High-ductility prefabricated vibration-resistant concrete pile

A concrete pile, high ductility technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of poor ductility, poor flexural performance, poor overall performance, etc., achieve full hysteresis curve, improve seismic performance, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

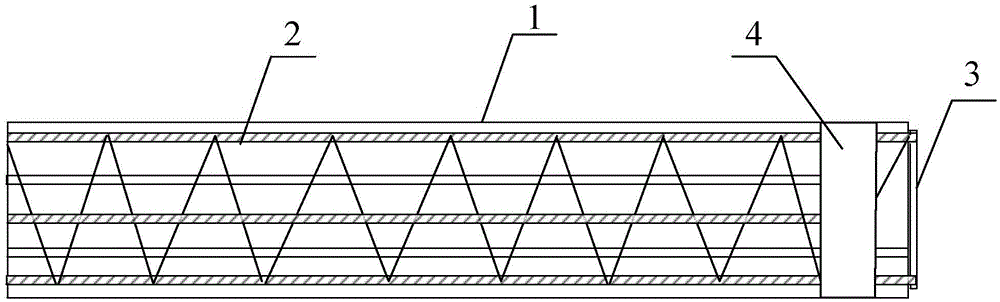

[0022] as attached figure 1 to attach image 3 shown

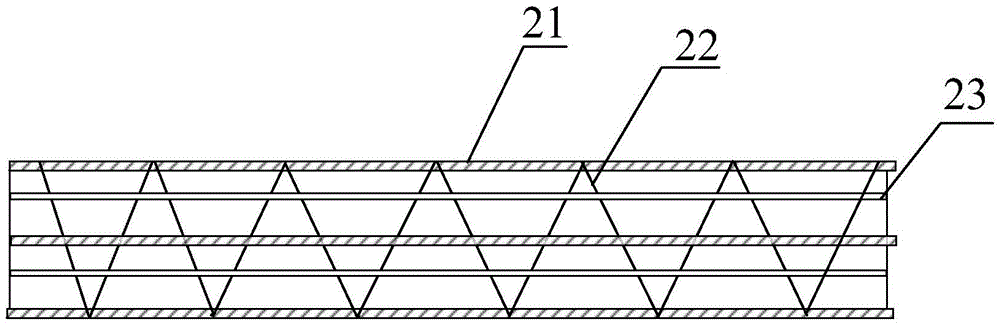

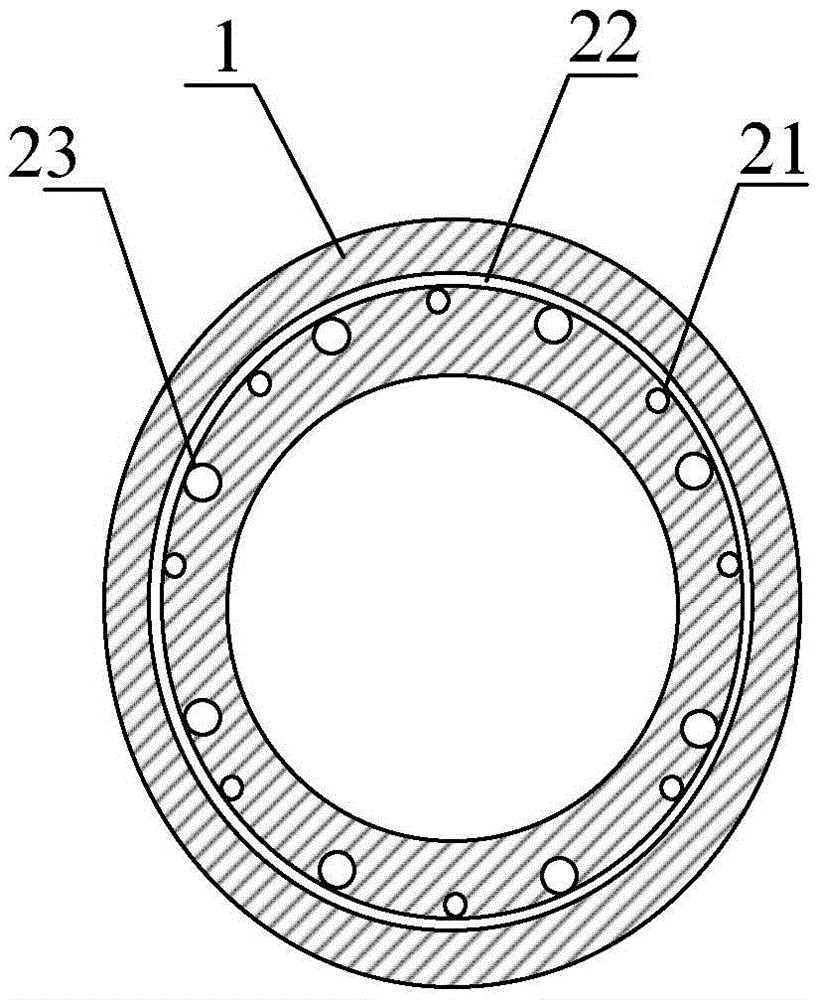

[0023] The present invention provides a high ductility prefabricated anti-seismic concrete pile, comprising concrete 1, reinforcement cage 2, end plate 3 and pile hoop 4, the reinforcement cage 2 is arranged inside the concrete 1; the reinforcement cage 2 Two ends are provided with end plate 3; The outside of described end plate 3 is provided with pile hoop 4; Described reinforcement cage 2 comprises prestressed reinforcement 21, stirrup 22 and high ductility non-prestressed reinforcement 23, so The prestressed steel bars 21 and the spiral stirrups 22 are rolled and welded to form a reinforcement cage; the high ductility non-prestressed steel bars 23 are longitudinally fixed on the stirrups 22.

[0024] The prestressed steel bar 21 is specifically distributed along the circumference of the stirrup bar 22, and it is beneficial to improve the flexural bearing capacity and deformation capacity of the PHC pipe pile by cooper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com