Device for high temperature solid power medium assisting titanium alloy plate superplasticity drawing and bulging integration and method thereof

A high-temperature solid, titanium alloy technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of uneven wall thickness of parts and parts that cannot be used, and achieve simple structure, no need for sealed space, and production cycle. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

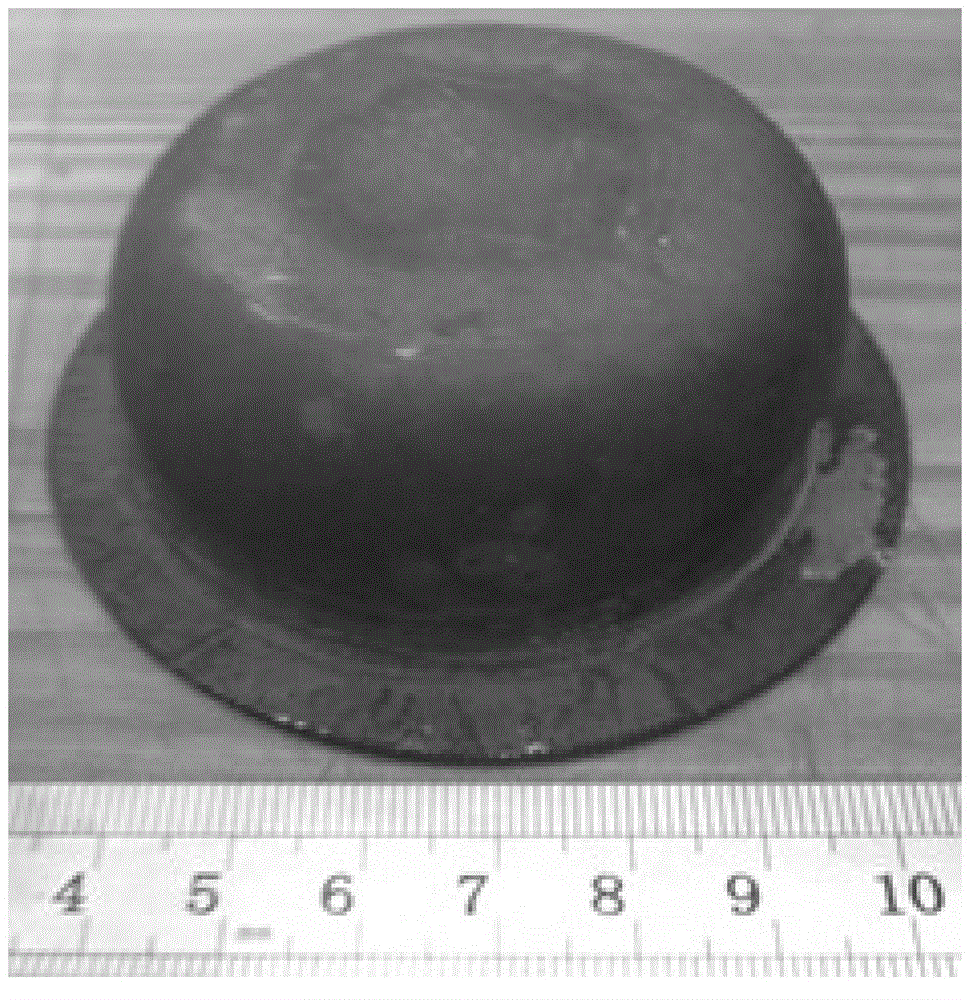

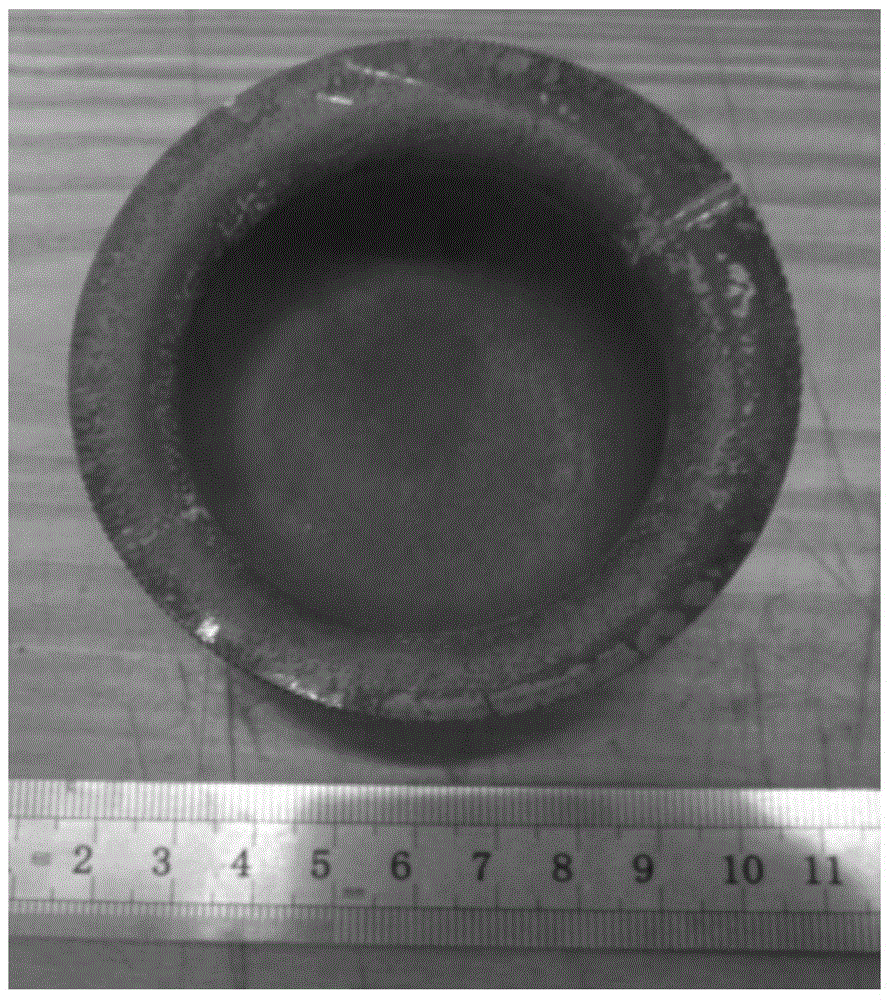

Examples

specific Embodiment approach 1

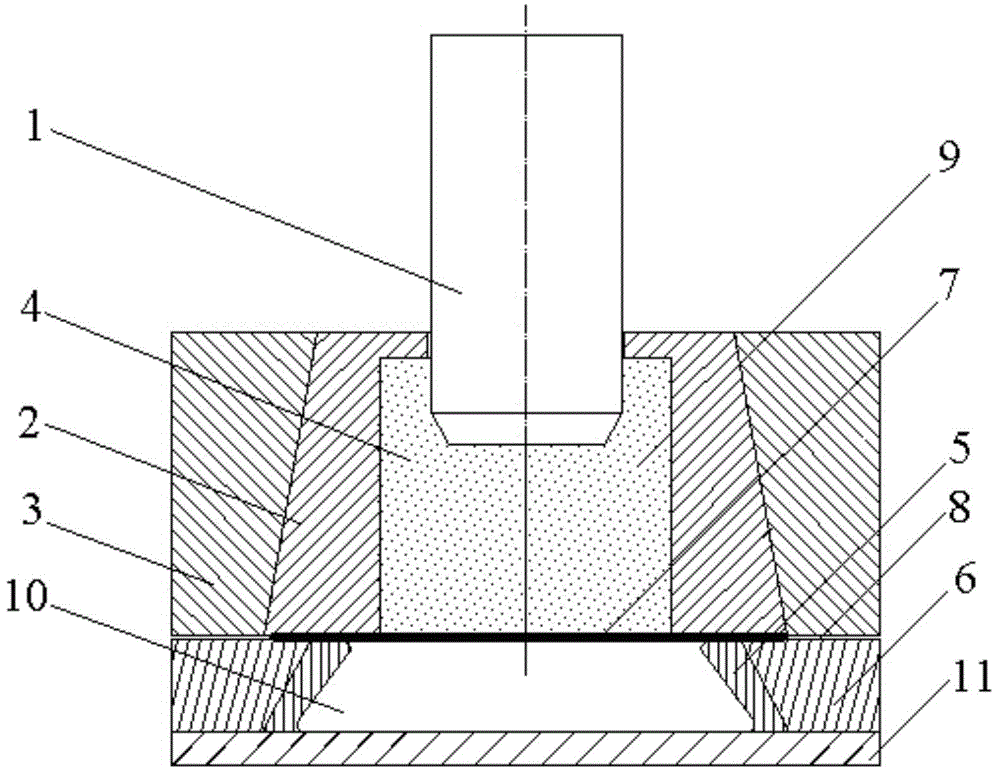

[0024] Specific Embodiment 1: This embodiment is a high-temperature solid powder medium-assisted superplastic drawing and bulging integration device for titanium alloy plates, including a punch 1, an upper mold part 2, an upper mold cover 3, a lower mold part 5, Lower die set 6, gasket 8, upper die cavity 9, lower membrane cavity 10 and pad 11;

[0025] The inside of the upper die part 2 is provided with an upper die cavity 9; the lower end of the punch 1 is arranged in the upper die cavity 9, and the outer part of the upper die part 2 is provided with an upper die cover 3; the lower die part 5 and the lower die cover 6 It is arranged on the cushion block 11, and the lower mold cover 6 is arranged outside the lower mold part 5; the lower mold part 5 is provided with a lower membrane cavity 10, and a gasket 8 is provided between the upper die cover 3 and the lower die cover 6.

[0026] figure 1 It is a structural schematic diagram of a high-temperature solid powder medium assi...

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the lower end of the punch 1 is in the shape of a truncated cone, and the diameter of the small end of the truncated cone is 2 / 3 of the diameter of the large end of the truncated cone. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the small diameter of the upper mold part 2 is 2 mm larger than the large diameter of the lower frustum of the punch 1 . Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com