Process for preparing non-amine asphalt antistripping agent with amphiprotic activity

A technology of anti-stripping agent and production method, applied in the direction of organic chemistry, etc., can solve the problems of difficult to stabilize the performance of asphalt mixture, high cost, difficult operation, etc., to improve the performance of water damage resistance, prolong the service life, and the production method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

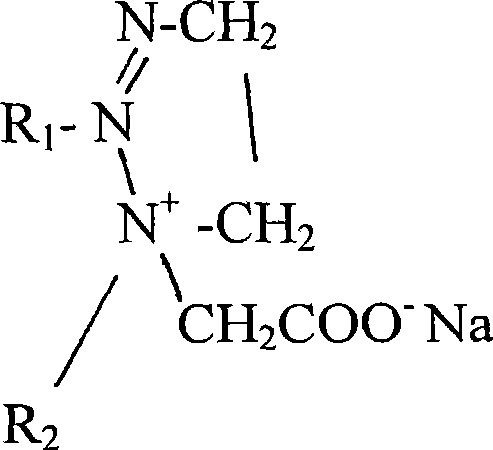

Image

Examples

Embodiment 1

[0018] Into a 4-neck detachable glass flask equipped with a stirrer, a thermometer, a reflux condenser and a nitrogen inlet, 470 parts of soyoleic acid, 60 parts of ethylenediamine and 40 parts of ethylene polyamine were added, followed by stirring. Heating while stirring and feeding nitrogen, when the temperature rises to 100-120°C, after 3-4 hours of reaction from the beginning, then continue to heat up to 160-180°C, react for 2-3 hours, after cooling, A non-amine asphalt anti-stripping agent with amphoteric activity is obtained.

Embodiment 2

[0020] 370 parts of coconut oleic acid and 95 parts of aniline were added to a 4-neck detachable glass flask equipped with a stirrer, thermometer, reflux condenser and nitrogen inlet, and then heated while stirring and feeding nitrogen. When the temperature rises to 100-120°C, after 2-3 hours of reaction from the beginning, then continue to heat up to 160-180°C, and react for 2-3 hours during this process. Exfoliating agent.

Embodiment 3

[0022] Add 200 parts of soybean oleic acid and 200 parts of tallow oleic acid, 23 parts of aniline and 75 parts of polyethylene polyamine into a 4-neck detachable glass flask equipped with a stirrer, thermometer, reflux condenser and nitrogen inlet, and then It heated while stirring and feeding nitrogen gas. When the temperature rises to 100-120°C, react for 2-3 hours from the beginning, then continue to heat up to 160-180°C, react for 3-4 hours, and after cooling, a non-amine asphalt anti-stripping agent with amphoteric activity is obtained .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com