Copper-palladium-silver alloy bonding wire and method for preparing same

A palladium-silver alloy and bonding wire technology, which is applied in the field of metal bonding wires for microelectronic packaging, can solve the problems of not being fully suitable for packaging, too long tails of the second solder joint, and increased packaging costs, and achieve superior product performance, Ensure the effect of adhesion and material density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1) Select copper ingots with a purity of ≥99.9999%, palladium ingots with a purity of ≥99.9999%, and silver ingots with a purity of ≥99.9999%, first wash them with 10% sodium hydroxide, then rinse them with deionized water, and dry them in an oven for later use.

[0055]2) Prepare copper-palladium-silver alloy ingots: Put copper ingots with a purity of ≥99.9999%, palladium ingots with a purity of ≥99.9999%, silver ingots with a purity of ≥99.9999%, and calcium and rare earth into a high-purity graphite crucible, and place In the vacuum casting furnace, medium-frequency induction heating is carried out to 1100°C, and vacuum treatment is performed during the heating process. After the material is completely melted, fill it with high-purity nitrogen and keep it warm for 30 minutes. Pour the liquid copper-palladium-silver alloy into a high-purity graphite tank to obtain a copper-palladium-silver alloy ingot with a width of 5 cm, a thickness of 1 cm, and a palladium content ...

PUM

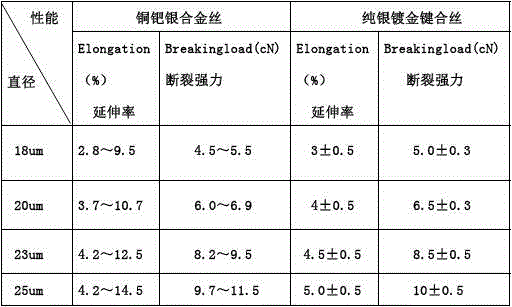

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com