Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79 results about "Moisture Damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

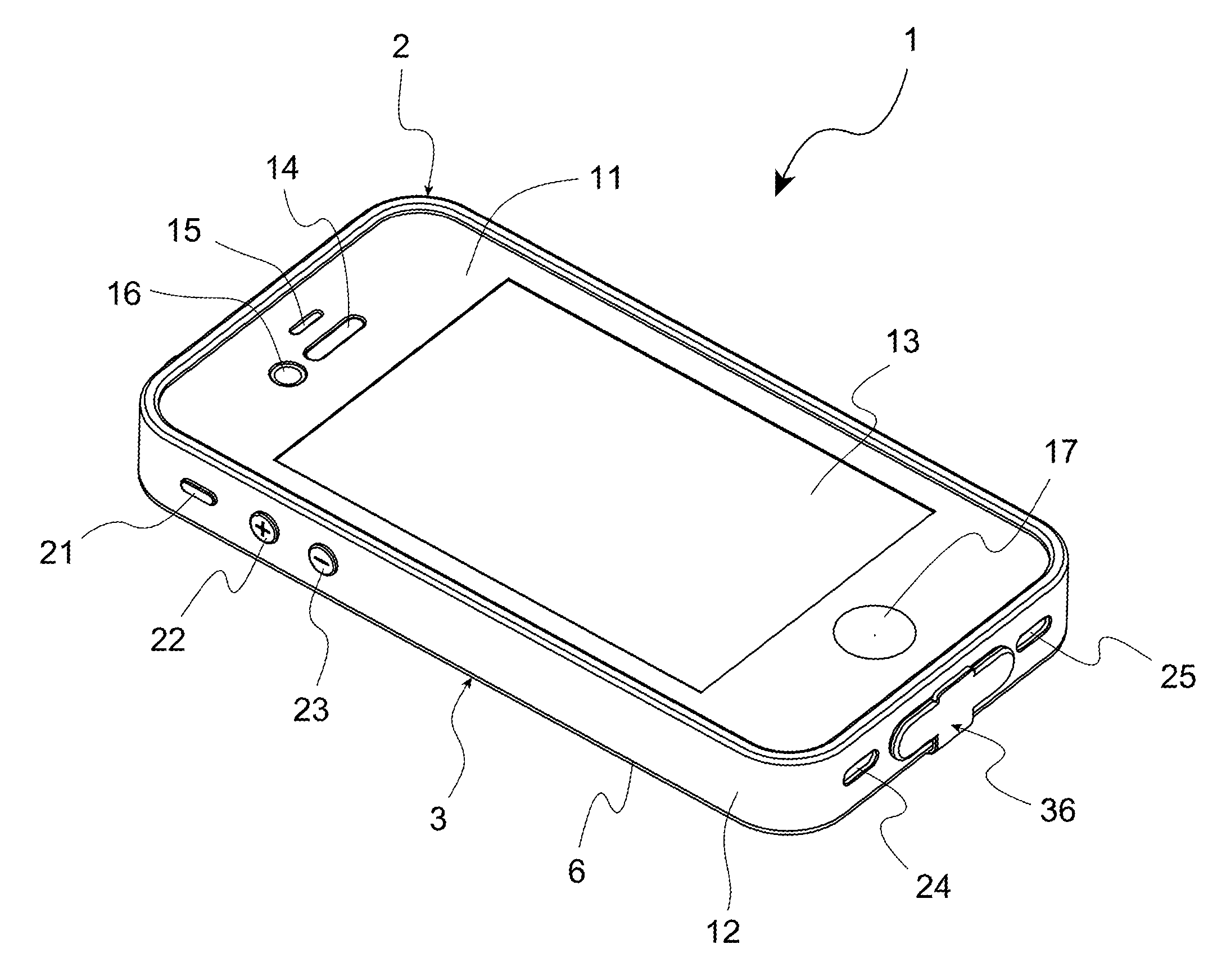

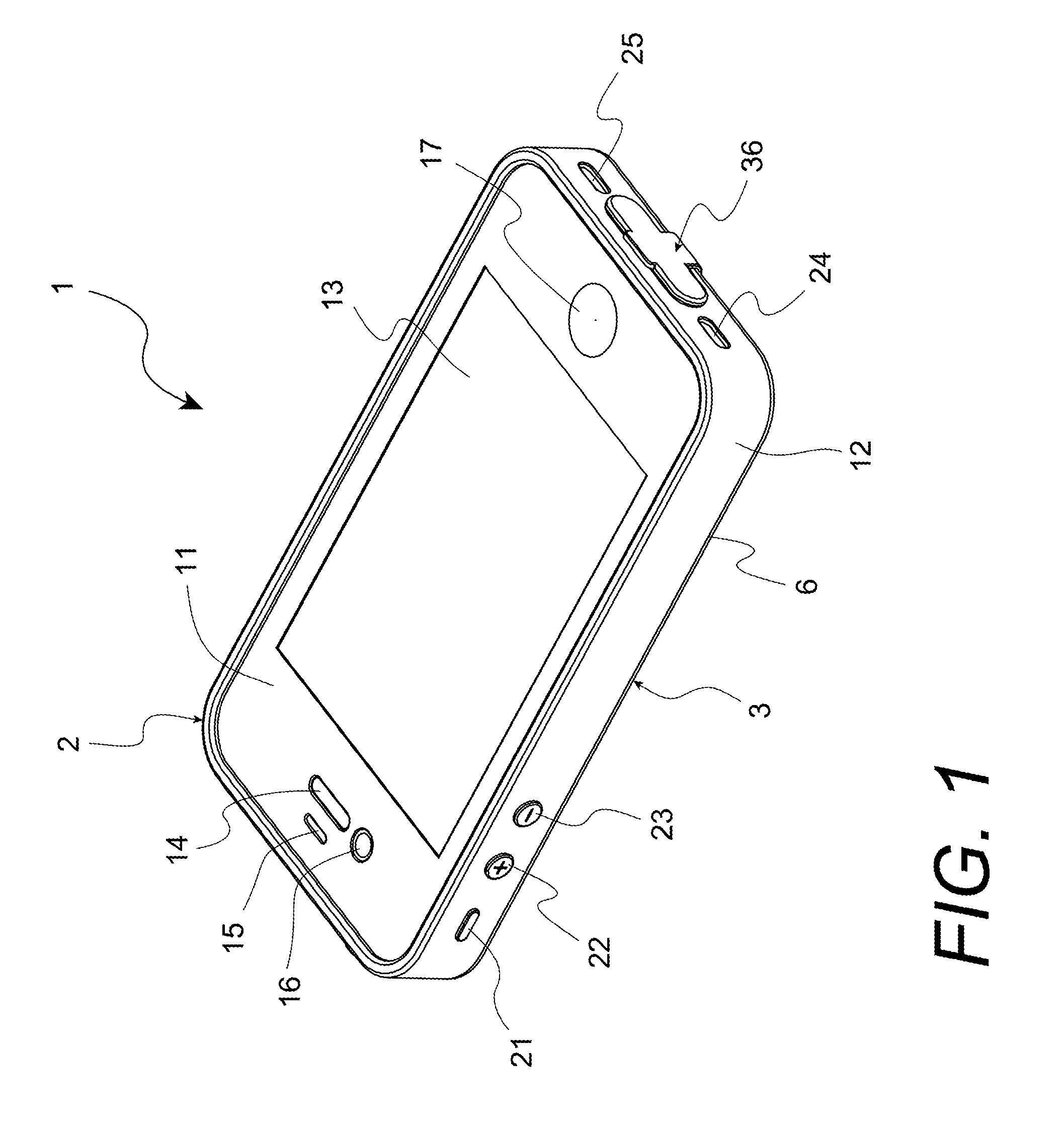

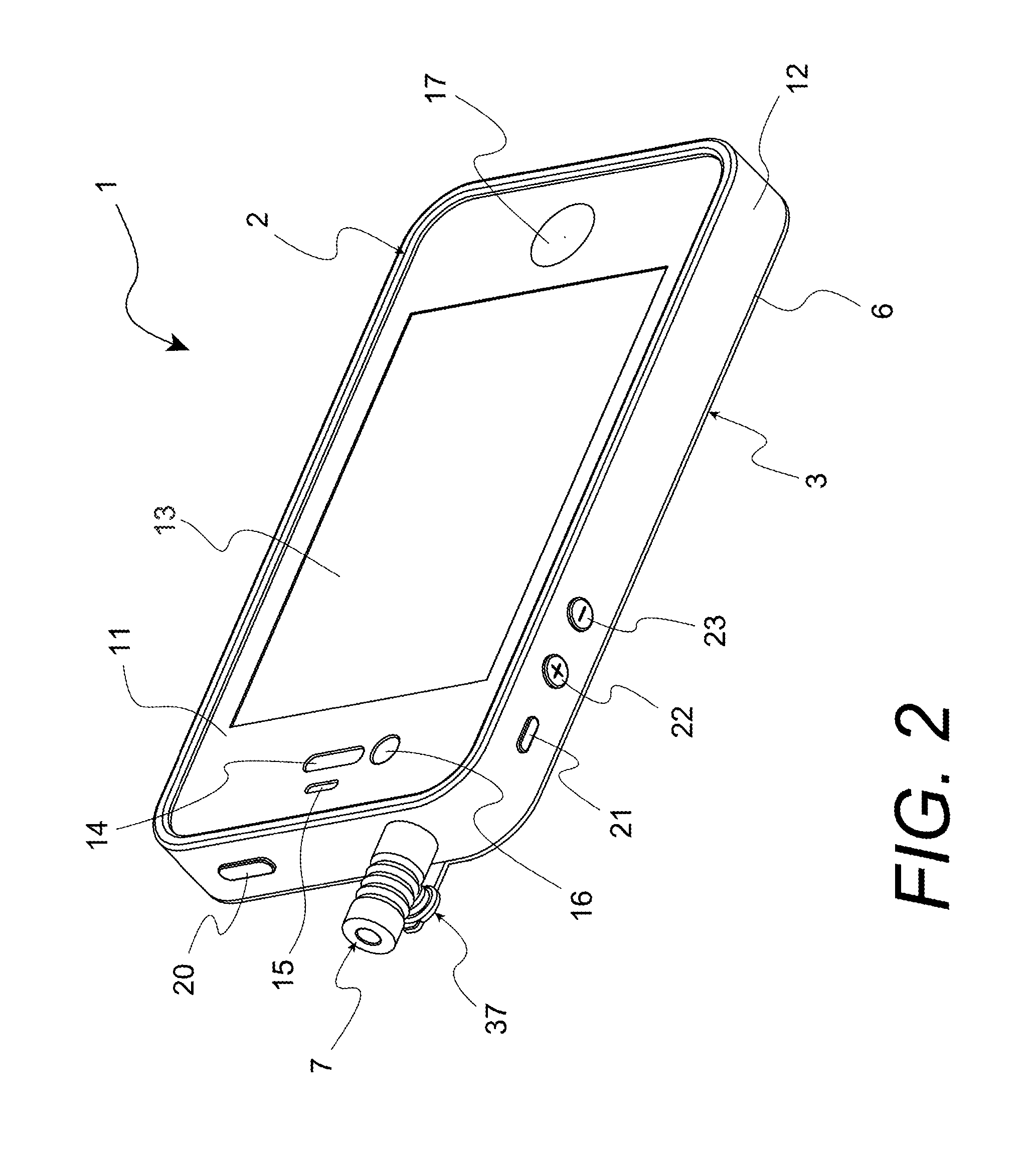

Case for housing and protecting an electronic device

InactiveUS20140055014A1Avoid damageCasings/cabinets/drawers detailsFurniture partsElectricityElectrical connection

A case for housing and protecting an electronic device against moisture damage and contaminants is disclosed. The case comprises a first member having a first plainer section and a first perimetric wall formed thereon, and a second member having a second planer section and a second perimetric wall formed thereon. The first perimetric wall and the second perimetric wall are engaged forming an overlap and a sealing structure for a watertight seal. The sealing structure includes a mated ring and a ridge-to-groove interlock. The case further comprises a plurality interface feature accesses, including an optical access, an audio access, a button, and at least one open access for electrical connection. The case provides a cover with a plug adapted to cover up the open electrical connection access to form a watertight seal.

Owner:OCTOPROD

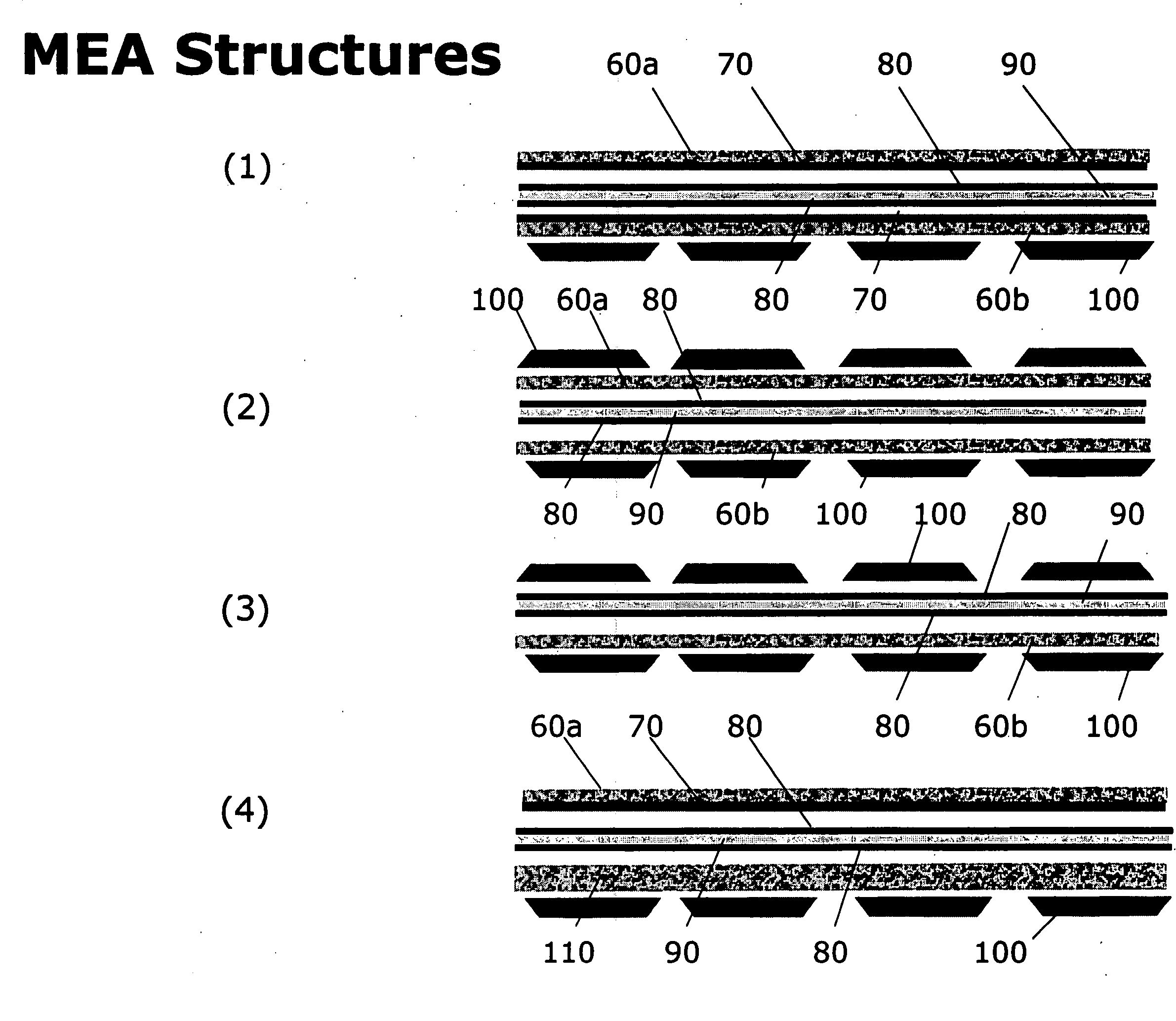

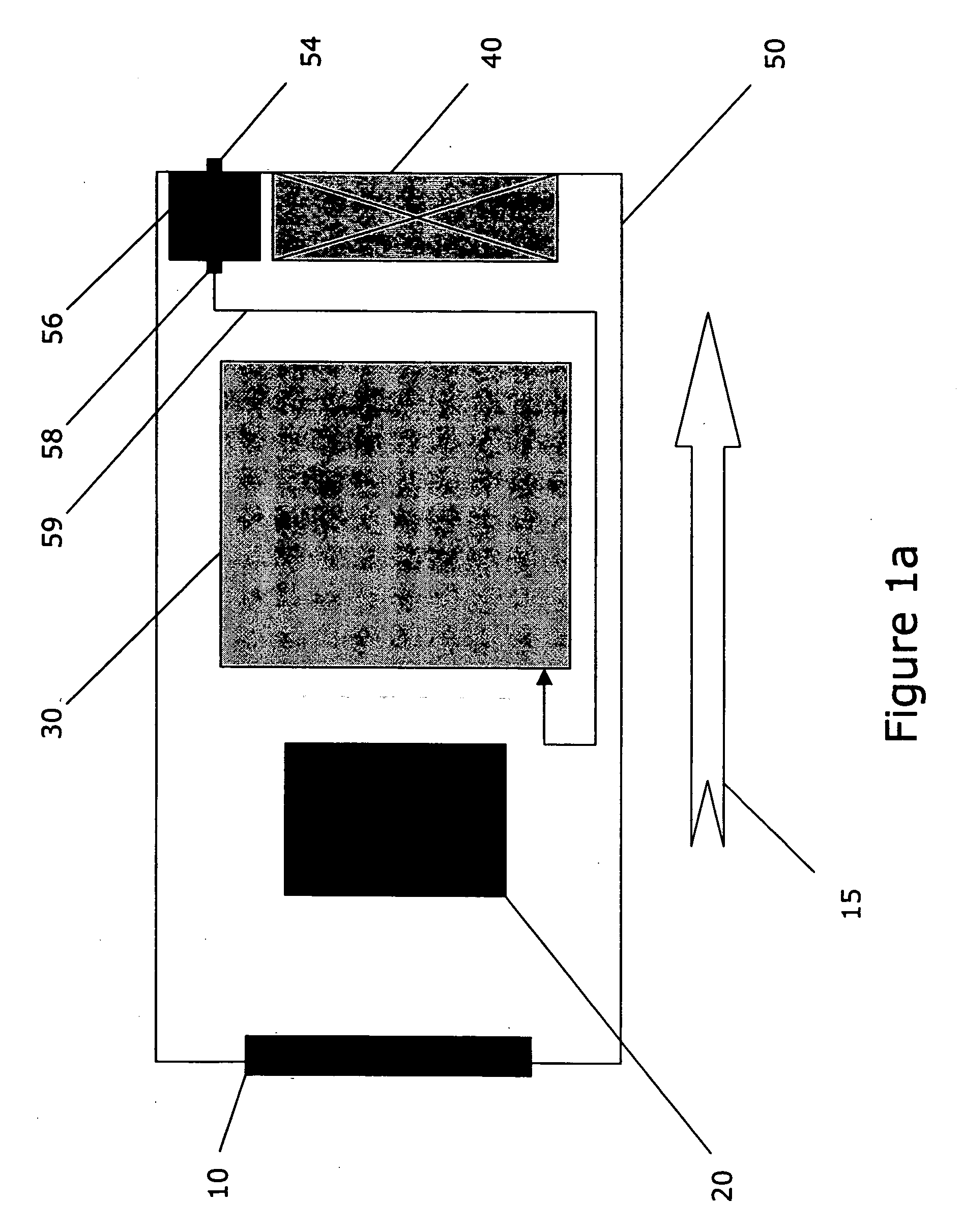

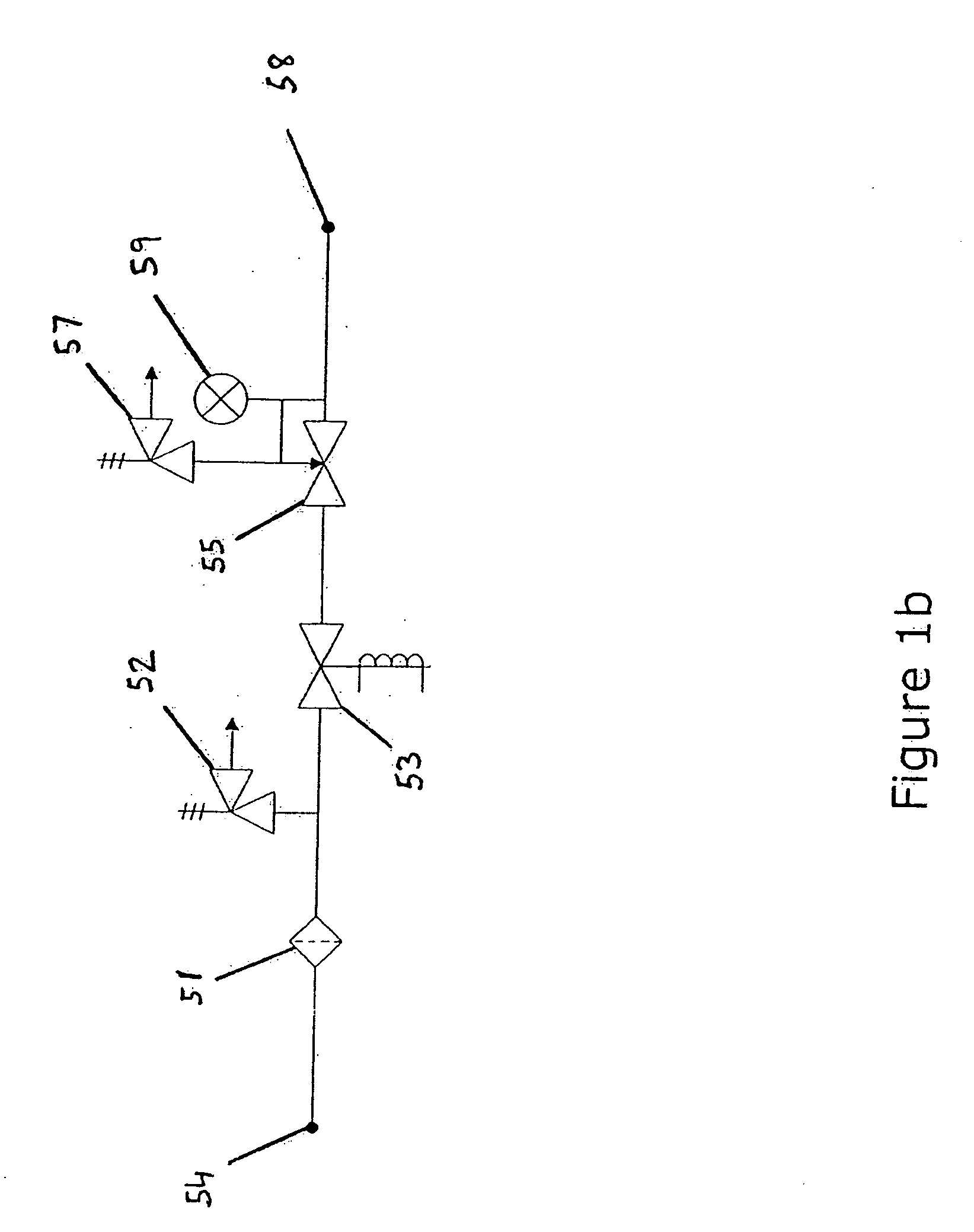

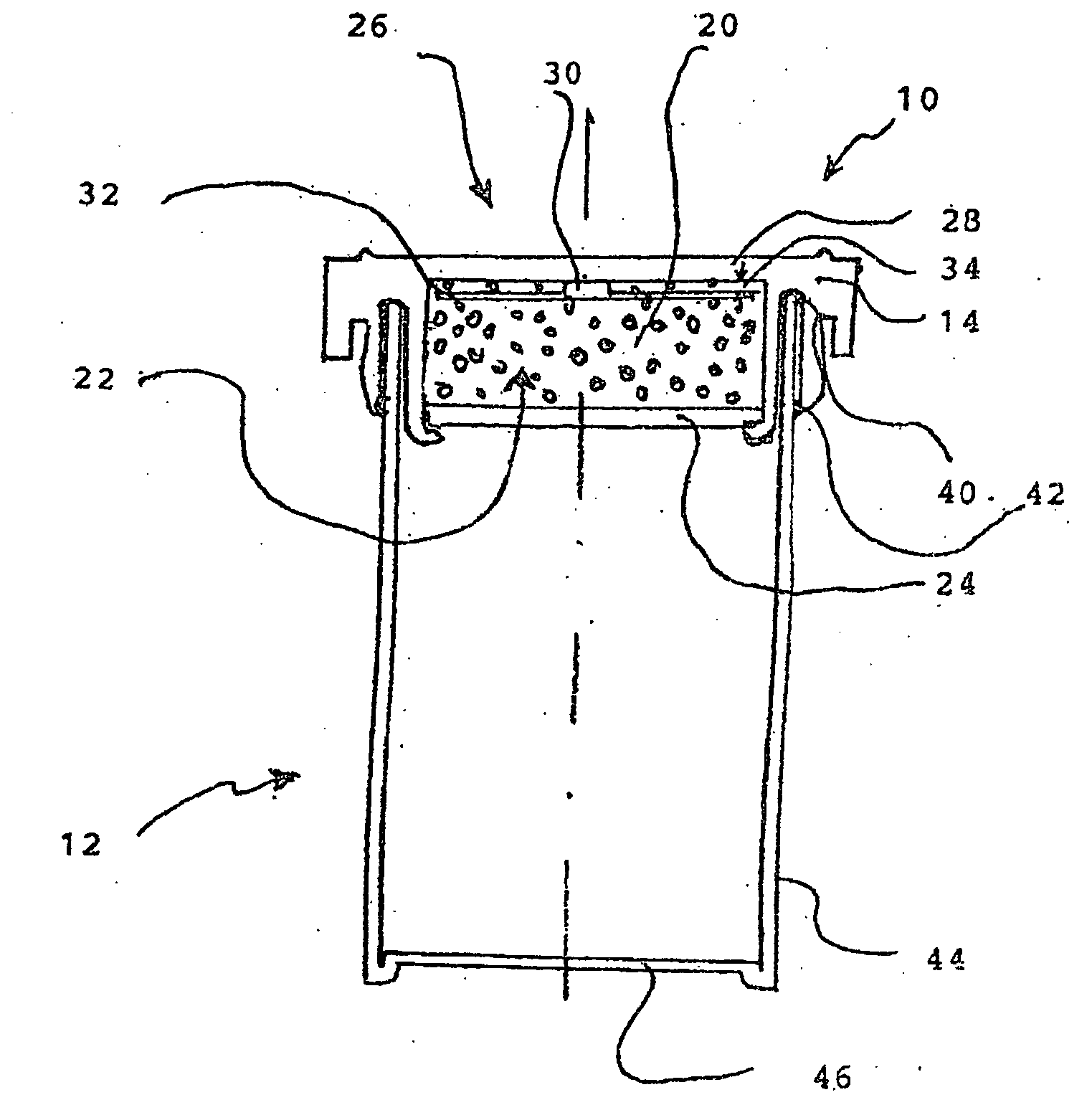

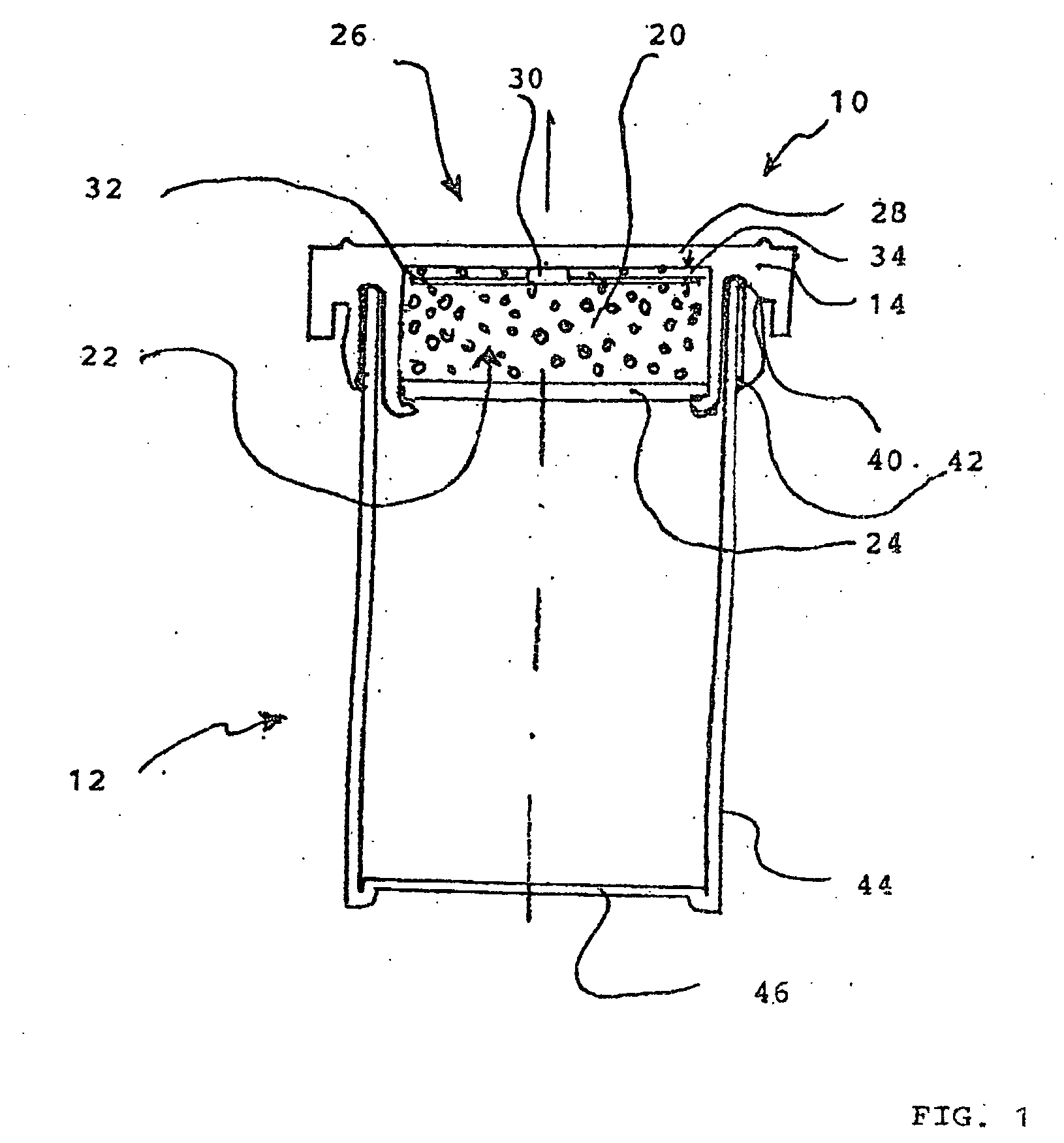

Fuel cell electric power generating system

ActiveUS20070148509A1Increase air circulationReduce riskFuel cell heat exchangeFuel cells groupingElectrochemical responseAir cycle

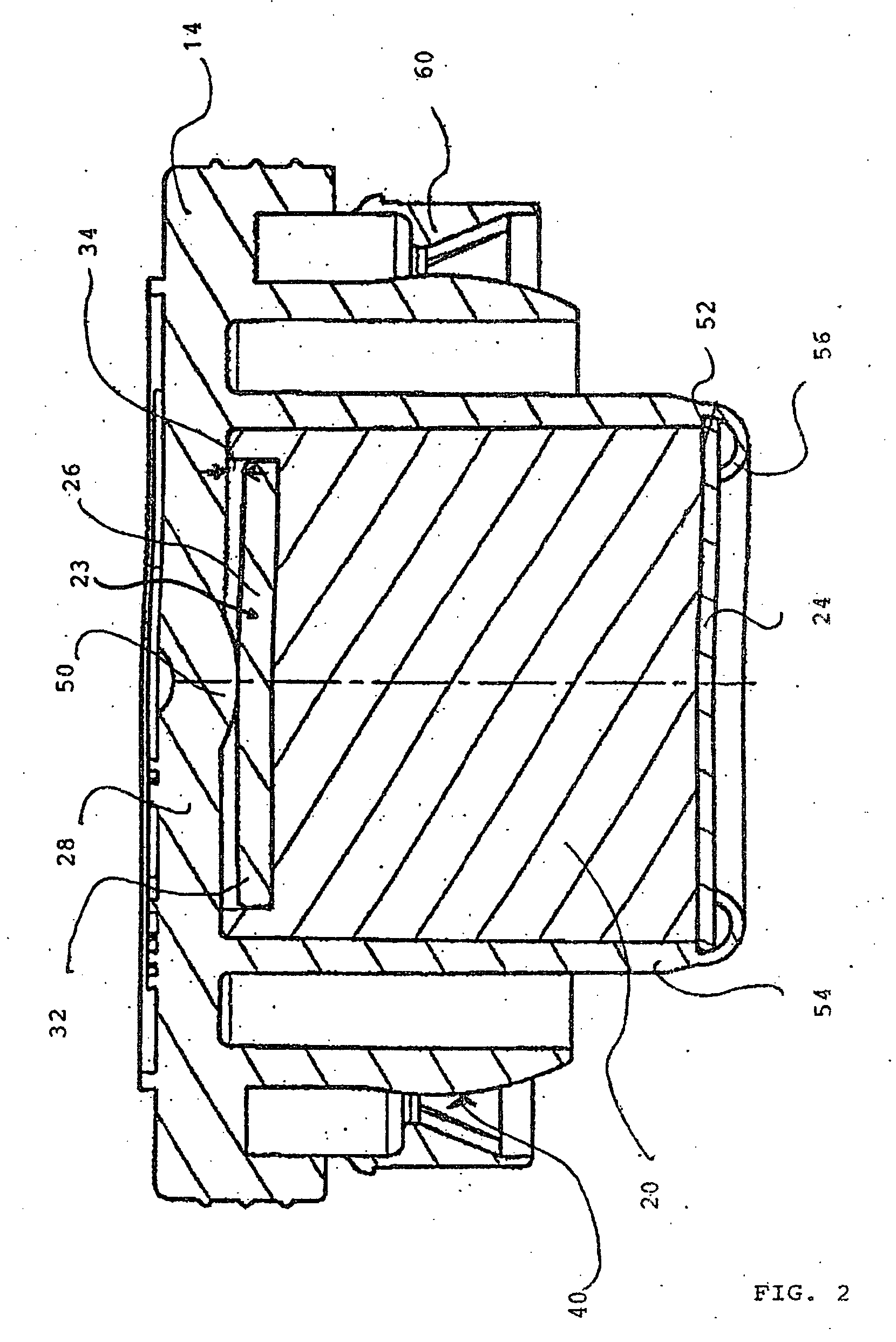

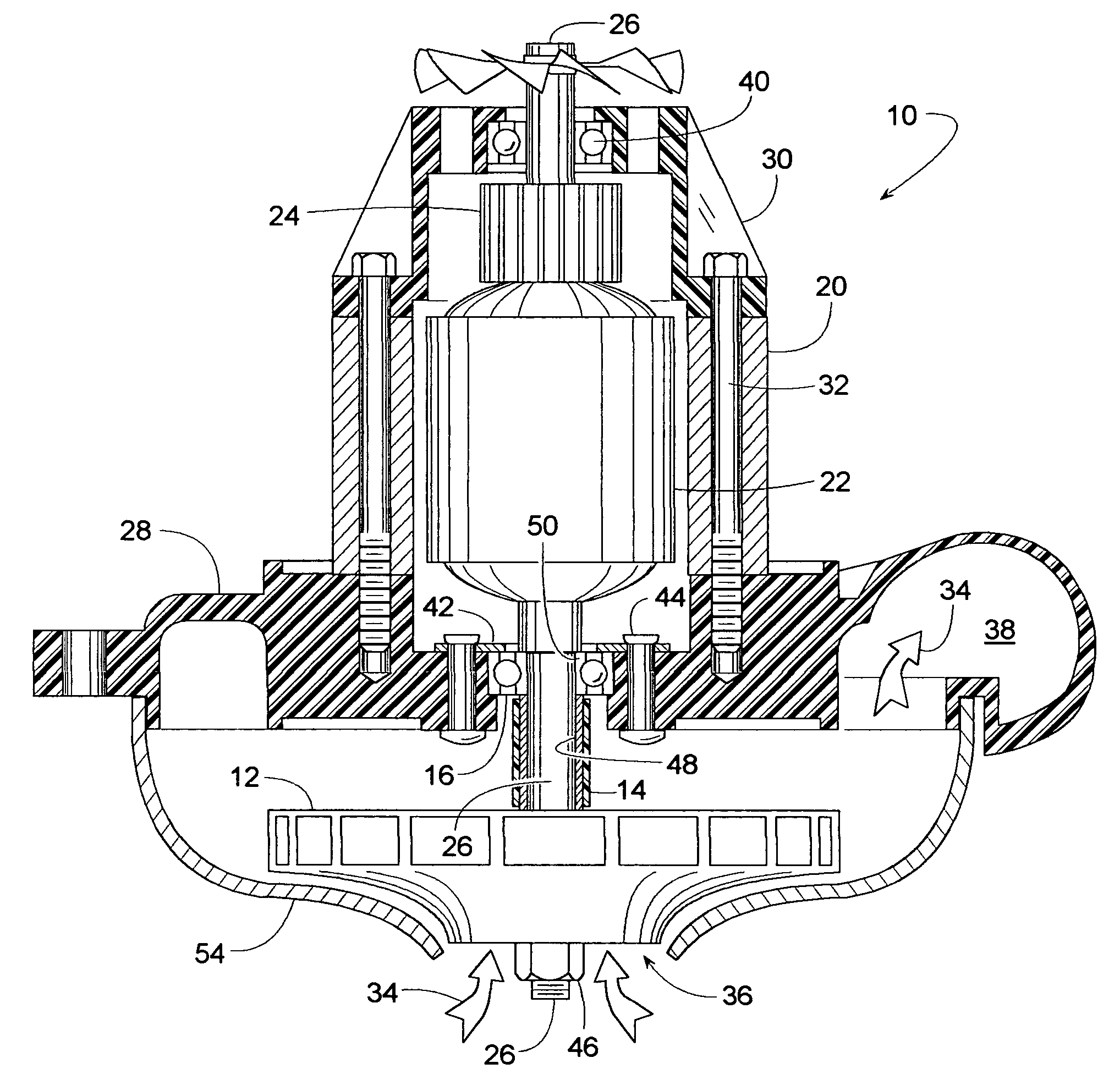

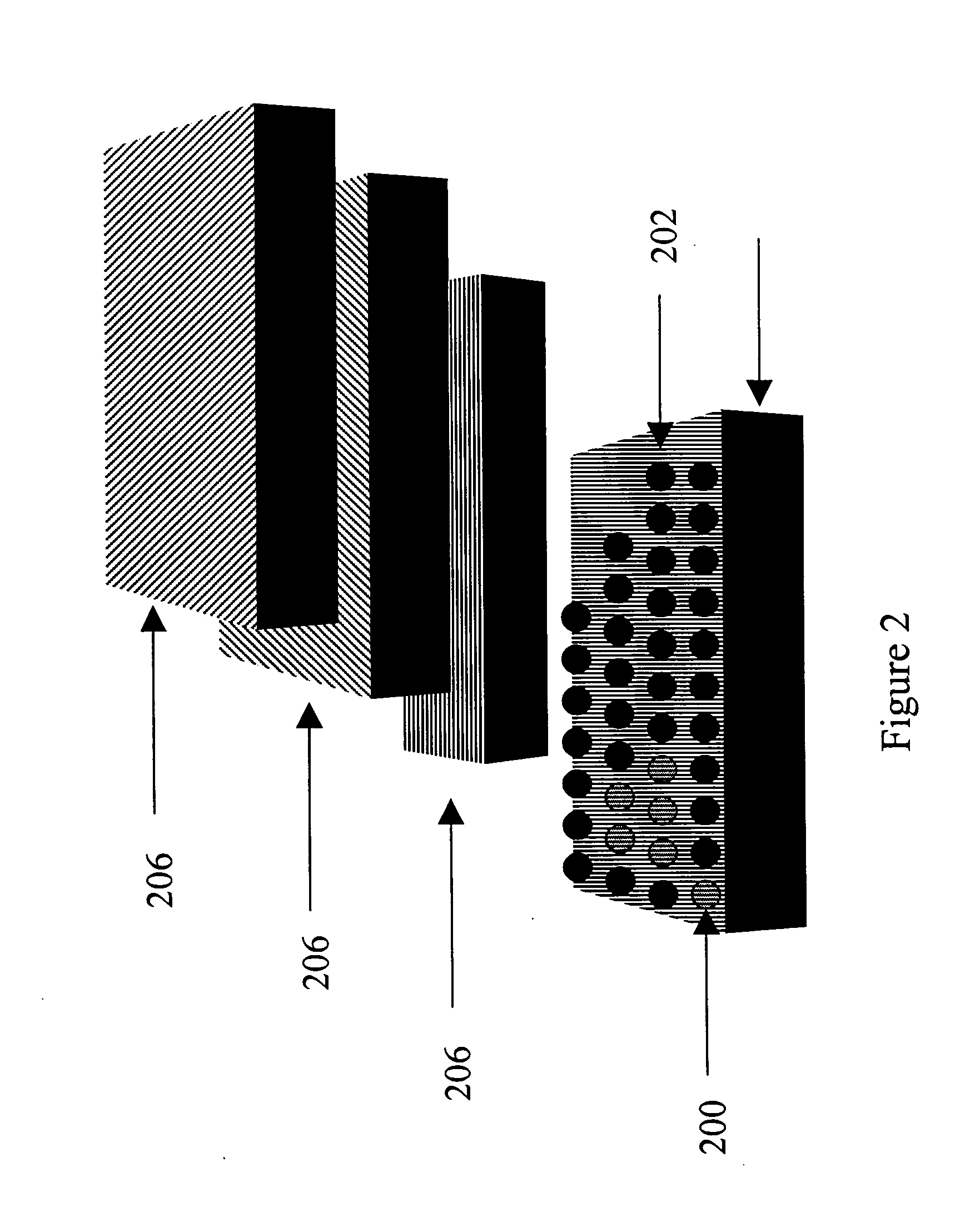

A fuel cell electric power generation system using air as both a coolant and an oxidant comprises an electric power generation subsystem, an air filter subsystem, a power and control electronics unit (PEU) subsystem comprising a DC / DC converter, and an air fan subsystem. The subsystems are arranged such that air circulation through the system is improved and the risk of moisture damage to sensitive PEU components is reduced. In one embodiment, the air filter subsystem is positioned ahead of the PEU subsystem, which is positioned ahead of the power generation subsystem, which is positioned ahead of the air fan subsystem in the direction of air flow, such that air is drawn by the air fan subsystem through the air filter subsystem, over the PEU subsystem, and through the electric power generation subsystem, providing filtered air to cool the PEU prior to entering the fuel cell stack to provide oxygen for the electrochemical reaction.

Owner:BALLARD POWER SYSTEMS

Container and capsule

InactiveUS20070114140A1Easy to handleInexpensive and easy to manufactureContainer decorationsLevel indicationsDesiccantEngineering

The invention relates to a container, in particular for moisture-sensitive goods, with a container body and a container cover which can be opened and closed, and with a transponder which is arranged in the container cover. The transponder is covered by at least a layer of a desiccant material and is therefore protected against moisture damage which could influence the electrical characteristics of the antenna.

Owner:AIRNOV INC

Water repellent motor sleeve

A high-speed universal motor running at over 10,000 or even over 20,000 rpm includes a non-rubbing water repellent sleeve that protects the bearings from moisture damage. Rather than having a sliding contact seal that can quickly wear out under such high speeds, the sleeve is made of material having a low solid surface energy so that the seal material itself repels waters on its own. TEFLON is the preferred material, which is relatively soft, so to prevent the compressibility of the seal from affecting the axial positioning of parts on the motor shaft, the seal is installed such that the seal does not contribute to the critically precise positioning of the shaft and the parts mounted to it. In some embodiments, for example, the relatively soft seal simply overlies a much stiffer, accurately machined metal spacer.

Owner:ELECTRO MOTOR

Methods and materials for the reduction and control of moisture and oxygen in OLED devices

InactiveUS20050186123A1Extend your lifeImprove efficiencySamplingOther chemical processesChange colorPolymer bonding

Novel uses and methods of use for inorganic and macroreticulate polymer bonding to metals to control moisture and oxygen in OLED, and other like devices, are provided. Materials having color change capacity are also provided for the removal of moisture from an OLED, where the material changes color upon reaching its capacity and thereby signals the user that the OLED is no longer protected from moisture damage.

Owner:MATHESON TRI GAS

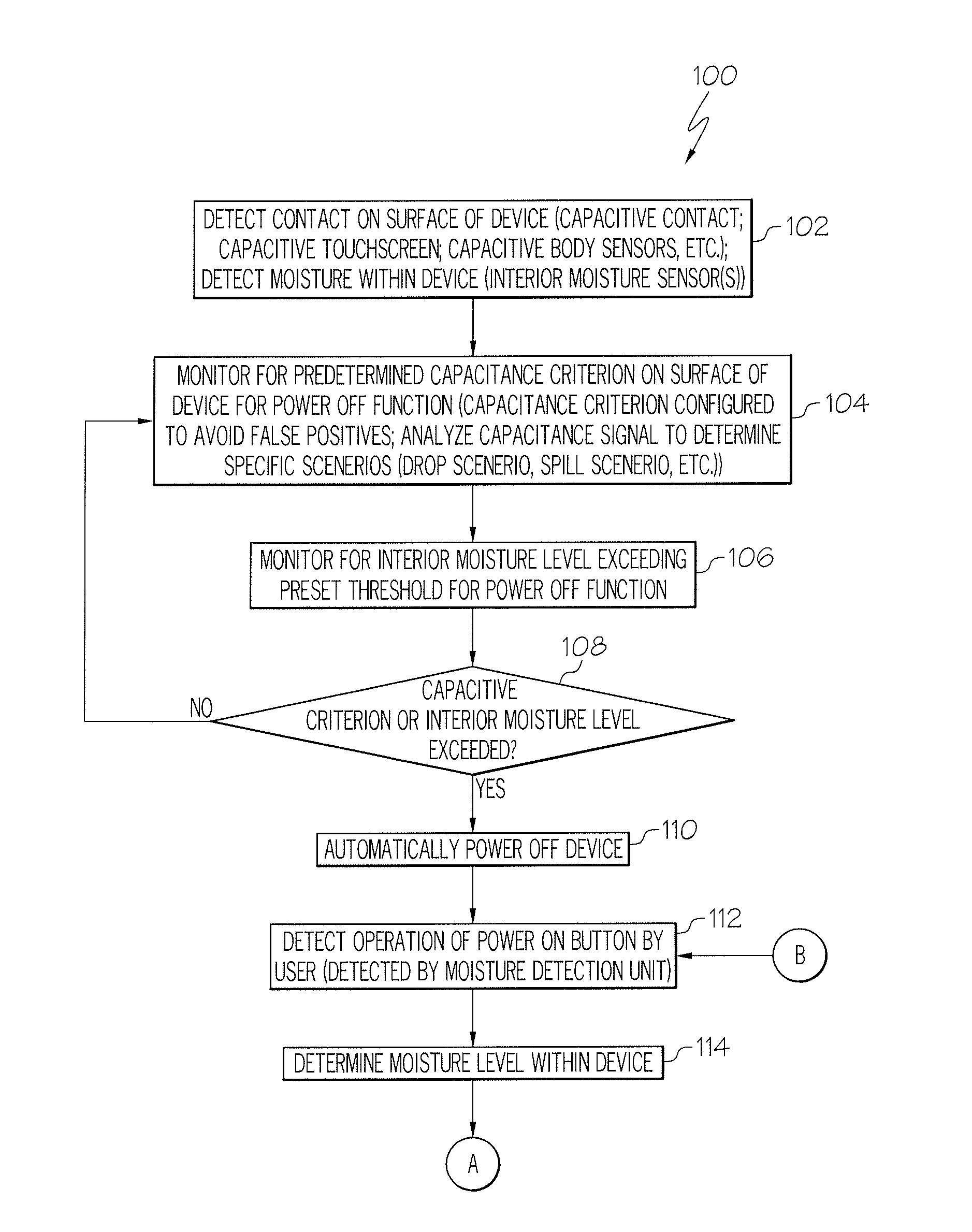

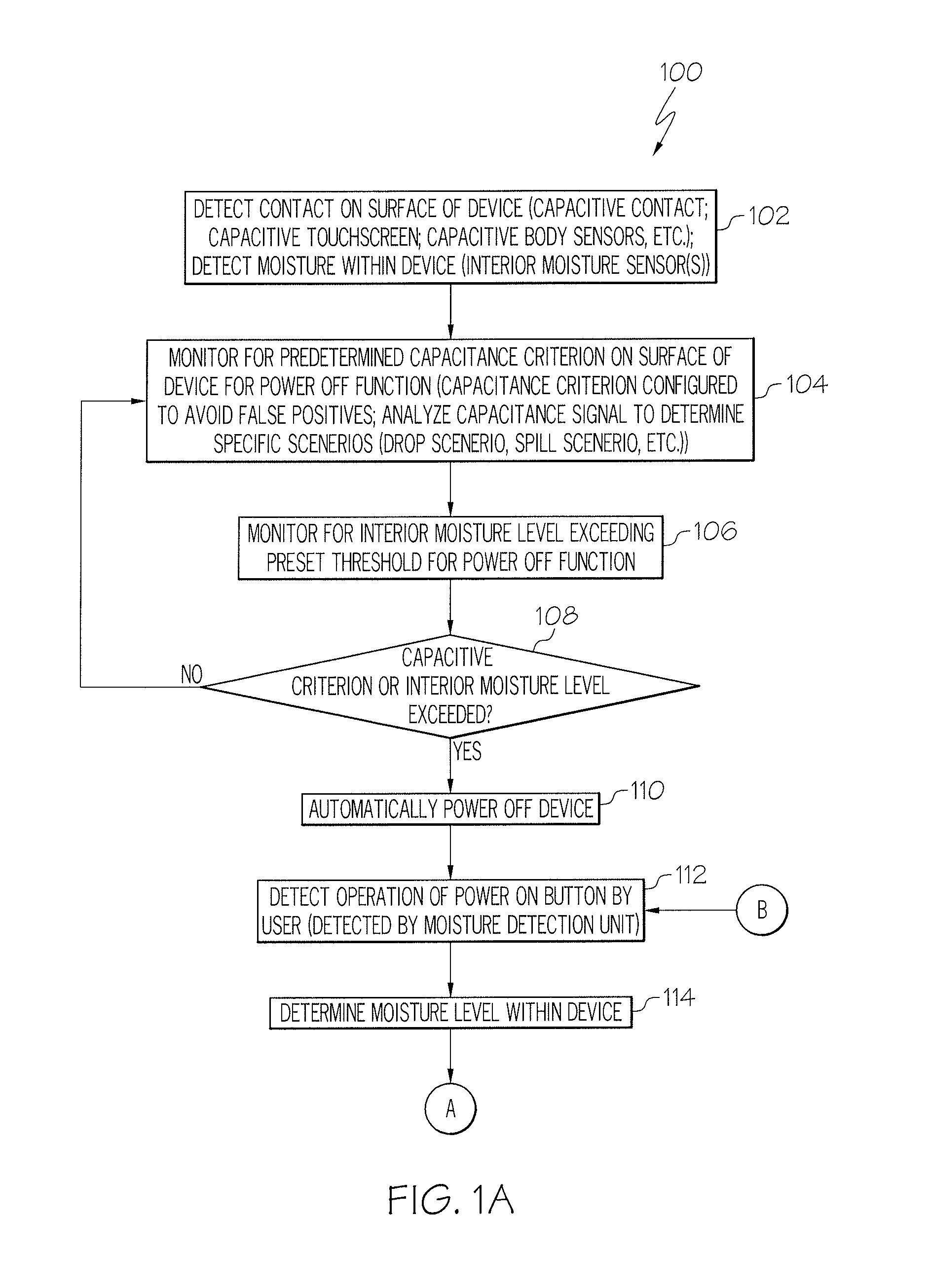

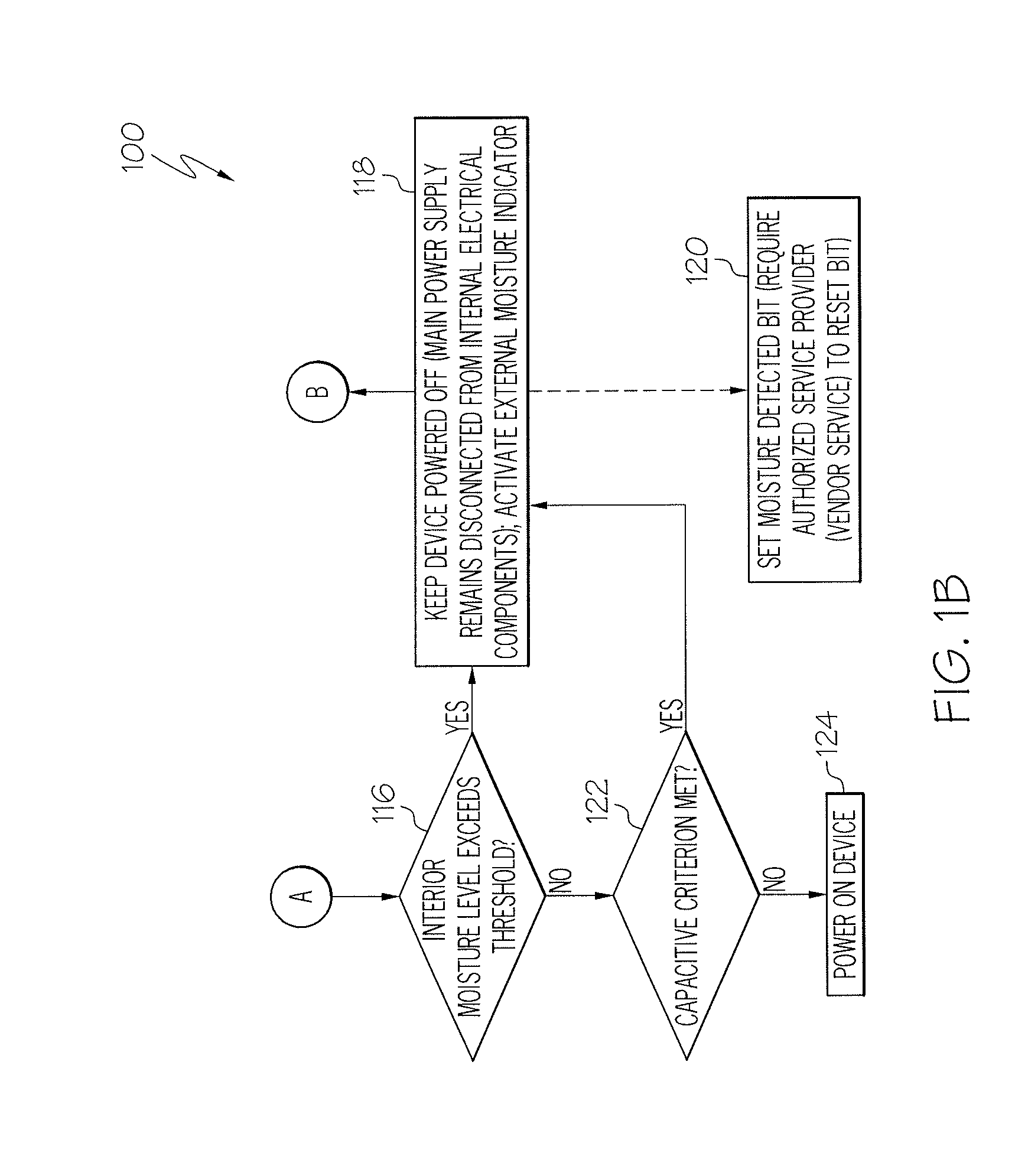

Preventing moisture damage to a device

InactiveUS20150016001A1Avoid moisture damageAvoid powerEmergency protective arrangements for automatic disconnectionCapacitanceMoisture Damage

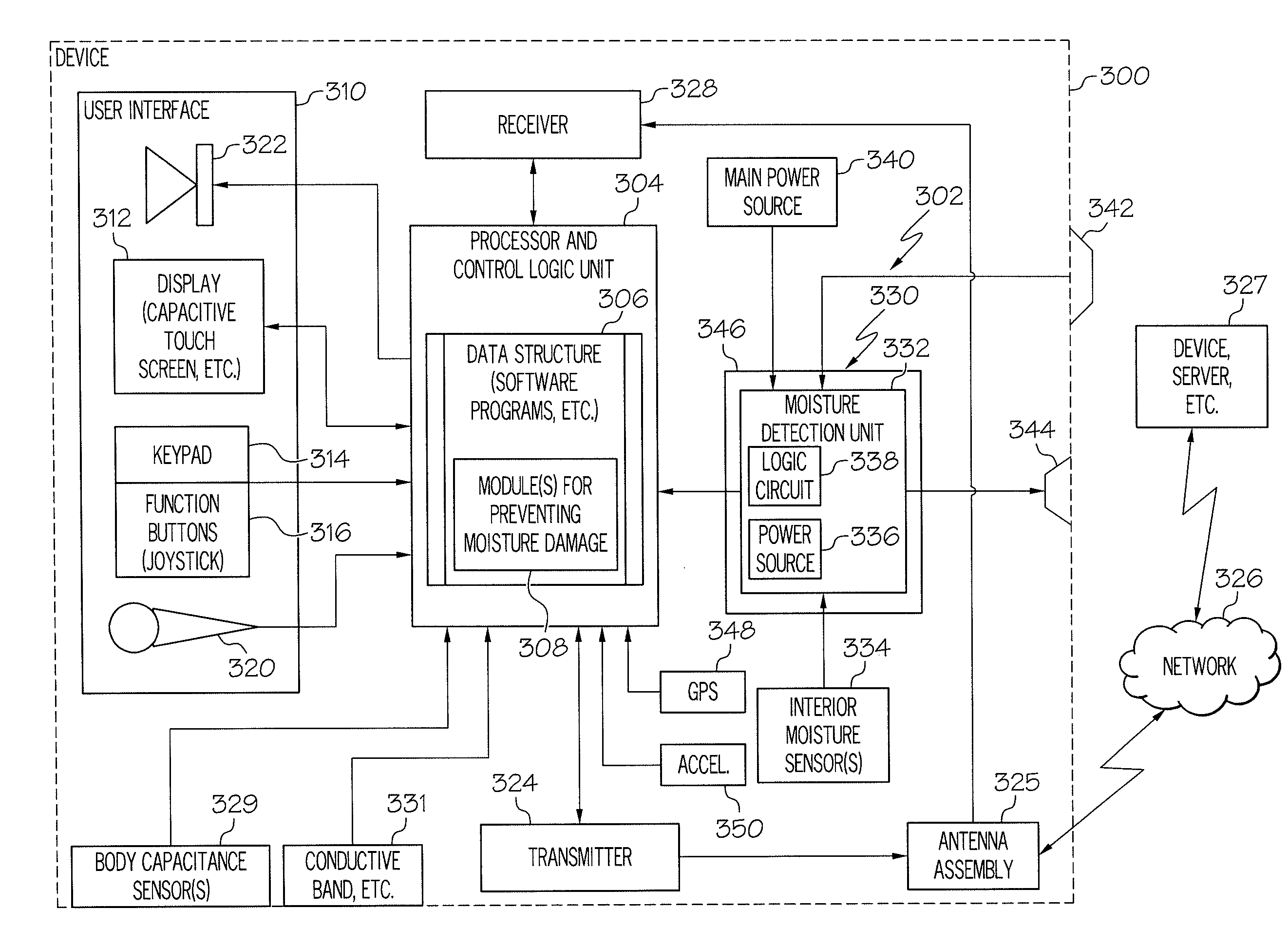

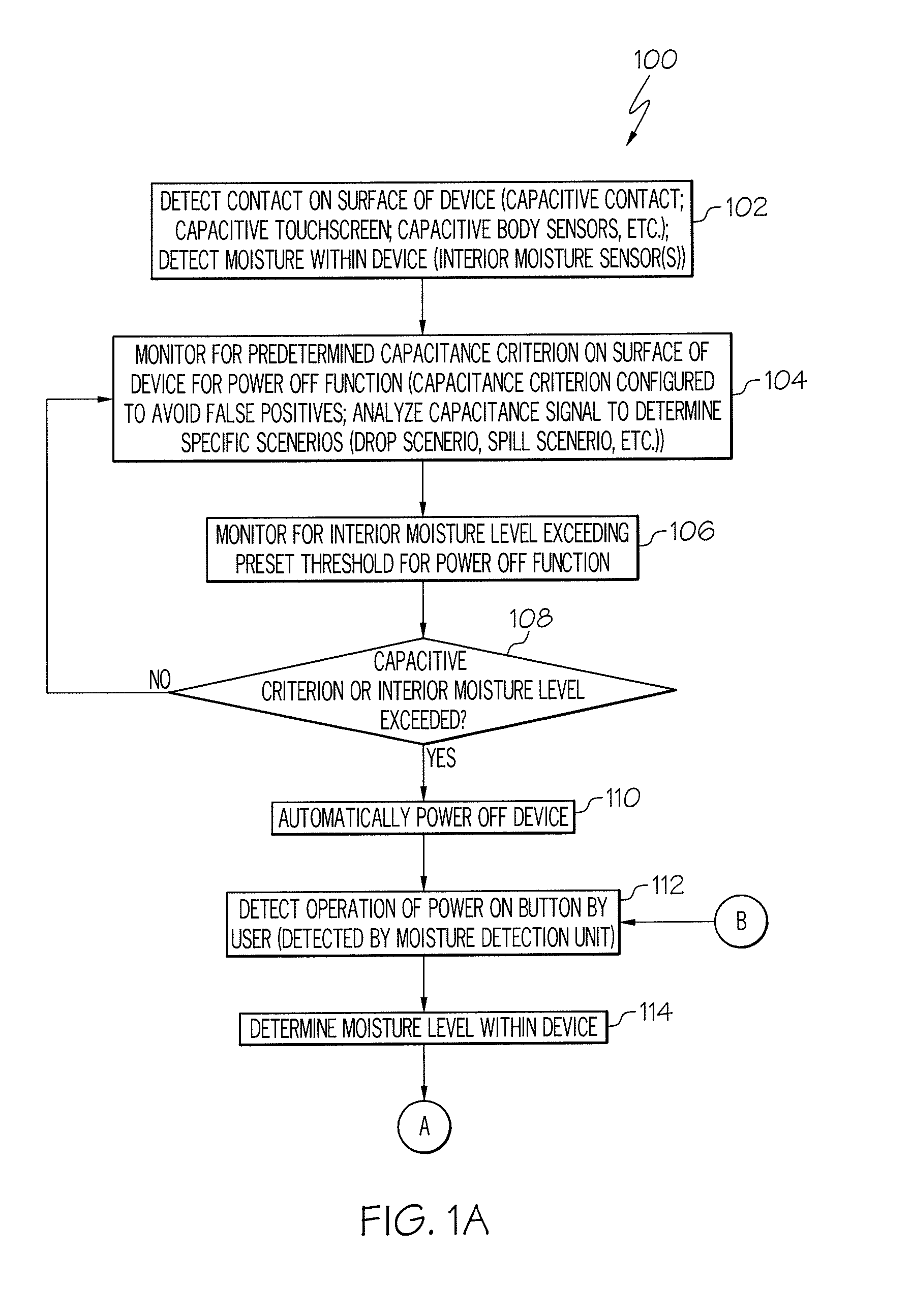

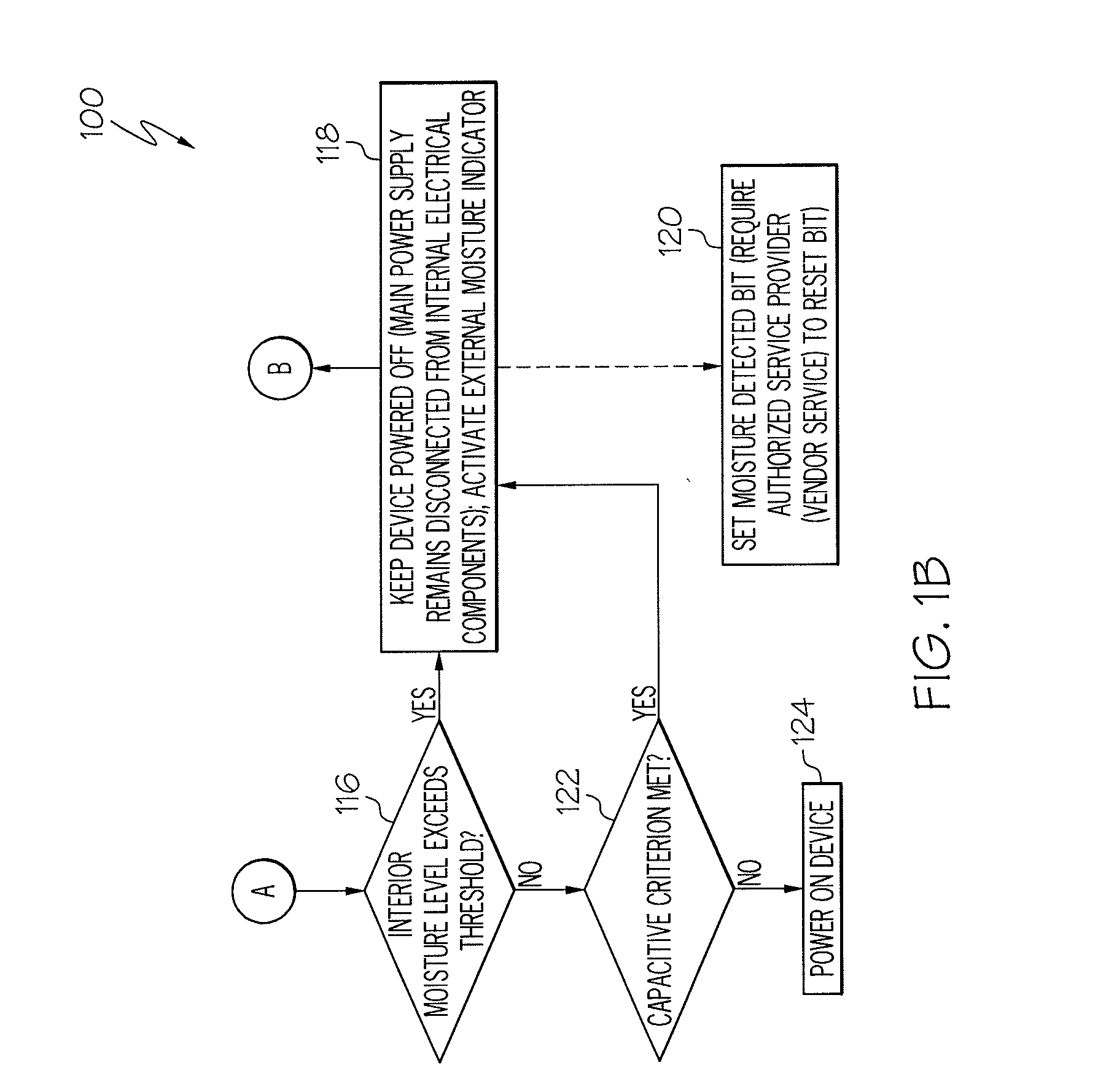

A method, device and computer program product for preventing moisture damage to electronic circuitry of a device may include monitoring for a predetermined capacitance criterion on a surface of the device; and automatically powering off the device in response to detecting the predetermined capacitance criterion.

Owner:GLOBALFOUNDRIES INC

Moisture reduction and mold and moisture damage preventative system and method in construction

ActiveUS20050011962A1Reduce moistureRemove moistureSpace heating and ventilation safety systemsSpace heating and ventilation control systemsEngineeringMoisture

A moisture removal system and method employing air movers, dehumidifiers, heaters and attendant methods for reducing moisture in a construction project. The method and system include operating moisture removal equipment and testing moisture content levels sufficient to reduce the moisture content levels to a desired threshold to reduce the likelihood of mold growing or moisture damage in the construction after it is completed.

Owner:SAVANNAH IP

Methods and materials for the reduction and control of moisture and oxygen in OLED devices

InactiveUS7553355B2Extend your lifeImprove efficiencyCombination devicesAuxillary pretreatmentPolymer bondingChange color

Novel uses and methods of use for inorganic and macroreticulate polymer bonding to metals to control moisture and oxygen in OLED, and other like devices, are provided. Materials having color change capacity are also provided for the removal of moisture from an OLED, where the material changes color upon reaching its capacity and thereby signals the user that the OLED is no longer protected from moisture damage.

Owner:MATHESON TRI GAS INC

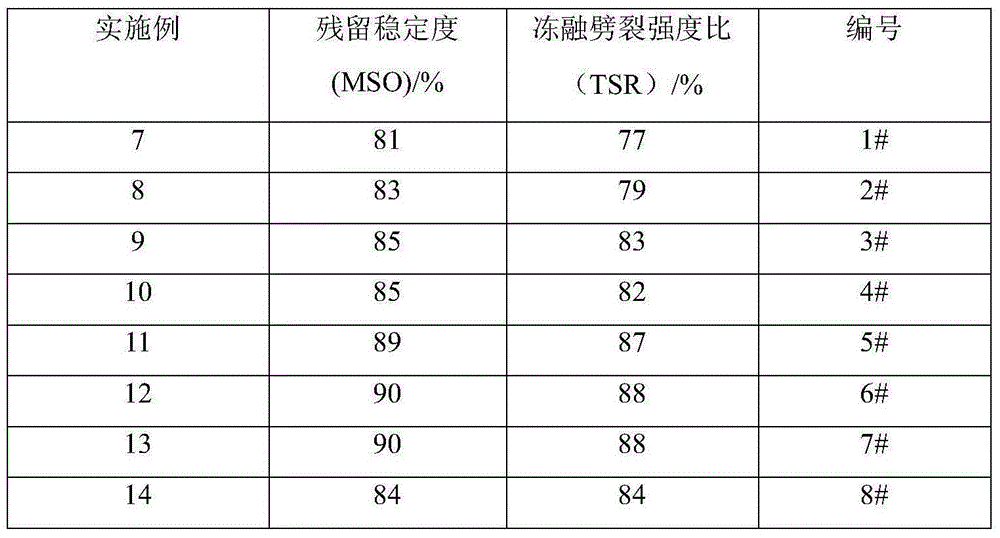

Cement stabilized base material, preparation, application and preparation method of road base

The invention discloses a cement stabilized base material, a preparation, an application and a preparation method of a road base. The cement stabilized basic material comprises the following materials: 1%-3% of basic slag and 1%-3% of cement and base materials, wherein the basic materials comprises 0.5%-8% of desulfurization gypsum and 92%-99.5% of crushed stone in mass percentage of the basic materials. The preparation method of the cement stabilized base material comprises the step of uniformly mixing the components. According to the preparation method of the road base, the road base is prepared from the cement stabilized base material with the conventional preparation process and conditions. The cement stabilized base material has the advantages as follows: the material cost is reduced, the service life of a road structure is prolonged, the economic benefit is increased, the cement setting time is delayed, the strength, the airtightness, the water retention, the water resistance, the shrinkage crack resistance, the freeze-thaw resistance, the moisture damage resistance and sulfate corrosion resistance of the material are improved, novel application of the desulfurization gypsum is exploited, and the environment is protected effectively.

Owner:SHANGHAI HIGHWAY BRIDGE (GRP) CO LTD +1

Composite stabilizer for SBS modified asphalt

ActiveCN104513489ASolve the problem of high temperature storage stabilityImprove high and low temperature stabilityBuilding insulationsHigh temperature storageBenzoyl peroxide

The invention relates to a composite stabilizer for SBS modified asphalt. The composite stabilizer comprises the following components in parts by mass: 30 to 60 parts of a cross-linking agent, 10 to 40 parts of an accelerator, 10 to 20 parts of an activating agent and 5 to 20 parts of a compatilizer, wherein the cross-linking agent is one or more of sulfur, dithiomorpholine, polyphosphoric acid and maleic anhydride; the accelerator is one or more of tetraethylthiuram disulfide, 2-mercaptobenzothiazole, benzoyl peroxide, dicumyl peroxide and sodium isopropyl xanthate. Compared with the prior art, the composite stabilizer has the advantages that after the composite stabilizer is added into the SBS modified asphalt, the problem that the high-temperature storage stability of the SBS modified asphalt is poor is well solved, the performances such as high-temperature and low-temperature stability and water stability of an asphalt mixture are comprehensively improved, and high-temperature anti-rutting performance, low-temperature anti-cracking performance, moisture damage resistance and ageing resistance are remarkably improved.

Owner:山西省交通科技研发有限公司

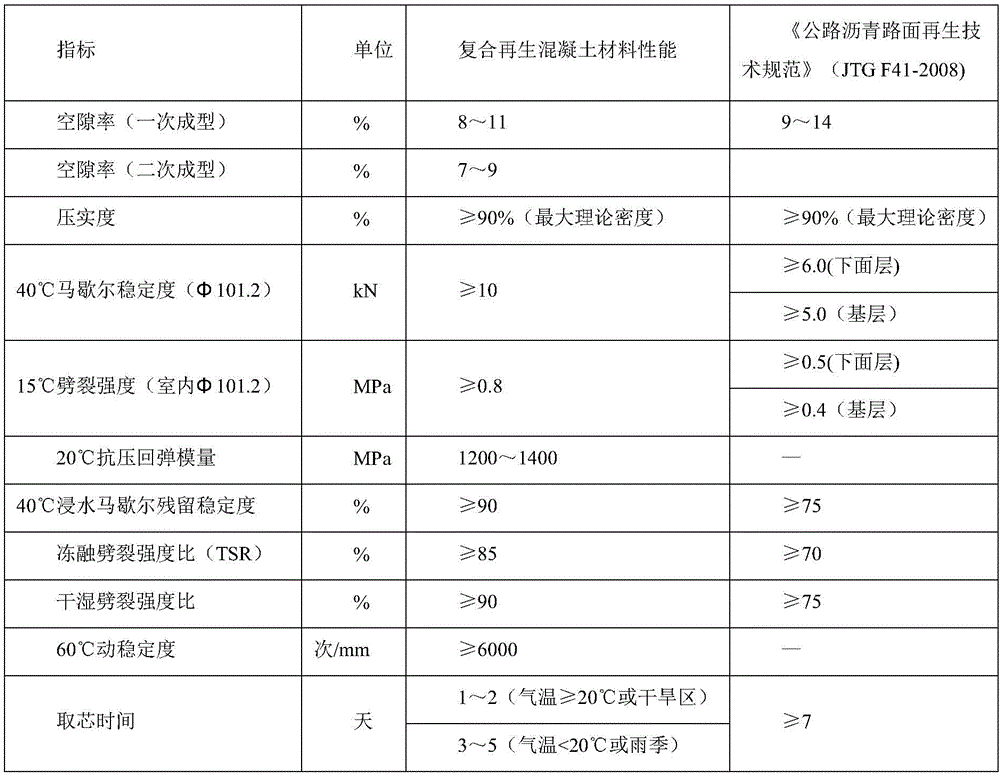

Compound regenerative asphalt concrete

The invention provides compound regenerative asphalt concrete, which is prepared from the following ingredients (by weight): 30 parts of 0-5 mm regenerative asphalt concrete RAP, 25 parts of 5-10 mm regenerative asphalt concrete RAP, 28 parts of 10-30 mm regenerative asphalt concrete RAP, 15 parts of 10-30 mm new aggregate, 2 parts of mineral powder, 1.5 parts of cement, 3.5-4.2 parts of emulsified asphalt and 0.5-1.5 parts of a regenerant. By adding a certain proportion of the regenerant, an asphalt pavemill material undergoes compound regeneration. Thus, material performance of a regenerated mixture is enhanced. Voidage is lower, the material is more compact, moisture damage resistance is stronger, and durability is better.

Owner:BEIJING SAINT GROUND HIGHWAY TECH

Preventing moisture damage to a device

InactiveUS20150016000A1Avoid powerAvoid moisture damageEmergency protective arrangements for automatic disconnectionCapacitanceEngineering

A device including a system for preventing moisture damage to the device includes a processor and a module operable on the processor for monitoring for a predetermined capacitance criterion on a surface of the device. The device is automatically powered off in response to detecting the predetermined capacitance criterion.

Owner:GLOBALFOUNDRIES INC

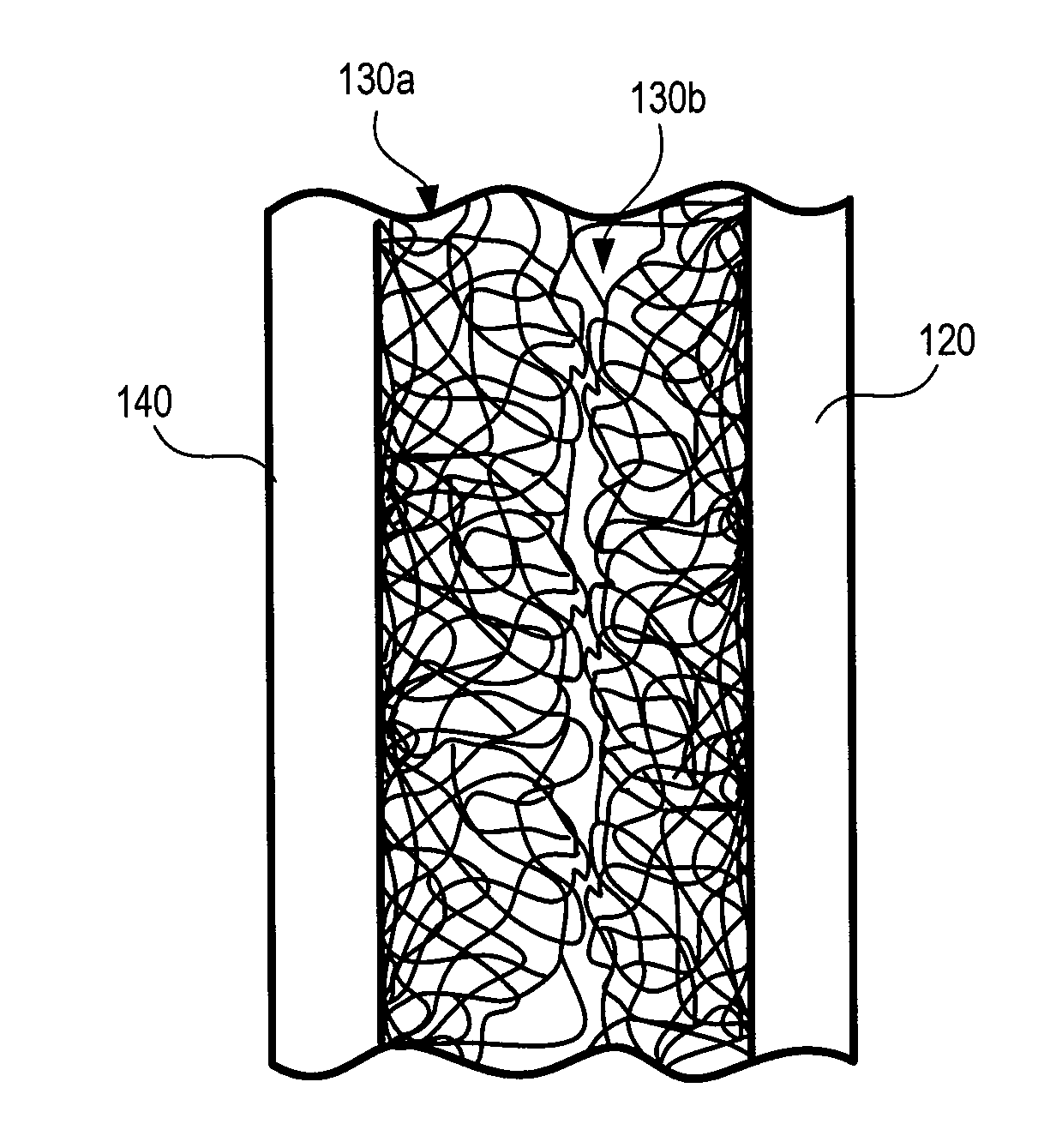

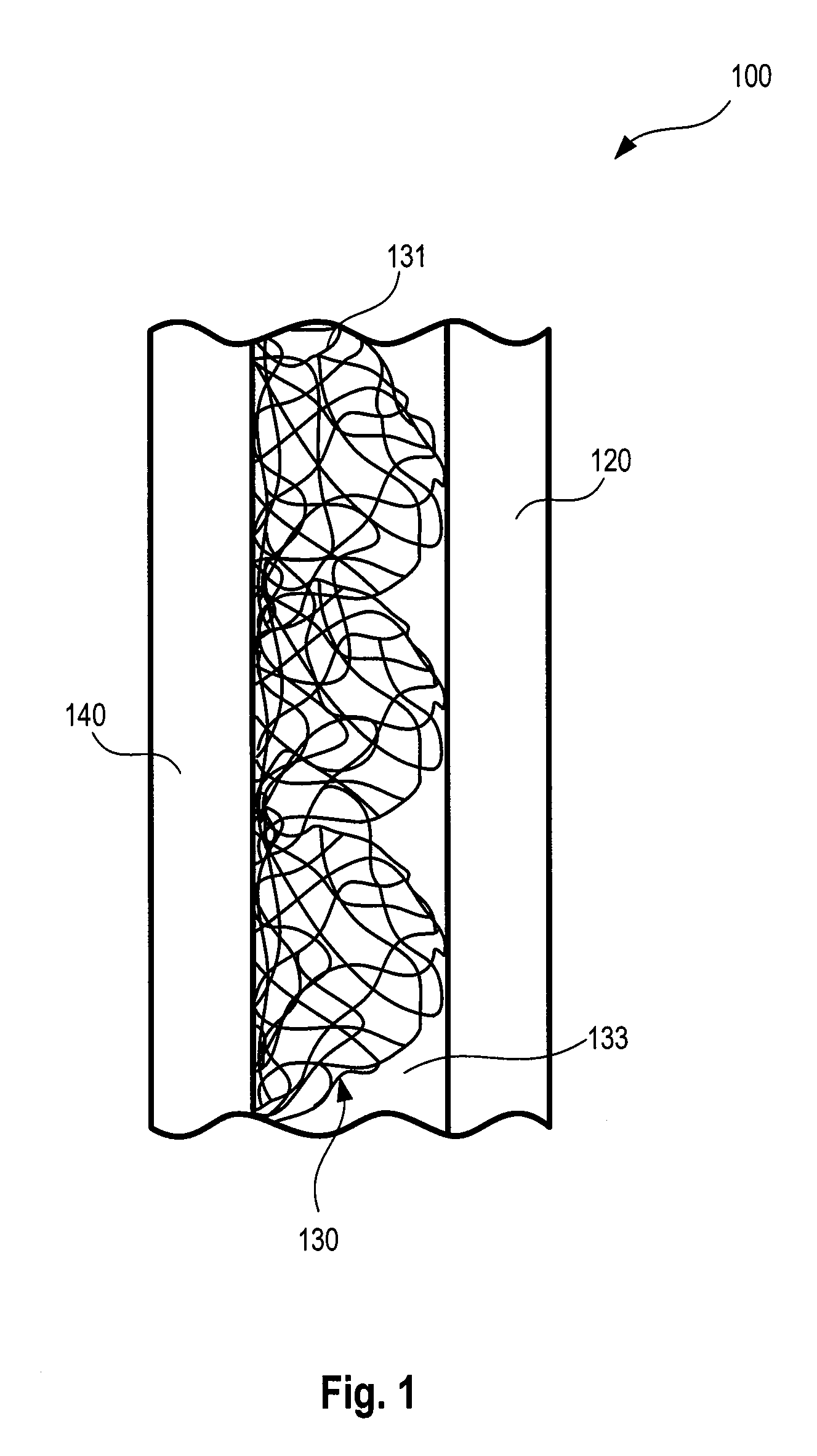

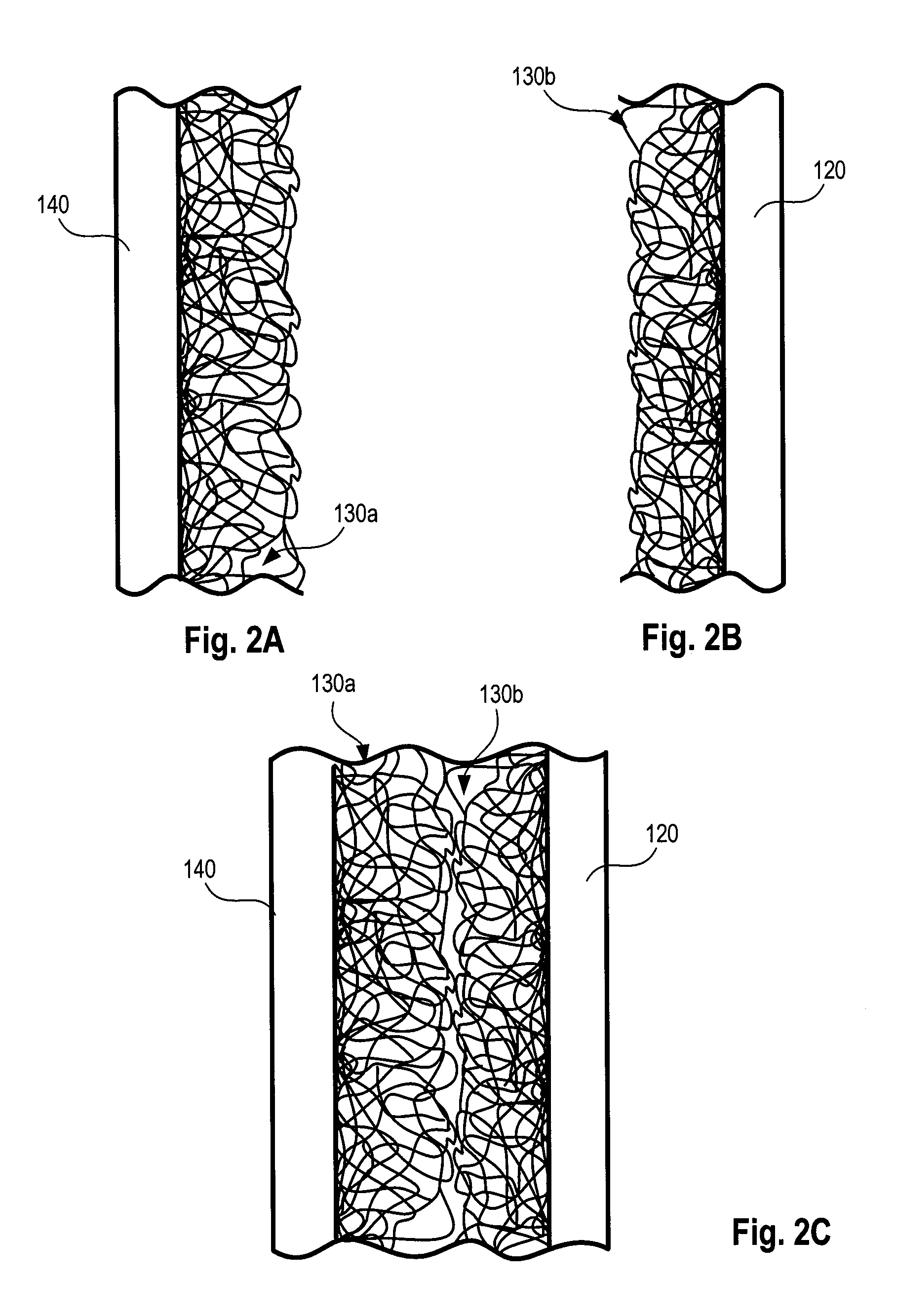

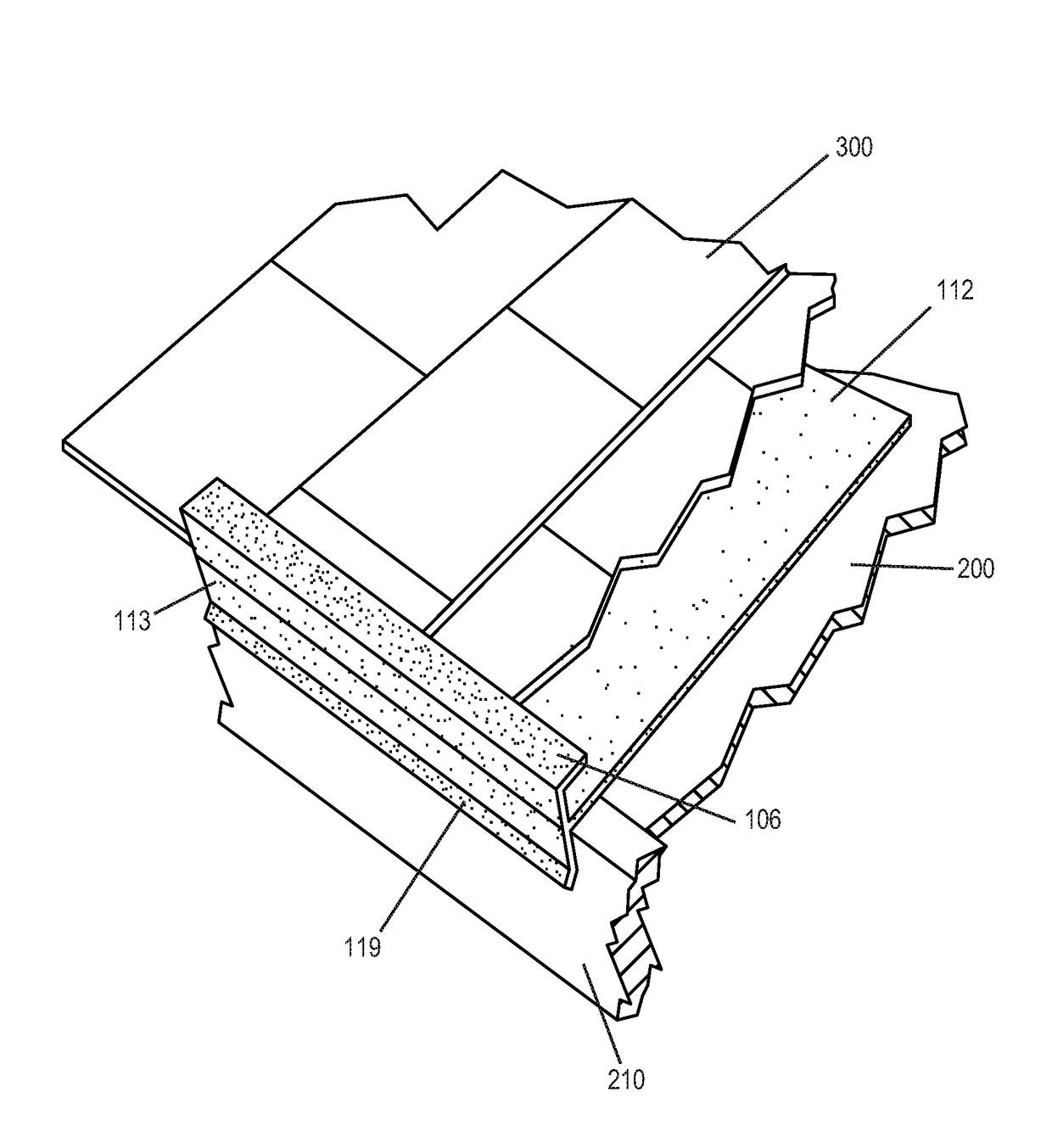

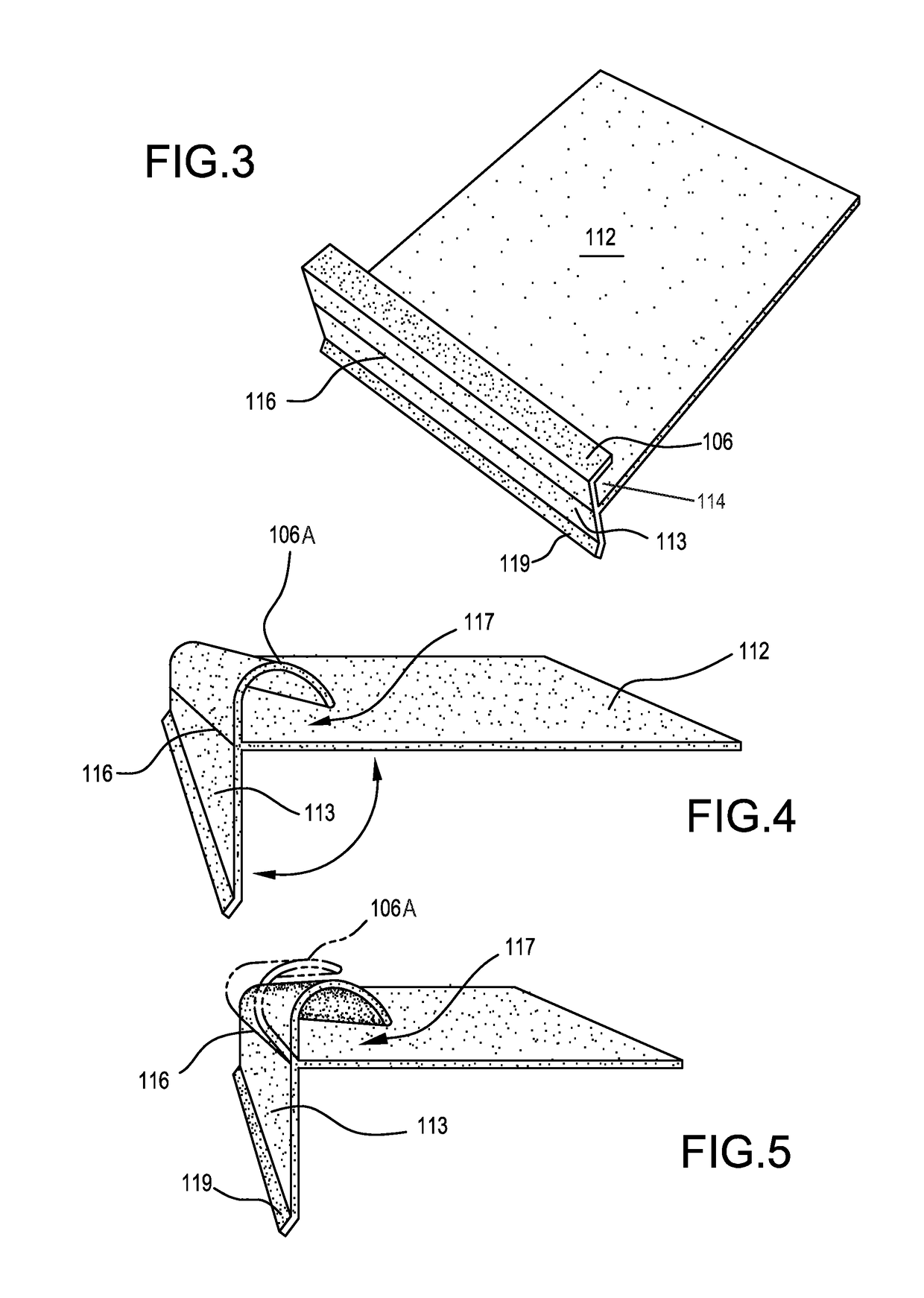

Multilayer laminate system and method used within building structures

InactiveUS7807011B2Avoid moisture damageFloorsSynthetic resin layered productsResistive barrierEvaporation

Trapped moisture in the walls of a building structure may result in the building materials prematurely deteriorating unless there is a way for the moisture to escape. A rainscreen drainage mat provides an open cavity for the trapped moisture to escape by evaporation or gravity by draining the moisture out of the wall cavity. The multilayer laminate system includes a weather resistive barrier, drainage mat, and facer material as one application to be used within building structures to prevent moisture damage. In addition, the multilayer laminate system and method is configured to create a water resistive envelope at building material interfaces.

Owner:STUC O FLEX INT

Coal mining ground fissure moisture damage detection method taking space-time difference and rainfall impact into consideration

ActiveCN103076437AEliminate the effects ofFull impact scienceEarth material testingEcological environmentData information

The invention relates to a coal mining ground fissure moisture damage detection method taking space-time difference and rainfall impact into consideration, and belongs to the technical field of environmental monitoring. The method comprises the following steps: establishing a spatial coordinate system for ground and underground comparison, and selecting an undisturbed area at the front end of the working plane mining progress as a moisture monitoring area; determining moisture background value and moisture spatial distribution of the monitoring area; acquiring fissure position located in a moisture contour line, of the monitoring area; determining soil moisture background value around a fissure; actually measuring the soil moisture background value around the fissure in the whole ground fissure development cycle; correcting moisture content in which rainfall impact is excluded; and obtaining moisture content in which spatial variability impact is removed. By adopting the method provided by the invention, the moisture damage impact of ground fissure on the surrounding soil can be more fully and scientifically grasped to provide data information for regional land reclamation and ecological environment.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

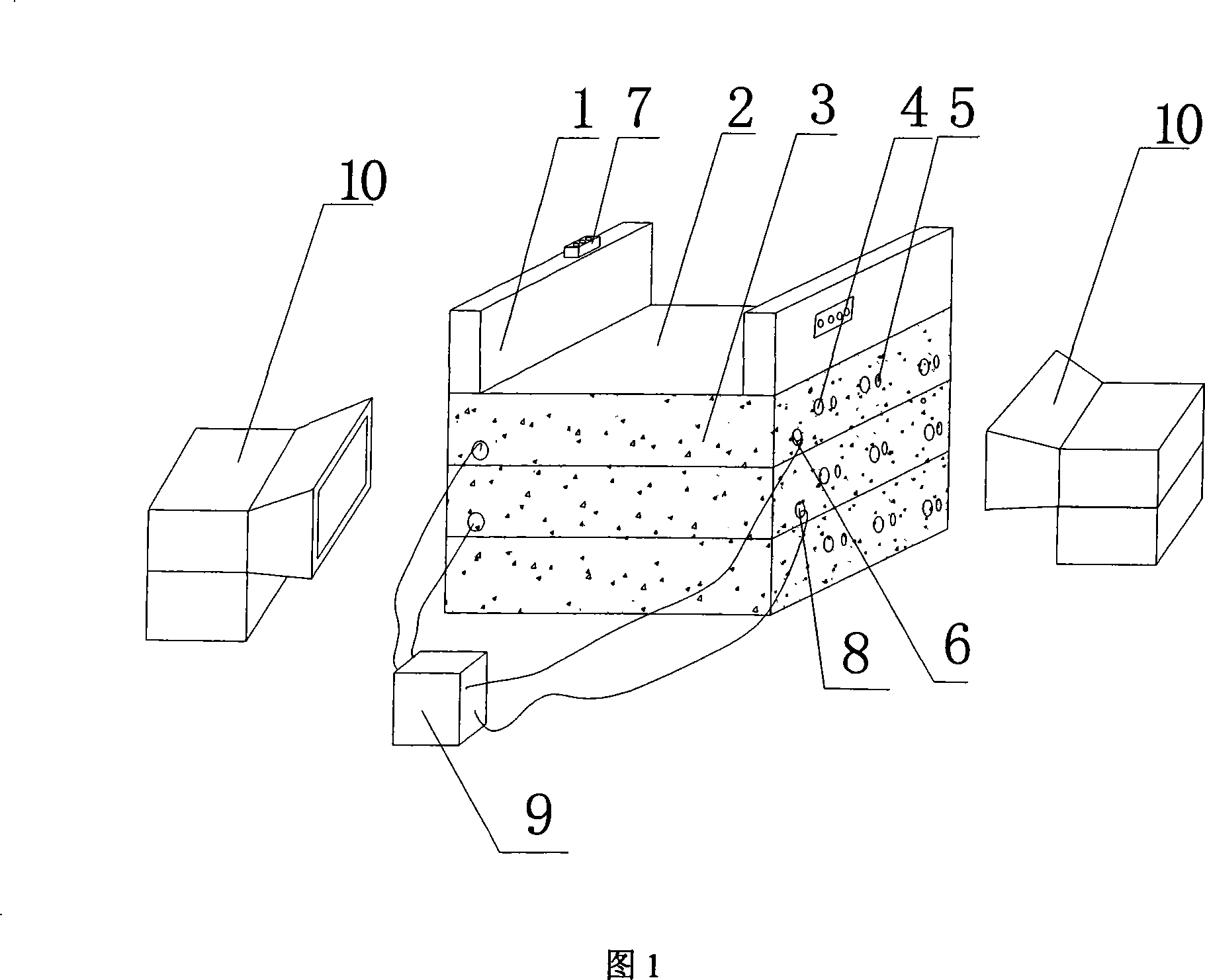

Simulation test testing device for asphalt concrete pavement water destruct

InactiveCN101226187AEasy to observeEasy to recordOptically investigating flaws/contaminationMaterial testing goodsEngineeringRoad surface

The invention relates to a simulation test device of moisture damage on pitch concrete road, which comprises a shell made from transparent material, a groove on the upper of the shell, a pitch concrete sample in the shell, a heater and a refrigerator in the sample, a plurality of test points on different positions on the shell, resistivity test points provided on the test points and connected with a test device outside the shell via wires, and a plurality of cameras on different parts of the shell. When in use, user sprays colorful water on the upper of the pitch concrete sample, after permeation, uses a roller to roll in the groove, uses the heater or refrigerator to simulate the internal temperature change of pitch concrete road, uses high-speed camera to record the water condition of roadbed section, tests the resistivities of different regions to obtain the water distribution and obtain the rule and reference of roadbed pore water damage on roadbed, therefore, user can take relative processes to reduce road damage and save resource.

Owner:SHANDONG UNIV

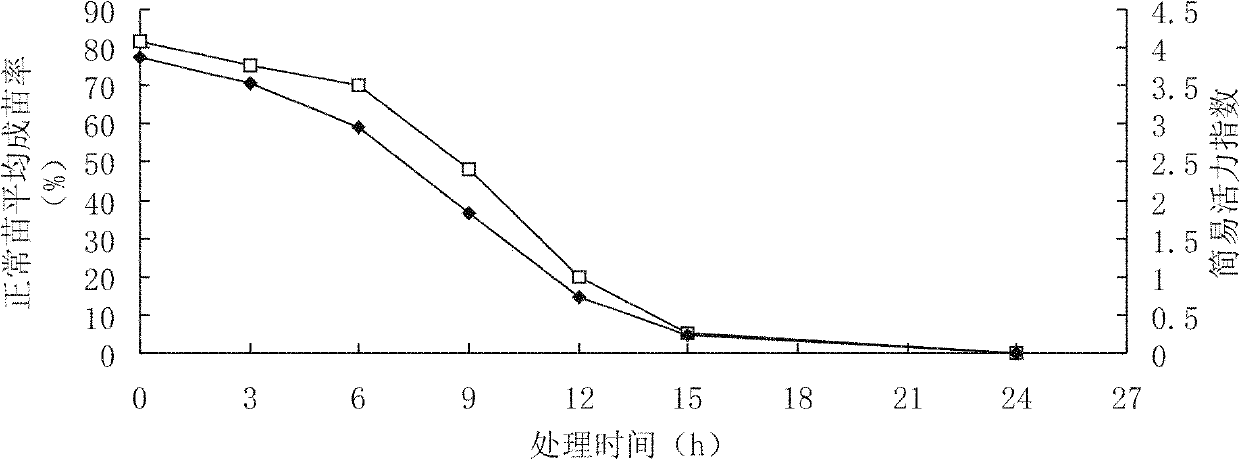

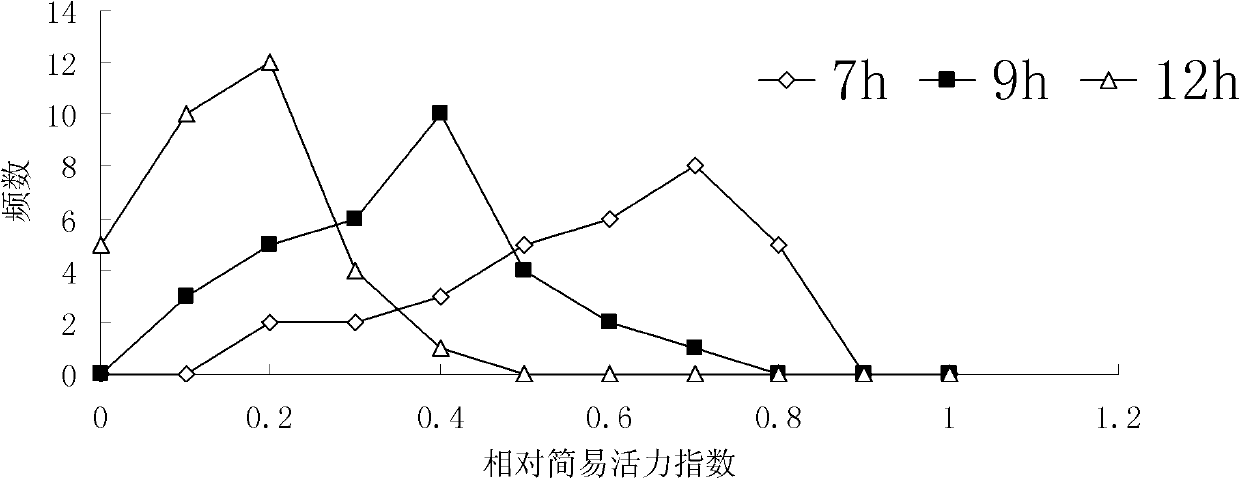

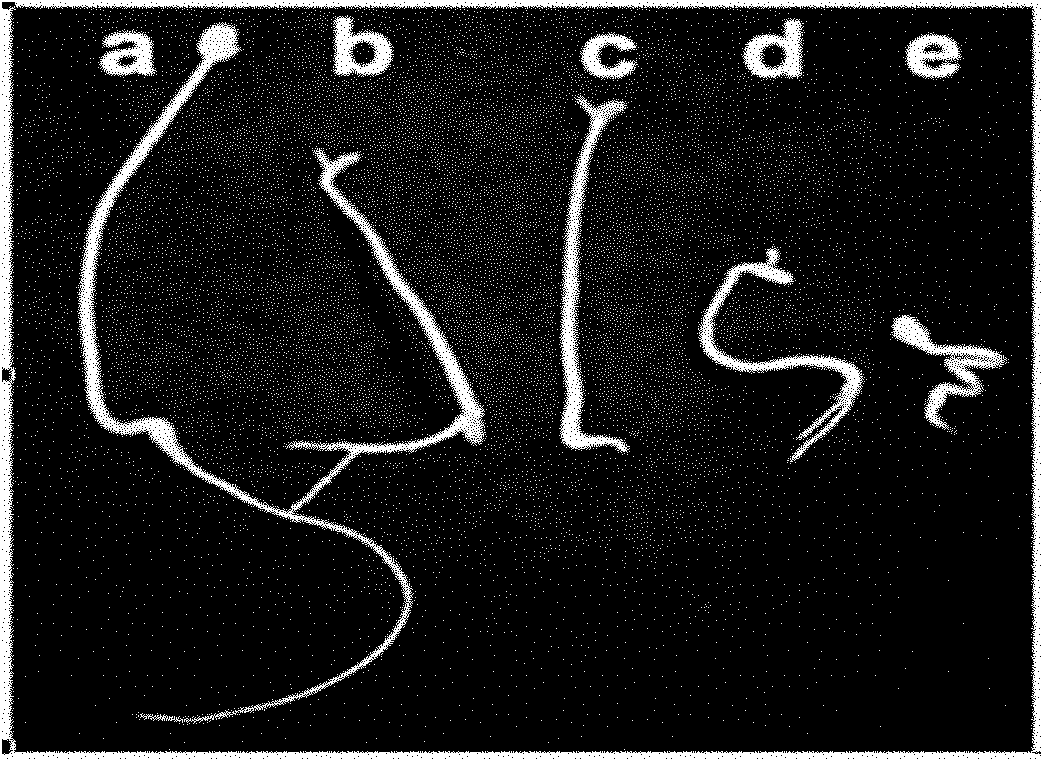

Method for identifying moisture resistance of sesame during germination

InactiveCN101990821AImprove controllabilityReduce investmentSeed and root treatmentHorticulture methodsSesamum orientaleDistilled water

The invention relates to a method for identifying moisture resistance of sesame during germination, which comprises the following steps of: (1) germinating the sesame seed until sprout emerges; (2) soaking treatment; soaking one part of seed; cultivating the other part of seed at constant temperature of 28-30 DEG C, wherein the cultivating time is equal to soaking time, and the cultivated seed is used for non-soaking comparison; (3) aftertreatment: washing the emerged seed subjected to soaking treatment in the step (2) with distilled water and then cultivating the seed at constant temperature of 28-30 DEG C; keeping on cultivating the emerged seed subjected to non-soaking comparison treatment, wherein the cultivating time is equal to the cultivating time of the seed subjected to soaking treatment; (4) measuring and calculating relative survival rate of normal seedling; and (5) dividing moisture resistance level into high moisture resistance, moisture resistance, middle moisture resistance, available moisture resistance and unavailable moisture resistance according to the relative survival rate of the normal seedling. The method is easy to operate, low in cost and reliable in result, has the characteristic of exactly reflecting the reaction to moisture damage during the germination of the sesame, and provides technical and material support for cultivating moisture-resistant variety and identifying moisture resistance of new variety.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Fiber compound regenerative asphalt concrete

The invention provides fiber compound regenerative asphalt concrete, which is prepared from the following ingredients (by weight): 30 parts of 0-5mm regenerative asphalt concrete RAP, 25 parts of 5-10 mm regenerative asphalt concrete RAP, 28 parts of 10-30 mm regenerative asphalt concrete RAP, 15 parts of 10-30 mm new aggregate, 2 parts of mineral powder, 1.5 parts of cement, 4 parts of emulsified asphalt, 1 part of a regenerant and 1.2 parts of glass fiber. The glass fiber of 6 mm long is added to improve material performance of a cold recycled mixture. The glass fiber is obviously better than other fibers. The special fiber has obviously more excellent dispersion effect in the cold recycled mixture than other fibers, and the regenerative mixture is smooth to discharge. The fiber compound regenerative asphalt concrete provided by the invention has obviously more excellent material performance than the code requirements. Tension strength, namely cleavage strength, of the mixture is raised. Material anti-cracking ability is more excellent, reflection crack resistance is stronger, the material is more compact, moisture damage resistance is stronger, and durability is better.

Owner:BEIJING SAINT GROUND HIGHWAY TECH

Oilseed rape ridge culture plantation method

InactiveCN105123179AHigh yieldImprove production efficiencyFertilising methodsHorticultureDiseaseRidge

The invention relates to the field of oilseed plantation and in particular relates to an oilseed rape ridge culture plantation method comprising the following steps of selecting double-low hybrid high-yield oilseed type, broadcasting and nursing seeds, ploughing a growing field, and unloading soil and forming ridges. Acquired oilseed seedlings are transplanted to the ridge surface; the plantation density is 1300 to 1600 plants / mu; base fertilizer is applied during field ploughing; fertilizers are applied during the growth of the oilseed; and insect and diseases are prevented until the oilseed is harvested. Special oilseed types are employed for broadcasting and nursing by the plantation method; oilseeds are planted in ridges to reduce moisture damage; the oilseed are planted in low density, so individual environment relationship can be cooperated, great ventilation and light transmission capability are achieved and plant individual growth can be facilitated; oilseed per unit area yield of the production area can be improved and oilseed production efficiency can be improved; oilseed production level can be enhanced; obvious economic, ecological and social benefits can be achieved; reliable scientific foundation is laid for systematic oilseed ridge thin planting mode in a paddy field is formed; and practical production can be guided.

Owner:覃宇春

Direct-vat type high-adhesion bituminous mixture modifier and preparation method thereof

InactiveCN104693823AControl "Secondary Pollution"Low costBuilding insulationsBulk chemical productionCrack resistancePolymer science

The invention discloses a direct-vat type high-adhesion bituminous mixture modifier and a preparation method thereof. The modifier is prepared by regenerated rubber with high desulfurization degree, modified high-temperature coal tar pitch and a skeleton proppant at the mass ratio of (30-50) to (30-50) to (5-20) in stirring and extruding manners. The preparation method of the modifier comprises the following steps: deeply activating waste rubber through high-temperature and high-shearing action of a double-screw extruder, thus obtaining the high-desulfurization degree regenerated rubber; fully mixing a mixture of the modified high-temperature coal tar pitch, the high-desulfurization degree regenerated rubber and a skeleton backing material, which is modified by rubber pyrolysis oil under the blending action of a screw; and extruding and pelleting, so as to prepare the direct-vat type high-adhesion bituminous mixture modifier. The modifier disclosed by the invention is directly fed when the mixture is stirred, no extra equipment is used, and the process is simple and easy to operate; the bituminous mixture prepared by the method has excellent moisture damage resistance, good high-temperature anti-rutting performance, low-temperature crack resistance and excellent economic and social benefits.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

Wind preventive roofing drip edge starter strip

InactiveUS20180209153A1Eliminate needSafe installationRoof covering using tiles/slatesRoof drainageEngineeringMoisture Damage

Owner:HEO BAL

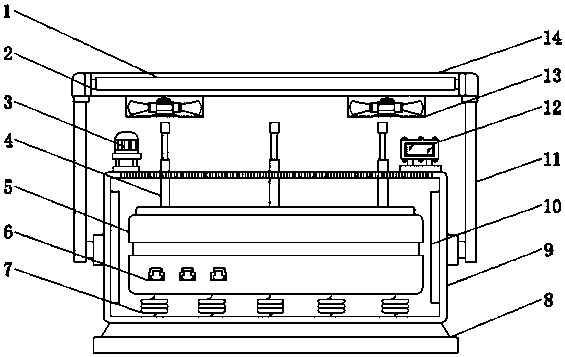

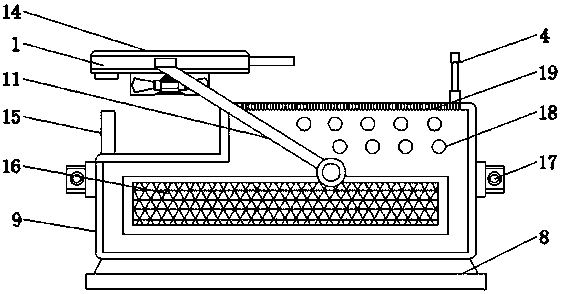

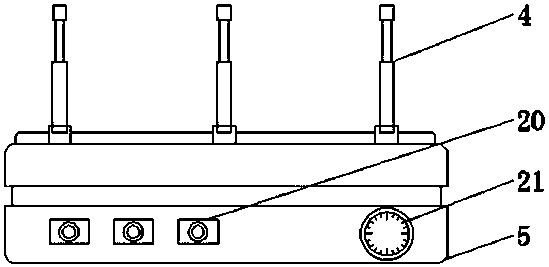

Router with environment monitoring function

InactiveCN107613740AImprove crash performanceAvoid breakingCasings/cabinets/drawers detailsAlarmsControl systemEngineering

The invention discloses a router with an environment monitoring function. The router comprises a router body, a sucker, an installation shell and a dust cover; the router body is installed in the installation shell, reset springs are evenly installed between the bottom of the router body and the inner bottom wall of the installation shell, an alarm is installed at one end of the top of the installation shell and close to a cable interface, and a humidity sensor is installed at one end of the top of the installation shell and away from the cable interface. The humidity sensor, the alarm and fans are installed at the top of the installation shell, humidity around the router is detected through the humidity sensor at anytime, the humidity sensor transmits signals to a control system in time,the control system controls the alarm to give alarms timely to have working staff notified, the fans blows on the router timely to kept the router dry, and moisture damage to internal components of the fans is avoided.

Owner:南宁恒腾科技有限公司

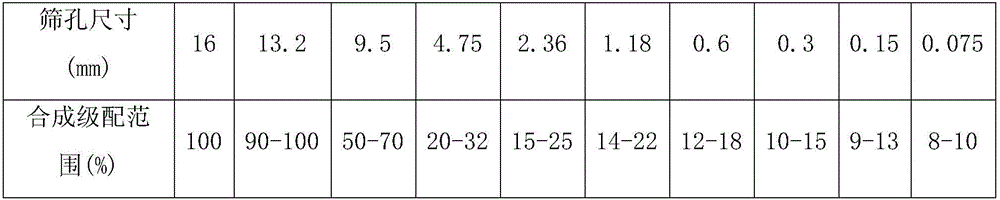

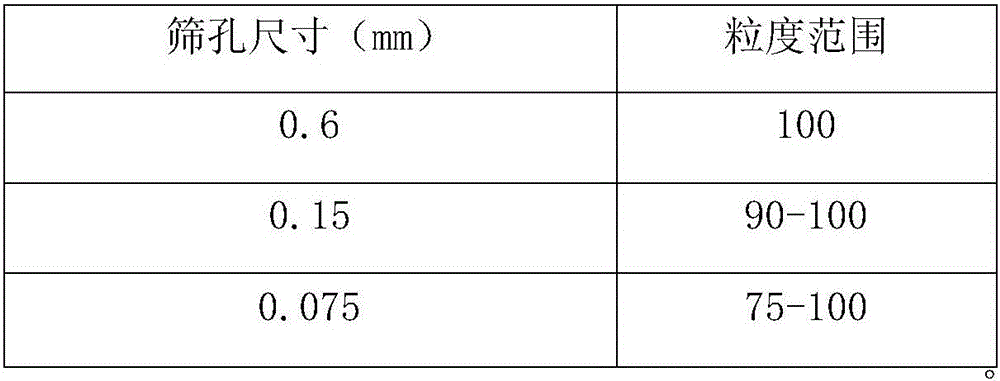

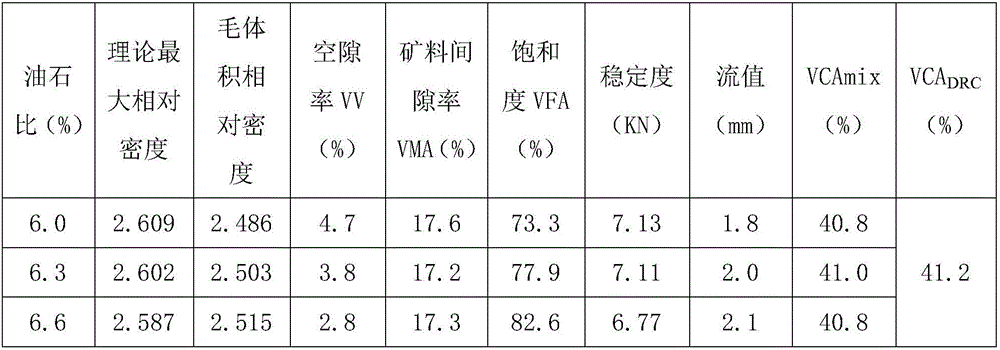

Preparation method of rubber asphalt mastic crushed stone mixture

The invention discloses a preparation method of a rubber asphalt mastic crushed stone mixture. The method comprises the following steps that radial tires or diagonal tires are selected, waste tire mouth ring parts are removed, and the treated tires are smashed into 30-mesh rubber powder at room temperature; applied aggregates are sieved grade by grade according to full meshes from 0.075 mm to 16 mm; asphalt is heated, the rubber powder is added simultaneously, and the mixture is conveyed to a storage tank for stirring and development; graded aggregates, lignocellulose and a high modulus agent are stirred to be uniform, the rubber asphalt is added, mixing is conducted to be uniform, and the rubber asphalt mastic crushed stone mixture is obtained. The binding force of the asphalt and crushed stone can be well improved, and the water sealing performance is good; after the lignocellulose is added, fibers form a net structure in an asphalt mixture, the reinforced effect can be formed, and meanwhile heating expansion of rubber is stable; rubber asphalt mastic and the aggregates have high binding force, and moisture damage resistance of the mixture is very high.

Owner:THE FIRST ENG CO LTD OF CTCE GRP

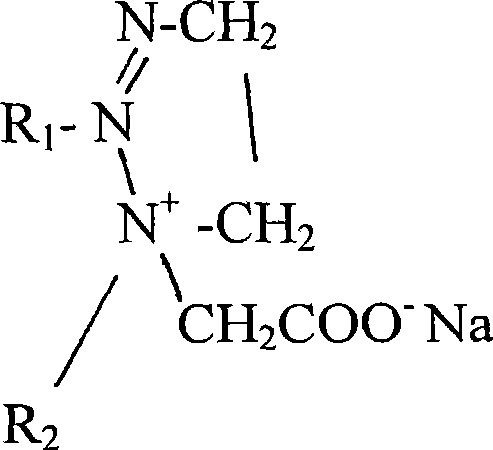

Process for preparing non-amine asphalt antistripping agent with amphiprotic activity

InactiveCN101508680AImprove anti-agingImproves resistance to water damageOrganic chemistryNitrogenRoad surface

The invention discloses a manufacturing method of an asphalt anti-stripping agent which has amphiprotic activity and contains no amine. The manufacturing method is characterized by employing the following formula and manufacturing process flow: a. formula: 20-80 parts of oleic acid by weight and 5-40 parts of amine by weight; and b. manufacturing process flow: adding the oleic acid and the amine to a reaction vessel according to weight ratio, heating to the temperature of 100-120 DEG C while stirring and introducing nitrogen, reacting for 2-4h, continuing to stir and heating to the temperature of 160-180 DEG C, reacting for 2-4h, and cooling to obtain the asphalt anti-stripping agent which has amphiprotic activity and contains no amine. The method overcomes the disadvantages of difficult former operation, high cost and unstable performances of asphalt mixtures due to repulsion between cationic asphalt anti-stripping agents and alkali stones. The manufacturing method is simple, and the asphalt anti-stripping agent manufactured by the method can greatly improve the moisture damage resistance of asphalt pavement, prolong the service life of asphalt pavement, and reduce the maintenance cost.

Owner:江苏文昌新材料科技有限公司

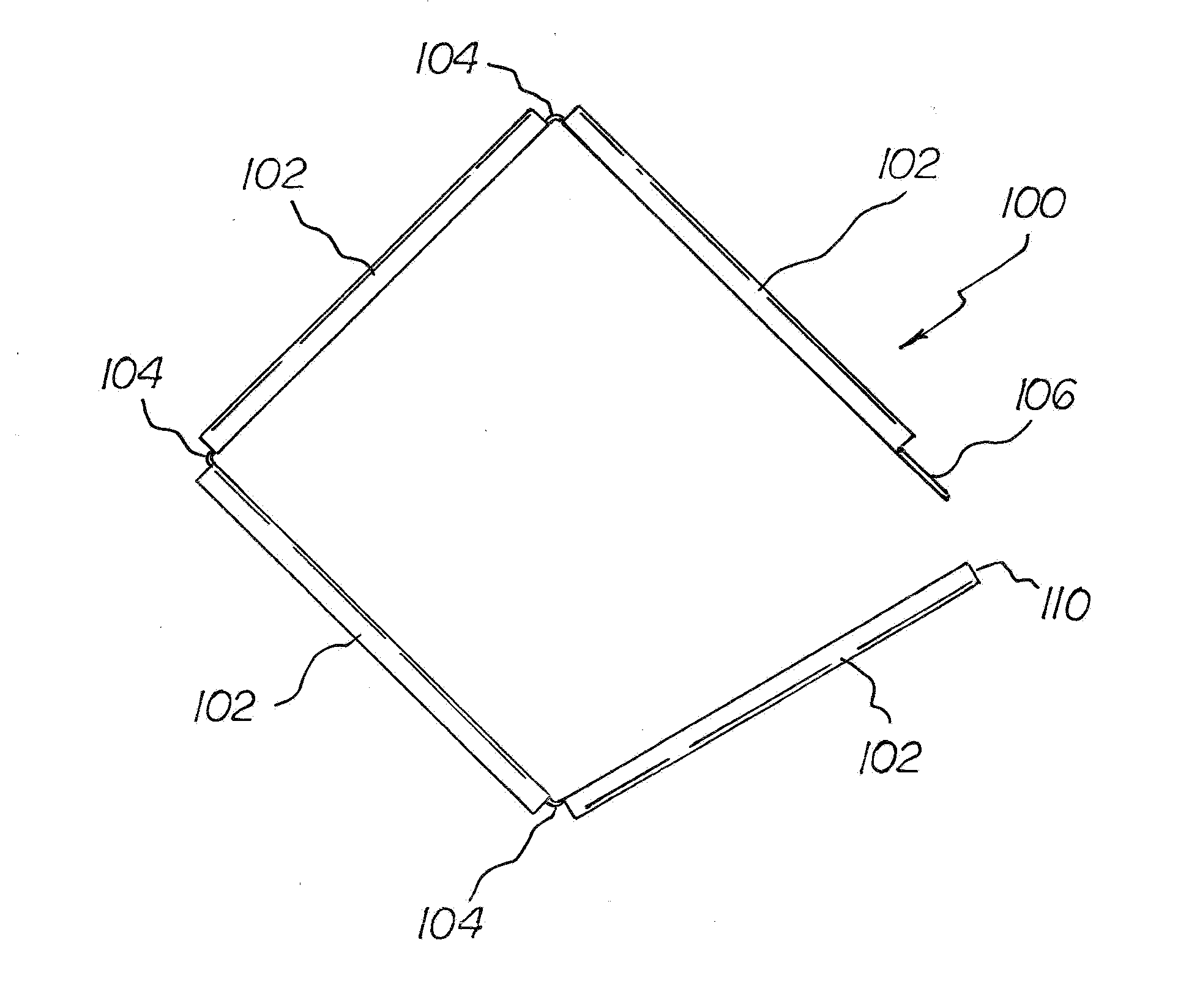

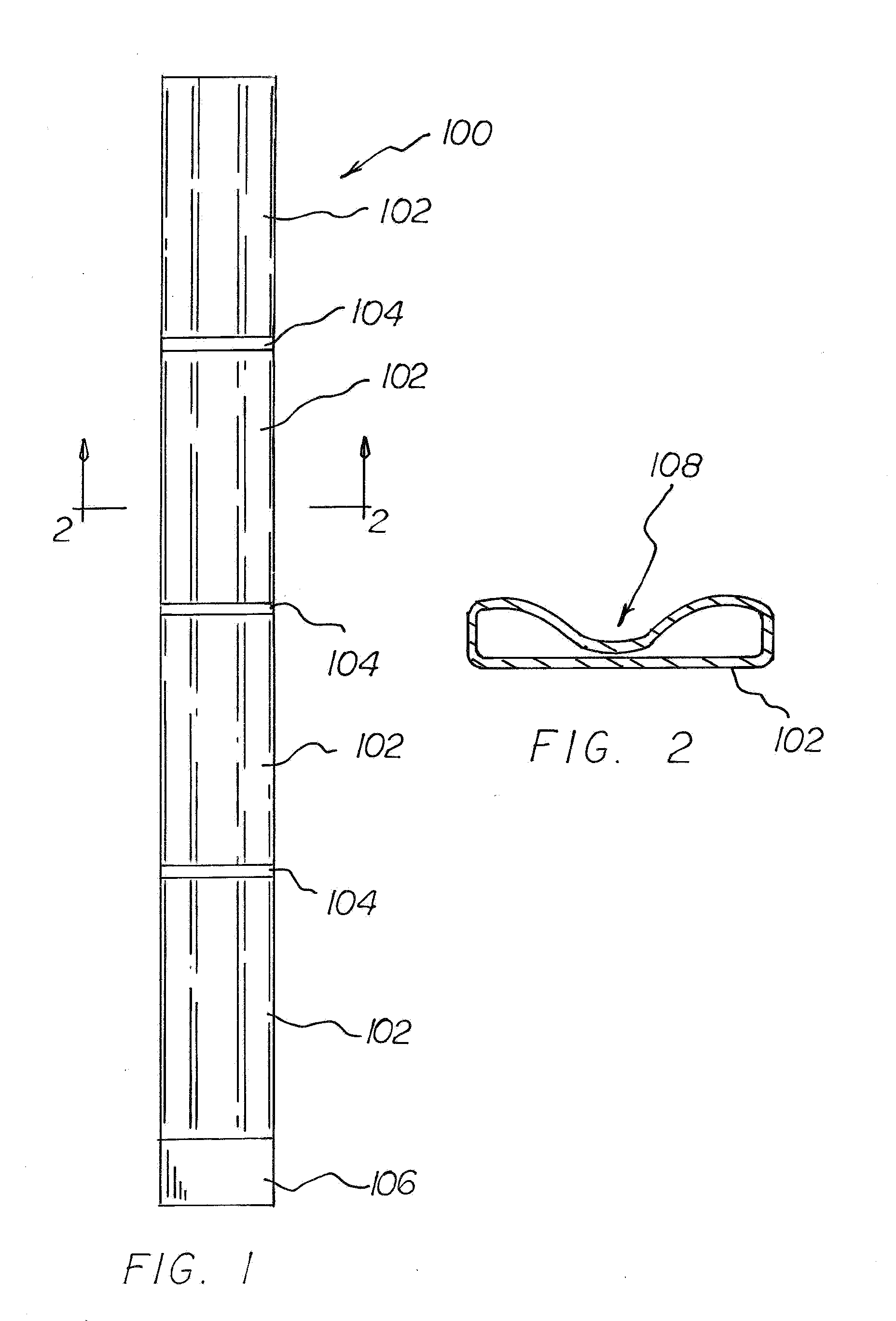

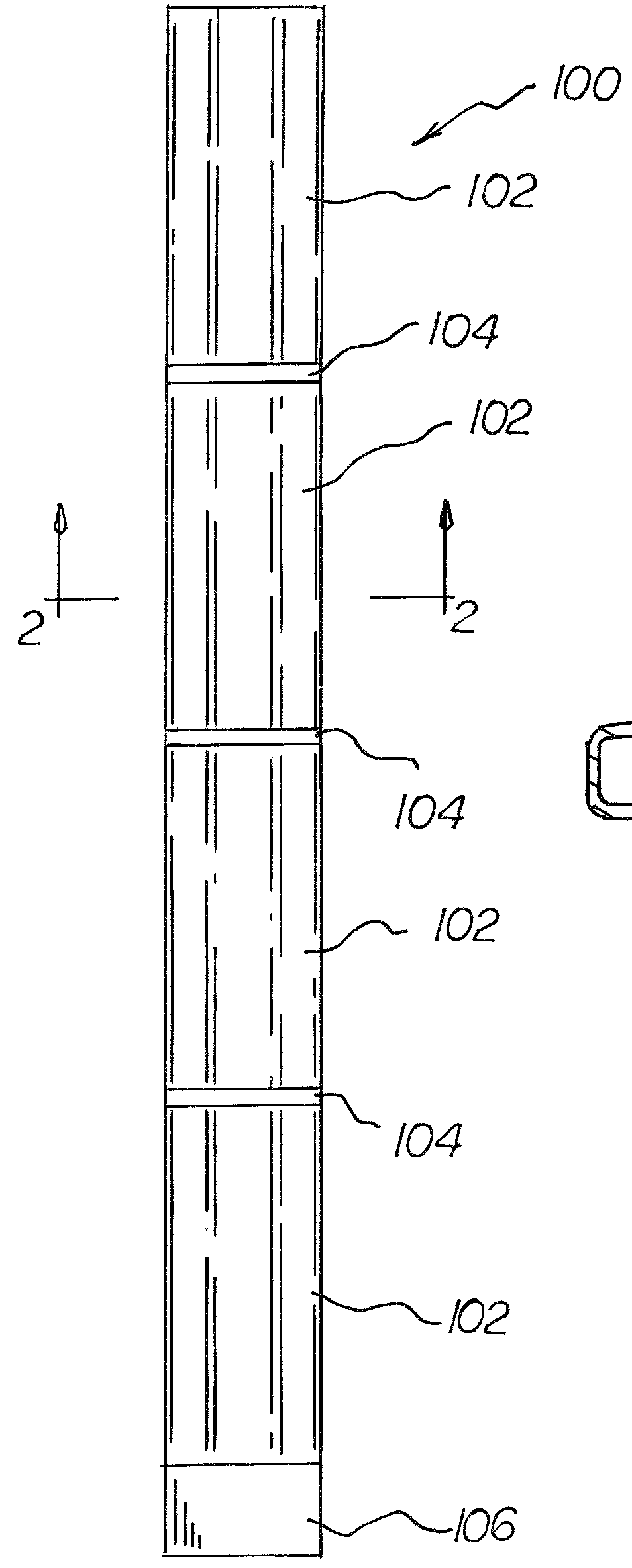

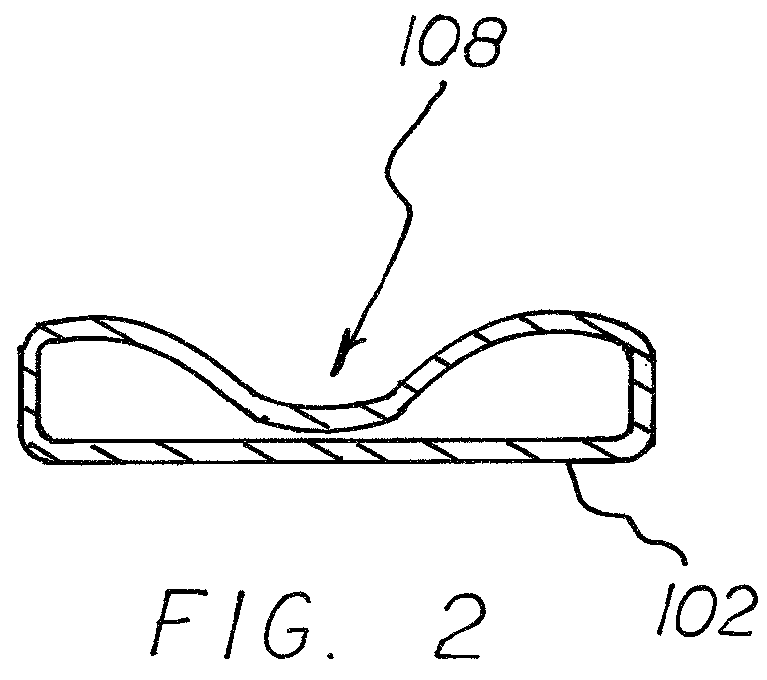

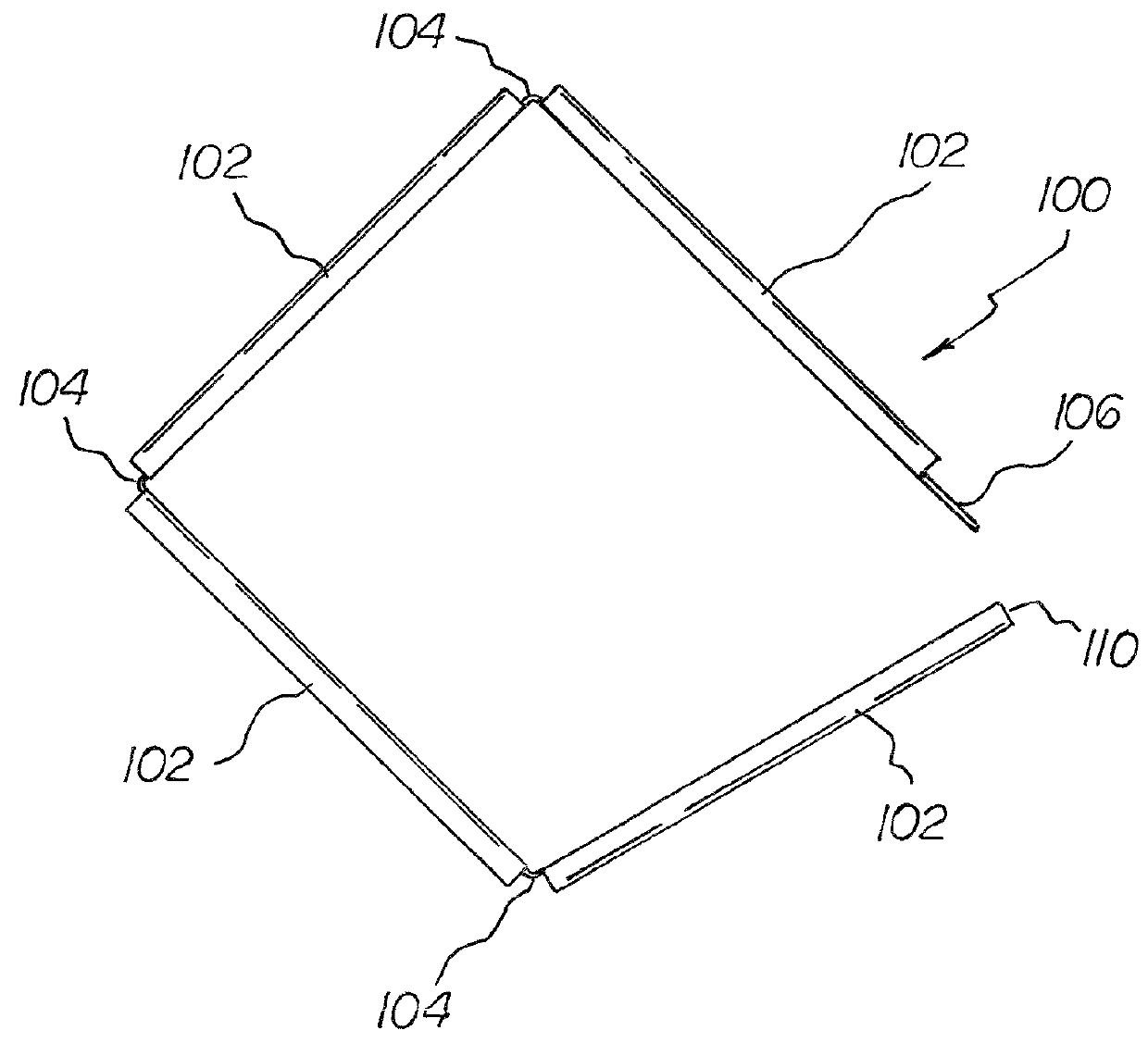

Collapsible cardboard concrete form

A collapsible cardboard concrete form is disclosed. In a particular embodiment the form includes a cardboard box beam having a depressed longitudinal section along an outer portion of its length for added structural integrity. A lateral notch is disposed in the outer portion of the form at intervals and across a width of the form to divide the form into what will be the sides of the form when assembled. The lateral notches include a flexible planar connector of an inner portion of the form to allow the notch to act as a hinge and bend to create each corner of the form. A tab extends from one end of the form and is used to tuck in an opposing end of the form. The surfaces of the form may be coated with wax, or other sealant, to prevent moisture damage to the form as the concrete is curing.

Owner:HUNT MARTY

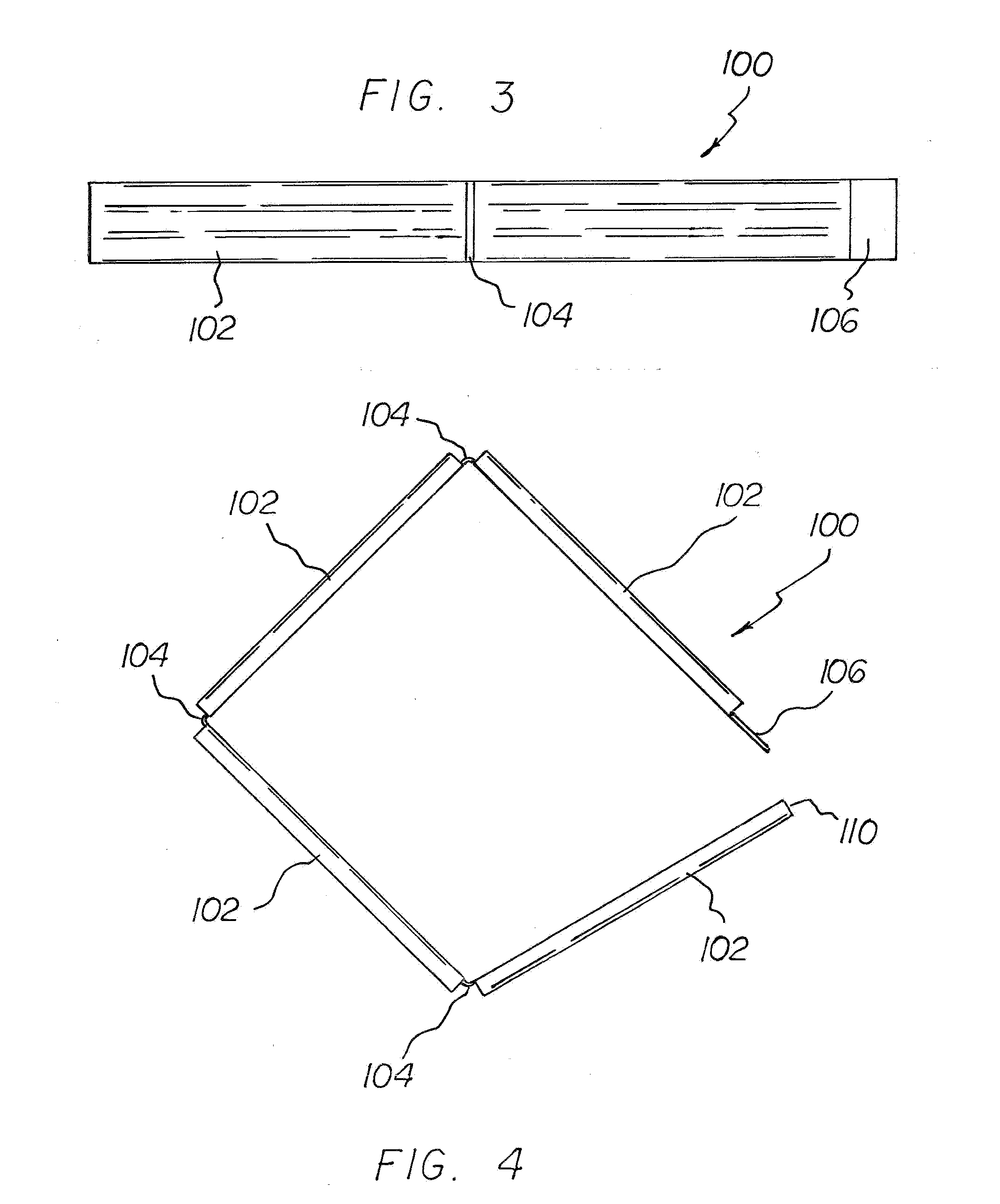

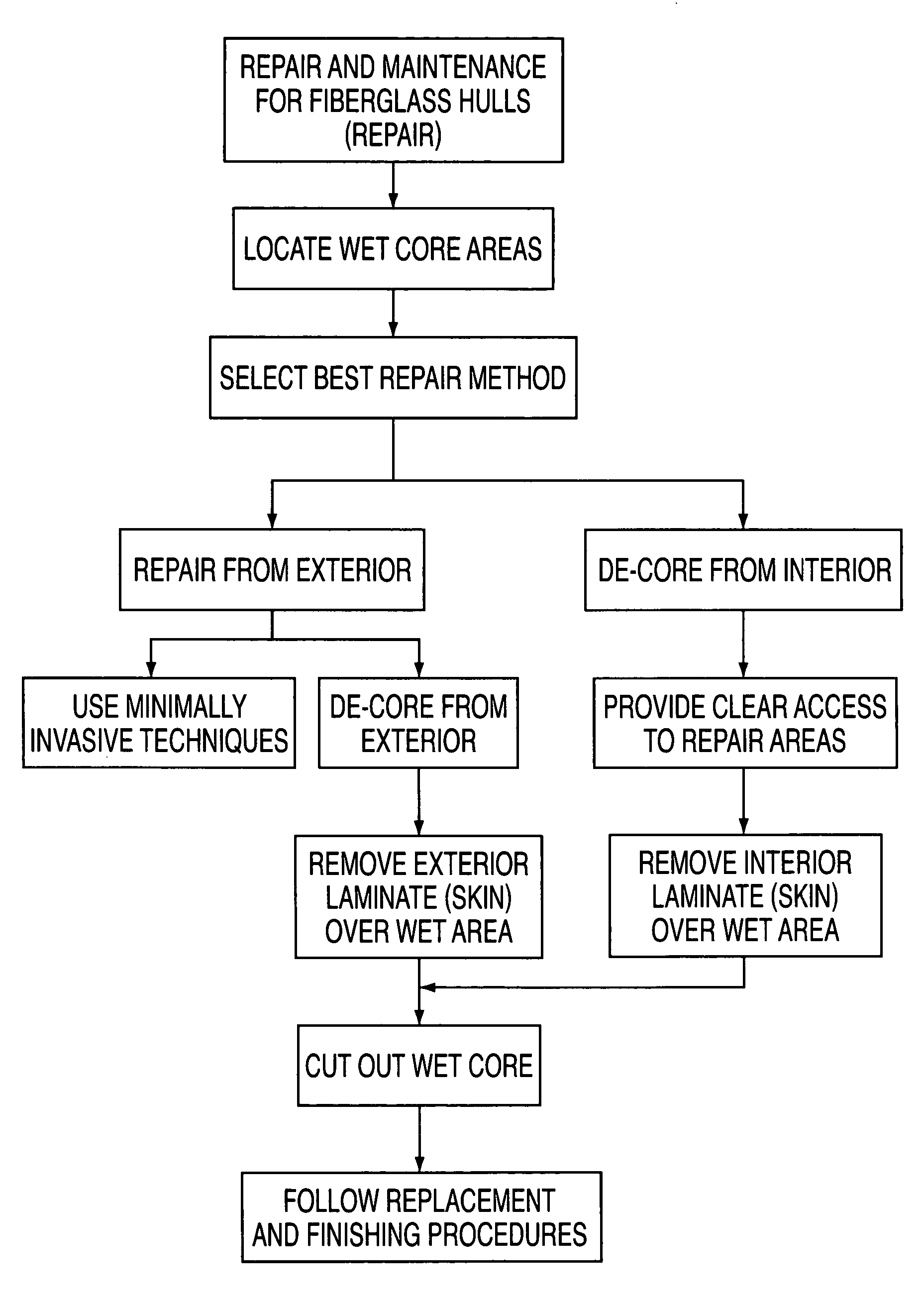

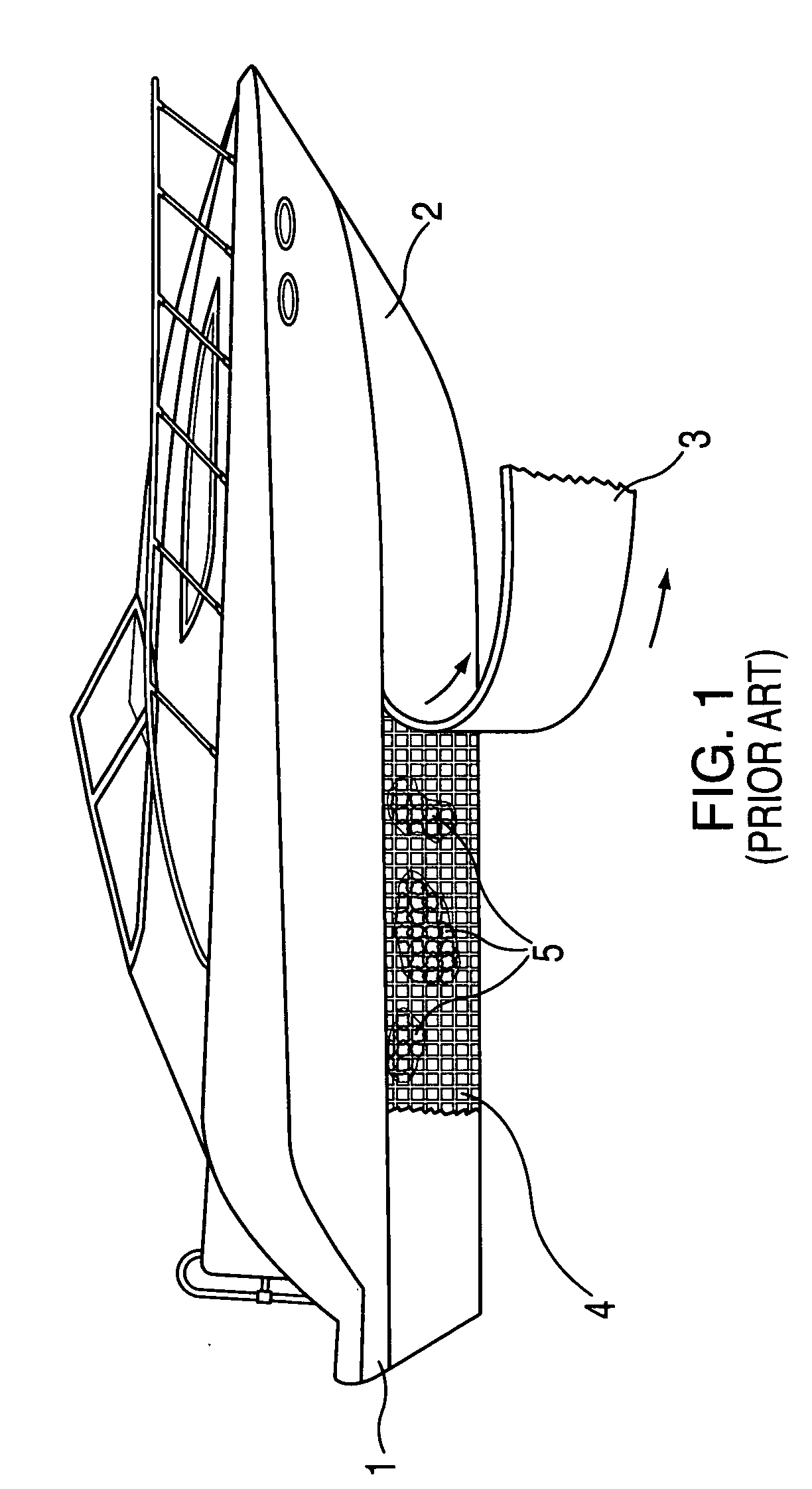

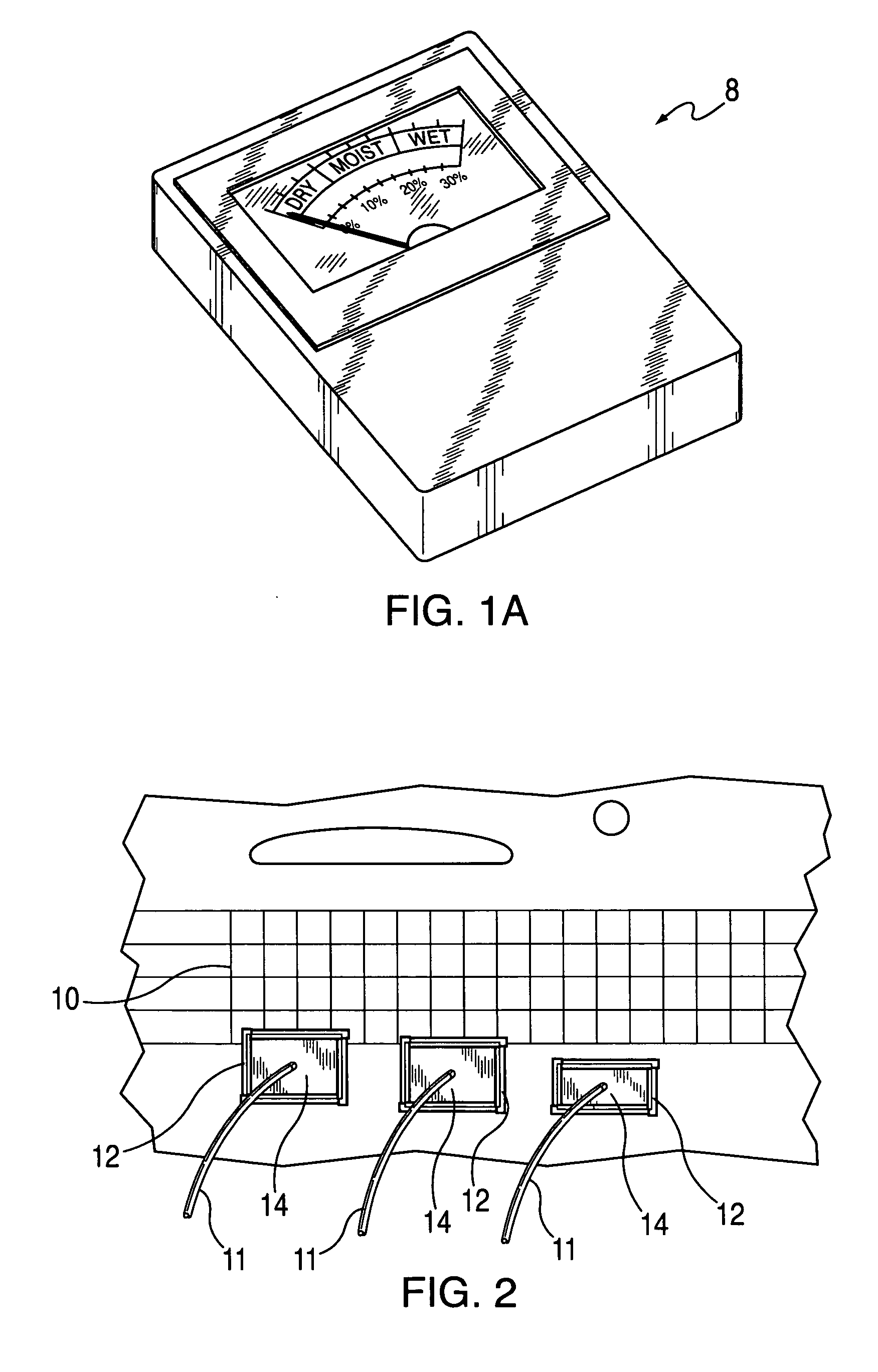

Repair system and method for fiberglass boats

InactiveUS7252727B2Minimizes surgical incisionAvoid damageLayered productsLaminationGlass fiberSurface moisture

A method to repair moisture damaged wood core boat hulls remotely identifies and repairs all wet core hull areas and optionally performs preventive maintenance on dry hull areas to restore the integrity of a fiberglass boat hull and prevent new water infiltration damage to a boat hull. The wet area repair guidelines using a surface moisture mete Any balsa cored area reading 15% or above is considered a wet area. Any wood cored area reading 20% or above is considered a wet area. The repair steps involves removing all through-hull fittings or hardware. Wet core areas are then dried out using heat lamps, lights or heaters, hot-vac systems, or octopus vacuum with grid system. If necessary, any area not drying out is de-cored and repaired accordingly. After repairs are finished, all through-hull fillings or hardware is reinstalled using new sealant.

Owner:DETURRIS STEPHAN

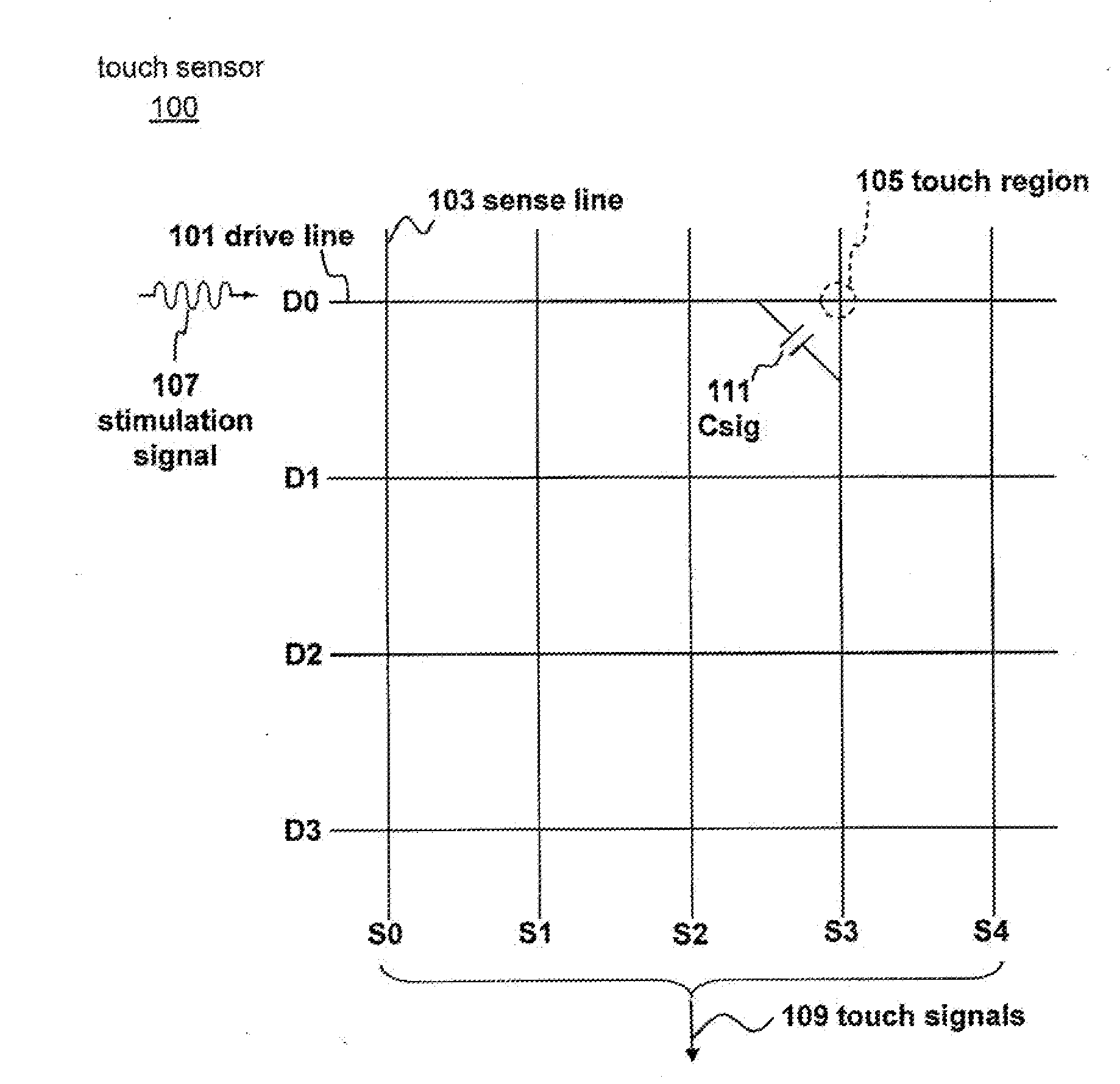

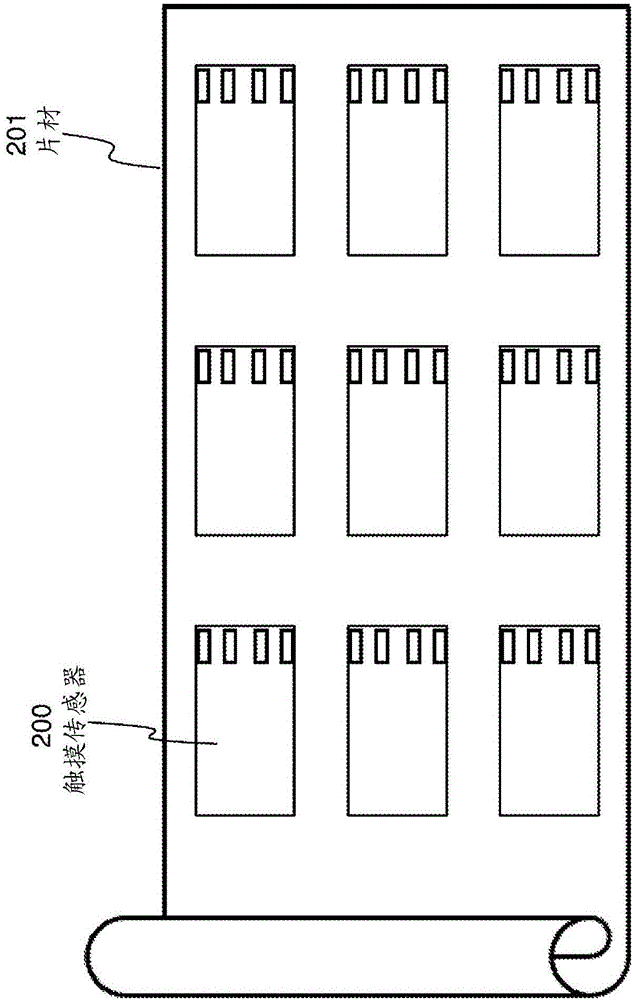

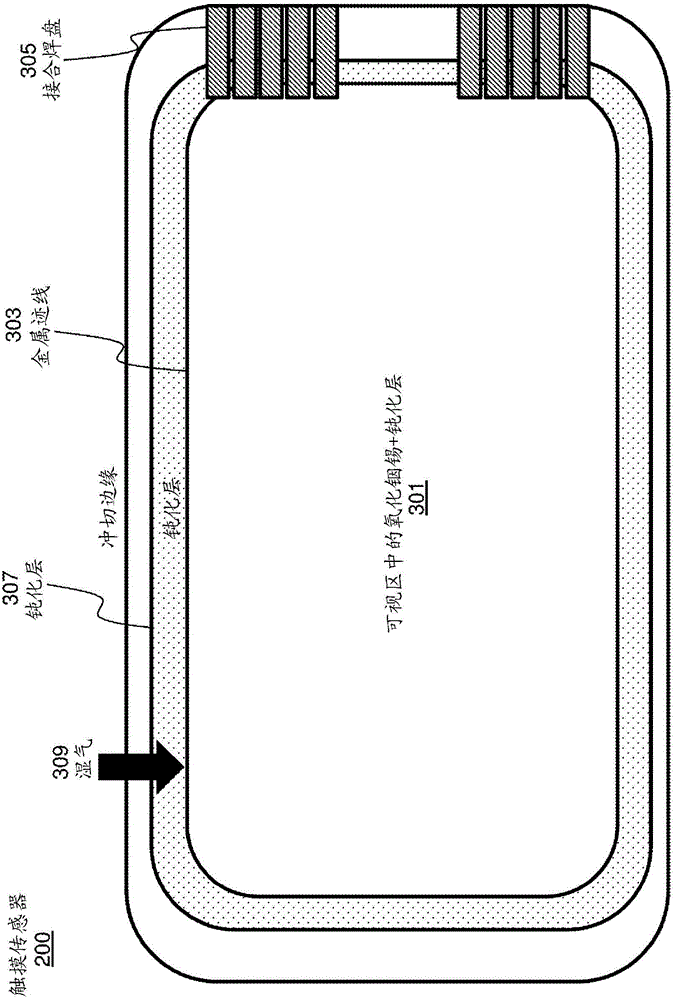

Corrosion mitigation for metal traces

ActiveUS20160085342A1Reduce the impactReduce impactSelector switchesContact electric connectionIndium tin oxideEngineering

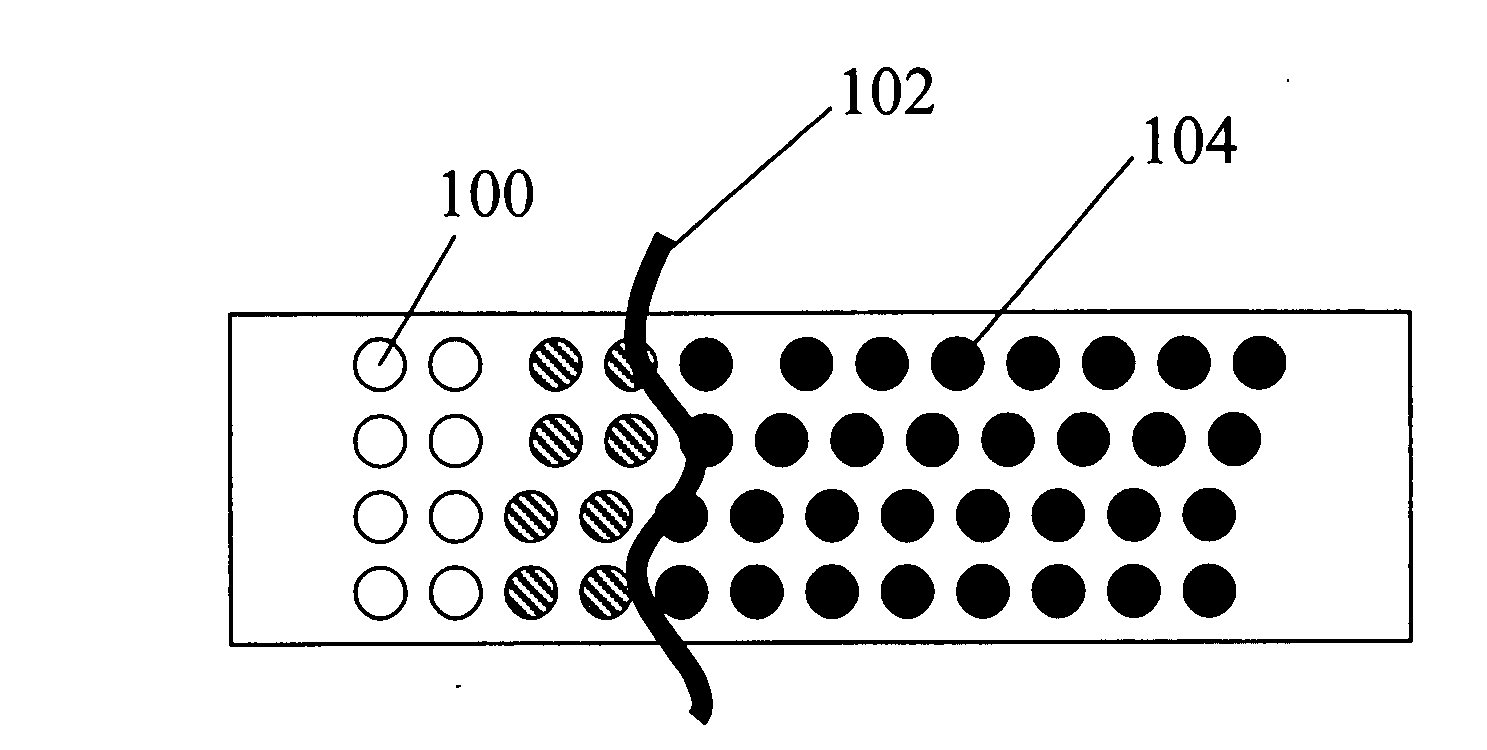

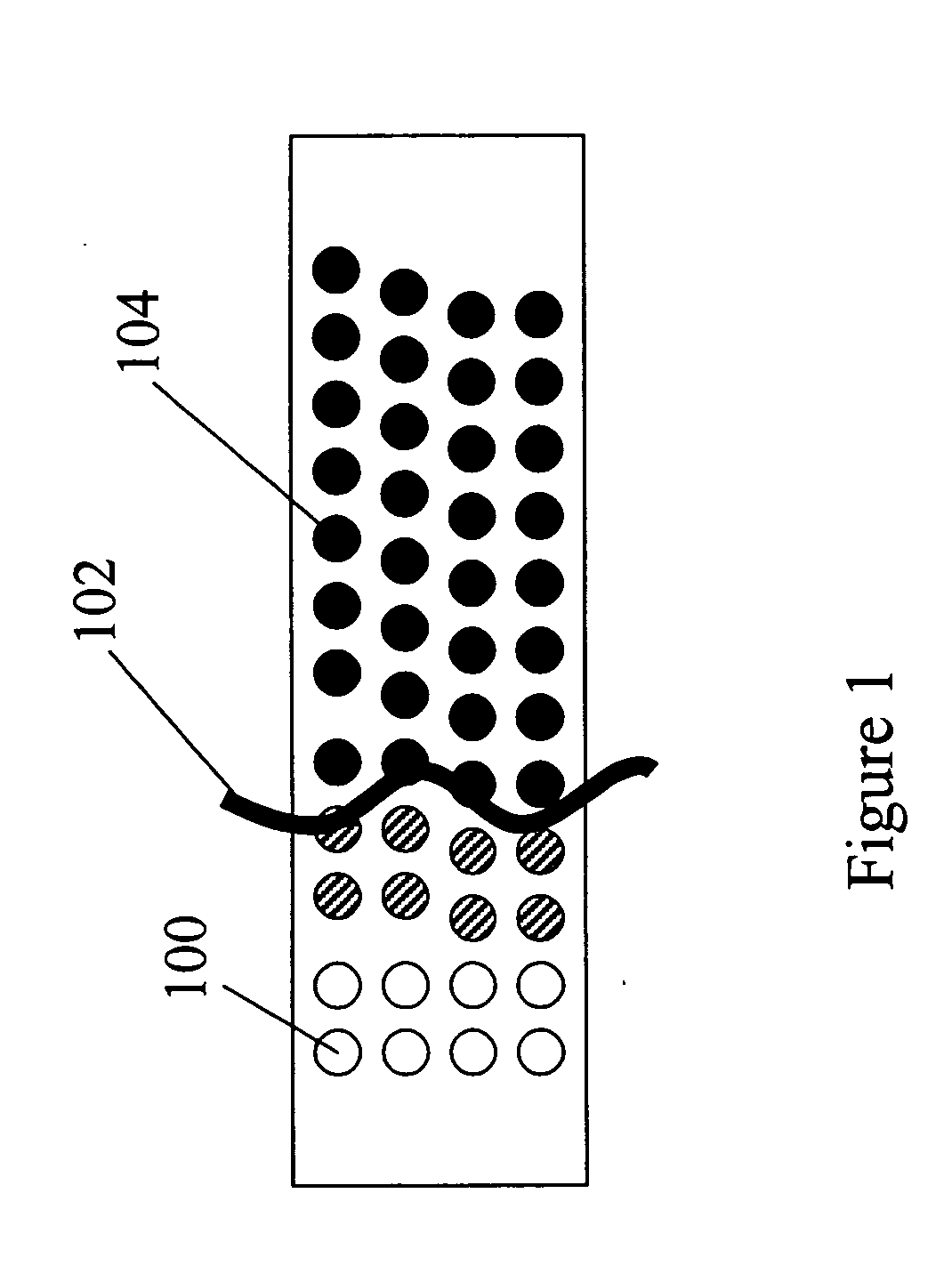

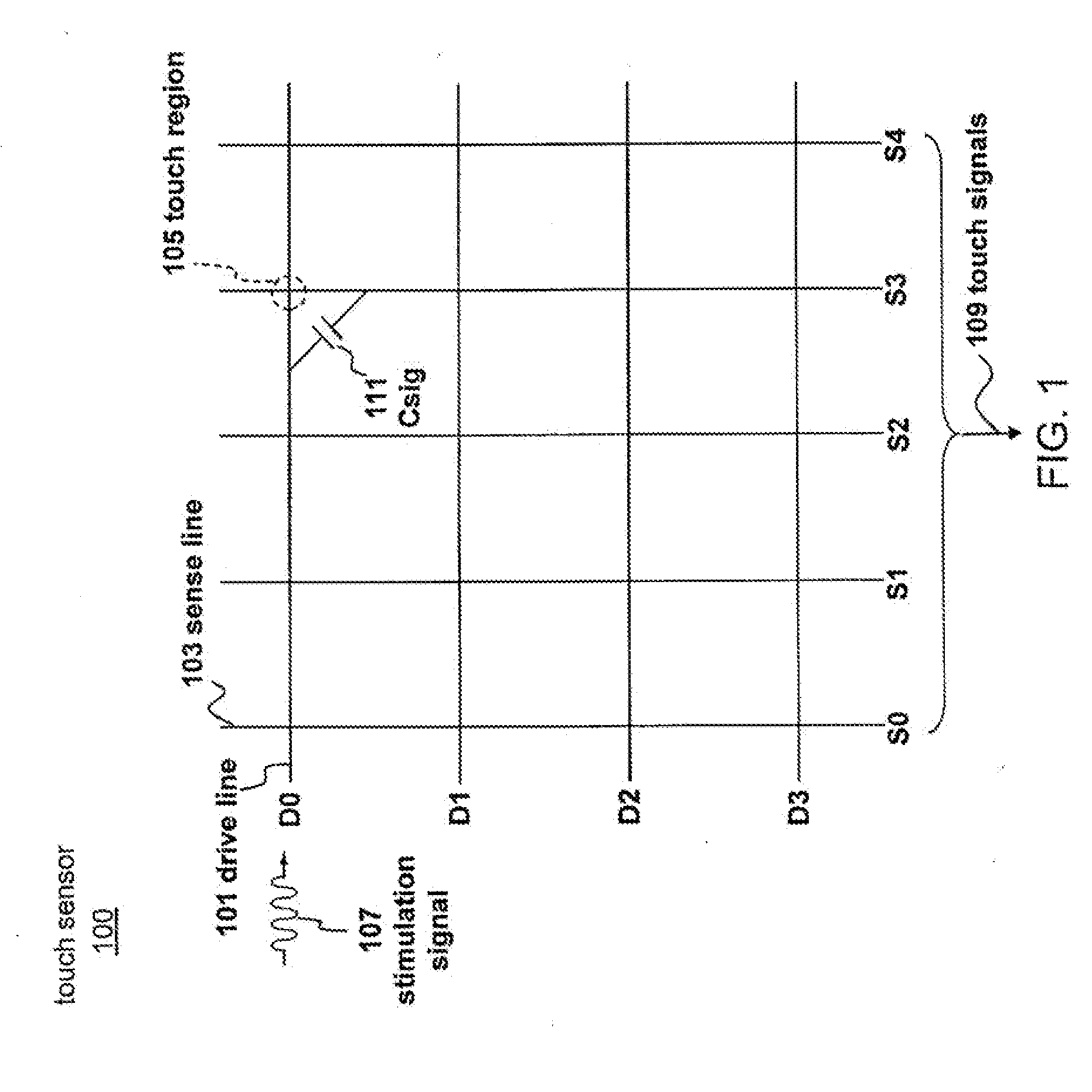

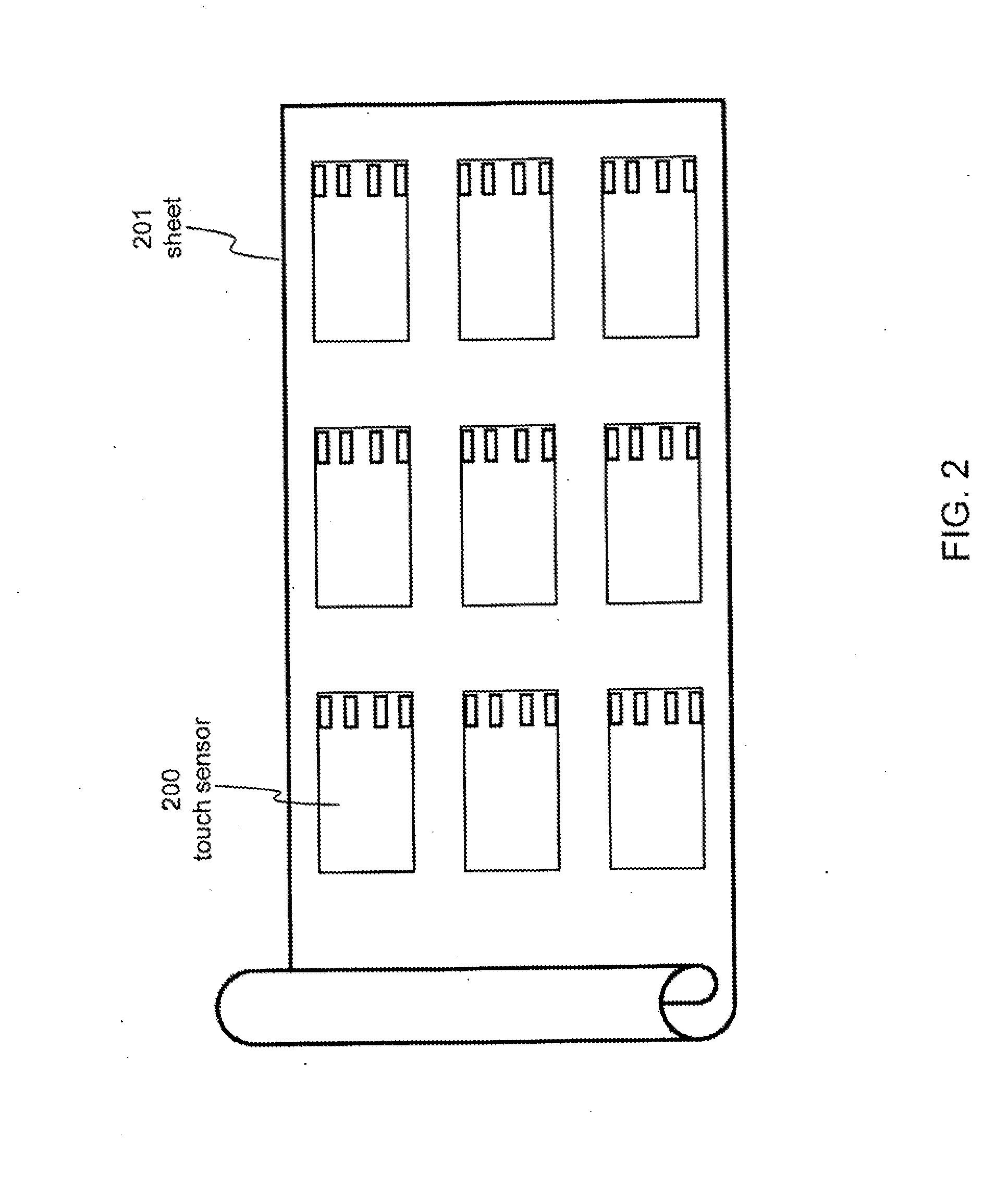

Processes for manufacturing touch sensors with one or more guard traces to reduce the effect of moisture damage are provided. One example process can include forming one or more guard traces between an edge of the touch sensor and the metal traces that route the drive and sense lines to bond pads. The one or more guard traces can be uncoupled from the drive lines and sense lines to protect the inner metal traces from moisture damage. In some examples, ends of the one or more guard traces can be coupled to ground by copper. In other examples, ends of the one or more guard traces can be coupled to ground by indium tin oxide or the one or more guard traces can be coupled to ground by a strip of indium tin oxide. In yet other examples, the guard trace can be floating (e.g., not coupled to ground).

Owner:APPLE INC

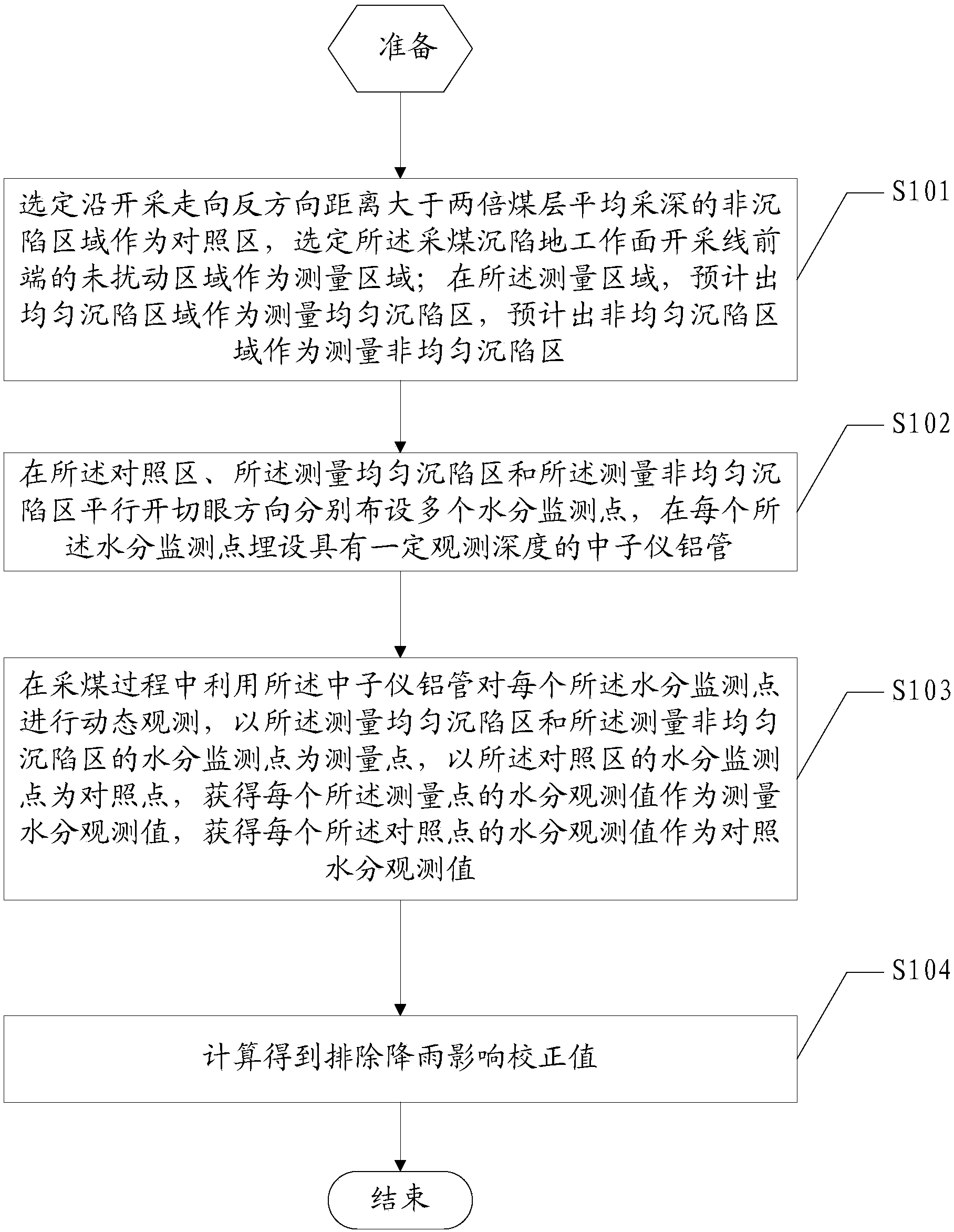

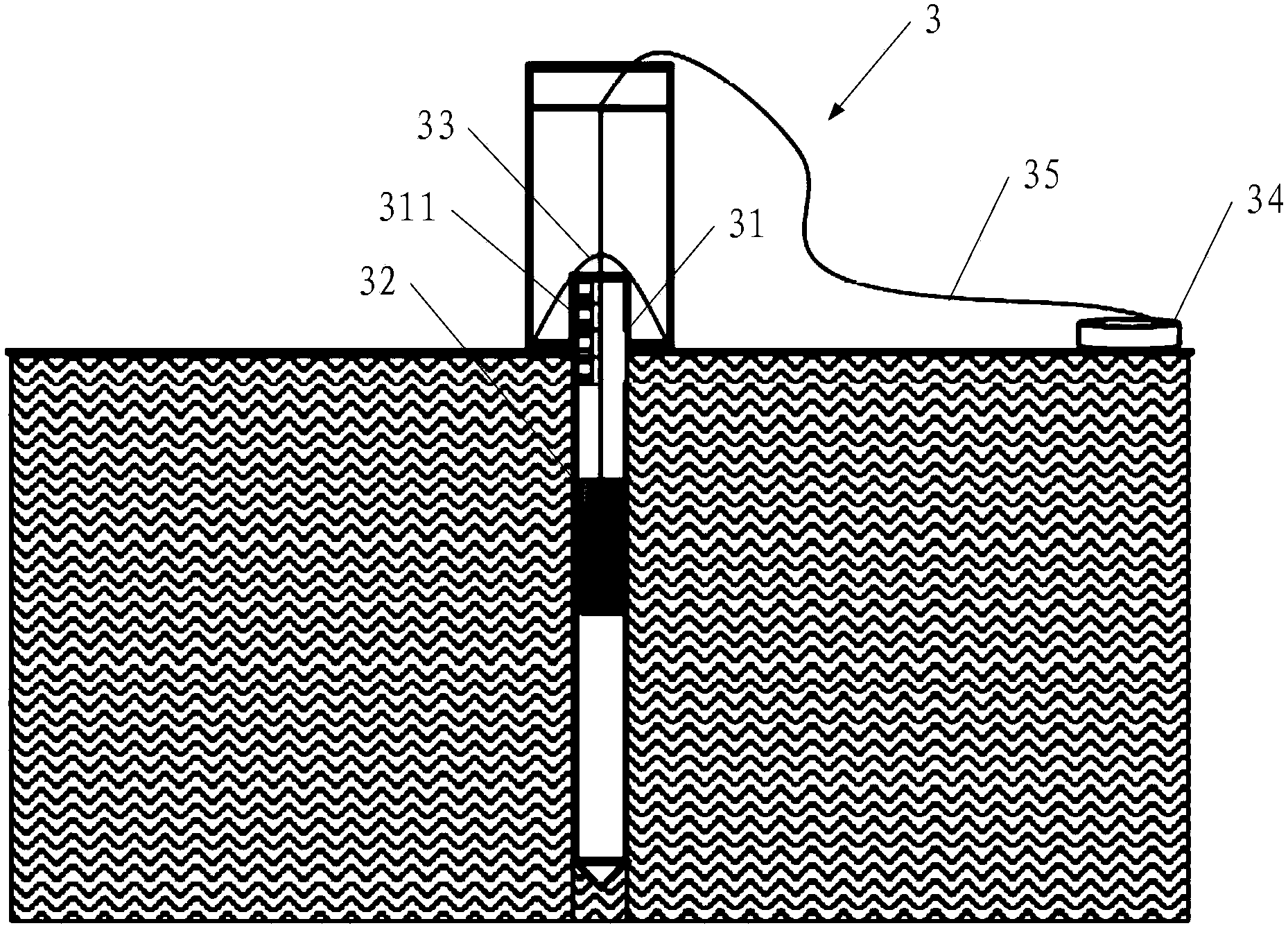

Monitoring method of dynamic change of vertical water content of coal-mining subsidence soil

ActiveCN104076048AVertical moisture content is accurateGrasp the moisture damageMaterial analysis by transmitting radiationNuclear radiation detectionEcological environmentSoil science

The invention discloses a monitoring method of the dynamic change of the vertical water content of coal-mining subsidence soil. The monitoring method comprises the following steps: selecting a reference area, and selecting an undisturbed area in the front end of an exploitation line of a coal-mining subsidence working surface as a measuring area; predicting a uniform measuring subsidence area and a nonuniform measuring subsidence area in the measuring area; obtaining moisture observed values of each measuring point as measuring moisture observed values and moisture observed values of each reference point as reference moisture observed values for many times by using moisture monitoring points of the uniform measuring subsidence area and the nonuniform measuring subsidence area as measuring points and moisture monitoring points of the reference area as reference points; and calculating to obtain an corrected value without the influence of rainfall. The vertical water content of the coal-mining subsidence soil, which is measured by using the monitoring method, is more accurate, the moisture damage condition of the whole coal-mining subsidence process to the soil can be comprehensively and scientifically held, and data information is provided for regional land reclamation and ecological environment remediation.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Repair system and method for fiberglass boats

InactiveUS20050271800A1Minimize damageAvoid further damageLayered productsLaminationGlass fiberSurface moisture

A method to repair moisture damaged wood core boat hulls remotely identifies and repairs all wet core hull areas and optionally performs preventive maintenance on dry hull areas to restore the integrity of a fiberglass boat hull and prevent new water infiltration damage to a boat hull. The wet area repair guidelines using a surface moisture mete Any balsa cored area reading 15% or above is considered a wet area. Any wood cored area reading 20% or above is considered a wet area. The repair steps involves removing all through-hull fittings or hardware. Wet core areas are then dried out using heat lamps, lights or heaters, hot-vac systems, or octopus vacuum with grid system. If necessary, any area not drying out is de-cored and repaired accordingly. After repairs are finished, all through-hull fillings or hardware is reinstalled using new sealant.

Owner:DETURRIS STEPHAN

Corrosion mitigation for metal traces

ActiveCN104603730AContact electric connectionInput/output processes for data processingIndium tin oxideEngineering

Owner:APPLE INC

Collapsible cardboard concrete form

A collapsible cardboard concrete form is disclosed. In a particular embodiment the form includes a cardboard box beam having a depressed longitudinal section along an outer portion of its length for added structural integrity. A lateral notch is disposed in the outer portion of the form at intervals and across a width of the form to divide the form into what will be the sides of the form when assembled. The lateral notches include a flexible planar connector of an inner portion of the form to allow the notch to act as a hinge and bend to create each corner of the form. A tab extends from one end of the form and is used to tuck in an opposing end of the form. The surfaces of the form may be coated with wax, or other sealant, to prevent moisture damage to the form as the concrete is curing.

Owner:HUNT MARTY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com