Corrosion mitigation for metal traces

A technology of metal traces and traces, which is applied in the field of manufacturing touch sensors to reduce moisture damage, and can solve problems such as moisture damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following description of the disclosure and examples, reference is made to the accompanying drawings, in which are shown by way of illustration specific examples that may be practiced. It is to be understood that other examples may be practiced and structural changes may be made without departing from the scope of the present disclosure.

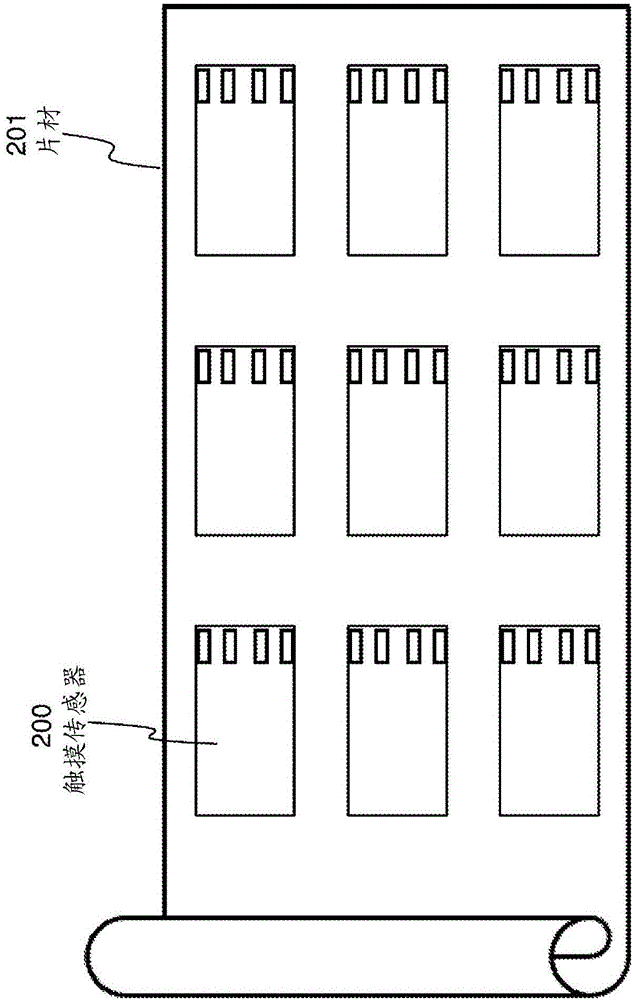

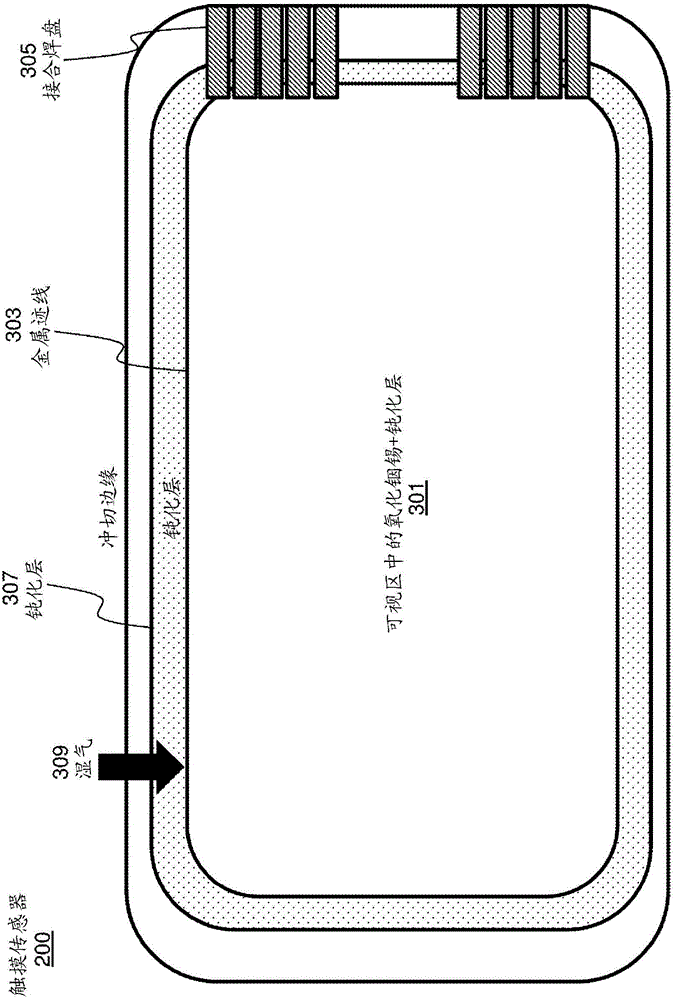

[0018] The present invention relates to a method for manufacturing a touch sensor having one or more guard traces to reduce the effects of moisture damage. The method may include forming one or more guard traces between an edge of the touch sensor and metal traces that route the drive and sense lines to the bond pads. The one or more guard traces can be decoupled from the drive and sense lines and can protect the internal metal traces from moisture damage. The one or more guard traces may be formed from a metal such as copper. In some examples, the ends of the one or more guard traces may be grounded through copper. In other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com