Portable automatic milk powder dissolving apparatus and method for applying same

An automatic flushing and portable technology, applied in the field of food equipment, can solve problems such as inability to use, and achieve the effects of simplified mechanism, small size and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

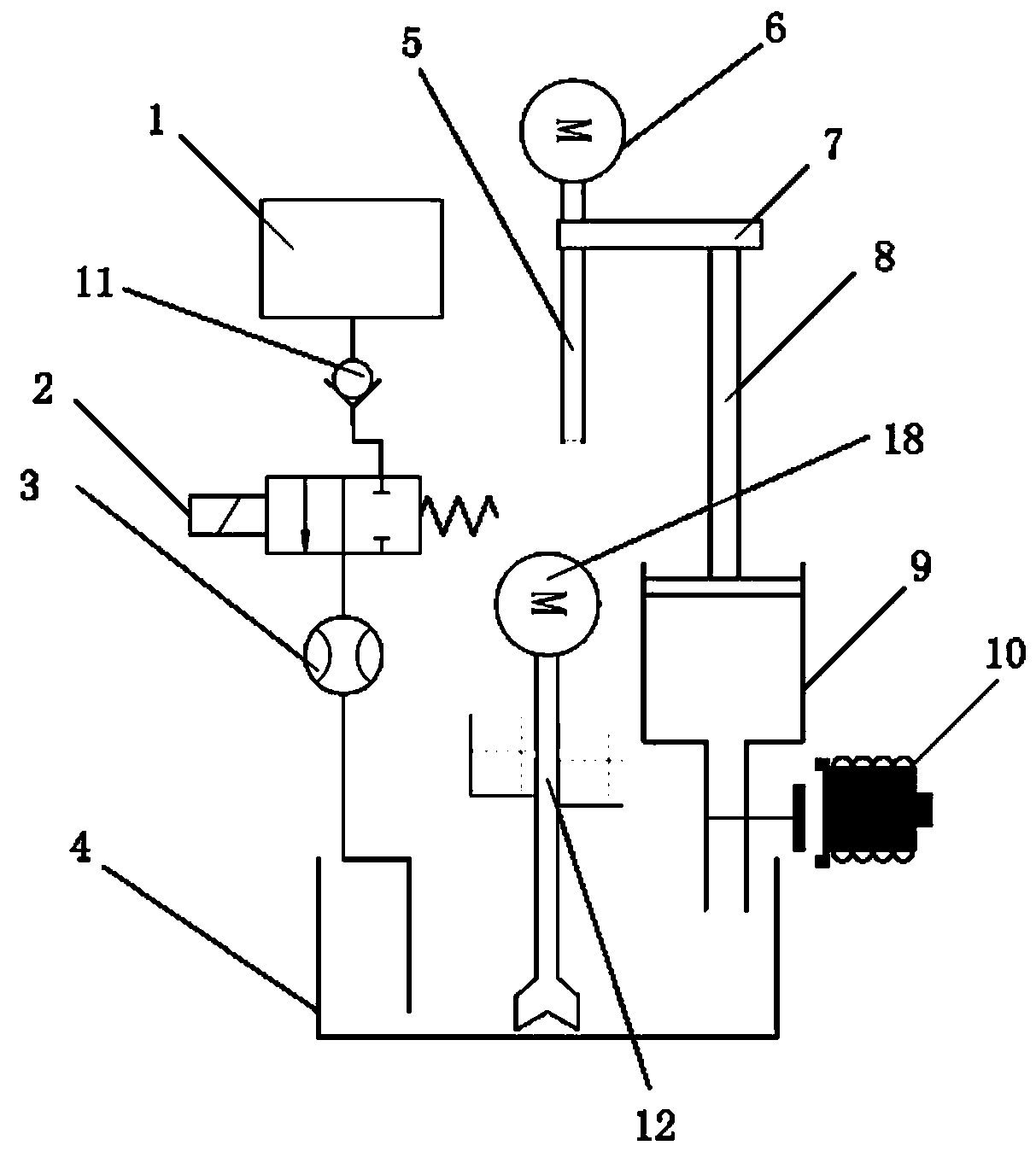

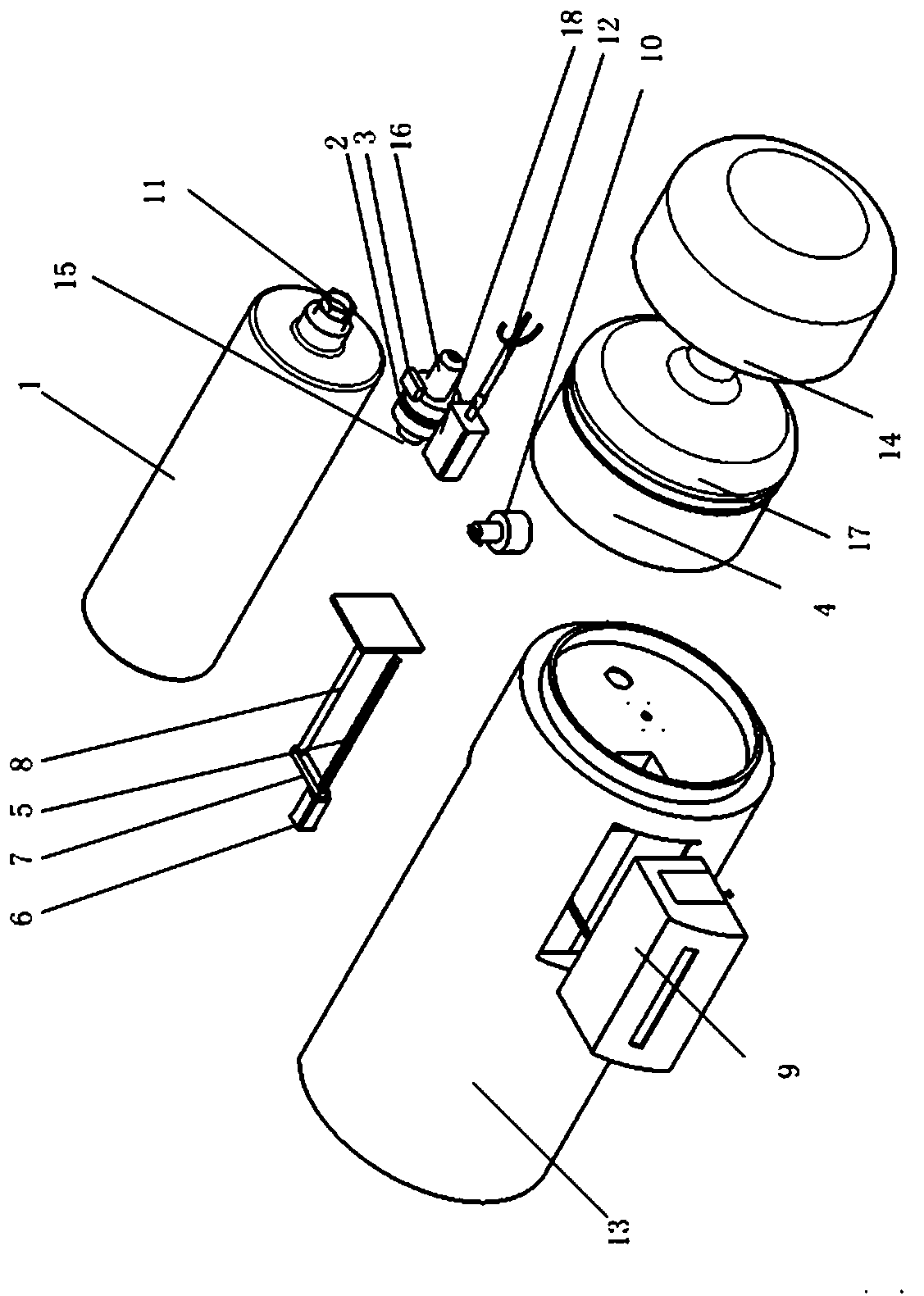

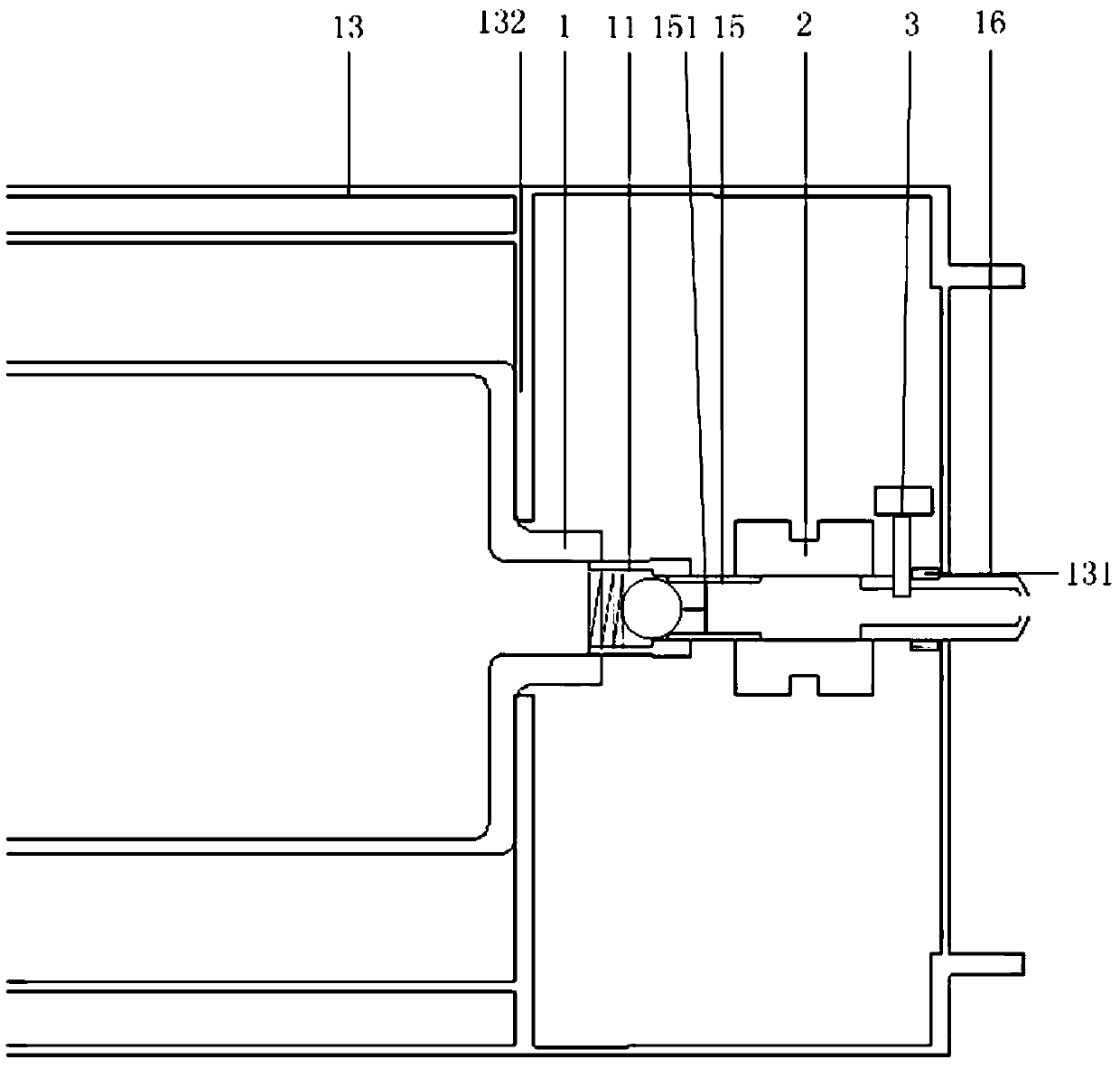

[0035] Such as Figure 1-10 As shown, the portable milk powder automatic brewer includes a control module, a housing 13, a water supply mechanism, a powder supply mechanism, a stirring mechanism and a brewing container; the brewing container is connected to the housing with a detachable structure ; When the brewing container is fixed on the housing, the output ends of the water supply mechanism and the powder supply mechanism are located at the input port of the brewing container, and the stirring rod 12 of the stirring mechanism is inserted into the brewing container; The mechanism includes a milk powder box 9 and a powder pushing device, the powder outlet of the milk powder box is located at the output of the powder supply mechanism, and a milk powder pushing plate 8 is arranged in the powder pushing device; the powder pushing device is provided with a pressure sensor to measure the pressure on the pushing plate, A displacement sensor is also provided to measure the travel d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com