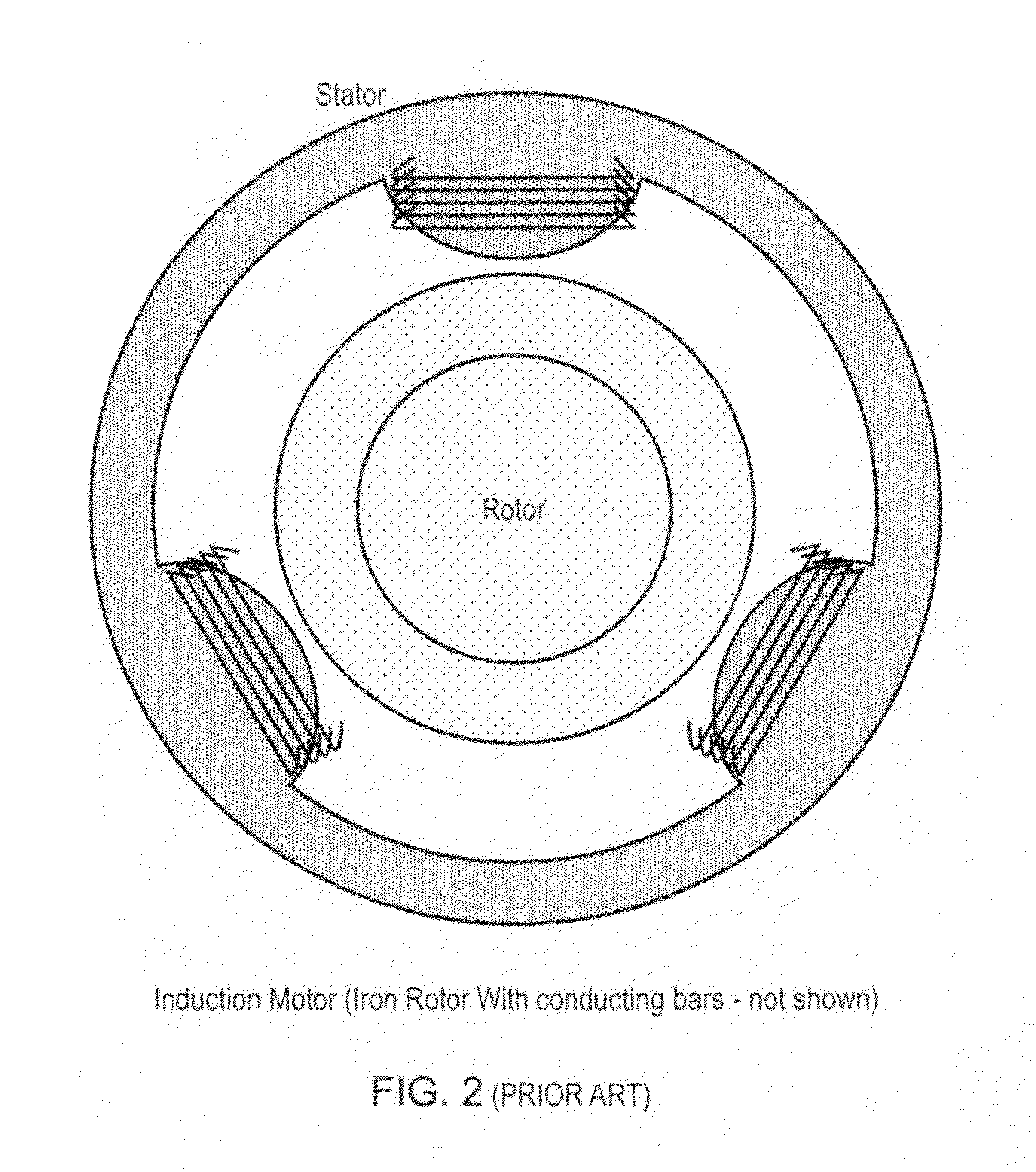

The universal motor is a type of electric motor that can operate on either AC or DC power and uses an electromagnet as its stator to create its magnetic field. It is a commutated series-wound motor where the stator's field coils are connected in series with the rotor windings through a commutator. It is often referred to as an AC series motor. The universal motor is very similar to a DC series motor in construction, but is modified slightly to allow the motor to operate properly on AC power. This type of electric motor can operate well on AC because the current in both the field coils and the armature (and the resultant magnetic fields) will alternate (reverse polarity) synchronously with the supply. Hence the resulting mechanical force will occur in a consistent direction of rotation, independent of the direction of applied voltage, but determined by the commutator and polarity of the field coils.

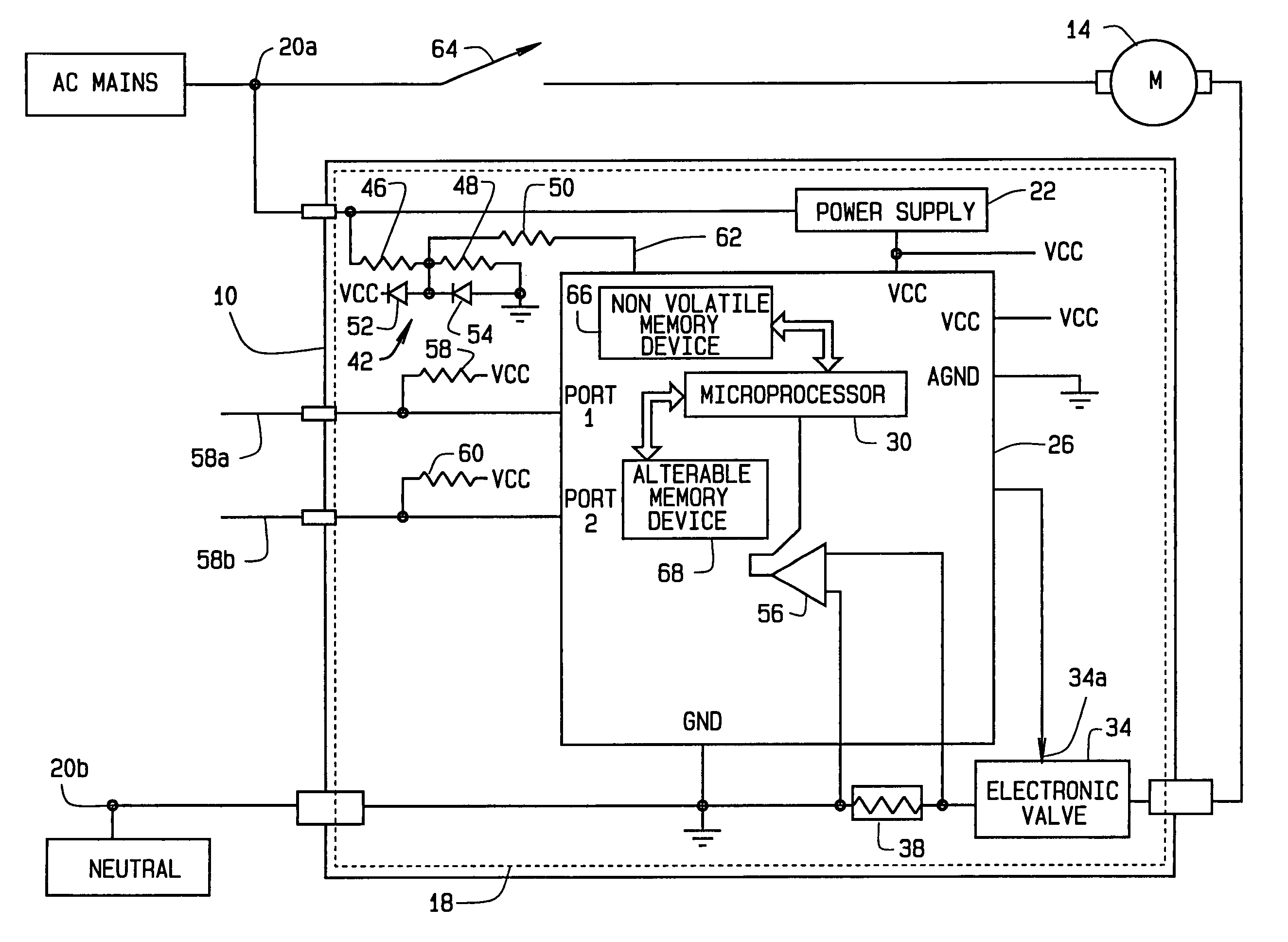

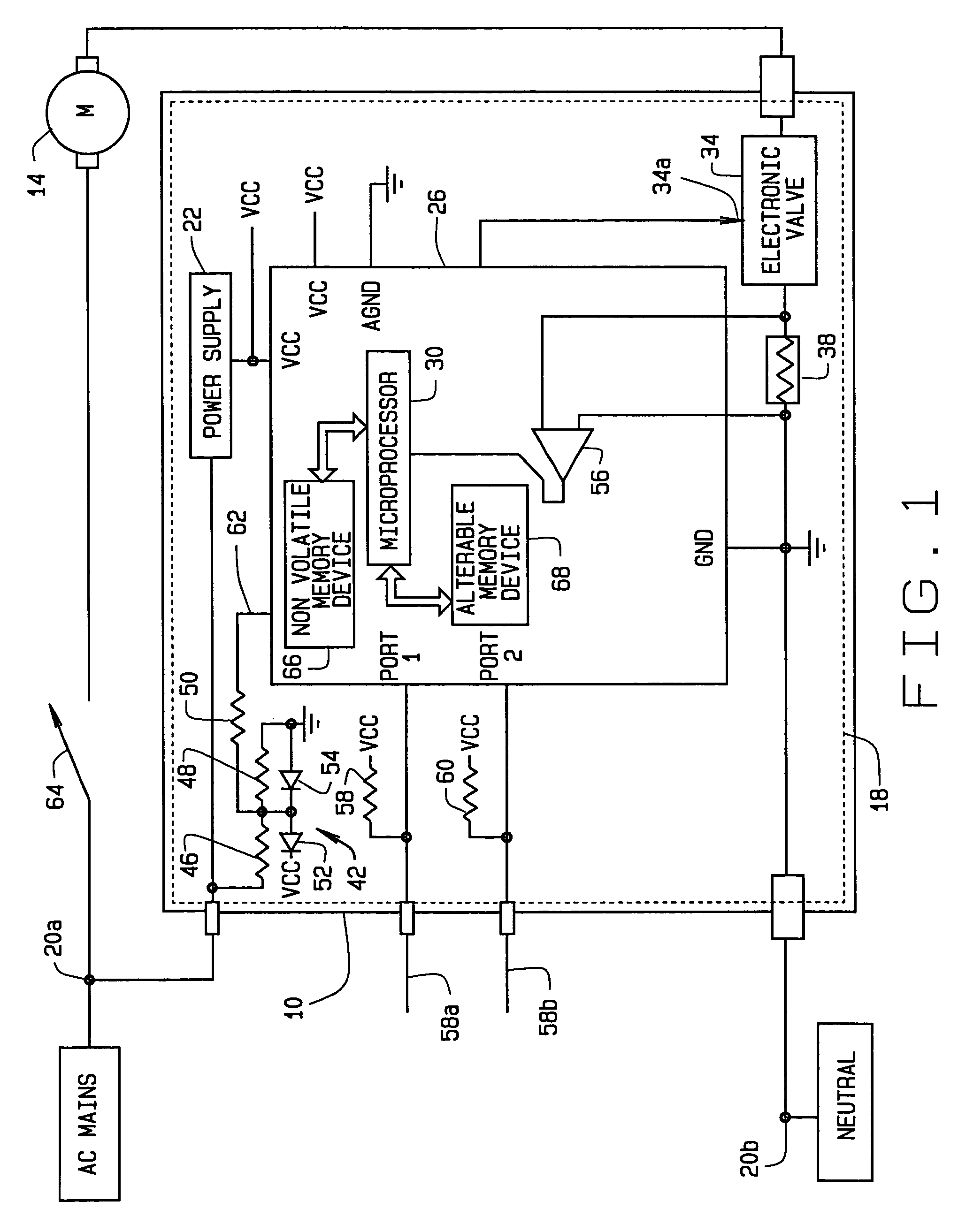

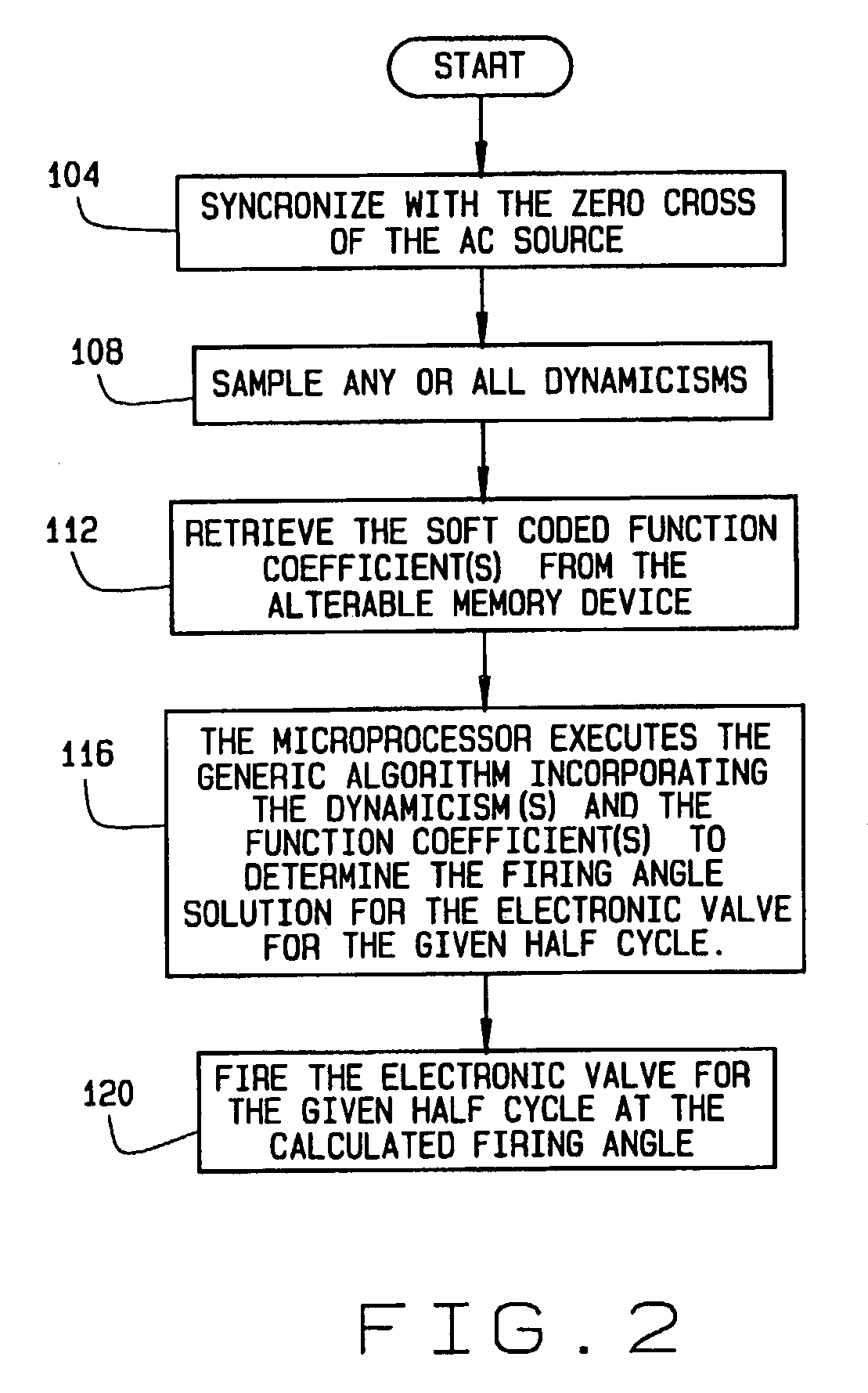

Generic motor control system and method

InactiveUS7102303B2Electronic commutation motor controlMotor/generator/converter stoppersMotor controlMotor function

A method for controlling the operation of a motor utilizing a universal motor control module. The method includes sampling at least one motor operating criterion during operation of the motor and executing a universal control algorithm at a predetermined periodic interval of an AC line signal. Execution of the algorithm provides a firing angle solution for an electronic valve for each periodic interval, thereby controlling the behavior of the motor. Additionally, the method includes firing the electronic valve at the calculated firing angle during each periodic interval such that the motor functions in accordance with desired operational parameters.

Owner:BLACK & DECKER INC

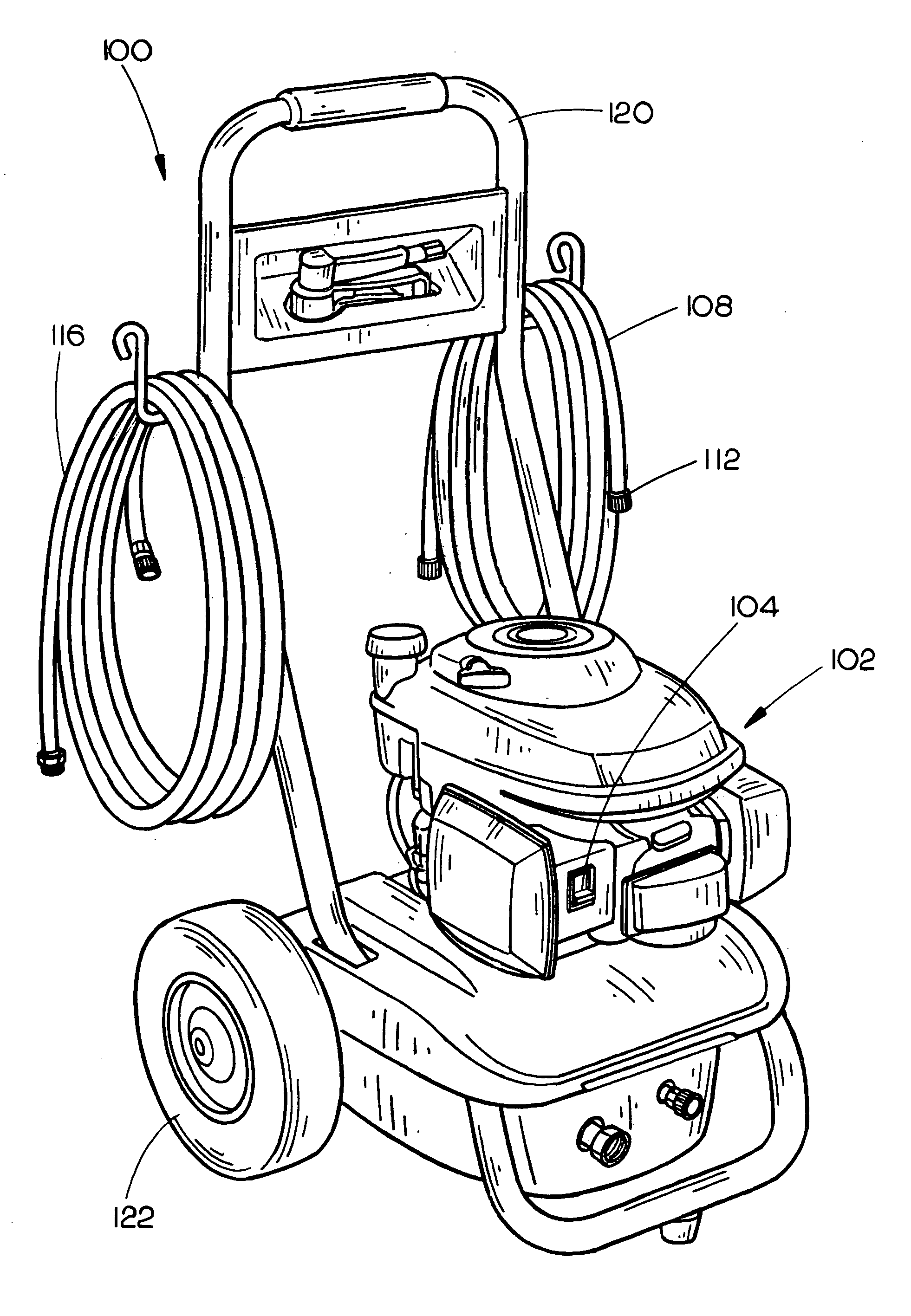

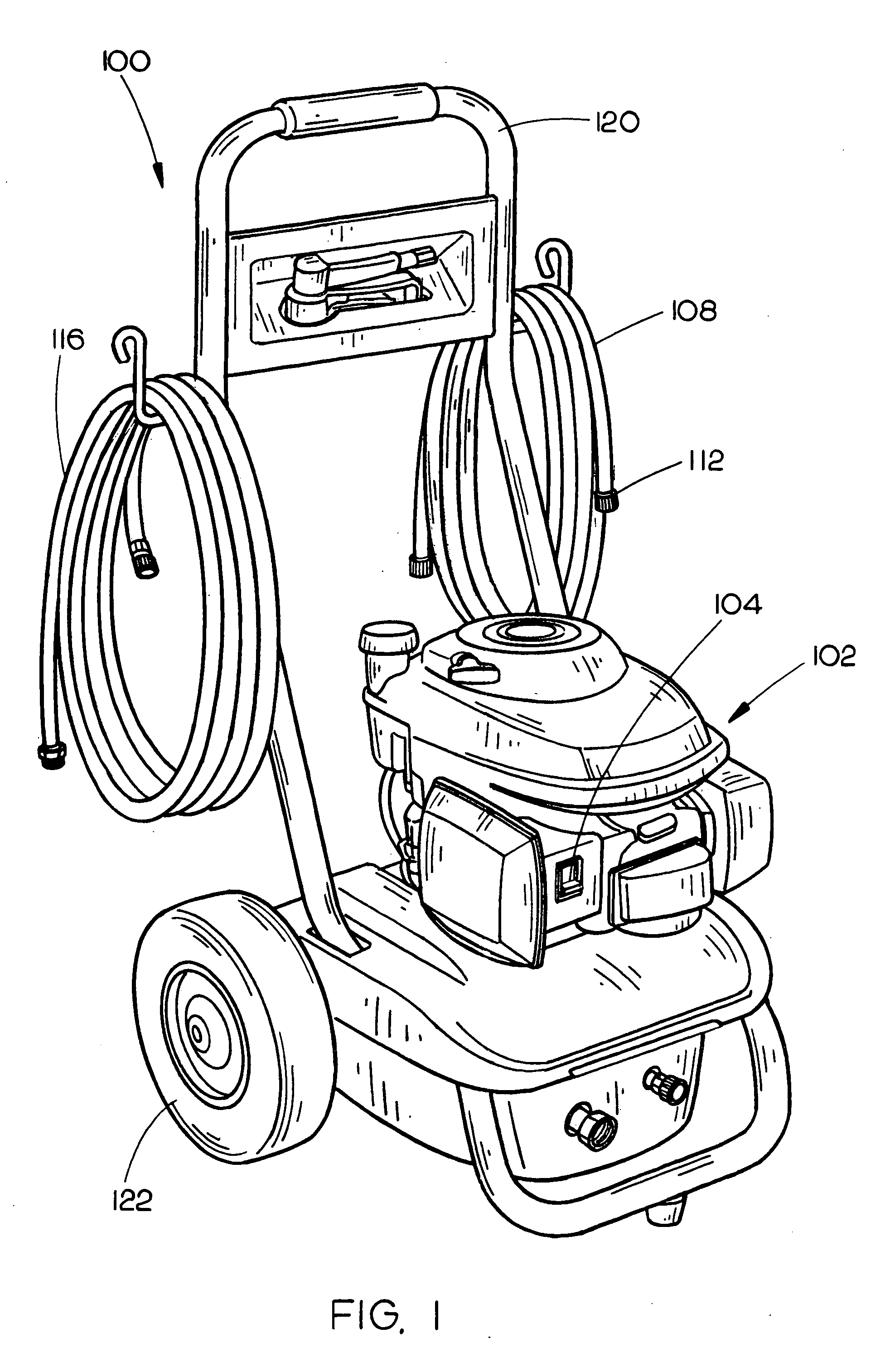

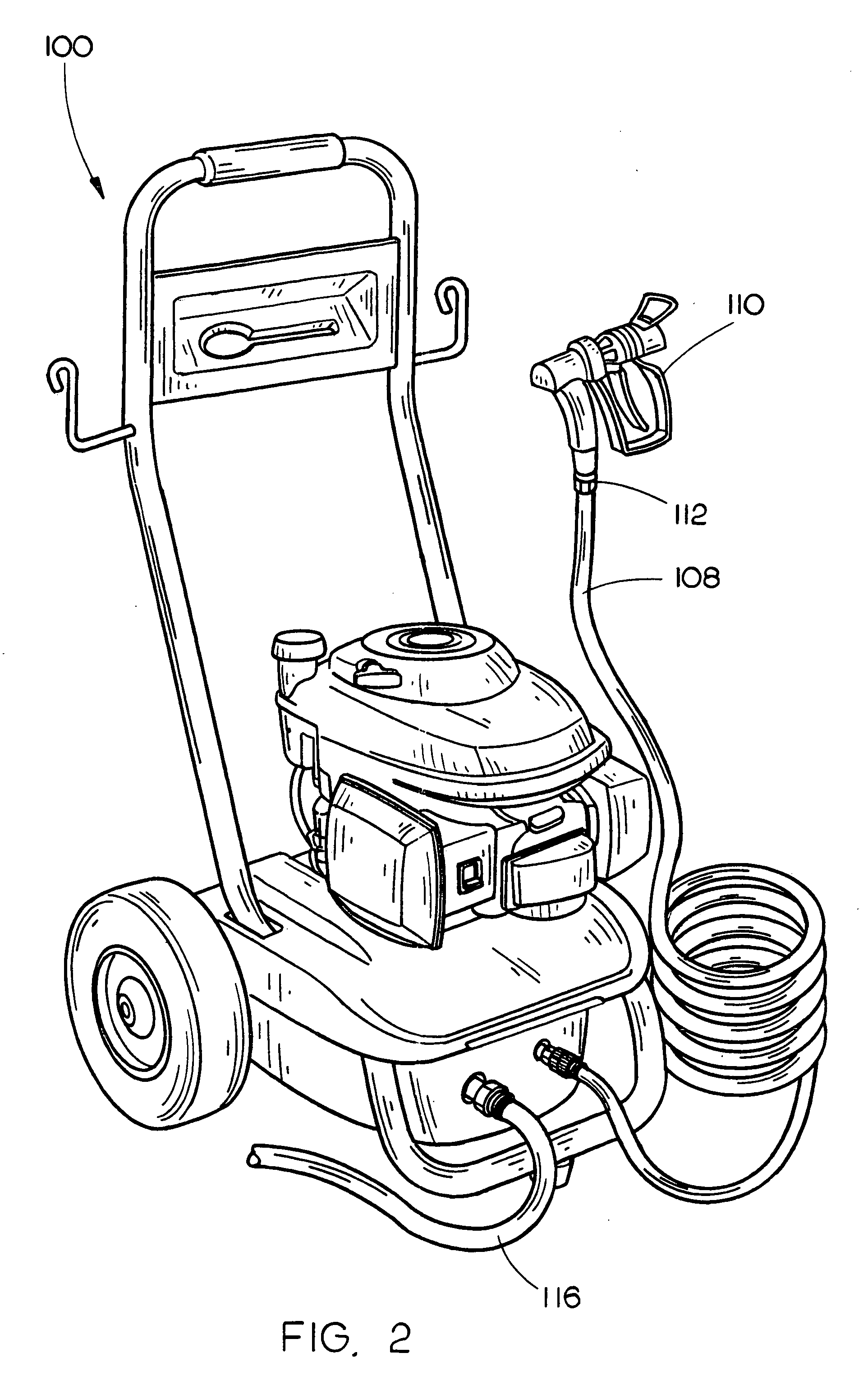

Paint sprayer and pressure washer assembly

A paint sprayer and pressure washer assembly is comprised of a universal motor capable of operating at at least a first speed and a second speed. Further, a pump assembly is coupled to the motor for pressuring a fluid for delivery of the fluid to a surface. In use, the motor drives the pump at one of the first speed for pumping a first fluid so that the first fluid is output at a first pressure and flow rate and the second speed for pumping a second fluid so that the second fluid is output at a second pressure and flow rate.

Owner:BLOCK & DECKER

Water repellent motor sleeve

A high-speed universal motor running at over 10,000 or even over 20,000 rpm includes a non-rubbing water repellent sleeve that protects the bearings from moisture damage. Rather than having a sliding contact seal that can quickly wear out under such high speeds, the sleeve is made of material having a low solid surface energy so that the seal material itself repels waters on its own. TEFLON is the preferred material, which is relatively soft, so to prevent the compressibility of the seal from affecting the axial positioning of parts on the motor shaft, the seal is installed such that the seal does not contribute to the critically precise positioning of the shaft and the parts mounted to it. In some embodiments, for example, the relatively soft seal simply overlies a much stiffer, accurately machined metal spacer.

Owner:ELECTRO MOTOR

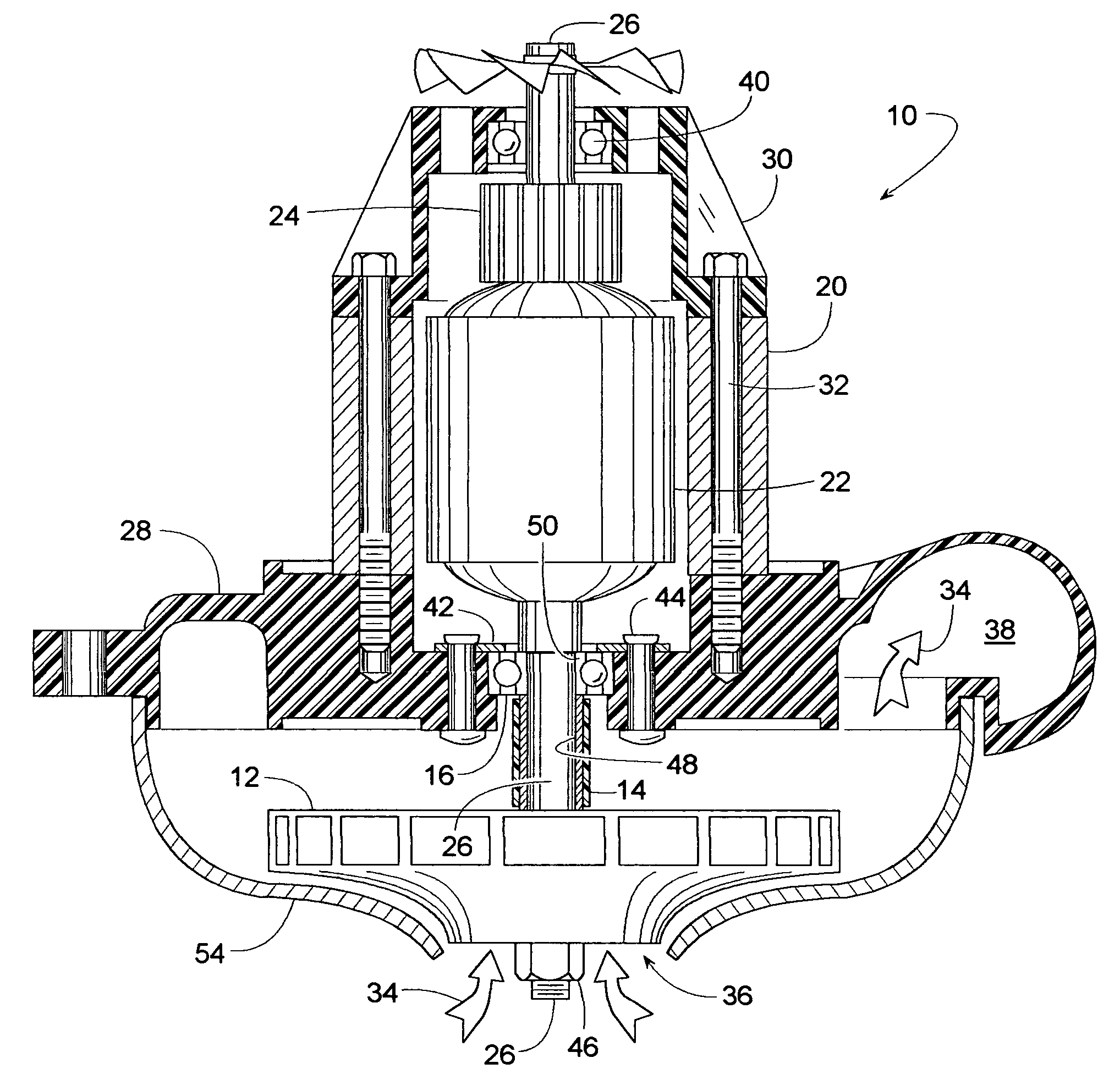

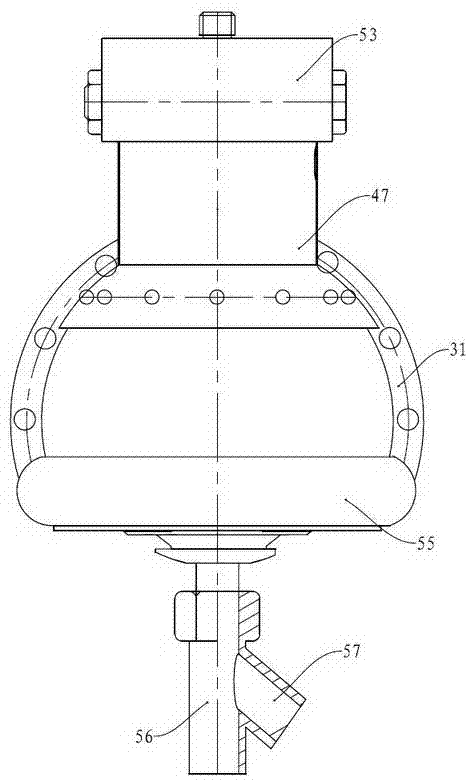

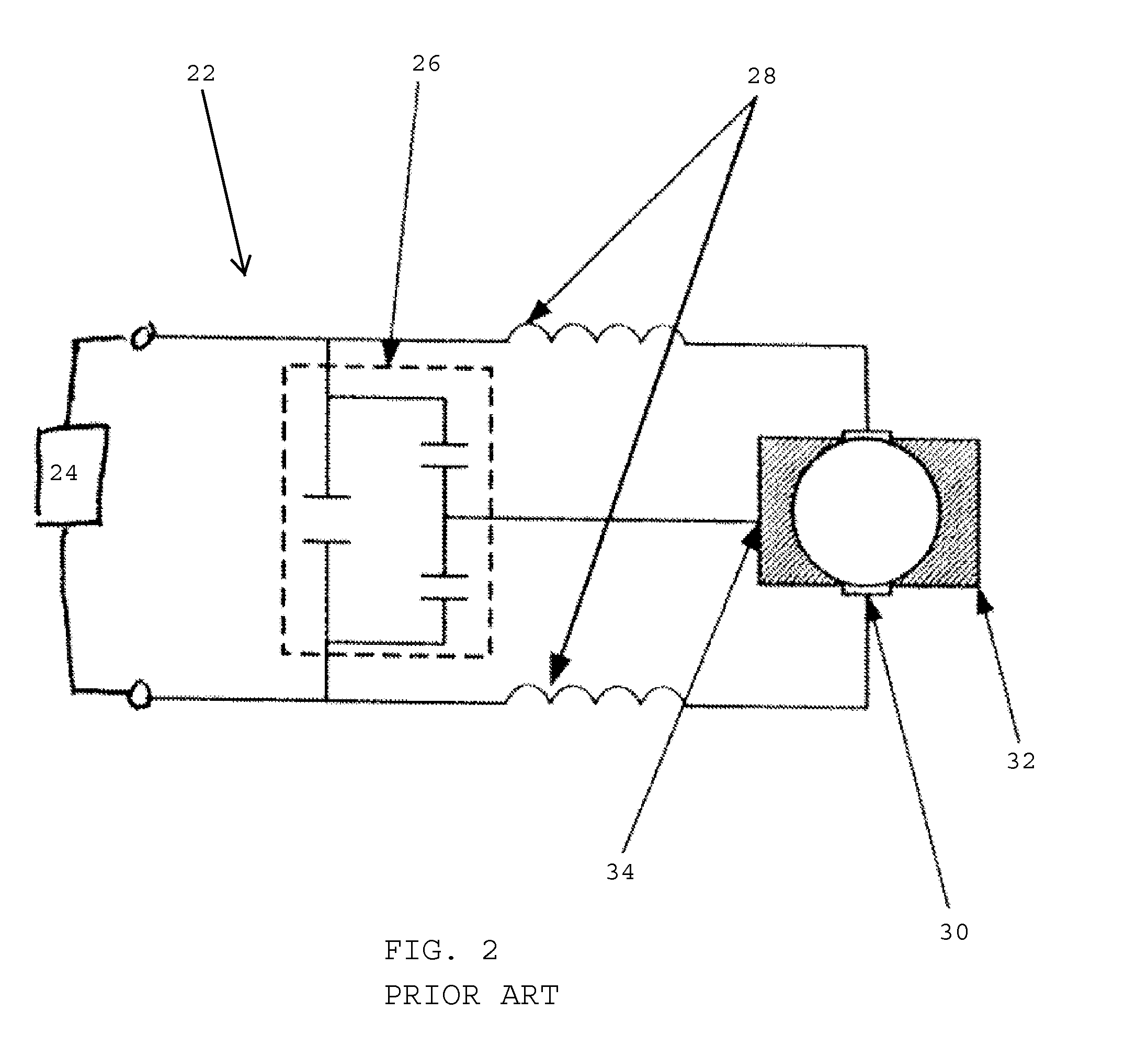

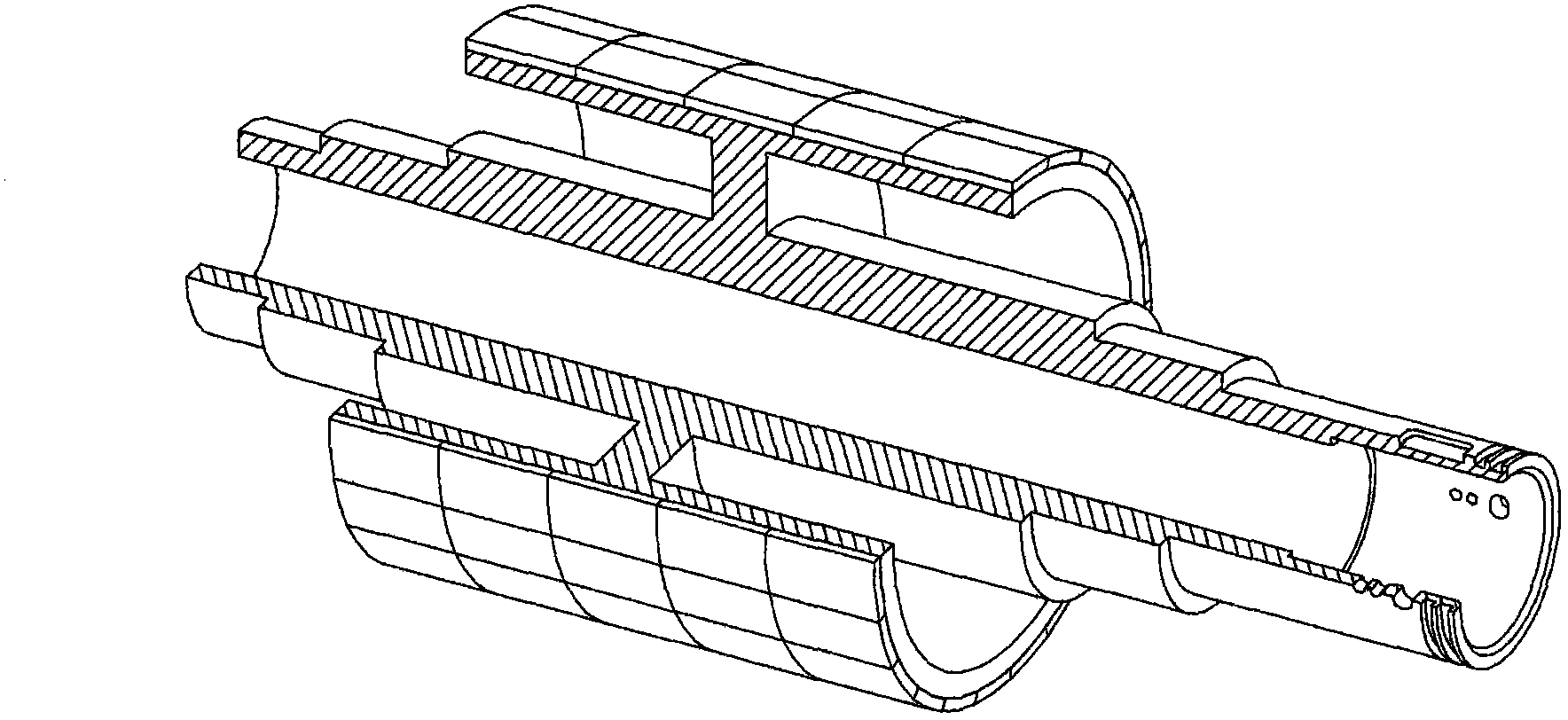

Spherical hinge universal rotary motor, and manufacturing method and operating method thereof

ActiveCN103780041AChange tilt angleAchieving freedom of movementMagnetic circuit rotating partsMagnetic circuit stationary partsJoint componentElectric machine

The invention provides a spherical hinge universal rotary motor, and a manufacturing method and an operating method thereof. The motor comprises a stator body made of a permanent magnet, wherein the permanent magnet is magnetized into a plurality of magnetic poles, the stator body is internally provided with a rotor body, the rotor body is provided with multiple layers of armatures, two adjacent layers of armatures are provided with a spacer layer therebetween, the multiple layers of armatures and the multiple layers of spacer layers are fixedly connected through a bolt, the bolt is connected with a rotor shaft, and the rotor body is of a spherical shape. A first layer of coils is wound on a rotor core of the armature, and the first layer of coils is wound on a rotor core of an armature at the same layer. The invention further provides a manufacturing method and an operating method of the motor. The motor provided by the invention can rotate in various directions, and comprises rotation around a Z-axis and oblique rotation relative to the Z-axis. The spherical hinge universal rotary motor is divided into a type with an air pump assembly mechanism and a type without the air pump assembly mechanism according to the air supply mode, and is widely applied to intelligent bionic robots to act as a joint component.

Owner:何国华

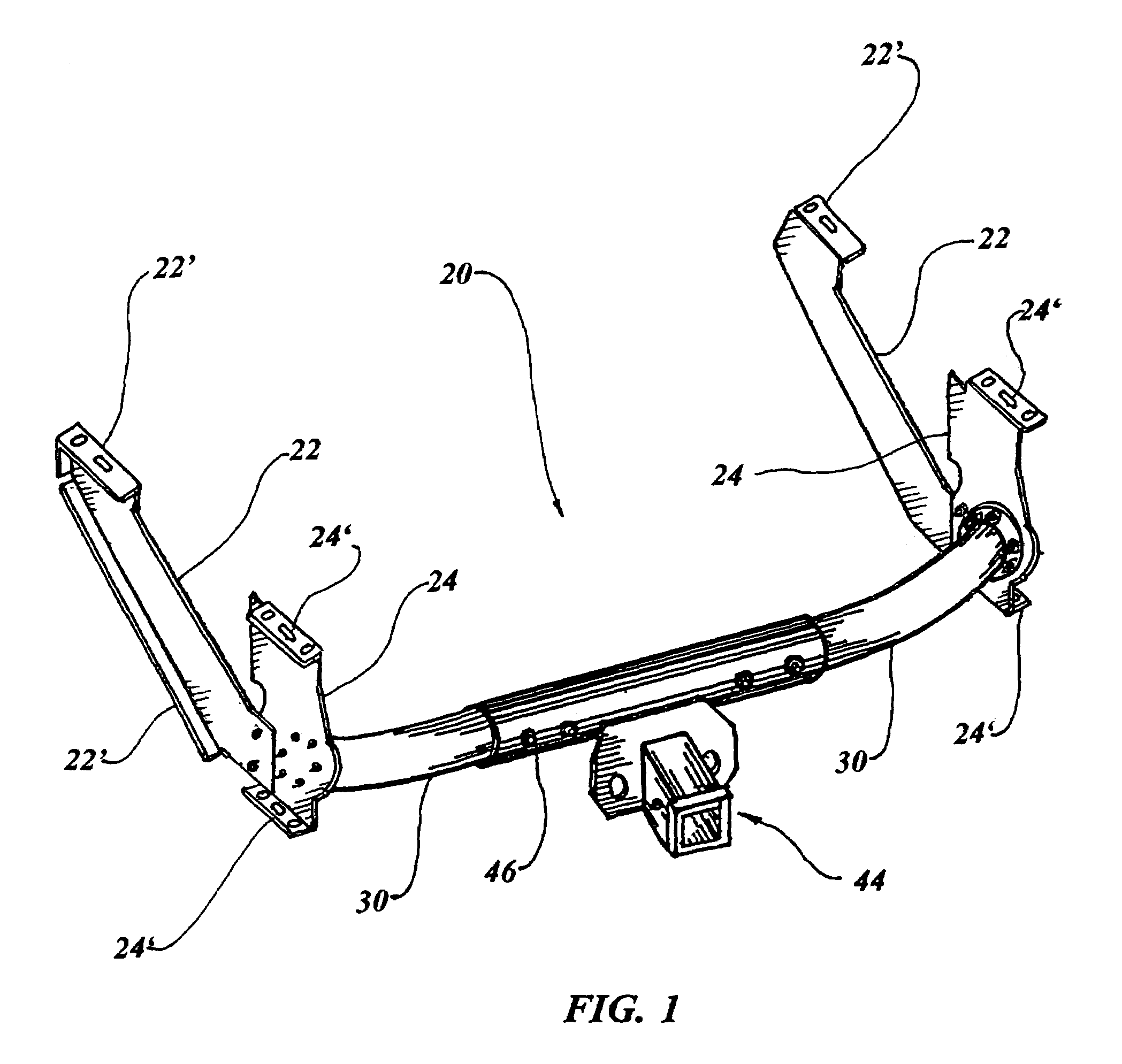

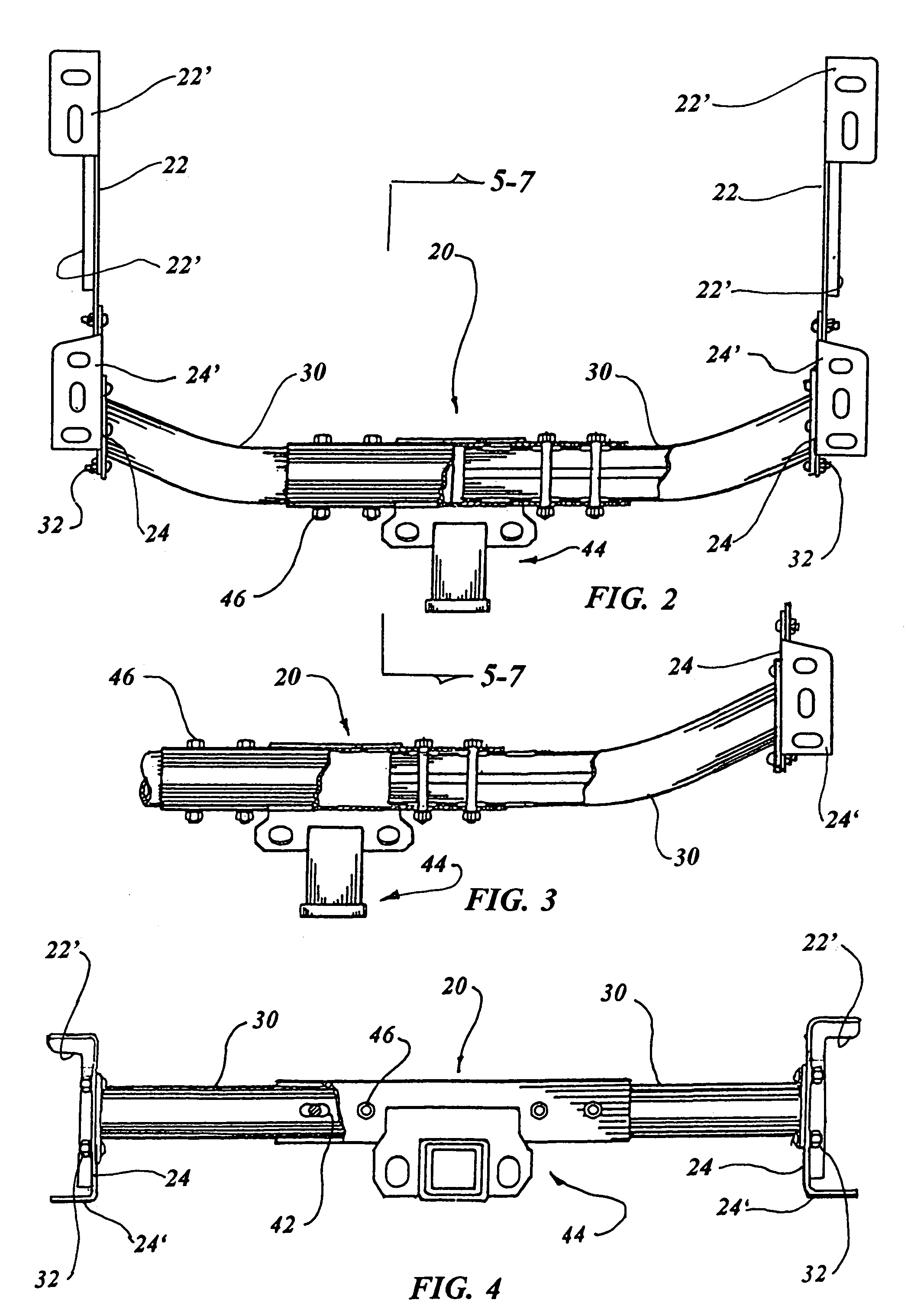

Universal motor vehicle trailer hitch

A trailer hitch (20) for attachment onto a motor vehicle for pulling a trailer. The hitch (20) consists of a pair of forward and aft mounting brackets (22 and 24) that are connected into existing holes in the vehicle's frame. Each mounting bracket has flanges (22′ and 24′) with the aft brackets (24) having thru-holes (26) arranged in a bolt circle array. The pair of forward mounting brackets (22) are connected to the aft mounting brackets (24) for length adjustment of the trailer hitch relative to the hitch position on the motor vehicle. The height of the trailer hitch (20) is regulated by the right side up or upside down position of the aft mounting brackets (24) properly orienting the thru-holes. A box hitch (44) is adjustably attached for width regulation onto the thru-holes of the aft mounting brackets (24) by inserting arms (30) into a tubular sleeve (50) of the box hitch at an appropriate distance. A receiver box (48) is connected on the bottom of the tubular sleeve for receiving a hitch ball mounted on a trailer ball mount.

Owner:CHENG JOHN C +2

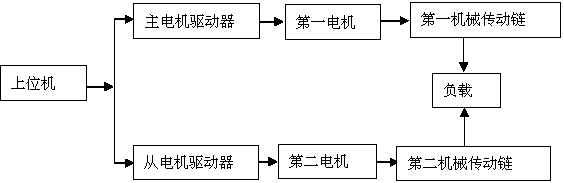

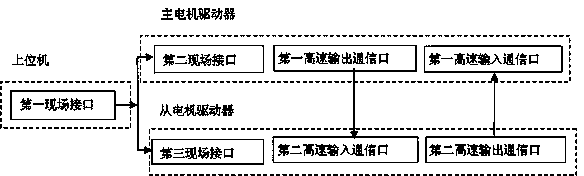

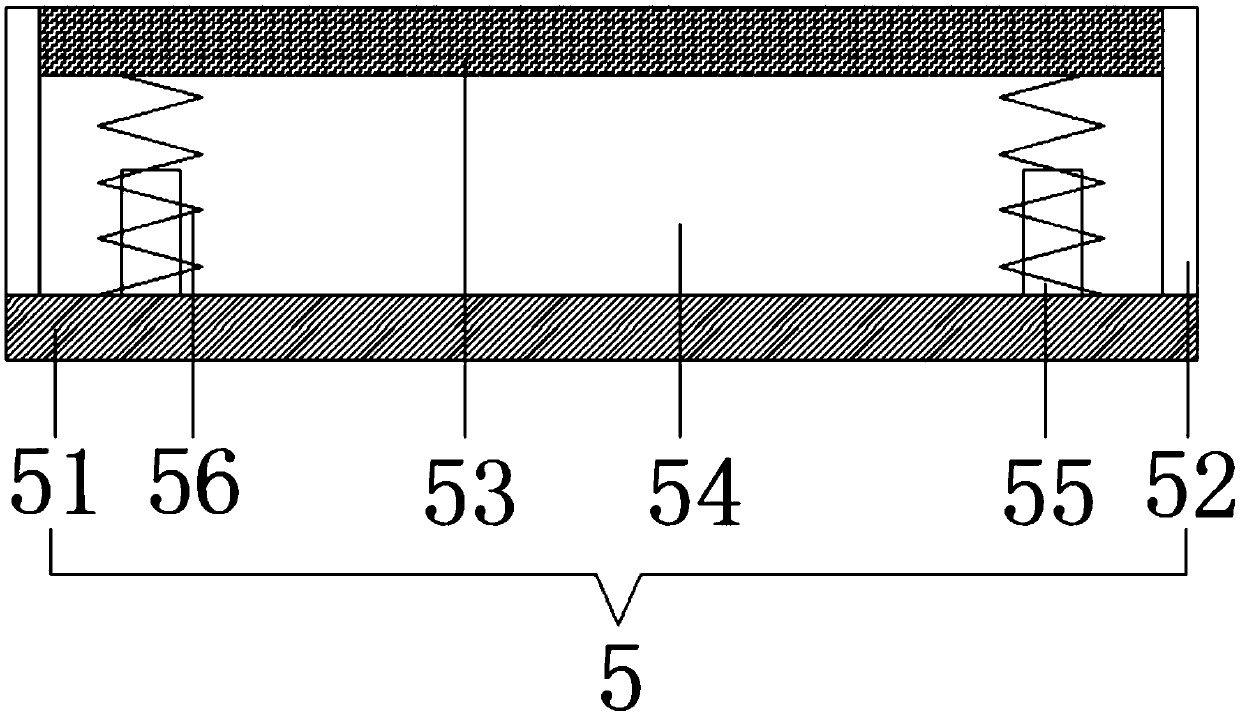

Double-motor coaxial driven backlash elimination control system and backlash elimination control method thereof

ActiveCN103997259AReduce the amount of data exchangePrevent Differential VibrationMultiple dynamo-electric motors speed regulationControl engineeringElectric machinery

The invention discloses a double-motor coaxial driven backlash elimination control system which comprises a principal computer, a master motor driver, a slave motor driver, a first motor, a second motor, a first mechanical transmission chain and a second mechanical transmission chain. The principal computer is connected with the master motor driver and the slave motor driver respectively through a field bus. The master motor driver is connected with the first mechanical transmission chain through the first motor. The slave motor driver is connected with the second mechanical transmission chain through the second motor. The first mechanical transmission chain and the second mechanical transmission chain are respectively connected to a load driven by the system. The invention further discloses a backlash elimination method based on the double-motor coaxial driven backlash elimination control system. According to the invention, secondary programming is performed in the digitally-controlled motor drivers, a backlash elimination control link is added, double-motor coaxial driven backlash elimination control by universal motor drivers is realized, the backlash elimination torque can be conveniently set as required, and speed feedback signals of the double motors can be accessed into a control circuit to avoid the problem of differential oscillation.

Owner:南京中润泊车设备科技股份有限公司

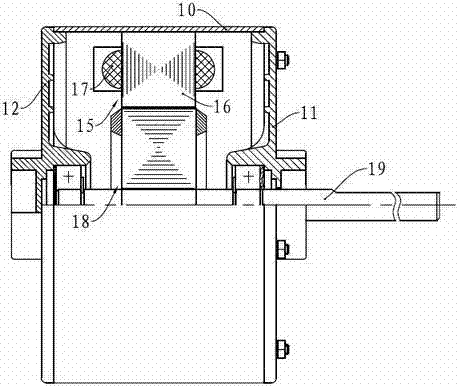

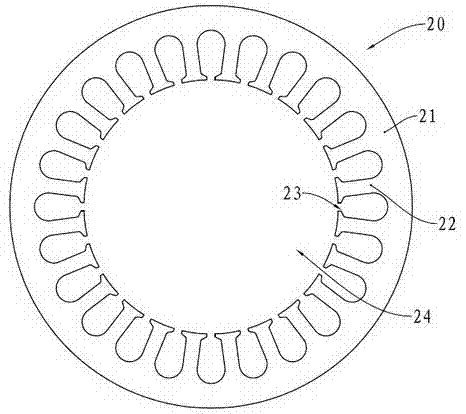

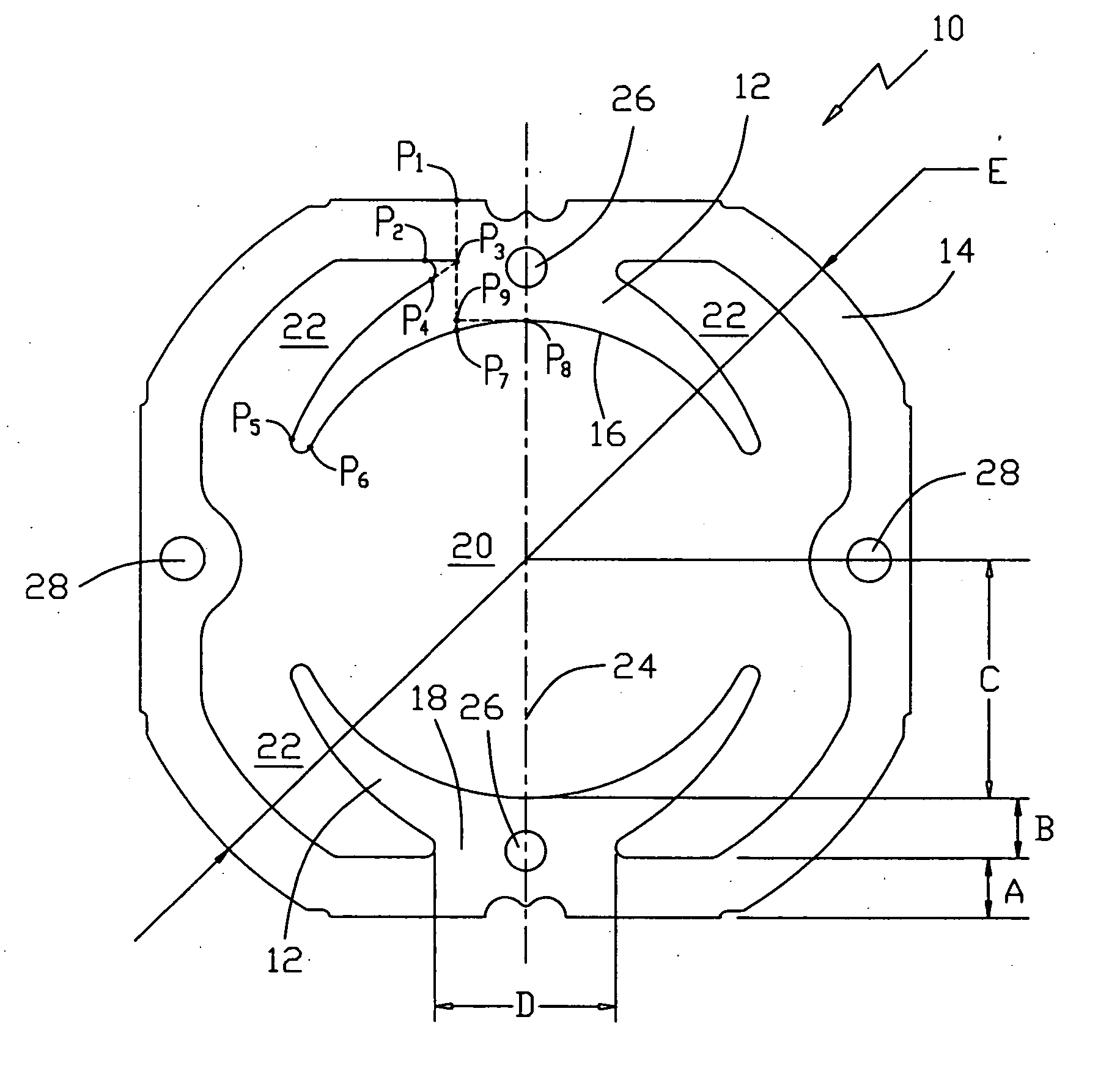

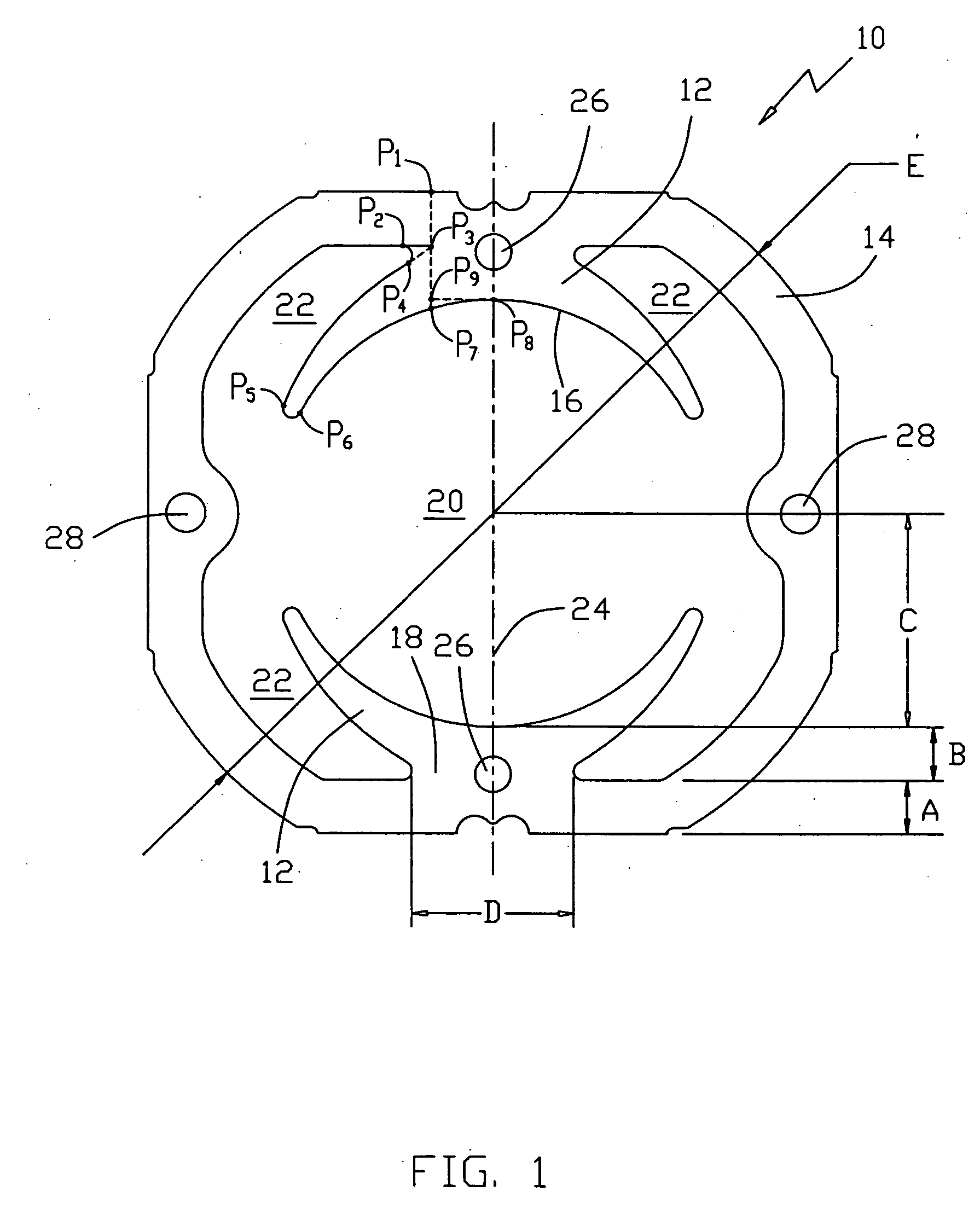

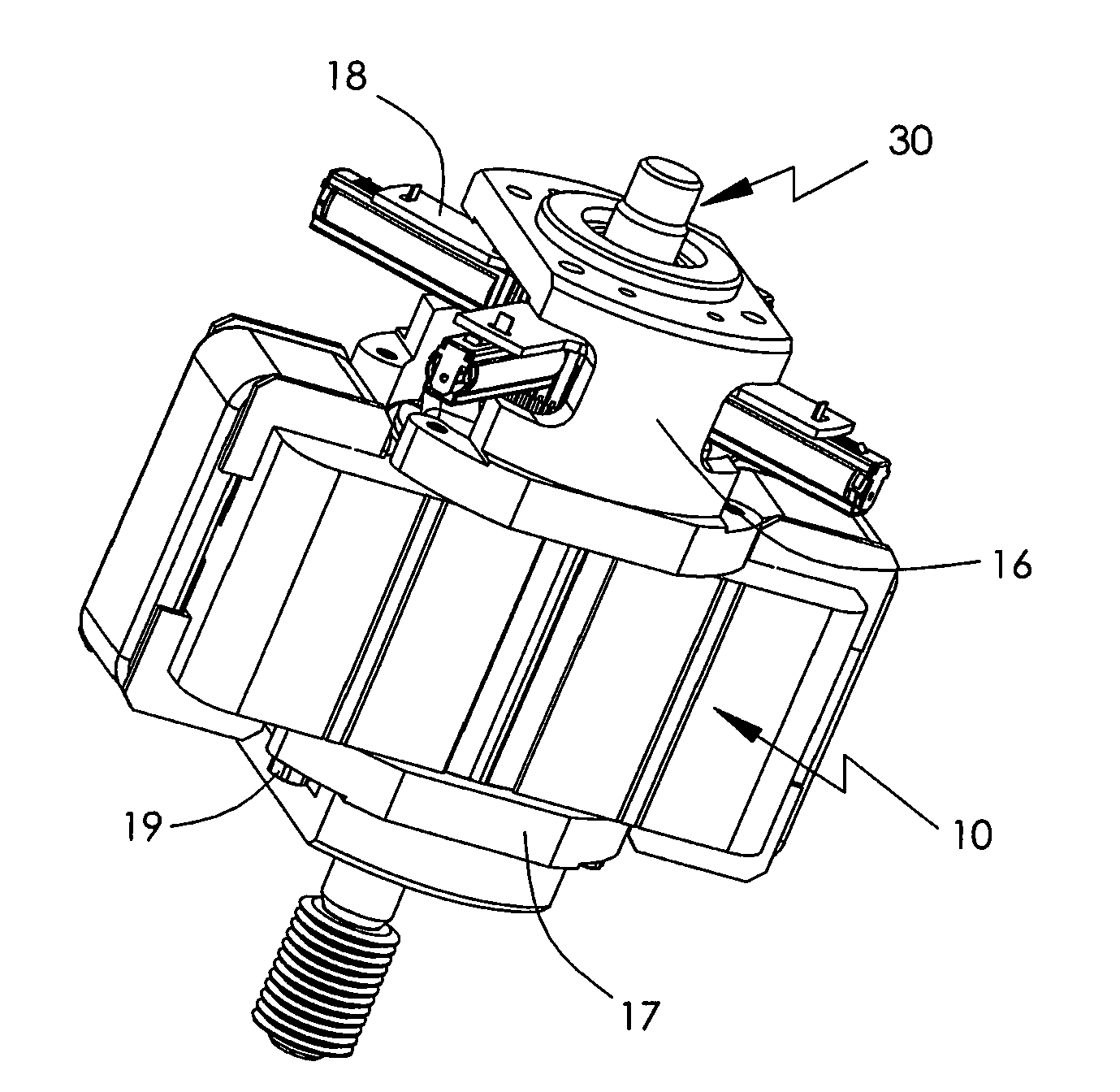

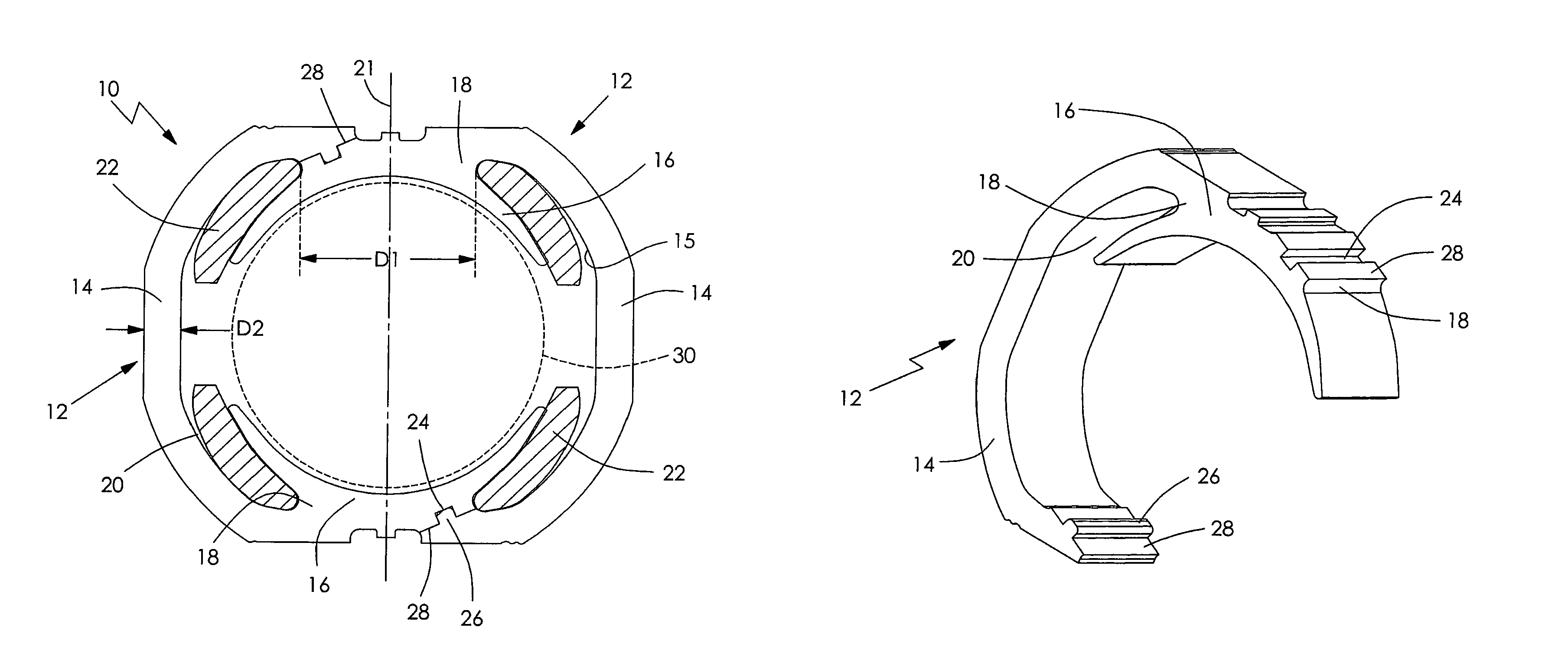

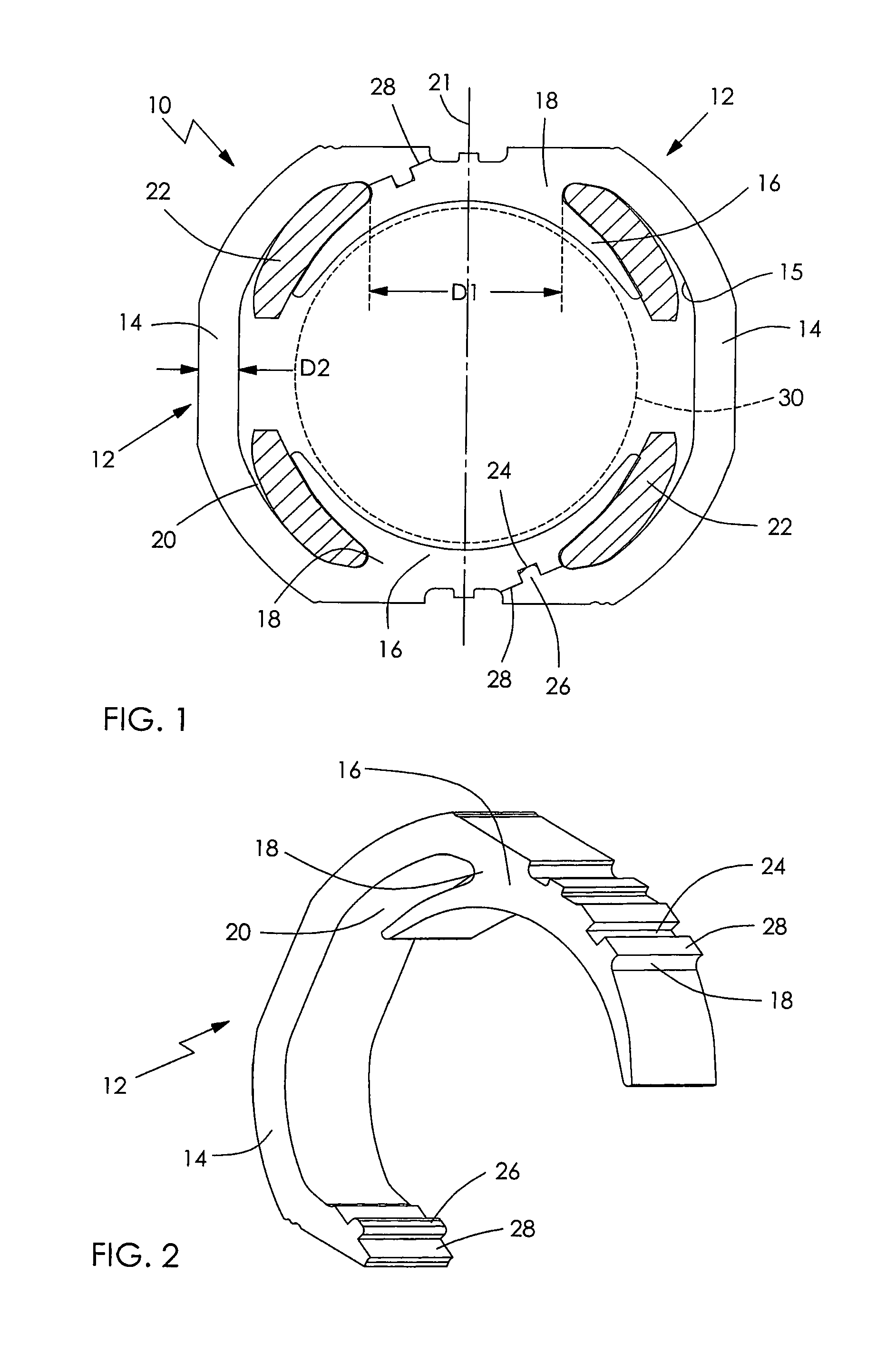

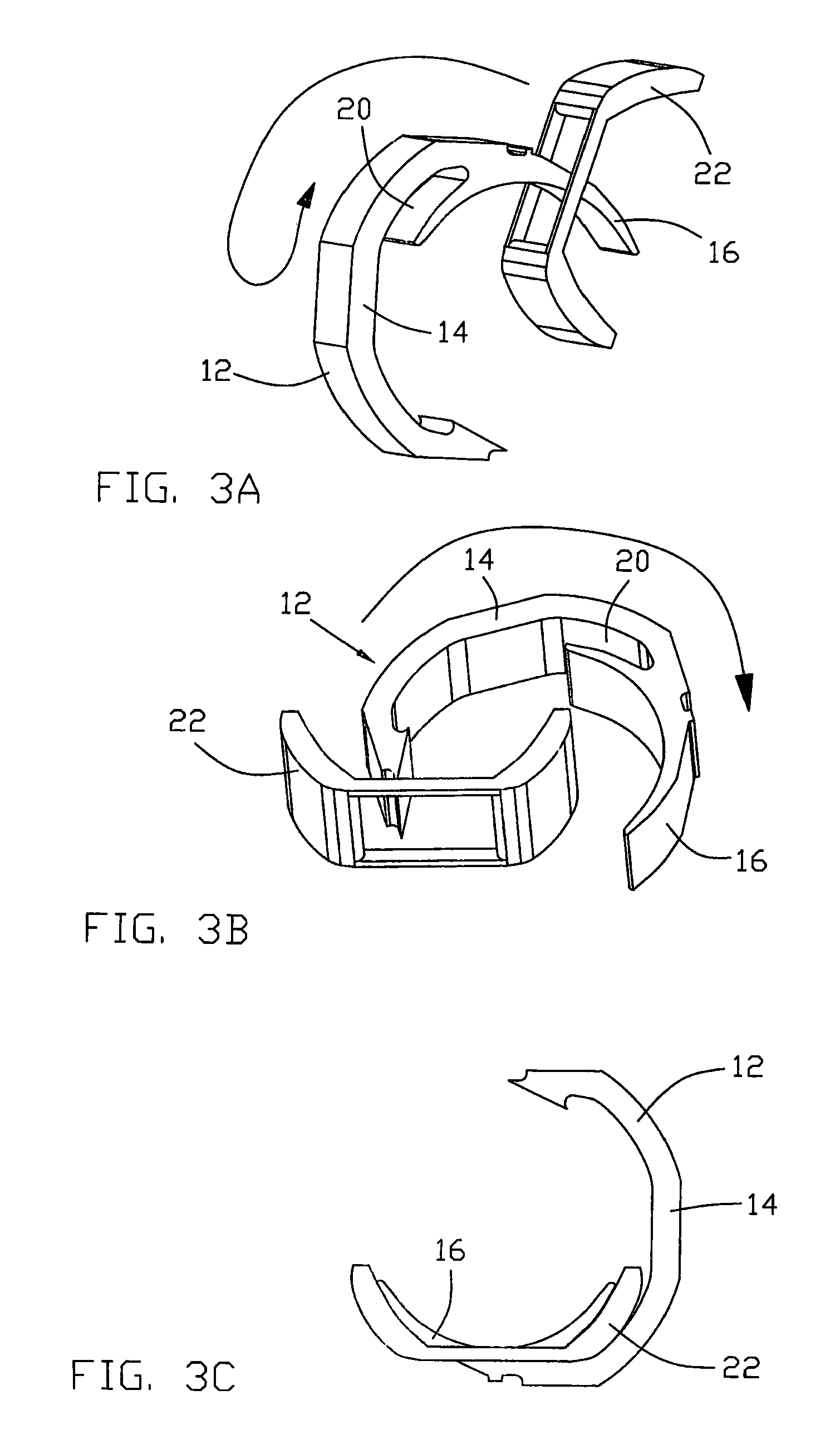

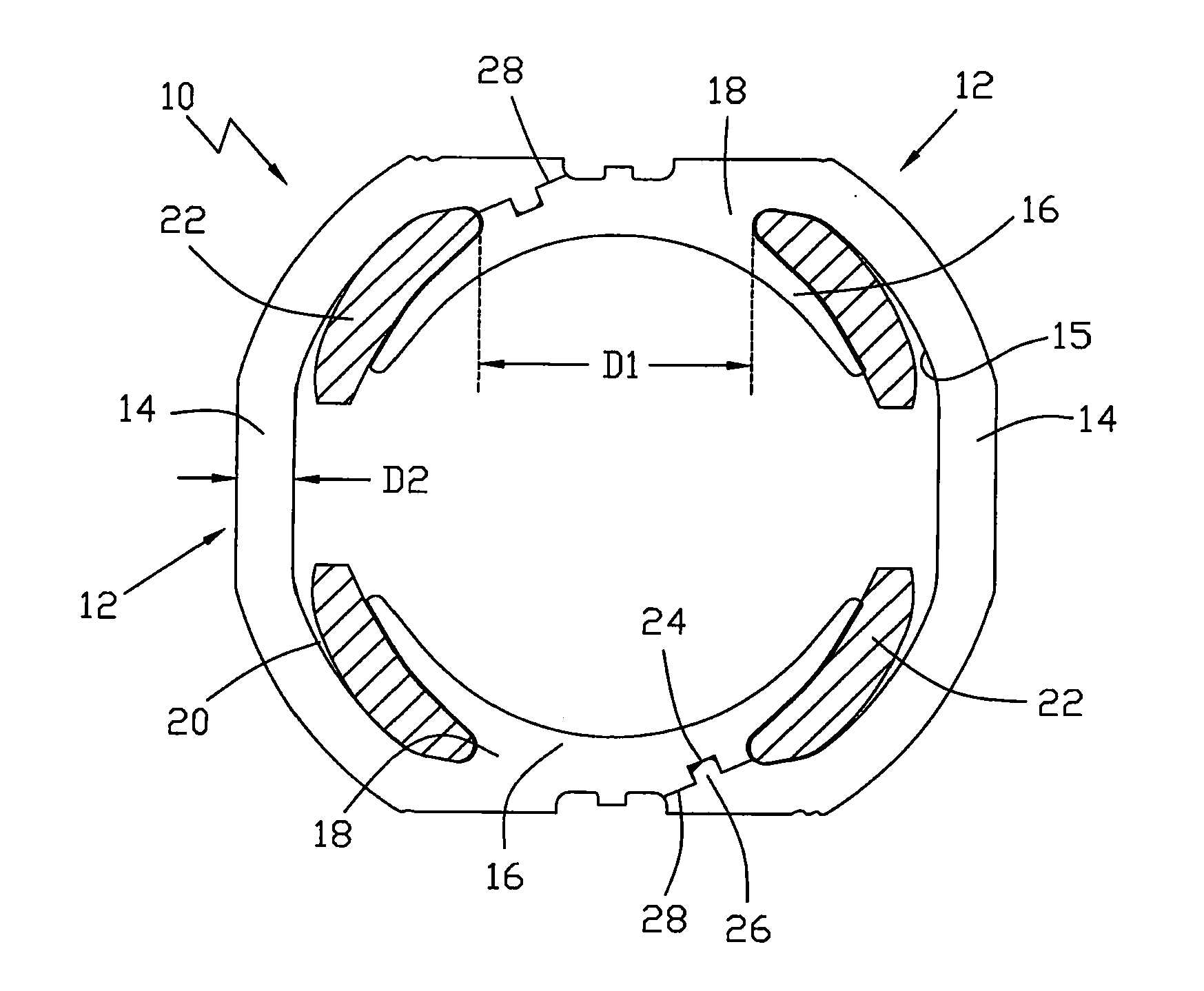

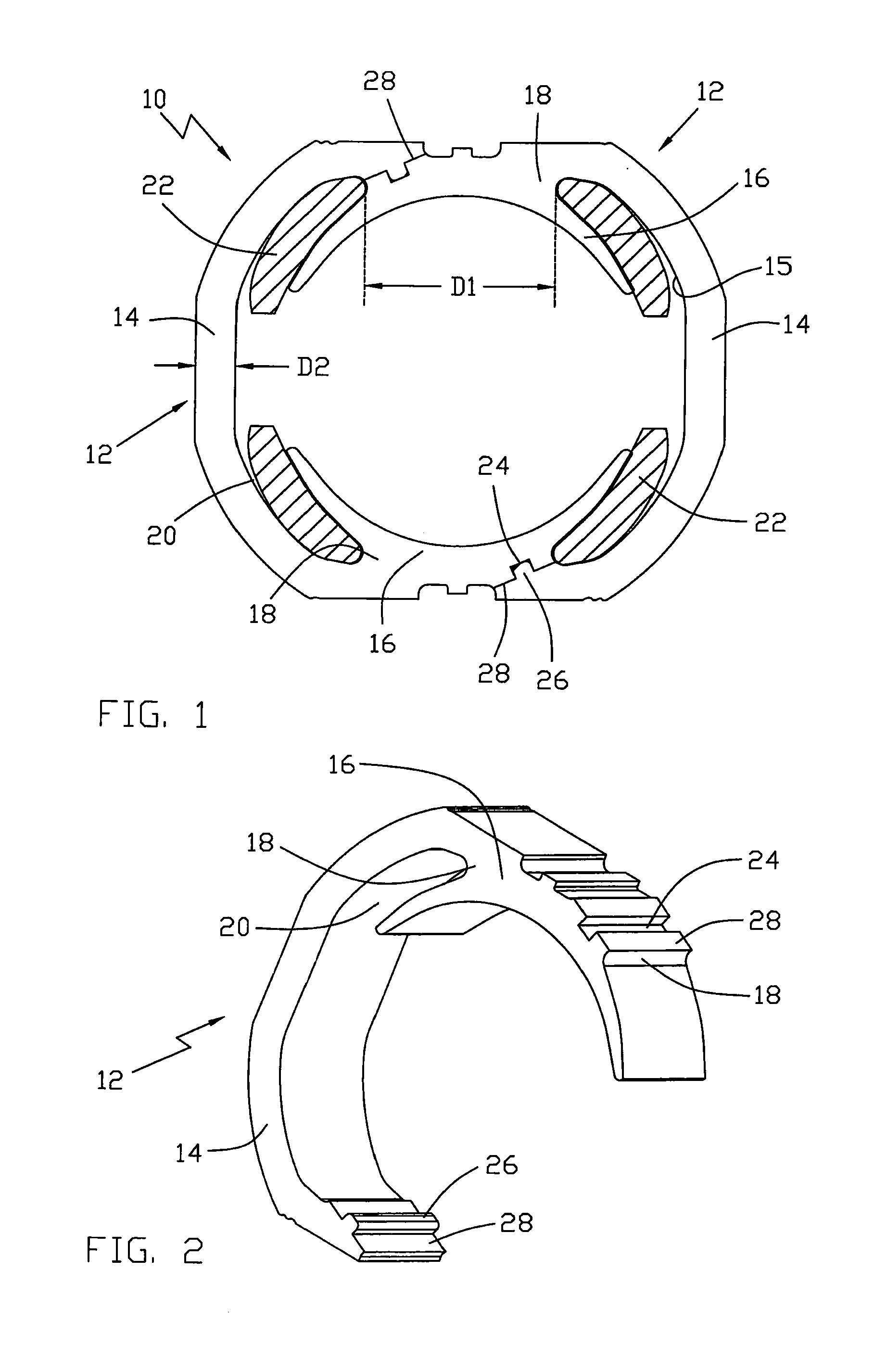

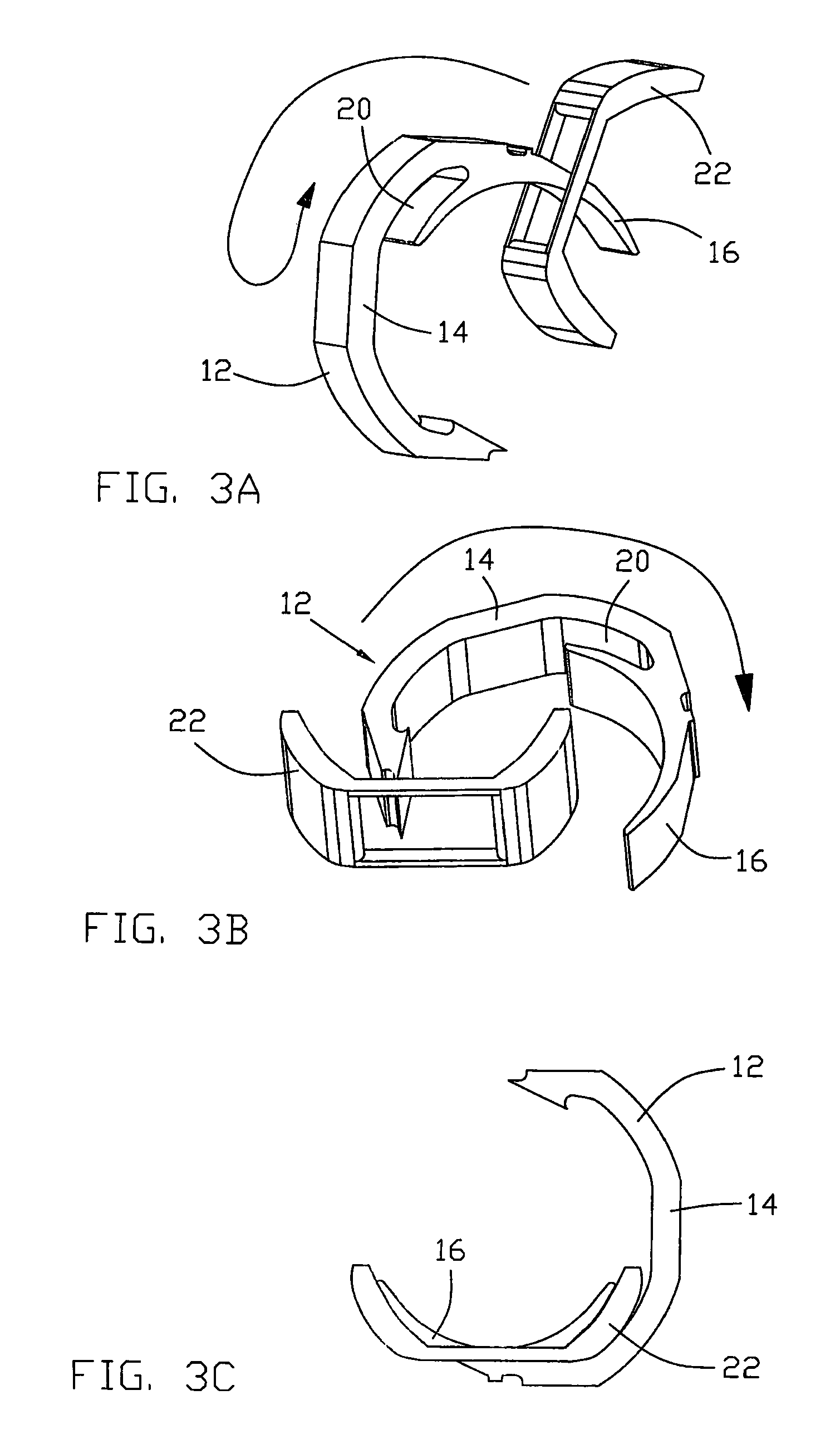

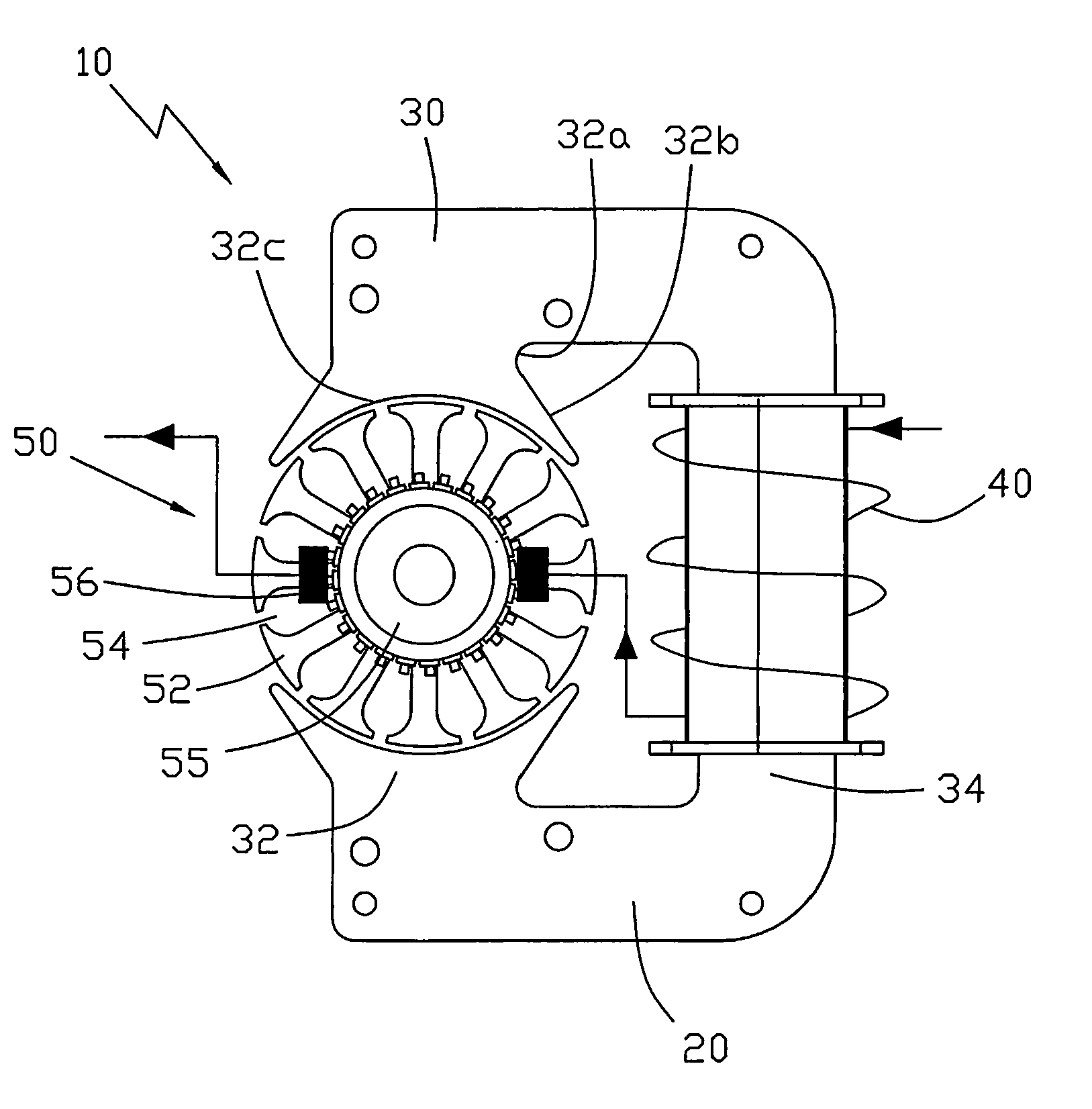

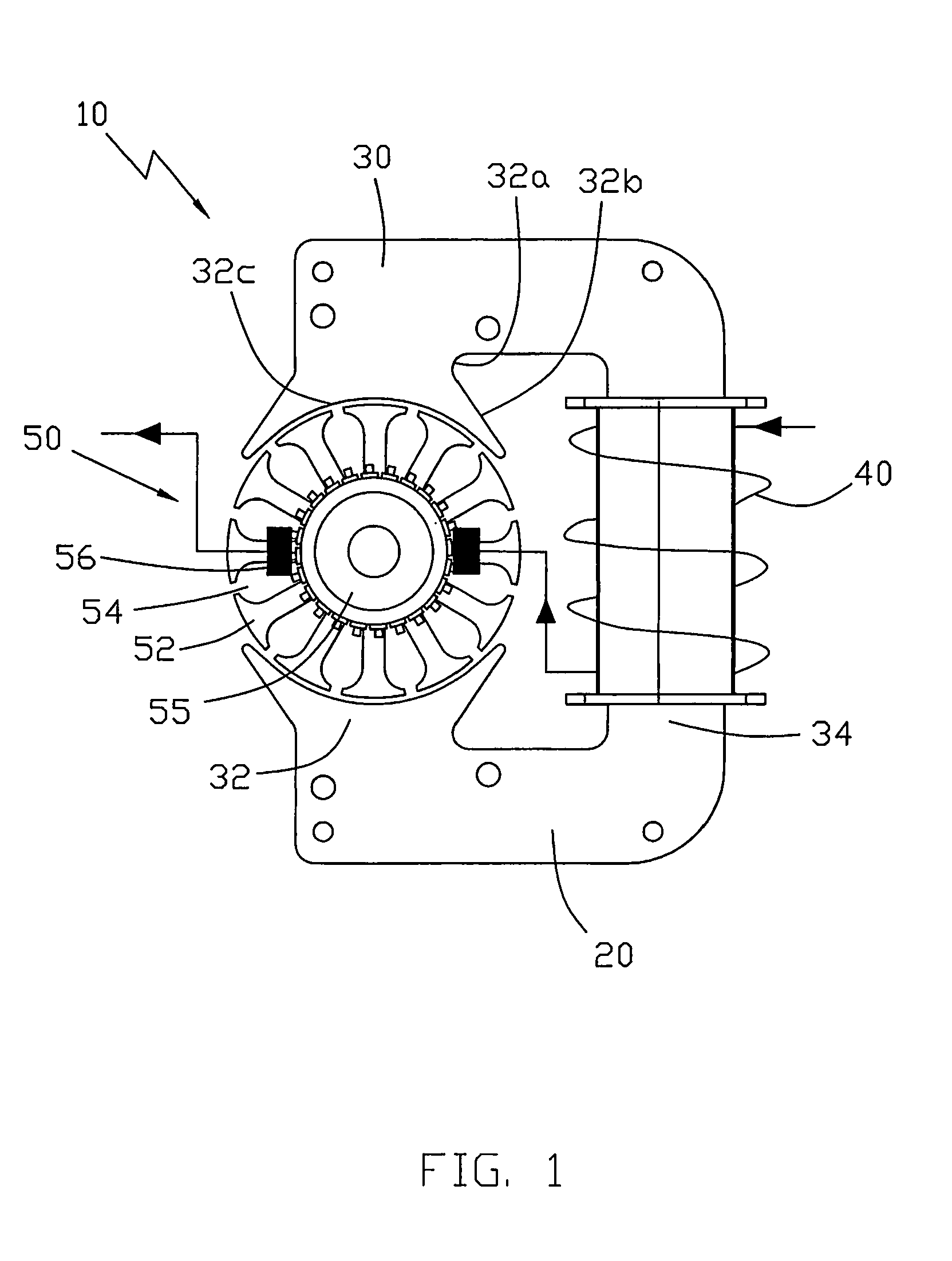

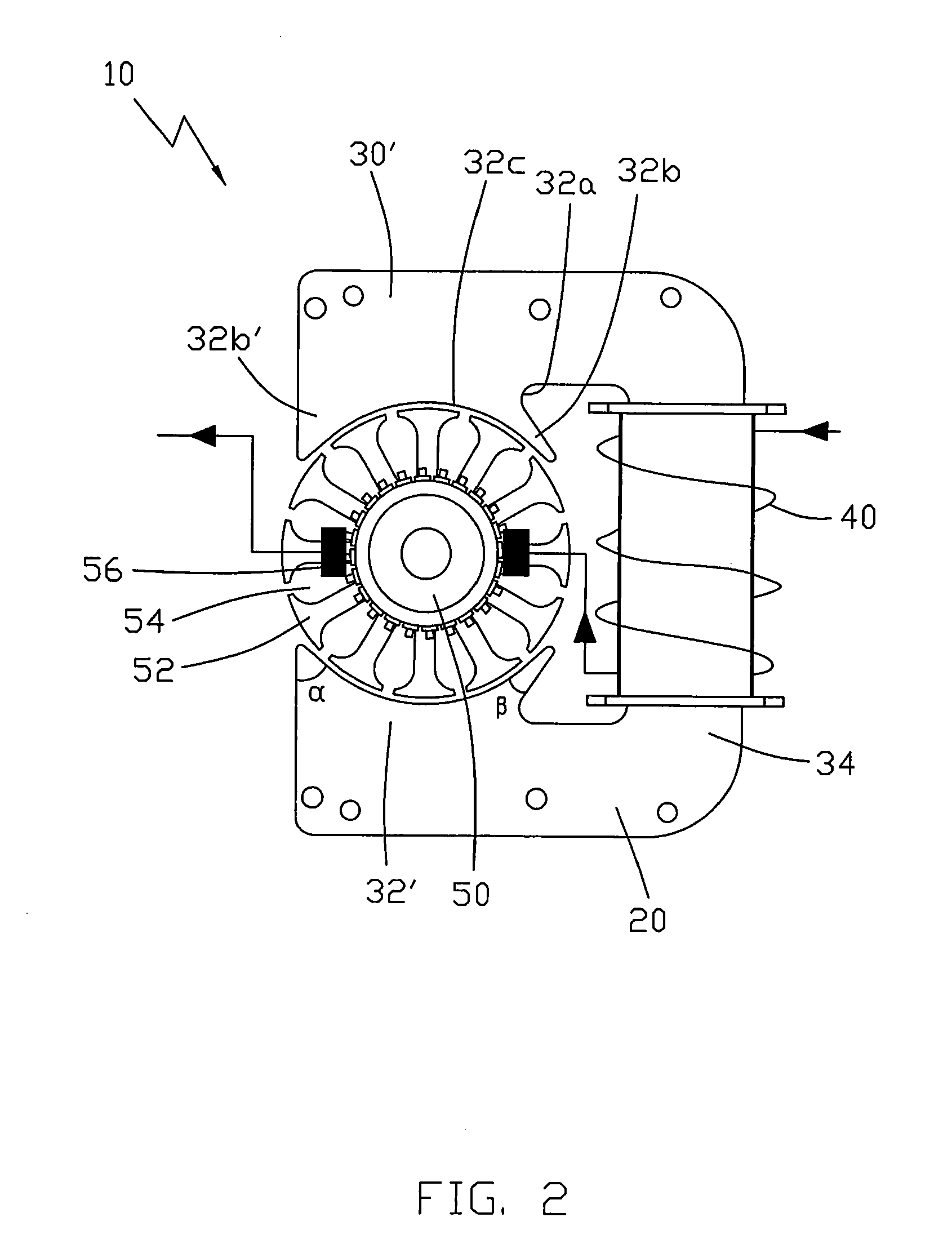

Universal motor and lamination for stator thereof

A lamination 10 for the stator of a universal motor has two poles 12 and a flux return path in the form of a ring 14 joining the two poles together. Each pole 12 has a pole face 16 defining there between a rotor space 20 for accommodating a rotor and each pole 12 has a neck portion 18 for receiving stator field windings. The width A of the ring 14, the length B of the pole 12, the radial distance C between the pole faces 16 and the width D of the neck portion 18 are selected according to formulae to achieve improved power output and output torque.

Owner:JOHNSON ELECTRIC SA

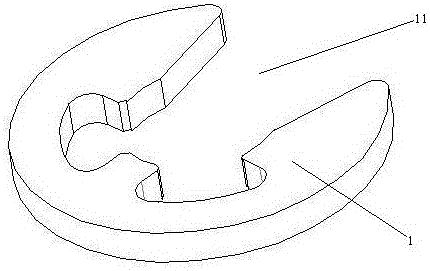

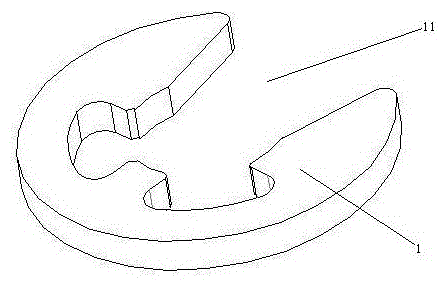

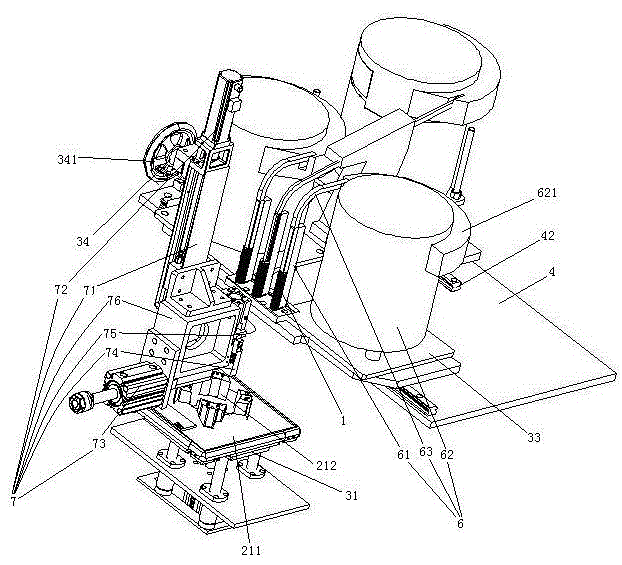

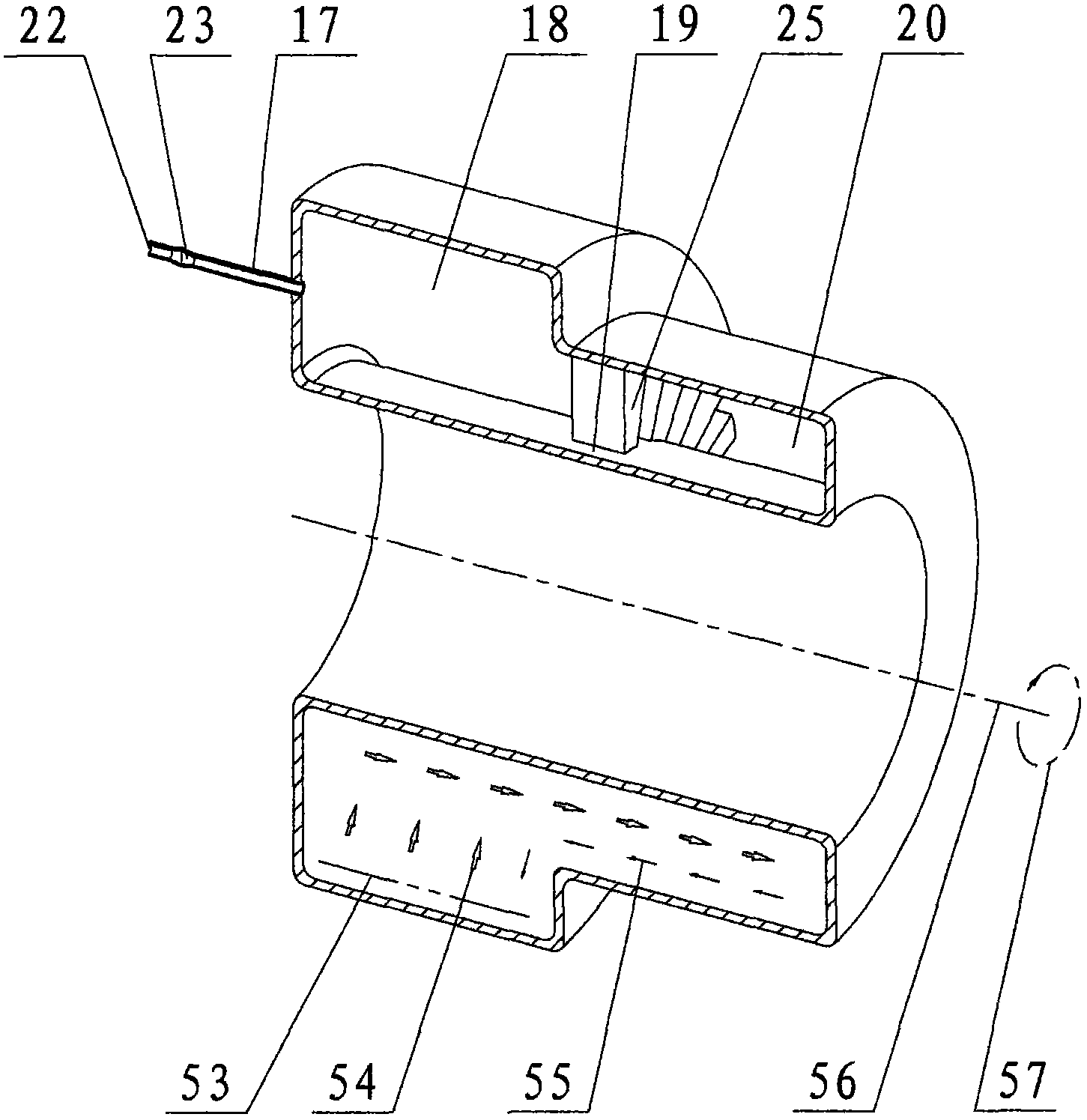

Snap spring mounting mechanism of universal motor snap spring assembling machine

ActiveCN105033618ARealize automated assemblyGood degree of automationManufacturing dynamo-electric machinesMetal working apparatusEngineeringMotor shaft

The invention relates to equipment for motor production and discloses a snap spring mounting mechanism of a universal motor snap spring assembling machine. The snap spring mounting mechanism comprises a fixing mechanism, a snap spring clamp, a base, at least two snap spring feeding mechanisms which are arranged on the base and provided with snap spring penetrating connecting rods, a third driving mechanism for driving the base to move to the snap spring penetrating connecting rod in one snap spring feeding mechanism to be aligned with the snap spring clamp, and a fourth driving mechanism for driving the snap spring clamp to assemble snap springs on the snap spring penetrating connecting rods onto a motor shaft to be assembled on the fixing mechanism one by one. The snap spring mounting mechanism of the universal motor snap spring assembling machine is used for assembling snap springs onto the motor shaft, and the problems that much labor is cost when the snap springs are manually assembled on the motor shaft and the automation degree is low are solved.

Owner:ZHEJIANG CANYUAN HOME TEXTILE

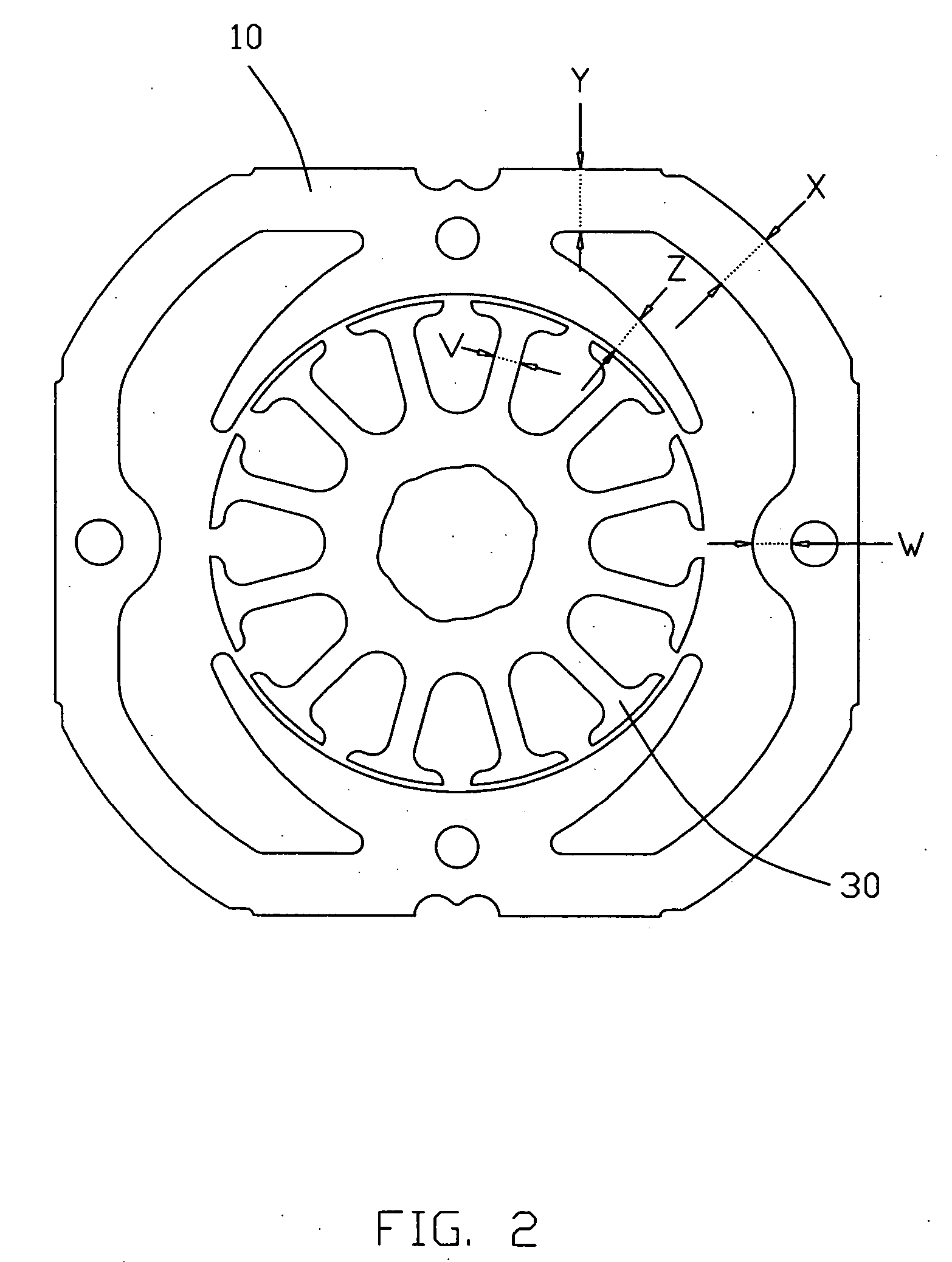

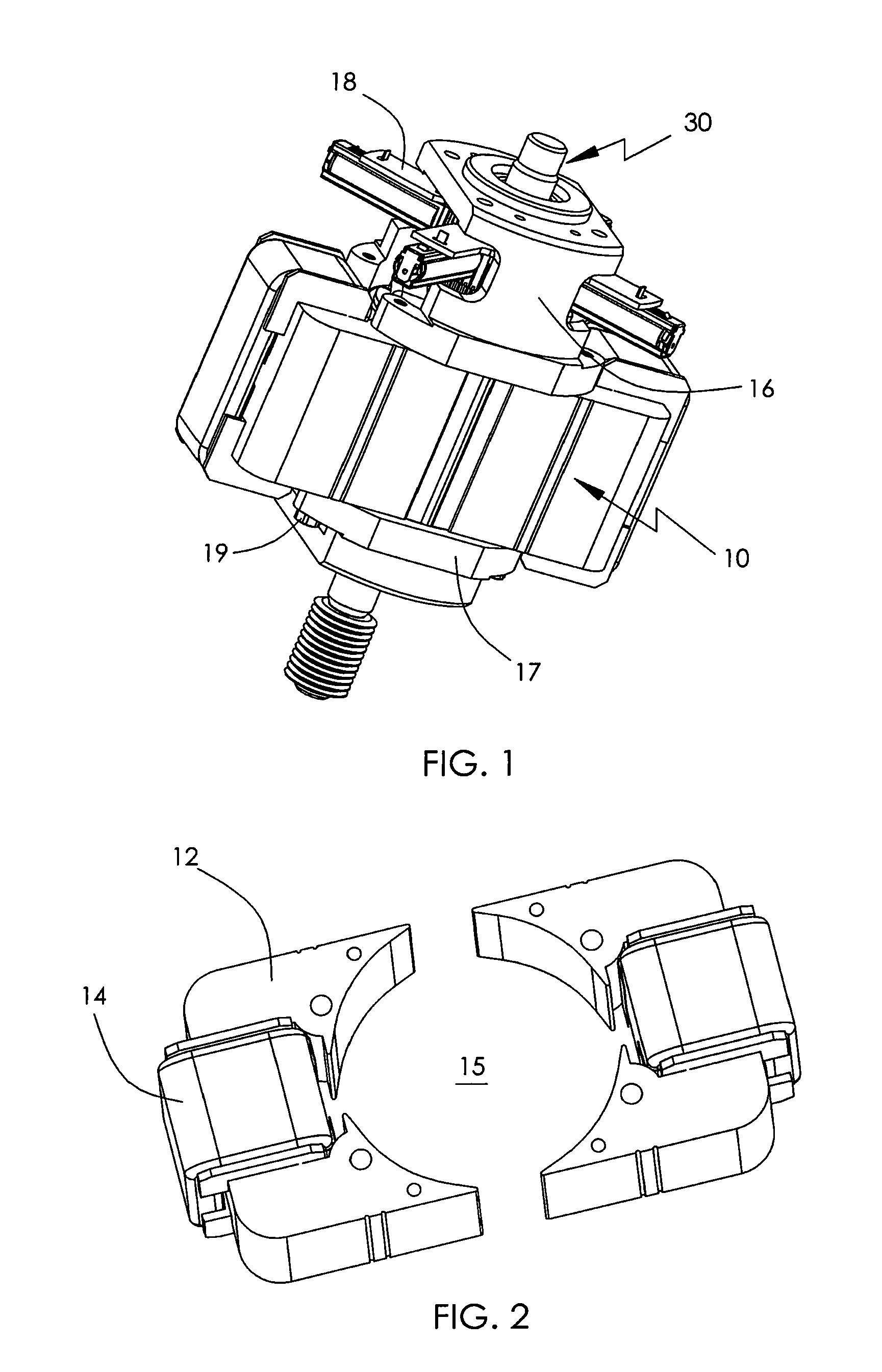

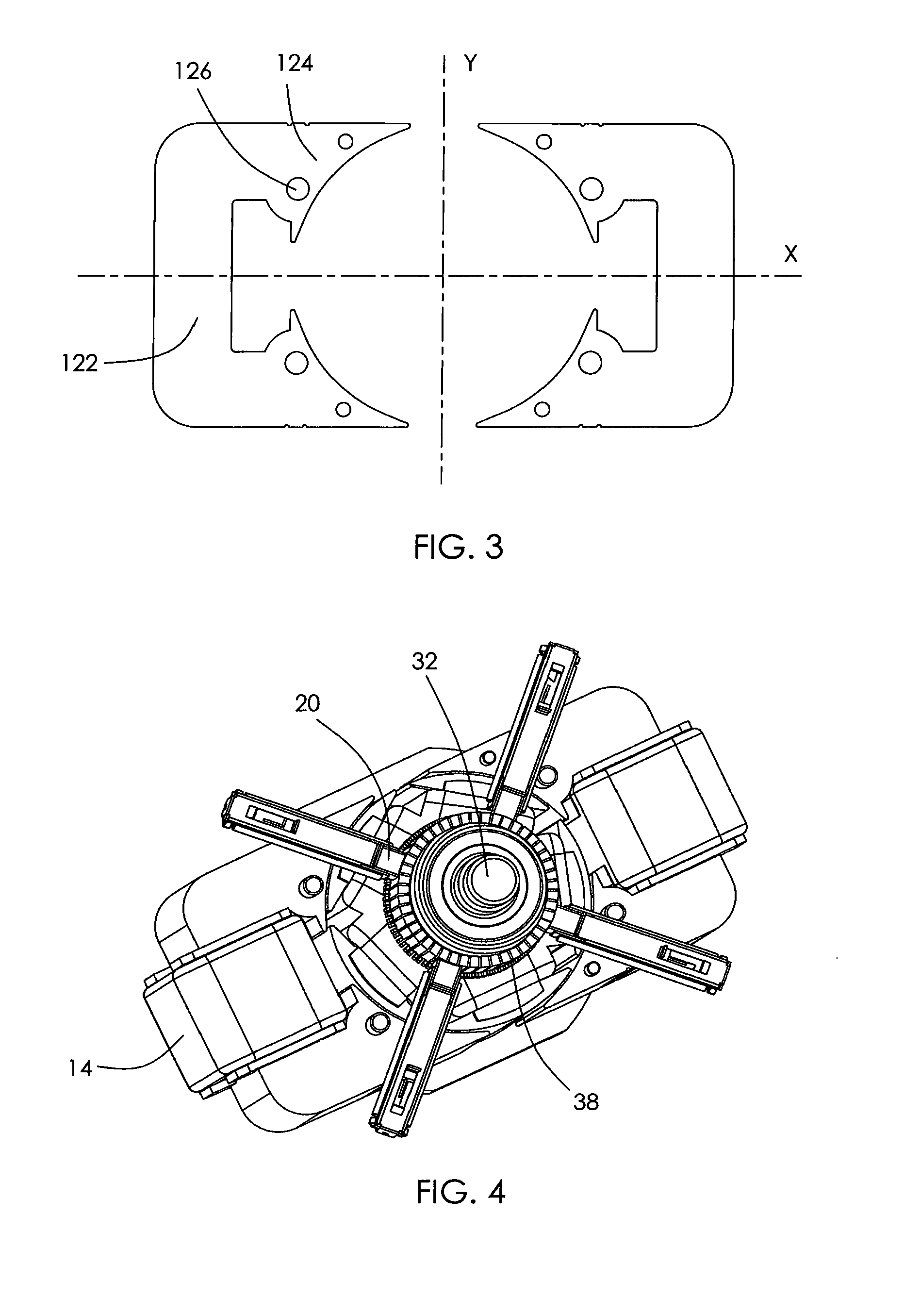

Universal motor

InactiveUS20110043067A1Increased use of materialRotary current collectorMagnetic circuitConductor CoilUniversal motor

A universal motor has a rotor and a stator. The stator comprises a pair of symmetrical C-shaped stator cores and two windings respectively wound on the stator cores. Each stator core comprises a yoke and a pair of poles extending from opposite ends of the yoke. The windings are wound on the yokes. Each pole has a curved surface and the surfaces of the poles cooperatively form an opening. The rotor is rotatably received in the opening.

Owner:JOHNSON ELECTRIC SA

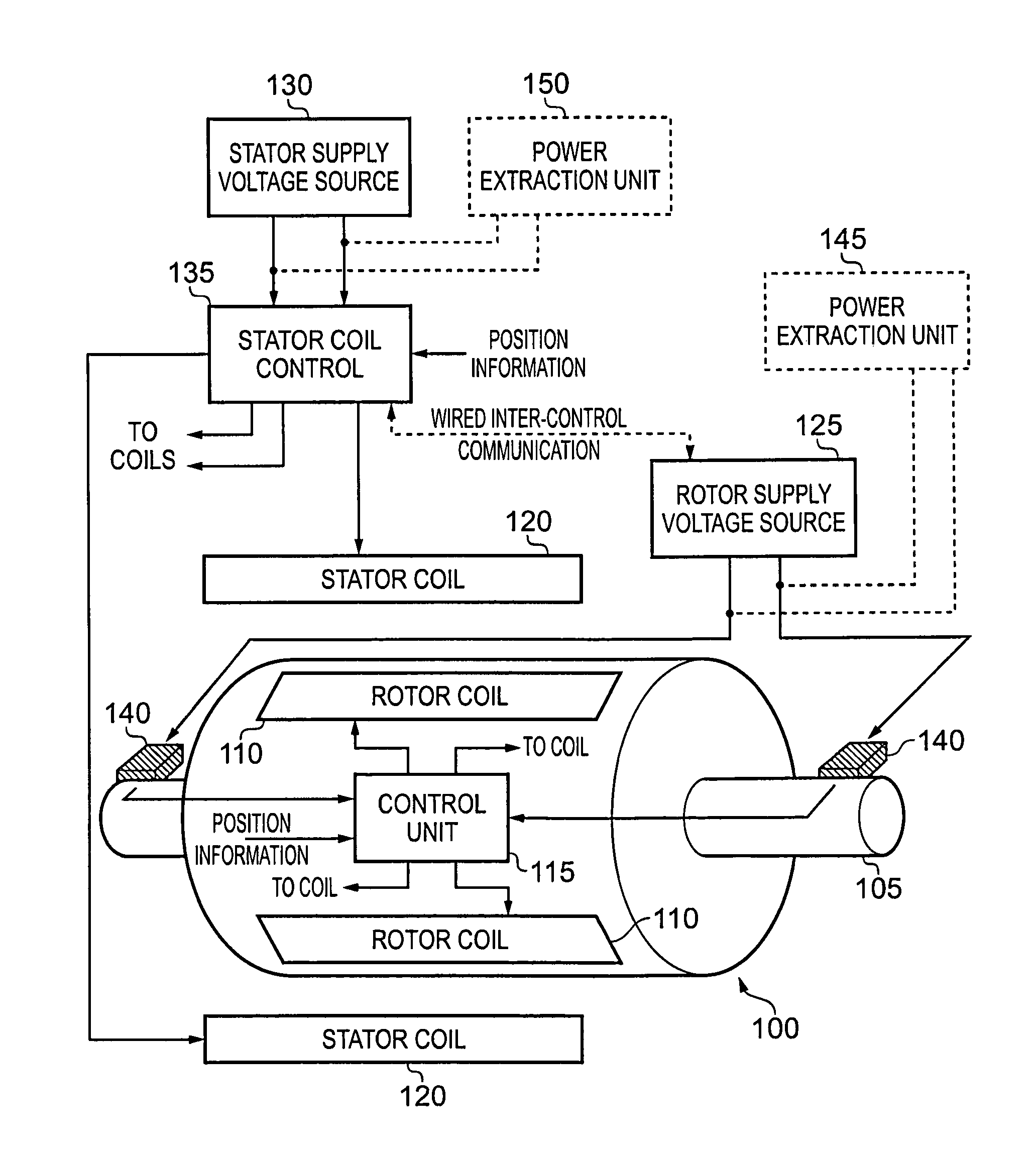

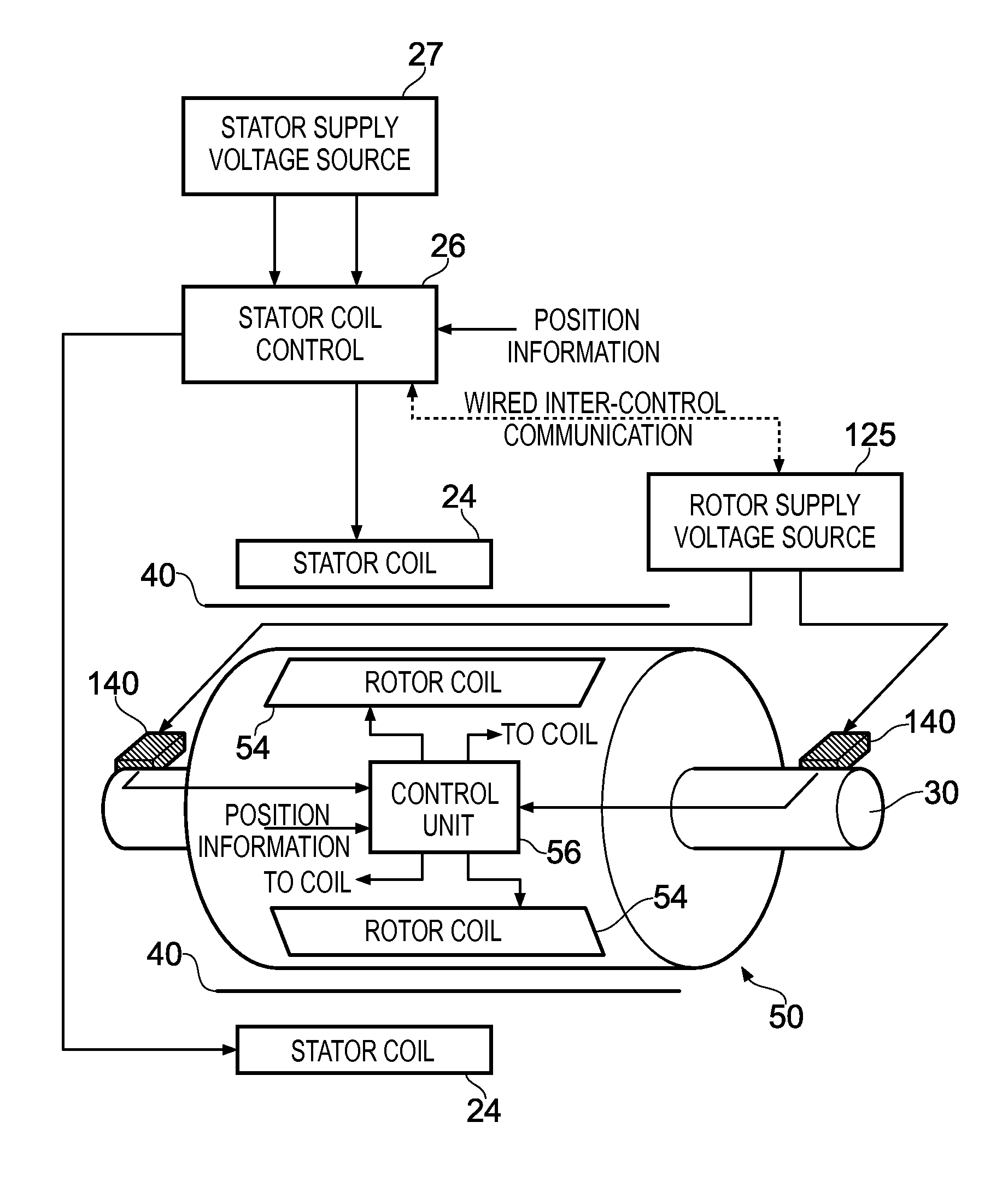

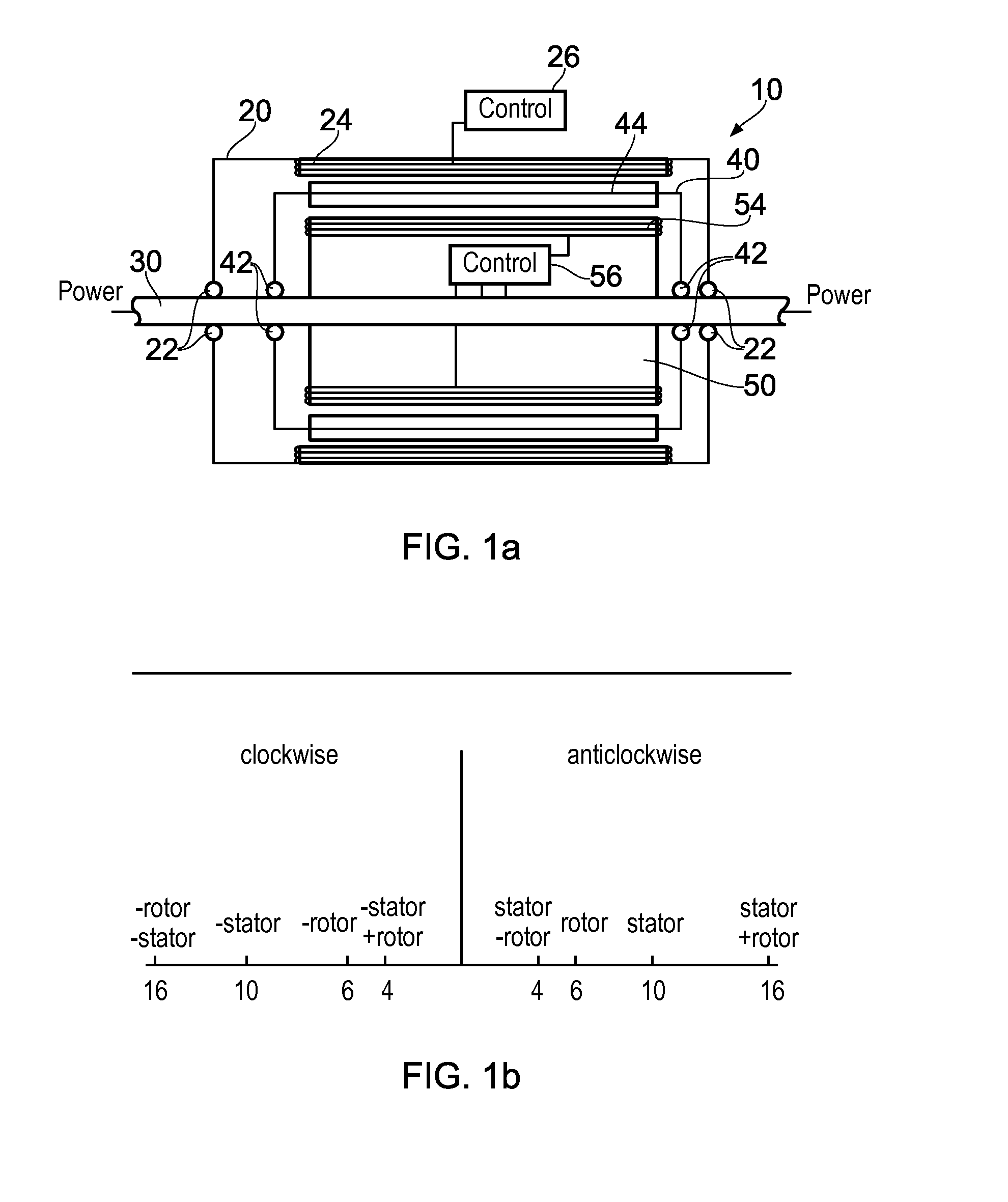

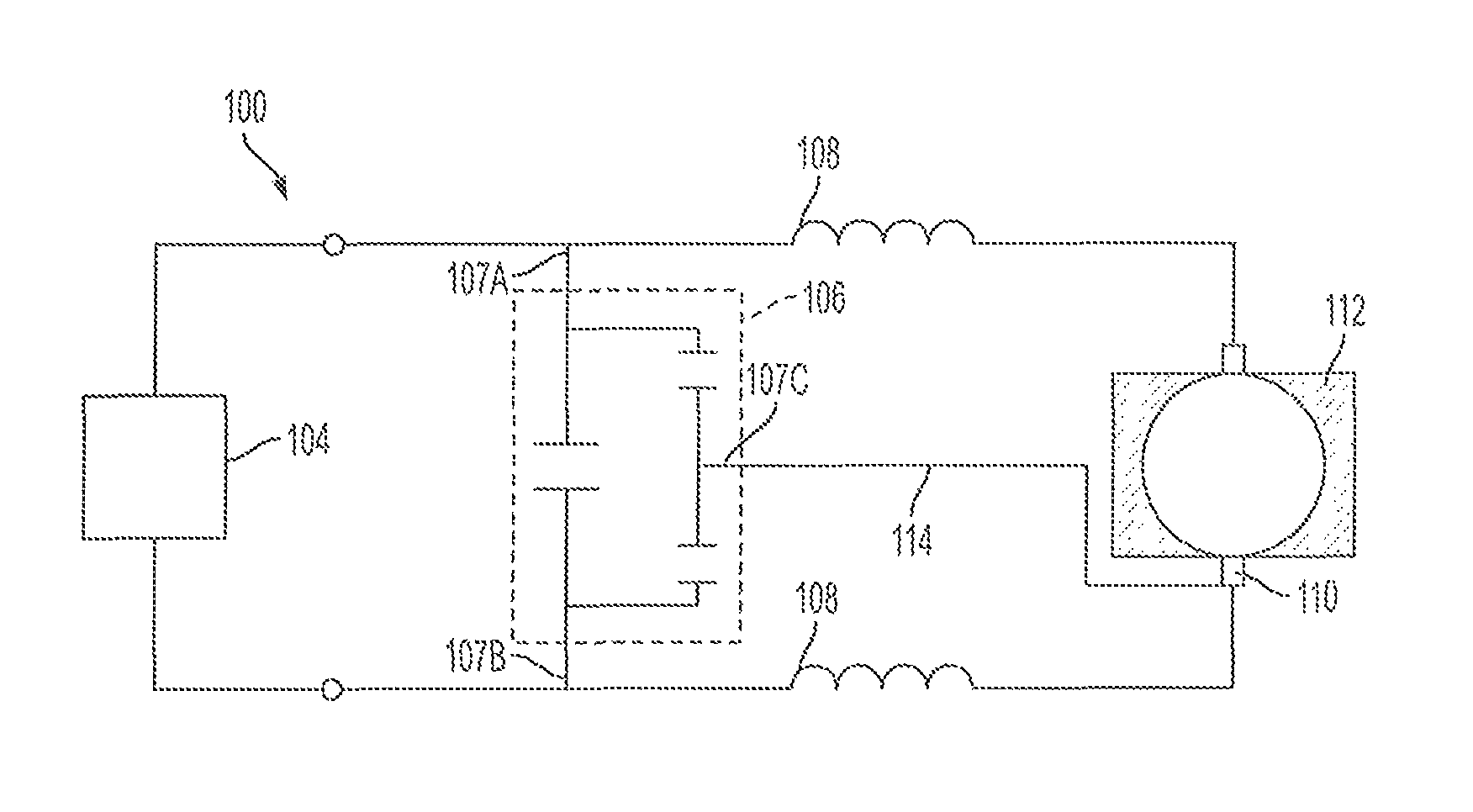

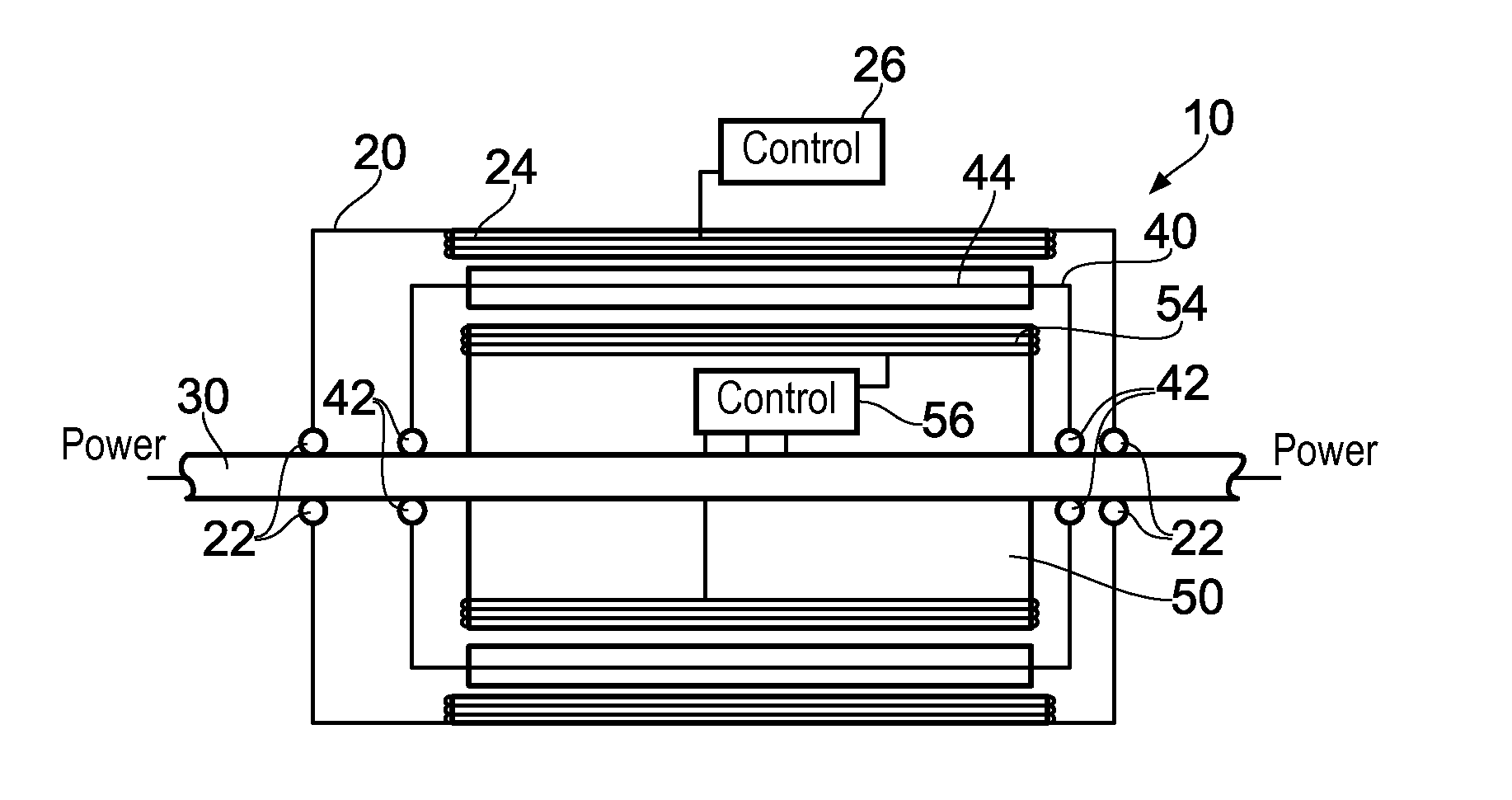

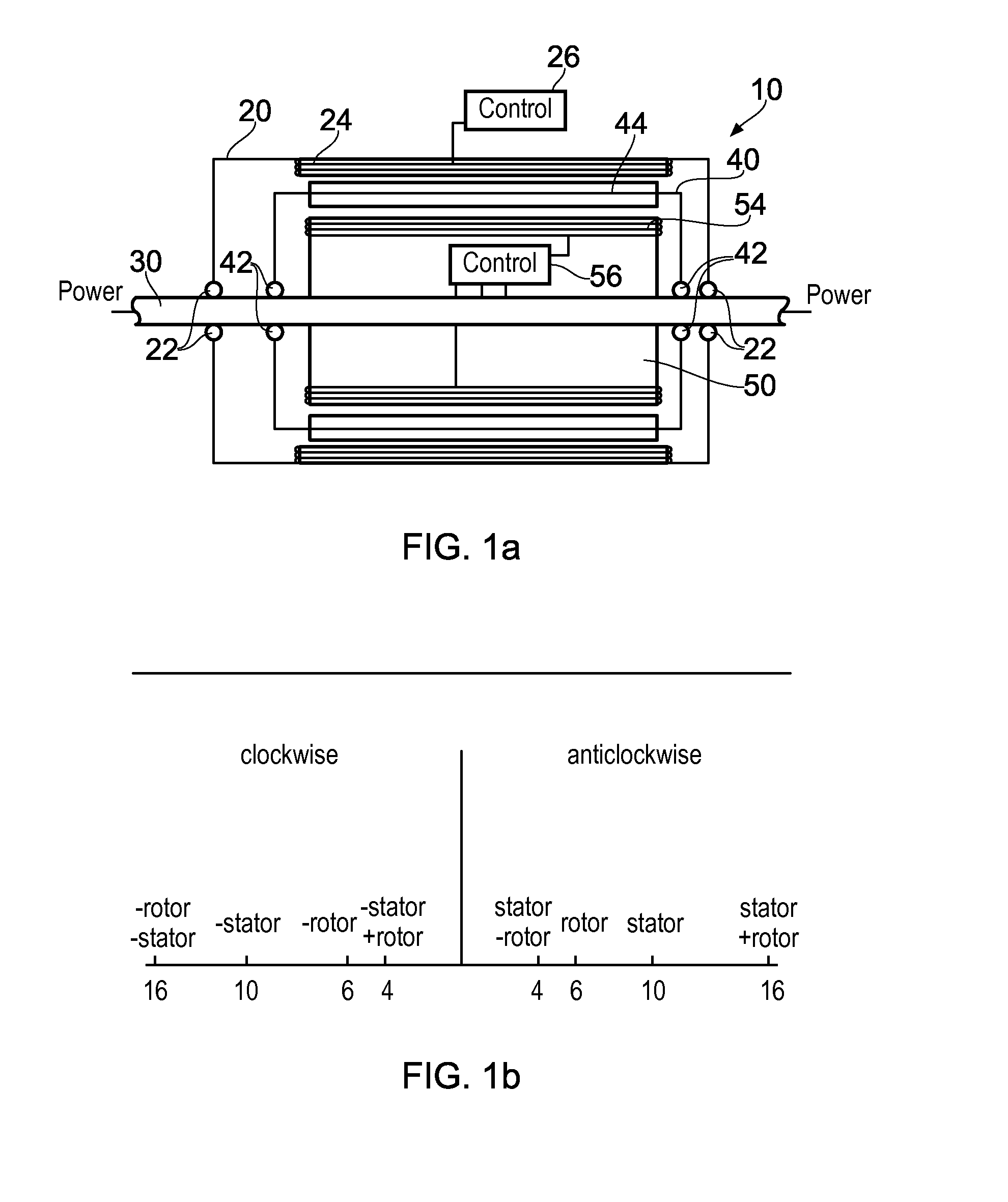

Electronically controlled universal motor

ActiveUS8450954B2Manufacturing complexity associated with numerous slip rings are each avoidedImprove cooling effectAssociation with control/drive circuitsMotor/generator/converter stoppersElectric machineUniversal motor

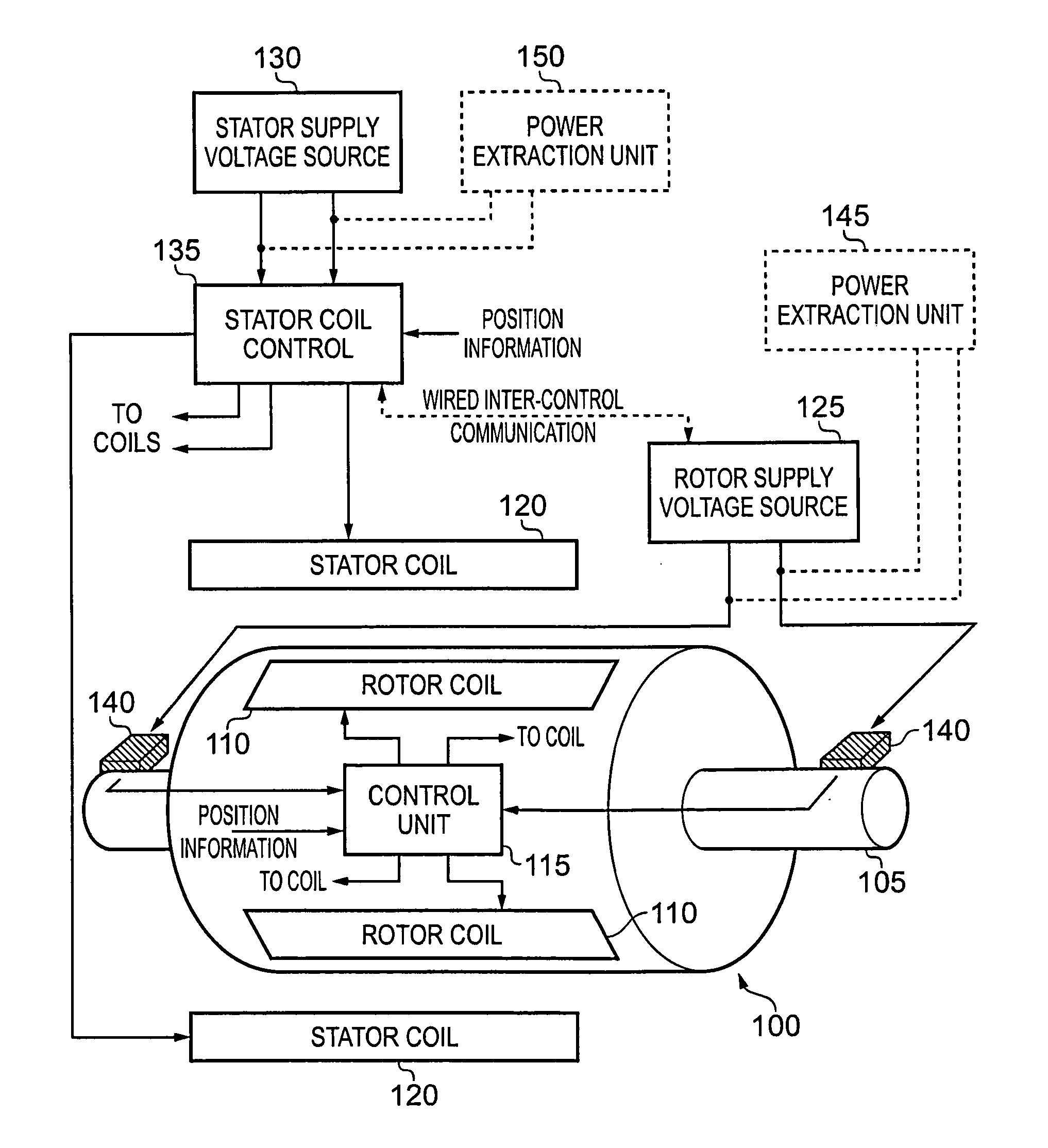

An electric motor apparatus comprising a rotor component rotating with respect to a stator component. A rotational position indicator generates rotational position information indicative of a relative orientation of the rotor and stator components. A rotor winding control unit is fixedly mounted on the rotor component and is coupled to a rotor supply voltage supplied to the rotor component. The rotor control unit generates a rotor waveform in dependence on the rotational position information and applies the rotor waveform to a rotor winding arrangement. A stator winding waveform generator generates a stator waveform in dependence on the rotational position information and applies the stator waveform to a stator winding arrangement. The rotor waveform and stator waveform are generated in synchronization with the relative orientation of the rotor and stator components in order to synchronize mutual interactions of the rotor winding arrangement and the stator winding arrangement with the relative orientation.

Owner:ARM LTD

Electronically controlled universal motor

ActiveUS20130069566A1Manufacturing complexity associated with numerous slip rings are each avoidedImprove cooling effectAssociation with control/drive circuitsMotor/generator/converter stoppersElectric machineEngineering

An electric motor apparatus comprising a rotor component rotating with respect to a stator component. A rotational position indicator generates rotational position information indicative of a relative orientation of the rotor and stator components. A rotor winding control unit is fixedly mounted on the rotor component and is coupled to a rotor supply voltage supplied to the rotor component. The rotor control unit generates a rotor waveform in dependence on the rotational position information and applies the rotor waveform to a rotor winding arrangement. A stator winding waveform generator generates a stator waveform in dependence on the rotational position information and applies the stator waveform to a stator winding arrangement. The rotor waveform and stator waveform are generated in synchronization with the relative orientation of the rotor and stator components in order to synchronize mutual interactions of the rotor winding arrangement and the stator winding arrangement with the relative orientation.

Owner:ARM LTD

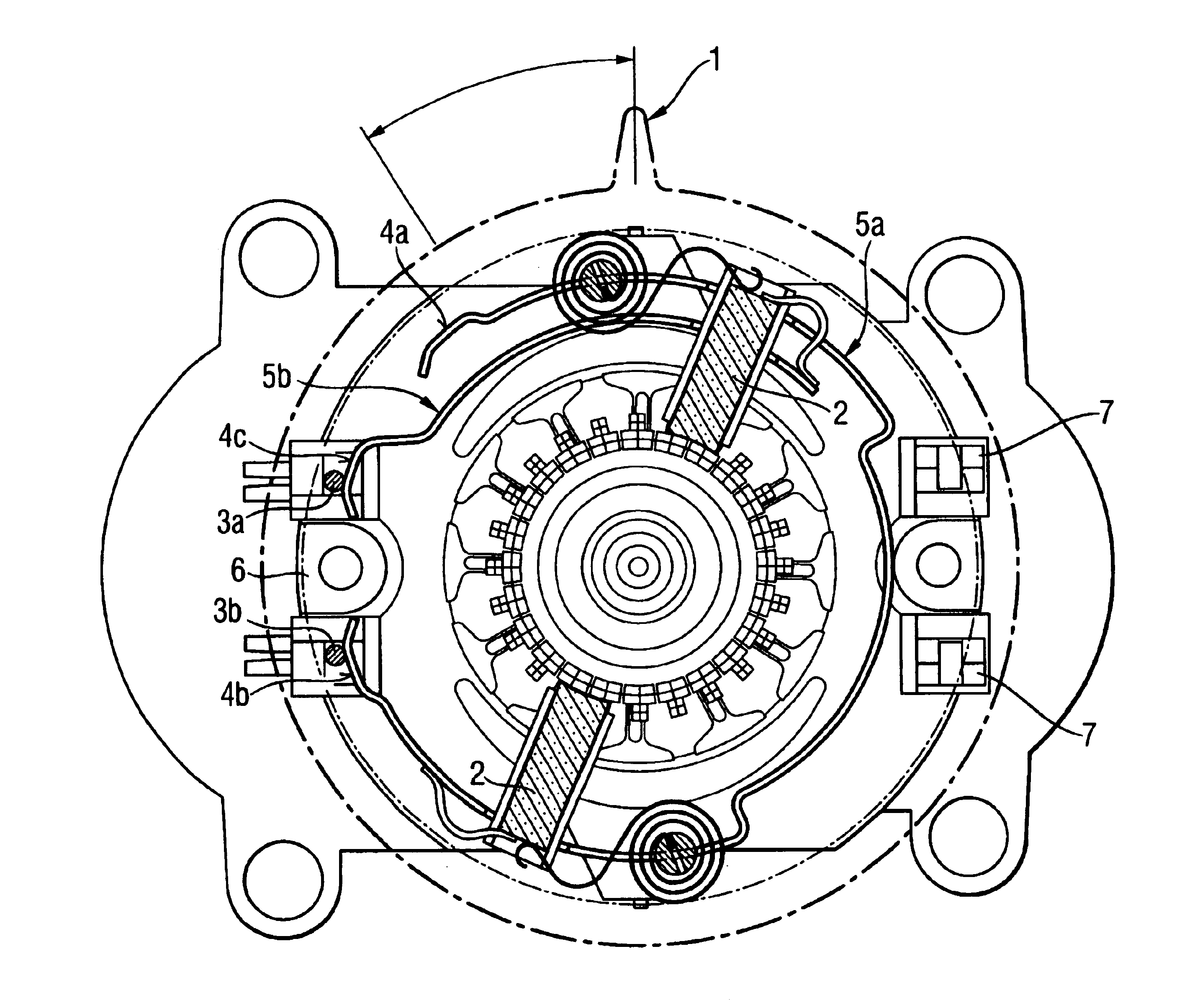

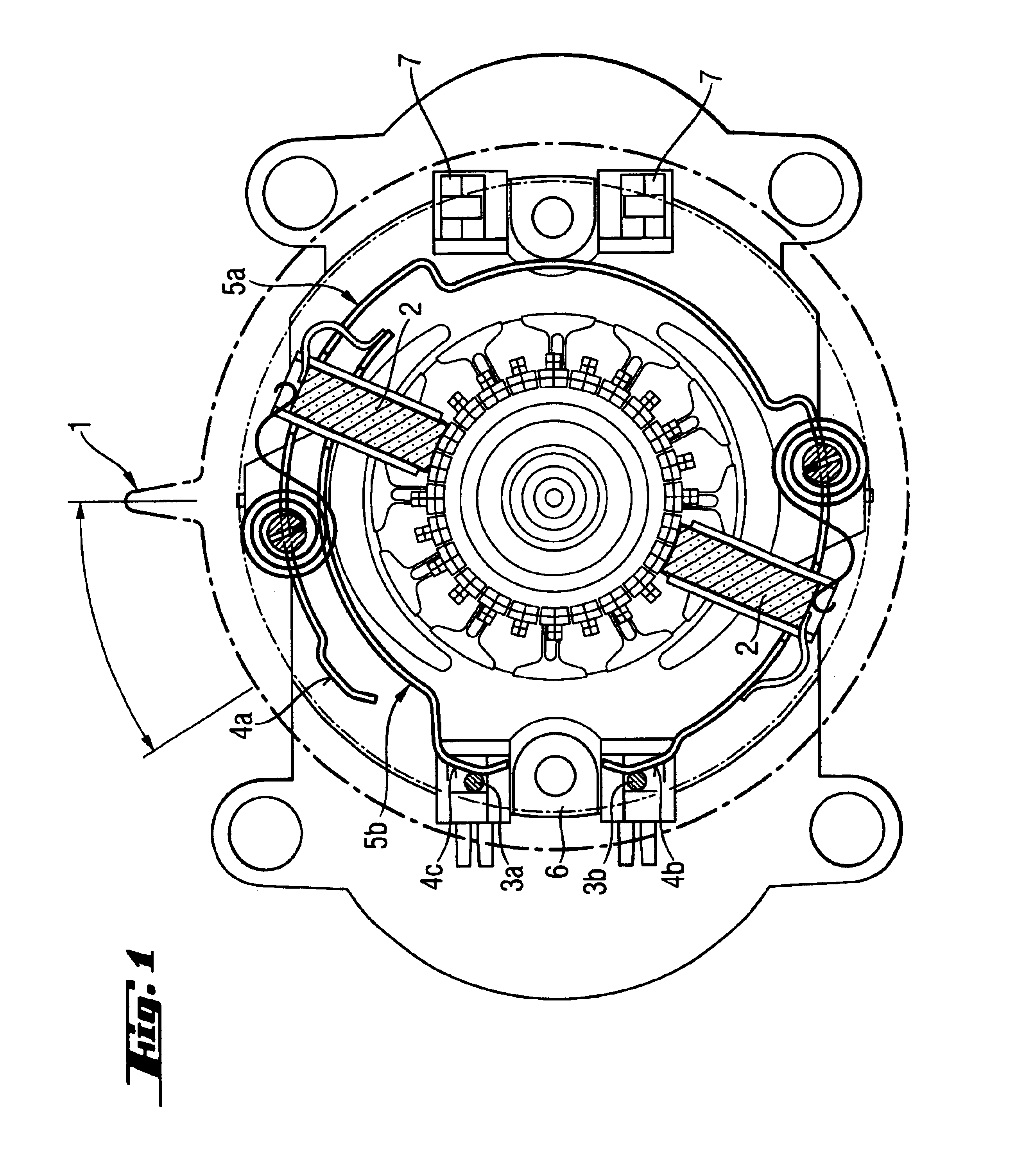

Commutating rotary switch

InactiveUS6933632B2Save construction spaceImprove reliabilityRotary current collectorDC commutatorRotary switchEngineering

A turning-pivoting commutating rotary switch (1) with brush guides (2) for reversing the direction of rotation of a universal motor, which has two stator contacts (3a, 3b) each making contact with a contact rail (5a, 5b) running partially peripherally at at least one contact point (4a, 4b, 4c), which are conducting connected with the two diametrically opposing brush guides (2), wherein a contact rail (5a) with two contact points (4a, 4b) extends over at least a half periphery and wherein both stator contacts (4a, 3b), at which at least one contact point (4a, 4b, 4c) can be rotatably switchable at a contact rail (5a, 5b) running partially peripherally, are arranged on only one side of the stator (6).

Owner:HILTI AG

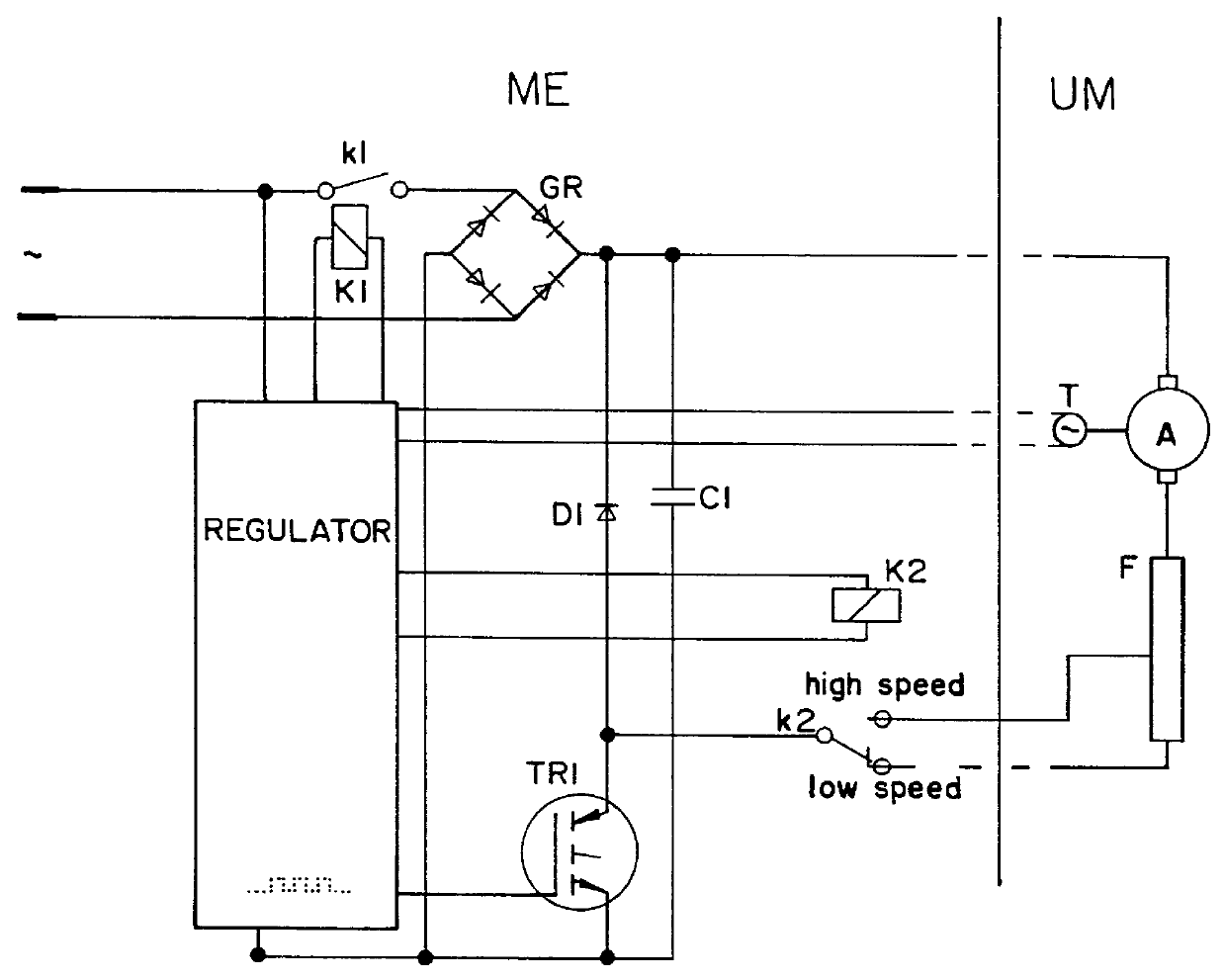

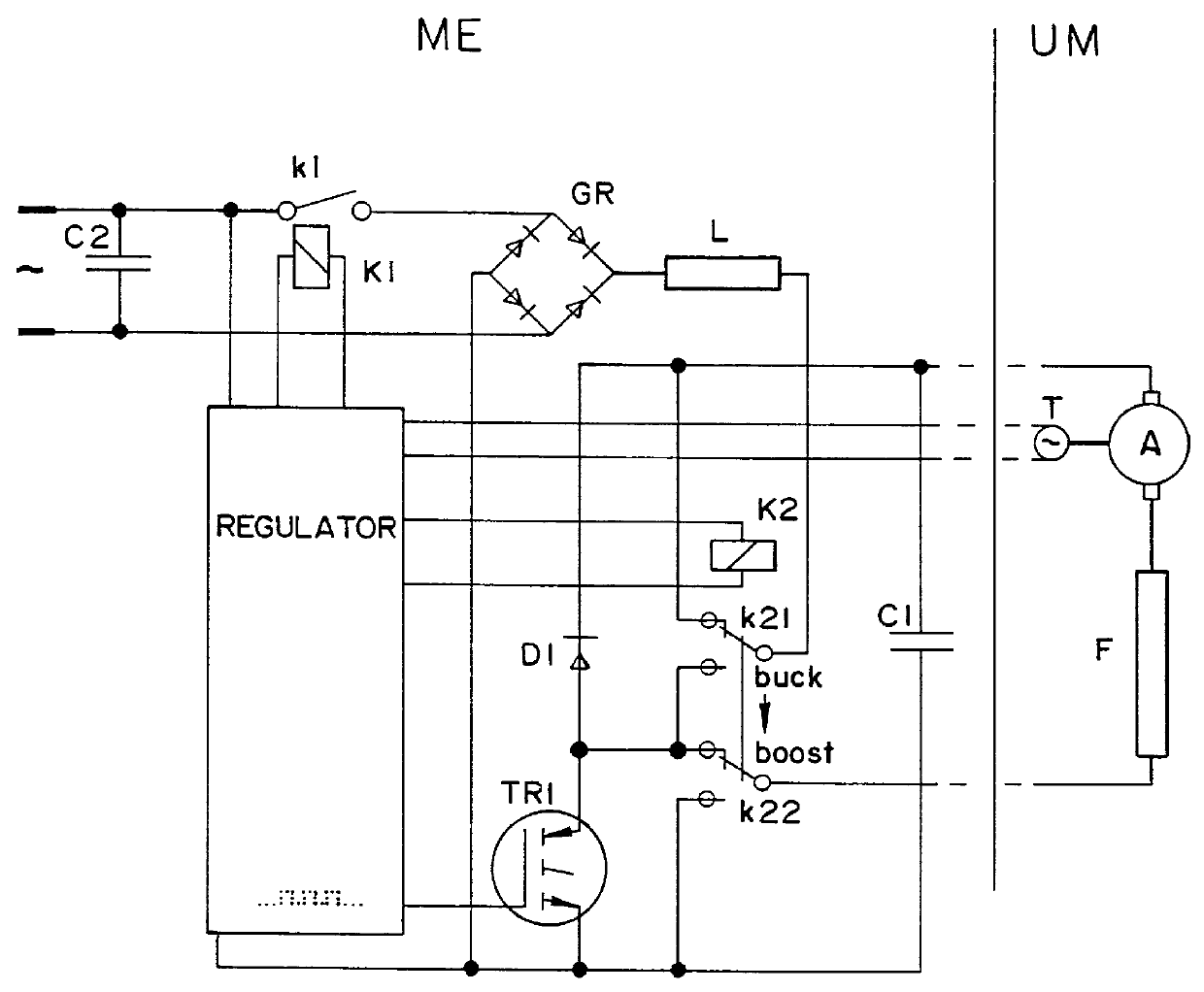

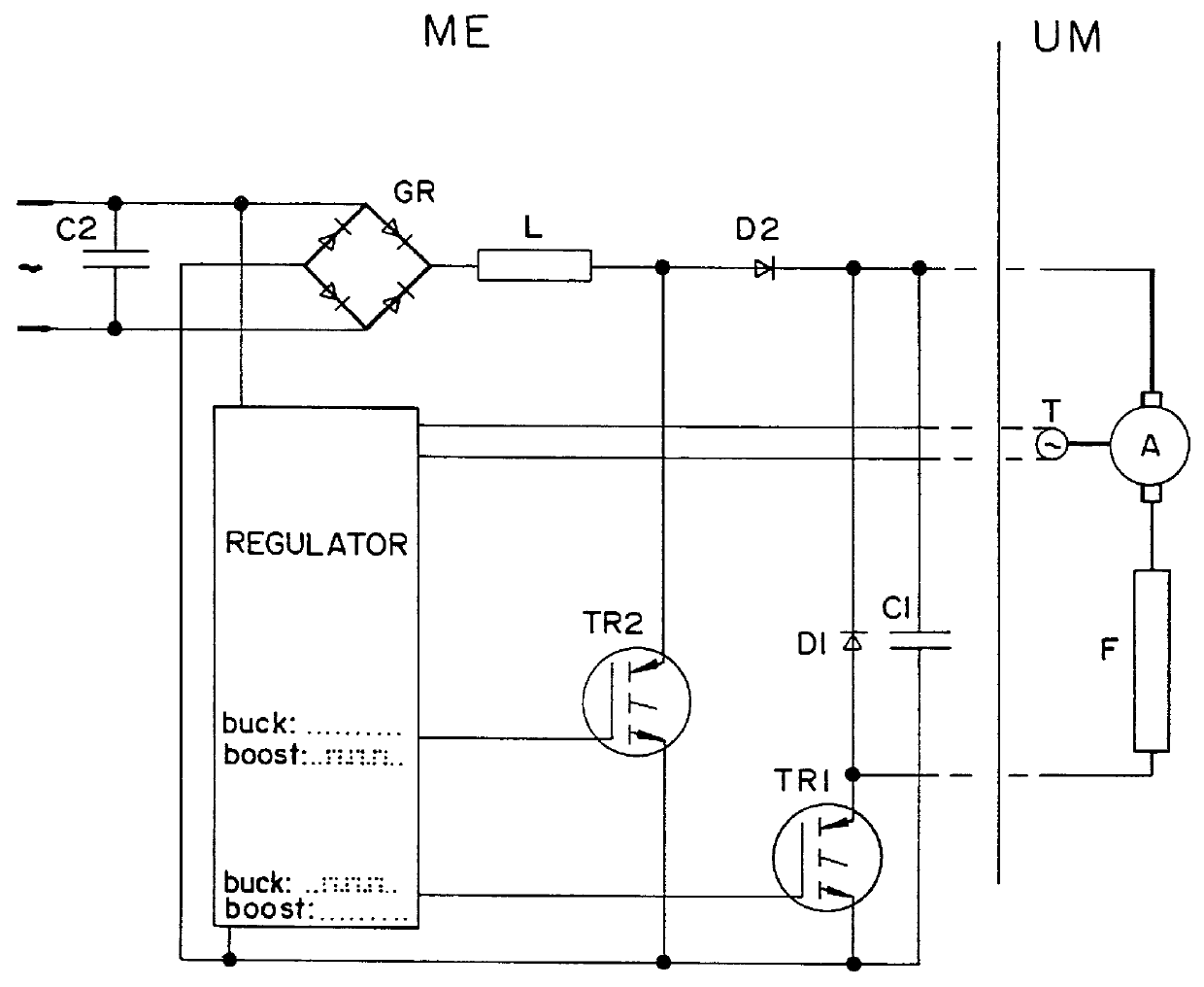

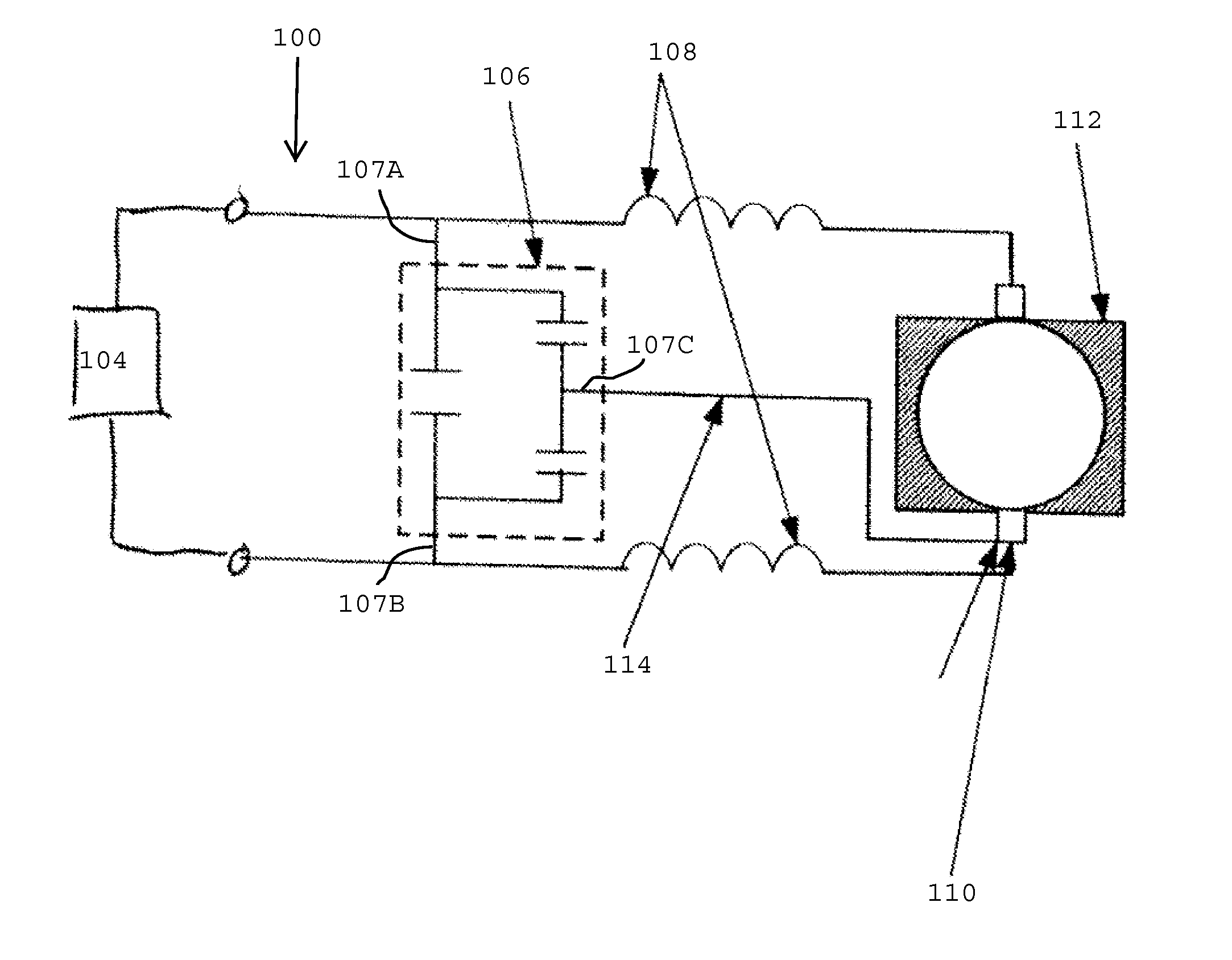

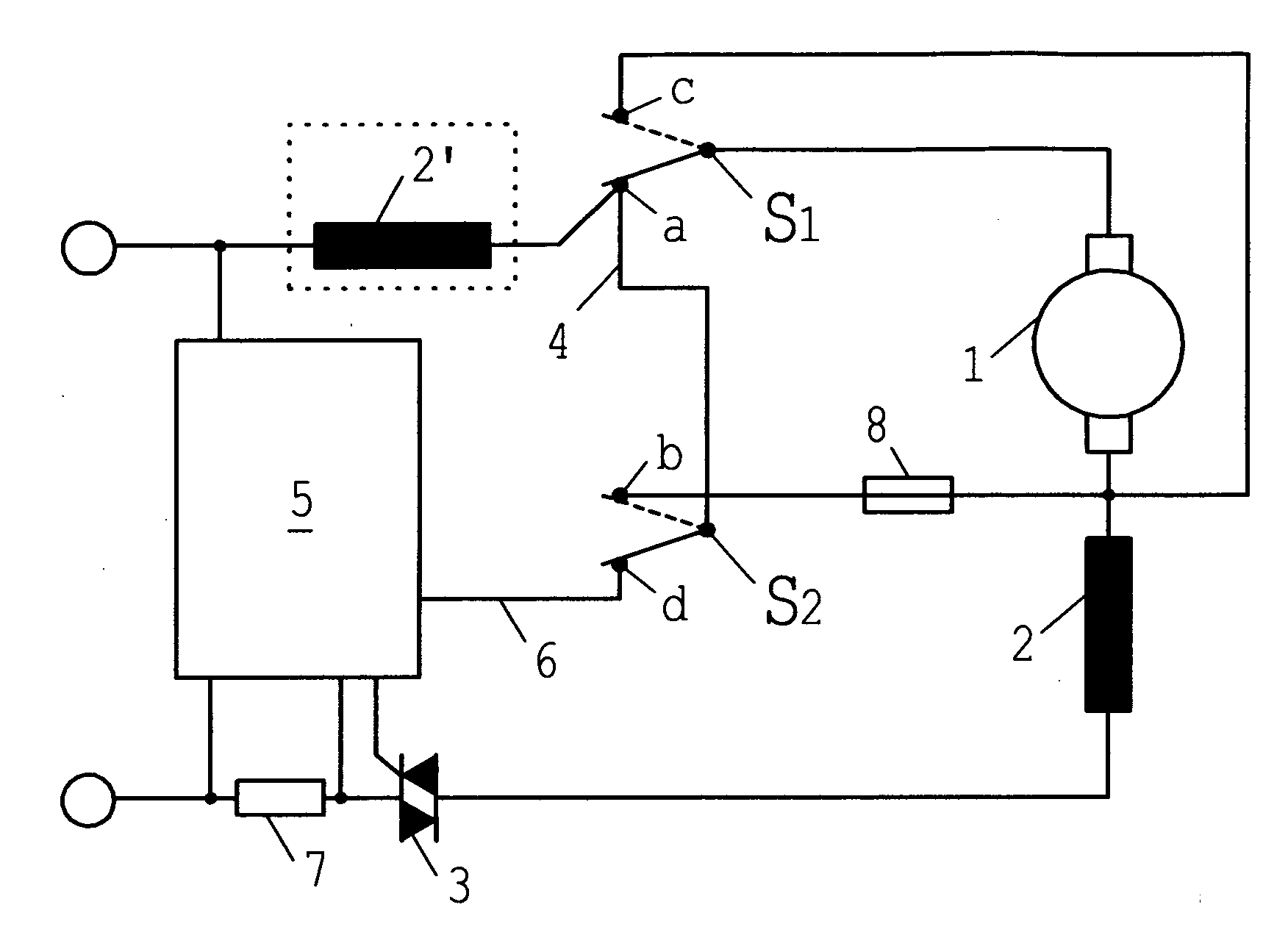

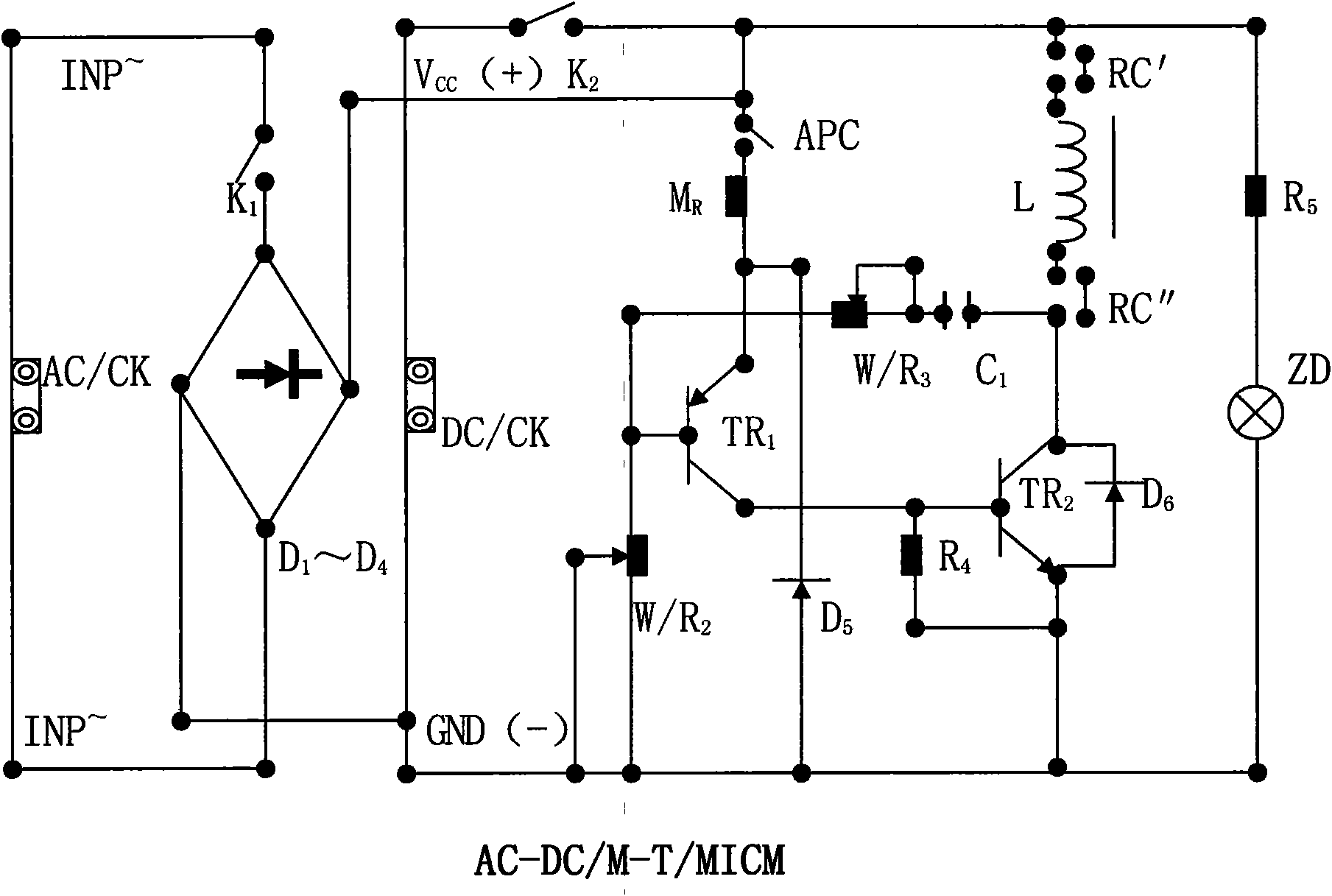

Rotary speed control circuit for feeding a dc universal motor

InactiveUS6016041AWide rangeReduce power lossMotor/generator/converter stoppersAC motor controlInductorControl circuit

A rotary speed control circuit for feeding a dc universal motor for driving a washing machine. A rectifier and a smoothing capacitor derive the operating voltage of the motor from the mains ac voltage and provided for control of the rotary speed is a regulating device (R) which controls a power stage for the motor, the power stage including a power switch (TR1) and a commutation diode (D1) in the topology of a low-setting device. The power stage feeding the motor includes a high-setting inductor (L) and can be switched over from the topology of a low-setting device to the topology of a high-setting device.

Owner:AKO WERKE

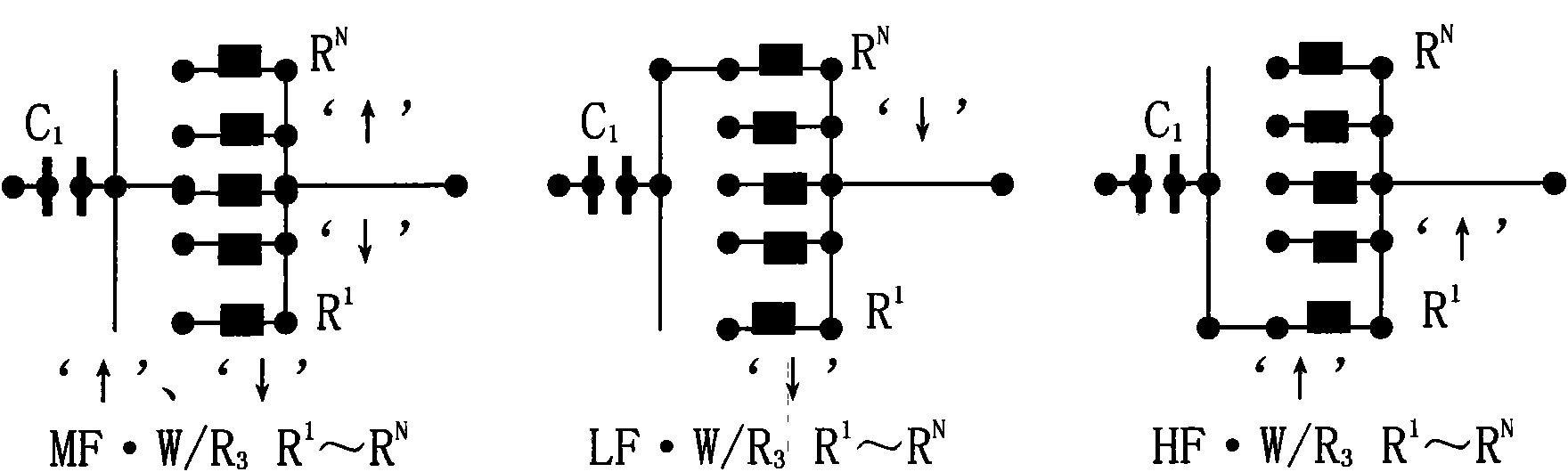

Universal motor driving matching method

InactiveCN106870343AReduce maintenance costsSave human effortPump controlPositive-displacement liquid enginesMotor driveEngineering

The invention relates to the field of motor drive, and discloses a generalized motor drive matching method, which automatically matches compressors according to identified motor parameters, thereby obtaining corresponding drive parameters and realizing generalization of matching with various types of compressors. The method includes the following steps: a. matching the eeprom parameters of various types of compressors adapted to it according to product requirements; b. writing all the parameters in the eeprom of each compressor that have been matched into the driver program; c. when driving the motor , first identify the relevant parameters of the motor, and then judge the model of the motor according to the identified motor parameters, so as to call the driving parameters of the motor of this type in the driver program to drive the motor. The invention is suitable for generalized matching of motor drives of household appliances.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

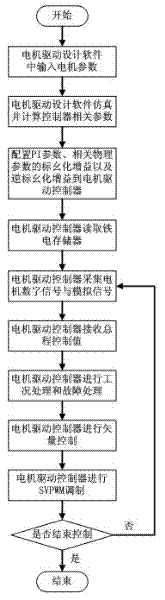

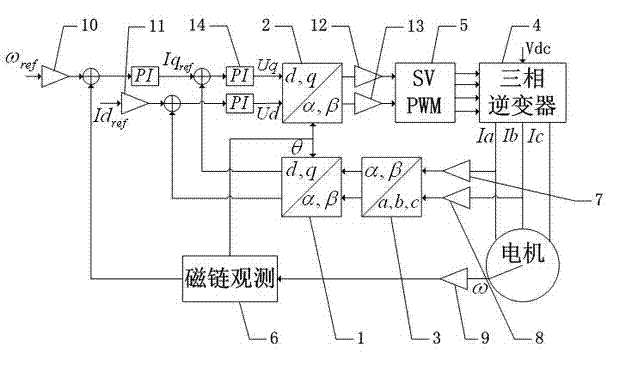

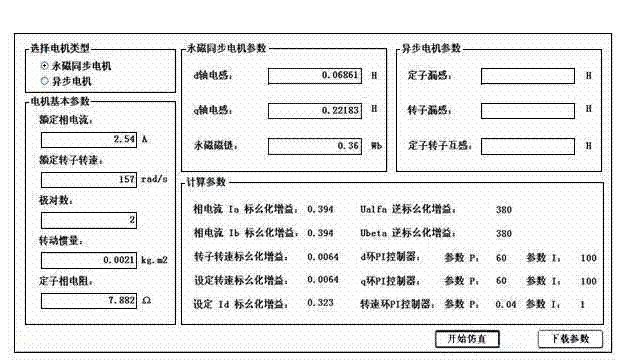

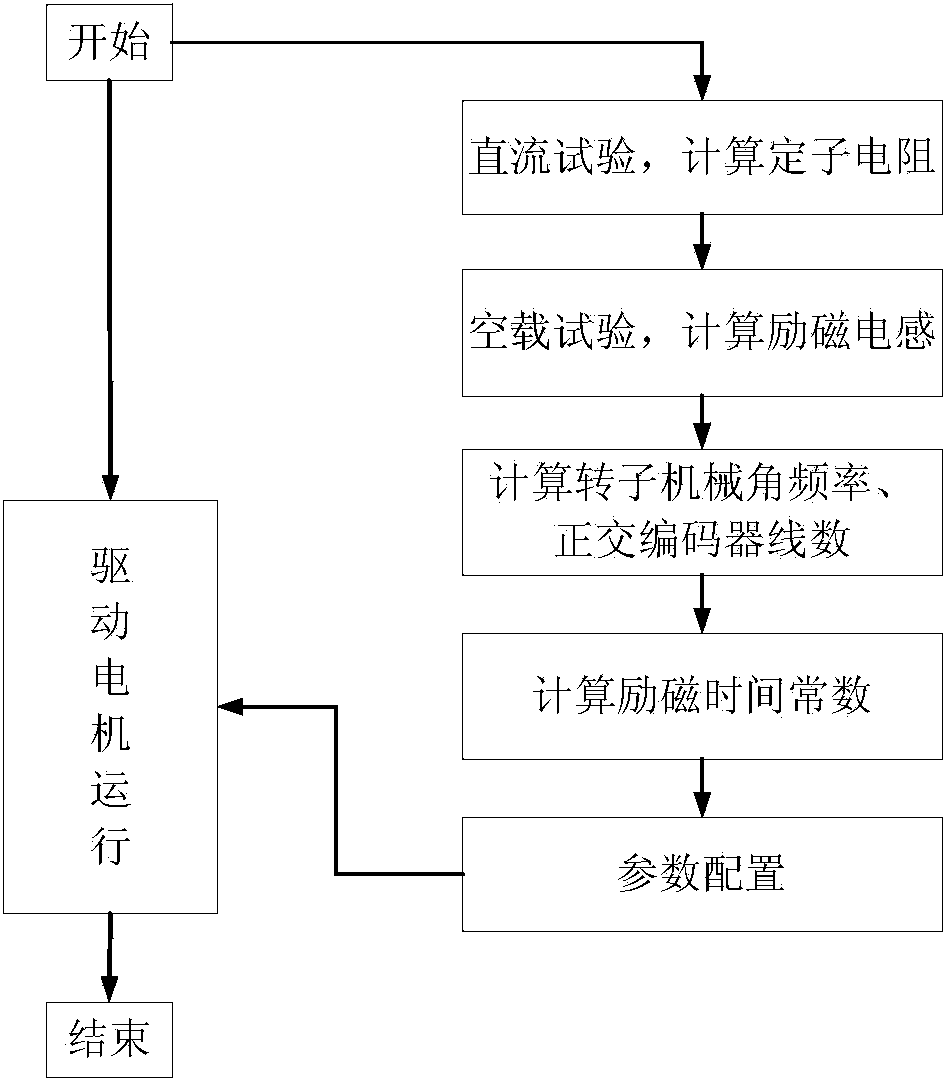

Method for designing universal motor drive controller of electric vehicle

InactiveCN102684593AGuaranteed uptimeImprove design efficiencyElectronic commutation motor controlVector control systemsControl signalDesign software

The invention belongs to the motor control technology for electric vehicles and relates to a method for designing a universal motor drive controller of an electric vehicle. A motor parameter is inputted to upper computer motor drive design software, a PI (Proportional-Integral) controller parameter is automatically designed, per-unit gain and inverse per-unit gain required by corresponding parameters in the calculation of vector control are also automatically designed, and after simulation, the parameters are configured to the motor drive controller; the controller reads corresponding downloaded values and samples digital signals and analog signals of a motor connected with the controller, the controller also receives assembly control signals of an assembly controller connected with the controller, system working condition processing and fault treatment are performed according to the signals, subsequently, vector control is carried out, space vector pulse-width modulation is finally performed, the steps are circularly performed, and the motor control flow is finished. According to the method, corresponding parameters only need to be inputted to the upper computer motor drive design software, the calculated parameters are configured in the motor drive controller, and accordingly, drive controllers for motors in different models can be designed.

Owner:中国东方电气集团有限公司

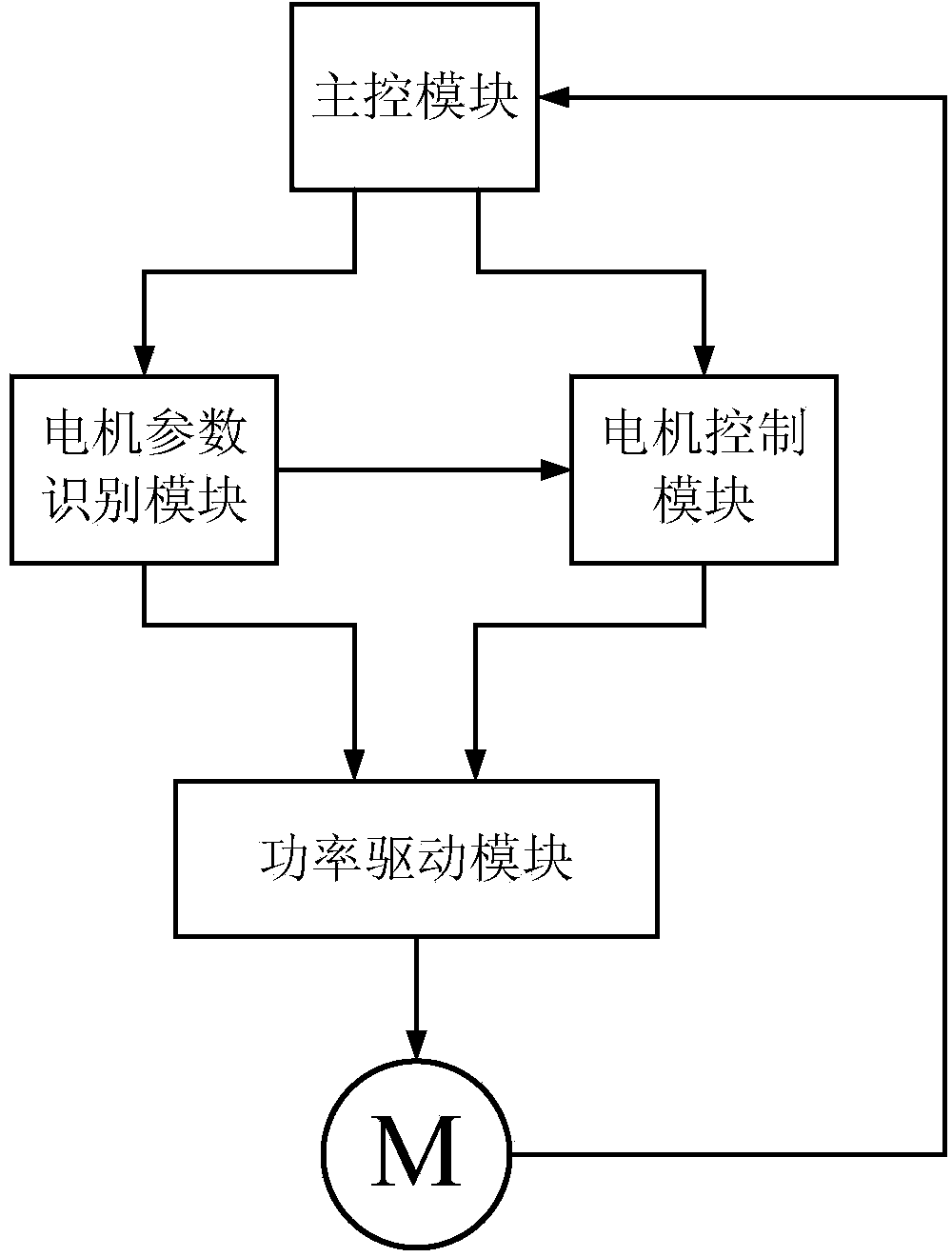

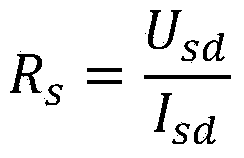

Universal motor controller based on parameter self-learning

InactiveCN103840731AReduce measurement work linksLow costElectronic commutation motor controlVector control systemsControl vectorElectric machinery

The invention discloses a universal motor controller based on parameter self-learning. The universal motor controller comprises a master control module, a power supply module, a motor control module, a motor parameter identification module and a power drive module connected with the motor parameter identification module and the motor control module, wherein the power supply module, the motor control module and the motor parameter identification module are in signal connection with the master control module. The universal induction motor controller can conduct automatic identification on motor parameters required for rotor field directional vector control, wherein the motor parameters include stator resistance Rs, magnetic inductance Lm, the orthogonal encoder line number Qn and rotor excitation time constant Tr; then, the motor parameters are automatically configured to a motor control module of an induction motor; in this way, the shortcomings that in the prior art, motor parameter identification operation is complex, technical requirements are high, and the application range of the controller is small are overcome, and the advantage that the controller is capable of automatically identifying the motor parameters and high in universality is realized.

Owner:TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

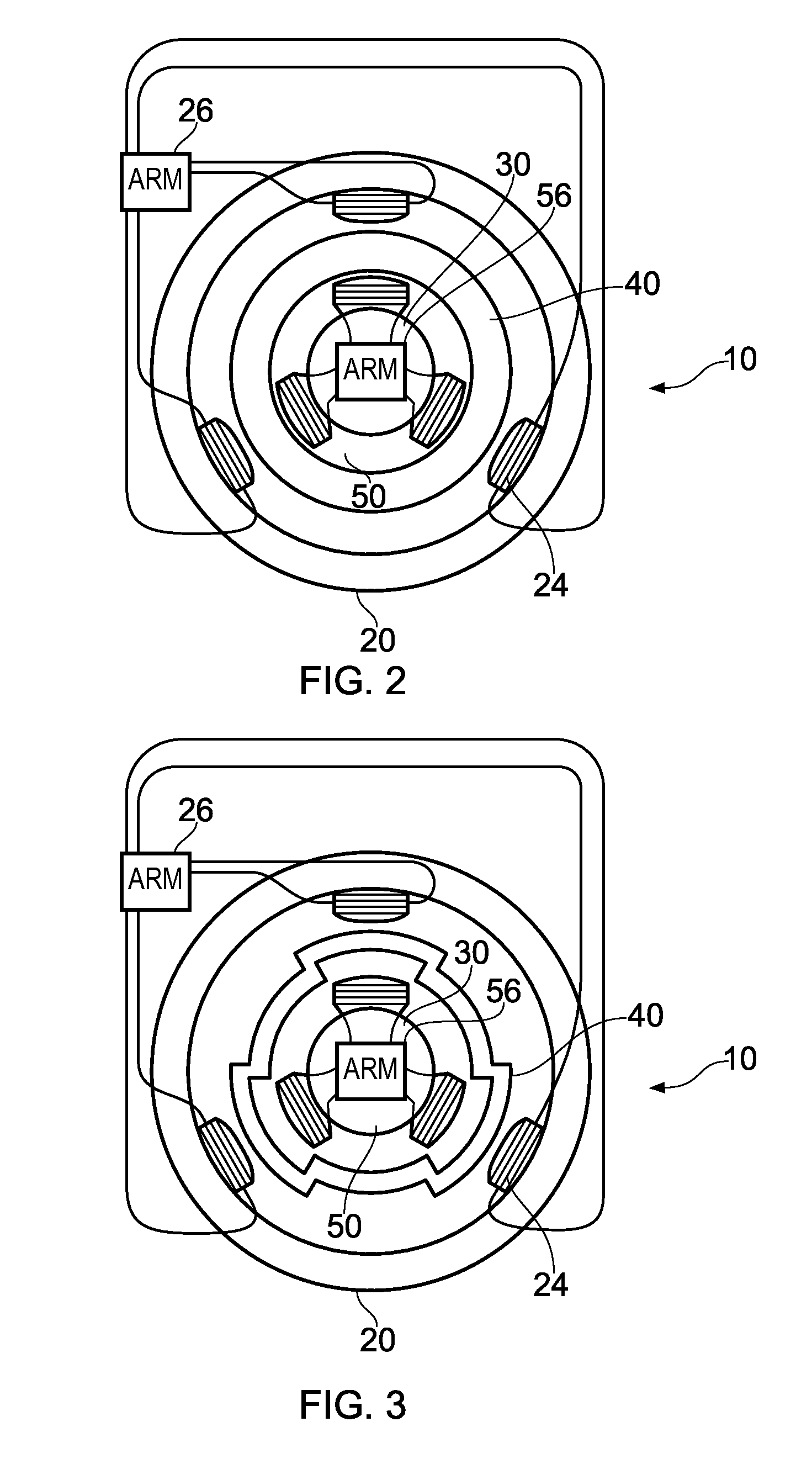

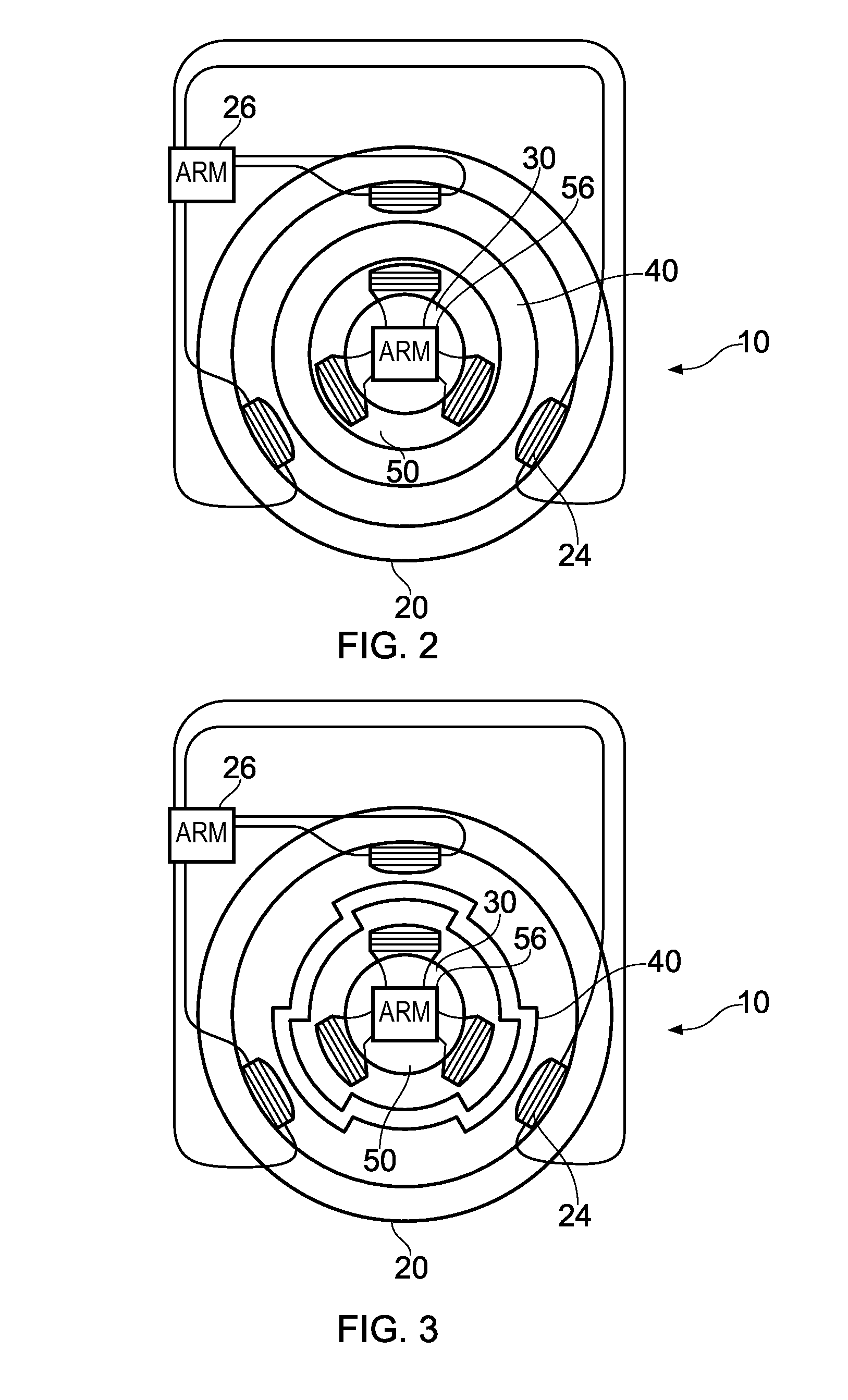

Electronically controlled universal motor

ActiveUS9130433B2Improve system efficiencyExtended speed rangeSynchronous motors startersAC motor controlElectric machineElectromagnetic field

An electric motor apparatus comprising: a stator component and a rotor component rotationally mounted coaxially with and within the stator component. The stator component and the rotor component each comprise windings configured to generate an electromagnetic field from an electric current. The electric motor further comprises an intermediate screening component rotationally mounted between the stator component and the rotor component and configured to provide at least some magnetic screening between the rotor component and the stator component. The intermediate screening component comprises at least some magnetically active sections configured such that changing magnetic fields generated by changing electric currents in the windings on either the rotor component or the stator component generate a force on the magnetically active sections causing the intermediate screening component to rotate; and control circuitry for independently controlling power supplied to the windings on the rotor component and the stator component in dependence upon a desired output rotational speed.

Owner:ARM LTD

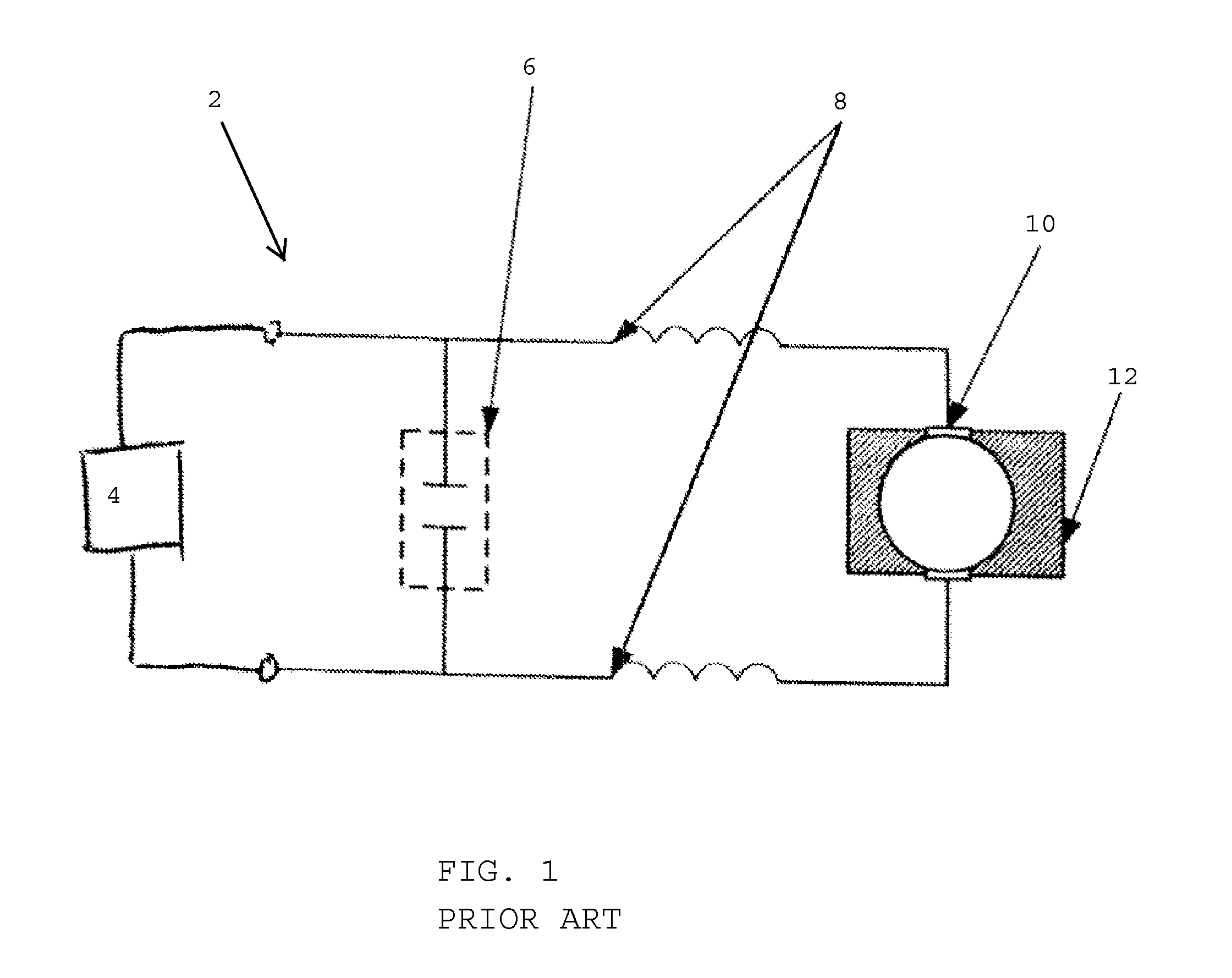

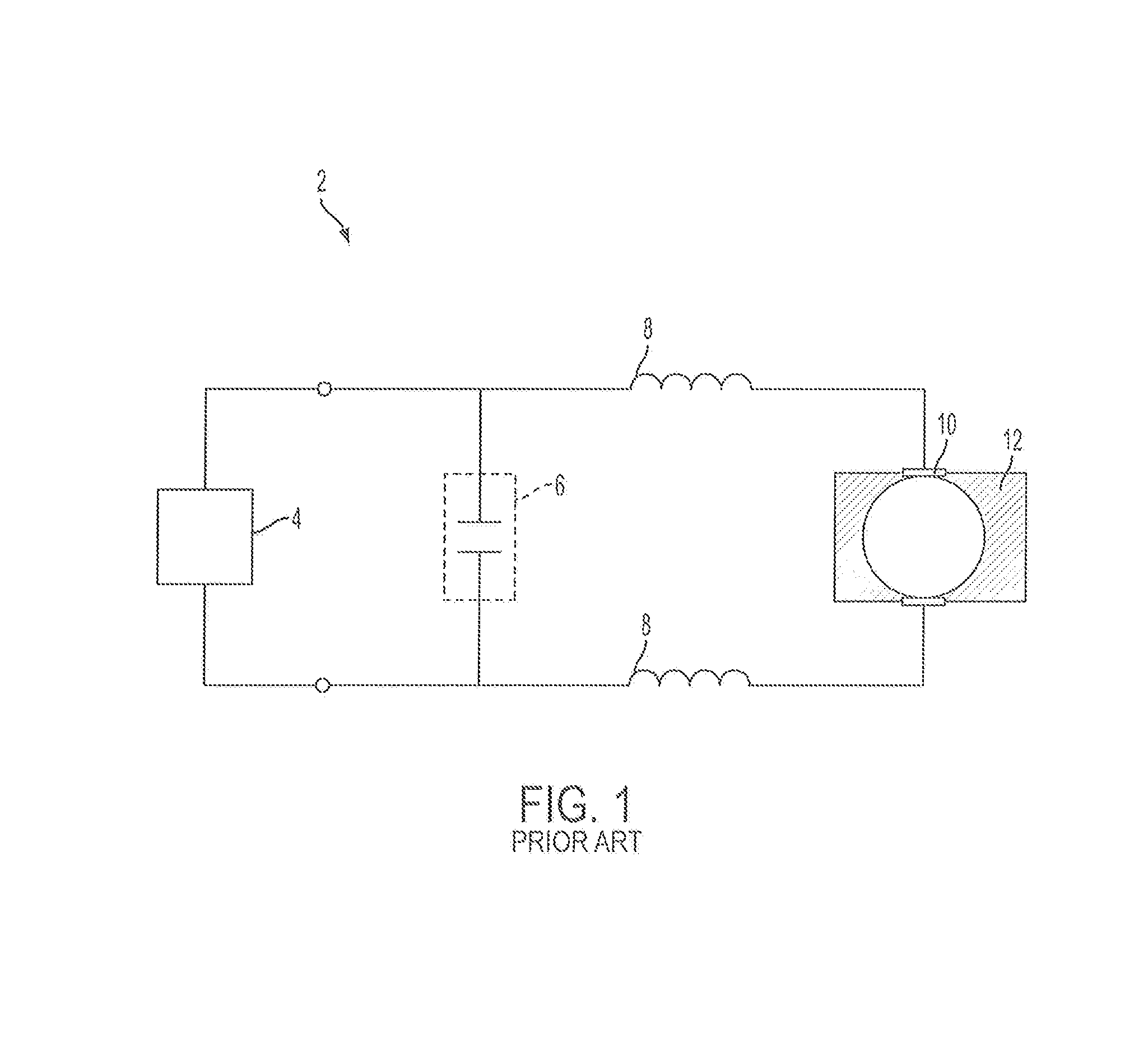

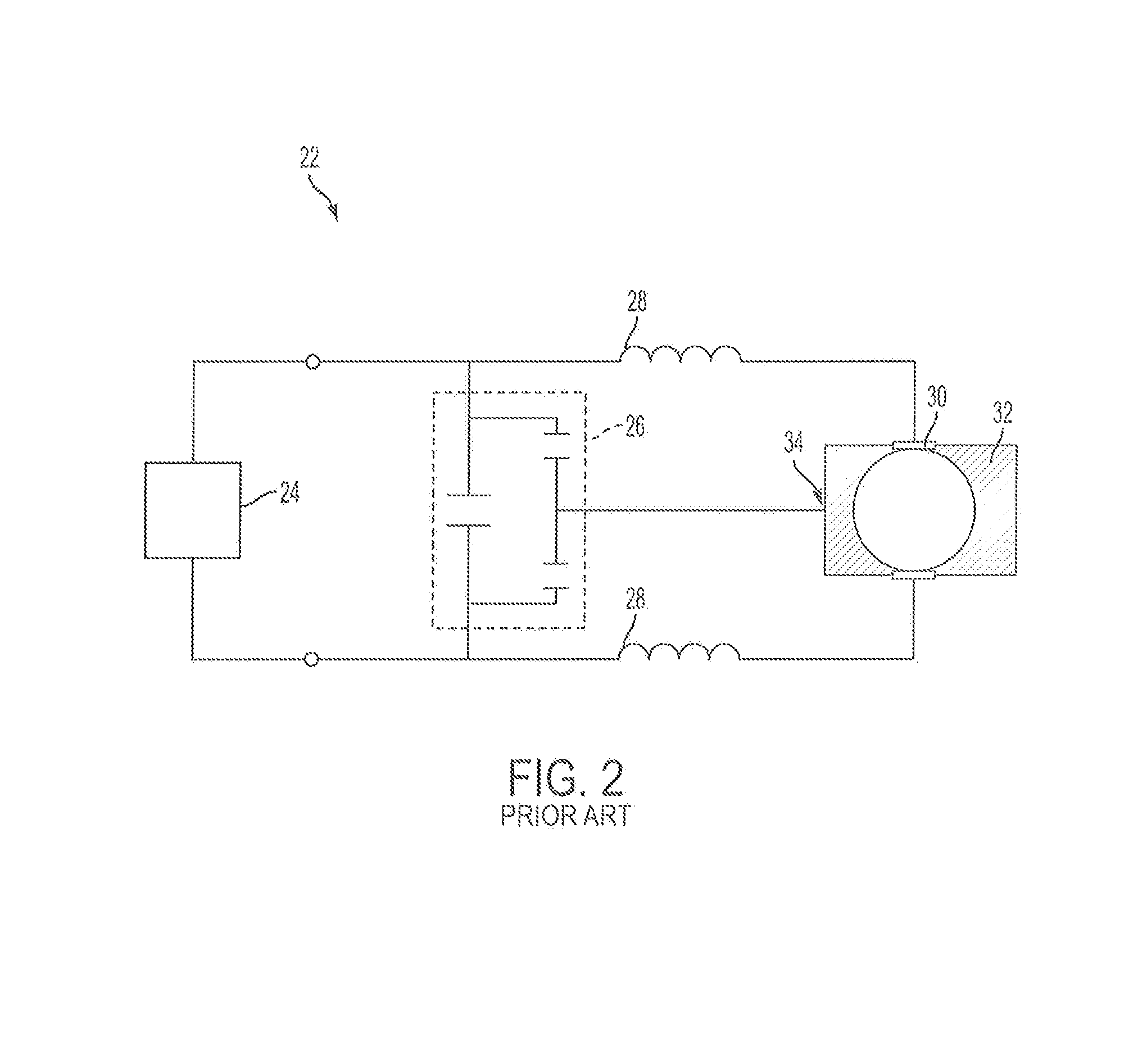

Electric motors having EMI reducing circuits and methods therefor

ActiveUS20110018377A1Reduce EMI emissionReduce electromagnetic interferenceRotary current collectorSuppressing electromagnetic interferenceElectricityElectromagnetic interference

An electric motor having a circuit for reducing electromagnetic interference (EMI) includes a field stack such as a stator, an armature including a shaft, a commutator mounted on the shaft, and an armature core electrically connected to the commutator, whereby the armature core is rotatably mounted within the field stack. The electric motor includes a brush assembly adapted to deliver electrical power to the commutator. The circuit includes a delta capacitor network and a conductive lead electrically interconnecting the delta capacitor network and the brush assembly. In one embodiment, the circuit includes motor field windings or coils, and a power source electrically interconnectable with the delta capacitor network and the motor field windings. In one embodiment, the motor is a universal motor.

Owner:BLACK & DECKER INC

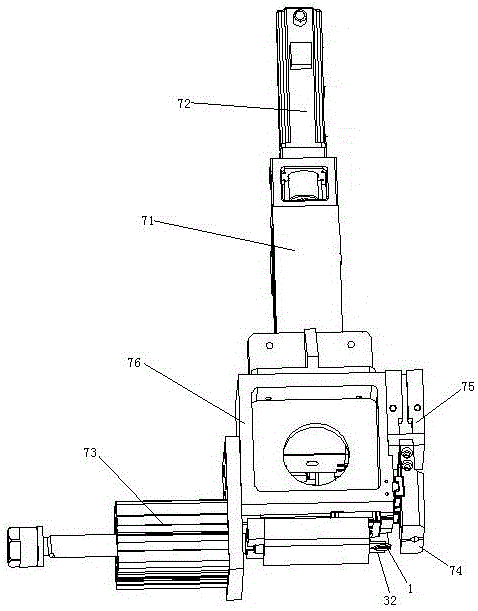

Universal motor clamp spring assembly machine

ActiveCN105048724ARealize automated assemblyGood degree of automationManufacturing dynamo-electric machinesSupports/enclosures/casingsMotor driveEngineering

The invention relates to equipmen for motor production t, and discloses a universal motor clamp spring assembly machine, which comprises a positioning mechanism and an upper clamp spring mechanism, wherein the positioning mechanism comprises a first fixing mechanism, a rotating wheel, a motor driving the rotating wheel to rotate, a first driving mechanism, stop blocks and a second driving mechanism for driving the stop blocks to approach to a positioning plane on the motor shaft; the upper clamp spring mechanism comprises a second fixing mechanism, a clamp spring clip, a base, at least two clamp spring feeding mechanisms arranged on the base and provided with clamp spring passing and connecting rods, a third driving mechanism driving the base to move to the clamp spring passing and connecting rod in one of the clamp spring feeding mechanisms to be aligned with the clamp spring clip and a fourth driving mechanism for driving the clamp spring clip to assemble clamp springs on the clamp spring passing and connecting rods to be on a to-be-assembled motor shaft on the second fixing mechanism in place one by one. The universal motor clamp spring assembly machine of the invention has the advantages that the clamp spring can be assembled on the motor shaft, and the problems that labor is consumed and the automatic degree is low when the clamp spring is manually assembled to the motor shaft can be solved.

Owner:ZHEJIANG CANYUAN HOME TEXTILE

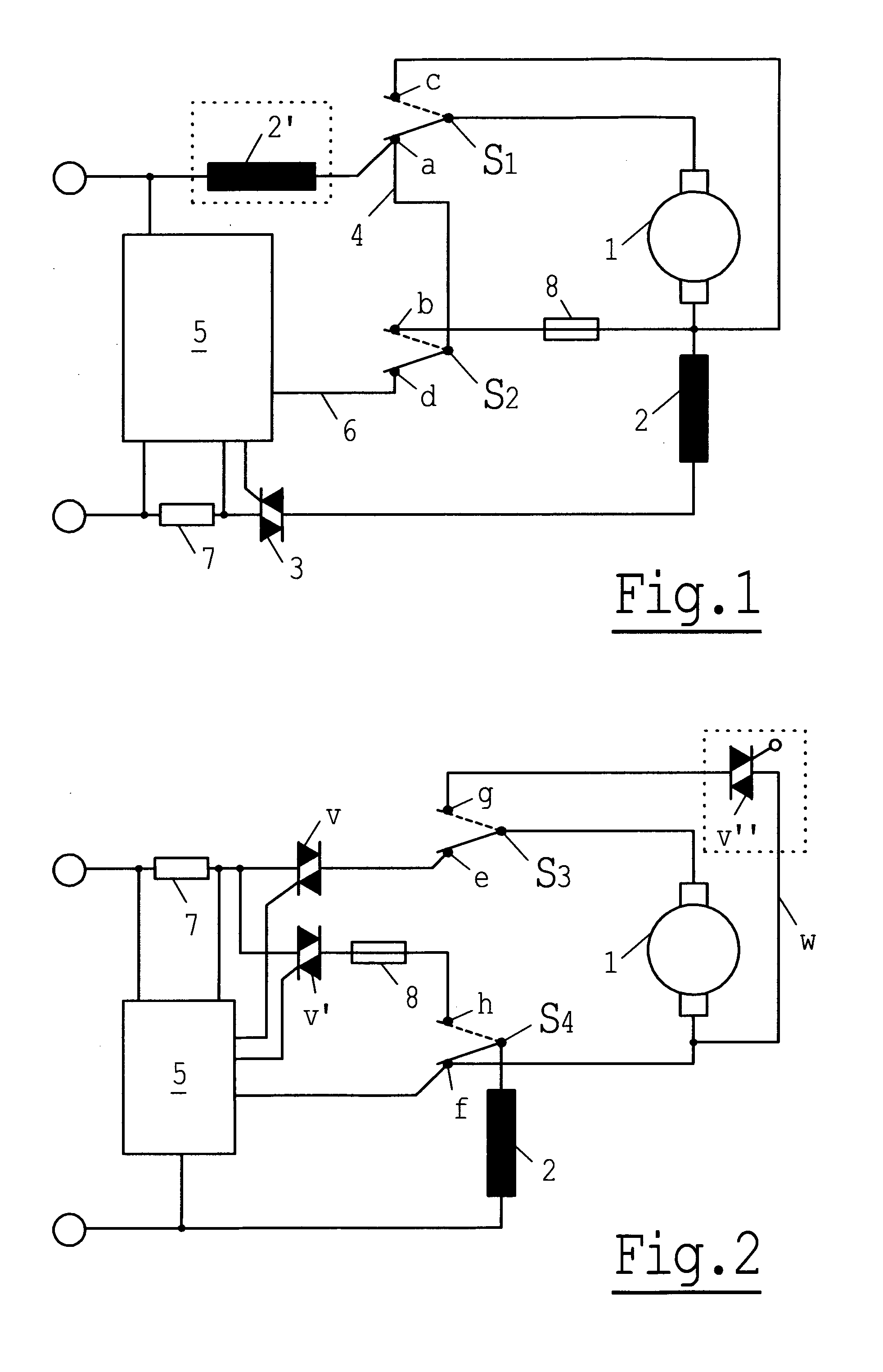

Electrodynamic braking device for a universal motor

ActiveUS20120091932A1Easy to brakeReduced brush sparkingAC motor controlDc motor stoppersElectronic systemsControl electronics

An electrodynamic braking device for a universal motor is proposed, wherein during a braking operation a field winding is supplied from a network, and an armature is directly short-circuited, and a braking operation is carried out using a program of a controller of a control electronics system, whereby good braking is achieved with relatively low brush wear. Such an electrodynamic braking device is advantageously applied in a power tool equipped with a dangerous tool.

Owner:ROBERT BOSCH GMBH

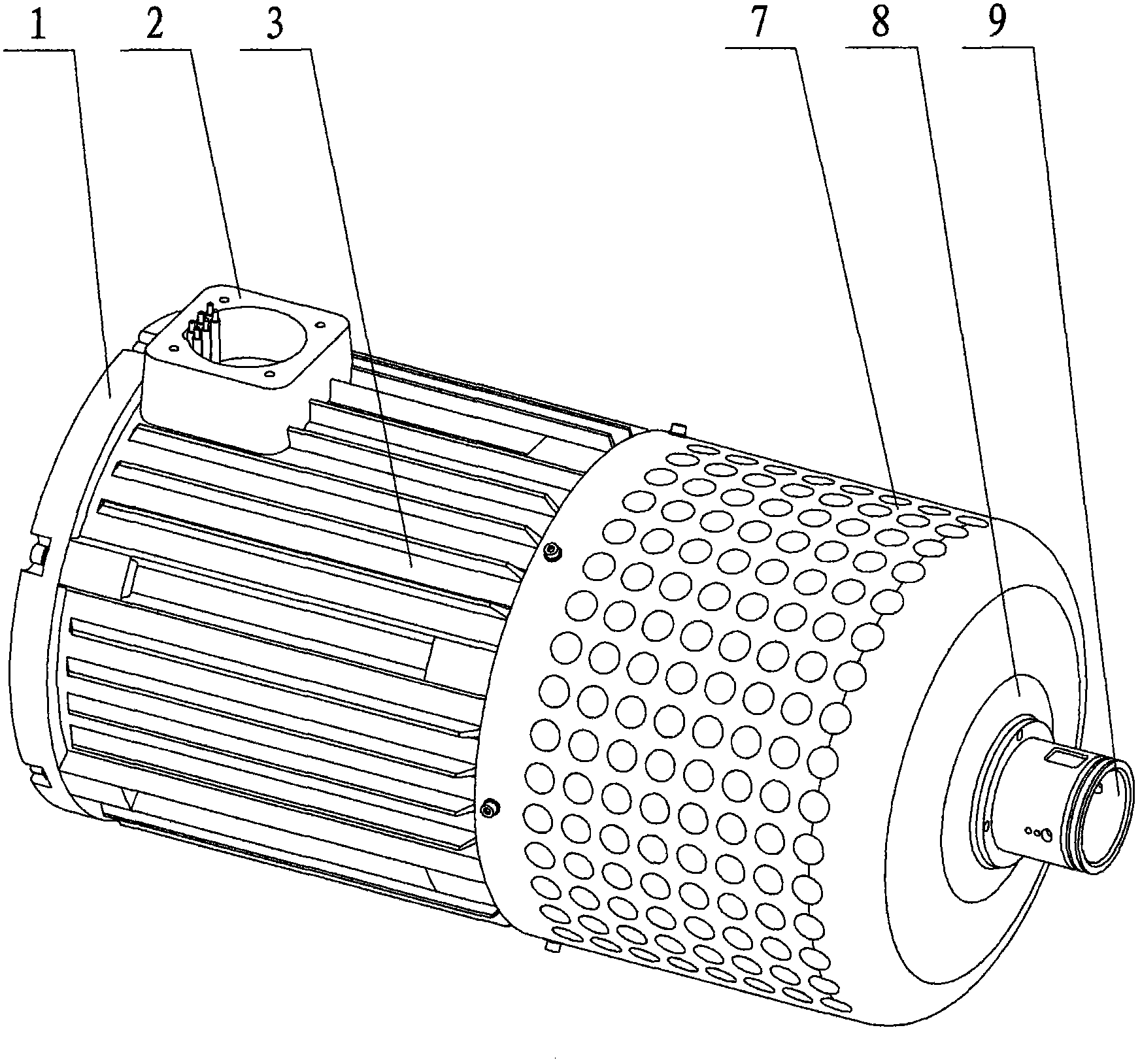

Permanent magnet synchronous motor with dual annular rotation heat tube for cooling rotor

ActiveCN102710079AMagnetic circuit rotating partsCooling/ventillation arrangementAtmospheric airPermanent magnet synchronous motor

The invention discloses a permanent magnet synchronous motor with a dual annular rotation heat tube for cooling a rotor, which is composed of a base end cover component, a motor base component, a cooling end cover component, a rotor component and a protective component. When the motor is in operation, heat generated by the rotor is conducted onto the outer surface of a rotating shaft sleeve by a dual annular rotation heat tube cooler; when a screw pump oil pumping unit is driven, the heat conducted onto the outer surface of the rotating shaft sleeve is radiated into the atmosphere in a natural air cooling manner, and a fan assists in convective circulation, so as to quickly cool a rotor permanent magnet and avoid demagnetization caused by over-temperature rising; and heat generated by the copper loss and iron loss of a stator is radiated into the atmosphere via cooling fins on the outer surface of the motor base. When the permanent magnet synchronous motor with the dual annular rotation heat tube for the cooling rotor is taken as a universal motor, heat conducted onto the outer surface of the rotating shaft sleeve is radiated by an air flow generated by the fan at a high rotation speed, and the air flow flows through the ventilation slots of the cooling end cover component to cool the ventilation fins on the outer surface of the motor base.

Owner:湖北久特机电科技有限公司

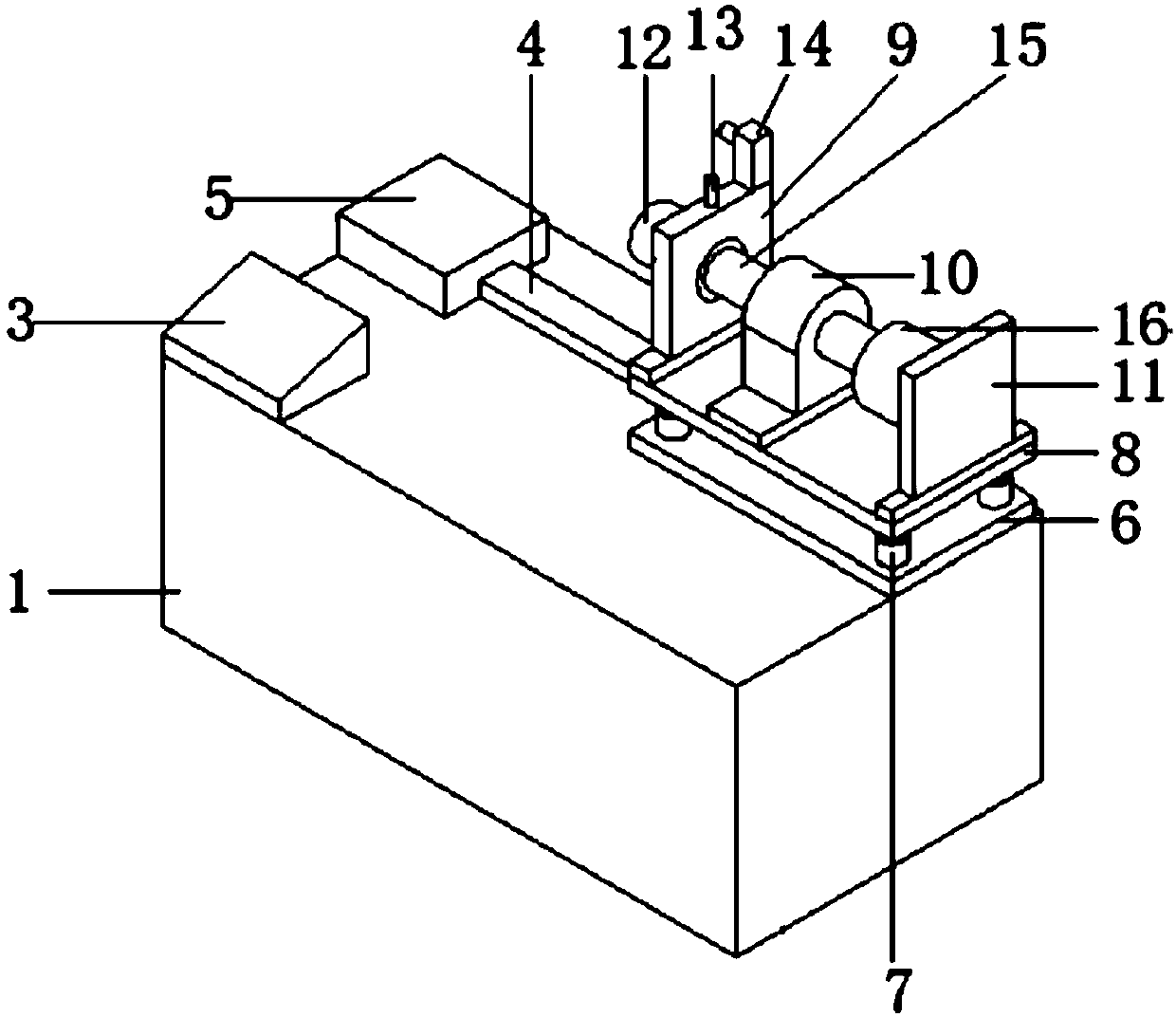

Multifunctional motor test table for different models

InactiveCN109541464ASimple structureEasy to operateSubsonic/sonic/ultrasonic wave measurementWork measurementMotor testingCoupling

The invention discloses a multifunctional motor test table for different models. The motor test table comprises a test table, a display screen is arranged on the front side of the top of the test table, and a motor supporting table, a sliding rail and a testing device fixing plate are sequentially arranged on the rear side of the top of the test table from left to right, wherein a brake is installed on one side of the supporting plate; a torque rotating speed tester is arranged between an output shaft of a to-be-tested motor and a coupling; and an acceleration sensor and a temperature sensor are arranged at the top of a coupling supporting seat. The test table in the invention is simple in structure and convenient for operation; the to-be-tested motor is fixed on a motor supporting table;the models of the motors are different, so the distance between the to-be-tested motor and the testing device fixing plate can be adjusted through the sliding of the motor supporting table on a slideway; the multifunctional universal motor test table can be used for simultaneously testing the rotating speed, the torque and the vibration technical parameters of the motor.

Owner:苏州艾斯巴尔机械科技有限公司

Electric motor

InactiveUS8212448B2Magnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringConductor Coil

A universal motor has a stator and a rotor installed in the stator. The stator comprises a pair of stator segments. Each segment has a yoke with first and second ends, a pole and a neck connecting the pole to the first end of the yoke. The second end of each yoke is connected with the first end of the other yoke. A pair of pre-formed windings are mounted on respective poles of the stator segments.

Owner:JOHNSON ELECTRIC SA

Electric motor

A universal motor has a stator and a rotor installed in the stator. The stator comprises a pair of stator segments. Each segment has a yoke with first and second ends, a pole and a neck connecting the pole to the first end of the yoke. The second end of each yoke is connected with the first end of the other yoke. A pair of pre-formed windings are mounted on respective poles of the stator segments.

Owner:JOHNSON ELECTRIC SA

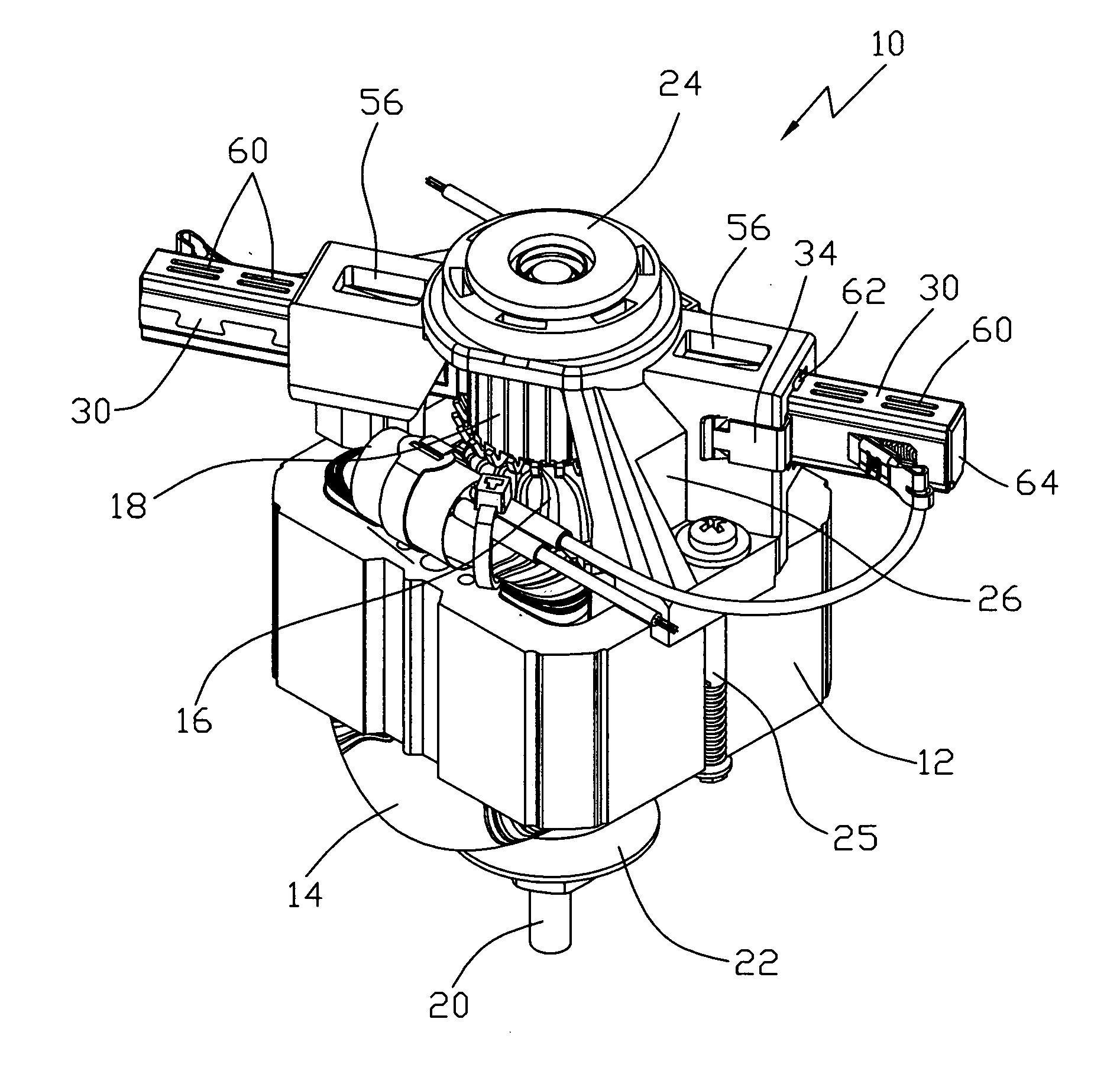

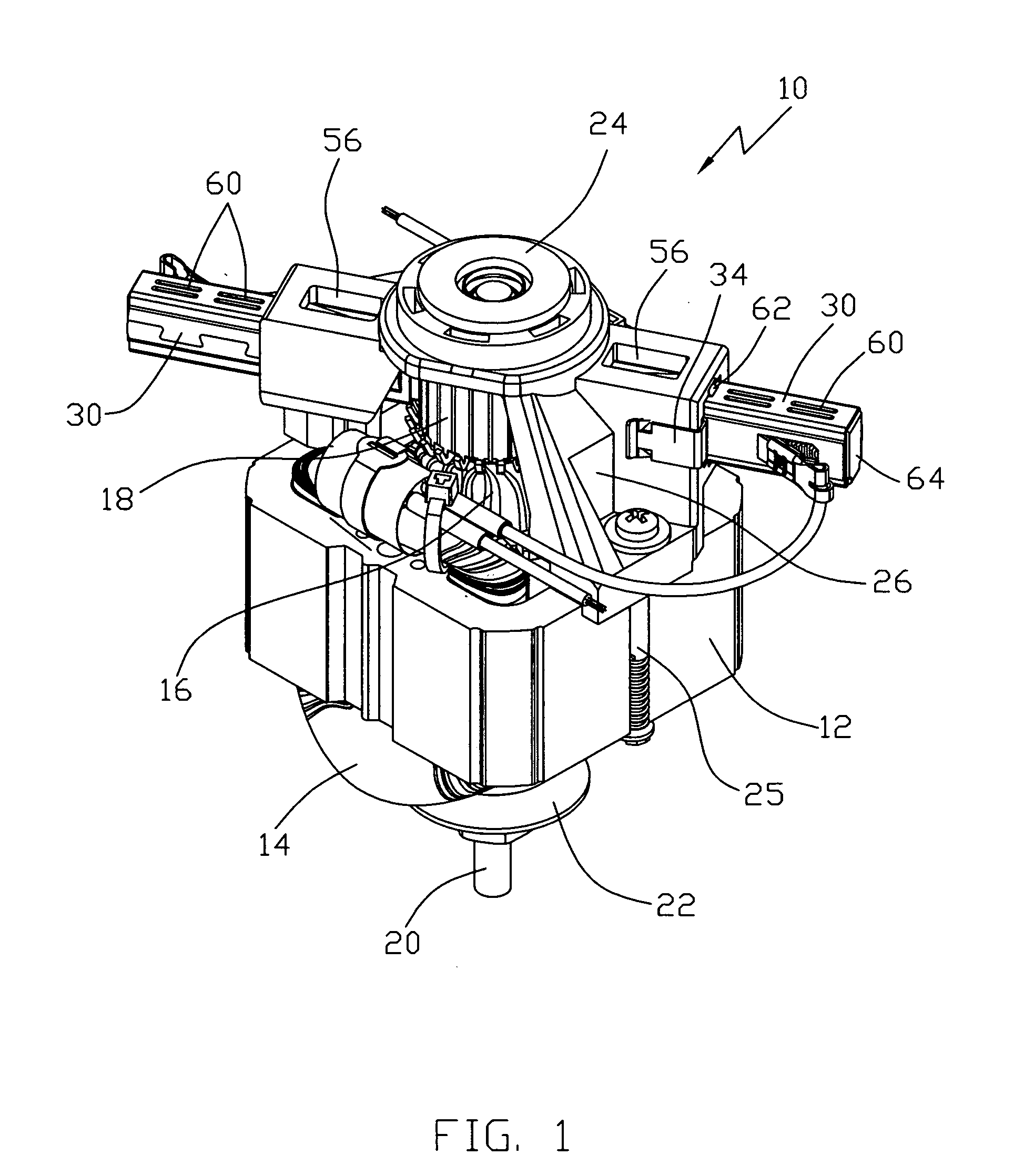

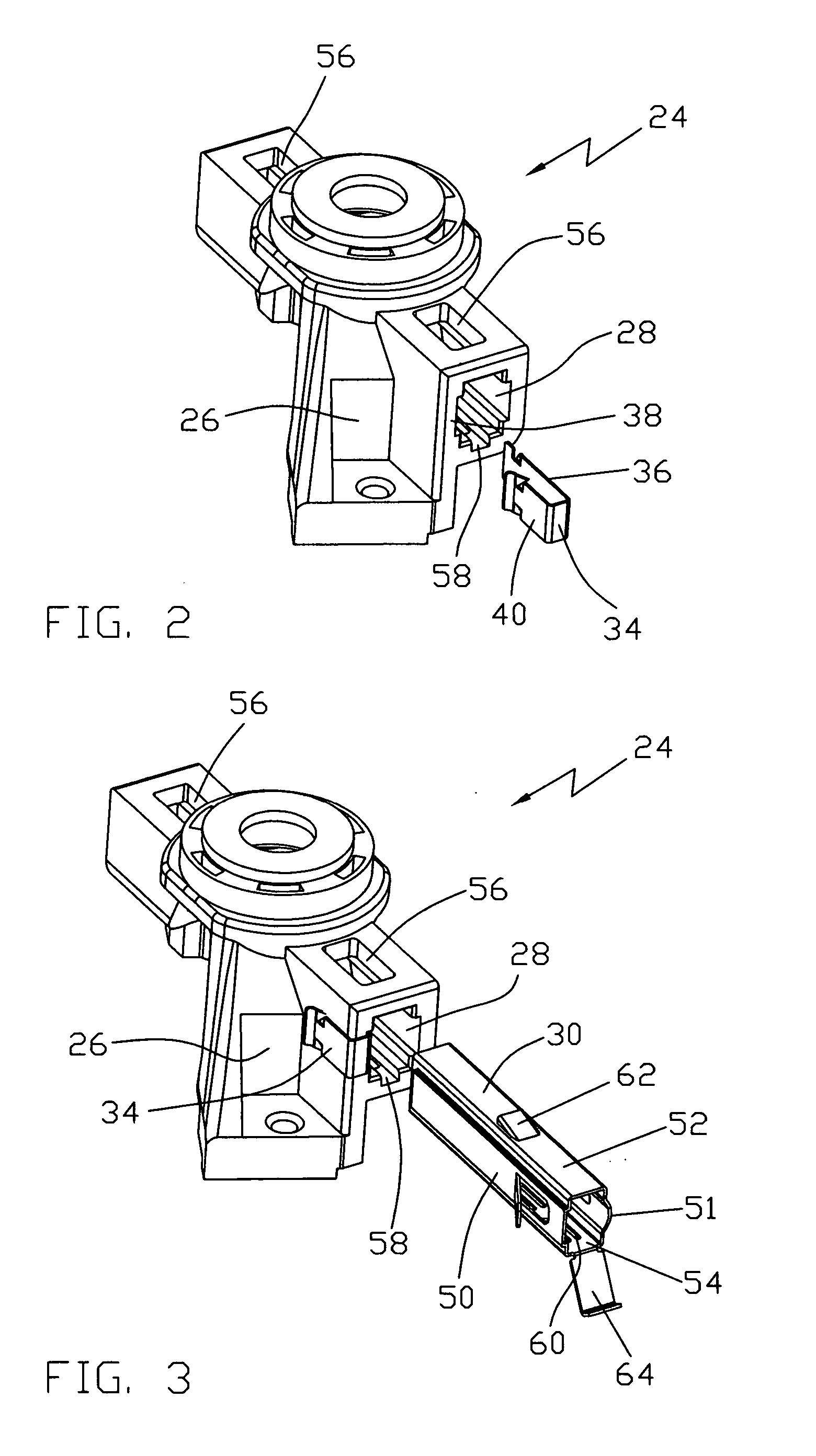

Brush holder assembly for an electric motor

ActiveUS20050121994A1Reduce lateral playPrevent withdrawalRotary current collectorSupports/enclosures/casingsElectric machineClassical mechanics

A universal motor has a brush cage assembly in which a U-shaped clip 34 is located about a wall of a through hole 28 of a bearing bracket 24 for receiving a brush cage 30. The clip 34 has an outer limb 42 with inwardly and rearwardly directed barbs 44 to grip an outer surface of the wall to prevent removal of the clip 34 and an inner limb 36 with outwardly and forwardly directed barbs 42 which resiliently deform as the cage 30 is inserted to snare the cage 30 should it move in the opposite direction. The clip 34 thus prevents withdrawal of the brush cage 30 and provides a lateral spring force against the cage 30 to reduce cage lateral position tolerance and movement.

Owner:JOHNSON ELECTRIC SA

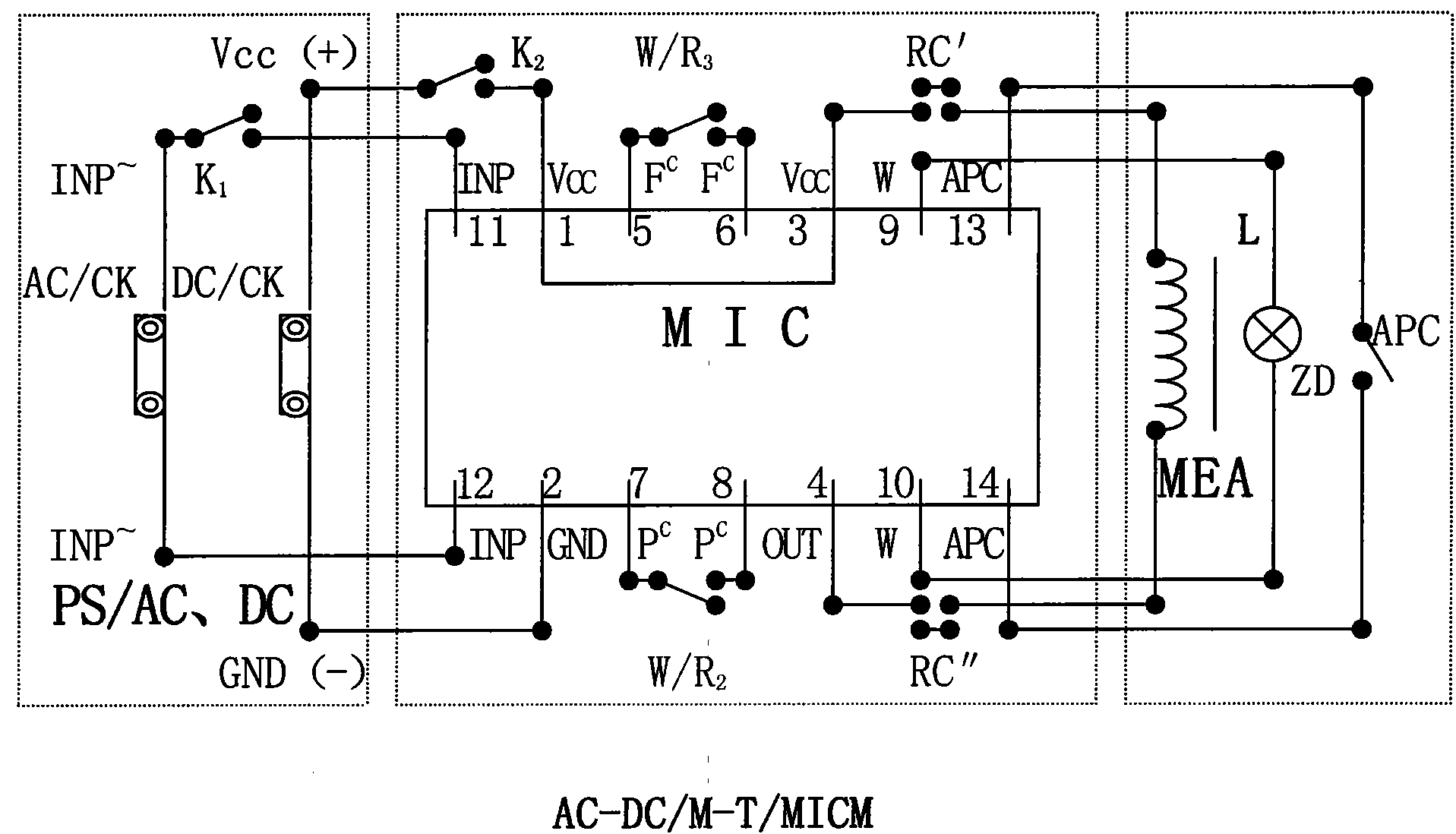

AC and DC multifunctional molecular integrated circuit electromotor

InactiveCN101986525AWith AC and DC power processing functionAssociation with control/drive circuitsAC motor controlInput controlEngineering

The invention discloses an AC and DC multifunctional molecular integrated circuit electromotor which utilizes the technical principle of molecular integrated circuit electrical equipment. A function processing system comprises a stator having a magnet coil, a rotor mounted inside or outside the stator, a spinning controller connected to the magnet coil and a molecular integrated circuit of the electromotor special for an AC and DC power supply processing function, a frequency regulating and controlling function, a power regulating and controlling function, a speed regulating and controlling function, a work state indicating function, and an automatic phase input control processing function. According to different application demands, various special and universal AC and DC multifunctional molecular integrated circuit electro motors can be formed by alternating and combining the function processing system with various signals and circuits. The electromotor of the invention can be used as the green power for the power products of traditional product structure and electric technique, such as a DC motor, an AC motor, a universal motor, and the like, namely replaces the industrial development of the traditional electric energy motor.

Owner:PINGJIANG SANXIANG ELECTRONICS ELECTRICAL APPLIANCE TECH DEV

Electric motors having EMI reducing circuits and methods therefor

ActiveUS8552615B2Reducing electromagnetic interference (EMI) emissionRotary current collectorStructural associationElectricityElectromagnetic interference

An electric motor having a circuit for reducing electromagnetic interference (EMI) includes a field stack such as a stator, an armature including a shaft, a commutator mounted on the shaft, and an armature core electrically connected to the commutator, whereby the armature core is rotatably mounted within the field stack. The electric motor includes a brush assembly adapted to deliver electrical power to the commutator. The circuit includes a delta capacitor network and a conductive lead electrically interconnecting the delta capacitor network and the brush assembly. In one embodiment, the circuit includes motor field windings or coils, and a power source electrically interconnectable with the delta capacitor network and the motor field windings. In one embodiment, the motor is a universal motor.

Owner:BLACK & DECKER INC

Electronically controlled universal motor

ActiveUS20150130390A1Reduce material usageReduce thicknessElectronic commutation motor controlMotor/generator/converter stoppersElectric machineElectromagnetic field

An electric motor apparatus comprising: a stator component and a rotor component rotationally mounted coaxially with and within the stator component. The stator component and the rotor component each comprise windings configured to generate an electromagnetic field from an electric current. The electric motor further comprises an intermediate screening component rotationally mounted between the stator component and the rotor component and configured to provide at least some magnetic screening between the rotor component and the stator component. The intermediate screening component comprises at least some magnetically active sections configured such that changing magnetic fields generated by changing electric currents in the windings on either the rotor component or the stator component generate a force on the magnetically active sections causing the intermediate screening component to rotate; and control circuitry for independently controlling power supplied to the windings on the rotor component and the stator component in dependence upon a desired output rotational speed.

Owner:ARM LTD

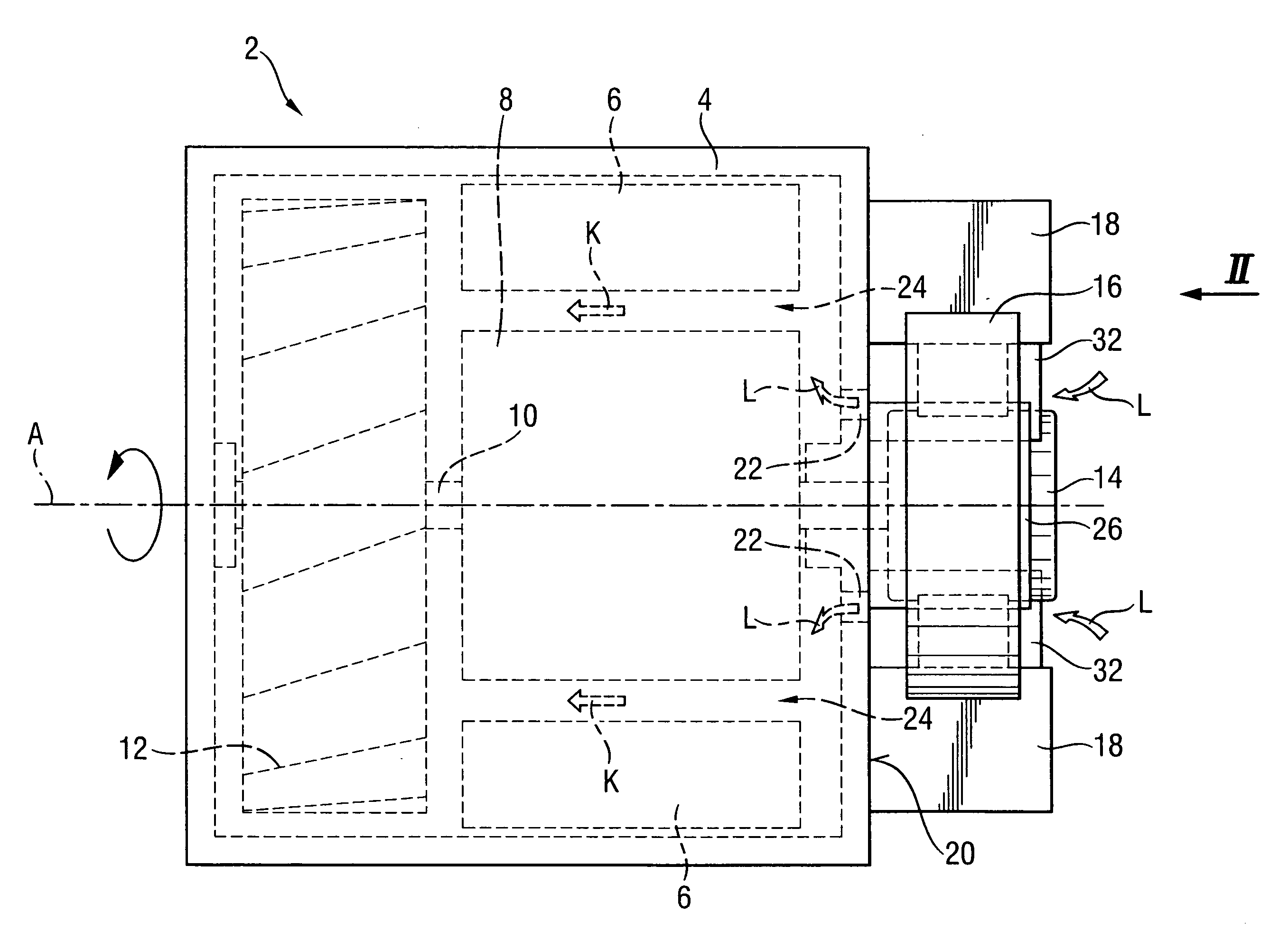

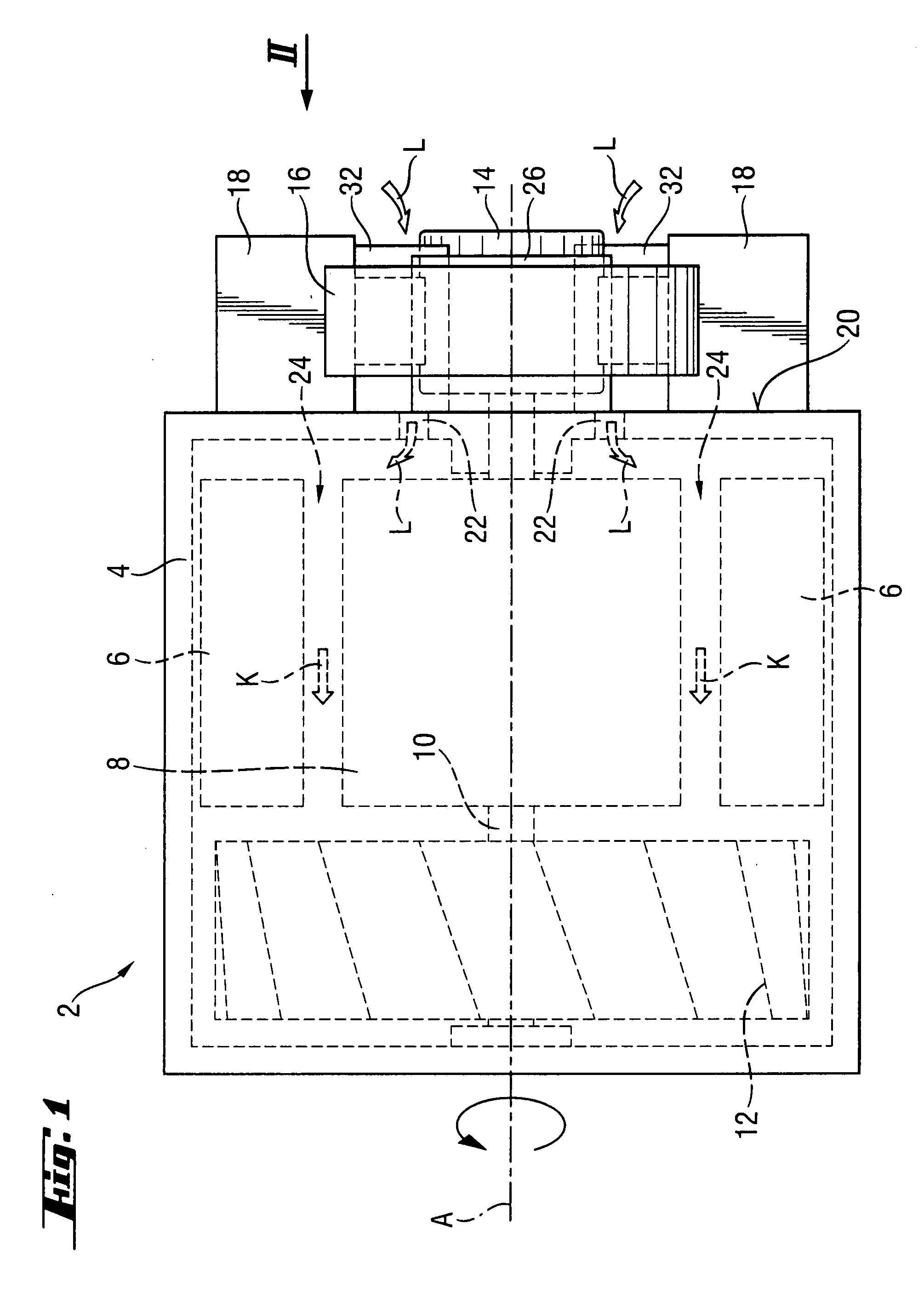

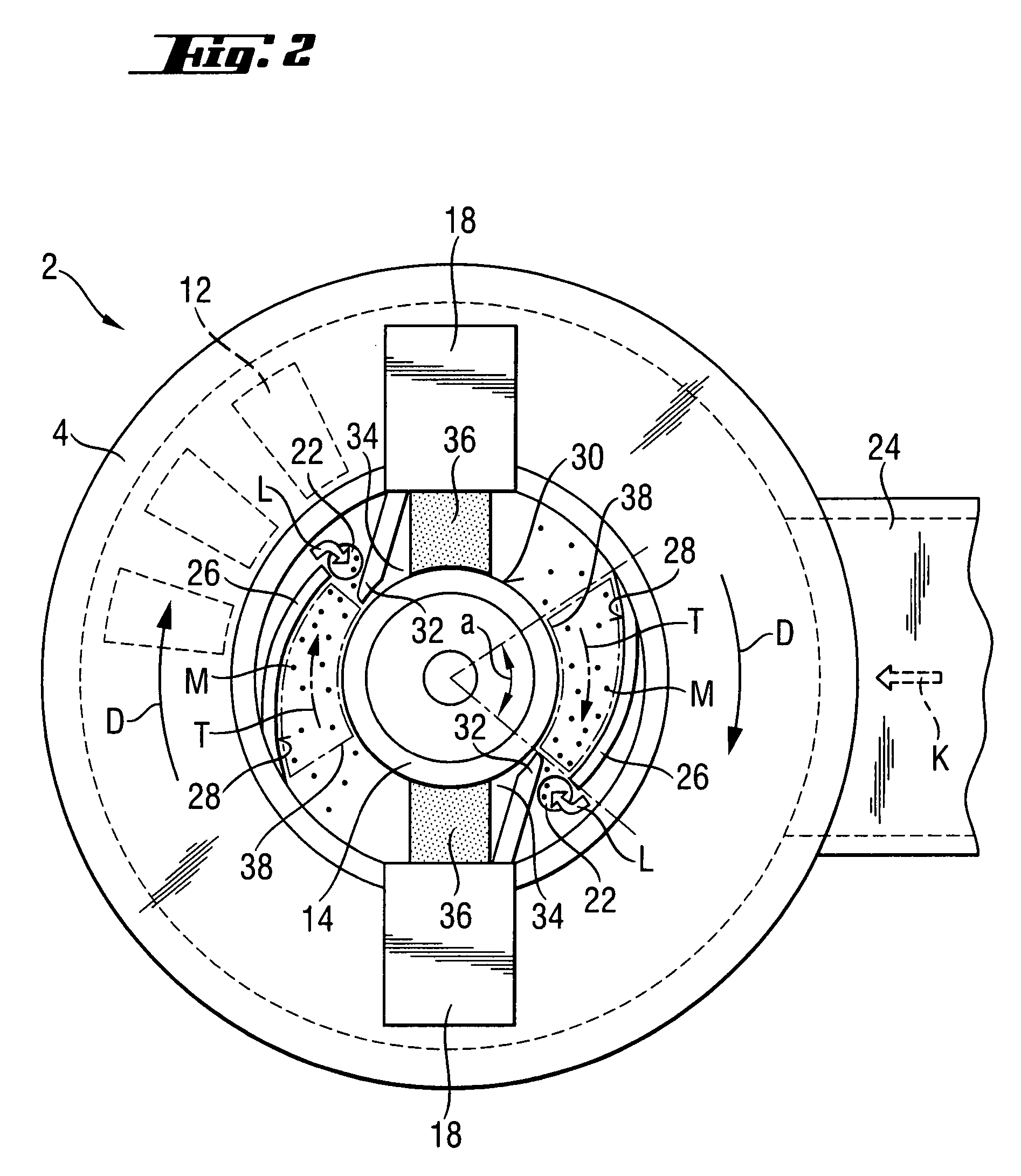

Universal motor with a device for removing dust

InactiveUS20080001493A1Easy to installGood removal effectRotary current collectorDC commutatorMechanical engineeringUniversal motor

A universal motor (2) includes at least two carbon brushes (36) contacting the commutator (14), a ventilation device (12) for producing a cooling flow (K), and a dust protection arrangement for preventing penetration of material particles (M) into the commutation region (34) and including at least one guide member (26) that provides for delivering of the material particles (M) in the cooling flow (K), with the at least one guide member (26) having a smooth concave guide surface (28) located between the two carbon brushes (36) and extending adjacent to an outer surface (30) of the commutator (14) and toward a suction opening (22) connected with the cooling flow path (24).

Owner:HILTI AG

Electric motor

InactiveUS20090302704A1Avoid excessive widthMagnetic circuit rotating partsDC commutatorConductor CoilUniversal motor

A universal motor has a stator and a rotor. The stator has stator core and a stator winding. The stator core has a yoke with two ends and two equivalent salient poles formed at the ends of the yoke respectively. The stator winding is wound on the yoke.

Owner:JOHNSON ELECTRIC SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com