Central running-gate mould cavity of extruding mould

A technology of central gate and extrusion die, which is applied in the field of extrusion die in metal casting, can solve the problems of air bubbles, unsmooth transmission, large pressure loss, etc., and achieve the effect of reducing stamping and clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

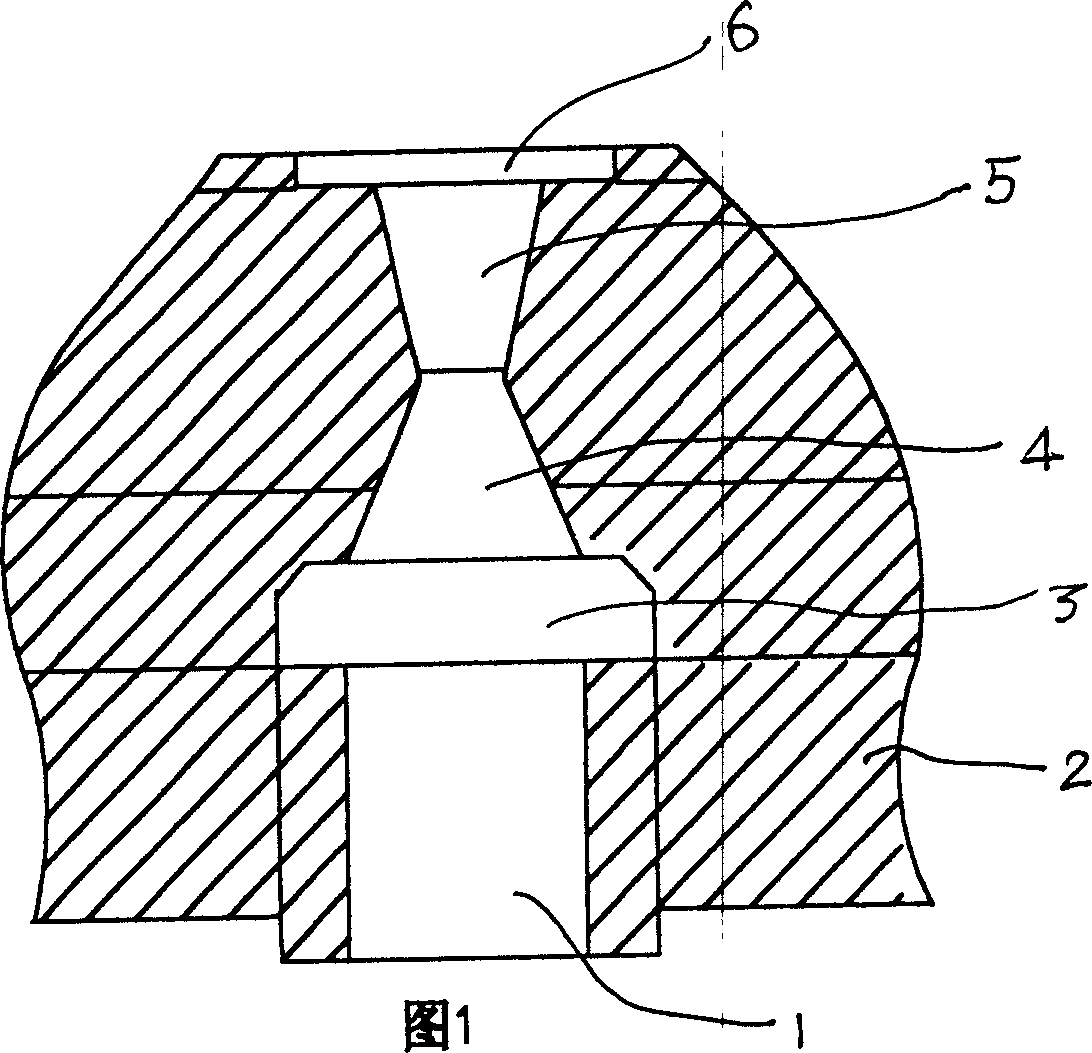

[0012] As shown in FIG. 1, the center gate cavity of an extrusion die of the present invention is placed in the template 2 of the mold, and consists of three parts: a material tank 1, a pour cup 3 and an inner gate. It is directly connected to part of the mold cavity 6 of the product; the inner gate is divided into upper and lower sections, and on the path where the molten metal is pressed from bottom to top, the cross-sectional area of the inner gate is gradually reduced first, and then expanded; the lower half of the inner gate 4 is a truncated cone, the cross-sectional area gradually decreases from bottom to top, and the optimal taper is 35°. The upper half of the gate 5 is an inverted cone shape, and the cross-sectional area gradually expands from bottom to top, and the best taper is 15°.

[0013] In order to facilitate slag discharge during the casting process, the cross-sectional area of the sprue 1 is set to be smaller than that of the sprue cup 3, so as to form a sl...

Embodiment 2

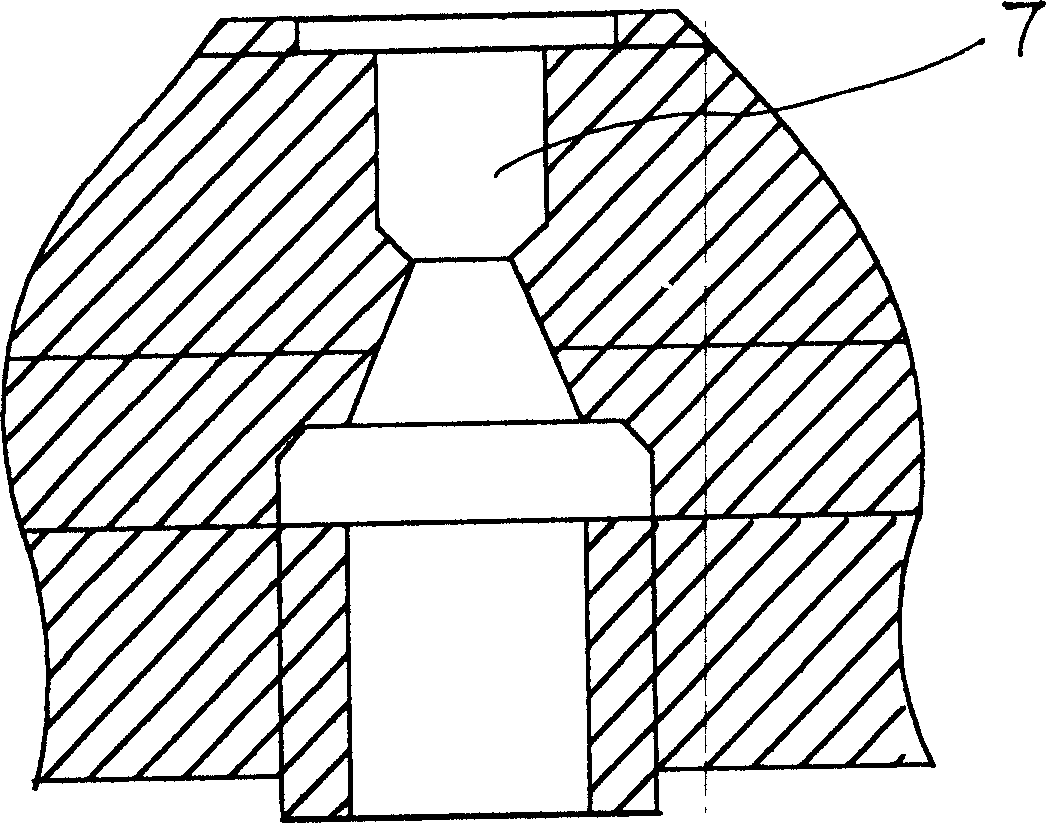

[0015] attached by figure 2 As shown, the center gate cavity of an extrusion die of the present invention, the lower half of the inner gate is a truncated cone, the cross-sectional area is gradually reduced from bottom to top, and the upper half of the inner gate 7 is cylindrical. The junction of the lower half of the inner gate transitions with a tapered surface that gradually expands from bottom to top.

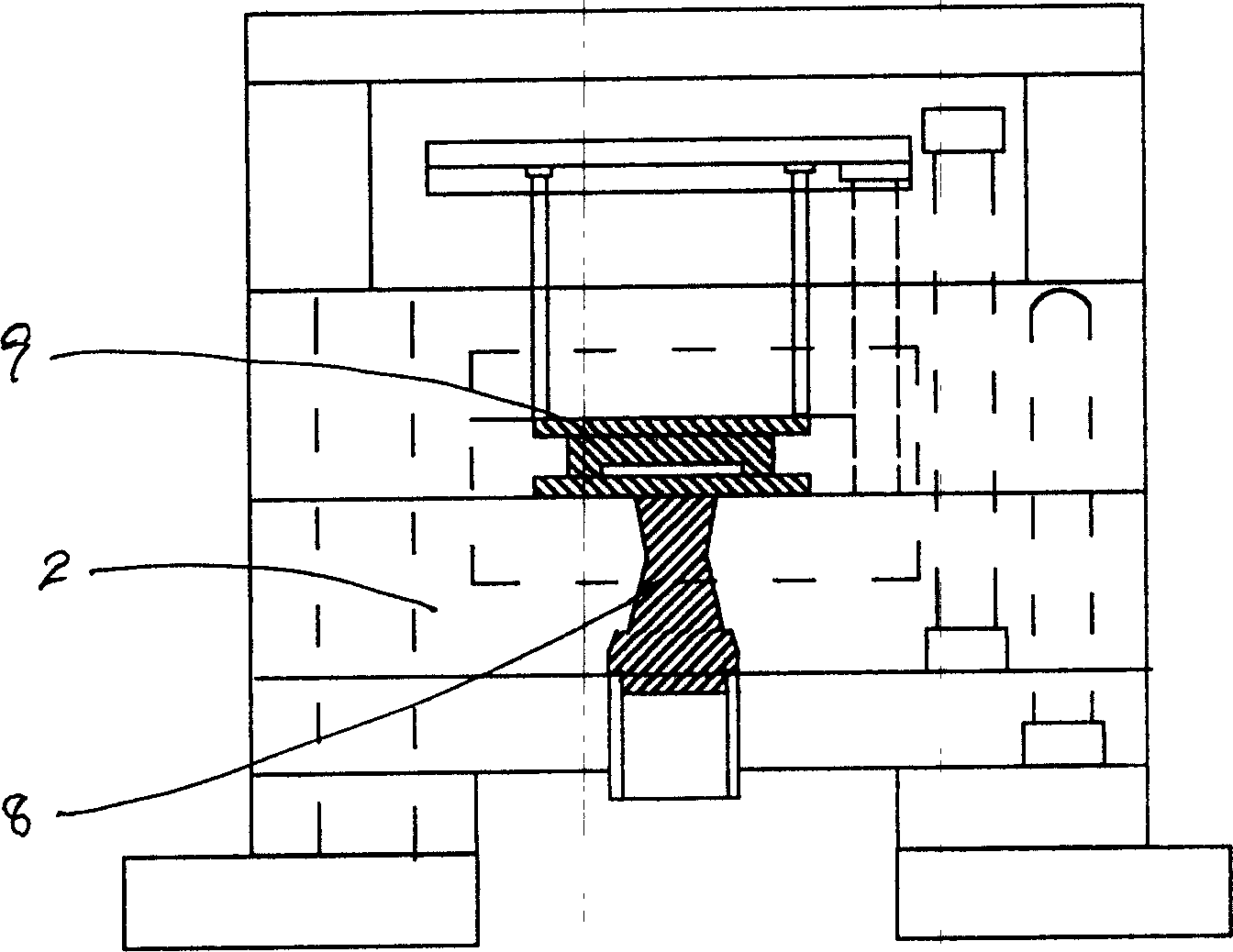

[0016] Depend on image 3 As shown, the center gate cavity of the extrusion die of the present invention is located in the template 2, directly below the center position of the product 9, and the product 9 and the gate 8 are formed after extrusion molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com