Operation method of three-dimensional modeling expansion and lofting coordinate generation based on Autodesk inventor software

A three-dimensional modeling and operation method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of no setting out operation method, unable to directly obtain the shape and size of the upper and lower sections, and reduce repetition. The effect of drawing and lofting process, stable product performance and high manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

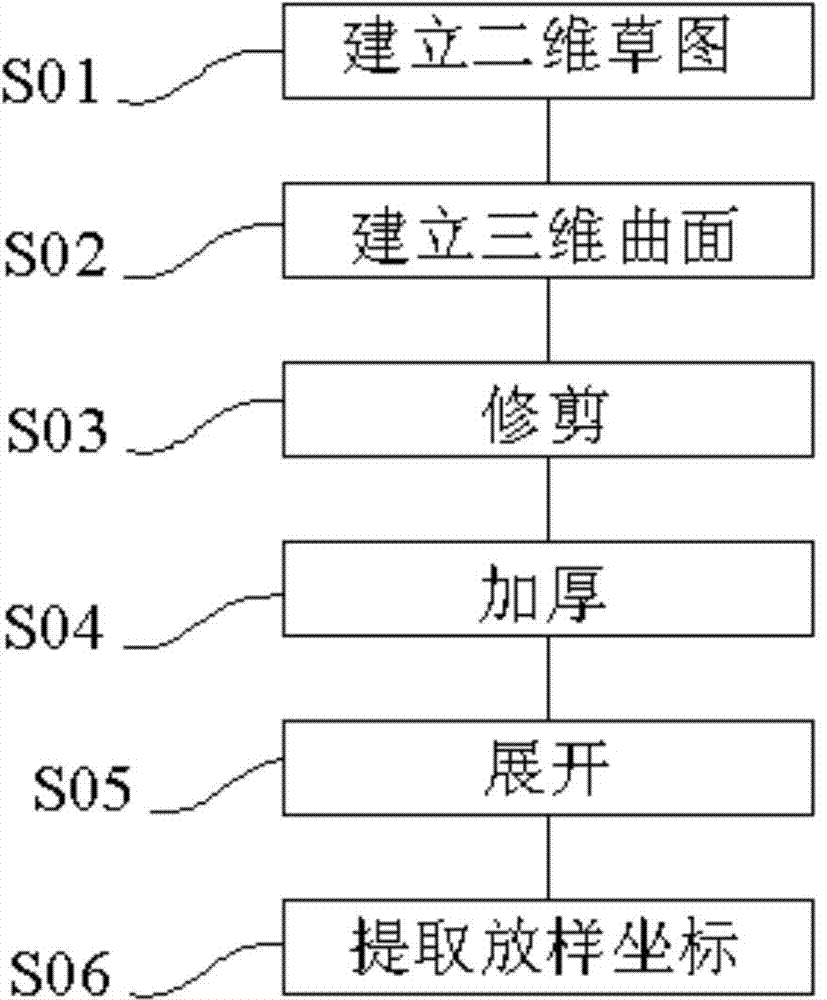

[0039] as attached figure 1 As shown, the present invention based on Autodesk inventor software three-dimensional modeling expands and generates the operating method of lofting coordinates, comprises the steps:

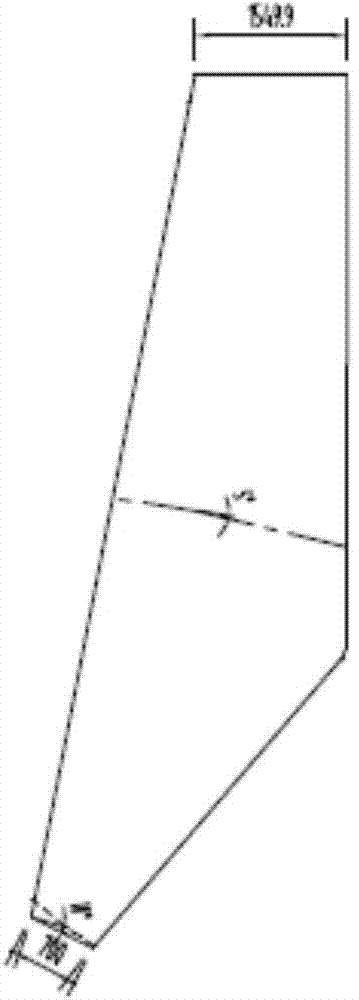

[0040] S01: Create a 2D sketch; open the Autodesk inventor software, create the first file Sheet Metal.ipt and enter the sheet metal mode, import the part design drawing and generate a 2D sketch of the part, save the 2D sketch as a basic sketch after completing the 2D sketch, and close the second file One file; the part design drawing is attached figure 2 As shown, it is a single section of crescent-ribbed steel bifurcation pipe with three sides chamfered.

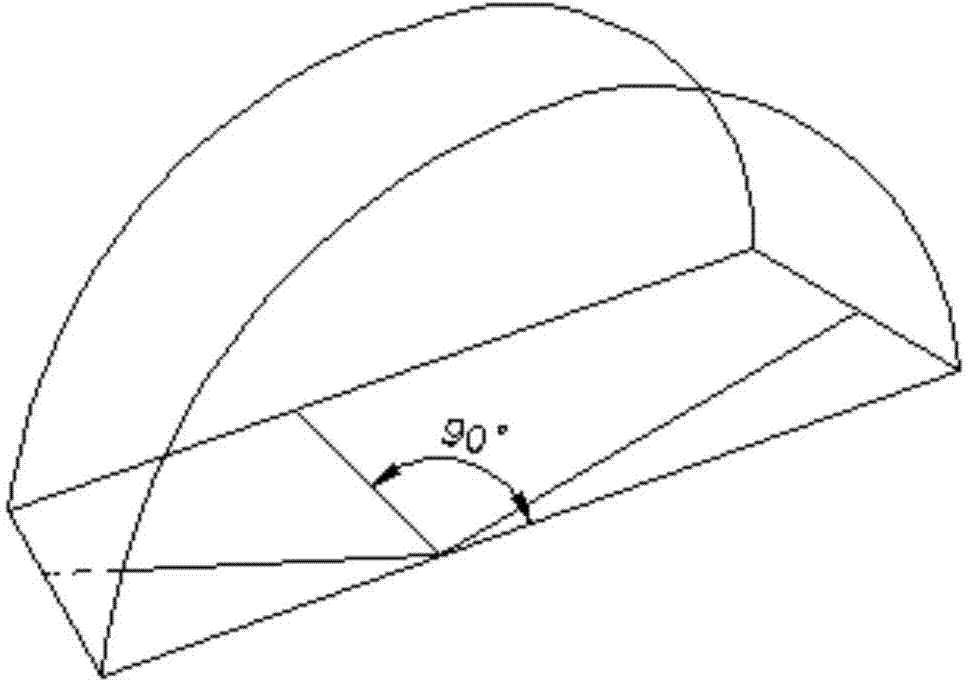

[0041] S02: establish a three-dimensional surface; such as image 3 As shown, create a second file Sheet Metal.ipt, enter the two-dimensional sketch state and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com