Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154results about How to "Control delivery volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

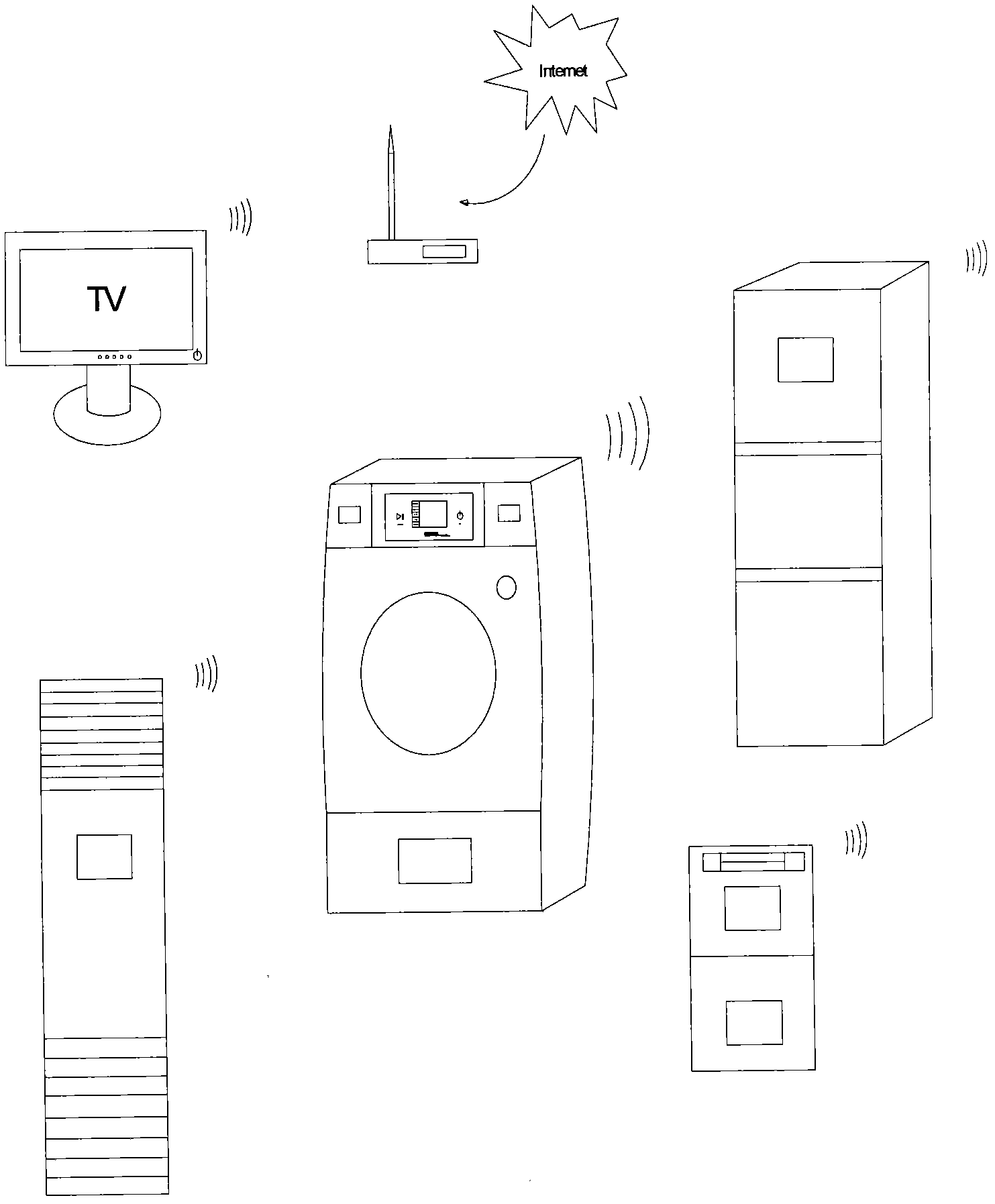

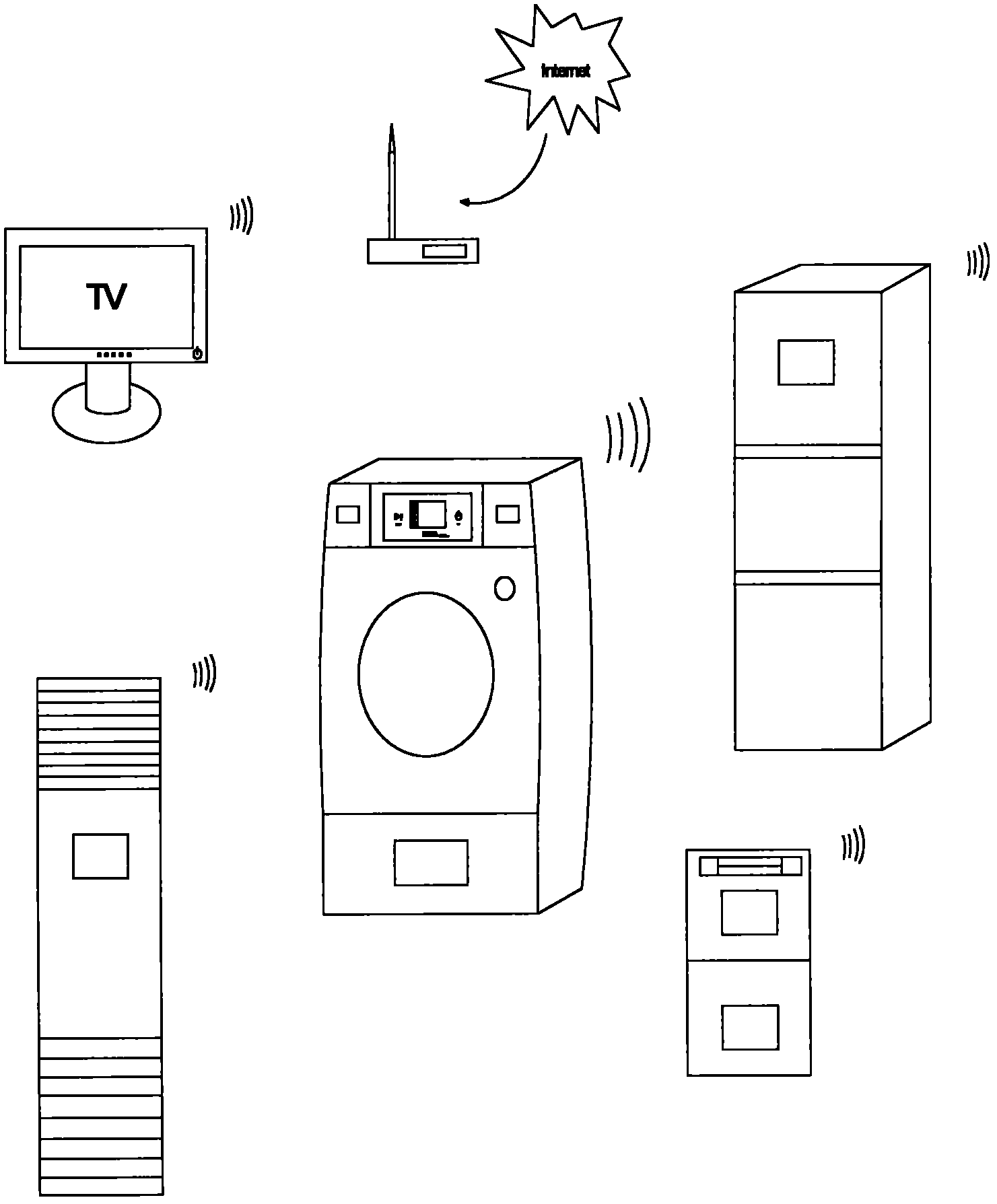

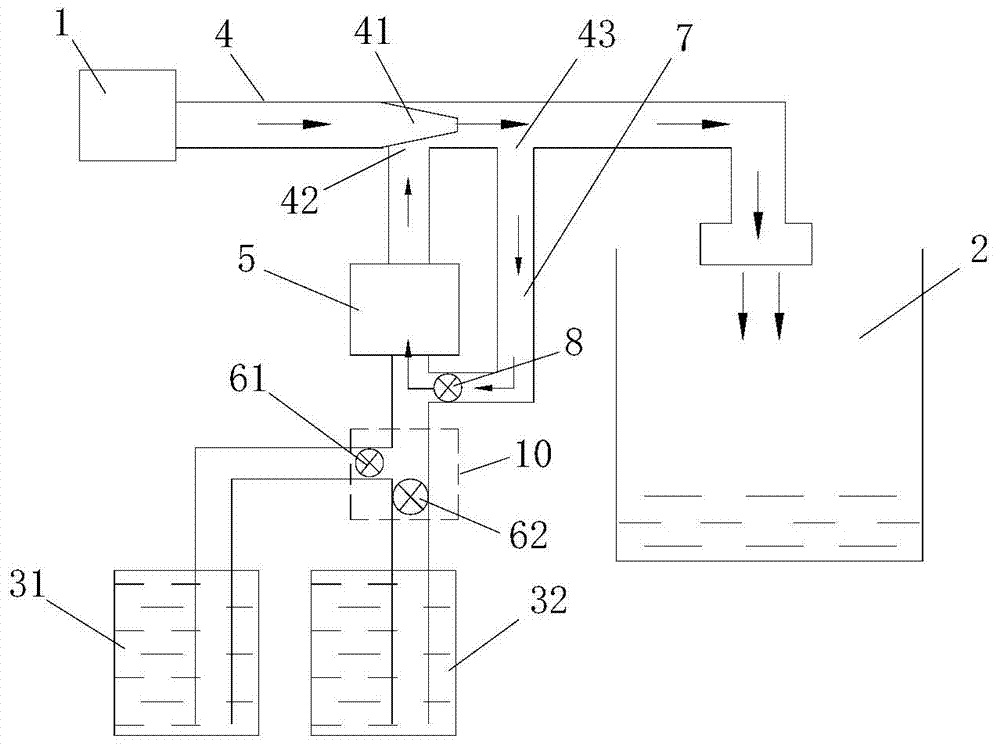

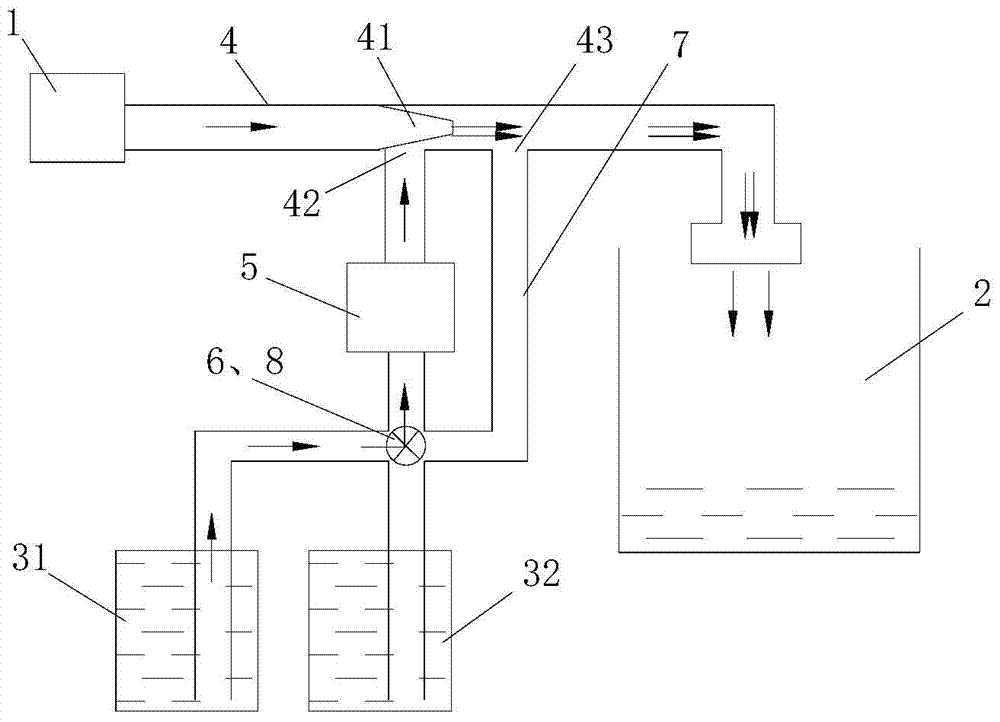

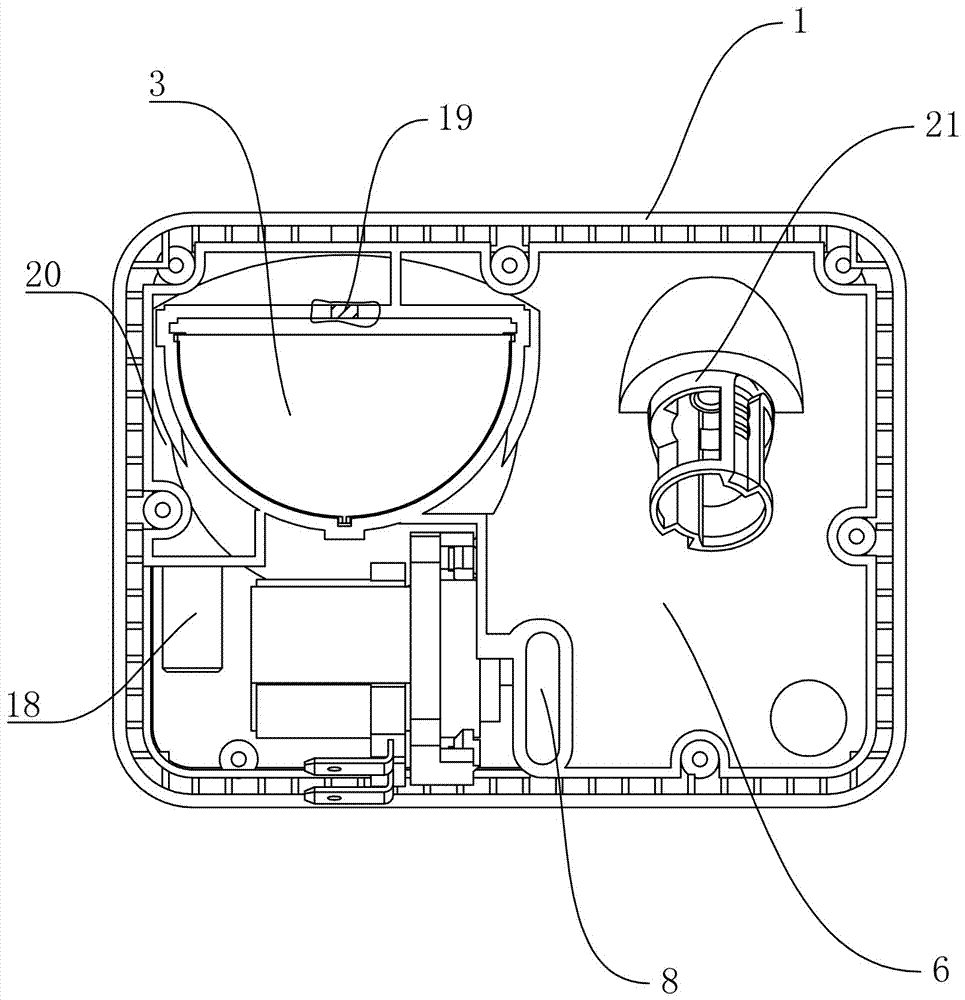

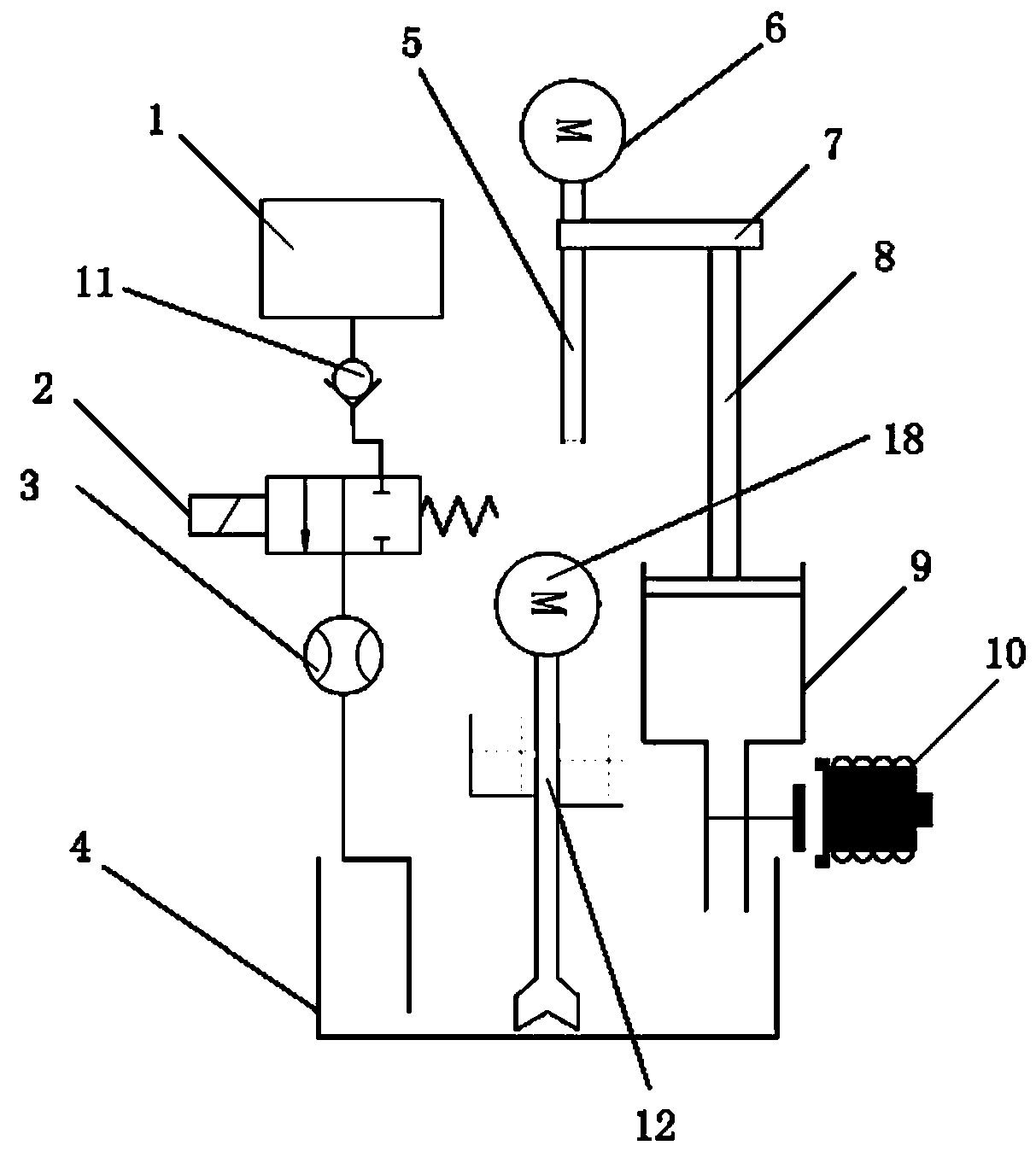

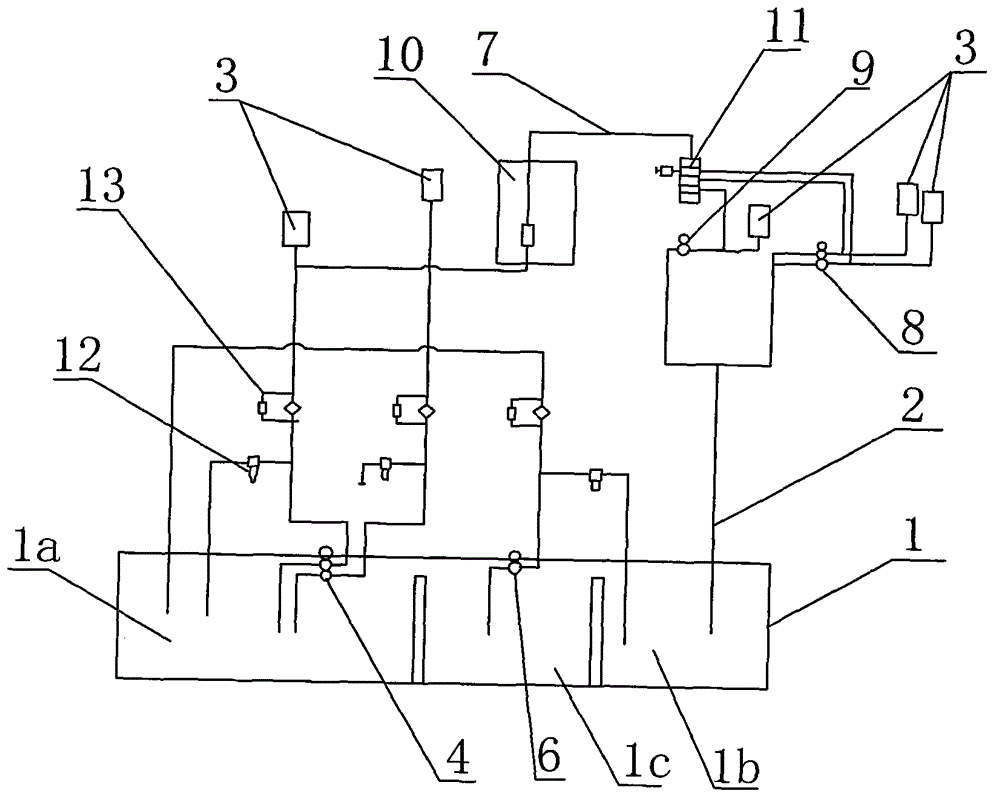

Intelligentized internet-of-thing washing machine

ActiveCN102383286ARealize function controlControl delivery volumeOther washing machinesControl devices for washing apparatusUpgradeProcess engineering

The invention discloses an intelligentized internet-of-thing washing machine, which belongs to the field of home appliances. By the aid of a wireless module, connection among the washing machine and other home appliances indoors and control and allocation of functions are realized, so that duplication of functional units of the home appliances can be avoided. Since various control modules are mounted on the washing machine, the washing machine can be controlled intelligently and can be adjusted and controlled automatically according to conditions including materials of clothes, types and content of washing agent, current temperature, air speed and the like, efficiency is improved, time is shortened and simultaneously cost is reduced. Due an internet-of-thing module connected with the network, functions of the washing machine including function upgrade, information collection, goods purchase and payment are realized. Further, the washing machine can offer daily assistances for users, such as payment for charges of water and electricity and purchase of gas, and brings great convenience for the users, and further time is saved, duplication of functions of other home appliances is avoided and cost for each link is saved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

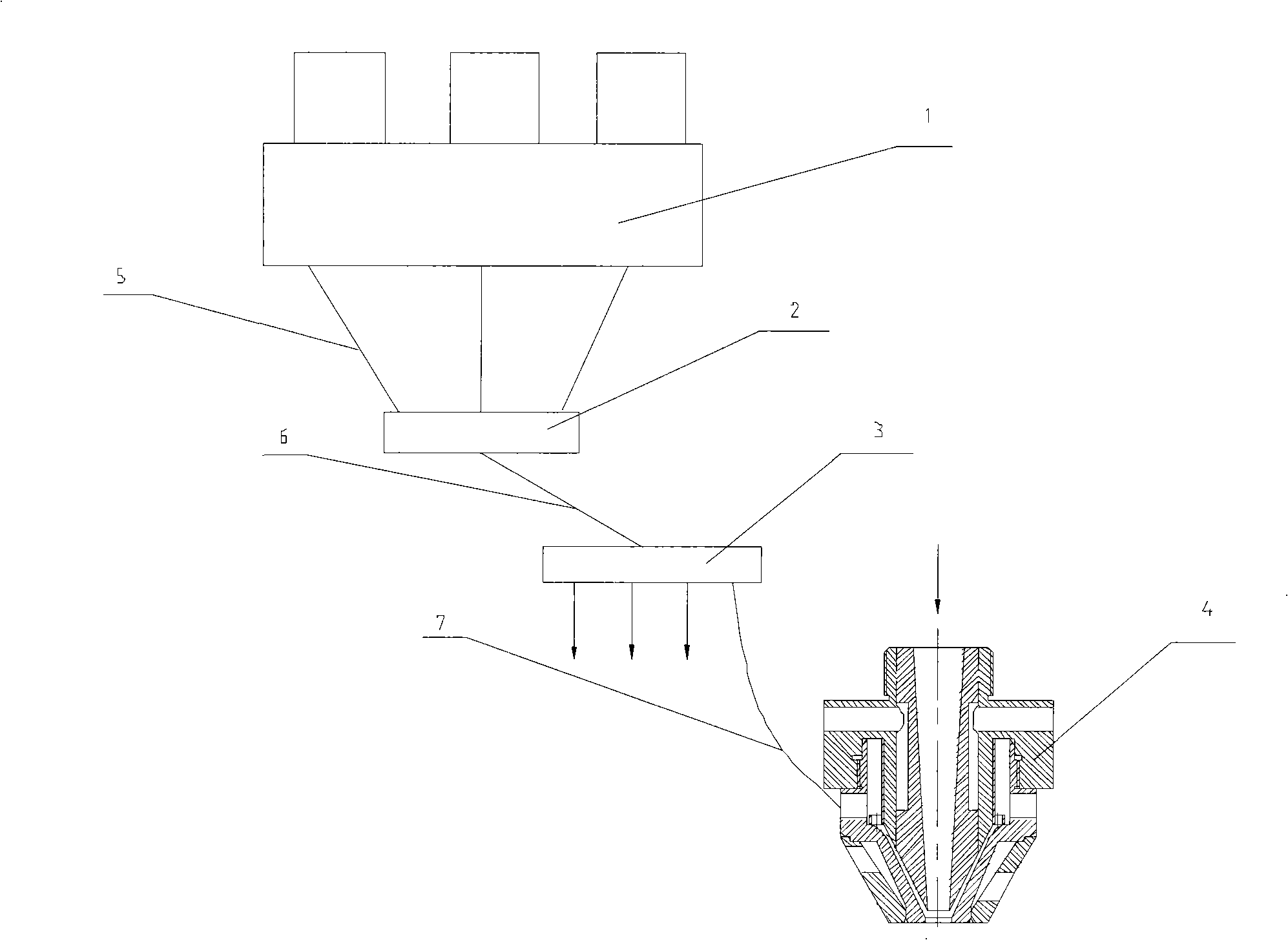

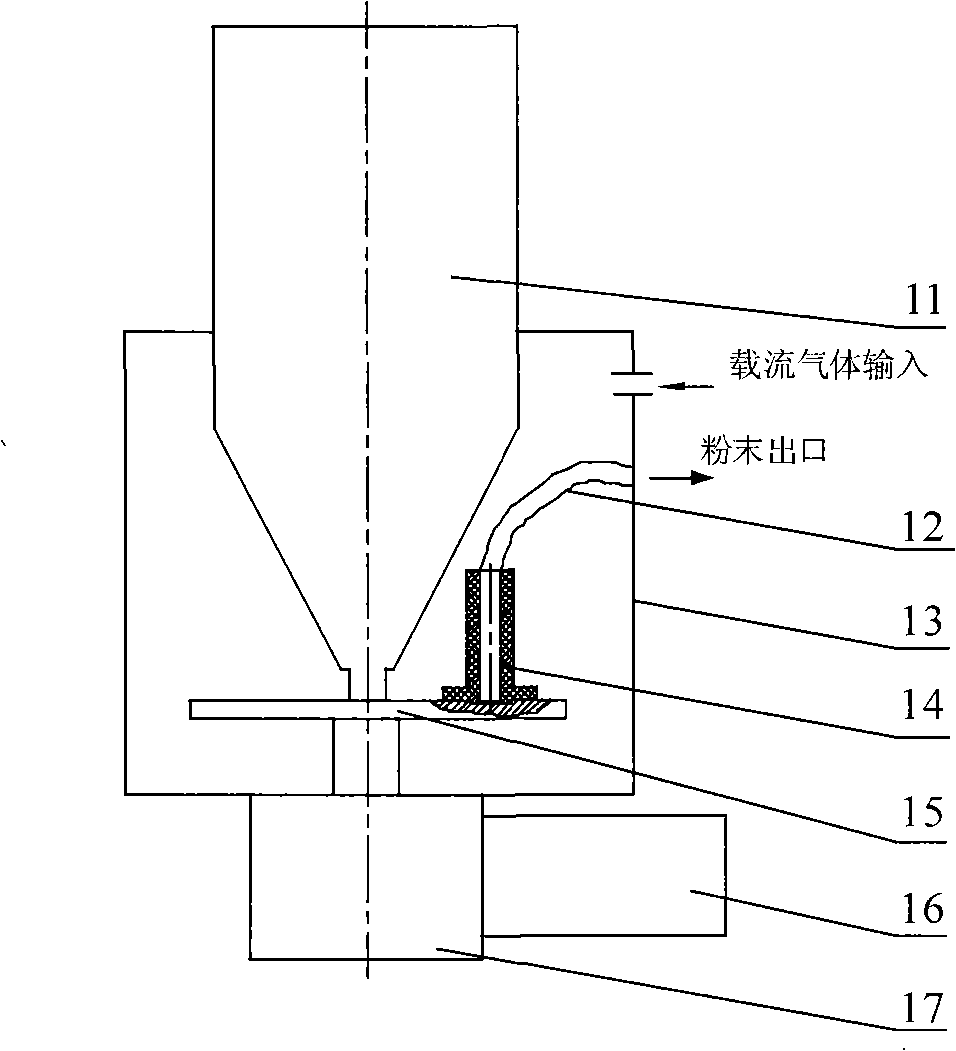

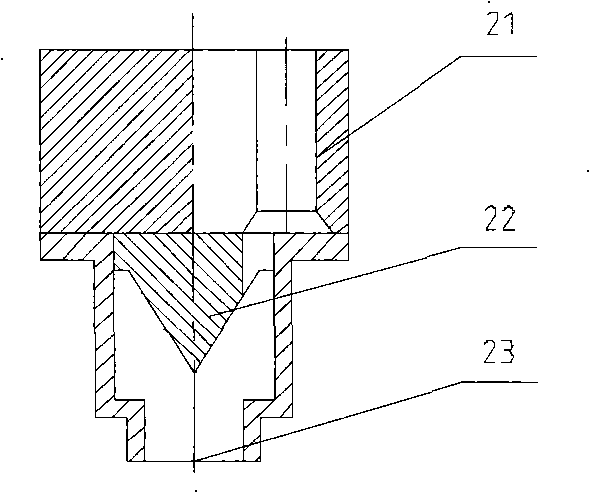

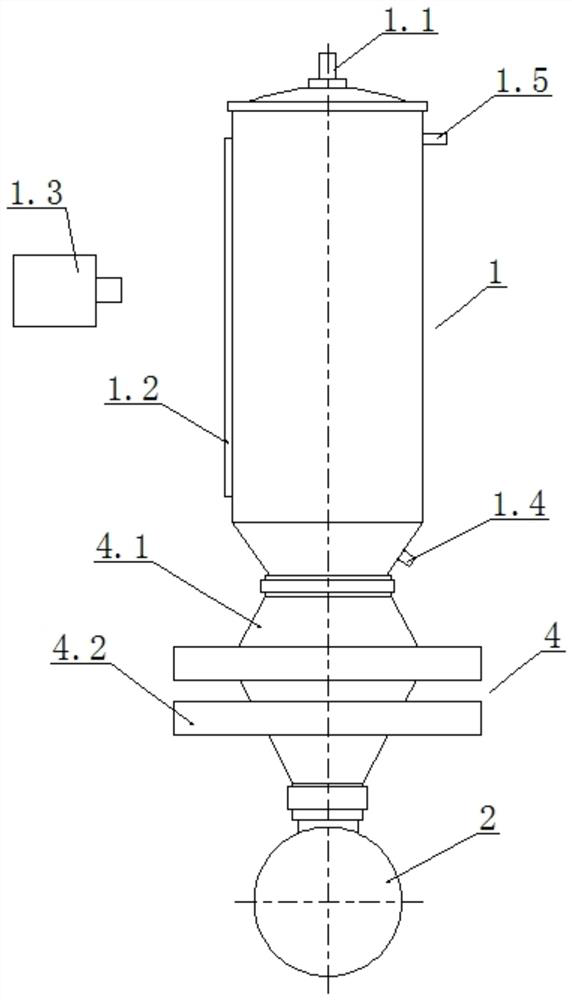

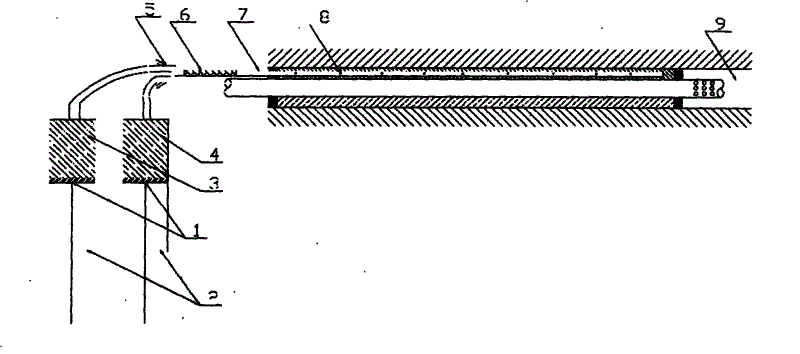

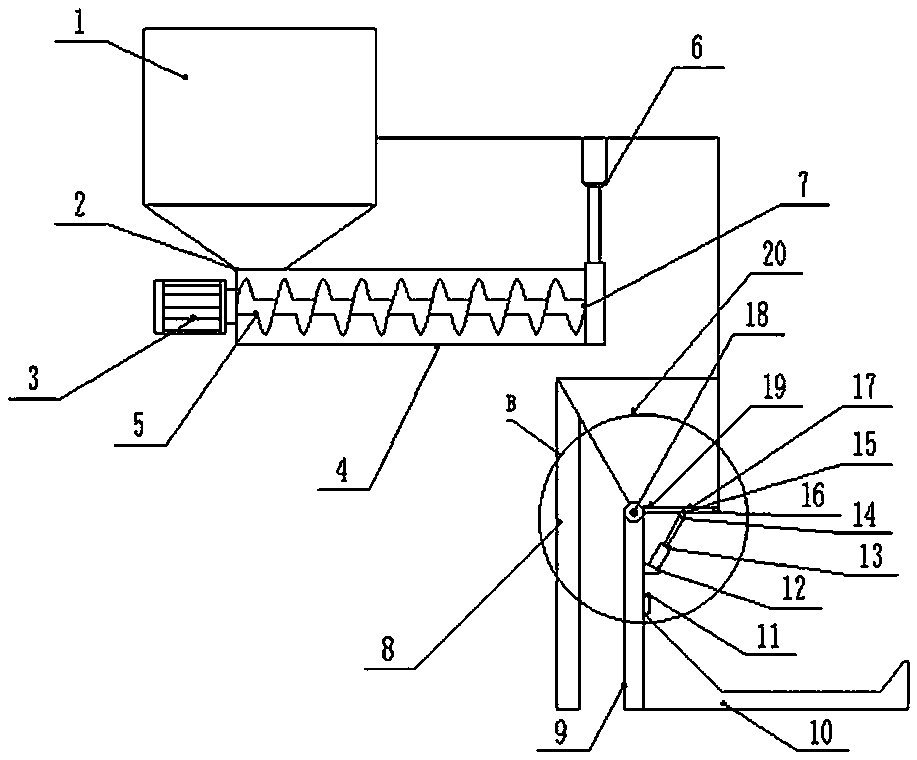

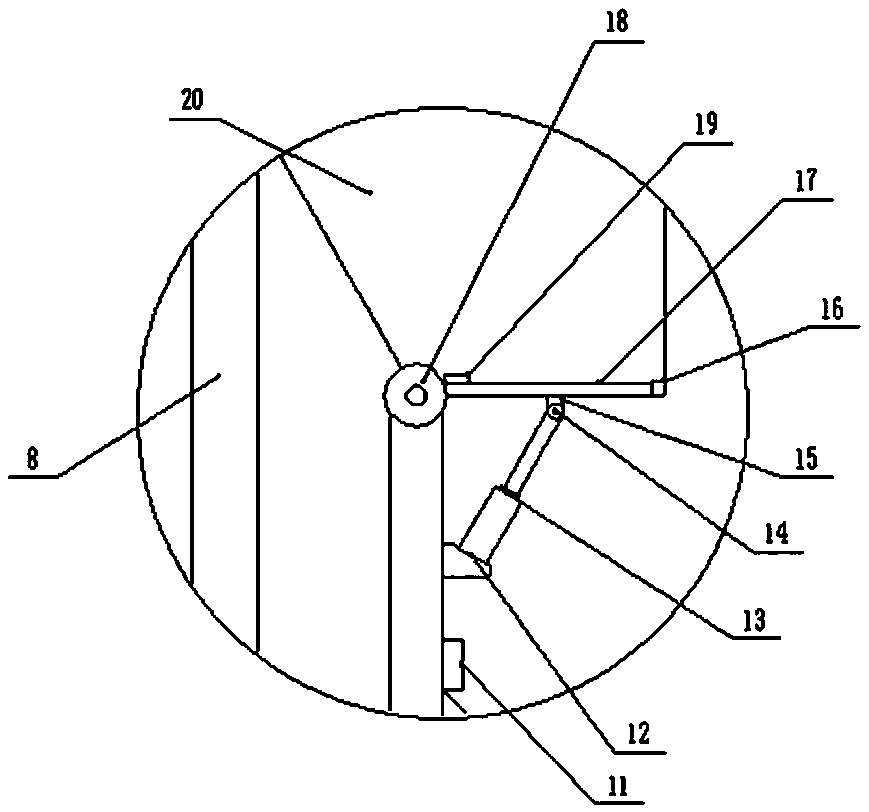

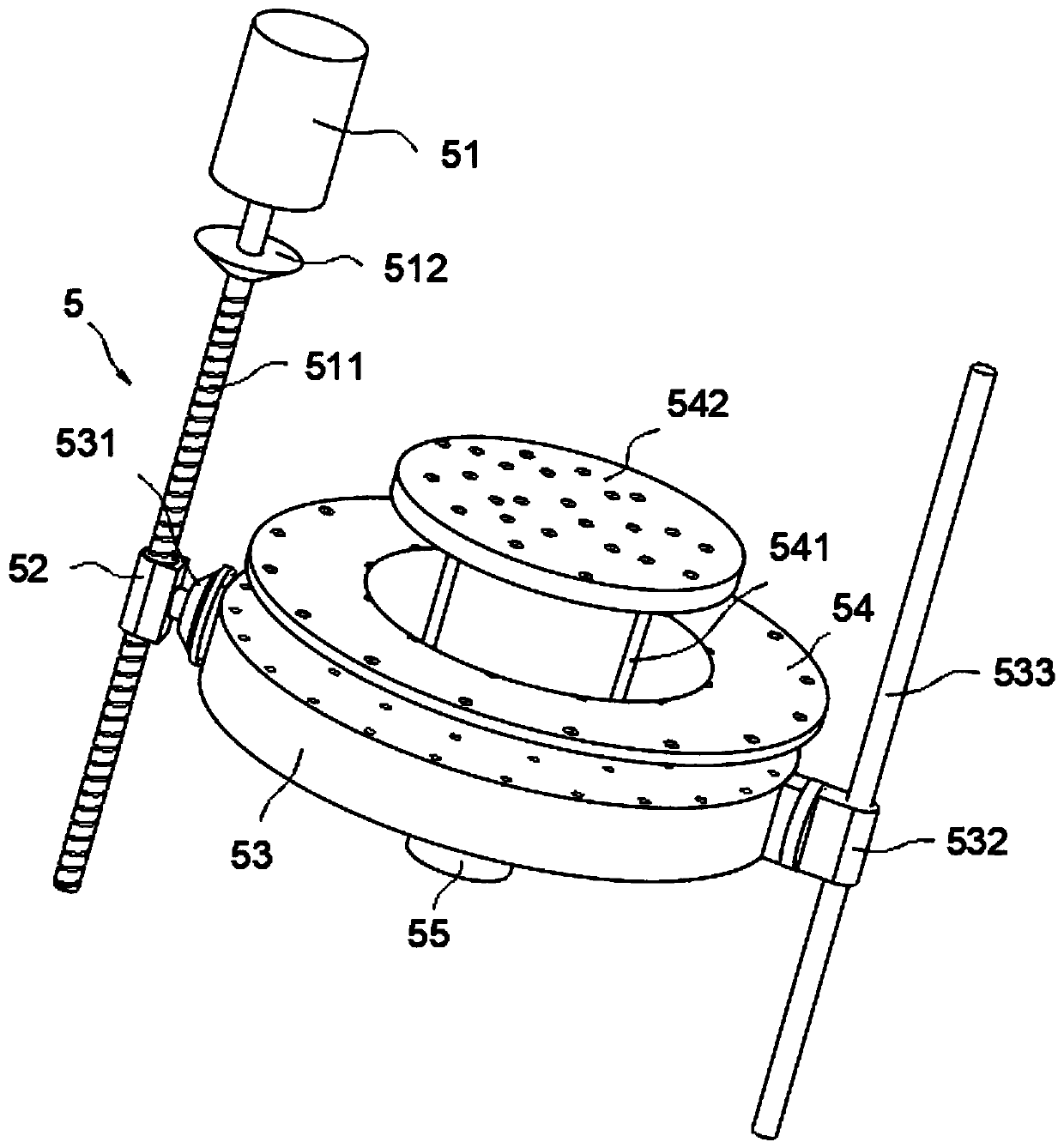

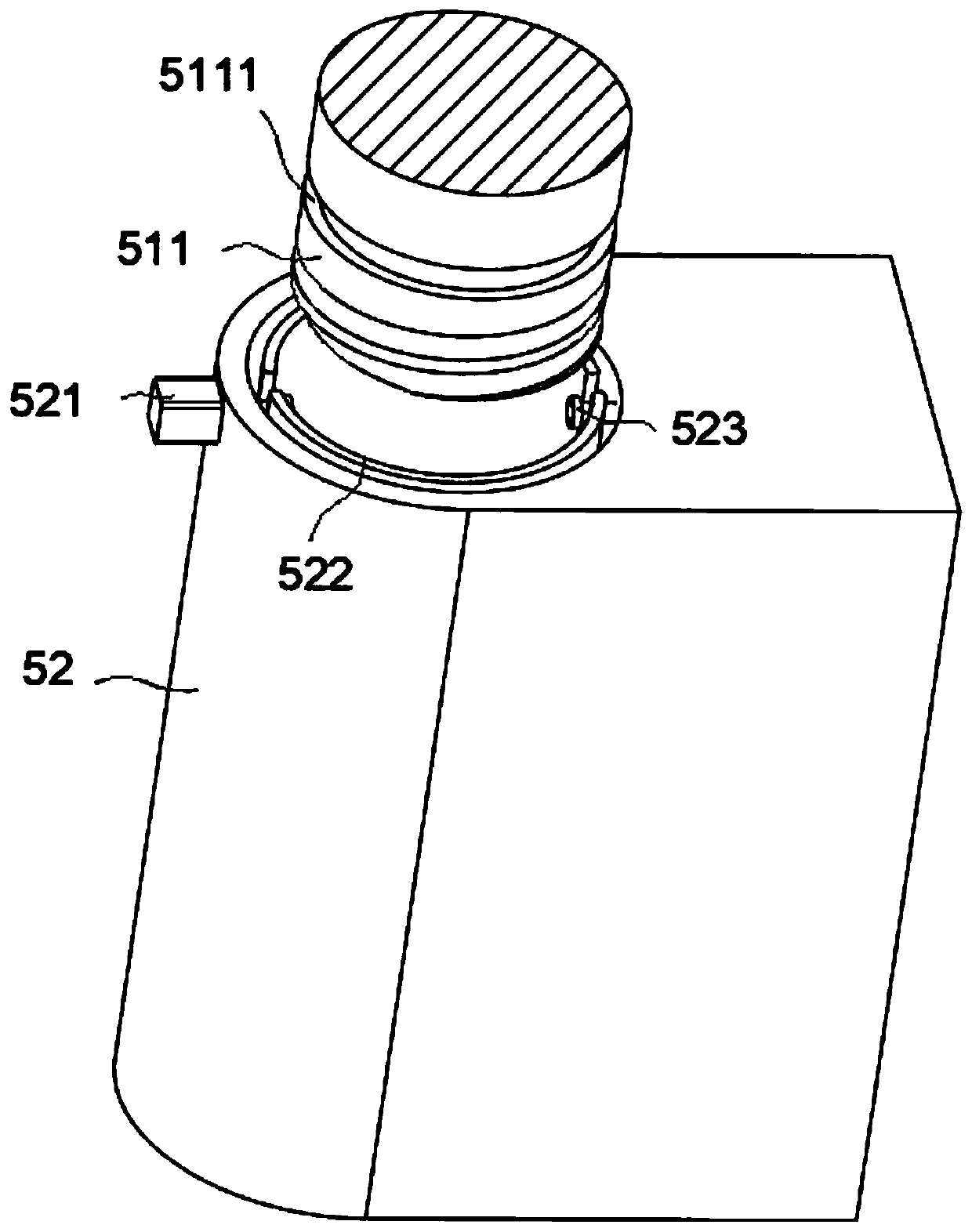

Coaxial powder feeding system for quickly molding and producing functional gradient material with laser

InactiveCN101342640AWell mixedImprove uniformityIncreasing energy efficiencyLaser beam welding apparatusNozzleRapid prototyping

The invention relates to a coaxial powder feeding system of laser rapid prototyping preparation function gradient material, comprising a powder inlet device, and the powder is absorbed and conveyed by carrier gas. The powder inlet device is communicated with a powder mixer through a first conveying pipe. The powder mixer is used for mixing the powder which has been conveyed. The mixed powder enters into a powder separate device through a second conveying pie. The powder separate device is used for separating the mixed powder into multi-path. The powder separate device is communicated with the powder inlet of a nozzle through a third conveying pipe. The nozzle makes the multi-path powder flock together in a molten pool formed by laser. The function gradient material is prepared under the cladding action of laser and powder. The mix of the powder is uniform. The coaxial powder feeding system has good power feeding property, which can realize the optimum processing, and at the same time, can be suitable for different processing distances. The powder utilization rate is high. The manufacturing accuracy is good. At the same time, the powder conveying distance can be adjusted with a certain scope, and so the coaxial powder feeding system can not be limited to the manufacturing space.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

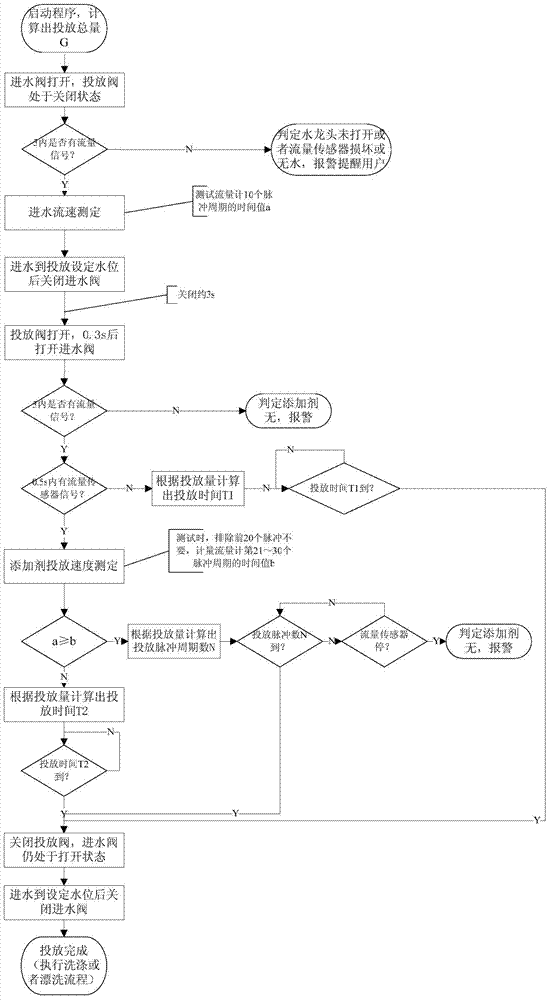

Control method of automatic additive adding

ActiveCN104727099AEasy to washImprove rinsing performanceOther washing machinesControl devices for washing apparatusInlet valvePulse number

The invention discloses a control method of automatic additive adding. The method includes: opening an additive adding control valve, opening a water inlet valve, using negative pressure generated by water inlet to extract additives, measuring water pressure, additive viscosity and additive adding speed, selecting adding time or adding pulse number to judge whether a total adding amount reaches the required additive amount G, and closing the additive adding control valve when the additive adding amount reaches G to complete additive adding. The control method has the advantages that a flow sensor and a negative pressure structure are used in coordination, precise adding of various liquid additives is achieved by combining the on and off of the adding control valve, the influence of the water pressure and the precise detection of the flow sensor and by precise judgement, washing and rising effects are increased, and the control method is simple and practical.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

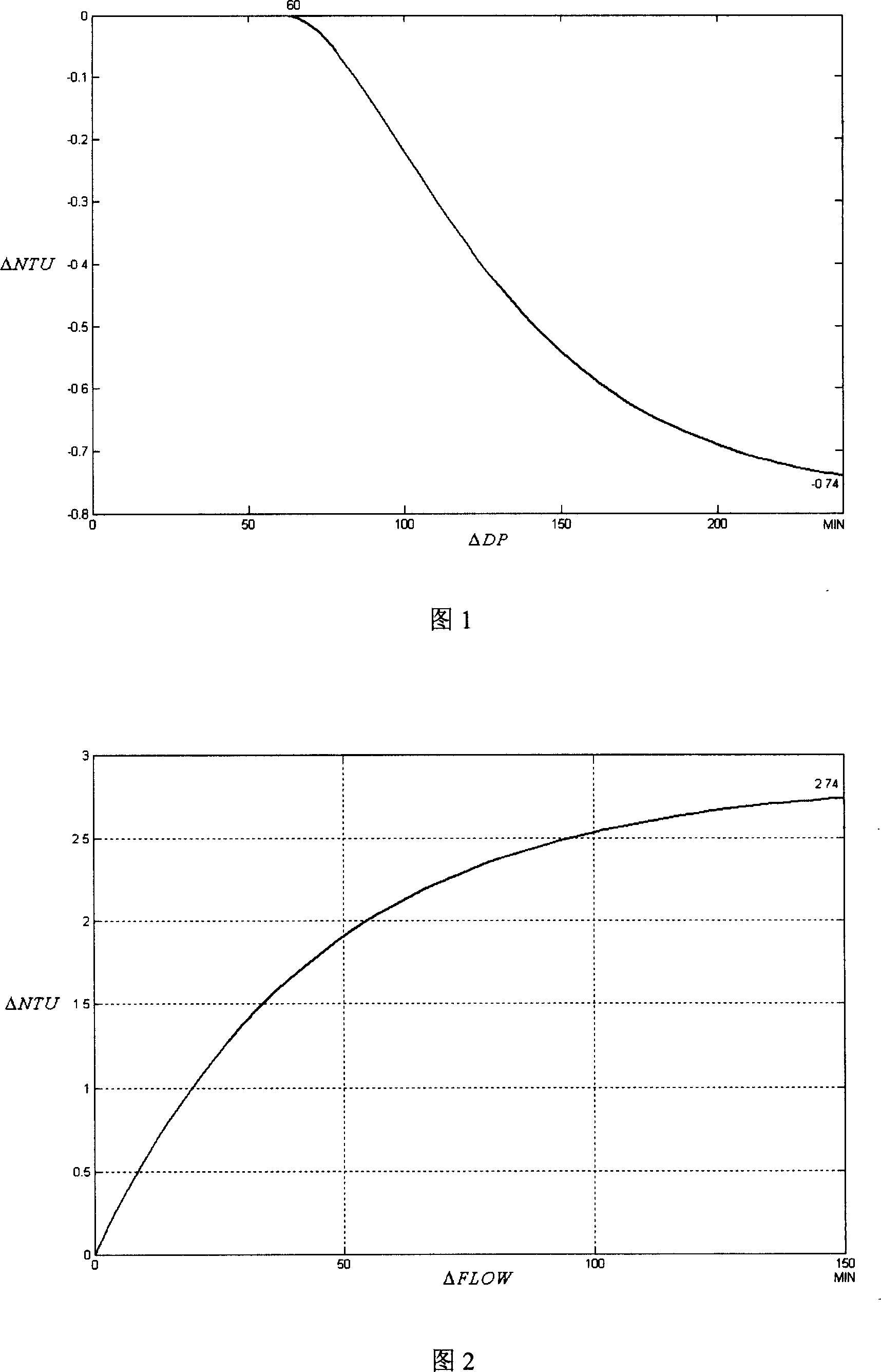

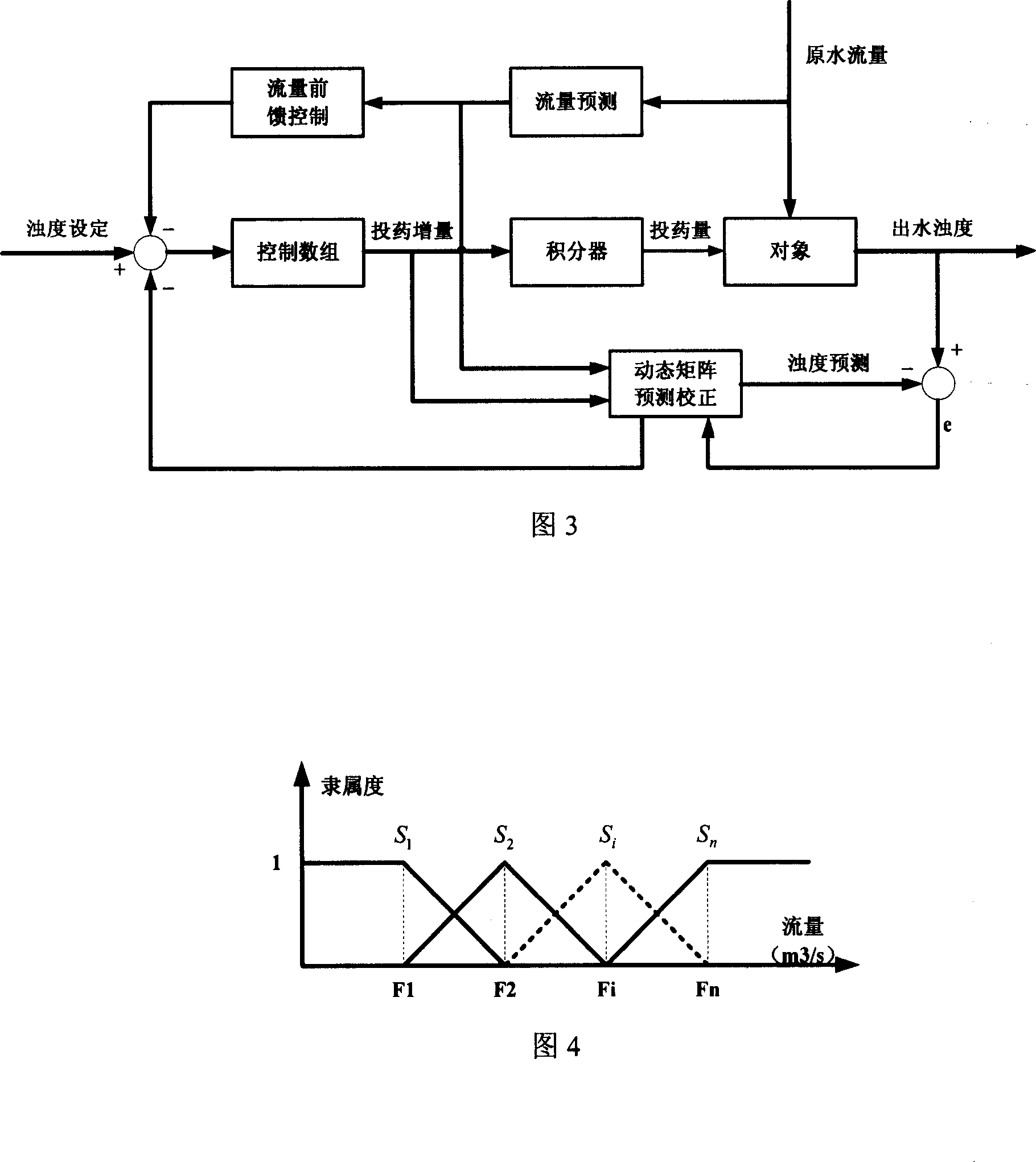

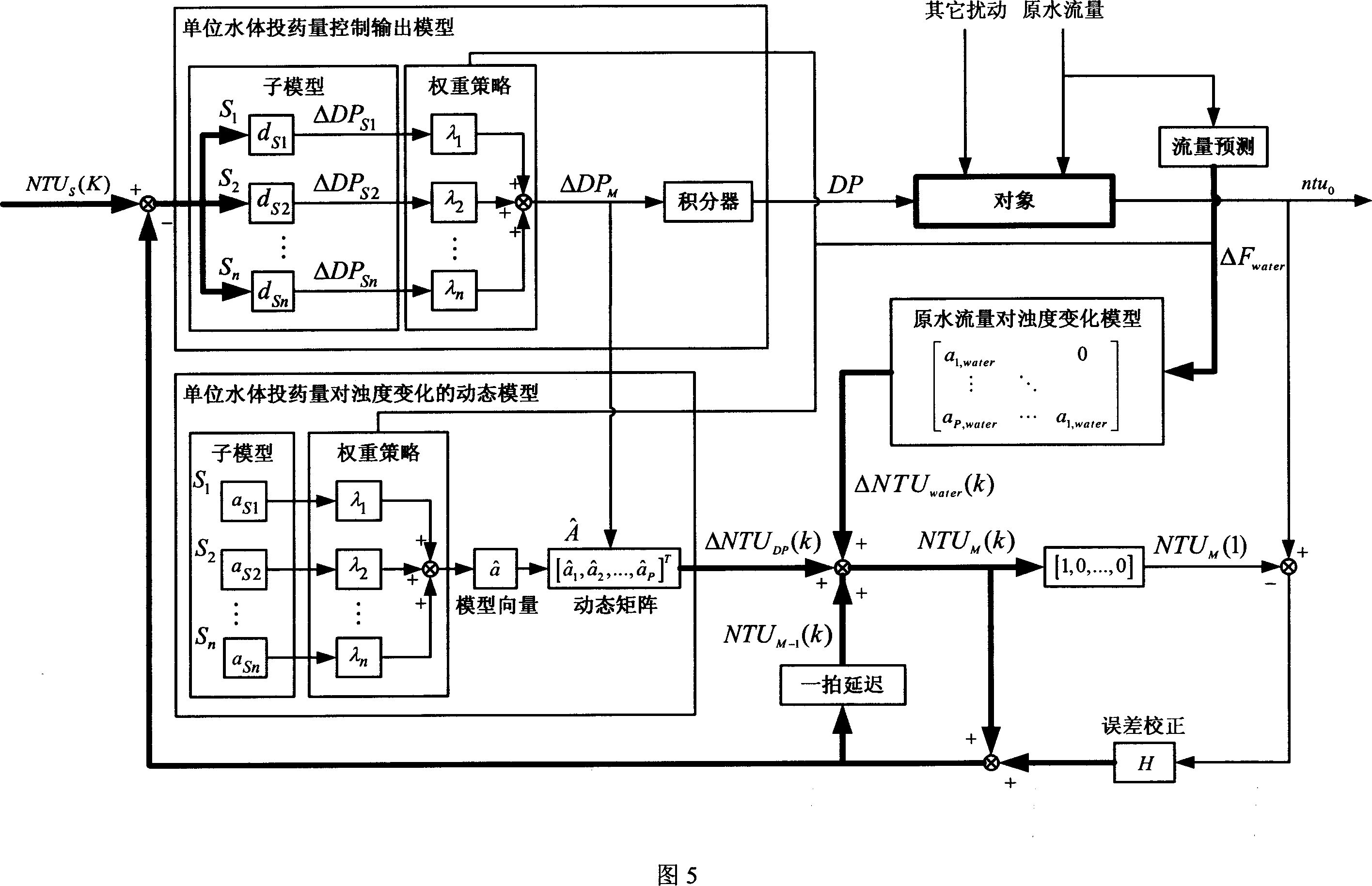

Multi-model dynamic matrix feeding amount control method for coagulation system in waterworks

InactiveCN101020128AApplicable to coagulation dosing controlSmall amount of calculationSedimentation separationWater/sewage treatment by flocculation/precipitationModel dynamicsDynamic models

The multi-model dynamic matrix feeding amount control method for coagulation system in waterworks features that dynamic matrix predicting controller is constituted based on comprehensive multi-model dynamic matrix control theory and by means of using raw water flow rate as the control target, separating the whole system into several subspaces and separate experiments to obtain sectional linear models of the subspaces; and that outflow water turbidity is controlled through determining the dynamic model of the system, predicting the outflow water turbidity, weighting treatment to obtain overall control increment and regulating the feeding amount based on the current work conditions, practical water flow rate and certain weighting police. The present invention can ensure smooth outflow water turbidity, system running economic performance, high robustness and low cost.

Owner:SOUTHEAST UNIV +1

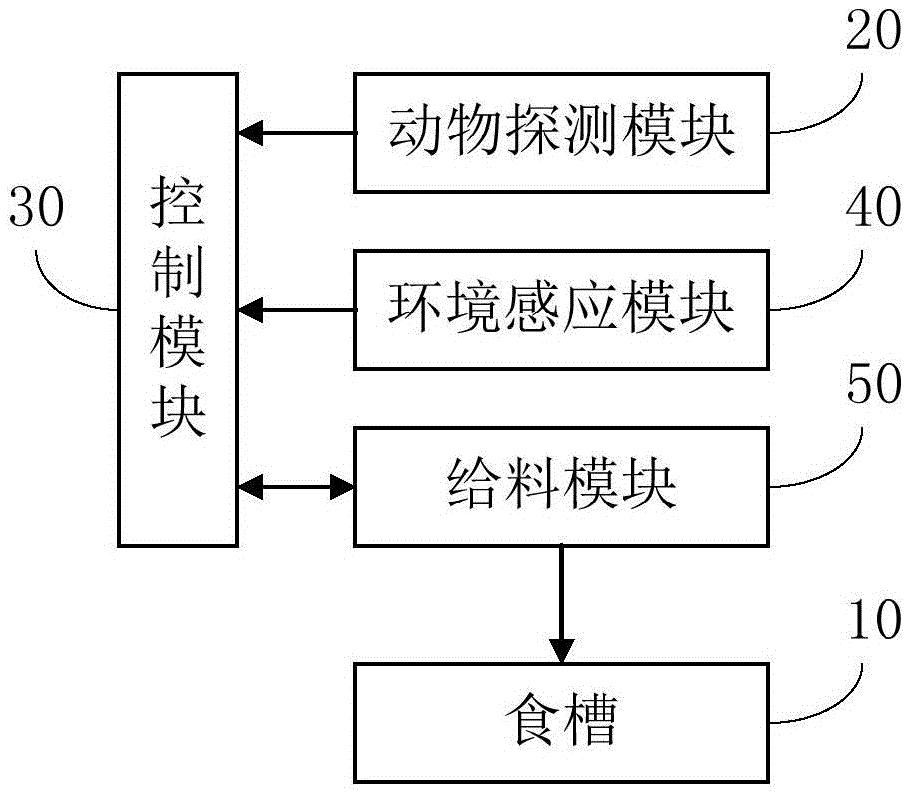

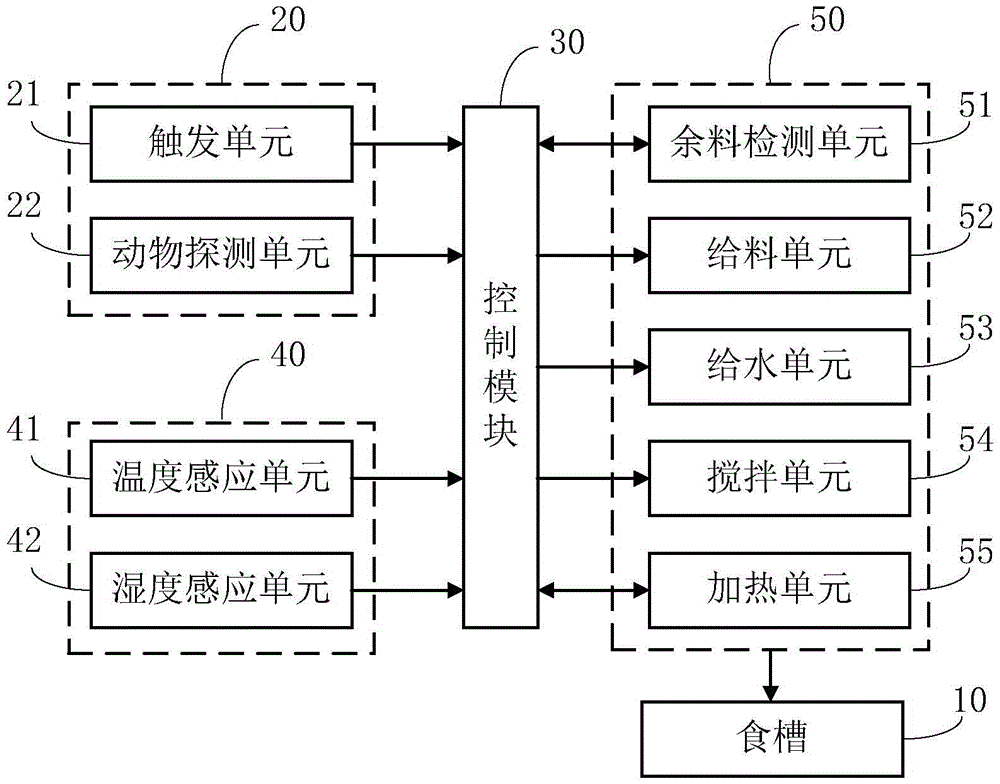

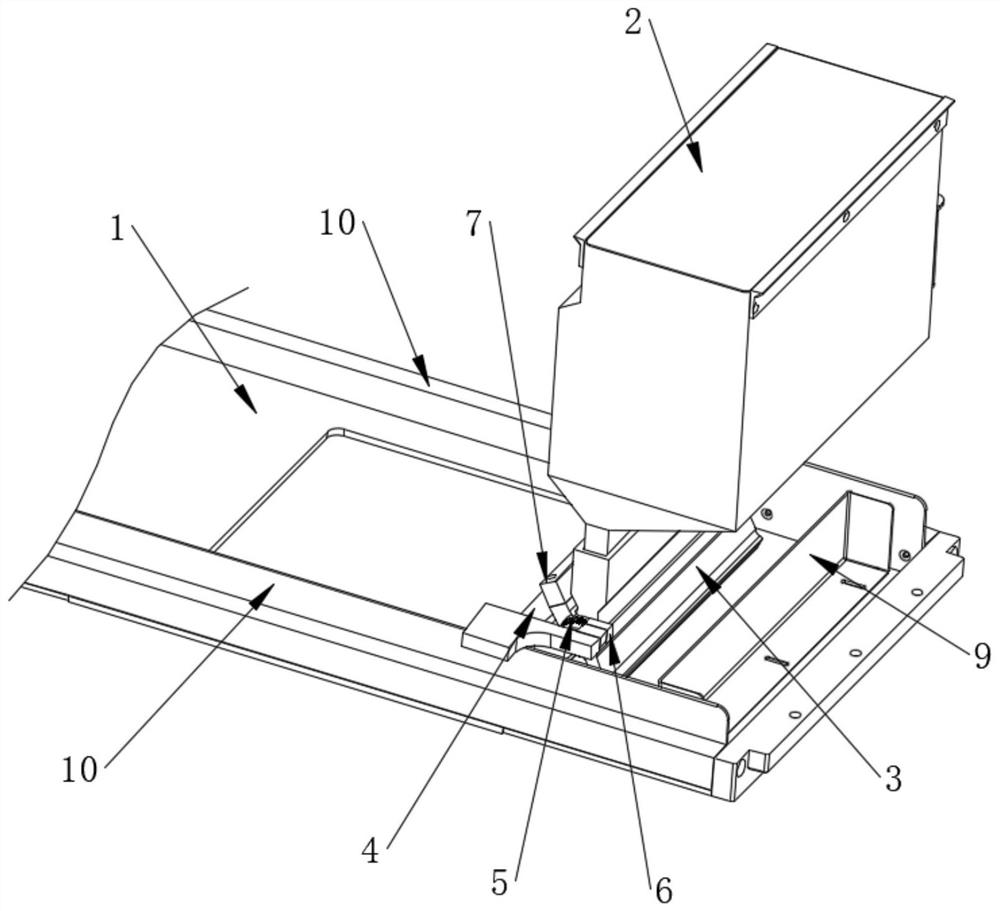

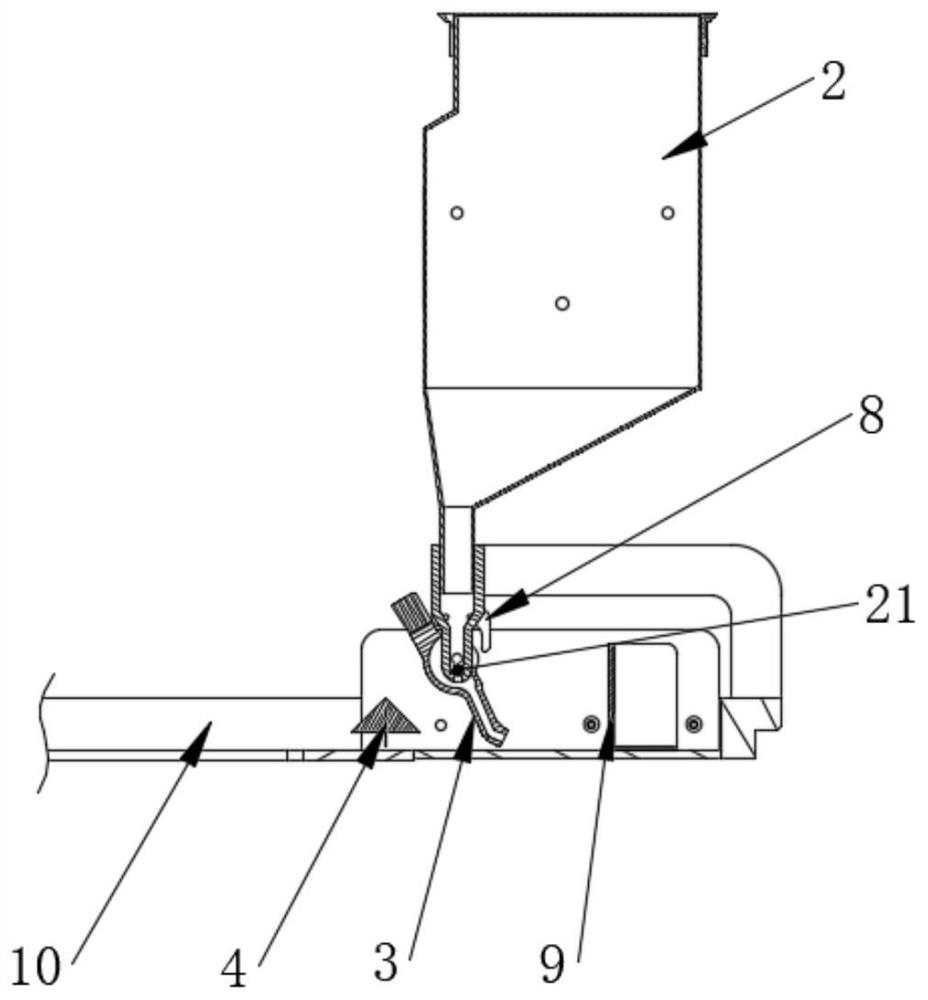

Intelligent feed put-in system and method

The invention is applicable to the field of animal breeding, and provides an intelligent feed put-in system and method. The system comprises a trough, and further comprises an animal detecting module for sensing animals entering an eating area and for detecting the number and weights of the animals, a control module for calculating the equivalent number and body sizes of the animals according to the number and weights of the animals, an environment sensing module for sensing the environment parameters around the intelligent feed put-in system, a feed module for detecting the residual amount of feed in the trough and processing a prefixed amount of feed and water into a feed and water mixture with preset humidity according to the equivalent number and body sizes of the animals, the environment parameters and the residual amount of feed, and putting the feed and water mixture into the trough. The animals entering the eating area can be sensed, and the put-in amount and humidity of feed can be controlled according to the residual amount of feed, the environment parameters and the equivalent number and body sizes of the animals, feed surplus and deficiency can be effectively avoided, and breeding benefits are improved.

Owner:深圳市润农科技有限公司

Water and fertilizer integrated soilless culture system and culture method

InactiveCN104082116ARealize integrationReduce volumePressurised distribution of liquid fertiliserAgriculture gas emission reductionUltrasound attenuationNutrient solution

The invention discloses a water and fertilizer integrated soilless culture system and a culture method. The system comprises a seedling growing system, a planting system and a water and fertilizer spraying system; the method comprises steps of seed selection, seedling substrate preparation, seed disinfection treatment, seeding, seedling stage management, cleaning and disinfection of planting pipelines and nutrient solution pond, management after transplantation, seedlings transplantation, attenuation of nutrient solution, and the like. The device adopts an irrigation and fertilization method of uniformly, accurately and directly conveying fertilizer solution to substrate adhered to roots of plants with small flow through a pipeline system and emitters mounted on the planting pipelines, can quantificationally, periodically and directly feed water and nutrient to the plants according to growth requirements of the plants, and improves utilization factors of water and fertilizer.

Owner:阳江市阳东区绿康春农业科技有限公司

Pollution-free paddy rice planting method

InactiveCN105248209AImprove disease resistanceIncrease productionCalcareous fertilisersClimate change adaptationGreen manureRice grain

The invention discloses a pollution-free paddy rice planting method. The method comprises the following steps: A, planting milk vetch as green manure in a rice field, and applying a basic manure, wherein 500-800 kg of the basic manure is applied to each mu of the rice field; B, after the rice field is subjected to exposure, performing rotary tillage, ridge separation, irrigation and rice transplanting; C, applying a compound fertilizer to seedlings after the seedlings are inserted; D, grazing 8-15 7-10-day-old ducks to each mu of the rice field after 15-20 days of rice transplanting, evicting the ducks from the rice field after 25-40 days, spraying a biological pesticide, draining for 7-10 days, topdressing 30-100 kg of the compound fertilizer used in the step C to each mu of the rice field, irrigating till the depth of water is 8-10 cm, grazing 5-10 7-10-day-old ducks to each mu of the rice field again, and evicting the ducks from the rice field before 15-20 days of rice mature. According to the pollution-free paddy rice planting method, the yield is high, pollution is avoided, produced rice tastes good, and meanwhile, high-quality duck is obtained.

Owner:ANHUI MUMAHU AGRI DEV GRP

Planting method for organic high-yield rice

InactiveCN105393862APlay a sustained release roleImprove disease resistanceCalcareous fertilisersExcrement fertilisersGreen manurePaddy field

The invention discloses a planting method for organic high-yield rice. The method comprises: planting broad beans in a rice field, after harvesting the broad beans, performing green manure dressing and retting, and applying base fertilizer; performing water-controlling harden-seedling on rice seedlings whose seedling age is 15-20 days for 2-3 days; performing rotary tillage, ridge dividing, irrigation on the rice field, and then transplanting rice seedlings; after the rice seedlings survive, dressing a compound fertilizer to promote rice seedling tiller; 13-18 days after rice transplanting, putting newly-hatched ducklings whose day-age is 12-20 in the rice field according to amount of 8-15 per mu, 25-40 days after putting the ducks in the rice field, driving the ducks out of the rice field, spraying biopesticide, performing field draining for 7-10 days, topdressing a nitrogen-phosphorus-potassium composite fertilizer according to amount of 20-50 kg per mu, and then irrigating to 8-10 cm, and driving the ducks in the rice field, 15-20 days before the rice is mature, taking back the ducks, and cutting off water and drying the field. The planting method for organic high-yield rice is high in yield, and obtained rice is good in quality, and high-quality duck meat is obtained.

Owner:ANHUI MUMAHU AGRI DEV GRP

Method for planting high-yield organic rice by rice-duck integrated farming

ActiveCN105284512ASimple structureStrong nitrogen fixation abilityThomas phosphate fertilisersAlkali orthophosphate fertiliserAstragalus sinicusIntegrated farming

The invention discloses a method for planting high-yield organic rice by rice-duck integrated farming. The method comprises the steps of: planting astragalus sinicus in a rice field, carrying out green manuring and adding water for retting, and applying a base fertilizer in 10-25 days according to the amount of 800-1000 kg / mu; exposing the rice field to the sun, rotatably tilling the rice field, separating ridges and carrying out rice transplanting after irrigation; when the roots of the rice seedlings survive, applying a composite fertilizer according to the amount of 20-35 kg / mu; in 12-20 days after rice transplanting, putting in 10-15-day old ducks according to the amount of 5-10 ducks / mu; carrying out field draining in 10-15 days, and additionally applying the base fertilizer in A according to the amount of 100-300 kg / mu; then putting 7-10-day old ducks in the rice field when water is irrigated to 8-10 cm, wherein the inputting amount is 8-15 ducks / mu, taking the ducks back 10-15 days before the rice is mature, and drying the rice field after water-break. The method for planting high-yield organic rice by rice-duck integrated farming disclosed by the invention is high in yield, and the obtained rice is good in organic property, and meanwhile, high quality duck meat can be obtained, so that the economical benefit is improved.

Owner:ANHUI MUMAHU AGRI DEV GRP

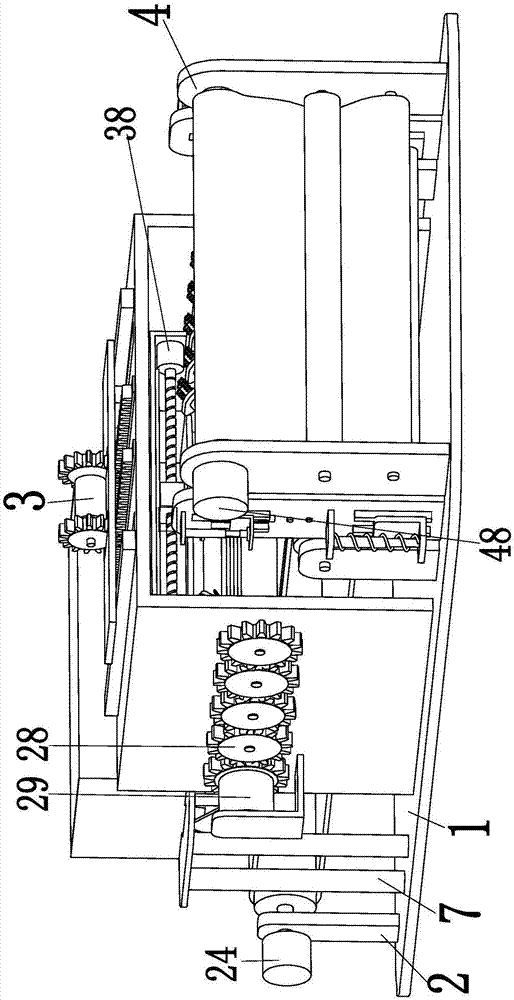

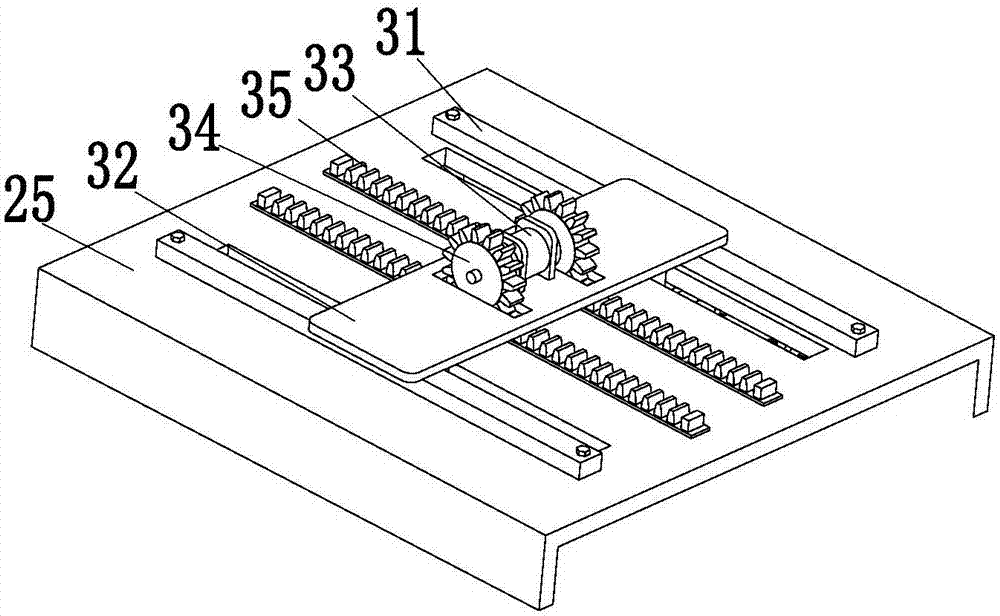

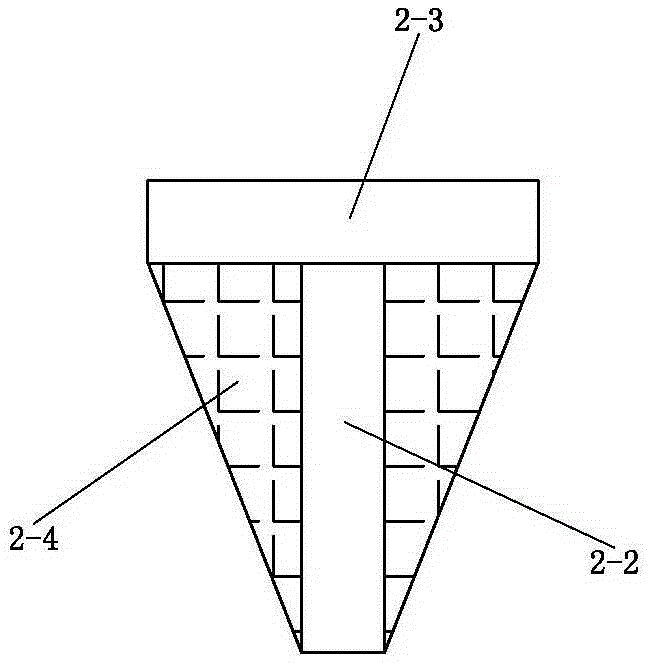

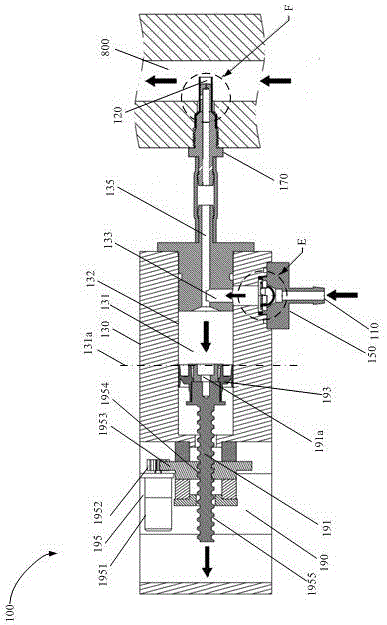

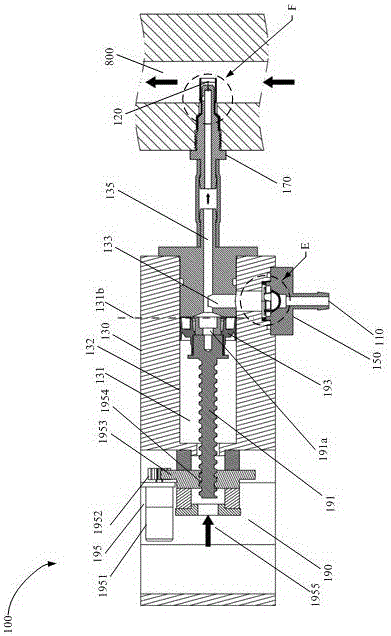

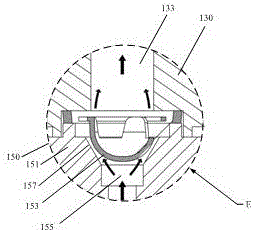

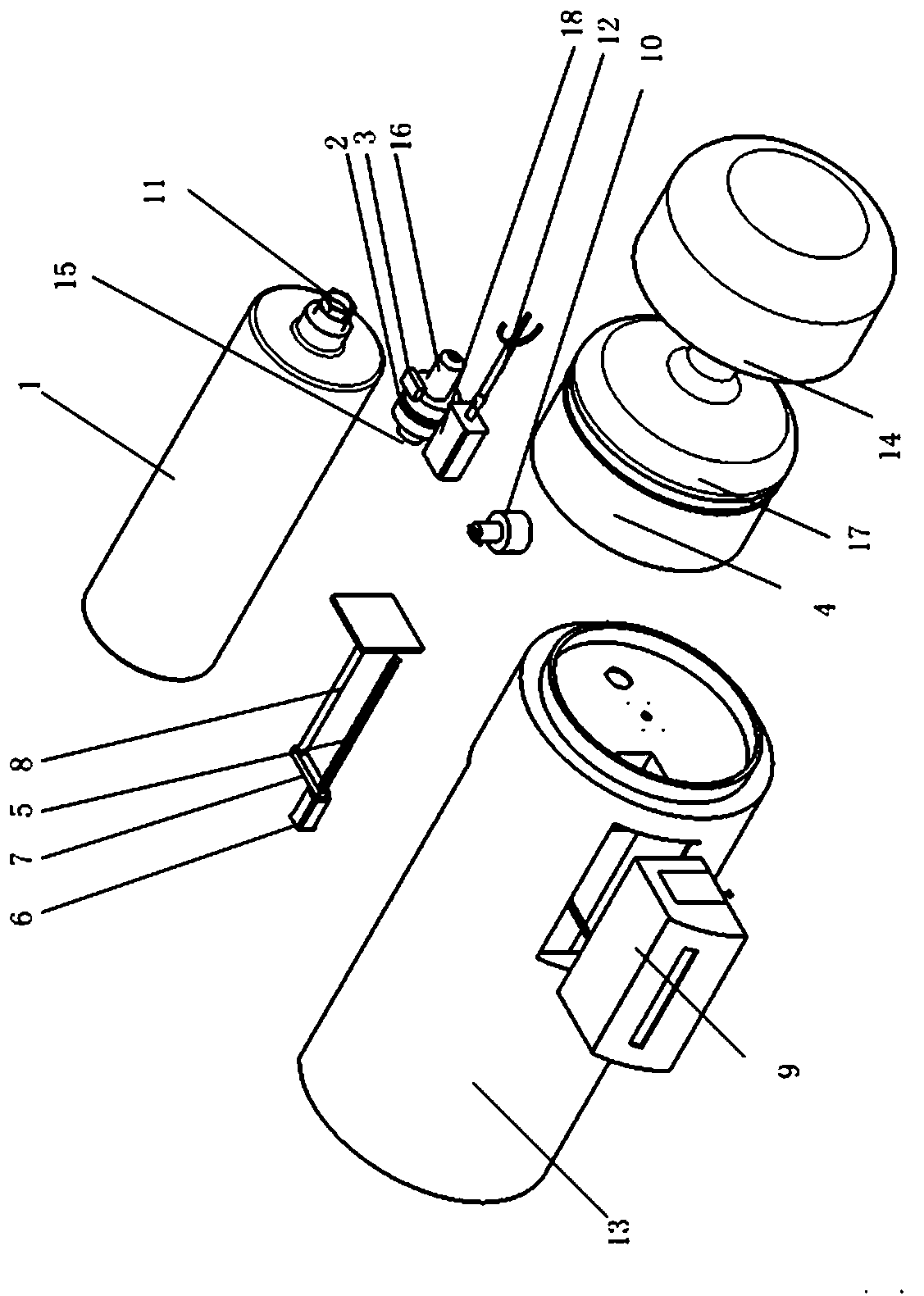

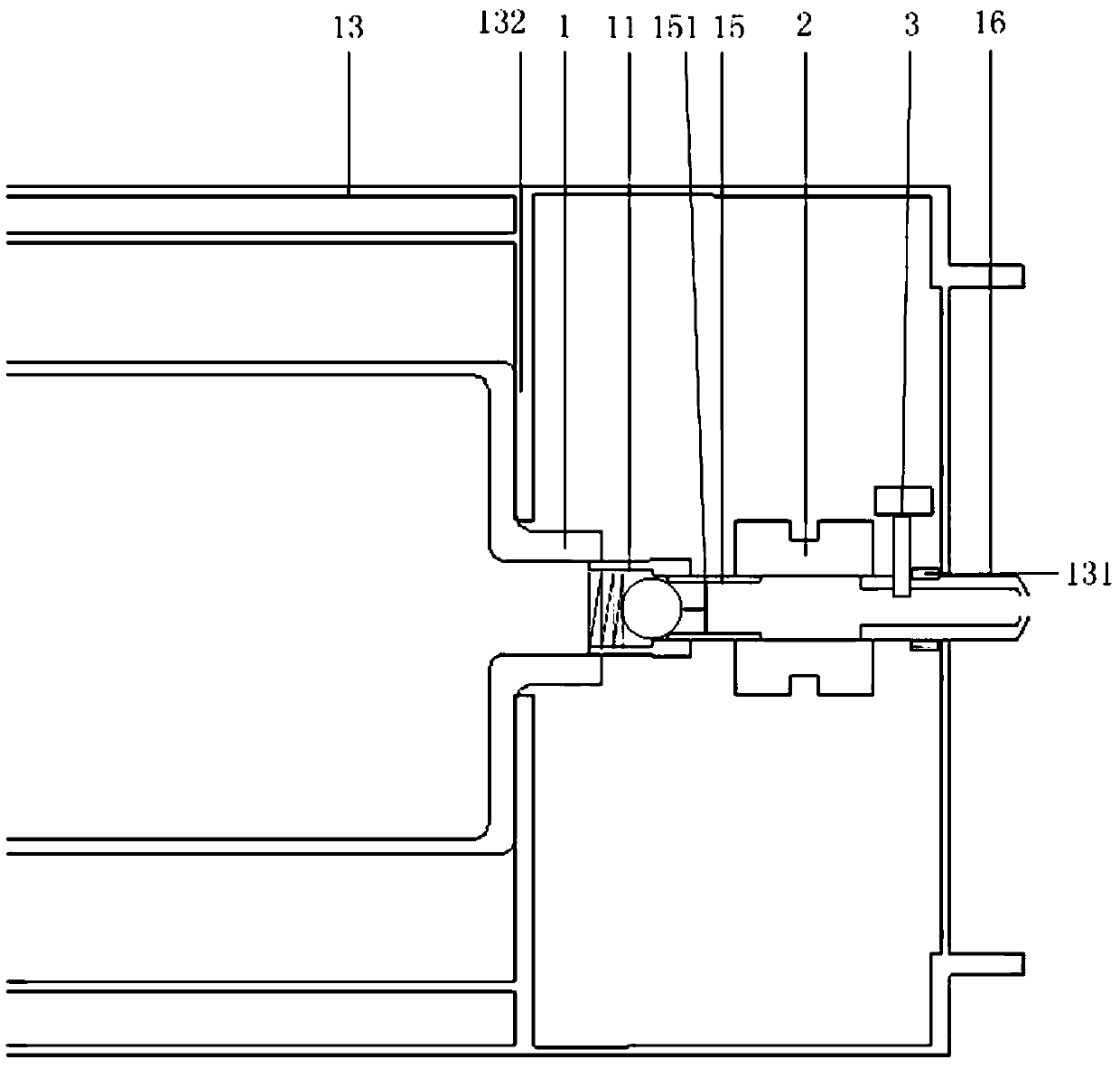

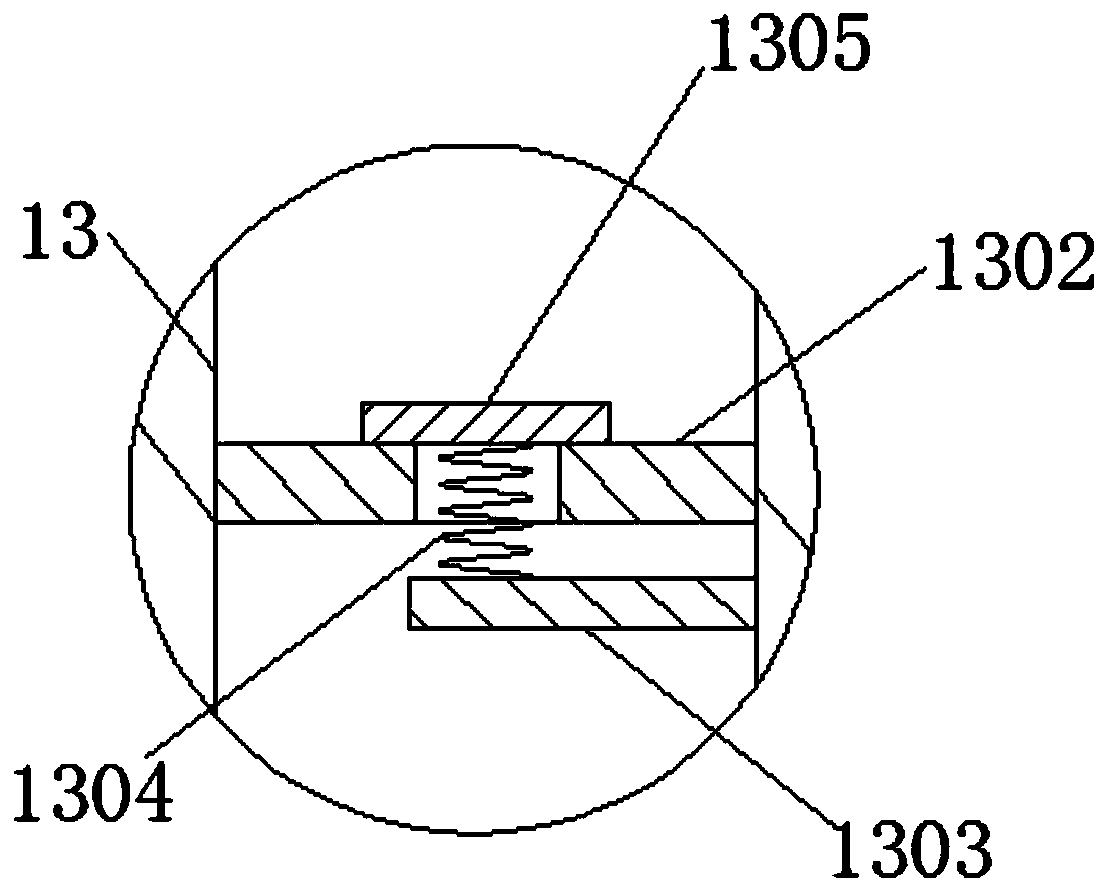

Powder spreading device and additive manufacturing device

PendingCN111702178AAchieve rotationControl delivery volumeAdditive manufacturing apparatusIncreasing energy efficiencyMechanical engineeringAdditive layer manufacturing

The invention belongs to the technical field of additive manufacturing, and discloses a powder spreading device and an additive manufacturing device. The powder spreading device comprises a powder spreading platform, a powder tank, a powder pouring box and a scraper, wherein the powder spreading platform is provided with a first position and a second position; the powder tank is arranged above thepowder spreading platform; the powder pouring box is rotatably connected to the powder tank and can open or close a powder outlet of the powder tank through rotation; the scraper is slidably arrangedon the powder spreading platform and can drive the powder pouring box to rotate; when the scraper slides to the second position from the first position, the powder pouring box opens the powder outlet, and powder in the powder tank is conveyed to the powder scraping side of the scraper; and when the scraper leaves the second position, the powder pouring box closes the powder outlet. According to the powder spreading device and the additive manufacturing device provided by the invention, the scraper is moved between the first position and the second position, so that the powder pouring box canbe rotated, the powder in the powder tank is conveyed to the powder scraping side of the scraper through the powder pouring box, the conveying capacity of the powder in the powder tank can be effectively controlled, each layer of conveyed powder capacity is ensured to be enough, and the occurrence of the phenomenon that the powder is too much or too little is avoided.

Owner:QUICKBEAM CO LTD

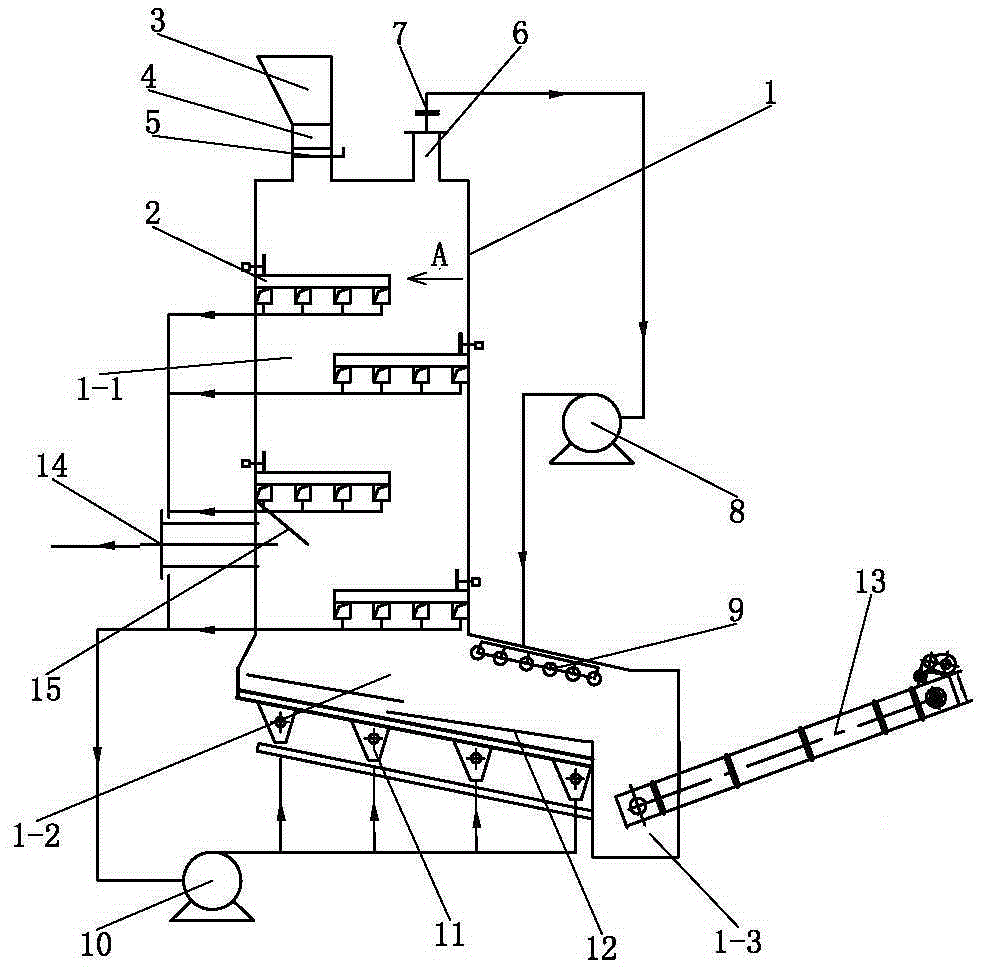

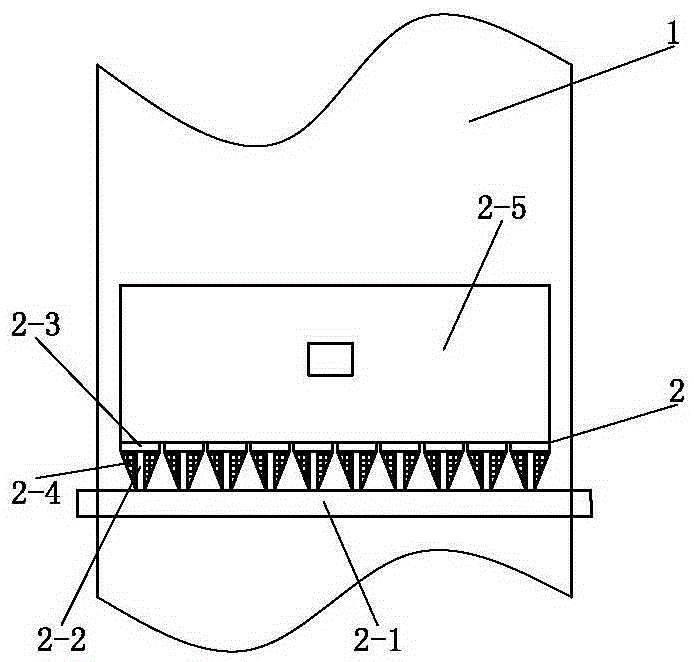

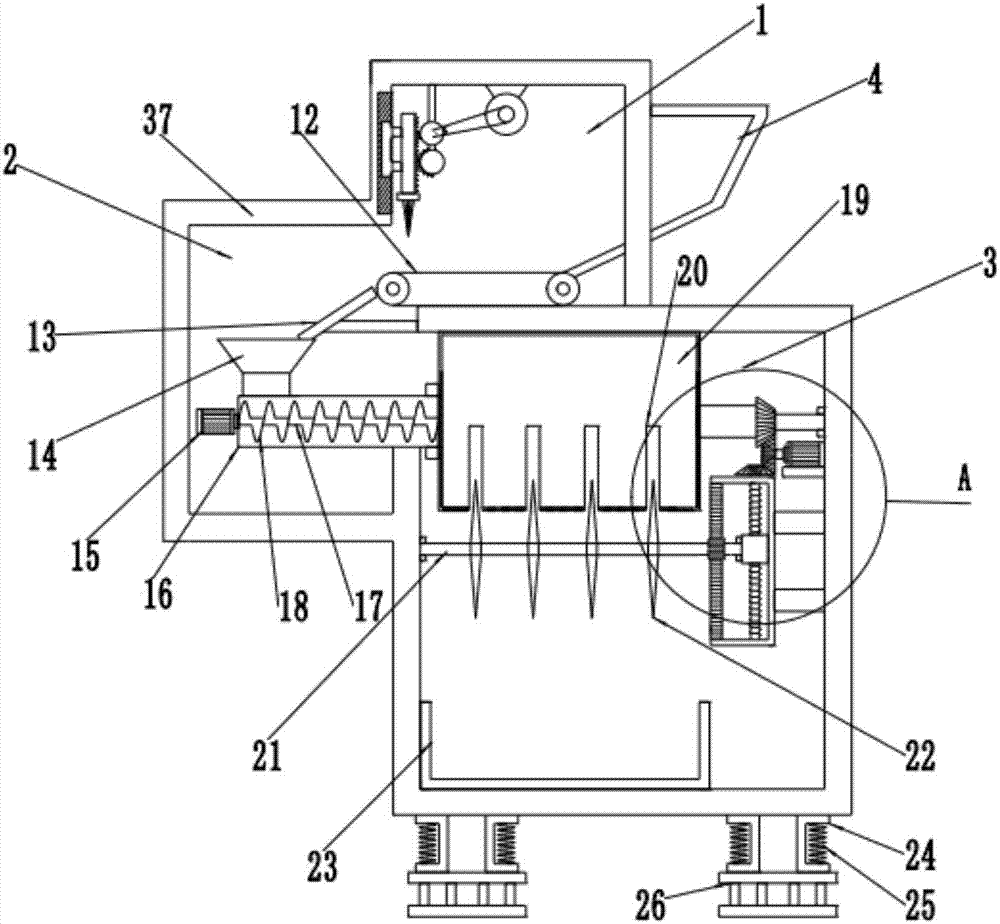

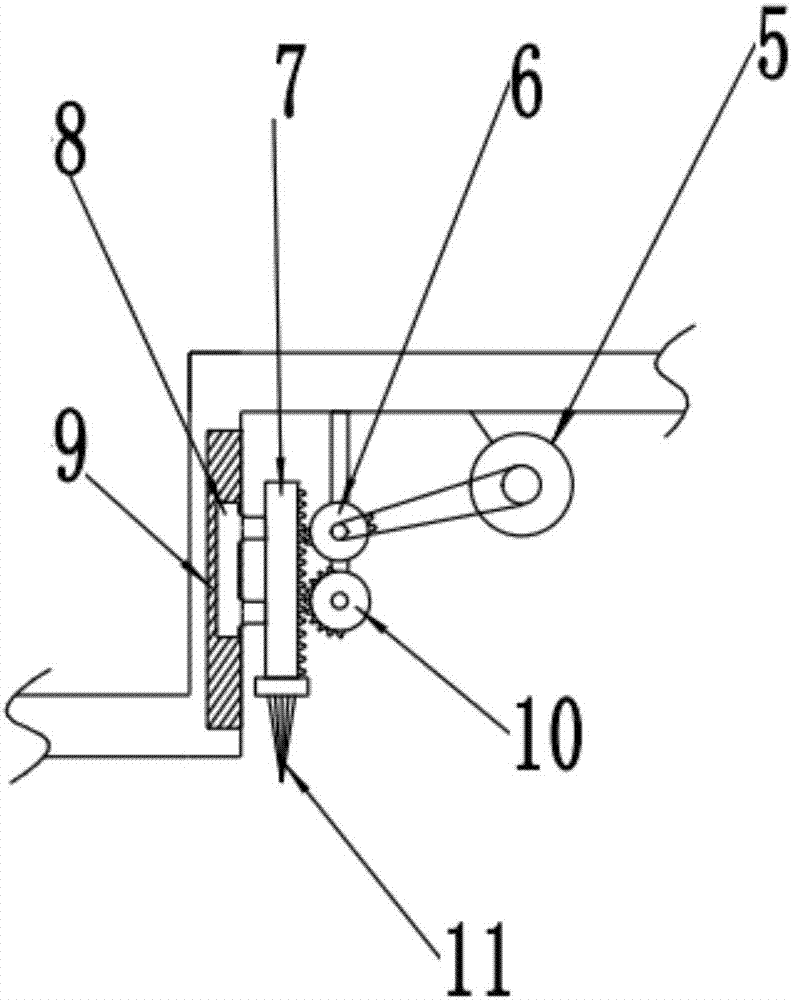

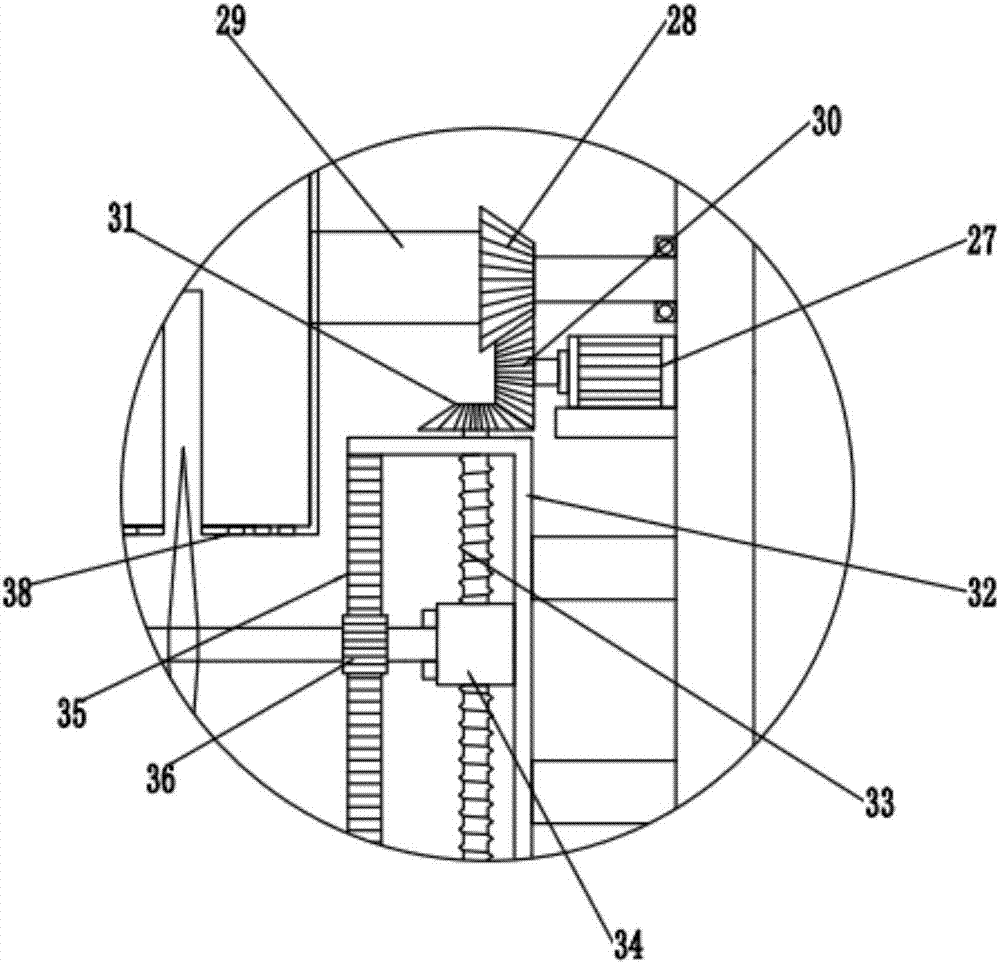

Special integrated and automatic processing robot for technology for preparing rice noodles from rice

InactiveCN107173684ARealize integrated automatic processingRealize the function of integrated automatic processingDrying gas arrangementsFood shapingUltimate tensile strengthAutomatic processing

The invention relates to an integrated automatic processing robot dedicated to the process of making rice noodles from rice, which includes a bottom plate, a material distributing device is installed at the rear end of the bottom plate, a conveying and rolling device is installed in the middle of the bottom plate, an air-drying device is installed on the conveying and rolling device, and a front end of the bottom plate is installed. The rolling and winding device, the conveying and rolling device, the air-drying device and the rolling and winding device cooperate with each other to complete the integrated automatic processing of rice noodles. The present invention can solve the problems existing in the existing small-scale processing and production of rice noodles in the traditional way, the need to manually use tools to control the thickness of the rice noodle raw material, the need to manually transport and extrude the rice noodle raw material, and the need to manually cool down the extruded rice noodle. Rice flour extrusion processing and cooling treatment cannot be carried out at the same time. The cooled rice noodles are manually wound and stretched. The traditional method of processing rice noodles has problems such as uniform distribution of raw materials, complex operations, high labor intensity and low work efficiency.

Owner:安庆米锐智能科技有限公司

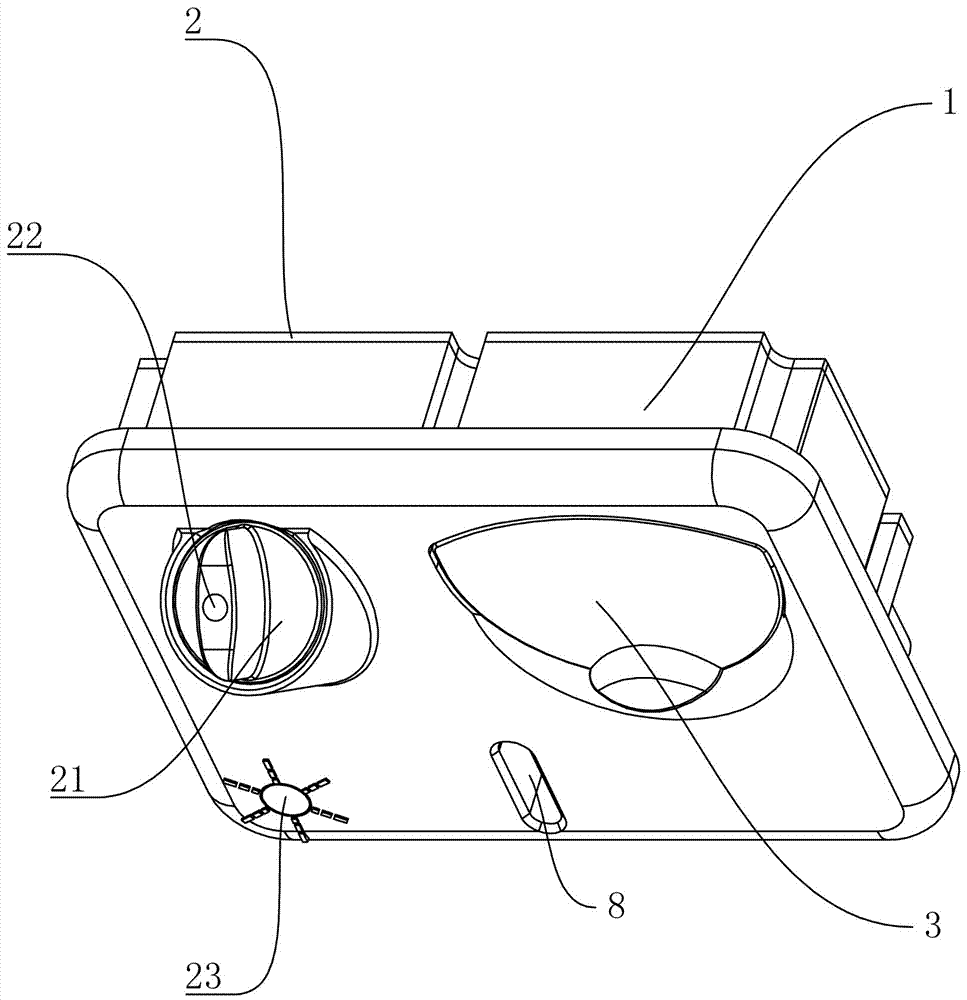

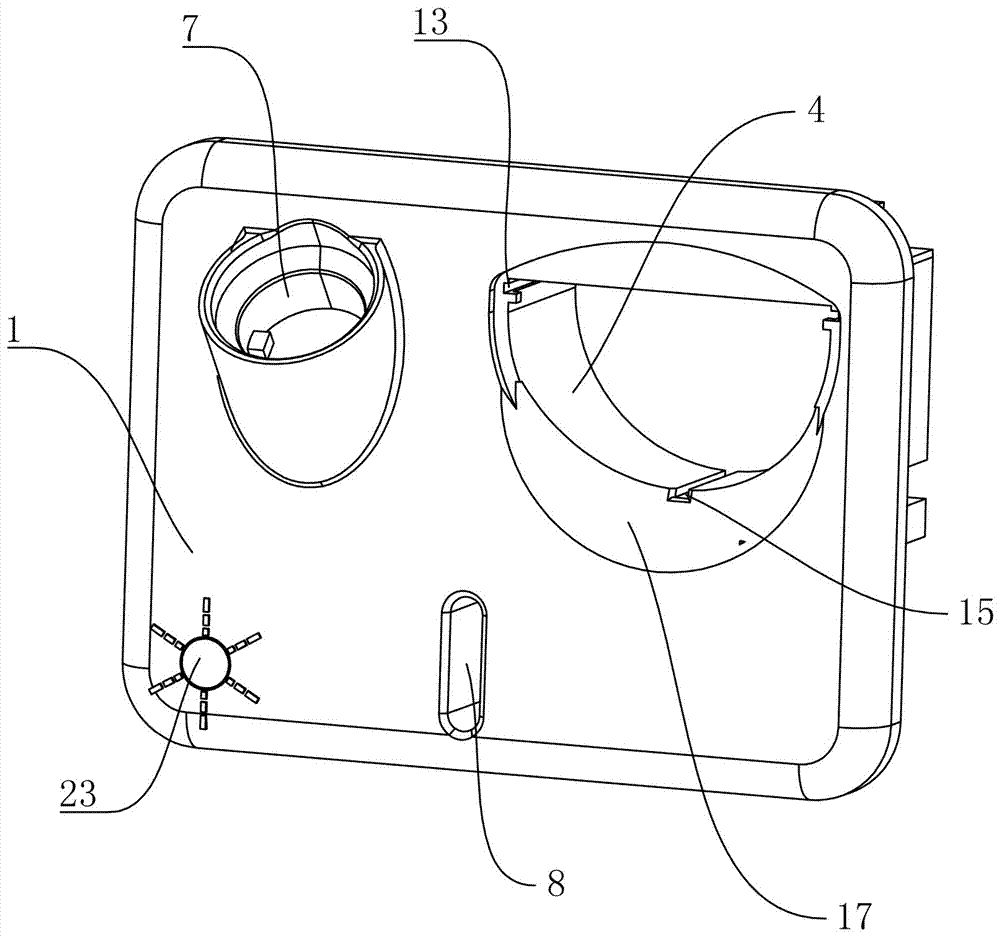

Dish washing machine distributor and dish washing machine using it

PendingCN107224255AEasy loadingControl scheduleTableware washing/rinsing machine detailsPulp and paper industry

The invention discloses a dish washing machine distributor, which comprises a base body, a back cover and a dish washing powder box; the back cover is fixedly connected with the base body, and the dish washing powder box is in the shape of a drawer; a holding cavity matched with the dish washing powder box is arranged on the base body, and the dish washing powder box is plugged in the holding cavity; the bottom part of the dish washing powder box is provided with a dish washing powder outlet, and a rinse agent cavity forms between the back cover and the base body, and a rinse agent adding opening connected with the rinse agent cavity is arranged on the base body; a rinse agent outlet is further arranged on the base body, and connected with the rinse agent cavity through the connecting channel. The dish washing machine distributor, is simple in structure, and can fill the dish washing powder and the rinse agent conveniently; besides, the feeding time and amount of the dish washing powder and the rinse agent can be controlled. The invention further provides a dish washing machine using the distributor, and is featured by simple structure and good using performance.

Owner:宁波安佳卫厨电器有限公司

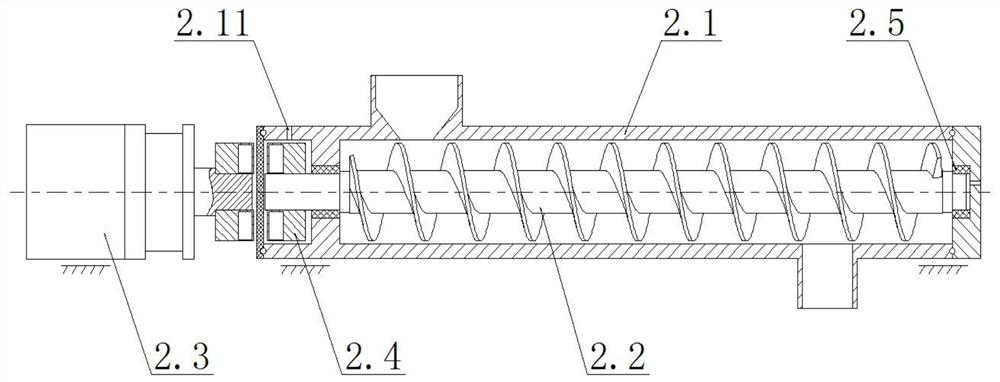

Powder feeding system of nano powder preparation process

PendingCN111761070AControl delivery volumeReach particle sizeNanotechnologyPinch valveElectric machinery

The invention relates to a powder feeding system of a nano powder preparation process. The powder feeding system comprises a storage bin, a spiral feeder, a powder feeder and a flexible pinch valve. The storage bin is provided with a material level meter, and a feeding screw rod in the spiral feeder is connected with a speed regulating motor through magnetic coupling. The diameter of the powder feeder is larger than the inner diameter of a powder feeding barrel, and a plurality of feeding through holes are arranged in the circumferential direction of a powder feeding disk. When the powder feeding disc rotates, the feeding through holes which are screwed out of the inner cavity of the powder feeding barrel correspondingly communicate with a discharging hole and an air inlet hole. The flexible pinch valve comprises a rubber tube and two pairs of pinch rods, and each pair of pinch rods are connected with an electric push rod. When the electric push rod moves, the pair of pinch rods clampthe rubber tube. An air tap is arranged at the discharge end of the rubber tube; the air tap is connected with a vacuumizing device and a working gas recharging device. The powder feeding system of the nano powder preparation process solves the problems of sealing, transmission, conveying and the like of micron-level powder raw materials which are difficult to solve in the powder feeding process,and the delivery value of the powder raw materials can be stably and accurately controlled, so that the plasma flame flow is stable, and the required particle size of nano powder is further achieved.

Owner:HENAN NENGWEI NEW MATERIAL TECH CO LTD

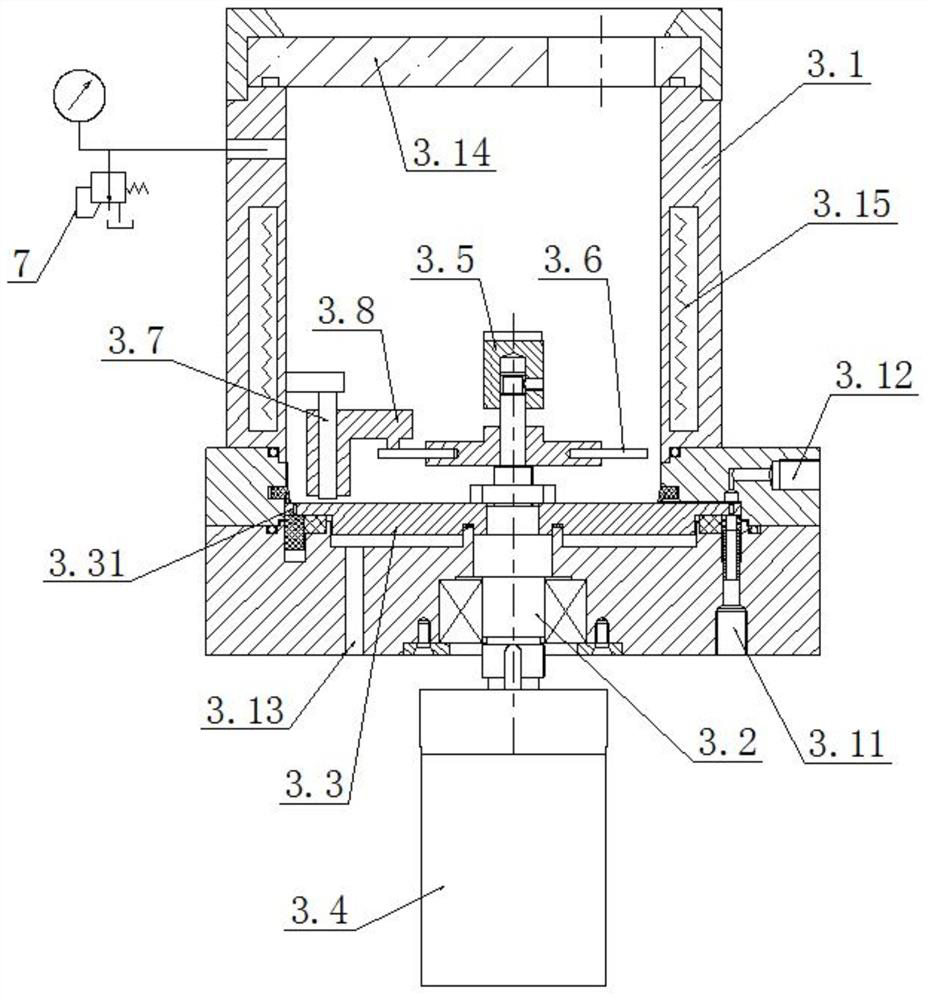

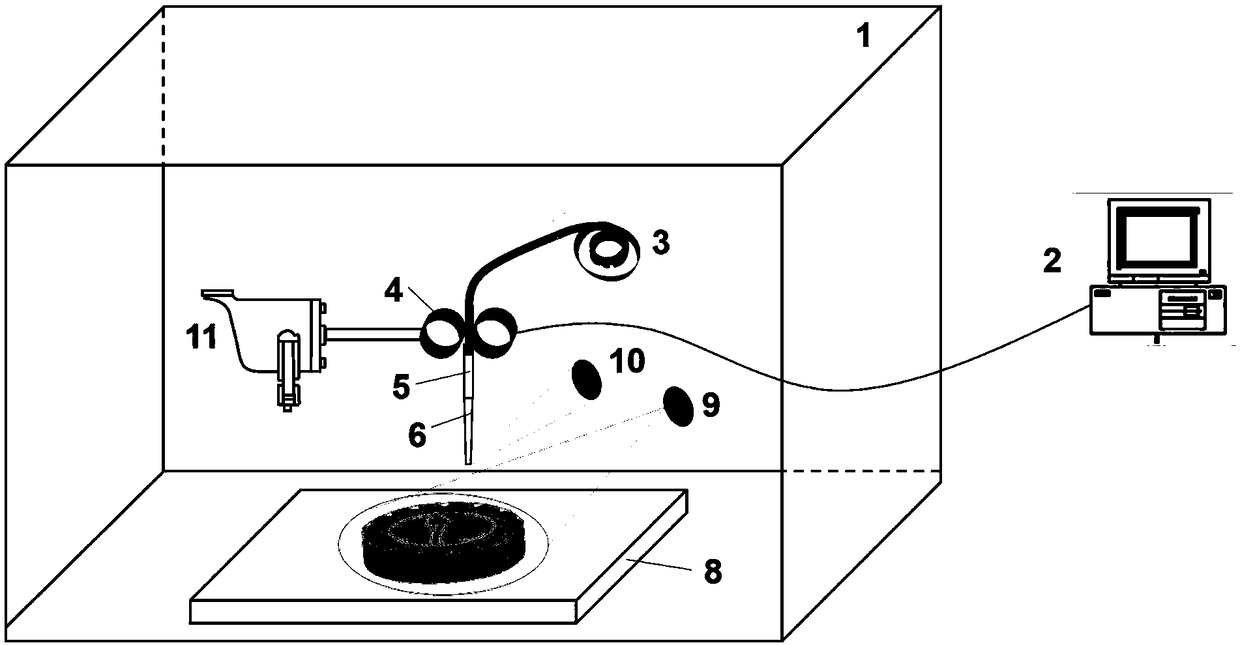

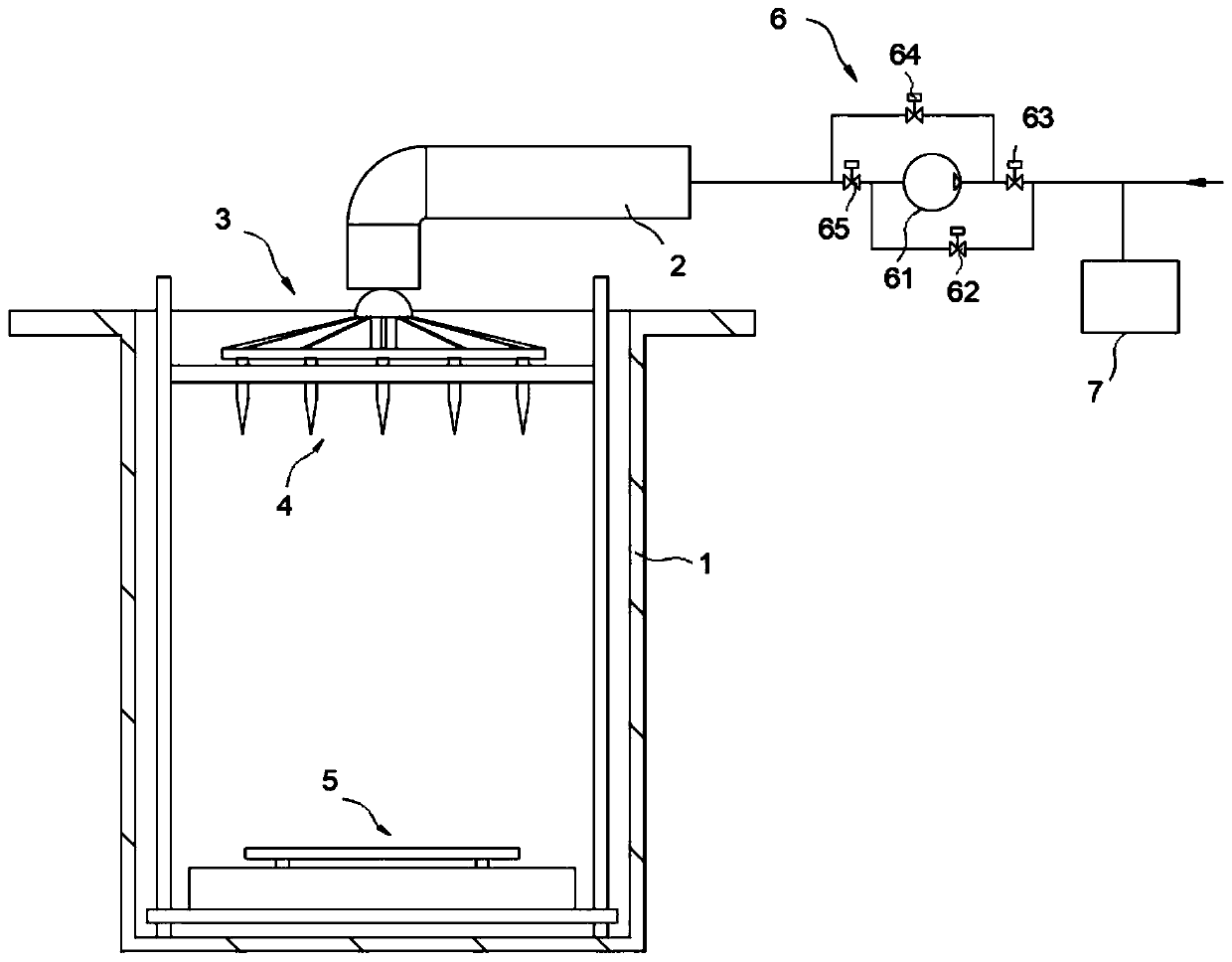

Space 3D printing system based on amorphous alloy superplastic welding

PendingCN109434112AAvoid the risk of high temperature crystallizationImprove job stabilityAdditive manufacturing apparatusSpace environmentOrbit

The invention discloses a space 3D printing system based on amorphous alloy superplastic welding. The space 3D printing system comprises a shell (1), a control unit (2), a workbench (8) arranged inside the shell (1), an amorphous alloy material (3), a heating device, a mechanical loading device (11) and a conveying device, wherein the mechanical loading device (11) controls the speed of the conveying device and the pressure load of a spray head (6) according to the material use requirements of 3D printing molding parts, and the heating device performs local heating and welding on the amorphousalloy material (3) to realize part molding. According to the space 3D printing system based on the amorphous alloy superplastic welding, the heating device only heats an area near the spray head, thecrystallization risk of amorphous alloy under a long-time high-temperature condition is avoided, and the amorphous alloy is heated to a superplastic state of a supercooled liquid phase area to realize molding, a laser or electron beam heating device is cancelled, the equipment working stability is increased, and the space 3D printing system based on the amorphous alloy superplastic welding is especially suitable for in-orbit fabrication in the space environment.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY +1

Hole sealing method for gas drainage drill

Provided is a hole sealing method for a gas drainage drill. A hole sealing process is that two pistons capable of lifting synchronously are pushed by using compacted air, and two reacting components of components A and components B of polyurethane foam in two material vats are injected out simultaneously. The components A and the components B are first packaged through soft package bags, and the package bags are provided with discharging pipes respectively. The components A and the components B pass through the discharging pipes to a five-way member, and the five-way member is provided with two connectors to be connected with the compacted air. After the components A and the components B are mixed with the compacted air in the five-way member and mixed into material liquid through a mixing element connected with the five-way member, the material liquid jet-flows to a hole sealing area of the gas drainage drill from discharging ports distributed on a material conveying soft pipe wall, then reacts, and foams to seal an annular gap between the gas drainage drill and a drainage pipe.

Owner:BEIJING TIANHAI ZONGHENG TECH

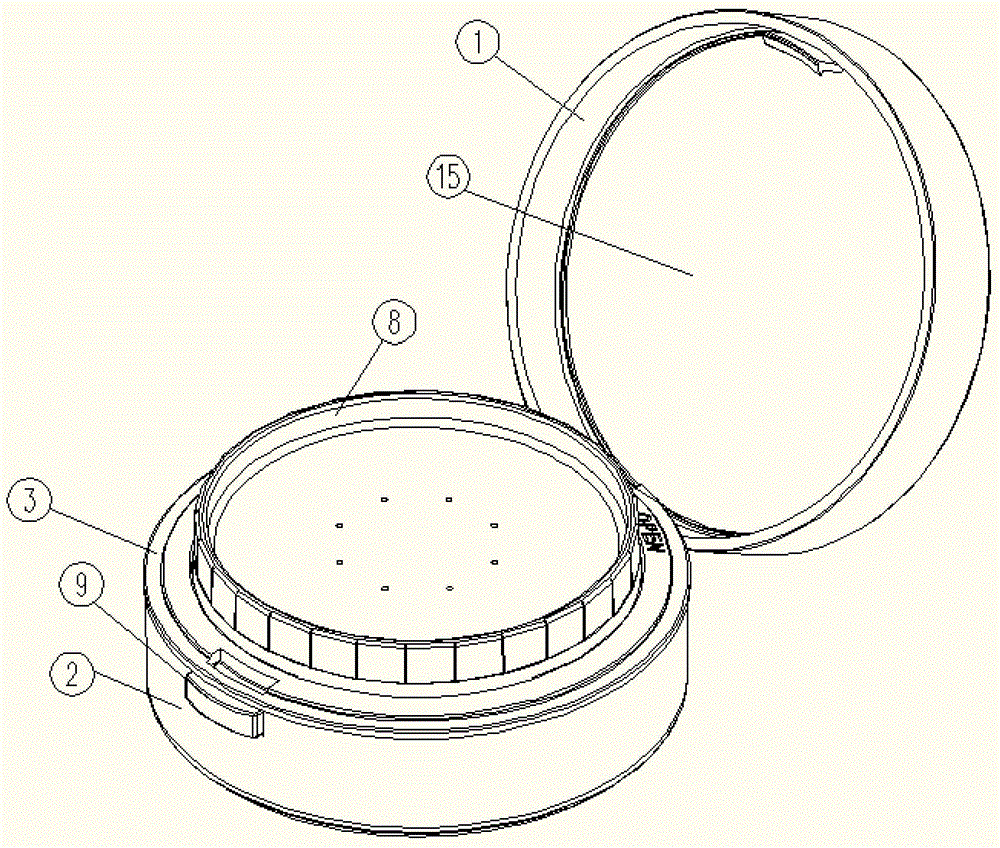

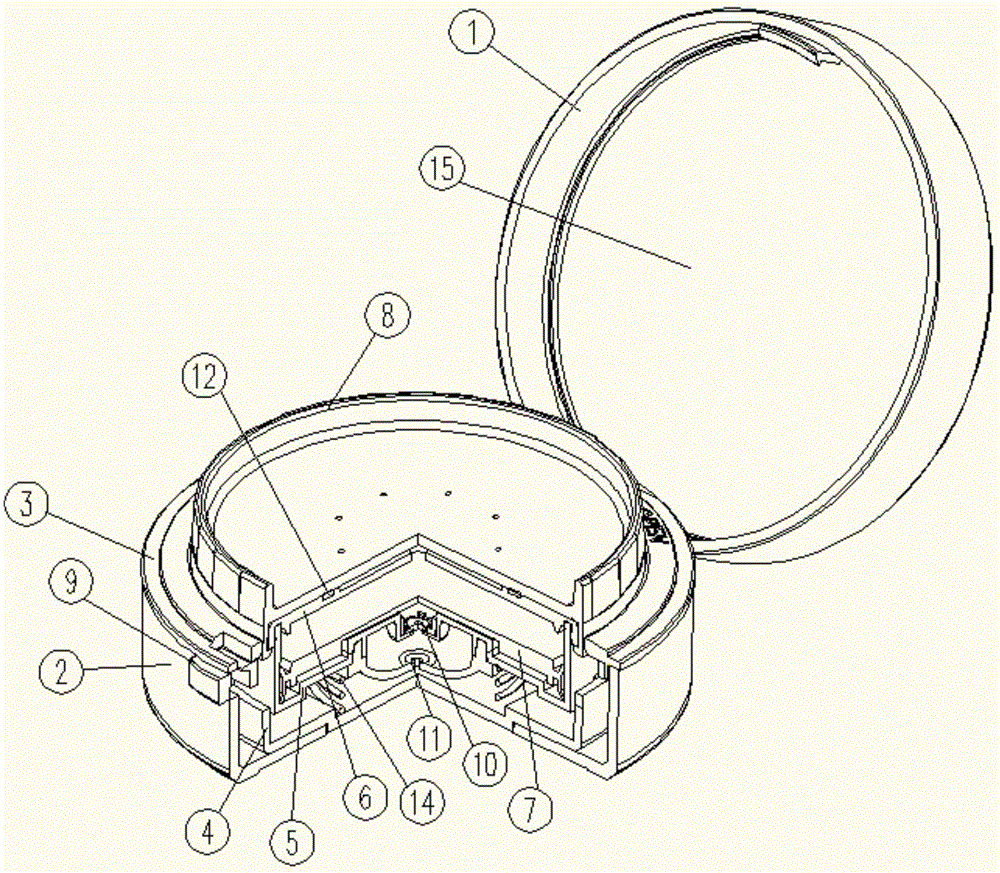

Vacuum pump cosmetic container

ActiveCN105639989AControl delivery volumeReduce wastePackaging toiletriesPackaging cosmeticsEngineeringCheck valve

The invention discloses a vacuum pump cosmetic container which comprises a bottom box body, a top box body and a middle box body. A cavity is formed between the bottom box body and the top box body and internally provided with a basic pump. The basic pump comprises a bottom support installed on the bottom box body, a cylinder body installed on the bottom support, a piston connected into the cylinder body in a sliding mode, a cylinder cover covering the cylinder body, a rotating switch connected to the cylinder cover in a rotatable mode and vertically moving along the cylinder cover, and a gas pump bag installed on the lower end face of the cylinder body. A check valve is arranged at the bottom of the cylinder body. After the gas pump bag is compressed, the check valve is switched on to supply gas into the cylinder body so as to push the piston to move upwards, and cosmetics on the piston are sent out of an opening of the cylinder cover and an opening of the rotating switch in sequence. The piston in the cylinder body is ejected through the gas pump bag, the cosmetics are sent out of the opening of the cylinder cover and the opening of the rotating switch, and the send-out amount of cosmetics can be effectively controlled, and the waste of cosmetics is reduced.

Owner:殷昌(苏州)包装有限公司

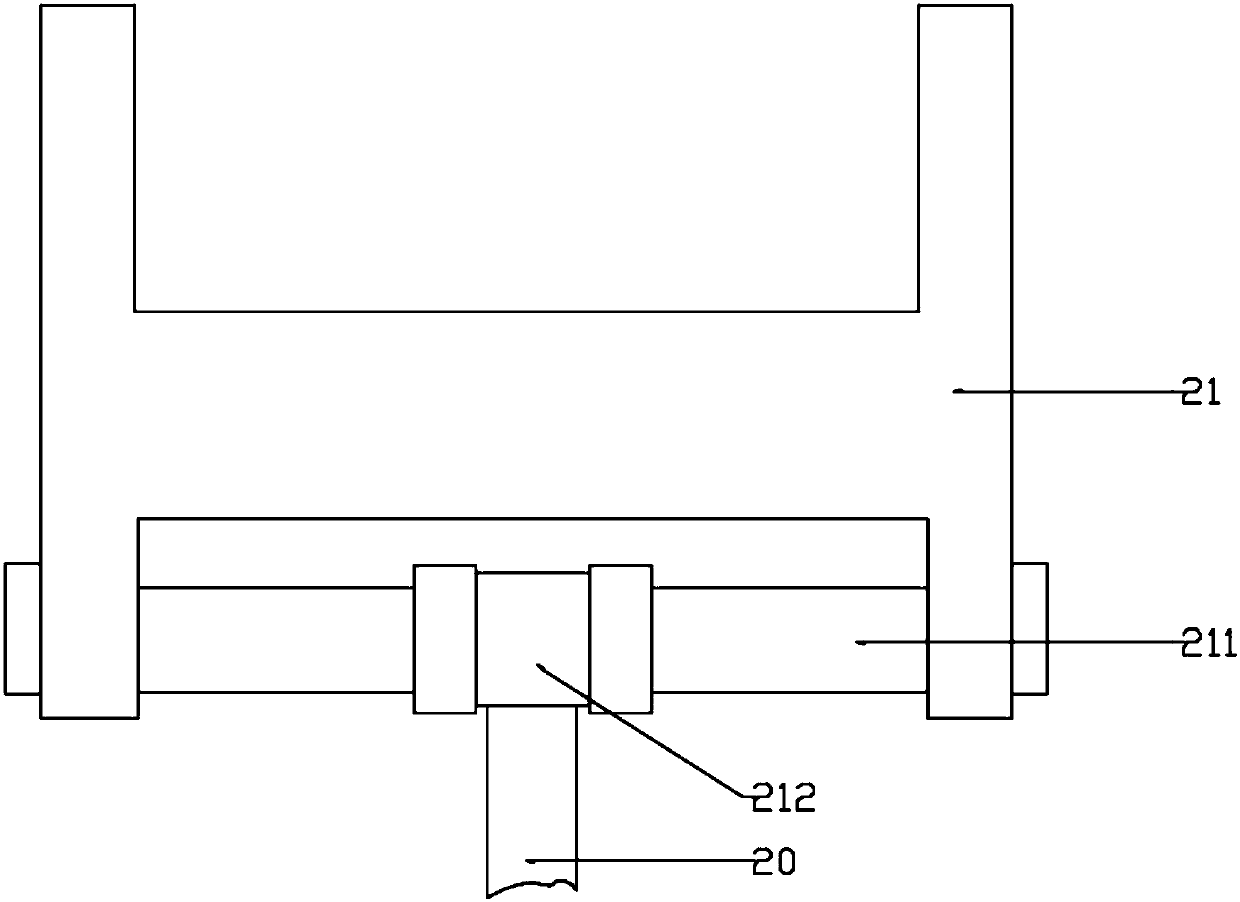

Paint spraying device for wheel hubs

ActiveCN107755130AGreat suctionLarge deformationSpraying apparatusProgrammable logic controllerLacquer

The invention discloses a paint spraying device for wheel hubs. The paint spraying device for the wheel hubs structurally comprises a spray head body, a feeding pipe, a cross beam, a paint spraying quantitation mechanism, a programmable logic controller (PLC), a control panel, a main body, a wheel hub sliding seat, a wheel hub placing frame, a spray head, a flow sensor and a frequency converter. The main body is of a U-shaped structure; the wheel hub sliding seat is arranged in a U-shaped groove; the wheel hub placing frame is arranged in the center of the wheel hub sliding seat and directly faces the spray head; and two ends of the main body are connected through the cross beam. According to the paint spraying device for the wheel hubs provided by the invention, a reverse take-up device,a hopper opening and closing mechanism, a paint conveying device, a feeding starting mechanism, a conveying switching system and an indirect transmission device are arranged, and manual starting and programming are combined, so that an intelligent degree of the device is improved; and the rotation speed of a screw rod is changed according to the rotation speed of a motor, so that the conveying capacity of paint is further controlled, the paint spraying amount can be accurately controlled, and the occurrence of the phenomenon that the paint spraying waste is caused due to excessive paint is avoided.

Owner:新沂市达婷黄沙有限公司

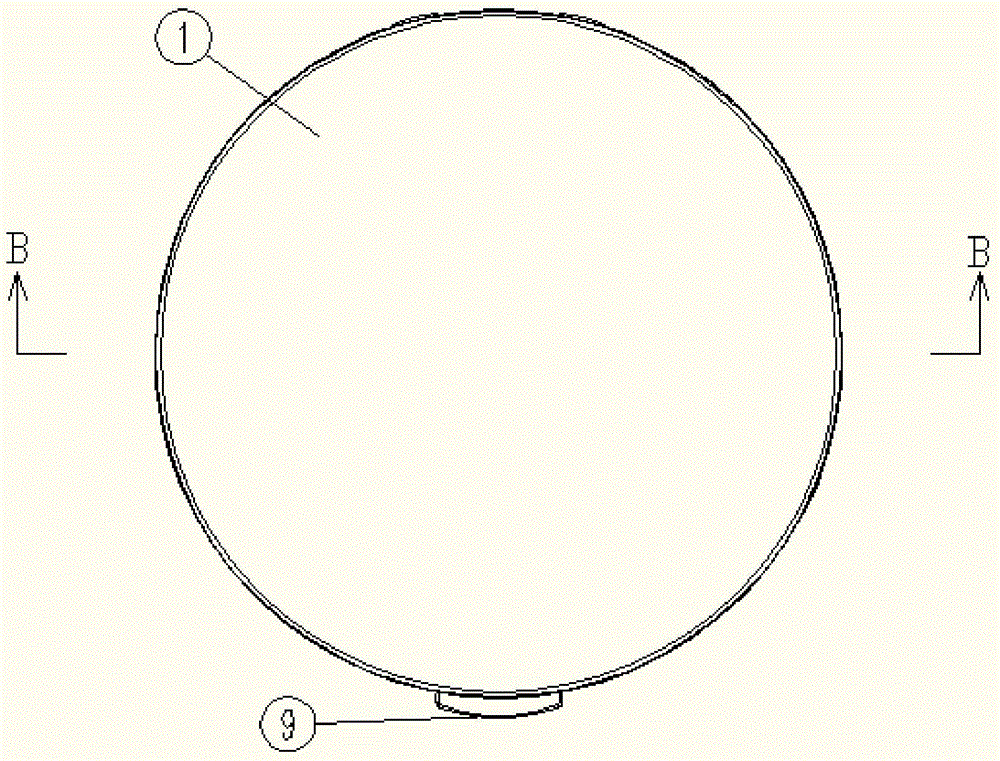

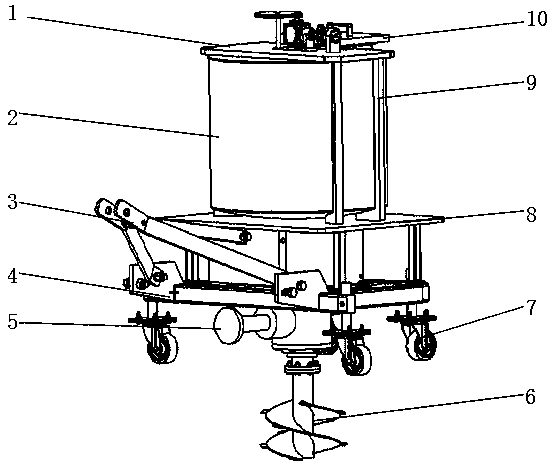

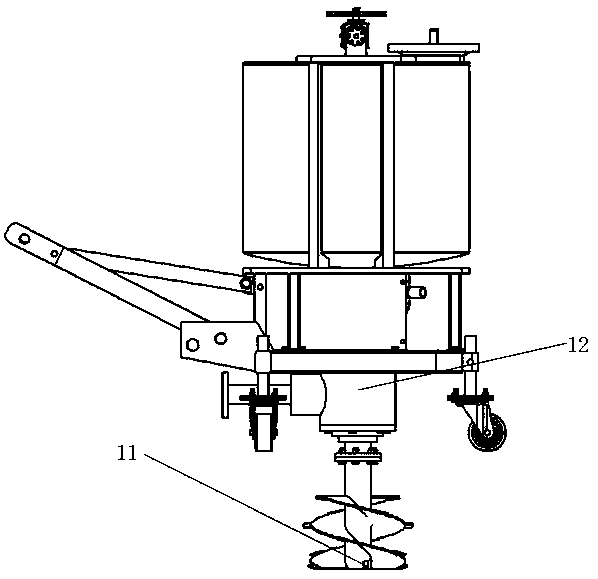

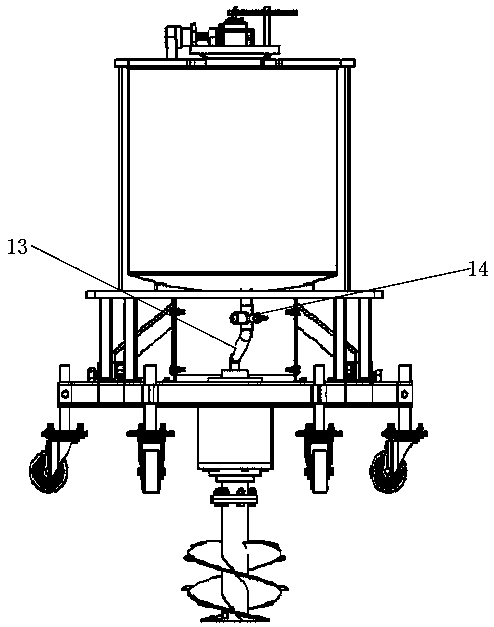

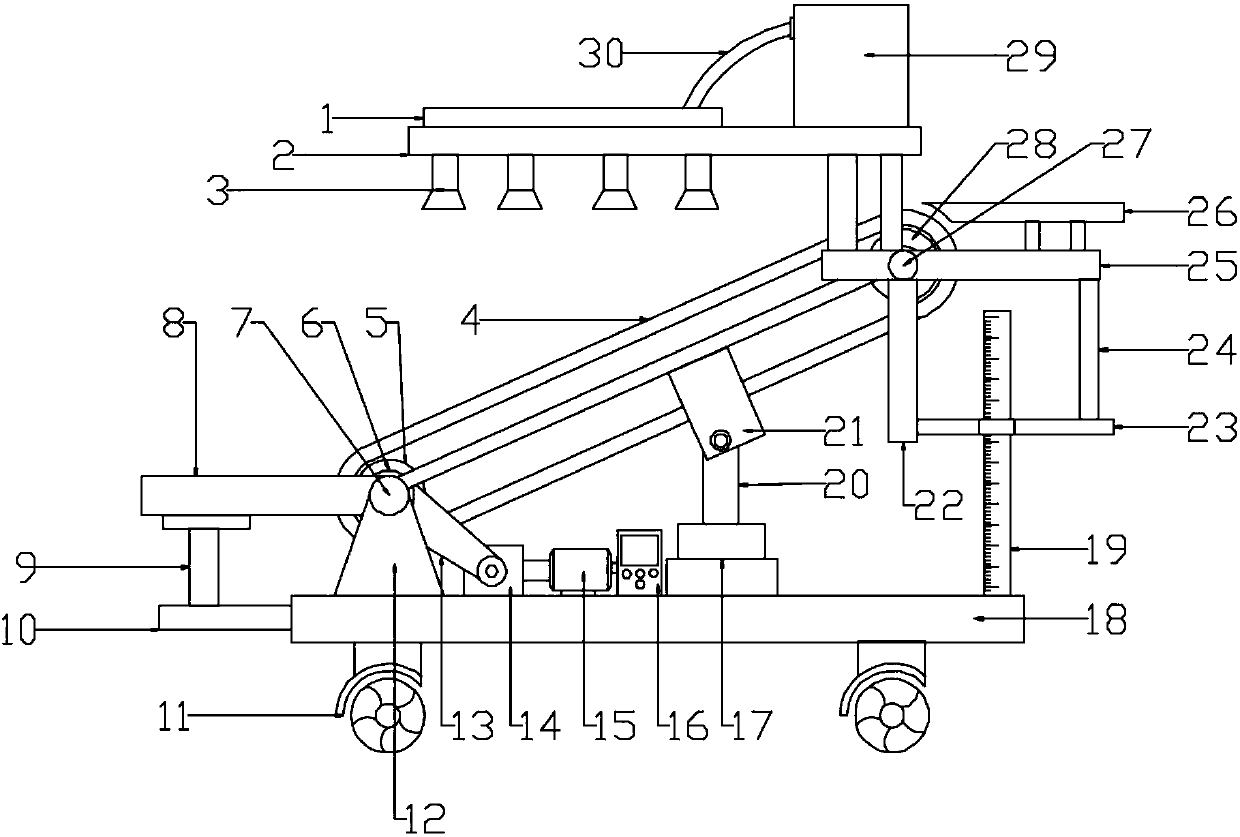

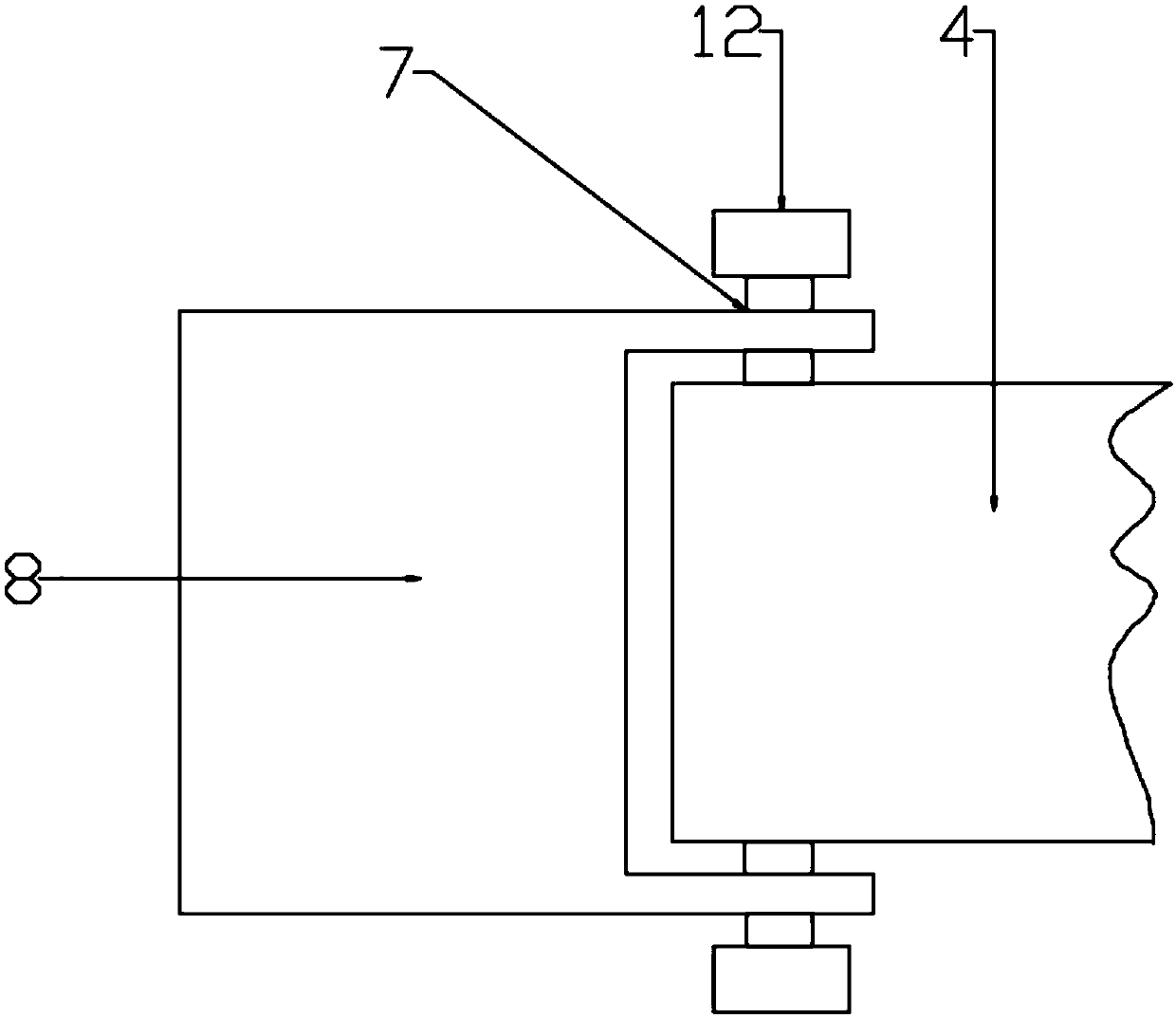

Orchard organic fertilizer drilling and fertilizer applying machine and use method thereof

PendingCN109964586ARealize automatic controlGradient control of fertilization ratePlantingPressurised distribution of liquid fertiliserEngineeringOrganic fertilizer

The invention relates to an orchard organic fertilizer drilling and fertilizer applying machine and a use method thereof. The drilling and fertilizer applying machine comprises a machine frame, a fertilizer bucket and a drilling device, wherein the fertilizer bucket and the drilling device are arranged on the machine frame. The drilling device is connected with a driving device. A cavity communicated with the fertilizer bucket through a conveying pipe is formed in the drilling device. A fertilizer discharge hole is formed in the cavity wall of the cavity. Drilling is conducted through the drilling device, a fertilizer in the fertilizer bucket is conveyed into the drilling device and finally pumped into drilled fertilizer applying holes through the fertilizer discharge hole, and the fertilizer applying depth can be controlled according to demands; by controlling the opening time of an electromagnetic switch nozzle, the control over the fertilizer conveying amount can be realized, and therefore the precise control over the fertilizer applying amount and the fertilizer applying depth is realized, the control over the gradient of the fertilizer amounts at different fertilizer applyingdepths can be completed, the problem that the fertilizer applying mechanical level of an organic fertilizer in an orchard in a hilly area is solved, and the machine can be suitable for composts, animal mature, commercial granular organic fertilizers, powdery organic fertilizers and the like and is widely suitable for applying the organic fertilizer in the orchard in the hilly area.

Owner:SHANDONG AGRICULTURAL UNIVERSITY +1

Automatic feeder for rare birds

The invention provides an automatic feeder for rare birds. The automatic feeder comprises a charging barrel, a hopper, a control valve, a striker plate, a height adjusting bolt, a feed conveyor belt, a tail end gate, a water valve, a draining tank, fan-shaped striker plates, ultraviolet bactericidal lamps, and drying blast tubes, wherein the hopper is arranged at the lower part of the charging barrel; the control valve is arranged at the tail end of the hopper; the tail end of the hopper is connected with the feed conveyor belt; the striker plate is arranged in front of the hopper; the water valve is arranged in front of the striker plate; the feed conveyor belt is arranged at the inner sides of two fan-shaped striker plates; one side of each fan-shaped striker plate is connected with the striker plate, and the other side of each fan-shaped striker plate is connected with the draining tank; the ultraviolet bactericidal lamps are embedded in the fan-shaped striker plates; and the drying blast tubes are arranged on the fan-shaped striker plates. The automatic feeder provided by the invention adopts closed and integrated operations of cleaning, drying and sterilization, and is convenient and quick to operate, thereby ensuring the sanitary safety of raising diets of the rare birds.

Owner:天津市华野生态养殖有限公司

Gasifying combustion furnace with fixed furnace body

ActiveCN105402739AFlammable gasificationImprove gasification combustion efficiencyIncinerator apparatusMetallurgyMaterials science

The invention discloses a gasifying combustion furnace with a fixed furnace body. The gasifying combustion furnace comprises a furnace body, wherein at least one interactive type pouring combustion device repeatedly pouring materials in the combustion process is arranged in the furnace body. The number of the interactive type pouring combustion devices is four, the four interactive type pouring combustion devices are sequentially distributed from top to bottom, two adjacent interactive type pouring combustion devices are staggered with each other, and the two interactive type pouring combustion devices adjacent to one interactive type pouring combustion device are opposite. Each interactive type pouring combustion device comprises square steel pipes, a grate plate and a hydraulic material pusher, the square steel pipes are horizontally arranged in the furnace body, the grate plate is arranged on the square steel pipes, and the hydraulic material pusher is arranged above the grate plate. The gasifying combustion furnace can greatly improve the gasifying combustion efficiency of wet garbage and enlarge the treatment range. At the same time, the size of the grate can be greatly reduced, and accordingly, space close to the ground, occupied by the gasifying combustion furnace with the fixed furnace body can be greatly reduced.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

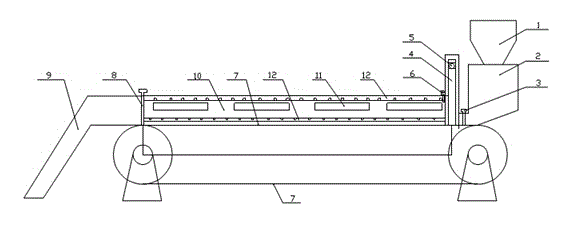

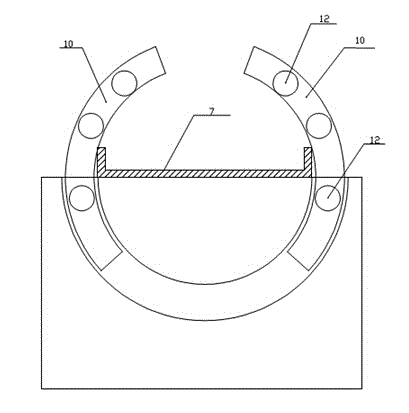

Device for transporting construction materials

InactiveCN107585498AEasy to shipControl delivery volumeConveyorsLoading/unloadingArchitectural engineeringDrive motor

Owner:孙启成

Liquid pump and liquid put-in system

ActiveCN106762509AAchieve dischargeStable deliveryPumpsPositive-displacement liquid enginesInlet channelReciprocating motion

The invention discloses a liquid pump and a cleaning solution put-in system. The liquid pump comprises a feed port, a discharge port, a pump body, a feed valve, a discharge valve and a piston mechanism. The pump body comprises a liquid storage cavity used for storing liquid. The liquid storage cavity communicates with fluid of the feed port through a liquid inlet channel and communicates with fluid of the discharge port through a liquid outlet channel. The feed valve is coupled in the liquid inlet channel and is arranged to only allow liquid to flow to the liquid storage cavity from the feed port along the liquid inlet channel. The discharge valve is coupled in the liquid outlet channel and is arranged to only allow the liquid to flow to the discharge port from the liquid storage cavity along the liquid outlet channel. The piston mechanism comprises a piston rod, a piston and a piston driver. The piston makes contact with the inner wall of the pump body so as to limit the liquid storage cavity together with the inner wall of the pump body. The piston is connected to the first end of the piston rod. The piston rod is arranged to be driven by the piston driver to move in the axial direction of the pump body so as to drive the piston to move back and forth between the liquid suction position and the liquid discharge position in the pump body. By means of the liquid pump, the liquid put-in amount can be precisely controlled.

Owner:XIAOWEI (SHANGHAI) BIOTECH CO LTD

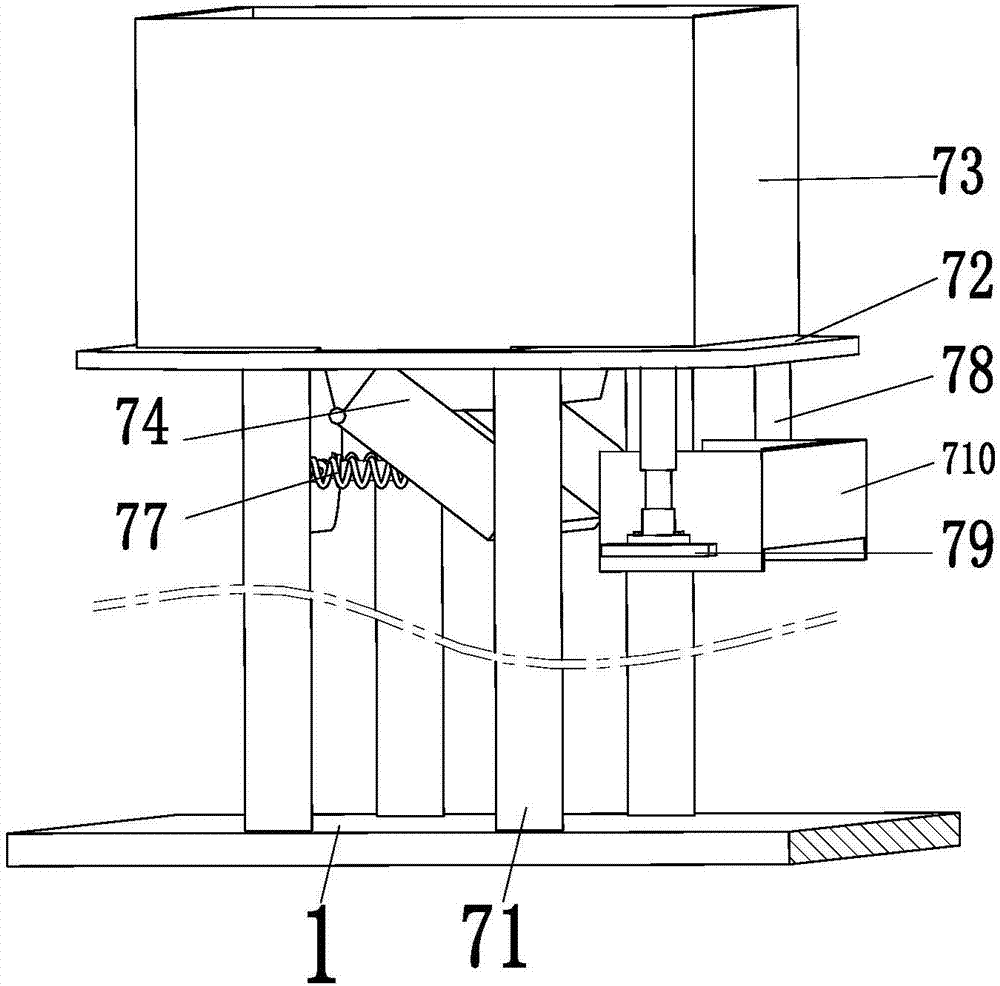

Portable automatic milk powder dissolving apparatus and method for applying same

The invention provides a portable automatic milk powder dissolving apparatus and a method for applying the same. The portable automatic milk powder dissolving apparatus comprises a control module, a shell, a water supply mechanism, a powder supply mechanism, a stirring mechanism and a dissolving container. Output ends of the water supply mechanism and the powder supply mechanism are positioned atan input port of the dissolving container, and the stirring mechanism extends into the dissolving container; the powder supply mechanism comprises a milk powder box and a powder push device, and a milk powder push plate is arranged in the powder push device; the powder push device is provided with a pressure sensor and a displacement sensor, the pressures borne by the push plate can be measured bythe pressure sensor, and the advancing distances of the push plate can be measured by the displacement sensor; milk powder in the milk powder box can be pushed and compressed towards the direction ofa powder outlet of the milk powder box by the milk powder push plate when the milk powder is about to be inputted into the dissolving container; the powder outlet of the milk powder box is opened when the pressures borne by the push plate reach thresholds, the push plate can advance towards the powder outlet of the milk powder box under the control of the control module, and the milk powder outlet can be closed after the milk powder is pushed into the dissolving container according to preset quantities. The portable automatic milk powder dissolving apparatus and the method have the advantagesthat the portable automatic milk powder dissolving apparatus is small and is easy to operate and applicable to short-distance travel, and the release quantity of the milk powder can be accurately controlled.

Owner:XIAMEN UNIV TAN KAH KEE COLLEGE

Automatic pig feed supply device

InactiveCN109952967AControl delivery volumeAvoid serious wasteAnimal feeding devicesHydraulic cylinderEconomic benefits

The invention discloses an automatic pig feed supply device. The automatic pig feed supply device comprises a storage hopper, a conveying mechanism, a quantitative bin and a feeding trough, the lowerend of the storage hopper is provided with a discharging port, the conveying mechanism is arranged below the discharging port, a baffle is arranged on the right side of a conveying pipe, a quantitative hopper is arranged below the right side of the conveying mechanism, a rotating plate is arranged at a lower opening of the quantitative hopper, a fixing block is fixedly connected to the lower end of the rotating plate, an electric hydraulic cylinder B is arranged below the fixing block, a contact switch is arranged on the right side of the rotating plate, a pressure sensor is arranged on the rotating plate, and the feeding trough is arranged below the quantitative hopper. According to the automatic pig feed supply device, a screw conveyer is adopted to convey a feed, so that the feed conveying speed can be effectively controlled, the feed can be easily controlled when entering the quantitative hopper, the quantitative hopper is arranged, so that the feeding amount of the feed is effectively controlled, the serious waste of the feed is effectively avoided, the production cost is saved, the economic benefits are improved, and the automatic supply function greatly lowers the labor intensity of operators.

Owner:福州和暄实业有限公司

Pneumatic-transport lobster bait casting machine applied to deep sea net cage

ActiveCN111264447AAchieve separationIncrease profitClimate change adaptationPisciculture and aquariaElectric machineryDeep sea

The invention discloses a pneumatic-transport lobster bait casting machine applied to a deep sea net cage. The machine comprises the deep sea net cage and a bait casting pipe disposed at the center ofthe top of the cage, wherein a material uniformizing device is disposed on the bottom of the bait casting pipe, the material uniformizing device comprises a casting disk, casting disk baffles are uniformly disposed on the top of the casting disk, a semi-circular shell is disposed at the center of the top of the casting disk, the semi-circular shell is connected to external torque, a bait recoverydevice is installed on the inner wall of the bottom of the deep sea net cage, the bait recovery device comprises a silt storage body, a motor is installed on the side wall of the top of the deep seanet cage, an output shaft of the motor is movably connected to a lead screw by a coupler, the lead screw is sleeved by a lead screw nut sleeve outside, a guide rod is also fixed by welding on the sidewall of the top of the deep sea net cage, and the silt storage body is disposed between a slide sleeve and the lead screw nut sleeve. The machine is characterized by a feed recovery function and goodcleaning effects.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

Forage grass smashing device for animal husbandry

InactiveCN107535201AImprove crushing efficiencyCrushed fullyFeeding-stuffCuttersAnimal ForagingSpiral blade

The invention discloses a pasture crushing device for animal husbandry, which comprises a support, a cutting chamber, a feeding chamber, a crushing chamber, a collecting tank and a shock absorbing mechanism; the upper end of the support is provided with a cutting chamber, the cutting chamber is provided with a cutting mechanism, and It includes a first rotating motor, an irregular gear A, a bar-shaped tooth plate, a slide bar, a chute, an irregular gear B and a cutting knife; a feeding chamber is arranged on the left side of the cutting chamber, and a feeding hopper is arranged in the feeding chamber. The lower end of the hopper is provided with a feeding mechanism, and the feeding mechanism includes a second rotating motor, a feeding chamber, a first rotating shaft and a spiral blade; a crushing chamber is arranged on the right side of the feeding chamber, and a crushing bucket is arranged in the crushing chamber; the lower end of the support is symmetrical A shock absorbing mechanism is provided, and the shock absorbing mechanism includes an inverted U-shaped plate, a spring and a bottom plate. The invention cuts through the cutting mechanism and then crushes through the crushing bucket, which increases the grass crushing efficiency.

Owner:周建明

Lubricating oil focus cycle utilization system for preventing oil pump suction

InactiveCN102913734AAvoid vacuumingControl delivery volumeDrip prevention valvesEngine lubricationFuel tankDistributor

The invention relates to a lubricating oil focus cycle utilization system for preventing oil pump suction. The lubricating oil focus cyclic utilization system comprises an oil box, an oil pipe, a gear pump, an oil return pump, a cycle gear pump and a suction prevention branch circuit, wherein the gear pump is used for sending lubricating oil from a clean cavity of the oil tank to a lubricating point; the oil return pump is used for sending lubricating oil of the lubricating point back to a sump oil cavity of the oil tank; the cycle gear pump is used for pumping lubricating oil precipitated in the sump oil cavity of the oil tank into the clean cavity; the suction prevention branch circuit is arranged on the oil pipe from the gear pump to the lubricating point and connected with the oil return pump; and the suction prevention branch circuit is connected with a progressive distributor which is connected with the oil return pump. After the structure is adopted, the lubricating oil focus cycle utilization system for preventing the oil pump suction can be used for effectively preventing the oil pump from having a suction phenomenon so as to prolong the service life of the oil pump, reduce the maintenance cost and enhance the lubricating effect.

Owner:青岛青锻锻压机械有限公司

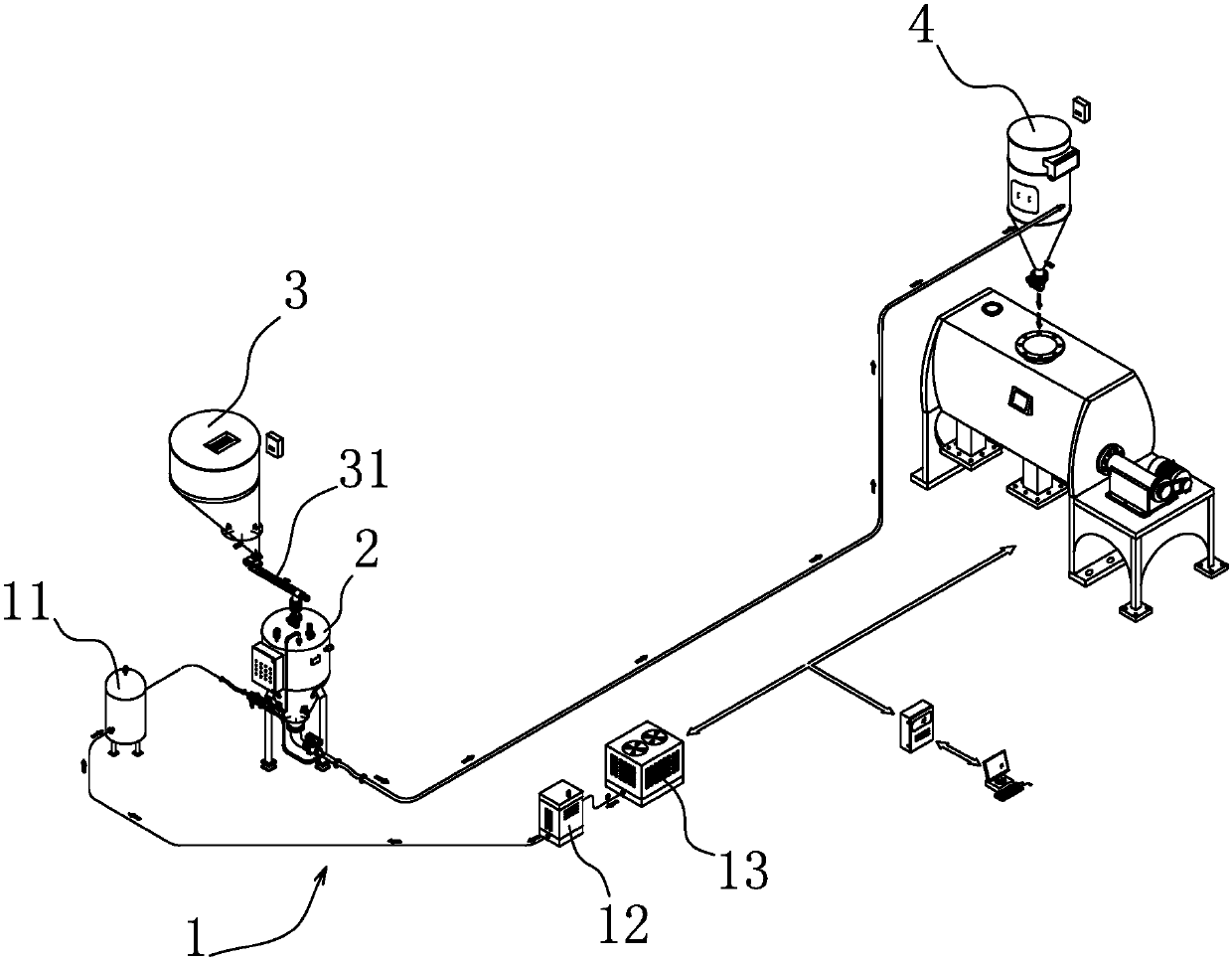

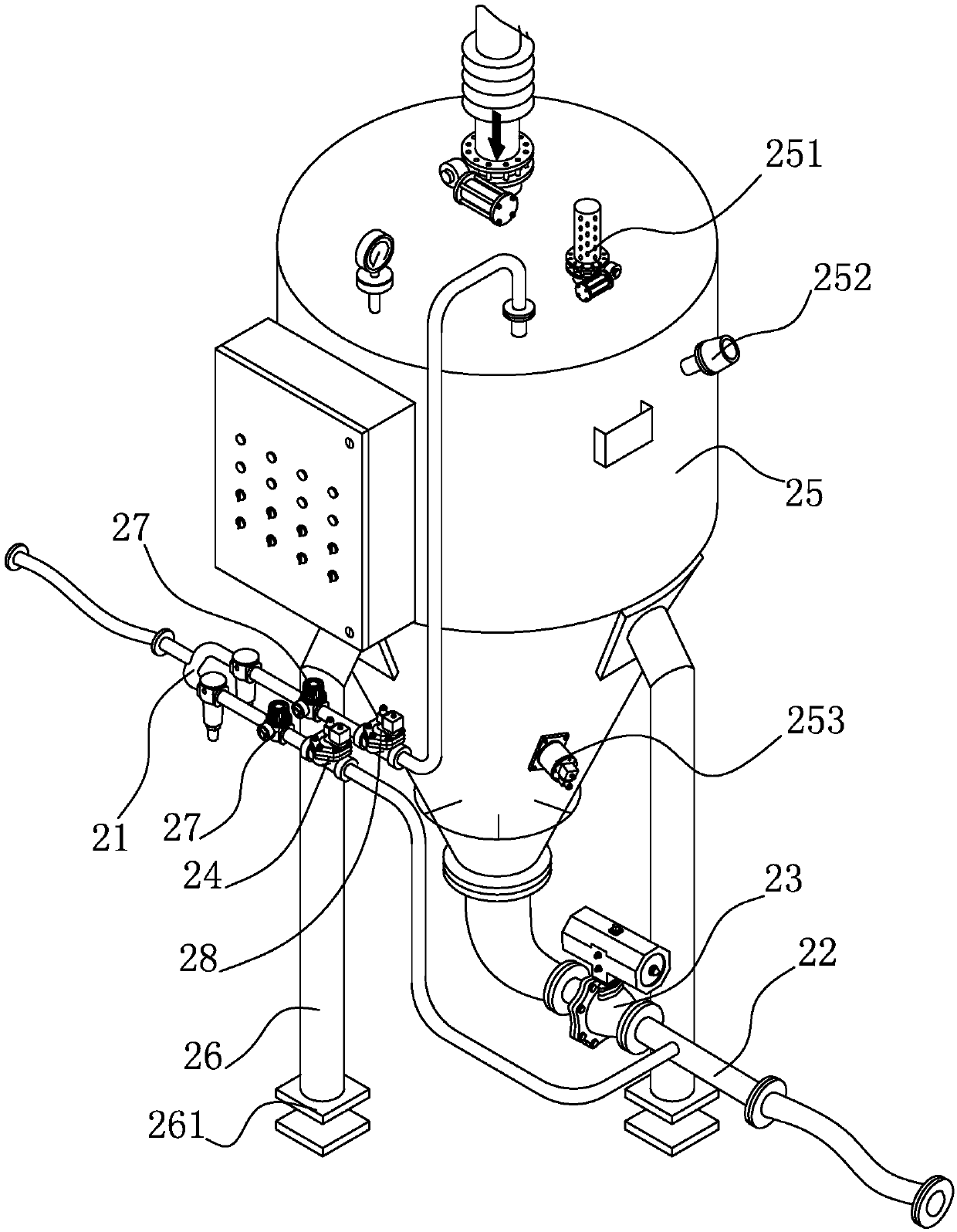

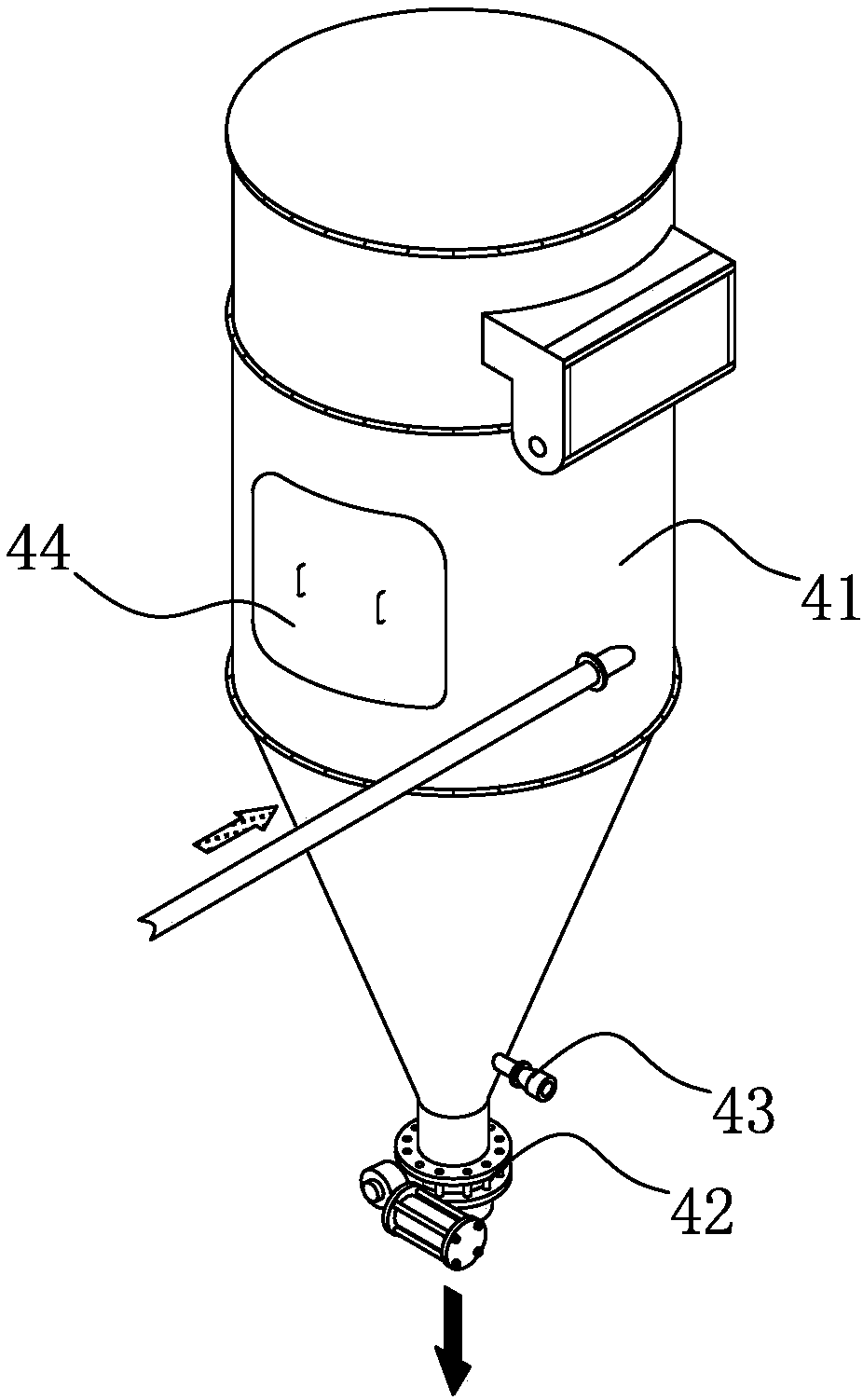

Pulse dense phase pneumatic conveying system for manufacturing vacuum stone

PendingCN109969799AStable deliveryControl delivery volumeBulk conveyorsLoading/unloadingPneumatic valveEngineering

The invention discloses a pulse dense phase pneumatic conveying system for manufacturing vacuum stone. The pulse dense phase pneumatic conveying system is characterized in that an air source, a pulsedense phase low-speed pneumatic conveying bin pump, a material bin and a pulse dust remover are included, the material bin is connected with the bin pump, the bin pump is connected with the dust remover, and the lower portion of the bin pump is provided with an air pipe and a conveying pipeline; the air pipe is connected with the air source, the conveying pipeline is connected with the bin pump through a pneumatic discharging valve, and the air pipe is connected with the conveying pipeline through a pulse pneumatic valve; and the pulse pneumatic valve controls the conveying pipeline to adopt the pulse conveying manner of a section of materials, a section of compressed gas and a section of materials in sequence. The pulse dense phase low-speed conveying manner is adopted in the pulse densephase pneumatic conveying system for powder conveying, powder conveying is smoother, the powder conveying amount can be better controlled, and the purpose of accurate weighing is achieved.

Owner:ANHUI UISTONE GREEN MATERIAL HI TEC CO LTD

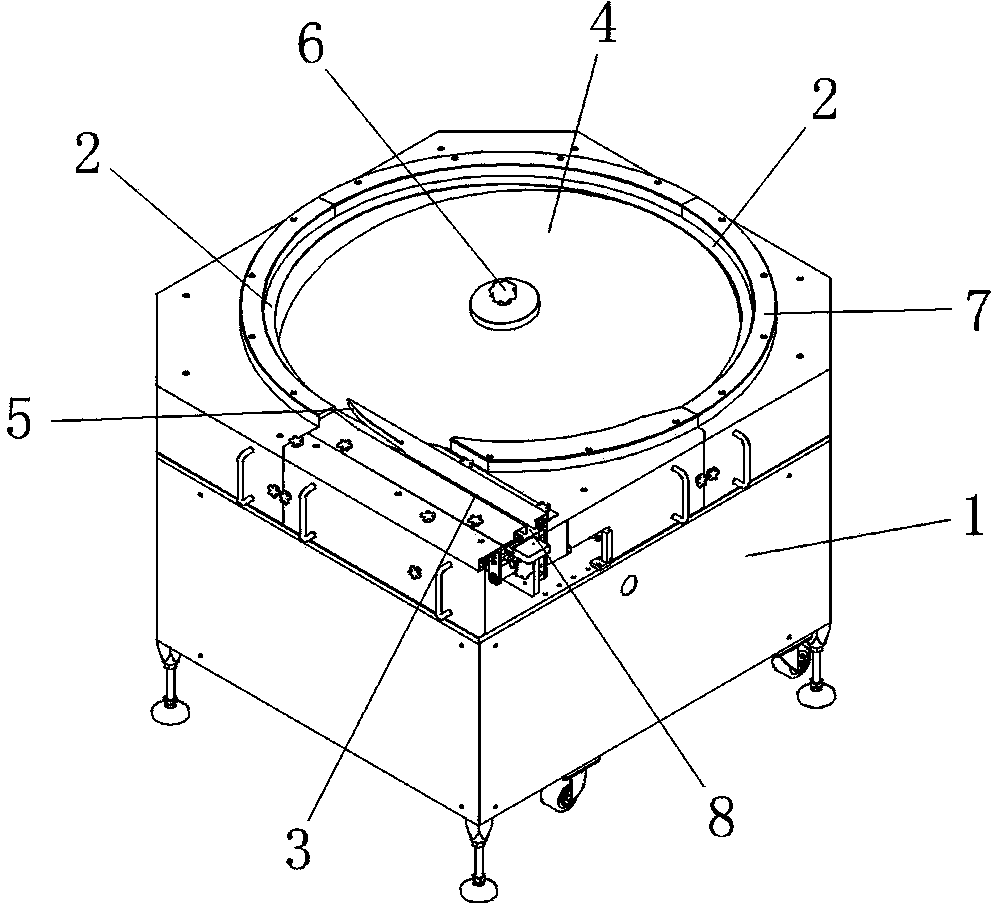

Material arrangement machine with inclined tray

The invention provides a material arrangement machine with an inclined tray, and belongs to the technical field of machines. The material arrangement machine solves the problems that an existing packaged material conveying machine is poor in continuity and high in manufacturing cost. The material arrangement machine comprises a machine frame and a round material pot embedded into the top of the machine frame, wherein the machine frame is internally provided with a first motor used for driving the material pot to rotate in the circumferential direction; the top of the machine frame is provided with a conveying line communicated with the material pot; the conveying line is in a strip shape and is tangent with the material pot; a rotary shaft is arranged at the center of the material pot in a penetrating mode; a second motor used for driving the rotary shaft to synchronously rotate along the material pot is arranged below the machine frame; the rotary shaft is sleeved with the material tray located inside the material pot; the material tray is inclined; the upper end face of the material pot is flush with the bottom of the conveying line. The swash plate material arrangement machine has the advantages of being good in continuity, good in stability, low in equipment cost and the like.

Owner:浙江金鸿智能科技有限公司

Practical intelligent reminding device for formaldehyde removal

InactiveCN110523269AEfficient removalSolve concentrationDispersed particle separationMaterial resistanceEngineeringPhotoresistor

The invention relates to the technical field of devices for formaldehyde removal, and discloses a practical intelligent reminding device for formaldehyde removal. The device includes a casing, whereina mixed liquid is arranged inside a closed box, a transparent glass plate is connected to a position right above the closed box, and a photoresistor is arranged right above the transparent glass plate; and a sodium hydroxide solution is arranged on the left side of the inner part of a filter box, an activated carbon adsorption plate is connected to the interior of the filter box, and a quicklimelayer is connected to the interior of the filter box. After chlorine gas is introduced into a hydrogen peroxide solution, peroxide ions are oxidized into superoxide ions firstly, a further reaction isperformed on formaldehyde and the superoxide ions, and a reaction is performed between formaldehyde and hydroxide ions further; since the superoxide ions are extremely unstable, excess energy is released in the form of photons when excited-state oxygen atoms are turned into ground-state oxygen atoms, and the resistance value of the photoresistor can be changed through the brightness of red light,so that the content of indoor formaldehyde is predicted further, the transfer amount of chlorine gas is controlled accordingly, and waste of materials is avoided.

Owner:温州捷朴环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com