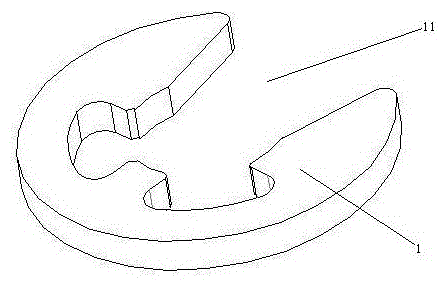

Universal motor clamp spring assembly machine

A general-purpose, assembly machine technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of labor-intensive automation, achieve good automation, good versatility, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

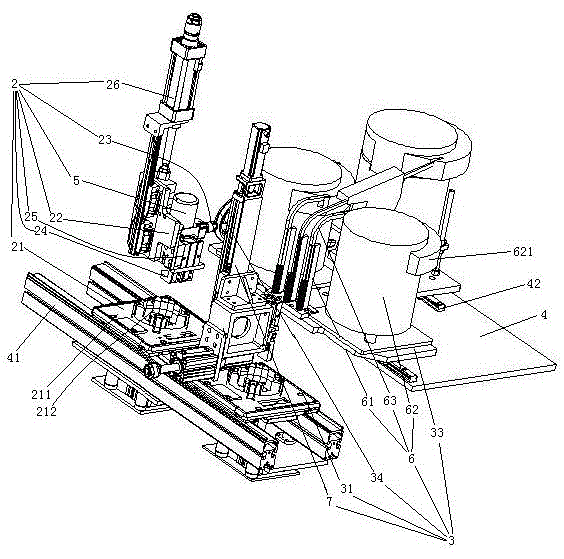

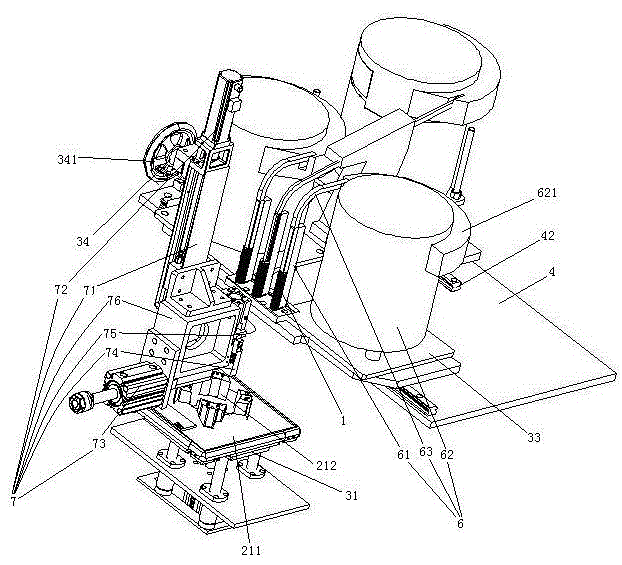

[0035] Embodiment one, see figure 2 , a universal motor circlip assembly machine, including a frame 4, a positioning mechanism 2 and an upper circlip mechanism 3. The frame 4 is provided with a first slide rail 41 and a second slide rail 42 . The first slide rail 41 extends in the left-right direction. The second slide rail 42 is parallel to the first slide rail 41 . The second slide rail 42 is located behind the first slide rail 41 .

[0036] The positioning mechanism 2 includes a first fixing mechanism 21 , a first connecting seat 22 , a motor 5 , a first driving mechanism 23 , a rotation stop block 24 , a second driving mechanism 25 and a lifting cylinder 26 . The first fixing mechanism 21 includes a panel 211 . The panel 211 is slidably connected to the first slide rail 41 . A fixing hole 212 is defined on the panel 211 . The first fixing mechanism 21 fixes the motor through adsorption by the electromagnet. The first connection seat 22 is fixedly connected with the...

Embodiment 2

[0047] Embodiment two, the difference with embodiment one is:

[0048] see Figure 10 , The motor 5 includes a rotating shaft 51 and a motor housing 52 . The rotating shaft 51 is supported by the motor housing 52 through two bearings 55 . An oil filling chamber 56 is formed between the motor housing 52 and the two bearings 55 . A first gear 58 and a second gear 57 are arranged in the oil filling chamber 56 . The first gear 58 and the second gear 57 mesh together. The first gear 58 is connected with the rotating shaft 51 . The second gear 57 is rotationally connected with the motor housing 52 through a short shaft 571 .

[0049] see Figure 11 , the first gear 58 is provided with a refueling mechanism 8 . The number of refueling mechanisms 8 is equal to the number of teeth of the first gear 58 .

[0050] see Figure 12 , The refueling mechanism 8 includes an oil outlet 81 , an air supply port 82 , a sealing head 83 , a first spring 84 , a cylinder 85 and a piston 86 . ...

Embodiment 3

[0055] Embodiment three, the difference with embodiment two is:

[0056] see Figure 14 , each circlip vibrating plate 62 is provided with a tilt self-off switch 9. Tilt self-cutting switch 9 is used for controlling circlip vibrating plate 62 to stop vibrating. The tilt self-cutting switch 9 includes a shell 91 and a connecting pin 92 . The shell 91 is fixedly connected with the circlip vibrating plate 62 .

[0057] see Figure 15 , The tilt self-disconnecting switch 9 also includes a power-disconnecting spring 93 , a conductive sheet 94 , a weight guide cavity 95 , a weight 96 , a swing arm 97 and a barb 98 .

[0058] The shell 91 is made of insulating material, specifically made of plastic. The shell 91 is connected with the frame 2 together. The housing 91 is provided with an assembly cavity 911 . A recess 915 is formed in the middle of the bottom wall of the assembly cavity 911 .

[0059] There are two connecting pins 92. The two connecting pins 92 are distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com