Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1844results about How to "Improve manufacturing precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

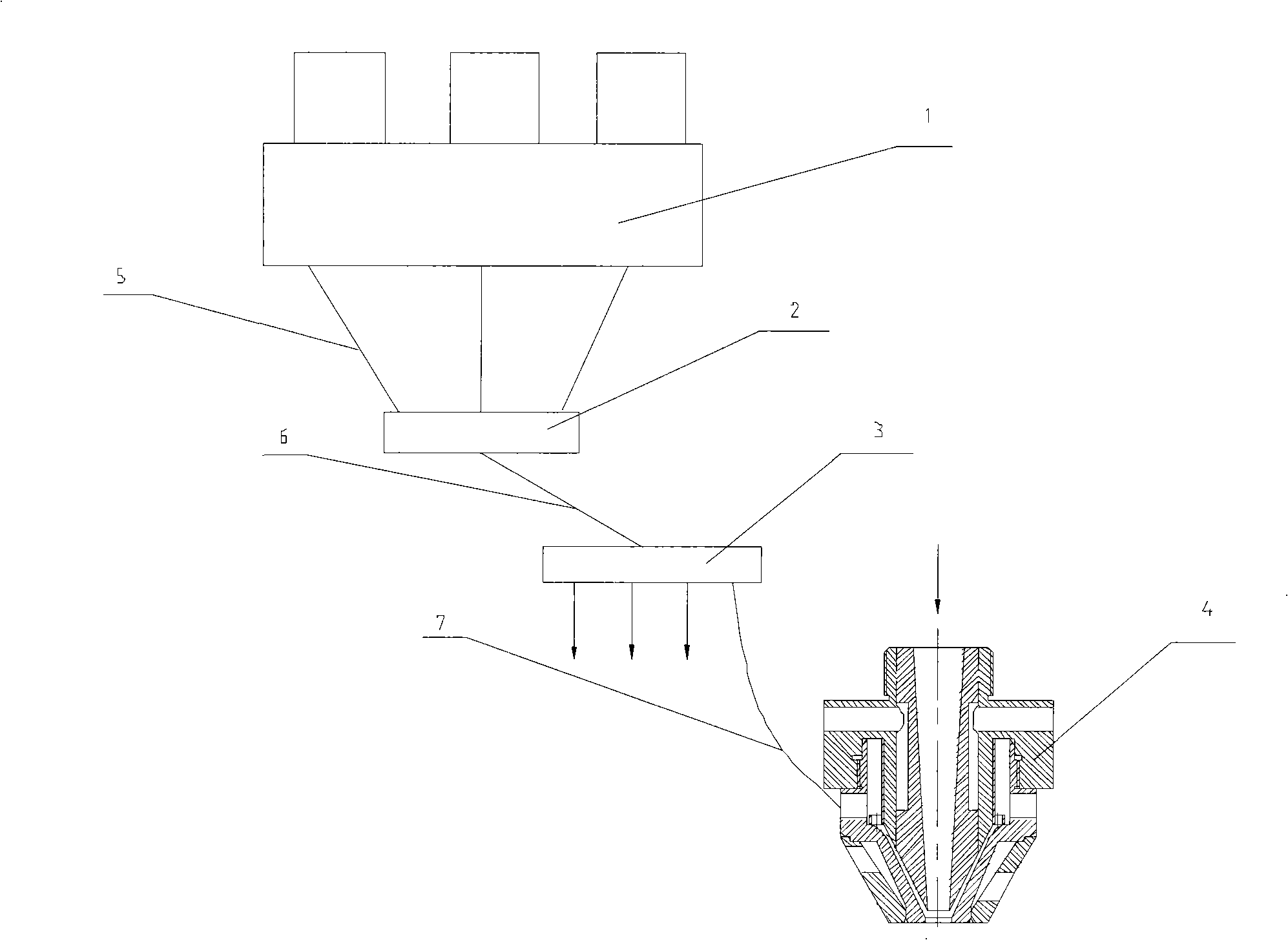

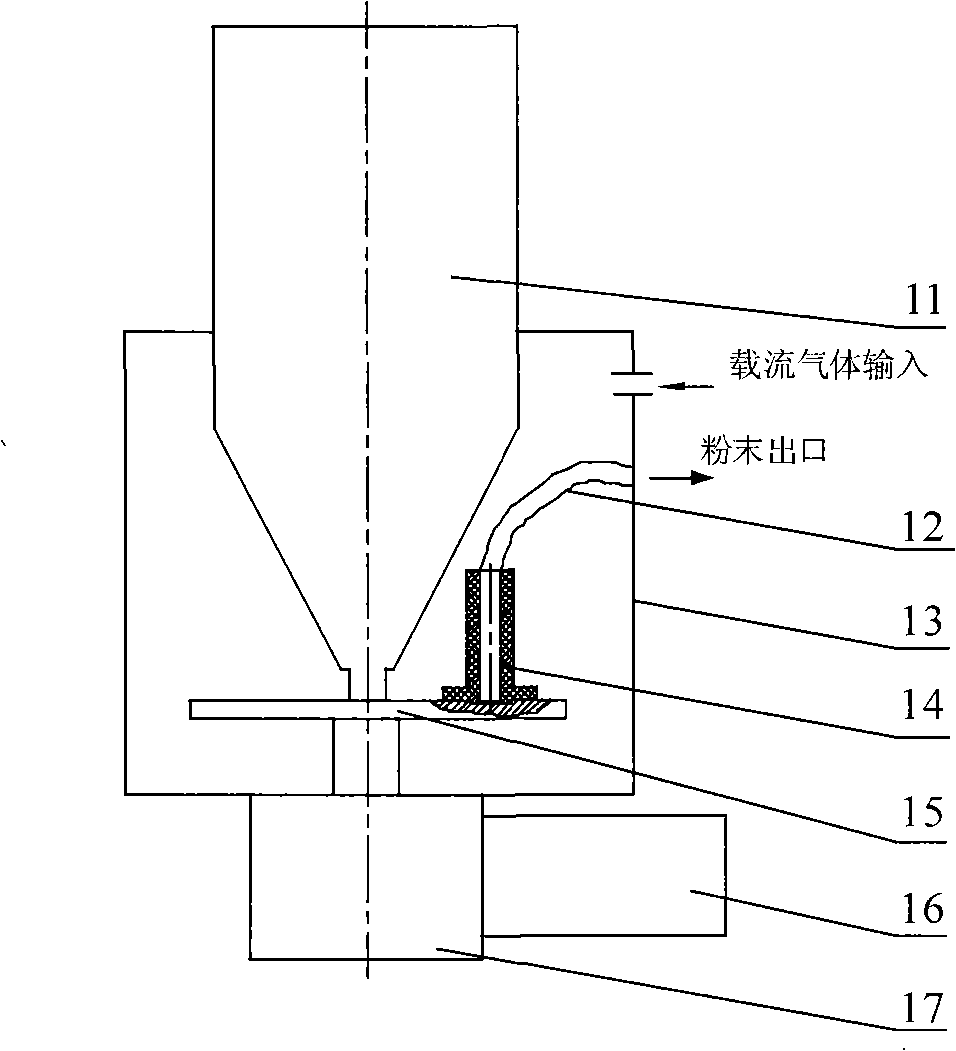

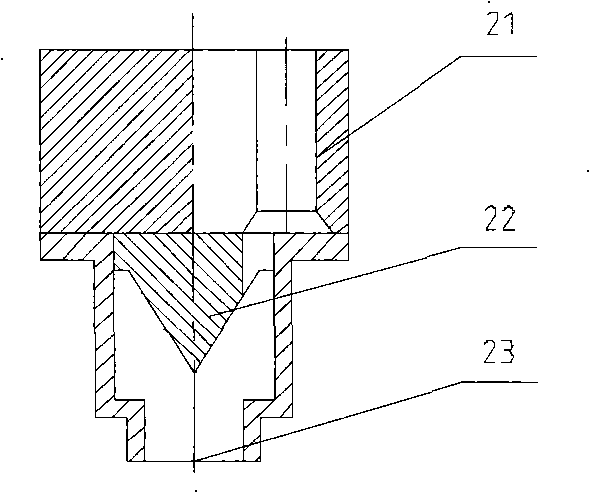

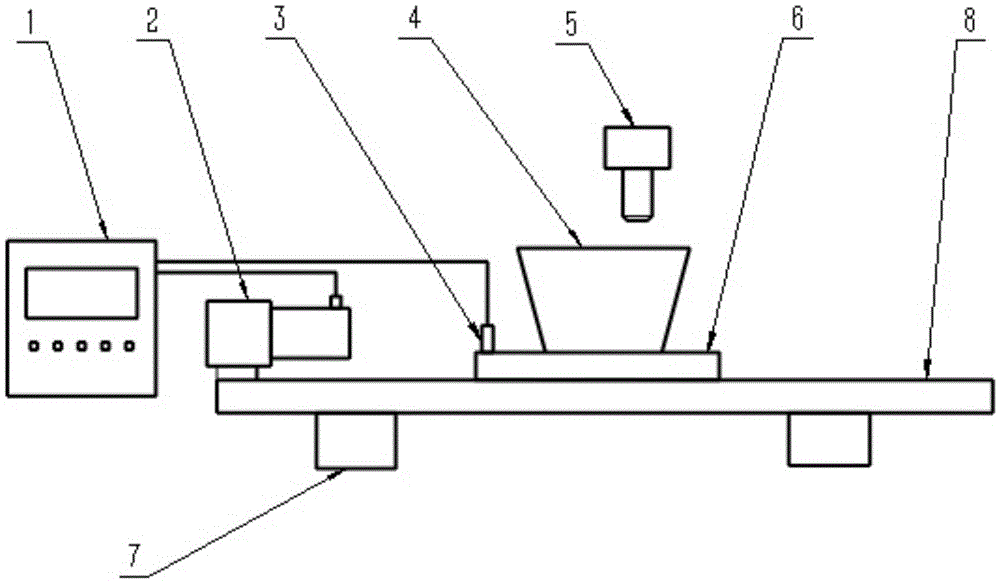

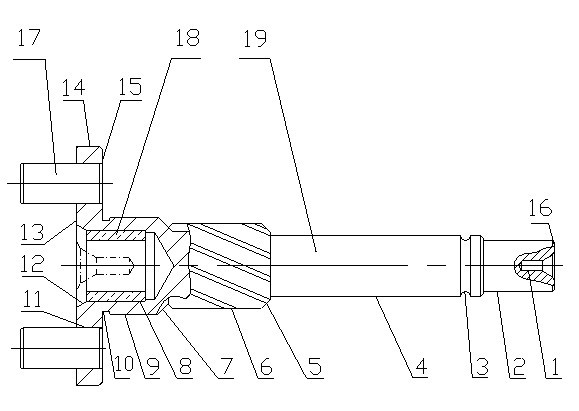

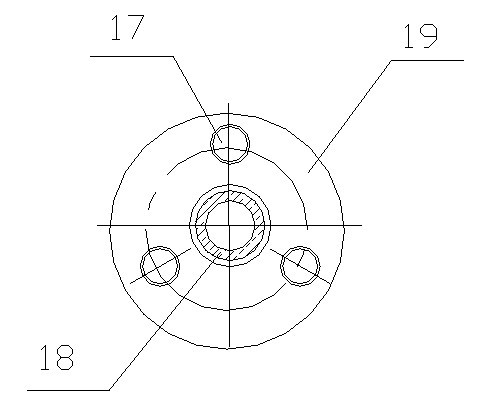

Coaxial powder feeding system for quickly molding and producing functional gradient material with laser

InactiveCN101342640AWell mixedImprove uniformityIncreasing energy efficiencyLaser beam welding apparatusNozzleRapid prototyping

The invention relates to a coaxial powder feeding system of laser rapid prototyping preparation function gradient material, comprising a powder inlet device, and the powder is absorbed and conveyed by carrier gas. The powder inlet device is communicated with a powder mixer through a first conveying pipe. The powder mixer is used for mixing the powder which has been conveyed. The mixed powder enters into a powder separate device through a second conveying pie. The powder separate device is used for separating the mixed powder into multi-path. The powder separate device is communicated with the powder inlet of a nozzle through a third conveying pipe. The nozzle makes the multi-path powder flock together in a molten pool formed by laser. The function gradient material is prepared under the cladding action of laser and powder. The mix of the powder is uniform. The coaxial powder feeding system has good power feeding property, which can realize the optimum processing, and at the same time, can be suitable for different processing distances. The powder utilization rate is high. The manufacturing accuracy is good. At the same time, the powder conveying distance can be adjusted with a certain scope, and so the coaxial powder feeding system can not be limited to the manufacturing space.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

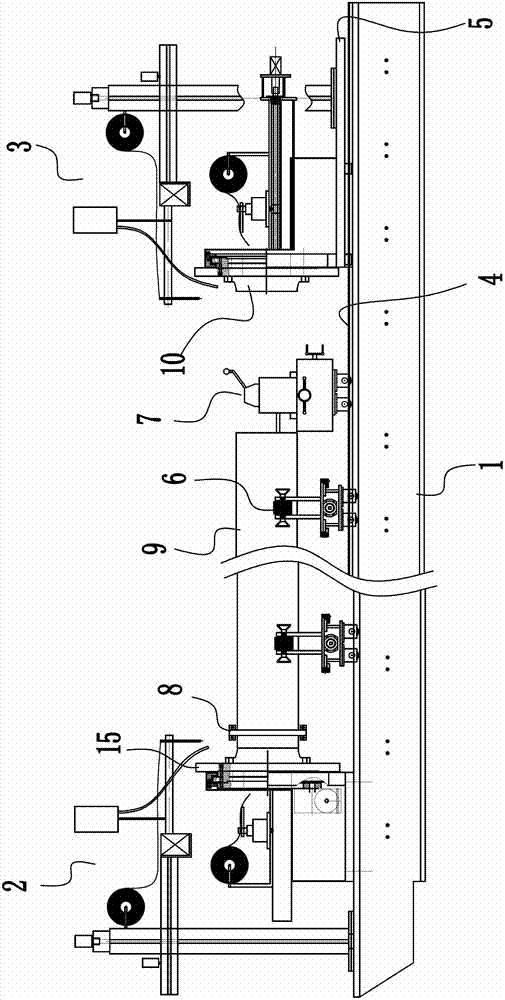

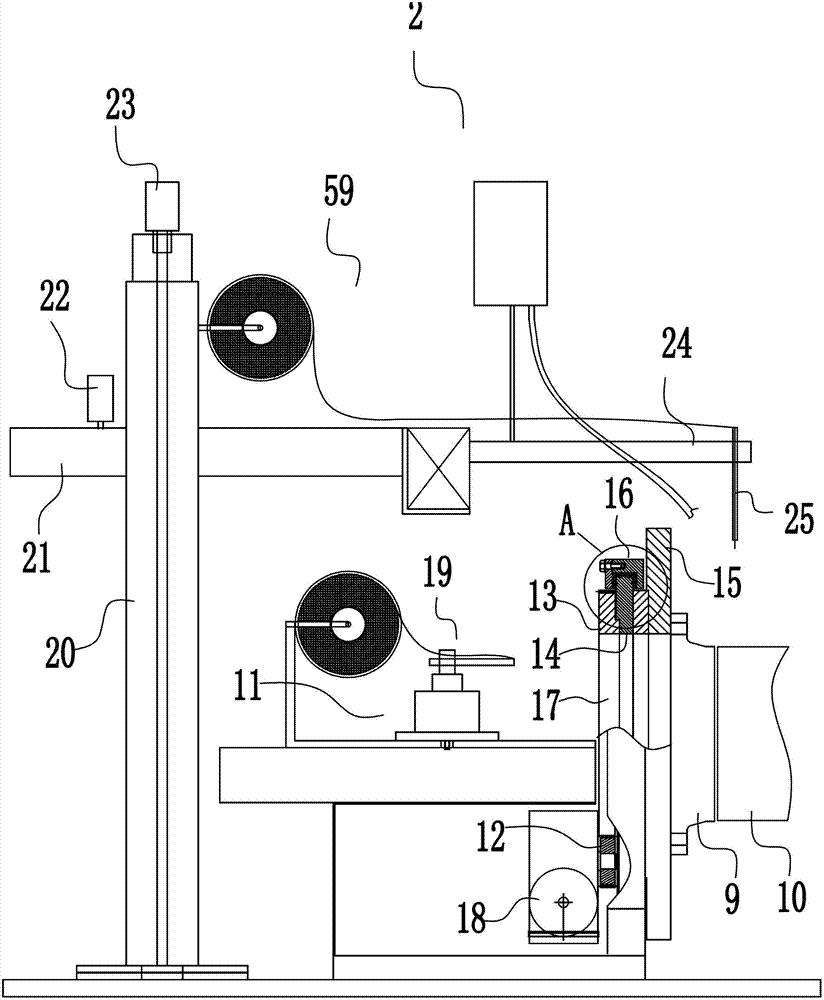

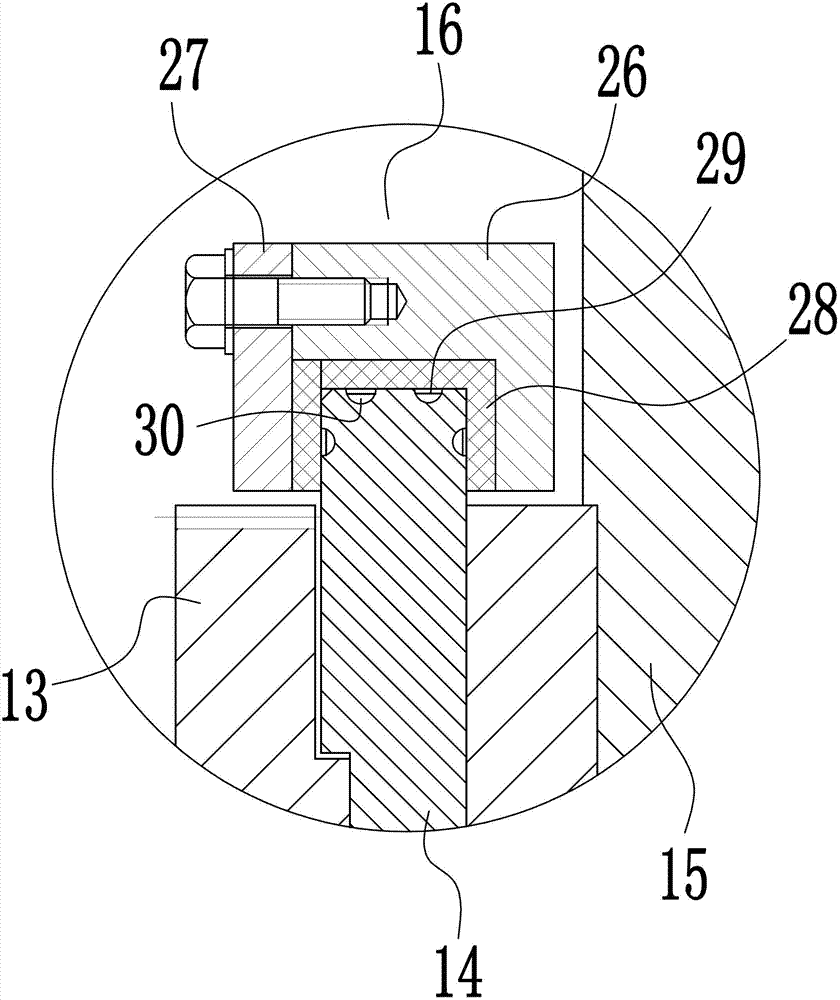

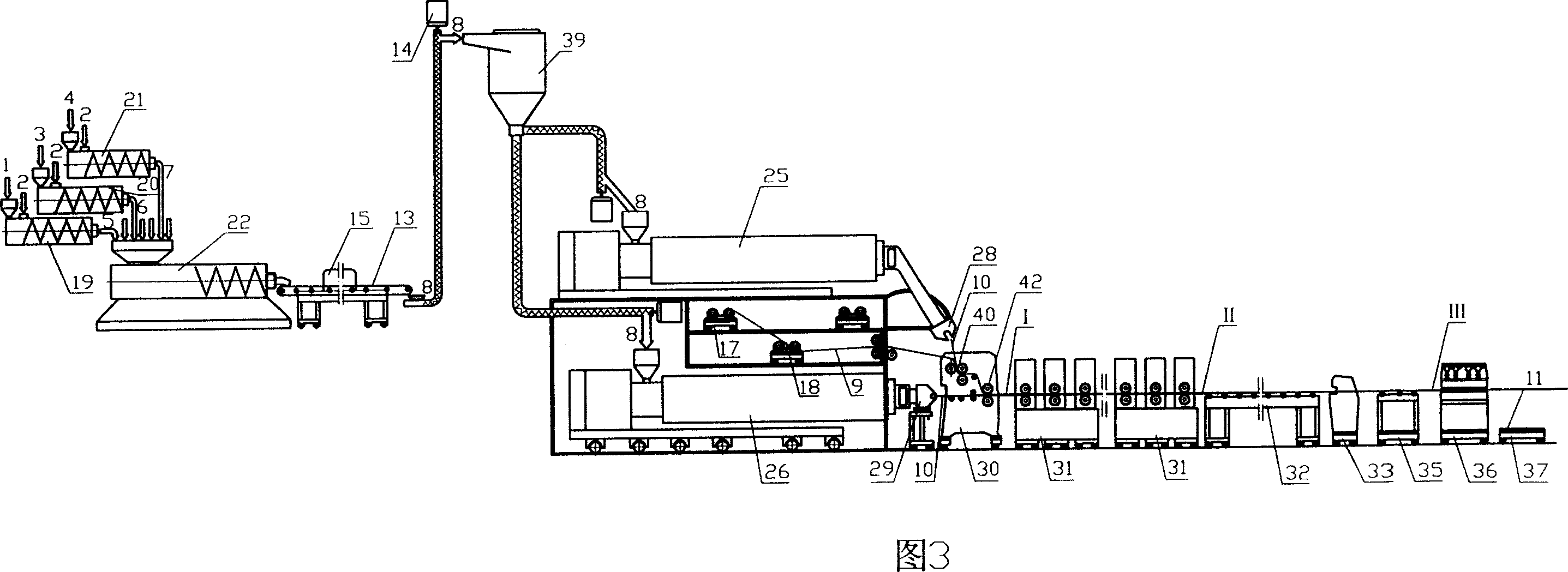

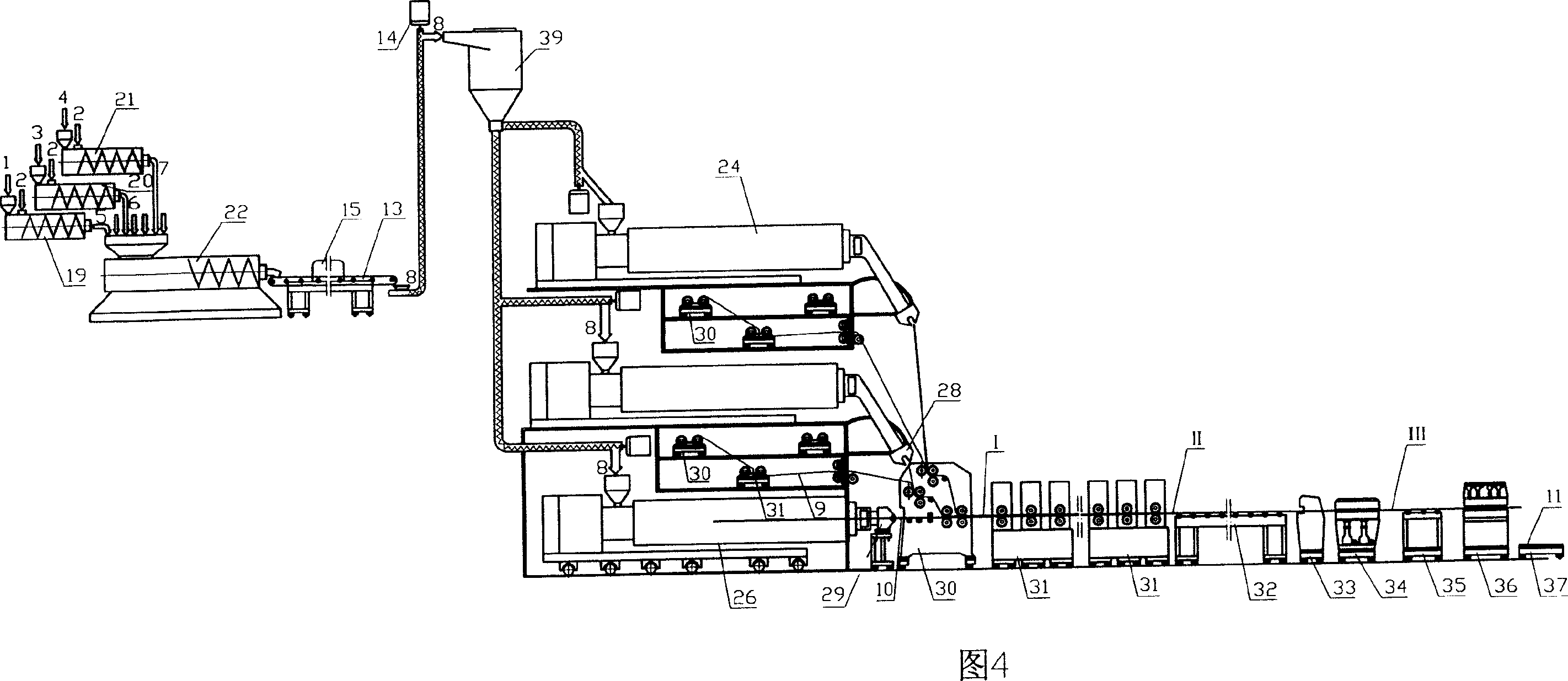

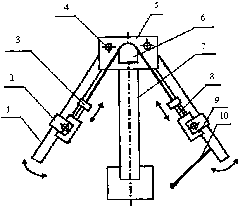

Integrated steel pipe and flange splicing and machining machine and machining process thereof

InactiveCN102729045ALarge amount of welding depositionImprove welding speed and qualityArc welding apparatusOther manufacturing equipments/toolsSteel tubeMachining process

The invention discloses an integrated steel pipe and flange splicing and machining machine and a machining process thereof and aims to provide an integrated steel pipe and flange splicing and machining machine which can improve the manufacturing precision and the production efficiency and reduce the labor intensity and is high in steel pipe and flange welding quality and a machining process of the machine. The integrated steel pipe and flange splicing and machining machine comprises a working platform, and a supporting bracket which is arranged on the working platform and is used for supporting a steel pipe, wherein one end of the working platform is provided with a first welding device; a first guide rail which extends to the other end of the working platform is arranged on the top of the working platform; a first mounting plate is arranged on the first guide rail in a sliding mode; a second welding device is arranged on the first mounting plate; and flange fixing templates are arranged on the first welding device and the second welding device. The machining process comprises the following steps of: lifting the steel pipe to the supporting bracket, and fixing the flange to a flange fixing template; and welding annular gaps of the inner and outer side faces of the steel pipe and the flange through the first welding device and the second welding device.

Owner:戴刚平

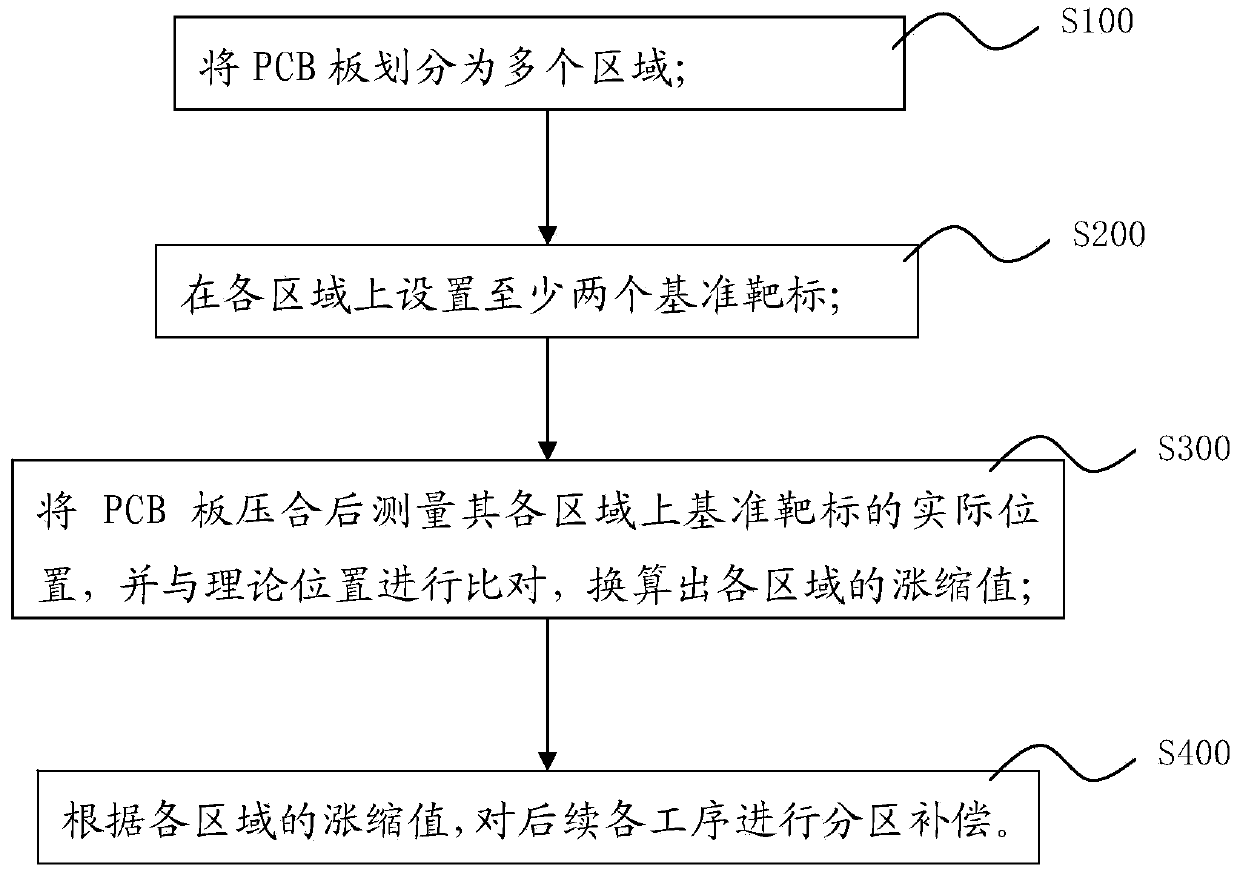

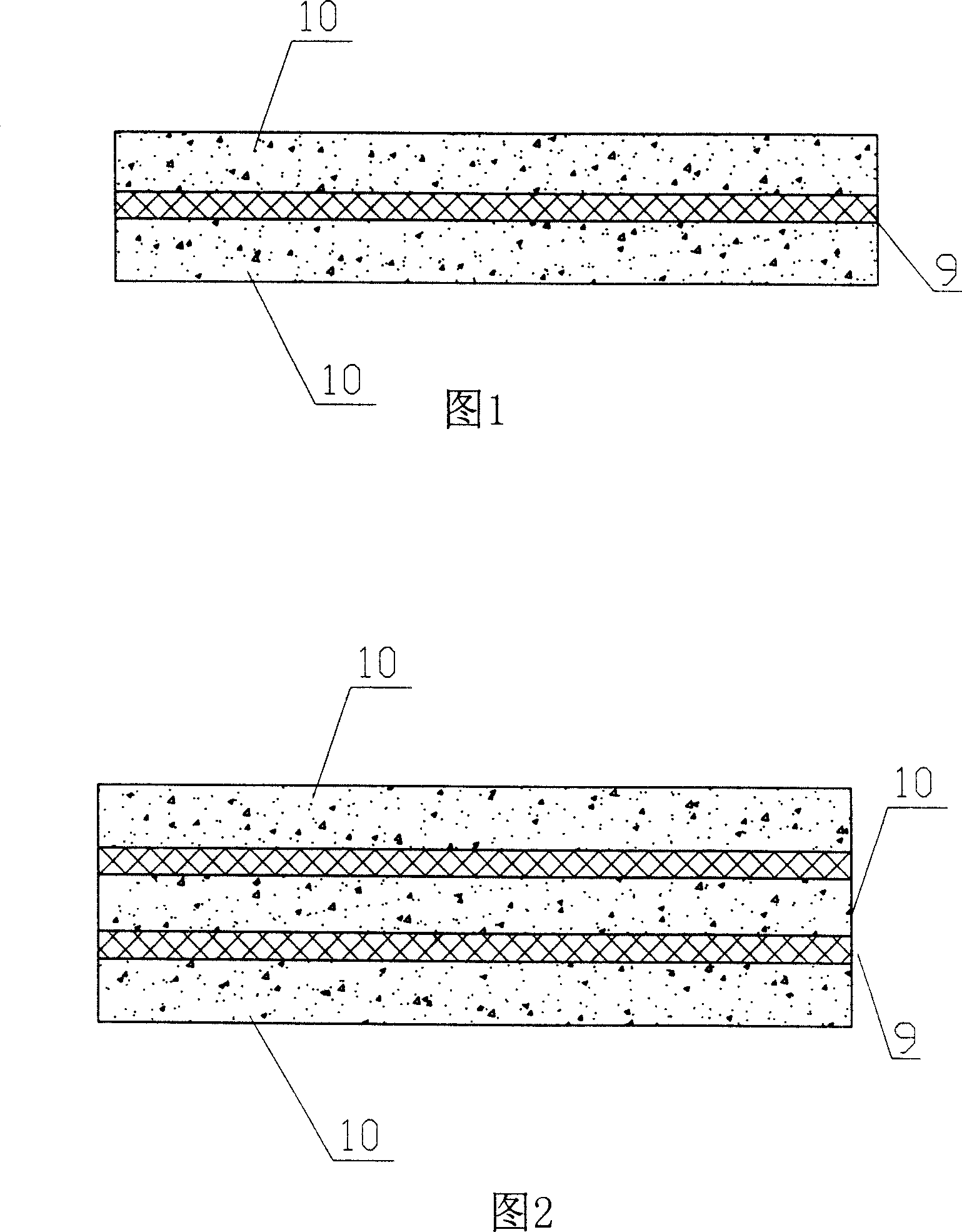

PCB expansion compensation method

ActiveCN103747617AReduce expansion and contraction deviationImprove manufacturing precisionPrinted circuits stress/warp reductionPrinted circuit manufactureEngineeringCompensation methods

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

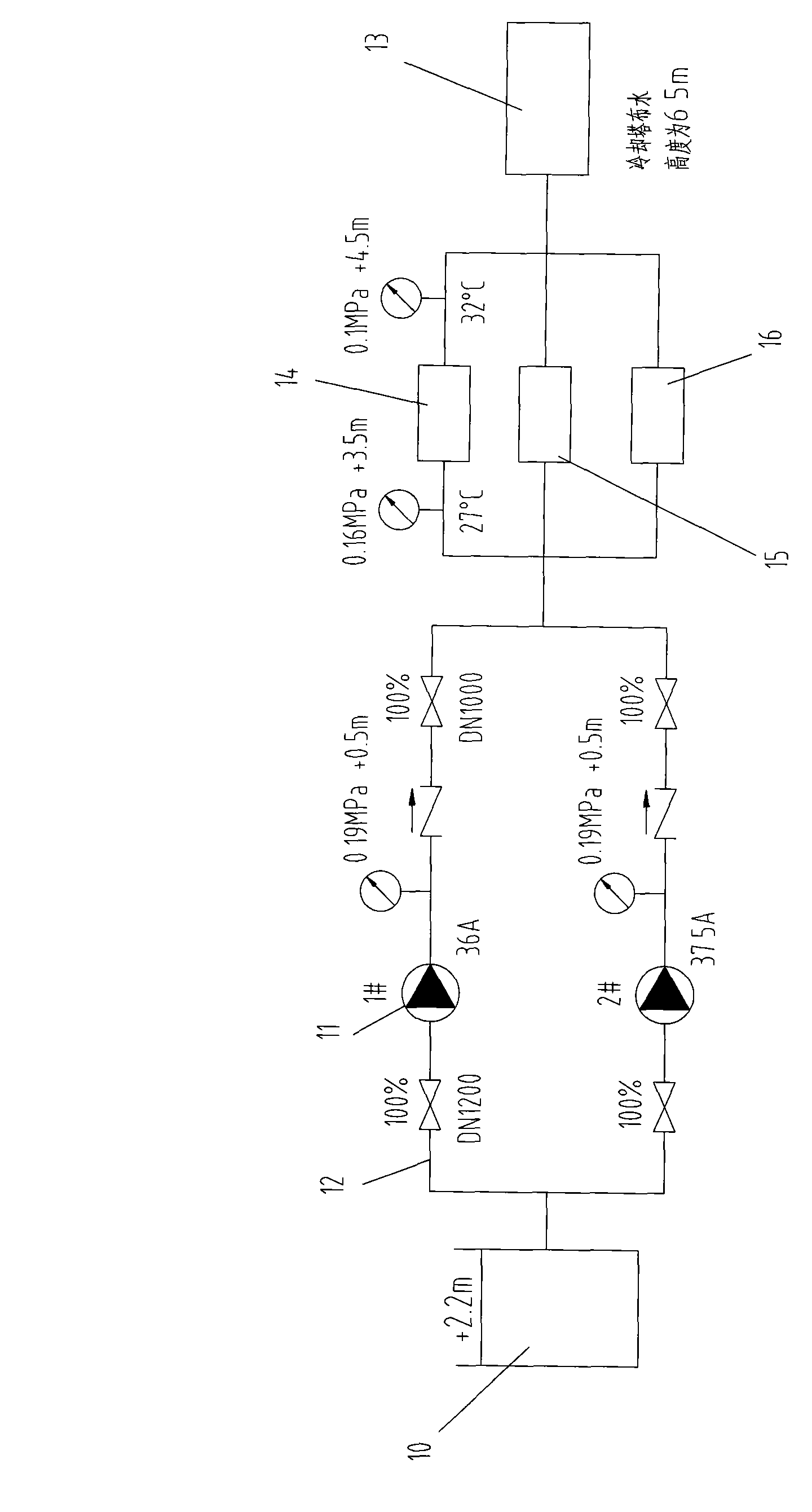

Energy saving method for circulating water system

InactiveCN101666319AImprove efficiencyImprove manufacturing precisionPump installationsNon-positive displacement fluid enginesCooling towerOperating point

The invention discloses an energy saving method for a circulating water system. The method comprises the following steps: firstly, detecting duty parameters of the current operation of the system andparameters of related devices; then, in accordance with the principle of economic operation of the circulating water system, creating a standard for the balance test and the calculation of the systemenergy by starting with a circulating water pump group, a pipe network, a heat-exchange device, a refrigeration device, a cooling tower and the like, analyzing the use efficiency of the system energy,evaluating the current use efficiency index of the system energy, and finding out the cause for the high energy consumption of the system; finally, by combining production process requirements, accurately finding out the optimum operating point where the devices are matched with the liquid transportation, and giving an optimum solution for the process energy of the system so as to achieve the purposes of high efficiency and energy saving. By detecting and analyzing the circulating water system, the invention provides a comprehensive, systemic and thorough energy saving method for the circulating water system.

Owner:长沙翔鹅节能技术有限公司

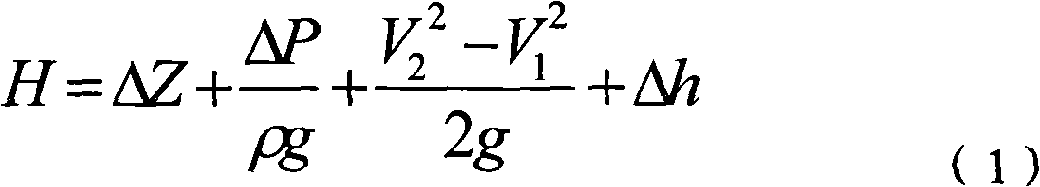

Method for press punching a hole in sheet metal and press die

InactiveUS8087333B2Shorten the overall cycleHigh-quality punching reliablyMetal working apparatusPunchingCoil spring

A punch unit for a press die is provided for punching a hole in sheet metal. The punch unit includes a piercing punch provided with a sharp projection, a plunger for pressing the piercing punch, a cylinder for supporting the piercing punch and the plunger slidably in a punching direction, and a coil spring for retracting the piercing punch and the plunger. Also disclosed is a press die for punching a hole in sheet metal using the punch unit.

Owner:WANTS CO LTD +1

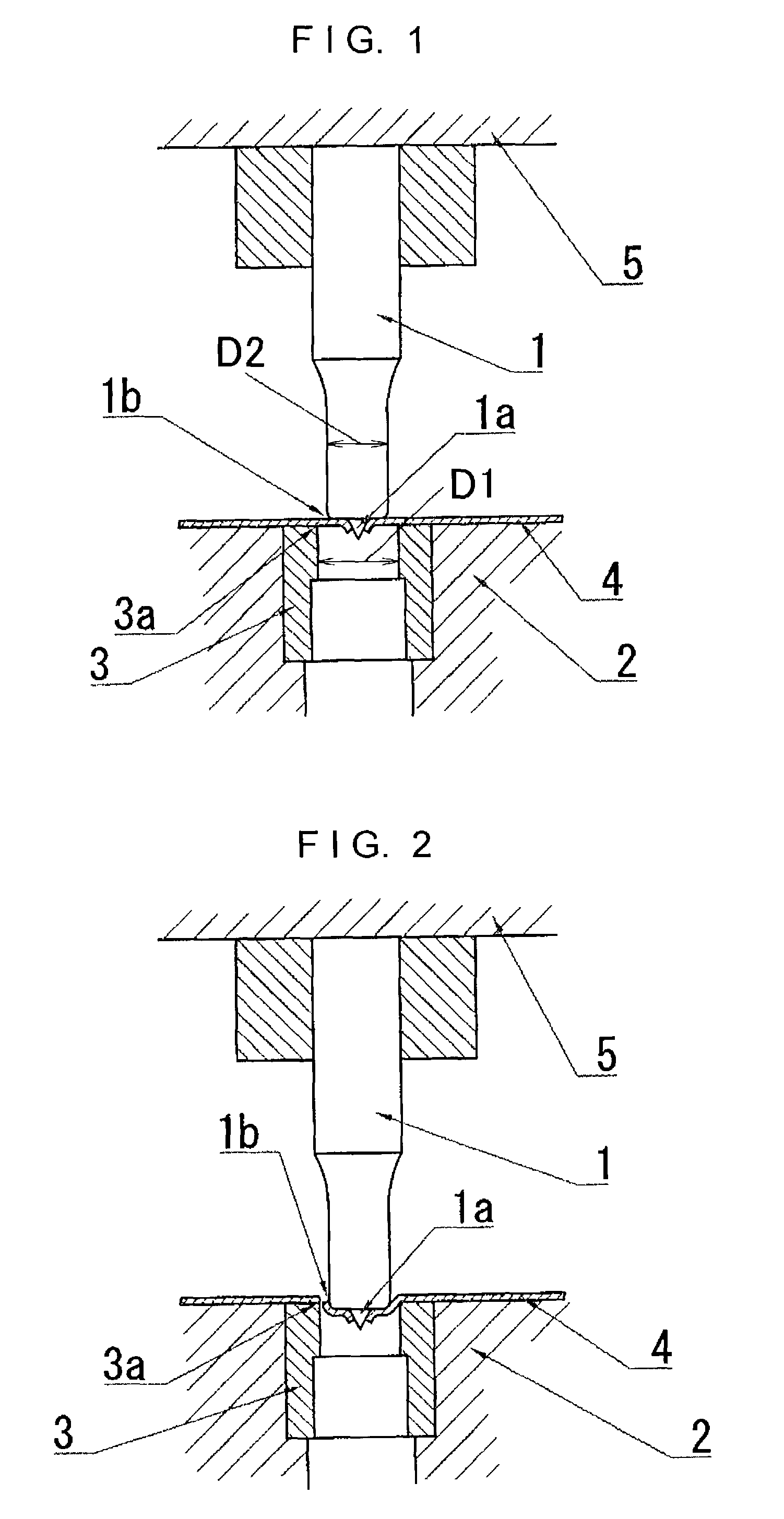

Wood-plastic formwork for construction engineering

InactiveCN1987018AExcellent mechanical propertiesFlat and smooth appearanceSolid waste managementLaminationFiberGlass fiber

A wood-plastics shuttering board for building engineering is composed of at least two basic wood-plastic ply layers made of the filler (vegetative fibers, glass fibers and plastics) and assistant (calcium carbonate, modifier, coupling agent and lubricant), and at least one lattice material layer between two basic wood-plastic ply layers and with two adhesive layers coated on its both surfaces. Its manufacture technology is also disclosed.

Owner:徐肖虎

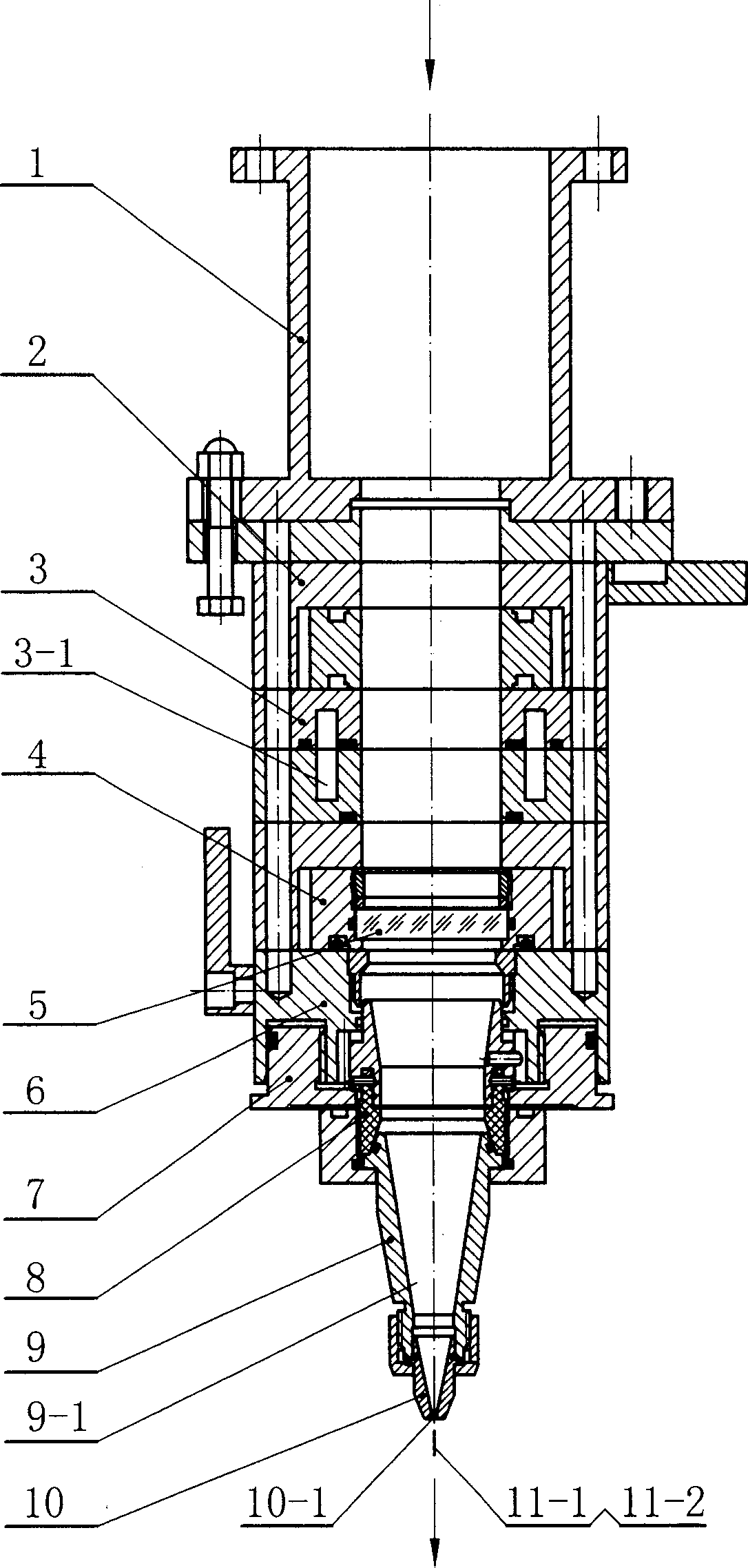

Digital-control laser cutting head and method for making same

InactiveCN1827282AIncreasing the thicknessIncrease profitLaser beam welding apparatusLight energyLaser cutting

The invention discloses a digital control laser cutter head used in CO2 digital control laser cutter and relative producing method. Wherein, the digital control layer cutter head comprises a connecting tube 1, a glass base box 2, a water cooling element 3, a focusing glass base element 4, a focusing glass 5, an aeration element 6, an adjusting nut 7, a high-strength insulated separating sheath 8, a transition nozzle 9, and a cutting nozzle 10. The inner hole 9-1 of said transition nozzle is in reverse taper shape; the upper and lower parts of water cooling element are integrated annular cooling water channels, while the annular cooling water channel 3-1 is one-time mechanically processed; the main elements as glass base box 2, water cooling element 3, focusing glass base element 4, aeration element 6 and adjusting nut 7 are made from ultrahigh strength rigid duralium LC4. With said invention, the consumed pressure and light energy of digital control laser cutter head is lower and the focusing effect is better. And said invention has better sealing property, thicker cut plate, high plate utilization, high strength, high pressure resistance and high heat conductivity.

Owner:LONGYAN LISHANG PRECISION MACHINERY

Recording head and information recording apparatus

To generate a satisfactory recording magnetic domain on a recording medium and to improve the durability of a recording head, an information recording apparatus for generating an optical near field and thermo-magnetically recording information on the recording medium is provided with a light source, a magnetic pole for applying a magnetic field to the recording medium and a diffuser that generates an optical near field in the vicinity of the recording medium when light from the light source is radiated. The diffuser is formed with it in contact with the magnetic pole so that the face which light from the light source irradiates is substantially perpendicular to the recording medium. Thereby, recording density in the information recording apparatus can be increased, simultaneously the reliability can be also enhanced and as a result, the cost can be reduced.

Owner:HITACHI LTD

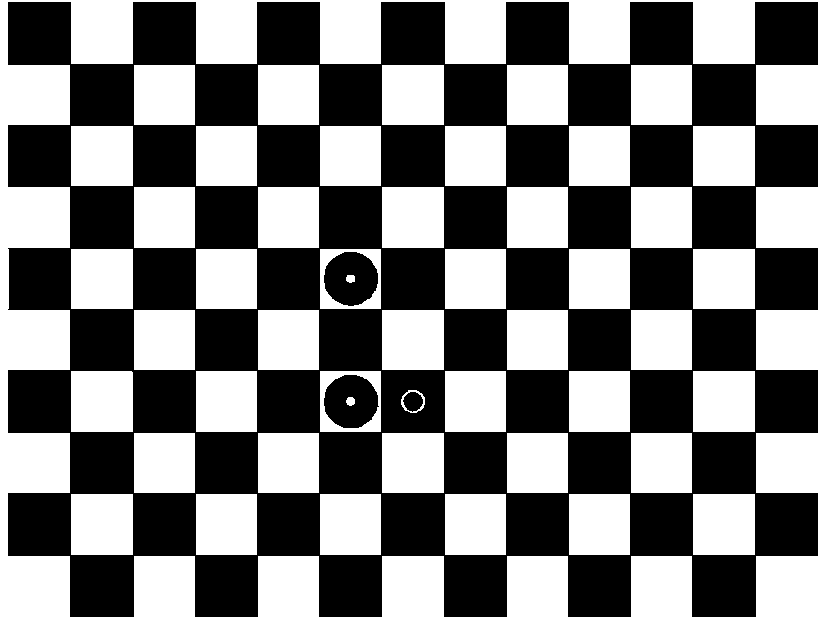

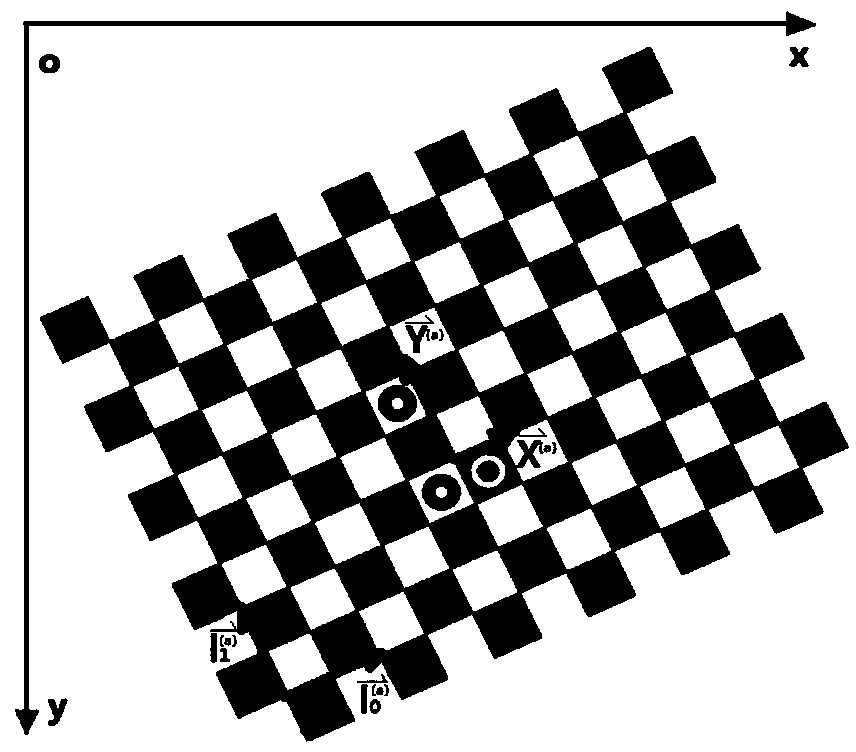

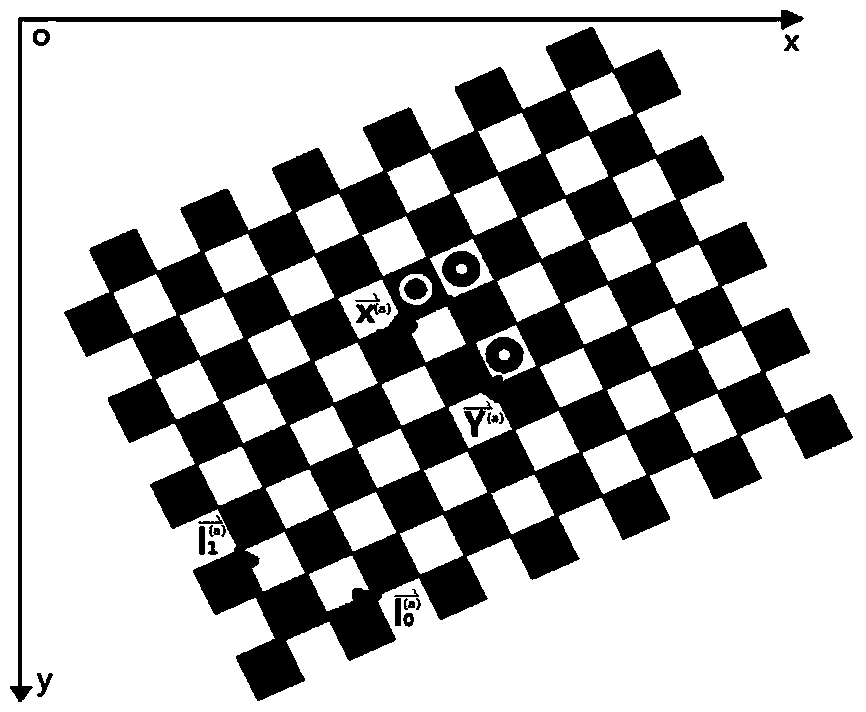

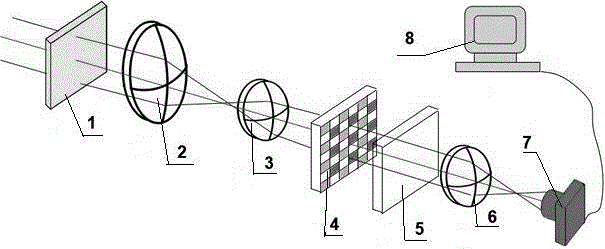

Camera intrinsic and extrinsic parameter automatic calibration method based on directional calibration target

ActiveCN104933717AIncrease flexibilityImprove practicalityImage analysisThree-dimensional spaceAngular point

The invention discloses a camera intrinsic and extrinsic parameter automatic calibration method based on a directional calibration target. The method is characterized in that subpixel coordinates of all feature angular points in a target image are extracted by use of an improved Harris angular point detection algorithm; a target coordinate system is established by use of a directional symbol pattern on the calibration target, so as to determine and acquire target coordinates in the target coordinate system respectively corresponding to all feature angular points in the target image; rotation and translation of the calibration target in a three-dimensional space are estimated by use of a plane target space posture estimation algorithm, so as to realize rotation direction judgment of the directional calibration target; and G calibrated images meeting conditions are acquired, then camera intrinsic and extrinsic parameters are resolved by use of a Zhengyou Zhang calibration algorithm. Through adoption of the method, automatic calibration of camera intrinsic and extrinsic parameters can be realized, so that flexibility and practicability of calibration of camera intrinsic and extrinsic parameters are improved.

Owner:HEFEI UNIV OF TECH

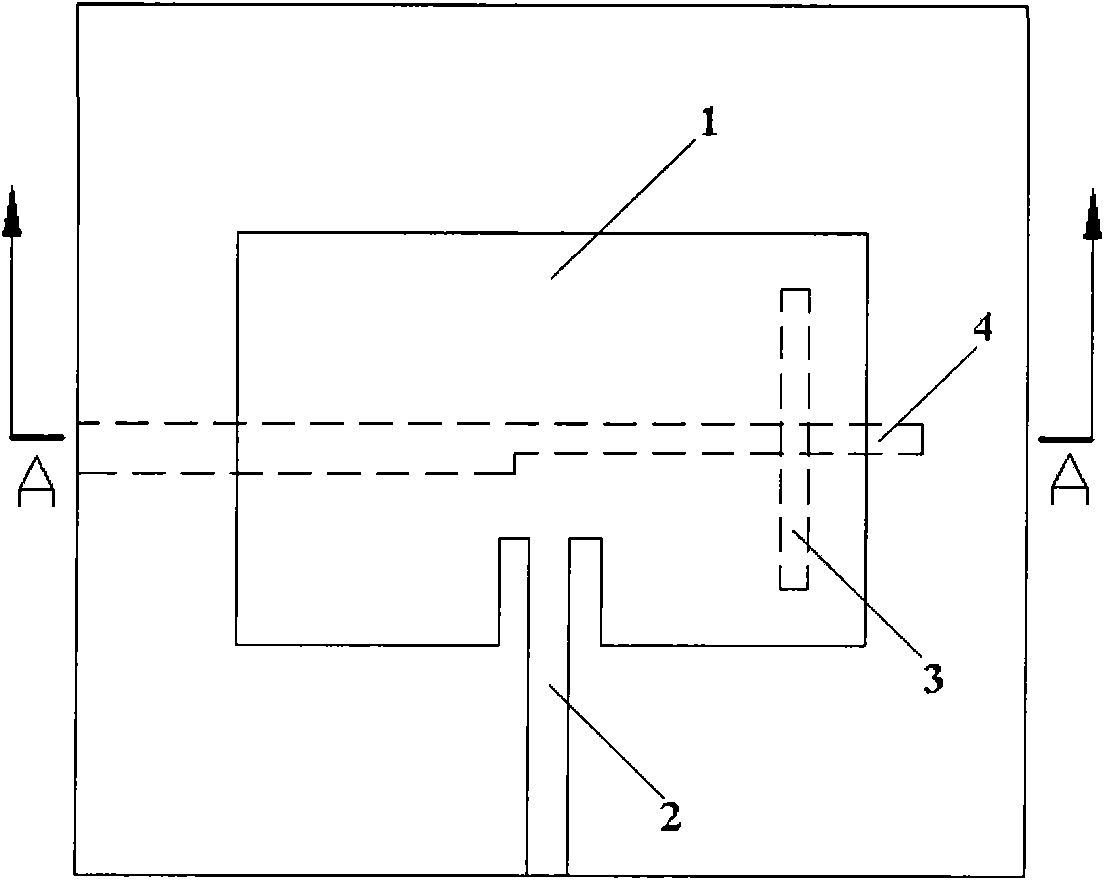

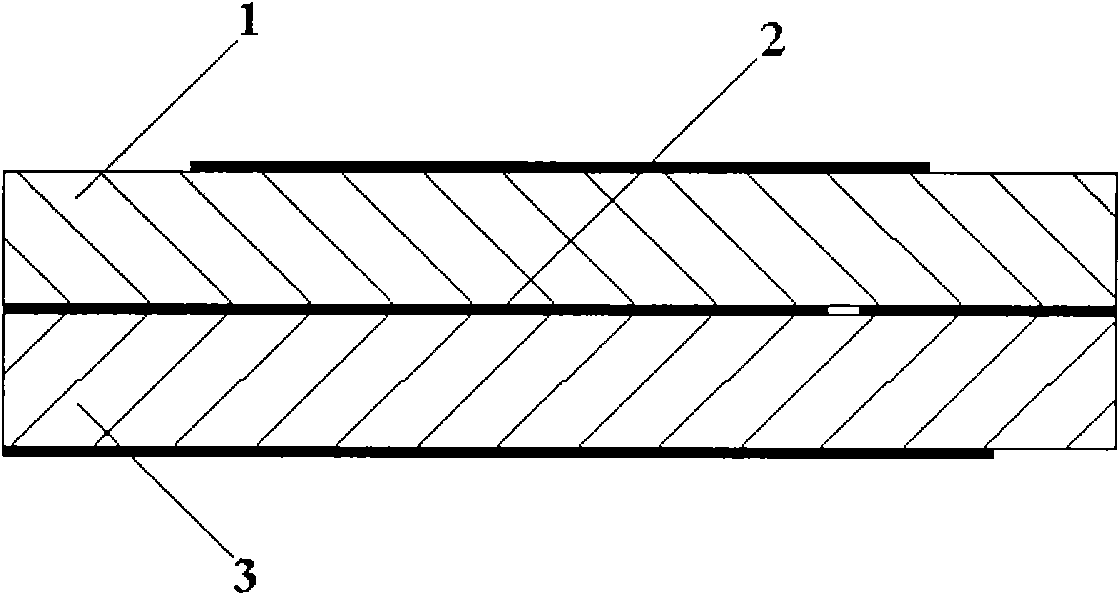

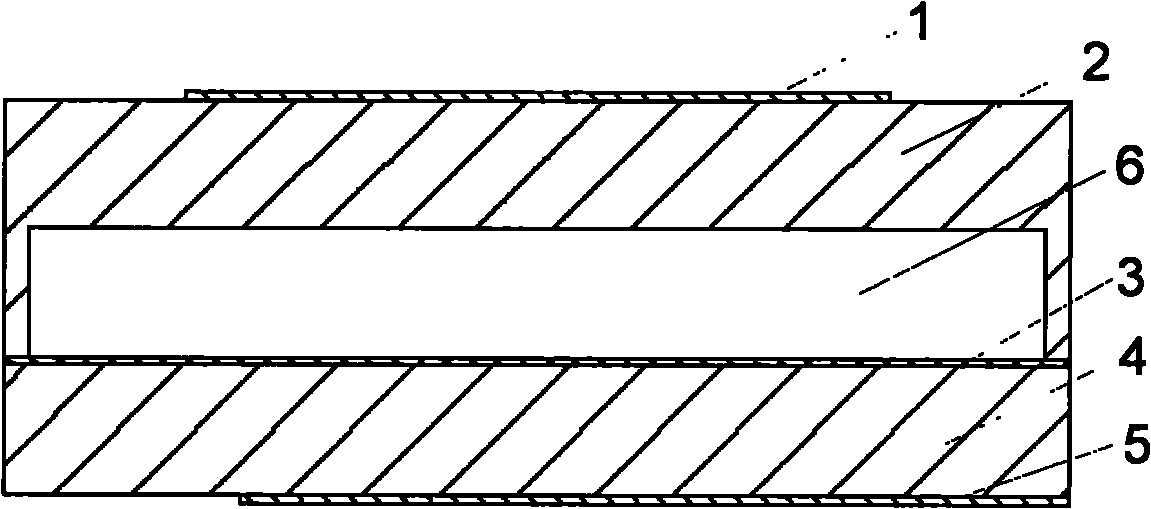

C/X dual-band microstrip antenna

InactiveCN101931122AAchieve Impedance MatchingIncrease output powerAntenna arraysSimultaneous aerial operationsPhysicsSatellite

The invention discloses a C / X dual-band microstrip antenna, and belongs to the technical field of antennas. The antenna adopts a dual-layer high-resistance silicon medium structure in which two frequency bands share a rectangular radiation patch; an upper layer of high-resistance silicon media bears a rectangular patch and an X frequency band feed line; an air cavity is etched on an upper layer of high-resistance silicon to reduce a composite dielectric constant of the high-resistance silicon; a lower layer of high-resistance media bear a C frequency band feed line; an X frequency band adopts microstrip coplanar feeding; and a C frequency band adopts slot coupling feeding. The C / X dual-band microstrip antenna or a C / X dual-band two-element microstrip antenna has the following advantages of: 1, singlechip and dual modes, simple structure and flexible design; 2, multiple frequencies; 3, miniaturization and light weight; and 4, integration. The C / X dual-band microstrip antenna can be widely applied to airborne point-to-point communication tools, such as satellite communications, control, guide and radars.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Preparation method and application of photosensitive resin for ultrasonic curing 3D printing

InactiveCN104570603AEliminate cure shrinkageImprove curing forming accuracyPhotosensitive materials for photomechanical apparatusPolymer scienceAcrylate ester

The invention discloses a preparation method and application of photosensitive resin for ultrasonic curing 3D printing. The photosensitive resin mainly comprises the following raw material components in percentage by mass: active components: 70-90 percent (in percentage by total mass of the active components, and the same below) of a mixture of a low polymer A, a low polymer B and an acrylic ester monomer according to the ratio of 50: 15: 35 and 10-30 percent of an active diluent, and auxiliaries: 1-10 percent of a cationic initiator, 1-6 percent of a free radical photoinitiator, 1-8 percent of a promoter, 0.1-1.5 percent of a flatting agent and 0.1-1.5 percent of a defoaming agent. The raw material components are mixed according to the mass percentage, and then heated and stirred into transparent light-yellow liquid to prepare the photosensitive resin. After ultrasonic curing 3D printing molding, the volume shrinkage of a product is smaller than or equal to 1.0 percent, the warpage factor CF (6) is equal to + / - 0.2 percent, and the warpage factor CF (11) is equal to + / - 0.8 percent. The molded product is high in precision and can be applied to manufacturing of key parts for aviation.

Owner:QINGDAO ADVANCED MATERIAL TECH

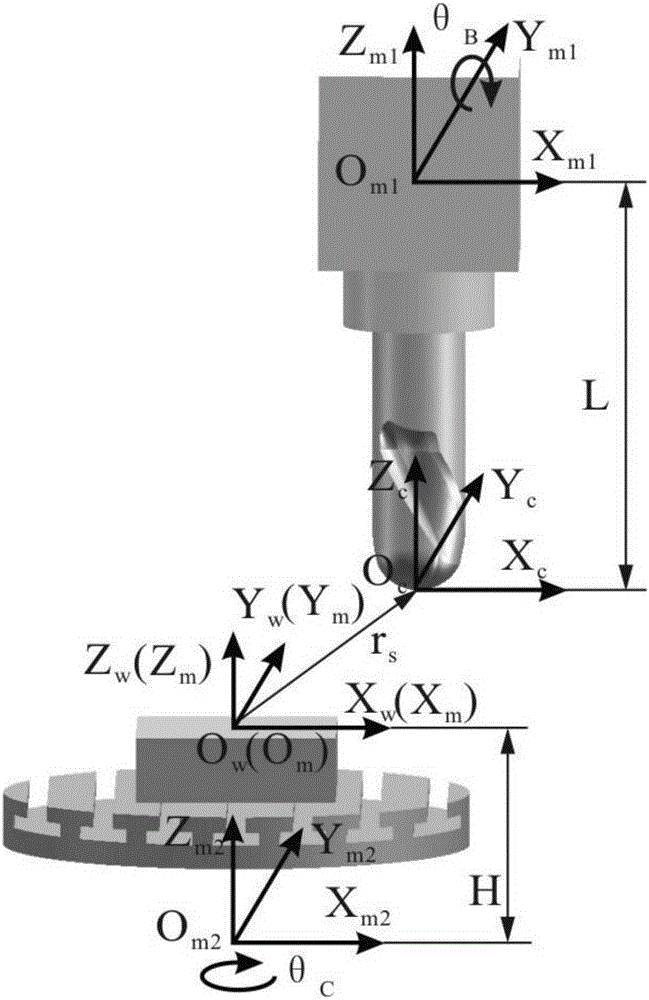

Double-turntable five-axis numerical control machine tool virtual assembling and numerical control machining simulation method

InactiveCN102866638AImprove Simulation EfficiencyImprove manufacturing precisionSimulator controlNumerical controlDimensional modeling

The invention discloses a double-turntable five-axis numerical control machine tool virtual assembling and numerical control machining simulation method and provides a simulation method capable of improving simulation efficiency under the premise of guaranteeing simulation correctness. The method includes: modeling; conducting three-dimensional modeling of blanks and clamps required in all moving components, a machine tool body and numerical control machining; connecting all moving components and the machine tool body to conduct virtual assembling according to a moving relation by using a Pro / E three-dimensional platform; operating a virtual simulating machine tool; outputting models of all components in a standard template library (STL) form on the basis of the same coordinate system; establishing a double-turntable five-axis numerical control machine tool virtual model; establishing a model tree in VERICUT, and the sequence of model components includes two branches: machine tool body Base - Y axis - X axis - A axis - C axis - clamp - blank and machine tool body Base - Z axis - main axis - tool; the STL assembly model output by Pro / E is led into corresponding components in VERICUT directly, namely the double-turntable five-axis numerical control machine tool virtual model is established; and numerical control machining simulation is operated.

Owner:TIANJIN UNIV OF COMMERCE

Added material manufacturing method under vibration condition

ActiveCN105458264AImprove manufacturing precisionGrain refinementAdditive manufacturing apparatusIncreasing energy efficiencyLean manufacturingMetal

The invention proposes an added material manufacturing method under a vibration condition. In an arc wire feeding added material manufacturing or laser powder feeding melting added material manufacturing process, mechanical vibration with a certain frequency is synchronously introduced, so that parts are located in a micro vibrating state; and the mechanical vibration acts on a micro liquid-state molten bath formed in the added material manufacturing process to refine grains, so that the structure becomes more uniform, and such phenomenon as air holes, inclusions and incomplete fusion is reduced or even eliminated. Meanwhile, the vibration acts on metal just condensed, so that the stress generated by vibration and residual stress generated in the added material manufacturing process are superposed to generate local plastic deformation to achieve the purpose of reducing residual stress and deformation of added material manufacturing parts, and the added material manufacturing parts under vibration condition are more excellent in performances.

Owner:HUAZHONG UNIV OF SCI & TECH

Aeroplane buffet air tunnel model integration design and manufacturing method

InactiveCN101509825ASpeed up developmentImprove manufacturing precisionAerodynamic testingJet aeroplaneIntegrated design

The invention relates to an integrated design and manufacture method of a full resin airplane low-velocity flutter wind tunnel model based on photocuring rapid prototyping. The method first conducts the integrated design of the flutter model according to the actual structure of an airplane, the requirement of a wind tunnel experiment and the parameters of photocuring resin material and based on the photocuring resin material, and makes the full resin flutter model in an integrated way on the basis of the optimization of the photocuring rapid process. The method proposes a new design and manufacture concept of the flutter model of low modulus material, gets rid of unnecessary assembly links by the use of the advantages of accuracy, quickness and low cost of the photocuring rapid prototyping technology, the uniformity of the model material, the low modulus of the resin material and isotropy characteristic, and designs and manufactures the full resin flutter wind tunnel model meeting the full dynamic similarity. The method overcomes the defects of traditional technologies, improves the manufacture precision of the wind tunnel model, reduces cost, shortens the period and realizes structural similarity, thus boosting the development speed of an airplane.

Owner:XI AN JIAOTONG UNIV

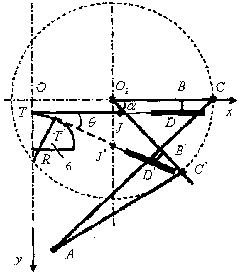

Method of manufacturing an optical element using a hologram

InactiveUS7061626B1Uniform linear densityIncrease powerUsing optical meansOptical elementsAxis of symmetryLight beam

Owner:CARL ZEISS SMT GMBH

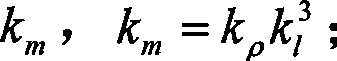

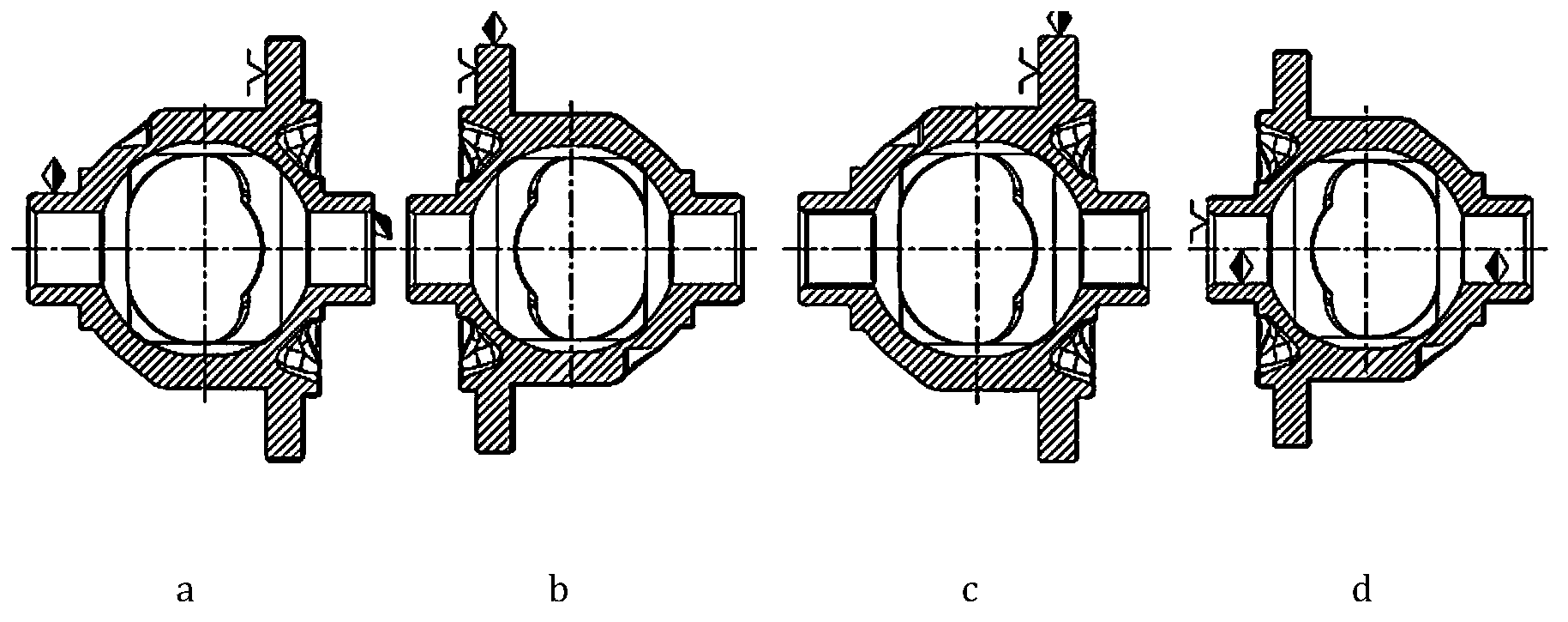

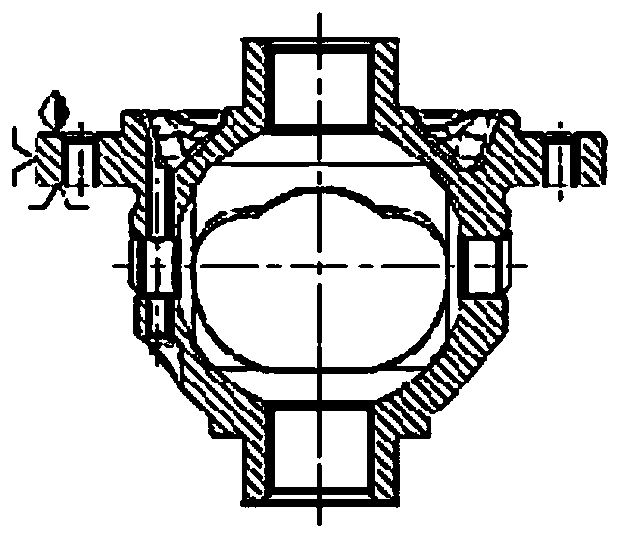

Device and process for machining differential housing

ActiveCN103753322ARealize batch production processingRealize inputWork clamping meansExpansion mandrelsNumerical controlCar manufacturing

The invention belongs to the technical field of automobile manufacturing and discloses a device and process for machining a differential housing. The device is composed of a rotary jig, an internally-expanding lathing jig and a spherical surface lathing jig, wherein the rotary jig is arranged on a machining center and comprises an operation part with the two ends arranged on the machining center through rotating assemblies, and the internally-expanding lathing jig and the spherical surface lathing jig are arranged on a common numerically-controlled lathe. Synchronous machining of two parts can be achieved through the high-precision rotary jig when the machining center is used for machining various axial inner holes, and therefore efficiency is higher; a high-precision numerically-controlled indexing table is applied to the jigs, rotating accuracy is as high as 20'' or higher, and precision of the critical size of a product is better guaranteed; the parts can be automatically clamped and dismounted by the jigs through numerical control programs, and therefore labor can be saved.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

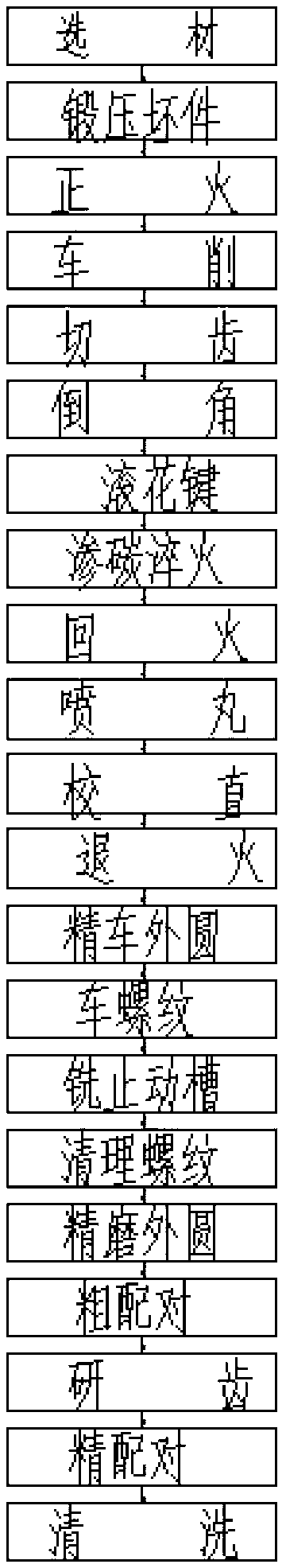

Processing technology for rear axle drive bevel gear

ActiveCN103286533AImprove manufacturing precisionImprove bevel gear accuracyCarbon layerInternal pressure

The invention discloses a processing technology for a rear axle drive bevel gear which is characterized by including steps of selecting raw materials, forging a blank, normalizing, turning, cutting a gear, chamfering, rolling a spline, carburizing and quenching, tempering, blasting shots, straightening, annealing, finely turning an outer circle, threading, milling a locking groove, cleaning a thread, finely grinding an outer circle, roughly matching, shaving the gear, finely matching and rinsing, and obtaining a finished product after rinsing the a workpiece. By the processing technology, machining precision of threads of the rear axle drive bevel gear is improved and reaches a grade of H6; quenching to harden the carbon layer is totally omitted through machining after heat treatment; hardness of a product surface and a core is reduced after annealing, internal pressure of the gear is eliminated, and a metallographic structure of the core of the gear is improved; the processing technology for the gear axle drive bevel gear is high in precision, and requirements of assembling is favorably achieved; service life of the gear axle drive bevel gear is prolonged.

Owner:重庆市綦江区华丰变速箱有限公司

Method for producing accurate steel balls

InactiveCN101049665AHigh precisionImprove manufacturing precisionEdge grinding machinesPolishing machinesQuenchingSuperfine grinding

A technology for manufacturing precise steel balls includes such steps as providing the light-drawn steel wire, cold forging, shaping plus soft grinding, heat treating through heating, quenching and tempering in protective gas, cooling strengthening surface, hard grinding by abrasive ceramic disc, beautifying appearance by photoelectric eddy, ageing, cold treating, and superfine grinding.

Owner:SHANDONG DONGE STEEL BALL GRP

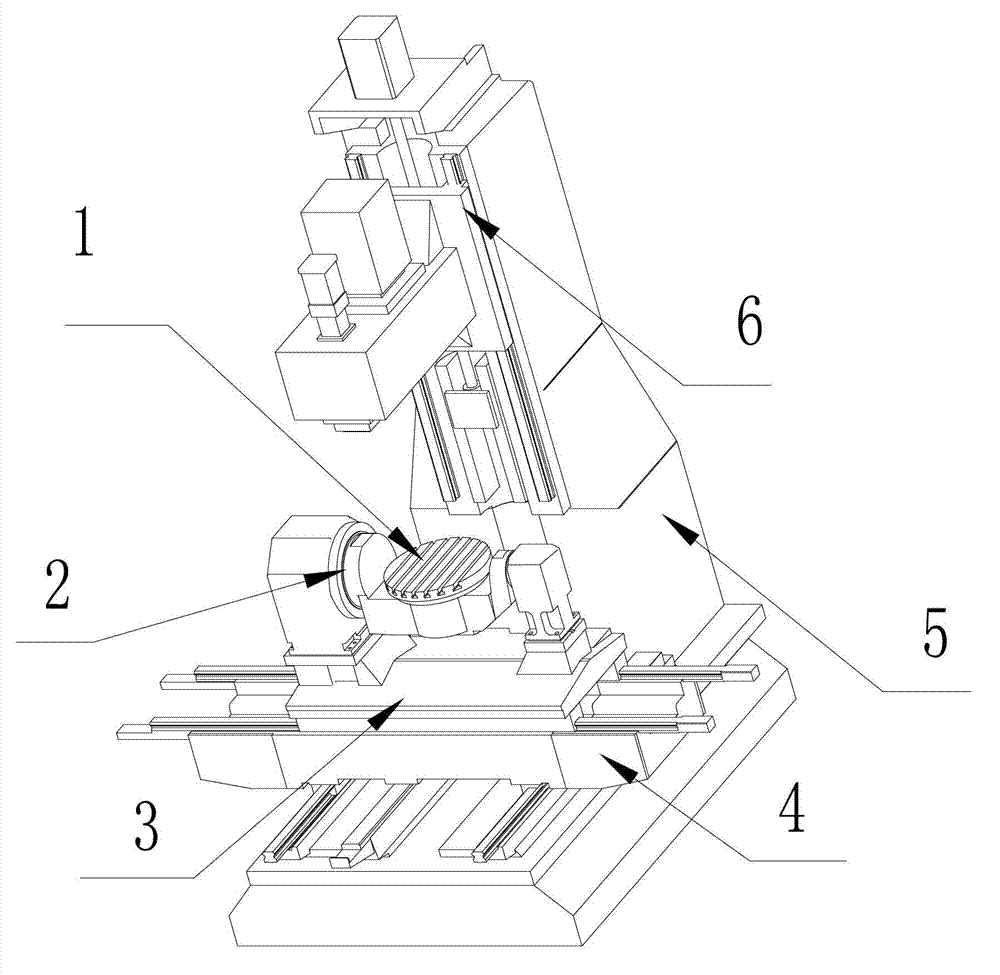

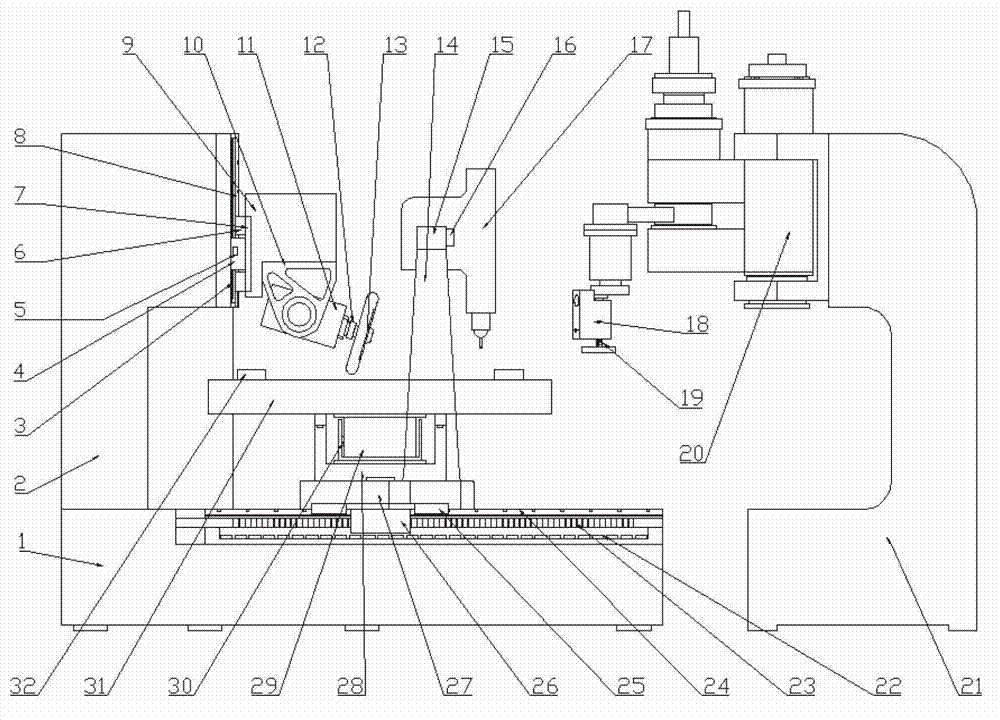

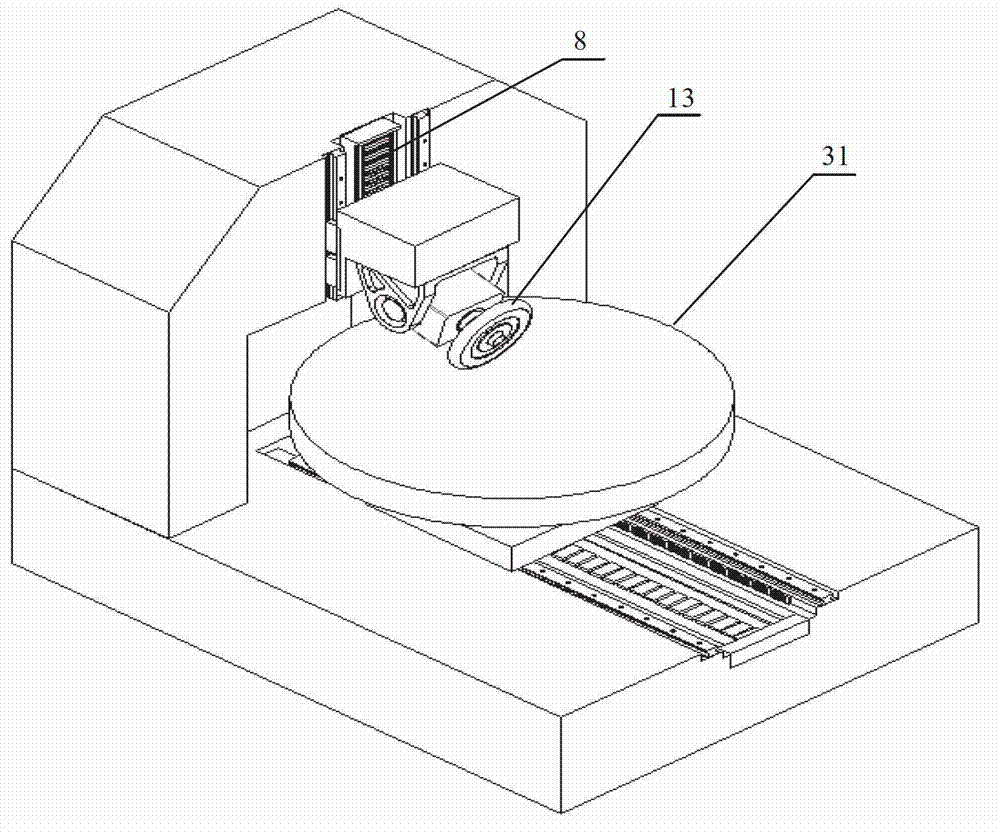

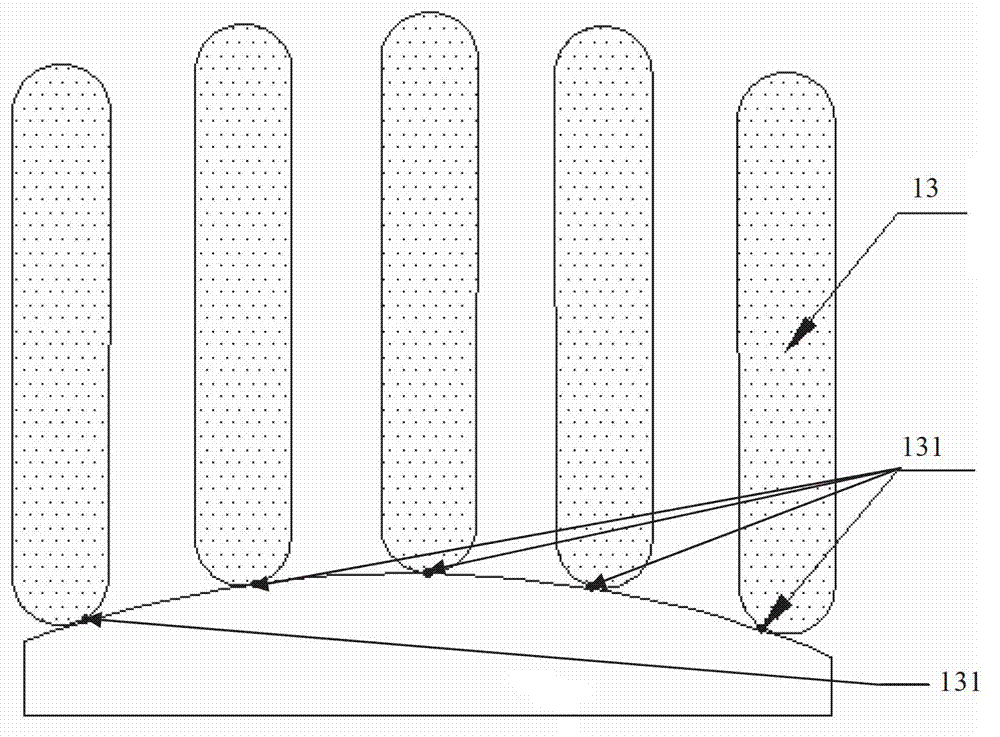

Ultra-precise processing integrated platform for large caliber optical mirror surface

ActiveCN102756316AEasy to moveAchieve multi-axis ultra-precision grindingOptical surface grinding machinesOptical processingSurface grinding

An ultra-precise processing integrated platform for a large caliber optical mirror surface solves the problem that processing and detection are not integrated while processing the large caliber optical mirror surface in the conventional optical processing technical field. The platform integrates grinding, detection and milling for processing the large caliber optical mirror surface, and comprises a base, a horizontal moving device, a rotation device, an ultra-precise grinding device, a mirror surface detection device and a milling device, wherein the horizontal moving device drives the rotation device to move to a workpiece mounting position, a grinding position, a surface shape detection position and a milling position in a horizontal direction; a vertical moving device drives a spindle system and a diamond grinding wheel to move up and down in a vertical direction; the spindle system can adjust the inclined angle of the diamond grinding wheel; the diamond grinding wheel has a cambered surface; when in the workpiece mounting position, the rotation device can conduct cambered surface grinding on a workpiece; when in the surface shape detection position, the rotation device can conduct surface shape detection on the workpiece; when in the surface shape detection position, the rotation device can mill the workpiece.

Owner:SHANGHAI JIAO TONG UNIV

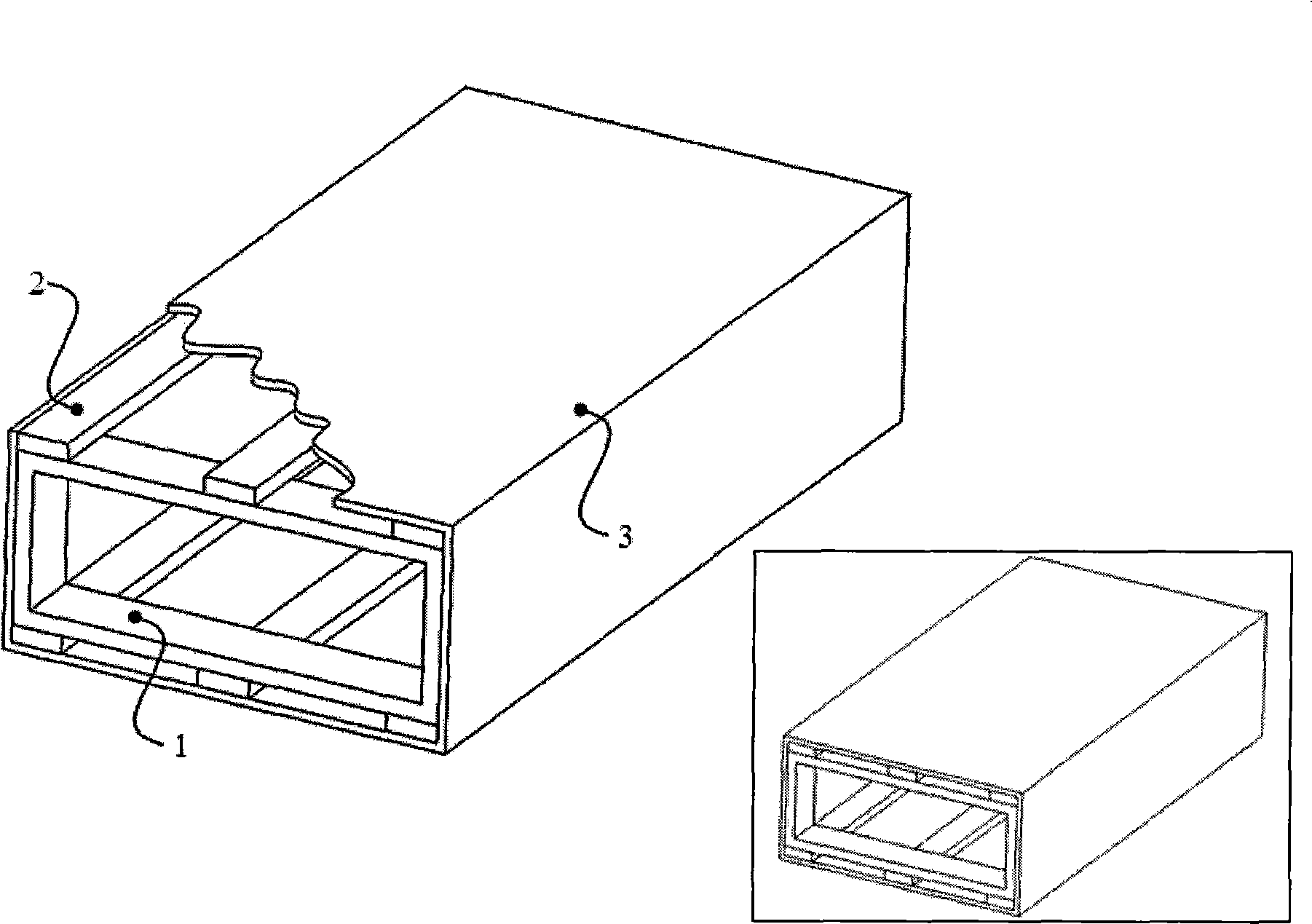

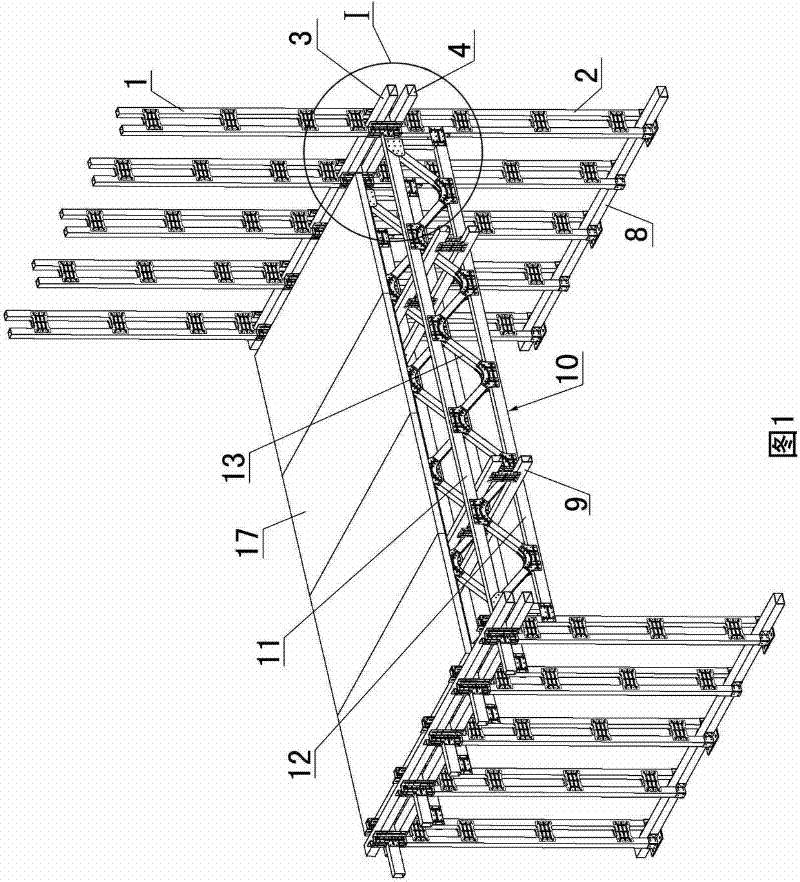

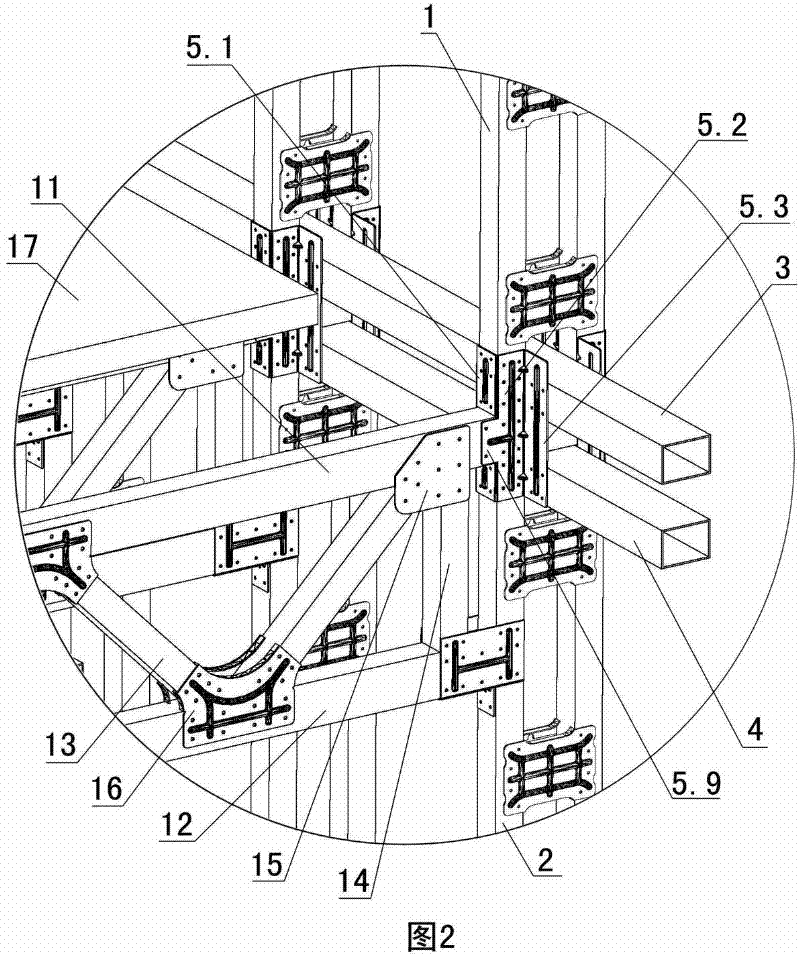

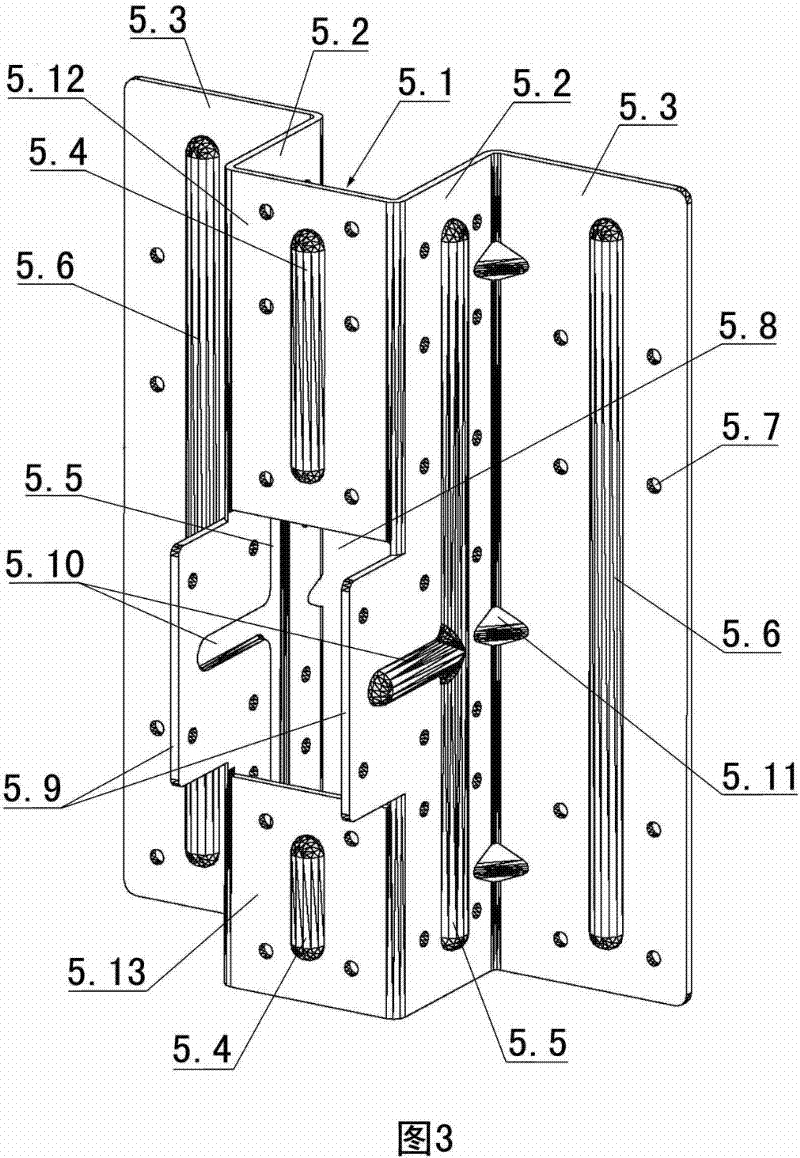

Truss combined beam and upper and layer connected light steel structure and construction method thereof

InactiveCN102359180ATroubleshoot simultaneous connectionsSolve the shortcomings that the pressure is not easy to meet the force requirementsGirdersJoistsRear quarterKeel

The invention discloses a truss combined beam and upper and layer connected light steel structure and a construction method thereof. The light steel structure comprises upper wall sheet columns distributed at intervals, lower wall sheet columns distributed at intervals, upper wall sheet column lower connecting pipes connected among the lower parts of the upper wall sheet columns, lower wall sheet column upper connecting pipes connected among the upper parts of the lower wall sheet columns, and truss combined beams connected between the upper wall sheet columns and the lower wall sheet columns through upper and lower connectors, wherein the upper and lower connectors are beam passing buckles, the web plates of the beam passing buckles consist of upper web plates and lower web plates, a square connecting port is formed between the upper web plates and the lower web plates, upper chord member connecting plates are extended from the left and right sides of the square connecting ports, and the upper chord member connecting plates and side plates of the beam passing buckles are positioned in the same plane. Through the light steel structure, the structural stability of a light steel keel house system is enhanced, and the floor surface beams, the connecting pipes and the floor panels do not easily vibrate.

Owner:筑巢(北京)科技有限公司

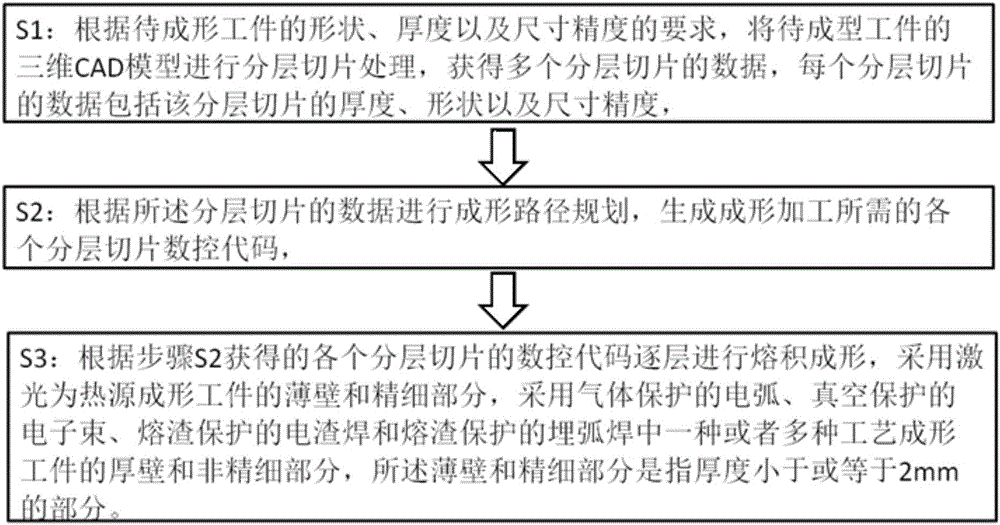

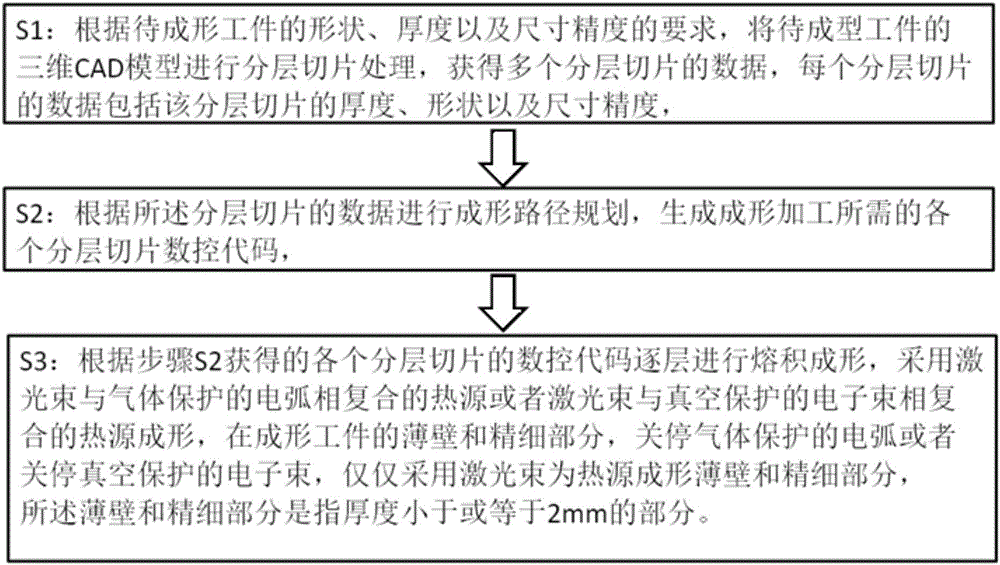

Deposition forming manufacturing method of parts and molds

ActiveCN105945281AImprove mechanical propertiesImprove metallurgical qualityAdditive manufacturing apparatusIncreasing energy efficiencyElectricityStructure property

The invention discloses a deposition forming manufacturing method of parts and molds, and belongs to the field of non-mold growing manufacturing and remanufacturing. The method comprises the following steps that S1, the three-dimensional CAD model of a workpiece to be formed is subjected to hierarchical slicing; S2, the CNC codes of all hierarchical slices are acquired; S3, deposition forming is conducted layer by layer according to the CNC codes of all the hierarchical slices, the fine portions of the workpiece are formed by laser, and one or more technologies in electric arc welding, electron beam welding, electroslag welding and submerged-arc welding is or are adopted to form the thick wall and the non-fine portions of the workpiece; or in the S3, a heat source which is compounded by laser beams and gas protection electric arcs or a heat source which is compounded by the laser beams and vacuum protection electronic beams is adopted for forming the thin wall and the fine portions of the workpiece, and the gas protection electric arcs or the vacuum protection electron beams are shut down. According to the deposition forming manufacturing method, direct deposition forming can be achieved to obtain parts and molds which are stable in structure property and high in manufacturing precision and are provided with thin walls or fine portions.

Owner:HUAZHONG UNIV OF SCI & TECH

Production method for dedicated steel ball for bearing of high-speed high-precision numerical control machine tool

InactiveCN103008994AImprove manufacturing precisionExtend your lifeSpherical surface grinding machinesFurnace typesNumerical controlCarbon potential

The invention discloses a production method for a dedicated steel ball for a bearing of a high-speed high-precision numerical control machine tool. The method comprises the following steps of steel ball cold heading, namely machining blank by sleeve cutting, shaping, cold heading multi-station and high-speed cold heading ways; rough machining by adopting a macrocyclic light bulb technology; performing controllable atmosphere quenching, cold treatment and tapering treatment by adopting a continuous drum furnace, automatically controlling carbon potential; surface strengthening by adopting a frequency conversion speed adjusting multi-beating-plate structure; hard grinding by adopting a ceramic sand wheel to perform macrocyclic process to machine; after primary grinding, adopting double-roller sorting; after fine grinding, performing photoelectric eddy current test; performing ultra-fine grinding machining after aging treatment; and performing photoelectric detection after ultra-fine grinding. The diameter variation of the steel ball which is machined and produced by the method provided by the invention is less than 0.07 micron, the roundness is less than 0.05 micron, the spherical error is less than 0.05 micron, the surface roughness Ra is less than 0.07 micron, the variation of the diameter of the ball lot is less than 0.09 micron, and the bearing dmn value of the steel ball after being sleeved is more than 2.5*10<6> mm*r / min.

Owner:SHANDONG DONGE STEEL BALL GRP

Method for machining output shaft assembly

InactiveCN101954574AImprove manufacturing precisionImprove processing efficiencyNumerical controlPunching

The invention discloses a method for machining an output shaft assembly. The method comprises the following steps of: machining an output shaft; and assembling a gear shaft, an oil-retaining bearing and the output shaft. The process flow for machining the output shaft comprises blank preparation, blank fabrication, machining, non-traditional machining and auxiliary treatment, and is characterized in that the blank fabrication comprises blank prefabrication and blank fabrication by adopting cold extrusion forming technology. In the method, a blank is fabricated by adopting the cold extrusion forming technology; an involuting spiral spline is machined by adopting cold roll forming technology; machining is performed by adopting a computerized numerical control (CNC) lathe; punching and assembly are performed by adopting a special punching die and a riveting extrusion assembly die; and specific machining steps and method are adopted. Therefore, the fabricating precision and the machining efficiency of the output shaft assembly are improved; the comprehensive quality and the yield of products are improved; raw material and energy consumption is reduced; and environmental protection is reduced.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Deflection error compensation method for five-axis machining center tool

InactiveCN105234743AImprove manufacturing precisionVerify validityAutomatic control devicesFeeding apparatusNumerical controlData information

The invention discloses a deflection error compensation method for a five-axis machining center tool. The deflection error compensation method includes the steps that the milling force is computed according to a built five-axis machining milling force model; the theoretical tool location point and a tool-axis vector serve as the benchmark of mirror image reversible deflection compensation; the tool deflection error, caused by the milling force, of the current tool position is worked out according to the tool deflection; mirror image reversible deflection compensation is conducted on the current tool location point and the tool-axis vector, and a new tool location point and a new tool-axis vector are worked out according to the tool deflection error; a new tool deflection error is computed according to the compensated tool location point data, and whether the new error exists or not is judged; if the requirement is met, operation is stopped, and the tool location point information is stored; and the compensated tool location point data information corresponding to the tool path positions from 1 to N is collated, accordingly the compensated tool location locus is obtained, and a compensated numerical control program is generated through post-processing software.

Owner:TIANJIN UNIV

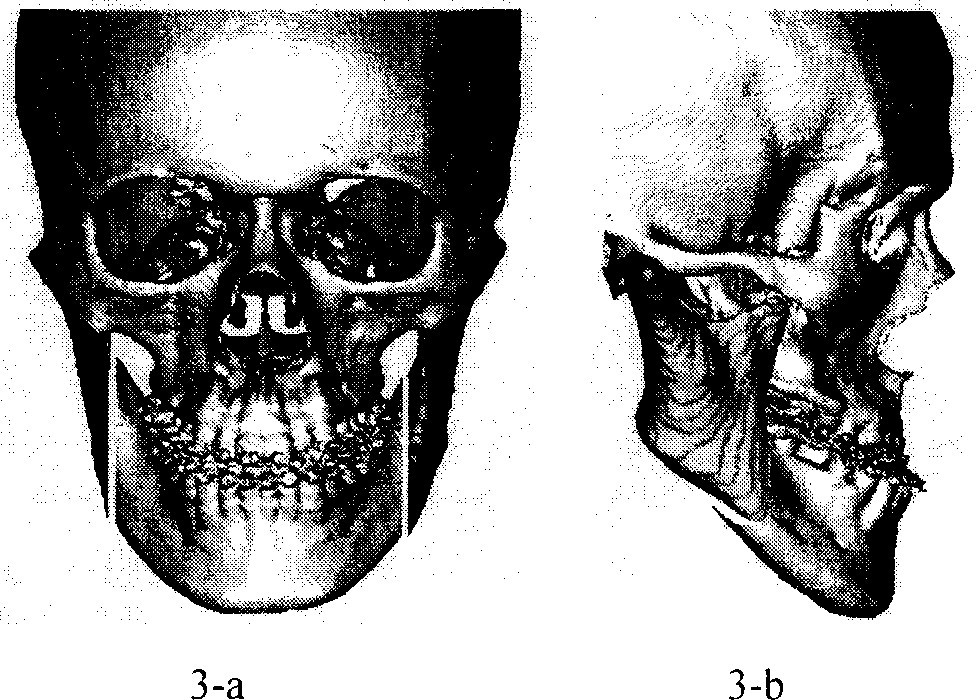

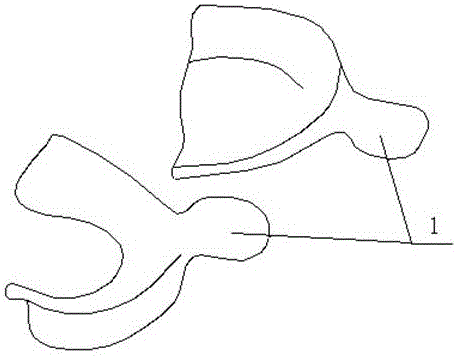

Prodn method of computer aid generating positioning board

InactiveCN1833617AShorten surgery preparation timeImprove production accuracy and production efficiencyFastening prosthesisTomographyComputer-aided

Owner:SHANGHAI JIAO TONG UNIV

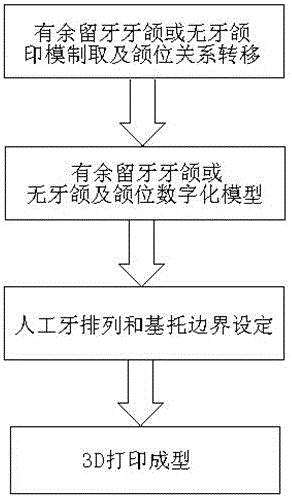

Method for producing immediate complete or half denture based on 3D printing technique

ActiveCN106037967AComfortable to wearSimple preparation steps3D printingDental prostheticsDenture baseBite registration

The invention discloses a method for producing an immediate complete or half denture based on a 3D printing technique. The method comprises the steps of preparing an impression with a remaining tooth jaw or a tooth-free jaw, transferring a jaw position relation, acquiring digital models of the remaining tooth jaw or the tooth-free jaw and the jaw position relation, setting the arrangement and the denture border of artificial teeth of the immediate complete or half denture corresponding to the form of the remaining tooth jaw or the tooth-free jaw and the jaw position relation, invoking data in a preset database, designing the artificial teeth and polishing surfaces of the artificial teeth, regulating the occlusion of the teeth to enable alveolar ridge supporting tissues to bear proper pressure distribution, and manufacturing a three-dimensional model of the immediate complete or half denture by virtue of a photo-healing three-dimensional printing technique in the 3D printing technique. The method has the advantages that the production steps are simple, the production time is short, the precision is high, the denture can be conformably worn by a patient, and meanwhile, the production cost is lowered.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

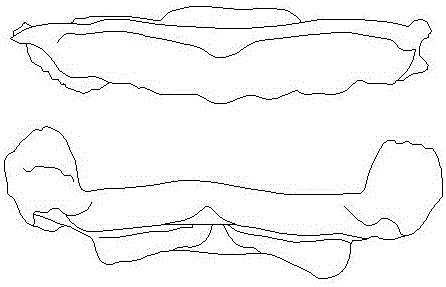

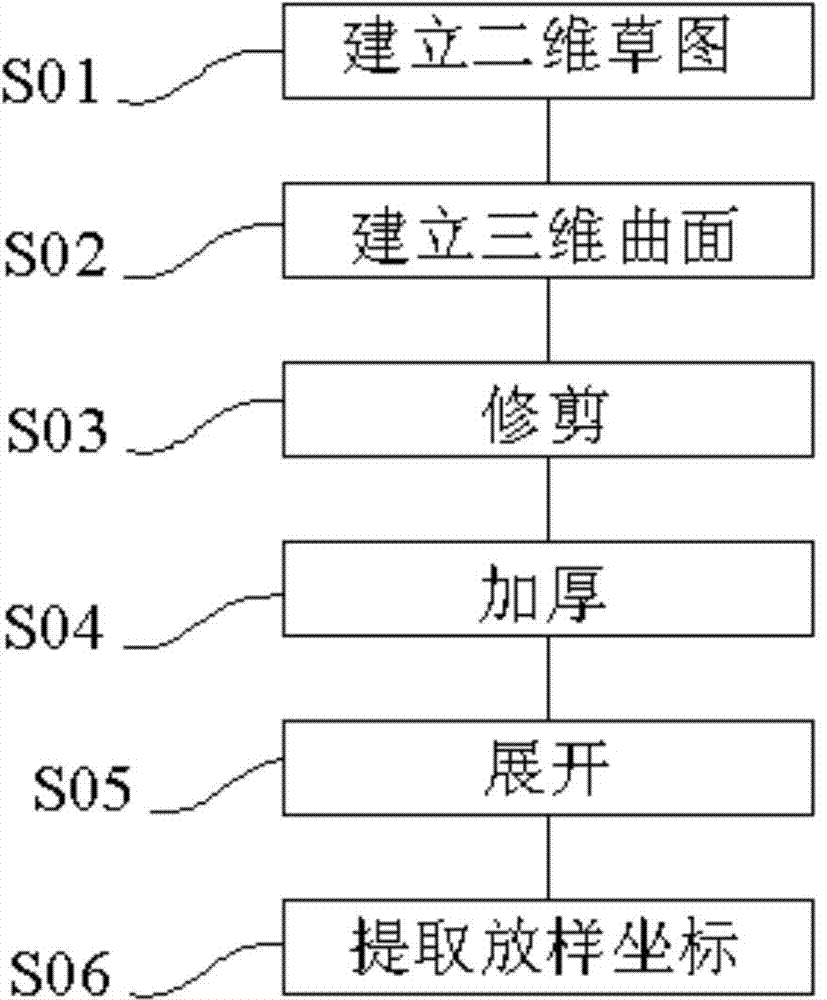

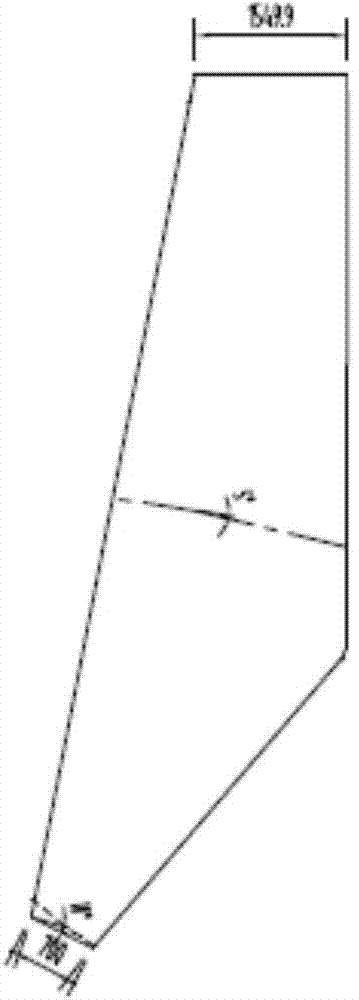

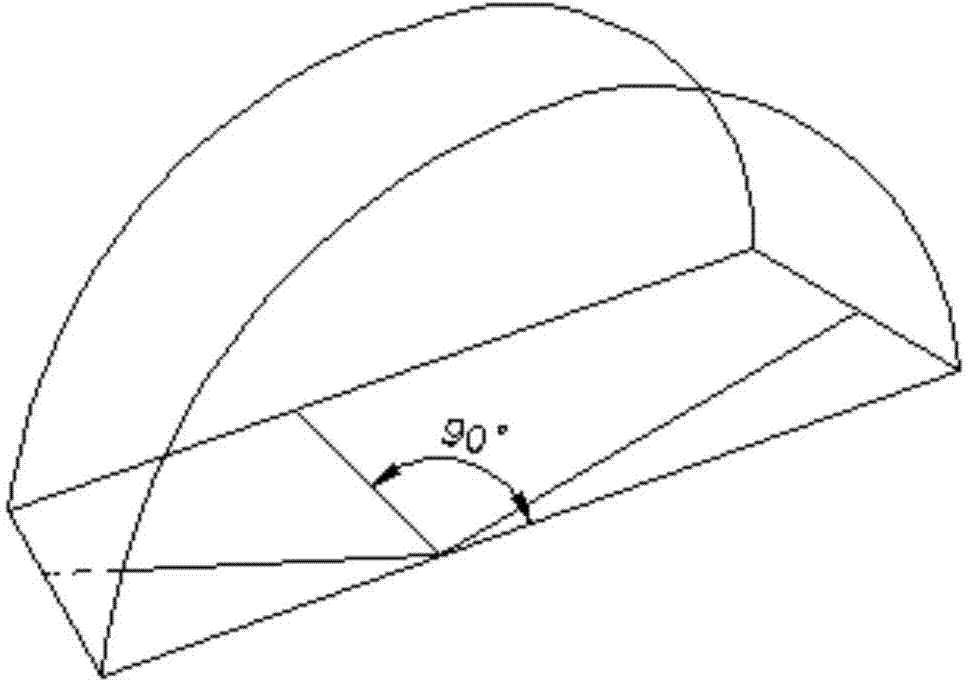

Operation method of three-dimensional modeling expansion and lofting coordinate generation based on Autodesk inventor software

ActiveCN104765936AReduce duplicationFully automatedSpecial data processing applicationsEconomic benefitsDimensional modeling

The invention relates to an operation method of three-dimensional modeling expansion and lofting coordinate generation based on Autodesk inventor software. The method at least comprises the following steps that S01, a two-dimensional rough draft is built; S02, a three-dimensional curved surface is built; S03, trimming is performed; S04, thickening is performed; S05, expansion is performed; S06, lofting coordinates are extracted. The method has the advantages that the expanded view repeated drawing and lofting procedures are reduced after the operation method is adopted, automation of the discharging process of a numerically controlled cutting machine is achieved, the manufacturing precision is high, product performance is stable, the cost is reduced, economic benefits are improved, and the labor cost is reduced by 3% based on manual lofting time cost.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD

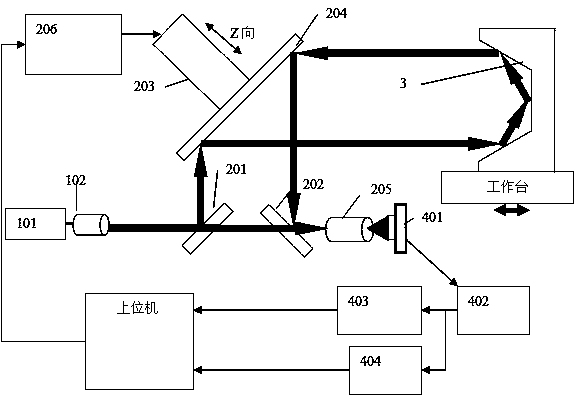

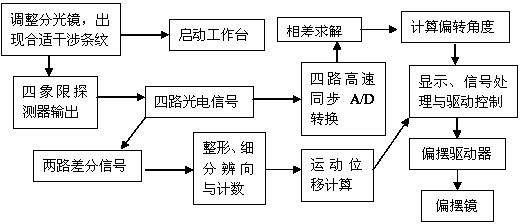

Device and method for detecting movement errors of working platform in multiple degrees of freedom

ActiveCN103940348AAvoid feedbackAvoid the problem of returningMeasurement/indication equipmentsUsing optical meansEngineeringMotion error

The invention discloses a device and a method for detecting movement errors of a working platform in multiple degrees of freedom. Reflected light is reflected onto a three-surface reflector fixed on the working platform through a light path regulation reflector, returns to the light path regulation reflector after being reflected by the three-surface reflector in sequence, is reflected onto a second light splitting piece, enters a beam expanding mirror after being reflected by the second light splitting piece, and is projected onto a detector. Transmission light enters the beam expanding mirror after being transmitted by the second light splitting piece and is projected onto the detector. Two beams of light generate interference on the detector, and measurement on deflection and movement displacement of the working platform can be achieved by regulating shapes of interference fringes and measuring phase displacement. By means of the device and the method for detecting movement errors of the working platform, synchronous and real-time measurement on an angle of oscillation, an angle of pitch and axial movement displacement of the working platform can be performed, real-time compensation is performed according to the measurement result to eliminate effect caused by movement errors, and measurement precision and manufacturing precision can be improved. The angle measurement ranges from +3rad to -3mrad, and measurement requirements of the working platform can be met.

Owner:LINGYUN GROUP WUHAN

Stretch-bending molding process of angle steel component of vehicle body

ActiveCN101823092AHigh quality and precisionImprove manufacturing precisionPull forceMathematical model

The invention relates to a stretch-bending molding process of an angle steel component of a vehicle body and mainly aims to scientifically and rationally overcome the defects of overlarge rebound modulus and section bending deflection of workpieces and the like during the stretch-bending molding of the angle steel component of the vehicle body. The process realizes the emulation of pretension and post-tension corresponding to the minimum rebound modulus, provides a computing formula for the initial length of profiles and a trajectory model of a clamp, improves the forming quality, precision and work efficiency of a stretch-bending workpiece and the manufacturing quality of vehicle steel structure, reduces the manufacturing and maintenance cost, overcomes stretch-bending defects and provides basis for the stretch-bending molding precision control of profile parts. The process initially establishes a mathematical model for length rebound modulus of a multi-curvature profile, can precisely determine the initial length of a blank profile of parts, determines the optimal pretension and post-tension by a simulation method and precisely determines the trajectory of the clamp by establishing a multi-curvature profile stretch-bending module, thereby obtaining the ideal forming quality of the formed profile.

Owner:白城市瑞程汽车部件有限公司

Instantaneous remote-sensing polarization imaging device based on microwave plate array and realizing method thereof

InactiveCN104833977AImprove performanceImprove manufacturing precisionLight polarisation measurementElectromagnetic wave reradiationMicrowaveImage resolution

The invention relates to an instantaneous remote-sensing polarization imaging device based on a microwave plate array and a realizing method thereof. The microwave plate array is used for performing polarization modulation on a remote sensing image which is acquired by a telescope. Then the remote sensing image is converted to two-dimensional light intensity distribution through a unidirectional polaroid. Data inversion is performed on the two-dimensional light intensity for obtaining the polarization information of the remote sensing image. The used microwave plate array is manufactured through ultrafast laser microprocessing. Four different kinds of phase modulations are introduced to each micro area of the image. After the polarization information is converted to the light intensity through the polaroid, the Stocks vector of the area can be calculated, thereby obtaining the complete polarization information of the whole image. The instantaneous remote-sensing polarization imaging device can perform dynamic target remote-sensing measurement, and furthermore realizes complete polarization measurement with high time resolution and high space resolution.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com