Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

170results about How to "Dense material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

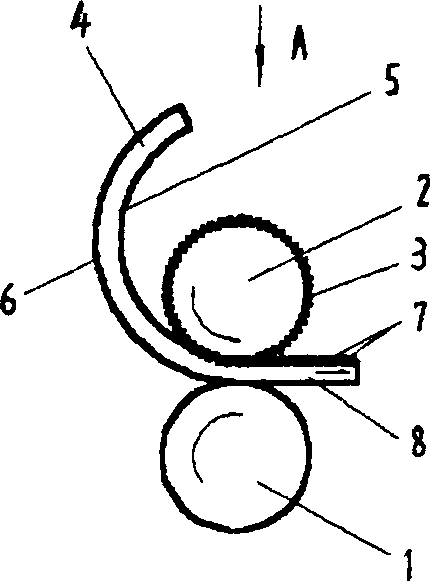

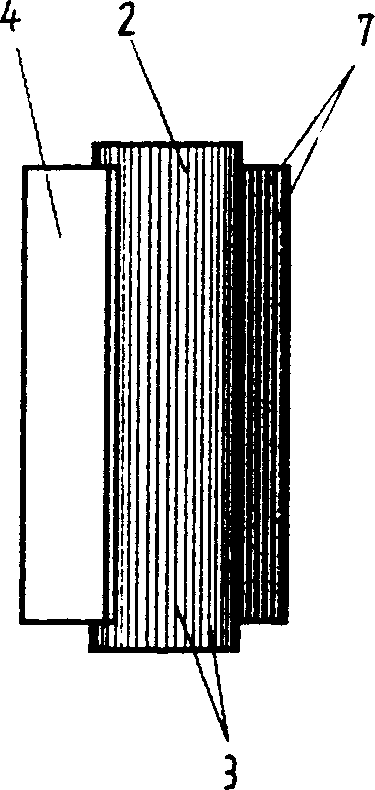

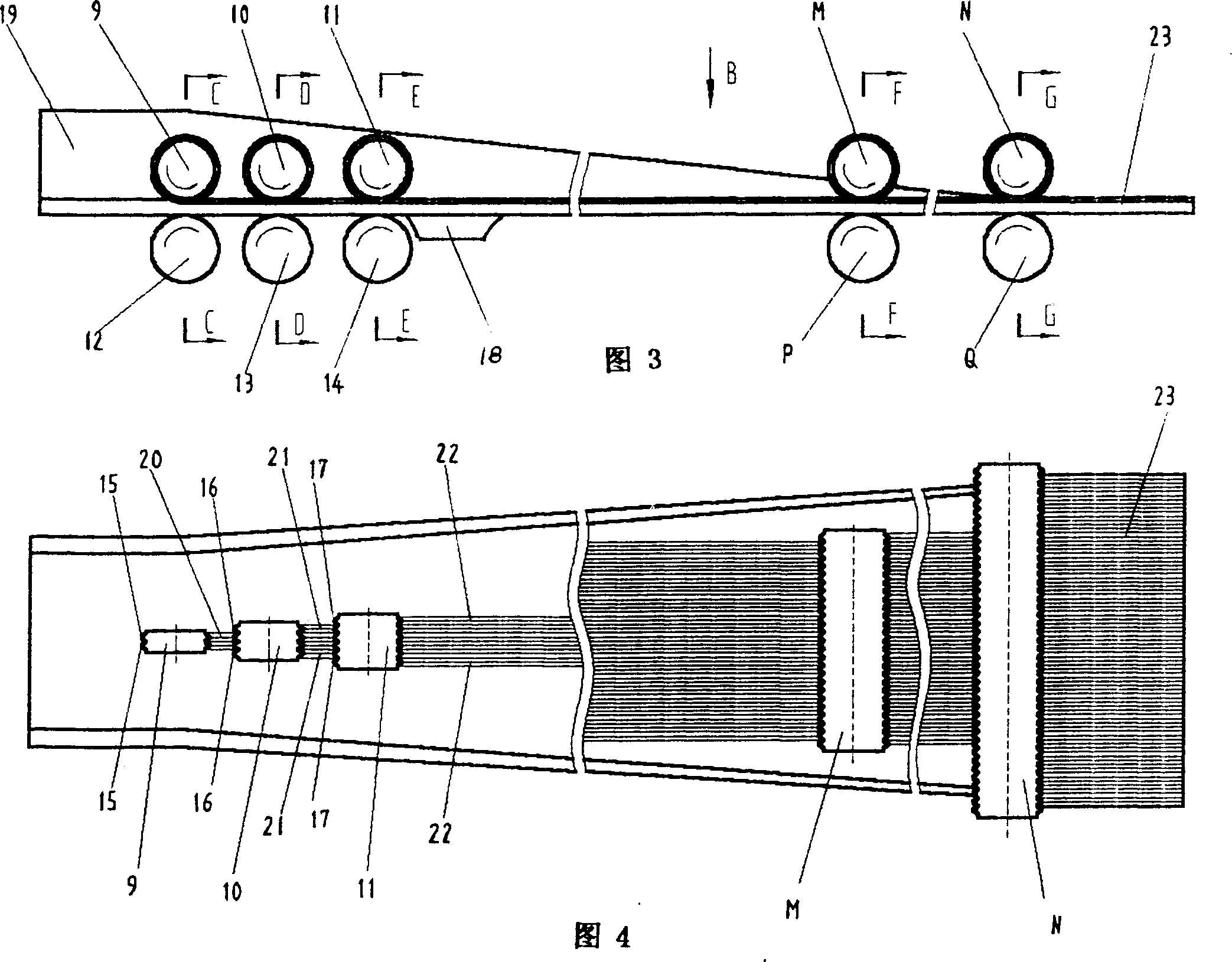

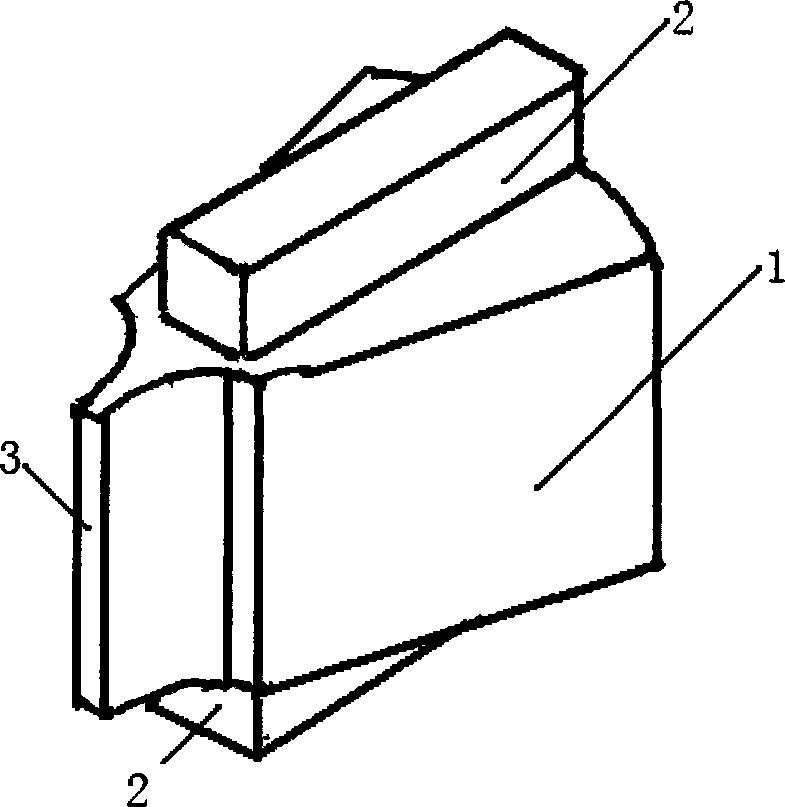

Method and apparatus for flattening bamboo wood without flaws

InactiveCN1485182AAvoid stretchingAvoid crackingOther plywood/veneer working apparatusWood treatment detailsEngineering

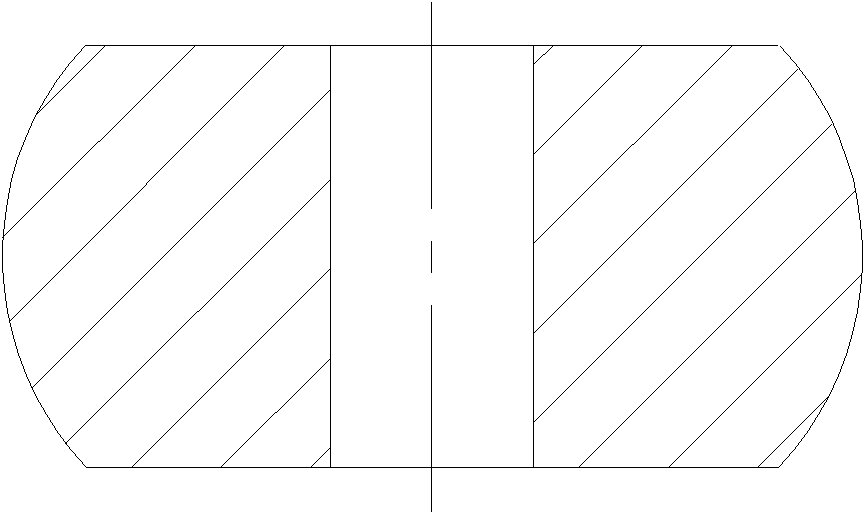

A method of spreading bamboo material without cracks and its device. First, remove bamboo green portion and outside nodes, cut open the bamboo sections, remove bamboo yellow portion and inner nodes, preheat to make bamboo sections soft, apply rollers with teeth to press and roll longitude grooves in the inner wall of bamboo material, to extend the arc length of bamboo material, thus flat bamboo material. The bamboo material could be fed along circumference of bamboo or in longitude direction, so there have two kinds of flatting devices: one has a smooth roller, a longitude toothed roller parallel to the smooth roller; another has two rows of rollers, each roller on one of rows has at least two teeth along the circumference, each end of the next roller have at least one more tooth than that of the former roller. when spreading bamboo material with more than 180íÒ,there wouldn't have cracks, then a flat bamboo plate is obtained.

Owner:刘觉春

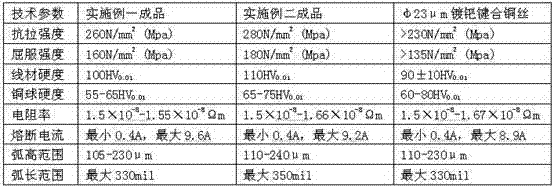

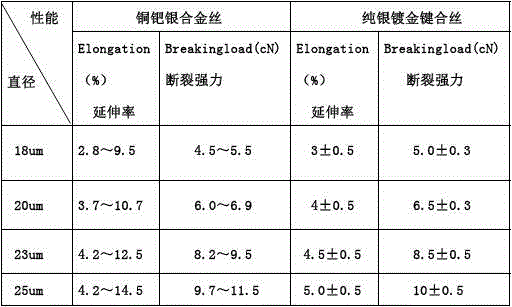

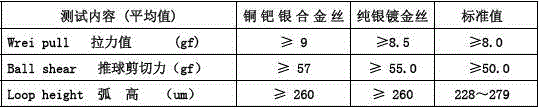

Palladium-plated bonded copper wire and production method thereof

InactiveCN101707194ADense materialUniform materialSemiconductor/solid-state device detailsSolid-state devicesHigh densityCopper wire

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

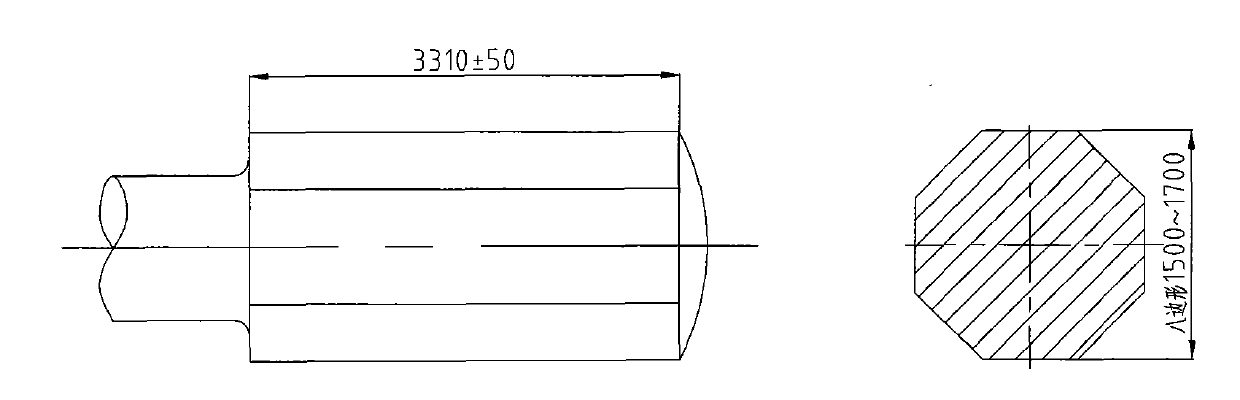

Forging method of main pipe blank with branch pipe nozzles used in nuclear power station

The invention discloses a forging method for a main pipe blank with branch pipe nozzles used in a nuclear power station, comprising following steps: firstly, rolling the ingot body of a forged piece, pressing the ingot to form a clamping handle; secondly, upsetting the ingot; thirdly, drawing out the ingot, and determining the directions of the branch pipe nozzles; fourthly, marking the forged piece, and heating the forged piece to the temperature of 1180 to 1220 DEG C, determining the dimension of each segment to be forged according to the weight of each segment; fifthly, drawing out the straight pipe segment to the preset dimension of the forged piece; sixthly, drawing out the two branch pipe nozzles, and making sure that the angle formed by the two branch pipe nozzles is 45 DEG. The invention is advantageous in that the branch pipe nozzles configured to form an angle can be accurately forged on the pipe wall of the main pipeline, and the properties of the branch pipe nozzles are stable, thereby the main pipe blank with branch pipe nozzles accords with the design requirements of the AP1000 nuclear power station.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

Double-metal hot jacket integrated automobile brake drum and machining method thereof

ActiveCN103953669AHigh strengthIncrease the strength of actionBraking drumsSlack adjustersEngineeringMachining

The invention provides a double-metal hot jacket integrated automobile brake drum, which consists of a drum-shaped shell and a tube-shaped casting liner, wherein the tube-shaped casting liner is arranged on the inner wall of the drum-shaped shell; the wall of the drum-shaped shell is made of constant-strength spinning steel. According to the double-metal hot jacket integrated automobile brake drum, a shell of the brake drum is made by a spinning technique of a spinning machine, the material of the brake drum shell is compact and has high strength, and the tube-shaped casting is taken as the liner so as to have the uniform thickness and simpleness and convenience in machining; a step of heating the shell of the brake drum specifically comprises the steps of bushing the tube-shaped casting liner into the shell under the condition of expansion of the diameter of the shell, condensing, fixedly fastening, and reinforcing the fixation between the shell of the brake drum and the casting liner by utilizing a pin; therefore the brake drum is ensured to have the advantages that the integrated strength is high, the material is utilized reasonably, the weight is light, the heat radiation performance is good, and the manufacturing technique process is suitable for automatic line operation.

Owner:泉州市泰智机械发展有限公司

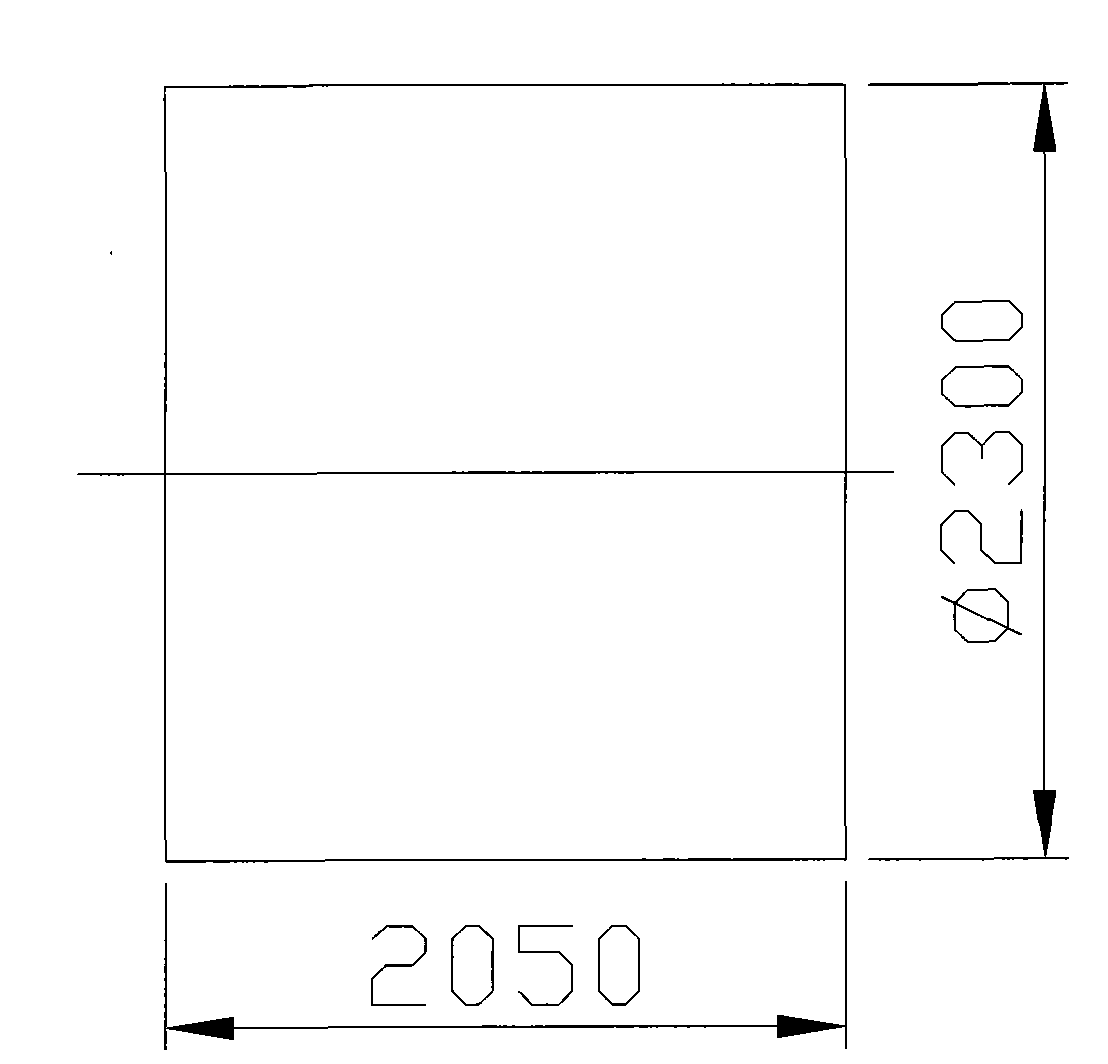

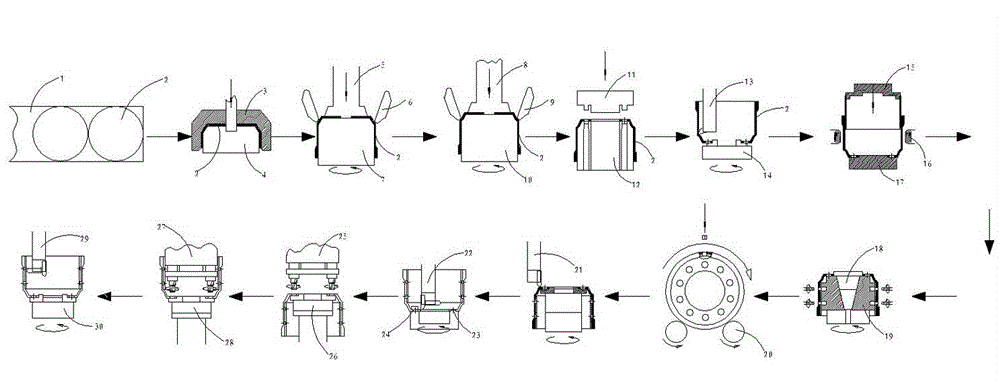

Forging method for water chamber head of steam generator of third-generation nuclear power station

InactiveCN102554084AReduce processing difficultyReduce the amount of cuttingMetal-working apparatusNuclear powerNuclear engineering

The invention discloses a forging method for a water chamber head of a steam generator of a third-generation nuclear power station, which is used for forging the water chamber head of the steam generator of the third-generation nuclear power station. The internal spherical radius of the water chamber head is no less than 1500mm, the water chamber head comprises a bent section, a straight section and a nozzle, and double vacuum steel ingots are used as raw materials. The forging process includes the steps: firstly, cogging; secondly, combined forging; and thirdly, rotating extrusion. A megaton free forging press is used for forging the double vacuum steel ingots into cylindrical billets, and then the internal shape of a forging is forged by means of rotating extrusion through a mould. The forging manufactured by the forging method can meet the technical requirement of the water chamber head, water chamber head forging materials are compact, reasonable in metal flow line distribution and not easy to crack, difficulty in machining is reduced, metal cutting output is less, and machining difficulty and cost can be reduced.

Owner:SHANGHAI HEAVY MACHINERY PLANT

Casting method of thin-walled pipe casting with spatially asymmetric structure

InactiveCN102527947ASolve the deformationAvoid uneven wall thicknessFoundry mouldsFoundry coresAlcoholGraphite

The invention provides a casting method of a thin-walled pipe casting with a spatially asymmetric structure. The method comprises the following steps: manufacturing a cavity sand core internally provided with a core bar and pores by utilizing animi resin sand; brushing a alcohol-based graphite coating on the surface of the sand core; after a white die is attached to the sand core, plugging a gap at the upper end of the joint of the core head and the white die by use of plaster; after the combination of the white die and the sand core is wholly soaked and coated in a water-borne quartz powder coating and then dried, removing coating layers at the head of the sand core and an exhaust port, and modeling and casting the combination. The method can be used for effectively solving the problems of deformation, uneven wall thickness, water and gas leakage and the like of a thin-walled pipe casting with a spatially asymmetric structure, and the obtained casting has the advantages of accurate size, uniform wall thickness, compact material texture, beautiful appearance and low cost. The method has the advantages of simple process, easiness for operation, low rejection rate, low labor intensity and high reliability.

Owner:广西玉柴模具装备有限公司

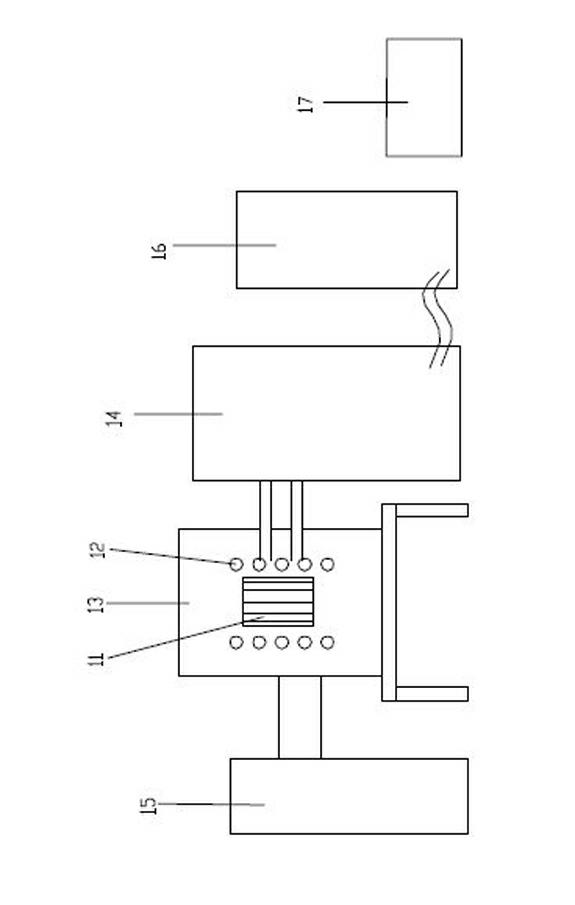

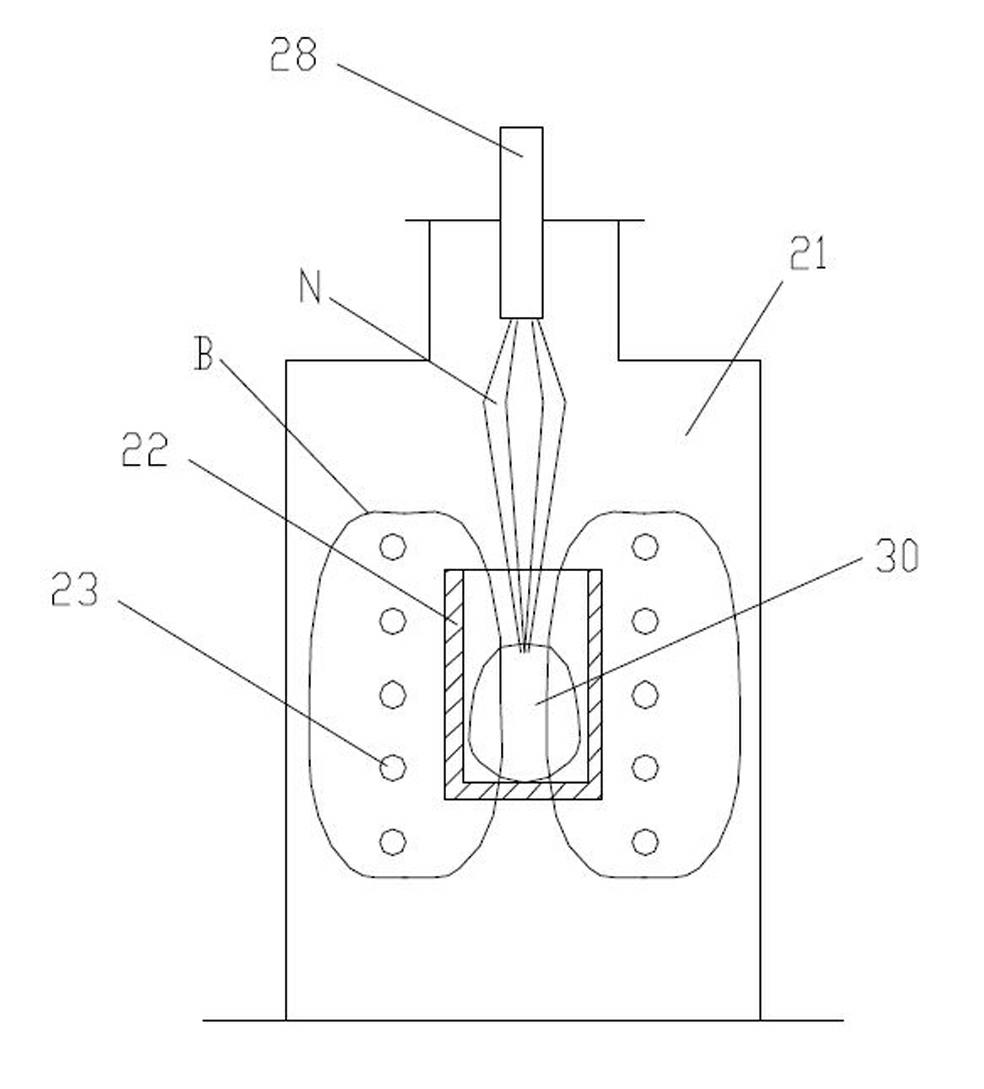

Cold crucible vacuum inductive smelting device having energy beam auxiliary heat source

InactiveCN102183144AUniform compositionAccurate ingredientsCrucible furnacesIntermediate frequencyEngineering

The invention relates to a cold crucible vacuum inductive smelting device having an energy beam auxiliary heat source, which comprises a vacuum chamber, a cold crucible, an induction coil, a high frequency / intermediate frequency induction power supply used for supplying electric power to the induction coil, a vacuum argon-filling system, a control cabinet, a cooling system used for cooling the cold crucible, an energy beam launching head and an energy beam generator, wherein the cold crucible is arranged in the vacuum chamber; the induction coil is arranged in the vacuum chamber; the induction coil is encircled on the exterior of the cold crucible; the energy beam launching head is arranged on the top of the vacuum chamber and is positioned above the cold crucible; the energy beam generator is connected to the energy beam launching head; and the energy beam generator is used for generating an energy beam and transmitting the energy beam to the energy beam launching head. The device provided by the invention can be used for preparing the refractory metal and alloy which are characterized by accurate and uniform components, consistent tissues and compact materials.

Owner:张森

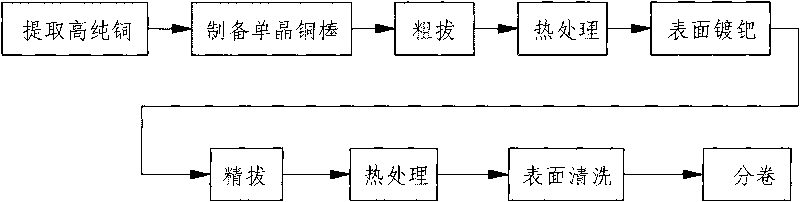

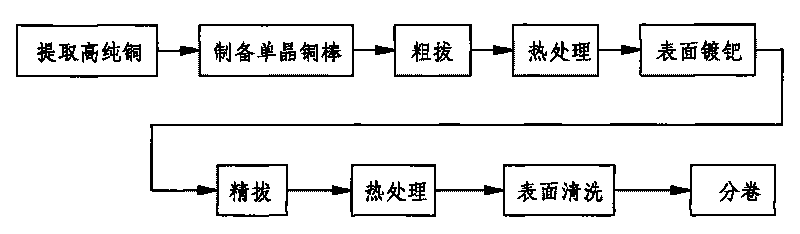

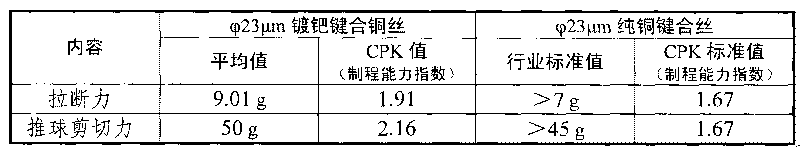

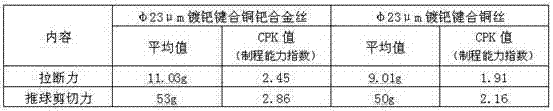

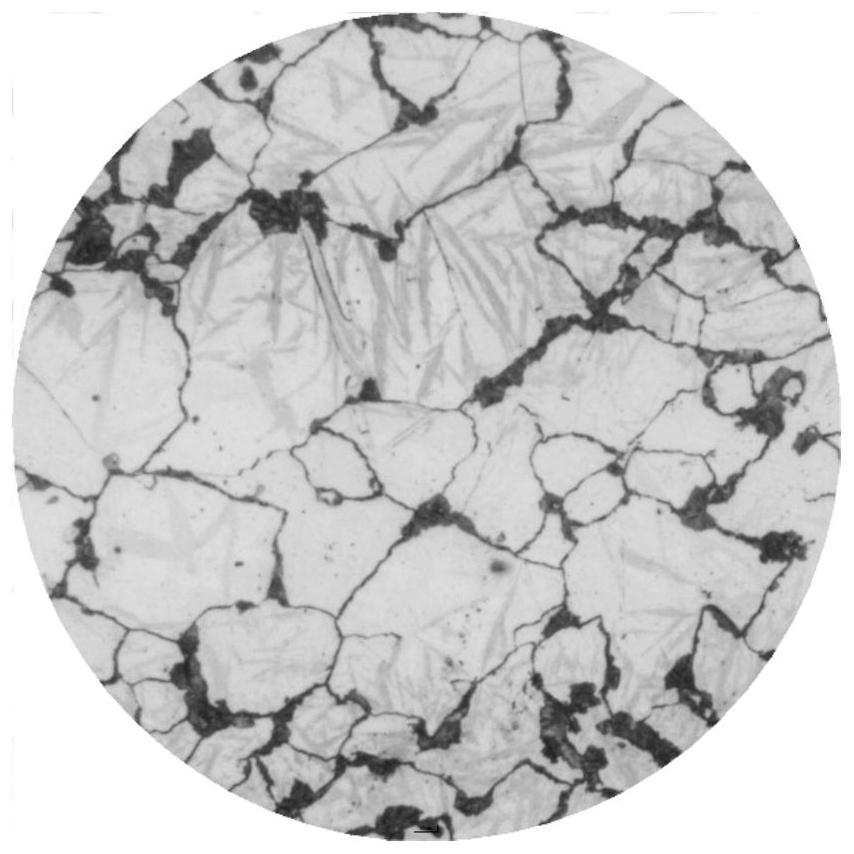

Copper palladium alloy monocrystal bonding wire and manufacturing method thereof

ActiveCN102226991ADense materialFlat surfacePolycrystalline material growthSemiconductor/solid-state device detailsIntegrated circuitSingle crystal

A copper palladium alloy monocrystal bonding wire and a manufacturing method thereof are disclosed. Base material of the copper palladium monocrystal bonding wire comprises, by weight, 1.35%-10.18% of palladium, 0.0001%-0.0003% of Calcium, 0.0002%-0.0008% of Rhenium and the balance copper. The manufacturing method comprises the following steps: extracting high purity copper and high purity palladium; preparing monocrystalline copper palladium alloy rod; plating palladium on surface; coarse drawing and fine drawing; carrying out a heat treatment; cleaning the surface; shunting winding. The invention abandons the traditional technique: drawing firstly and then electroplating. In the method of the invention, the monocrystalline copper palladium alloy wire with a wire diameter of less than 3mm is produced, then palladium layer is electroplated, and finally, the palladium copper alloy bonding wire finished product is produced by drawing. By using the invention, oxidation resistance of bonding copper wire can be effectively raised; the oxidation resistance of the bonding copper wire can be equal to the oxidation resistance of bonding gold wire; shelf-life of the bonding copper wire product after being sealed off can be substantially prolonged. Mechanical strength of alloy finished products which are added elements, such as palladium, calcium, rare earth and the like, can be higher than materials produced by other ways, which is beneficial to further reduce the wire diameter of the bonding wire and shorten welding spacing, and is suitable for integrated circuit package with high-density and multi-pin.

Owner:江西蓝微电子科技有限公司

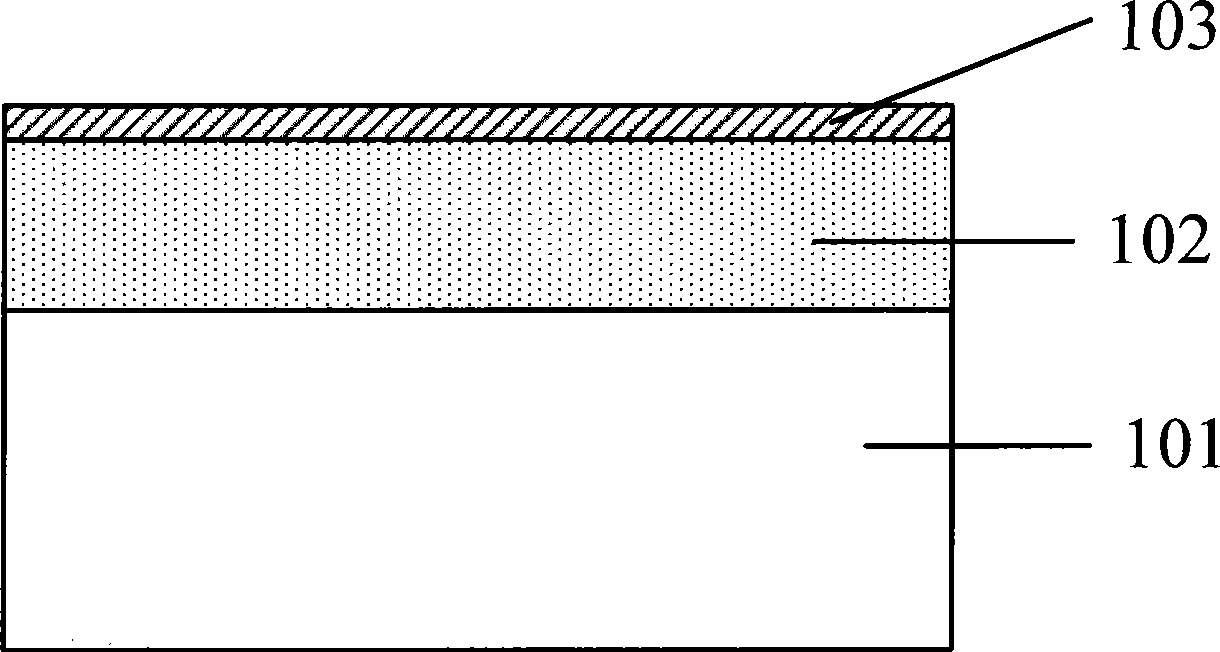

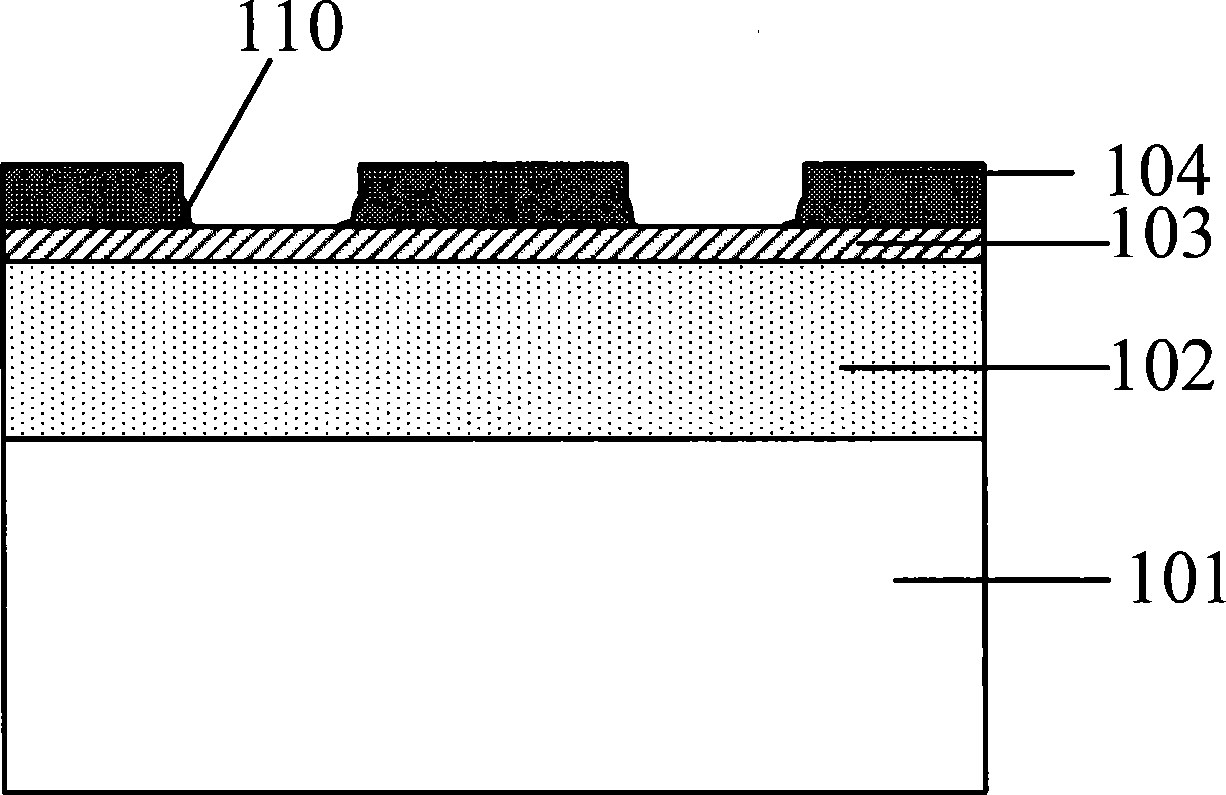

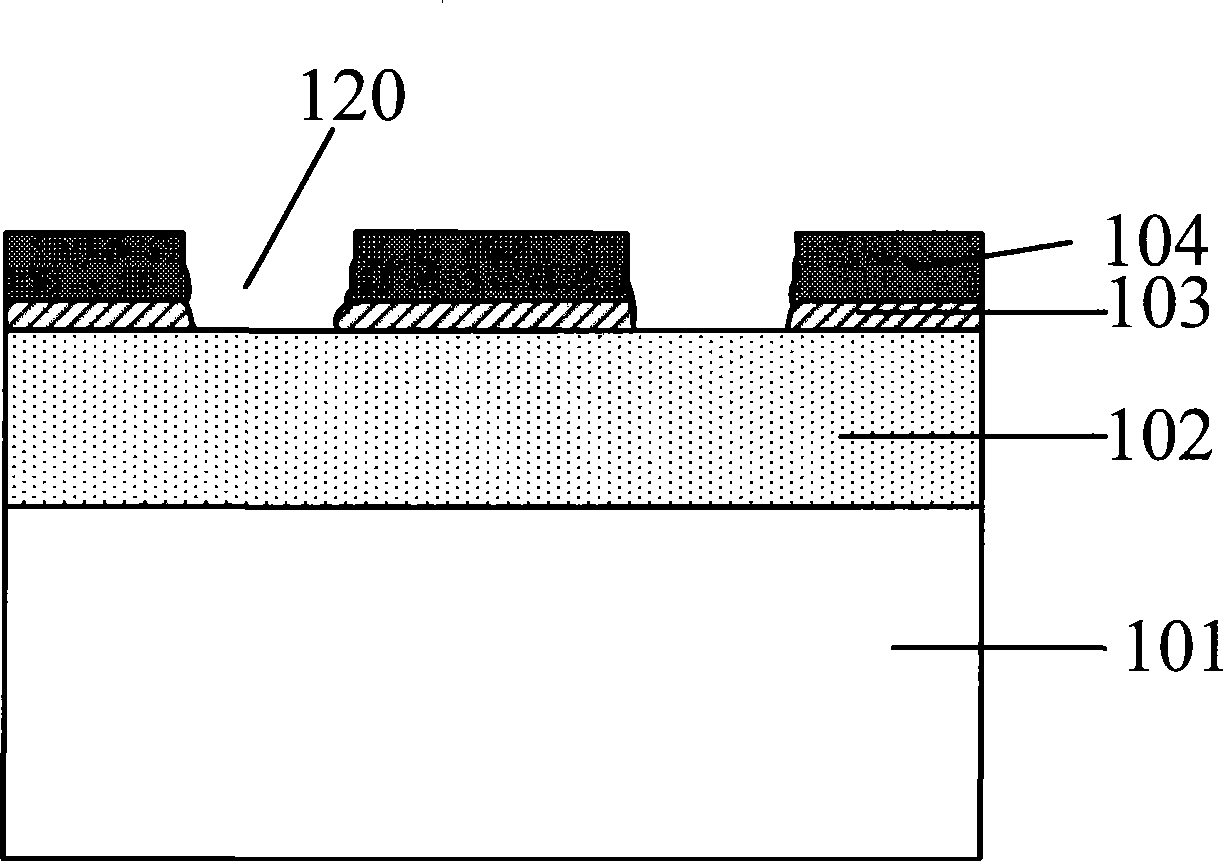

Method for forming and etching hard mask layer

ActiveCN101441996AFlat surfaceQuality improvementSemiconductor/solid-state device manufacturingPlasma processingLithography

The invention discloses a method for forming a hard mask layer, which comprises the following steps: providing a substrate; forming an initial hard mask layer on the substrate; and performing plasma processing on the initial hard mask layer to form the hard mask layer. The invention also correspondingly discloses a method for etching by using the hard mask layer. With the adoption of the method for forming the hard mask layer and the method for etching, a photoetching figure with better quality can be formed, the etching quality is improved, and the consistency of key size of figure subjected to photoetching or etching is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Flame-retardant type wood-plastic material

The invention discloses a flame-retardant type wood-plastic material. The material is prepared from, by weight, 60-70 parts of wood fibers, 11-16 parts of pentaerythritol, 21-28 parts of modified fire retardant, 21-28 parts of modified smoke inhibitor, 17-25 parts of polypropylene, 17-25 parts of high-density polyethylene, 8-13 parts of vermiculite, 5-9 parts of dioctyl phthalate, 6-13 parts of polyethylene glycol monostearate, 12-15 parts of unsaturated polyester resin, 5-9 parts of vinyl trimethoxy silane, 2-5 parts of luffa stems, 2-5 parts of polyethylene wax, 1-3 parts of PE wax, 1-3 parts of magnesia, 1-2 parts of graphite, 1-2 parts of herba taraxaci, 1-2 parts of ligusticum sinense olivers and 0.1-0.3 part of peanut oil. The wood-plastic material has high flame retandance and a good smoke inhabitation effect and does not release toxic and harmful substances at the high temperature, secondary harm to the human body is avoided, the heat insulation property is quite good, scalds to the human body are avoided, the quite good insulating property is achieved, and meanwhile the wood-plastic material is compact in material, good in mechanical performance and quite durable.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

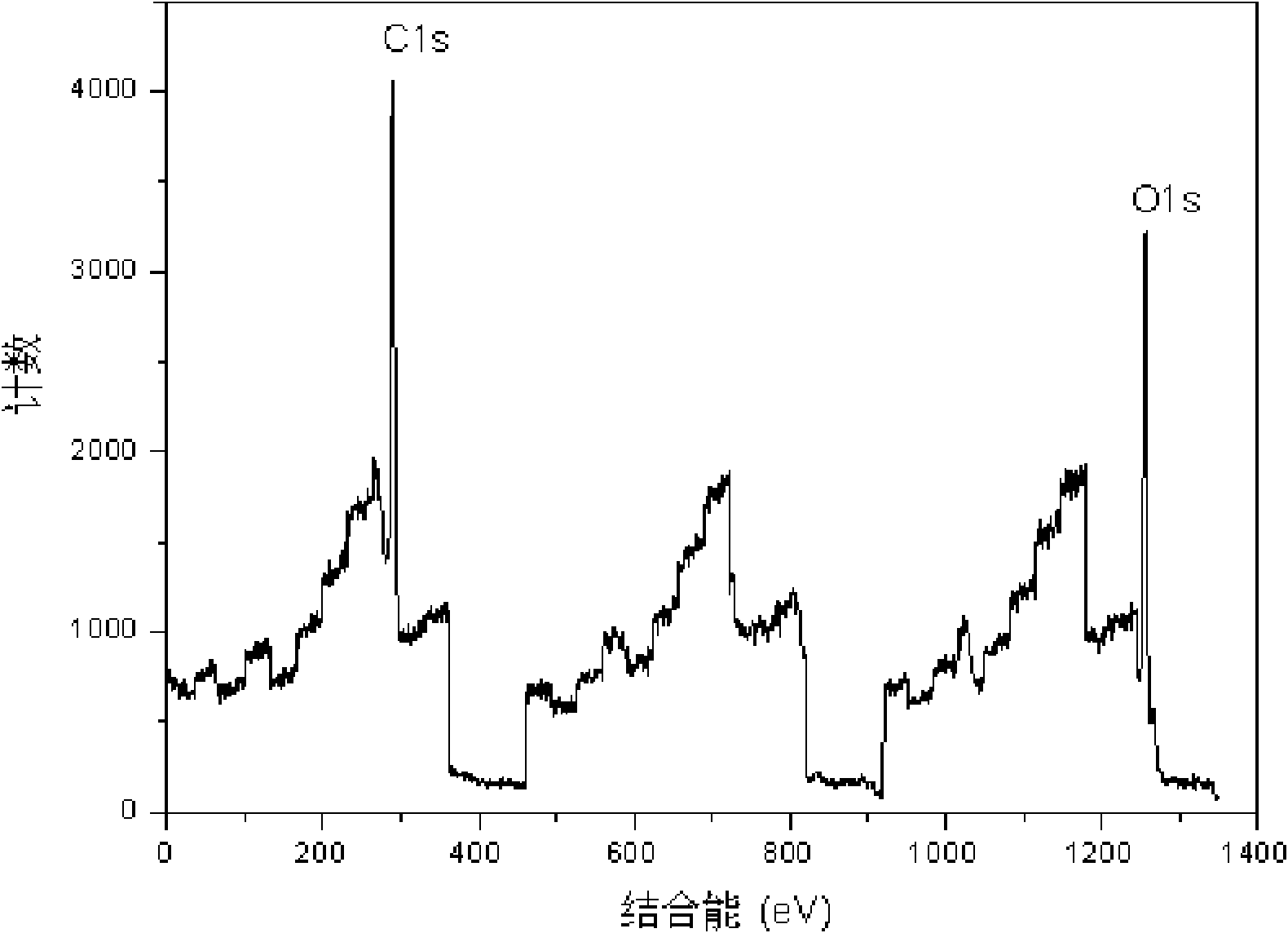

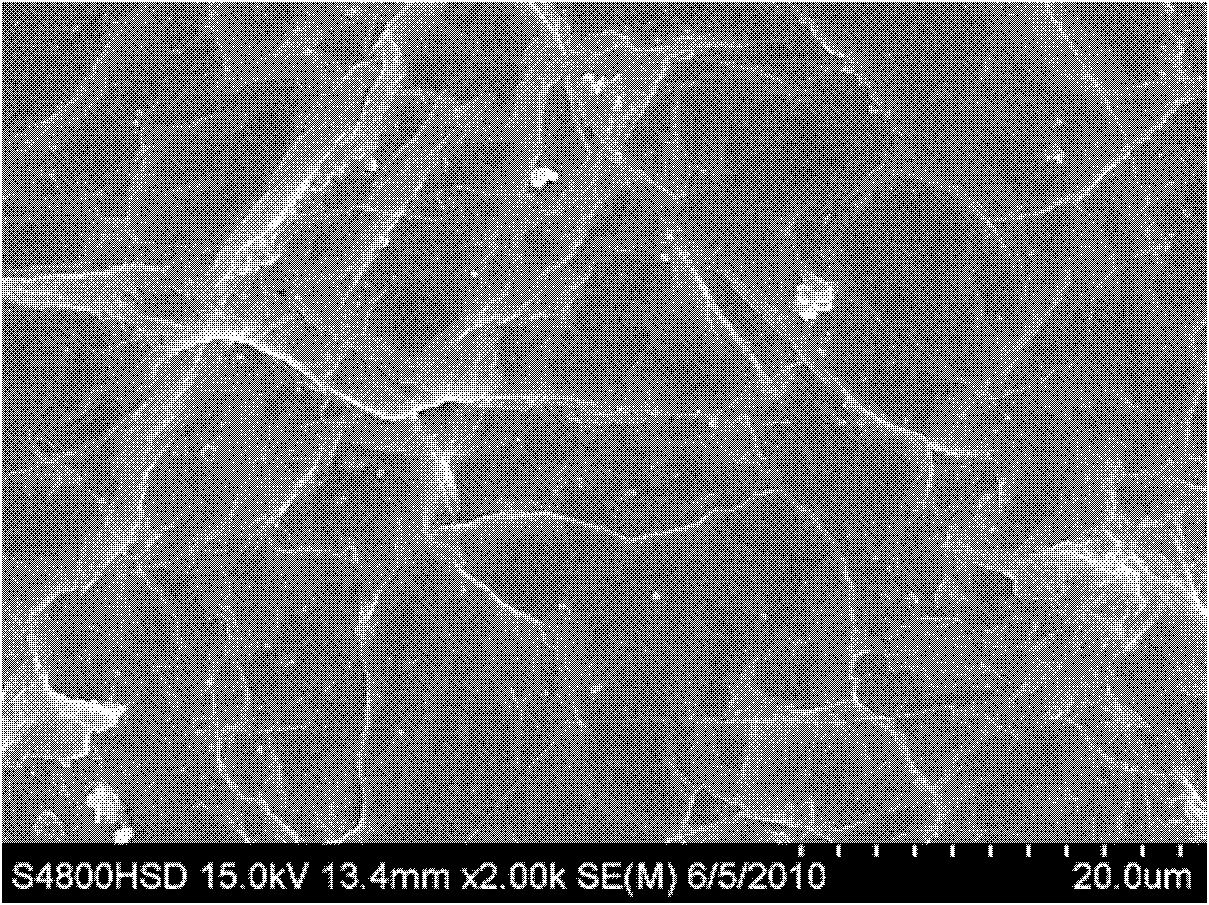

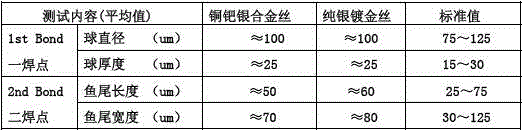

Carbon film obtained by self assembly of graphene oxide or its derivatives and preparation method thereof

The invention discloses a carbon film obtained by self assembly of graphene oxide or its derivatives and a preparation method thereof, and relates to a preparation method for a highly ordered carbon film. The objective of the invention is to solve the problems existing in the prior art that the combination between a carbon film and a substrate is poor, the preparation technology is complex, the cost is high, and the thickness of carbon films is difficult to control in the process of preparation. The carbon film provided in the invention uses graphene oxide or its derivatives as the raw material and is obtained through the process of self assembly. The carbon film is prepared by the following steps: dispersing graphene oxide or its derivatives in a solvent so as to obtain a solution, immersing a substrate into the solution and allowing the solution to stand at a constant temperature for assembly, wherein the temperature is in a range of 50 to 100 DEG C. The carbon film prepared in the invention has smooth surfaces, strong bonding force to the substrate and good light transmittance and mechanical properties; the modulus of the carbon film is 80 to 120 GPa, and the hardness is 7 to 9 Gpa; the carbon film is orderly orientated along the surface of the substrate, and the thickness of the carbon film is 10 nm to 2 mu m. The preparation process is controllable and concise and produces products with controllable thickness. The carbon film provided in the invention has broad application prospects in such fields as electrode materials, electronic chips, solar cells and high efficient catalysis.

Owner:HARBIN INST OF TECH

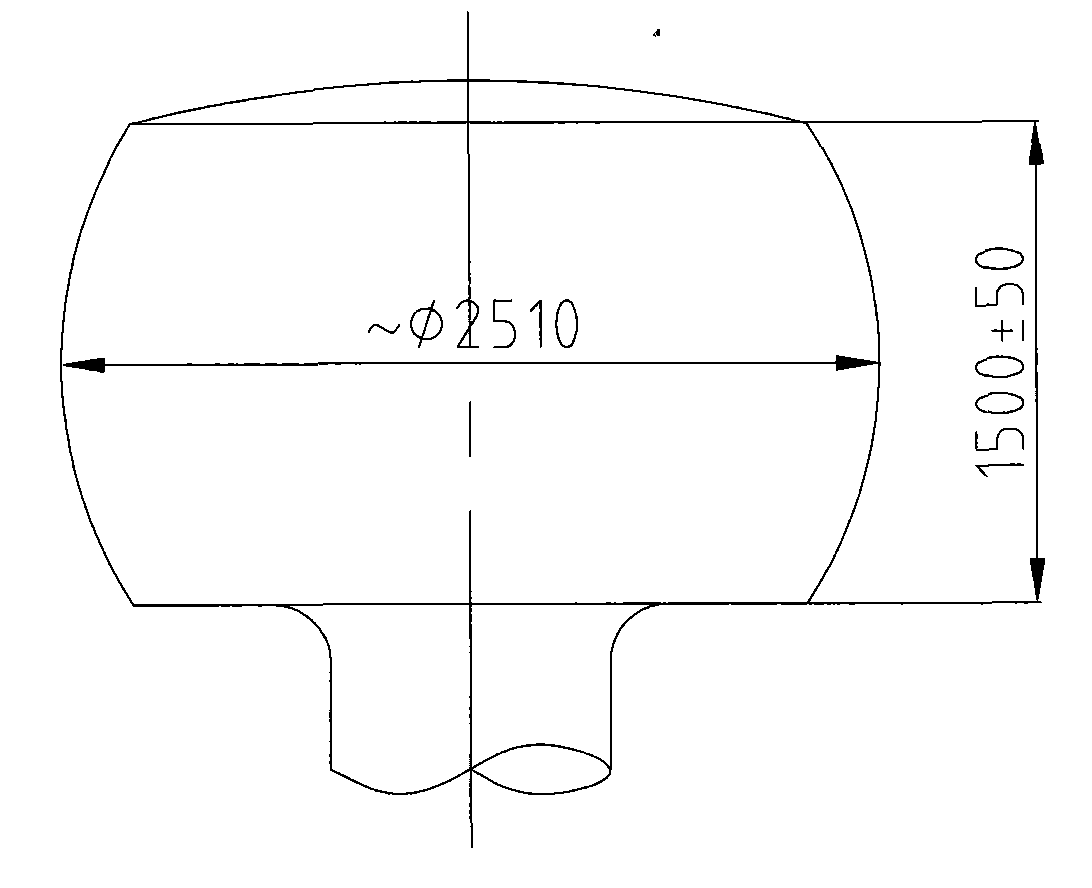

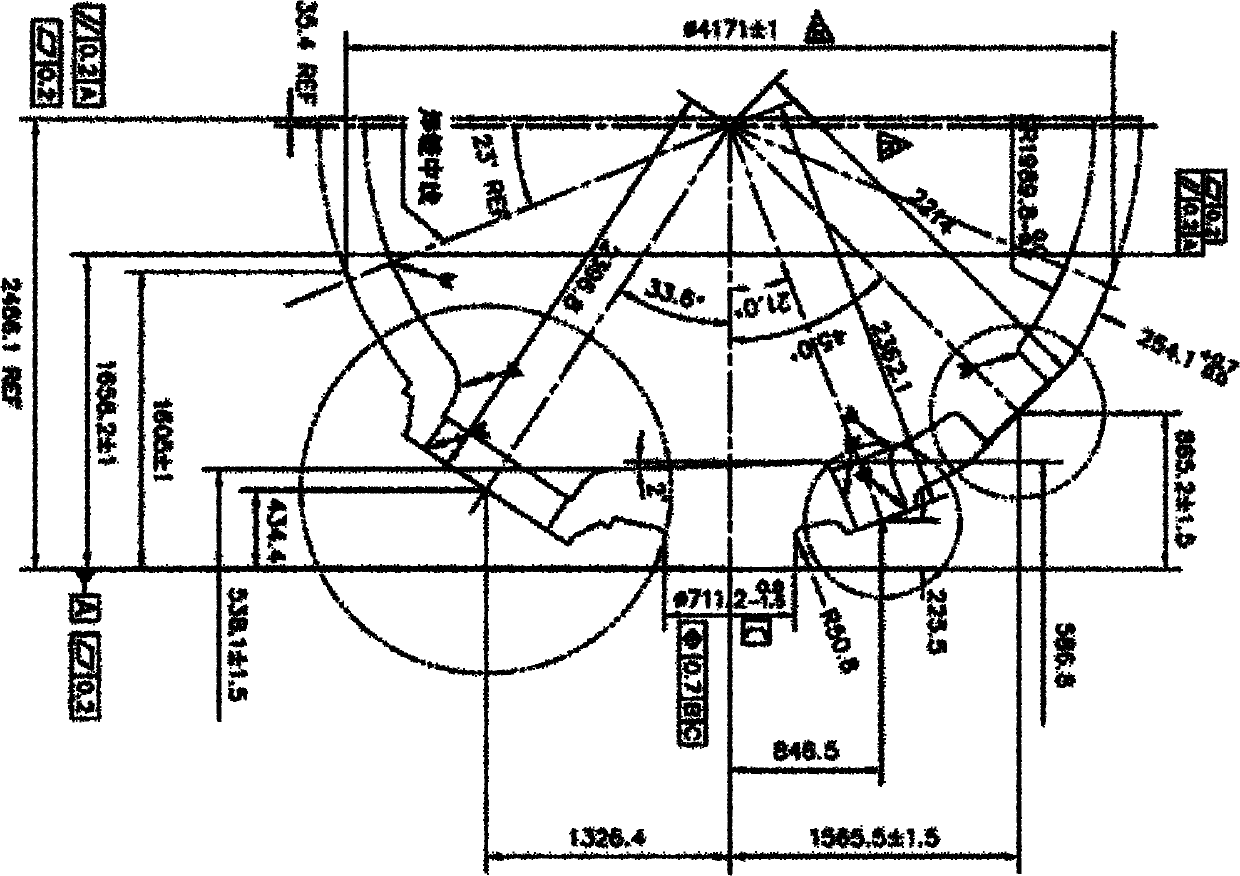

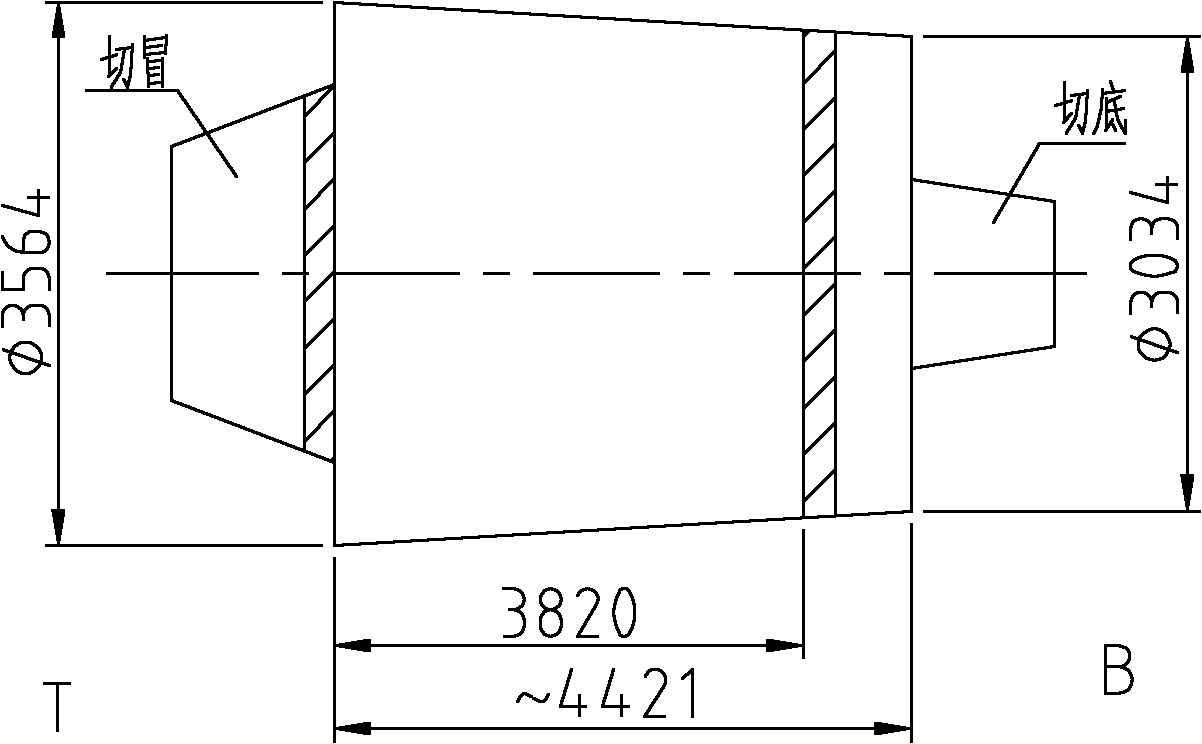

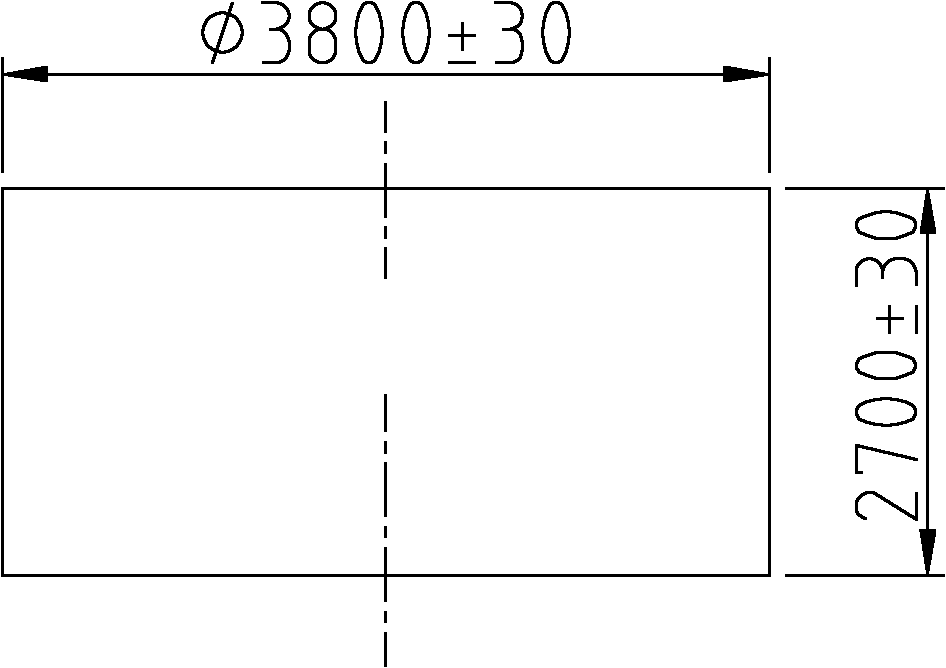

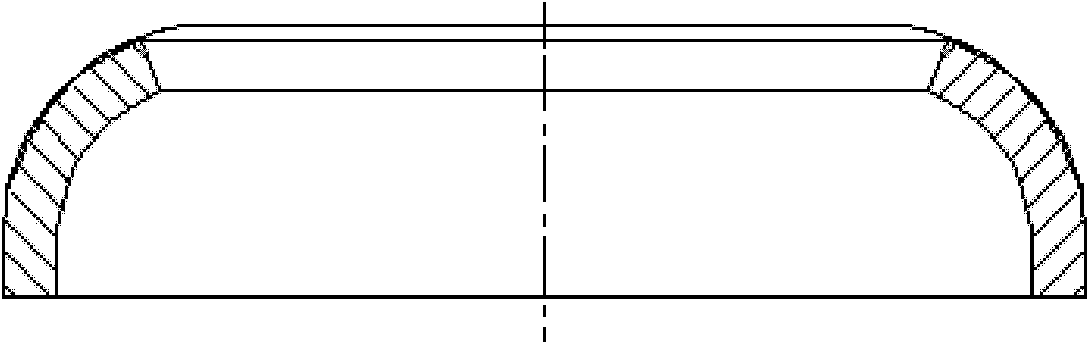

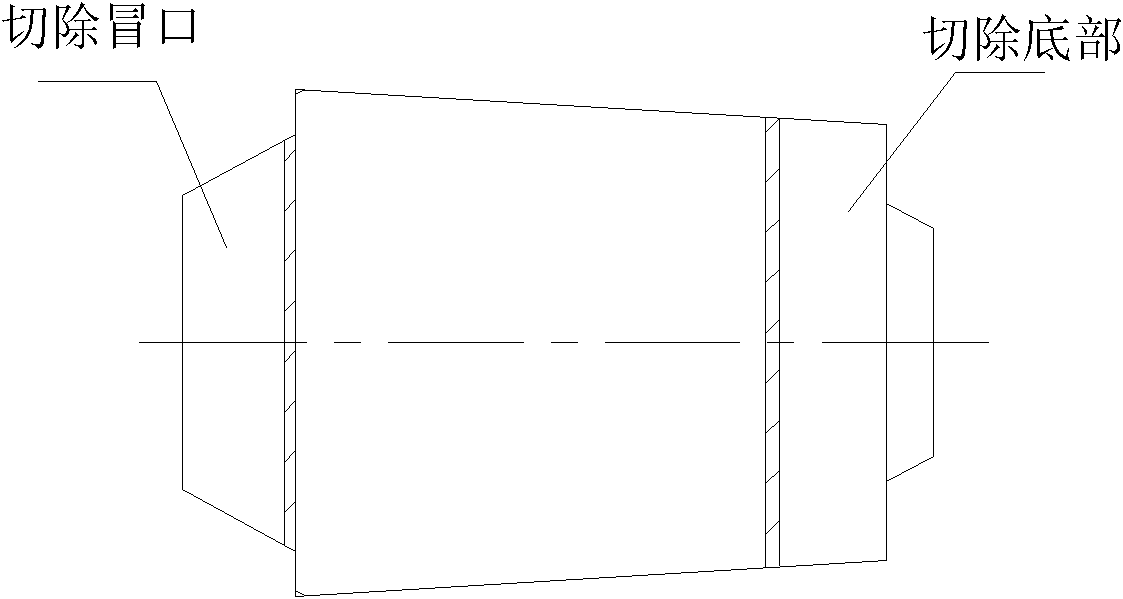

Forging method for ellipsoidal head ring forge piece of third generation nuclear power plant steam generator

The invention discloses a forging method for an ellipsoidal head ring forge piece of a third generation nuclear power plant steam generator. The manufactured forge piece comprises a bending section and a straight section; the forging method is executed by using a megaton-level free forging press, forging a dual-vacuum steel ingot into a whole straight section and then forging the straight section into the bending section by rotary die pressing by a die; the forging process comprises the following steps of: firstly, cogging: cutting a feeder head and a bottom from the dual-vacuum steel ingot; secondly, upsetting: heating work pieces to be 1220 plus or minus 20 DEG C, so that the heights of the work pieces are reduced and the diameters of the work pieces are increased after the work pieces are subjected to upsetting; thirdly, chambering: heating the work pieces to be 1220 plus or minus 20 DEG C, so that the wall thicknesses of the work pieces are reduced and the diameters of the work pieces are increased after the work pieces are subjected to chambering; and fourthly, carrying out a rotary die pressing process: heating the work pieces to be 1200 plus or minus 20 DEG C, so that the diameters of the work pieces are reduced and the wall thicknesses of the work pieces are increased after the work pieces are subjected to the rotary die pressing process. By adopting a forge piece forged by the forging method, dense material, reasonable distribution of a metal flow line and low possibility of cracking of the ellipsoidal head ring forge piece can be guaranteed.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

Lid or seat-ring of toilet bowl and production technique thereof

InactiveCN101361640ADense materialFlat surfaceBathroom coversCompression moldingVolumetric Mass Density

The invention discloses a lid or a seat ring of a toilet bowl and a production technique thereof. The lid or the seat ring is produced by adopting a compression molding technique, a density plate is arranged inside, and a mixed SMC material covers the outside, thus forming a sandwich shape; the production technique comprises following steps: 1. SMC is prepared: various materials are synthesized according to a certain proportion, broken up by a high-speed blender for being completely mixed, and then prepared into a sheet shape for use; 2. a sandwich layer is prepared: the density plate is cut into required shapes and dried, thus leading the density plate not to contain moisture; the density plate is vacuated and air contained in the density plate is exhausted; the density plate is placed into a freezing case for storage; 3. compression molding is carried out: a die is heated until the temperature reaches 150 DEG C, the density plate and a certain amount of SMC are placed into the die, compressed for 3 to 6 minutes and taken out. The invention is characterized by having the advantages of good surface lustrousness and good product flatness, with weight of lighter than that of toilet lids made of pure SMC materials, adoption of the one-time compression molding technique without usage of paints, long service life and the like.

Owner:童晔波

Fiber compound regenerative asphalt concrete

The invention provides fiber compound regenerative asphalt concrete, which is prepared from the following ingredients (by weight): 30 parts of 0-5mm regenerative asphalt concrete RAP, 25 parts of 5-10 mm regenerative asphalt concrete RAP, 28 parts of 10-30 mm regenerative asphalt concrete RAP, 15 parts of 10-30 mm new aggregate, 2 parts of mineral powder, 1.5 parts of cement, 4 parts of emulsified asphalt, 1 part of a regenerant and 1.2 parts of glass fiber. The glass fiber of 6 mm long is added to improve material performance of a cold recycled mixture. The glass fiber is obviously better than other fibers. The special fiber has obviously more excellent dispersion effect in the cold recycled mixture than other fibers, and the regenerative mixture is smooth to discharge. The fiber compound regenerative asphalt concrete provided by the invention has obviously more excellent material performance than the code requirements. Tension strength, namely cleavage strength, of the mixture is raised. Material anti-cracking ability is more excellent, reflection crack resistance is stronger, the material is more compact, moisture damage resistance is stronger, and durability is better.

Owner:BEIJING SAINT GROUND HIGHWAY TECH

Alloy-doped gold bonding wire and cryogenic-treatment preparation method thereof

The invention relates to an alloy-doped gold bonding wire and a cryogenic-treatment preparation method thereof. The alloy-doped gold bonding wire formed by using high-purity gold as a main ingredient and being doped with high-purity silver and high-purity palladium, which is provided by the invention, is prepared from the following ingredients in percentages by weight: 60 to 80 percent of gold, 0.5 to 3.5 percent of palladium and the balance of silver. A bonding wire product has favorable oxidation resistance; an appearance is basically golden; the performance of the product is approximate to that of a pure-gold bonding wire; and the alloy-doped gold bonding wire is suitable for IC (Integrated Circuit) and COB (Chip On Board) encapsulation and high-end LED (Light-Emitting Diode) encapsulation. During the bonding of encapsulation, any gas shield is not needed; and in comparison with a gold bonding wire, the cost of the product is only approximately 3 / 5 to 4 / 5 of that of the gold bonding wire. In the preparation process of the product, the cryogenic treatment is carried out on a bonding wire twice; the arrangement of internal crystal textures of a material is improved; the physical properties of the material are enhanced; and the bonding properties of the alloy-doped gold bonding wire is improved. When the product is used for downstream encapsulation and wire bonding modes are BSOB (Bond Stitch On Ball) and BBOS (Bond Ball On Stitch), a wire stock and a ball are guaranteed to be eutectic.

Owner:河北乐通金属材料有限公司

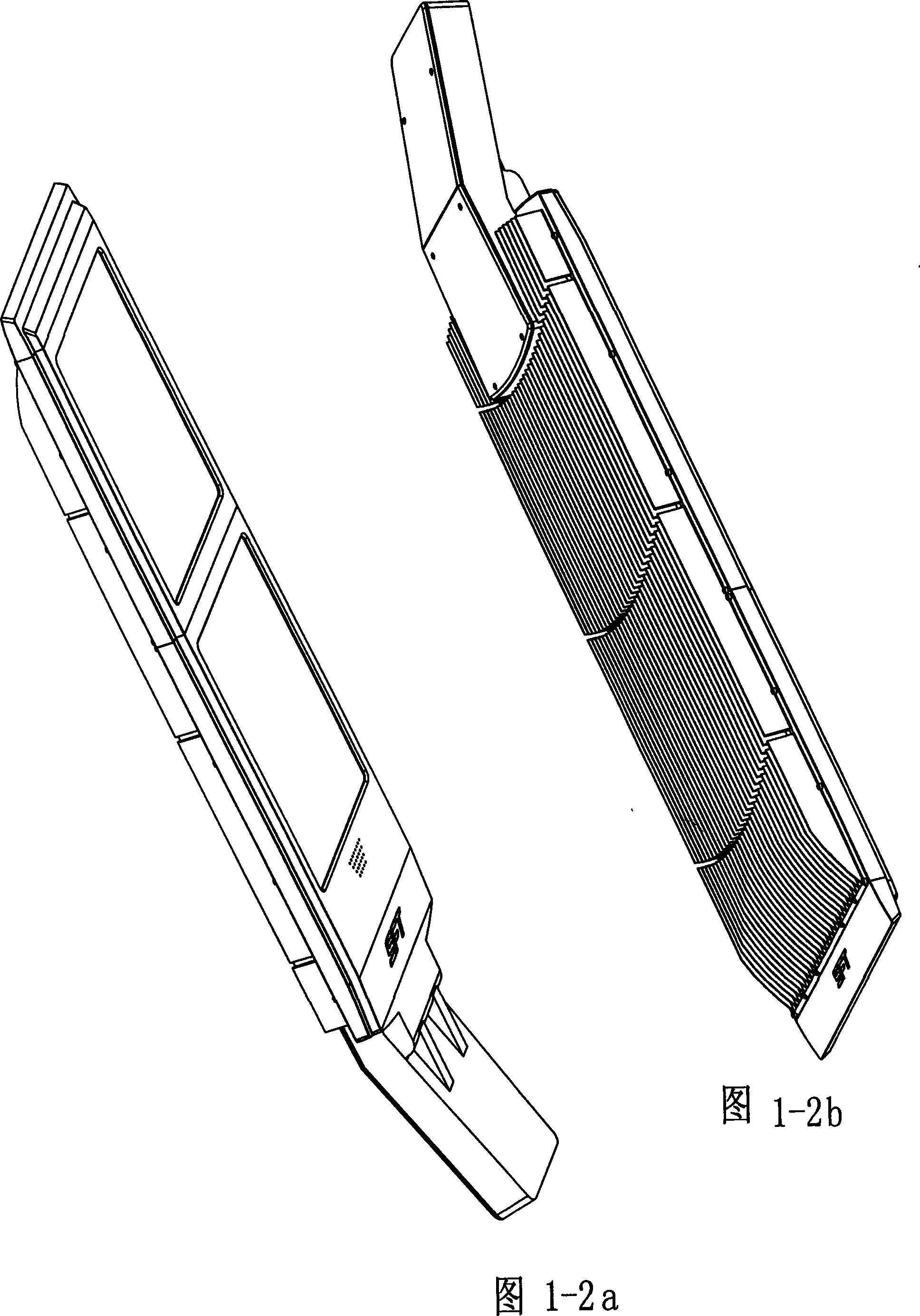

High-efficiency heat radiation high-power LED street lamp holder

InactiveCN101382259ASimple and scientific structureEasy to producePoint-like light sourceElectric circuit arrangementsEngineeringControl circuit

The invention discloses a heat-dissipation LED stress lamp cap with high efficiency and large power, comprising an independent general lamp body consisting of a lamp body shell, an electric apparatus chamber cover, a light transmission shielding plate, an LED light source component, an optical management device, an LED driving control circuit, a lamp body upper cover, a head cover, an installation cover and a sealing ring; the lamp body shell, the lamp body upper cover and the light transmission shielding plate enclose a sealed chamber; the LED light source component is arranged in the chamber and is closely attached to the lower surface of the upper cover of the lamp body; the external side of the upper cover of the lamp body is provided with a plurality of heat dissipation ribs which are used for increasing the whole heat dissipation area of the lamp cap; the optical management device is arranged at the LED light source component; simultaneously, the lamp body shell and the electric apparatus chamber cover plate enclose another sealed chamber; the chamber body is internally provided with the LED driving control circuit. The LED street lamp cap has the advantages of scientific, reasonable and simple structure, easy production and manufacture, low cost, convenient installation and assembly, good heat dissipation effect, high luminescence efficiency and long service life.

Owner:史杰

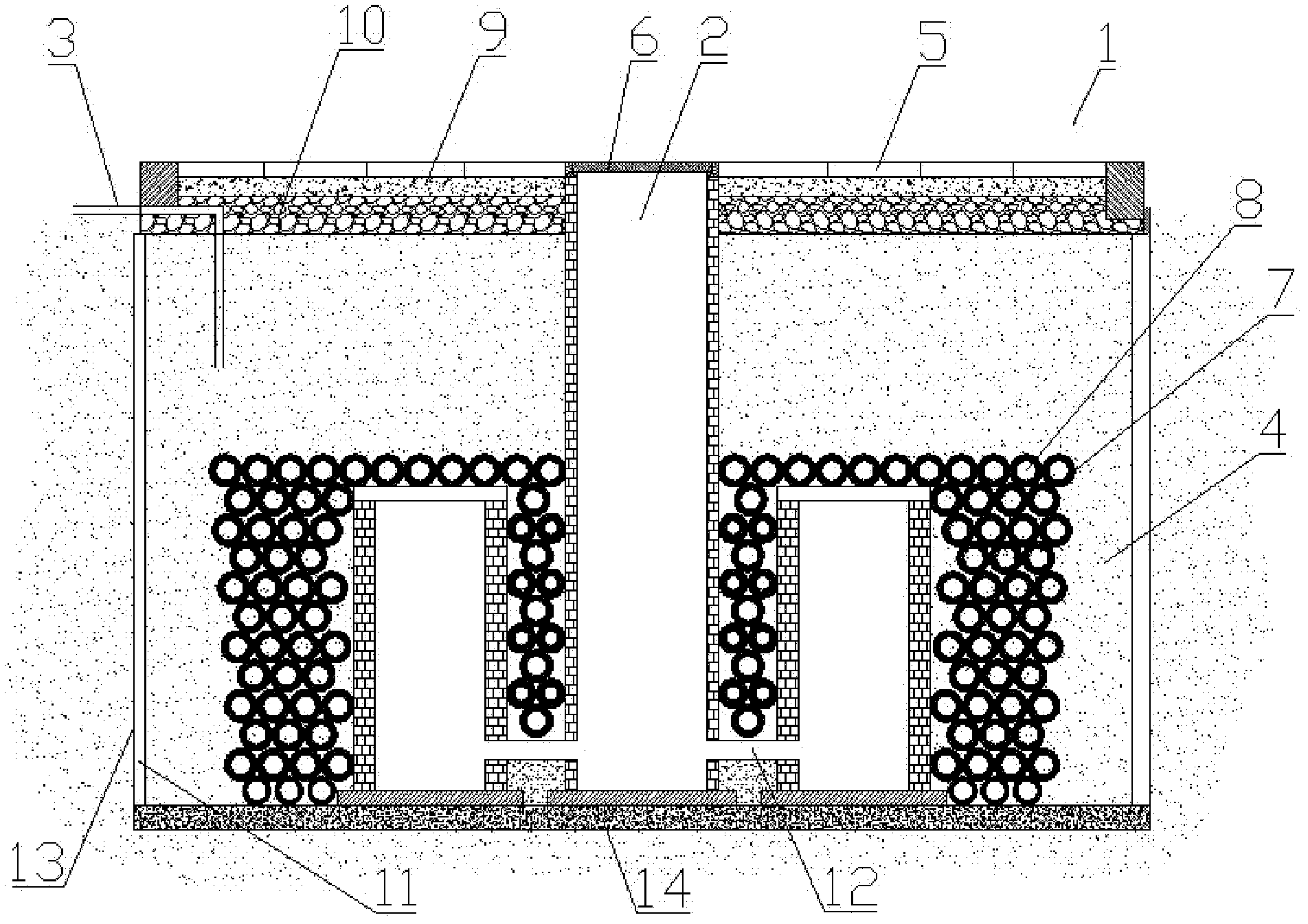

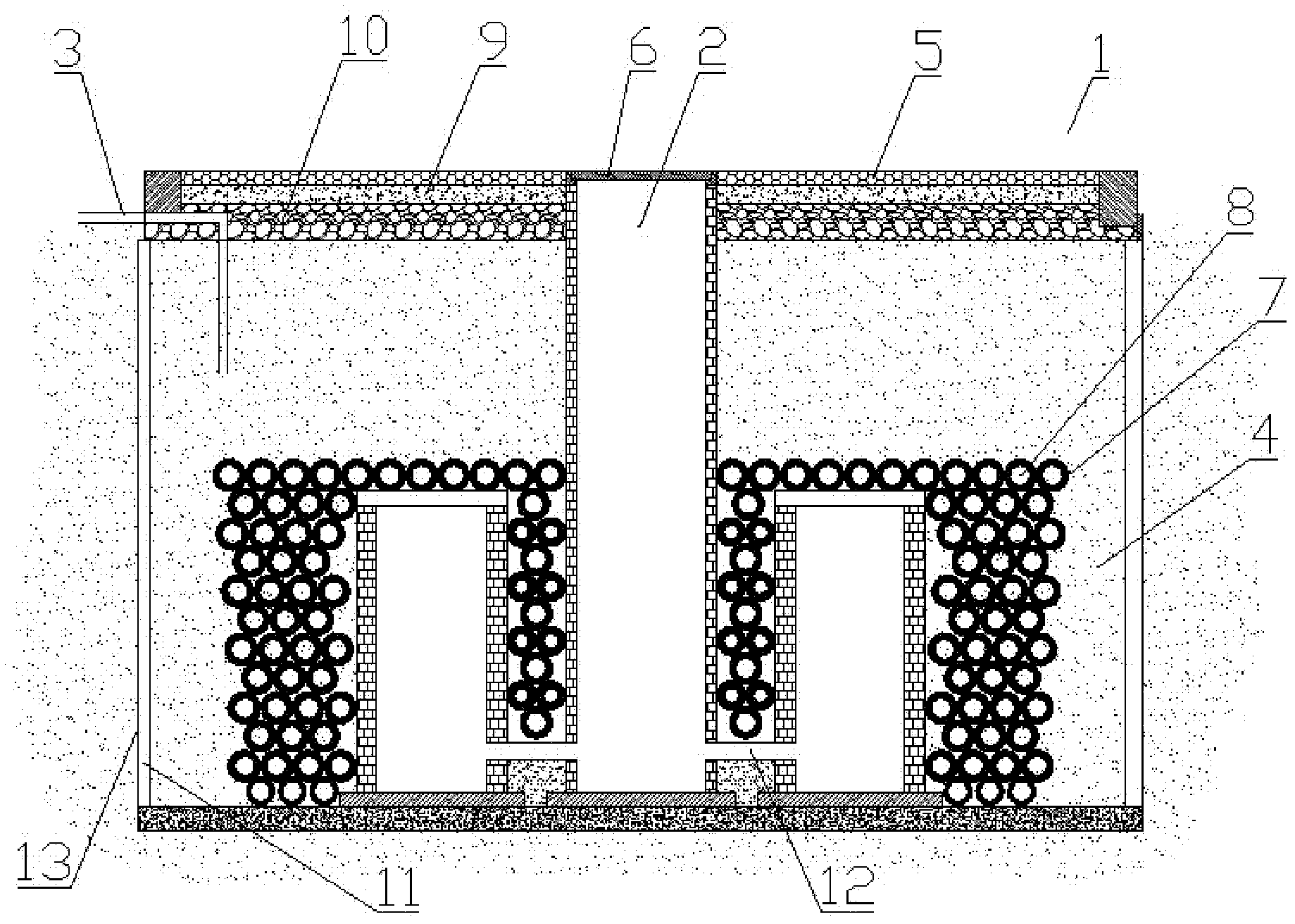

Water storage system

ActiveCN103174189AGuaranteed anti-seepage effectGuaranteed air permeabilitySewerage structuresGeneral water supply conservationWater storageWater quality

The invention relates to a water collection and purification system, in particular to a water storage system which is firm in building and easy to construct. The water storage system comprises a water storage container, a water collection well and water permeability padding which is filled between the water collection well and the water storage container, water is filled into the water storage container through a water inlet pipe or a water permeability surface layer paved above the padding, the container wall is a seepage prevention air permeability wall which is composed of seepage prevention air permeability particles, the boundary of the seepage prevention air permeability wall is limited through air permeability wall bags, and fine sand particles are piled up on two sides of the seepage prevention air permeability wall to fix the seepage prevention air permeability wall in a squeezing mode. The container wall of the water storage system adopts the air permeability wall bags and are filled with the seepage prevention air permeability particles, thin sand are filled on two sides of the side wall to squeeze and reinforce the side wall, the water can be prevented from being leaked outwardly through seepage prevention performance of the seepage prevention air permeability particles, so that the seepage prevention performance of the water storage system is ensured, meanwhile, an air permeability degree of the whole water storage system is also ensured through the air permeability performance of the seepage prevention air permeability particles, and the stored water is enabled not to go bad easily.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

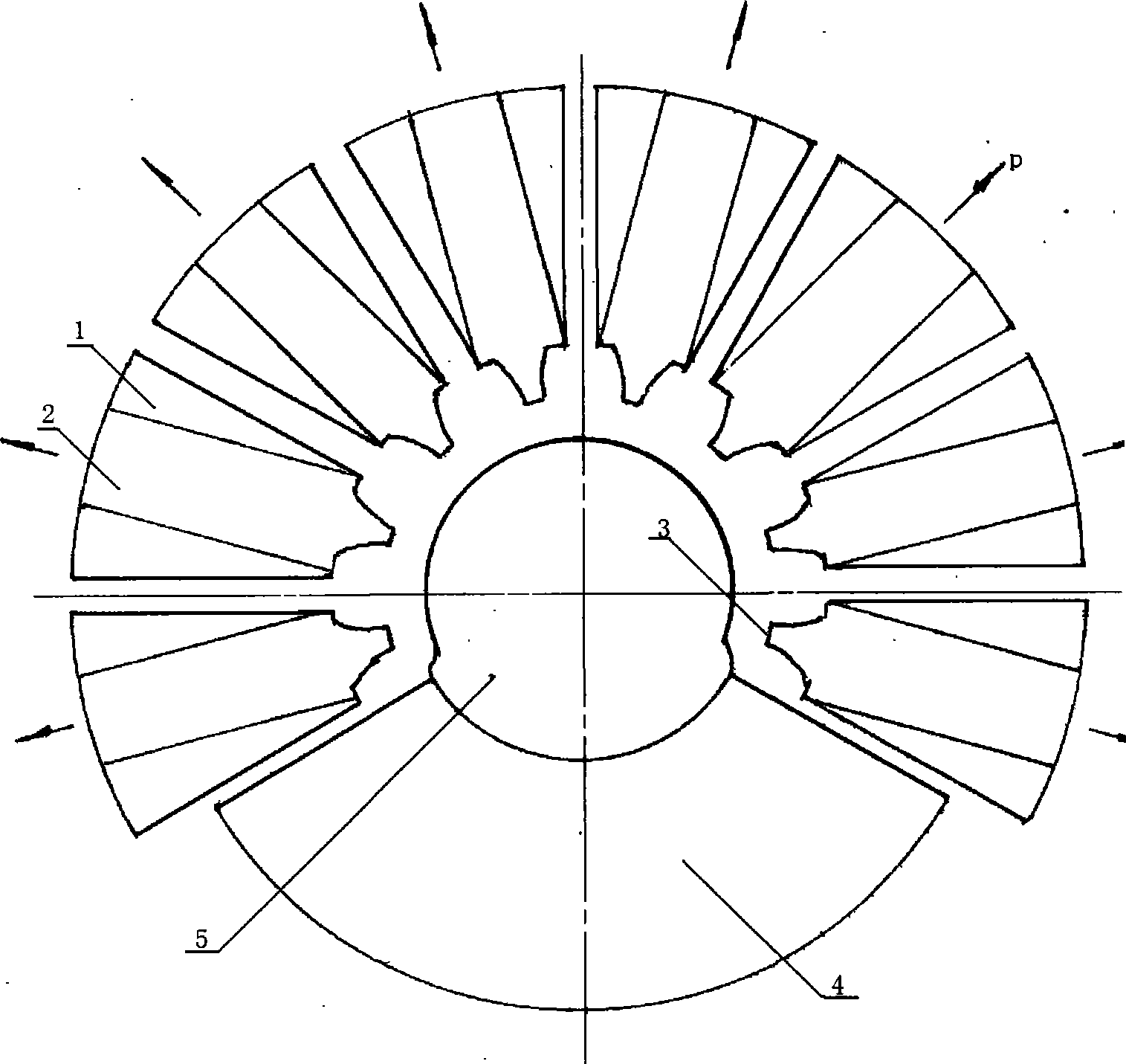

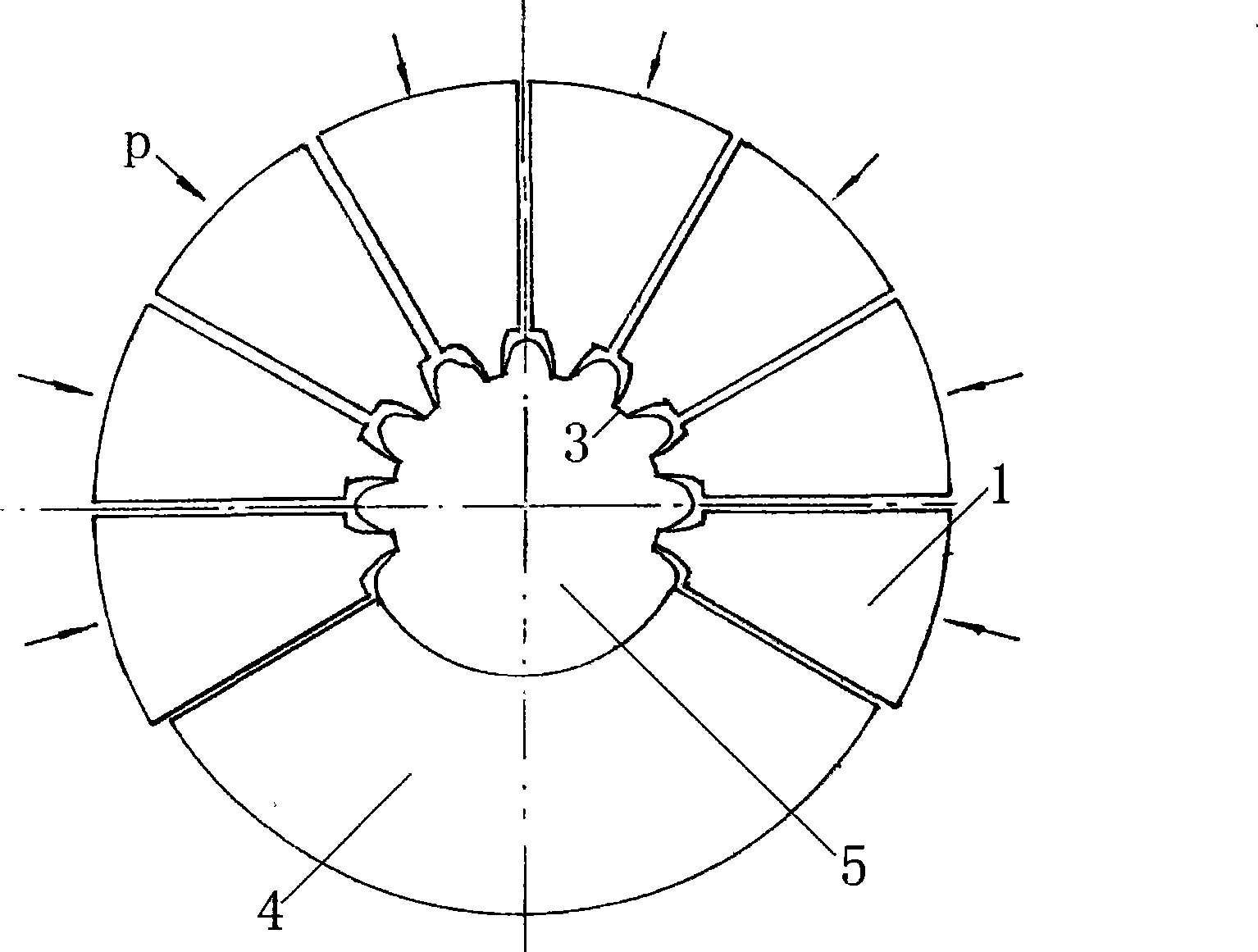

Method for wedge pressure forming process gear wheel

The invention discloses a method for processing gear by inlaid-pressure formation, which comprises the following steps of: manufacturing tooth-shaped inserts with a number identical to that of tooth channels; manufacturing two insert bases with radial guide grooves on the inner sides; arranging the tooth-shaped inserts in the radial guide grooves of the insert bases to surround the to-be-processed surface of a gear blank workpiece; and applying a radial pressure to the workpiece at the periphery of the tooth-shaped inserts by pressurization equipment to make the workpiece inlaid in the front edge notch of the tooth-shaped inserts while extruding the workpiece, so that the surface of the gear blank material locally deforms to form the gear. The method has the advantages of simple steps, no need for rotating the workpiece, no cutting, one-step formation, accurate size precision, high efficiency, short manufacture time (only a few seconds), high yield and low cost. The tooth-shaped insert has simple structure and only bears the pressure, thus improving the service life. Accordingly, a gear shaft and an integral gear or a non-integral gear or a non-circular gear can be manufactured without cutting. The involute, cycloid as well as arc gear surface, and spur gear, helical gear as well as bevel gear can be achieved.

Owner:皮开勇

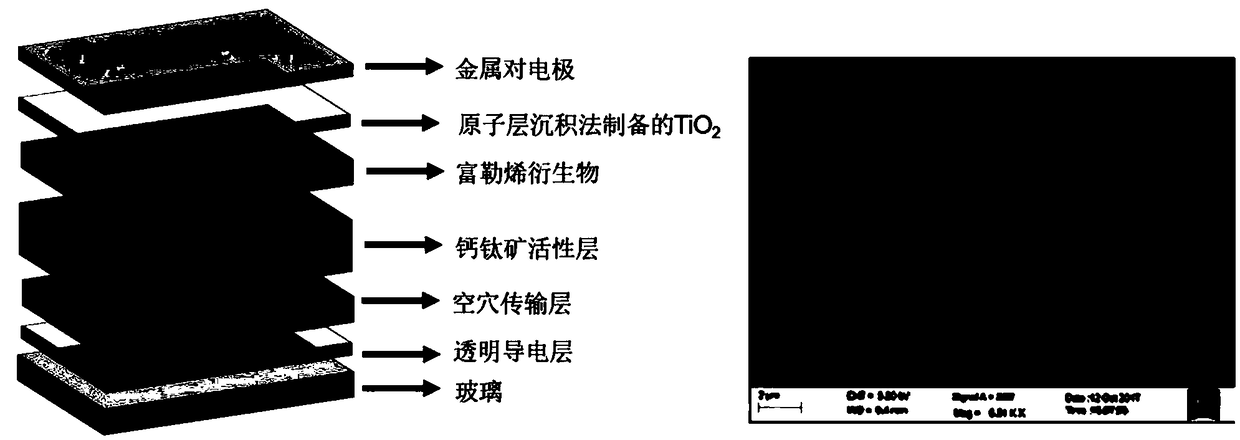

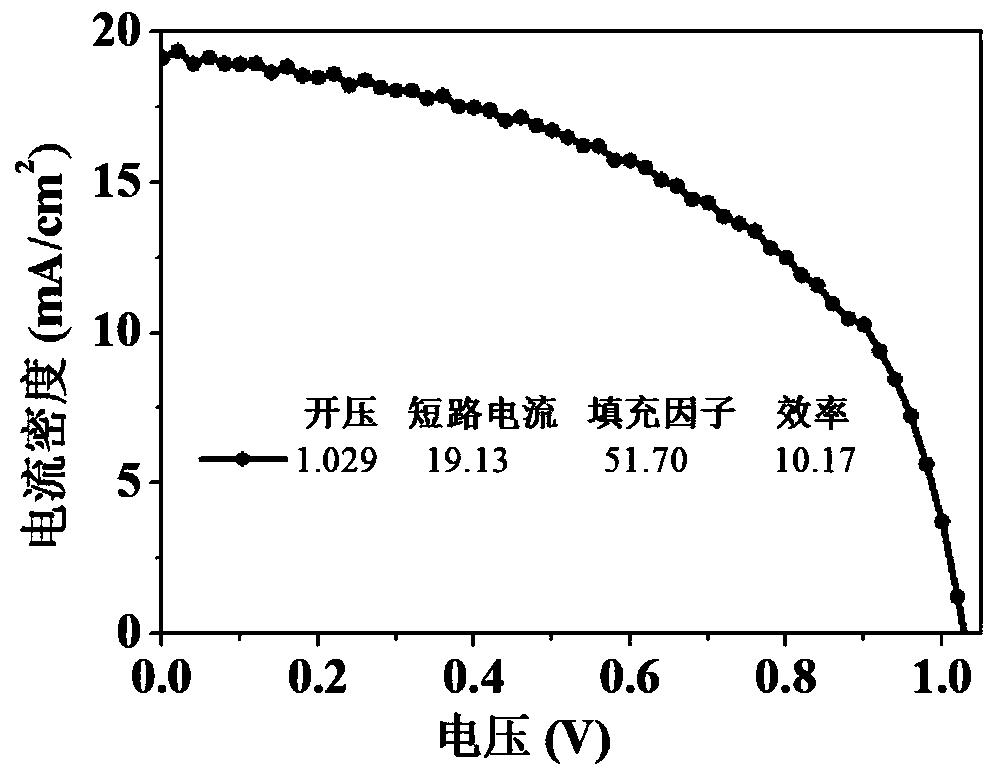

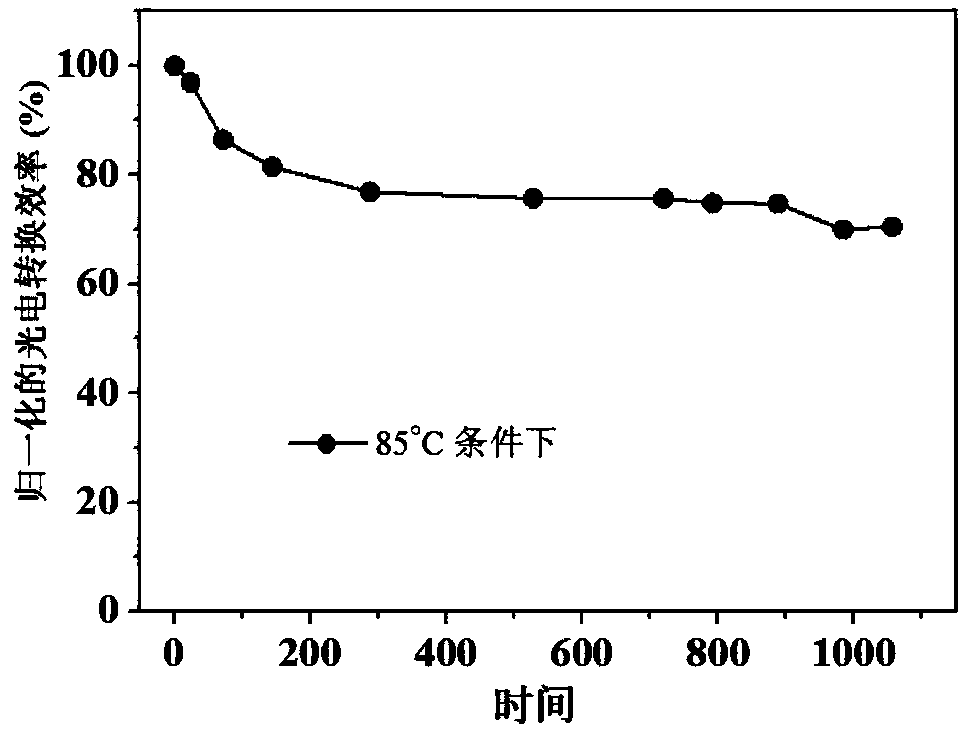

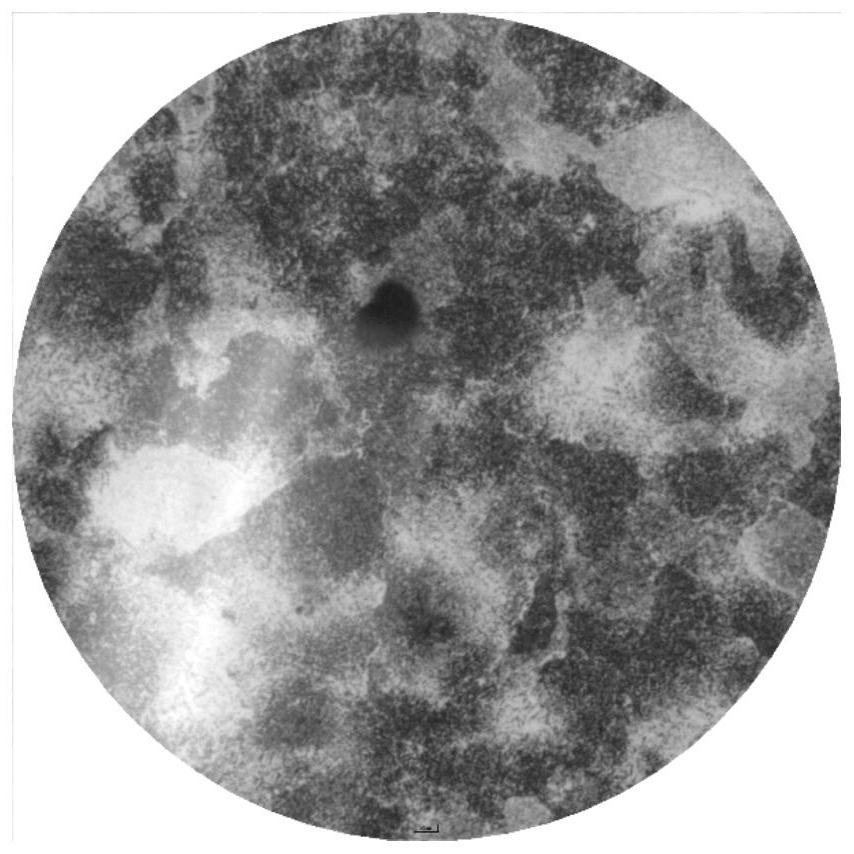

Composite electron transfer layer perovskite solar cell prepared by using atomic layer deposition method and preparation method thereof

InactiveCN108807677ADense materialBlock interdiffusionFinal product manufactureSolid-state devicesOrganic moleculesPolymer

The invention discloses a composite electron transfer layer perovskite solar cell prepared by using an atomic layer deposition method and a preparation method thereof. The composite electron transferlayer perovskite solar cell is characterized in that a fullerene / titanium dioxide composite electron transfer layer prepared by using the atomic layer deposition method is used, the structural features of the cell are transparent top electrode and metal counter electrode, and small organic molecules, polymers and inorganic matters are used as hole transfer materials. The perovskite solar cell hasextremely high heat stability, and moreover the photovoltaic conversion performance of the perovskite solar cell also can be preferable.

Owner:PEKING UNIV

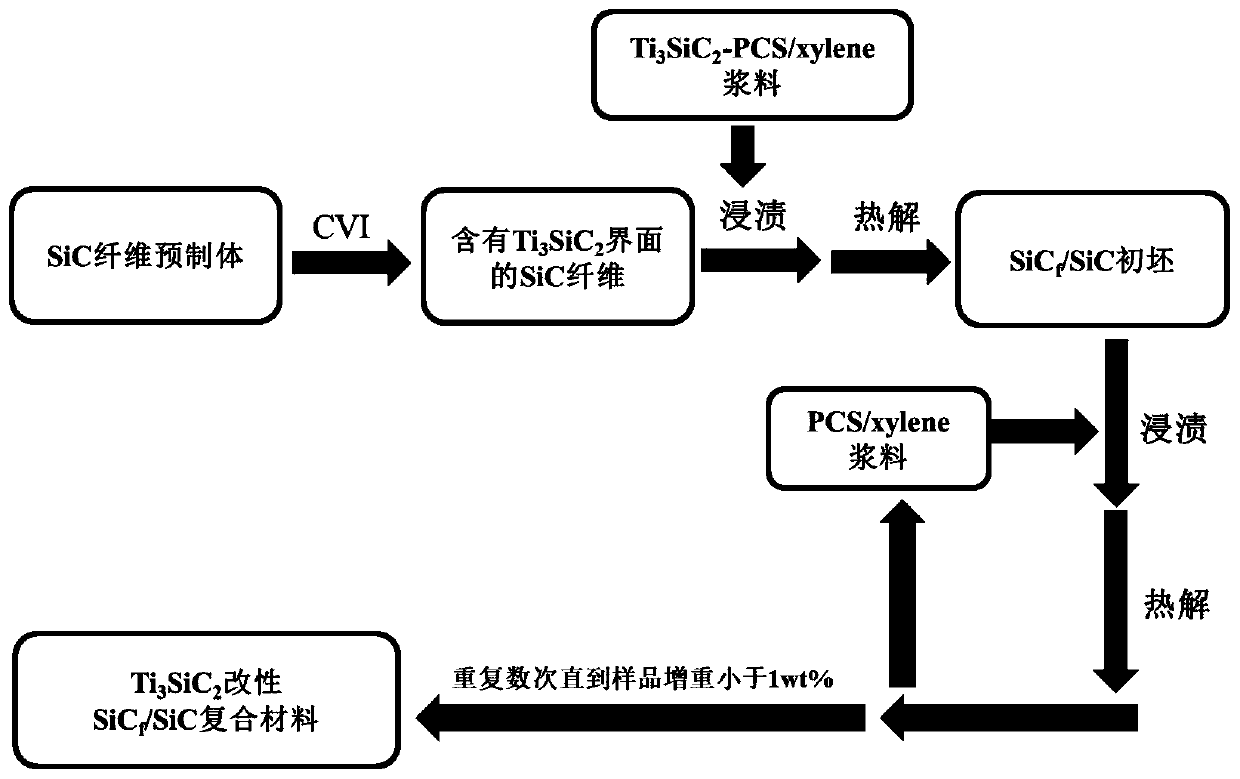

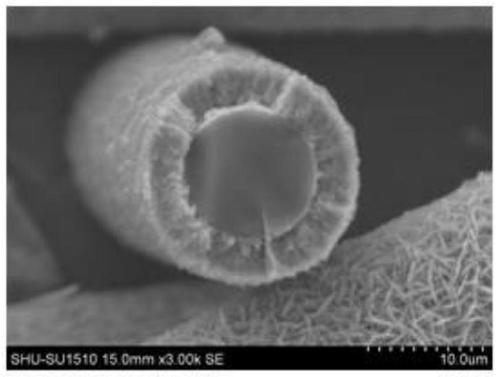

Titanium-silicon-carbon interface modified SiCf/SiC wave-absorbing composite material and preparation method thereof

ActiveCN111592371AReduce particle agglomerationReduce clumpingMagnetic/electric field screeningCarbide siliconSic fiber

The invention discloses a titanium-silicon-carbon interface modified SiCf / SiC wave-absorbing composite material and a preparation method thereof. The preparation method comprises the steps: putting asilicon carbide fiber prefabricated body in a constant-temperature area of a CVD furnace, and depositing a titanium-silicon-carbon interface layer on the surface of silicon carbide fibers through a chemical vapor infiltration method within a proper temperature range; and soaking in slurry containing polycarbosilane and titanium silicon carbon to be impregnated; and preparing the ceramic matrix composite material through a precursor impregnation pyrolysis method (PIP). The SiCf / SiC composite material containing the Ti3SiC2 interface is prepared, the process is simple, the cost is low, the dielectric constant of the wave-absorbing composite material is effectively regulated and controlled, and a good wave-absorbing effect is achieved.

Owner:SHANGHAI UNIV +1

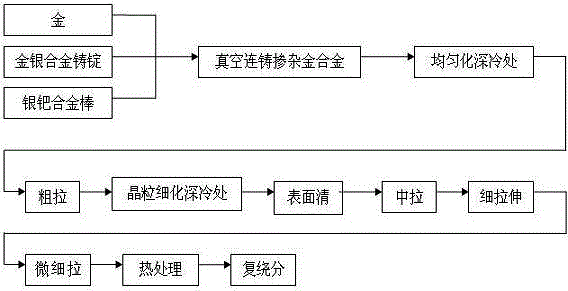

Copper-palladium-silver alloy bonding wire and method for preparing same

ActiveCN104835797ALow priceReduce packaging costsSemiconductor/solid-state device detailsSolid-state devicesSurface cleaningMicrometer

The present invention discloses a copper-palladium-silver alloy bonding wire and a method for preparing the same. The copper-palladium-silver alloy bonding wire is characterized in that a palladium plating protection layer is arranged on the surface of the copper-palladium-silver alloy bonding wire, the diameter of the copper-palladium-silver alloy bonding wire is between 0.015 mm and 0.05 mm, and the thickness of the palladium plating layer is between 0.2 micrometers and 0.6 micrometers. The preparation method comprises the steps of selecting a copper ingot, a palladium ingot and a silver ingot to clean and dry for standby application, preparing a copper-palladium-silver alloy ingot casting, preparing a copper-palladium-silver alloy bar, carrying out homogenizing annealing on the copper-palladium-silver alloy bar, and carrying out the rough tension, the grain refinement annealing, the medium tension, the fine tension, the surface cleaning, the surface palladium plating, the slight tension, the heat treatment, the compound winding and the subpackaging operations orderly. According to the present invention, the copper-palladium-silver alloy bonding wire substitutes for a fine silver gold plating bonding wire, so that the insufficiency of the fine silver gold plating bonding wire is overcome, and the material push-pull effort, the antioxidation performance and the bonding performance of the copper-palladium-silver alloy bonding wire all can reach the performance requirements of the fine silver gold plating bonding wire.

Owner:王东明

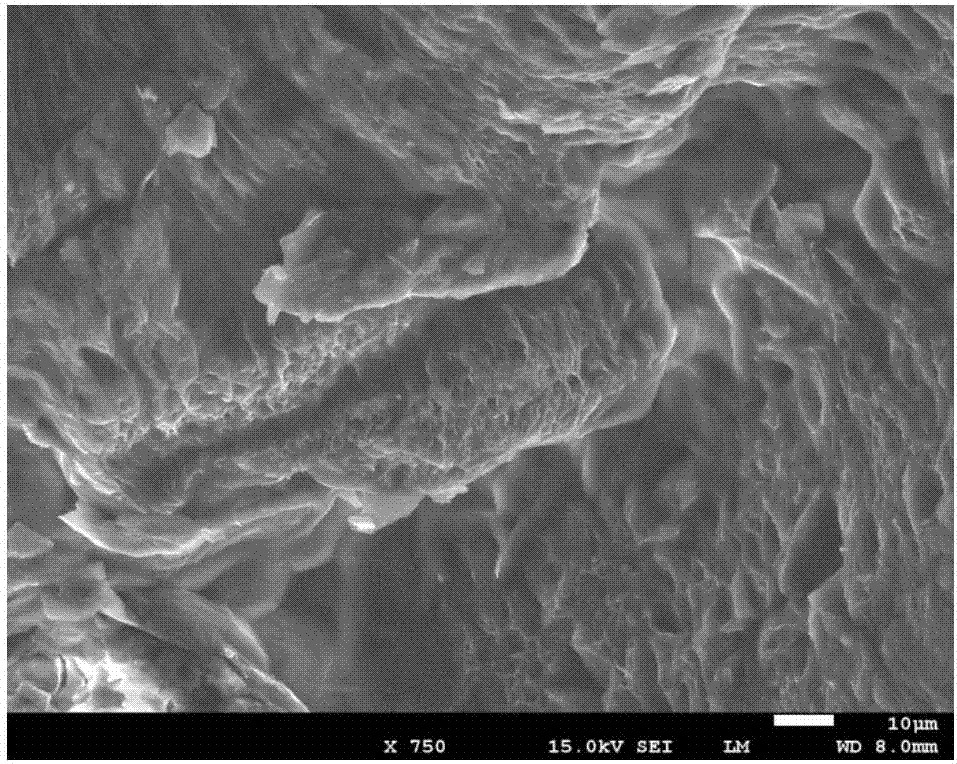

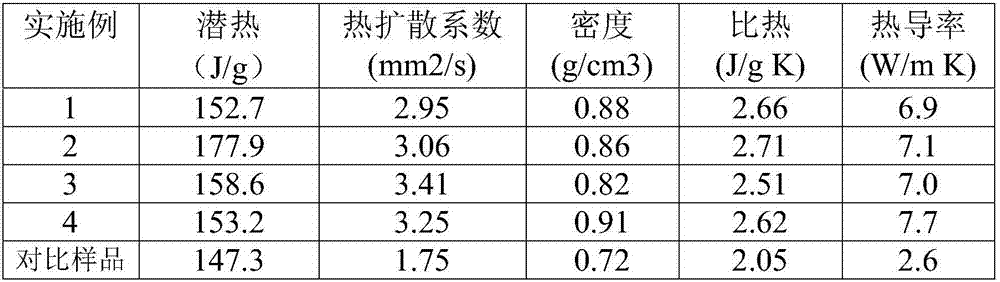

Packaged phase-change energy-storage composite material with super-high thermal conductivity and processing technology thereof

ActiveCN106905928ADense materialReduce porosityHeat-exchange elementsThermal diffusion coefficientHigh energy

The invention relates to a packaged phase-change energy-storage composite material with super-high thermal conductivity and a processing technology thereof and brings forward an expandable graphite / nanographene sheets combined thermal conductance enhanced packaged phase-change energy-storage composite material. The invention brings forward the structural optimal range of a packaging body, namely an expandable graphite material, used as a waxy phase-change material. The expansion rate reaches 200 times and above, and average pore size is 0.5-20 micrometers. Meanwhile, the range of ratio of the expandable graphite to nanographene sheets with high thermal conductivity is determined. The invention also brings forward a corresponding preparation technology of the composite material. Thermal diffusion coefficient of the phase-change energy-storage composite material reaches 2.9 mm<2> / s and above, and thermal conductivity reaches 6.9 W / mK and above. The thermal conductivity is nearly 30 times higher than thermal conductivity of a simple paraffin material, and energy storage density of the composite material is nearly 90% of energy storage density of the paraffin material. The phase-change energy-storage composite material has very high energy storage density and thermal conductivity, is green and environment-friendly, and has a very good application prospect.

Owner:杭州诺麦科科技有限公司

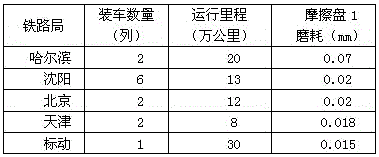

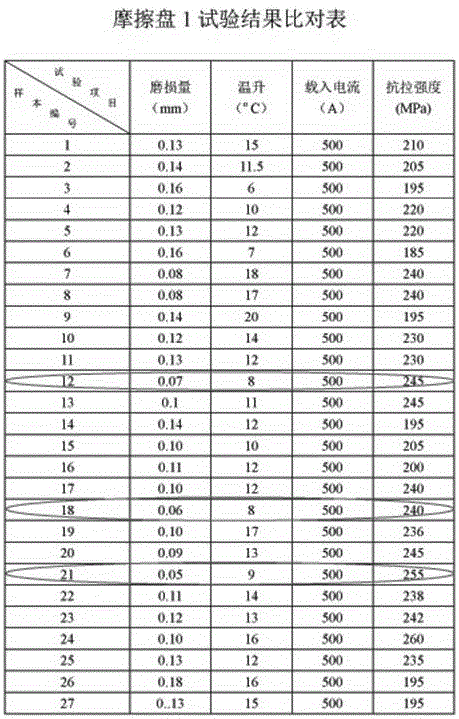

Friction disc for high-speed rail and preparation method of friction disc

InactiveCN106399747AThe result data is idealLiquid metal is better filledFoundry mouldsFoundry coresSand castingLiquid metal

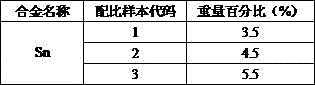

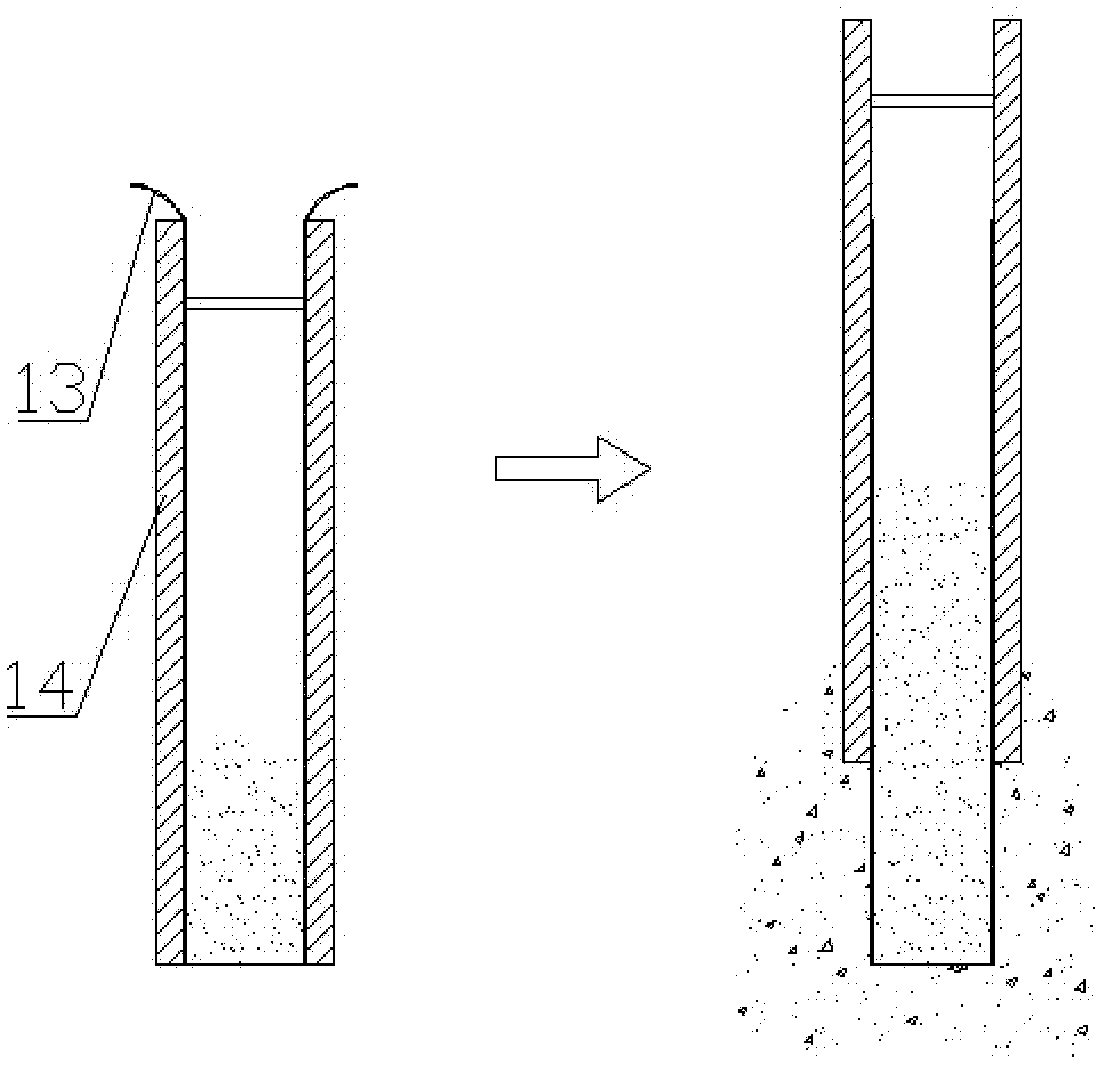

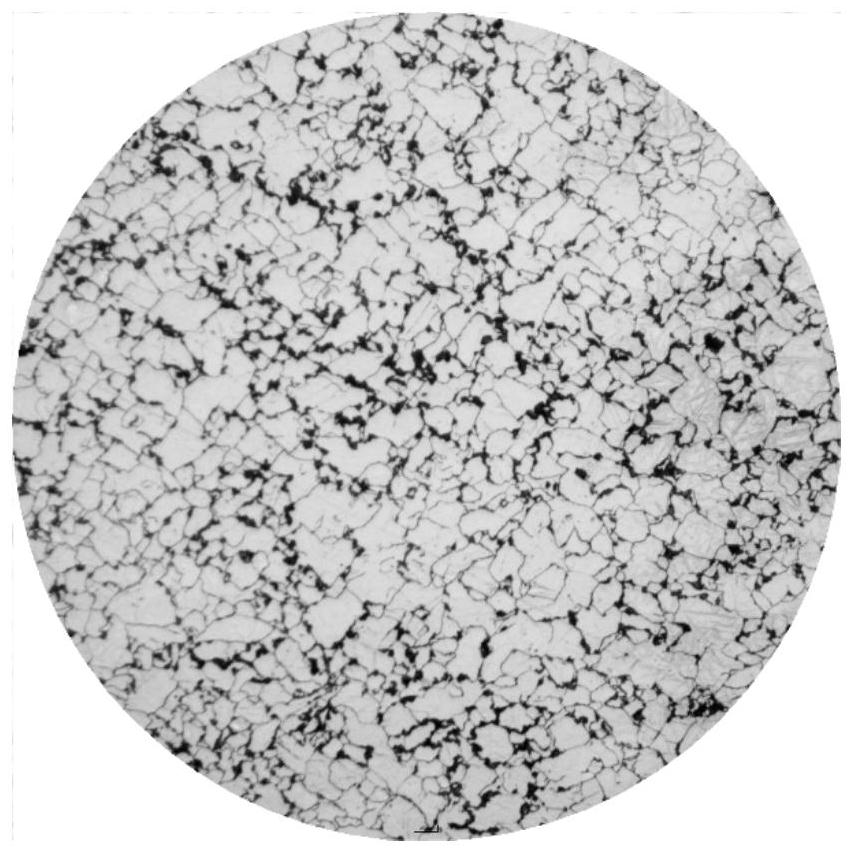

The invention relates to a friction disc for a high-speed rail and a preparation method of the friction disc. The friction disc comprises the following components including, by weight, 3.5-5.5% of Sn, 4.0-6.0% of Zn, 1.0-3.0% of Ni, 1.5-3.5% of Pb, 0.2-0.4% of Be and the balance Cu. A vacuum suction fired mold is adopted for casting, gas in a cavity is sucked away from tiny pores in a shell, the cavity is better filled with liquid metal, the phenomena of pores and insufficient pouring are prevented, the appearance and inherent quality of products are improved, and the machining yield is up to 98%. The requirements of the friction disc for the abrasion resistance and electrical conductivity are higher, common sand casting structures are loose, casting defects are prone to occurring, and meanwhile the hardness is low. Precise die forging manufacturing is adopted, the blank allowance is even, the texture is compact, the hardness can reach the drawing requirement, and tests show that the abrasion resistance reaches and exceeds the level of foreign similar products.

Owner:YANGZHOU YIFENG BRONZE PROD

Water storage system with surface layer capable of being used for planting

ActiveCN103161198AGuaranteed air permeabilityPrevent infiltrationGeneral water supply conservationWater supply tanksWater storageSurface layer

The invention relates to a water collection purification device, in particular to a water storage system with a surface layer capable of being used for planting. The water storage system with the surface layer capable of being used for the planting comprises a water storage container, a water-collecting well and water-permeable padding, wherein the container wall is in a waterproof structure, the well wall is in a waterproof structure and the water-permeable padding fills between the water-collecting well and the water storage container. Collected water is poured into the water storage container through a water pipe, an anti-seepage breathable layer is laid on the upper layer of the water-permeable padding, the anti-seepage breathable layer is formed by anti-seepage breathable granules, pores are formed among the anti-seepage breathable granules, wherein gas molecules can pass through the pores and liquid water molecules cannot penetrate through the pores. According to the water storage system with the surface layer capable of being used for the planting, due to the fact that the anti-seepage breathable layer is arranged on the top surface layer of the water storage container, on the one hand, planting moisture can be prevented from permeating and polluting stored water quality, on the other hand, air permeability of the anti-seepage breathable layer can guarantee the quality of water of the whole water storage system. The water storage system with the surface layer capable of being used for the planting can be effectively applied to water storage of cultivated wetlands.

Owner:BEIJING RECHSAND SCI & TECH GRP

Carbide-containing high-strength high-toughness bainite wear-resistant steel and preparation method thereof

The invention provides carbide-containing high-strength high-toughness bainite wear-resistant steel and a preparation method thereof, and relates to the technical field of wear-resistant steel. The wear-resistant steel comprises the following chemical components: 0.6 to 1.2 percent by weight of C, 1.2 to 2.5 percent by weight of Si, 0.8 to 2.0 percent by weight of Mn, 5 to 10 percent by weight of Cr, less than or equal to 0.015 percent by weight of P, less than or equal to 0.01 percent by weight of S, 0.3 to 0.7 percent by weight of Mo, 0.3 to 0.7 percent by weight of Ni and the balance of Fe and inevitable trace impurities. The preparation method comprises the following steps of firstly smelting and casting into a cast ingot according to designed components, then forging or rolling into a plate blank, and carrying out spheroidizing annealing treatment; and finally, carrying out heat treatment through an isothermal quenching process, then heating to 850 to 950 DEG C, carrying out heat preservation for 2 to 6 hours to finish austenitizing, then cooling to 310 to 380 DEG C at a cooling speed sufficient to avoid pearlite phase change, carrying out isothermal treatment for 8 to 15 hours, then transferring to an air furnace with the temperature of 200 to 280 DEG C for isothermal treatment, and finally carrying out air cooling to room temperature. A microstructure of the prepared wear-resistant steel is as follows: a matrix is micro / nano-scale bainite ferrite and film-shaped austenite which are distributed alternately, spherical carbide with the diameter of 0.5 to 2 microns is dispersed and distributed on the matrix, the volume percentage of the spherical carbide is 7 to 12 percent, and the performance is excellent.

Owner:JIANGXI NAIPU MINING MASCH CO LTD

Novel wood-plastic material

InactiveCN106009750AImprove flame retardant performanceHigh smoke suppression effectAntifungalPlastic materials

The invention discloses a novel wood-plastic material. The novel wood-plastic material is prepared from, by weight, 32-58 parts of peach tree powder, 22-38 parts of reed straw powder, 8-12 parts of hard wrapping paper powder, 6-10 parts of woven bag plastic particles, 6-8 parts of filling agent, 4-6 parts of synthesizing agent, 1-2 parts of lubricating agent, 1-2 parts of mould-proof antifungal agent, 1-2 parts of moisture absorbent, 2-4 parts of flame retardant, 2-4 parts of smoke suppression agent and 6-10 parts of binding agent. The novel wood-plastic material can be widely applied to decoration of hotels, restaurants and buildings, is good in flame-retardant effect, cannot burn or form a flame and is stable and reliable in performance.

Owner:广西南宁桂尔创环保科技有限公司

Functional crystallization master batch and preparation method thereof and waterproof material

InactiveCN102863170AImprove self-healing performanceImprove anti-re-pressure penetration functionNanotechnologyCalcium carbonateMethyl cellulose

The invention provides a functional crystallization master batch, a preparation method thereof and a waterproof material and belongs to the field of inorganic materials. The functional crystallization master batch is composed of a nanoscale calcium carbonate aluminum oxide composite powder body and chelated titanate. The preparation method includes preparing and mixing calcium carbonate powders and the nanoscale calcium carbonate aluminum oxide composite powder body. The waterproof material is composed of, by weight, 6-8% of the functional crystallization master batch, 4-6% of methyl cellulose thickening agents, 2-4% of anhydrous citric acids retarders, 25-35% of finely grinding quartz sands, and the balance cements. The functional crystallization master batch has excellent crystallization performance and usage performance, the preparation method is simple, low in production cost, safe in operation and suitable for industrial production, and the waterproof material has excellent impermeability pressure, compression strength and rupture strength.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Mouth mold material of alloy cast iron glass mold and preparation method of mouth mold material

The invention discloses a mouth mold material of an alloy cast iron glass mold and a preparation method of the mouth mold material. The mouth mold material of the alloy cast iron glass mold comprises the following components in mass percentage: 3.3-3.5% of C, 2.4-2.9% of Si, 0.3-0.5% of Mn, less than 0.05% of P, less than 0.03% of S, 1.5-2.0% of Mo, 0.6-0.9% of Al and the balance of Fe and inevitable impurities. According to the mouth mold material of the glass mold and the preparation method of the mouth mold material, by designing reasonable chemical components and the mixture ratio and adopting a reasonable preparation process, the linear expansion coefficient of the prepared mouth mold material of the alloy cast iron glass mold is close to or slightly higher than the linear expansion coefficient of heat-resistant alloy welding powder, the cracking sensitivity of a cladding layer is reduced, and the situation that cracking and shedding often occur in the process of the subsequent machining procedure of the existing mouth mold material of the alloy cast iron glass mold is further effectively solved.

Owner:SUZHOU DONGHAI GLASS MOLD

Novel environment-friendly flame-retardant wood-plastic composite

InactiveCN106065195AImprove flame retardant performanceHigh smoke suppression effectAdhesiveUltraviolet lights

The invention discloses a novel environment-friendly flame-retardant wood-plastic composite which comprises the following raw materials in parts by weight: 44-78 parts of poplar wood powder, 33-48 parts of sorghum stalk powder, 12-14 parts of watermelon vine powder, 10-13 parts of woven bag plastic particles, 6-8 parts of a filler, 4-6 parts of composition, 1-2 parts of a lubricant, 1-2 parts of an anti-fungus and anti-mildew agent, 1-2 parts of a moisture absorbent, 2-4 parts of a flame retardant, 2-4 parts of a smoke inhibitor, 6-10 parts of an adhesive, 2-4 parts of a tackifier , 1-3 parts of a softener, and 1-2 parts of an ultraviolet light absorber. The novel environment-friendly flame-retardant wood-plastic composite can be widely applied to hotel, restaurant and building decoration, is good in flame-retardant effect, cannot be burnt or form flame, and is stable and reliable in performance.

Owner:冯可发

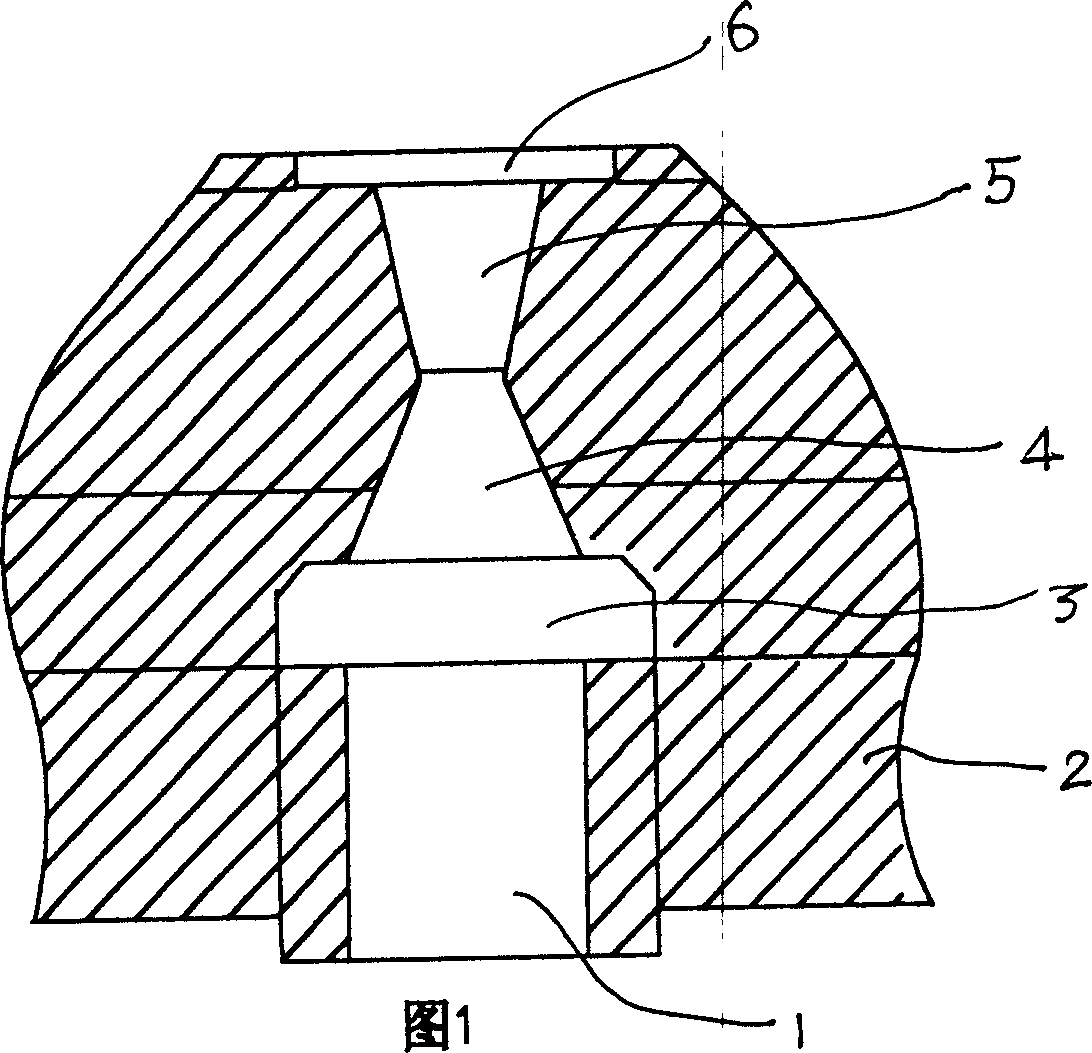

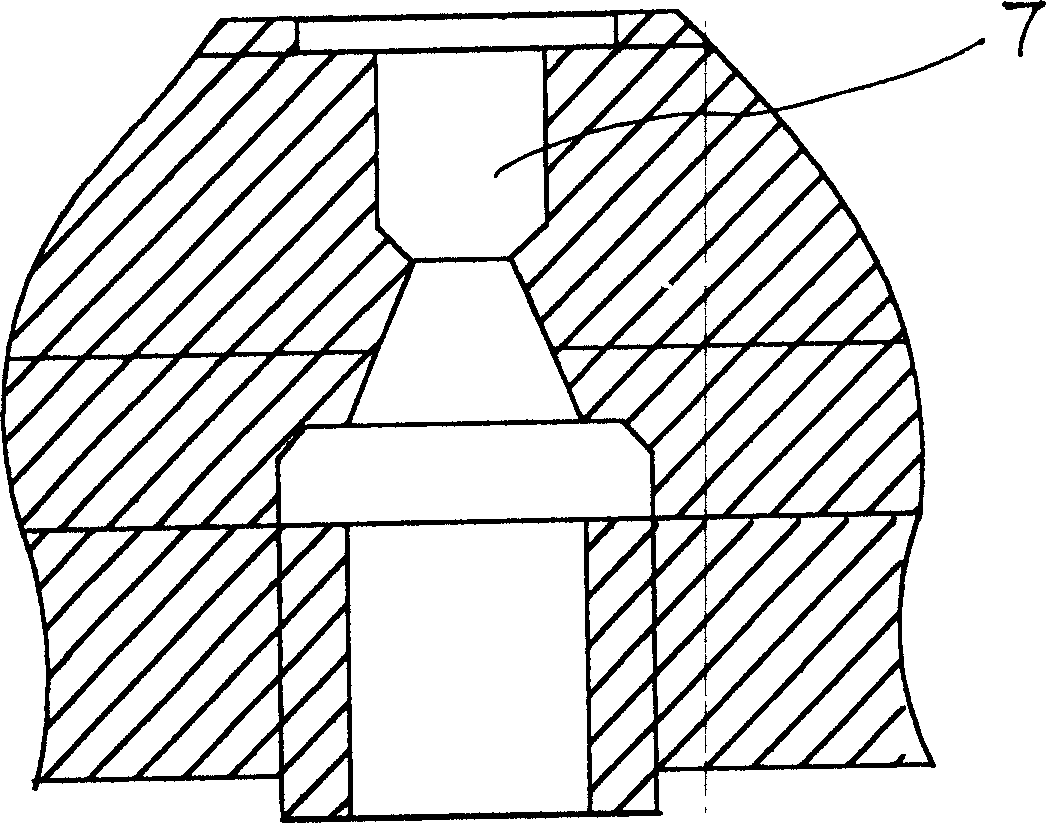

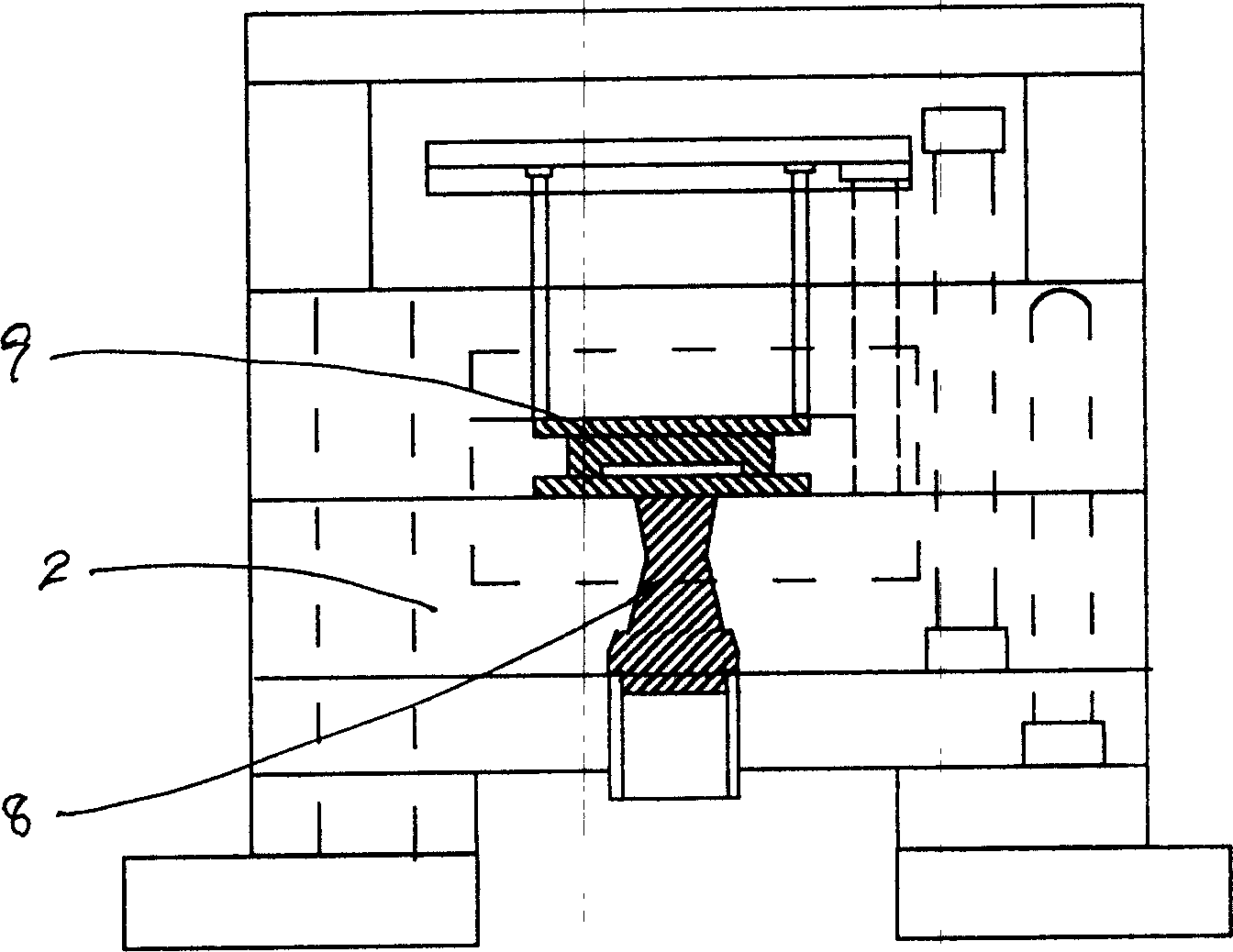

Central running-gate mould cavity of extruding mould

A central sprue cavity of pressig die is composed of raw material staying tray, sprue cup, and internal sprue consisting of upper segment whose cross-section is gradually decreased and lower segment whose cross-section is gradually increased. Its advantages are low pressure to die and die locking force, and easy breaking off of prue on demoulding.

Owner:象山昌盛汽车空调模具厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com