Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146results about How to "Improve rinsing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

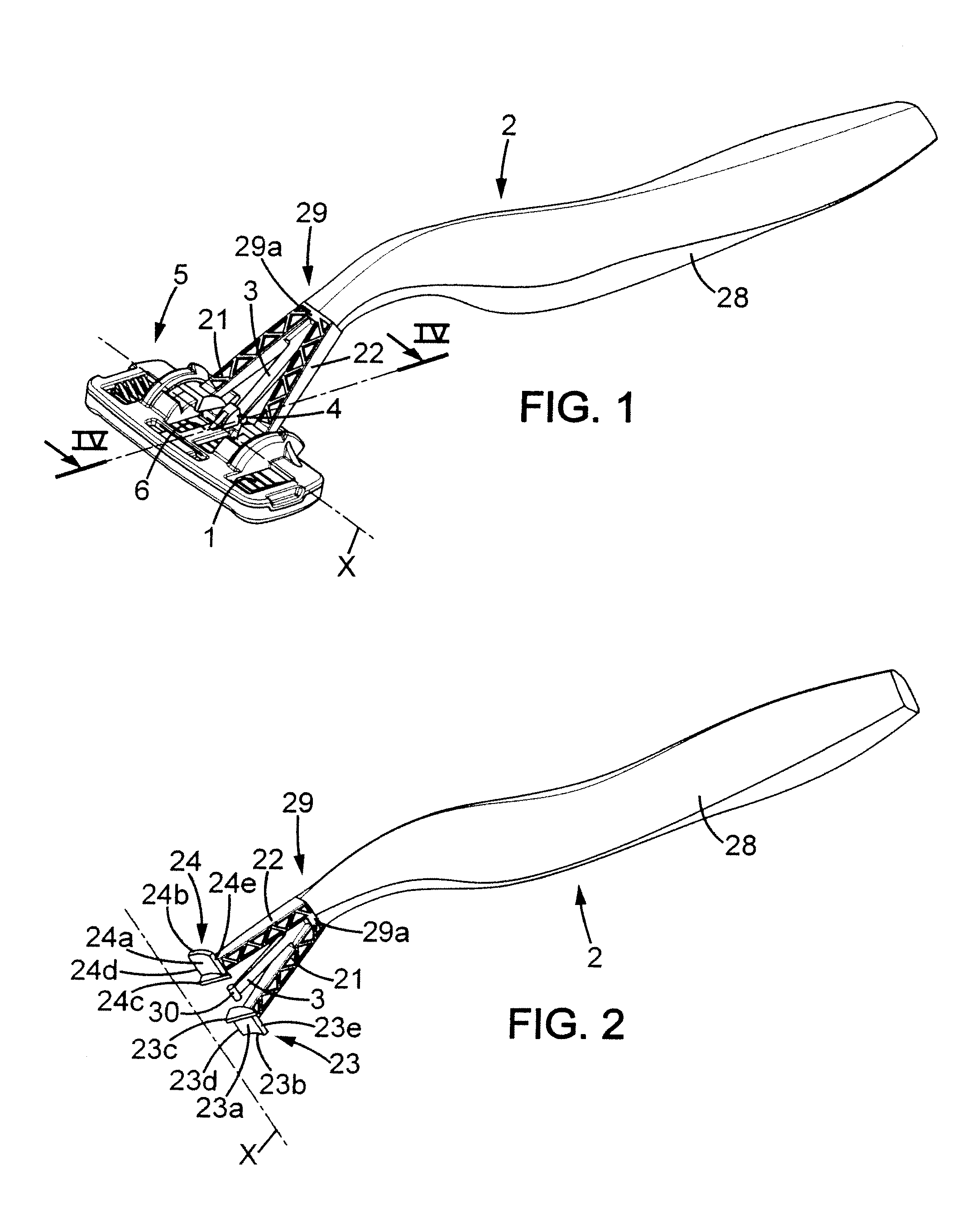

Wet shaver

ActiveUS20120124840A1Improve rinse capabilitySimplified cam surface designMetal working apparatusCamEngineering

Owner:BIC VIOLEX SA

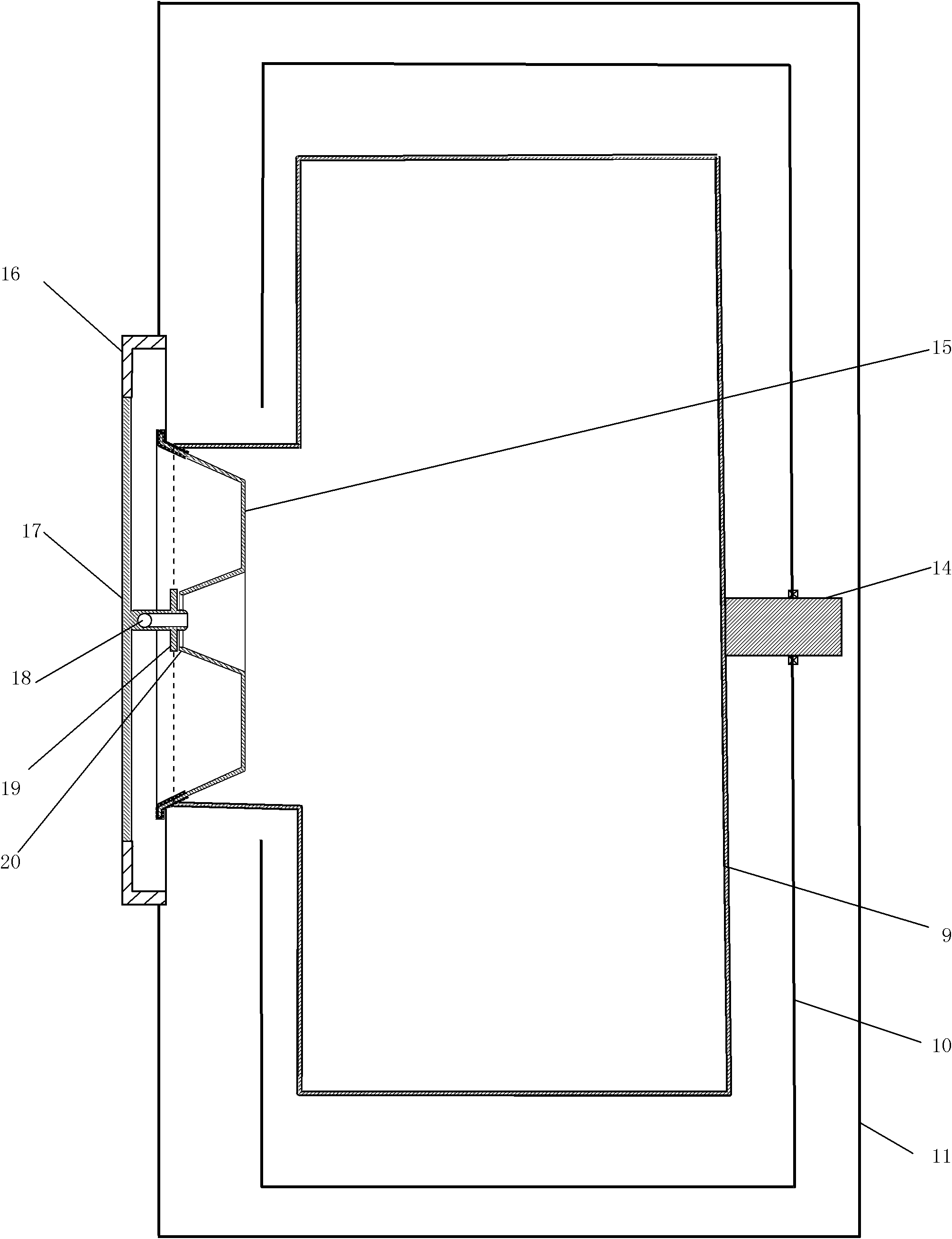

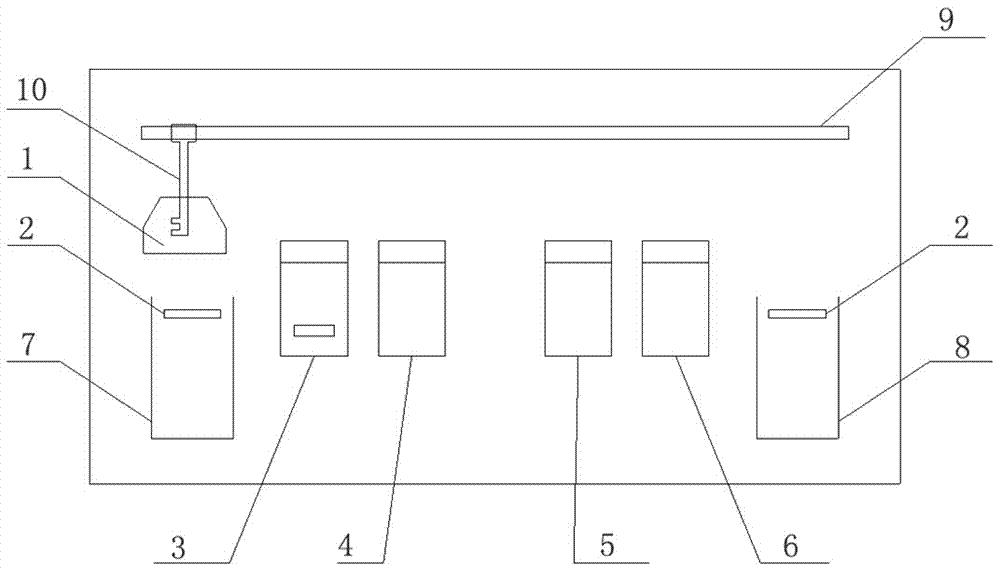

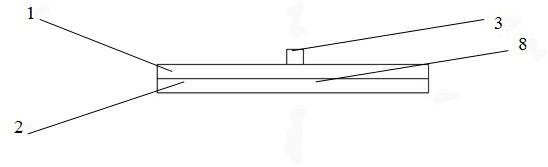

Single-drum front loading washing machine

InactiveCN102080325AImprove rinsing performanceLow failure rateOther washing machinesTextiles and paperEngineeringFront loading

The invention relates to a single-drum front loading washing machine, in particular to a door of the single-drum front loading washing machine. During washing, the drum of the single-drum front loading washing machine contains washing water, but the outer drum does not contain washing water. At present, the single-drum front loading washing machine still uses the machine door of a drum type washing machine, and the porthole of the machine door of the drum type washing machine cannot directly seal the clothes filling opening of the drum. As a result, the highest washing water level can only reach the lower edge of the clothes filling opening of the drum, so high-water level washing or rinsing cannot be performed. In the invention, a door frame 1 is openably arranged on the shell 11 of the washing machine by a hinge, the porthole 2 is fixed on the door frame by a bearing system and a shock absorbing device, or the machine door which is formed by fixedly combining the door frame and the porthole is arranged on the drum by a hinge, and thus, the porthole seals the clothes filling opening of the drum 9 when the door is closed. Therefore, the washing machine provided by the invention can perform high-water level washing or rinsing, the rinsing effect is improved consequently; and during washing, the small clothes in the drum are prevented from entering the space between the drum and an outer barrel 10 to cause a fault.

Owner:任文涛

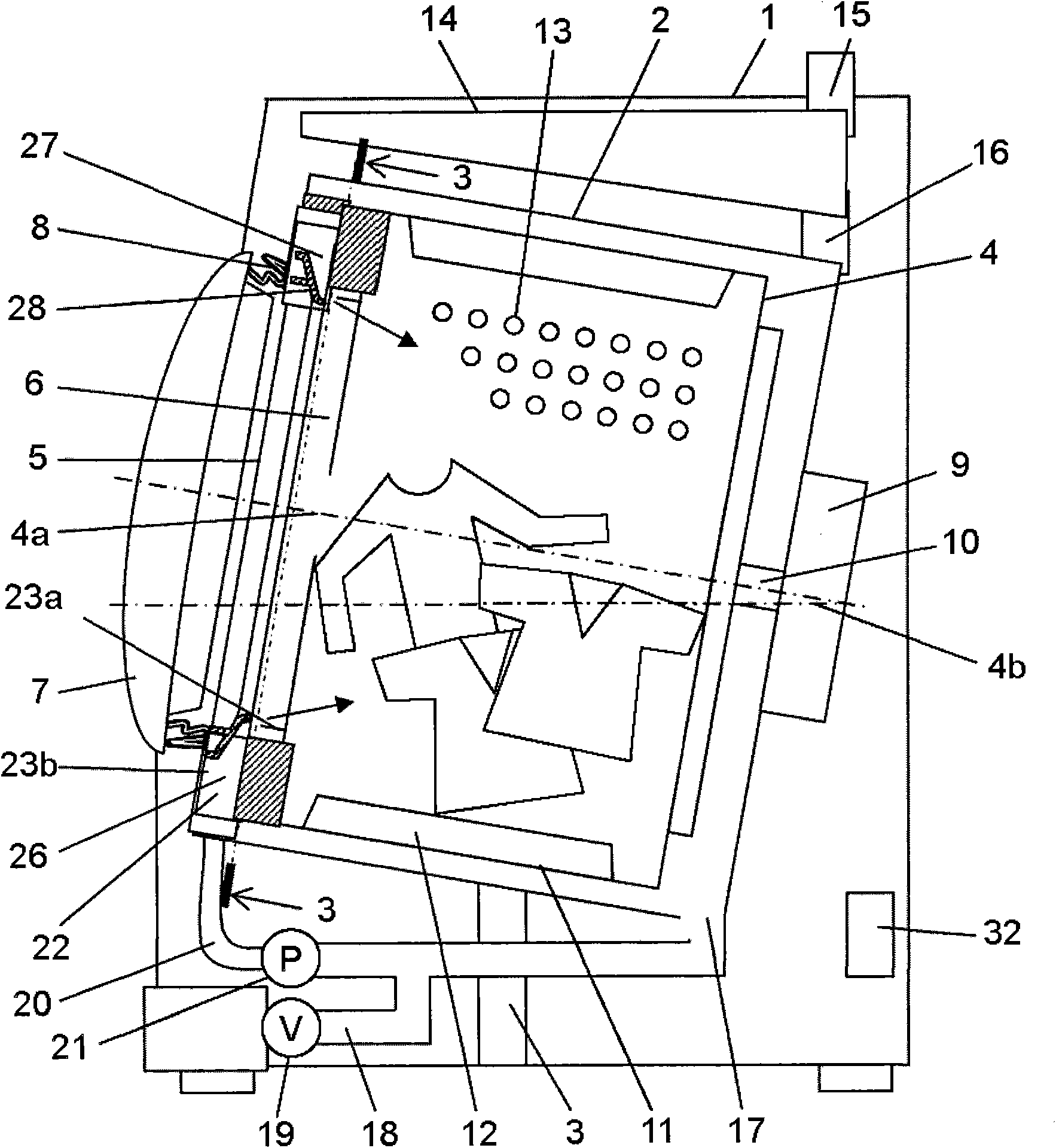

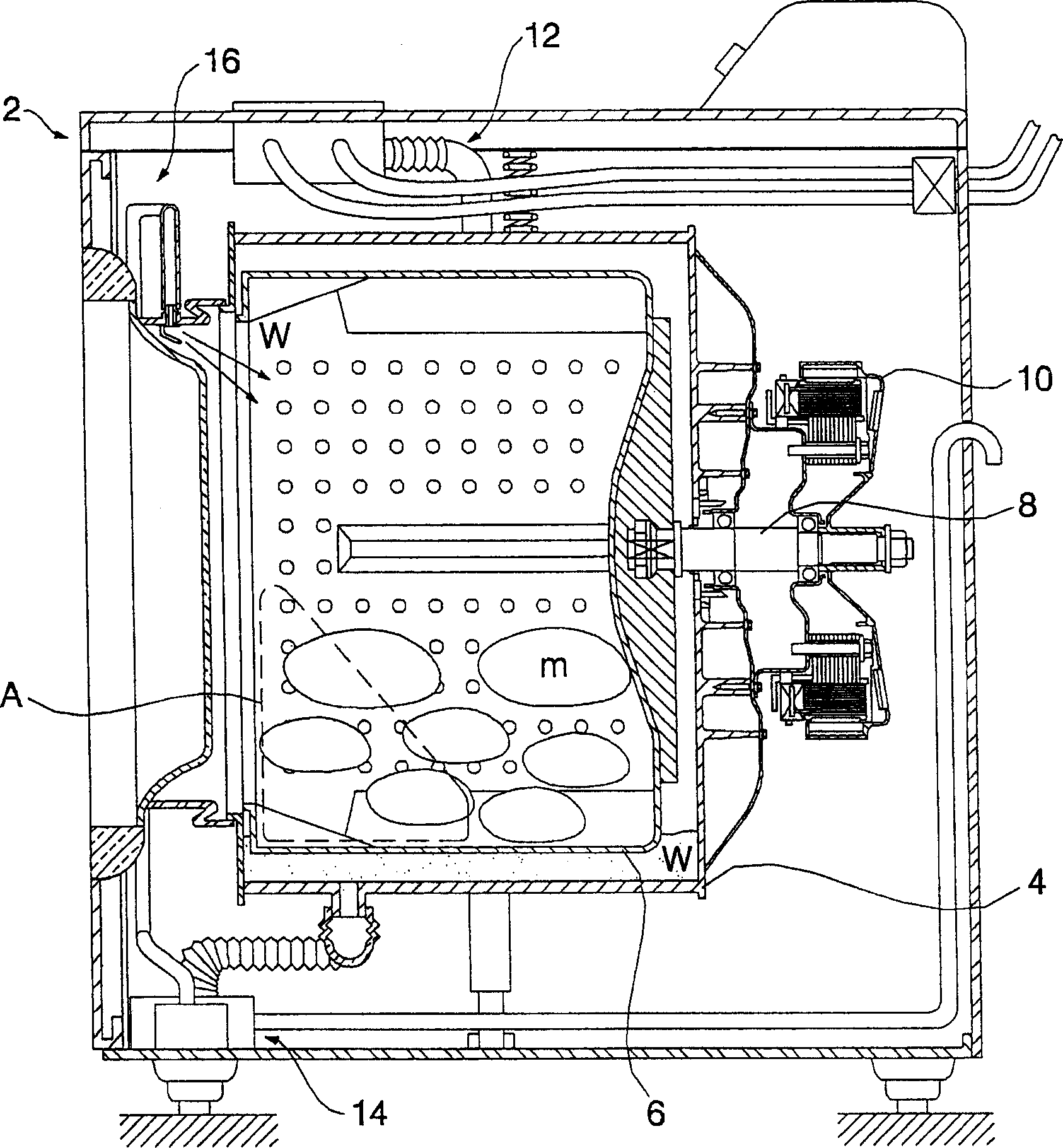

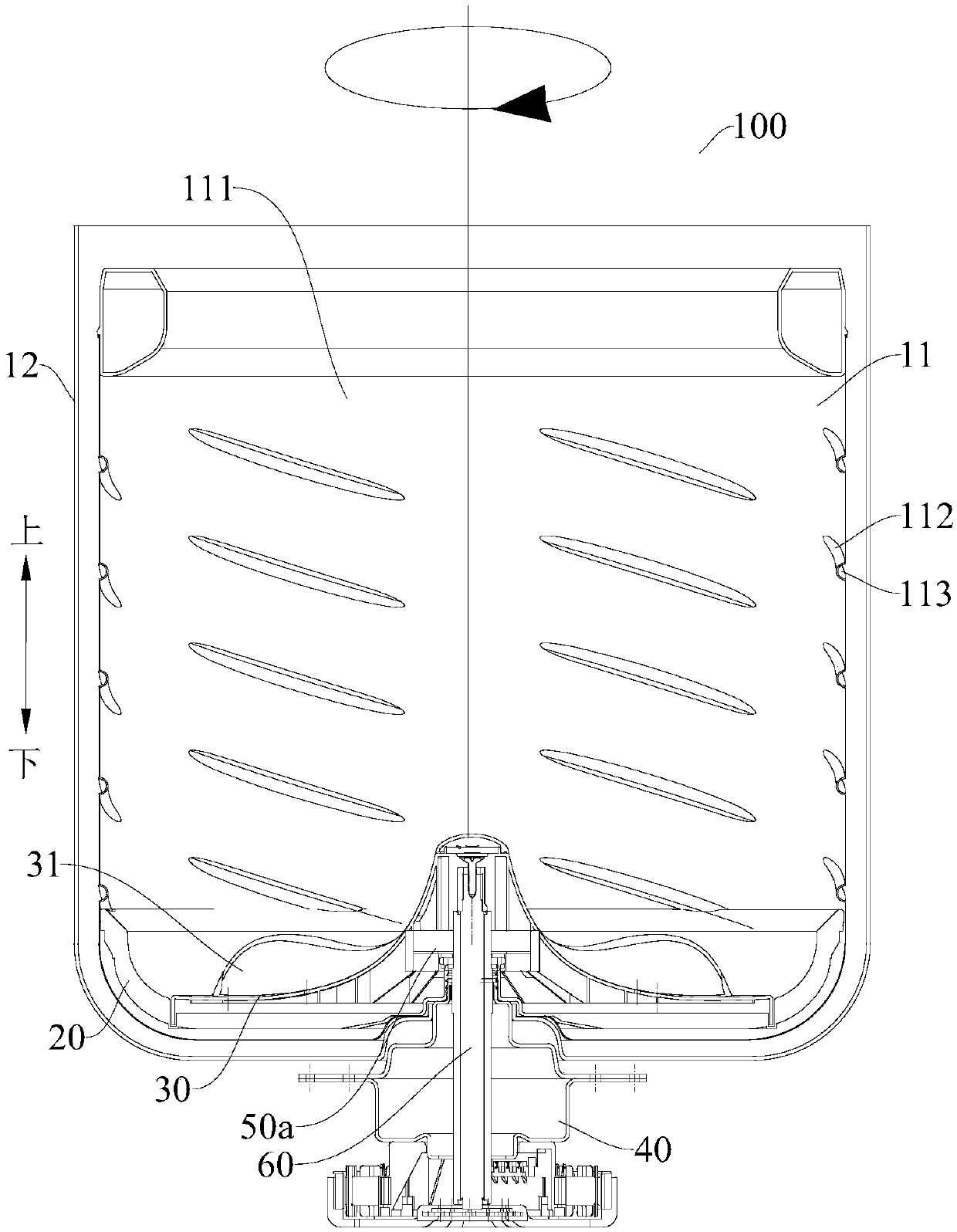

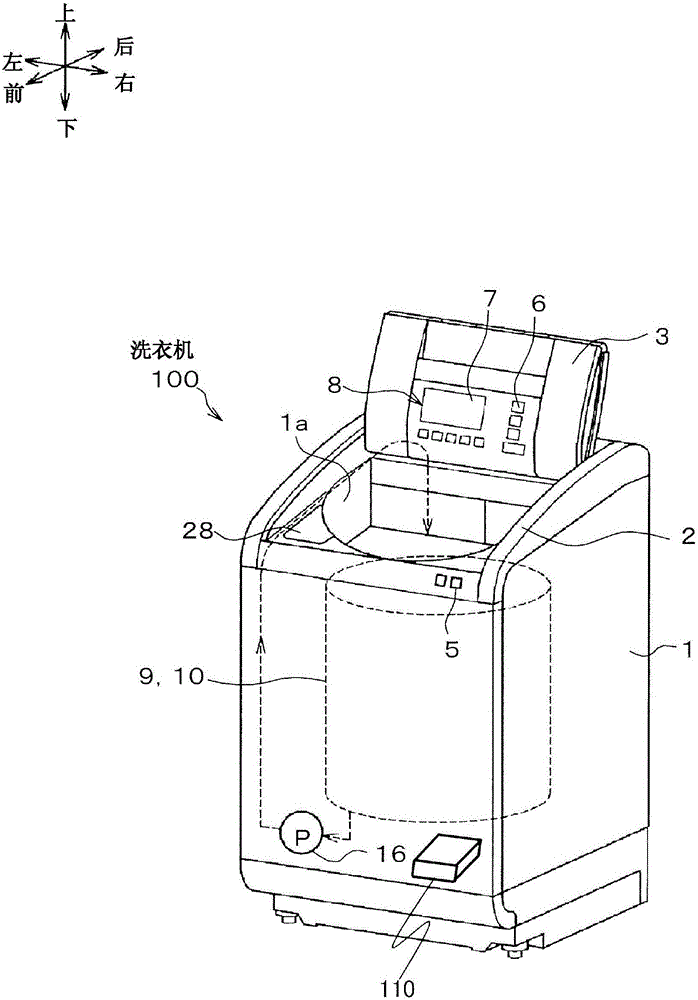

Washing machine

ActiveCN102121186AIncreases chances of spraying wash waterUniform supplyOther washing machinesWashing machine with receptaclesWash waterElectric motor

A drum-type washing machine includes a water tub for storing wash water, a rotary drum placed rotatably in the water tub and having an opening at the front, a motor for driving the rotary drum, a water circulating path for circulating the wash water stored in the water tub to the drum, a pump for conveying the wash water stored in the water tub to the water circulating path, multiple nozzles for jetting the wash water, conveyed to the nozzle water path by the pump, into the rotary drum, and a nozzle water path formed around a front face of the water tub for conveying the wash water from the water circulating path to the nozzles.

Owner:PANASONIC CORP

Washing machine

InactiveCN1760425AFast and even supplyEasy to washOther washing machinesWashing machine with receptaclesWash waterDrive shaft

A washing machine designed to uniformly and rapidly supply wash water into a drum through a drive shaft. The washing machine comprises a cabinet, a tub supported in the cabinet, a drum rotatably disposed within the tub for containing laundry, a spider mounted to the drum, a drive shaft connected to the spider to rotate the drum, at least one lifter mounted on an inner surface of the drum, and a water supply path formed to allow wash water to be supplied into the drum after passing through the drive shaft, the spider, the drum and the lifter. After sequentially passing through the drive shaft, the spider, the drum and the lifter, the wash water is then injected into the drum from the lifter, so that the wash water is rapidly and uniformly supplied to laundry, thereby enhancing washing and rinsing performance.

Owner:LG ELECTRONICS INC

Detergent Composition

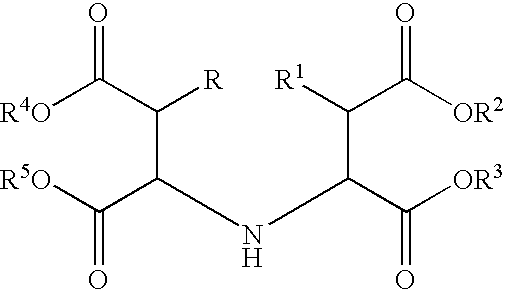

InactiveUS20100160202A1Efficient removalImprove enzyme stabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsDivalent metal ionsLotion

A detergent composition comprising; a) a non-phosphorous based builder which is an amino acid based compound or a succinate based compound, b) one or more enzymes which are destabilised by the non-phosphorous containing builder and c) a stabilisation system for the one or more enzymes. The stabilising system comprising one or more divalent metal ion salts and a non-ionic surfactant. Preferably the builder is the tetrasodium salt of glutamic-N,N-diacetic acid and the enzyme comprises protease. The preferred divalent metal ion salts are calcium salts.

Owner:RECKITT BENCKISER NV

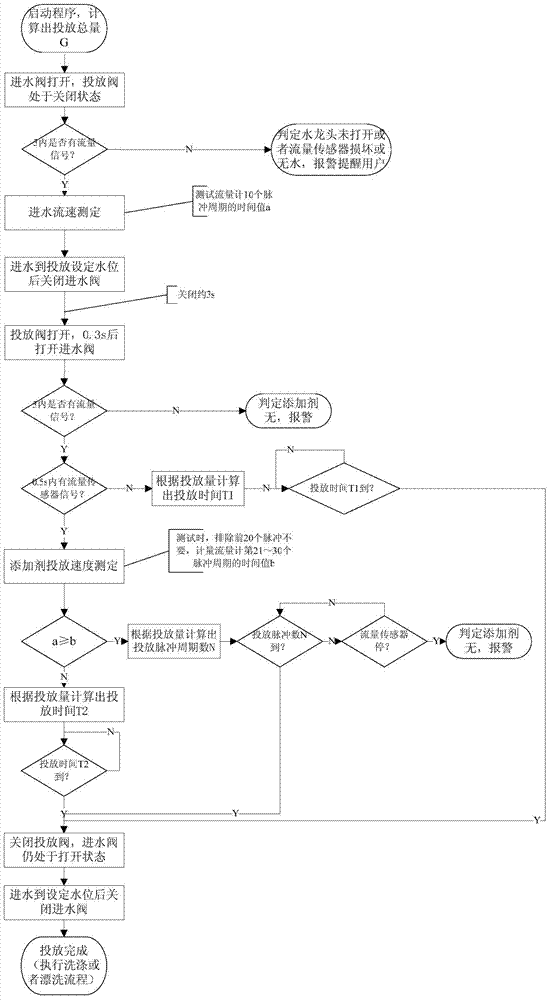

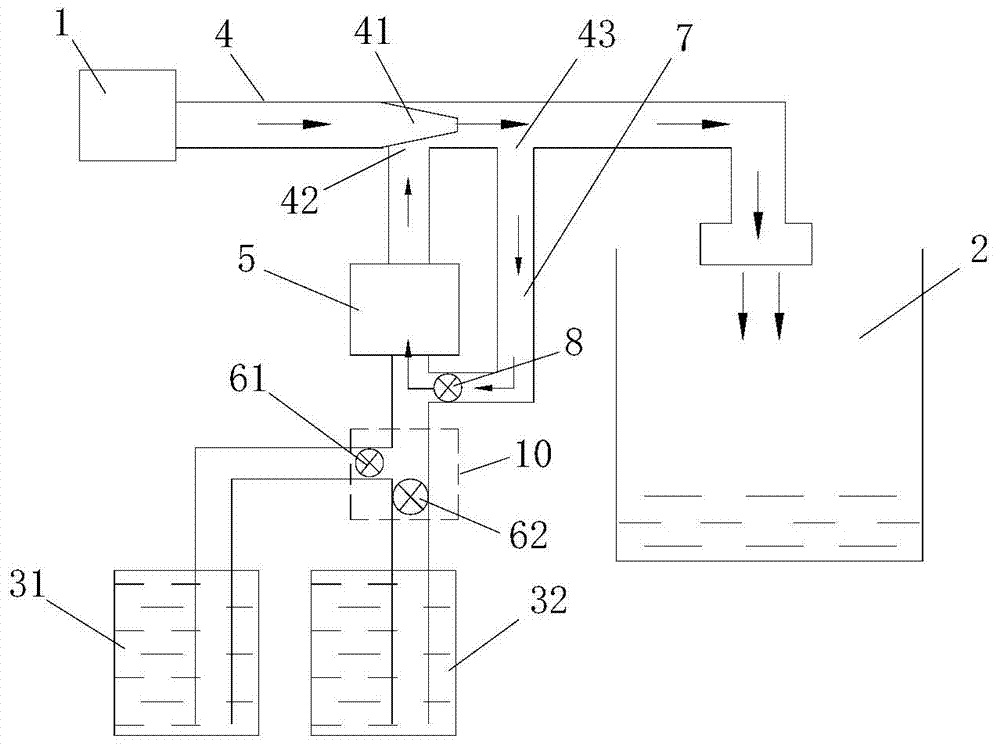

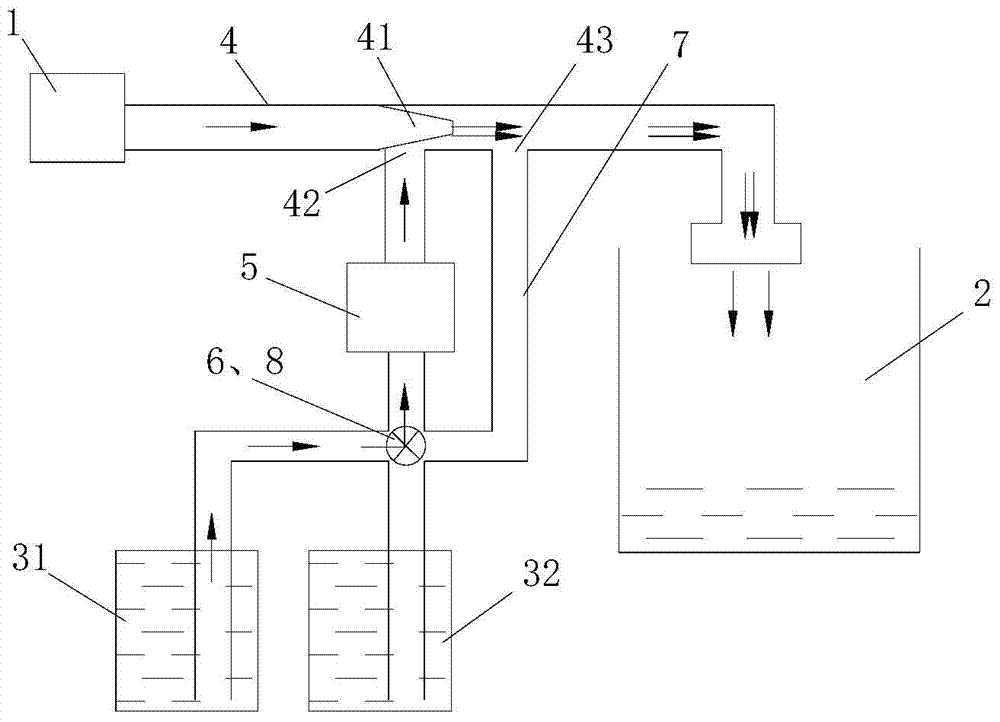

Control method of automatic additive adding

ActiveCN104727099AEasy to washImprove rinsing performanceOther washing machinesControl devices for washing apparatusInlet valvePulse number

The invention discloses a control method of automatic additive adding. The method includes: opening an additive adding control valve, opening a water inlet valve, using negative pressure generated by water inlet to extract additives, measuring water pressure, additive viscosity and additive adding speed, selecting adding time or adding pulse number to judge whether a total adding amount reaches the required additive amount G, and closing the additive adding control valve when the additive adding amount reaches G to complete additive adding. The control method has the advantages that a flow sensor and a negative pressure structure are used in coordination, precise adding of various liquid additives is achieved by combining the on and off of the adding control valve, the influence of the water pressure and the precise detection of the flow sensor and by precise judgement, washing and rising effects are increased, and the control method is simple and practical.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Washing machine and washing control method thereof

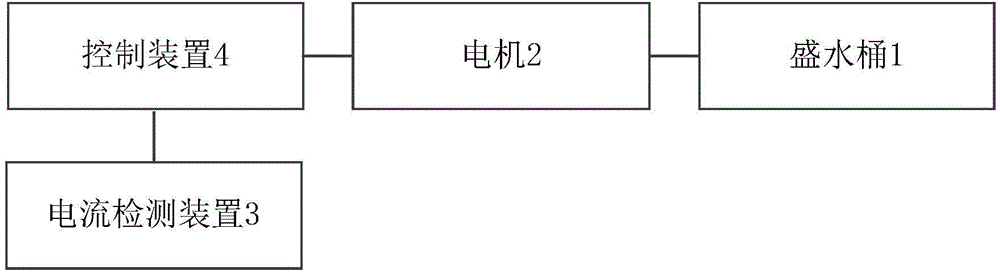

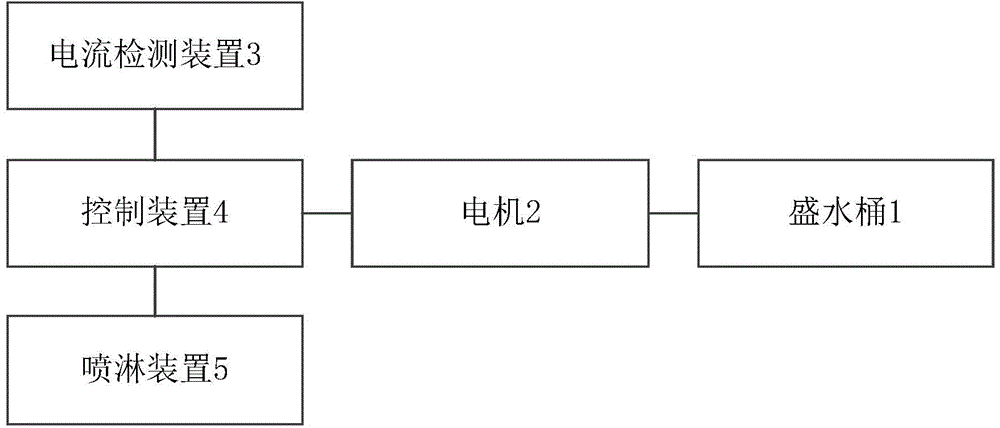

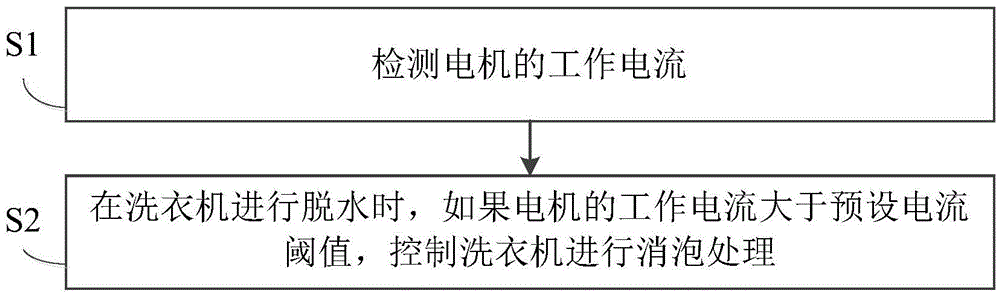

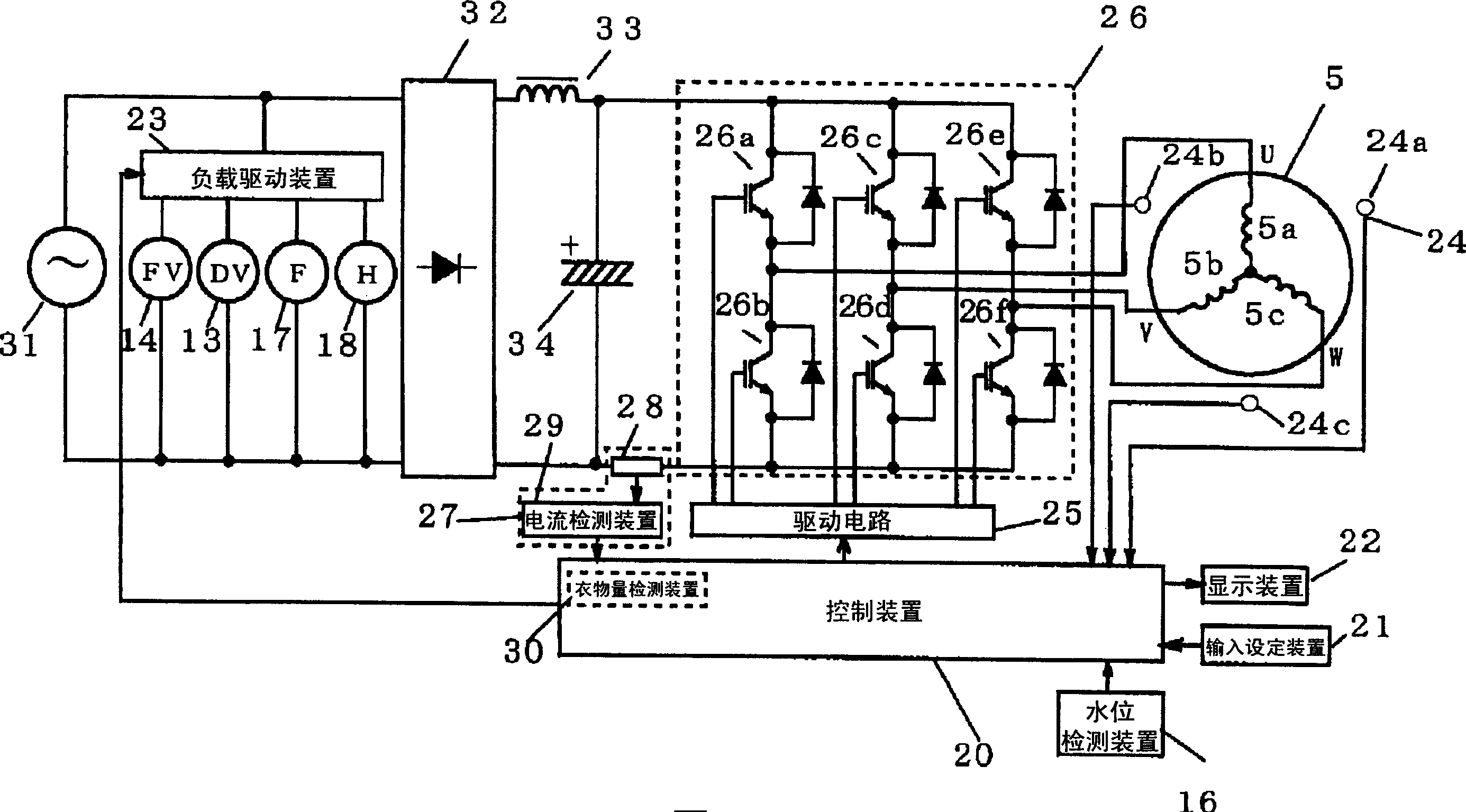

InactiveCN105671857AReduce energy consumptionLow powerOther washing machinesControl devices for washing apparatusPower flowCurrent threshold

The invention discloses a washing machine. The washing machine comprises a water holding bucket, a motor used for driving the water holding bucket to operate, a current detection device used for detecting working current of the motor, and a controlling device connected with the current detection device and driving the water holding bucket to operate by controlling rotation speed of the motor. When the washing machine is used for hydrating, the controlling device is used for controlling the washing machine to performing de-foaming operation if the working current of the motor is larger than the pre-set current threshold value. Therefore, the washing machine is capable of effectively eliminating foams generated during washing so that rinsing performance is improved and a computer board is prevented against short circuit due to overflow of foams. The machine is capable of reducing residual washing agents in clothes so that human health is ensured and clothes and the skin of a user are protected. In addition, the energy loss of the washing machine is reduced and motor power is decreased. The invention further discloses a controlling method of the washing machine.

Owner:WUXI LITTLE SWAN CO LTD

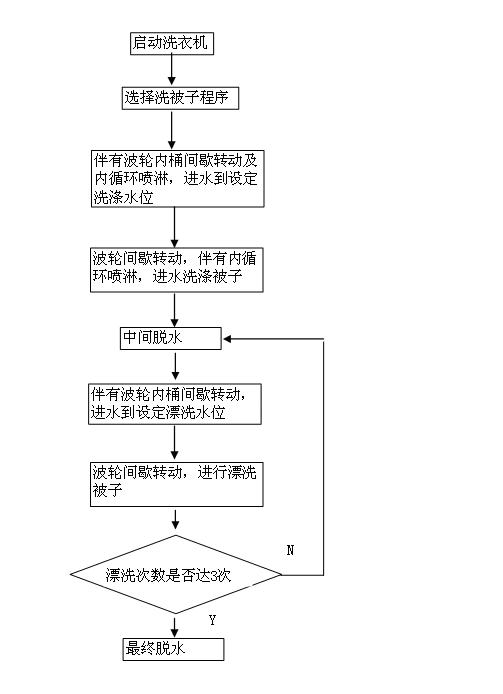

Control method for washing quilts by washing machines and full-automatic washing machine

ActiveCN102677419AEffective water absorptionImprove washing effectControl devices for washing apparatusWashing machine with receptaclesImpellerRinse water

The invention relates to washing machines, in particular to a control method for washing quilts by the washing machines. The method includes the following steps that water is fed to a set washing water level while an intermittent rotation of an impeller inner barrel and an internal circulation spray are performed; the impeller is in the intermittent rotation, and the quilts are washed while the internal circulation spray is performed; an intermediate dewatering is performed; water is fed to a set rinse water level while the impeller inner barrel is in the intermittent rotation; the impeller is in the intermittent rotation, and the quilts are rinsed; and the intermediate dewatering, rinse water feeding and rinsing are repeated, and the final dewatering is performed. The invention further relates to a washing machine using the control method. The spraying is performed by means of an internal circulation pump, the washing is performed by the aids that the cycle of starting and stopping of a motor is prolonged and the starting and stopping of the motor are alternately changed, and three-time rinsing at a medium high water level and a gland structure are utilized, so that when the quilts are washed by the washing machines, the cleaning ratio is high, the rinsing effect is good, the abrasion is slight, and the individual needs of consumers are met.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

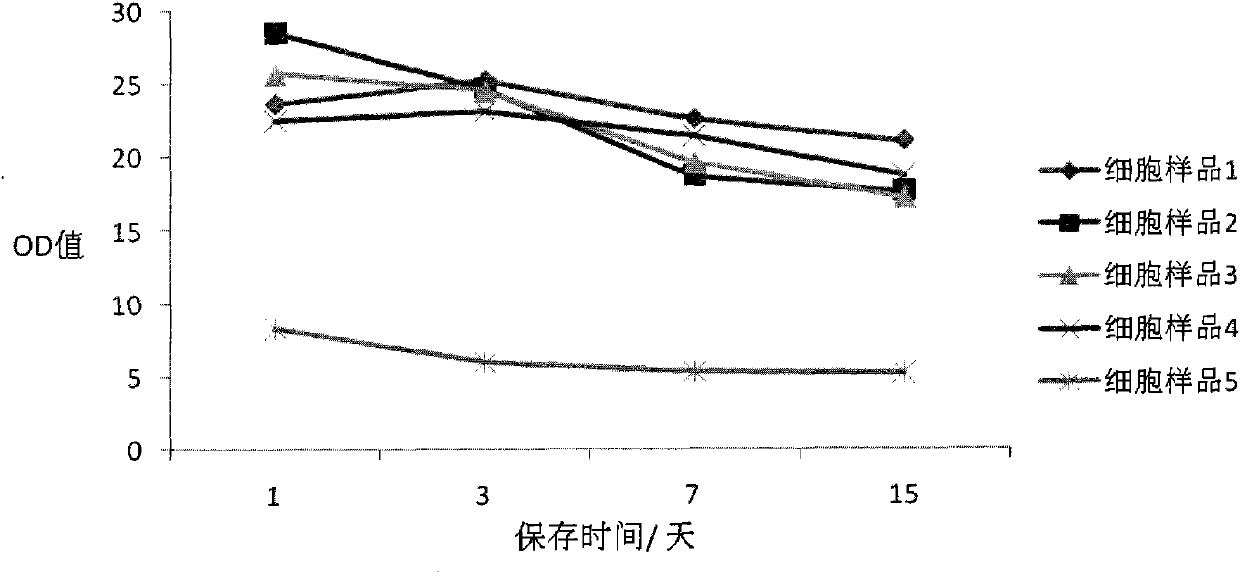

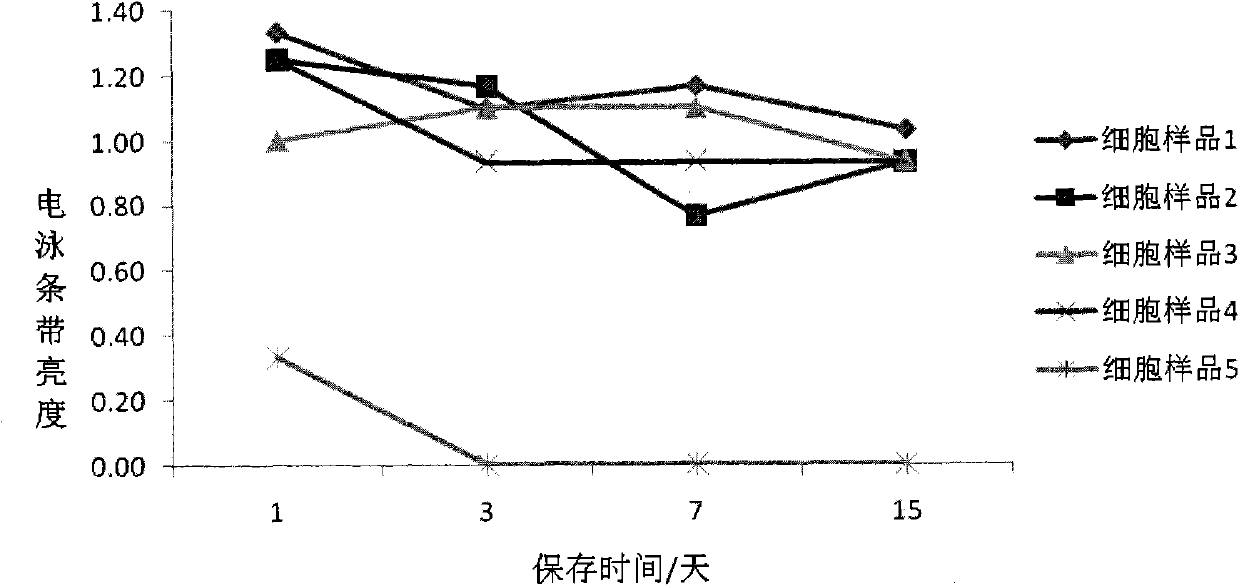

Cell preserving fluid and preparation method and use thereof

ActiveCN101999343AAvoid degradationConducive to follow-up detectionMicrobiological testing/measurementDead animal preservationDisulfide bondChemistry

The invention belongs to the field of cell biology, relating to a cell preserving fluid and a preparation method and use thereof. Concretely, the cell preserving fluid comprises a fixing agent, a fixing agent assistant, an anticoagulant, a cushion fluid and an ionic strength maintenance agent. The cell preserving fluid is characterized in that the content of the anticoagulant is 0.01% to 1.5%(w / w); the content of the ionic strength maintenance agent is 0.01% to 1%(w / w); and the cell preserving fluid does not contain a disulfide bond open reagent. The cell preserving fluid can effectively preserve cell DNA (deoxyribonucleic acid) and virus DNA infecting the cell, is convenient to collect the cast-off cells and extract DNA and can give attention to storage of the cell structure. The invention also relates to the preparation method and the use of the cell preserving fluid. The invention also relates to a kit and a method for detecting HPV (Human Papilloma Virus) or HPV DNA.

Owner:BGI GENOMICS CO LTD

Washing methods of automatic washing machine and automatic washing of using the method

InactiveCN1796646AReduce secondary pollutionImprove cleaning ratioControl devices for washing apparatusWashing machine with receptaclesWater savingInlet valve

A washing method of automatic washer includes controlling water inlet valve to let washer flow water in continuously; checking whether water level in washer is reached on water overflow level or not and starting up timing if water overflow level is reached as well as closing water inlet valve when timing is on preset time; enabling to drain out oil stain in clothes, washing powder foam, detergent foam and floated ¿C dirt from overflow outlet before water is discharged when washing procedure is finished in order to raise cleaning ration.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

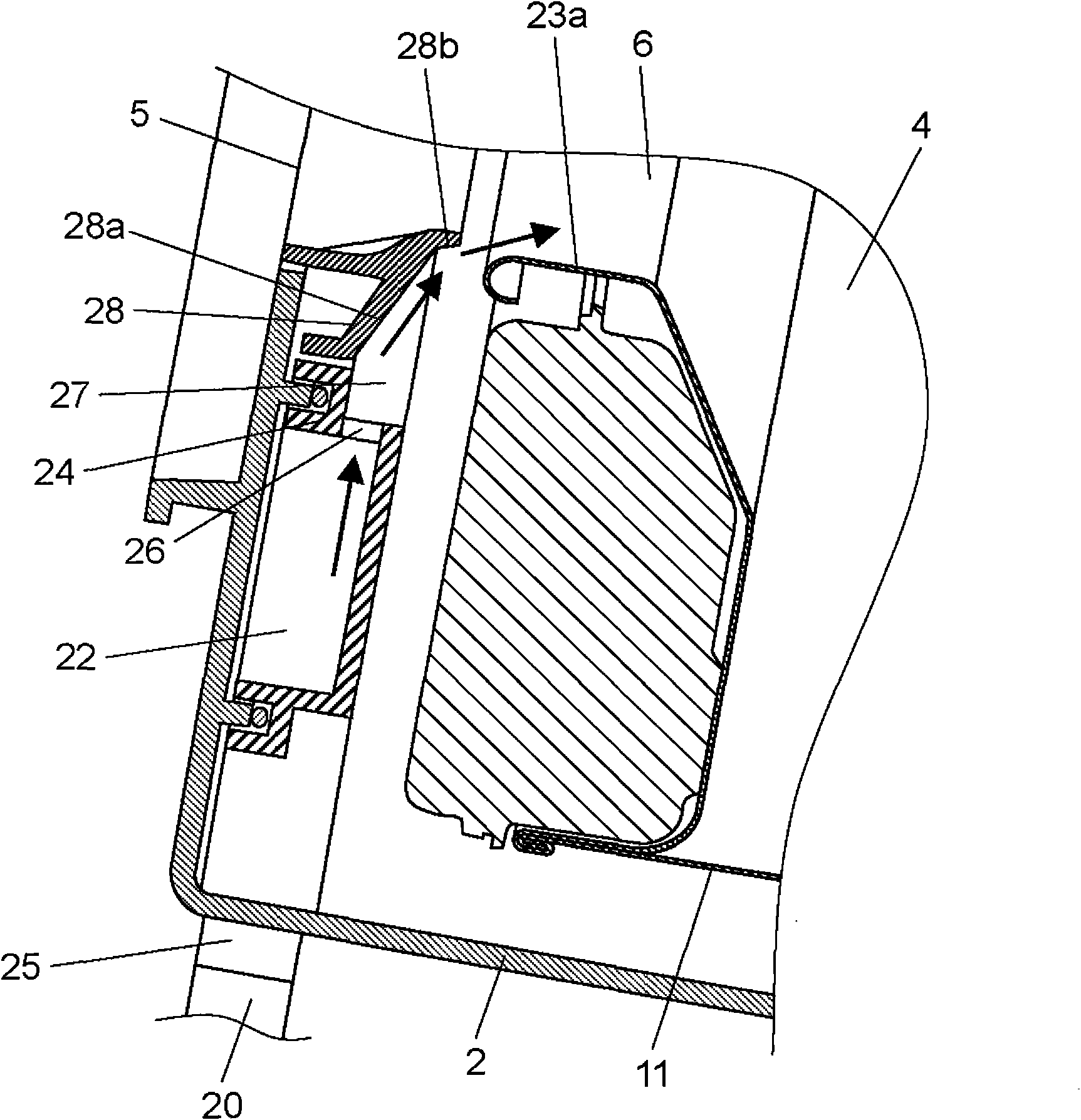

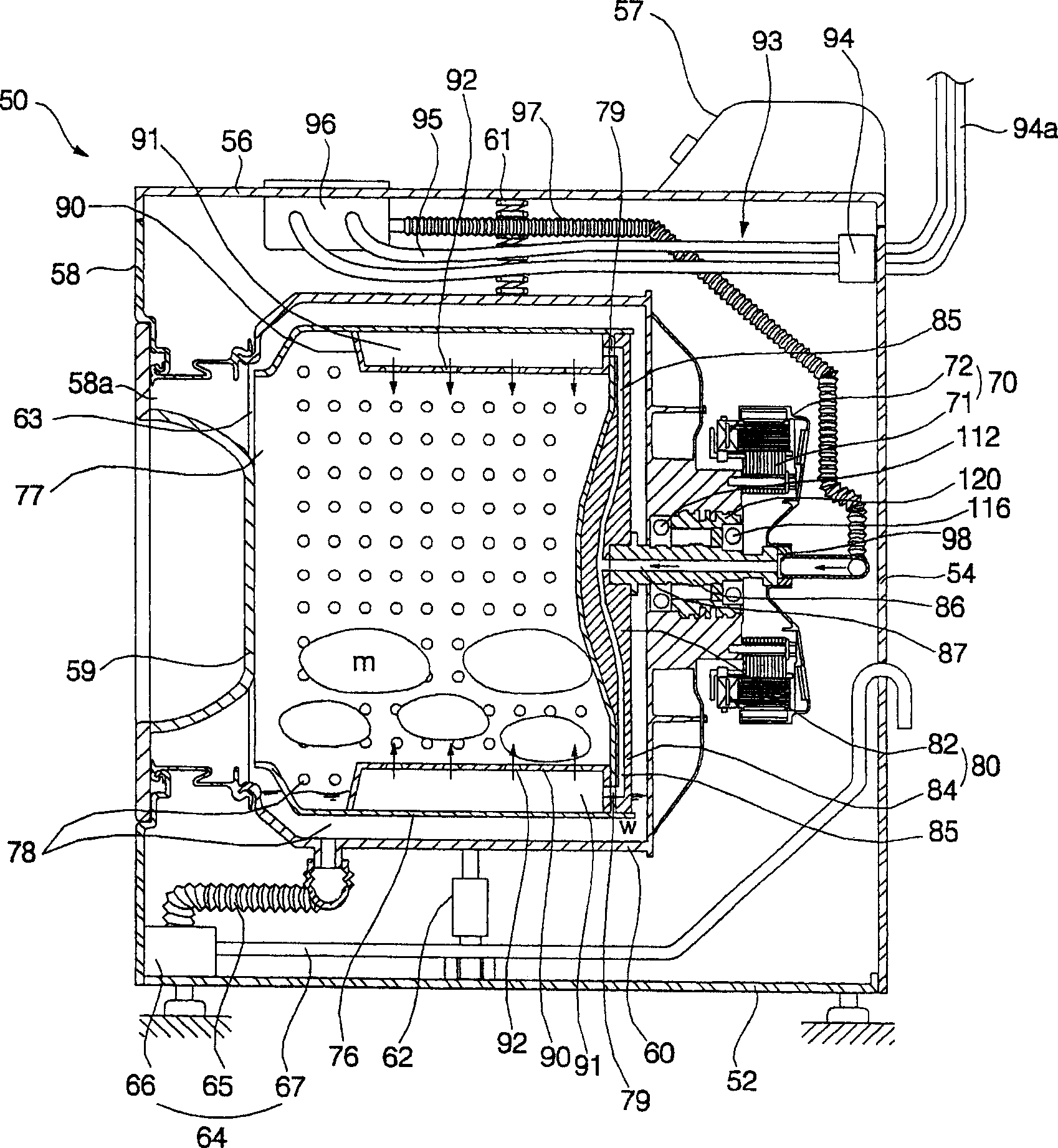

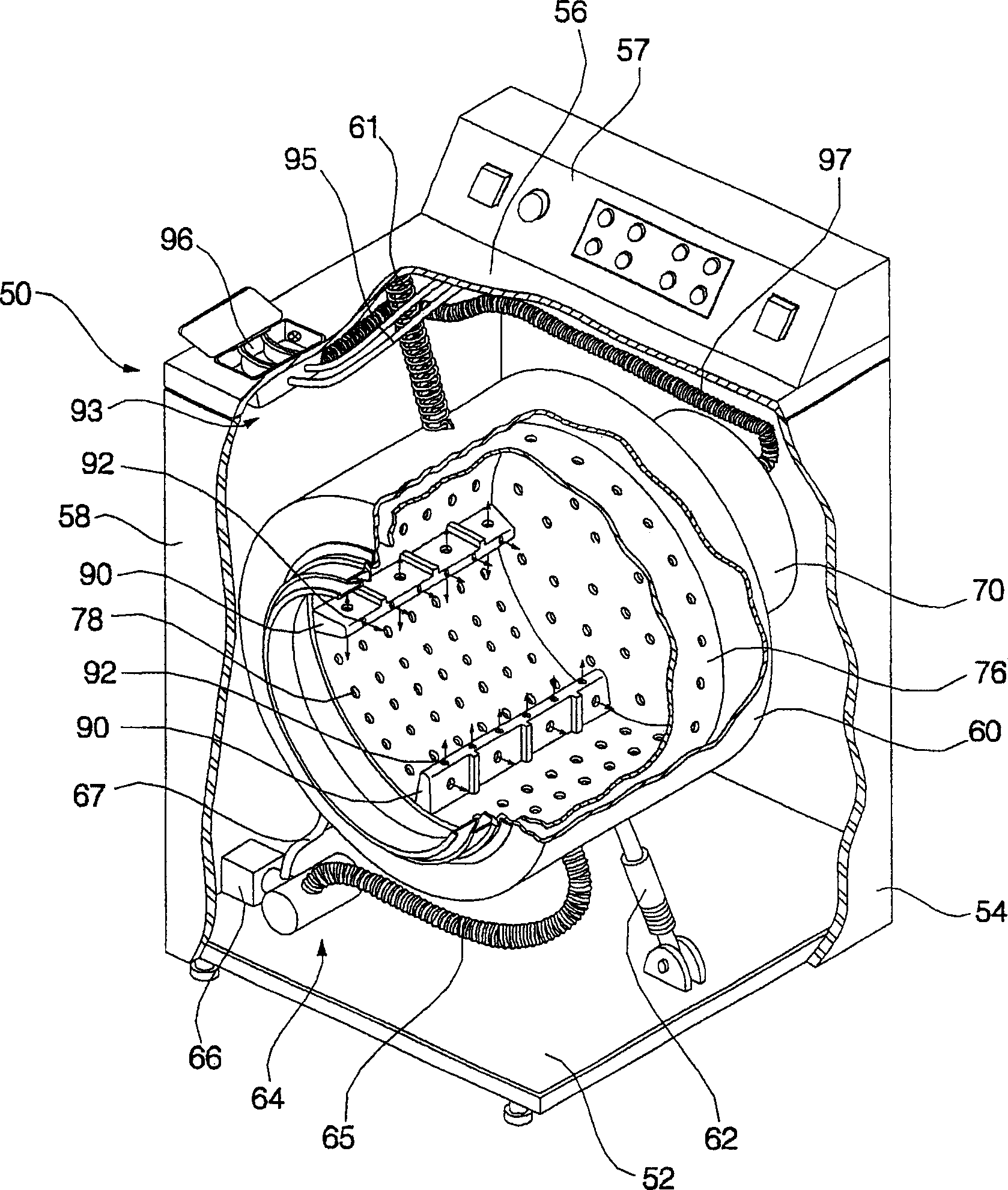

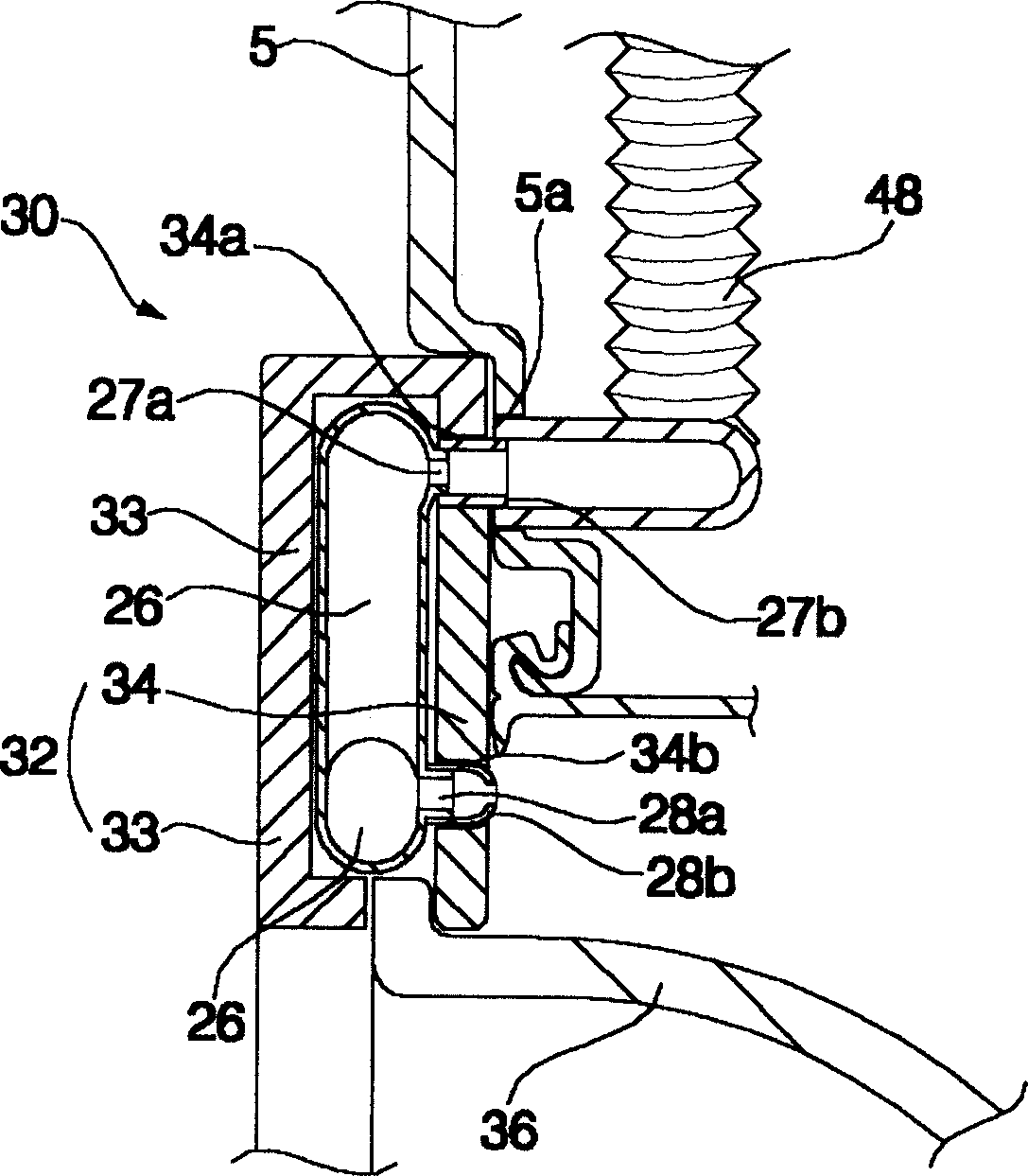

Drum-type washing machine and washing method using the same

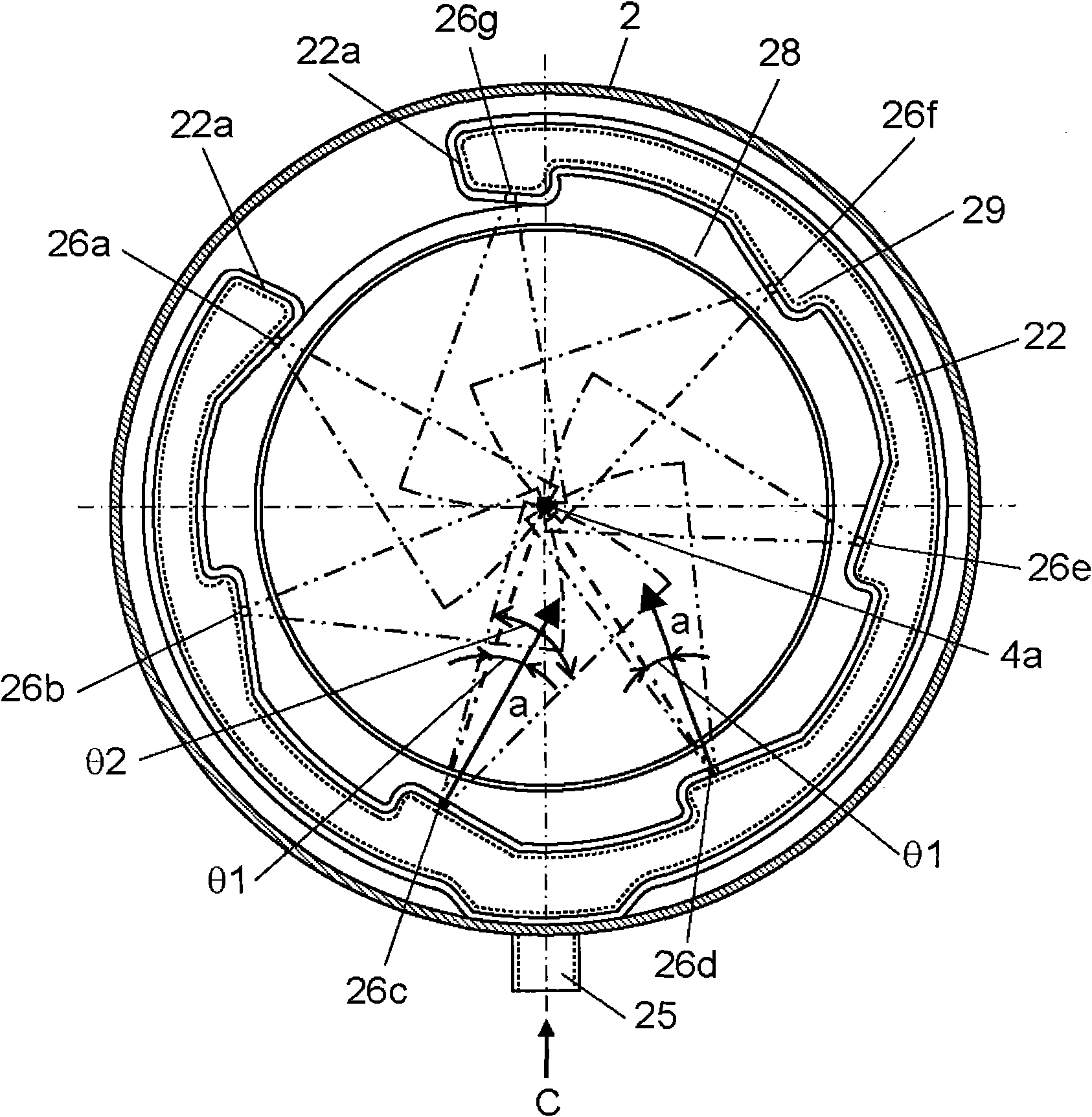

InactiveCN1948596ARinse unevenness is reducedCycle positiveOther washing machinesControl devices for washing apparatusWash waterWater channel

Provided is a drum type washing machine (50) which is arranged with a circulating water channel (22, 26, 27, 28) rotating along the rotating drum (5) for the wash water. The wash water is inducted from the diversion gap (20) of the water pot (6) and then the wash water inducted from the diversion gap (20) is discharged from the discharge opening (34) to the interior of the rotating drum (5) to make the wash water rotate and spray to the washings. In this way, the wash water contained in the washings and the wash water inside and outside of the rotating drum (5) actively process circulation to improve the cleansing power and the rinsing performance and reduce the irregular rinsing.

Owner:PANASONIC CORP

Drum type washing machine

InactiveCN102454091AImprove cleanlinessImprove rinsing performanceOther washing machinesTextiles and paperEngineeringElectric motor

The invention provides a drum type washing machine, which comprises a washing machine casing containing a rotary drum with an opening part, a water bucket freely and rotatably provided with a rotary drum, a motor used for driving the rotary drum to rotate, a plurality of water paths, a water supply valve, a circular opening part of the water bucket, a rectangular diversion opening part and a nozzle arranged at the diversion opening part. The opening part of the rotary drum is arranged at the front part of the casing. The water supply valve is provided with a plurality of valves capable of opening and closing the plurality of water paths respectively. The opening part of the water bucket is arranged at the inner circumferential side of the opening end portion of the front part of the waterbucket. The diversion opening part is positioned at the upper circumferential part of the front part of the water bucket and is in a long shape along the circumferential direction. The nozzle is provided with a guide claw extending into the water bucket from the diversion opening part when being installed at the diversion opening part. The drum type washing machine can be easily expanded in various types of machines and can prevent the mis-assembly of components during the production of various types of machines.

Owner:PANASONIC CORP

Multi-stage treatment and recovery system and method for PET release films

ActiveCN110435044AReach the purpose of recyclingIncrease profitPlastic recyclingDrying gas arrangementsRecovery methodEngineering

A multi-stage treatment and recovery system for PET release films comprises a mechanical dust removal mechanism, a cleaning mechanism, a drying mechanism and a winding mechanism, wherein the release film sequentially passes through the mechanical dust removal mechanism, the cleaning mechanism and the drying mechanism and is wound on the winding mechanism; traveling of the release films in the mechanical dust removal mechanism, the cleaning mechanism, the drying mechanism and the winding mechanism and transition among the mechanisms are guided by a guide roller in rolling fit with the release films; and the actions of the mechanical dedusting mechanism, the cleaning mechanism, the drying mechanism and the winding mechanism are uniformly and coordinately controlled by an electric control system. According to the multi-stage treatment and recovery system for the PET release films, the release films are subjected to dust removal, cleaning, drying and winding in sequence, so that surface impurities of the used release films can be effectively removed, wound and recycled, the purpose of recycling the release films is achieved, the utilization rate of the release films is improved, and the production cost is reduced. The invention also provides a multi-stage treatment and recovery method for the PET release films.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Clothes treating apparatus and control method thereof

ActiveCN109652953AEasy to washImprove rinsing performanceOther washing machinesControl devices for washing apparatusWater flowVertical displacement

The invention discloses a clothes treating apparatus and a control method thereof. The clothes treating apparatus comprises an inner cylinder, a rotatable pulsator, a driving device and a clutch device, the inner cylinder defines a cavity with an open top, the driving device is used for driving the pulsator to rotate, the clutch device can be switched among a separation state, a first joint stateand a second joint state, the pulsator is free from vertical displacement in the separation state and can be driven to rotate in the first joint state, the inner cylinder and the pulsator can synchronously rotate in the first joint state, and the pulsator can be driven to rotate and can vertically shift relative to the inner cylinder in the second joint state. According to the clothes treating apparatus, when the clutch device is switched to the second joint state, the pulsator rotates and can vertically shift, three-dimensional stirring effects of water flow can be achieved, and washing and rinsing effects and use experience of the clothes treating apparatus are improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Drum washer

InactiveCN1746411AShorten washing timeImprove washing effect and rinsing effectOther washing machinesTextiles and paperEngineeringMechanical engineering

A roller washing machine is provided. It contains shell with entrance, washing beck, roller, door of water-applying pipe and water-applying device for water-applying pipe and the particular device for water-applying pipe. The particular device can reduce washing times and improve the washing effects.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Assembly for Dispensing a Canister's Liquid Contents Into a Vessel and for Rinsing a Residue of the Liquid Contents

ActiveUS20140090749A1Improve rinsing performanceEfficient rinseLiquid fillingHollow article cleaningEngineeringMechanical engineering

An assembly for purging a canister into a tank and for rinsing the canister, the canister having a floor, the assembly including a “A” configured lance having a plurality of legs and a bar, each leg among the plurality of legs forming a blade having an upper end and an outer edge, the blades' upper ends and outer edges being sharpened for, upon upward impingement against the canisters' floor, dividing the floor into a plurality of sections, each section among the plurality of sections being configured as a flexible leaf, the bar member forming and functioning both as a leaf deflecting mandrel, and as a rotatable sprinkler head, the “A” configured lance and associated sprinkler head configured mandrel being mountable within the tank by suspension hooks.

Owner:ECK ETHAN

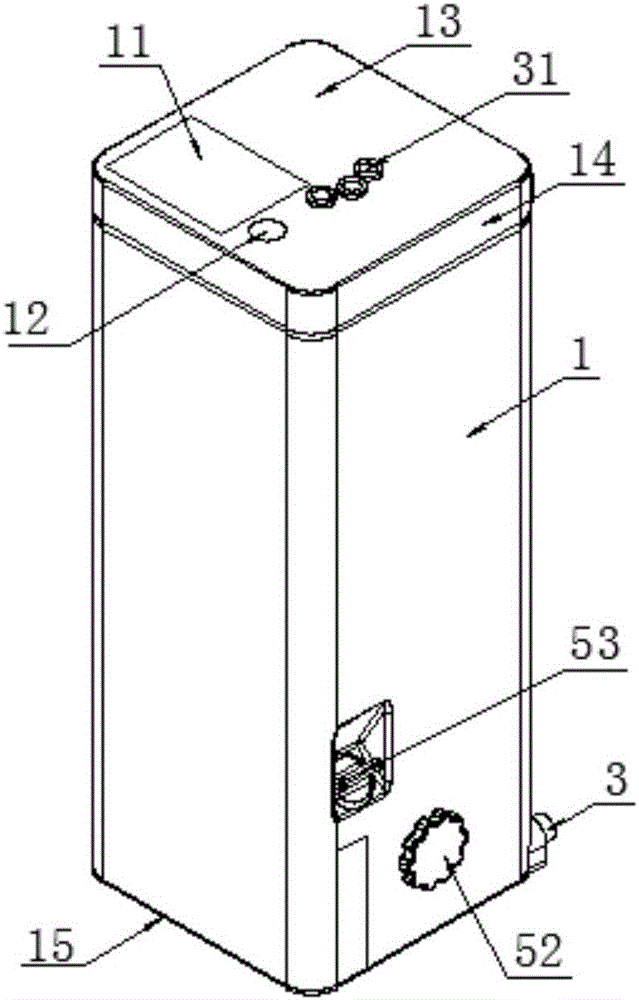

Chopstick washing machine with high-temperature disinfection function

InactiveCN105769090AEasy to cleanShorten cleaning timeWashing controlling processesTableware washing/rinsing machine detailsSolubilityWater use

The invention discloses a chopstick washing machine with a high-temperature disinfection function. The chopstick washing machine comprises a shell, a pipeline, a connector, an electric control system, a structure device, a functional device and a connection device, wherein the electric control system comprises a circuit board, an ultrasonic generator and a temperature sensor; and the functional device comprises a water returning nozzle and a heating pipe. The chopstick washing machine is used for washing through ultrasonic waves; the solubility of a washing solution and the cavitation effect of ultrasonic waves are improved through heating, and sterilization and disinfection are carried out through heating to a high temperature so that the washing effect of the chopstick washing machine is relatively good; a mini-type water pump is used as a core water circulating system so that the technical effect that water is supplied for one time and can be used for a plurality of times is realized; a wireless device is wirelessly connected with intelligent equipment of a user, so that the user can be more flexibly and conveniently use the washing machine; and the chopstick washing machine has relatively good washing effect and relatively less water use amount and is relatively safe and convenient to use.

Owner:SUZHOU LUZHIYAO TECH

Washing machine and control method of washing machine

ActiveCN106048965AImprove rinsing performanceOther washing machinesControl devices for washing apparatusEngineeringWater collection

The invention provides a washing machine capable of further improving the rinsing performance. The washing machine includes; an outer barrel for storing water; an inner barrel arranged in the outer barrel; a driving portion for performing rotation driving on the inner barrel; a water supplying portion for supplying water; a discharge portion for performing discharging on the outer barrel; and a control device for performing a multiple rinsing step. The rinsing step includes: allowing the discharge portion to perform discharging action and allowing the water supplying portion to spray washing articles in the inner barrel with rinsing water so as to achieve rotation spraying rinsing operation while the driving portion is controlled to allow the inner barrel to rotate at a low speed; and controlling the water supplying portion and the discharge portion to collect rinsing water in the outer barrel, and controlling the driving portion to allow positive and negative rotation of the inner barrel to stir the washing articles so as to achieve water collection rinsing operation.

Owner:日立グローバルライフソリューションズ株式会社

Precise and high-strength sheet metal part and corrosion-resistant vacuum heat treatment technology thereof

InactiveCN107829035AEmission reductionImprove rinsing performanceCleaning using liquidsMetallurgyRare earth

The invention discloses a precise and high-strength sheet metal part. The precise and high-strength sheet metal part comprises a sheet metal part body. The sheet metal part body comprises, by weight,0.03-0.09% of Zr, 1.56-1.98% of Re, 1.32-1.59% of Bi, 0.05-0.16% of C, 3.32-3.56% of Si, 1.26-1.38% of Mn, 0.12-0.15% of Mo, 0.6-0.9% of Ni, 2.23-2.58% of Cu, 1.19-1.25% of Ti, 25-29% of lanthanide-series rare earth, and the balance Fe and trace impurities. The rare earth comprises, by weight, 9.6-9.9% of Ce, 11-15% of La, 9-18% of Y, 11-15% of Sc, 6-9% of Gd, 2-6% of Sm, and the balance Gd.

Owner:博维恩冷冻科技(苏州)有限公司

Water-based environment-friendly cleaning method and cleaning device of soldering flux on radar electronic module

ActiveCN107413760AEasy to cleanMeet the highest cleanliness class requirementsDrying gas arrangementsDrying machines with progressive movementsWater basedAlcohol

The invention provides a water-based environment-friendly cleaning method of soldering flux generated in the welding process of a radar electronic module. The cleaned object is the radar electronic module of which a ceramic substrate and a related connector are installed and welded. A cleaning system comprises a cleaning clamp, a moving mechanism, a soaking ultrasonic flow spraying cleaning mechanism, a reverse spraying rinsing mechanism, a solvent dehydration bubbling mechanism, a baking mechanism and a feeding and discharging table. According to the operation steps, 1, the radar electronic module to be cleaned is clamped; 2, soaking ultrasonic flow spraying cleaning is carried out, and a multi-component composite water-based cleaning solution is adopted as a soaking cleaning solution; 3, pure water is used for carrying out reverse spraying rinsing; 4, solvent dehydration bubbling treatment is carried out, and dehydration solvent is ethyl alcohol with concentration being over 95% or other alcohol solutions easy to volatilize; and 5, hot wind baking is carried out.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Composite washing machine

ActiveCN109537235AImprove rinsing performanceEasy to washOther washing machinesWashing machine with receptaclesImpellerUltrasonic vibration

The invention discloses a composite washing machine which comprises a machine body, an impeller washing component and a barrel washing component, wherein the impeller washing component and the barrelwashing component are respectively mounted in the machine body; the impeller washing component comprises a first outer cylinder and a poreless inner cylinder which are coaxially arranged; a water drainage cavity is formed between the first outer cylinder and the poreless inner cylinder; the poreless inner cylinder comprises an inner cylinder body, a cylinder ring and an ultrasonic vibration source; the cylinder ring and the ultrasonic vibration source are respectively mounted inside the inner cylinder body; a water drainage channel is formed between the inner cylinder body and the cylinder ring; the poreless inner cylinder is communicated with the water drainage cavity through the water drainage channel; the barrel washing component is used for washing or drying clothes. The composite washing machine is of a whole dirt-free structure, good in washing effect, high in clothes washing cleanliness and small in vibration noise.

Owner:TCL HOME APPLIANCES (HEFEI) CO LTD

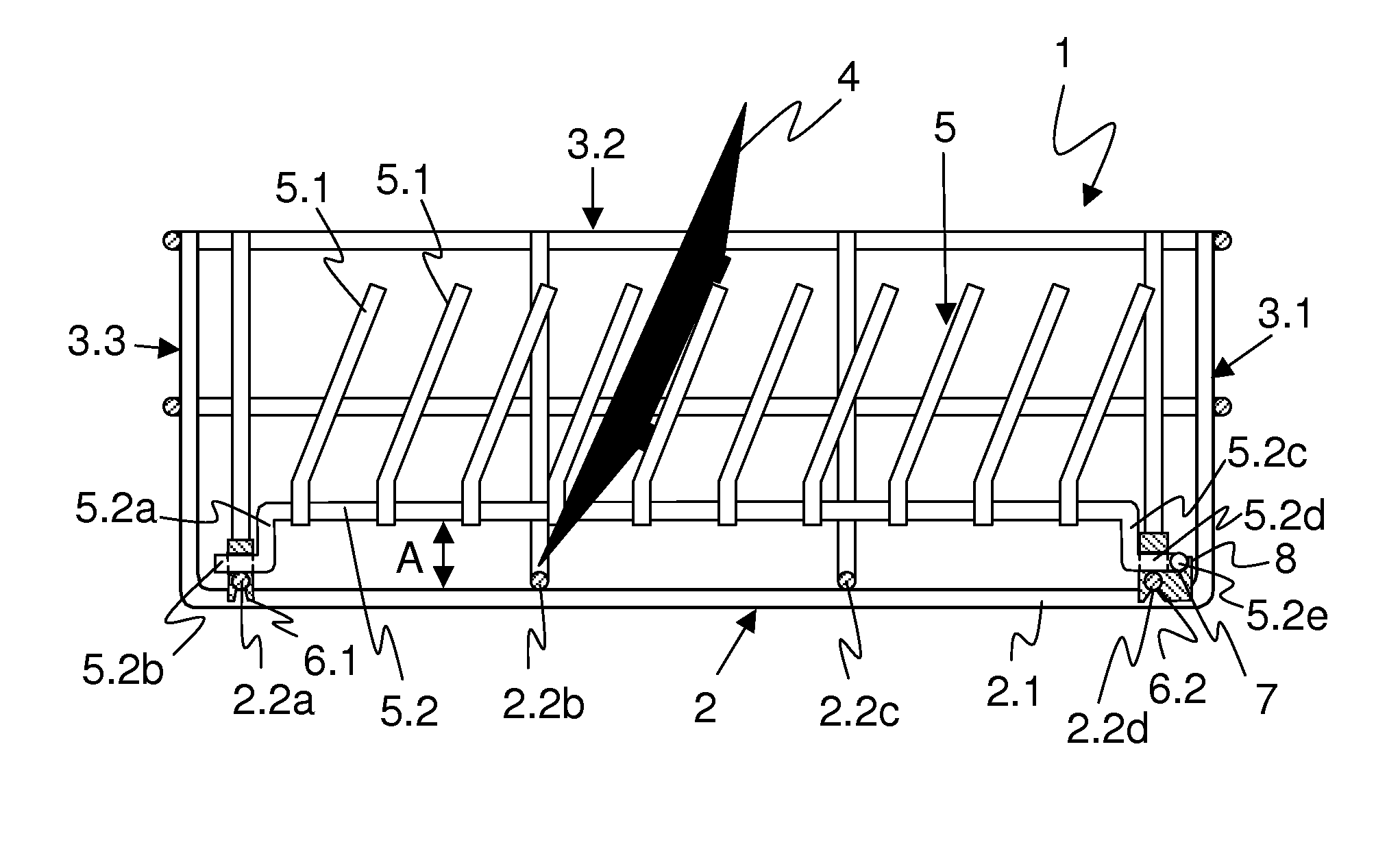

Crockery basket and dishwasher

ActiveUS8356719B2Avoid damageImprove rinsing performanceKitchen cabinetsPlatesEngineeringMechanical engineering

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

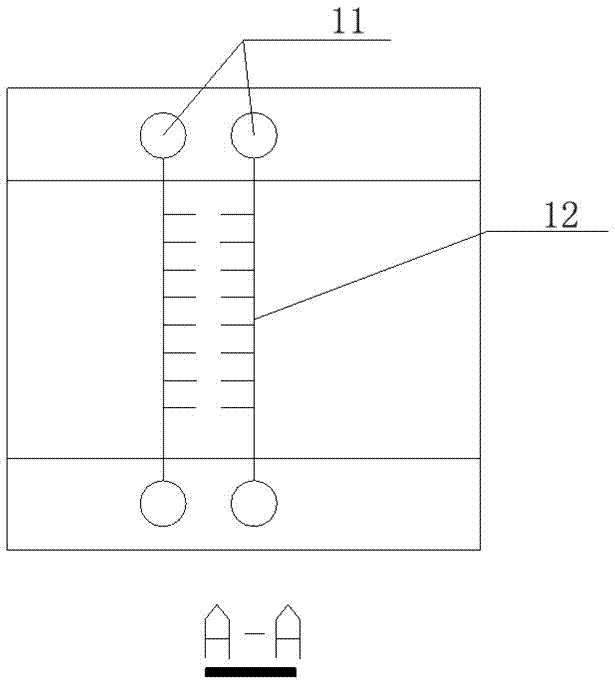

Spraying barrel cover of washing machine

InactiveCN102425063ASave spaceImprove cleanlinessOther washing machinesTextiles and paperAgricultural engineeringEngineering

The invention provides a spraying barrel cover of a washing machine. The purpose of effectively saving water can be achieved by the washing machine while the rinsing performance is ensured. Moreover, the washing machine has a simple structure and can be operated conveniently. The spraying barrel cover comprises a spraying barrel cover body, a spraying water chamber is arranged in the spraying barrel cover body, the spraying barrel cover also comprises an upper barrel cover and a lower barrel cover, the spraying water chamber is formed through surrounding by the upper barrel cover, water distribution ribs on the upper barrel cover and the lower barrel cover, the upper barrel cover is provided with a water inlet connected with a water feeding pipe, the lower barrel cover is provided with a main spraying port and an auxiliary spraying port, the diameter of the main spraying port is larger than the diameter of the auxiliary spraying port, and the water distribution ribs of the upper barrel cover are inserted into a clamping slot of the lower barrel cover.

Owner:WUXI FORMEN TECHN

Rolling drum washing machine

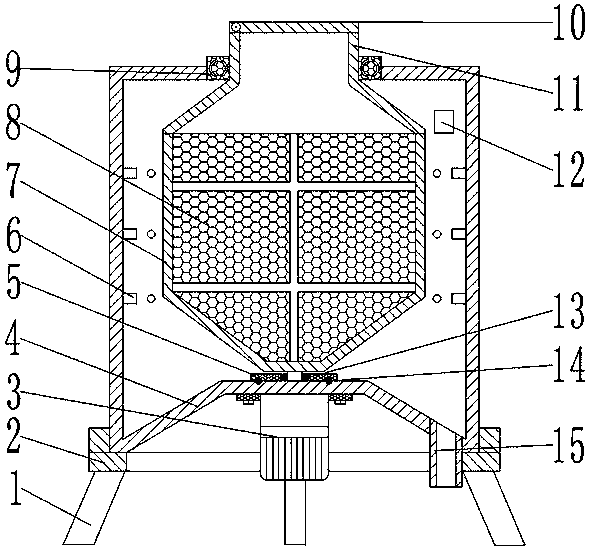

InactiveCN1749467AEliminate anxietyImprove satisfactionControl devices for washing apparatusWashing machine with receptaclesEngineeringWater level

The invention provides a drum type washing machine which enables the setting of an even higher water level or an even lower water level by the users' intentions. The washing machine has a rotary drum 1 having the horizontal or diagonal center shaft of rotation, a water receiving tub 3 which is supported elastically in the body 9 of the washing machine and rotatably holds the rotary drum 1 therein, a feed water valve 14 for feeding water into the water receiving tub, a cloth quantity sensing means 30 for detecting the amount of washing within the rotary drum, a water level display part 22e which displays the water level set corresponding to the amount of washing sensed by the cloth quantity sensing means and a water alteration input setting switch 21j capable of altering the water level set. The water level alteration input setting switch is so arranged as to enable the setting of an even higher water level and moreover, an even lower water level as compared with the range of the water level set corresponding to the amount of washing detected by the cloth quantity sensing means, thereby relieving the anxiety about the washing performance felt by the users.

Owner:PANASONIC CORP

Efficient rinsing device for chemical production

PendingCN107685038AImprove rinsing performanceEasy to understandCleaning using liquidsArchitectural engineeringHigh pressure water

The invention discloses an efficient rinsing device for chemical production. The efficient rinsing device for chemical production comprises a metal outer cylinder, the outer wall of the bottom end ofthe metal outer cylinder is provided with a halfpace-shaped sunken part, and a metal seat is fixed to the outer wall of the bottom end of the metal outer cylinder through bolts. Four equidistantly-distributed supporting legs are welded to the bottom end of the metal seat. A motor is fixed to the middle of the outer wall of the bottom end of the metal outer cylinder through bolts, a mounting hole is formed in the middle of the outer wall of the bottom end of the metal outer cylinder, and an output shaft of the motor is inserted in the mounting hole. A metal inner cylinder is fixed to the outputshaft of the motor through bolts, and a metal screen plate is arranged on the side wall of the metal inner cylinder and made of a hollowed-out stainless steel plate. Equidistantly-distributed high-pressure water spraying nozzles are fixed to the inner wall of the metal outer cylinder through bolts, and a bearing hole is formed in the outer wall of the top end of the metal outer cylinder. Chemicalmaterials can be rotated and stirred in the efficient rinsing device, the rinsing effect is improved, meanwhile, the materials can be dehydrated, the operation flow is simplified, and the rinsing efficiency is improved.

Owner:新乡市巨能合成材料有限公司

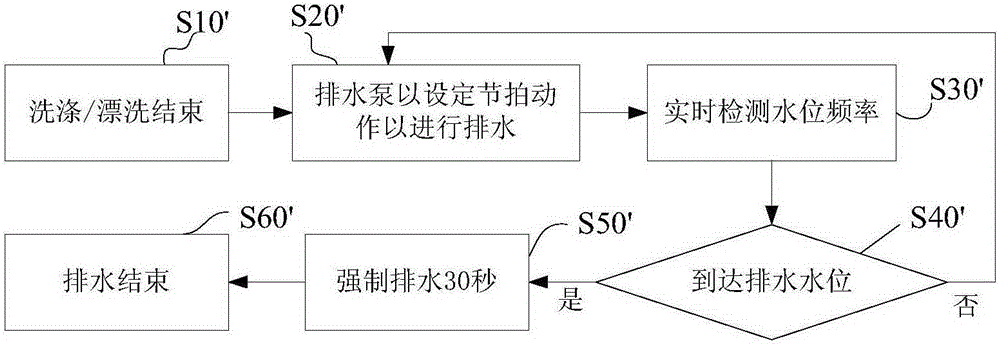

Drainage control method of washing machine

ActiveCN106319838AEfficient removalEffectively removes laundry residueControl devices for washing apparatusTextiles and paperPulp and paper industryControlled drainage

The invention discloses a drainage control method of a washing machine. The drainage control method includes the following steps: controlling a drainage pump of the washing machine to work at a first preset beat and controlling a motor of the washing machine to run at a second preset beat so as to drain water; detecting a water level of a washing barrel of the washing machine and recording the drainage time; and controlling drainage according to the water level of the washing barrel and the drainage time. The drainage control method of the washing machine can optimize the drainage time, and improve the effect of residue removing.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Cell preserving fluid and preparation method and use thereof

The invention belongs to the field of cell biology, relating to a cell preserving fluid and a preparation method and use thereof. Concretely, the cell preserving fluid comprises a fixing agent, a fixing agent assistant, an anticoagulant, a cushion fluid and an ionic strength maintenance agent. The cell preserving fluid is characterized in that the content of the anticoagulant is 0.01% to 1.5%(w / w); the content of the ionic strength maintenance agent is 0.01% to 1%(w / w); and the cell preserving fluid does not contain a disulfide bond open reagent. The cell preserving fluid can effectively preserve cell DNA (deoxyribonucleic acid) and virus DNA infecting the cell, is convenient to collect the cast-off cells and extract DNA and can give attention to storage of the cell structure. The invention also relates to the preparation method and the use of the cell preserving fluid. The invention also relates to a kit and a method for detecting HPV (Human Papilloma Virus) or HPV DNA.

Owner:BGI GENOMICS CO LTD

Powdered activated carbon rinsing method and equipment thereof

PendingCN107500293AReduce thicknessImprove rinsing performanceCarbon compoundsActivated carbonFilter press

The invention discloses a powdered activated carbon rinsing method and equipment thereof. A plurality of layers of alternatively arranged annular carbon channels and filtrate channels are formed in rinsing equipment; the carbon channels are formed by superposing multiple inverted trapezoids and have the width of 0.3-0.4m and the depth of 1.5-2m; the filtrate channels are formed by superposing multiple inverted trapezoids and have the width of 0.1-0.15m; filtering pore plates and filtering nets are arranged between the two channels; a bottom surface and two vertical faces serving as filtering surfaces are arranged on each carbon channel; and the filtering area of a carbon-water mixture is large. The method comprises the following steps: rinsing to-be-rinsed powdered carbon in the multiple layers of annular carbon channels, stirring and rinsing the carbon-water mixture for proper time by using compressed air, filtering the carbon-water mixture through the filtering nets and the filtering pore plates between the carbon channels and the filtrate channels, adding water into the rinsing equipment to perform repeated rinsing and filtering operations until the impurity content of the carbon meets the requirements; and finally, conveying the last rinsed carbon-water mixture into a filter press to perform filter pressing by using a mud pump.

Owner:ZHEJIANG FORESTRY ACAD

High-strength and anti-wear sheet metal part and production process thereof

InactiveCN108034292AEmission reductionImprove rinsing performanceHot-dipping/immersion processesCyclohexanoneFiber

The invention discloses a high-strength and anti-wear sheet metal part. The high-strength and anti-wear sheet metal part comprises a sheet metal part body, wherein the outer surface of the sheet metalbody is coated with a high-strength and anti-wear layer; the high-strength and anti-wear layer is prepared by compounding a high-strength layer and an anti-wear layer according to a ratio of the high-strength layer to the anti-wear layer of 2: 3; the high-strength layer is prepared from 15 to 19 parts of methyl acetate, 8 to 11 parts of trichloro ethylene, 9 to 16 parts of styrene, 12 to 19 partsof 2-butanone cyclohexanone, 14 to 20 parts of silicone modified epoxy resin, 13 to 17 parts of ATO powder, 7 to 9 parts of E-20 epoxy resin, 11 to 15 parts of alcohol soluble acrylate resin, 20 to 22 parts of carbon fiber powder and 12 to 17 parts of a film forming adjuvant; the anti-wear resistance is prepared from 14 to 19 parts of butadiene styrene rubber, 3 to 8 parts of methylbenzene, 9 to11 parts of water glass, 10 to 13 parts of sodium tetraborate, 22 to 28 parts of mixed phosphate, 18 to 22 parts of cyclohexanone, 11 to 18 parts of aromatic polyamide staple fiber, 19 to 23 parts ofa plasticizer, 32 to 39 parts of an auxiliary material, 13 to 19 parts of a solidifying agent and 29 to 32 parts of a defoaming agent.

Owner:博维恩冷冻科技(苏州)有限公司

Washing method implemented by washing machine

InactiveCN103696203AHigh activityImprove washing effectOther washing machinesControl devices for washing apparatusProcess engineeringEngineering

The invention discloses a washing method implemented by a washing machine. The washing method has the advantages that rinsing and washing are completed in a combined manner by a washing and pre-rinsing combining step, so that national standards on rinsing and washing parameters can be met, and energy consumption can be reduced.

Owner:NANJING LG PANDA APPLIANCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com