Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Increase ultimate load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

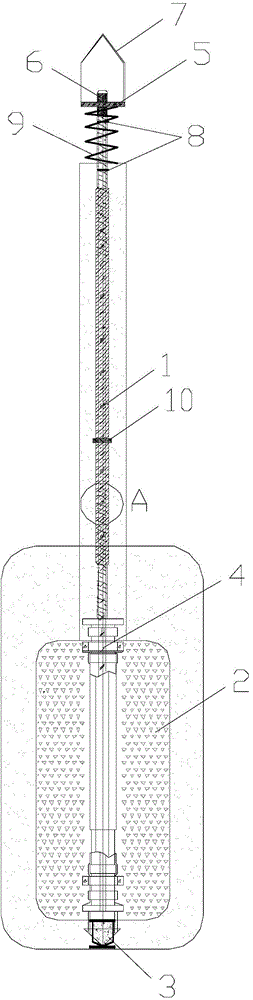

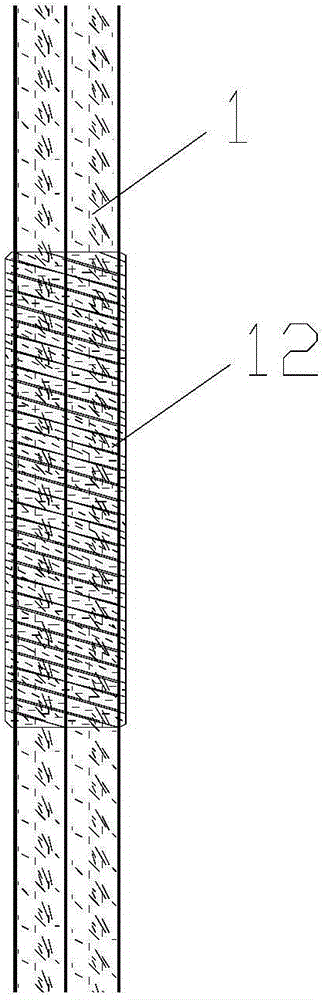

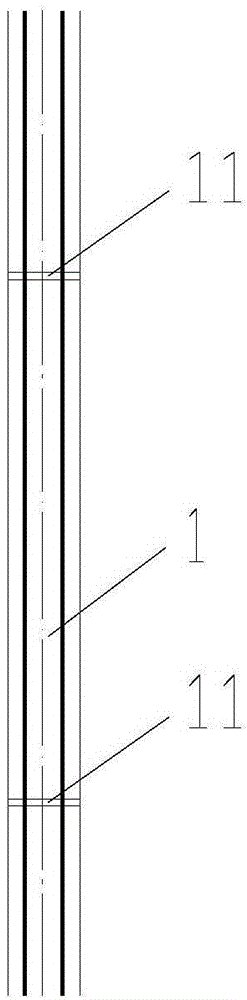

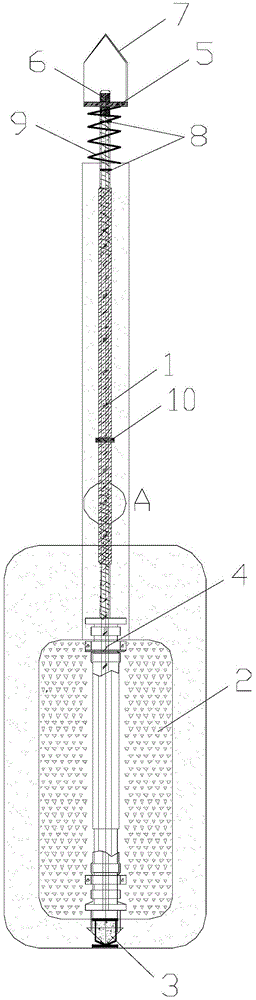

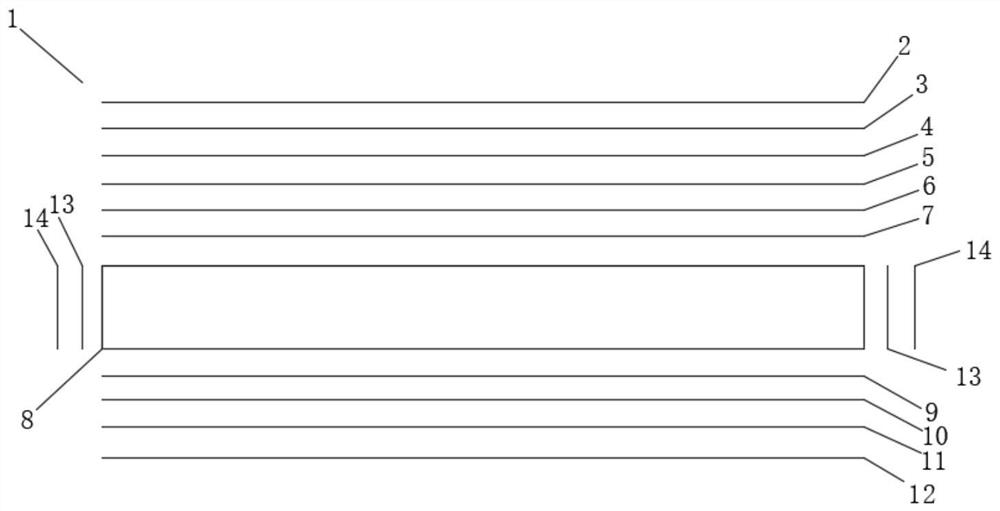

Expanded head capsule type anchor rod and construction method thereof

The invention discloses an expanded head capsule type anchor rod. The anchor rod comprises a finish rolled threaded reinforcing bar, a capsule type squeezing and expansion body and a bushing, wherein the finish rolled threaded reinforcing bar extends into the capsule type squeezing and expansion body; a grouting material seal bottom is arranged at the bottom in the capsule type squeezing and expansion body; a stop-grouting plug is arranged at an inlet of the capsule type squeezing and expansion body; a backing plate fixedly sleeves the upper part of the finish rolled threaded reinforcing bar; a pre-stressed nut sleeves the finish rolled threaded reinforcing bar; a conical iron hat with a reserved hole is fixedly arranged on the top surface of the backing plate and covers the finish rolled threaded reinforcing bar sleeved by the pre-stressed nut. The invention also discloses a construction method of the expanded head capsule type anchor rod. The method comprises the following steps: drilling and forming a hole; performing high-pressure rotary spray grouting to perform expanding construction; placing the expanded head capsule type anchor rod; grouting cement mortar into a pocket; supplementing the mortar; tensioning and locking. The expanded head capsule type anchor rod and the construction method have the beneficial effect that the conventional anchor rod which is widely used at present can be partially substituted at wider areas and in engineering projects.

Owner:ANHUI TONGJI CONSTR GRP

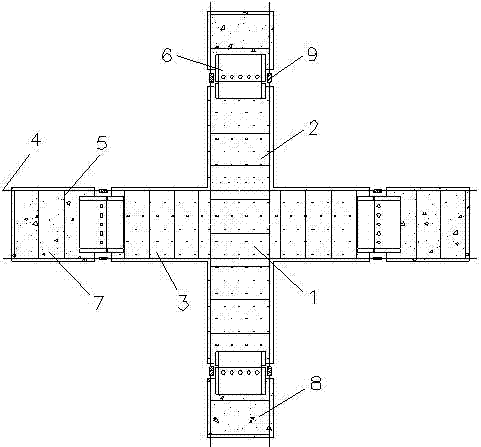

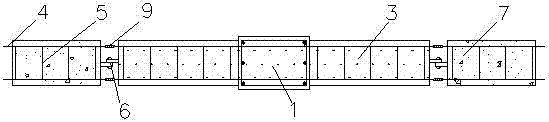

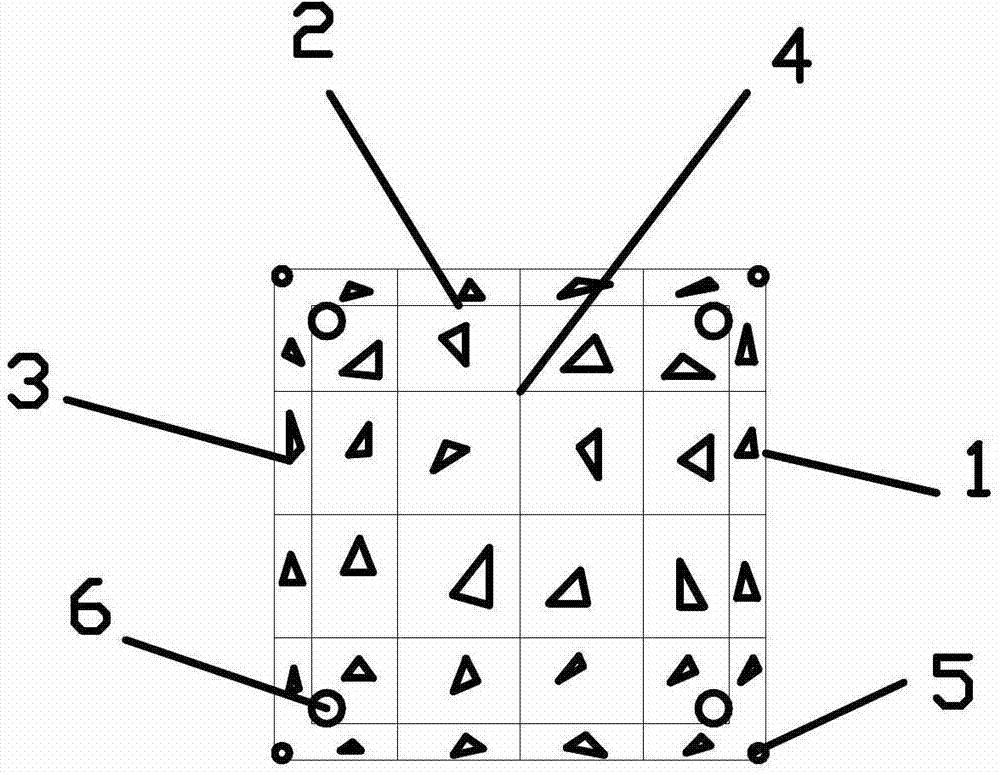

Prefabricated ECC-RC combination beam column joint component

InactiveCN103774754AReduce construction difficultyReduce labor costsClimate change adaptationBuilding constructionsJoint componentResidual deformation

The invention provides a prefabricated ECC-RC combination beam column joint component, wherein ECC refers to engineered cementitious composites, and RC refers to reinforced concrete. The prefabricated ECC-RC combination beam column joint component comprises a joint, an outward-extending column and an outward-extending beam, wherein the joint, the outward-extending beam and the outward-extending column are respectively composed of an ECC material, longitudinal bars and stirrups, the outward-extending length of the outward-extending column is about 1-2 times of the height of the column section, the outward-extending length of the outward-extending beam is about 1-2 times of the height of the beam section, H-shaped steel is embedded in the end of the outward-extending beam and the end of the outward-extending column, the embedded depth ranges from 10 cm to 20 cm, the H-shaped steel and the longitudinal bars extend out of the ends for 10-20 cm, the embedded part of the H-shaped steel is welded to the longitudinal bars, the embedded H-shaped steel of a prefabricated RC beam, the embedded H-shaped steel of a prefabricated RC column and the embedded H-shaped steel of the prefabricated ECC joint are connected through high-strength bolts, and the longitudinal bars are connected through a straight thread sleeve. According to the prefabricated ECC-RC combination beam column joint component, the prefabricated beam column joint component formed by pouring the steel bar reinforced ECC material is applied to an assembly type frame structure, compared with a general reinforced concrete joint component, the ductility and the anti-seismic property of the structure are improved remarkably, the number of joint stirrups in use is reduced substantially, pouring is facilitated, and construction is convenient; besides, the high tenacity of the ECC material can reduce residual deformation of the structure after an earthquake, and therefore post-earthquake repair expenses are reduced.

Owner:TONGJI UNIV

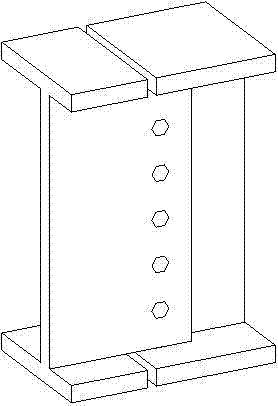

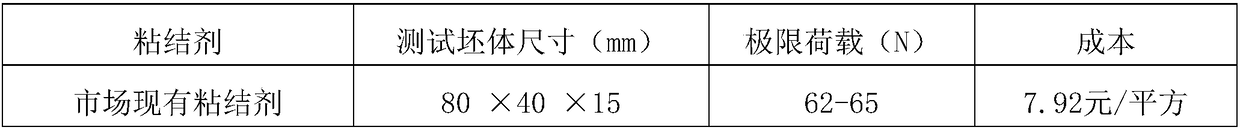

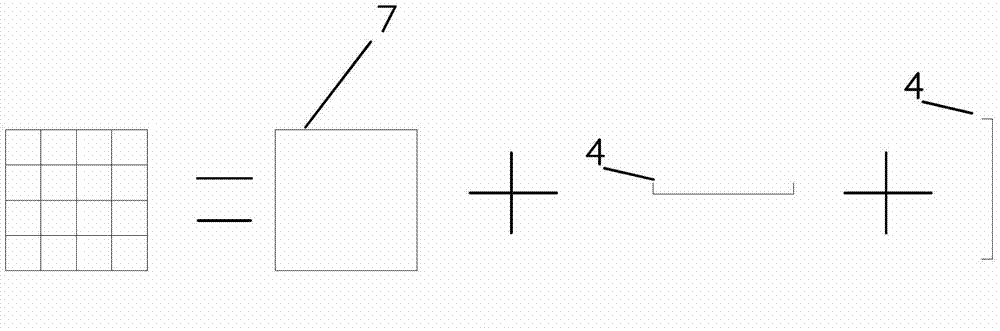

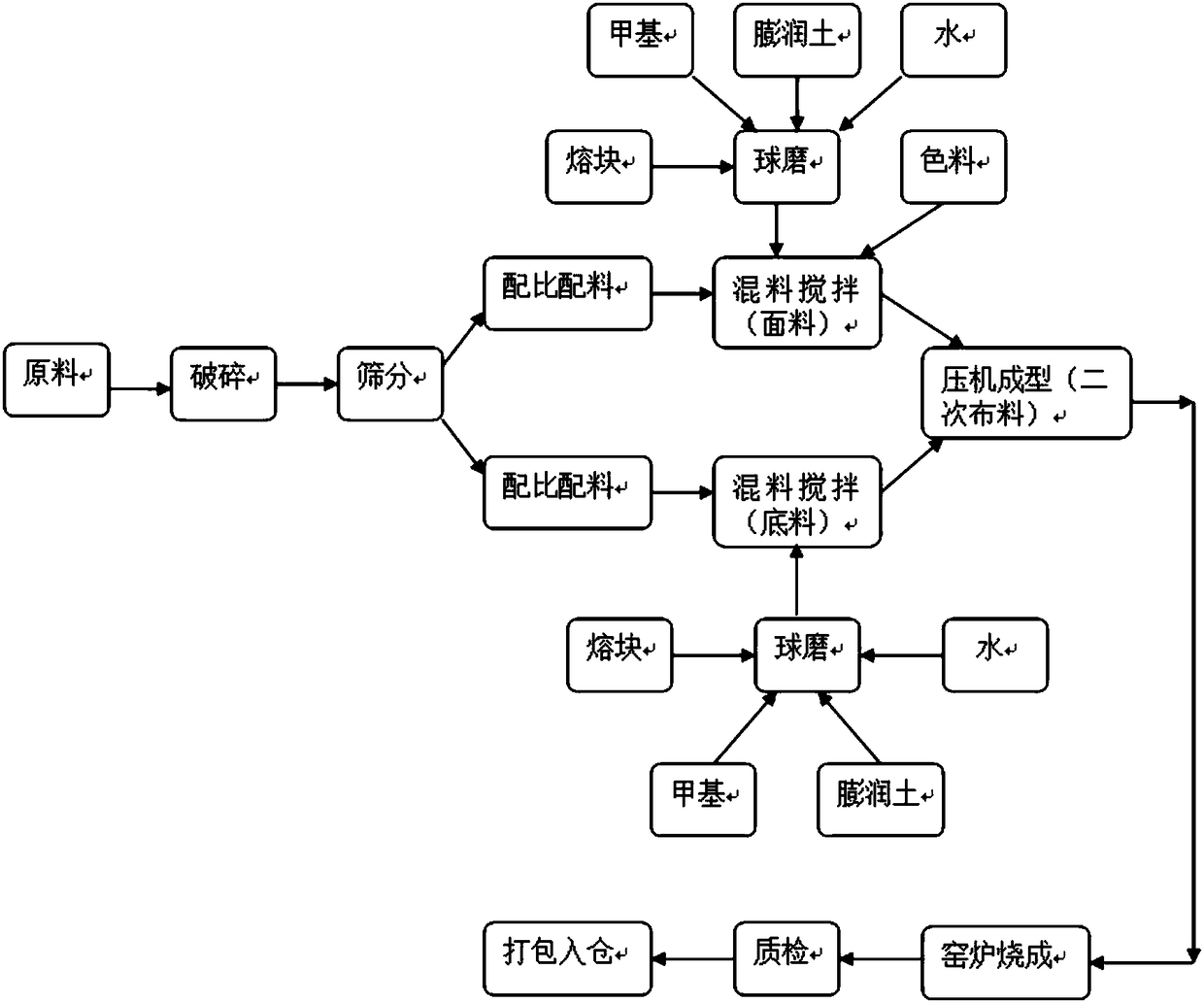

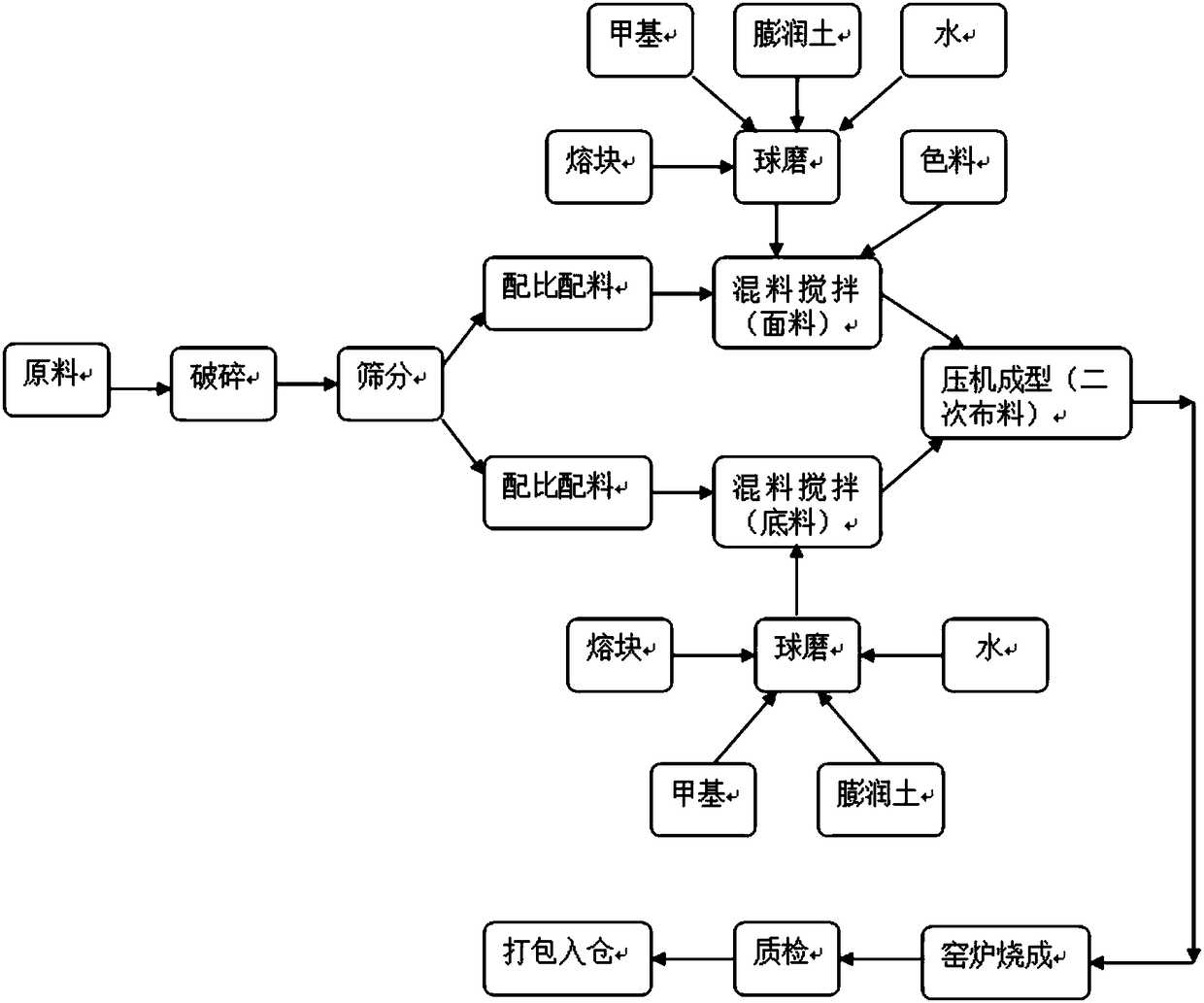

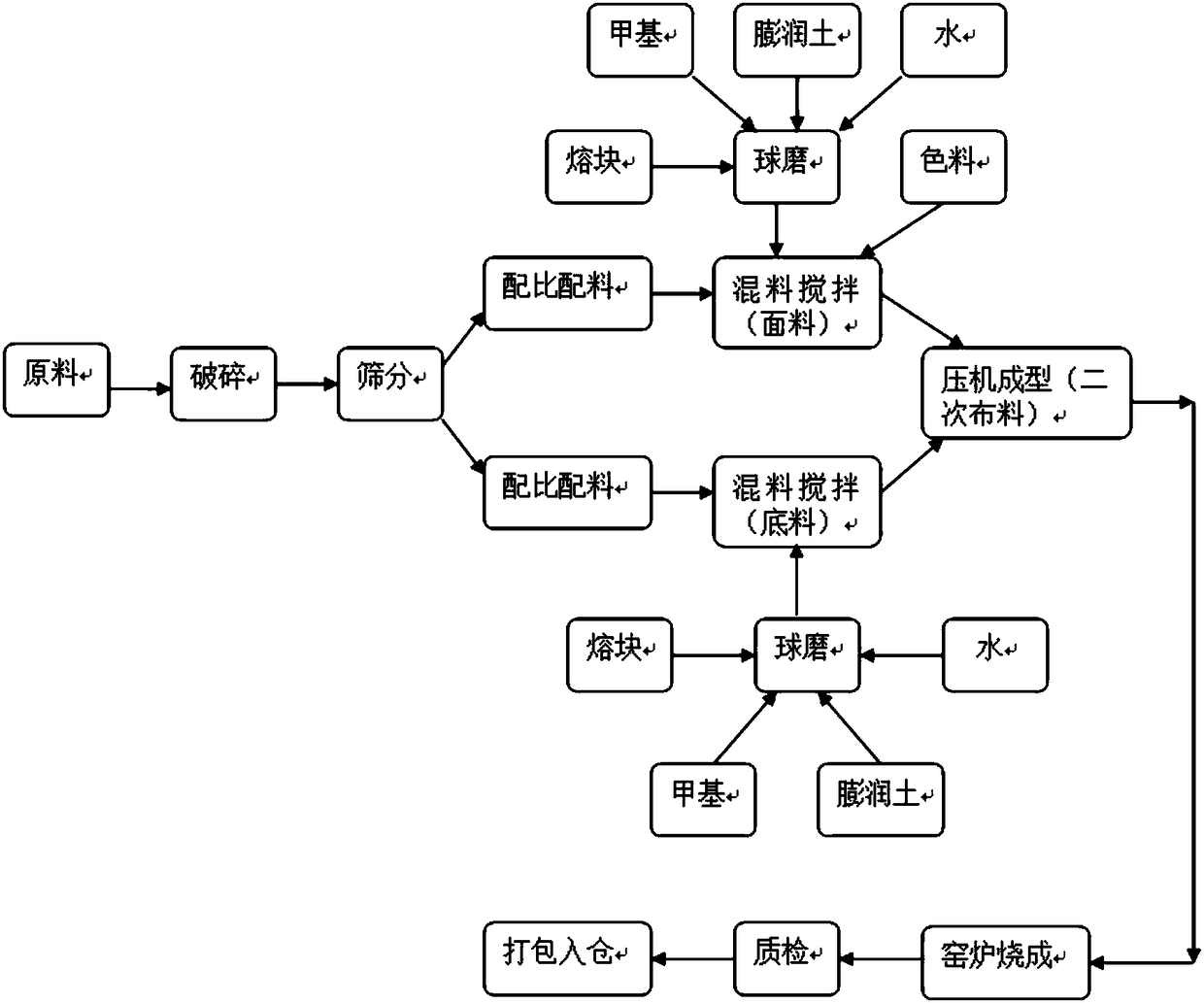

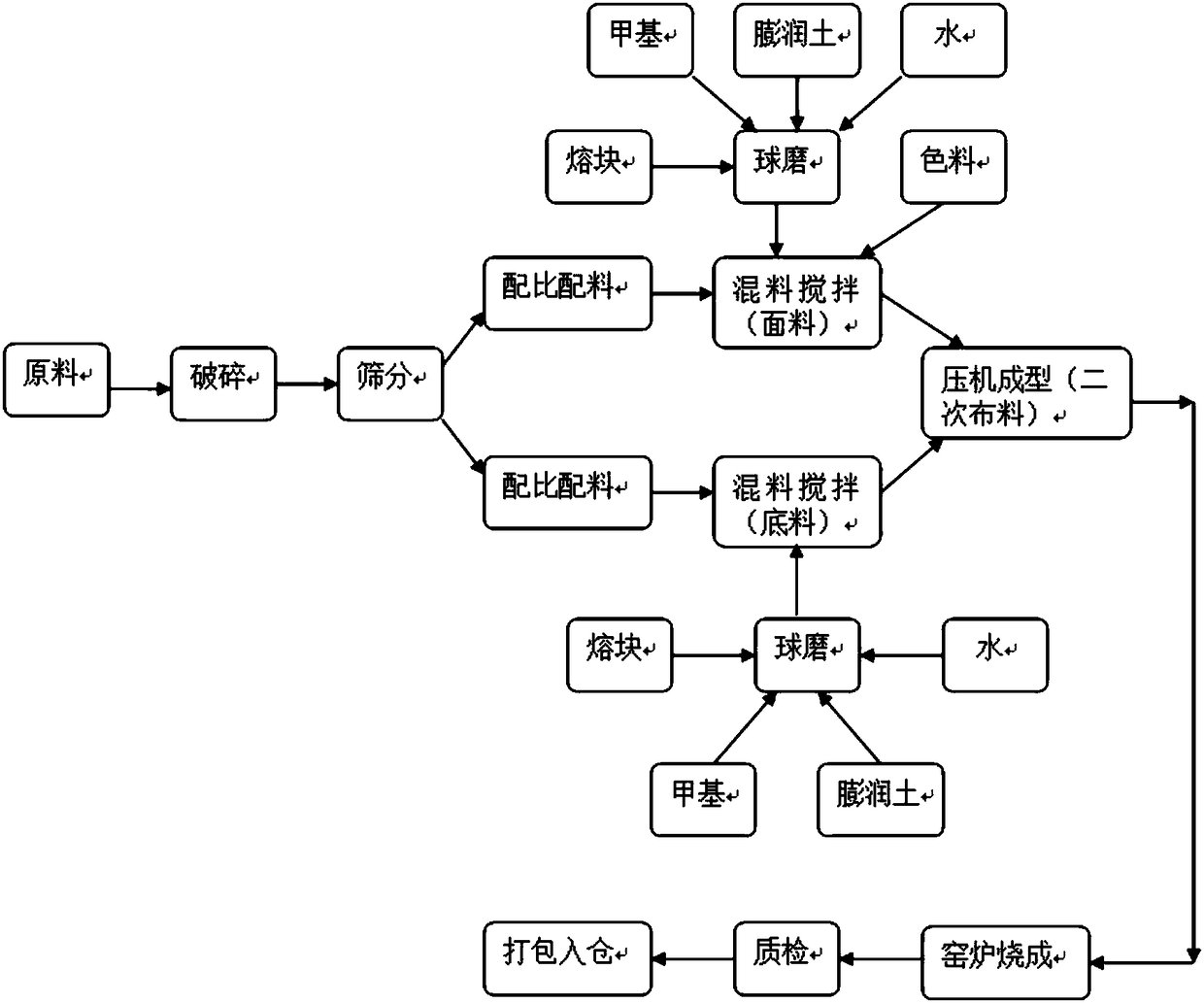

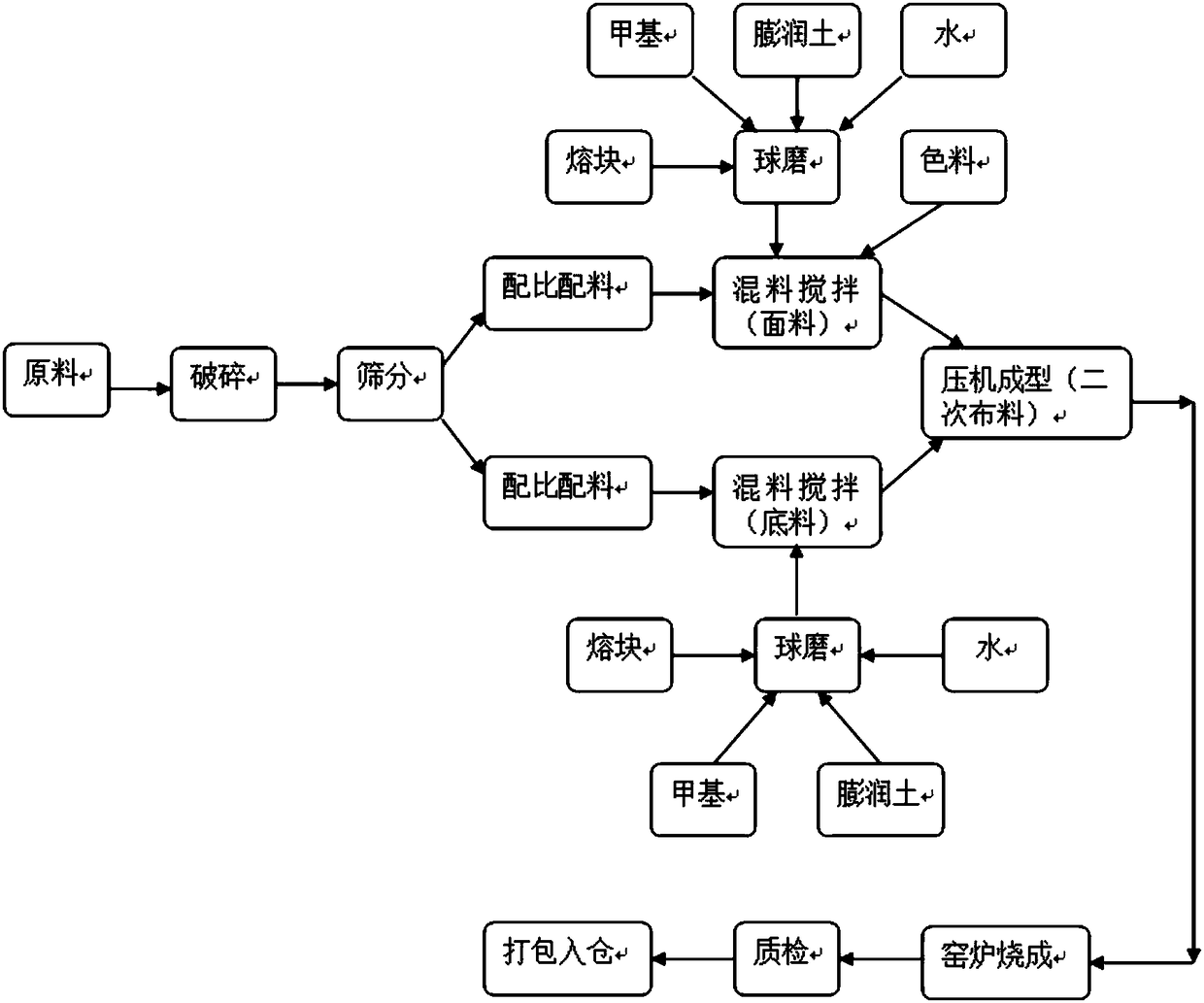

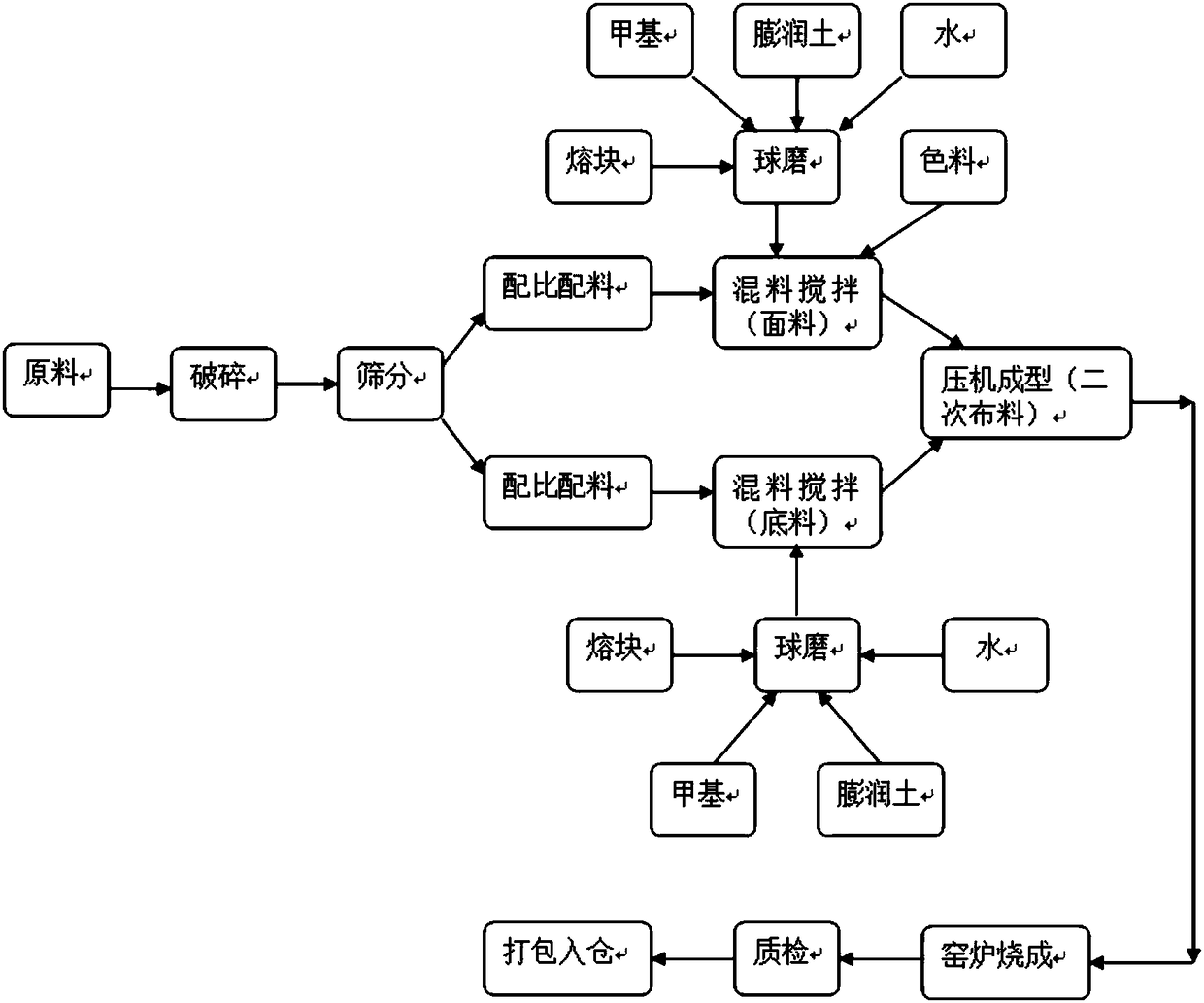

Preparation method of water permeable brick

ActiveCN108083767AGood water permeabilityStrong frost resistanceCeramic materials productionCeramicwarePore diameterSieve

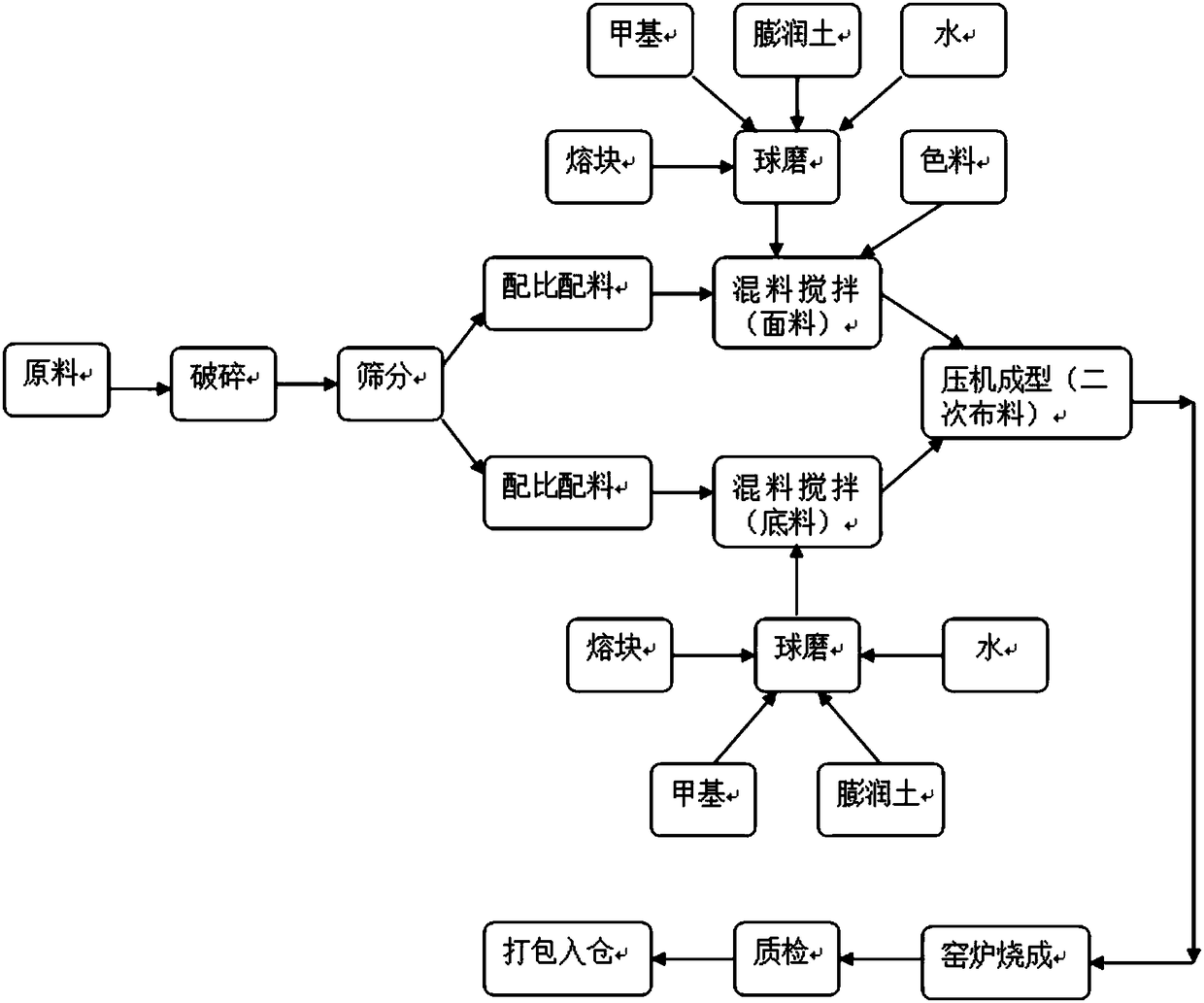

The invention discloses a preparation method of a water permeable brick. The preparation method comprises the steps: (1) crushing aggregates; (2) sieving the crushed aggregates by using sieves with different pore diameters to obtain particles with different particle sizes; (3) proportioning the sieved aggregate particles according to a bottom material formula, adding a bonding agent, and carryingout uniform stirring to obtain a bottom material mixture; proportioning the sieved aggregate particles according to a surface material formula, and adding a bonding agent and pigment to obtain a surface material mixture, wherein the bonding agent comprises a bonding base material and liquid glue; (4) respectively mixing and stirring the bottom material mixture and the surface material mixture; (5)distributing the stirred surface material mixture and bottom material mixture twice, and carrying out compression molding to obtain a green body; and (6) firing the green body in a kiln to obtain a finished product. The water permeable brick prepared by using the preparation method is high in strength, strong in freezing resistance and excellent in water permeability; and the preparation method is few and simple in process and capable of reducing the cost.

Owner:KEDA INDUSTRIAL GROUP CO LTD

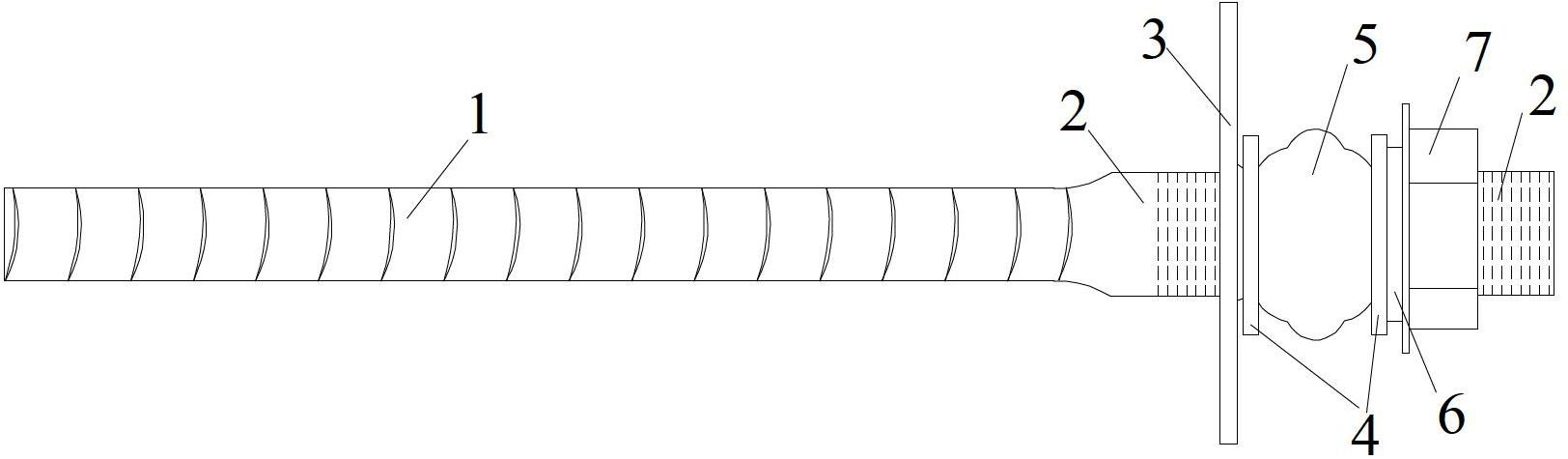

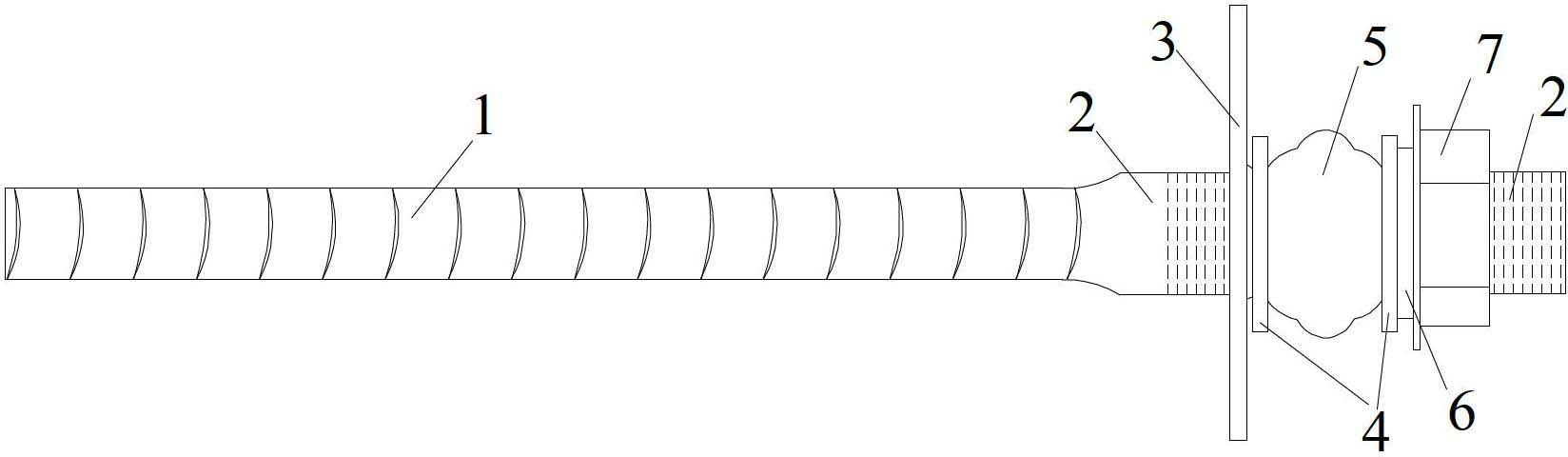

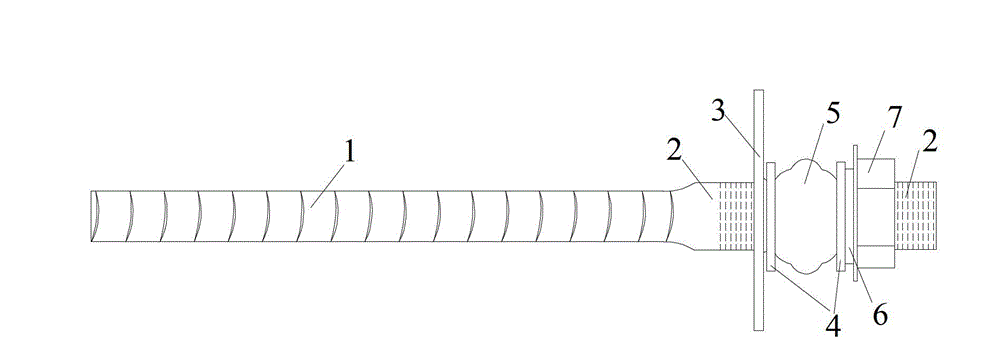

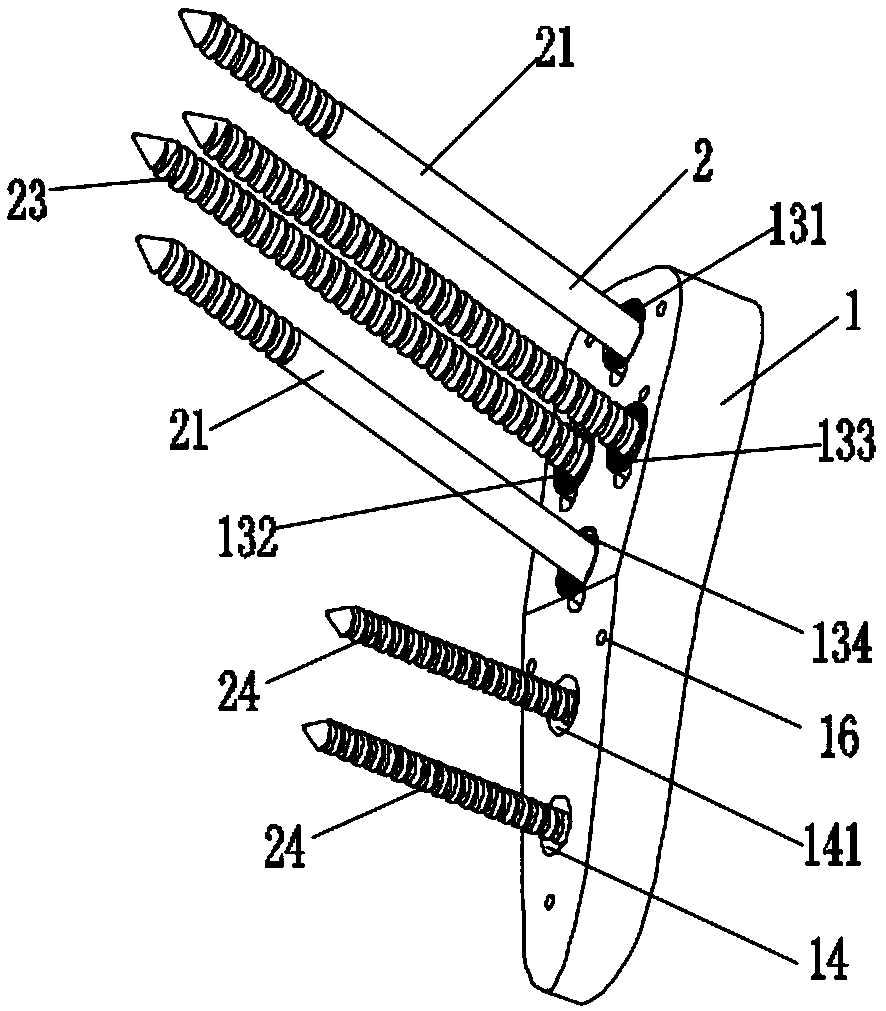

High-strength metal pressure-yielding anchor rod with headed tail

A high-strength metal pressure-yielding anchor rod with a headed tail comprises a rod body, a tray, a pressure-yielding pipe and a nut. The rod body is integrally formed by high-strength cylindrical threaded steel and comprises a head, a body and a tail. The tail is subjected to heading and thread rolling, and the surface thereof is provided with a thread in the diameter 4-5mm larger than that of the rod body. After being headed and subjected to thread rolling, the tail is subjected to high-temperature thermal treatment, so that the strength of the tail is higher than that of the rod body. The tray, the pressure-yielding pipe and the nut are sequentially sleeved on the tail, the length of the pressure-yielding pipe ranges from 30mm to 40mm, a rigidity washer is arranged between the tray and the pressure-yielding pipe, and another washer and a resin washer are arranged between the nut and the pressure-yielding pipe.

Owner:SHANDONG UNIV OF SCI & TECH

Method for changing old simple supported beam bridge into continuous beam bridge

InactiveCN101298757AReduce stiffnessReduce in quantityBridge erection/assemblyBridge strengtheningRebarContinuous beam

The invention relates to a method for converting an old and simple supported girder bridge into a continuous girder bridge. The method includes the following steps: 1. the concrete of bridge faceplate in a required connecting scope of the old and simple supported girder is removed; 2. dental plates are arranged on removed zones of reinforced concrete T girders and are positioned on two sides of ventral shields, and metal corrugated pipes are pre-embedded in the dental plates; 3. stranded wires are threaded through the metal corrugated pipes and one end of the stranded wire is anchored and the other end is adopted as a tensioning end, and the quantity of bundles of the stranded wire is defined according to a pre-set pre-stress; 4. ends of T girders to be connected are widened and a diaphragm plate is arranged in a gap between T girders to be connected, and the connecting ends and bridge faceplate concrete are cast respectively; 5. after the newly-cast concrete reaches the designed tension strength, the stranded wires are stretched and anchored, and the pre-stress is transmitted to a hogging moment zone of the reinforced concrete I-beam girder through both new and old concretes. The method of the invention converts the old and simple supported girder bridge into the continuous girder bridge by bringing pre-stress to the hogging moment zone, which leads the old and simple supported concrete girders to be used continuously by enhancing the bearing capability and rigidity of the old concrete girders.

Owner:SOUTHEAST UNIV

Frame-supporting column with high strength steel bars and super high strength concrete

InactiveCN103046692AReduce section sizeIncrease ultimate strainStrutsPillarsHigh strength concreteReinforced concrete

The invention relates to a reinforced concrete frame-supporting column, in particular to a frame-supporting column with high strength steel bars and super high strength concrete. The frame-supporting column overcomes defects that axial compression ratio limits of ordinary reinforced concrete frame-supporting columns and steel reinforced concrete frame-supporting columns are low, protective covers fall easily under earthquake force, longitudinal bars and steel flanges are easy to bend, the columns are difficult to repair after an earthquake, and high strength steel bars and super high strength concrete cannot be applied, and defects that node constructions of steel reinforced concrete and steel pipe concrete frame-supporting columns are complex, the steel pipe concrete frame-supporting columns do not constrain concrete fully, and steel pipes are easy to bend. The frame-supporting column comprises longitudinal high strength steel bars, high strength closed stirrups and self-compaction super high strength concrete; and constraints include that stirrup spacing of concrete protective covers in whole concrete ranges from 30mm to 35mm, outer surfaces are aligned to outer surfaces of concrete frame-supporting columns, and the stirrup spacing of longitudinal high strength steel bars is constrained to range from 60 mm to 120 mm. By aid of constraining of closely-matched high strength welding closed stirrups on the whole concrete, mechanical properties of super high strength concrete are improved, anti-seismic properties of the column are improved, and the frame-supporting column has a wide application prospect in high-rise or super high-rise structures.

Owner:贵州中建伟业建设(集团)有限责任公司

Fibre reinforced plastic and concrete composite arc structure and construction method

InactiveCN1609379AAccelerated corrosionImprove airtightnessArched structuresVaulted structuresPolyesterEngineering

The present invention relates to building member and its construction process and is especially composite arched structure of fiber reinforced plastic and concrete. The present invention proposes one kind of arced structure with laminated fiber reinforced plastic adhered to the surface of concrete and its construction process. The construction process includes forming concrete arch, milling surface with grinding wheel to eliminate floated surface mortar and roughen the surface, smearing epoxy resin-cement putty to flat the surface, painting primer with structural glue, coating with fiber fabric, soaking the fiber fabric with resin adhesive, covering with polyester film, extruding with scraper the excessive resin adhesive, curing and taking down the polyester film. The composite arched structure is corrosion resistant and durable, and has doubled bearing capacity and simple construction.

Owner:杨庆国 +3

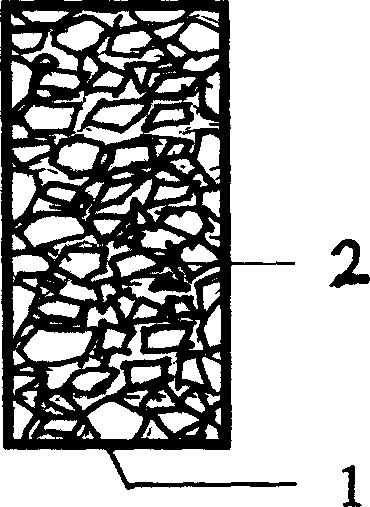

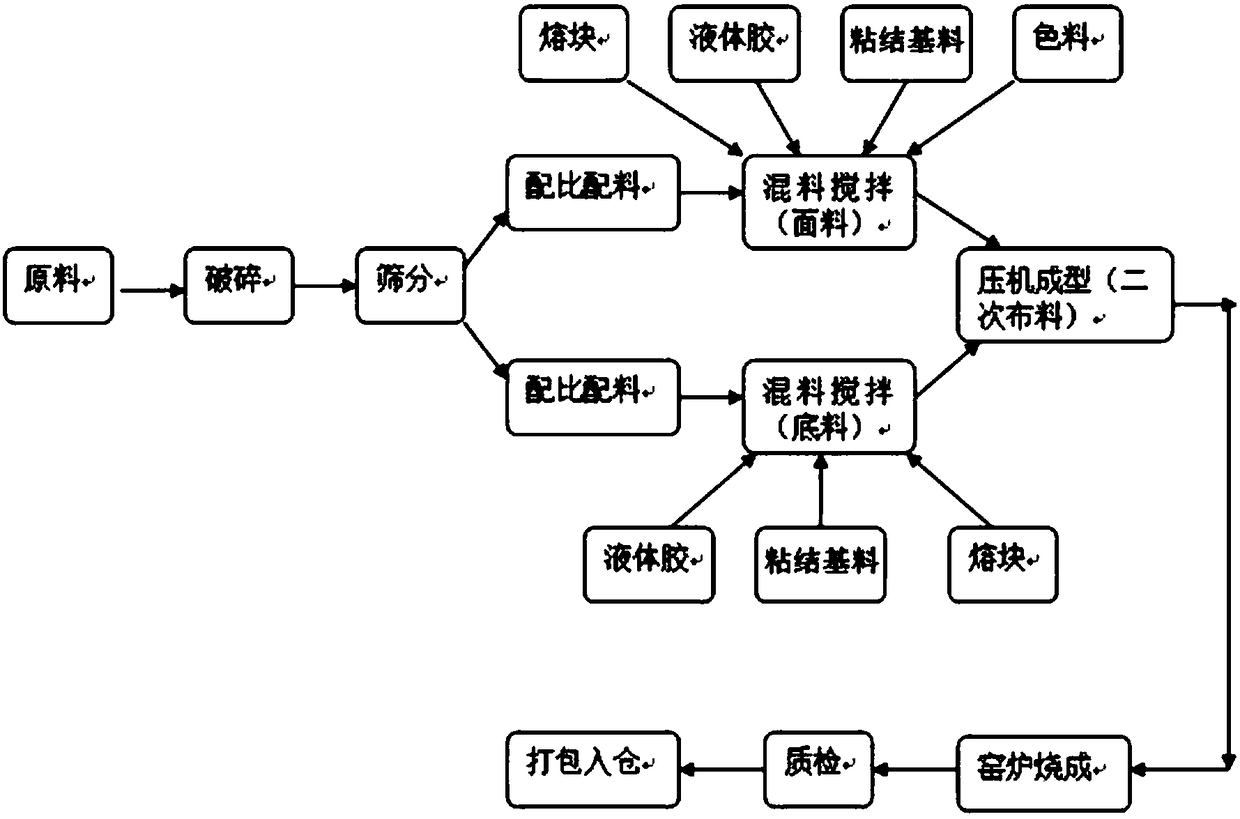

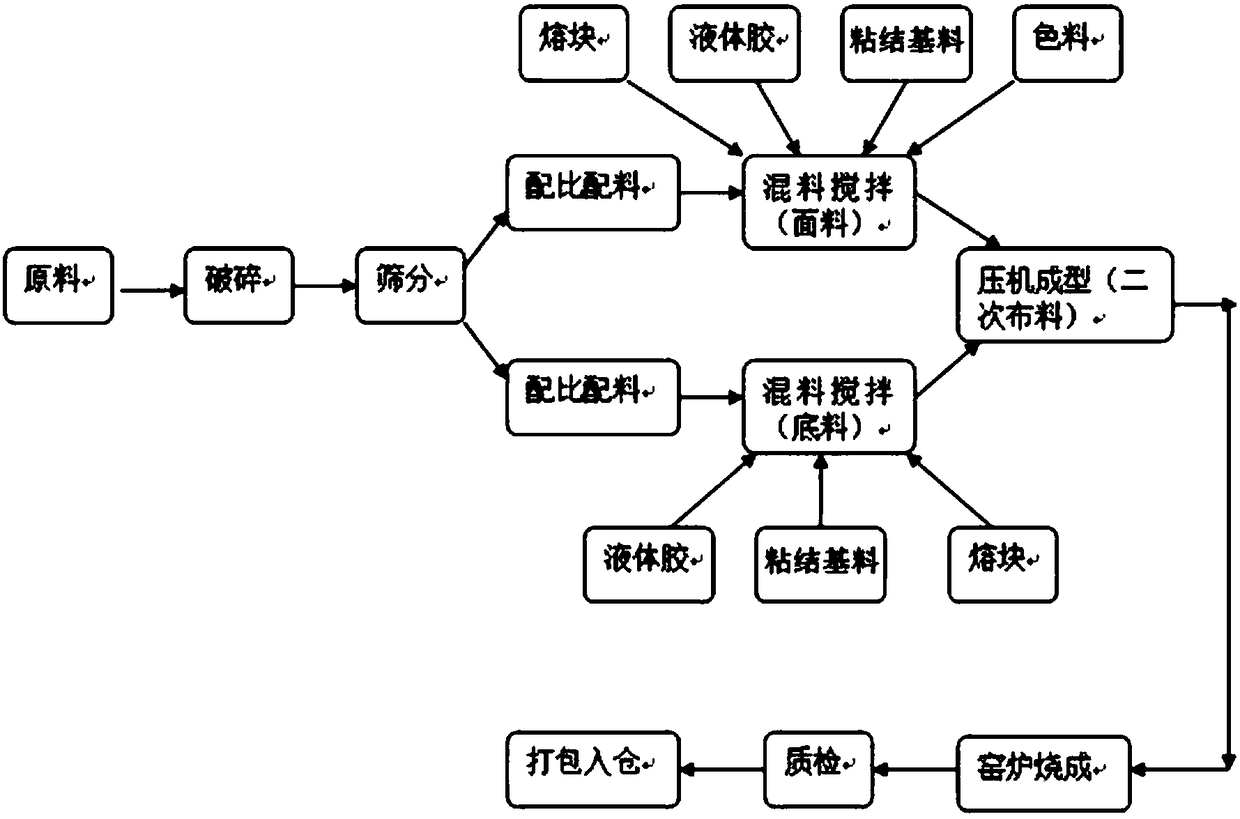

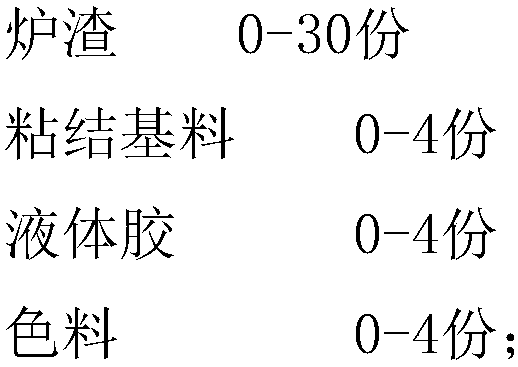

Sintering water permeable brick produced by using crushed stone material and preparation method thereof

InactiveCN108558359AIncrease dosageAchieve a high degree of recyclingCeramic materials productionCeramicwareSodium BentoniteBrick

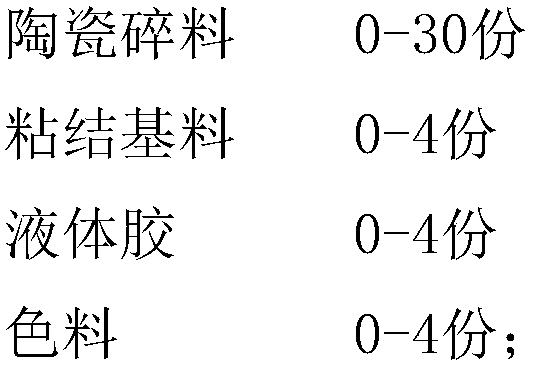

The invention discloses a sintering water permeable brick produced by using a crushed stone material. The brick comprises a surface material and a backing material, wherein the backing material is prepared from, by mass, 80-100 parts of crushed stone materials, 3-12 parts of bond base materials and 3-12 parts of glue solution; the surface material is prepared, by mass, 0-30 parts of stone crushedmaterials, 0-4 parts of bond base materials, 0-4 parts of glue solution and 0-4 parts of pigment; the bond base material is one or more of bentonite and clay; the glue solution is one or more of ludoxsolution, polyacrylamide solution and guar gum solution. The invention correspondingly discloses a preparation method for the sintering water permeable brick produced by using the crushed stone material. By adopting the method, the crushed stone material is taken as the main raw material, and the prepared water permeable brick is high in strength and freezing resistance and excellent in water permeability.

Owner:KEDA INDUSTRIAL GROUP CO LTD

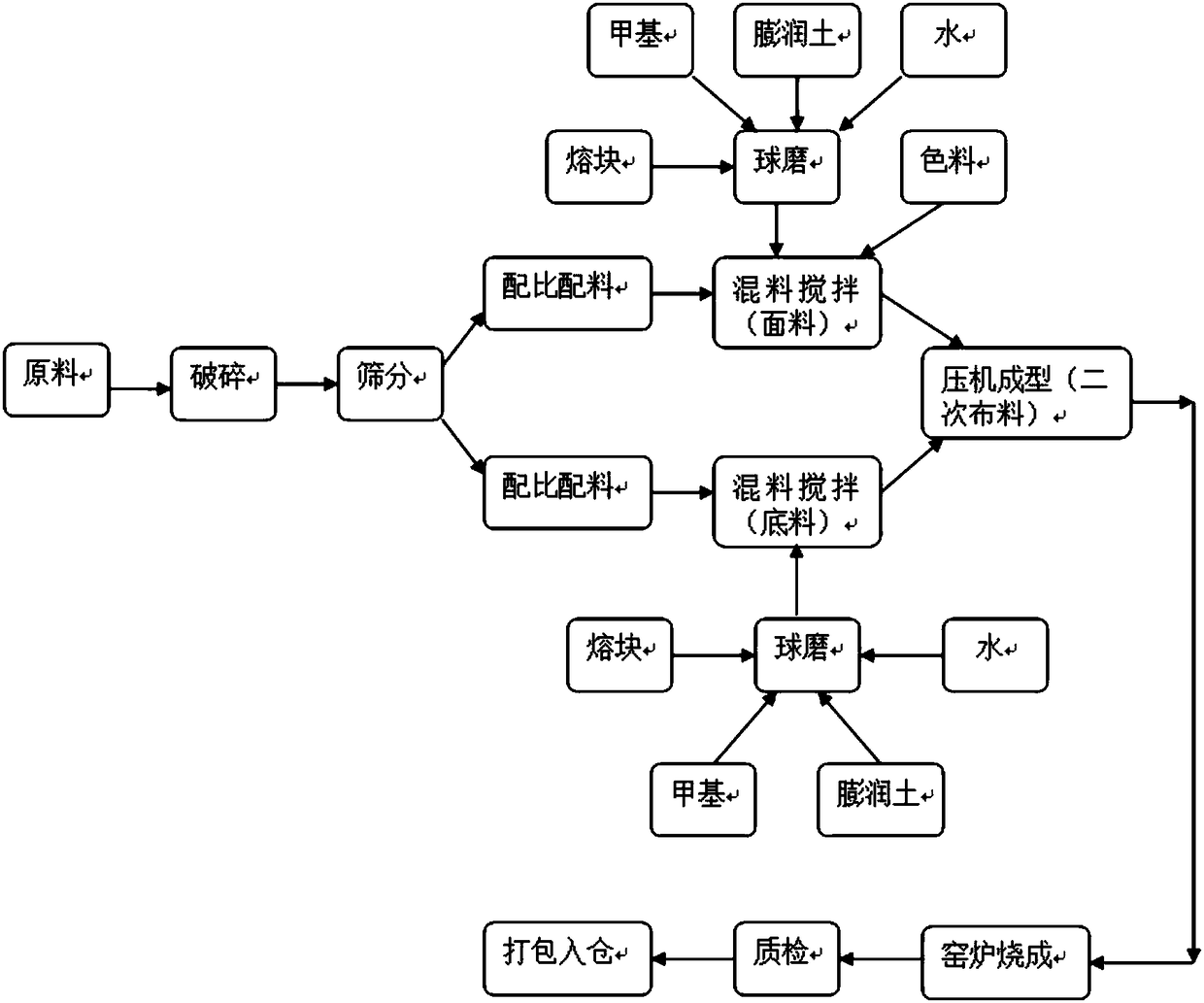

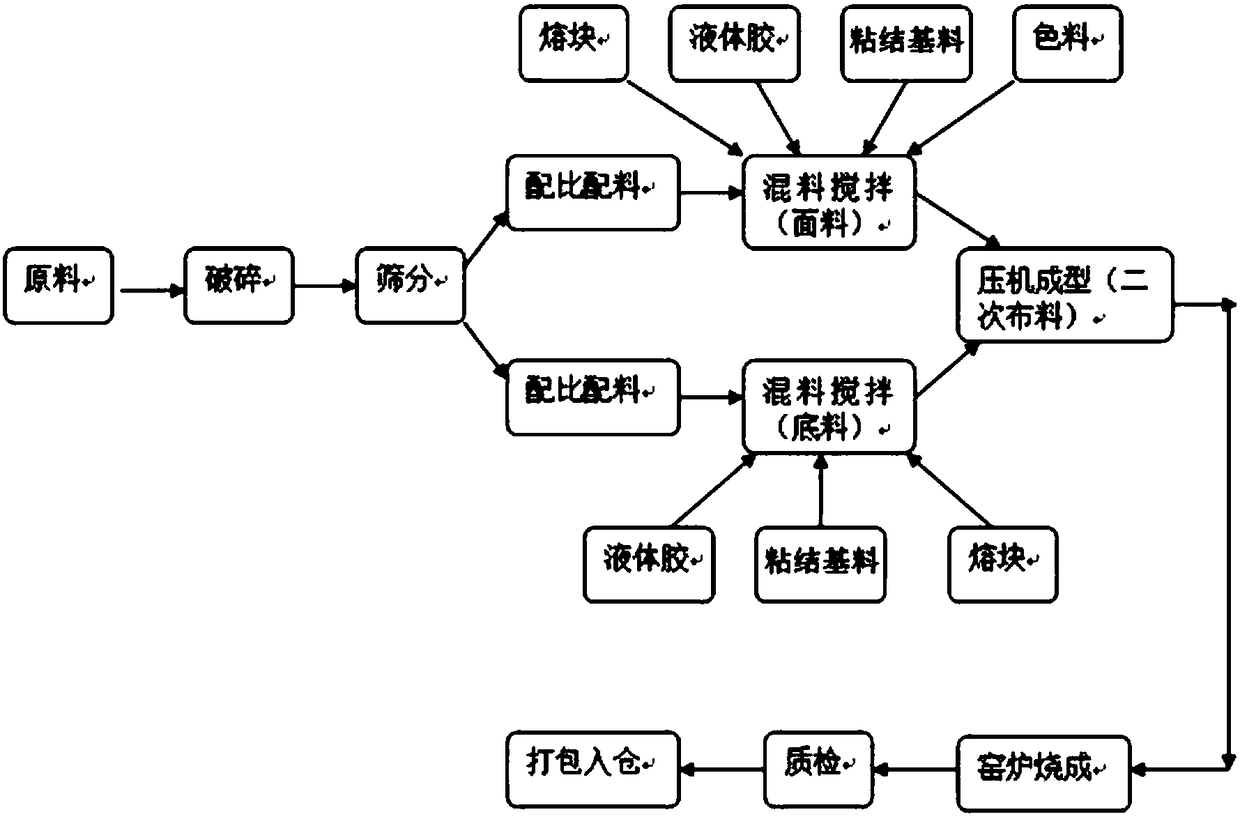

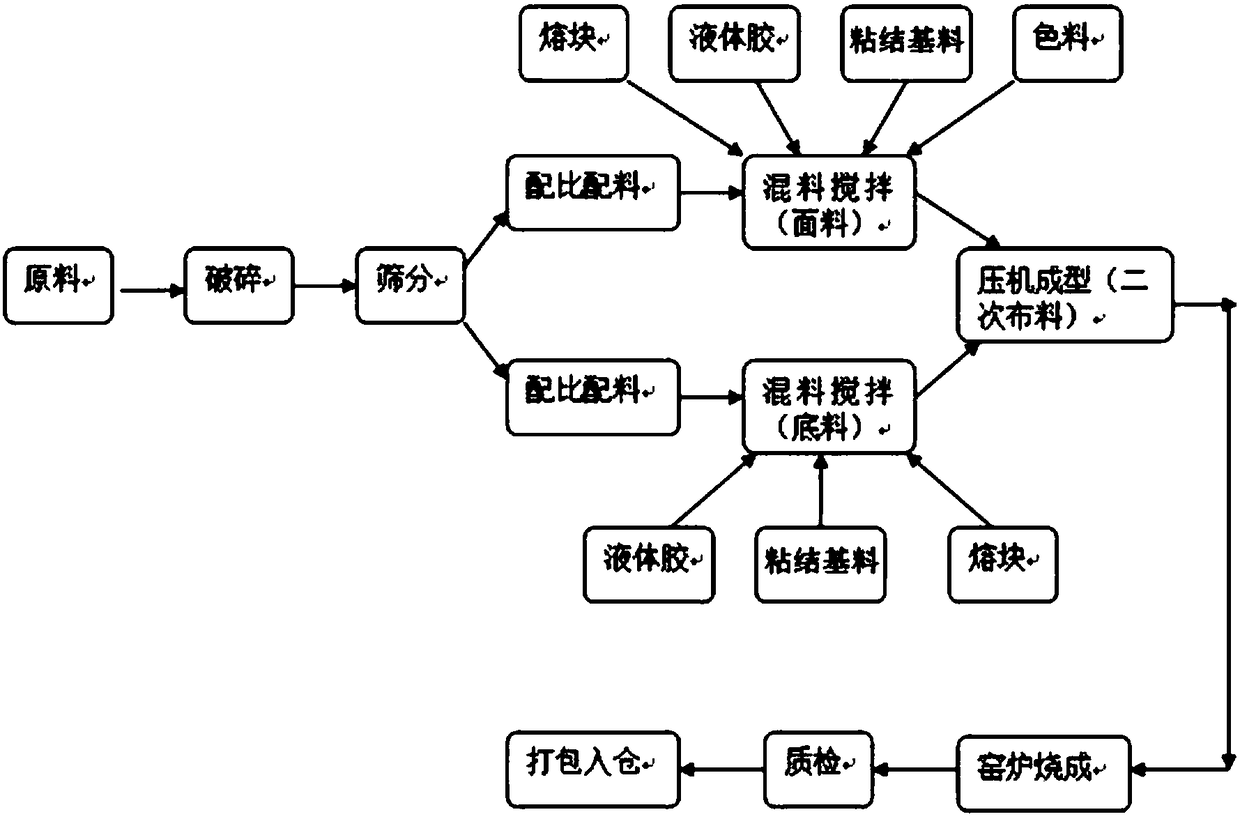

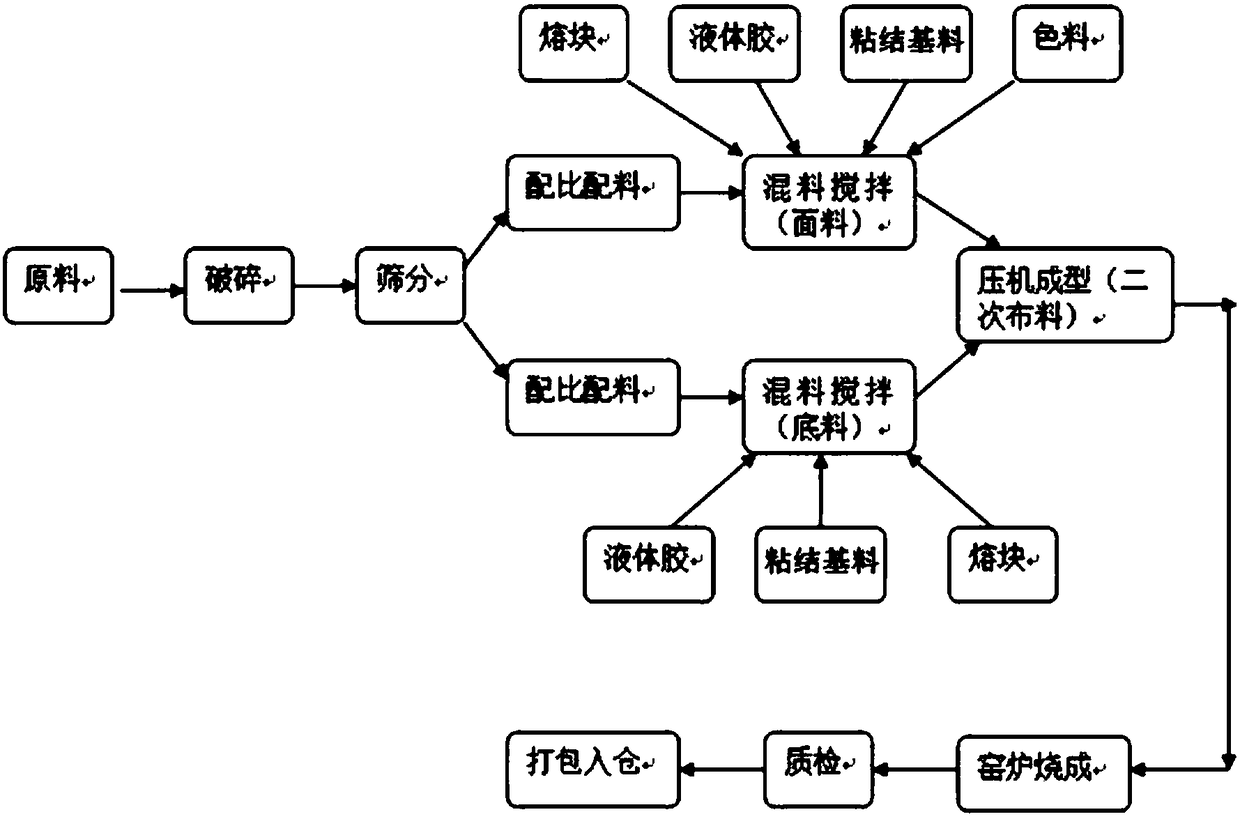

Sintered water-permeable brick which is not blocked easily and preparation method of sintered water-permeable brick

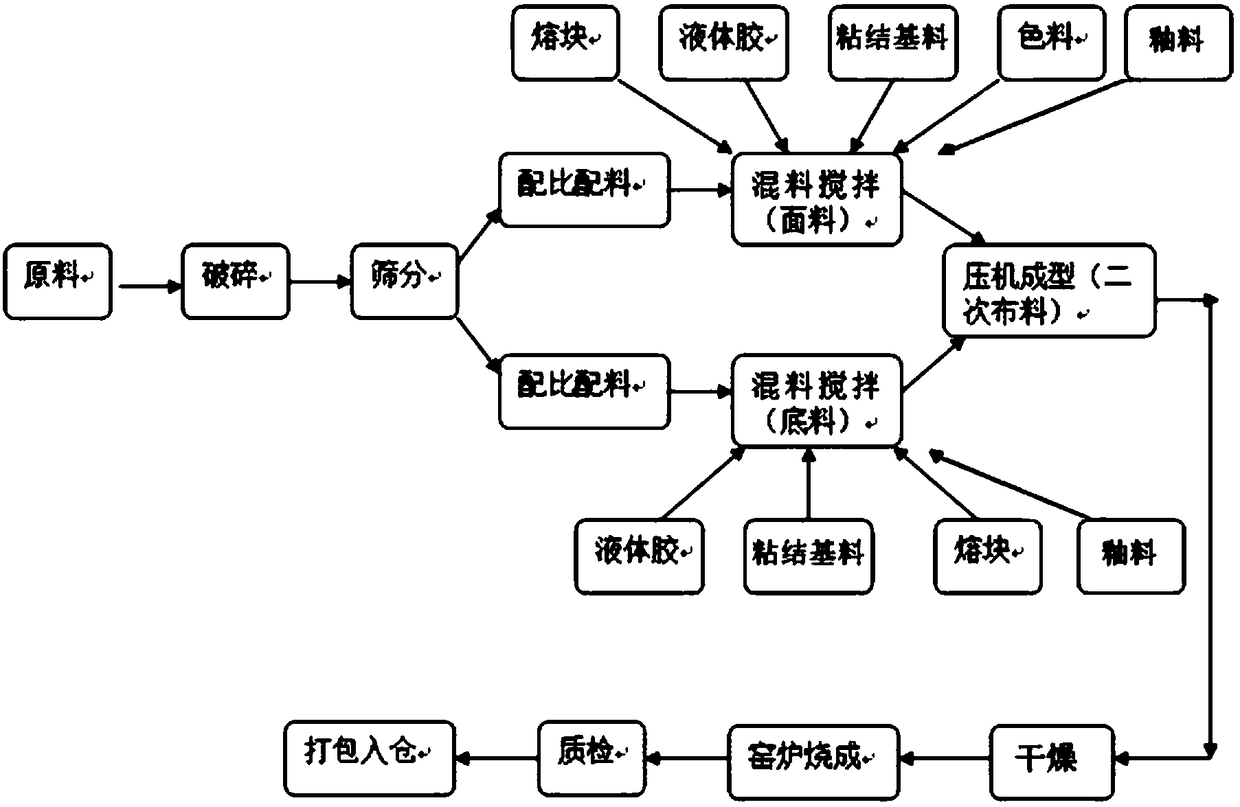

InactiveCN108191392AIncrease dosageIncrease ultimate loadCeramic materials productionClaywaresFiberFrost

The invention discloses a sintered water-permeable brick which is not blocked easily. The brick comprises a surface material and a bottom material, wherein the bottom material comprises the main raw materials of: in parts by mass, 80-100 parts of aggregate, 3-12 parts of a bonding base material, 3-12 parts of liquid glue and 0.1-5 parts of glaze, and the surface material comprises the following main raw materials of: in parts by mass, 0-30 parts of the aggregate, 0-4 parts of the bonding base material, 0-4 parts of the liquid glue, 0-2 parts of the glaze and 0-4 parts of color materials; the bonding base material is one or more of bentonite and clay, and the liquid glue is one or more of a silica sol solution, a polyacrylamide solution and a guar gum solution. Correspondingly, the invention discloses a preparation method of the sintered water-permeable brick. The water-permeable brick has high strength, strong frost resistance and excellent water permeability, particles or fiber substances in rainwater and other sewage are not hung on walls easily, and hole gaps of the water-permeable brick are not easily blocked.

Owner:KEDA INDUSTRIAL GROUP CO LTD

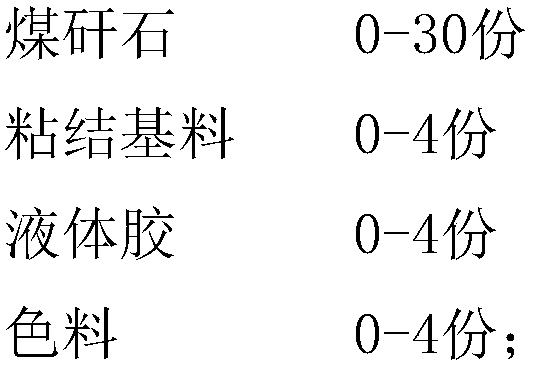

Sintered water permeable brick produced by using coal gangue and preparation method of sintered water permeable brick

The invention discloses a sintered water permeable brick produced by using coal gangue. The sintered water permeable brick comprises a surface material and a bottom material, wherein the bottom material comprises the following main raw materials in parts by mass: 80-100 parts of coal gangue, 3-12 parts of a bonding base material and 3-12 parts of liquid glue, the surface material comprises the following main raw materials in parts by mass: 0-30 parts of the coal gangue, 0-4 parts of the bonding base material, 0-4 parts of the liquid glue and 0-4 parts of pigment, the bonding base material is one or more selected from bentonite and clay, and the liquid glue is one or more selected from a silica sol solution, a polyacrylamide solution and a guar gum solution. Correspondingly, the invention discloses a preparation method of the sintered water permeable brick produced by using coal gangue. According to the invention, the water permeable brick prepared by using the coal gangue as a main rawmaterial has high strength, strong frost resistance and excellent water permeability.

Owner:KEDA INDUSTRIAL GROUP CO LTD

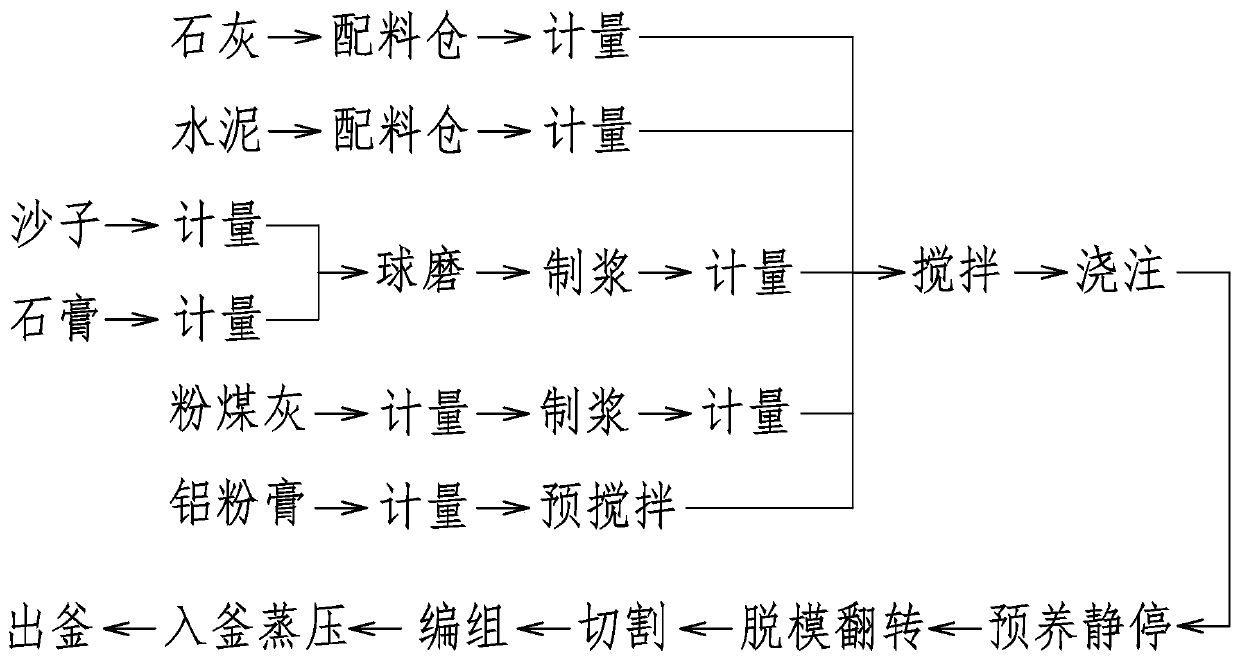

Autoclaved aerated concrete block and preparation process thereof

The invention discloses an autoclaved aerated concrete block and a preparation process thereof. The autoclaved aerated concrete block is prepared from, by weight, 100-130 parts of fly ash, 260-300 parts of sand, 8-12 parts of gypsum, 75-80 parts of lime, 80-85 parts of cement and 0.5-0.7 part of aluminum powder paste; according to the invention, the application range of the low-quality fly ash generated by the combustion of the boiler of the thermal power plant is expanded, so that the treatment ways of the fly ash generated by the coal-fired boiler are greatly increased, the technical difficulty of manufacturing the high-quality autoclaved aerated concrete block by using the low-quality fly ash is overcome, and the practical value is very high.

Owner:ZHEJIANG FUCHUNJIANG ENVIRONMENTAL THERMOELECTRIC CO LTD

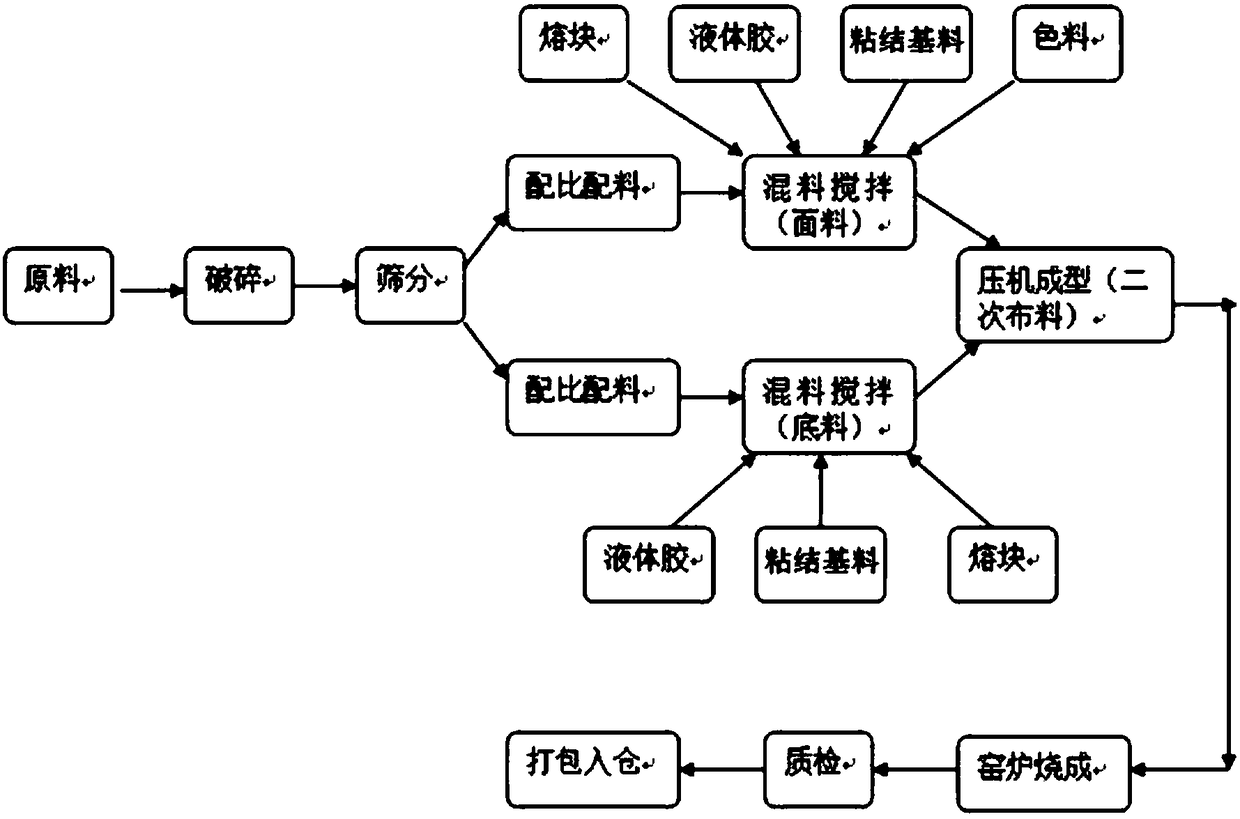

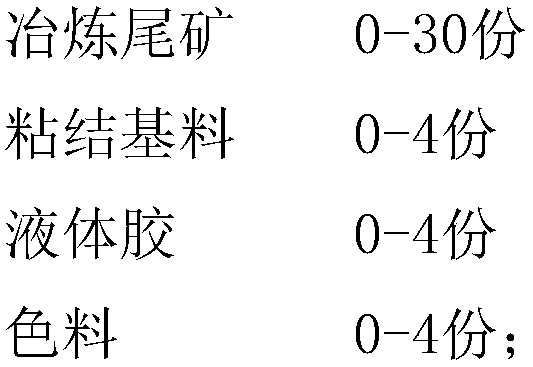

Sintered water-permeable brick produced by using smelting tailings, and preparation method thereof

InactiveCN108585788AIncrease dosageReach the purpose of highly recycling solid wasteCeramic materials productionCeramicwareBrickSodium Bentonite

The invention discloses a sintered water-permeable brick produced by using smelting tailings. The sintered water-permeable brick comprises a surface material and a bottom material, wherein the main raw materials of the bottom material comprise, by mass, 80-100 parts of smelting tailings, 3-12 parts of a binding base material, and 3-12 parts of a liquid glue, the main raw materials of the surface material comprise, by mass, 0-30 parts of smelting tailings, 0-4 parts of a binding base material, 0-4 parts of a liquid glue, and 0-4 parts of a color material, the binding base material is one or a plurality of materials selected from bentonite and clay, and the liquid glue is one or a plurality of materials selected from a silica sol solution, a polyacrylamide solution and a guar gum solution. Accordingly the present invention discloses a preparation method of sintered water-permeable brick produced by using smelting tailings. According to the present invention, through the preparation method, by using the smelting tailings as the main raw material, the prepared water-permeable brick has characteristics of high strength, strong frost resistance and excellent water permeability.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Enlarged Head Capsule Anchor and Its Construction Method

The invention discloses an expanded head capsule type anchor rod. The anchor rod comprises a finish rolled threaded reinforcing bar, a capsule type squeezing and expansion body and a bushing, wherein the finish rolled threaded reinforcing bar extends into the capsule type squeezing and expansion body; a grouting material seal bottom is arranged at the bottom in the capsule type squeezing and expansion body; a stop-grouting plug is arranged at an inlet of the capsule type squeezing and expansion body; a backing plate fixedly sleeves the upper part of the finish rolled threaded reinforcing bar; a pre-stressed nut sleeves the finish rolled threaded reinforcing bar; a conical iron hat with a reserved hole is fixedly arranged on the top surface of the backing plate and covers the finish rolled threaded reinforcing bar sleeved by the pre-stressed nut. The invention also discloses a construction method of the expanded head capsule type anchor rod. The method comprises the following steps: drilling and forming a hole; performing high-pressure rotary spray grouting to perform expanding construction; placing the expanded head capsule type anchor rod; grouting cement mortar into a pocket; supplementing the mortar; tensioning and locking. The expanded head capsule type anchor rod and the construction method have the beneficial effect that the conventional anchor rod which is widely used at present can be partially substituted at wider areas and in engineering projects.

Owner:ANHUI TONGJI CONSTR GRP

Sintered water permeable brick produced by using ceramic crushed materials

InactiveCN108083769AIncrease dosageReach the purpose of highly recycling solid wasteCeramic materials productionCeramicwareFrostBrick

The invention discloses a sintered water permeable brick produced by using ceramic crushed materials. The sintered water permeable brick comprises a fabric and a bottom material, wherein the bottom material comprises the following main raw materials in parts by mass: 80-100 parts of ceramic crushed materials, 3-12 parts of a bonding base material and 3-12 parts of liquid glue; the fabric comprisesthe following main raw materials in parts by mass: 0-30 parts of the ceramic crushed materials, 0-4 parts of the bonding base material, 0-4 parts of the liquid glue and 0-4 parts of pigment, the bonding base material is one or more selected from bentonite and clay, the liquid glue is one or more selected from a silica sol solution, a polyacrylamide solution and a guar gum solution. Correspondingly, the invention discloses a preparation method of the sintered water permeable brick produced by using ceramic crushed materials. According to the invention, the water permeable brick prepared by using the ceramic crushed materials as a main raw material has high strength, strong frost resistance and excellent water permeability.

Owner:KEDA INDUSTRIAL GROUP CO LTD

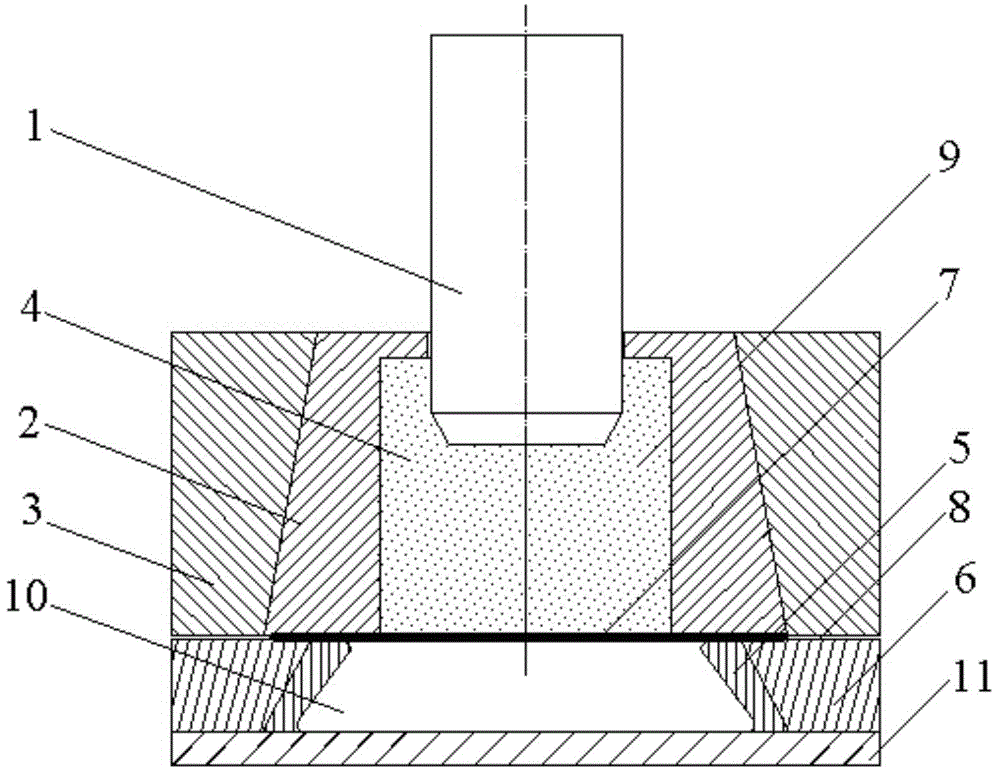

Device for high temperature solid power medium assisting titanium alloy plate superplasticity drawing and bulging integration and method thereof

ActiveCN104624799AEffective control of thickness distributionFast formingShaping toolsTitanium alloySuperplasticity

The invention provides device for high temperature solid power medium assisting titanium alloy plate superplasticity drawing and bulging integration and a method thereof and relates to a device for drawing and bulging integration and a method thereof. The device comprises a punch, an upper die petal, an upper die sleeve, a lower die petal, a lower die sleeve, a spacer, an upper die cavity, a lower die cavity and a cushion block. The lower end of the punch is arranged in the upper die cavity, and the upper die sleeve is arranged outside the upper die petal; the lower die petal and the lower die sleeve are arranged on the cushion block, and the lower die sleeve is arranged outside the lower die petal; the spacer is arranged between the upper die sleeve and the lower die sleeve. The method comprises the steps that an aluminium alloy plate to be molded is put into the interspace formed by the upper die petal, the lower die petal and the lower die sleeve of the device for the high temperature solid power medium assisting titanium alloy plate superplasticity drawing and bulging integration, a powder medium is added into the upper die cavity, and pre-compaction, heating and heat preservation are sequentially conducted on the powder medium; then compaction, pressure maintaining and cooling are sequentially conducted to obtain an aluminium alloy part. By means of the device for the high temperature solid power medium assisting titanium alloy plate superplasticity drawing and bulging integration and the method thereof, aluminium alloy parts with uniform thicknesses can be obtained.

Owner:HARBIN INST OF TECH

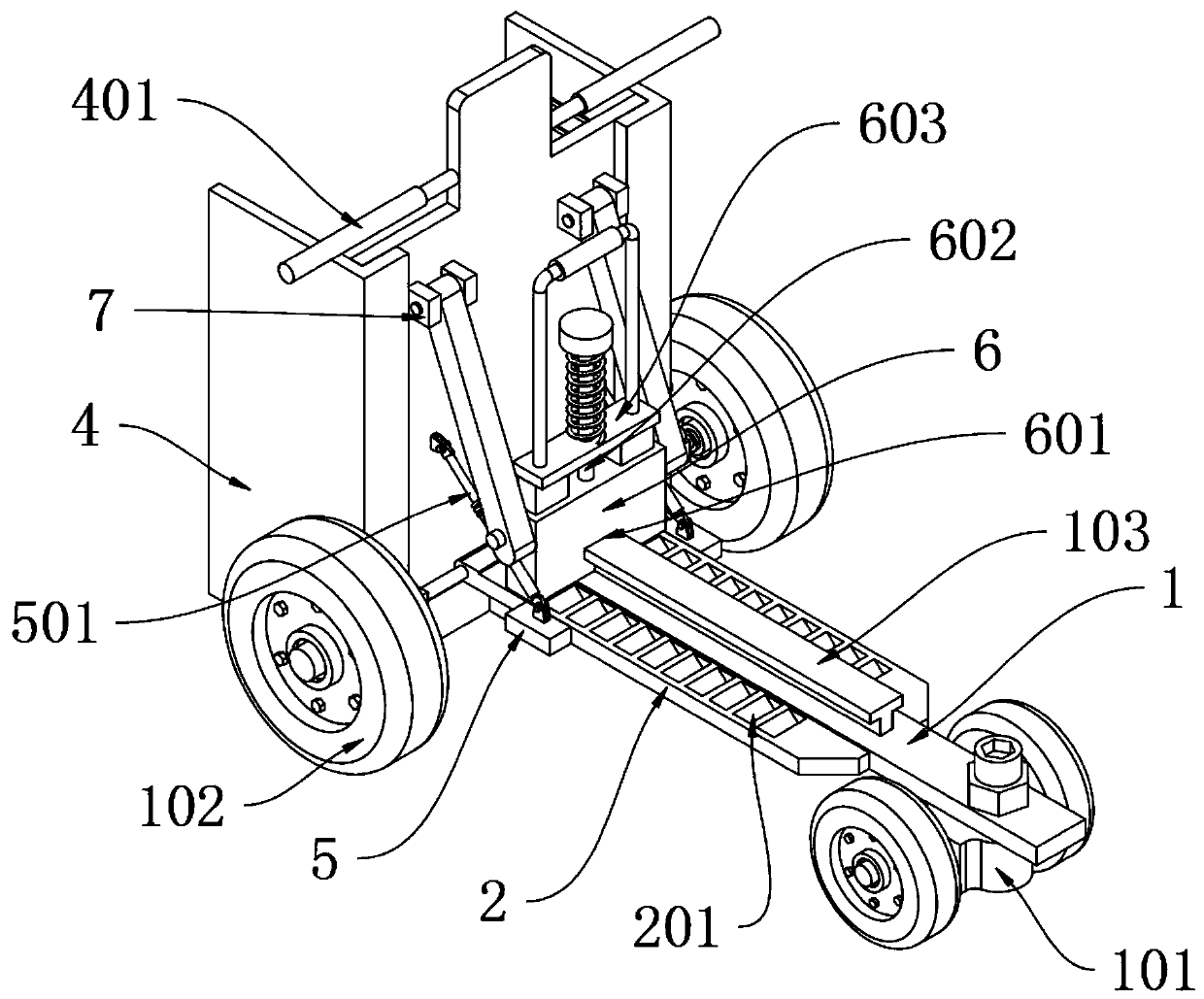

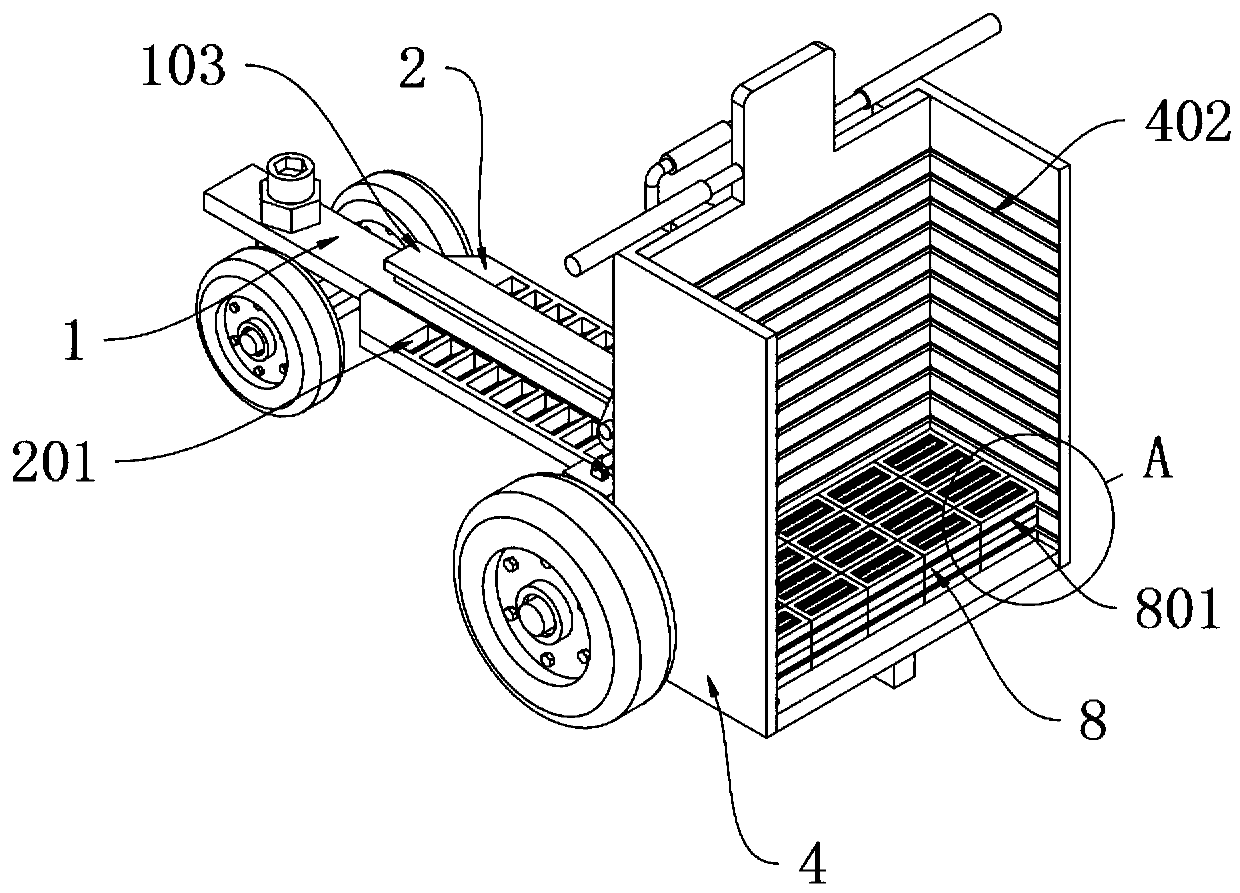

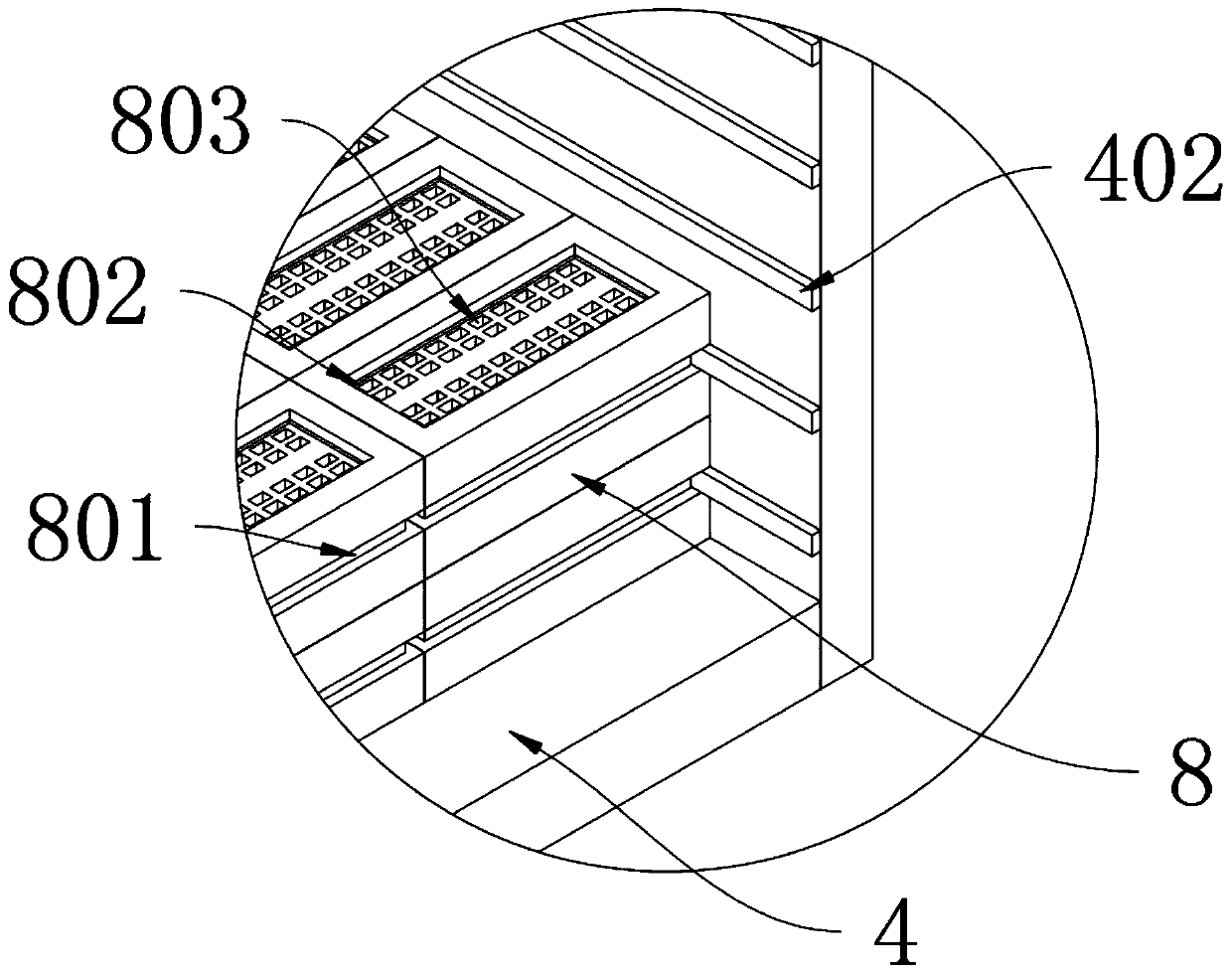

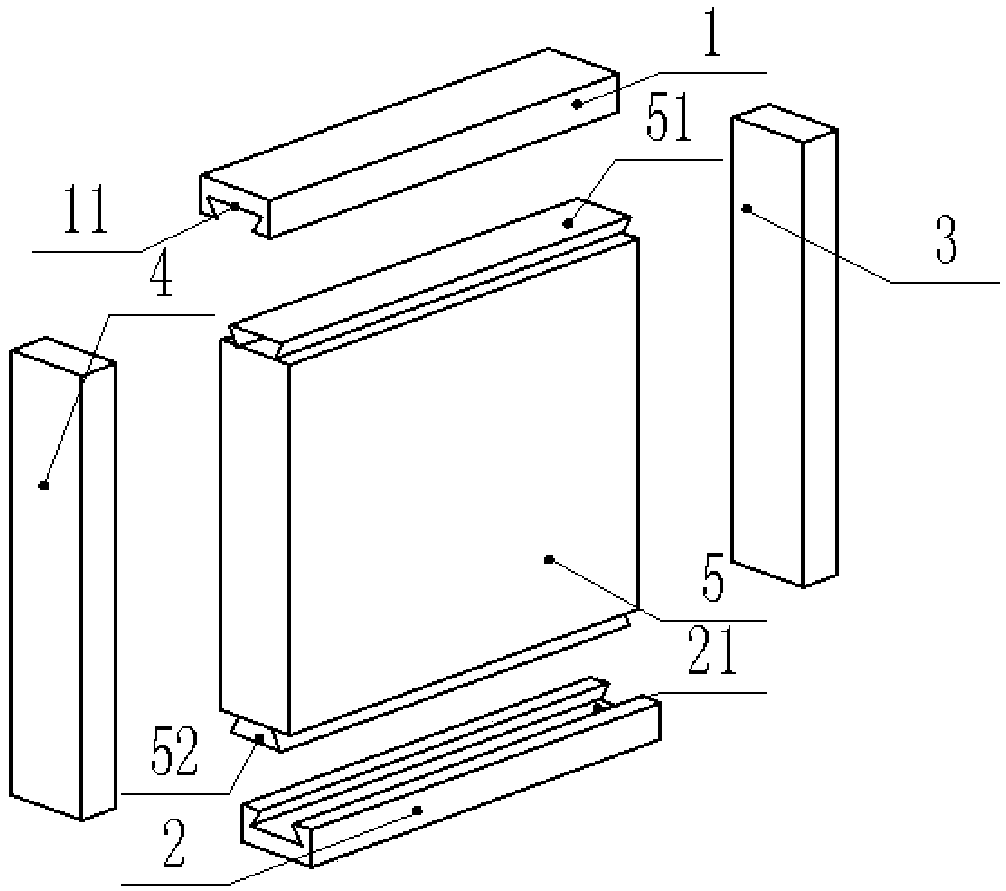

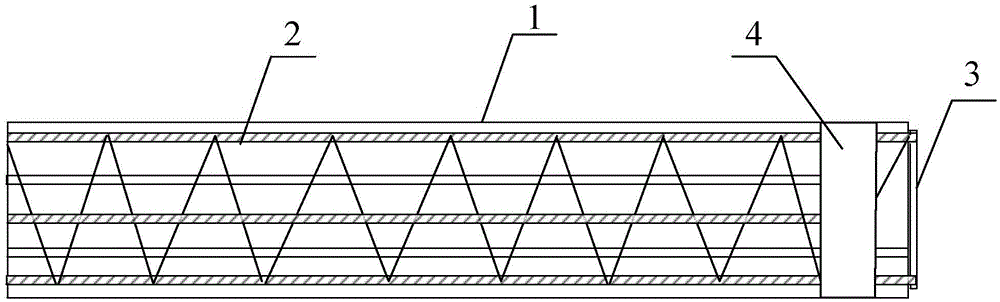

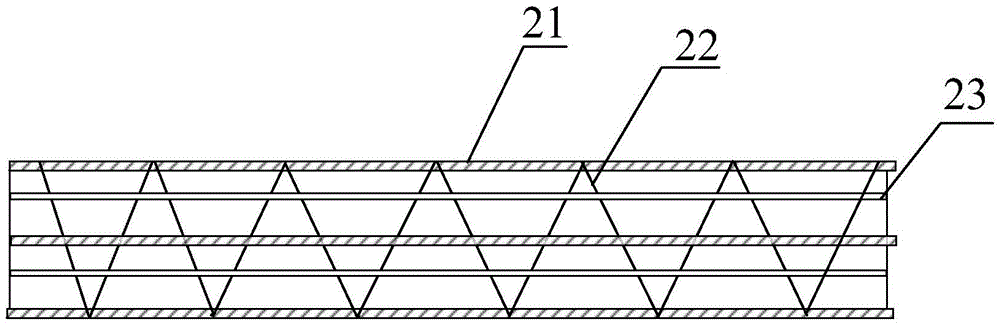

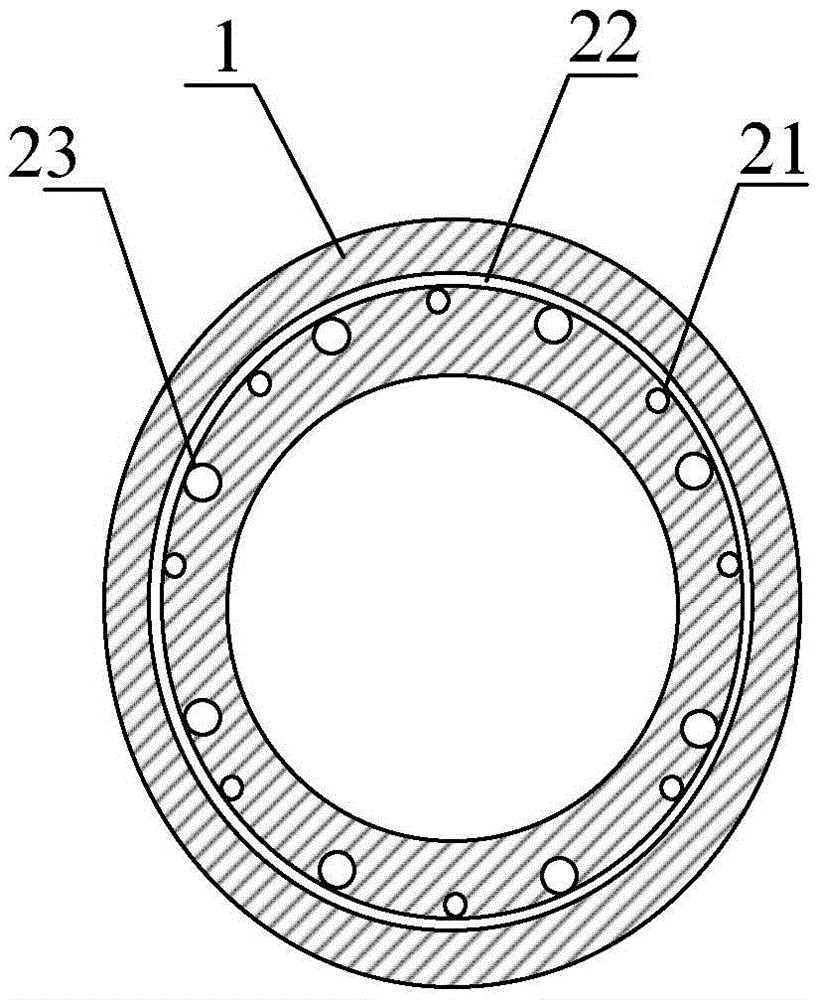

Sintered coal gangue brick composite heat preservation brick and transfer device thereof

InactiveCN111497911AIncrease ultimate loadImprove bearing capacityConstruction materialWallsVehicle frameEngineering

The invention provides a sintered coal gangue brick composite heat preservation brick and a transfer device thereof, and relates to the technical field of composite insulating bricks. The problem thatthe fireproof heat preservation structure of the composite heat preservation brickwork is damaged due to collision easily in the transferring process is solved. Moreover, due to smoothness of brick bodies, the brick bodies are prone to sliding in the transportation process and accordingly are likely to fall off, a common transfer device is mostly a flatcar or a cart, and in the loading and unloading process, the brick bodies and common brick bodies cannot be filled at will generally, the brick body transfer device comprises a frame body; and limiting plates are symmetrically mounted at the left end edge and the right end edge of the frame body correspondingly. The clamping grooves matched with the clamping strips on the box body are annularly formed in the vertical walls of the four sidesof the brick; the whole device can be pulled to move and the box body can be pulled to rotate through the push rod, bricks placed in the box body can be placed in a limited mode, the bricks are prevented from falling off or being damaged due to mutual collision in the transferring process, and the transferring integrity is guaranteed.

Owner:张祖超

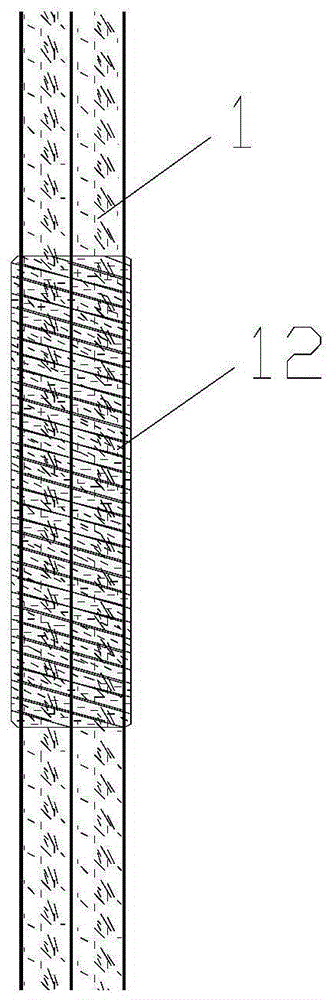

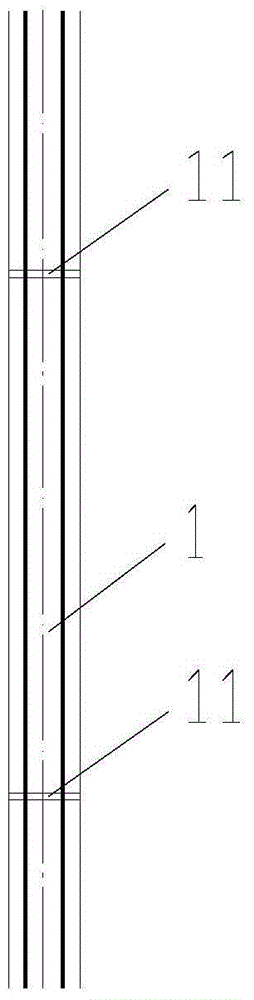

Anti-seismic ceramsite lightweight wall board

InactiveCN109469254APracticalImprove toughnessProtective buildings/sheltersCeramicwareCushioningEngineering

The invention relates to the field of building wall boards, in particular to an anti-seismic ceramsite lightweight wall board. The anti-seismic ceramsite lightweight wall board comprises an anti-seismic framework and a seism cushioning interlayer, wherein the anti-seismic framework is a rectangular framework and comprises an upper cross beam, a lower cross beam, a left side beam and a right side beam; both the upper cross beam and the lower cross beam are provided with grooves; tenons are arranged on the seism cushioning interlayer; the seism cushioning interlayer is connected with groove andtongues of the upper cross beam and the lower cross beam through the tenons; the anti-seismic framework and the seism cushioning interlayer are formed by casing a pouring material; the pouring material is prepared from ceramsites, high impact-resistance polystyrene particles, polypropylene fibers and hydroxypropyl methyl cellulose. By adopting the anti-seismic ceramsite lightweight wall board disclosed by the invention, the problems that an existing wall board has low rigidity and poor seismic resistance can be solved.

Owner:重庆成维轻质墙板有限公司

High-strength metal pressure-yielding anchor rod with headed tail

A high-strength metal pressure-yielding anchor rod with a headed tail comprises a rod body, a tray, a pressure-yielding pipe and a nut. The rod body is integrally formed by high-strength cylindrical threaded steel and comprises a head, a body and a tail. The tail is subjected to heading and thread rolling, and the surface thereof is provided with a thread in the diameter 4-5mm larger than that of the rod body. After being headed and subjected to thread rolling, the tail is subjected to high-temperature thermal treatment, so that the strength of the tail is higher than that of the rod body. The tray, the pressure-yielding pipe and the nut are sequentially sleeved on the tail, the length of the pressure-yielding pipe ranges from 30mm to 40mm, a rigidity washer is arranged between the tray and the pressure-yielding pipe, and another washer and a resin washer are arranged between the nut and the pressure-yielding pipe.

Owner:SHANDONG UNIV OF SCI & TECH

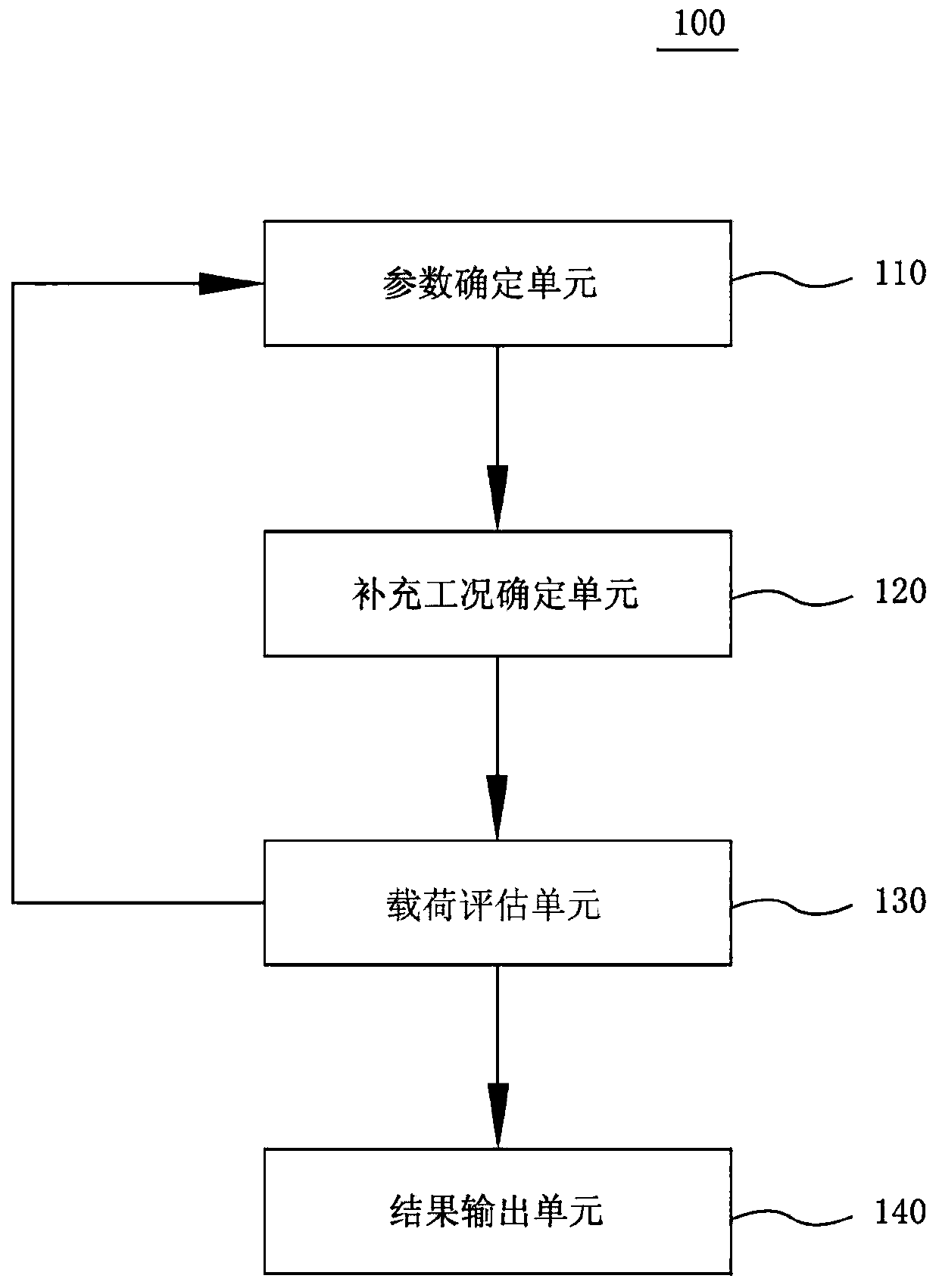

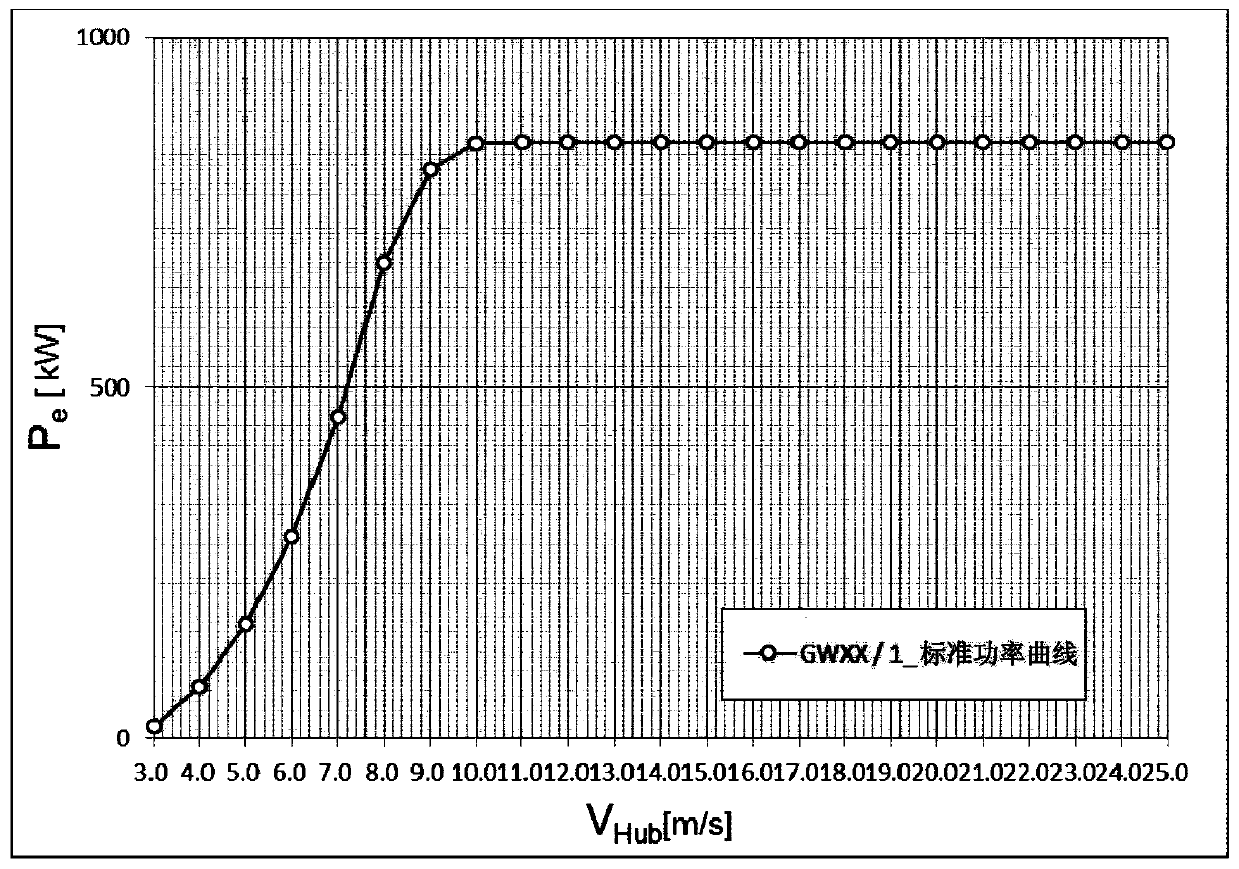

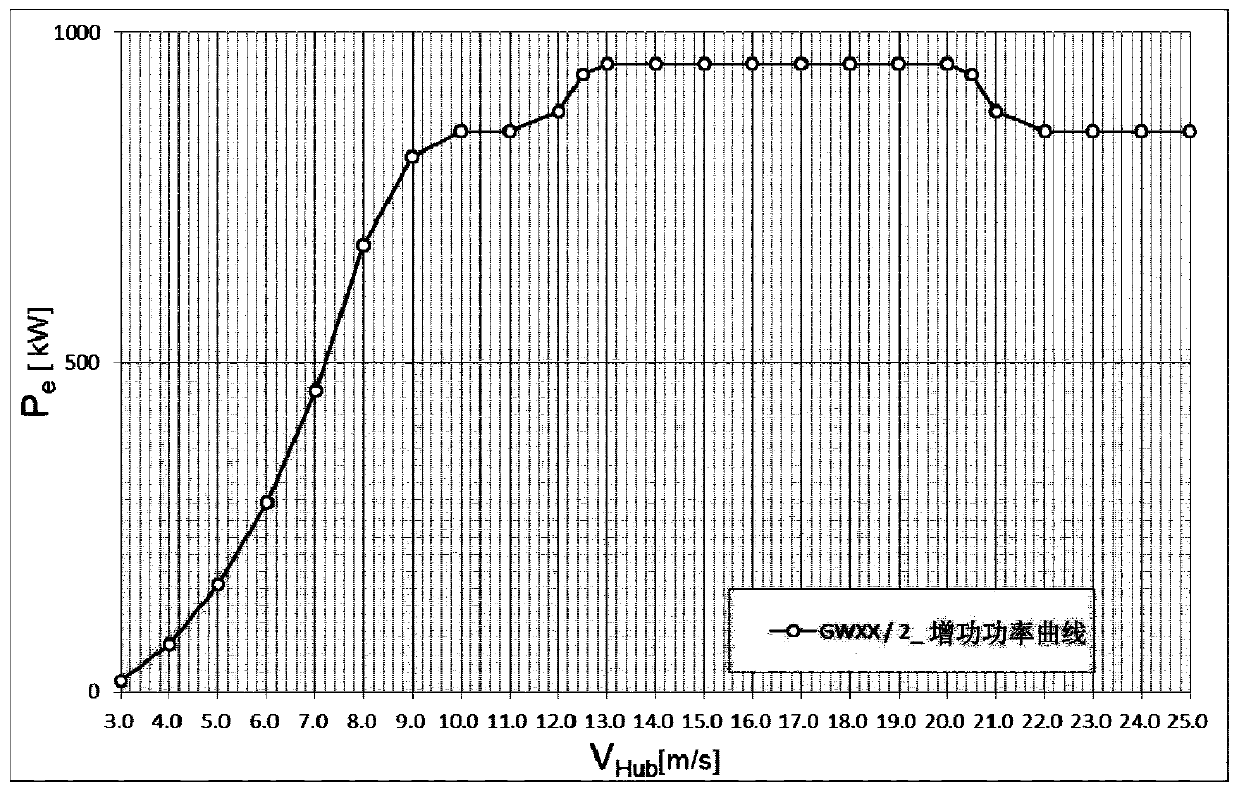

Power curve optimizing device and method for wind generating set

ActiveCN110566404AIncrease power generationReduce electricity costsWind motor controlMachines/enginesWind forceAutomotive engineering

The invention provides a power curve optimizing device and method for a wind generating set. The device comprises a parameter determining unit for determining the current power curve optimizing targetvalue, the current optimizing cut-in wind speed and the current optimizing cut-out wind speed of the wind generating set, a supplementing working condition determining unit for determining the supplementing working conditions of the wind generating set on the basis of the power curve optimizing target value, the optimizing cut-in wind speed and the optimizing cut-out wind speed, a load evaluatingunit for executing load evaluating on the basis of the determined compensating working conditions and determining whether the load evaluating result meets the design load requirements of the wind generating set or not, and a result outputting unit for improving the actual output power of the wind generating set on the basis of the power curve optimizing target value within the wind speed region between the optimizing cut-in wind speed and the optimizing cut-out wind speed when the load evaluating result meets the design load requirements of the wind generating set.

Owner:陕能榆林清洁能源开发有限公司 +1

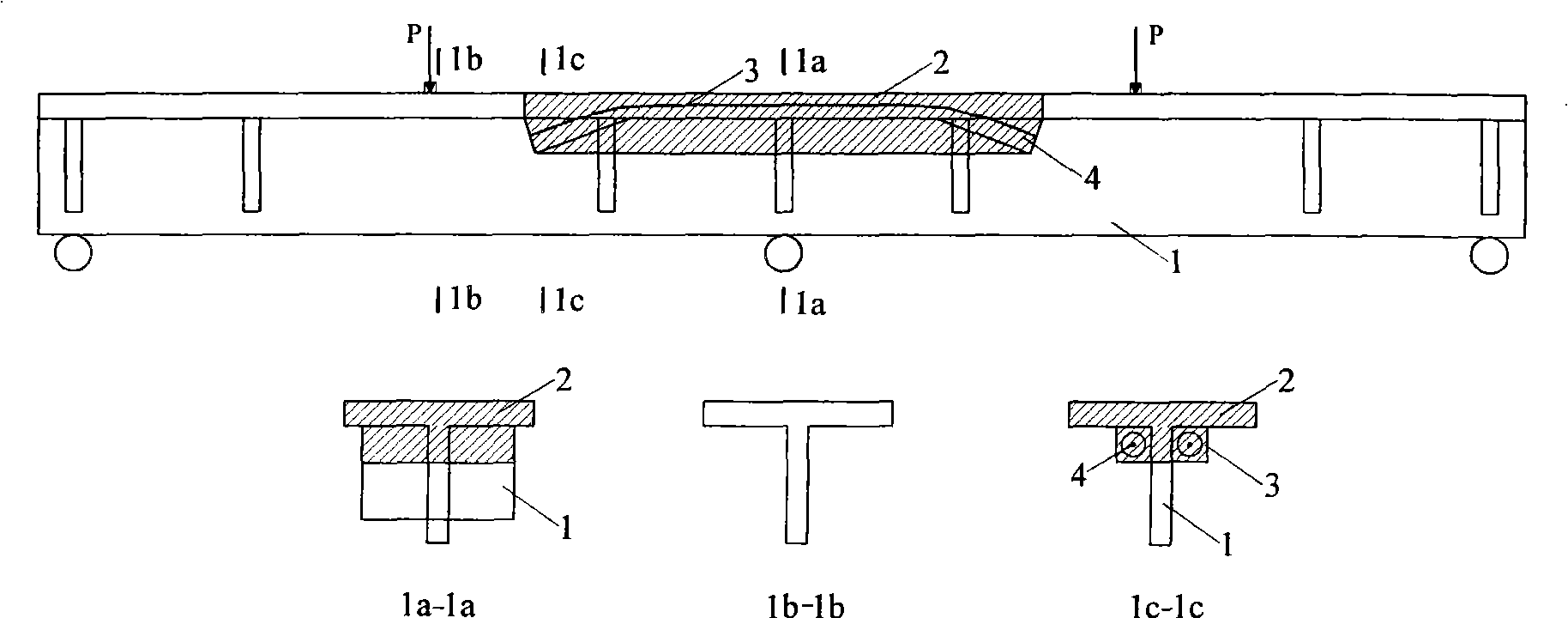

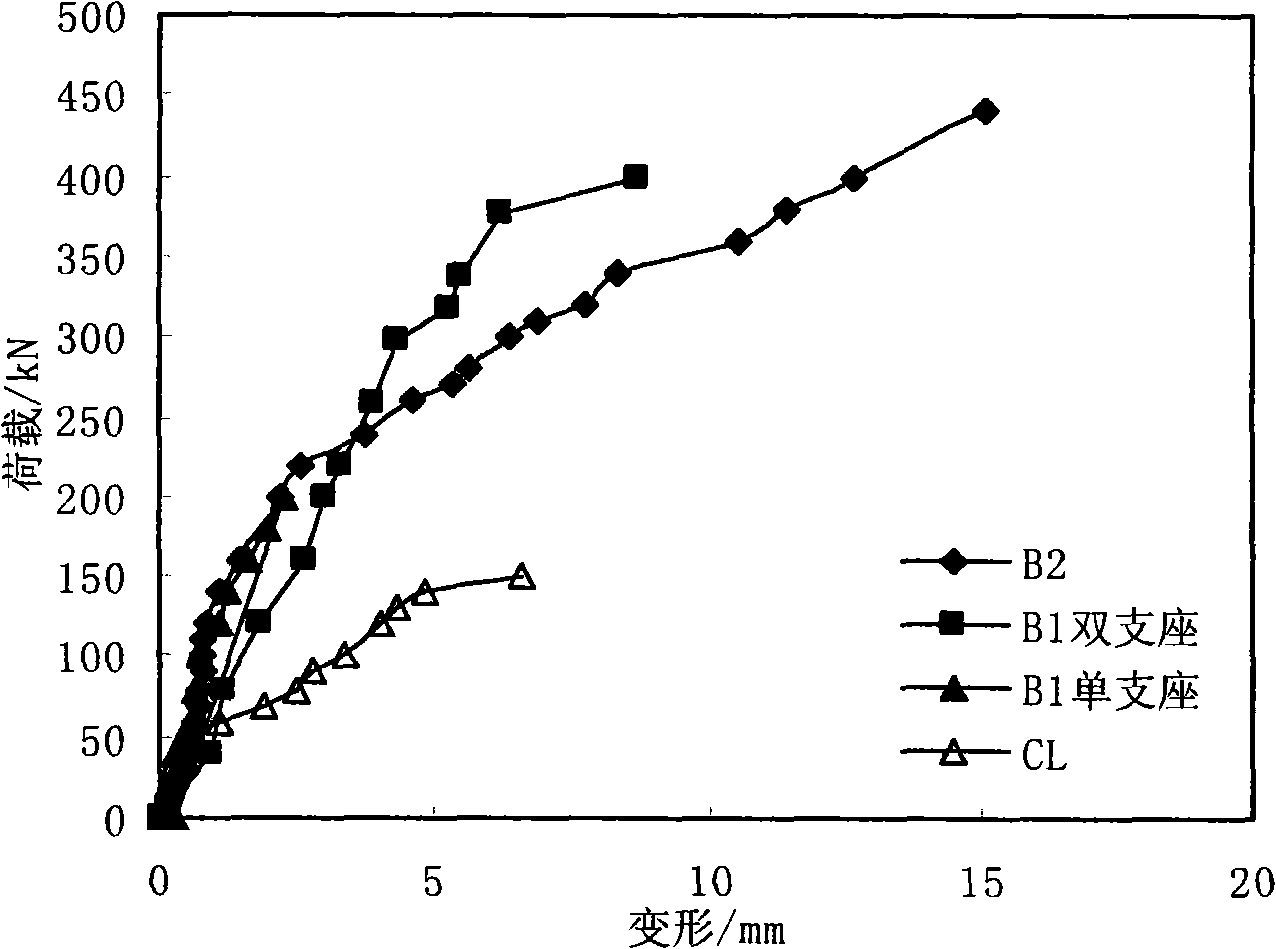

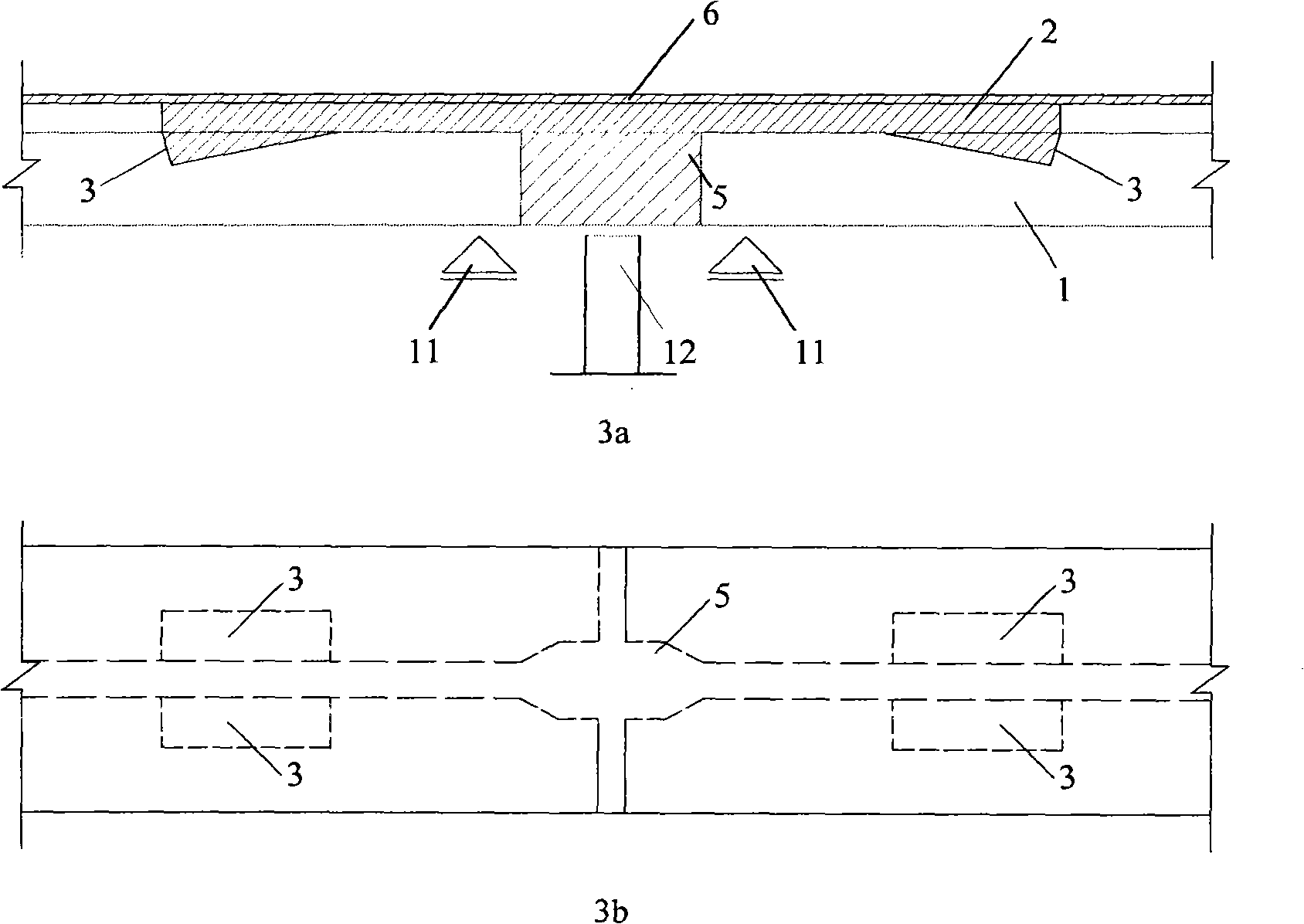

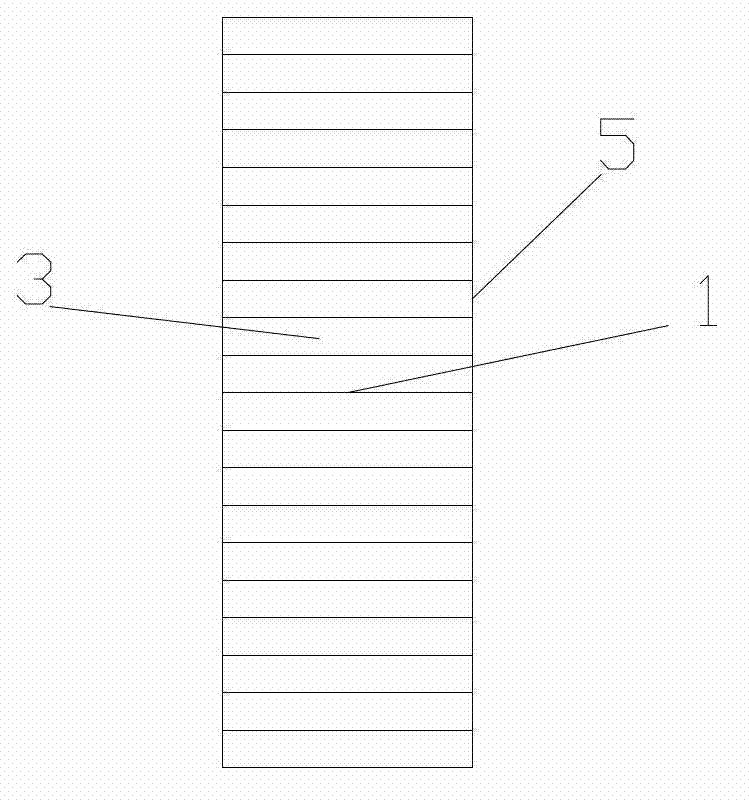

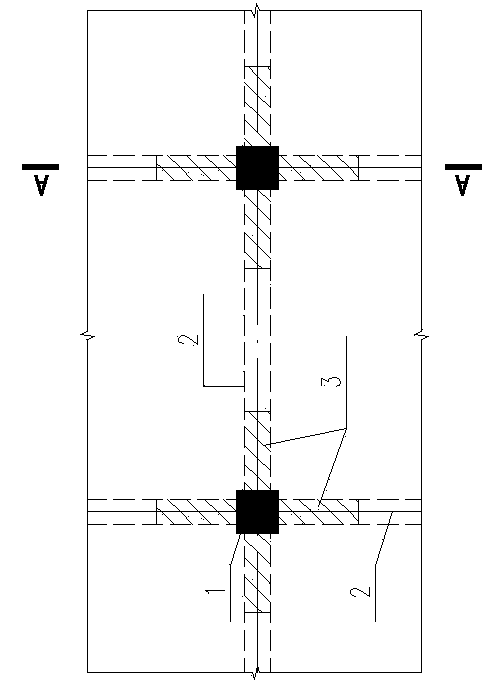

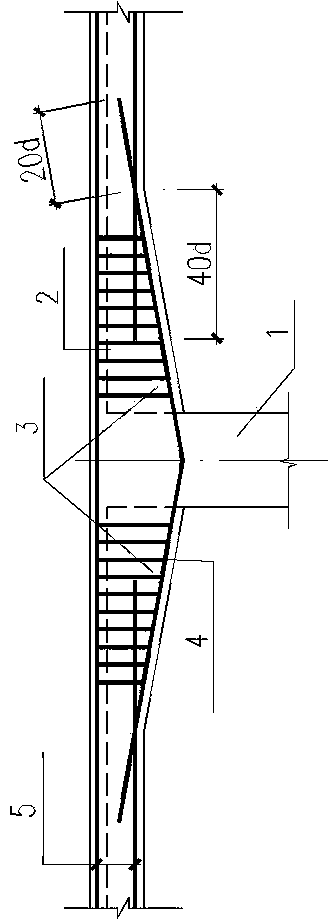

Cast-in-place reinforced concrete haunched beam structure

InactiveCN103590487AOptimize layoutIncrease net heightBuilding constructionsReinforced concreteRebar

The invention discloses a cast-in-place reinforced concrete haunched beam structure. The cast-in-place reinforced concrete haunched beam structure comprises a plurality of perpendicularly arranged frame columns, the tops of the frame columns are horizontally connected through frame beams, beam supporting seat haunched areas are arranged on the portions, where the frame columns and the frame beams are connected, of a cast-in-place reinforced concrete beam supporting seat, inclined rebars are arranged in the haunched areas, and the inclined rebars and rebars on the lower portions of beam midspan rebars are anchored mutually. Because the portions of the beam supporting seat are haunched, the height of the cross section of the supporting seat is increased, and reinforcing bars for the portions of the beam supporting seat are reduced under the action of the hogging moment; on the premise that internal force calculation is met, on the one hand, the using amount of concrete is effectively reduced, and the self weight of the structure is reduced, and on the other hand, the form of the cross section of the beam fits into an internal force graphic, the functions of the rebars on all the portions are fully played, and the long-span structure achieves the purposes of being light, attractive, economical and reasonable; moreover, the midspan height of the beam is relatively small, and thus the cast-in-place reinforced concrete haunched beam structure is favorable for layout of pipelines, and the clear height of a building room is increased.

Owner:SUZHOU INDAL PARK DESIGN & RES INST

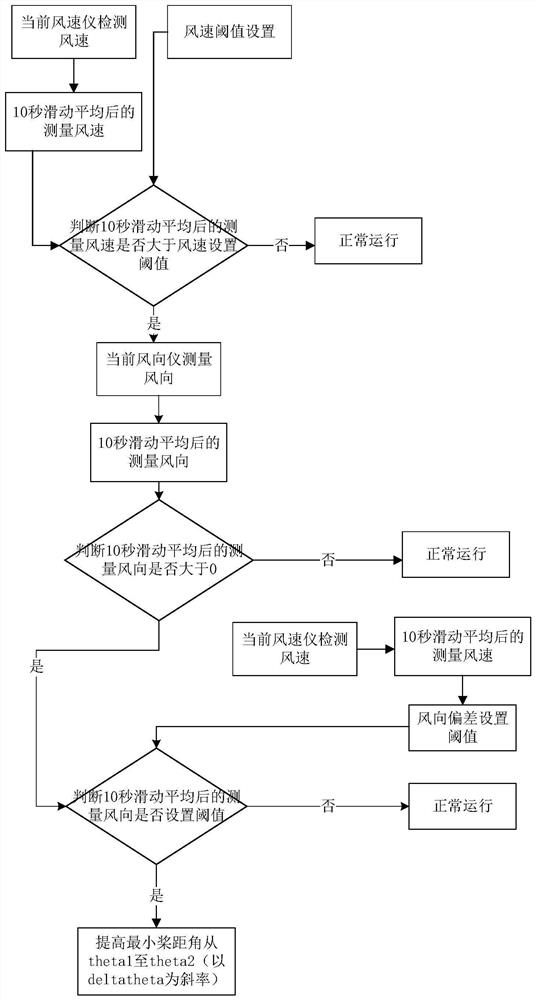

Control method and system for pitch angle of wind turbine generator set, equipment and storage medium

ActiveCN112796942AFixed slope increaseAvoid sudden changes in aerodynamic forceWind motor controlRenewable energy generationGenerating capacityControl mode

The invention discloses a control method and system for the pitch angle of a wind turbine generator set, equipment and a storage medium, and belongs to the field of wind power generation. Whether extreme wind direction changes occur or not is judged by detecting the wind direction measured by a wind indicator and comparing the wind direction with a preset threshold value, and the minimum pitch angle is dispatched to cope with the limit load caused by rapid wind direction changes. The positive and negative wind directions measured by the wind indicator are judged, and the load borne by a large part of the set is larger than that borne in a positive wind direction when the minimum pitch angle is increased during flow incoming in the negative wind direction, so that the limit load is reduced by only performing control of increasing the minimum pitch angle on the wind direction of the positive incoming flow. Compared with a control mode without distinguishing the wind directions, the limit load caused by the extreme wind direction changes of the set is further reduced. By means of a mode of judging the wind speed threshold value, the condition that the current measured wind speed exceeds the threshold value serves as the primary condition, and the problem of loss of the generating capacity of the set due to increase of the pitch angle under the condition that the wind speed is low but the bending moment of the set is not impacted is solved.

Owner:HUANENG CLEAN ENERGY RES INST

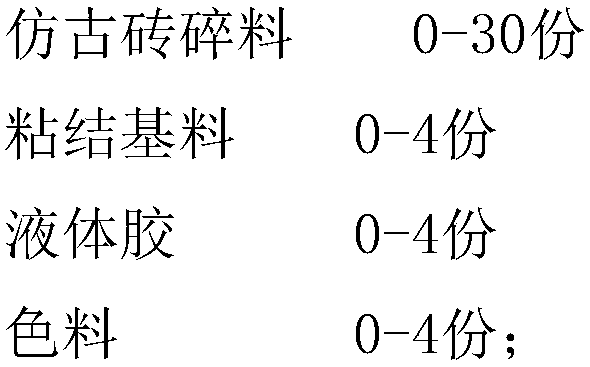

Sintered water-permeable brick produced by using archaized brick broken material and preparation method of sintered water-permeable brick

InactiveCN108249889AIncrease dosageAchieve a high degree of recyclingCeramic materials productionClaywaresFrostBrick

The invention discloses a sintered water-permeable brick produced by using an archaized brick broken material. The sintered water-permeable brick comprises a surface material and a bottom material, wherein the bottom material comprises the following main raw materials in parts by mass: 80-100 parts of the archaized brick broken material, 3-12 parts of a bonding base material and 3-12 parts of liquid glue; the surface material comprises the following main raw materials in parts by mass: 0-30 parts of the archaized brick broken material, 0-4 parts of a bonding base material, and 0-4 parts of liquid glue; the bonding base material is one or more of bentonite and clay; and the liquid glue is one or more selected from the group consisting of a silica sol solution, a polyacrylamide solution anda guar gum solution. Correspondingly, the invention discloses a preparation method of the sintered water-permeable brick produced by using the archaized brick broken material. By adopting the method provided by the invention, the archaized brick broken material is used as the main raw material, and the prepared water-permeable brick has high strength, strong frost resistance and excellent water permeability.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Anti-static calcium sulfate plate and preparation method thereof

PendingCN113152835AImprove water resistanceImprove corrosion resistanceLaminationLamination apparatusSulfatePhysical chemistry

The invention discloses an anti-static calcium sulfate plate and a preparation method thereof. The anti-static calcium sulfate plate comprises a UV conductive wear-resistant layer, a UV conductive finish paint layer, a pattern layer, a first UV conductive primer layer, a putty layer, a first UV penetrant layer, a calcium sulfate base material layer, a second UV penetrant layer, a second UV conductive primer layer, an adhesive layer and a color-coated plate which are sequentially connected from top to bottom. The anti-static calcium sulfate plate has the characteristics of excellent water resistance, corrosion resistance, wear resistance and high conductivity, and in addition, the surface layer of the anti-static calcium sulfate plate is not provided with an adhesive layer, so that the problems of tilting and hollowing of the surface layer of the plate caused by glue falling are effectively avoided.

Owner:湖北吉佩克环保科技有限公司

Sintered water permeable brick produced by using furnace slag and preparation method of sintered water permeable brick

InactiveCN108083772AIncrease dosageAchieve a high degree of recyclingCeramic materials productionCeramicwareSlagPolyacrylamide

The invention discloses a sintered water permeable brick produced by using furnace slag. The sintered water permeable brick comprises a surface material and a bottom material, wherein the bottom material is prepared from the following main raw materials in parts by mass: 80-100 parts of furnace slag, 3-12 parts of bonding base material and 3-12 parts of liquid glue; and the surface material is prepared from the following main raw materials in parts by mass: 0-30 parts of furnace slag, 0-4 parts of bonding base material, 0-4 parts of liquid glue and 0-4 parts of pigment; the bonding base material is one or more of bentonite and clay; and the liquid glue is one or more of a silica sol solution, a polyacrylamide solution and a guar gum solution. Correspondingly, the invention discloses a preparation method of the sintered water permeable brick produced by using furnace slag. The water permeable brick prepared from the furnace slag serving as the main raw material in the preparation methodis high in strength, strong in freezing resistance and excellent in water permeability.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Preparation method of environment-friendly autoclaved aerated concrete block

The invention discloses a preparation method of an environment-friendly autoclaved aerated concrete block. The method comprises the following steps: mixing and grinding a ceramic waste, loess, quicklime and desulfurized gypsum, and feeding the mixture into a sintering machine to obtain mixed aggregates; feeding methyl acrylate, ethylene oxide and an Al / Mg / Ce inorganic salt composite catalyst into a sealed reactor, carrying out heating, stirring, standing and cooling under nitrogen protection, adding rosin, phenol, sodium polynaphthalene sulfonate and concentrated sulfuric acid for mixing, and carrying out heating and stirring; sequentially adding sodium hydroxide and water for stirring to obtain a foaming agent; adding powdery sodium silicate, calcium lignosulphonate and anhydrous sodium sulfate to the mixed aggregates for ball-milling, and adding cement, polyvinyl alcohol and the foaming agent for stirring to obtain mixed slurry; and casting the mixed slurry into a mold for molding, and carrying out heating, pre-curing, demolding, cutting, autoclaved curing and cooling to obtain the environment-friendly autoclaved aerated concrete block.

Owner:浙江德义建筑设备有限公司

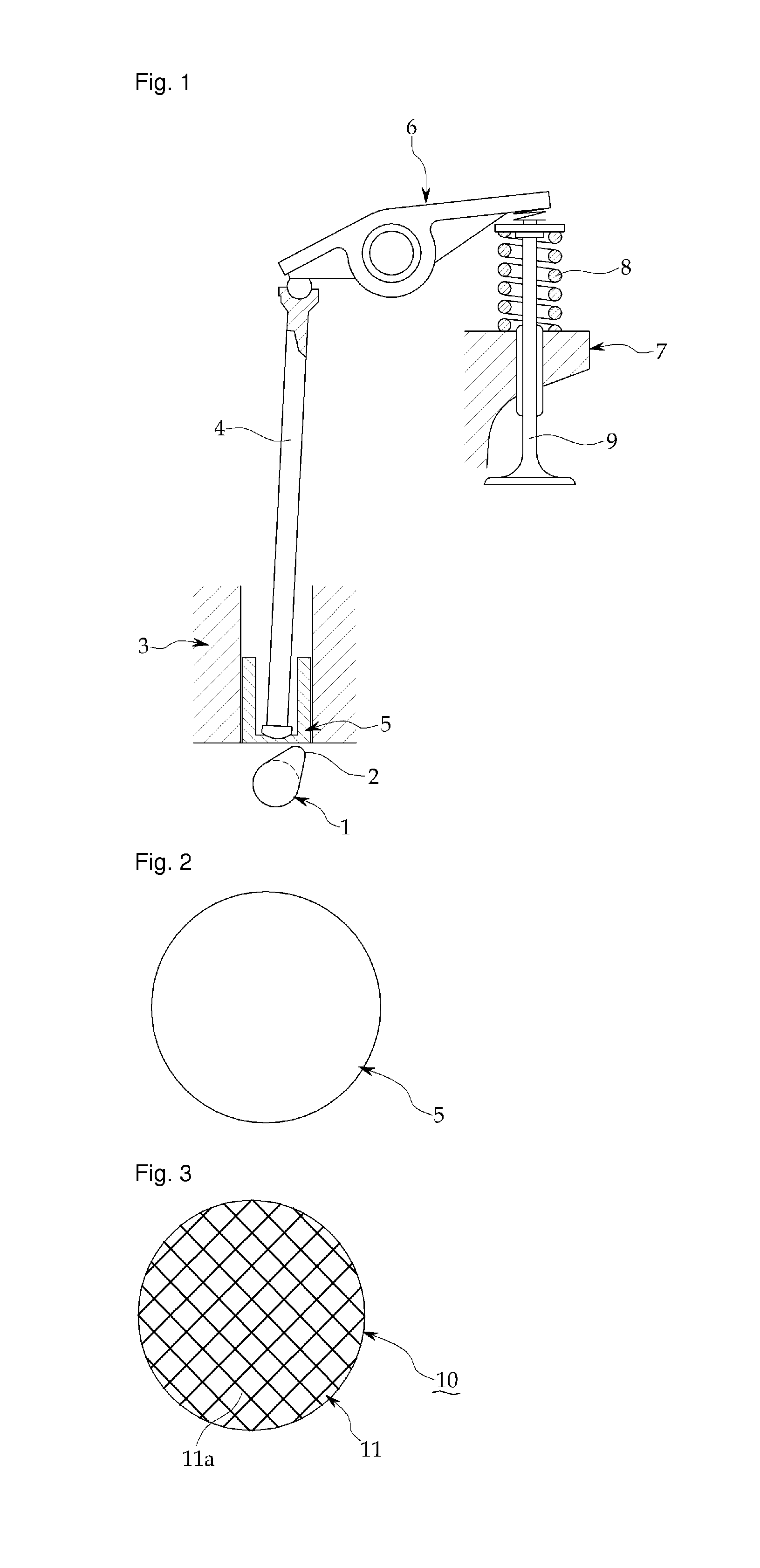

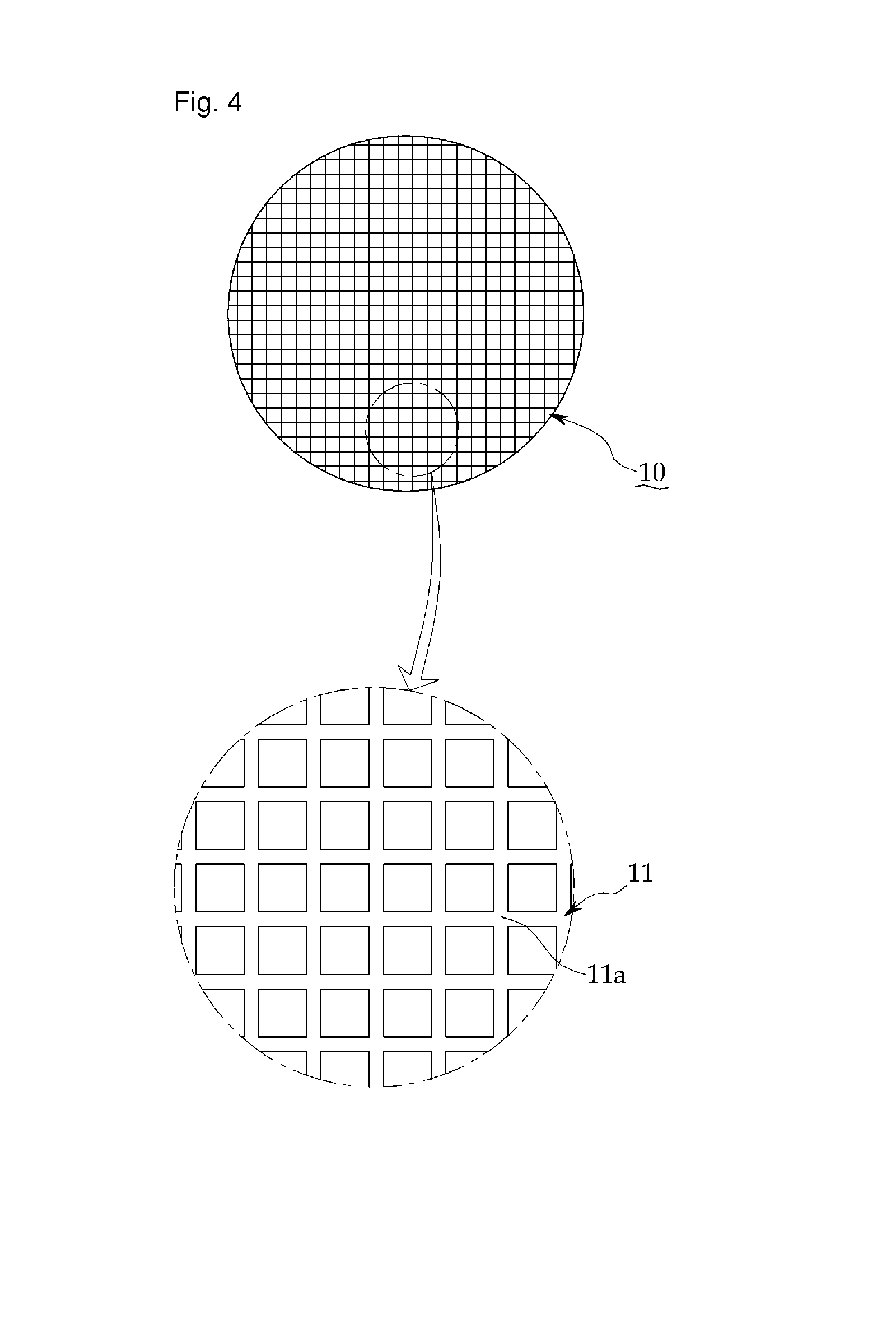

High-ductility prefabricated vibration-resistant concrete pile

InactiveCN105603968AIncreased cracking and ultimate loadsImprove seismic performanceBulkheads/pilesRebarBending moment

The invention provides a high-ductility prefabricated vibration-resistant concrete pile. The concrete pile comprises concrete, a steel reinforcement cage, end plates and pile hoops, and the steel reinforcement cage is arranged inside the concrete; the end plates are arranged at the two ends of the steel reinforcement cage; each pile hoop is arranged outside the corresponding end plate; the steel reinforcement cage comprises prestressed steel reinforcements, a stirrup and high-ductility non-prestressed steel reinforcements, and the steel reinforcement cage is formed by roll-welding the prestressed steel reinforcements and the spiral stirrup; the high-ductility non-prestressed steel reinforcements are longitudinally fixed to the stirrup. By means of the high-ductility prefabricated vibration-resistant concrete pile, the defects that existing prefabricated concrete piles are poor in bending performance and ductility, the failure is brittle failure, ductility is poor, cracks appearing in the prefabricated concrete piles spread rapidly, steel reinforcements in a tensile area are yielded and tightened quickly till fracture, and the difference between ultimate bending moment and the cracking bending moment is not large are overcome, ductility of a tube pile is improved well, it is helpful to improve vibration resistance, maintenance cost can be lowered, the service life is prolonged, and the high-ductility prefabricated vibration-resistant concrete pile has the advantages of being simple in process, high in cost performance, wide in application scope and the like.

Owner:TIANJIN BAOFENG BUILDING MATERIALS CO LTD

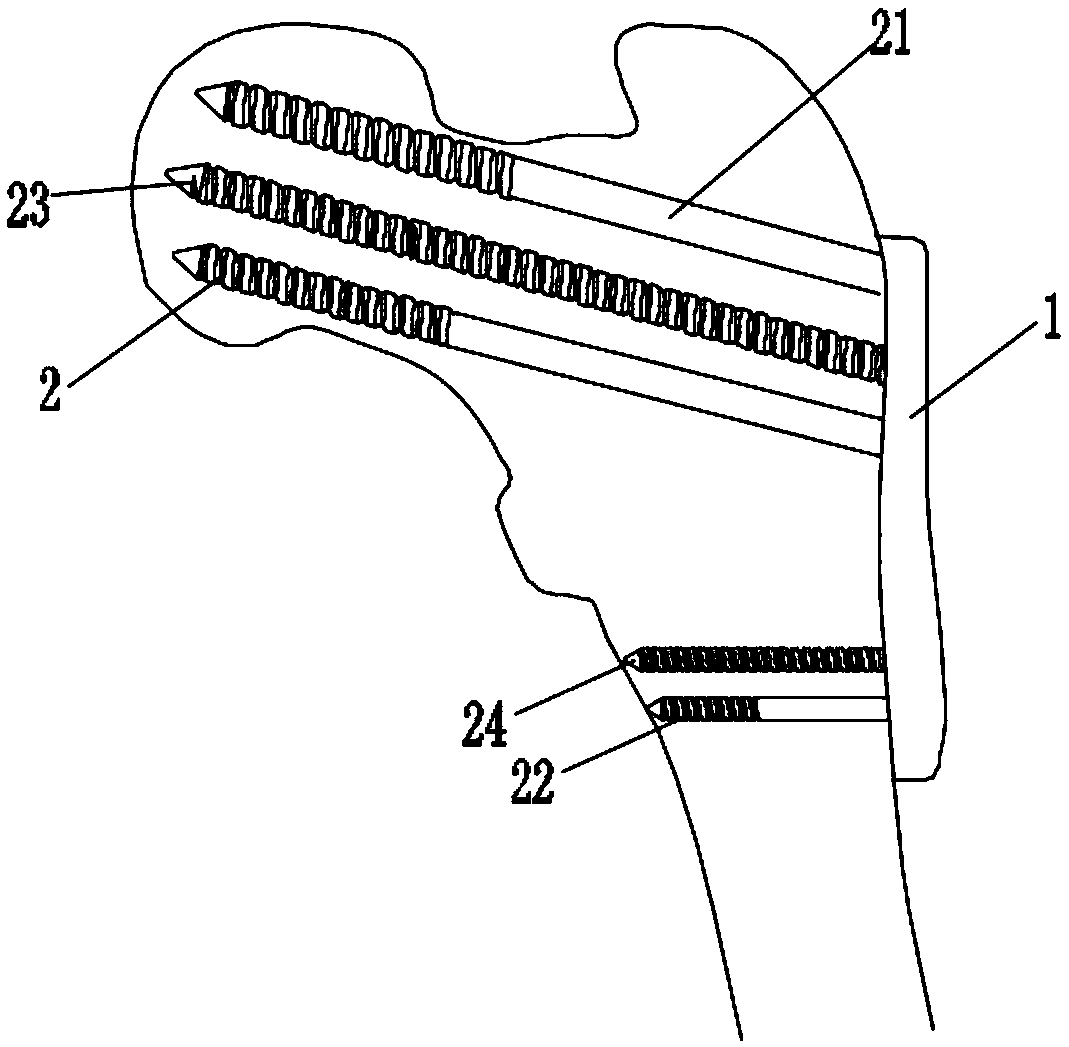

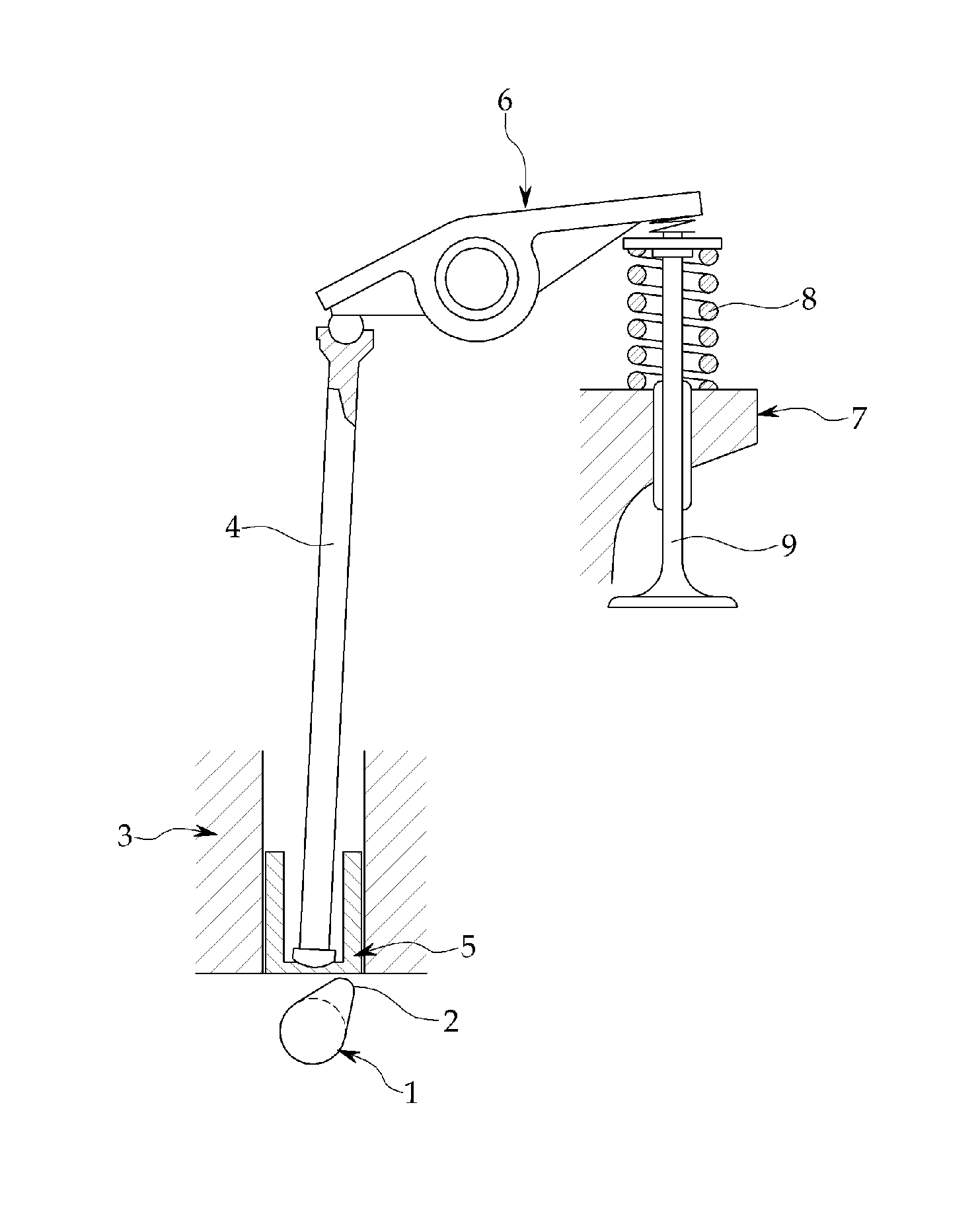

Universal locking device of femoral neck and femoral neck operation method

PendingCN108852494AReduce horizontal displacementIncreased torsional strengthInternal osteosythesisBone platesRight femoral headFemoral shaft

The invention provides a universal locking device of femoral neck and a femoral neck operation method. A femoral head fitting portion is provided with universal locking holes, including a first universal locking hole, a second universal locking hole, a third universal locking hole and a fourth universal locking hole; the first universal locking hole and the fourth universal locking hole are symmetrically arranged in spaced manner along the vertical direction; the second universal locking hole and the third universal locking hole are symmetrically arranged in spaced manner in the horizontal direction; a femoral shaft fitting portion is provided with two locking holes arranged evenly in spaced manner; fixing nails are tightened in the universal locking holes and the locking holes to fix thefemoral neck. The problem that an internal fixation system for femoral neck fracture operation has poor stability is solved. The femoral head fitting portion is fitted to the femoral head; the fixingnails are tightened in the four universal locking holes arranged in diamond form, and stable fixation is achieved; the fixing nails are tightened in the two locking holes for stable fixation; the femoral head experiences small sinking and horizontal displacements; the operations are simple, and less surgical pain is caused to patients.

Owner:李庆嵩

Cam follower with improved structure to increase limit load

ActiveUS8807105B2Increase ultimate loadImprove lubrication statusValve arrangementsMachines/enginesEngineeringCam

Owner:HD HYUNDAI INFRACORE CO LTD

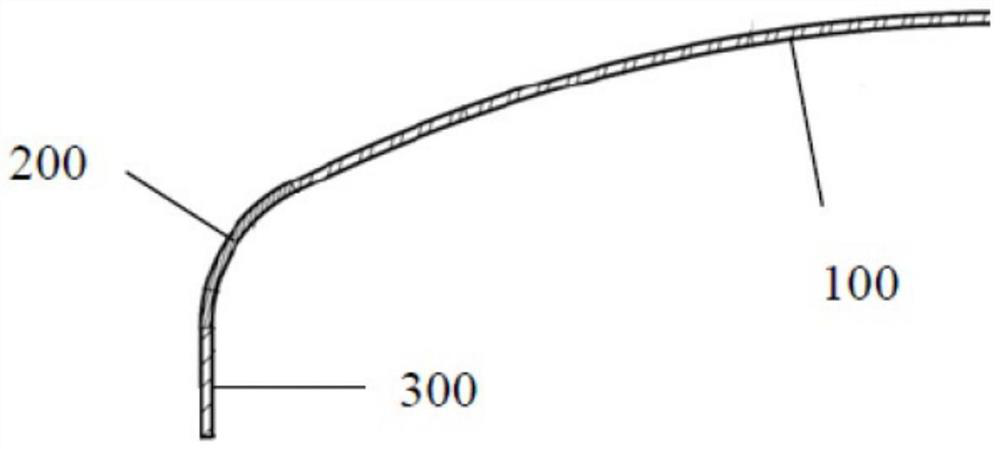

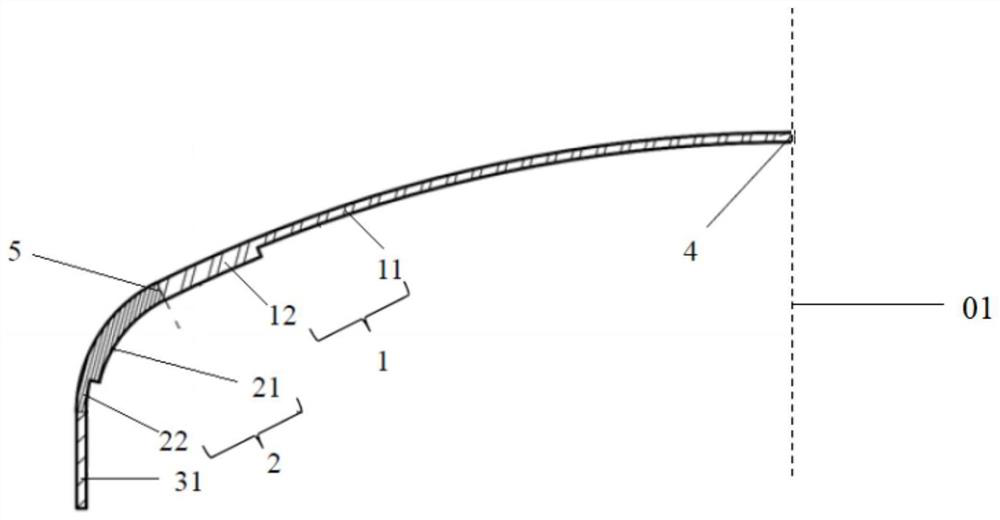

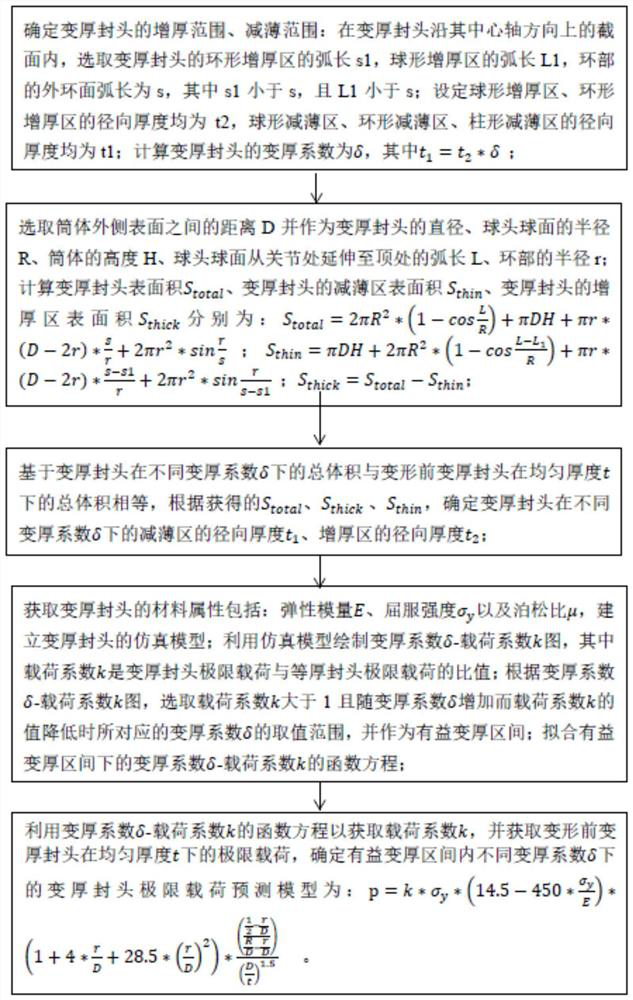

Thickening seal head and design method thereof

PendingCN114104187AReduce stress concentrationIncrease ultimate loadGeometric CADVessel designingVariable thicknessEngineering

The invention provides a thickened end socket and a design method thereof, and the thickened end socket comprises a ball head which is provided with a first thinning area and a first thickening area; the ring part comprises a second thickening area and a second thinning area, and the cylinder body comprises a third thinning area; the design method comprises the steps that an existing butterfly-shaped seal head is selected as a seal head before deformation, and the thickening range and the thinning range of a thickened seal head are determined; the superficial area of the thickened seal head, the superficial area of a thinning area and the superficial area of a thickening area are calculated; based on the fact that the total volume of the thickened end socket under different thickening coefficients is equal to the total volume of the end socket before deformation, the thickness t1 of the thinning area and the thickness t2 of the thickened area are determined; establishing a thickened end socket simulation model; drawing a variable thickness coefficient delta-load coefficient k graph, and selecting the value range of the corresponding variable thickness coefficient delta when the load coefficient k is greater than 1 and the value of the load coefficient k is reduced along with the increase of the variable thickness coefficient delta as a beneficial variable thickness interval; fitting a variable thickness coefficient delta-load coefficient k functional equation; and determining a variable-thickness seal head limit load prediction model under different variable-thickness coefficients delta.

Owner:JIANGSU UNIV OF SCI & TECH

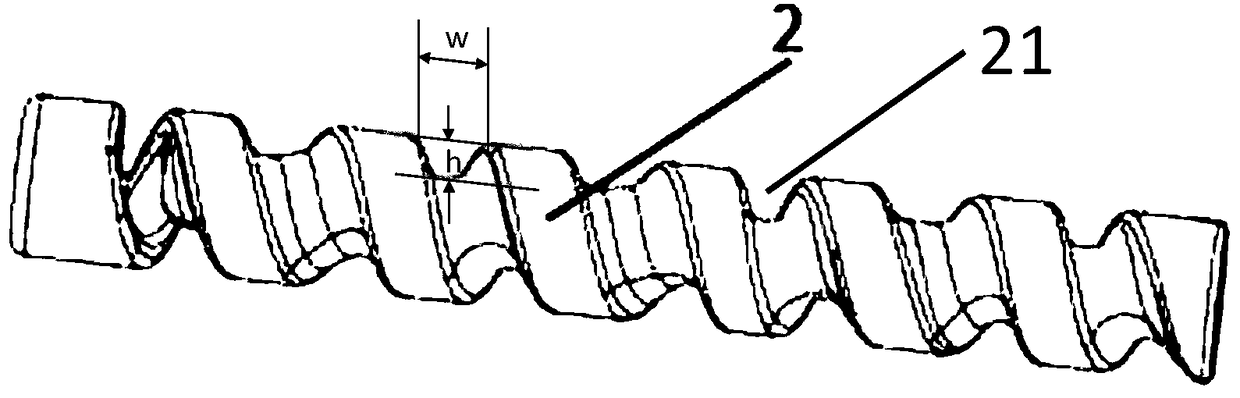

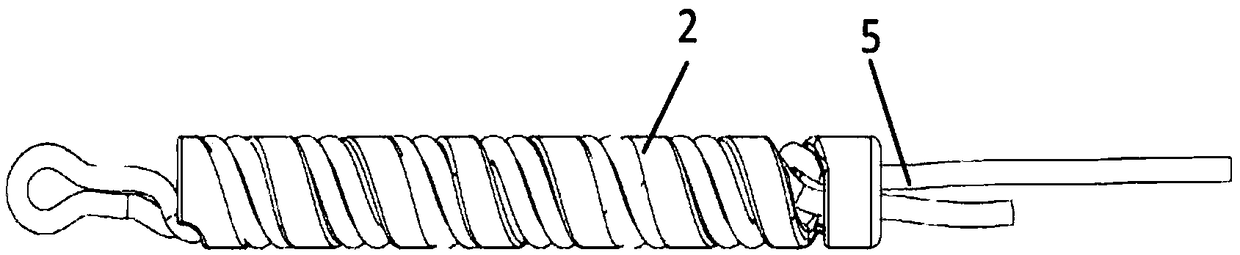

Spiral type rope locking device

PendingCN108194578AExtended service lifeIncrease the bearing areaRopes and cables for vehicles/pulleyTextile cablesEngineeringScrew thread

The invention provides a spiral type rope locking device which is mainly composed of a hoop, a spiral pillar, an optional optical ring and an optional pressing block. A rope is used for spirally winding the rope on a threaded groove of the spiral pillar and is hooped through the hoop. The pressing block arranged at one end of the rope locking device is further adopted for knotting the rope. The spiral type rope locking device has the beneficial effects that operation is simple, safety and reliability are achieved, and the rope is not damaged.

Owner:丹阳昊天飞行器技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com