Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

465results about How to "Good degree of automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

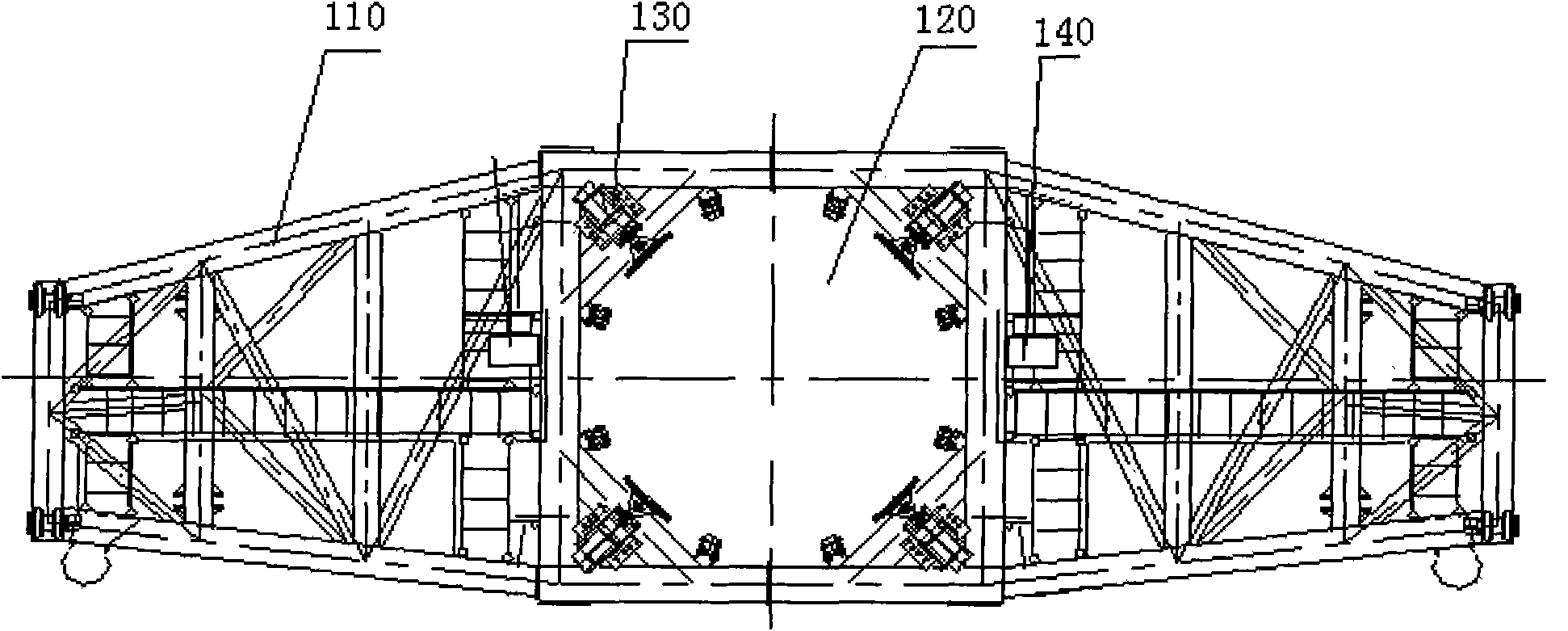

De-burring device for wheel

ActiveCN102975095AAvoid dealing with poorly performing problemsAvoid frequent switchingEdge grinding machinesControl theoryFlange

The invention discloses a de-burring device for a wheel. The de-burring device comprises a frame, an air cylinder, a motor, a corner cylinder and the like. Two lower hairbrushes auto-rotate at the same rotation speed and in different rotation directions and are driven to orbit by a lower motor I at the same time; and similarly, two upper hairbrushes auto-rotate at the same rotation speed and in different rotation directions and are driven to orbit by an upper motor I at the same time. When the de-burring device is used, the automatic rotating hairbrushes can be in contact with all parts capable of being brushed on a rear cavity of the wheel at the respective maximum linear speed; and the problems of low linear speed of the center hairbrushes and poor de-burring effect of the flange corner in the conventional large disc are avoided and the negative influence on the motors due to frequent reversing of the hairbrushes of the conventional disc in the de-burring process is avoided.

Owner:CITIC DICASTAL

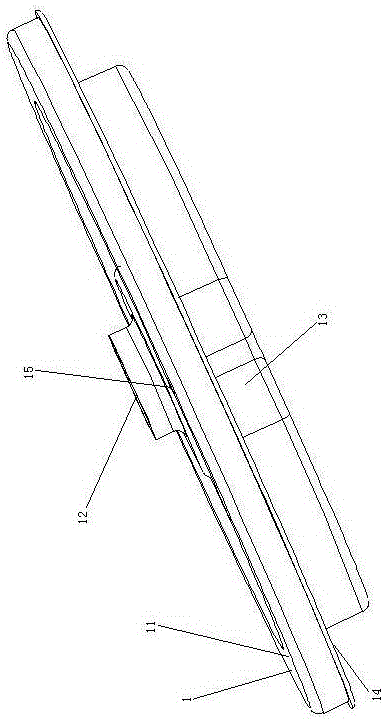

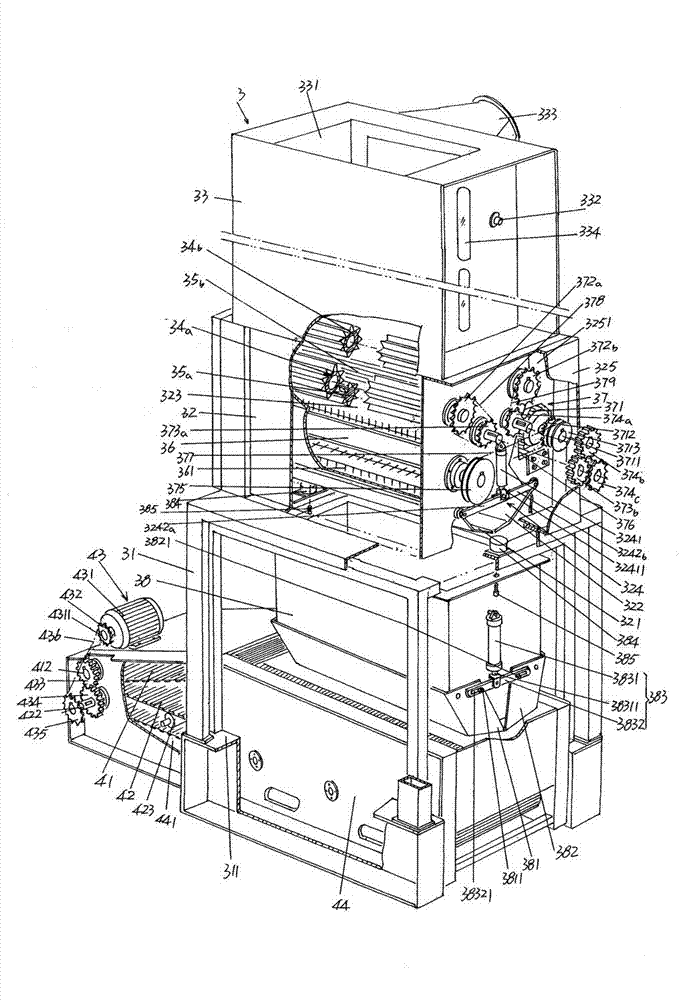

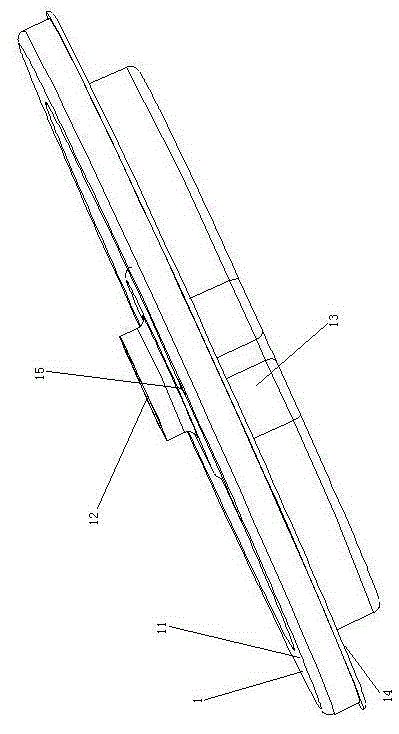

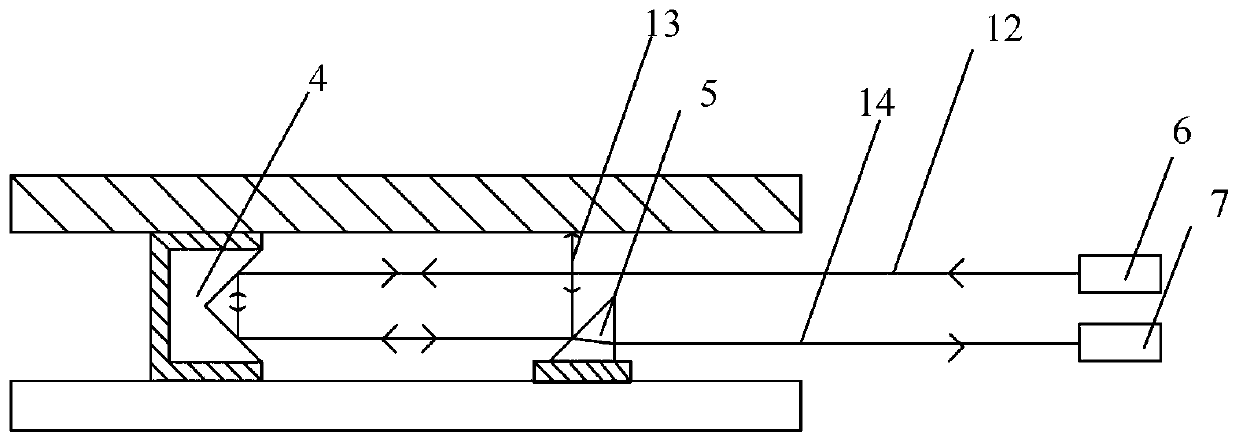

Automatic polishing machine for inner circle of long pipe

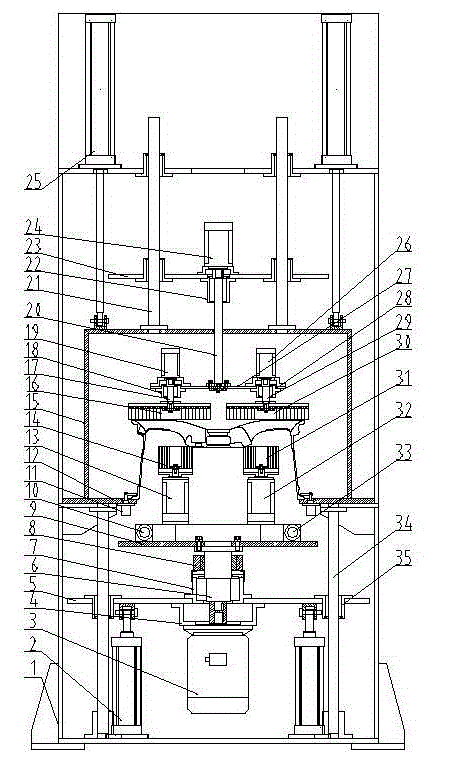

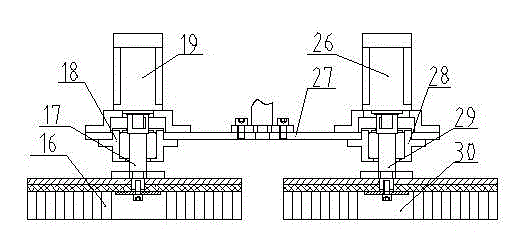

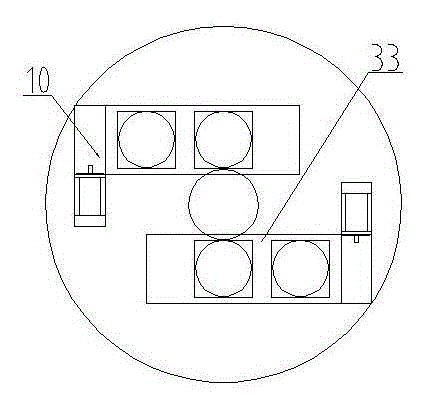

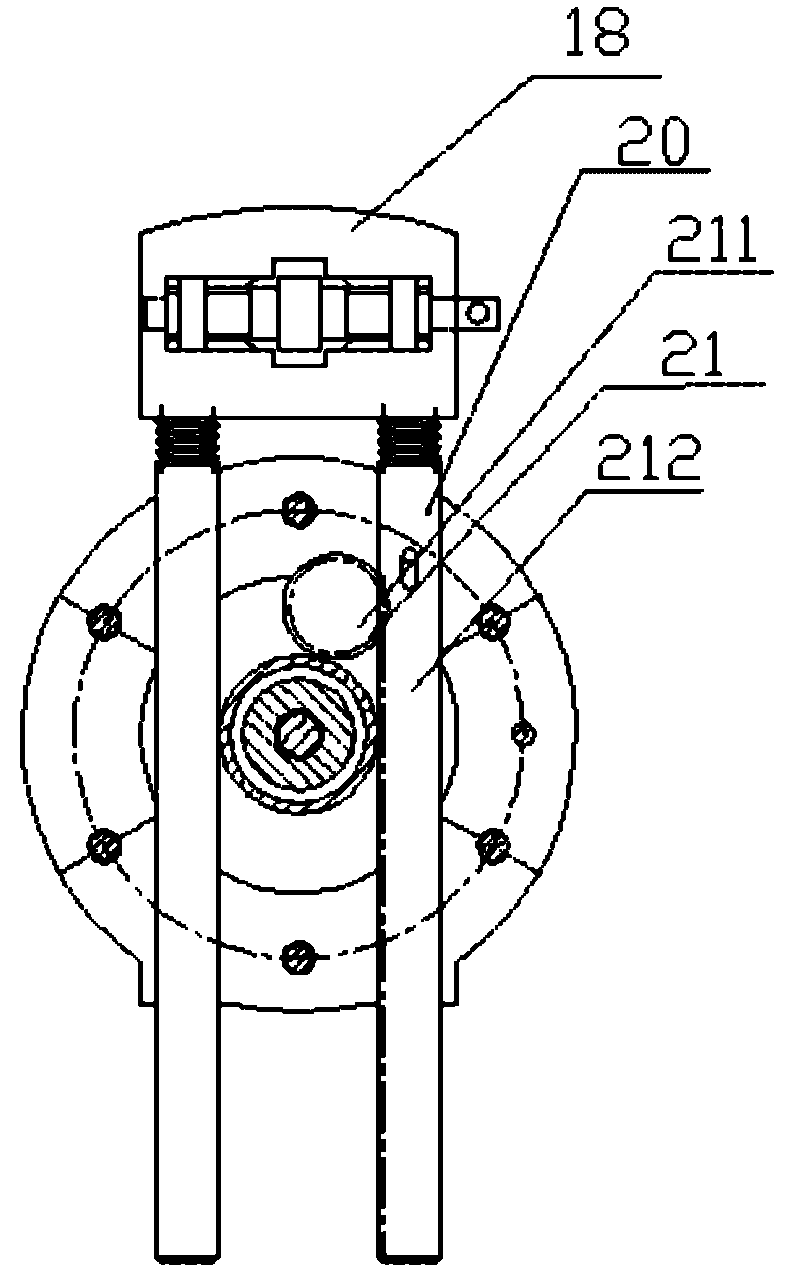

ActiveCN102320027AReduce energy consumptionGood degree of automationPolishing machinesMechanical engineering

The invention discloses an automatic polishing machine for an inner circle of a long pipe. The automatic polishing machine consists of a polishing mechanism and a travelling mechanism. The polishing mechanism consists of a circumferential feeding mechanism and a polishing chuck; the circumferential feeding mechanism is realized by driving a planet gear mechanism through a motor; the polishing chuck consists of an adjusting mechanism and a polishing head clamping mechanism; the adjusting mechanism of the polishing chuck is a gear rack mechanism; and the polishing head clamping mechanism consists of left and right spiral mechanisms and a V-shaped chuck, and can be used for clamping polishing heads of different types. The travelling mechanism mainly consists of an adaptive pipe diameter mechanism and a long pipe axial feeding mechanism; the adaptive pipe diameter mechanism consists of a lead screw and a connecting rod; and in the long pipe axial feeding mechanism, small wheels are drivento rotate by a motor fixed on the connecting rod so as to push the polishing machine to advance in the inner circle of the pipe along the axial pipe axis. The automatic polishing machine is mainly applied to polishing of the inner circle of the relatively long pipe with certain diameter.

Owner:ZHEJIANG UNIV OF TECH

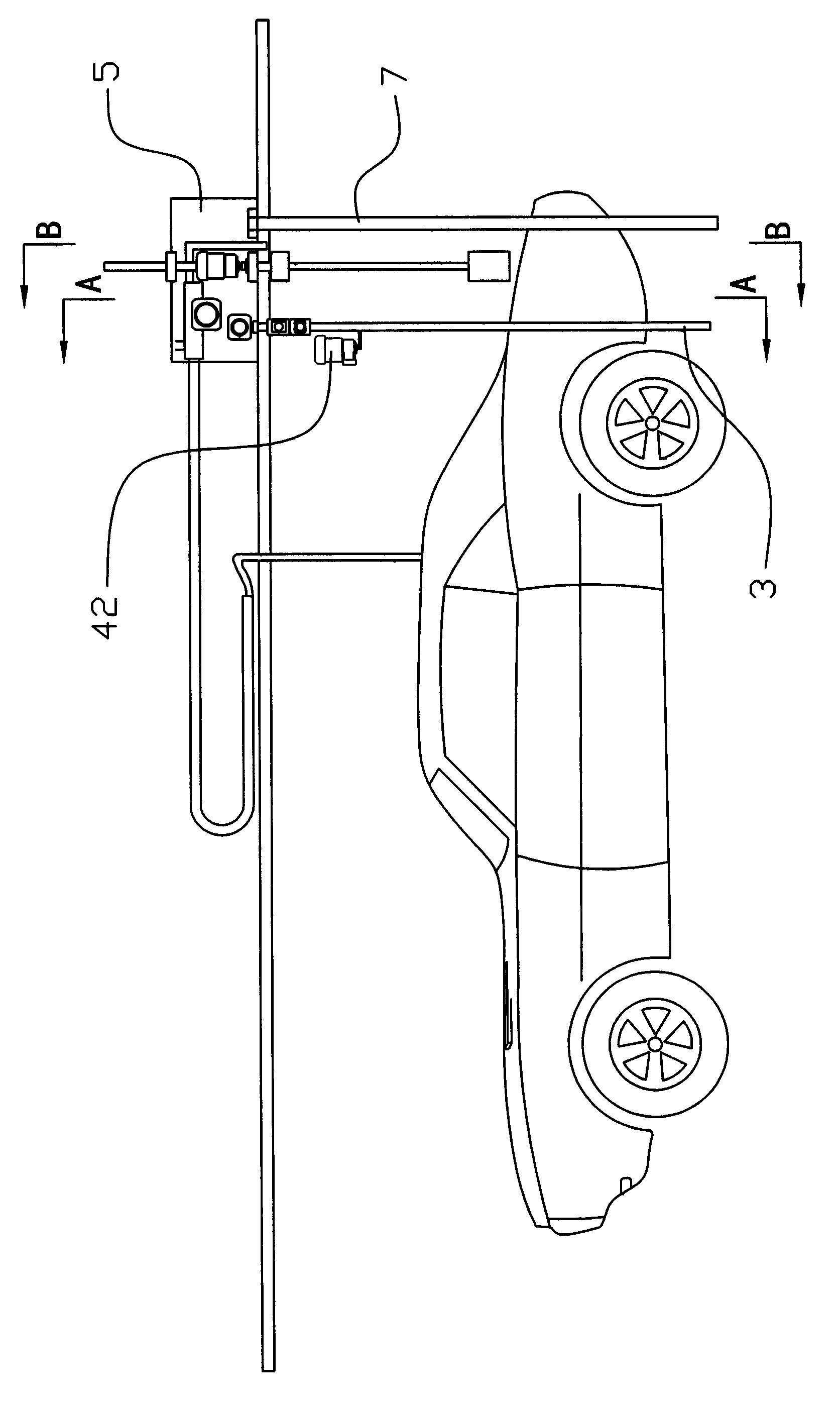

Full-automatic automobile washing device

ActiveCN104290718AShorten cleaning timeCar wash cleanCleaning apparatus for vehicle exteriorsElectric machineryDrive motor

A full-automatic automobile washing device comprises a spraying device. The spraying device comprises a top spraying rod and vertical spraying rods. The left vertical spraying rod and the right vertical spraying rod are each provided with a plurality of shower nozzles in the vertical direction, and the nozzles of the left vertical spraying rod are opposite to the nozzles of the right vertical spraying rod. Shower nozzles with nozzles facing downwards are distributed on the top spraying rod. The spraying rods are each provided with a switching mechanism, and the shower nozzles can be connected with a high-pressure water source and a high-pressure air source. The switching mechanisms can be in linkage with an output shaft of a switching motor. The top spraying rod, the left vertical spraying rod and the right vertical spraying rod are connected with a beam which is arranged on a guide rail in the manner of sliding forwards and backwards through a driving motor, the top spraying rod can be arranged on the beam in an ascending and descending mode through a lifting motor, the left vertical spraying rod and the right vertical spraying rod can be connected with the beam in the manner of moving left and right through respective motors, and the beam is provided with a detecting device which can detect the size of an automobile body. The full-automatic automobile washing device is ingenious and reasonable in structure, high in automation degree and more complete in function, effectively solves the problems of an existing automobile washing machine, and is a very practical automobile washing device.

Owner:绍兴市中令汽车服务有限公司

2D-3D image registration method based on contour coplanar four-point set

ActiveCN107392947AEasy to findEasy Match Transform SolutionImage enhancementImage analysisPoint cloud3d image

The invention discloses a 2D-3D image registration method based on a contour coplanar four-point set, and belongs to the technical field of computer vision. The coplanar four-point set is used as a registration primitive. Firstly a point cloud is perspectively projected along multiple visual angles so as to form multiple images, and point cloud images close to the image photographing visual angle are searched; then when the corresponding points of the coplanar four points on the point cloud image contour are searched in the object image contour points, the similar triangles of the triangles formed by the three points are searched firstly and then the approximate position of the fourth point is searched according to affine transformation of the plane; and finally an image and point cloud transformation matrix is calculated by using the homography of the plane, and the optimal transformation matrix is selected according to the registration accuracy corresponding to registration of each transformation matrix so that 2D-3D initial registration can be completed. Compared with the methods in the prior art, the matching corresponding points are searched on the contour so that the method is relatively reliable and simple and great in overall degree of automation of the algorithm.

Owner:XIDIAN UNIV

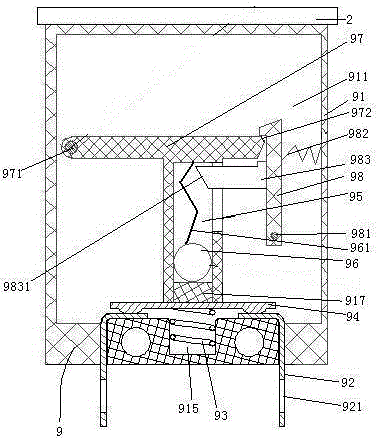

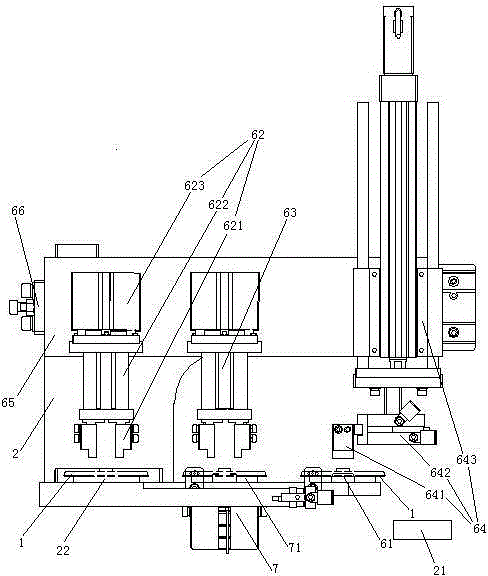

Motor end cover assembly machine

ActiveCN105099105ARealize automated assemblyGood degree of automationManufacturing dynamo-electric machinesEngineeringAssembly machine

The invention relates to a device for motor production. A motor end cover assembly machine comprises a rack, wherein the rack is provided with a motor shell fixing structure, a motor end cover storage mechanism, a separation mechanism and a motor end cover pre-installation mechanism, the motor end cover storage mechanism is provided with a vertically-arranged motor end cover penetrating connection rod, the separation mechanism is used for separating motor end covers sleeved on the motor end cover penetrating connection rod one by one, and the motor end cover pre-installation mechanism is used for transferring and assembling the motor end covers separated by the separation mechanism onto a motor shell arranged in the motor shell fixing structure. The invention provides a motor end cover assembly machine by which the motor end covers can be installed on motor shell, and the problems of labor waste existing in manual assembly of the motor end covers and low automatic degree are solved.

Owner:TONGXIANG SHENGHUI PRECISION MACHINERY

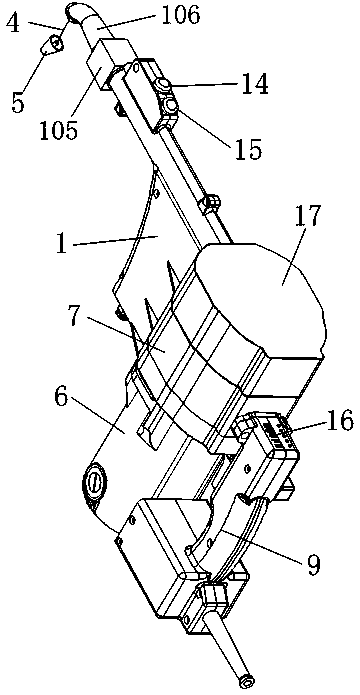

Automatic elastic sewing machine

InactiveCN105568568APerfect structure and functionControllable running strokeProgramme-controlled sewing machinesWork-feeding meansManipulatorControl mode

The invention discloses an automatic elastic sewing machine, which comprises a feeding device, a pull device, a turnover manipulator device, a feeding guide rail device and a sewing device, wherein the feeding device and the pull device are arranged at two ends of the turnover manipulator device respectively; the turnover manipulator device is connected and fixed with the feeding guide rail device; the feeding device is used for conveying an elastic band; a clamping mechanism of the pull device is used for clamping the end part of the elastic band at a discharge opening; the pull device drives the elastic band to displace and to pass through a first clamp and a second clamp of the turnover manipulator device under auxiliary feeding of the feeding device; the elastic band is cut off through a blanking mechanism; two ends of the elastic band are rotated for fixing; and the feeding guide rail device drives the elastic band to displace to the lower end of a needle head of the sewing device for sewing. According to the automatic elastic sewing machine, through improvement of the turnover manipulator device, the pull device and the feeding guide rail device in control mode and structure, the running stroke is controllable; the automatic degree is relatively good; the operation is convenient; and the production efficiency is greatly improved.

Owner:台州安卓缝纫机有限公司

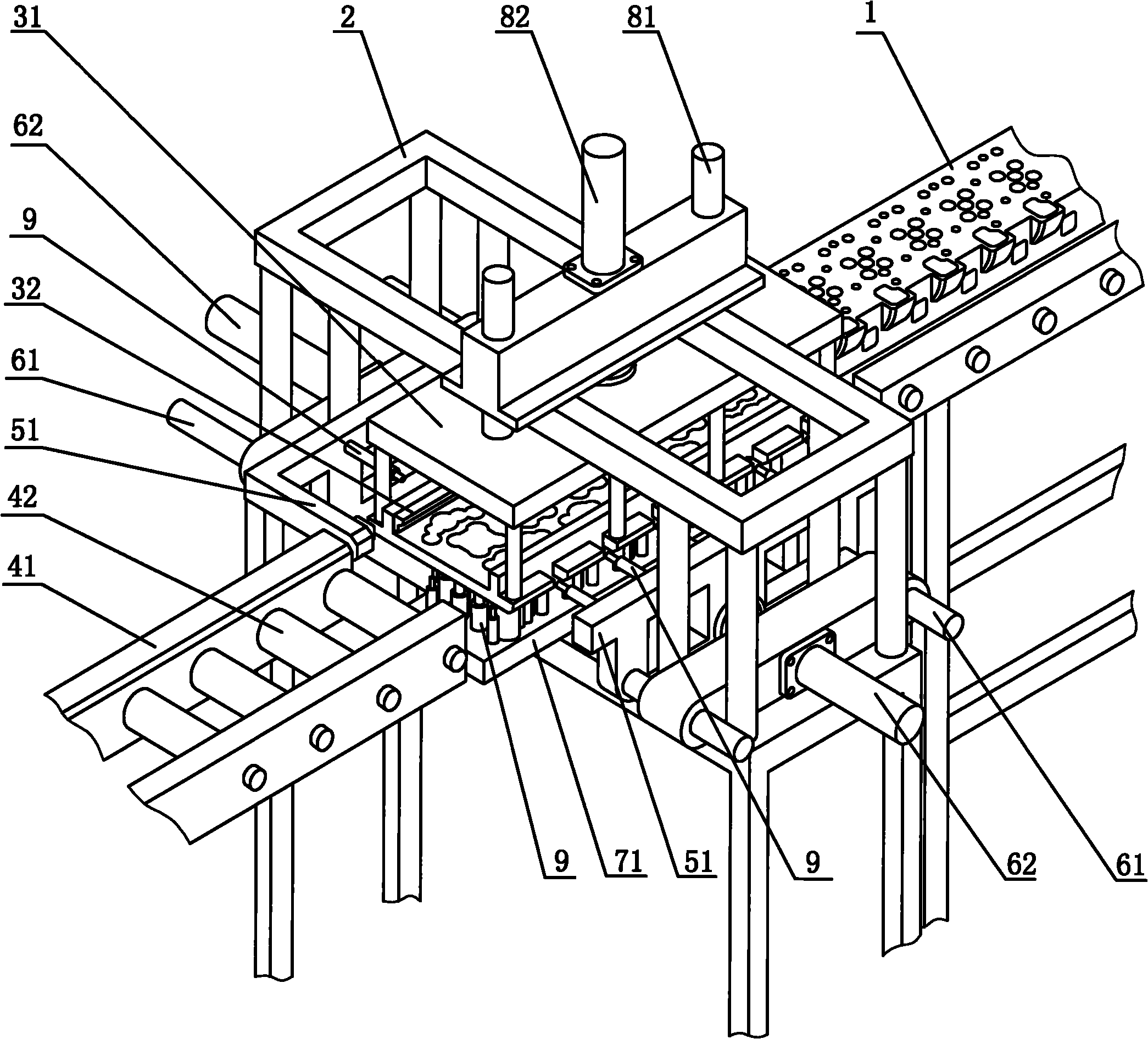

Automotive upholstery pre-shaping machine adopting air filling method

The invention provides an automotive upholstery pre-shaping machine adopting an air filling method, belonging to the technical field of automotive upholstery production devices. The automotive upholstery pre-shaping machine adopting the air filling method comprises a pre-shaping box, an airflow circulation mechanism, a fiber weighing and measuring mechanism, a fiber conveying mechanism and a hot air generation mechanism, wherein a box cover is formed on the top part of the pre-shaping box; an aspiration pipe adapting port is connected with the top of the box cover in a matching way; a box chamber opening / closing mechanism is arranged on one side of the pre-shaping box; a pre-shaping mould is arranged on the top of a box chamber; an aspiration hole is opened in the pre-shaping mould; a fiber feeding mechanism is arranged on the bottom of the pre-shaping box; the hot air generation mechanism is connected with the airflow circulation mechanism by a pipeline; and the airflow circulation mechanism comprises a working motor, a fan, an aspiration pipe, an air supply pipe, a connection cotton box and a cotton guide box. The automotive upholstery pre-shaping machine adopting the air filling method has the advantages that the quality of automotive upholsteries which are pressed and shaped by subsequent pressing processes can be reliably guaranteed, the overall structure is simple, and the labor intensity is decreased for workers; the processing efficiency is high and the energy is saved; and in addition, fibers with a low melting point are vitrified, so that the prototypes of the automotive upholsteries are formed.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

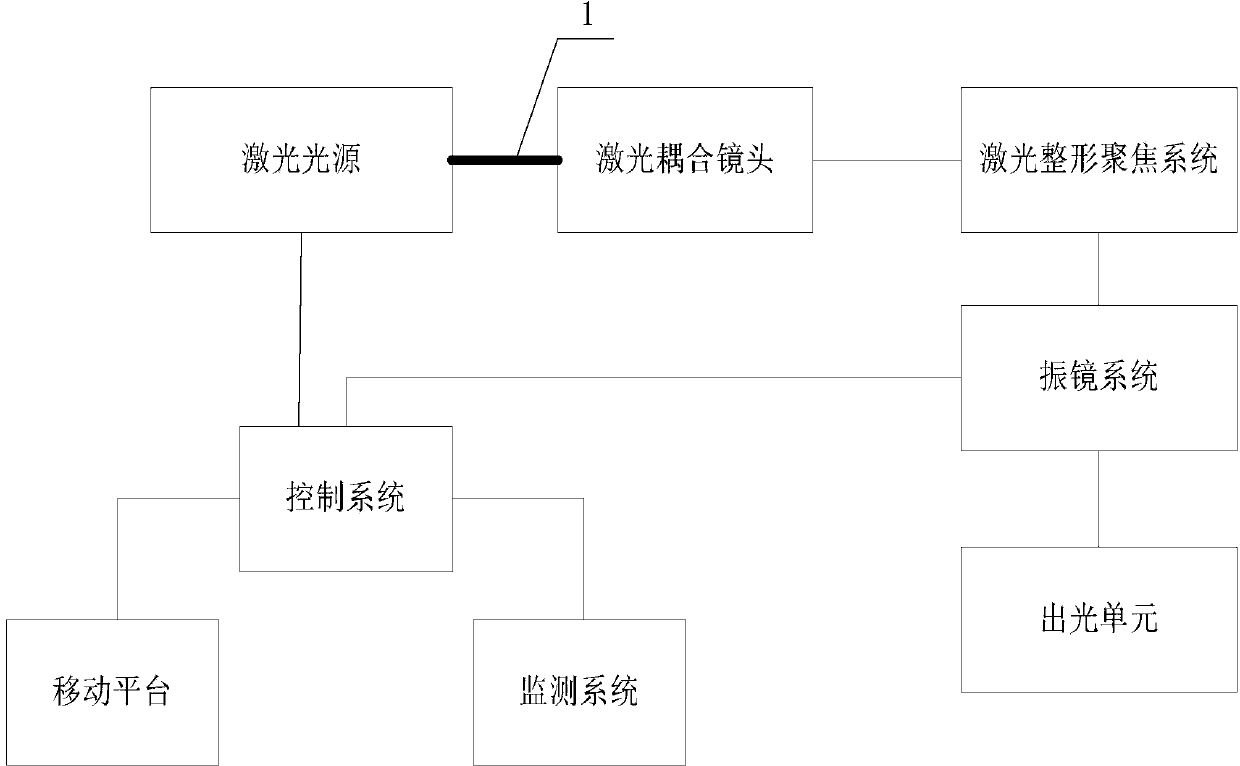

Fiber laser cleaning machine

InactiveCN104259142ACause damageAvoid secondary pollutionCleaning processes and apparatusControl systemMonitoring system

The invention relates to the technical field of laser equipment, in particular to a fiber laser cleaning machine. The fiber laser cleaning machine comprises a laser system, a laser transmission system, a light beam adjusting system, a dust collecting system, a monitoring system, a control system and a mobile platform. The light beam adjusting system, the dust collecting system and the monitoring system are arranged on the mobile platform. The laser system is connected with the laser transmission system; and the light beam adjusting system is arranged at the front end of the laser transmission system. An air port of the dust collecting system is formed in the front side of a workpiece. The monitoring system is connected with the control system; and the control system is connected with the light beam adjusting system, the dust collecting system and the mobile platform. The fiber laser cleaning machine, provided by the invention, has the advantages of good cleaning effect, high efficiency and high automation degree. The fiber laser cleaning machine, provided by the invention, cannot damage the workpiece. In addition, the fiber laser cleaning machine, provided by the invention, is further provided with the dust collecting system, so that impurities generated in the cleaning can be timely absorbed to prevent the cleaned workpiece from generating secondary pollution.

Owner:武汉和骏激光技术有限公司

Automotive upholstery pre-shaping machine adopting air filling method

The invention provides an automotive upholstery pre-shaping machine adopting an air filling method, belonging to the technical field of automotive upholstery production devices. The automotive upholstery pre-shaping machine adopting the air filling method comprises a pre-shaping box, an airflow circulation mechanism, a fiber weighing and measuring mechanism, a fiber conveying mechanism and a hot air generation mechanism, wherein a box cover is formed on the top part of the pre-shaping box; a box chamber opening / closing mechanism is arranged on one side of the pre-shaping box; a pre-shaping mould is arranged on the top of a box chamber; an aspiration hole is opened in the pre-shaping mould; a fiber feeding mechanism is arranged on the bottom of the pre-shaping box; the airflow circulation mechanism is connected with the box cover in a matched way, and further stretches to the bottom of a pre-shaping box frame; the fiber weighing and measuring mechanism is arranged on the terrace of a use place or configured on a support on the terrace; the fiber conveying mechanism is connected with the fiber weighing and measuring mechanism, and connected with the airflow circulation mechanism as well; and the hot air generation mechanism is connected with the airflow circulation mechanism by a pipeline. The automotive upholstery pre-shaping machine adopting the air filling method has the advantages that the density of a fiber cotton layer which is adsorbed onto the pre-shaping mould can be enabled to be consistent; the overall structure is simple, and moreover, the ideal automation degree can be reflected, and the labor intensity is decreased for workers; and additionally, the processing efficiency is ideal and the energy is saved.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

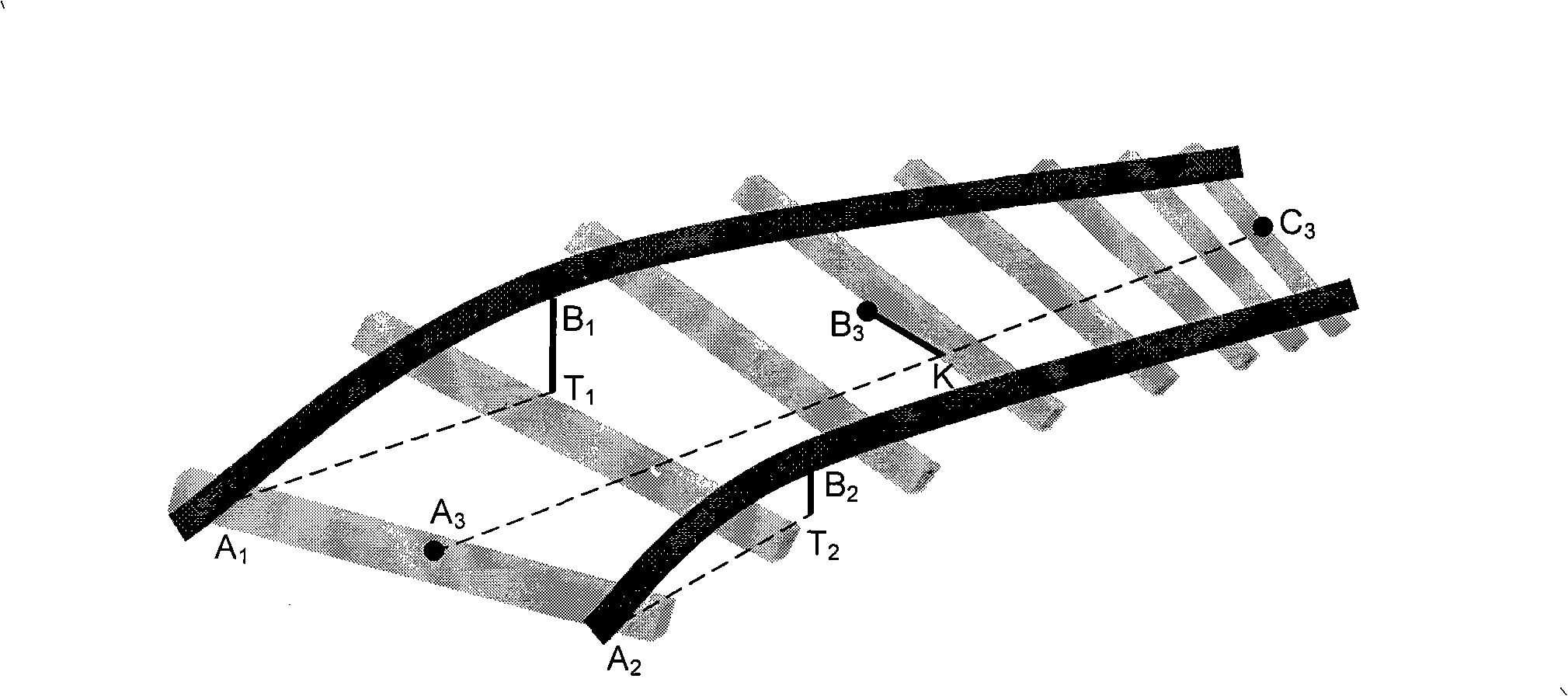

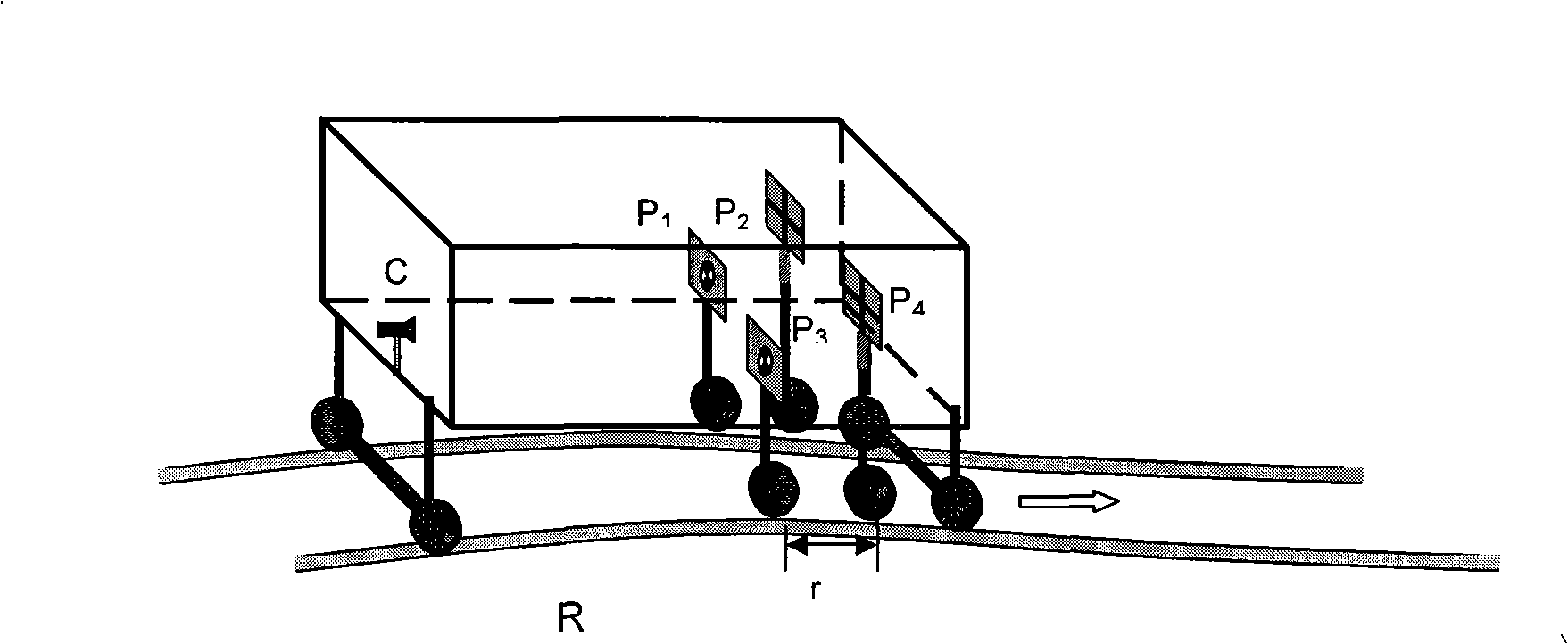

Camera shooting measuring method for track geometric parameter

InactiveCN101314932AImprove the level ofEasy to operatePhotogrammetry/videogrammetryUsing optical meansImaging processingOptical axis

A method for measuring geometric parameters of a track by adopting a camera comprises the following steps: a measuring vehicle is placed on the track to be measured; a camera device is fixedly installed on one end inside the measuring vehicle; an optical axis of the camera device is in parallel with the plane of the bottom of the measuring vehicle; two sign posts are arranged on the track at the other end inside the measuring vehicle and are respectively perpendicular to the two sides of the plane of the bottom of the measuring vehicle; the two sign posts are at different heights and at the distance of r; a cooperation sign is arranged at the top end of each sign post; the sign posts can only move in the direction perpendicular to the plane of the bottom of the vehicle and in the transversal direction; a wheel at the bottom of the sing post moves, and is tightly attached to the inner side of a steel track; when the measuring vehicle moves on the track to be measured, the camera device is utilized to capture images of the cooperation signs at different time; and the images is processed through image processing and data processing on a real-time basis so as to acquire the geometric parameters of the track. The method meets the requirements of modern track construction and development, satisfies the requirements of high precision, high reliability and high automatic degree detection, and has good application prospect in the railroad engineering field.

Owner:张小虎 +3

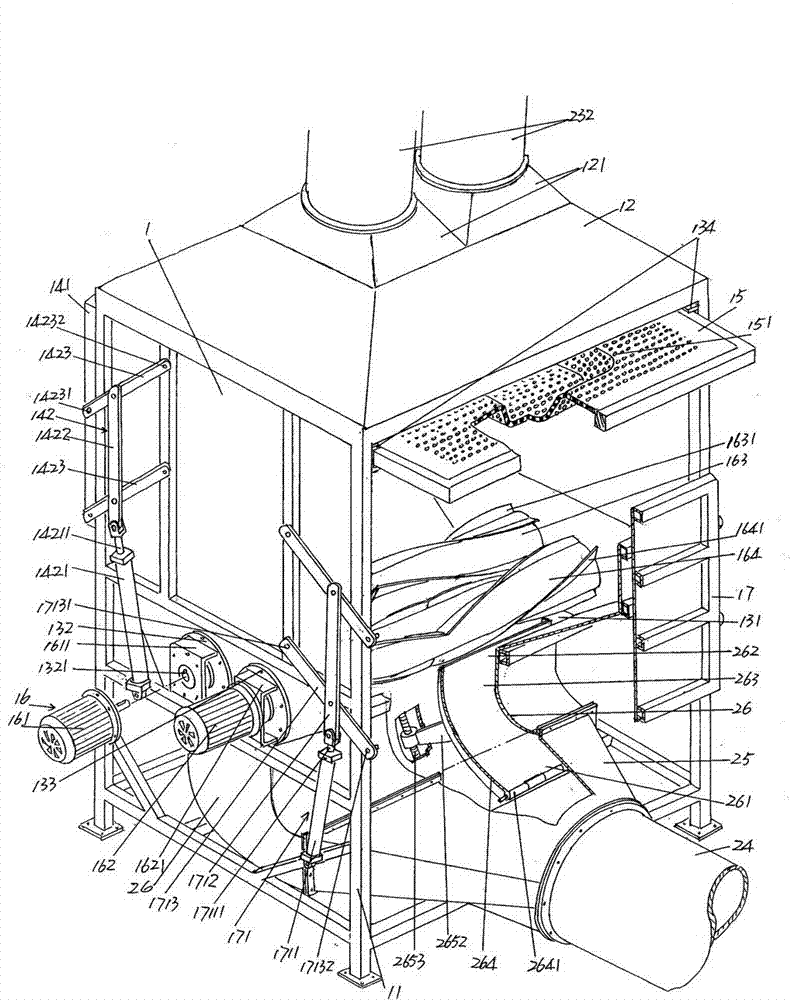

Automotive upholstery pre-shaping machine

ActiveCN102776718AEnsure consistencyQuality assuranceFelting apparatusElectric machineryProcess engineering

The invention provides an automotive upholstery pre-shaping machine, belonging to the technical field of automotive upholstery production devices. The automotive upholstery pre-shaping machine comprises a pre-shaping box, an airflow circulation mechanism, a fiber weighing and measuring mechanism and a hot air generation mechanism, wherein a box cover is formed on the top part of the pre-shaping box; a box chamber opening / closing mechanism is arranged on one side of the pre-shaping box; a pre-shaping mould is arranged on the top of a box chamber; an aspiration hole is opened in the pre-shaping mould; a fiber feeding mechanism is arranged on the bottom of the pre-shaping box; the airflow circulation mechanism is connected with the box cover in a matched way; the fiber weighing and measuring mechanism is arranged on a terrace; the hot air generation mechanism is connected with the airflow circulation mechanism by a pipeline; and the airflow circulation mechanism comprises a working motor, a fan, an aspiration pipe, an air supply pipe, a connection cotton box and a cotton guide box. The automotive upholstery pre-shaping machine has the advantages that the quality of automotive upholsteries which are pressed and shaped by subsequent pressing processes can be reliably guaranteed, the overall structure is simple, and the labor intensity is decreased for workers; and additionally, the processing efficiency is ideal and the energy is saved.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

Automatic cleaning device for inner hole of cylinder cover

InactiveCN101982651ASuitable for mass productionSmall pressure lossMachines/enginesEngine componentsBatch productionEngineering

The invention discloses an automatic cleaning device for an inner hole of a cylinder cover, which is used for cleaning the inner hole of the cylinder cover. The automatic cleaning device comprises a rack; a cylinder cover cleaning bracket is arranged on the rack; the cylinder cover cleaning bracket is provided with a cylinder cover feeding end and a cylinder cover discharge end; the cylinder cover feeding end and the cylinder cover discharge end are connected with a cylinder cover conveying device respectively; at least one telescopic cleaning device capable of extending to the inner hole of the cylinder cover for cleaning is arranged on the rack; and a telescopic driving device is arranged between the telescopic cleaning device and the rack. The cylinder cover enters the cylinder cover cleaning bracket through the cylinder cover conveying device, and the spray head part of each cleaning device enters the inner hole of the cylinder cover to perform spraying and cleaning, so the cleaning time is short and the cleaning efficiency is high; the cleaning solution is directly sprayed onto the hole wall in the inner hole of the cylinder cover, so the pressure loss of the cleaning solution is extremely low, and the cleaning effect is good; and the whole cleaning process does not need manual operation and has high automation degree. The automatic cleaning device has the advantages of high automation degree, good cleaning effect, high cleaning efficiency and suitability for large-batch production.

Owner:潍坊浩泰机械有限责任公司

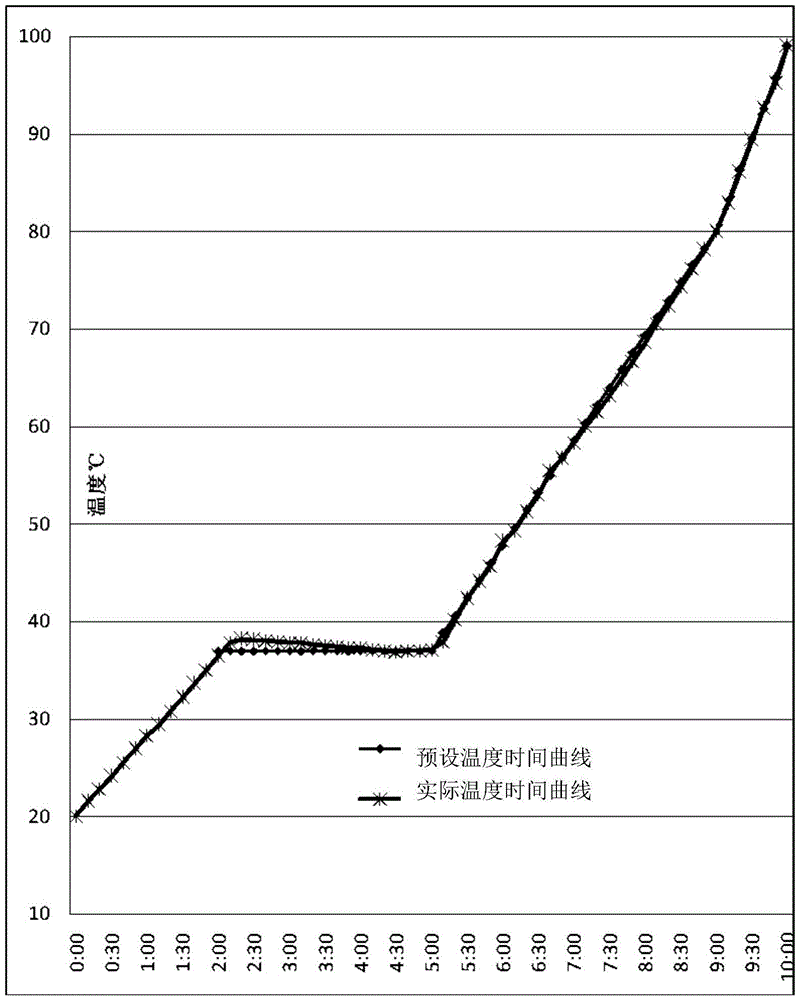

Heating method and heater

ActiveCN104955178AHigh intelligenceLow failure rateOhmic-resistance heatingHeating timeComputer module

The invention discloses a heating method and a heater. The heater comprises a weight detecting module, a timing module, a temperature detecting module, an input module and a processing module, the temperature detecting module is used for detecting temperature of a to-be-heated material, the input module is used for inputting a preset temperature-time curve which represents a corresponding relationship between different target temperature values and heating time of the to-be-heated material, and the processing module is connected with a heating part, the weight detecting module, the timing module, the temperature detecting module and the input module. The heater is conducive to energy conservation, fault rate of the heater is lowered, and service life of the heater is prolonged. Automation level and intelligent level of the heater are improved, standardization of heating processes is facilitated, and product quality stability can be improved due to reduction of artificial factors. Procedure for optimizing the heating processes is simplified, and optimization can be completed by modifying the preset temperature-time curve.

Owner:孙昊

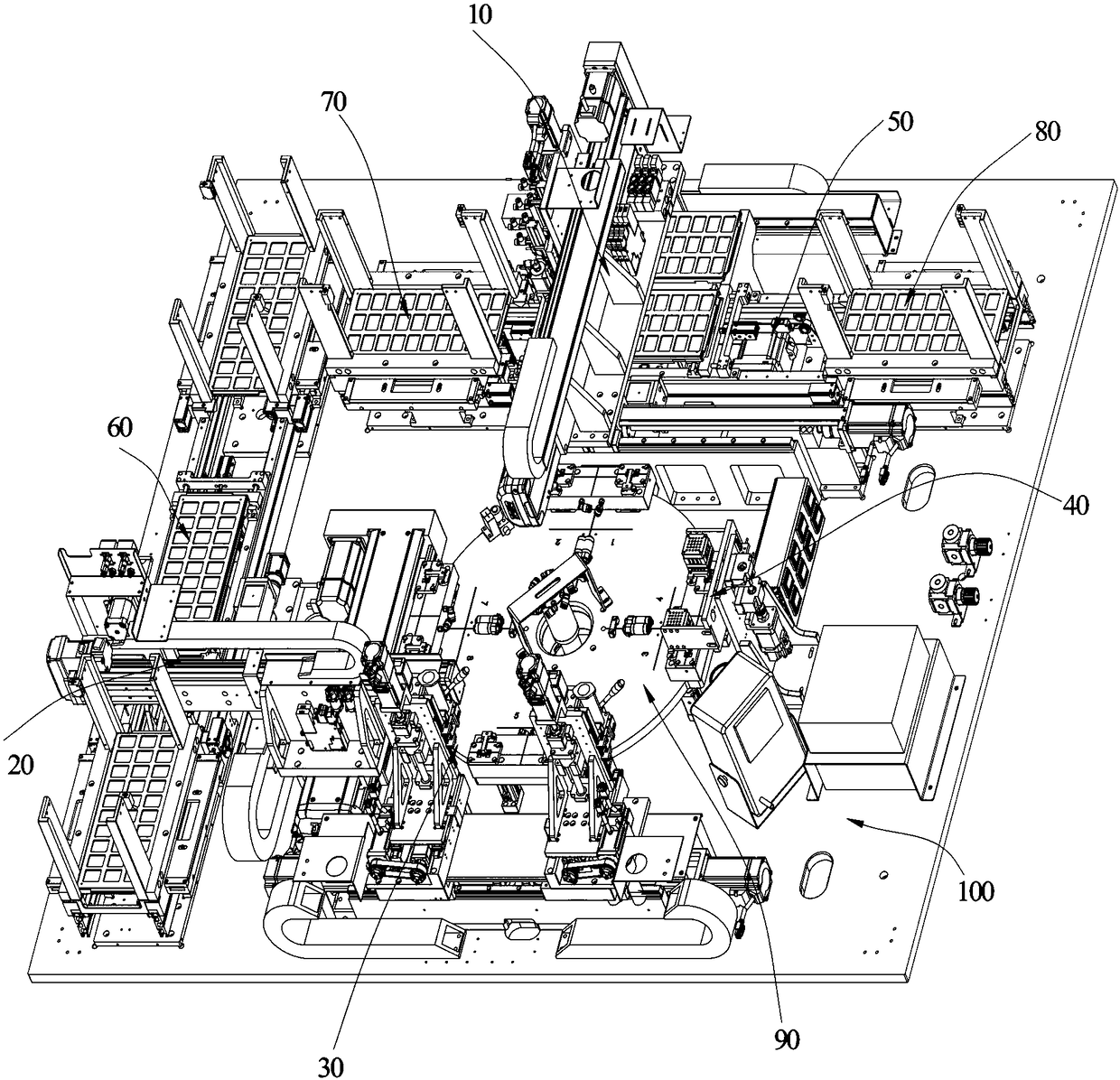

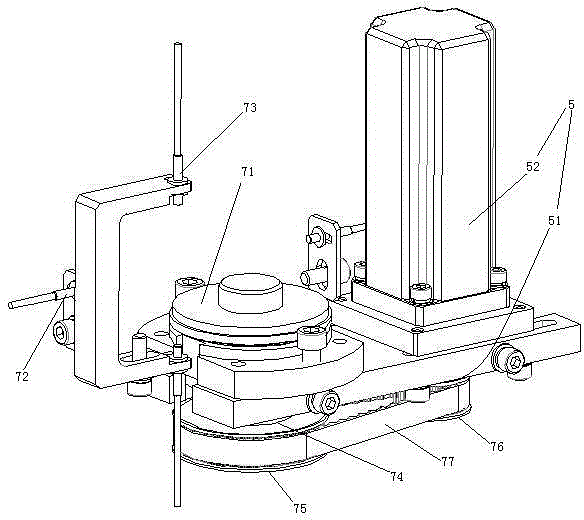

Automatic camera assembling machine

PendingCN108526886AGood degree of automationImprove assembly efficiencyAssembly machinesAdhesiveManipulator

The invention discloses an automatic camera assembling machine. The automatic camera assembling machine comprises a machine frame, a first manipulator, a second manipulator, a dispensing mechanism anda curing mechanism, wherein a rotary plate, a first fetching station, a second fetching station, a dispensing station and a curing station are arranged on the machine frame; the rotary plate is pivoted to the machine frame; the first fetching station, the second fetching station, the dispensing station and the curing station are located on the rotation track of the rotary plate and distributed along the center axis of the rotary plate in the circumferential direction at intervals; the rotary plate is provided with a workpiece carrier table; the first manipulator is arranged at the first fetching station and used for clamping a first workpiece to the workpiece carrier table; the second manipulator is arranged at the second fetching station and used for clamping a second workpiece to the workpiece carrier table; the dispensing mechanism is arranged at the dispensing station and used for carrying out dispensing between the first workpiece and the second workpiece on the workpiece carriertable; and the curing mechanism is arranged at the curing station and used for curing adhesive between the first workpiece and the second workpiece on the workpiece carrier table. By means of the automatic camera assembling machine, the first workpiece and the second workpiece can be sequentially fed, dispensed and cured automatically.

Owner:深圳眼千里科技有限公司

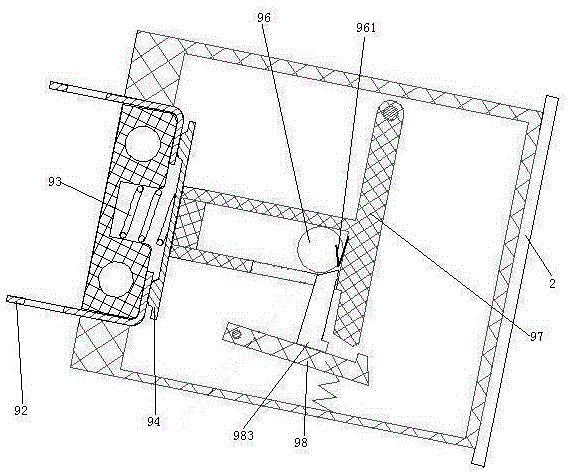

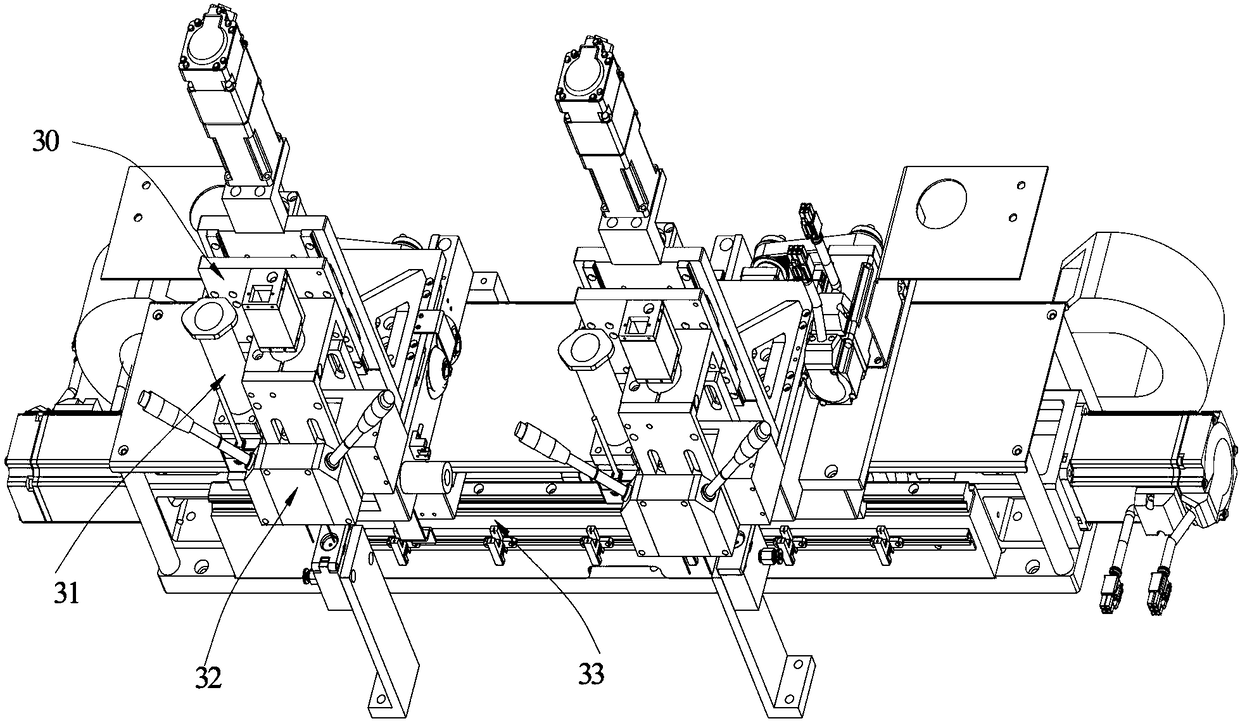

Preassembling mechanism for motor end cap

ActiveCN105048734ARealize automated assemblyGood degree of automationManufacturing dynamo-electric machinesEngineeringManipulator

The invention relates to the technical field of motor production equipment. A preassembling mechanism for a motor end cap comprises a frame with a discharging position, a motor housing fixing structure, a second motor end cap supporting block and a motor end cap aligning mechanism with a first motor end cap supporting block, a first manipulator shifting the motor end cap from the discharging position to the first motor end cap supporting block, a second manipulator shifting the motor end cap from the first motor end cap supporting block to the second motor end cap supporting block and a third manipulator shifting the motor end cap from the second motor end cap supporting block and installing onto a motor housing in the motor housing fixing structure. The invention provides a preassembling mechanism for preassembling the motor end cap onto the motor housing, and solves the problem that manual assembling of motor end cap is labor consuming and is low in automation level.

Owner:TONGXIANG SHENGHUI PRECISION MACHINERY

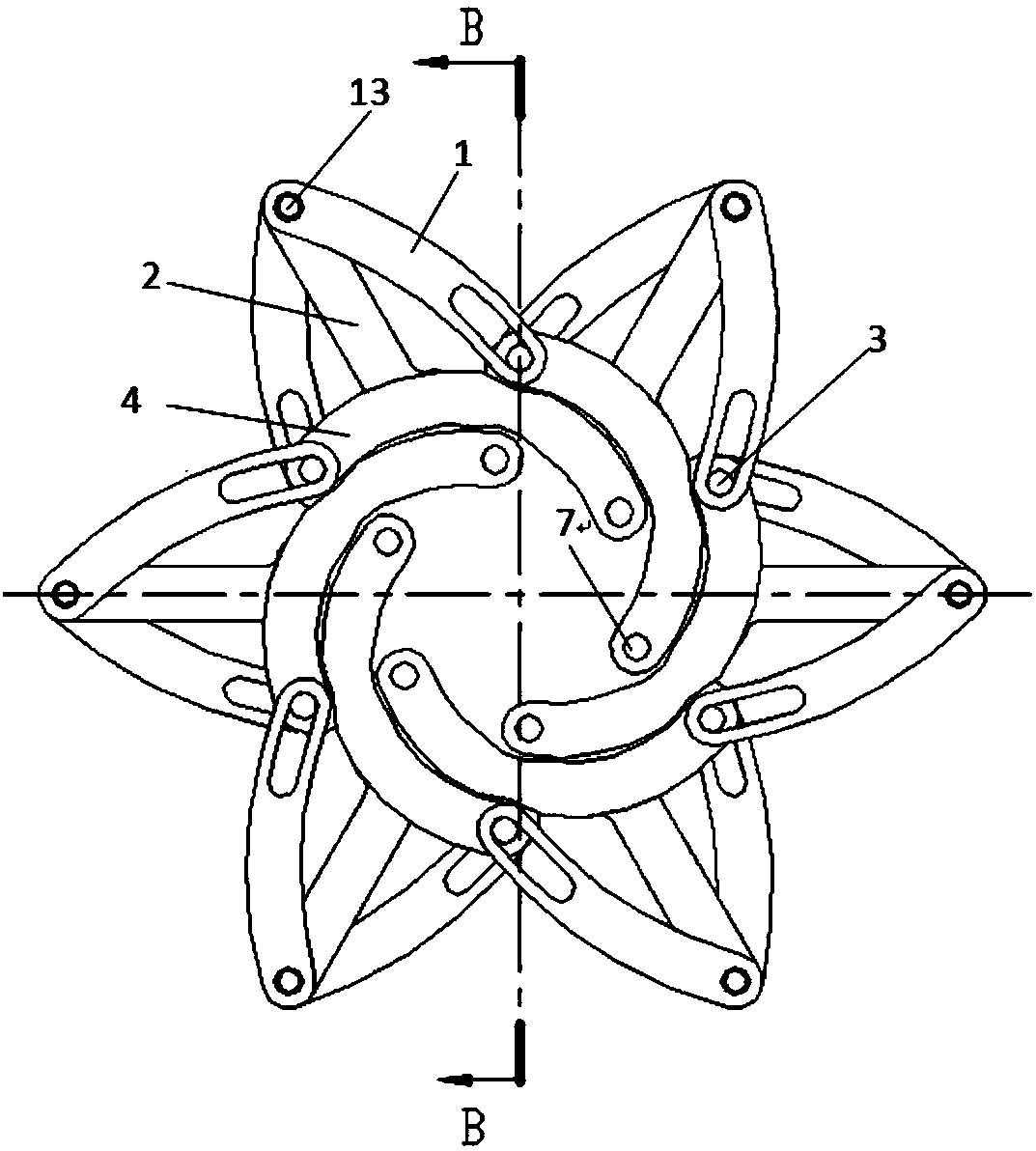

Deformable wheel capable of climbing stairs

ActiveCN108403318ACompact structureGuaranteed StrengthWheelchairs/patient conveyanceWheelsEngineeringClimbs stairs

The invention discloses a deformable wheel capable of climbing stairs. The wheel comprises an outer wheel hub and an inner wheel hub which are coaxially arranged and can relatively rotate; the outer edge of the outer wheel hub is evenly and fixedly provided with a plurality of fixed spokes, and wheel flanges are hinged to the two sides of the top of each fixed spoke respectively; every two adjacent wheel flanges are connected through a sliding groove and sliding pin structure; movable spokes the number of which is equal to that of the fixed spokes on the outer wheel hub are hinged to the innerwheel hub, and the other end of each movable spoke is connected with the two corresponding wheel flanges through the corresponding sliding groove and sliding pin structure. The inner wheel hub is controlled to rotate relative to the outer wheel hub, each movable spoke drives movable ends of the two corresponding wheel flanges to be folded or unfolded, all the wheel flanges can be changed into a pointed gear shape or a circular shape, and therefore the purpose of automatic conversion between the mode of walking on the ground and the mode of walking up and down stairs is achieved. The wheel hasthe advantages that the structure is compact, the strength is ensured, the stability is good, the functions are easy to achieve, the automation degree and followability are high, and the applicationrange is wide.

Owner:XIAN UNIV OF TECH

Deployment method of sensor nodes for manufacturing internet of things

InactiveCN103916871AAvoid situations where coverage cannot be adjustedImprove efficiencyNetwork topologiesHigh level techniquesGraphicsThe Internet

The invention discloses a deployment method of sensor nodes for manufacturing the internet of things. The sensor nodes are randomly deployed in a detection area; the sensor nodes broadcast information around, and all the sensor nodes can be communicated through information exchange and collection; hot spot location dynamic changes in the area are detected, location dissections of the sensor nodes are calculated according to hot spot location dynamic deployment and an MV-Voronoi method, the position of the maximum weight point is looked for in a dissection area of the sensor nodes, the sensor nodes gradually move to hot spot locations, the hot spot locations are determined, and a hot spot MV-Voronoi covering area is determined; if the weight value of a new hot spot MV-Voronoi covering area is larger than that of the hot spot MV-Voronoi covering area, the sensor nodes move to new hot spot locations. The deployment method is high in efficiency, low in energy consumption and high in automation degree, the density of the nodes is controllable, and a deployment graph having a moving characteristic is formed.

Owner:GUANGDONG UNIV OF TECH

Improved full-automatic threading apparatus

ActiveCN103825227APrevent clumps from knottingSolve problems encountered in actual useApparatus for laying cablesElectric machineTransmitted power

The invention discloses an improved full-automatic threading apparatus, comprising an air feeding mechanism, a lead tube, a take-up and pay-off mechanism, a guide line, a bullet, a motor, a limiting shutdown assembly, and a control system, wherein the air feeding mechanism is externally connected with an air compressor and transmits power to threading; the lead tube is arranged inside the air feeding mechanism; the take-up and pay-off mechanism corresponds to the position of the rear end of the lead tube; one end of the guide line is fixed and wound on the take-up and pay-off mechanism and the other end penetrates to an air outlet of the air feeding mechanism through the lead tube; the bullet is connected to one end of the guide line penetrating out of the lead tube; the motor provides take-up and pay-off power; the limiting shutdown assembly is arranged at the front part of the air feeding mechanism and connected with the front part of the lead tube. The previous generation of equipment is modified and innovated, the functions of paying off and taking up a clutch structure, wireless remote control and the like are added, the improved full-automatic threading apparatus is more reasonable to use, simpler and more convenient to control, the motive power mode, the original limit mechanism and the structure of the original wire-draw plate are also optimized, an excellent limiting shutdown function and the functions of fairing lines, arranging lines and paying off and taking up lines are achieved, and winding and knotting of the guide line in the take-up and pay-off processes are effectively prevented.

Owner:谢位强

Method for preparing solar array electrode by electro-brush plating

ActiveCN101789468AImprove conversion efficiencyImprove collection effectFinal product manufactureSemiconductor devicesElectrical resistance and conductanceSilicon solar cell

The invention discloses a method for preparing a silicon solar array electrode by electro-brush plating, which comprises the steps of: (1) coating of a protective film; (2) laser grooving; (3) surface activation treatment; (4) electro-brush plating: a general electroplating power supply is adopted; a cathode of the power supply is connected with a pretreated silicon semiconductor; an anode of the power supply is connected with an plating pen immersed with a plating solution; the power supply is started; the electro-brush plating is carried out on the plating pen on the surface of the pretreated silicon semiconductor; and the plating pen is a mobile plating pen or a pictographic plating pen; and (5) the removal of the protective film. The invention obviously enhances the production efficiency by adopting the electro-brush plating and realizes the preparation of the array electrode within a shorter time; the prepared electrode is uniform and bright; at the same time, the electroplating bath solution has easy maintenance; the electrode has high bonding strength with a base body and plating layers have high bonding force, thereby reducing contact resistance between the base body and a conducting wire; and the invention has good automatic degree, high electroplating speed, simple technological operation, easy mastery, relatively lower cost, high efficiency and less required tooling equipment.

Owner:SOUTH CHINA NORMAL UNIVERSITY

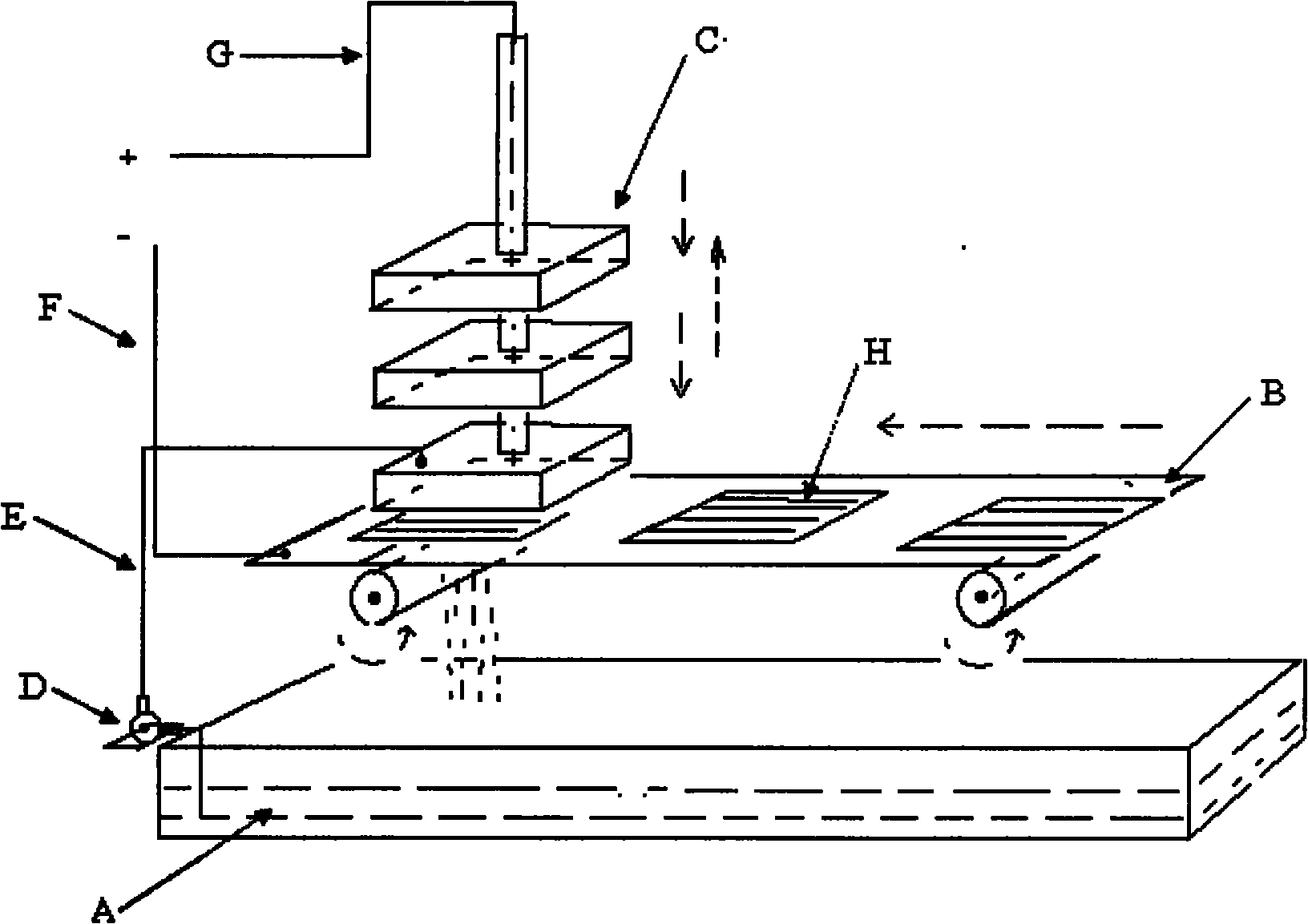

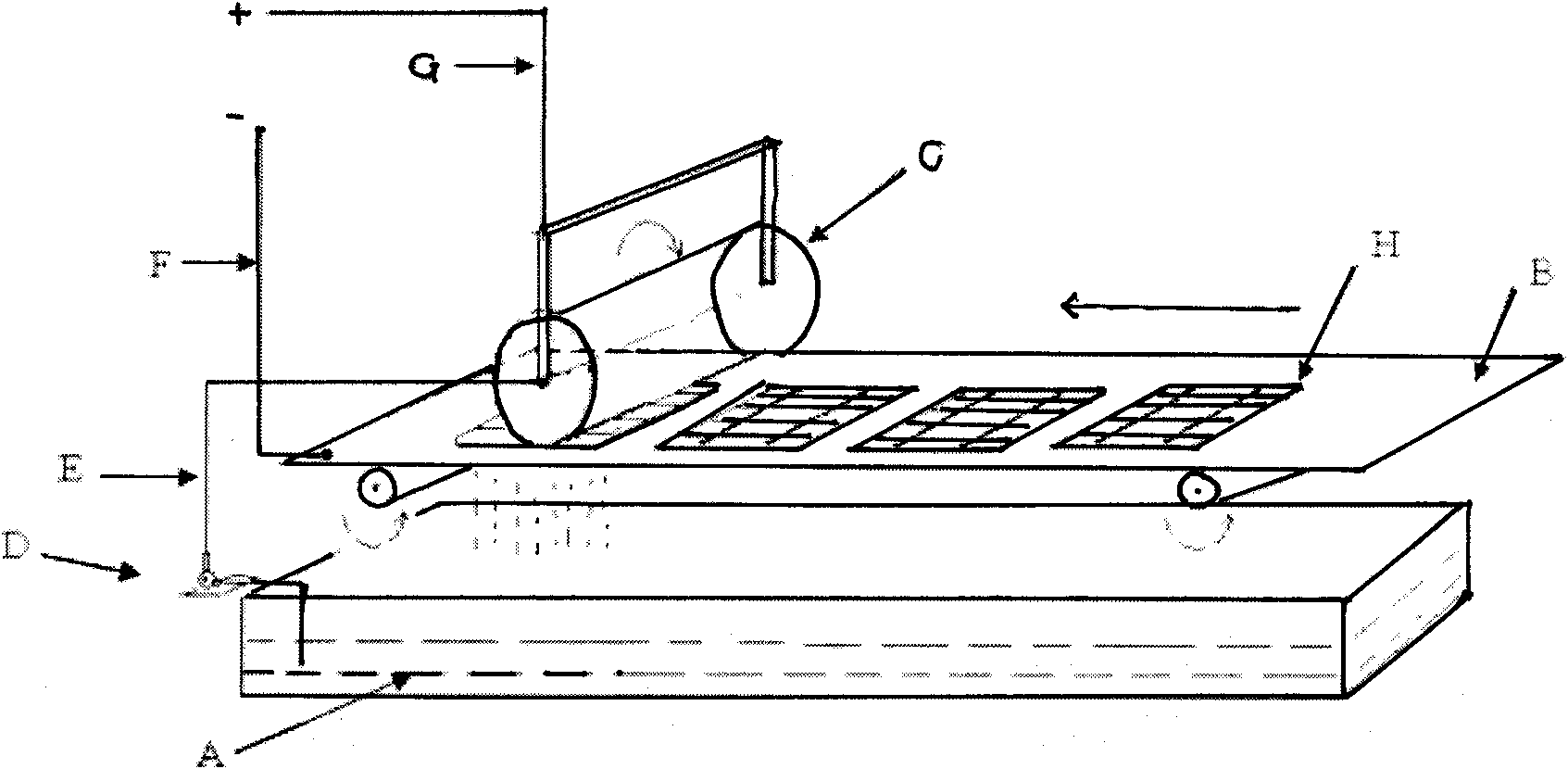

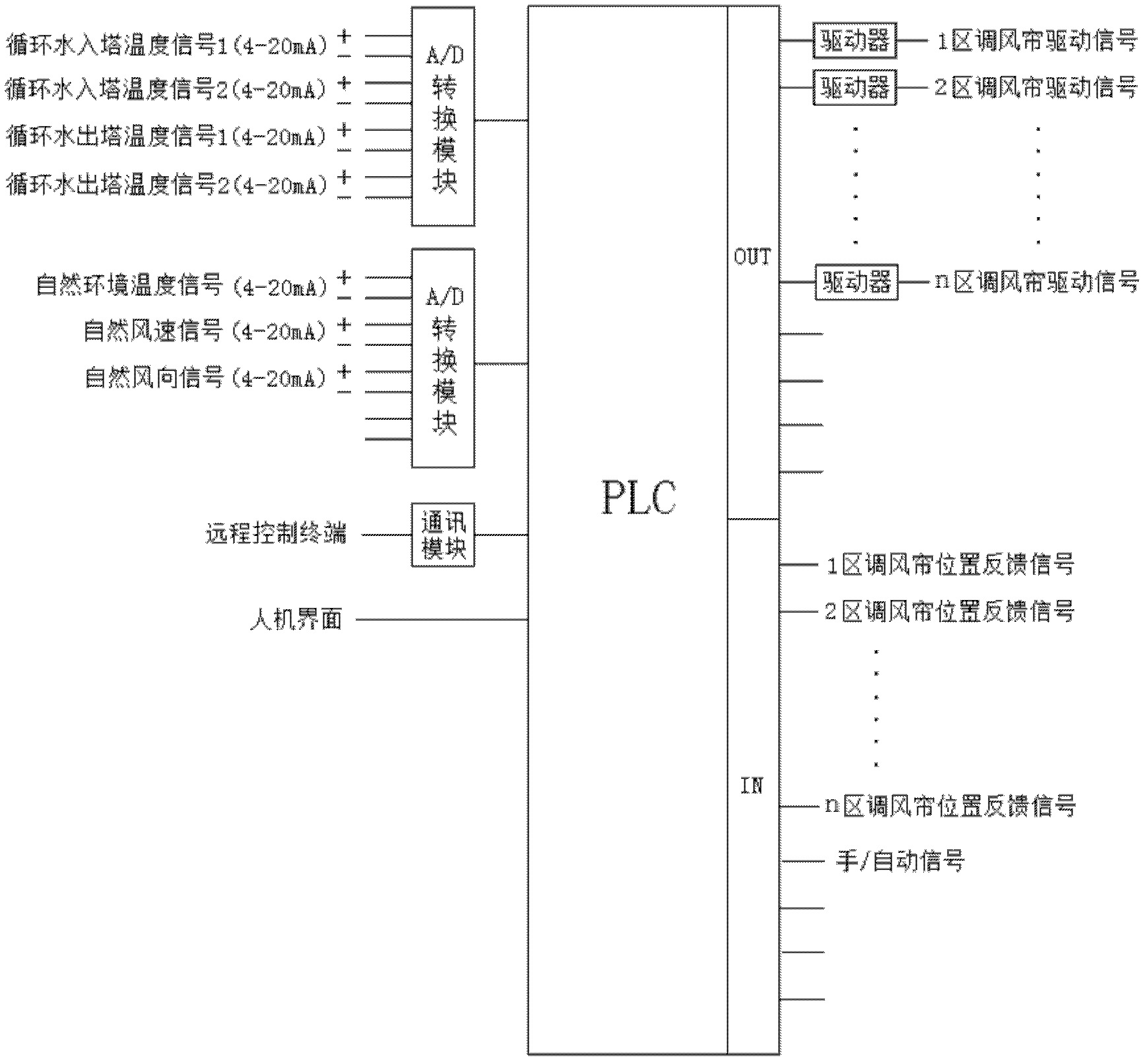

Optimized energy-saving cold-preventing system and method at air inlet sides of cooling tower

ActiveCN102538504APrevent freezingAvoid harmHeat exchange apparatusTrickle coolersCooling towerSoftware engineering

The invention discloses an optimized energy-saving cold-preventing system and method at air inlet sides of a cooling tower. The optimized energy-saving cold-preventing system comprises a plurality of electric air-curtain adjusting components, an acquisition unit and a control unit, wherein the plurality of electric air-curtain adjusting components are matched and arranged at the air inlet sides of all areas of the cooling tower and are used for adjusting the air inlet amount of the cooling tower and further controlling the temperature of circulating water; the acquisition unit is used for acquiring site information of the cooling tower in real time; the control unit is used for controlling the action of the electric air-curtain adjusting components to adjust and control the temperature ofthe circulating water on the basis of the site information of the cooling tower acquired by the acquisition unit; the acquisition unit is in signal connection with the control unit; and the pluralityof electric air-curtain adjusting components are respectively in communication connection with the control unit. According to the optimized energy-saving cold-preventing system and method disclosed by the invention, the defects of poor temperature adaptability, poor cold-preventing effect, poor energy saving effect, low automation degree, high cost, large labor amount and poor safety and the likein the prior art can be overcome so as to realize the advantages of good temperature adaptability, good cold-preventing effect, good energy saving effect, high automation degree, low cost, low labor amount and good safety.

Owner:中创清洁能源发展(沈阳)股份有限公司

Mechanism and method for stringing and knotting of portable paper bag handle rope

ActiveCN103568369ACause damageImprove convenienceBox making operationsPaper-makingEngineeringManipulator

The invention relates to a device and method for connecting a handle rope to a bag body. A mechanism for stringing and knotting of the portable paper bag handle rope comprises a machine frame, the machine frame is provided with a stringing mechanical hand, a first execution element and a lifting seat driven by the first execution element. The lifting seat is provided with a third execution element, a second execution element, a vertical rotating shaft driven by the third execution element and a lifting rod driven by the second execution element. The lower end of the rotating shaft is connected with a turntable, the turntable is provided with a rope winding mechanical hand located below the turntable, the lifting rod penetrates through the rotating shaft, and the lower end of the lifting rod extends out of the turntable. According to the mechanism for stringing and knotting of the portable paper bag handle rope and the handle rope installing method, the end of the handle rope can penetrate into the bag body and is knotted, and the problems that the bag body is damaged easily during manual stringing and knotting operation, operation is inconvenient and consistency of knots is poor are solved.

Owner:杭州汇八科技有限公司

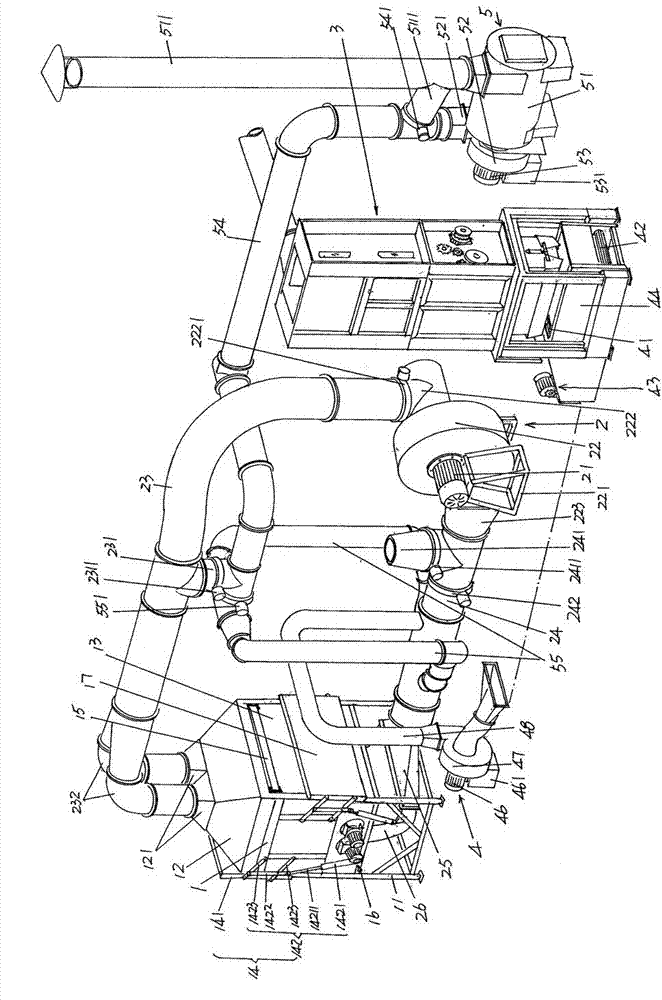

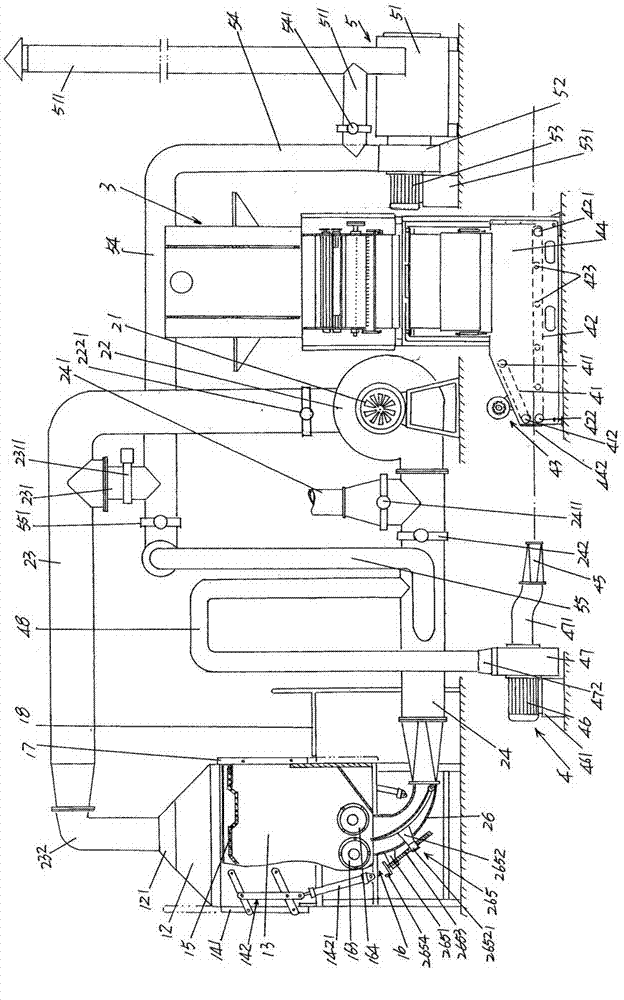

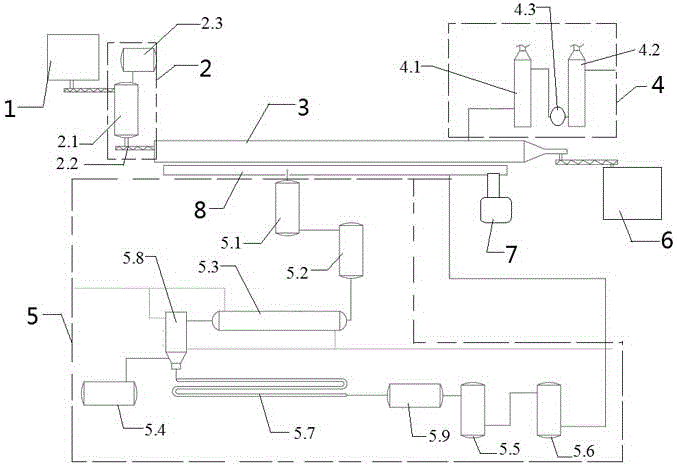

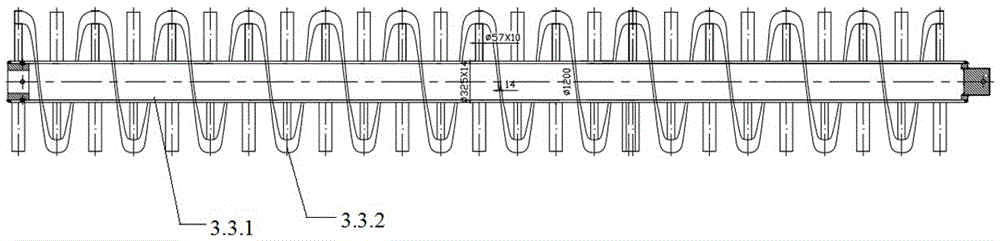

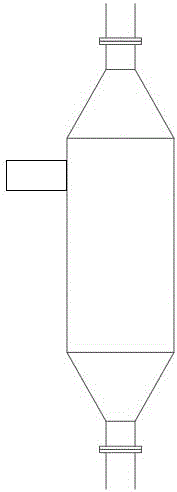

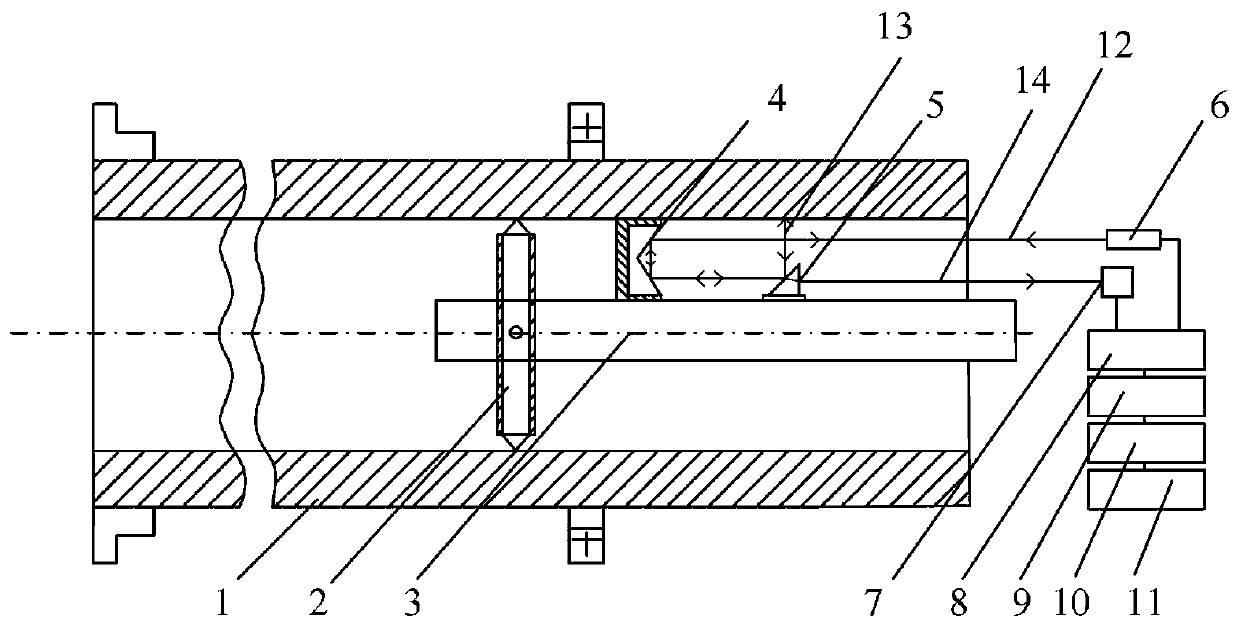

Waste tire low-temperature and normal-pressure continuous thermal cracking production device and technology

The invention relates to a waste tire low-temperature and normal-pressure continuous thermal cracking production device and technology. According to the technical scheme, the device comprises a preprocessing unit, a conveying and feeding unit, a thermal cracking unit, a desulfuration and atomization unit, an oil gas purifying and condensing unit, a carbon black deep processing unit, an oxygen supply air blower and a fuel gas spray gun, wherein the preprocessing unit, the conveying and feeding unit and the thermal cracking unit are connected in sequence, the desulfuration and atomization unit, the oil gas purifying and condensing unit, the carbon black deep processing unit, the oxygen supply air blower and the fuel gas spray gun are connected with the thermal cracking unit, a tail end outlet of the preprocessing unit is connected with the conveying and feeding unit, the thermal cracking unit mainly comprises a furnace body, the furnace body is connected with the oxygen supply air blower and the fuel gas spray gun, and the fuel gas spray gun comprises a natural gas spray gun and a waste gas spray gun. The waste tire low-temperature and normal-pressure continuous thermal cracking production device has the advantages that a full-sealed structure is adopted in the production process, and a strong atomization tower is adopted for performing cooling, dust removal and purification, so that environment pollution is lowered to the minimum; due to the fact that recycled combustible gas and cooling water is recycled, purified and secondarily utilized, energy is saved, the production cost is lowered, and the principle of energy conservation and emission reduction is met.

Owner:高义强

Method for detecting roundness and straightness of large deep hole part in boring process

ActiveCN110160462ARealize intelligent detectionEasy to implementUsing optical meansData acquisitionClosed loop

The invention discloses a method for detecting the roundness and straightness of a large deep hole part in a boring process. Firstly, a system for detecting the roundness and straightness of the largedeep hole part is established; laser light emitted by a laser displacement sensor is divided into two beams of light through a reflection prism; one beam of light is returned to the laser displacement sensor along an original light path, and the other beam of light is irradiated on a position sensitive detector through a spectroscope; the laser displacement sensor and the position sensitive detector transmits collected information to a data acquisition card in real time, and the information is processed through a data storage module and a pre-machining module; and finally measured roundness and straightness errors are evaluated in an error evaluation module. According to the detection method disclosed by the invention, machining parameters can be adjusted according to a detected error signal, and feedback closed-loop control is carried out on boring machining, so that the machining quality is improved, and the machining efficiency is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Leakage detection method using compressed air as medium

InactiveCN102062672AImprove efficiencyLow costMeasurement of fluid loss/gain rateCircular discProgrammable logic controller

The invention relates to a leakage detection method, in particular to a leakage detection method using compressed air as a medium. Automatic multi-station detection equipment is used in the method. All detection items are placed on a circular working disc, and five detection stations are uniformly distributed on the circumference of the disc. A rotary divider is driven by a motor so that the disc rotates, the detection stations are switched, detection is performed when the rotating disc stops, all operations generate various feedback signals, the signals are uniformly controlled and coordinated by a programmable logic controller (PLC), and meanwhile sequential detection and streamline operation are performed. The tested torque, pressure, flow and leakage are acquired by communication of a computer, the PLC, each instrument and each sensor and correspondingly processed; and all detection data are recorded in the computer and can be retrieved according to the date and item. The leakage detection method using the compressed air as the medium has high efficiency, good automation degree and low cost, and is suitable for large-scale production.

Owner:吴佳玲

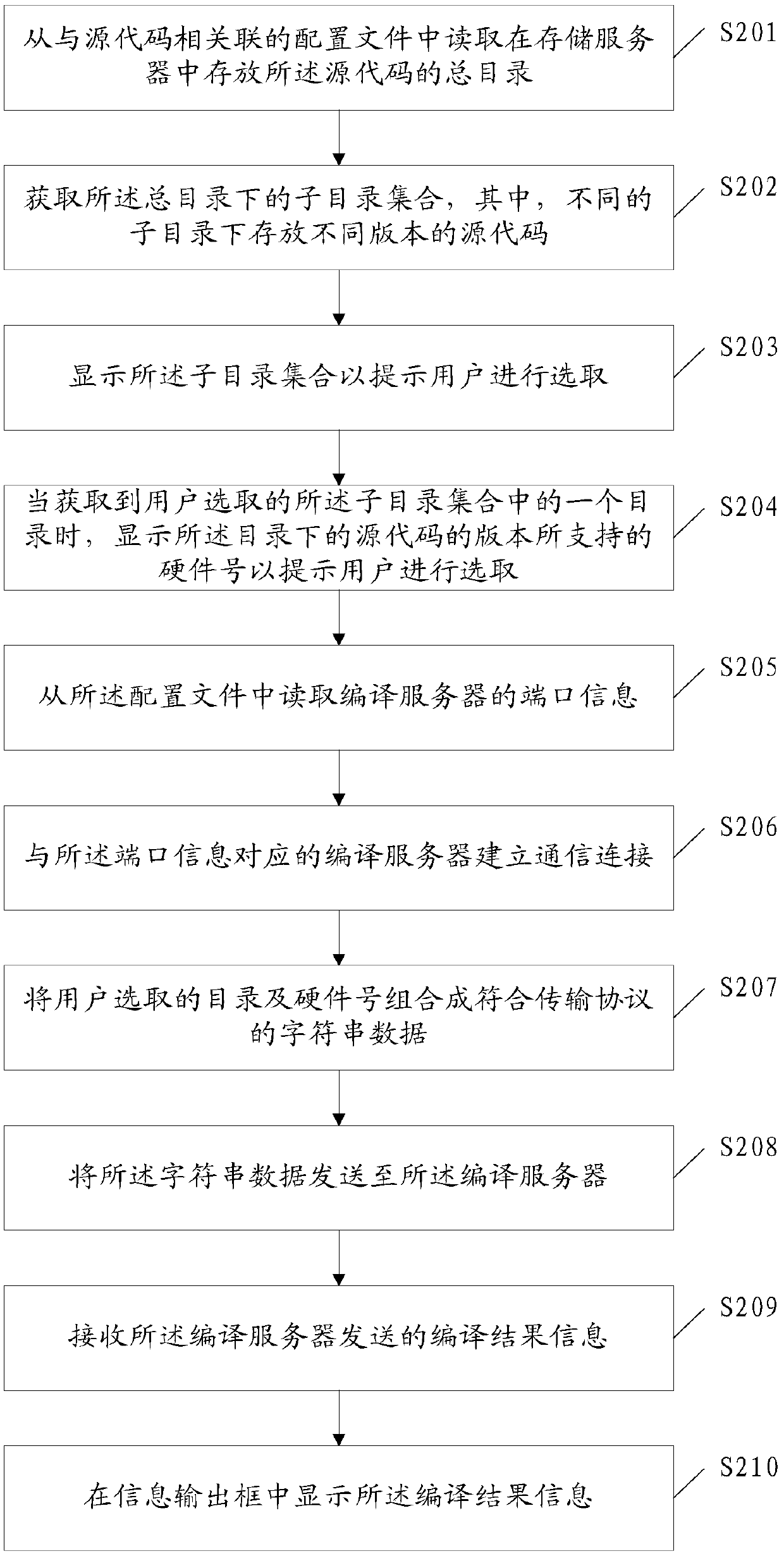

Compiling method of source code and related equipment

InactiveCN105511933ASimplify the interaction processGood degree of automationProgram controlMemory systemsClient-sideSource code

The embodiment of the invention discloses a compiling method of a source code and related equipment. The compiling method of the source code comprises the steps that a directory collection used for storing the source code is displayed so as to prompt a user to conduct selection; when a directory in the directory collection selected by the user is obtained, a hardware ID supported by a version of the source code in the directory is displayed to prompt the user to conduct selection; the directory selected by the user and the hardware ID are sent to a compiling server which downloads the source code to be compiled from the directory of a storage server, and the source code to be compiled is compiled to be software which can support the hardware ID. According to the compiling method of the source code and the related equipment, the man-machine interaction process can be simplified when a client side needs to compile the source code, and the degree of automation of the compiling process is optimized.

Owner:SHENZHEN SKYWORTH SOFTWARE +1

Method and device for controlling air conditioner and air conditioner device

ActiveCN105485849ARealize variable temperature and comfortable adjustmentGood for healthMechanical apparatusSpace heating and ventilation safety systemsEngineeringAutomation

The invention discloses a method and device for controlling an air conditioner and an air conditioner device. The method comprises the steps of detecting a heat source in the environment and adjusting the air outlet amount and / or the air outlet direction of the air conditioner based on the detected heat source. In the step of detecting the heat source in the environment, a temperature detection mechanism arranged in the environment is used for detecting the distribution position and / or the size of the heat source in the environment, and the detected distribution and / or the detected size of the heat source are / is fed back based on preset rules. According to the scheme, the defects that in the prior art, the automation degree is low, the energy saving effect is poor, and the user experience is poor can be overcome; and the beneficial effects that the automation degree is high, the energy saving effect is good, and the user experience is good are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Method for visible serial segmentation of human body slice images based on skeleton angular points

ActiveCN104008547ASplit continuous automaticImprove efficiencyImage analysisHuman bodyPattern recognition

Disclosed is a method for visible serial segmentation of human body slice images based on skeleton angular points. The method comprises the steps of loading a serial colored slice data set and a color similarity threshold value; developing a seed point set, selecting multiple seed points manually, and storing the seed points in the seed point set; calculating the color similarity between each seed point and a neighboring pixel, storing a mark if the color similarity is larger than the similarity threshold value, discarding the mark otherwise, and taking the obtained seed point set as the target binary image of the current image; ending the process if the current image is the last one; conducting skeleton extraction on the target binary image to obtain a target skeleton image, and emptying the seed point set; acquiring multiple angular points of the skeleton image with the angular point detection method to serve as the seed point of the next image, and storing the seed points in the seed point set; traversing the image sequence to achieve continuous segmentation until all the images to be segmented are segmented. By means of the method, a target human organ can be obtained from a three-dimensional colored slice image data set continuously and automatically through segmentation.

Owner:DALIAN UNIV OF TECH

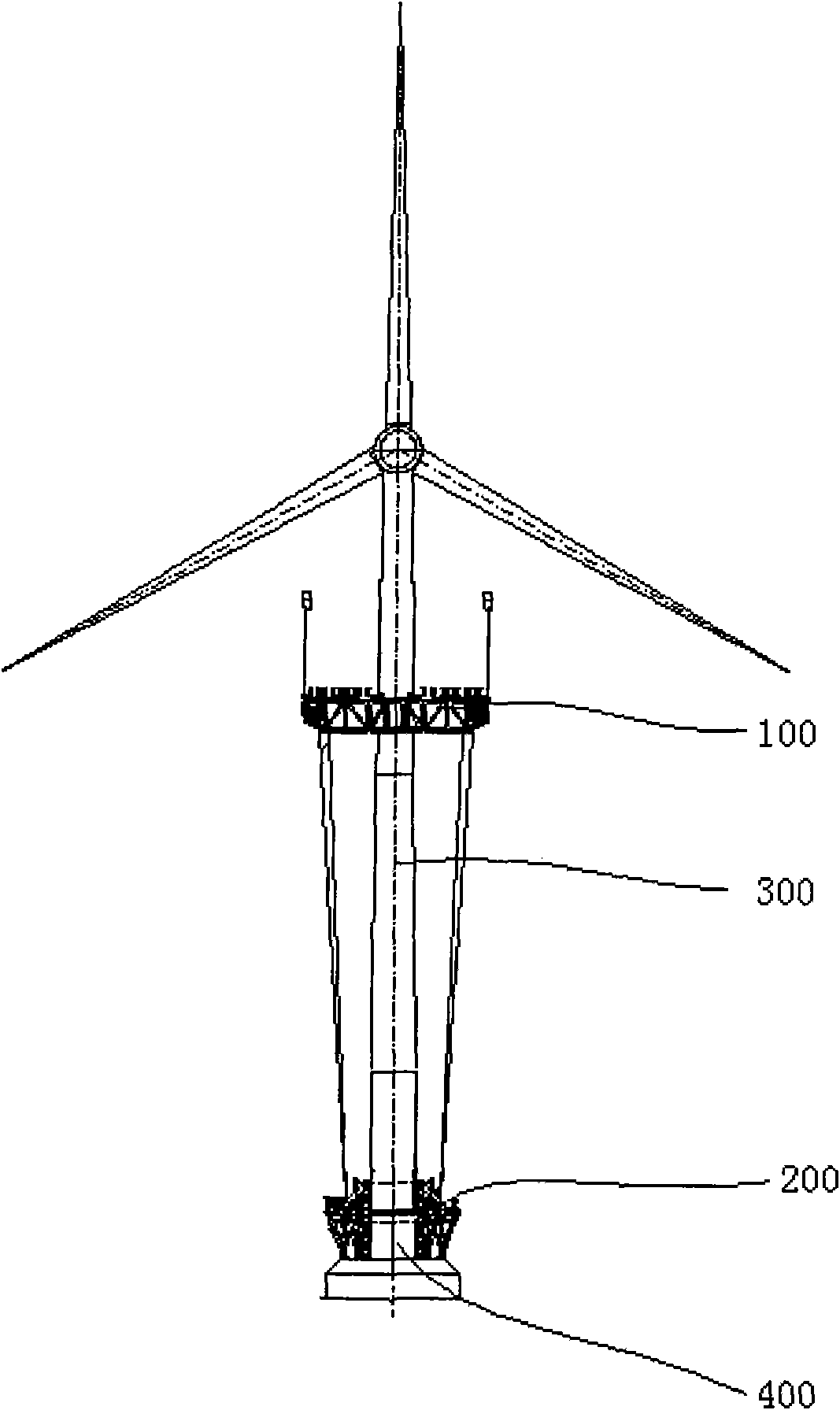

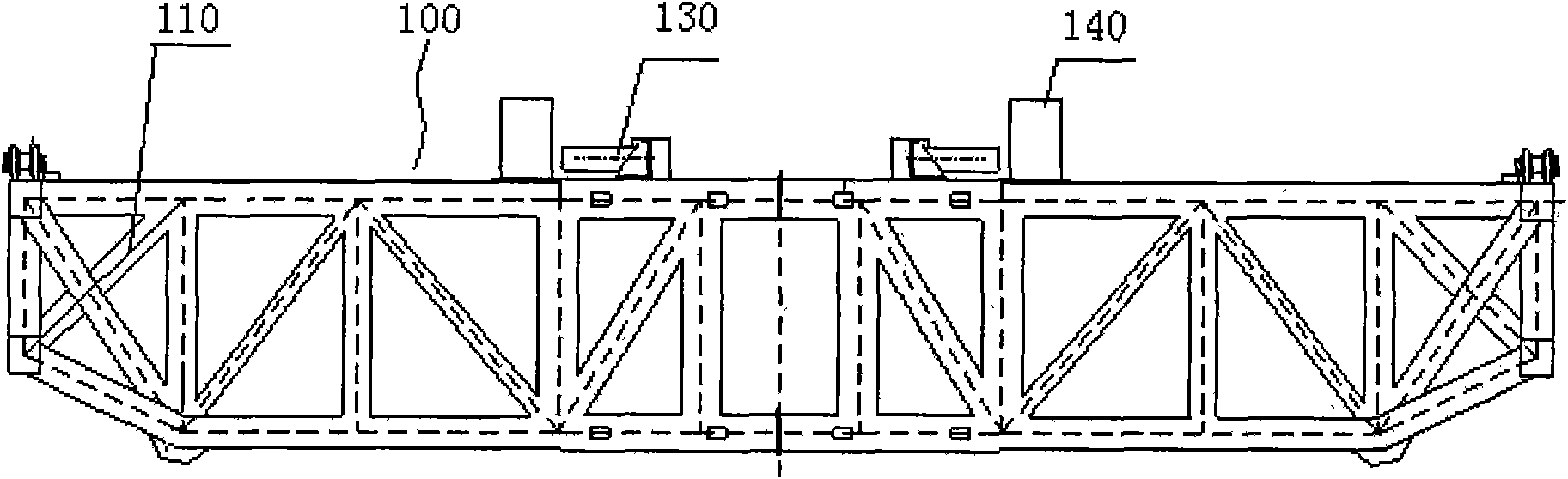

Flexible installation system for offshore wind turbine generator set and application thereof

InactiveCN102139829ASolve high center of gravitySolve the center of gravityLoad-engaging elementsButt jointTower

The invention discloses a flexible installation system for an offshore wind turbine generator set and application thereof. The flexible installation system comprises a balance device and a flexible butt joint device, wherein, the balance device is arranged at the upper part of a wind turbine body and plays a role of balancing, the balance device comprises balance beams which are symmetrically arranged on the right side and the left side, and the middle part of the balance beams is equipped with a hollow installation part corresponding to the wind turbine body; and the flexible docking device comprises an upper lifting frame and a lower frame body, wherein, the upper lifting frame is connected with the root of the wind turbine body and is equipped with a buffer gear, the lower frame body is connected with a tower tube base of an offshore base platform and is equipped with a bearing mechanism which plays a role of bearing the upper lifting frame and the wind turbine body, and the lower frame body is corresponding to the upper lifting frame. By utilizing the flexible installation system, the offshore wind turbine generator set can be safely and steadily installed.

Owner:CCCC THIRD HARBOR ENG +2

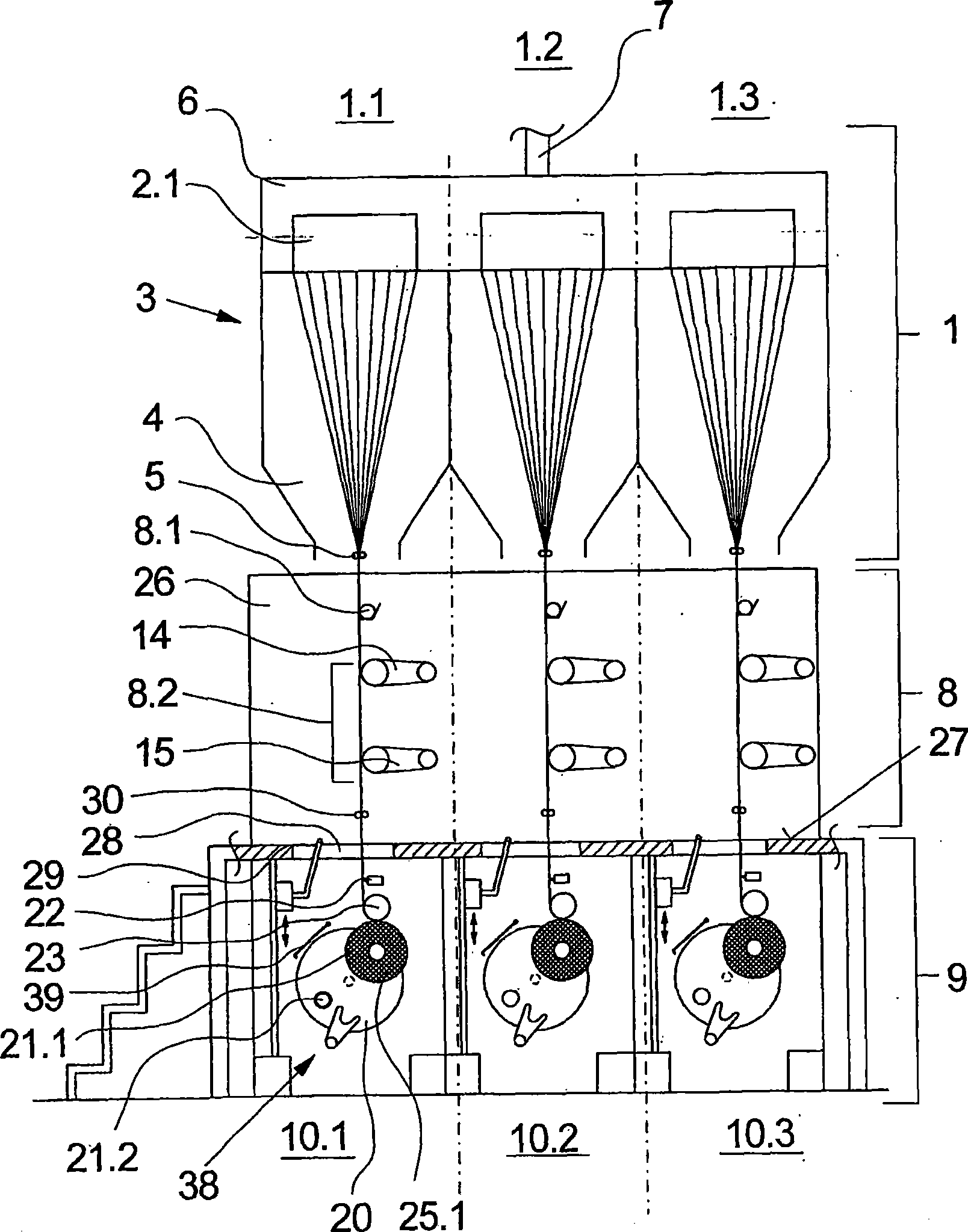

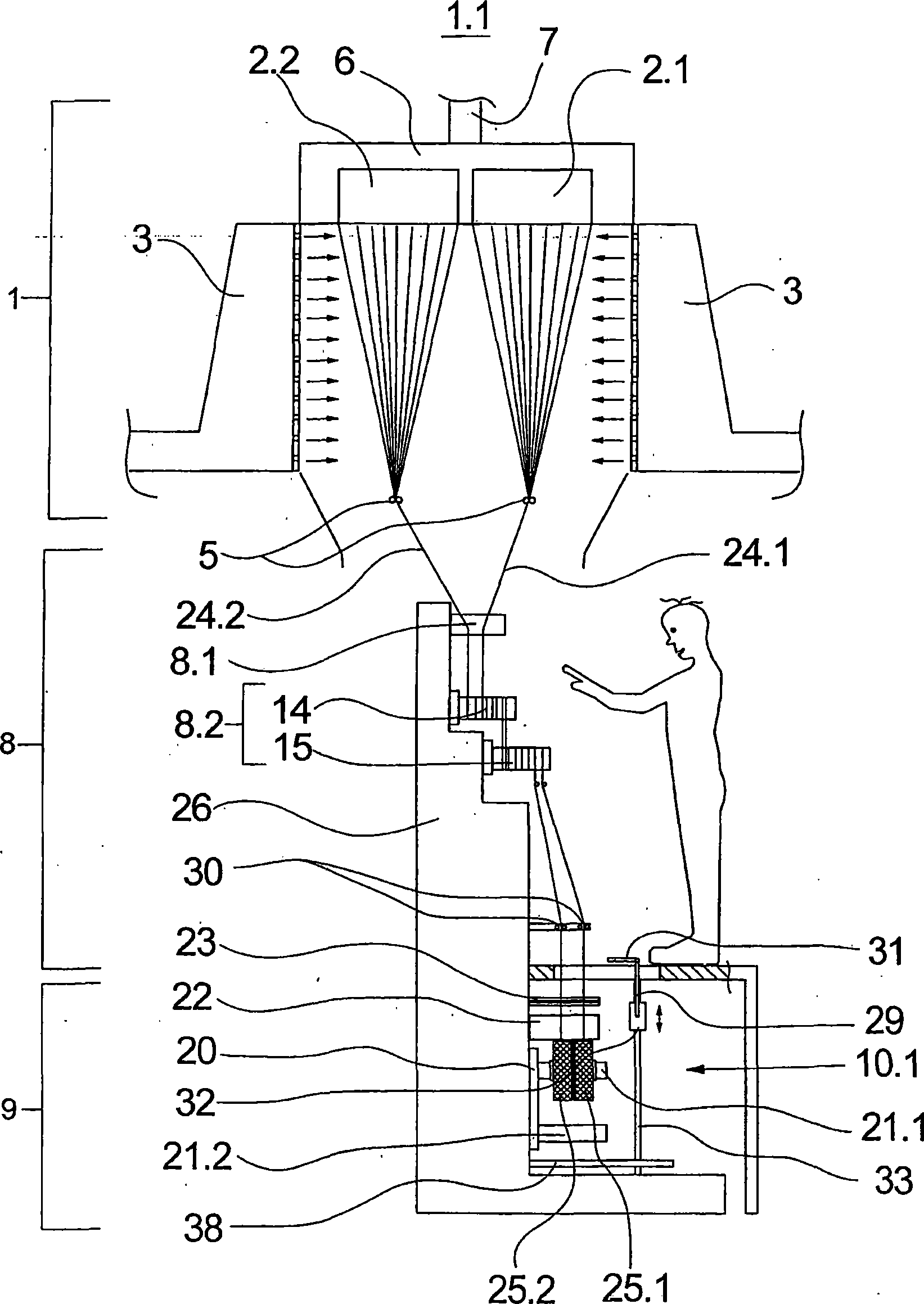

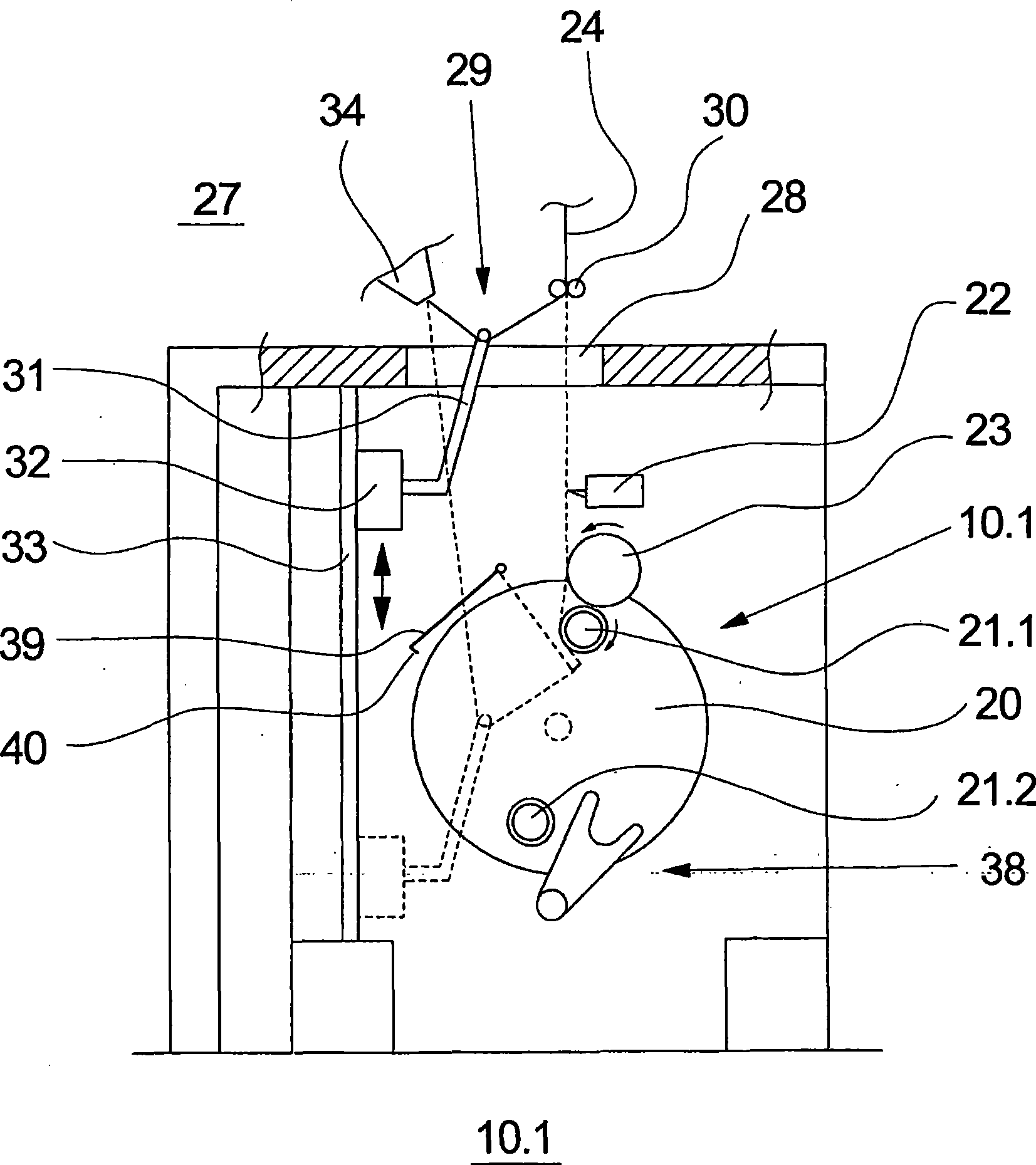

Device for melt spinning, treating and winding synthetic threads

InactiveCN101437991AGood degree of automationAvoid interactive broken wiresNew-spun product collectionArtificial thread manufacturing machinesMelt spinningEngineering

The invention relates to a device for melt spinning, treating and winding synthetic threads, said device consisting of a spinning unit, a treatment unit and a winding unit. The spinning unit, the treatment unit and the winding unit are arranged in tiers one above the other and form a plurality of single-thread or multi-thread production positions along the longitudinal side of a machine. According to the invention, to permit a rapid, simple operation, in particular at the start of a process and during interruptions of said process, an operator walkway is located at a height between the treatment device and the winding device.

Owner:OERLIKON TEXTILE GMBH & CO KG

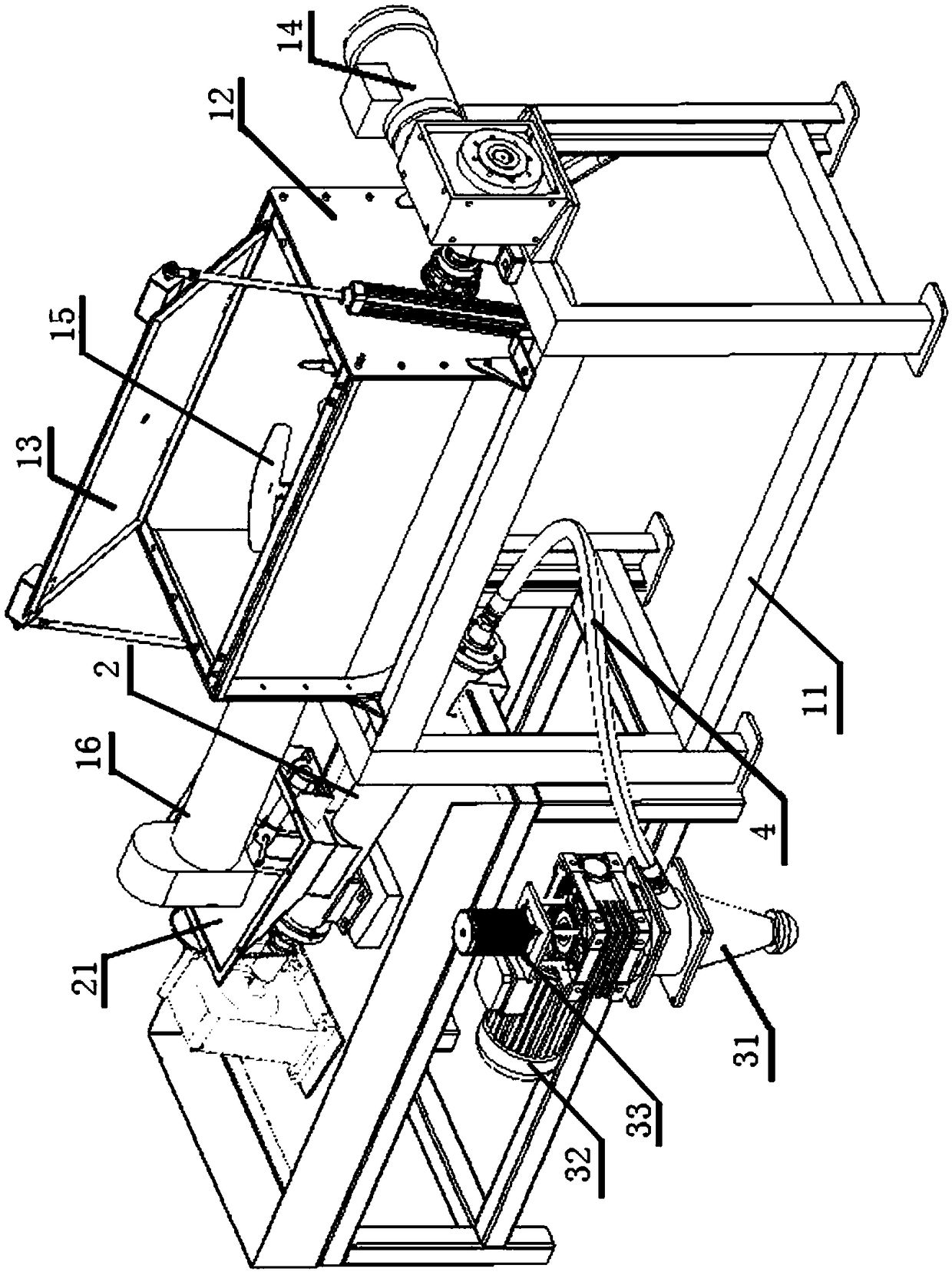

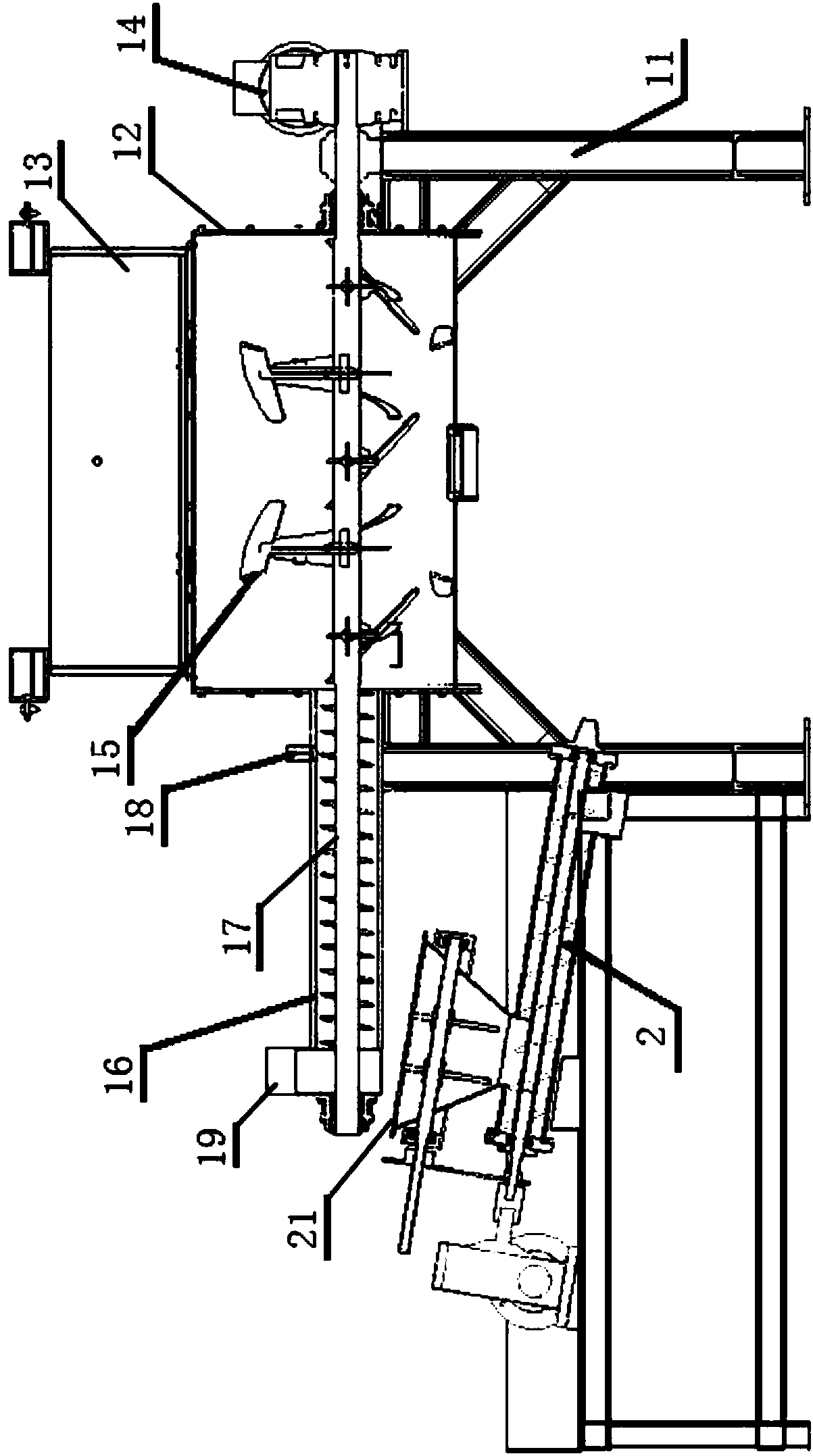

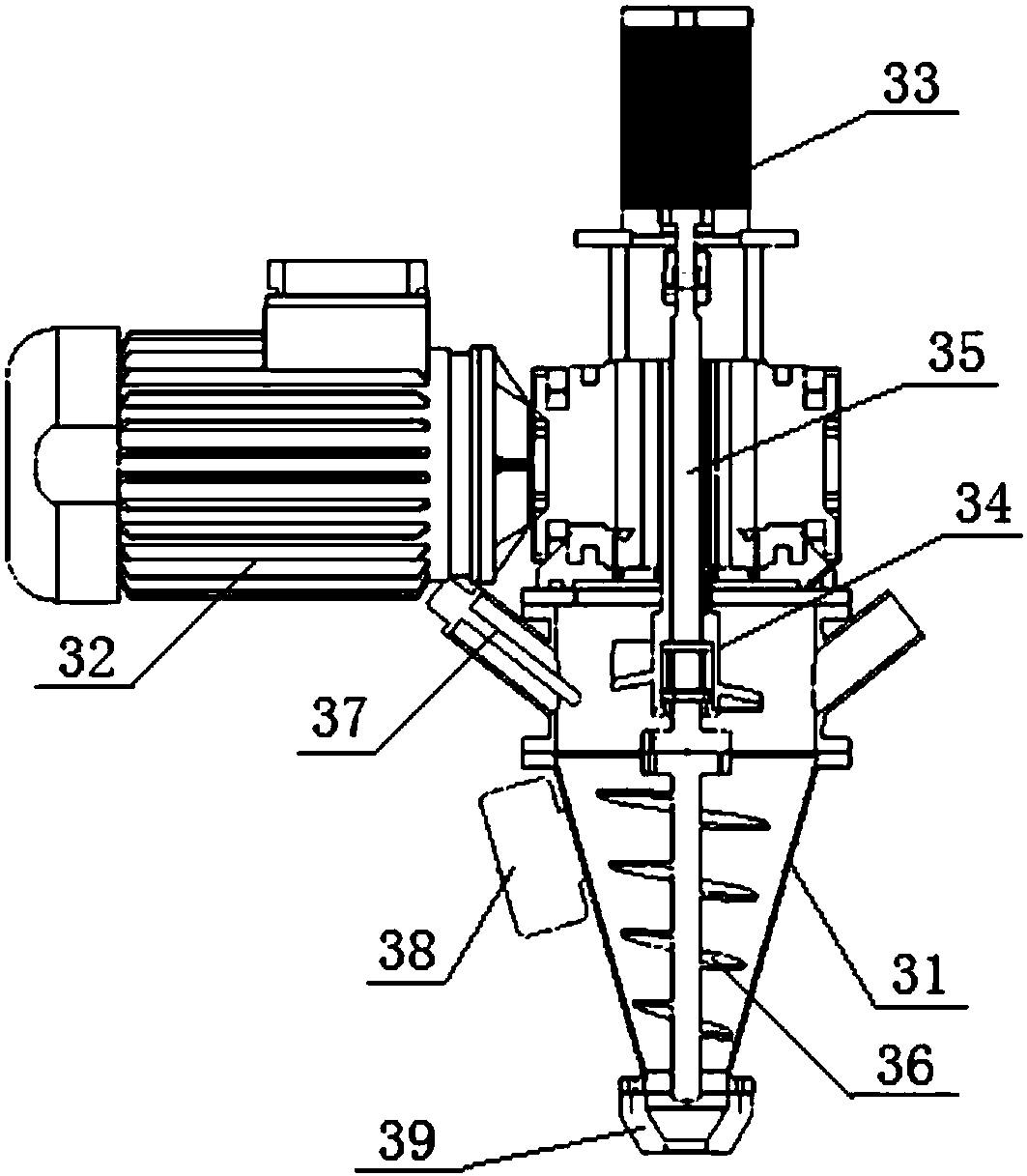

Continuous feeding system for building 3D printer

PendingCN108407042AExtrude evenly and continuouslyImprove printing qualityAdditive manufacturing apparatusCeramic shaping apparatusContinuous/uninterruptedPulp and paper industry

The invention discloses a continuous feeding system for a building 3D printer. The system comprises a continuous pulper, a spiral pumper and a stirring spiral extruder, wherein the continuous pulper comprises a stirring stock bin and a spiral discharge pipeline communicating to the stirring stock bin; the discharge port of the spiral discharge pipeline is connected to the feed inlet of the spiralpumper, and the feed inlet of the spiral pumper is connected to the feed inlet of the stirring spiral extruder; and the stirring spiral extruder comprises a stirring stock bin and a stirring blade shaft and a cone-shaped screw arranged in the stirring stock bin. Continuous intermittent feeding of the printer is achieved by efficient pulping by the continuous pulper and multi-level buffering of thestirring stock bin of the continuous pulper, the spiral pumper and a stirring hopper of the stirring spiral extruder.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com