Method for wedge pressure forming process gear wheel

A technology for forming and processing gears, applied in the field of non-cutting processing gears and press forming processing gears, can solve the problems of lack of high efficiency, high precision and low cost, and achieve the effect of saving materials, reducing production costs and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

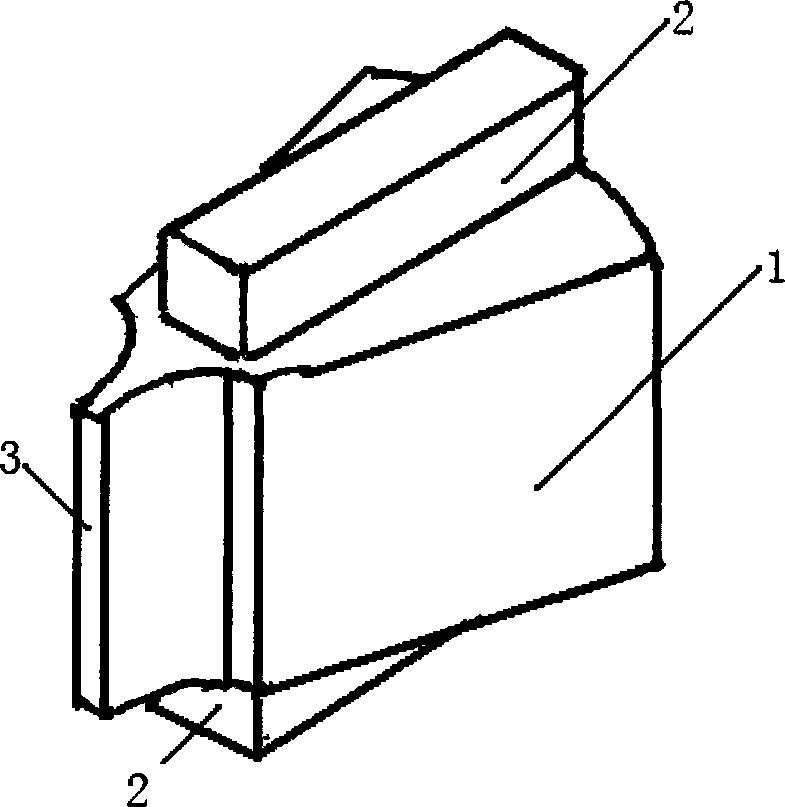

[0031] figure 1 Shown in is the axial perspective shape of a toothed insert 1 designed according to the principle of the present invention. The front end of the tooth-shaped insert 1 is formed with a tooth-shaped cutting edge working surface 3, and its cross-sectional geometric parameters are exactly the same as the geometric parameters of the tooth valley cross-section of the processed gear; Rectangular strip guide 2 protruding from the surface. The shape of the working surface of the tooth-shaped insert 1 is consistent with the shape of the processed gear, and the gear profile on it can be the tooth surface of involute, cycloid, arc, spur tooth, helical tooth, bevel tooth Tooth shape.

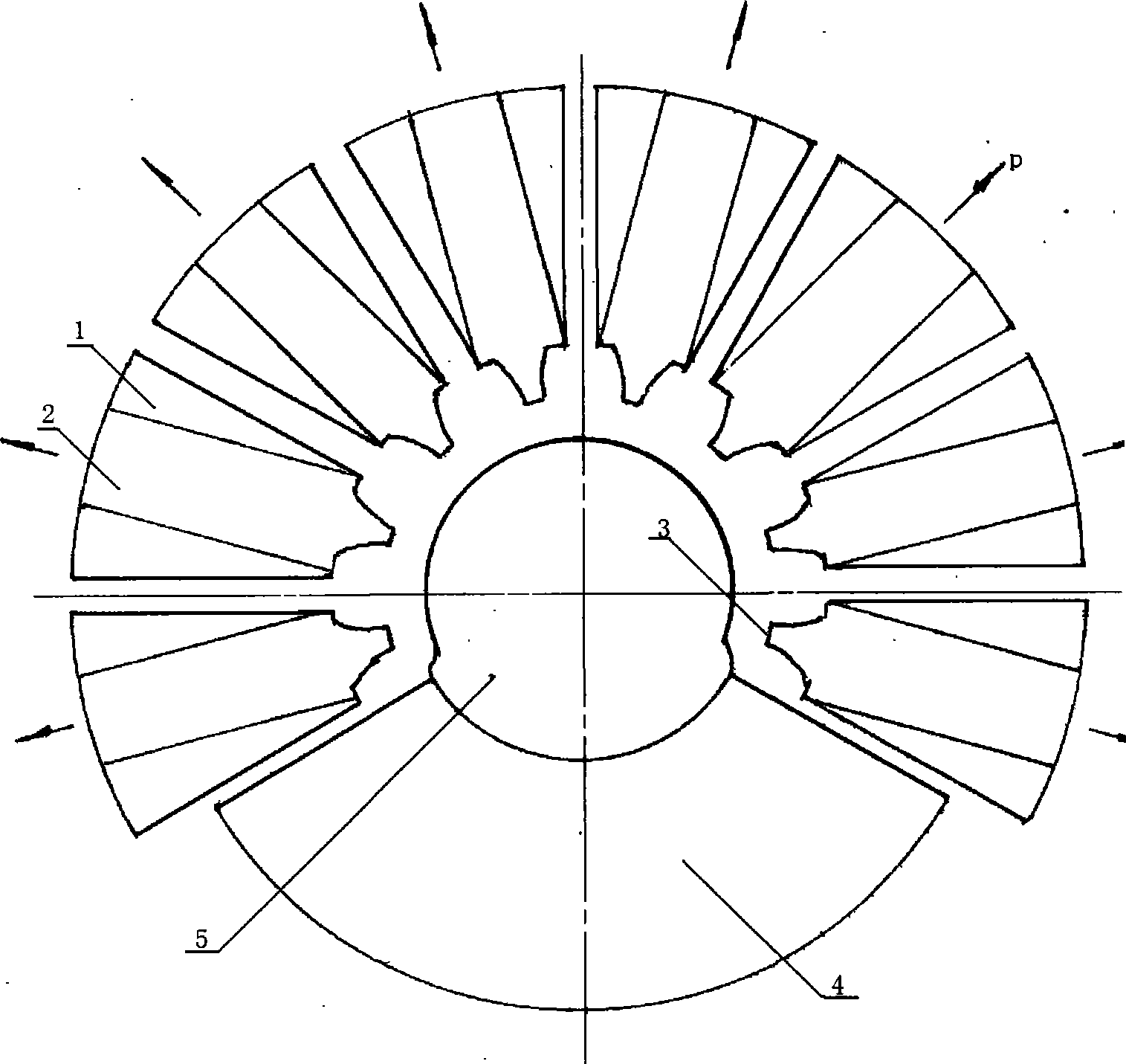

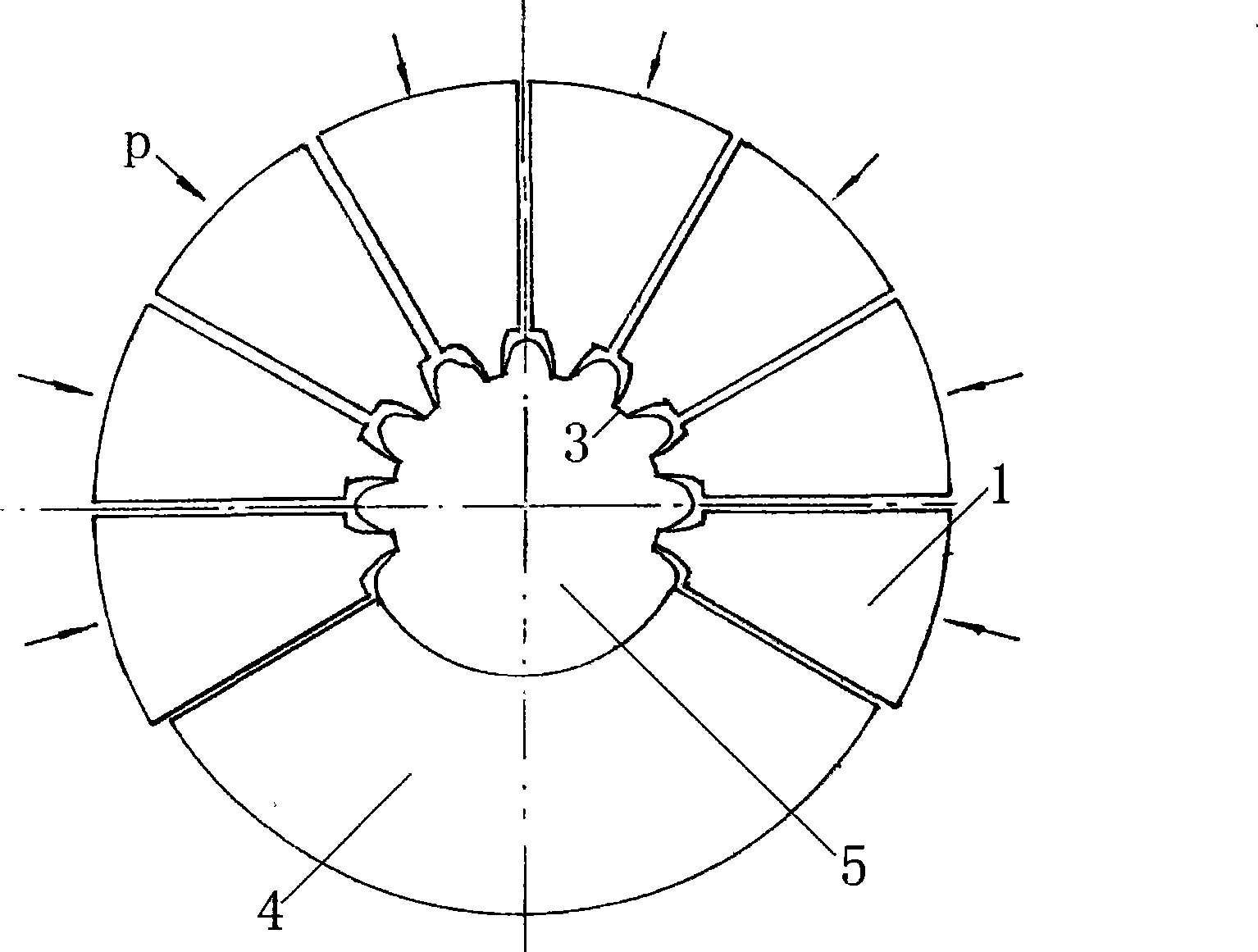

[0032] Figure 2 ~ Figure 4 One embodiment of the fabrication of a non-holonomic gear according to the method of the present invention is described. Usually when processing a complete gear, the number of tooth-shaped inserts 1 is the same as the number of teeth of the processed gear. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com