Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Avoid uneven wall thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

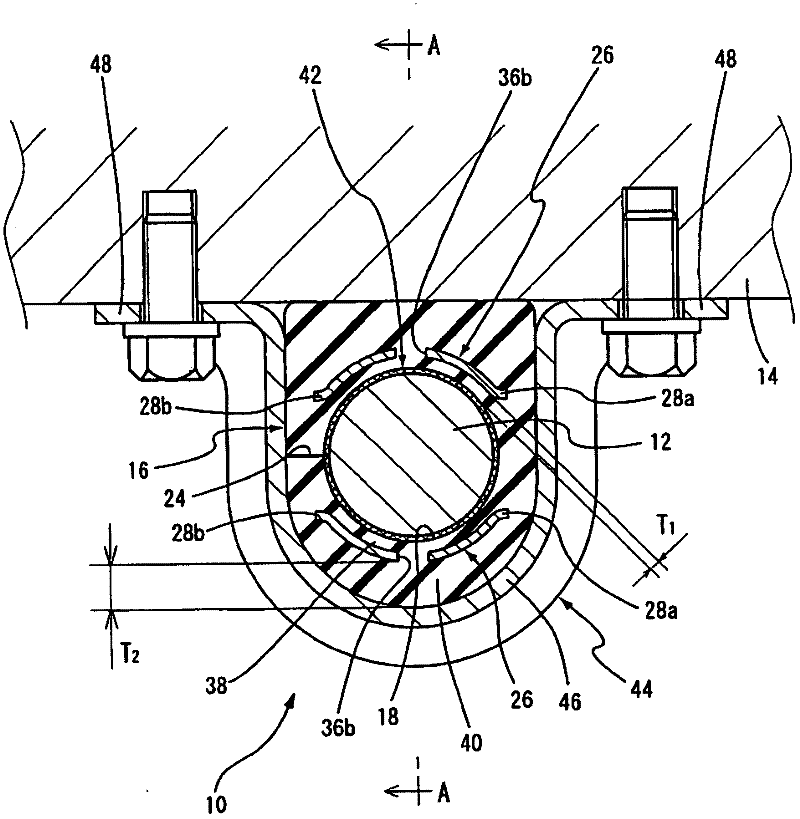

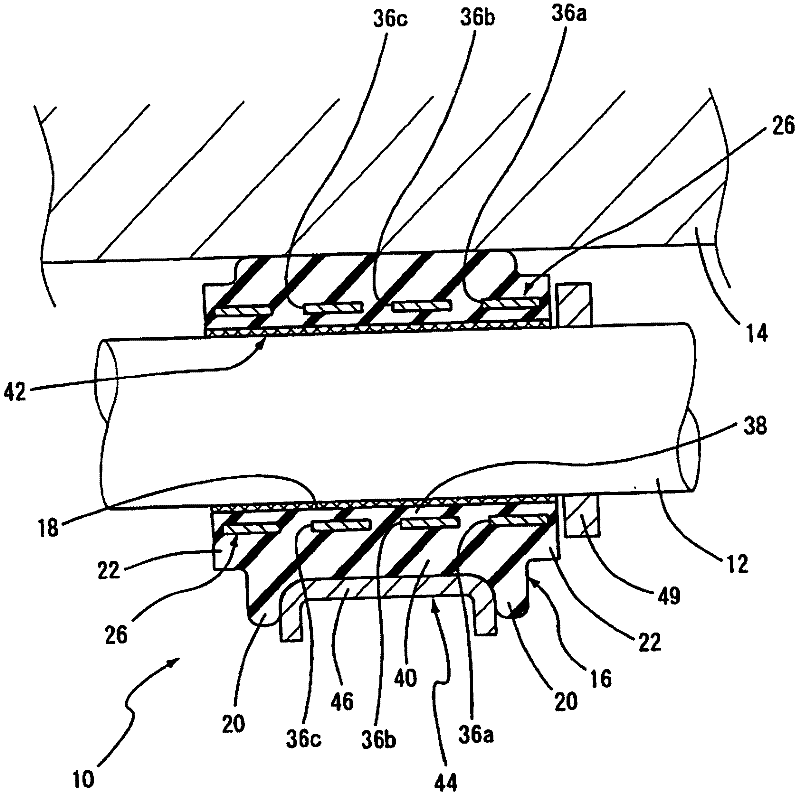

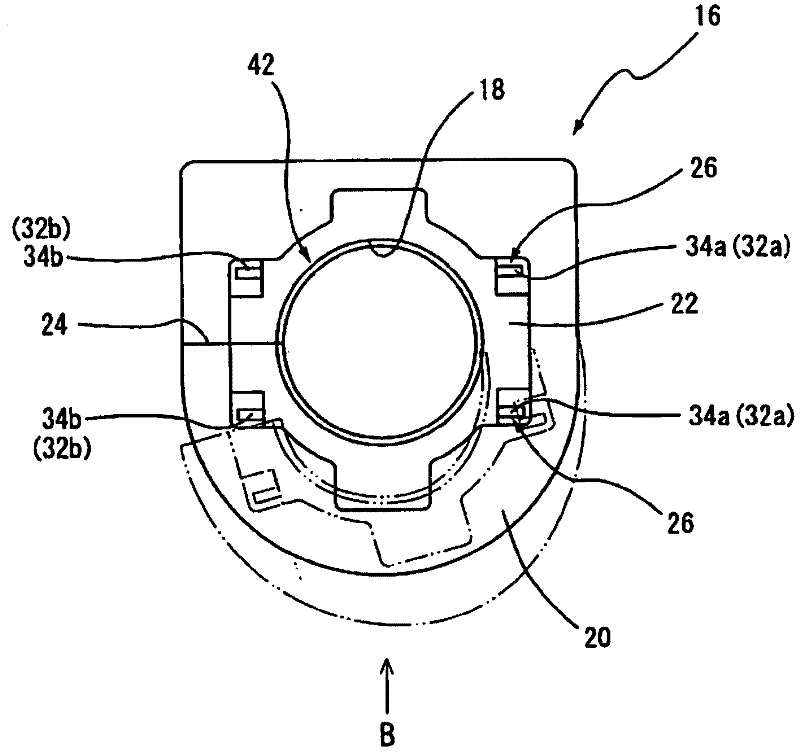

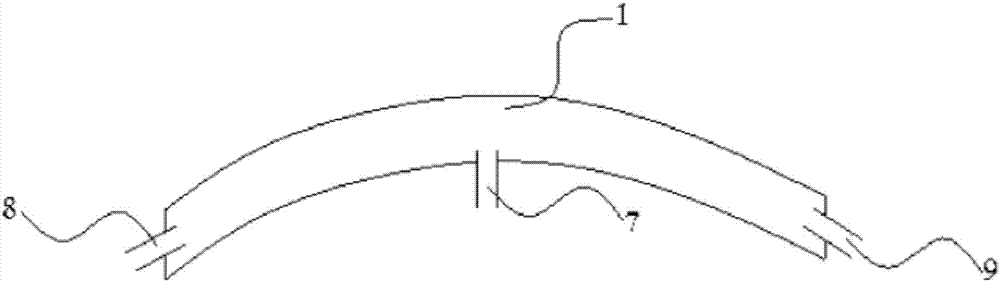

Vehicle stabilizer bushing

ActiveCN102470721AEliminate deflectionSmooth rotationSpringsNon-rotating vibration suppressionVulcanizationEngineering

Disclosed is a stabilizer bushing which more efficiently reduces torsional friction between a bushing main body and a stabilizer bar. A bushing main body (16) is formed from a cylindrical rubber elastic body to which a sliding member (42) is fixed to a surface of the inner circumference. In a middle area of the bushing main body (16) perpendicular to the axis thereof, two partition members (26, 26) are embedded so as to be positioned vertically, and are adhered by vulcanization. The bushing main body (16) is constituted from an inner rubber part (38) of a thickness so as not to allow elastic deformation by an input load, and an outer rubber part (40) thicker than said inner rubber part. Meanwhile, through-holes (36a, 36b and 36c) are formed only in positions that equally divide the partition members (26, 26) in the circumferential and axial directions.

Owner:SUMITOMO RIKO CO LTD +1

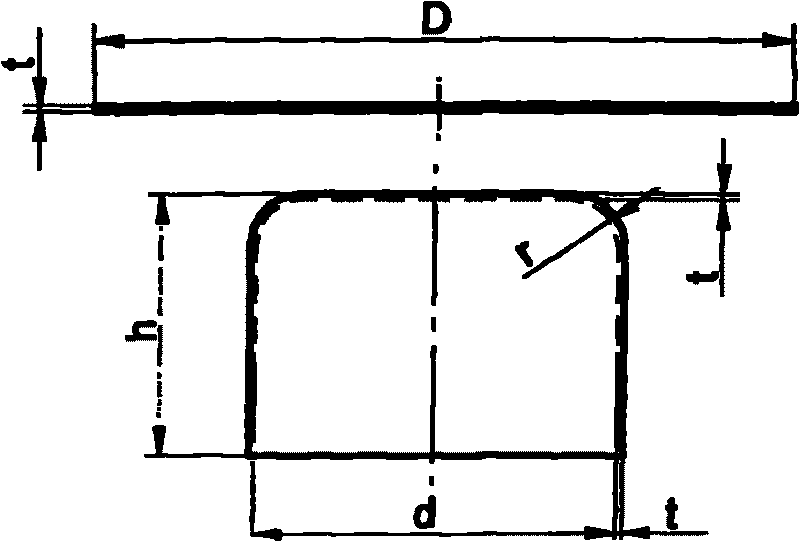

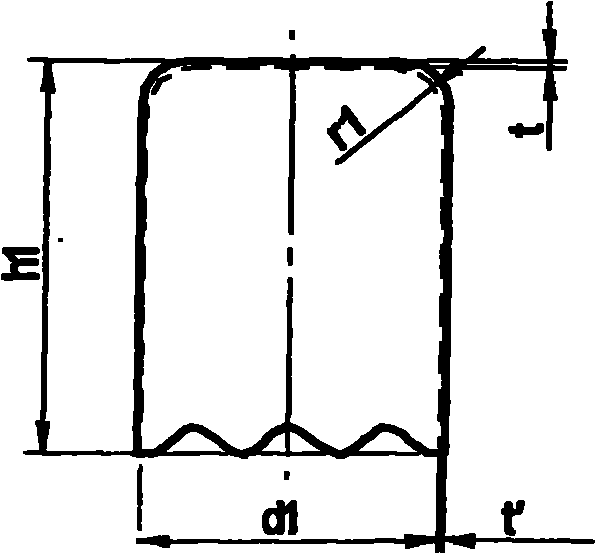

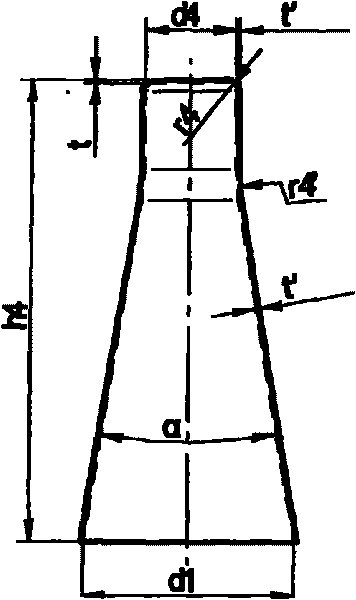

Forming technology of ultra-deep taper thin-wall part

InactiveCN101733338AIncrease productivitySolve molding difficultiesHollow articlesForm processingThin walled

The invention provides a forming technology of an ultra-deep taper thin-wall part, comprising the following technological steps of: cupping blanks; attenuating and deeply drawing; cutting; continuously tapering for three times; anaerobically annealing; and continuously tapering to finally obtain the products with the specified shapes, sizes, and the like. The forming technology is characterized by solving the problem of difficult forming of the ultra-deep taper thin-wall part by firstly forming a large-end taper hole and gradually contracting a small-end cylindrical aperture through tapering and combining with anaerobic annealing processing and effectively solving the problem of non-uniform wall thickness of the integral ultra-deep taper thin-wall part due to the partial attenuation of a bottom long filleted corner of a workpiece in the tapering process of the taper thin-wall parts. The invention can complete the forming processing of the ultra-deep taper thin-wall part on a mechanical punching machine, has the production efficiency far higher that that of a common hydraulic press (the production takt time of the mechanical punching machine is more than 25 times per minute, and the production takt time of the common hydraulic press is 2-3 times per minute) and is suitable for match production.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

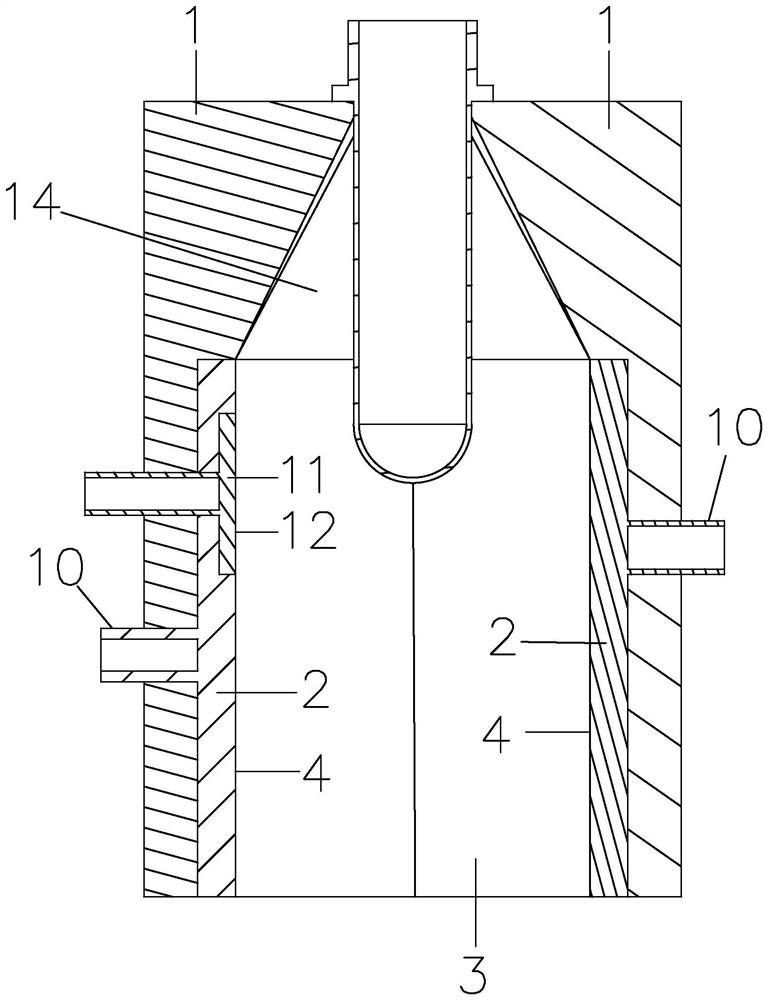

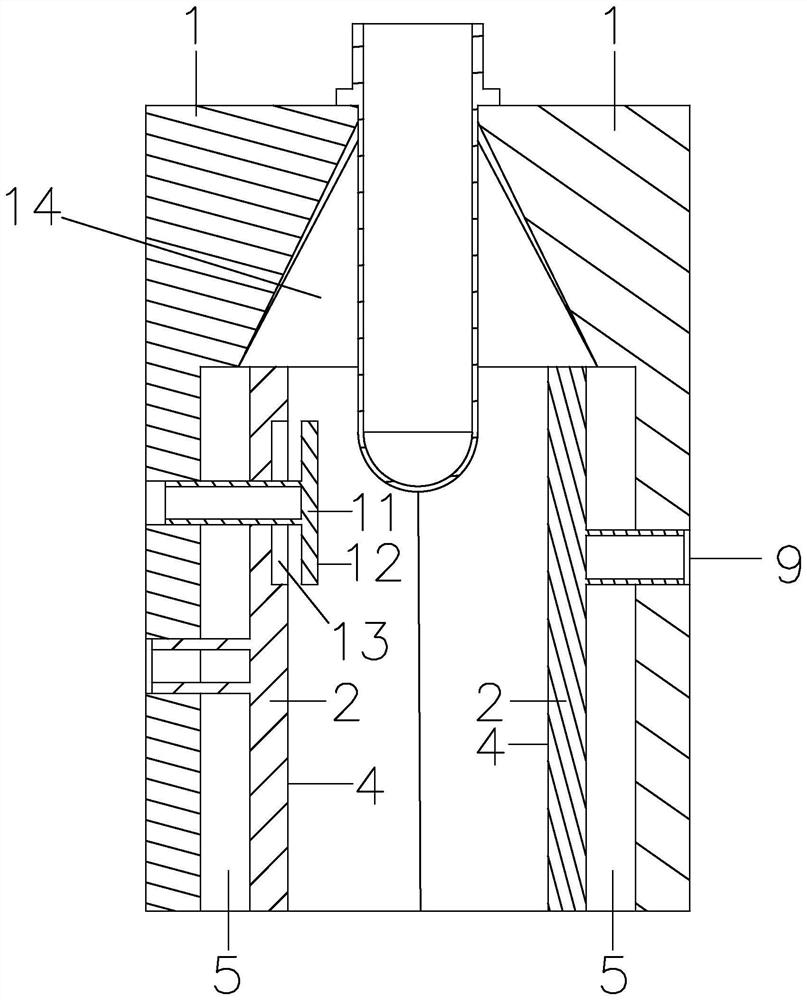

Casting method of thin-walled pipe casting with spatially asymmetric structure

InactiveCN102527947ASolve the deformationAvoid uneven wall thicknessFoundry mouldsFoundry coresAlcoholGraphite

The invention provides a casting method of a thin-walled pipe casting with a spatially asymmetric structure. The method comprises the following steps: manufacturing a cavity sand core internally provided with a core bar and pores by utilizing animi resin sand; brushing a alcohol-based graphite coating on the surface of the sand core; after a white die is attached to the sand core, plugging a gap at the upper end of the joint of the core head and the white die by use of plaster; after the combination of the white die and the sand core is wholly soaked and coated in a water-borne quartz powder coating and then dried, removing coating layers at the head of the sand core and an exhaust port, and modeling and casting the combination. The method can be used for effectively solving the problems of deformation, uneven wall thickness, water and gas leakage and the like of a thin-walled pipe casting with a spatially asymmetric structure, and the obtained casting has the advantages of accurate size, uniform wall thickness, compact material texture, beautiful appearance and low cost. The method has the advantages of simple process, easiness for operation, low rejection rate, low labor intensity and high reliability.

Owner:广西玉柴模具装备有限公司

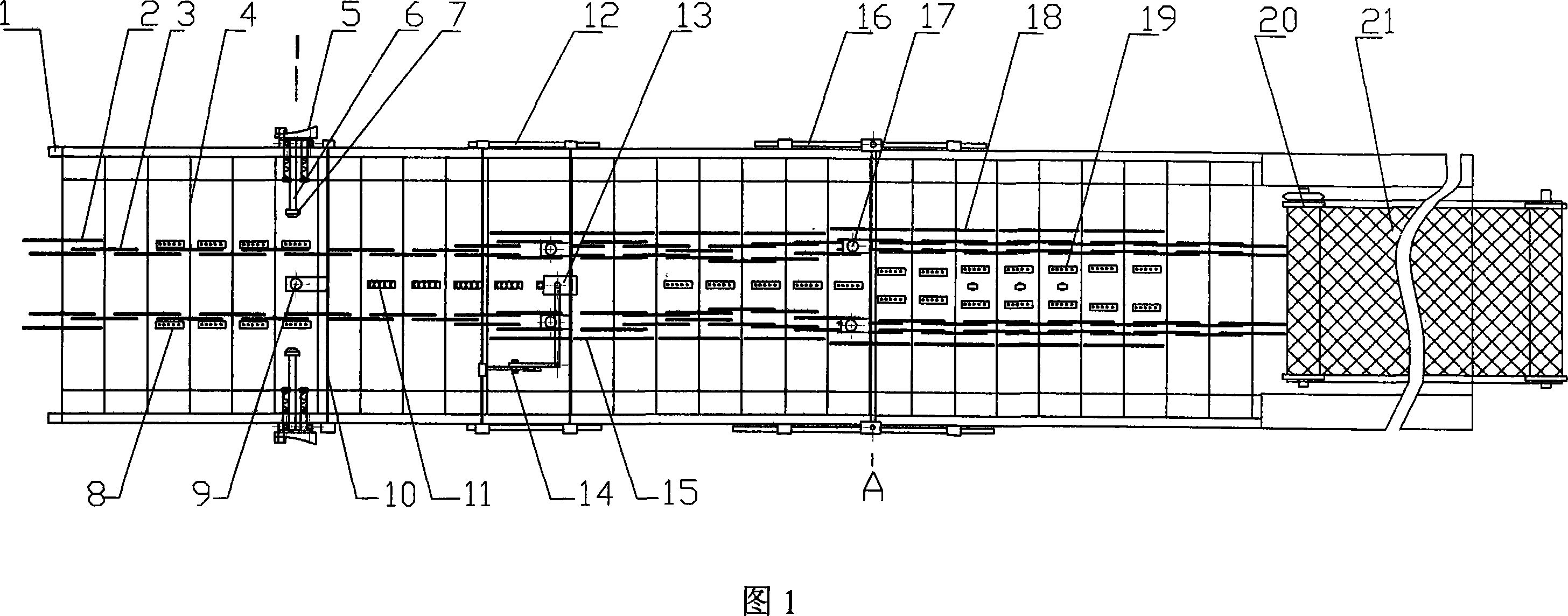

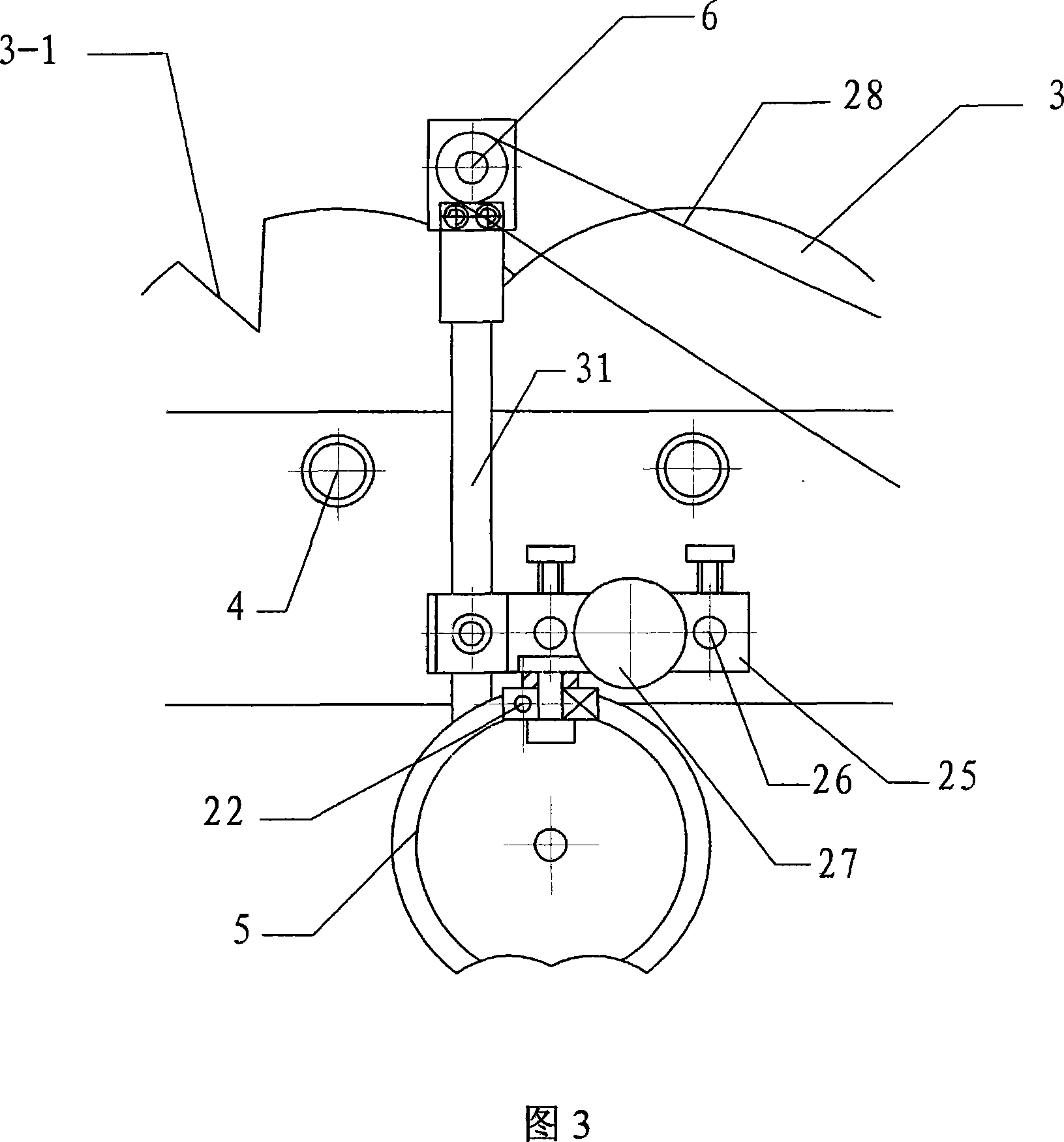

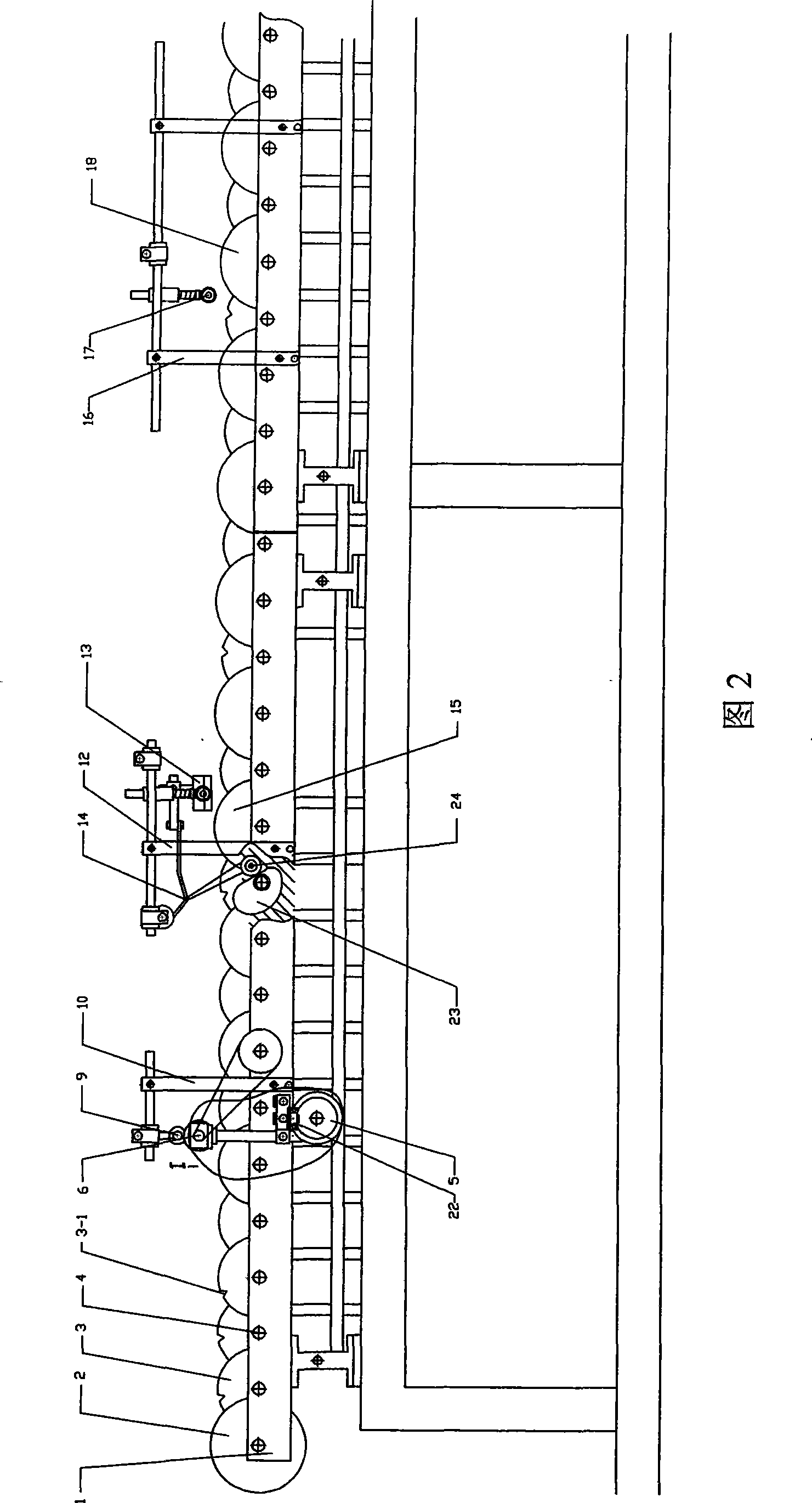

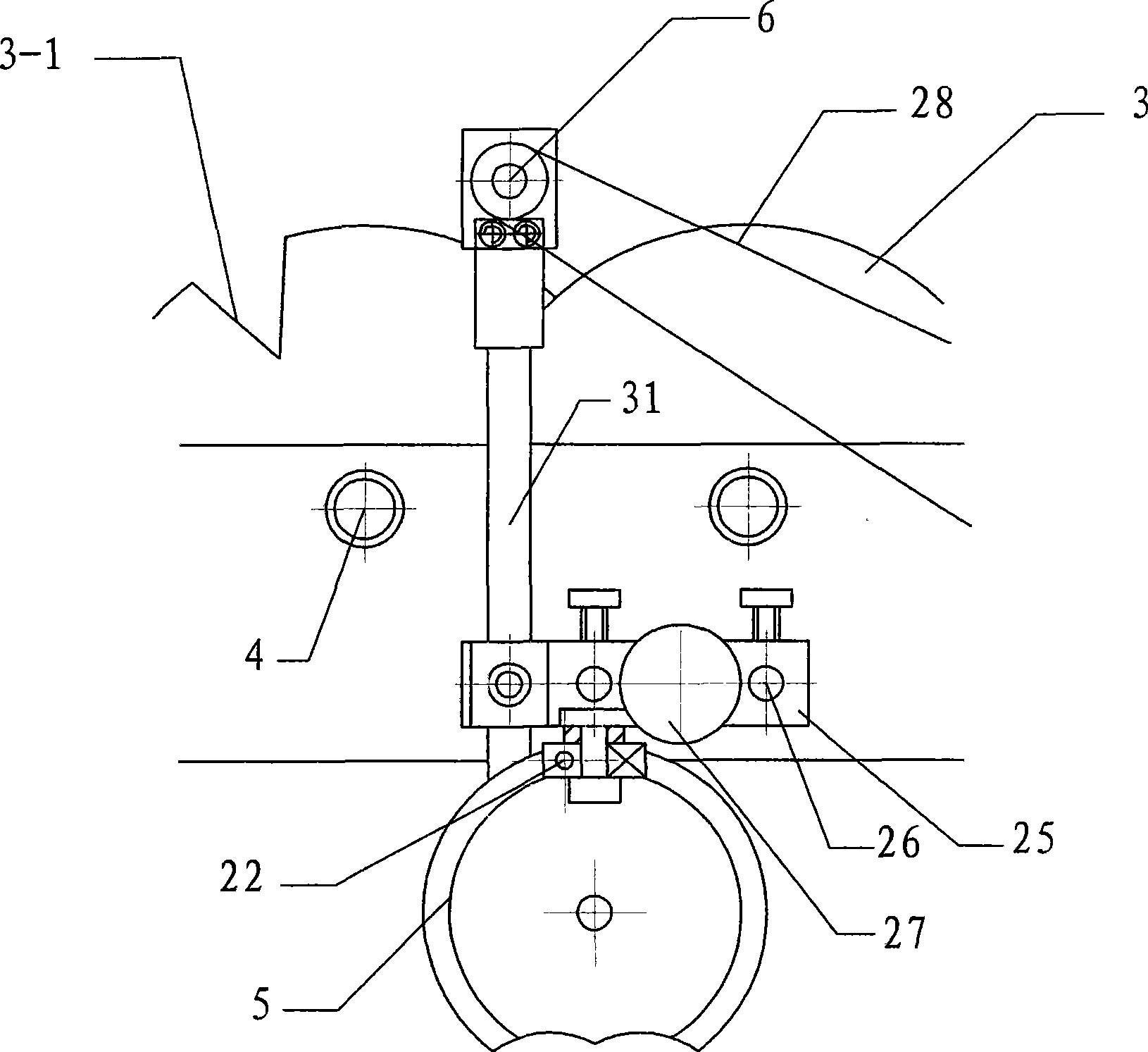

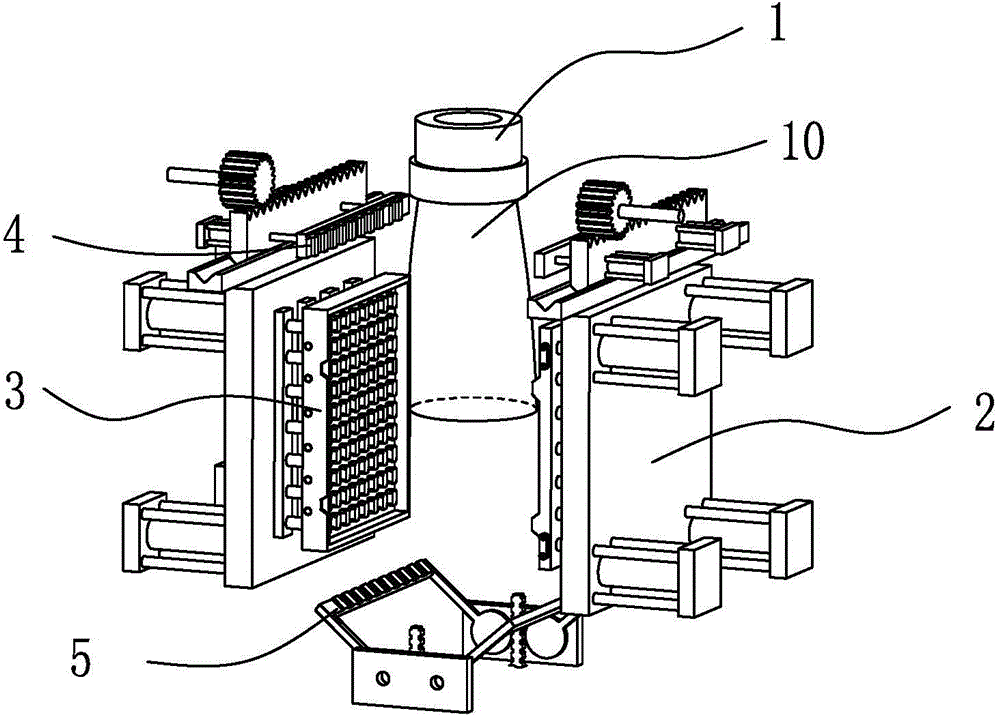

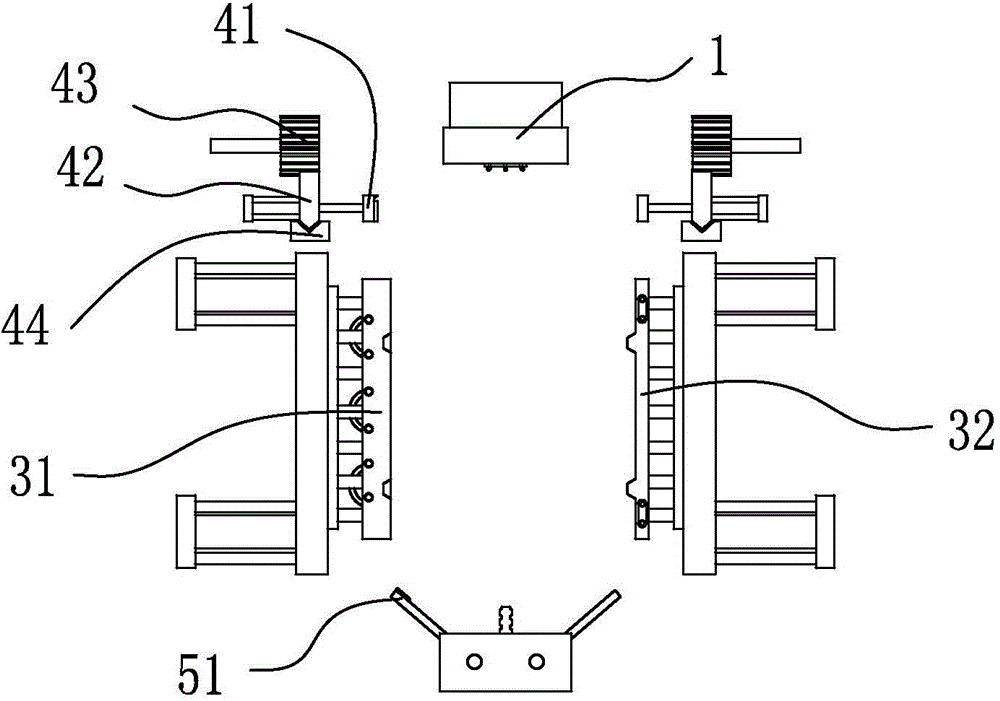

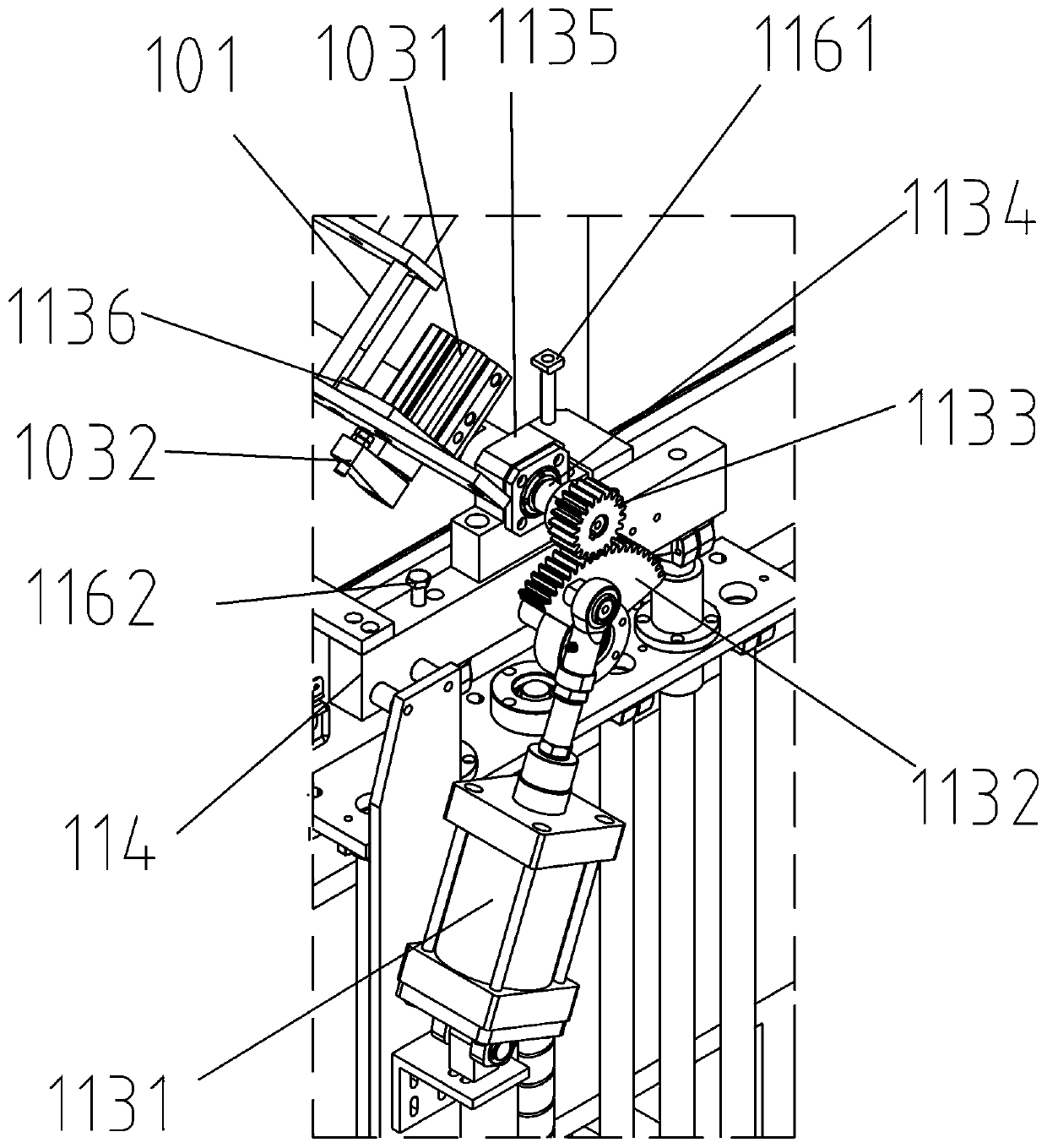

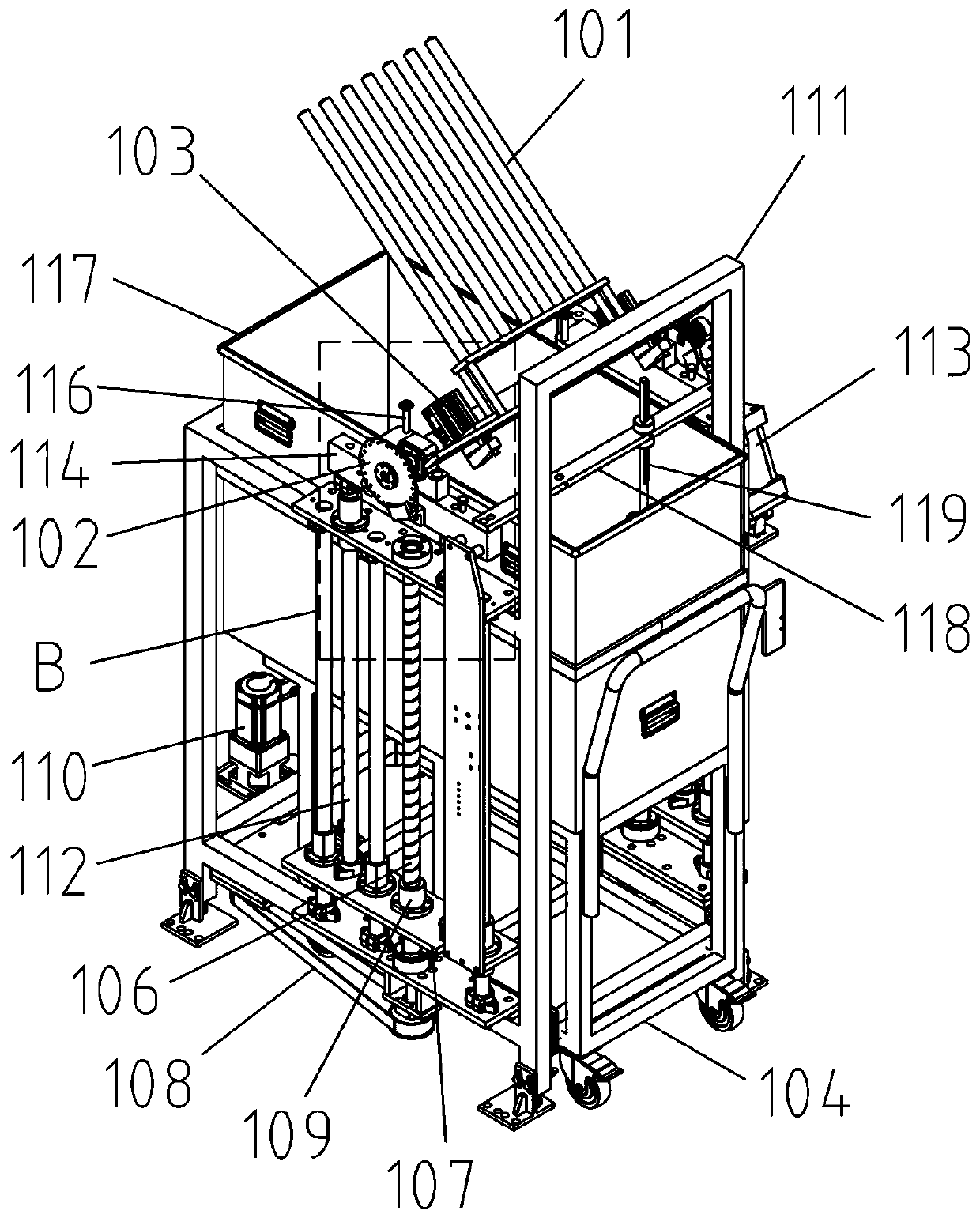

Method and equipment for producing cup of beaker

ActiveCN101050055AIncrease productivityGood lookingGlass reforming apparatusGlass productionCutting glassNeck parts

This invention provides method and apparatus for producing beaker. The method comprises: (1) cutting glass tube into 2.1-2.3 times of the height of beaker body, placing the cut glass tube on the transmission tray at the front end of the frame, moving by the channel on the transmission tray to the nozzle of the flaring device, heating both ends of the glass tube and flaring; (2) heating the middle part of the flared glass tube, pressing the middle part into bottle neck shape by a neck-pressing mold, cooling, heating the middle part again, and separating at the middle neck part by the force toward the two ends from the bottom pressure foot to obtain the bodies of two beakers; (3) pre-sealing the bottoms by the nozzle, sealing the bottoms, finishing, polishing, annealing, and outputting by a conveyer belt. The method has such advantages as high production efficiency, high product quality, and low raw material consumption.

Owner:YANCHENG HUAOU IND

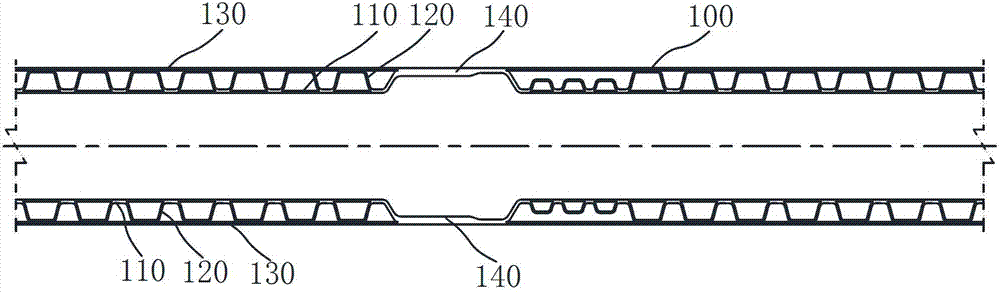

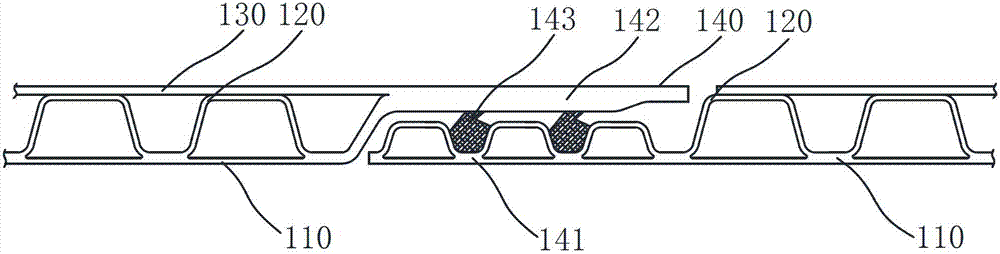

Three-wall corrugated pipe and manufacturing equipment thereof

The invention discloses a three-wall corrugated pipe and manufacturing equipment thereof. The pipe includes a pipe body, which includes a smooth inner wall layer, a corrugated intermediate layer and a smooth outer wall layer. The inner wall layer and the outer wall layer are closely connected with the crests or troughs of the intermediate layer, and the pipe body is provided with connection ports for mutual connection. Compared with prior arts, the inventive corrugated pipe has a smooth outer wall, which facilitates dragging and rolling during transportation and construction processes and avoids outer wall corrugation breakage and recess to further influence pipe use. Meanwhile, the outer wall layer is covered, in a molten state, on the outer wall of a double-wall corrugated pipe, which increases the pipe wave height and the moment of inertia to realize higher ring stiffness of the pipe and production of pipes with higher strength requirements on one hand, and increases the longitudinal bending strength of the pipe and improves the ring flexibility of the pipe on the other hand, thus realizing the purpose of the invention.

Owner:公元管道(上海)有限公司

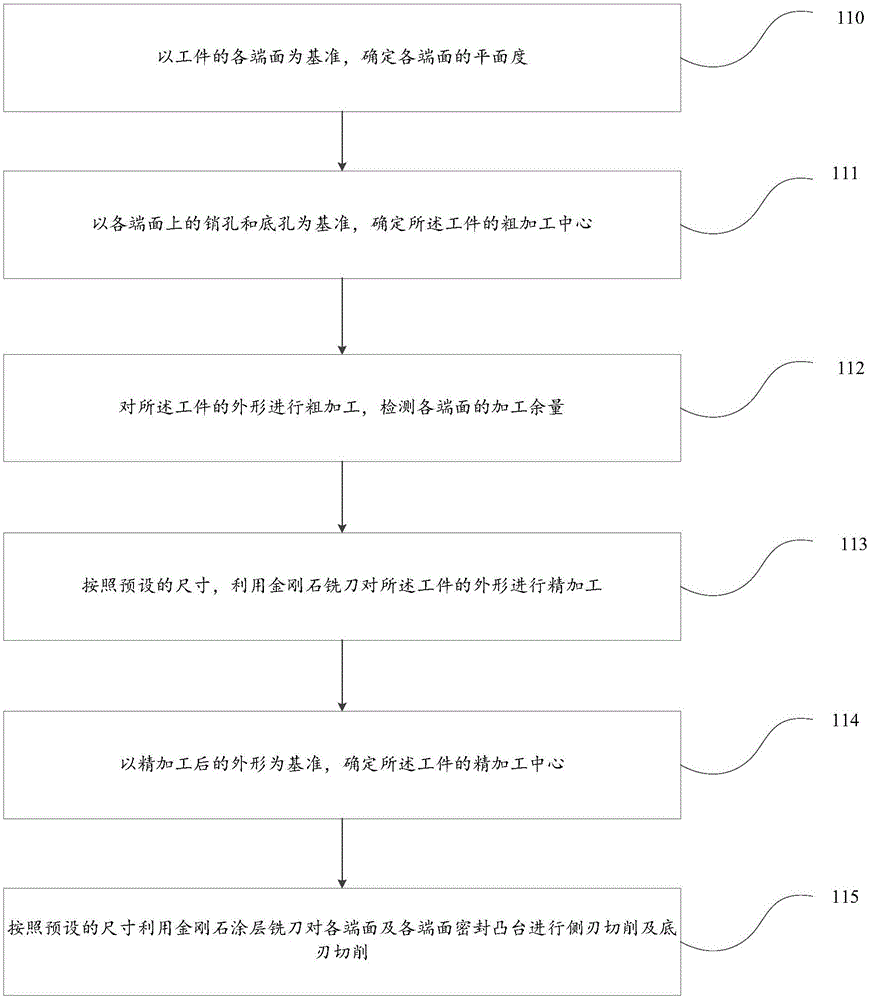

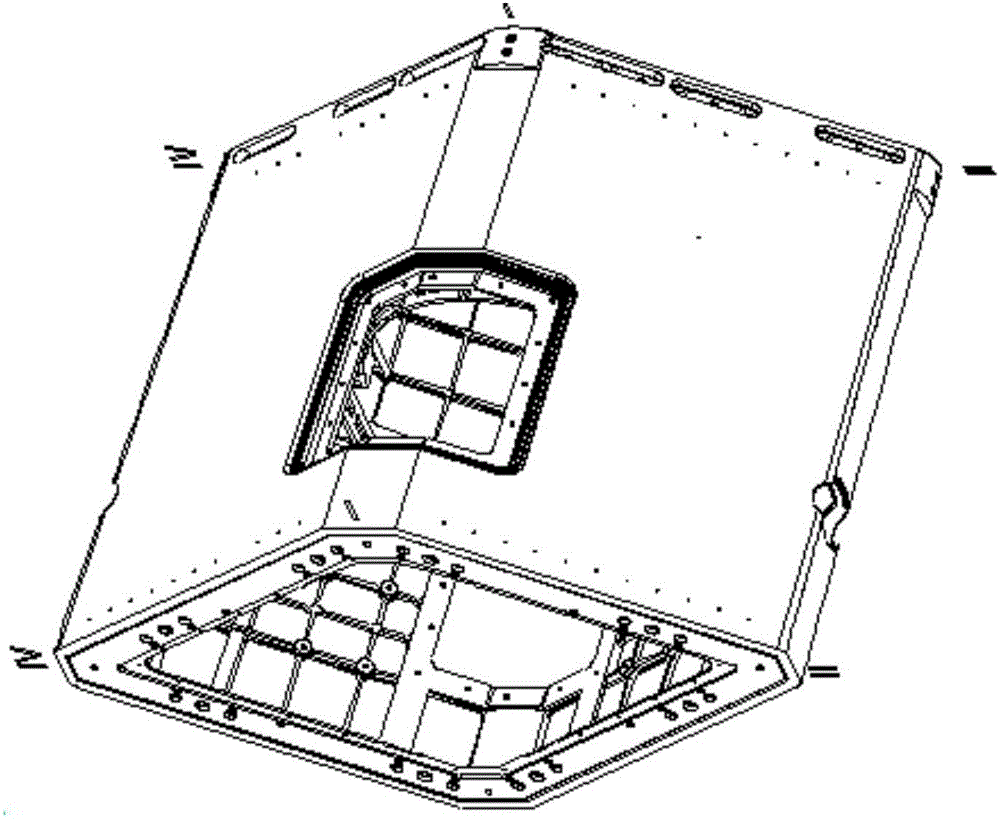

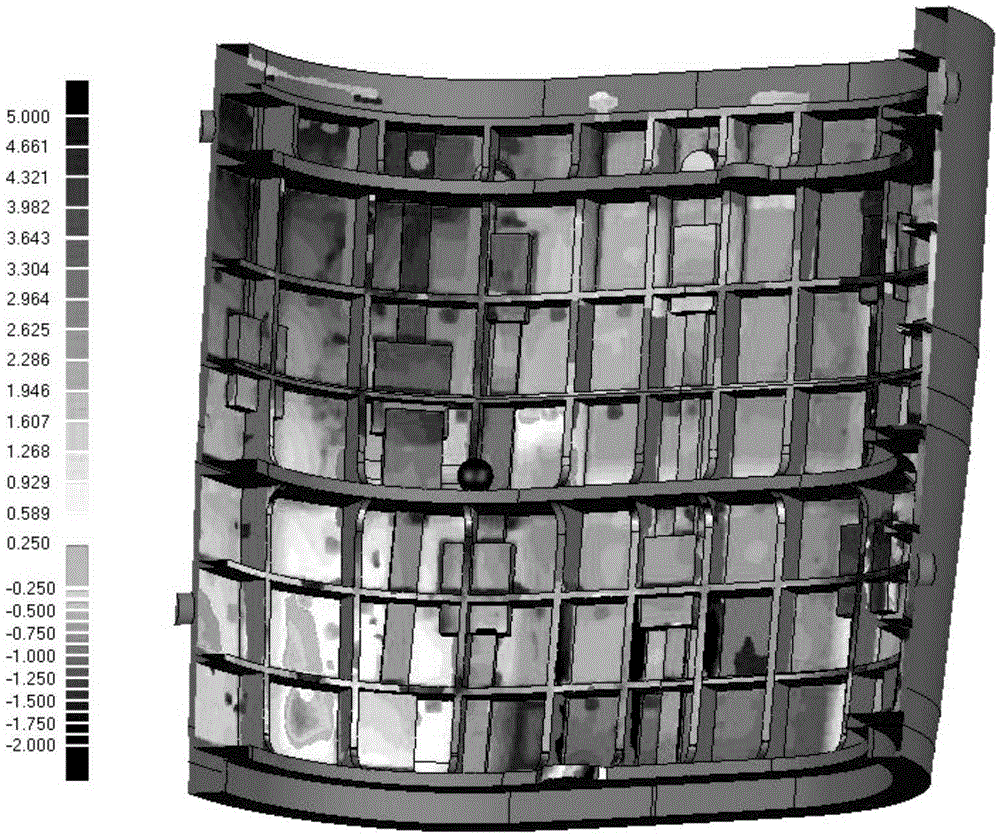

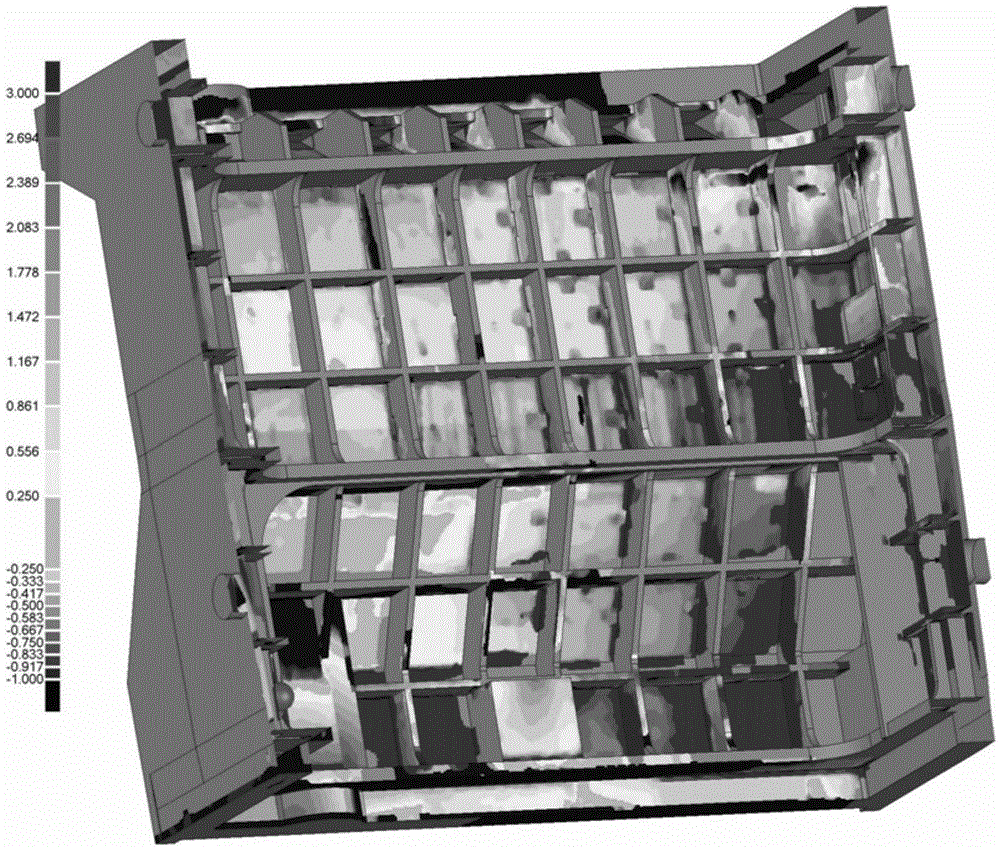

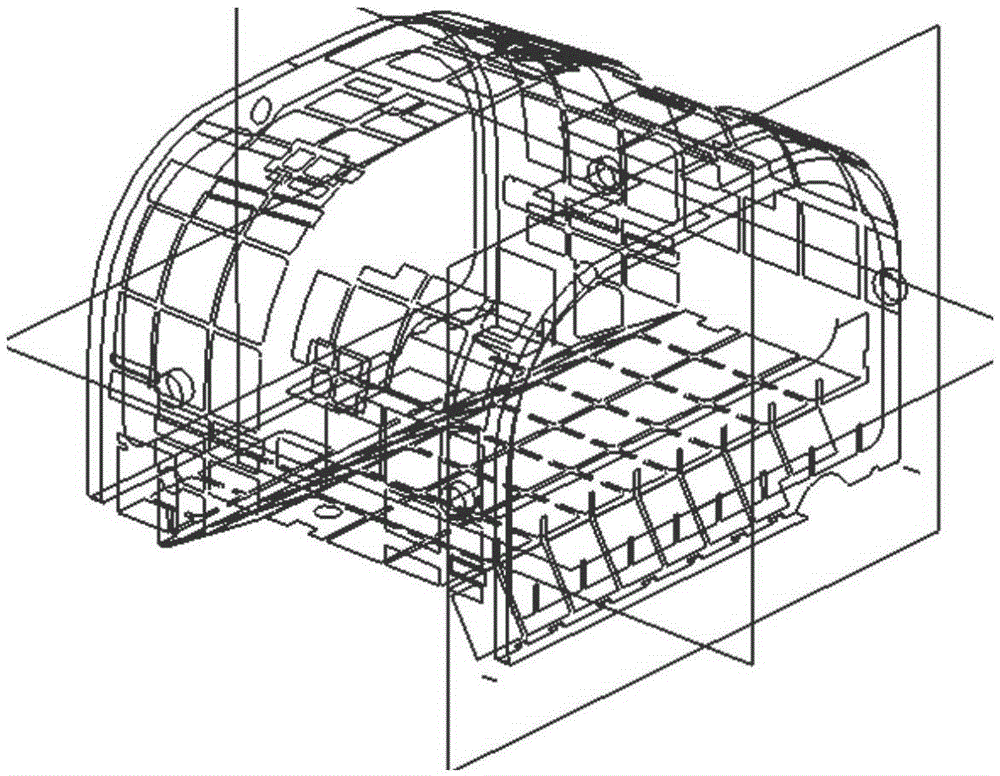

Machining method of cabin section work-piece

ActiveCN106239066AAvoid uneven wall thicknessSolve the problem of out-of-tolerance distance between butt pin holesAircraft componentsMilling cutterCoating

The invention provides a machining method of a cabin section work-piece. The work-piece comprises end faces. The method comprises the steps of: determining the planeness of the end faces by taking the end faces of the work-piece as benchmarks; determining a rough machining center of the work-piece by taking pin holes and bottom holes in the end faces as benchmarks; carrying out rough machining on a profile of the work-piece and detecting a machining allowance of each end face; carrying out finish machining on the profile of the work-piece by using a diamond milling cutter according to a preset size; determining a finish machining center of the work-piece by taking the finish-machined profile as a benchmark; carrying out side-edge cutting and bottom-edge cutting on the end faces and end face sealing lug bosses by using a diamond coating milling cutter; carrying out boring-machining on the pin holes in the end faces; pressing out notch edges of a notch by using a pressing plate; and carrying out segmental machining and layered machining on the notch with a preset cutting step length by using a spiral cutting method. Thus, by using a benchmark conversion machining method, the problem of non-uniform wall thicknesses caused by machining deformation in a single benchmark is solved, and the phenomena of scaling-off, breaking-up and delaminating appearing during machining are avoided.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

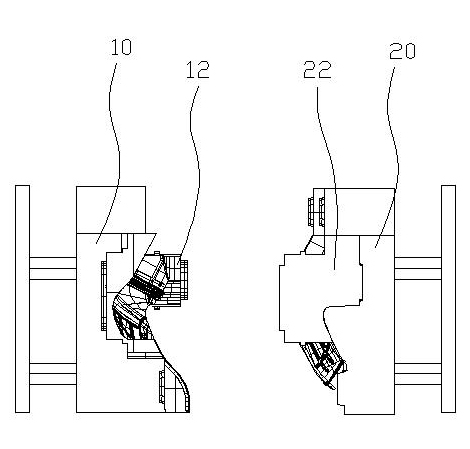

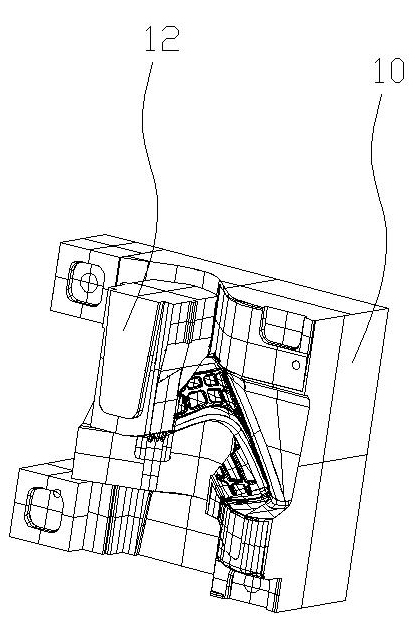

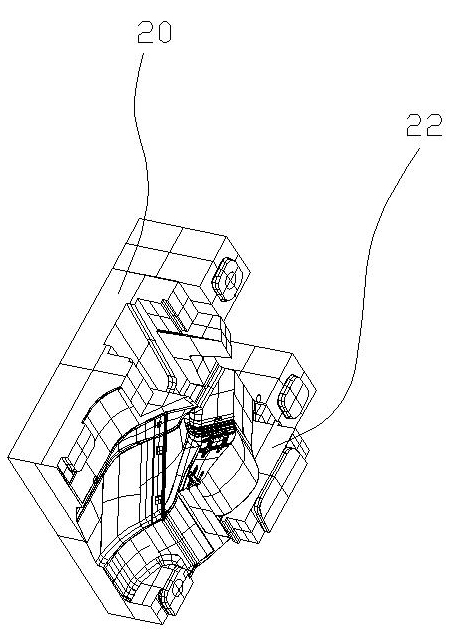

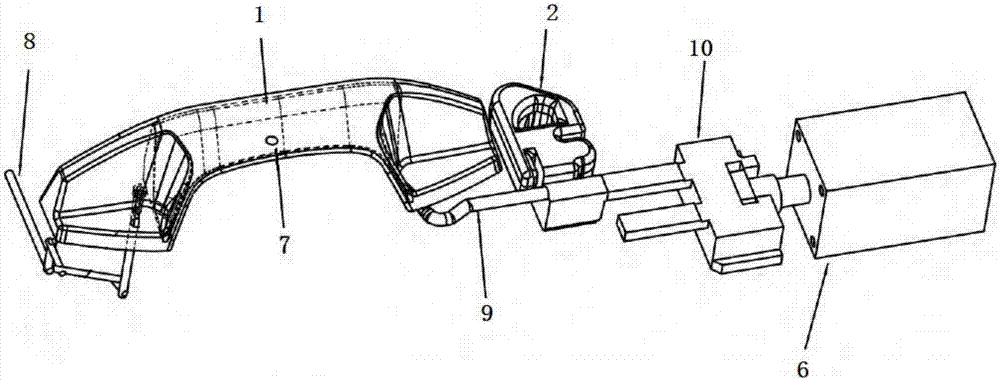

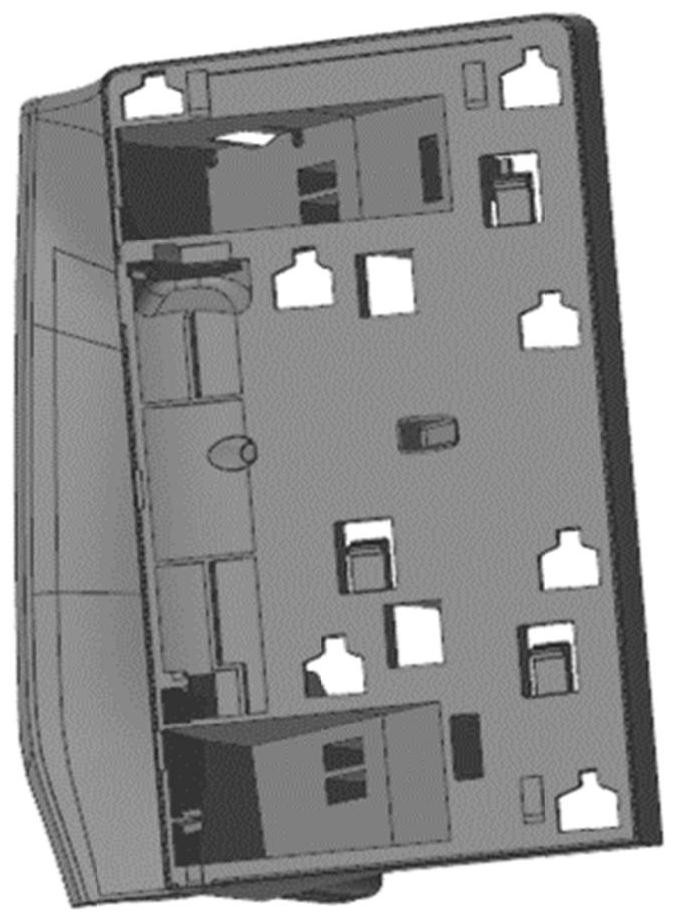

Mold and molding technology of special-shaped inlet air pipe,

The invention discloses a mold and a molding technology of a special-shaped inlet air pipe. The mold of the special-shaped inlet air pipe comprises a first mold half and a second mold half, wherein the first mold half is provided with a slide block, the second mold half is provided with a second slide block, and after the first mold half and the second mold half are combined together and the first slide block and the second slide block are combined together, a cavity formed by the first mold half, the first slide block, the second mold half and the second slide block is matched with the external surface of the special-shaped inlet air pipe. The molding technology comprises the following steps of: a) opening the mold; (b) extruding a blank to a mold cavity; c) combining the first mold half and the second mold half together; d) closing upper and lower sealing ports of the blank on the mold; e) respectively combining the first slide block and the second slide block together; f) blowing with a blow needle, and molding a product; g) opening the mold, and taking out the product. The mold and the molding technology can produce the special-shaped inlet air pipe through a two-dimensional blow molding method, and the produced special-shaped inlet air pipe is free of excess blanks and flashes.

Owner:NINGBO JOYSONQUIN AUTOMOTIVE SYST HLDG CO LTD

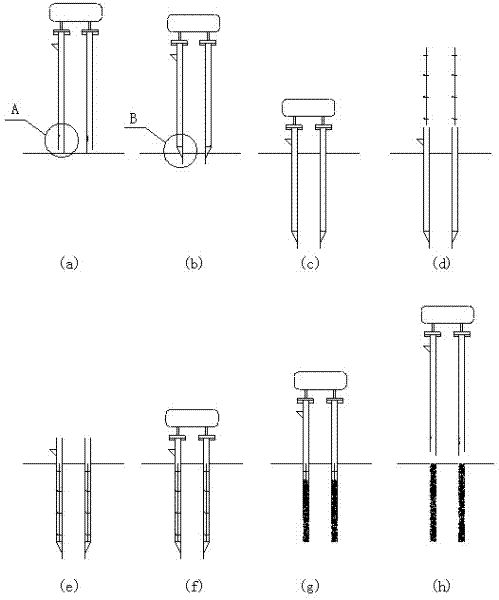

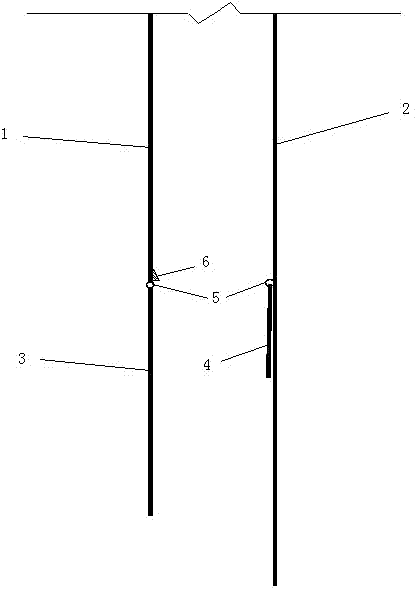

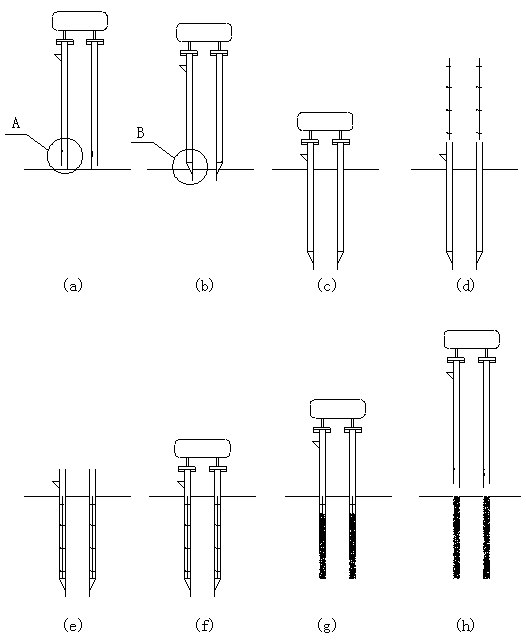

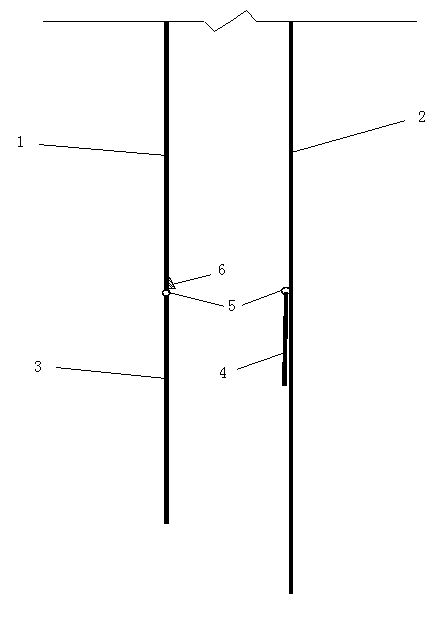

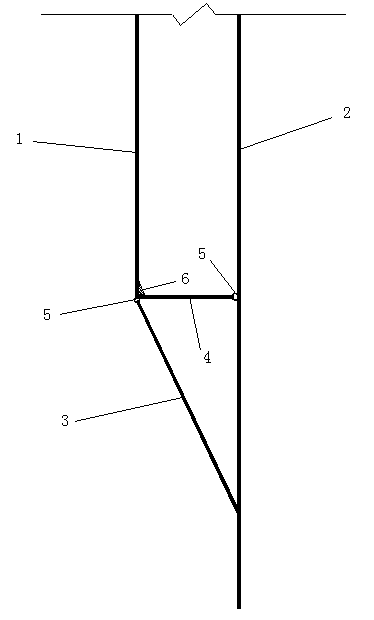

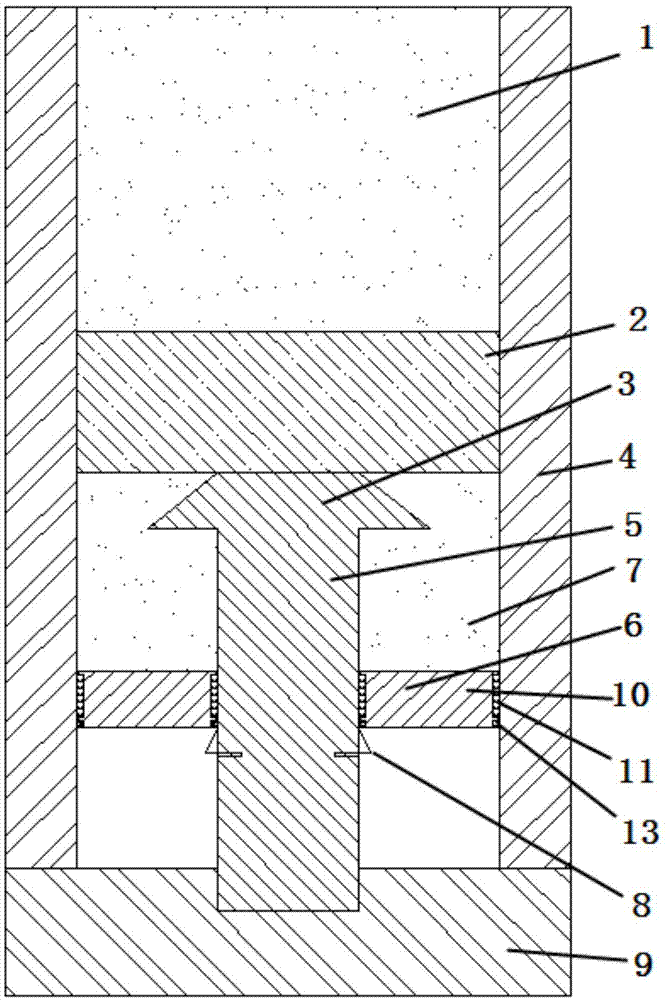

Construction Method of Cast-in-situ Reinforced Concrete Large Diameter Pipe Pile

The invention discloses a construction method of a PCC (cast-in-place concrete large-diameter pipe) pile, which comprises the following steps: taking a pile driver in place; rotating movable inner supports to close to limiting stoppers; closing a valve pile tip; sinking a pile mould; moving a vibration head; placing a reinforcement cage; arranging the vibration head; pouring concretes; drawing a tube in a vibrating manner; opening the valve pile tip and the inner supports; punching the concretes and the reinforcement cage into a foundation; and extracting a formed pile from the pile mould. The three or more than three movable inner supports and the limiting stoppers are uniformly arranged along the pile mould. Transverse spacer bars are arranged on the reinforcement cage, two end of each of the transverse spacer bars are provided with a semicircular elbow respectively, each transverse cross section of the reinforcement cage is provided with three or more than three transverse spacer bars, and one group of the transverse spacer bars is arranged along the horizontal direction at an interval of 3-5m. The movable inner supports and the reinforcement cage with the transverse spacer bars are arranged skillfully, thus the problem of construction of the PCC pile is solved, the application range of the PCC pile is expanded, the cost is low, and the higher bearing capacity is obtained with the less concrete consumption.

Owner:HOHAI UNIV

Construction method of PCC (cast-in-place concrete large-diameter pipe) pile

The invention discloses a construction method of a PCC (cast-in-place concrete large-diameter pipe) pile, which comprises the following steps: taking a pile driver in place; rotating movable inner supports to close to limiting stoppers; closing a valve pile tip; sinking a pile mould; moving a vibration head; placing a reinforcement cage; arranging the vibration head; pouring concretes; drawing a tube in a vibrating manner; opening the valve pile tip and the inner supports; punching the concretes and the reinforcement cage into a foundation; and extracting a formed pile from the pile mould. The three or more than three movable inner supports and the limiting stoppers are uniformly arranged along the pile mould. Transverse spacer bars are arranged on the reinforcement cage, two end of each of the transverse spacer bars are provided with a semicircular elbow respectively, each transverse cross section of the reinforcement cage is provided with three or more than three transverse spacer bars, and one group of the transverse spacer bars is arranged along the horizontal direction at an interval of 3-5m. The movable inner supports and the reinforcement cage with the transverse spacer bars are arranged skillfully, thus the problem of construction of the PCC pile is solved, the application range of the PCC pile is expanded, the cost is low, and the higher bearing capacity is obtained with the less concrete consumption.

Owner:HOHAI UNIV

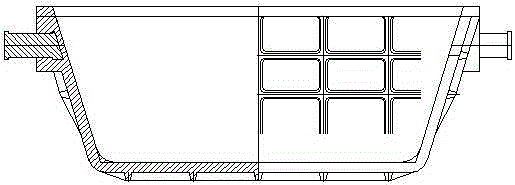

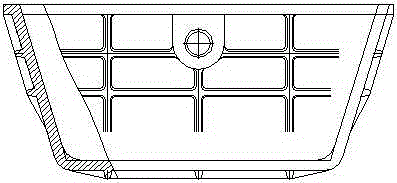

Metallurgical slag basin model-free casting method

ActiveCN105170904ASave mold costAvoid uneven wall thicknessFoundry mouldsFoundry coresMolding sandMetallurgical slag

The invention provides a metallurgical slag basin model-free casting method. The metallurgical slag basin model-free casting method includes the following steps: four corner cores of a slag basin are manufactured with a corner core box, the outer contour of the four corner ends of the casting slag basin are obtained, and a casting outer contour sand mold of the casting slag basin is formed; skin repairing is carried out, wherein a multi-layer plate or molding sand is adopted to filling and assembling of a casting cavity part, and the slag basin sand mold profile is formed; sand discharging is carried out to form a sand core box; and core discharging and box closing are carried out. Compared with an original method that casting is carried out through a manufacturing mold, the method has the beneficial effects that the length, the width and the wall thickness of the slag basin can be adjusted, so that the slag basin in any size can be manufactured, multiple molds are replaced, repeated utilization can be carried out, and the mold cost is greatly reduced; and meanwhile, the problem of uneven wall thickness of a casting is solved, and the wall thickness accuracy of the slag basin casting is improved.

Owner:山东瑞浩重型机械有限公司

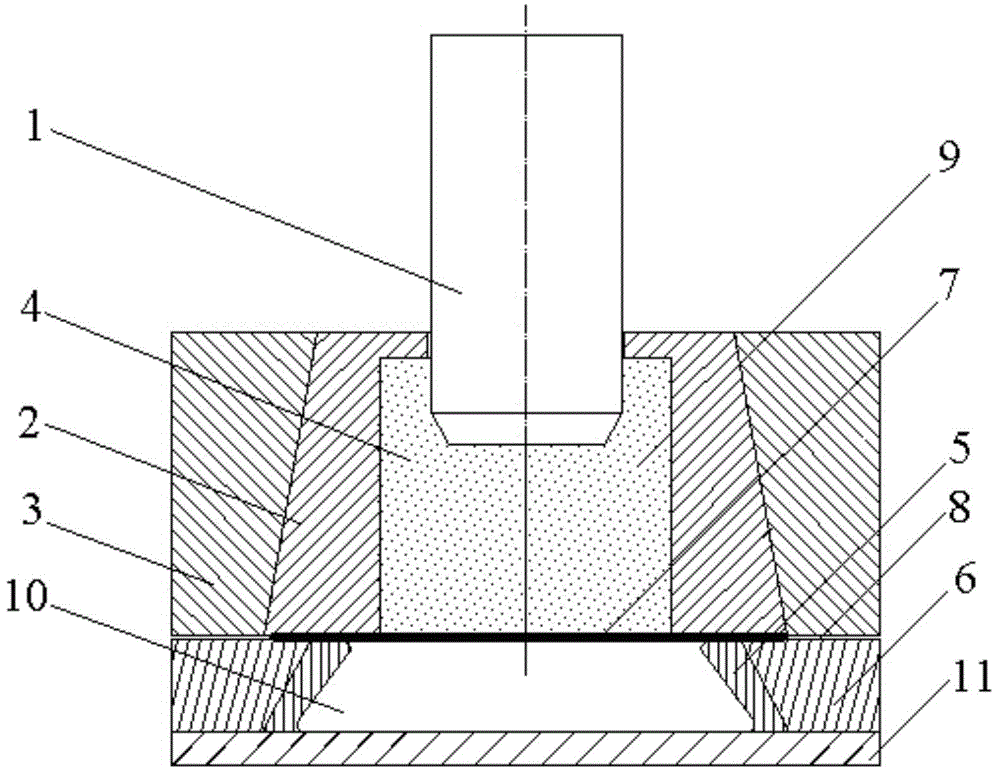

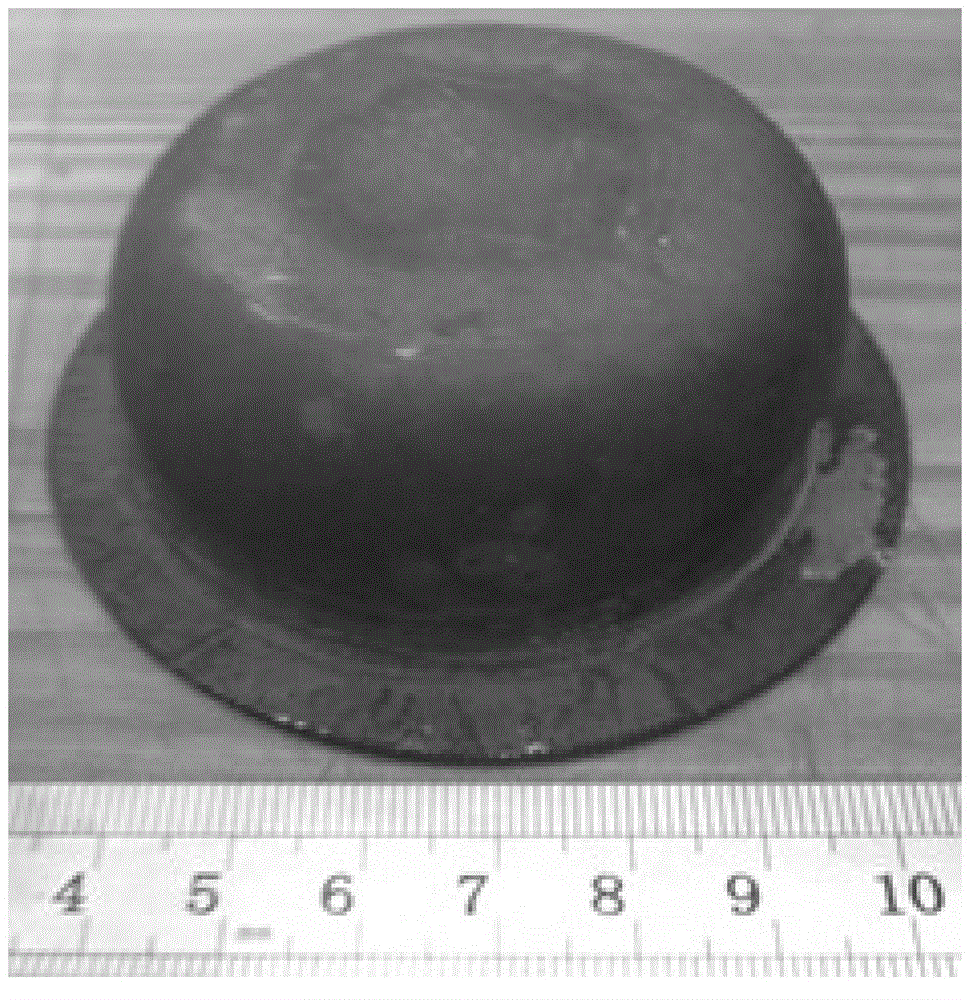

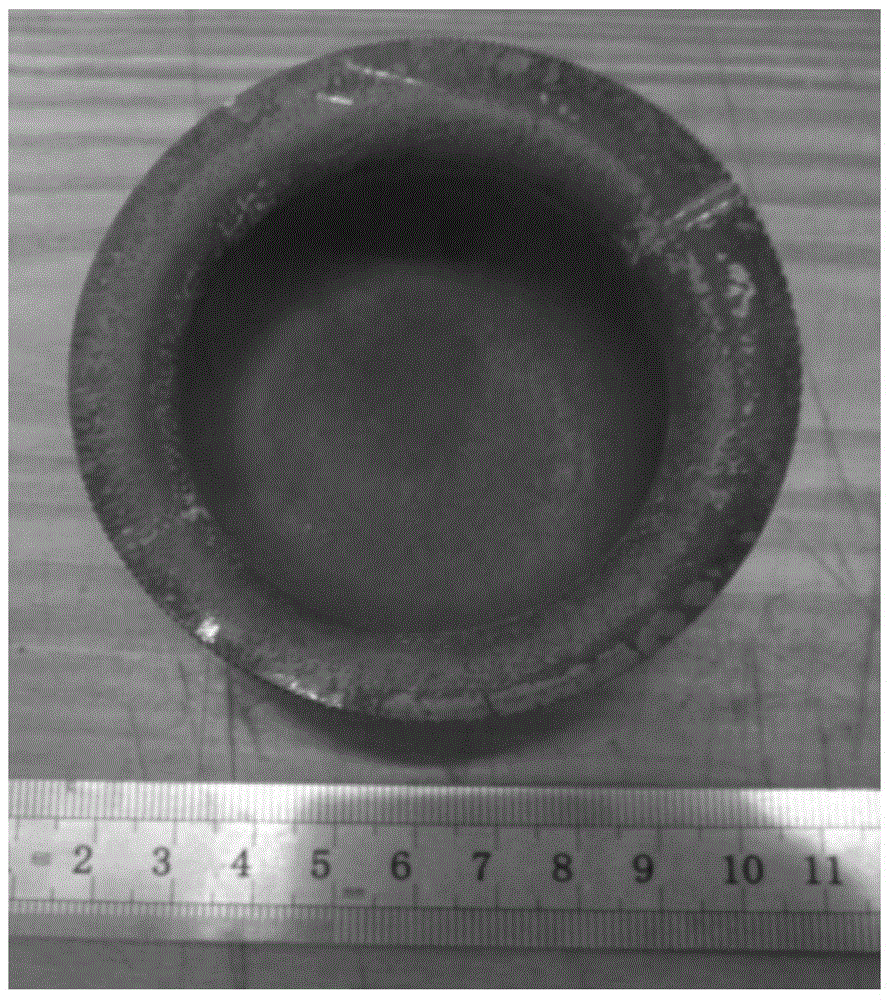

Device for high temperature solid power medium assisting titanium alloy plate superplasticity drawing and bulging integration and method thereof

ActiveCN104624799AEffective control of thickness distributionFast formingShaping toolsTitanium alloySuperplasticity

The invention provides device for high temperature solid power medium assisting titanium alloy plate superplasticity drawing and bulging integration and a method thereof and relates to a device for drawing and bulging integration and a method thereof. The device comprises a punch, an upper die petal, an upper die sleeve, a lower die petal, a lower die sleeve, a spacer, an upper die cavity, a lower die cavity and a cushion block. The lower end of the punch is arranged in the upper die cavity, and the upper die sleeve is arranged outside the upper die petal; the lower die petal and the lower die sleeve are arranged on the cushion block, and the lower die sleeve is arranged outside the lower die petal; the spacer is arranged between the upper die sleeve and the lower die sleeve. The method comprises the steps that an aluminium alloy plate to be molded is put into the interspace formed by the upper die petal, the lower die petal and the lower die sleeve of the device for the high temperature solid power medium assisting titanium alloy plate superplasticity drawing and bulging integration, a powder medium is added into the upper die cavity, and pre-compaction, heating and heat preservation are sequentially conducted on the powder medium; then compaction, pressure maintaining and cooling are sequentially conducted to obtain an aluminium alloy part. By means of the device for the high temperature solid power medium assisting titanium alloy plate superplasticity drawing and bulging integration and the method thereof, aluminium alloy parts with uniform thicknesses can be obtained.

Owner:HARBIN INST OF TECH

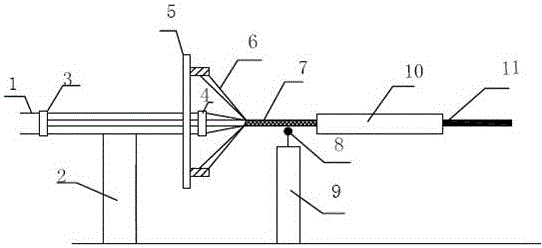

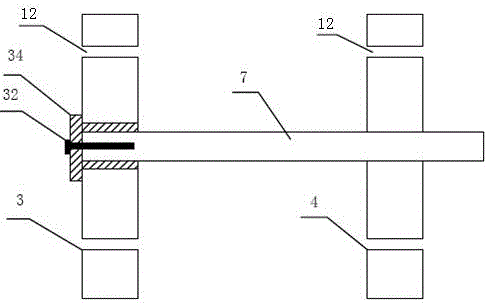

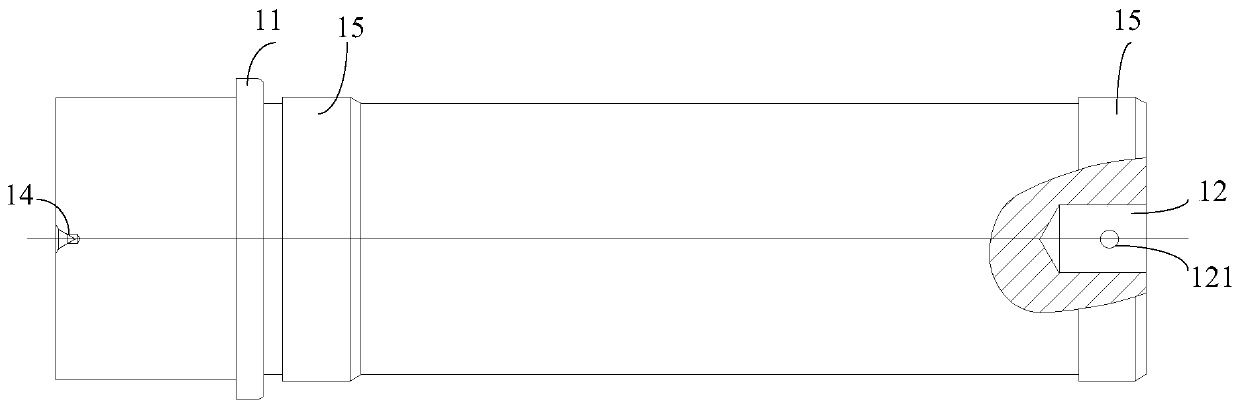

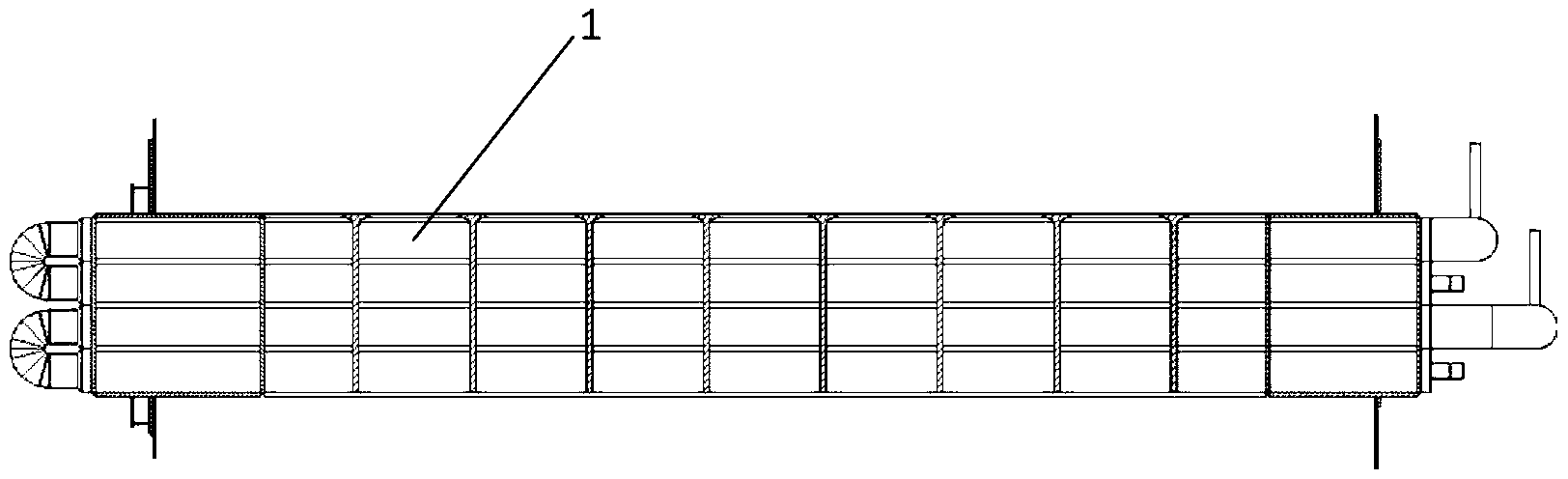

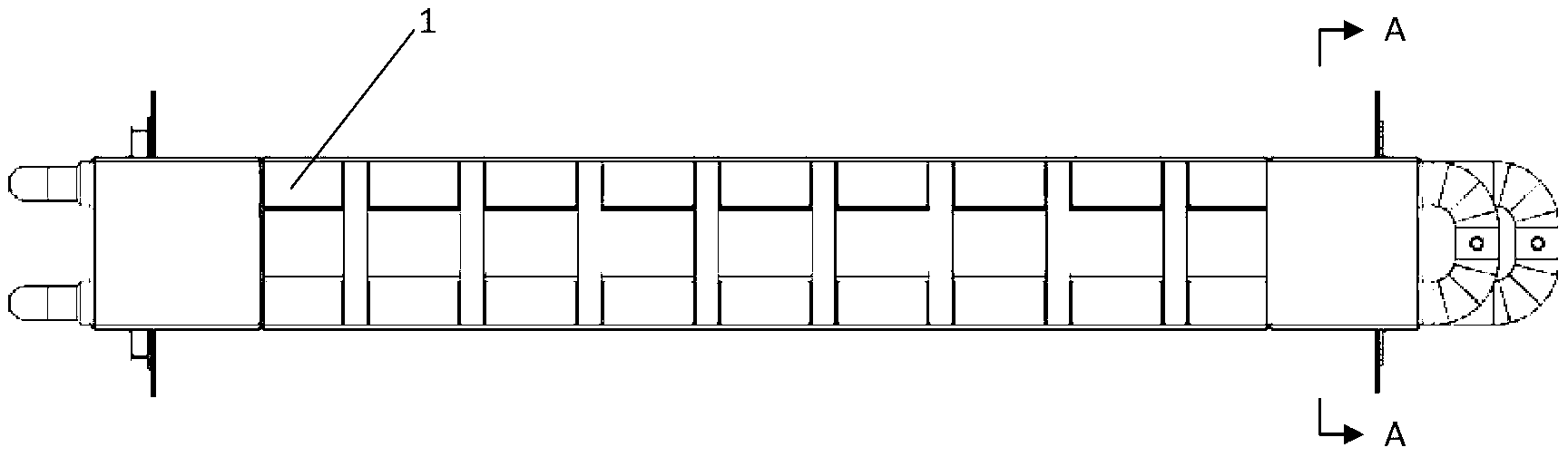

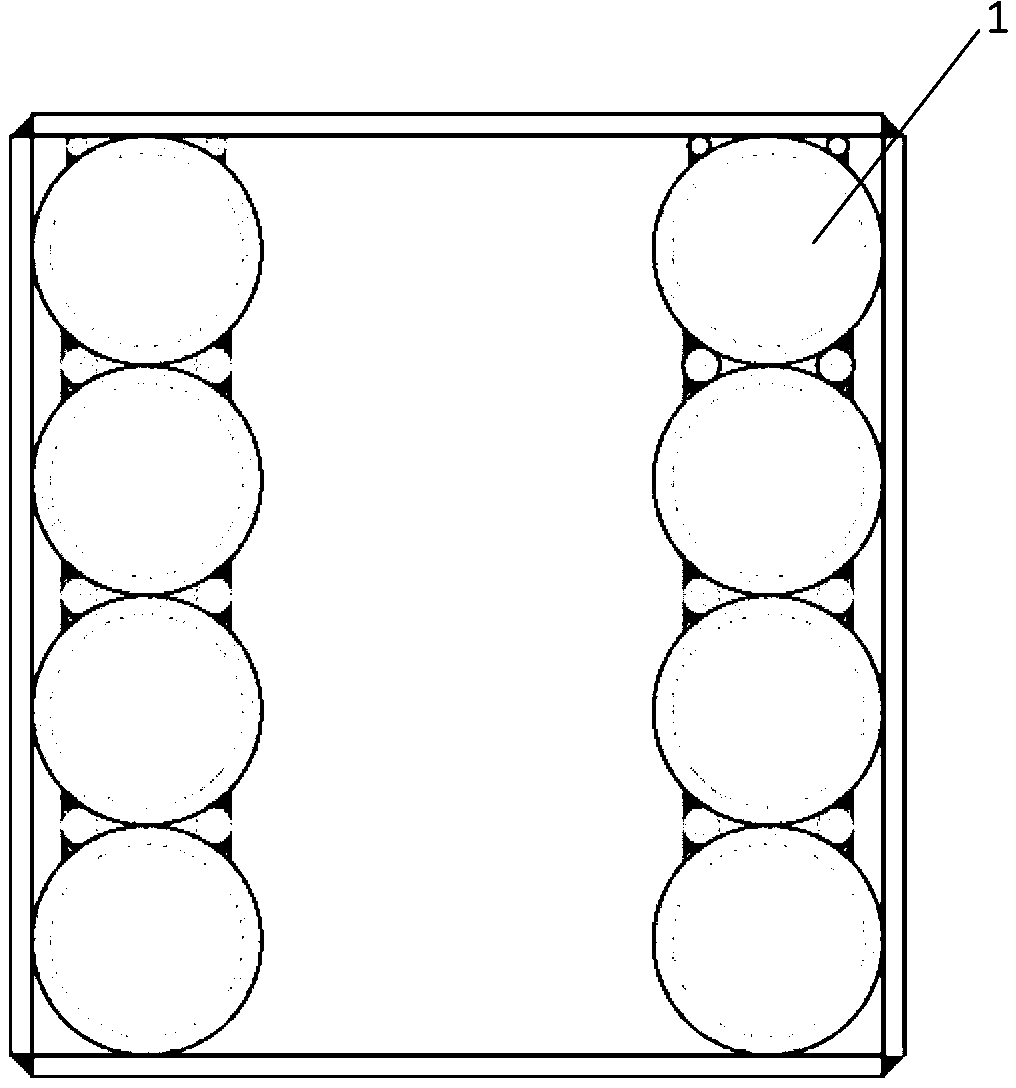

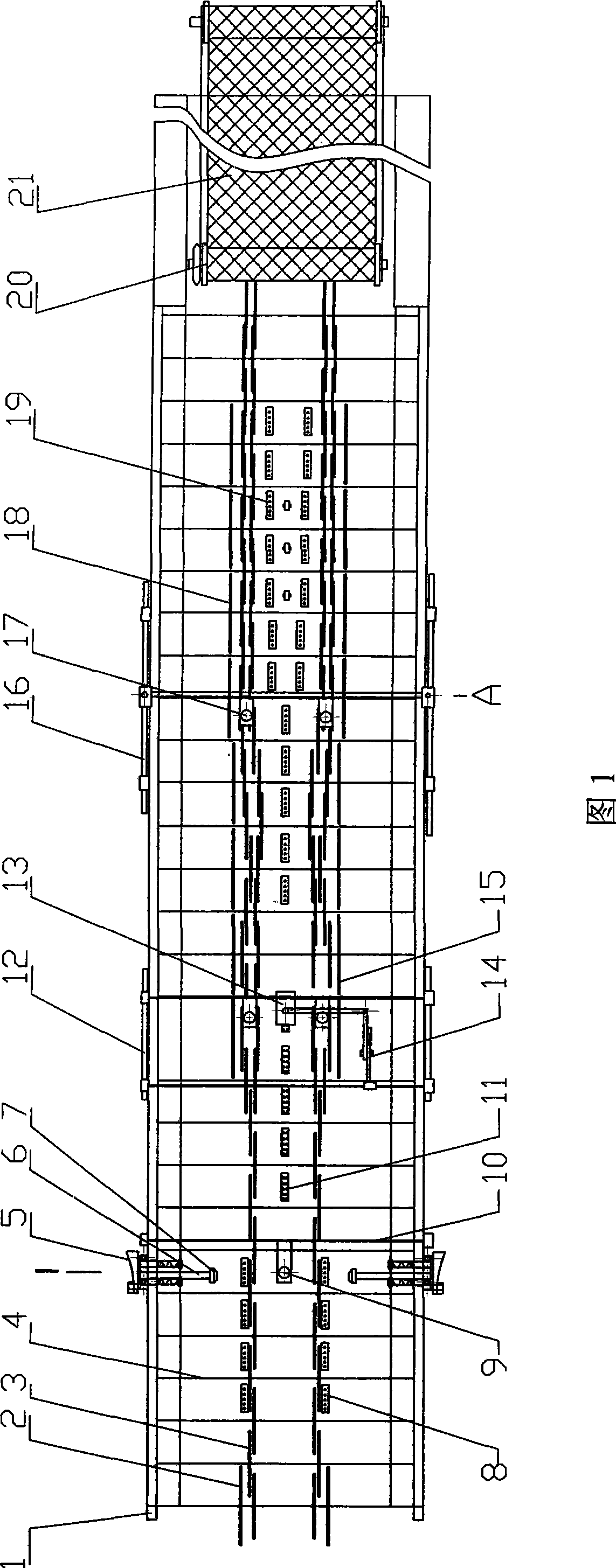

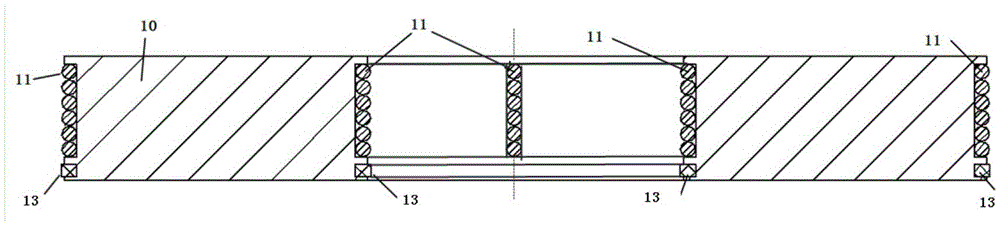

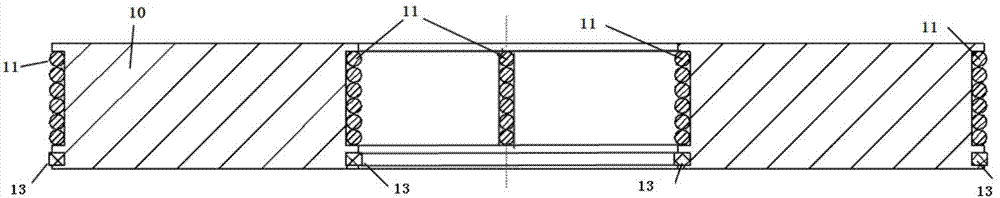

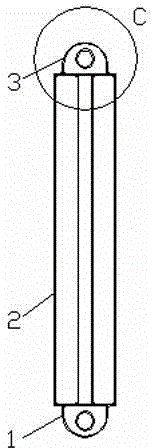

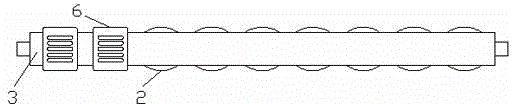

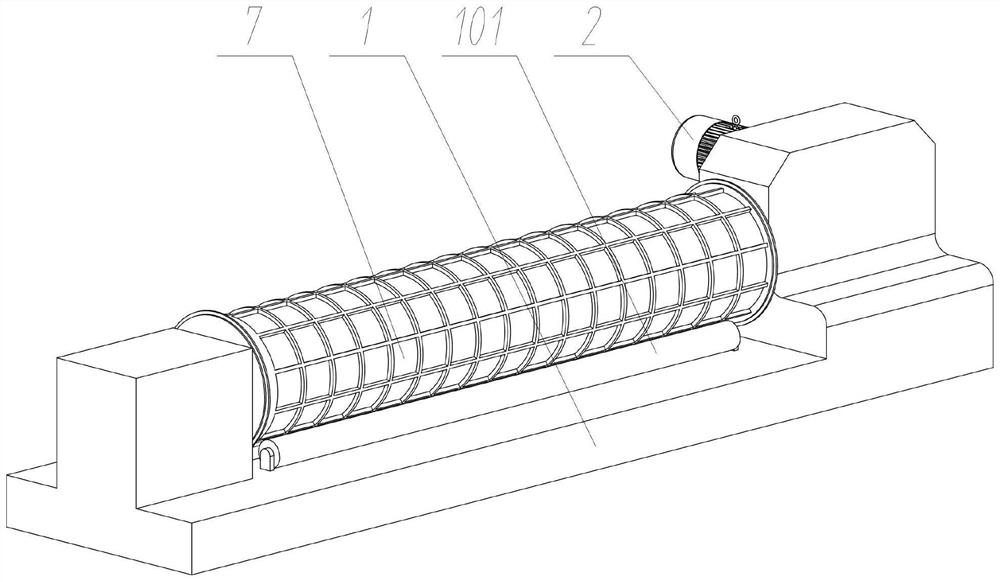

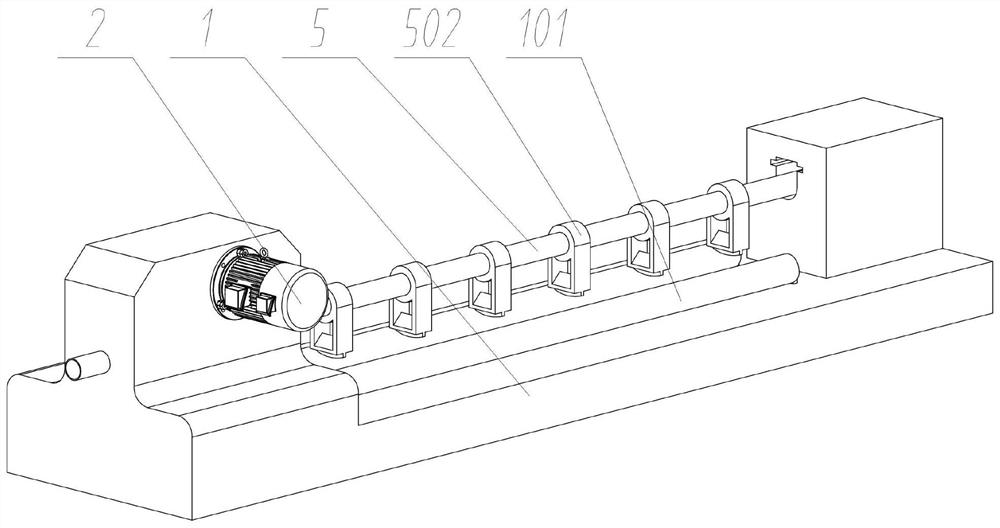

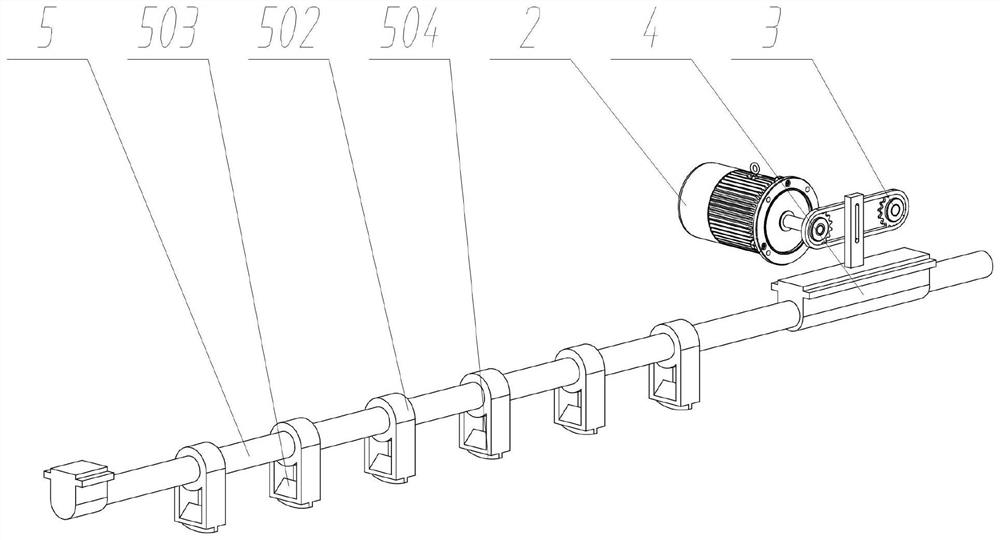

Long core mold location supporting device for tube pultruding and mounting method thereof

ActiveCN105690810AEnsure wall thickness uniformitySimple structureTubular articlesEngineeringSelf weight

The invention discloses a long core mold location supporting device for tube pultruding and a mounting method thereof.The device comprises a front support and a rear support, a first core mold location support and a second core mold location support which are arranged in parallel in the transverse direction are mounted at the front end and the rear end of the front support, and an adjustable supporting mechanism is mounted on the rear support.According to the supporting device, three-point location is conducted on a core mold through the first core mold location support, the second core mold location support and the supporting device, so that the problem that a composite tube is not uniform in wall thickness due to the fact that a long core mold droops as a result of self weight is solved, and the supporting device is simple in structure and convenient to mount, dismount and regulate.

Owner:HENGSHEN

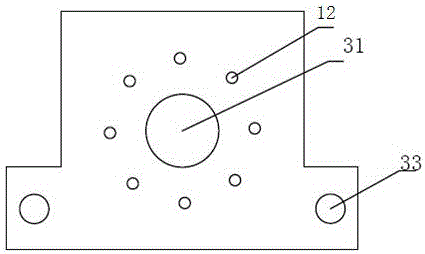

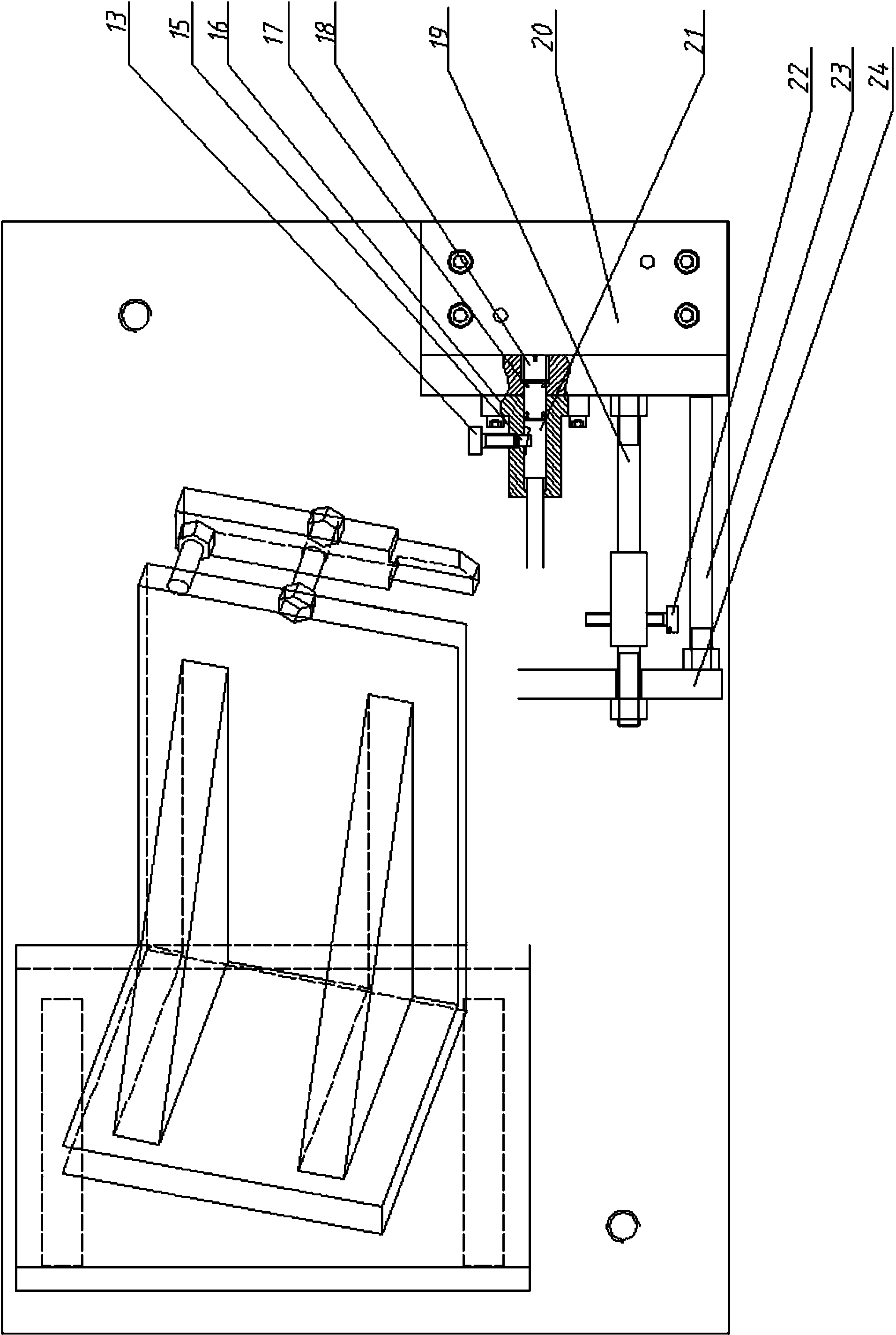

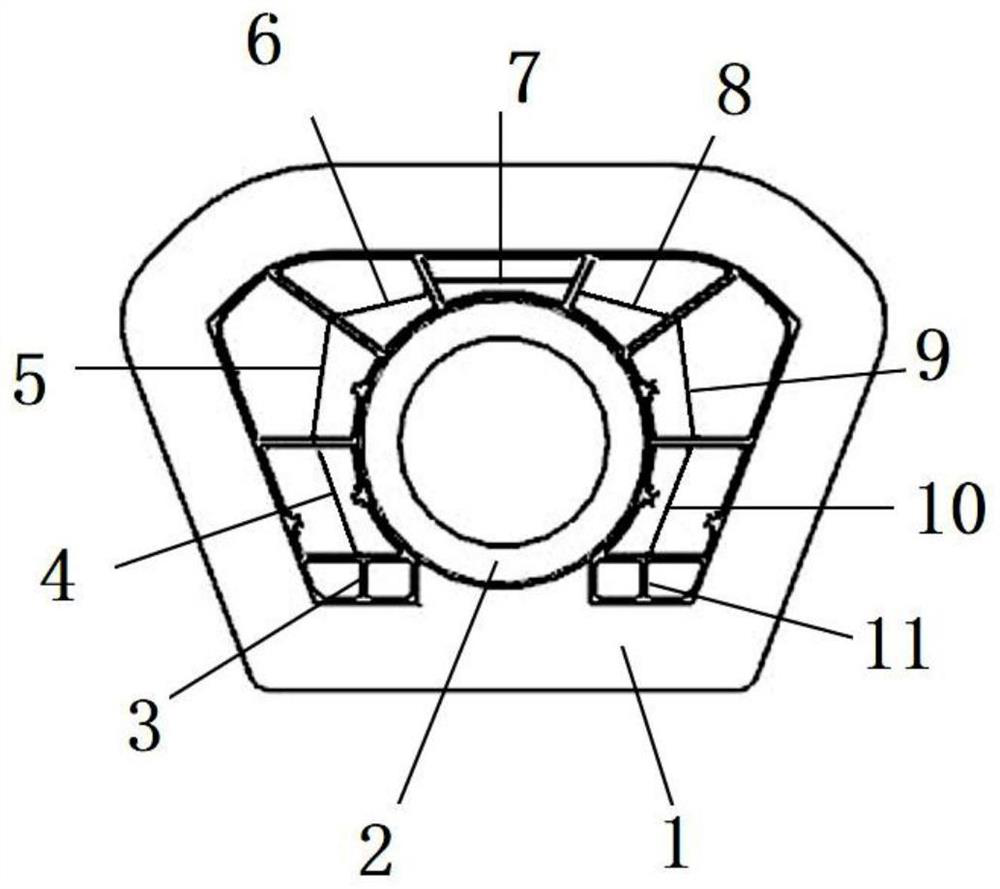

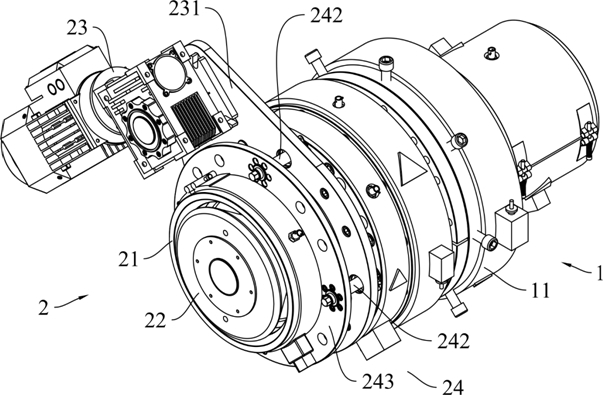

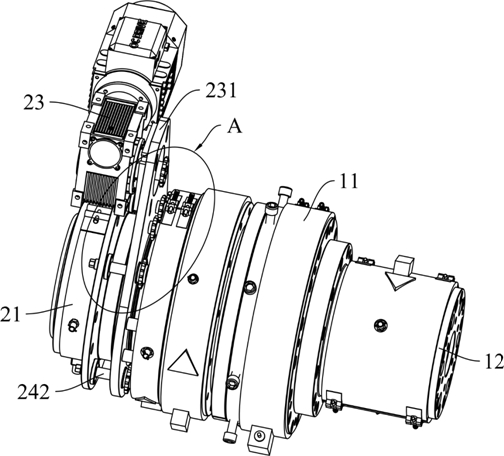

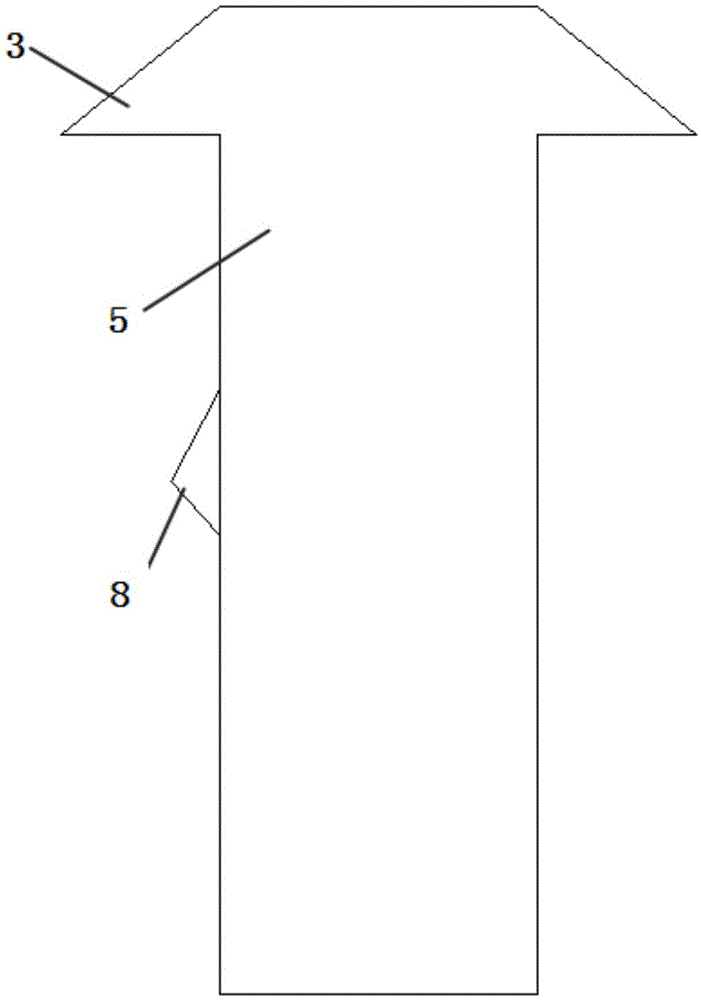

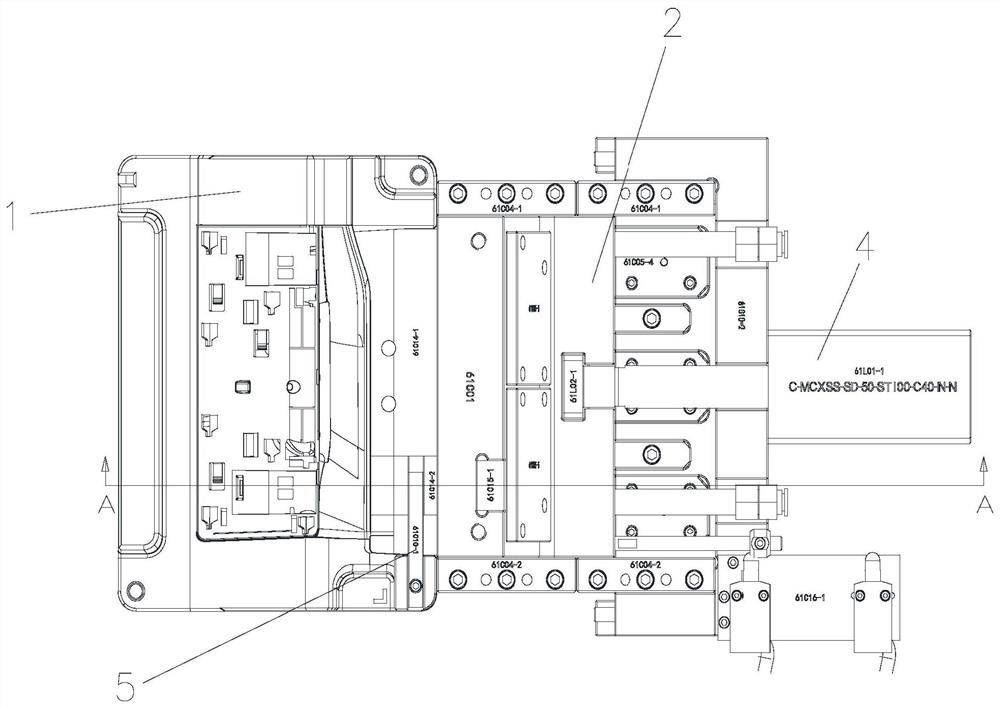

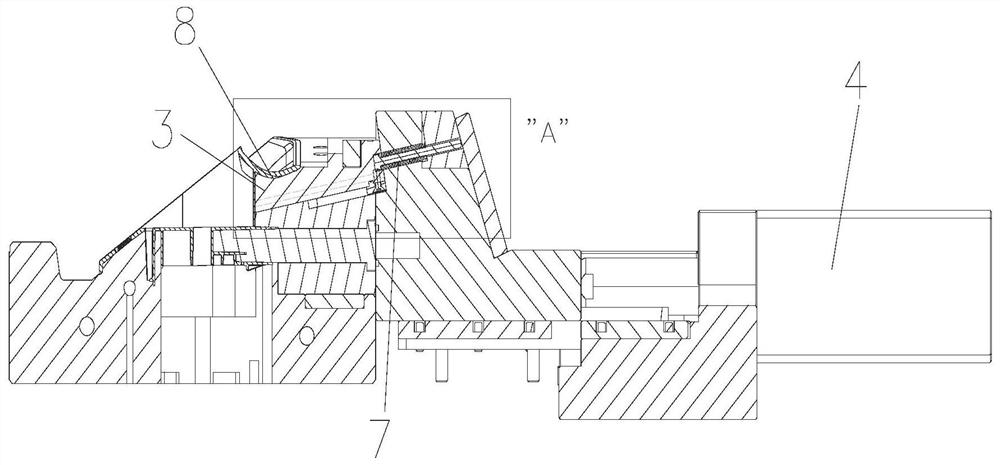

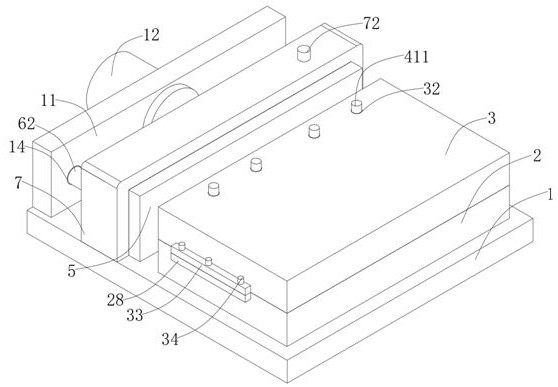

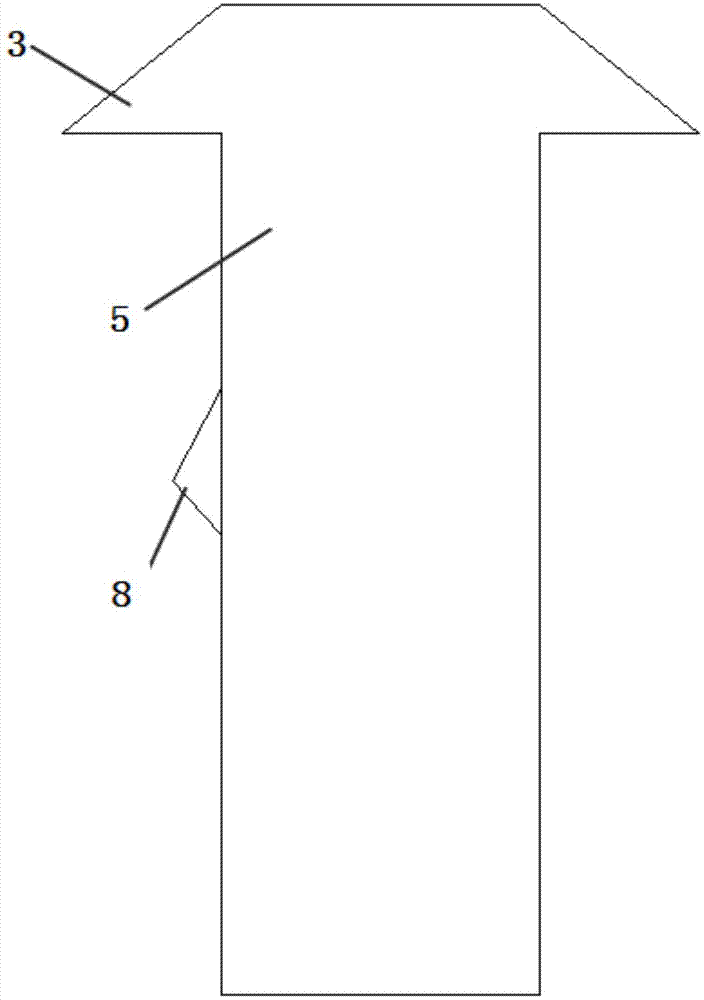

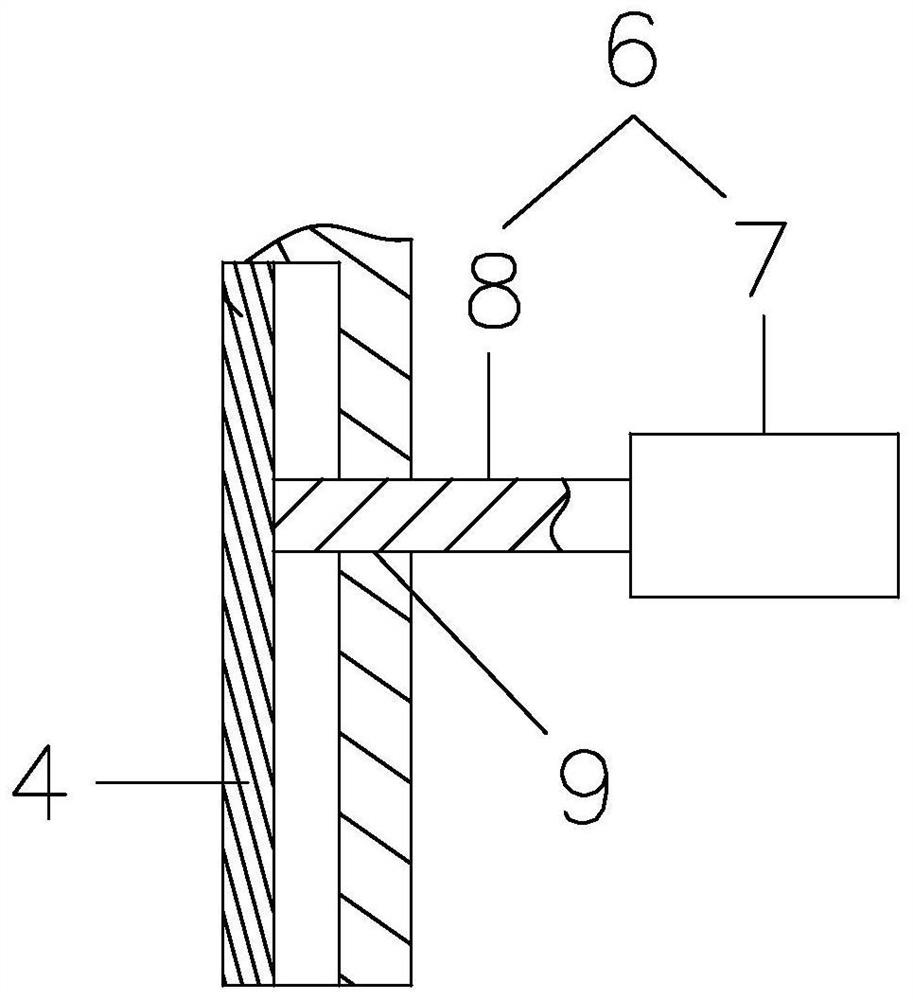

Aslant intake manifold orifice milling locating device

ActiveCN103433773ASolve uneven wall thicknessGuaranteed location requirementsPositioning apparatusMetal-working holdersInlet manifoldBatch production

The invention provides an aslant intake manifold orifice milling locating device which is characterized by comprising a bottom plate (1), an inclined plate (2), a flat plate (3), first angle iron (4), a first press plate (5), a first press plate screw (6), a second press plate (7), a third press plate (8), a first compressing screw rod (9), a compression nut (10) and a first support rod (11), wherein the triangular inclined plate (2) is vertically arranged on the bottom plate (1), the inclined plate (2) is provided with the flat plate (3), and the flat plate is provided with the first angle iron (4). The aslant intake manifold orifice milling locating device adopts a plane and pinhole locating mode, an orifice elastic-adjustable locating pin is adopted for locating, so that the position requirement of a product is ensured, an uneven wall thickness condition possibly caused by orifice processing due to blank deformation and orifice size unstability is solved, mounting requirements can be met, and reliable quality and batch production capability can be ensured.

Owner:惠州市群鑫五金制品有限公司

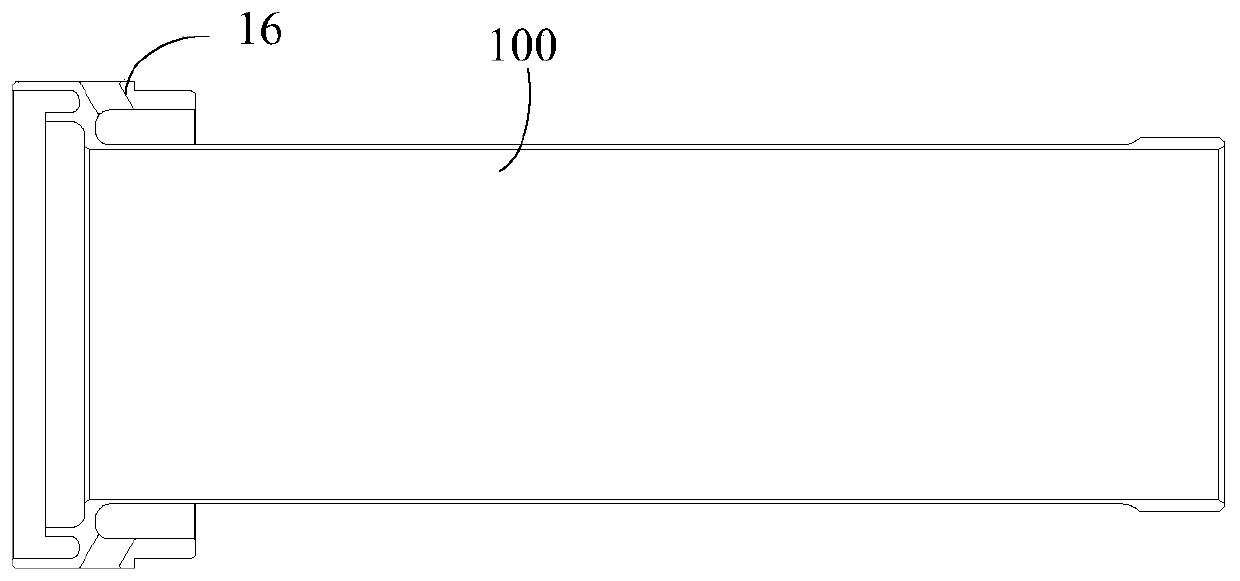

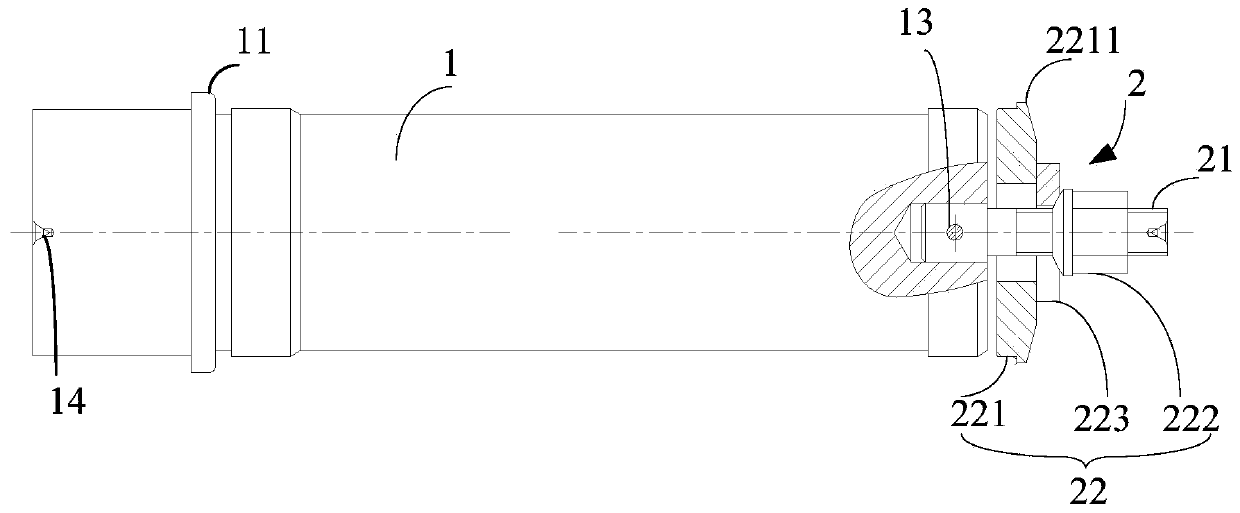

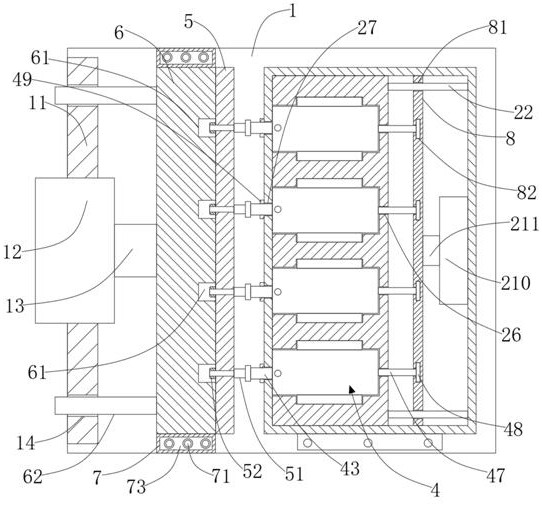

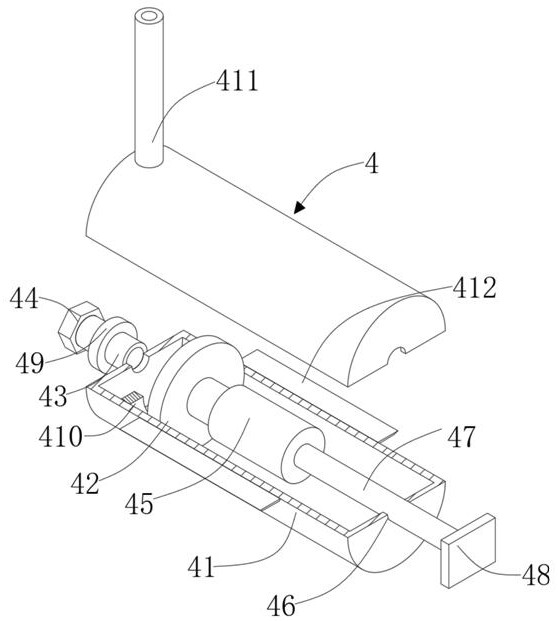

Clamp for air introduction pipe machining and clamping method

ActiveCN110370188APrevent uneven wall thicknessIncrease productivityWork holdersEngineeringRejection rate

The invention discloses a clamp for an air introduction pipe machining and a clamping method, and belongs to the field of machining clamps. The clamp comprises a core shaft and an end surface pressingmechanism, wherein the core shaft is used for being coaxially inserted into an air introduction pipe, and a first shaft shoulder abutting against one end of the air introduction pipe is arranged on the side wall of the core shaft; the end surface pressing mechanism is detachably connected to the end surface of one end of the core shaft, and the end surface pressing mechanism is used for pressingthe end surface of the other end of the air introduction pipe; and the air introduction pipe is arranged on the core shaft in a sleeving mode, then the air introduction pipe can be positioned in the radial direction, the first shaft shoulder can abut against one end of the air introduction pipe, and the end surface pressing mechanism presses the other end of the air introduction pipe, so that axial positioning of the air introduction pipe is realized. According to the clamp, the axial and radial stable clamping of the air introduction pipe can be quickly realized, and the phenomenon that the wall thickness is uneven due to the fact that the air introduction pipe is clamped to deform is avoided, so that the production efficiency of the air introduction pipe is improved, and the rejection rate is reduced.

Owner:WUHAN MARINE MACHINERY PLANT

Extruded profile correcting die and correcting method thereof

ActiveCN112474856AGuaranteed forming accuracyMeet high precision forming requirementsExtrusion diesFriction effectEngineering

The invention relates to an extruded profile correcting die and a correcting method thereof, and belongs to the technical field of metal precision forming. The problems that in the prior art, in the profile extrusion process, a strong friction effect is generated among a blank, an extrusion cylinder and an extrusion die, meanwhile, extrusion force impacts structures such as a die core of the die,so that poor forming precision defects of local waves, collapse, uneven wall thickness, poor profile tolerance and the like are caused are solved. The correcting die comprises expanding tires, core shafts, expanding petals and positioning plates, the expanding tires, the core shafts and the expanding petals are arranged on the outer side of an extrusion profile and the inner sides of different cavities separately, the configuration of the extrusion profile and the forming precision of the inner cavities can be effectively guaranteed, and the high-precision forming requirement of the large complex-section extrusion profile is met; and by means of the extruded profile correcting die, high-precision forming of extruded profiles is achieved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

High-temperature wear-resistant water beam of air-guiding wall

InactiveCN103063012AExtended service lifeIncreased ability to withstand thermal stress mutationsVertical furnacesWear resistantImpurity

The invention provides a high-temperature wear-resistant water beam of an air-guiding wall. The high-temperature wear-resistant water beam comprises a plurality of parallelly arranged water circulating steel tubes, and the steel tubes are manufactured via centrifugal casting method and made of superstrong heat resistant steel. The superstrong heat resistant steel comprises, by weight, 0.2-0.45% of C, 22-28% of Cr, 3.5-13% of Ni, 0.1-0.4% of Si, 0.1-0.4% of N, 0.01-3% of RE, 0.15-2.3% of Mo, 0.15-2.3% of W, 0-13% of Co, 1-13% of Mn, 0.0005-0.10% of Mg, and the balance Fe and impurities. The high-temperature wear-resistant water beam of the air-guiding wall is long in service life.

Owner:NANJING UNIV OF TECH +1

Method and equipment for producing cup of beaker

ActiveCN101050055BIncrease productivityGood lookingGlass reforming apparatusGlass productionCutting glassNeck parts

This invention provides method and apparatus for producing beaker. The method comprises: (1) cutting glass tube into 2.1-2.3 times of the height of beaker body, placing the cut glass tube on the transmission tray at the front end of the frame, moving by the channel on the transmission tray to the nozzle of the flaring device, heating both ends of the glass tube and flaring; (2) heating the middlepart of the flared glass tube, pressing the middle part into bottle neck shape by a neck-pressing mold, cooling, heating the middle part again, and separating at the middle neck part by the force toward the two ends from the bottom pressure foot to obtain the bodies of two beakers; (3) pre-sealing the bottoms by the nozzle, sealing the bottoms, finishing, polishing, annealing, and outputting by aconveyer belt. The method has such advantages as high production efficiency, high product quality, and low raw material consumption.

Owner:YANCHENG HUAOU IND

Automatic reducing plastic extrusion die

InactiveCN114147937AQuality assuranceAvoid uneven wall thicknessTubular articlesMechanical engineeringIndustrial engineering

The invention discloses an automatic reducing plastic extrusion mold, and relates to the technical field of plastic extrusion, the automatic reducing plastic extrusion mold comprises a mold body and a reducing mechanism, the mold body comprises a mouth mold and a core mold, the core mold is arranged in the mouth mold in a penetrating manner, an extrusion channel is formed between the mouth mold and the core mold, and the extrusion channel is provided with an extrusion section; the variable-diameter mechanism comprises a variable-diameter outer die, a variable-diameter inner die and a variable-diameter driving part, the variable-diameter outer die is movably arranged at the end, close to the extrusion section, of the mouth die, the variable-diameter inner die is arranged at the end, close to the extrusion section, of the core die, the variable-diameter inner die penetrates through the variable-diameter outer die, and the output end of the variable-diameter driving part is connected with the variable-diameter outer die. According to the plastic extrusion die capable of automatically reducing, the reducing outer die is driven by the reducing driving piece to move in the direction of the central axis of the mouth die, so that the distance between the port of the reducing outer die and the outer wall of the reducing inner die is changed, and the wall thickness adjustment of an extrusion pipeline is realized; meanwhile, by adjusting the reducing outer die in the axial direction, the phenomenon that the wall thickness is not uniform in the radial direction can be avoided, and the quality of the extruded pipeline is ensured.

Owner:广东巴斯特科技股份有限公司

Desktop plate blow-molding apparatus

The invention discloses a desktop plate blow-molding apparatus, which comprises a blow molding port, a blow molding die-locking machine, and a blow molding die fixed in the blow molding die-locking machine, the blowing die comprises a left half die and a right half die, an oval discharge hatch is arranged at the blow molding port, the raw materials can be extruded from the discharge hatch in an annular curtain shape, the left half die or the right half die comprise mold core plates, more than two independent fixed plates are arranged at outboard of the mold core plate, a support column is arranged between each fixed plate and the mold core plate, a top seal clamping plate capable of automatically sealing the top of the raw materials is arranged over the blow molding die, and a bottom seal clamping plate capable of automatically sealing the bottom of the raw materials is arranged below the blow molding die. The desktop plate blow-molding apparatus has the advantages that raw material waste amount is less, automatic sealing equipment can be used for substituting artificial sealing, work efficiency is increased, and die sticking problem of the products can be solved.

Owner:ZHEJIANG LIFAN FURNITURE

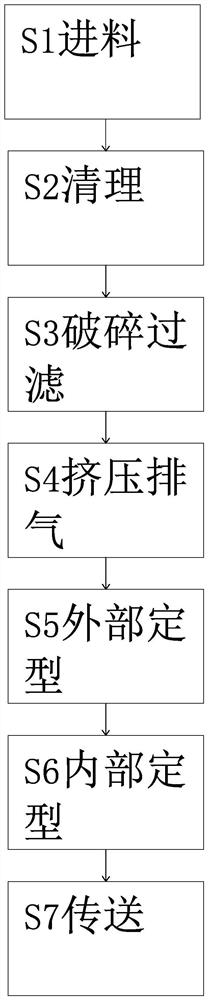

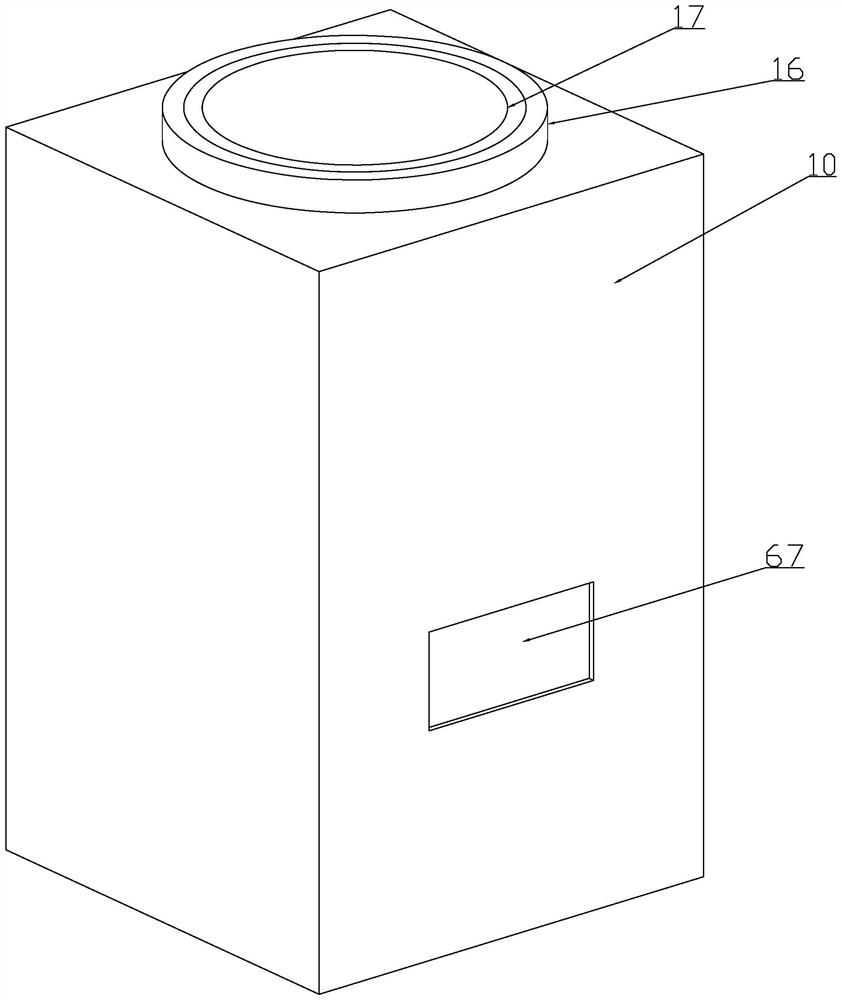

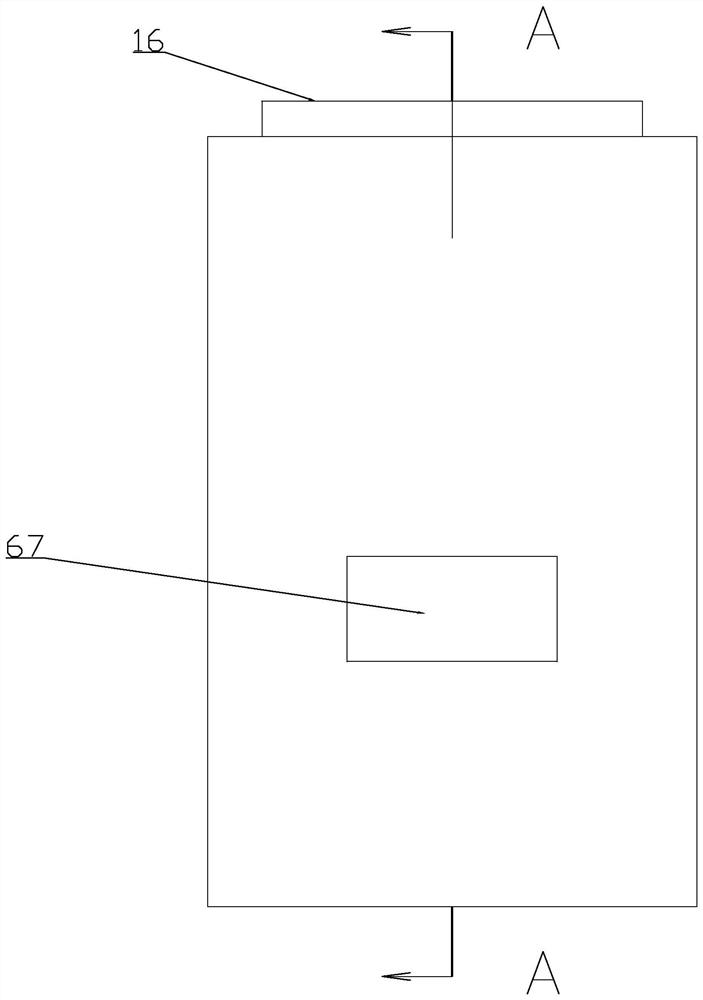

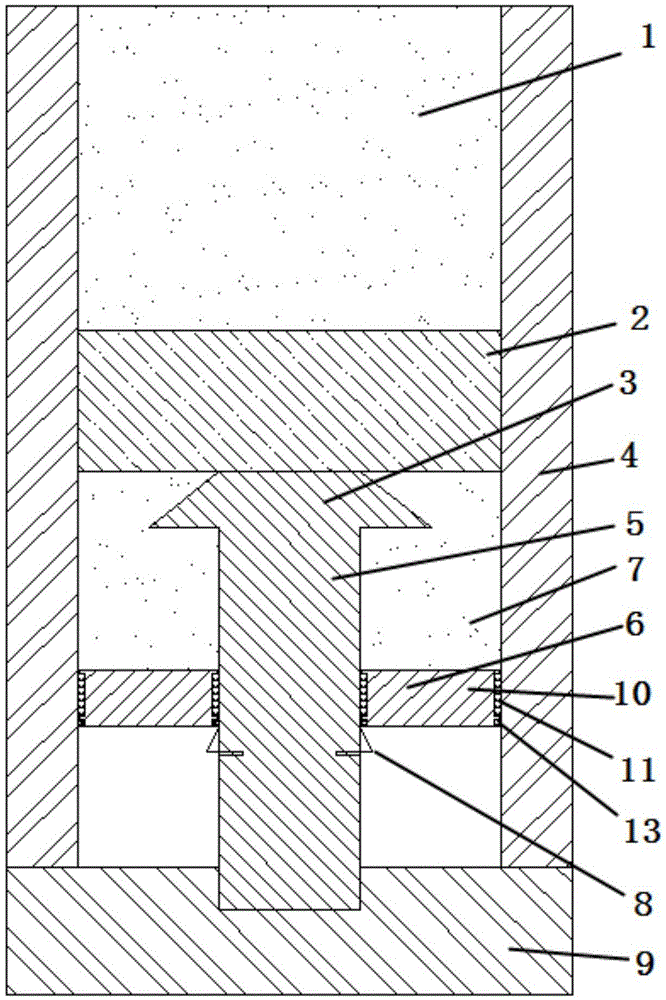

Ceramic production equipment and production process thereof

PendingCN114131752AImprove toughnessAvoid breakingCeramic shaping apparatusClay processing apparatusCeramicRaw material

The invention belongs to the field of ceramic production, and particularly relates to ceramic production equipment and a production process thereof.The ceramic production equipment is adopted for being matched for completion, the ceramic production equipment comprises a processing box, and a feeding part is arranged at the upper end in the processing box and used for discharging and cleaning raw materials; a crushing part is arranged below the feeding part to crush, filter and screen raw materials, an extrusion exhaust part is arranged below the crushing part to extrude ceramic clay to increase toughness and exhaust air in the ceramic clay, and a forming part is arranged below the extrusion exhaust part to conduct external shaping and internal shaping on the ceramic clay. And a conveying part is arranged above the forming part and used for conveying the ceramics out of the processing box for natural air drying. Raw materials can be crushed, filtered and screened for multiple times, clay can be extruded and vibrated for multiple times, air is discharged, the toughness of the clay can be improved, and ceramic is prevented from being broken.

Owner:王顺华

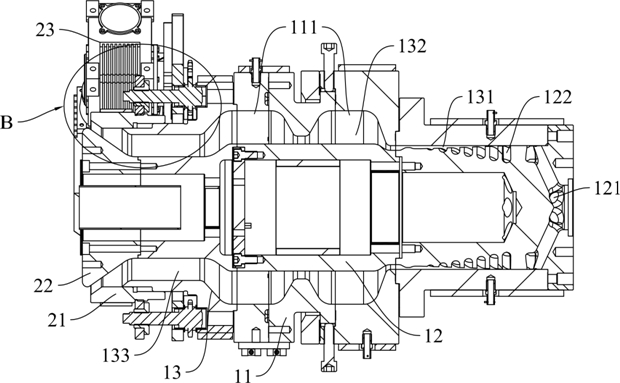

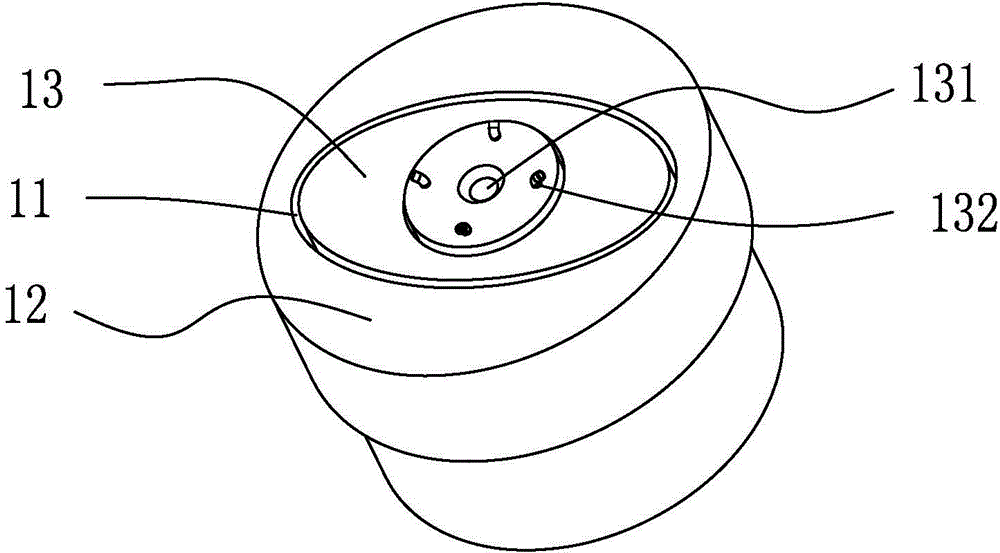

A device for hydrostatically extruding hollow profiles with mold cores and movable core supports

InactiveCN104511514BImprove the state of stressIncrease stiffnessStressed stateUltimate tensile strength

The invention discloses a hydrostatic extrusion hollow profile device with a movable core support for a die core. The hydrostatic extrusion hollow profile device comprises an extrusion barrel, the die core, an extrusion barrel base, the movable core support and a limiting element, wherein the extrusion barrel base is arranged at one end of the extrusion barrel; the die core is arranged in the extrusion barrel; the root part of the die core is fixed in the center of the extrusion barrel base; the limiting element is arranged on the side wall of the die core; the movable core support sleeves the outer wall of the die core in a supporting manner and is positioned above the limiting element, so as to support the core support and limit the motion of the core support; the inner wall of the movable core support slides along the side wall of the die core; the outer wall of the movable core support slides along the inner wall of the extrusion barrel. The hydrostatic extrusion hollow profile device has the advantages that the movable core support is additionally arranged on the die core, so that the stress state of the die core is improved, the rigidity of the die core is enhanced, and the intensity of the die core is improved.

Owner:NANJING UNIV OF SCI & TECH

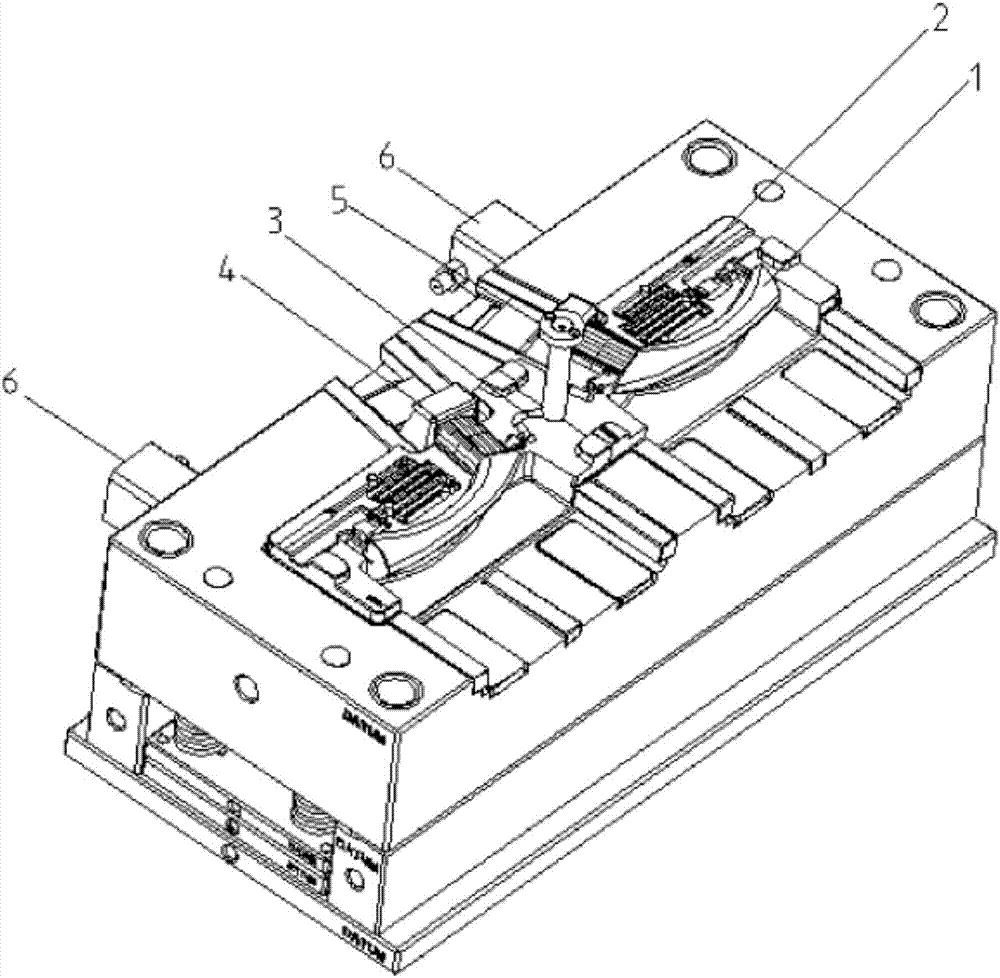

Automobile interior front door handle rear firing method gas-assisted injection mold

InactiveCN107042609ASolve the problem of defects caused by uneven wall thicknessLow costDomestic articlesInjection productEngineering

The invention discloses a rear-shot gas-assisted injection molding mold for a front door handle of an automobile interior, which comprises a mold cavity with a material inlet at one end and a material outlet at the other end, and an air blower for blowing air into the cavity device, the bottom of the cavity is provided with an air inlet, and the air inlet is connected with the blowing device. The mold adopts the design of back-shot gas-assisted injection molding. After the cavity of the product is completely filled, the gas is injected to remove the excess material in the cavity to the overflow tank; the whole process of first injection and then gas injection A slider is required to be closed to control the filling of the molten material in the overflow tank, and the closing process of the slider needs to be completed when the mold is closed, and the work of controlling the slider is completed by a self-locking cylinder. The gas-assisted molding mold sets the air inlet at the bottom of the cavity, which can prevent the material from accumulating at the bottom of the cavity due to the gravity of the material itself, resulting in uneven wall thickness of the injection molded product. The gas-assisted molding mold can prepare wall thickness Uniform injection molded products.

Owner:LIUZHOU TONGWEI MACHINERY

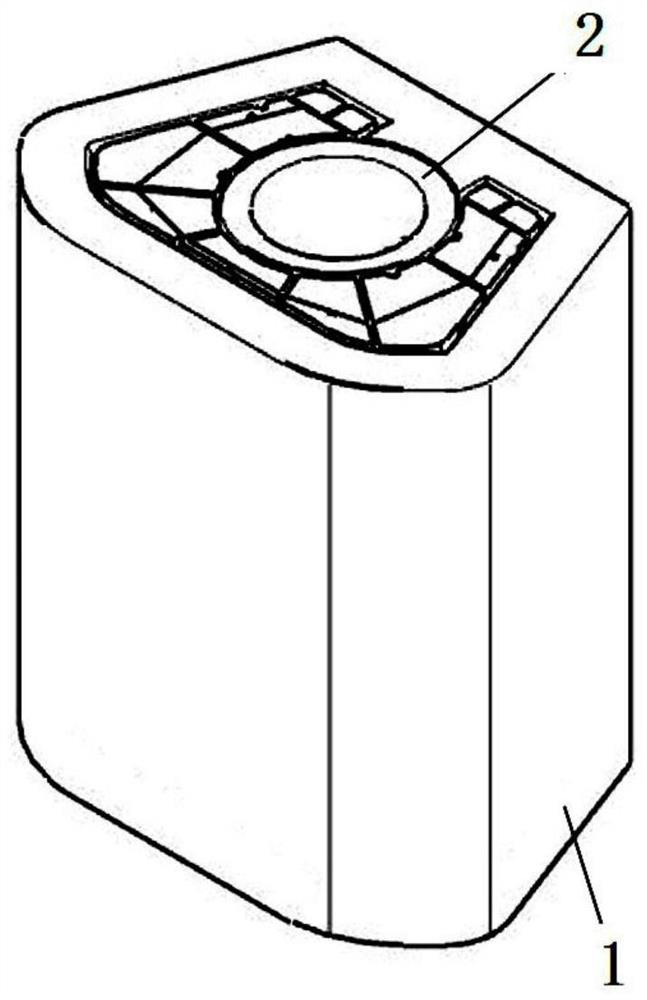

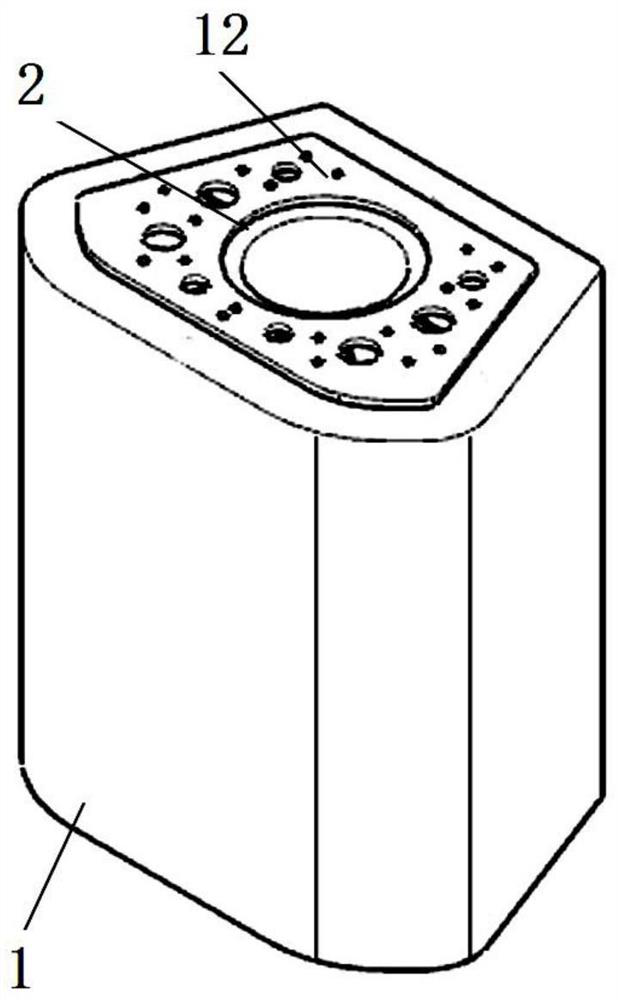

Washing machine handle injection mold

PendingCN112743777AAvoid uneven wall thicknessReasonable structureDomestic articlesLaundry washing machineProcess engineering

The invention relates to a washing machine handle injection mold which comprises an upper mold body and a lower mold body. The lower mold body is provided with a first sliding block, a second sliding block and a first limiting block; the upper surface of the head of the first sliding block is an inclined surface; the lower surface of the second sliding block is an inclined surface matched with the upper surface; a limiting groove is formed in one end of the upper surface of the second sliding block; the other end of the upper surface is an arc-shaped surface matched with the lower surface of a washing machine handle; and the first limiting block is clamped in the limiting groove in the mold closing state, and horizontal limiting of the second sliding block is achieved. Compared with the prior art, according to the washing machine handle injection mold provided by the invention, one-time injection molding of a washing machine handle product is achieved through a two-time sliding block mold structure, so that the structure is reasonable, flexible and safe; and the problem that the wall thickness of the washing machine handle product is not uniform can be solved through the two-time sliding block mold in the technical scheme, so that the appearance of the product is not subjected to shrinkage printing, the appearance shape and size are not changed, the production efficiency and the yield are remarkably improved, and the product quality is further improved.

Owner:SHANGHAI YONGXING PLASTICS

Quick-cooling extrusion blowing device of polypropylene combined cover for plastic infusion container

The invention discloses a fast-cooling extrusion blowing device of a polypropylene combined cover for a plastic infusion container. The fast-cooling extrusion blowing device comprises a working table, and the top surface of the working table is fixedly connected with a lower box body. The push rod structure is arranged at the piston, the spring is arranged in the push rod structure, when the piston is pushed for extrusion blowing, if the air pressure is large and the piston resistance is large, the contraction degree of the spring can be increased, the piston pushing speed is reduced, and then the air extrusion speed is adjusted according to the air pressure, and the air extrusion air pressure is balanced; meanwhile, a cooling cover is arranged, a finished product can be rapidly cooled through the cooling cover, then demolding is conducted, the product is put into water for secondary cooling, and the situation that the finished product deforms before demolding can be avoided; and when the extrusion blowing assembly needs to be maintained subsequently, the extrusion blowing assembly can be taken out only by opening the upper box body, so that the extrusion blowing assembly is convenient to maintain.

Owner:安徽创扬双鹤药用包装有限公司

Hydrostatic extrusion hollow profile device with movable core support for die core

InactiveCN104511514AImprove the state of stressIncrease stiffnessStressed stateUltimate tensile strength

The invention discloses a hydrostatic extrusion hollow profile device with a movable core support for a die core. The hydrostatic extrusion hollow profile device comprises an extrusion barrel, the die core, an extrusion barrel base, the movable core support and a limiting element, wherein the extrusion barrel base is arranged at one end of the extrusion barrel; the die core is arranged in the extrusion barrel; the root part of the die core is fixed in the center of the extrusion barrel base; the limiting element is arranged on the side wall of the die core; the movable core support sleeves the outer wall of the die core in a supporting manner and is positioned above the limiting element, so as to support the core support and limit the motion of the core support; the inner wall of the movable core support slides along the side wall of the die core; the outer wall of the movable core support slides along the inner wall of the extrusion barrel. The hydrostatic extrusion hollow profile device has the advantages that the movable core support is additionally arranged on the die core, so that the stress state of the die core is improved, the rigidity of the die core is enhanced, and the intensity of the die core is improved.

Owner:NANJING UNIV OF SCI & TECH

Precise scribing method for thin-wall special-shaped casting cabin

ActiveCN104070513BHigh marking accuracyUniform wall thicknessOther workshop equipmentPoint cloudData acquisition

The invention relates to a method for precision lineation of a thin-wall special-shaped cast cabin. A rough lineation mode of marking out outline processing molded surface lines based on the outline rough standard, a data collection mode of using a laser measuring machine to scan inner cavity molded surface, a mode of establishing a workpiece coordinate system according to inner cavity point cloud and a mode of accurately adjusting the outline processing molded surface lines are adopted. Machinability of parts can be pre-judged, wall thickness uniformity in the processing process is guaranteed, thin points do not occur, lineation precision of the thin-wall special-shaped cast cabin is improved, the problem of wall thickness unevenness is effectively solved, the product pass rate is improved, and the method can generate very large economic benefits when applied to actual production and is very high in application prospect.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

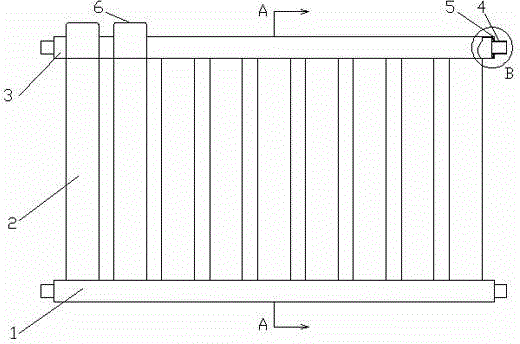

Double-column radiator and manufacturing method thereof

ActiveCN104896570AImprove cooling effectCoordinated and beautiful appearanceLighting and heating apparatusSpace heating and ventilation detailsEngineeringWelding

The invention discloses a double-column radiator and a manufacturing method thereof. The double-column radiator of the invention comprises a lower beam, an upper beam and radiating pipes, wherein the upper beam and the lower beam have the same structure, and each of the upper beam and the lower beam comprises an upper cover and a bottom plate; the upper covers and the bottom plates are welded together through two abreast radiating pipes; connecting water nozzles are arranged on two ends of the upper beam and the lower beam, and are fixedly connected with the upper beam and the lower beam through nozzle sealing plates. The double-column radiator has no weak points in lateral connection and has high strength; when mounting, a colorful cap is mounted on the upper beam, so that the radiating effect of the radiator is improved and the integral appearance is more coordinated and attractive; when manufacturing, the welding position is flat edge welding, so as to omit the polishing process, reduce the welding difficulty, shorten the production process, reduce the labor intensity of workers, ensure the welding quality and improve the yield.

Owner:圣劳伦斯(唐山)金属制品有限公司

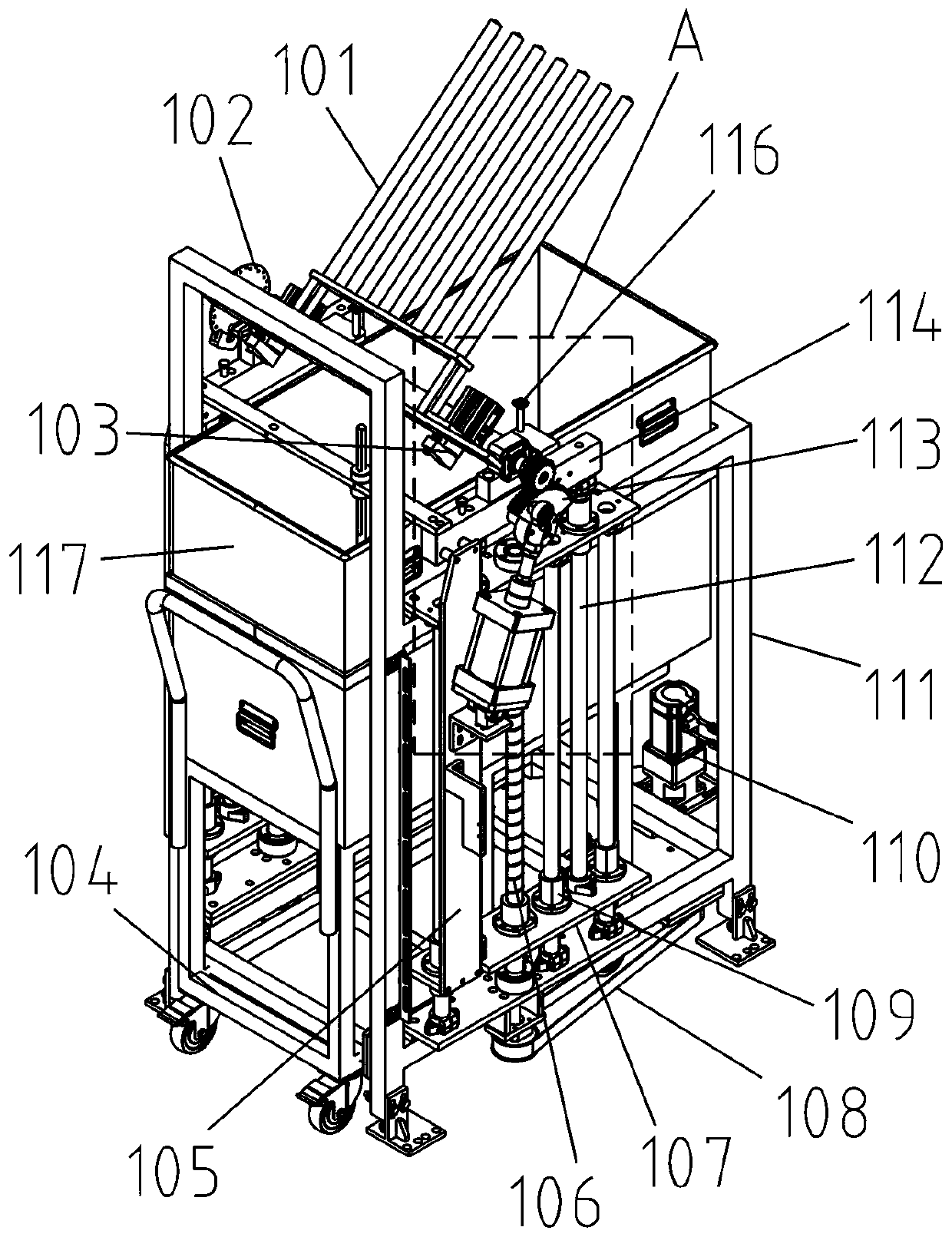

A concrete grouting device for reinforced cages for buildings

ActiveCN113134902BAdd evenlyAvoid accumulationShaping reinforcementsFeeding arrangmentsArchitectural engineeringSprocket

The invention discloses a concrete grouting device for steel cages used in buildings, which relates to the technical field of building construction, and solves the problem that the existing prefabricated parts generally only use one grouting pipe to grout the steel cages during the processing process, the grouting speed is slow, and the grouting is performed at the same time. Local mortar accumulation is easy to occur in the process, which affects the prefabrication effect, including the grouting main body; the grouting driving part is fixedly installed on the right side of the grouting main body; the grouting transmission component is installed on the right side of the grouting main body, and the The grouting transmission assembly is composed of a filling sprocket, a filling transmission chain, and a filling lever, wherein one set of the filling sprocket is coaxially and fixedly connected with the rotating shaft of the grouting driving part. The invention has a fast feeding speed and improves feeding efficiency. At the same time, it realizes reciprocating sliding grouting feeding, effectively prevents material accumulation, and ensures uniform grouting. At the same time, the material distribution part and scraper plate further avoid effectively avoiding mortar accumulation and prevent the wall thickness of the prefabricated part. uneven problem.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

Protective cover automatic dipping roll over machine and protective cover production line

The invention discloses a protective cover automatic dipping roll over machine and a protective cover production line. The protective cover automatic dipping roll over machine is characterized in thatvertical lead screws connected to two sides of a bracket are driven to rotate by a motor in order to drive a top plate to rise and fall, so that the automatic dipping action of a mold placed on the top plate is realized. Then, a driving wheel is driven to swing through a first cylinder in order to drive a transmission wheel to rotate, and a rotating shaft and a mold frame fixed to the rotating shaft are driven to rotate, thereby realizing rollover of the dipped mold fixed to the mold frame, making the surface of a product uniform, avoiding the formation of lacrimal points, achieving high automation degree, improving the production efficiency, and lowering the labor intensity. A braking structure is arranged at one end of a rollover mechanism, so that the control of the rollover angle is realized, and the situation of throwing of a material on the mold by inertia due to sudden collision or non-uniform wall thickness of the protective cover is avoided.

Owner:佛山市方普防护技术有限公司

Die cavity structure, die design method, blowing method and blowing control system

PendingCN114834022AUniform wall thicknessAvoid uneven wall thicknessDomestic articlesHollow articlesControl systemEngineering

The invention discloses a mold cavity structure, a mold design method, a blowing method and a blowing control system, and belongs to the technical field of blowing forming, the mold cavity structure comprises a mold cavity half mold and at least one first insert which are combined to form a mold cavity main body, and the mold cavity half mold is provided with a first forming surface for at least limiting part of the main body shape of a container; the first insert is provided with a second forming surface for at least limiting part of the main body shape of the container, the first insert is at least provided with a first position for initially stretching into the mold cavity main body and a second position for limiting part of the main body shape by the second forming surface after the first insert retracts, and the first insert can be suitable for blowing forming of the container with an irregular shape; and the device is also suitable for blowing forming of specific containers.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com