Single-drum front loading washing machine

A drum washing machine and single-tub technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of inability to wash at high water level, inability to seal the drum clothes opening, easy to lose water, etc., to reduce the failure rate and save money. Water and detergent, the effect of improving the rinsing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

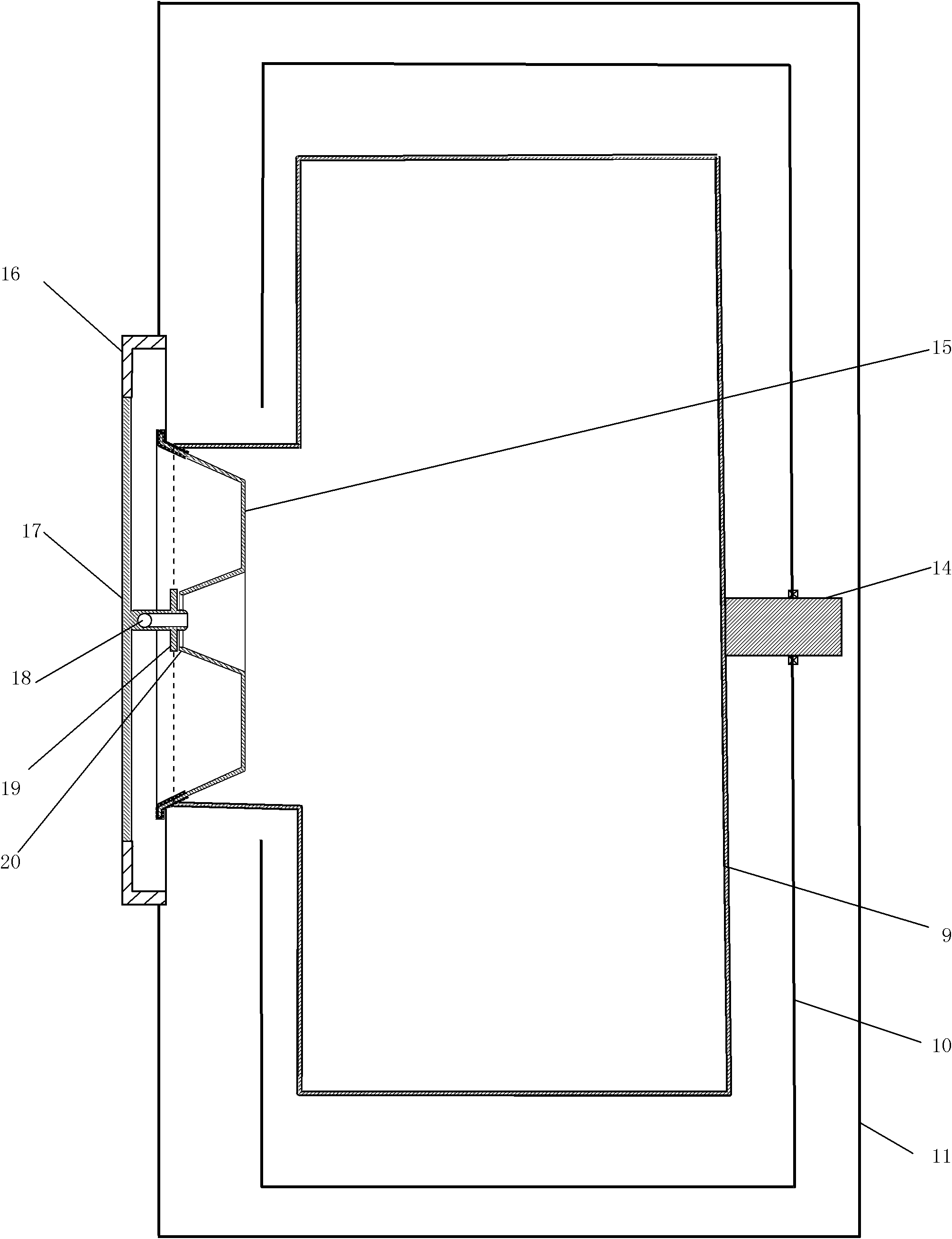

[0014] figure 1 figure 2 In the shown embodiment, the door frame 1 is the shape similar to the car tire of an inner side opening, and it is installed on the edge of the opening of the shell 11 by a hinge, and the opposite side of the door frame 1 hinge is provided with a locking device and a handle. The two ends of three damping springs 3 are symmetrically fixed on the front and rear edges of the inside of the door frame 1, and the tops of three spokes of the bracket 4 are respectively fixed on the middle parts of the three damping springs 3 to form a damping device, and the center of the bracket 4 faces the drum 9. The direction generating shaft 13 is provided with a through water inlet pipe 8 inside the shaft 13 , and the bellows passing through the side wall of the door frame 1 is connected to the water inlet pipe 8 . The center of the porthole 2 generates a cylinder 12 towards the outside of the washing machine. The shaft 13 is sleeved in the cylinder 12 through two bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com