Anti-static calcium sulfate plate and preparation method thereof

A calcium sulfate, anti-static technology, applied in the field of panels, can solve the problems of floor collapse, surface warping, bearing capacity not meeting the requirements, etc., to achieve the effect of improving concentrated load and ultimate load, high waterproofness and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of the present invention also provides a kind of preparation method of antistatic calcium sulfate plate, and this preparation method comprises the following steps:

[0038] (a) Carry out sanding, dedusting to calcium sulfate base material bottom surface, subsequently, lay UV penetrating agent and dry, form the second UV penetrating agent layer, lay UV conductive primer on the surface of the second UV penetrating agent layer and dry , forming the second UV conductive primer layer; then bonding the color-coated plate on the surface of the second UV conductive primer layer to obtain the bottom surface processing plate;

[0039] (b) Sanding and dedusting the side of the bottom surface processing plate, subsequently, laying UV penetrating agent and drying to form the third UV penetrating agent layer, laying UV conductive primer on the surface of the third UV penetrating agent layer and drying, Form the 3rd UV conductive primer layer, obtain side processing pla...

Embodiment 1

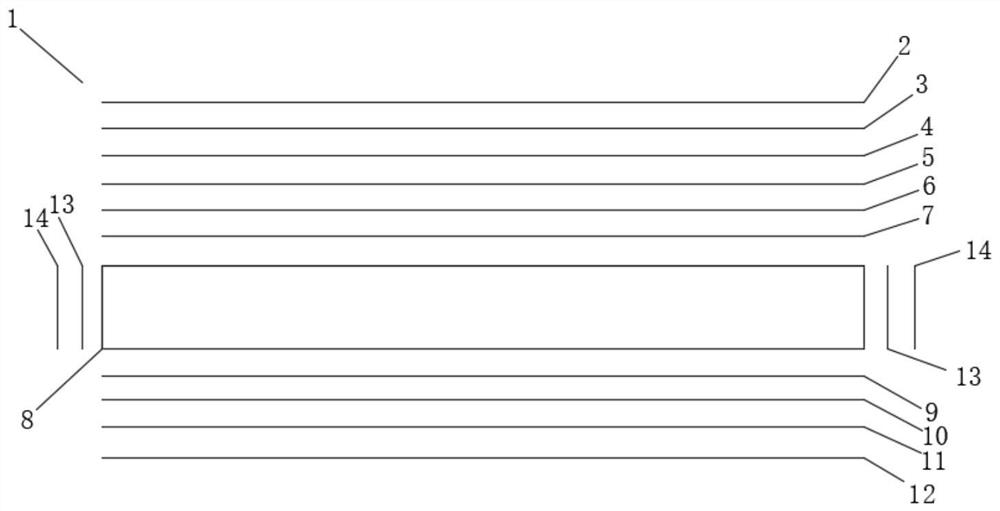

[0048] This embodiment is an antistatic calcium sulfate plate, such as figure 1 As shown, the antistatic calcium sulfate plate 1 includes a UV conductive wear-resistant layer 2, a UV conductive topcoat layer 3, a pattern layer 4, a first UV conductive primer layer 5, a putty layer 6, a first One UV penetrating agent layer 7, calcium sulfate substrate layer 8, the second UV penetrating agent layer 9, the second UV conductive primer layer 10, adhesive layer 11 and color-coated plate 12;

[0049] The antistatic calcium sulfate plate 1 also includes a third UV penetrant layer 13 and a third UV conductive primer layer 14;

[0050] The third UV penetrant layer 13 is arranged on the side of the calcium sulfate substrate layer 8;

[0051] The third UV conductive primer layer 14 is disposed on the outside of the third penetrant layer 13 .

Embodiment 2

[0053] Present embodiment is a kind of preparation method of antistatic calcium sulfate plate, and this preparation method comprises the following steps:

[0054] (a) Under a high pressure of 400t, the phosphogypsum is pressed to obtain a calcium sulfate substrate by means of upper and lower water filtration, and after natural curing for 48 hours, it is dried at 180°C and dimensionally processed to obtain a calcium sulfate substrate layer 8;

[0055] Use 400-mesh sandpaper to sand and remove dust on the bottom surface of the calcium sulfate substrate layer 8. Then, use a double-roll coater to lay a UV penetrant on the bottom surface of the calcium sulfate substrate, and then enter the UV dryer to dry to form the second UV penetrant. Agent layer 9, adopt infrared leveling machine to lay UV conductive primer on the surface of the second UV penetrating agent layer 9 and adopt UV drier to dry, form the second UV conductive primer layer 10; The surface of the layer 10 is sprayed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com