Automatic feeder for rare birds

A feeder and automatic technology, which is applied in applications, poultry farming, animal husbandry, etc., can solve the problems of complicated operation, low efficiency, time-consuming and labor-consuming, etc., and achieve the effect of simple operation, ensuring safety, and ensuring hygiene and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

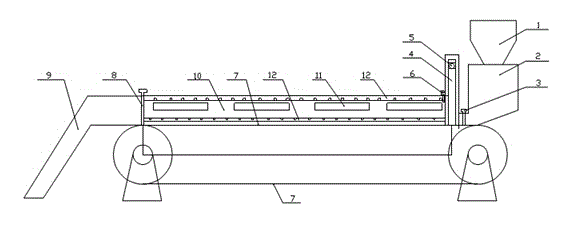

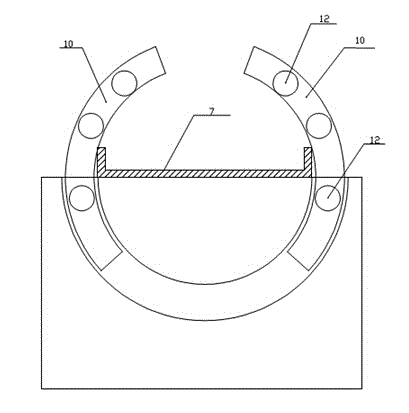

[0010] The present invention includes material barrel 1, lower hopper 2, control valve 3, material retaining plate 4, height adjustment screw 5, water valve 6, feed conveyor belt 7, end gate 8, drain tank 9, fan-shaped material retaining plate 10, ultraviolet germicidal lamp 11. Drying air supply pipe 12, lower hopper 2 is installed at the bottom of barrel 1, the bottom of lower hopper 2 is a slope surface, control valve 3 is installed at the end of lower hopper 2, feed conveyor belt 7 is connected to the end of lower hopper 2, feed conveyor belt 7 It is "凵" type, the front of the lower hopper 2 is the material stopper 4, the height adjustment screw 5 is installed on the material stopper 4, the height adjustment screw 5 can adjust the height of the material stopper 4, and the water valve is installed in front of the material stopper 4 6. The feed conveyor belt 7 is installed inside two fan-shaped material retaining plates 10, one side of the fan-shaped material retaining plate ...

Embodiment 2

[0012] When in use, pour the feed into the barrel 1, the feed flows into the lower hopper 2 through the bottom of the barrel 1, slides down from the slope of the lower hopper 2, opens the control valve 3, feeds the feed into the feed conveyor belt 7, unscrews the height adjustment screw 5, Adjust the height of the baffle plate 4 to an appropriate position according to the amount of food intake of the poultry, tighten the height adjustment screw 5, start the feed conveyor belt 7, and evenly transmit the feed on the conveyor belt. Stop the transmission, open the fan-shaped baffle 10, and the poultry begins to eat. When the poultry finishes eating, close the fan-shaped baffle 10, open the water valve 6 and the end gate 8, and rinse the residual feed on the feed conveyor belt 7. 9 flows out, start the feed conveyor belt 7, make the residual particles and water stains on the feed conveyor belt 7 drip during the transmission process of the belt, turn on the ultraviolet germicidal lam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com