Spherical hinge universal rotary motor, and manufacturing method and operating method thereof

A technology of a rotary electric machine and a manufacturing method, which is applied to the synchronous motor with a stationary armature and a rotating magnet, a synchronous motor with a rotating armature and a stationary magnet, and the manufacture of a motor generator, etc. Problems such as equipment operation and poor equipment working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

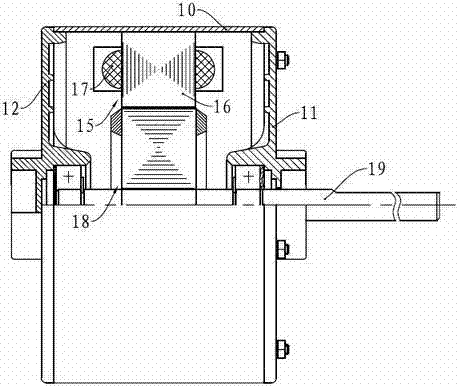

[0056] see image 3 , the present embodiment has a substantially spherical shell 31 , the rotor body is installed in the shell 31 , and the rotor body is spherical and can move in multiple directions relative to the shell 31 . Therefore, the motor of the present invention is different from the planar motor of transmission, and the motor of the present invention can realize the movement of multiple degrees of freedom, and can be called a three-dimensional motor.

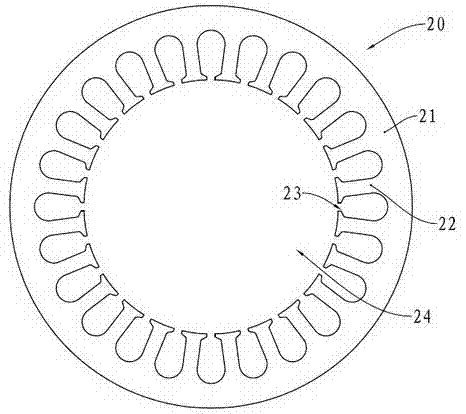

[0057] see Figure 4 and Figure 5 , The motor of the present invention has a spherical segment-shaped stator body 30, the stator body 30 is made of permanent magnets, and is magnetized into a plurality of magnetic poles. In practical applications, the permanent magnets can be magnetized into eight poles or sixteen poles as required. Moreover, the stator body 30 is not necessarily a complete permanent magnet, but can be spliced by multiple permanent magnets, and each permanent magnet is magnetized into correspond...

no. 2 example

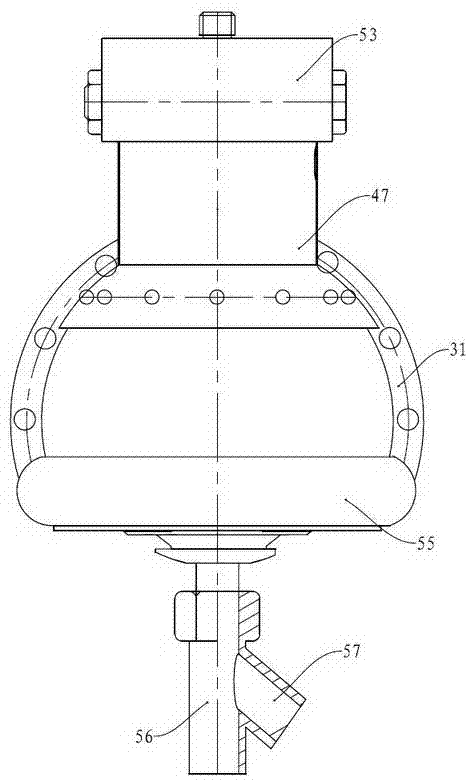

[0092] see Figure 19 to Figure 21 , the spherical joint universal rotary motor 80 of this embodiment has a casing 101, the casing 101 is composed of two hemispherical casings, the casing 101 is provided with a stator body 102, and the stator body 102 is magnetized by a permanent magnet, and the permanent magnet The magnet is magnetized into a plurality of poles.

[0093] The rotor body 103 is housed in the stator body 102, which is the same as the rotor body of the first embodiment. The rotor body 103 of this embodiment also has a multi-layer armature 104. Each armature 104 has a rotor iron made of multi-layer silicon steel sheets. core, and two layers of coils are wound on the rotor core, and the winding method of the coils is the same as that of the first embodiment. The rotor body 103 is provided with a rotor shaft 105, and the top of the ball joint universal rotary motor 80 is provided with an air inlet 106. The air inlet 106 can be connected with an external air pipe, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com