Method for designing universal motor drive controller of electric vehicle

A drive controller and motor drive technology, which is applied in the direction of motor generator control, electronic commutation motor control, electromechanical brake control, etc., can solve the problems of poor versatility and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

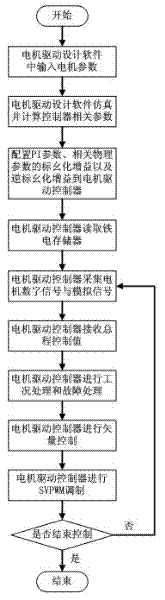

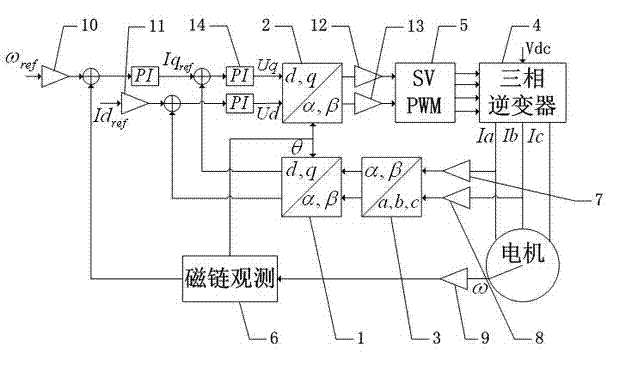

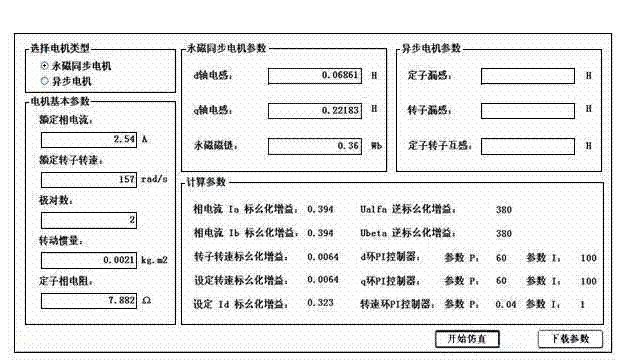

[0037] Such as figure 1 As shown, a design method of a universal motor drive controller for an electric vehicle is to input the motor parameters in the motor drive design software of the host computer, and the motor drive design software of the host computer automatically designs the parameters of the PI controller, and automatically calculates the parameters in the vector control. The p.u. gain and inverse p.u. gain required by the corresponding parameters, after the motor vector control simulation, the PI controller parameters and the p.u. And the inverse unitary gain is downloaded to the uninitialized motor drive controller, stored in the ferroelectric memory, and the motor drive controller is designed as an electric vehicle motor drive controller; the electric vehicle motor drive controller reads the ferroelectric memory The parameters of the PI controller in the PI controller and the corresponding parameters in the vector control required per unit gain and inverse per uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com