Copper palladium alloy monocrystal bonding wire and manufacturing method thereof

A palladium alloy and bonding wire technology, which is applied in the field of copper-palladium alloy single crystal bonding wire and its manufacturing, can solve the problems of low hardness of electroplating layer, poor resistance to friction, poor high temperature stability and high production cost, and can shorten the welding distance, Good anti-oxidation performance and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

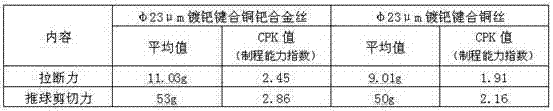

Examples

Embodiment 1

[0020] ① Extraction of high-purity copper: Dilute the copper nitrate solution with high-purity water at a ratio of 1:4 to prepare an electrolyte; use the national standard No. 1 pure copper as the anode to immerse in the electrolyte, and ensure that 95% of the volume ratio of pure copper is immersed in the electrolysis liquid; use high-purity copper foil as the cathode to immerse in the electrolyte, and also ensure that high-purity copper foil with a volume ratio of 955 is immersed in the electrolyte; input 7-9V, 2.5-3.5A direct current between the anode and cathode to Supplement fresh electrolyte to keep the temperature of the electrolyte not exceeding 60°C; when the cathode accumulates high-purity copper with a purity greater than 99.9995%, replace the high-purity copper foil in time, and then clean and dry it for later use.

[0021] ② Copper-palladium alloy rod: In a continuous casting room for horizontal continuous casting of metal single crystal with nitrogen protection, h...

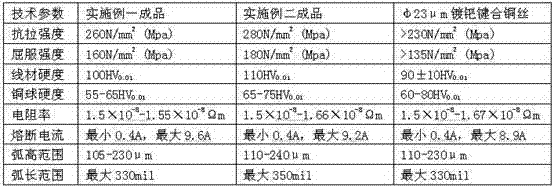

Embodiment 2

[0030] Step 1. to step 4. are the same as in Embodiment 1.

[0031] ⑤Palladium plating on the surface: Apply conventional electroplating equipment and technology to electroplate pure palladium anti-oxidation protective layer on the φ0.2mm copper-palladium alloy wire after annealing. The purity of palladium for electroplating is required to be greater than 99.999%; the current density is 4-4.5A / dm 2 , the speed of copper wire is 4-5m / min, and the thickness of the coating is controlled at 2μm-7μm; for copper-palladium alloy wire products after palladium plating, the sum of the weight of palladium inside the single crystal copper-palladium alloy and pure palladium on the surface accounts for the percentage of the total weight Controlled at 1.35%-10.18%; the rest is copper, and the rest is copper.

[0032] ⑥Precise drawing: Using conventional drawing equipment and technology, the φ0.2mm copper-palladium alloy wire plated with pure palladium anti-oxidation protective layer is precisi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com