Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2383 results about "Rear quarter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

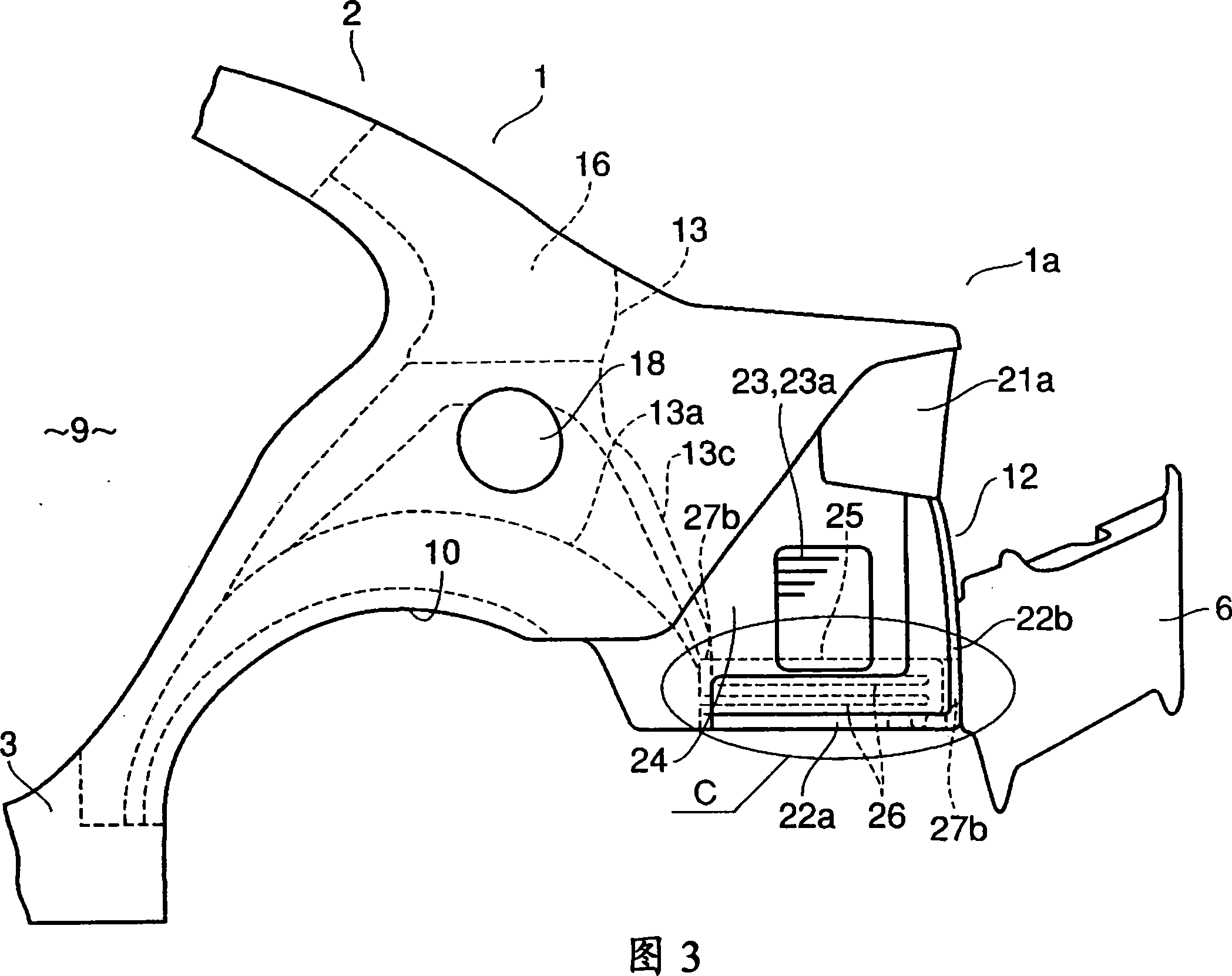

A quarter panel (British English: rear wing) is the body panel (exterior surface) of an automobile between a rear door (or only door on each side for two-door models) and the trunk (boot) and typically wraps around the wheel well.

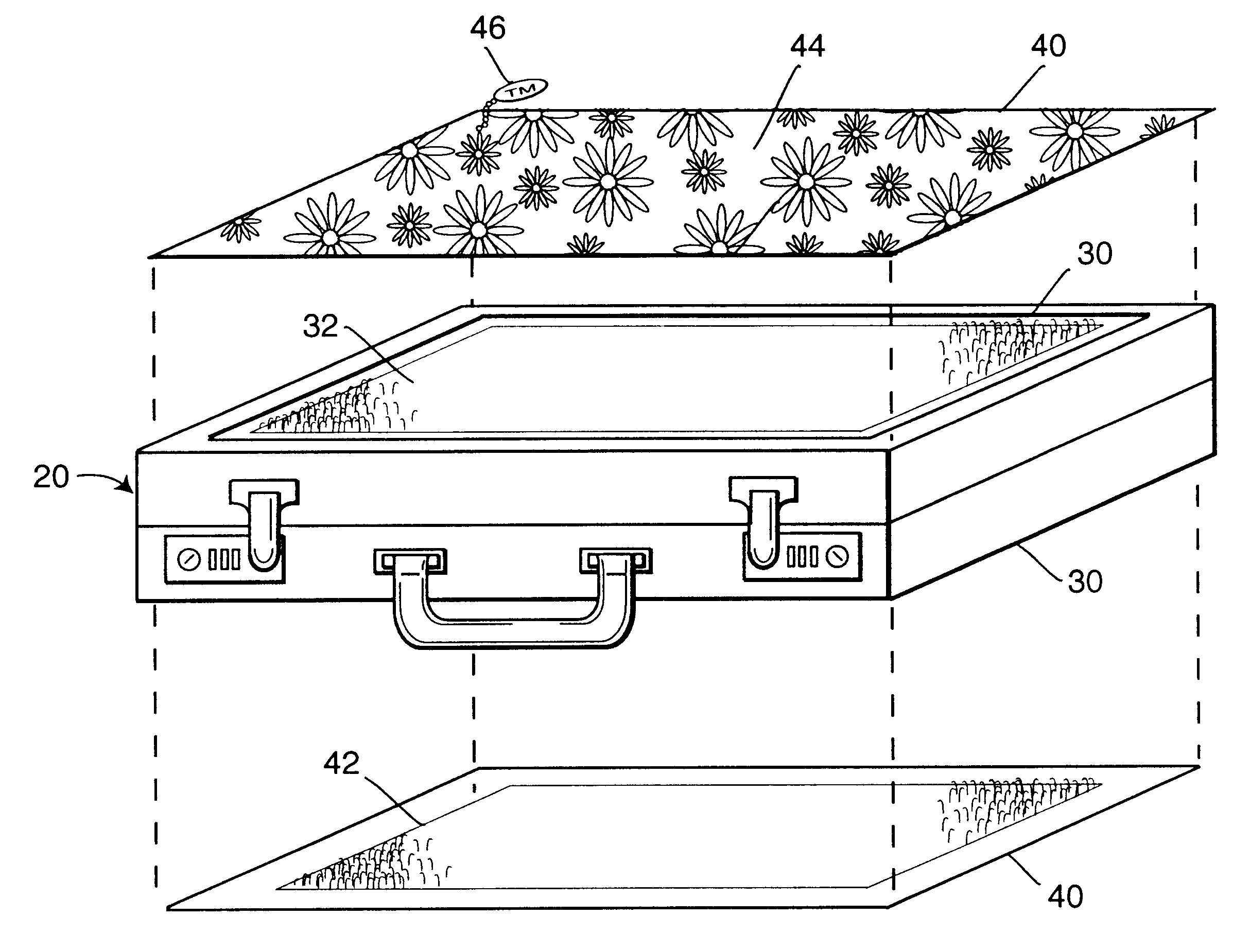

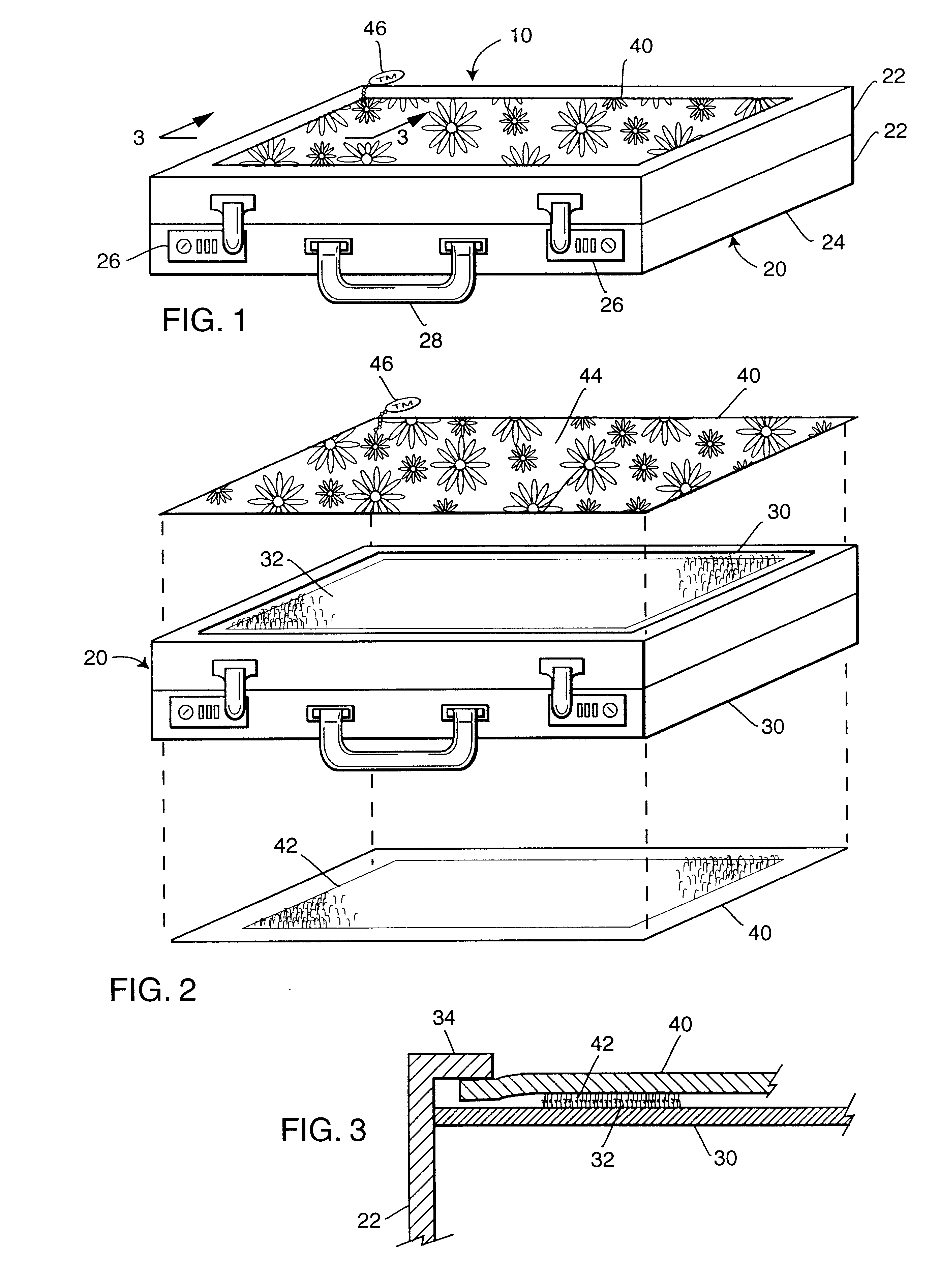

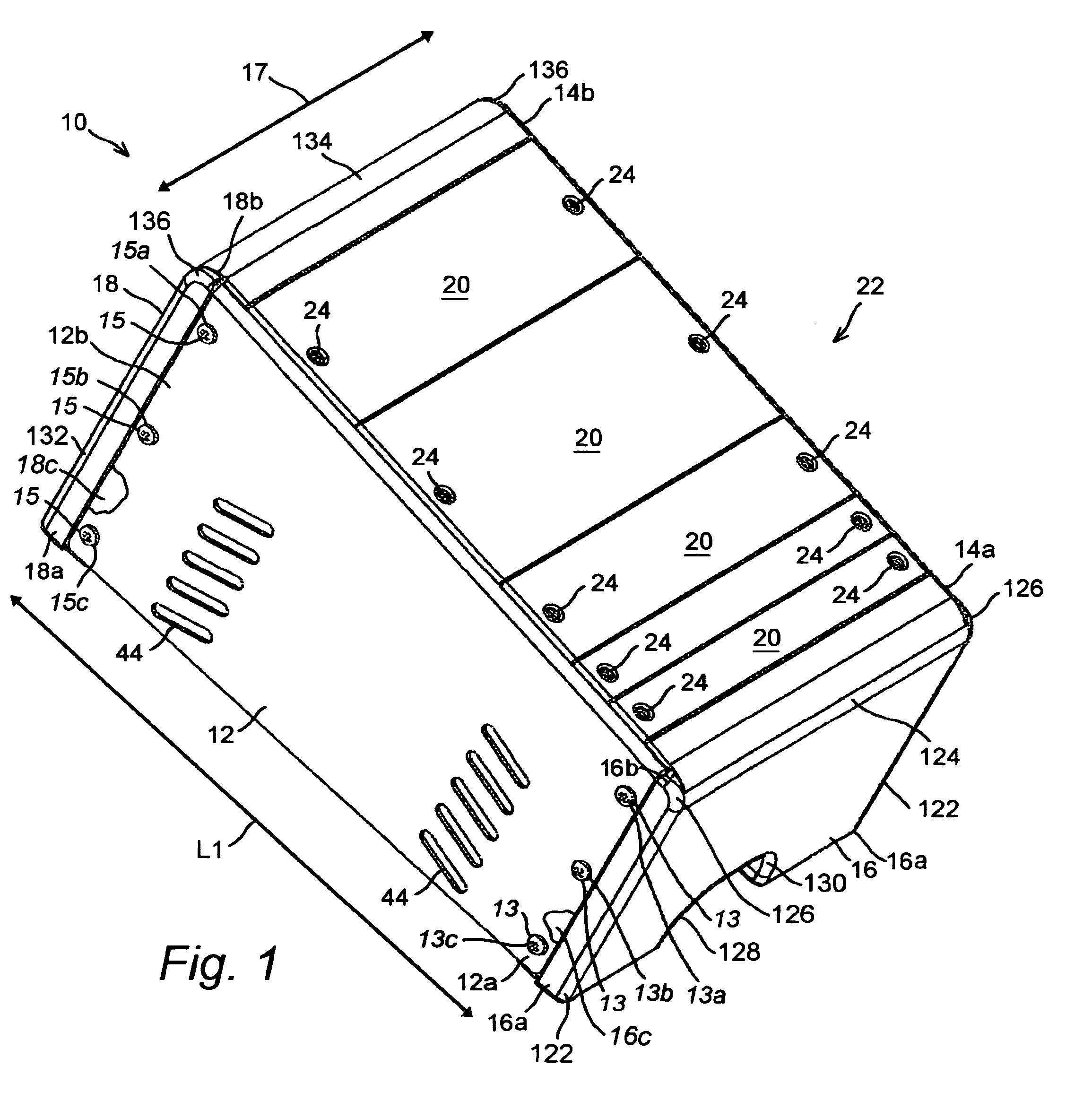

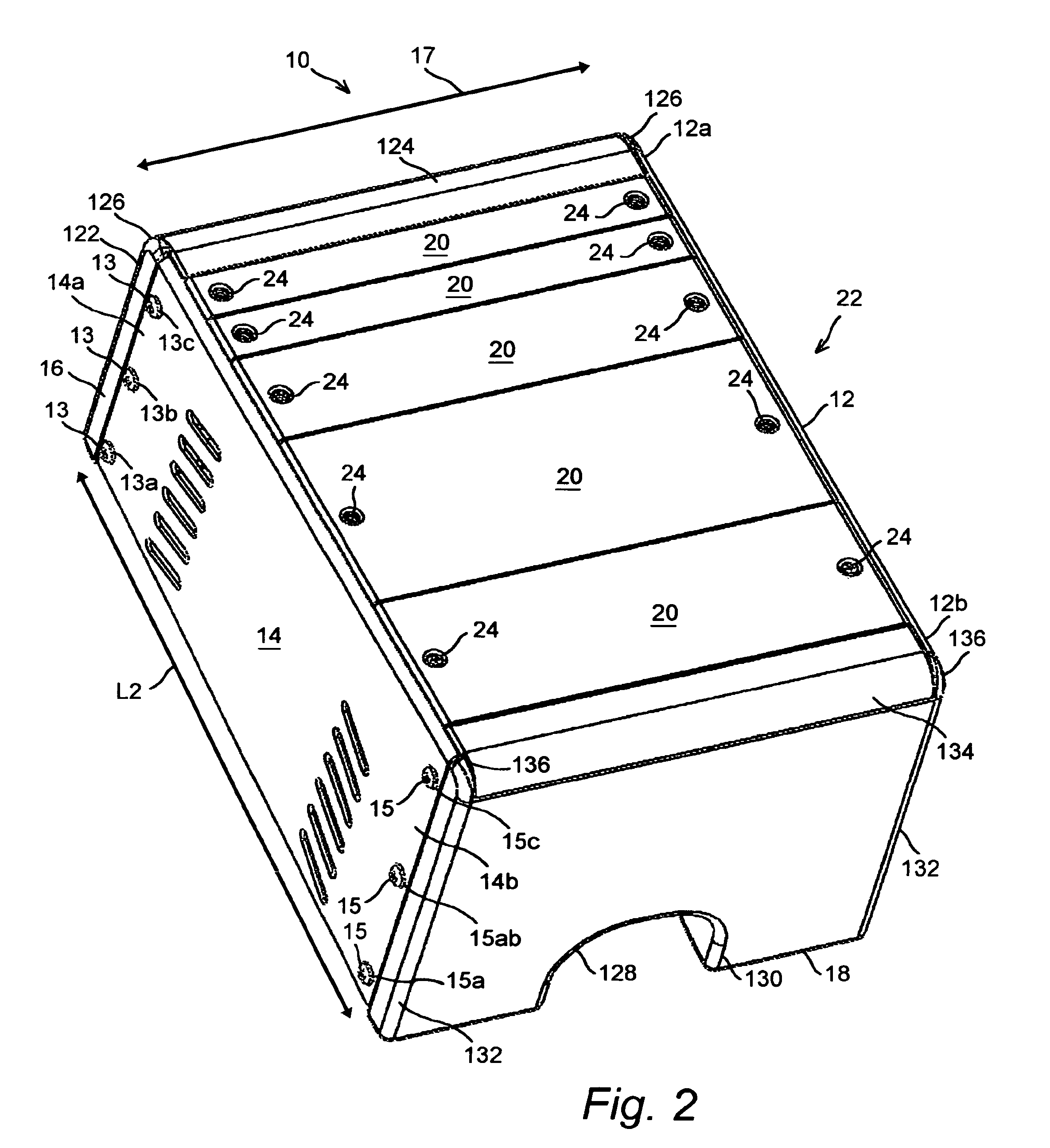

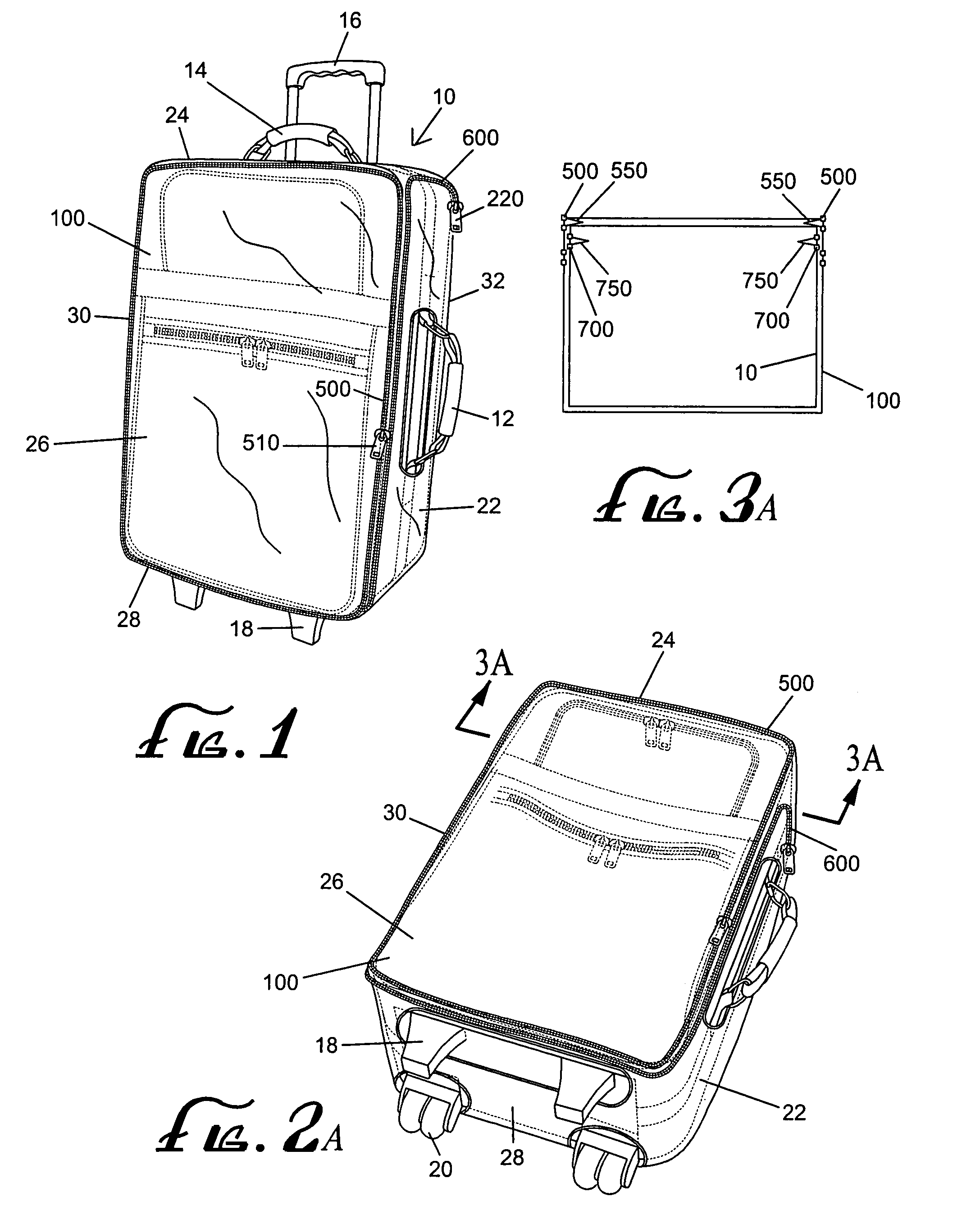

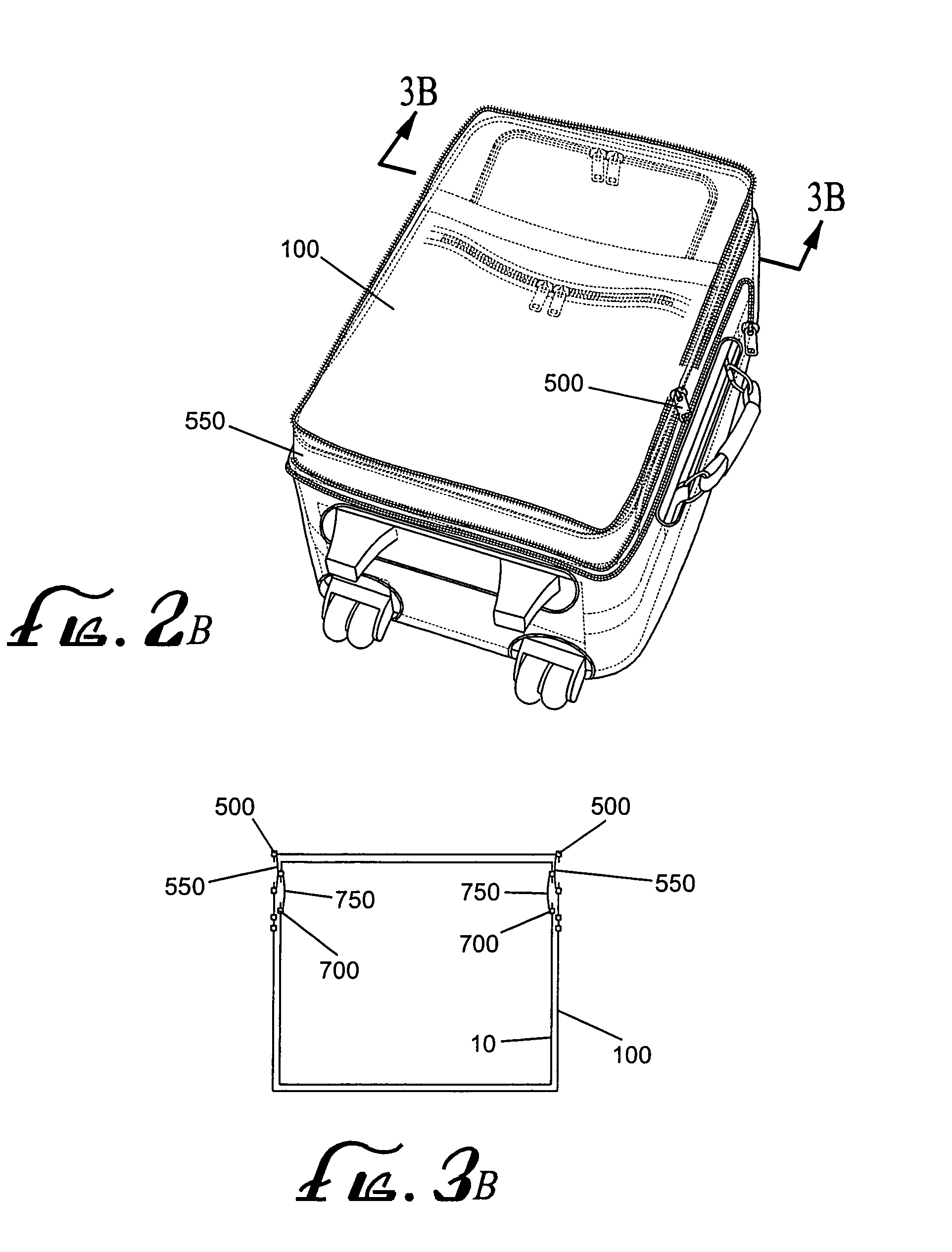

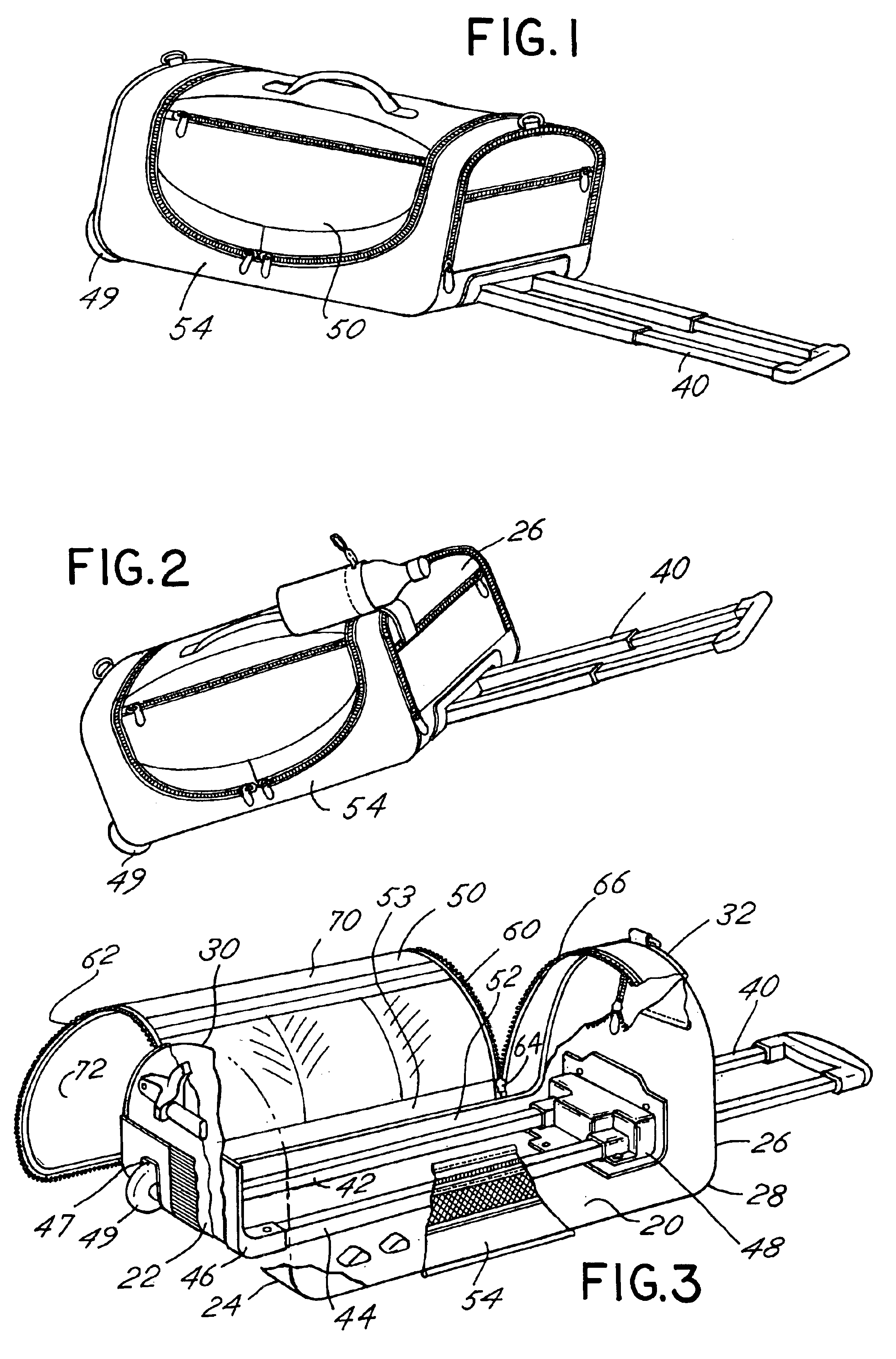

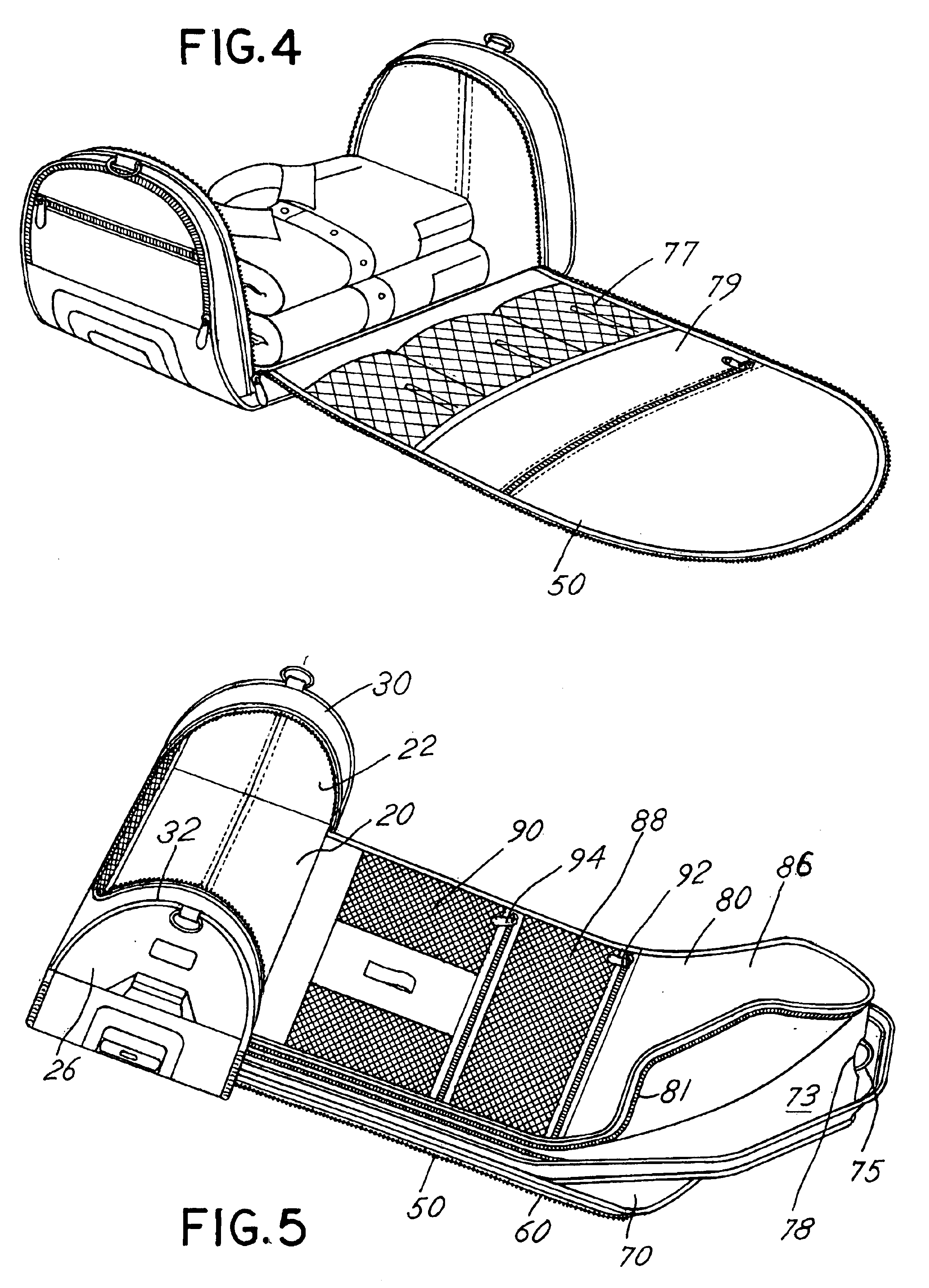

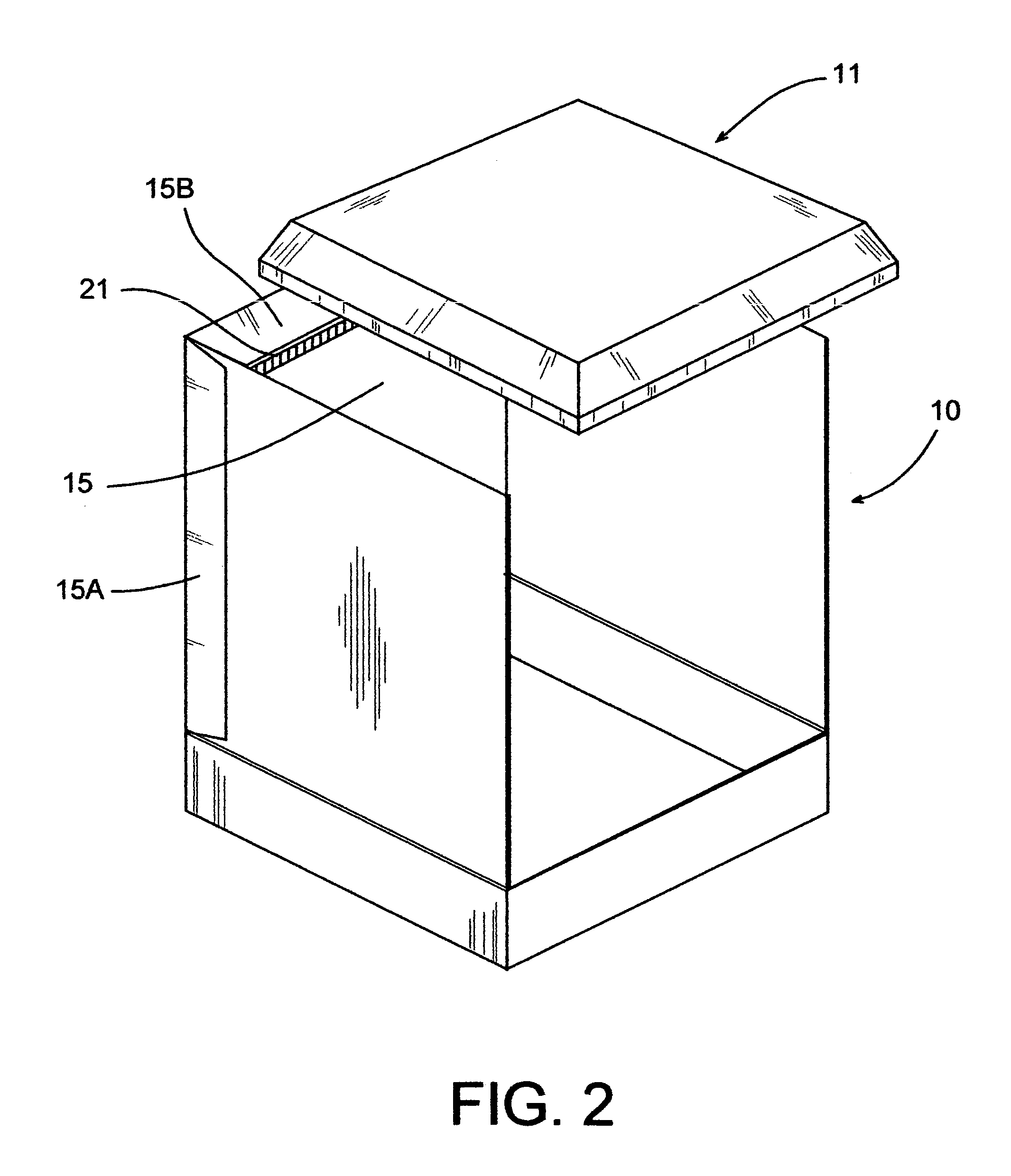

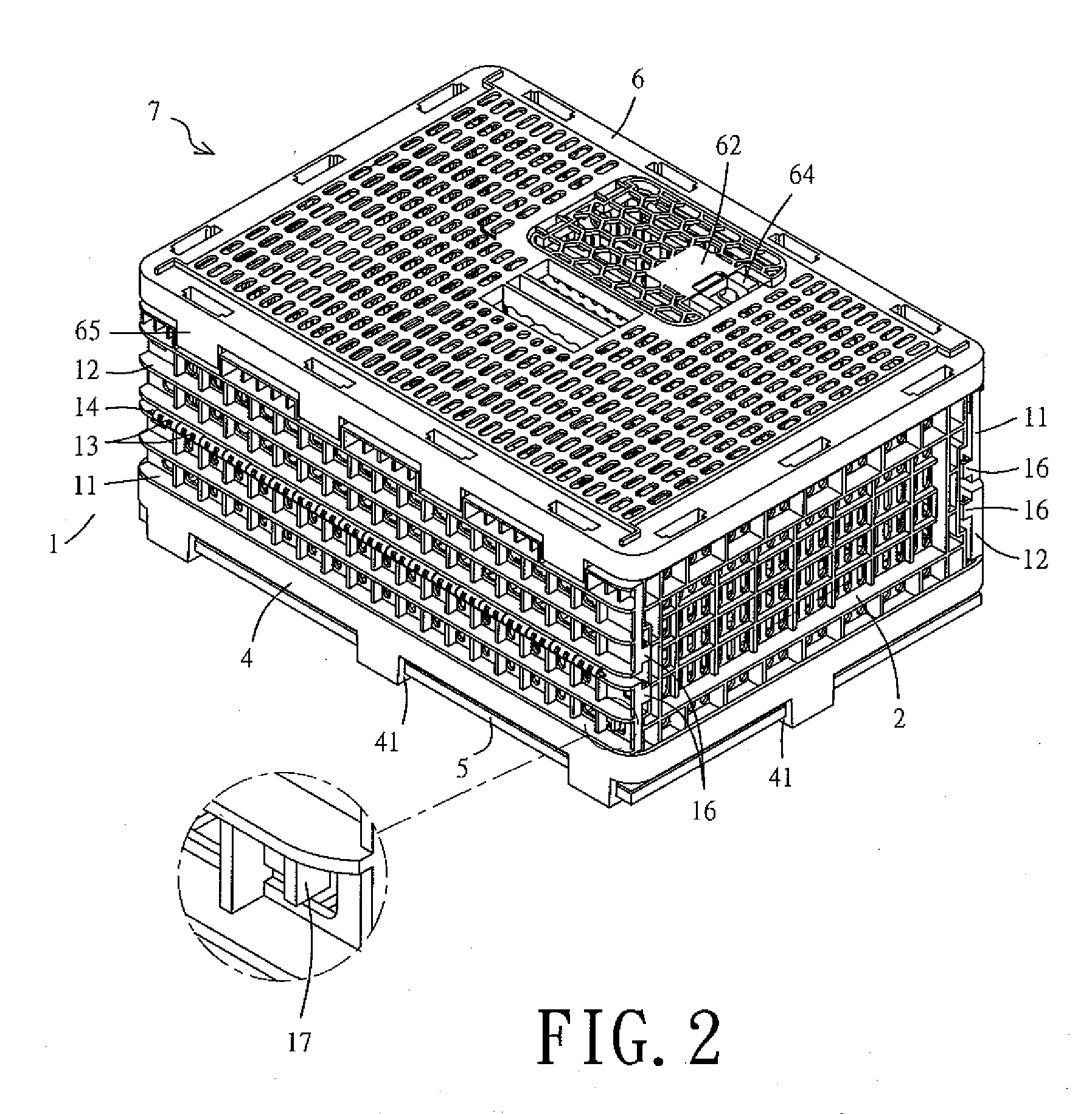

Carrying case with interchangeable side panels

Owner:MARCONI ELIZABETH

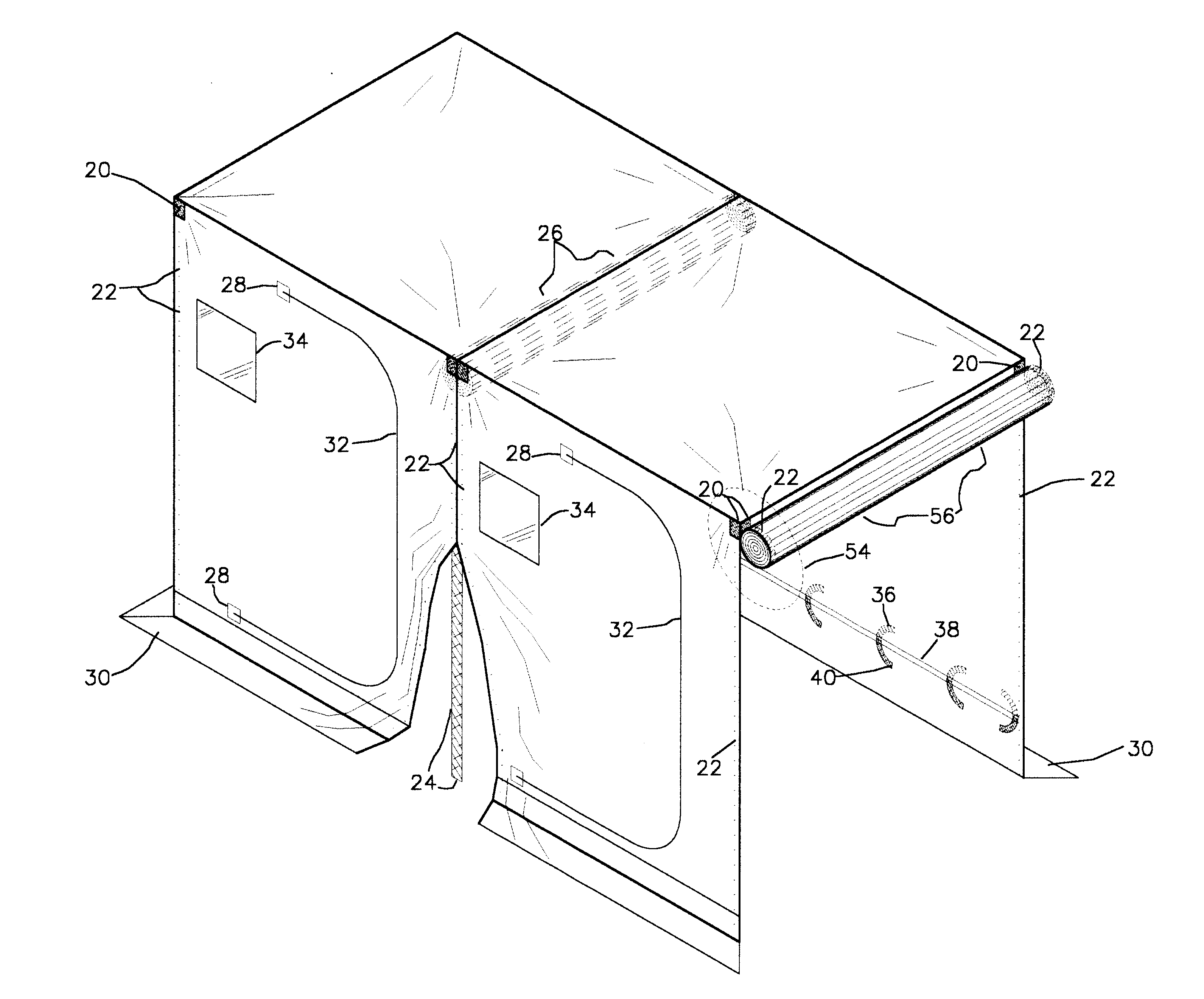

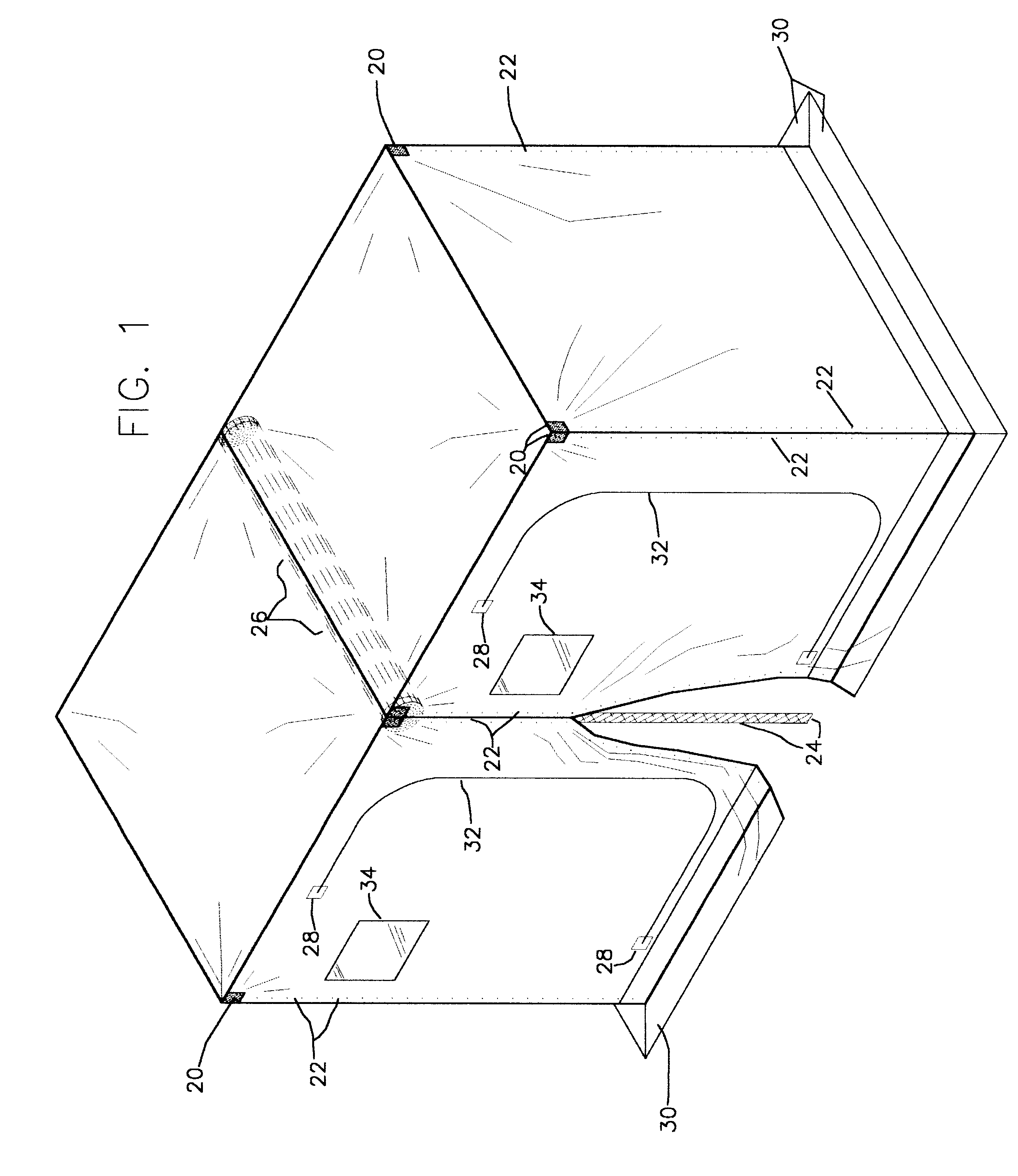

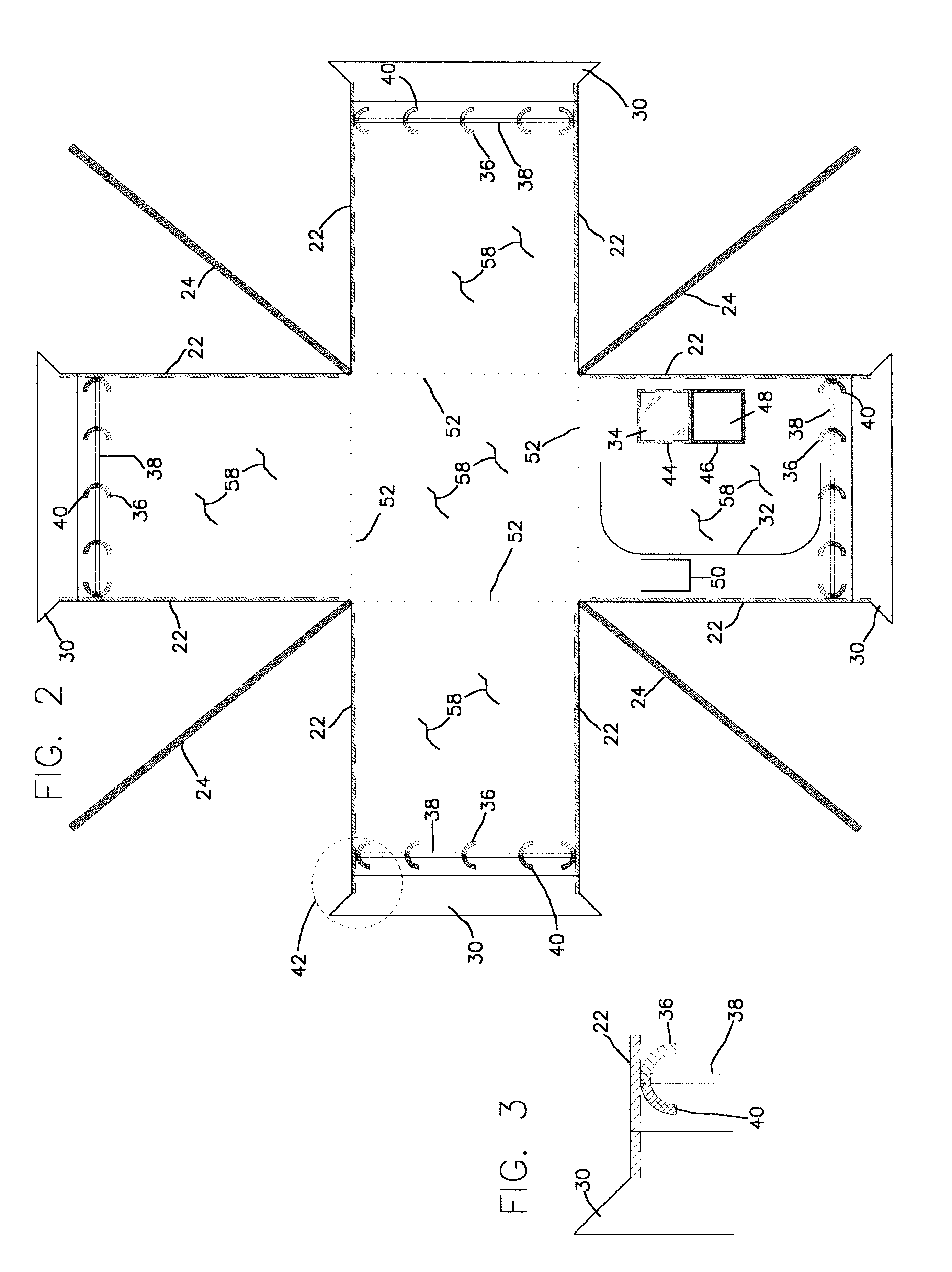

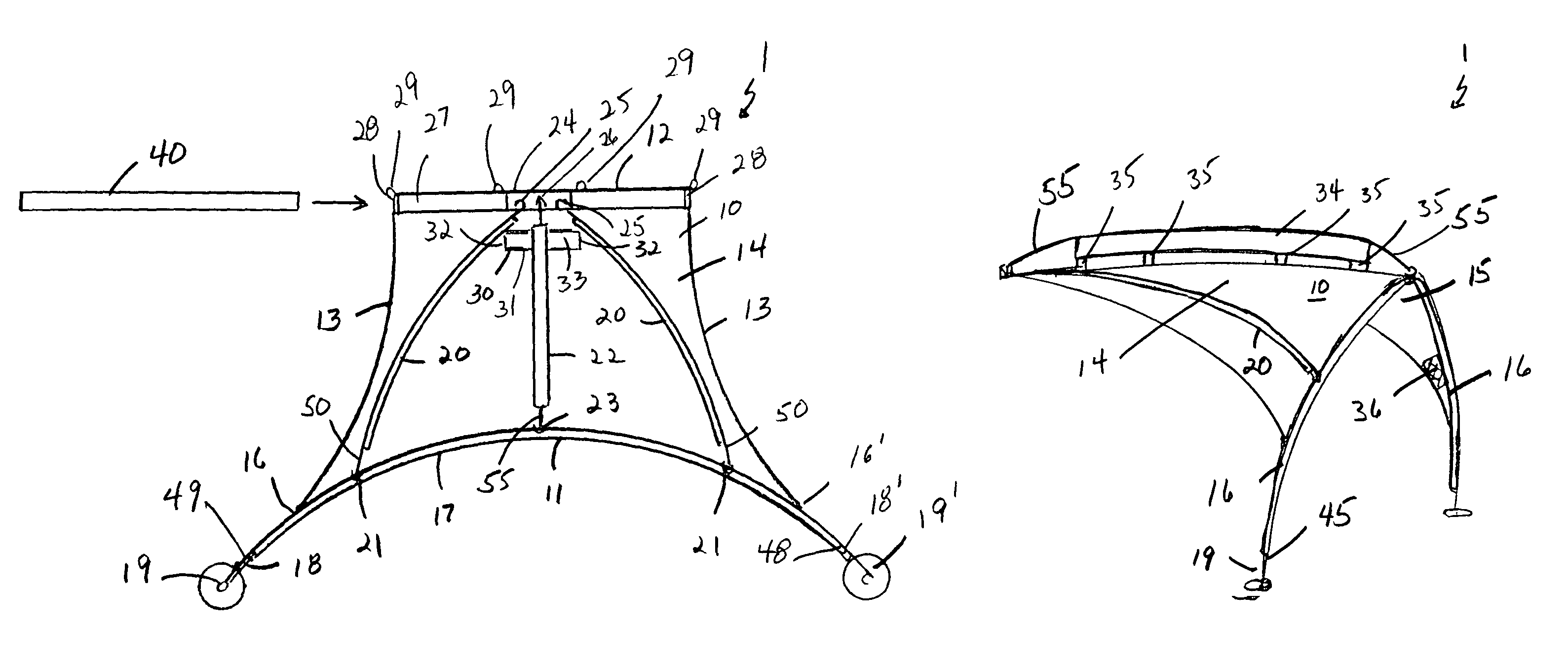

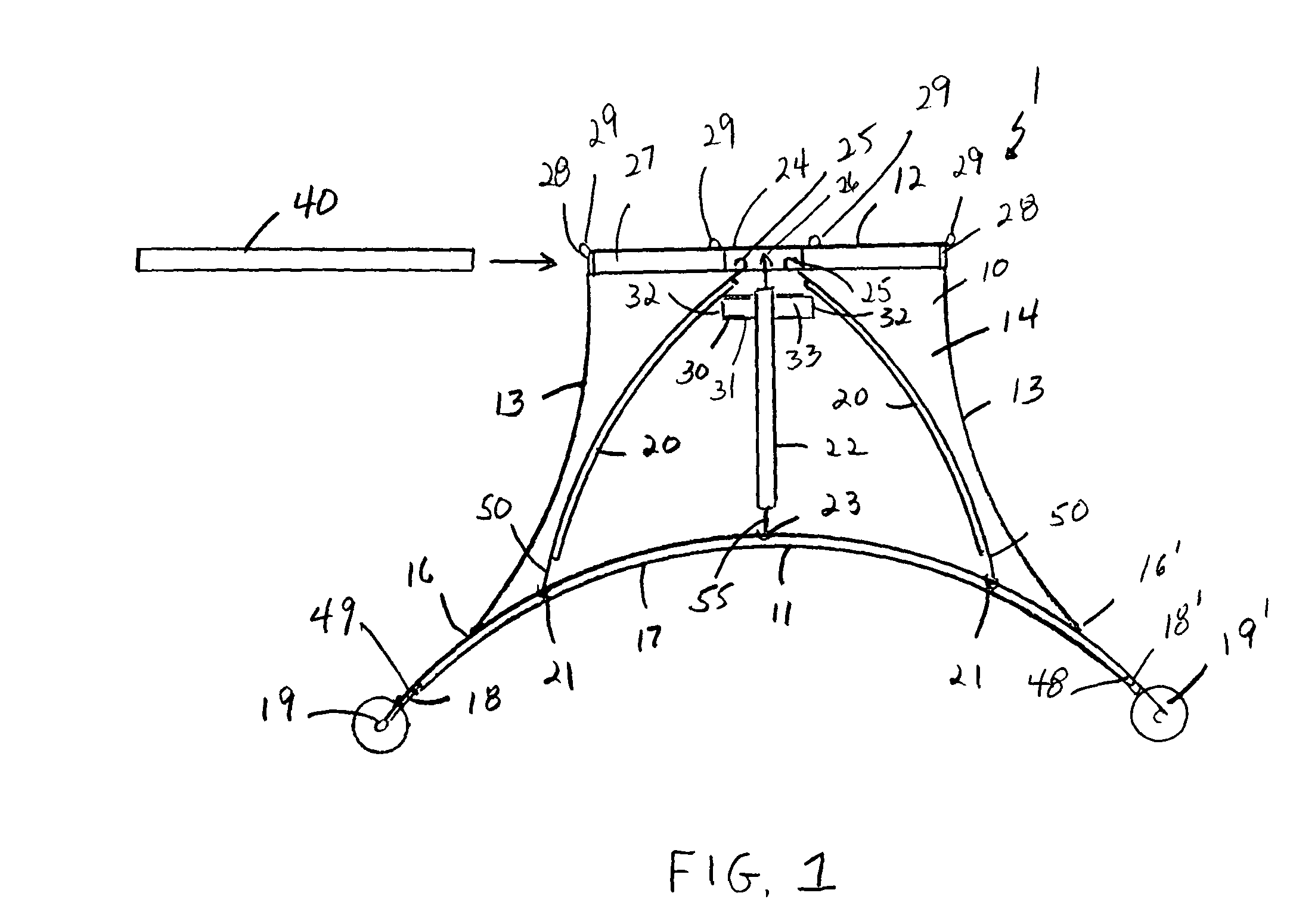

Portable shelter's modular shell including displaceable/connectable walls

An outdoor modular shelter shell with simplified connection system comprises a flexible covering having a central portion which overlays a supporting frame. Four displaceable / connectable side panels extend from the central portion to form an enclosure. A tail fastener / wall fastener connection system allows the user to completely displace walls and connect a plurality of shells to form a one room weather proof outdoor shelter with no restrictions between connected shells. Various individual wall panels may be added to transform the shelter from a fishing shelter to a hunting blind. The simplified connection system is very easy to use even with a gloved hand under low light conditions and provides a strong, weather tight, aesthetically pleasing, economical joint between the walls of an individual shelter or a plurality of connected shelters.

Owner:JOPP BRIAN DAVID +1

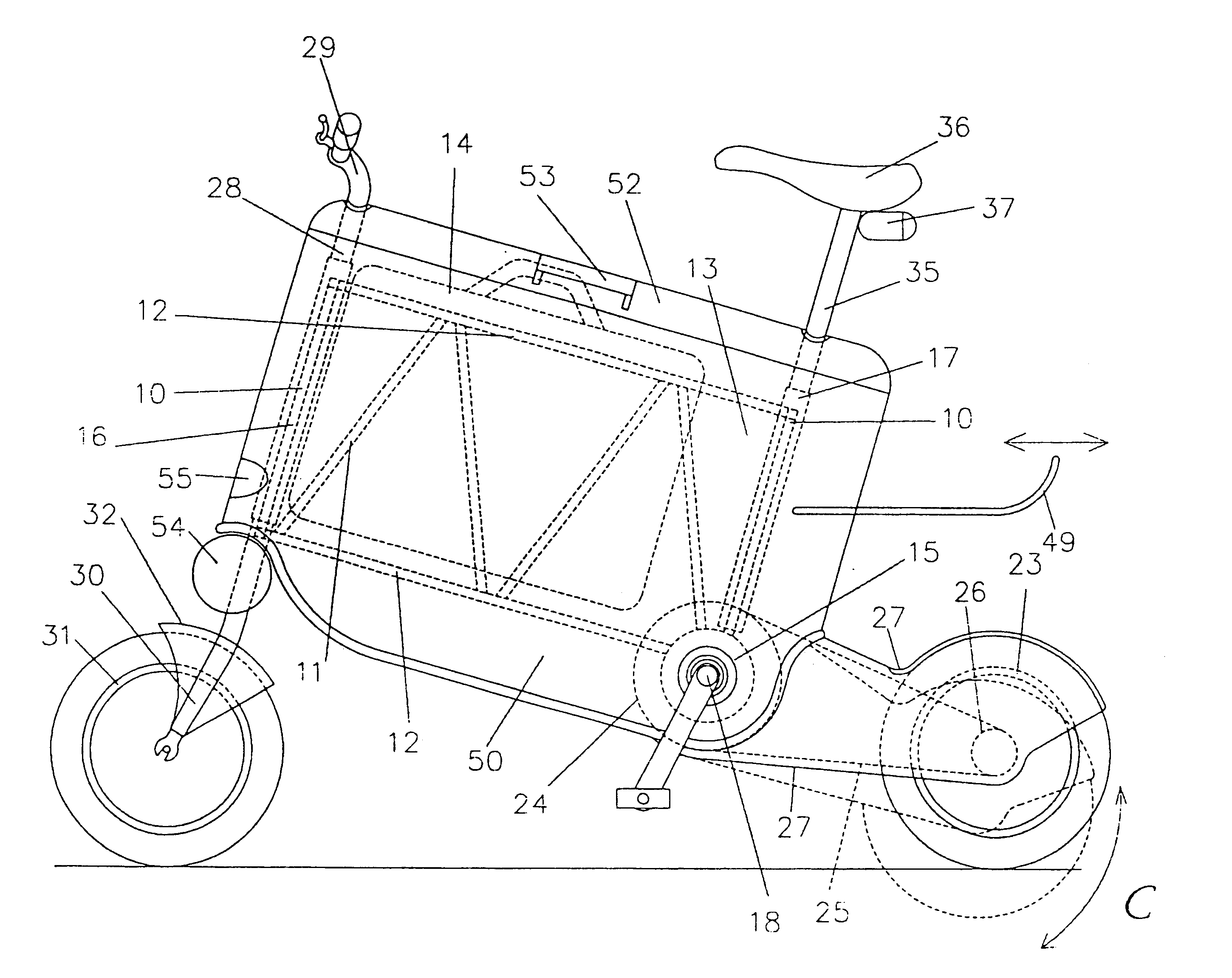

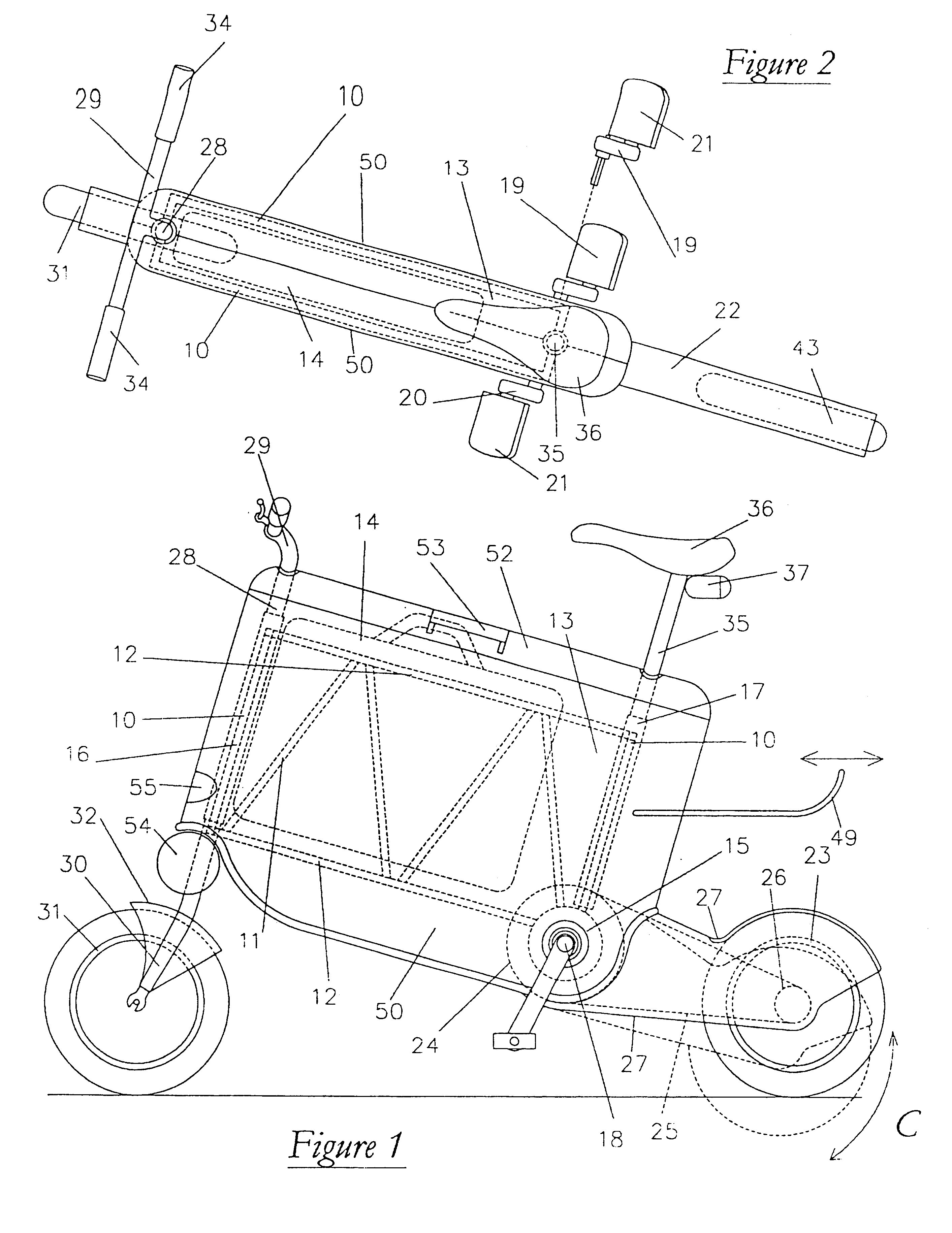

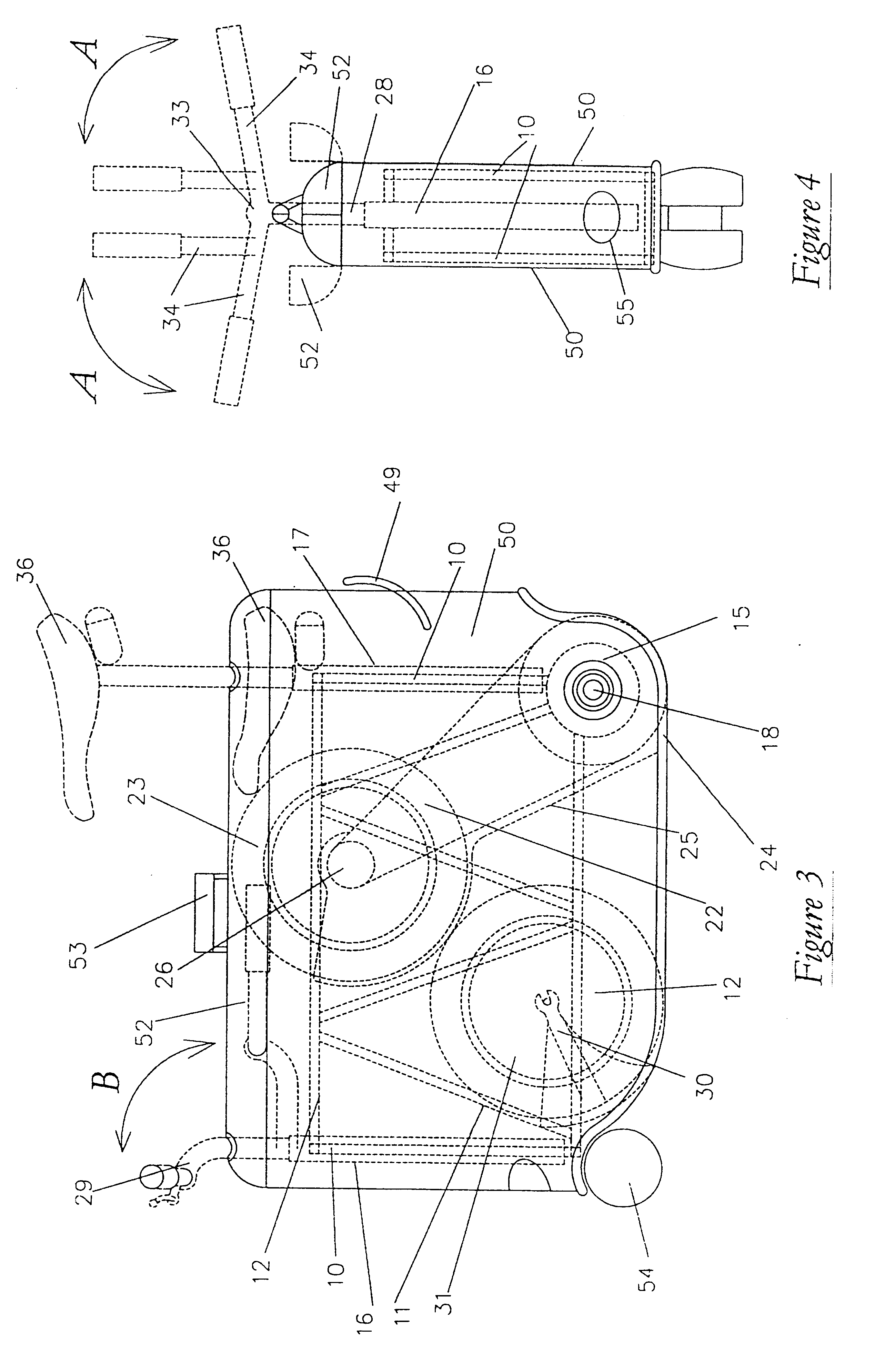

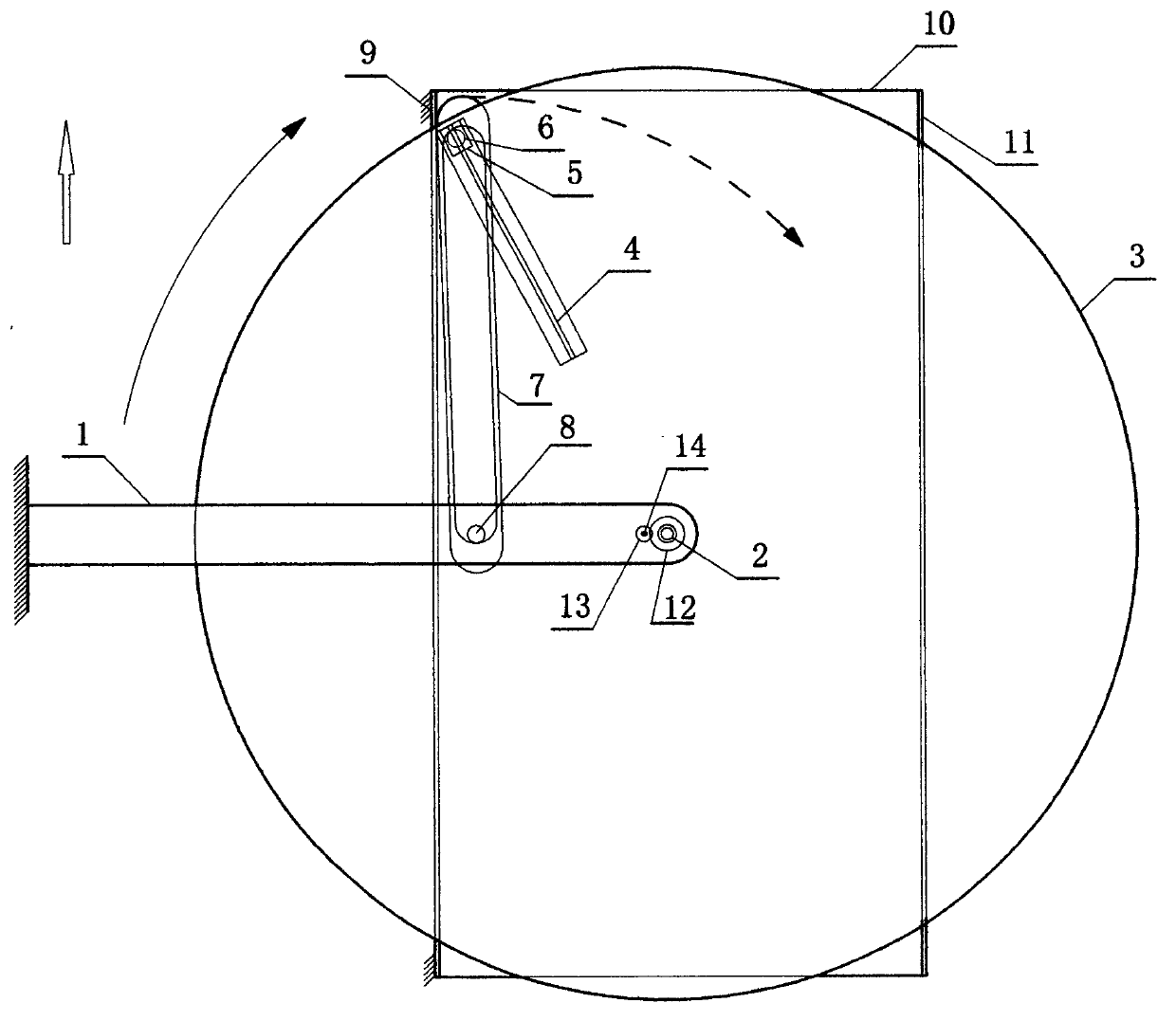

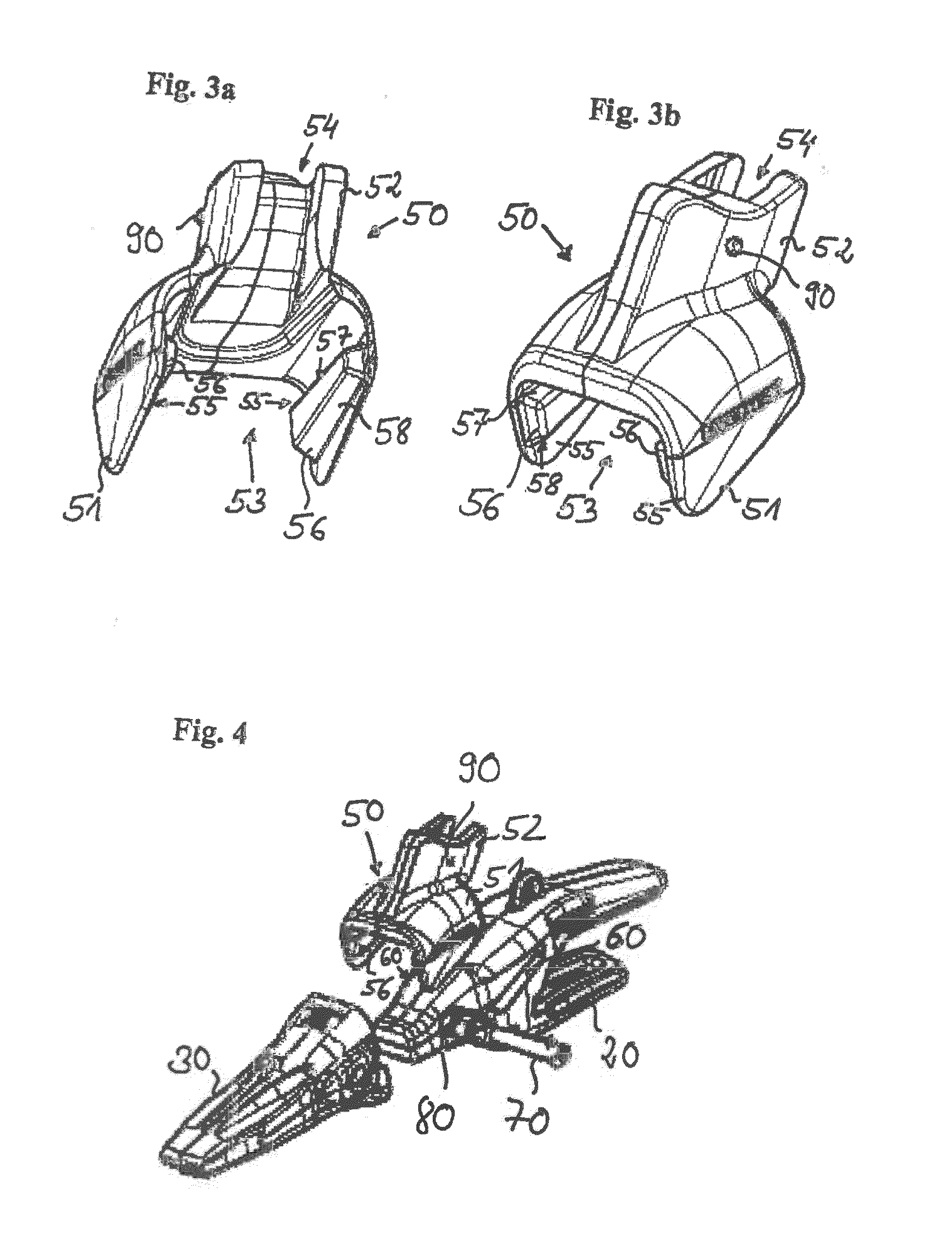

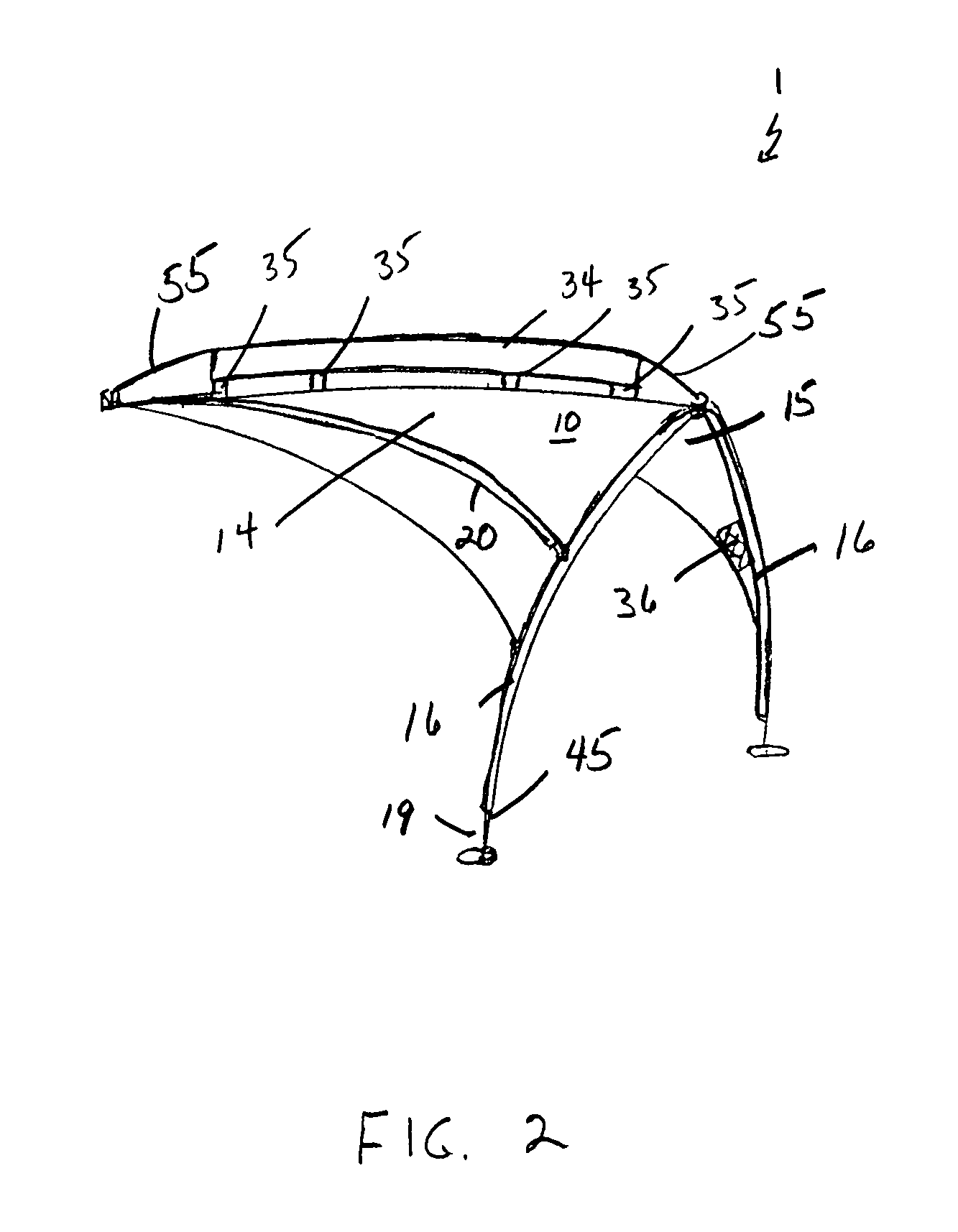

Folding two wheeled vehicle

InactiveUS6273442B1Easy to useEasy to carryPassenger cyclesMechanical apparatusRear quarterVehicle frame

A collapsible two wheeled vehicle comprises a substantially rigid main structural frame (10) defining a head section (16), a saddle pillar mount (17) and a bottom bracket (15). A rear wheel sub-frame (22) is pivoted to the frame (10) about the bottom bracket (15), and carriers a rear wheel (23), the sub-frame (22) being arranged for movement between a folded position where the rear wheel lies within the frame, between the head section (16) and the saddle pillar mount (17), and an active position where the sub-frame projects rearwardly beyond the frame. A pedal arrangement (19, 20, 21) is journalled in the bottom bracket (15) and drives the rear wheel (23) through an endless chain (25). A front wheel carrier is journalled to the head section (16) of the frame and has an arm (30) rotatably supporting a front wheel (31), the arm (30) being pivoted to the carrier for movement between a folded position where the front wheel (31) lies adjacent the rear wheel (23) when the sub-frame is in its folded position, and an active position where the arm projects generally downwardly from the carrier. The frame (1) carriers two opposed side panels (50) which are dimensioned so that the folded rear wheel sub-frame, rear wheel, front wheel carrier, folded arm and front wheel all lie substantially wholly within the confines of the side panels, the rear and front wheels lying outside the confines of the side panels when the sub-frame and arm are in their respective active positions.

Owner:SKOOT INT

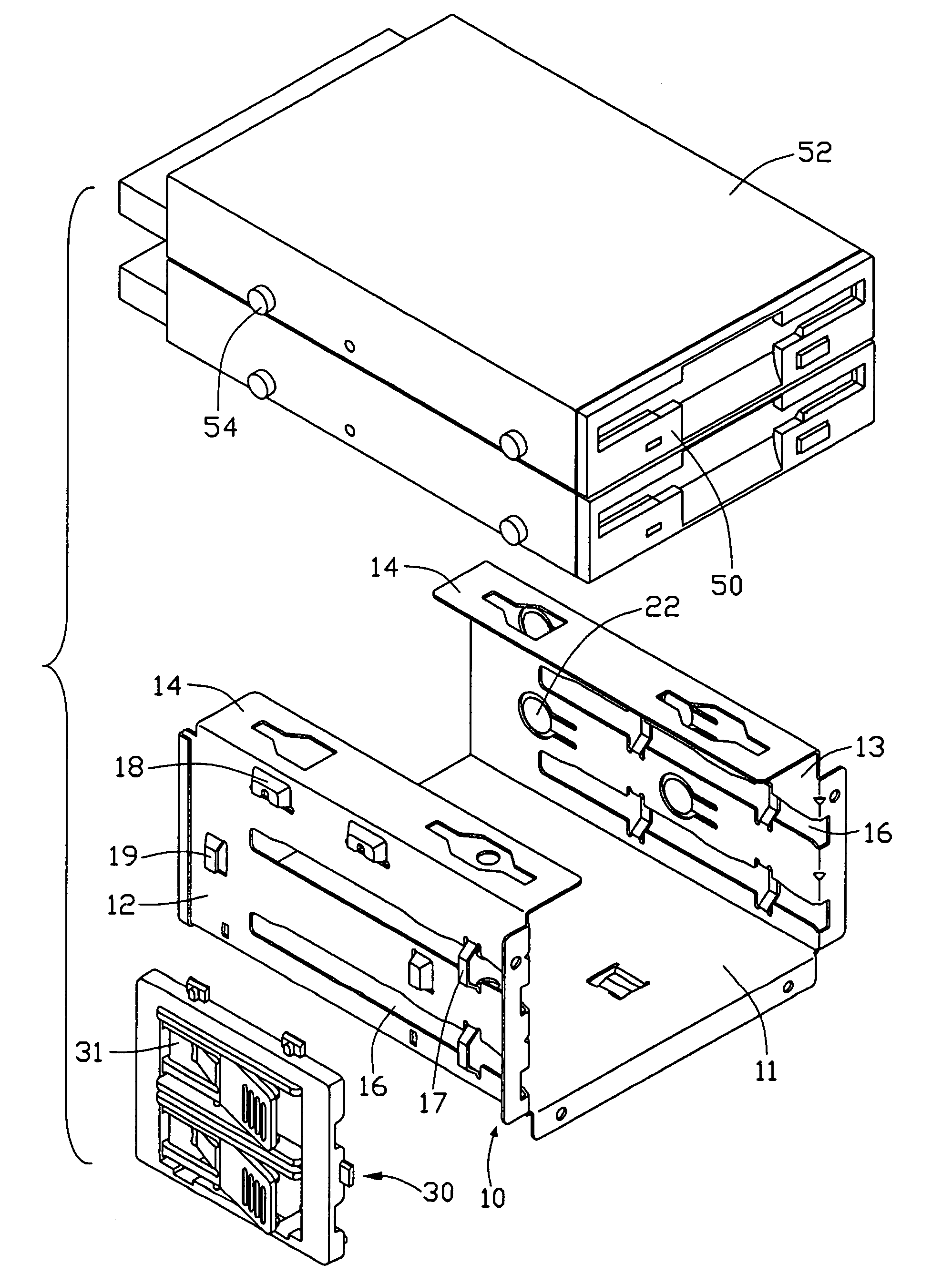

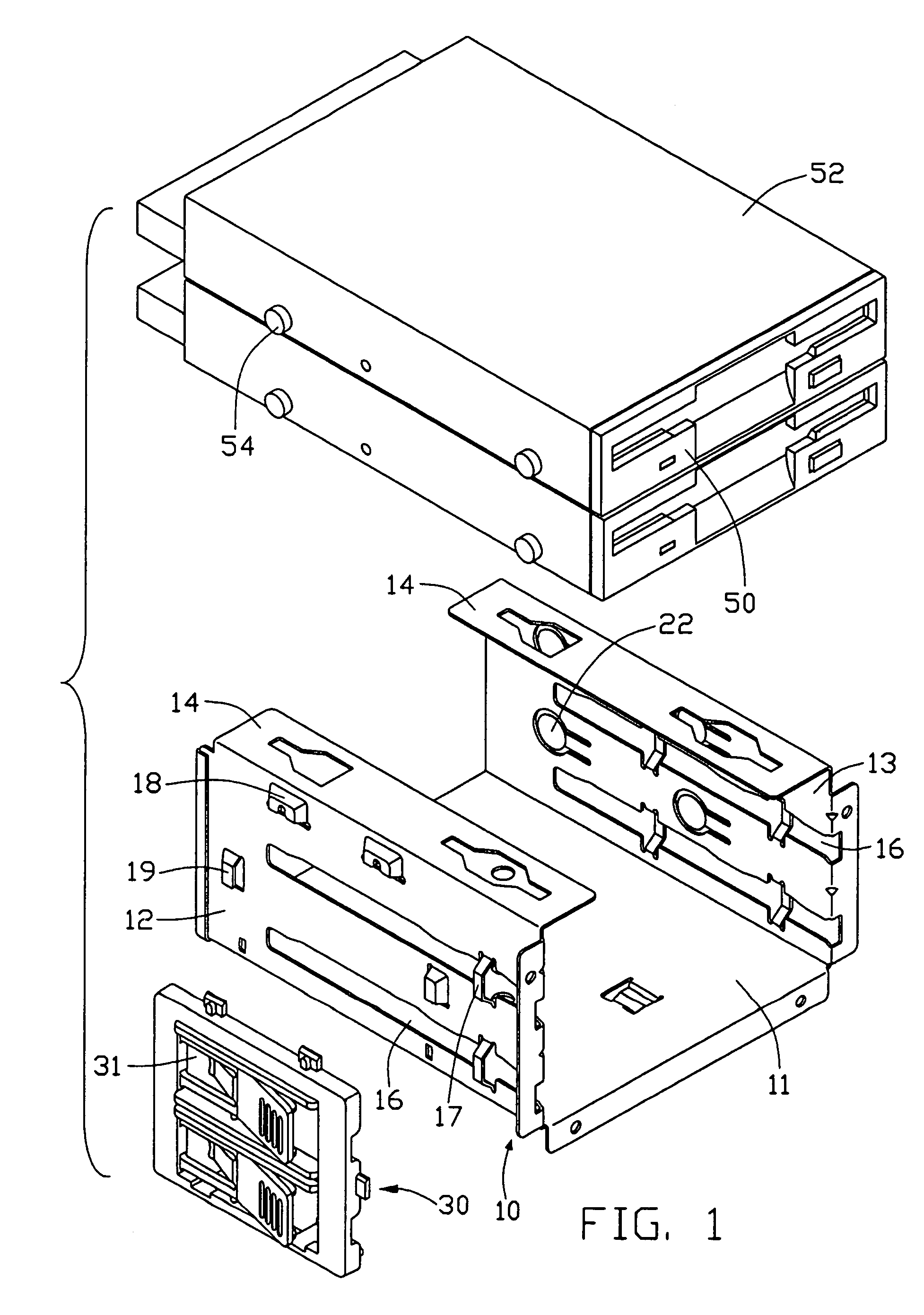

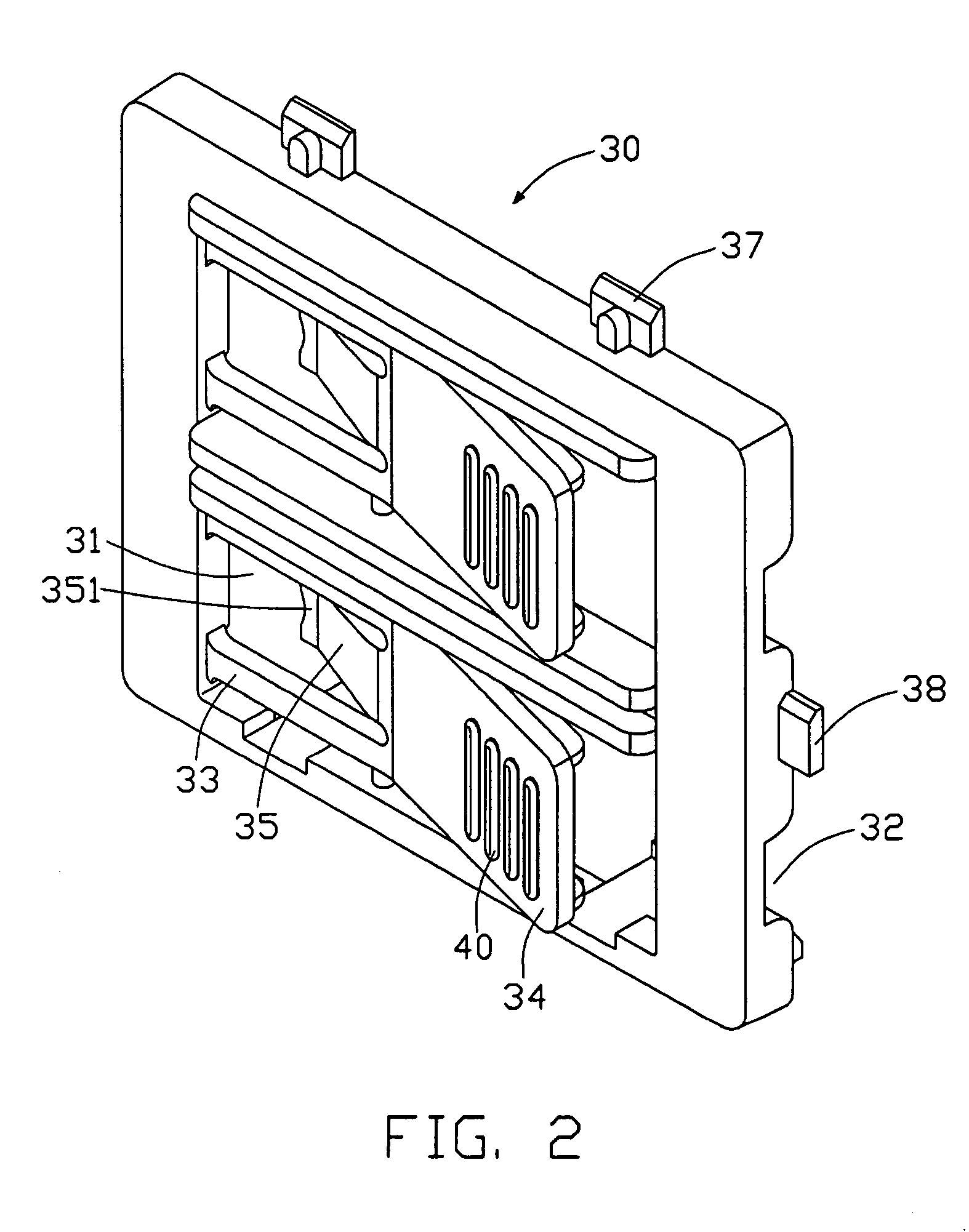

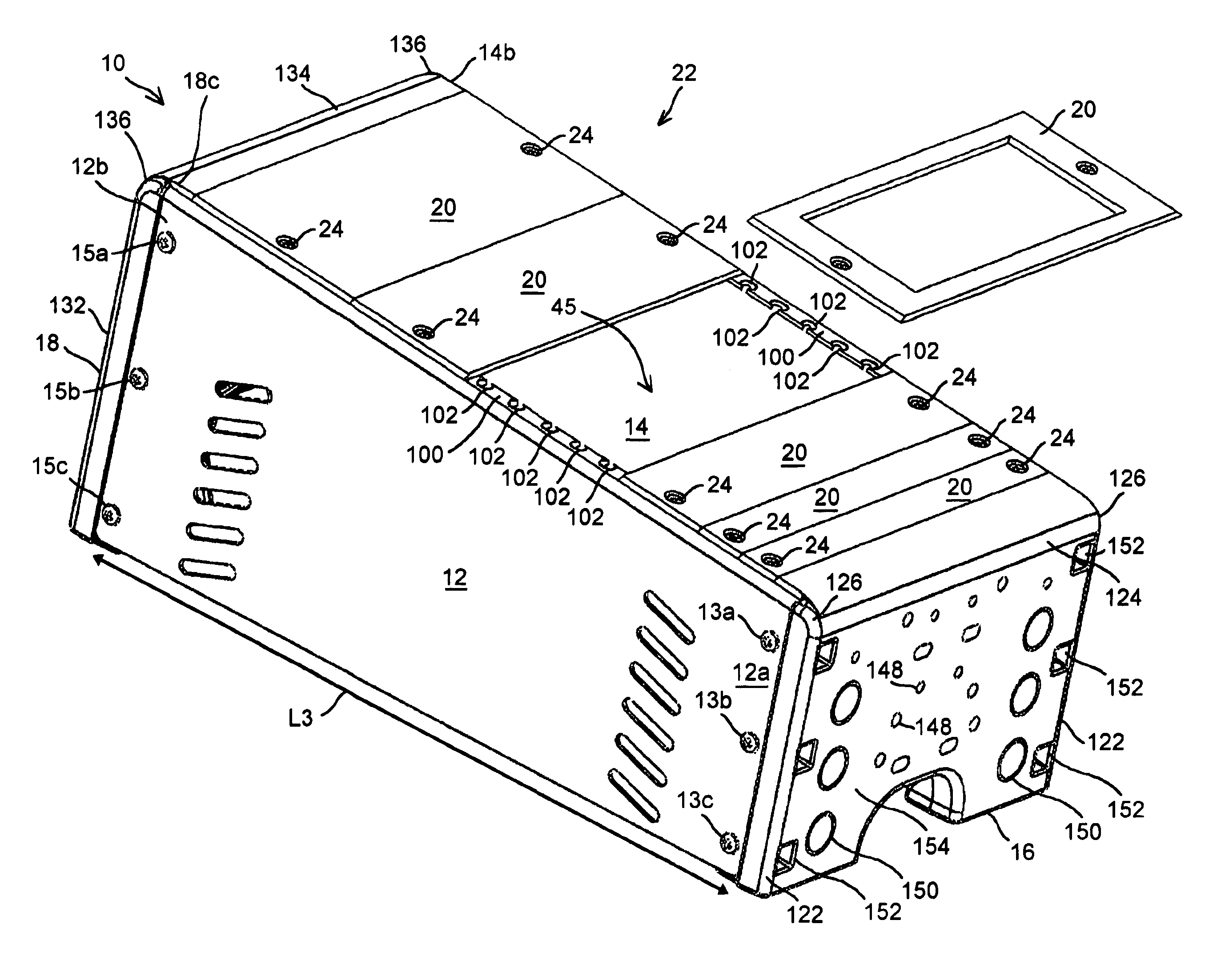

Drive bracket with locking device

InactiveUS7036783B2The process is convenient and fastEasy to separateCandle holdersLighting support devicesRear quarterEngineering

A drive bracket (10) includes a locking device (30) to secure data storage devices (50) therein. The drive bracket has a bottom plate (11), and first and second side plates (12, 13). A plurality of slots (16) is defined in the side plates. The locking device is attached to the first side plate, and defines openings (31) corresponding to the slots. Two connecting arms (33) extend from the locking device in each opening. A handle (34) extends forwardly and outwardly from the connecting arms. A fastening portion (35) extends rearward and inwardly from the handle between junctions of the handle and the connecting arms. Pins (54) of each data storage device slide in the slots, with one leading pin riding over the fastening portion, and restrained by an end of the fastening portion. When the handle is pushed, the fastening portion is moved outwardly, and disengaged from the leading pin.

Owner:HON HAI PRECISION IND CO LTD

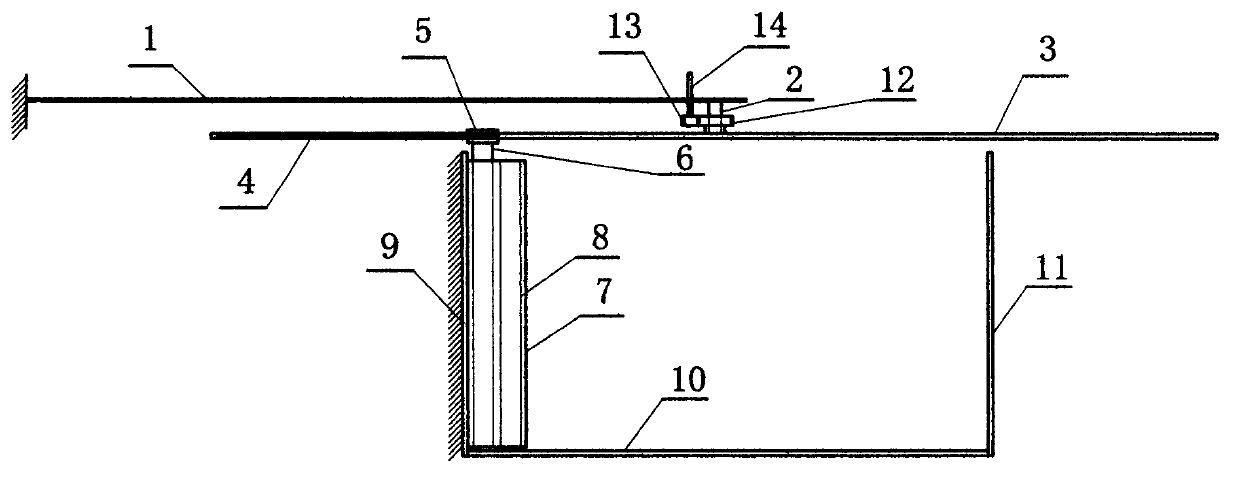

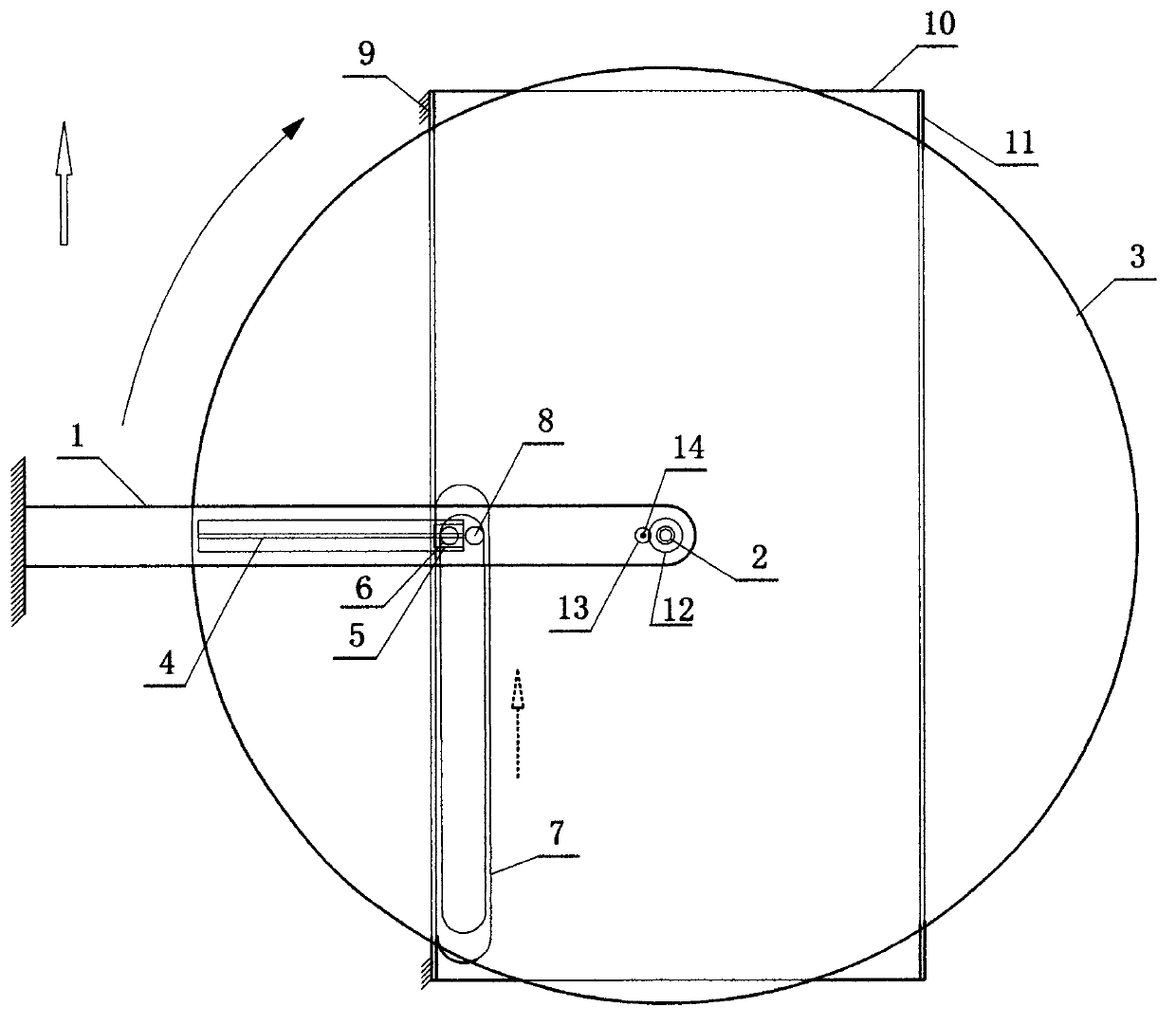

Annular flat plate paddle ship propulsion device

ActiveCN103121501AImprove mobilityThrust inefficiencyPropulsive elements of rotary typeRear quarterTrailing arm

The invention provides an annular flat plate paddle ship propulsion device and relates to the ship machinery technical field. The annular flat plate paddle ship propulsion device comprises a trailing arm, a rotary table shaft, a rotary table, a guide rail, a sliding block, a drag bar, a flat plate paddle, a paddle shaft, a guide plate, a base board, a side board, a driven gear, a driving gear and a power shaft, wherein the upper end and the lower end of the rotary table shaft are respectively connected with the right end of the trailing arm and the center of the rotary table; the guide plate, the base board and the side board surround to form a U-shaped groove which is placed below the rotary table; the flat plate paddle, the paddle shaft and the drag bar are vertically arranged in the U-shaped groove; power is transmitted to the rotary table through gears and then transmitted to the drag bar through the guide rail and the sliding block, and the drag bar drives the annular flat plate paddle to paddle and generate thrust. Due to limiting of the guide plate, the annular flat plate paddle moves ahead in a similar to a straight line mode after turning half circle. The annular flat plate paddle ship propulsion device is simple in structure, high in efficiency, and can be used as a thrust device for a ship and a ship model.

Owner:珠海杰腾造船有限公司

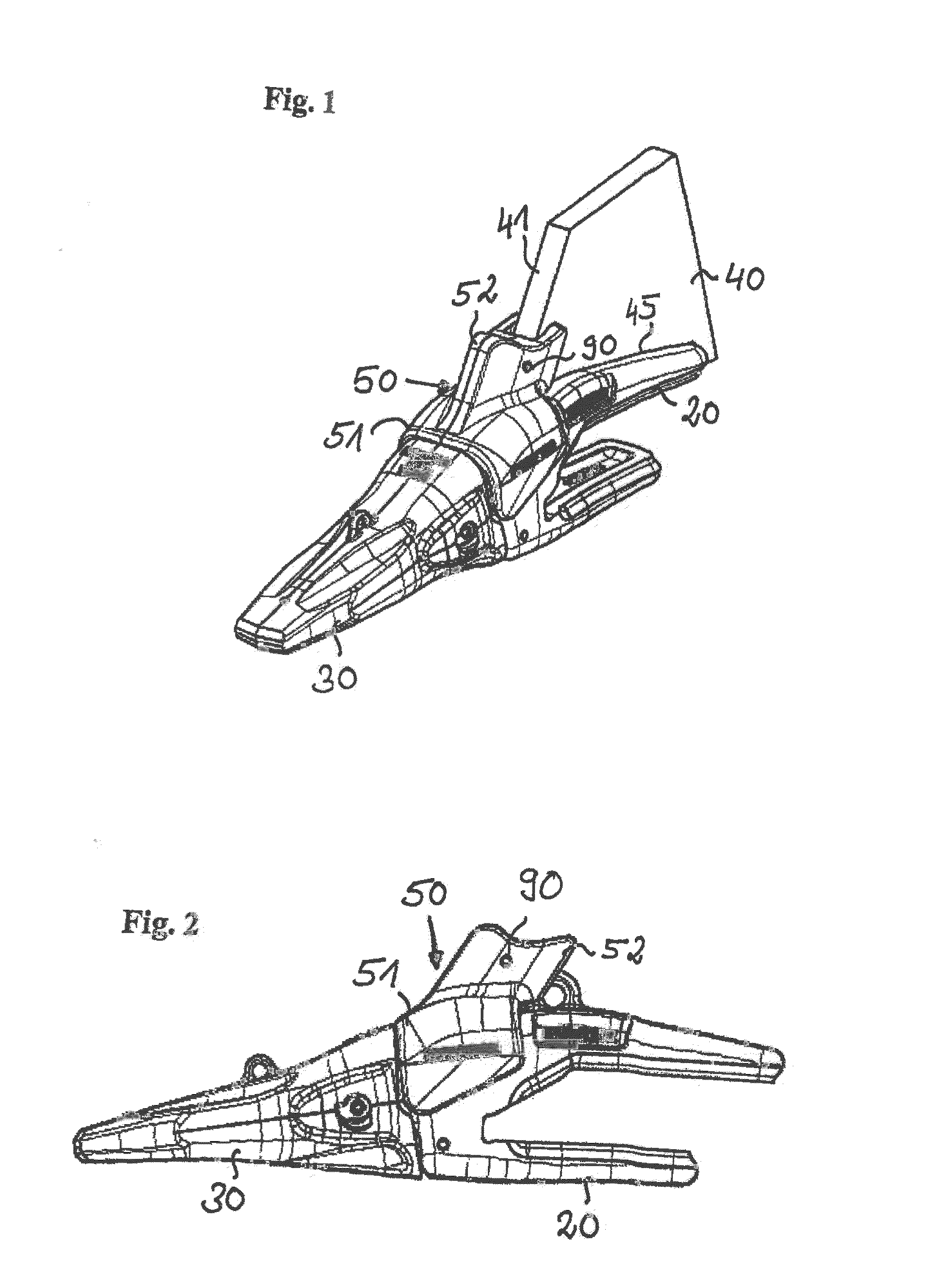

Wing shroud for an earth moving machine bucket, bucket and earth moving machine

ActiveUS20140082976A1Prolong lifeSufficient protectionSoil-shifting machines/dredgersRear quarterLocking mechanism

The present disclosure refers to a wing shroud for an earth moving machine bucket adapted to be positioned at least partially on a tooth adapter and / or at least partially on a lateral plate of the bucket for protecting wear sensitive bucket parts wherein the wing shroud comprises at least one self-lock mechanism for a detachable connection to the bucket.

Owner:LIEBHERR MINING EQUIP COLMAR

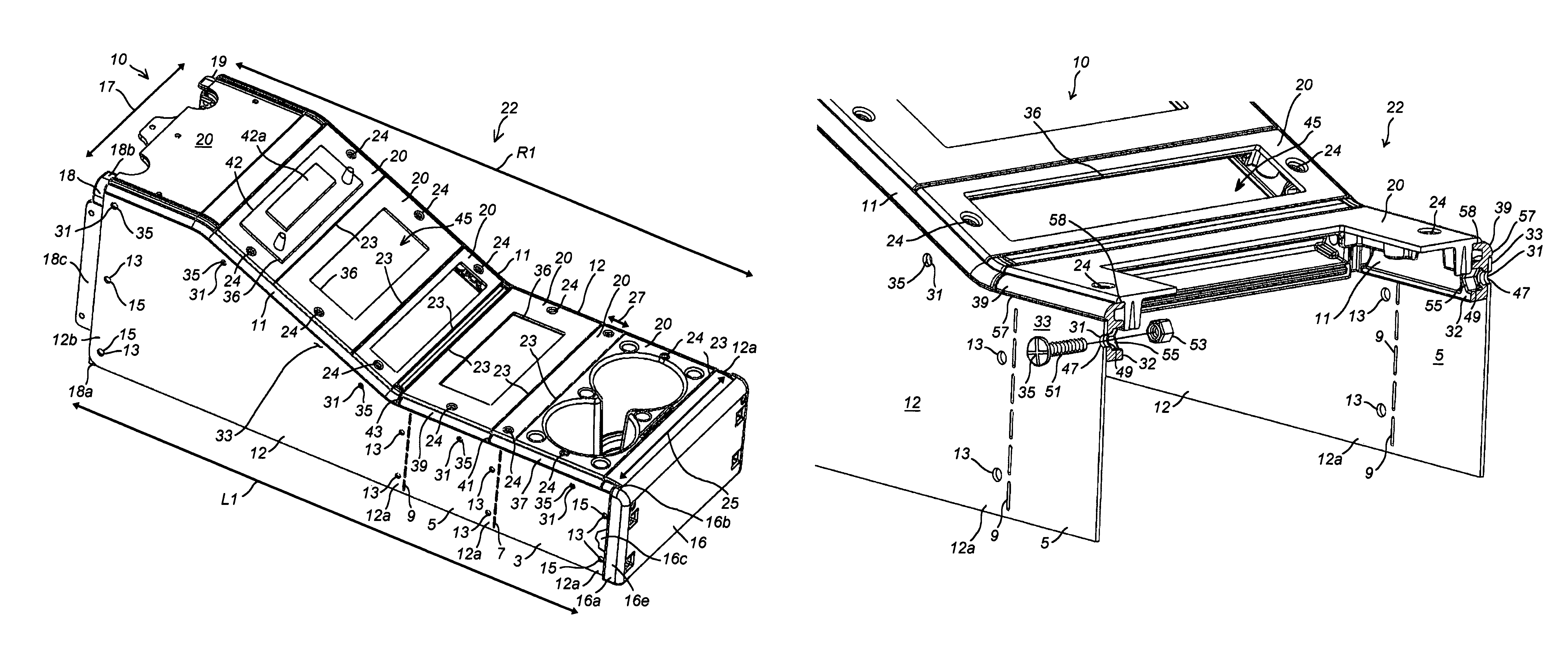

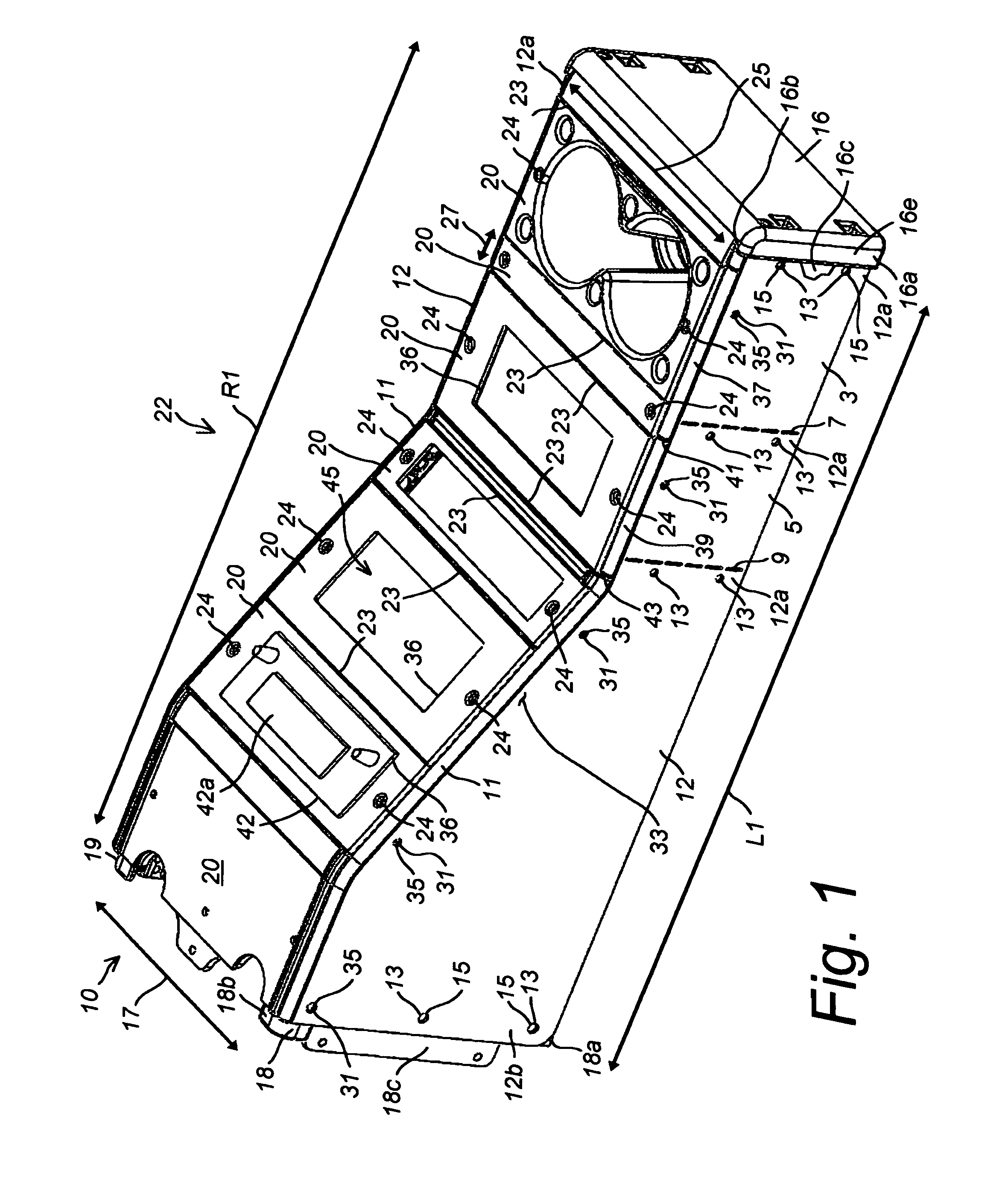

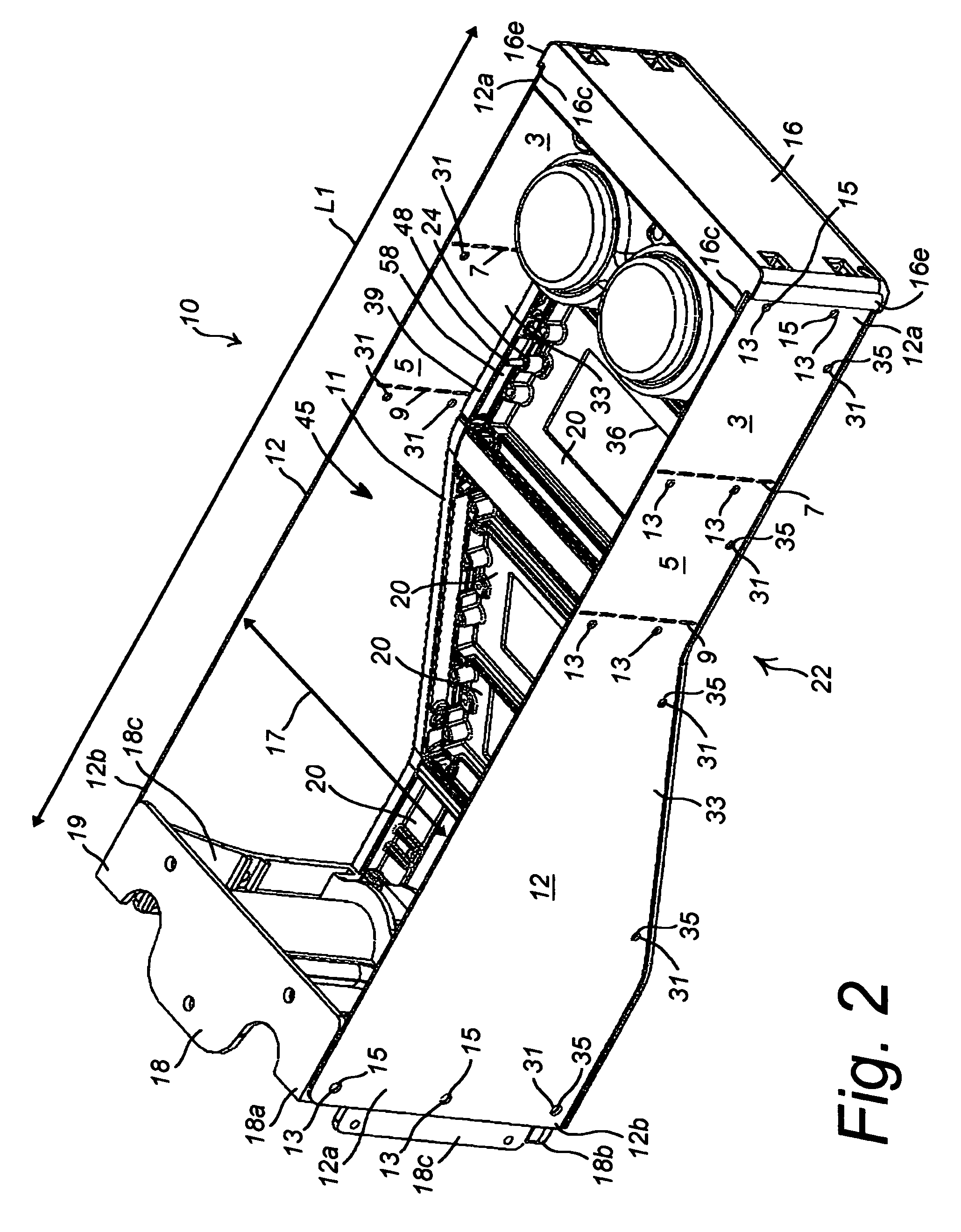

Vehicle console having molded end parts

Owner:CARNEVALI JEFFREY D

Side plate rudder system

InactiveUS6415729B1Reduce speedSimple methodSteering ruddersPropulsive elementsRear quarterLeading edge

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

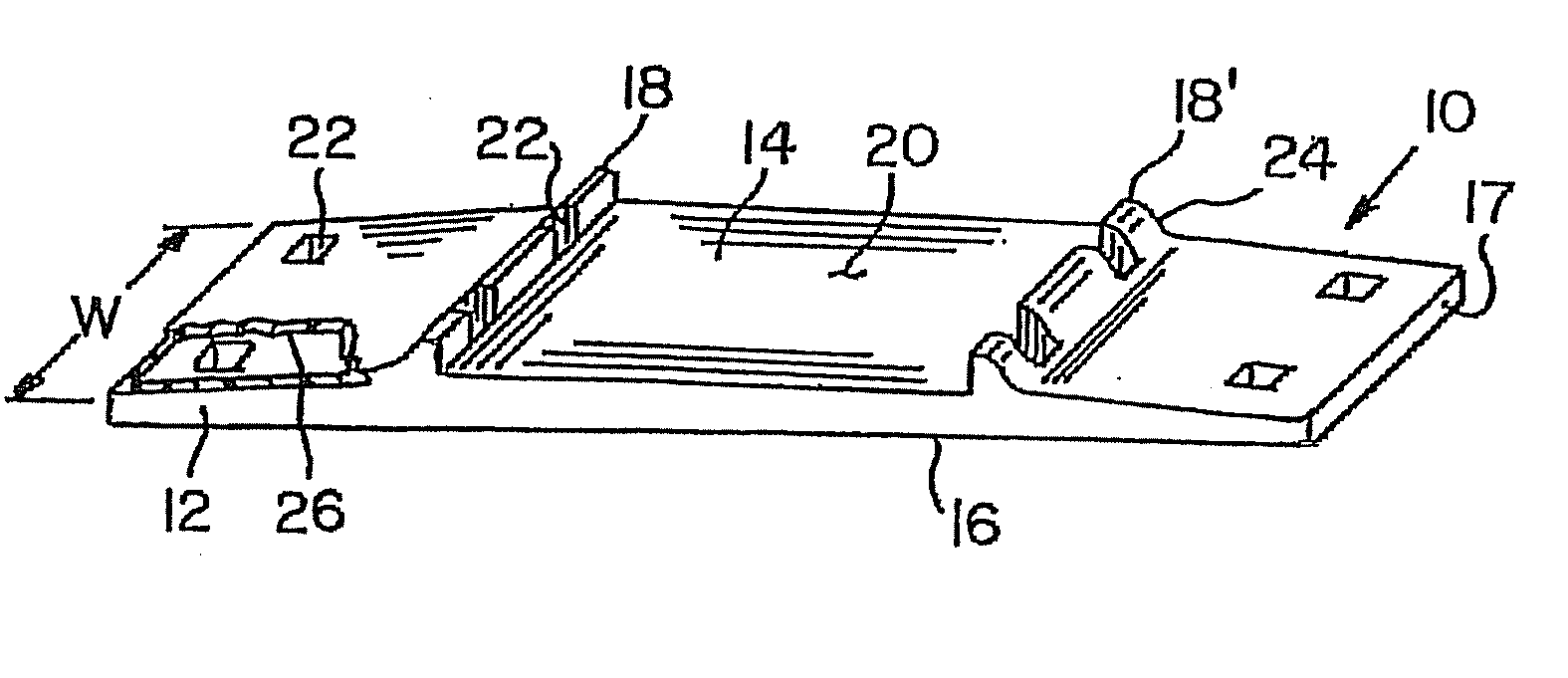

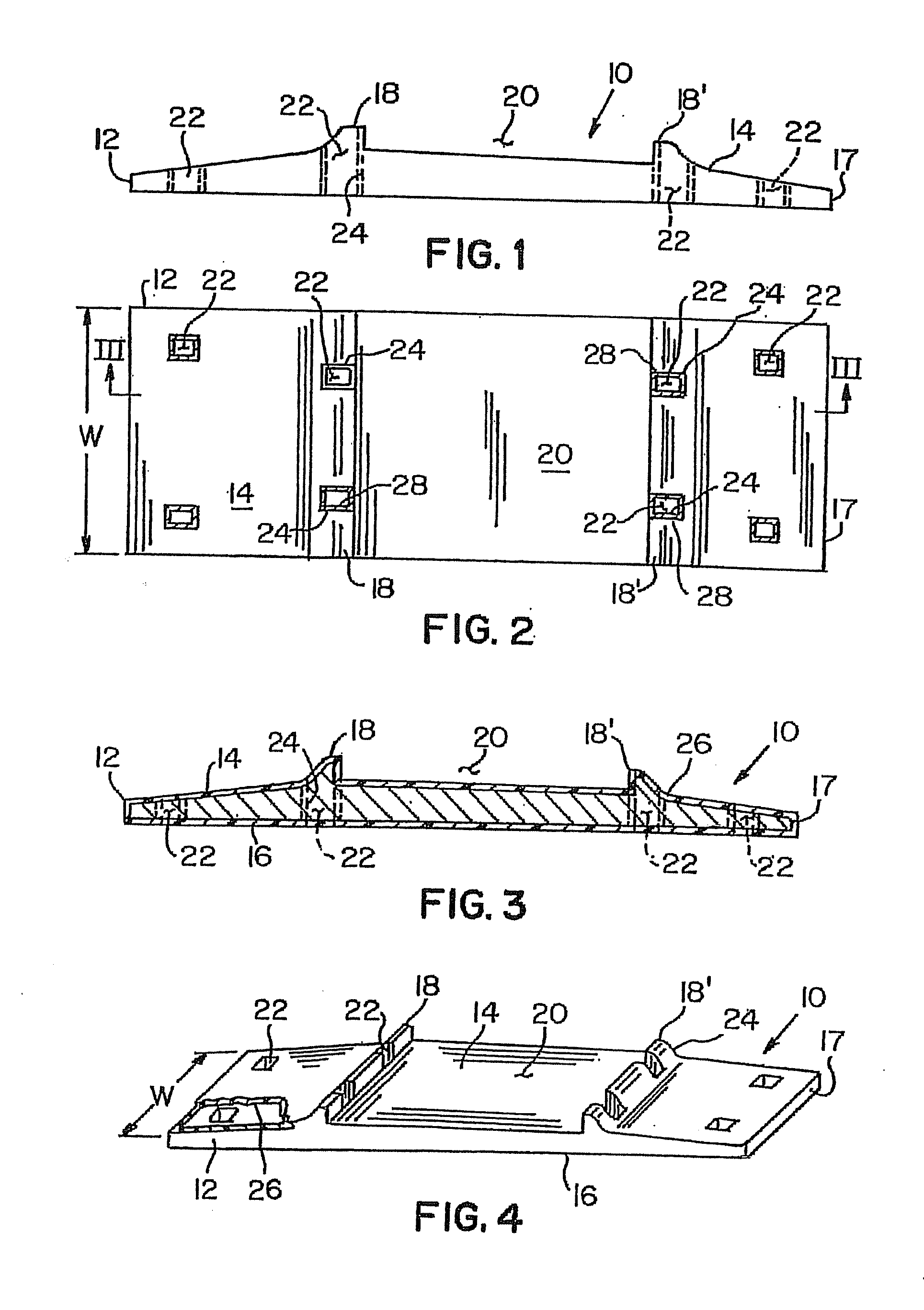

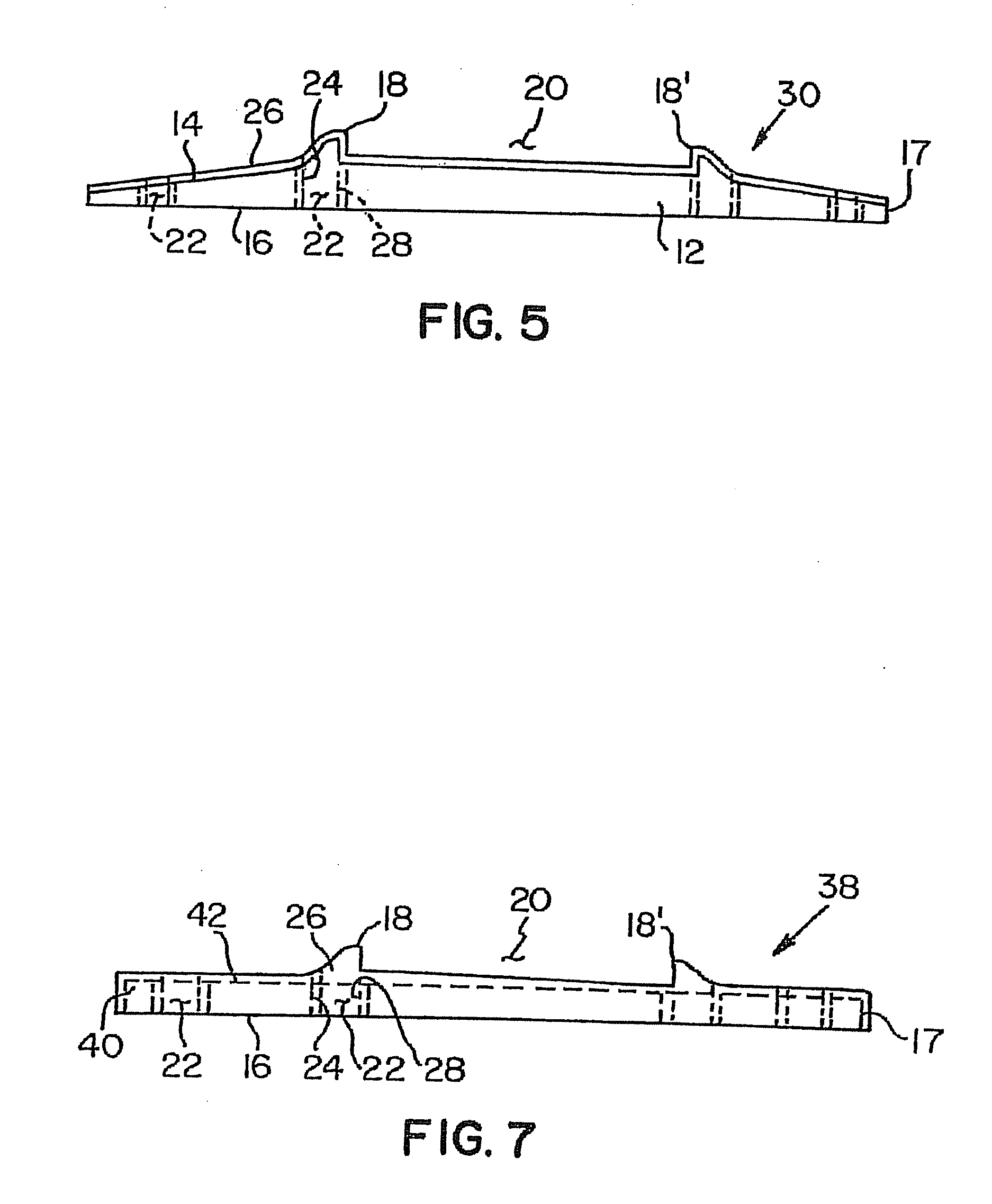

Vehicle console having molded side rails

Owner:CARNEVALI JEFFREY D

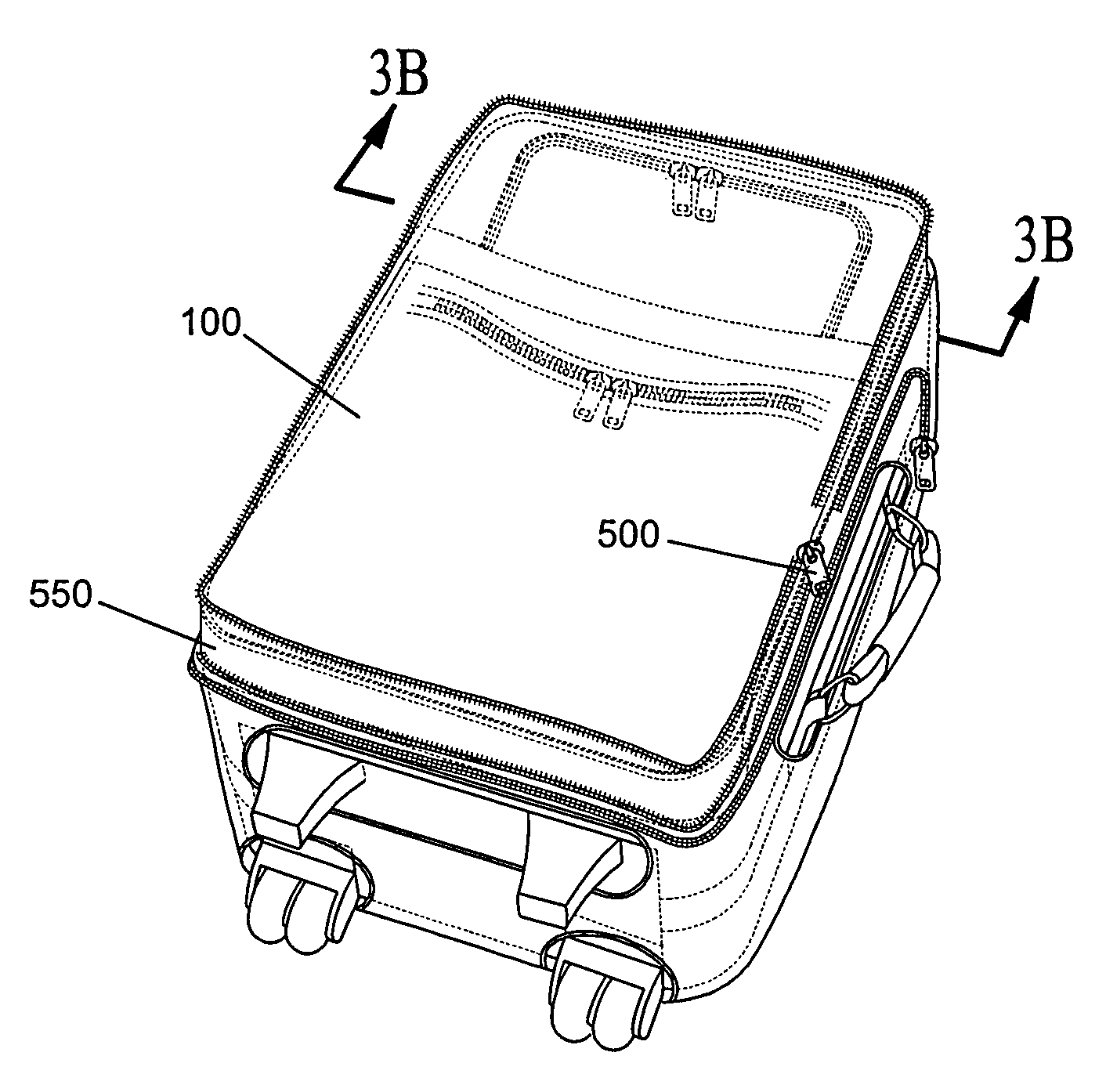

Luggage cover

A luggage cover for covering a luggage container, comprising a plurality of panels comprising a front panel, a rear panel, a top panel, a bottom panel, a first side panel, and a second side panel, the panels capable of being shaped into a protective shell for covering the luggage container, and a first fastening apparatus for detachably fastening the plurality of panels together to maintain the shape of the protective shell, wherein one of the plurality of panels is an expandable panel.

Owner:LUGGAGE AMERICA

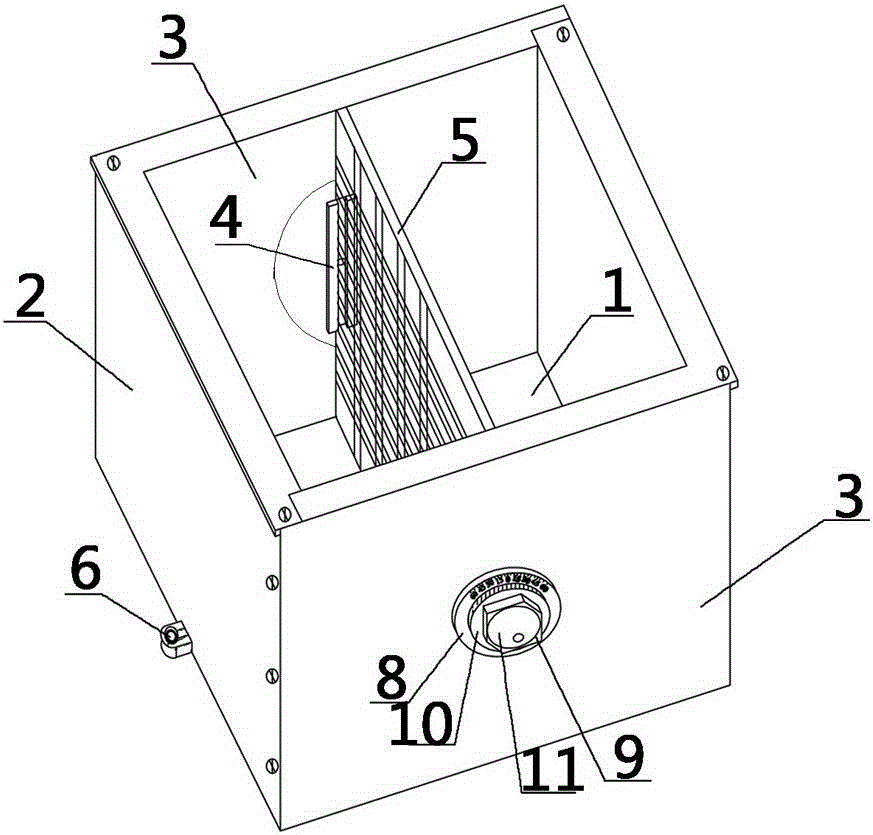

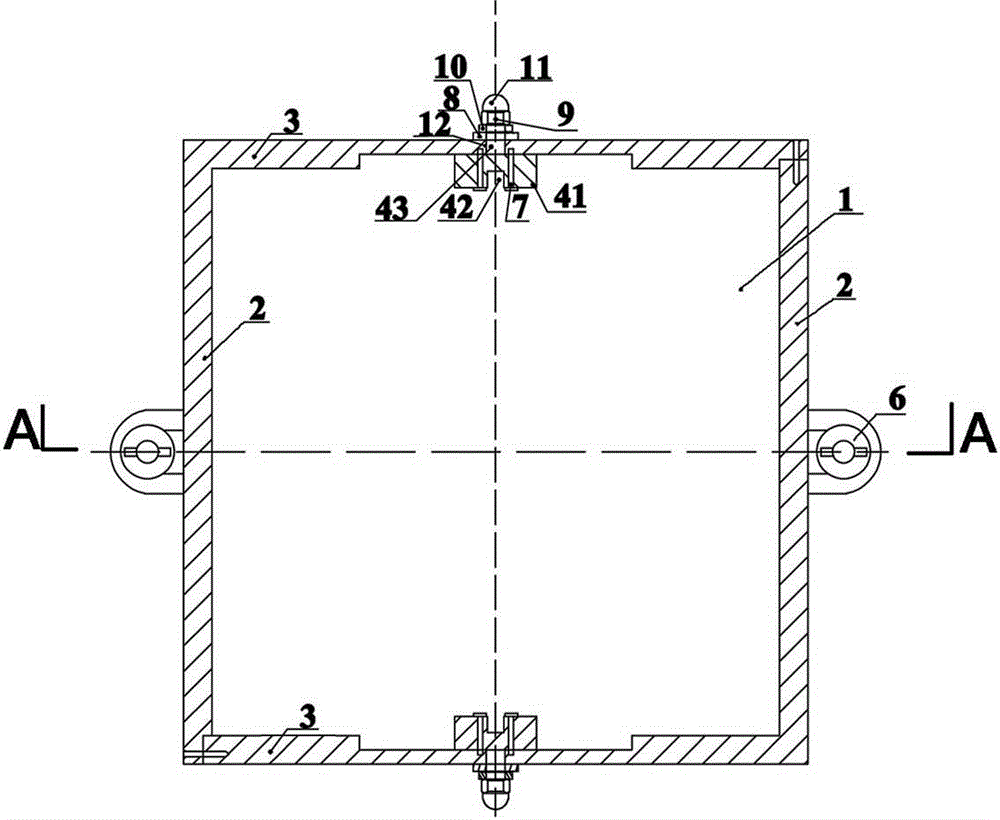

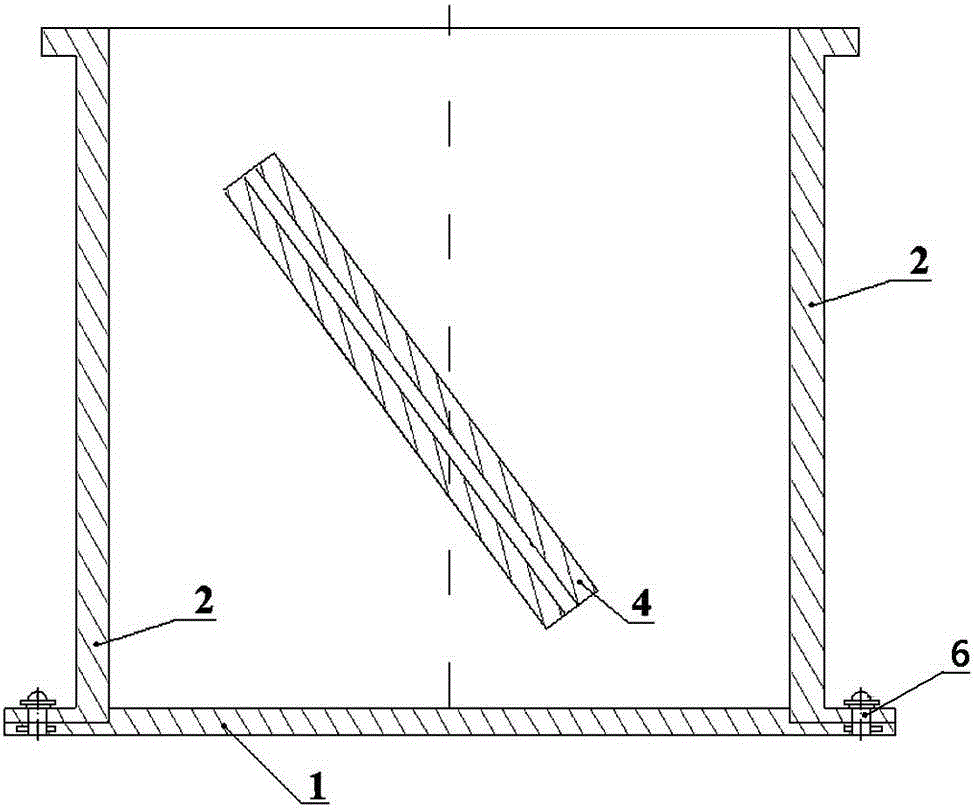

Mold for producing cracked rock test piece of different dip angles and production method thereof

InactiveCN105277406ASimple structureEasy to processPreparing sample for investigationRear quarterMechanical engineering

The invention relates to a mold for producing a cracked rock test piece of different dip angles and a production method thereof. A mold shell is a square cover-less box body formed by encircling a soleplate, a front side plate, a rear side plate, a left side plate and a right side plate, the middle parts of the front and rear side plates are correspondingly provided with a hole, and a rotation slot is respectively installed in each hole; the rotation slot is an integrally-formed T-shaped structure comprising a slot plate and a connection screw which is vertically raised from the bottom of the plate; the slot plate is installed in the box body, the connection screw respectively stretches out from the holes in the front and rear side plates, and the end part of the connection screw is fixed by a nut; a crack simulation frame is clamped between the two slots, and two ends of the crack simulation frame are respectively embedded into the slot; the crack simulation frame consists of an iron framework and tapes in the frame, the tapes are arranged in a net shape, and two ends of each tape are adhered on the edge of the frame. When the mold is in use, the angle of the crack simulation frame can be adjusted randomly according to the requirements, a rock test piece material is poured into the mold after the angle is determined so as to produce the crack rock test piece of different dip angles. The mold can conveniently, rapidly and accurately adjust the dip angle of the crack and is simple in structure, easy to assembly, convenient to disassemble and reusable.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

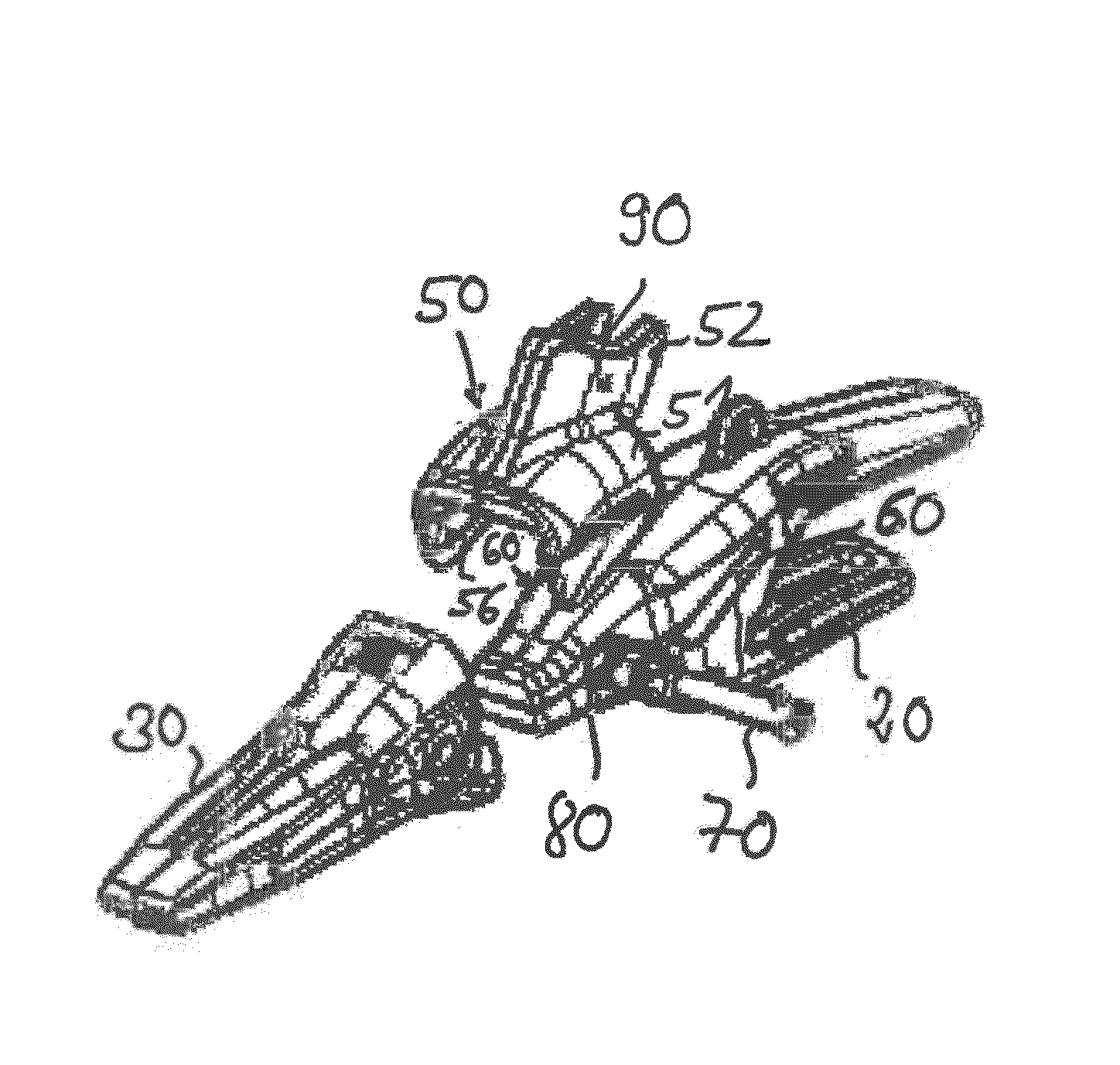

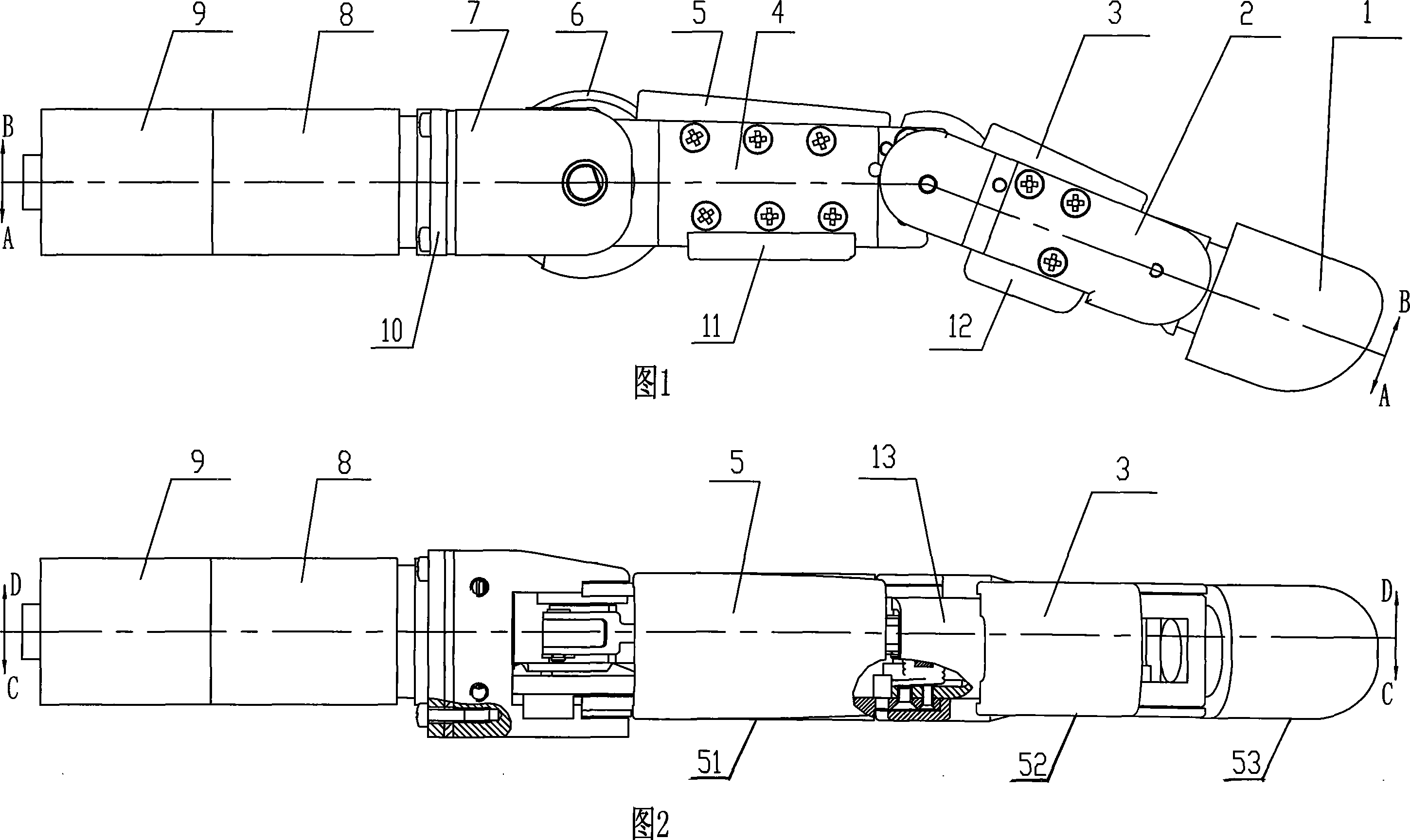

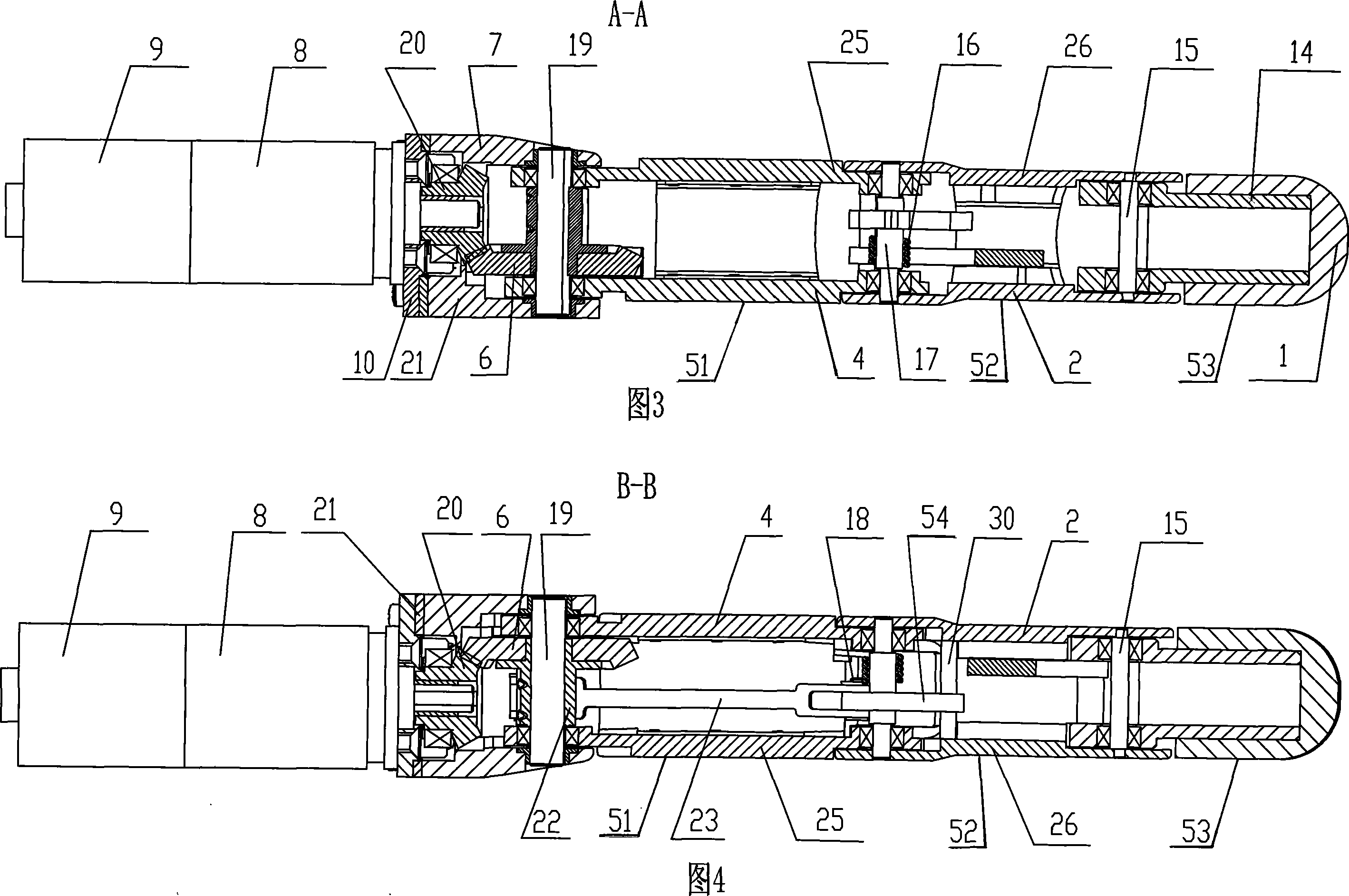

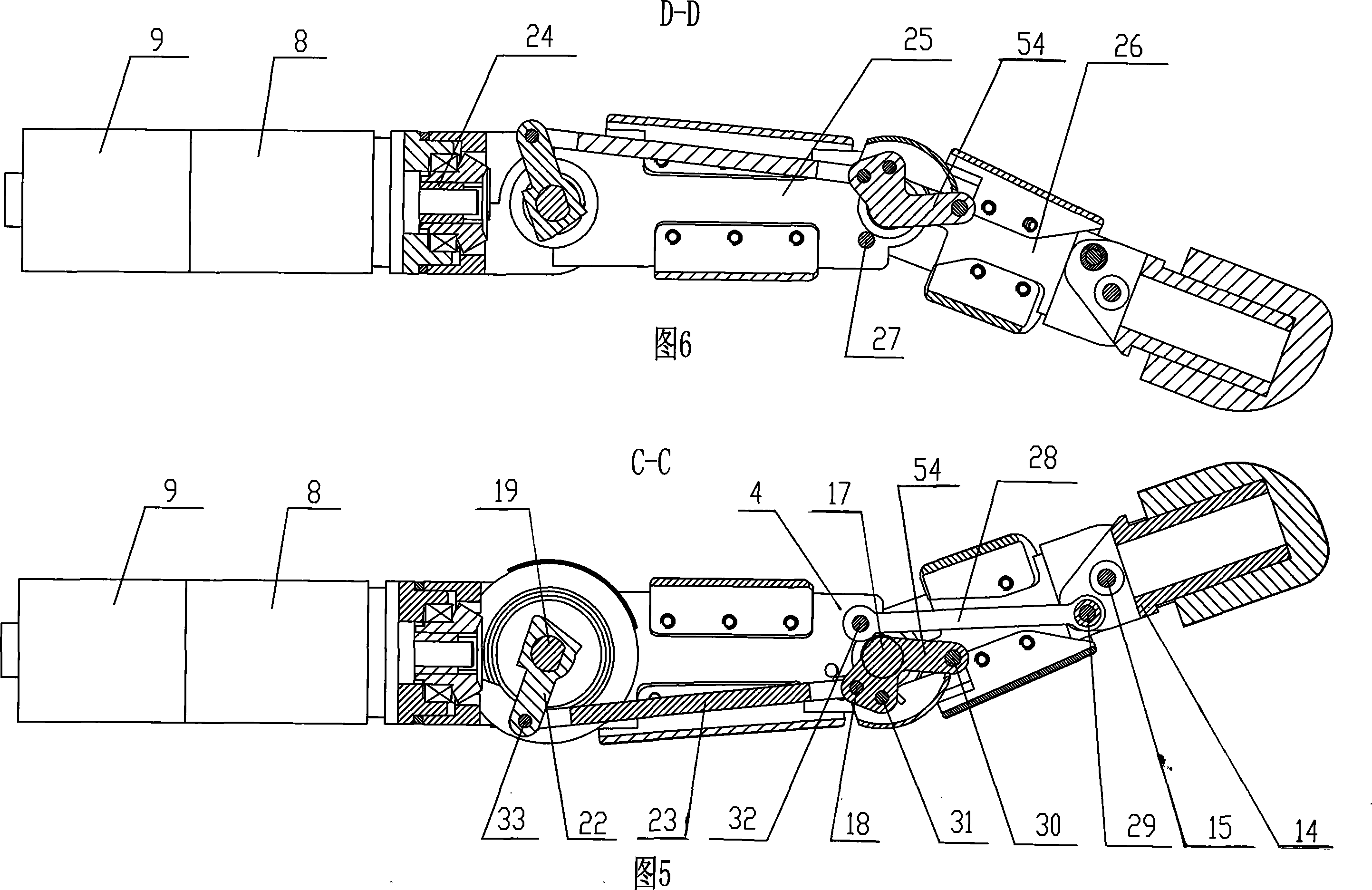

Under-actuated coupling transmission type imitation human finger mechanism

The invention provides an under-actuated coupling driving finger-imitating mechanism, in particular to a finger-imitating mechanism on the manipulator of a robot. The invention solves the problems of poor harmonization of all knuckles, being difficult to keep holding shape, slow speed when wrapping the article to be held, poor adaptability, etc. when the existing manipulator finger carries out a holding motion. One end of the invention, which is close to a knuckle connecting rod (23), is connected with a basic joint moment sensor (22); the other end close to the knuckle connecting rod (23) is connected with the shaft disc (54) of a central joint shaft; one end of a coupling connecting rod (28) is connected with a left plate (25) close to the knuckle and a right plate (4) close to the knuckle; the other end of the coupling connecting rod (28) is connected with a fingertip (14); a central knuckle left plate (26) and a central knuckle right plate (2) are connected with the shaft disc (54) of the central knuckle shaft by a coupling central knuckle shaft (30). By adopting the coupling transmission way, the central knuckle and the fingertip of the invention have the advantages of good motion harmony when the finger is bent, fast speed and convenient pre-tightening when the article to be held is wrapped.

Owner:HARBIN INST OF TECH

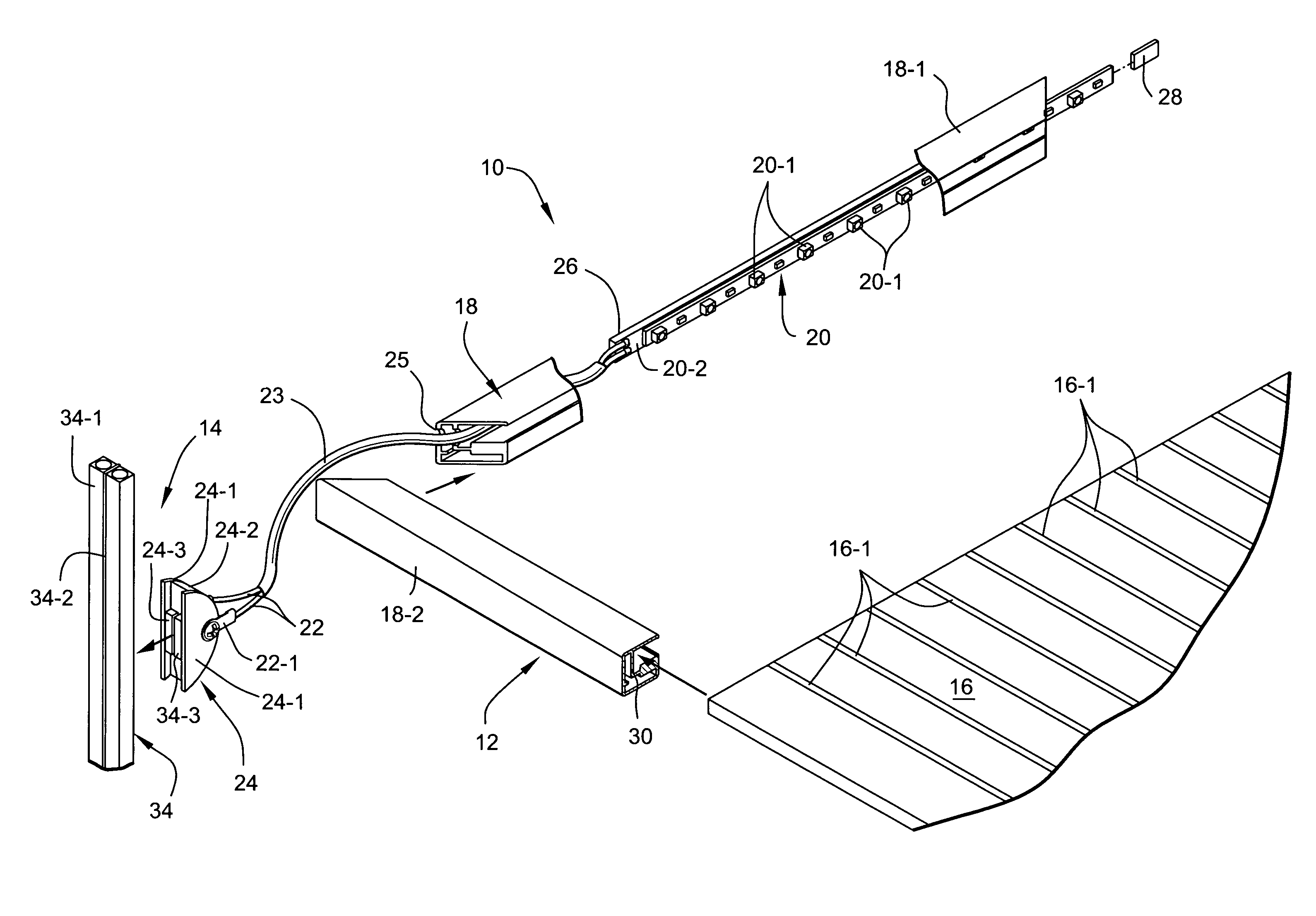

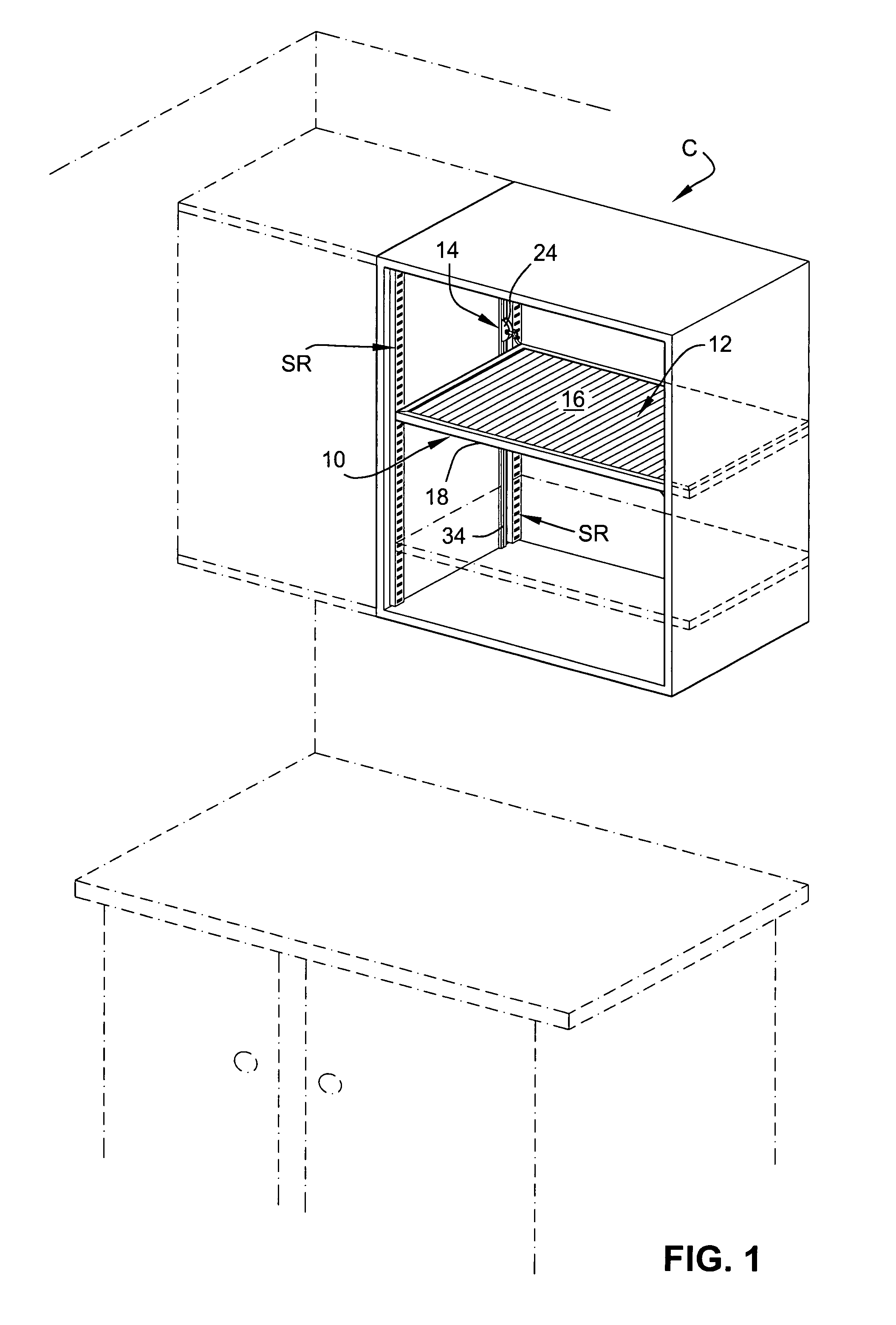

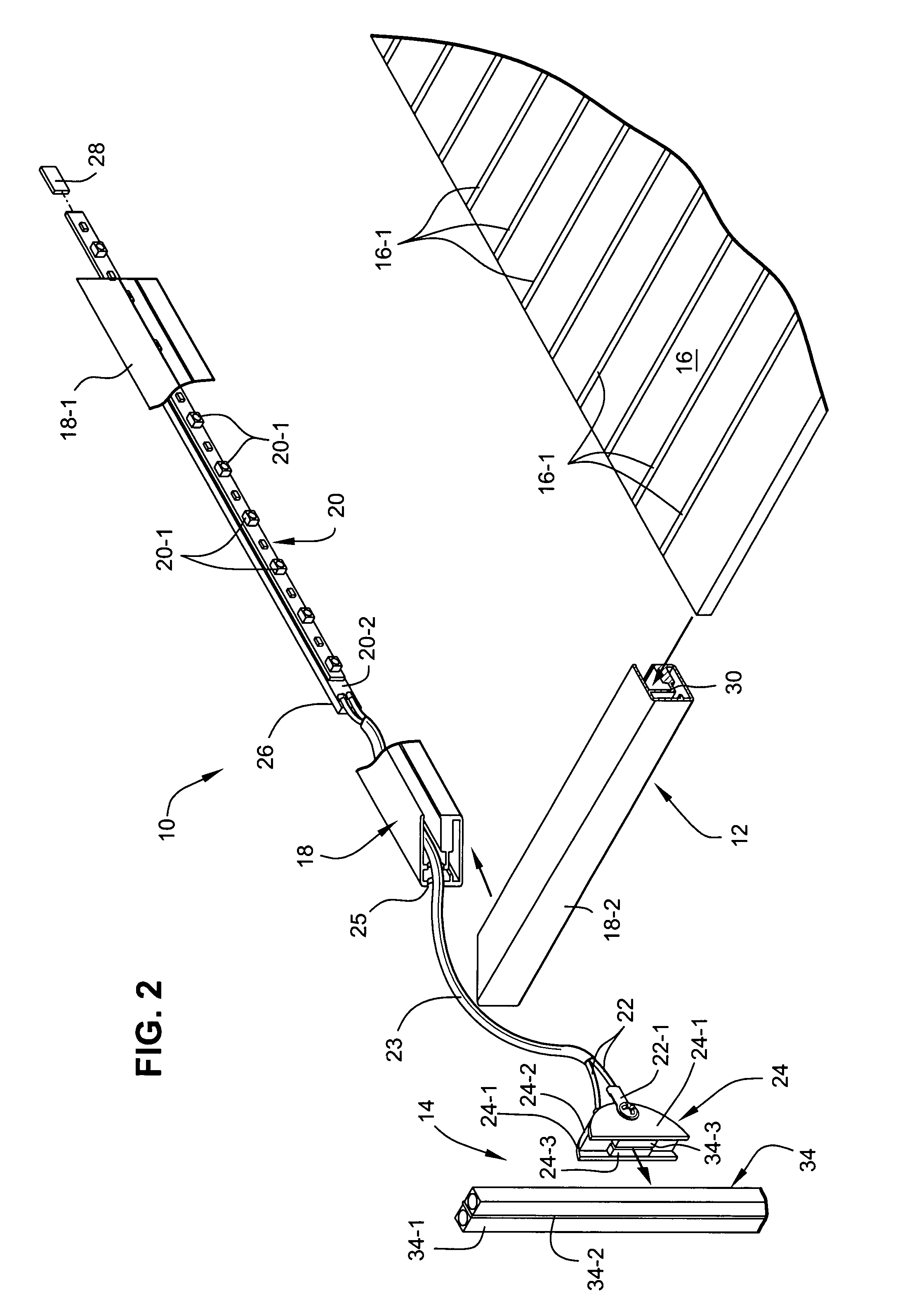

Self-illuminated structural panel units and systems including the same

Position adjustable self-illuminated panel units may be used in combination with conventional shelf supports. Preferred shelf-units include a light-transmissive panel, a shelf frame holding the panel and having an illumination element for providing a light source to illuminate the panel, and a magnetic connector electrically interconnected to the illumination element and adapted to being magnetically and electrically coupled to a source of electrical power. The illumination element most preferably includes an LED strip housed within one member of the frame and positioned adjacent to an edge of the panel. A magnetic connector includes a pair of electrically conductive side panels, an electrically non-conductive spacer sandwiched between the side panels, and a pair of magnet bars fixed to the spacer. The magnet bars define an air gap therebetween such that electrical contact may be established between the magnet bars and a respective one of the side panels. Shelf lighting systems according to the present invention will most preferably include a self-illuminated panel unit as described briefly above, and a ferromagnetic power strip for supplying electrical power thereto. The magnetic connector is therefore capable of magnetic and electrical interconnection to the power strip (e.g., via the magnet bars thereof so as to in turn supply power to the panel unit (e.g., via lead wires connecting the side panels to the LED strip).

Owner:REV A SHELF

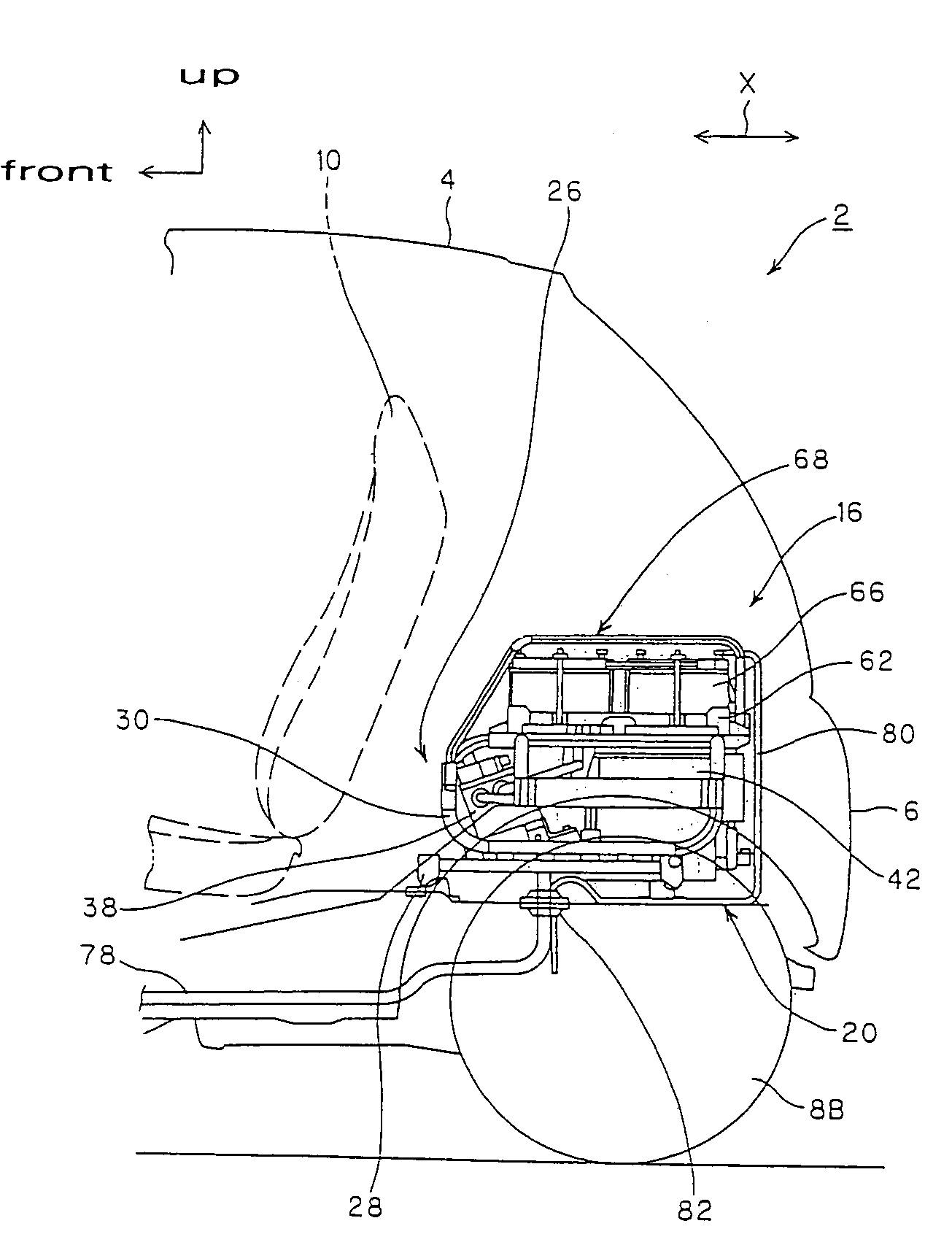

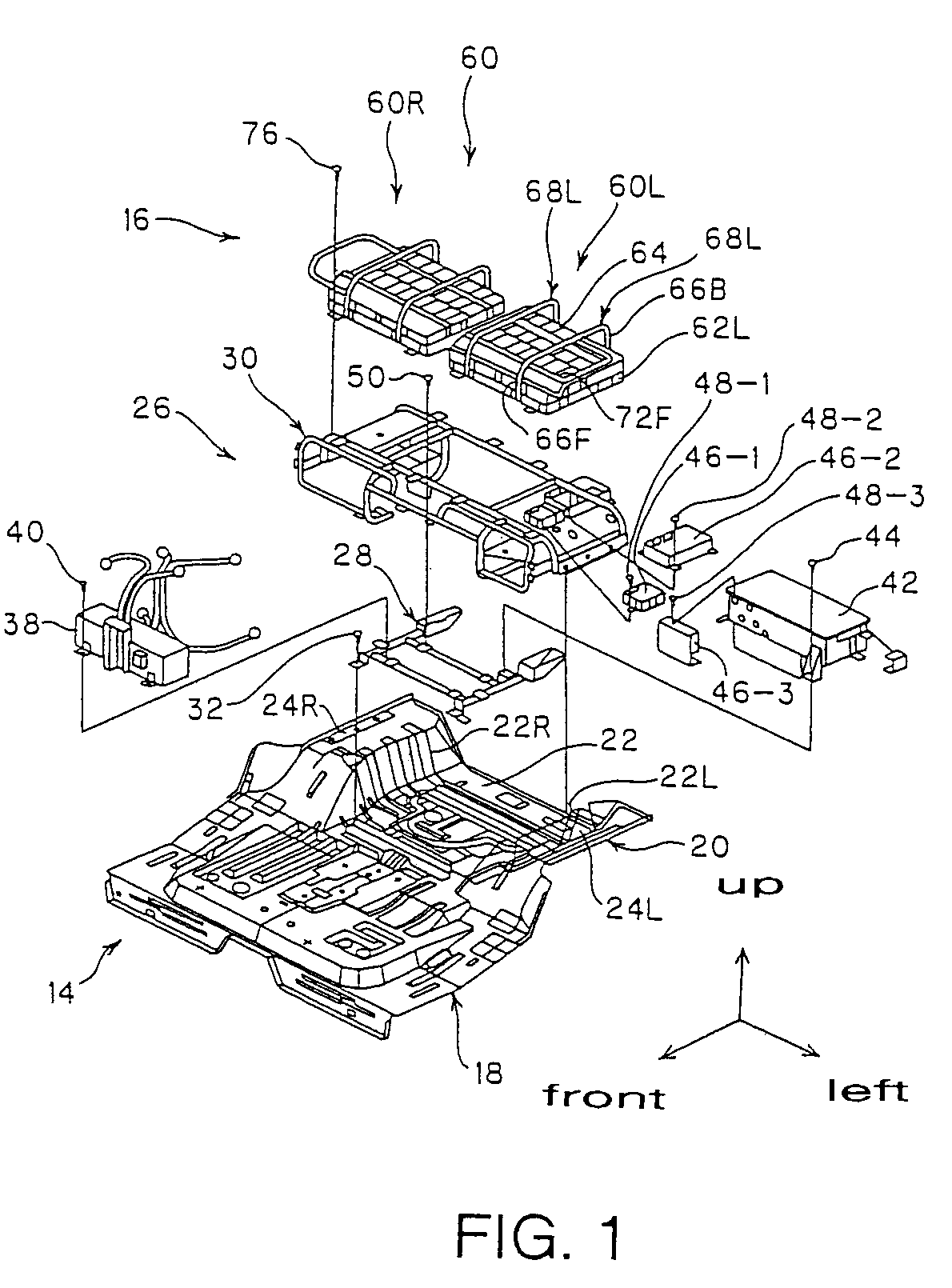

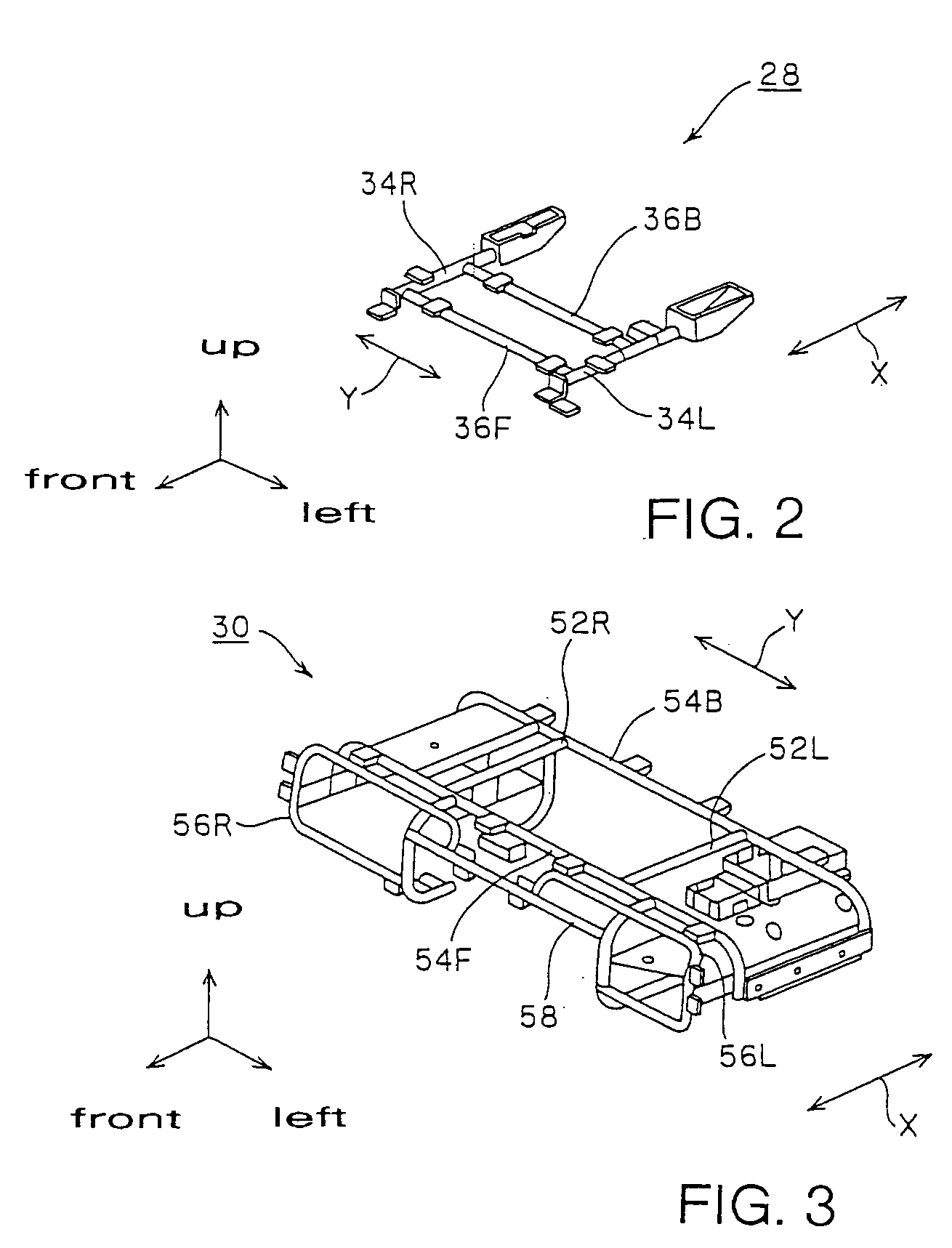

Apparatus for attaching electrical components to a vehicle

A structure for mounting electrical components to a vehicle. The structure includes a rear floor pan incorporating a U-shaped part transversely centered in the vehicle. Floor pan wing panels extend from each end of the U-shaped part and connect to vehicle side panels. An electrical component mounting rack includes a first frame attached to the U-shaped floor panel part, and a second frame attached to the top of the first frame and also to the floor pan wing panels. An electrical inverter device is mounted to the first frame and batteries are mounted to the second frame. The first and second frames form a structure that reinforces the rear floor pan in a manner capable of adequately supporting heavy electrical drive train components.

Owner:SUZUKI MOTOR CORP

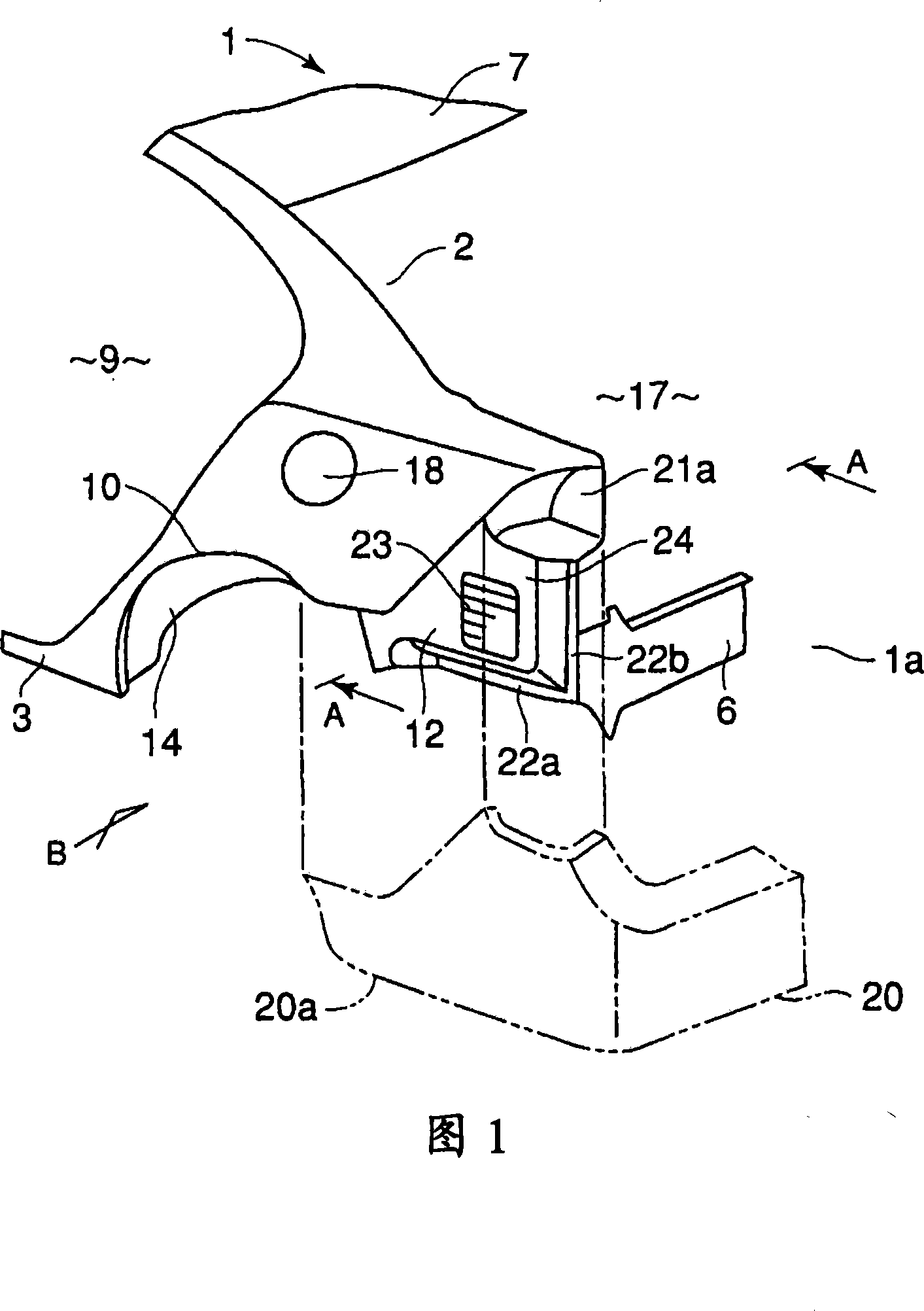

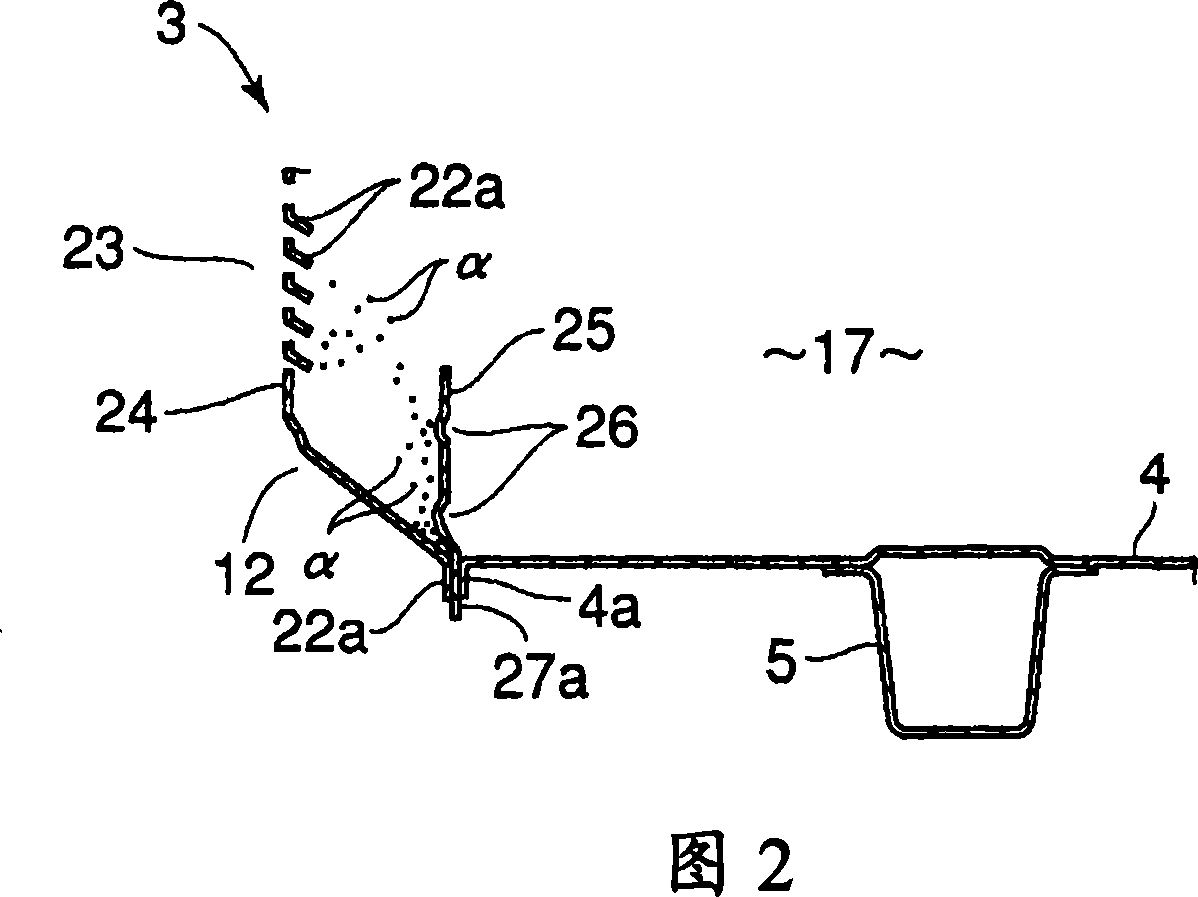

Vehicle main body structure

A main body structure of a vehicle, comprising: a rear wall outer panel arranged on both sides in a vehicle width direction in a rear portion of a vehicle; a rear wall inner panel arranged on an inner side of the rear wall outer panel in a vehicle width direction a floor member connected to the rear wall outer members at a junction, the floor member being disposed at the rear side of the vehicle in the longitudinal direction with respect to the rear wall outer members, and continuous between the rear wall outer members. a rear end panel connected to the rear end of the floor member and the rear end of the rear quarter outer panel; and a joint panel arranged along at least one of the junctions of the rear quarter outer panel and the floor member by three-point spot welding, A front end portion of the joining panel is joined to the rear inner panel, a rear end of the joining panel is joined to the rear end panel, and a middle portion of the joining panel is joined to the floor and the rear outer panel.

Owner:MITSUBISHI MOTORS CORP

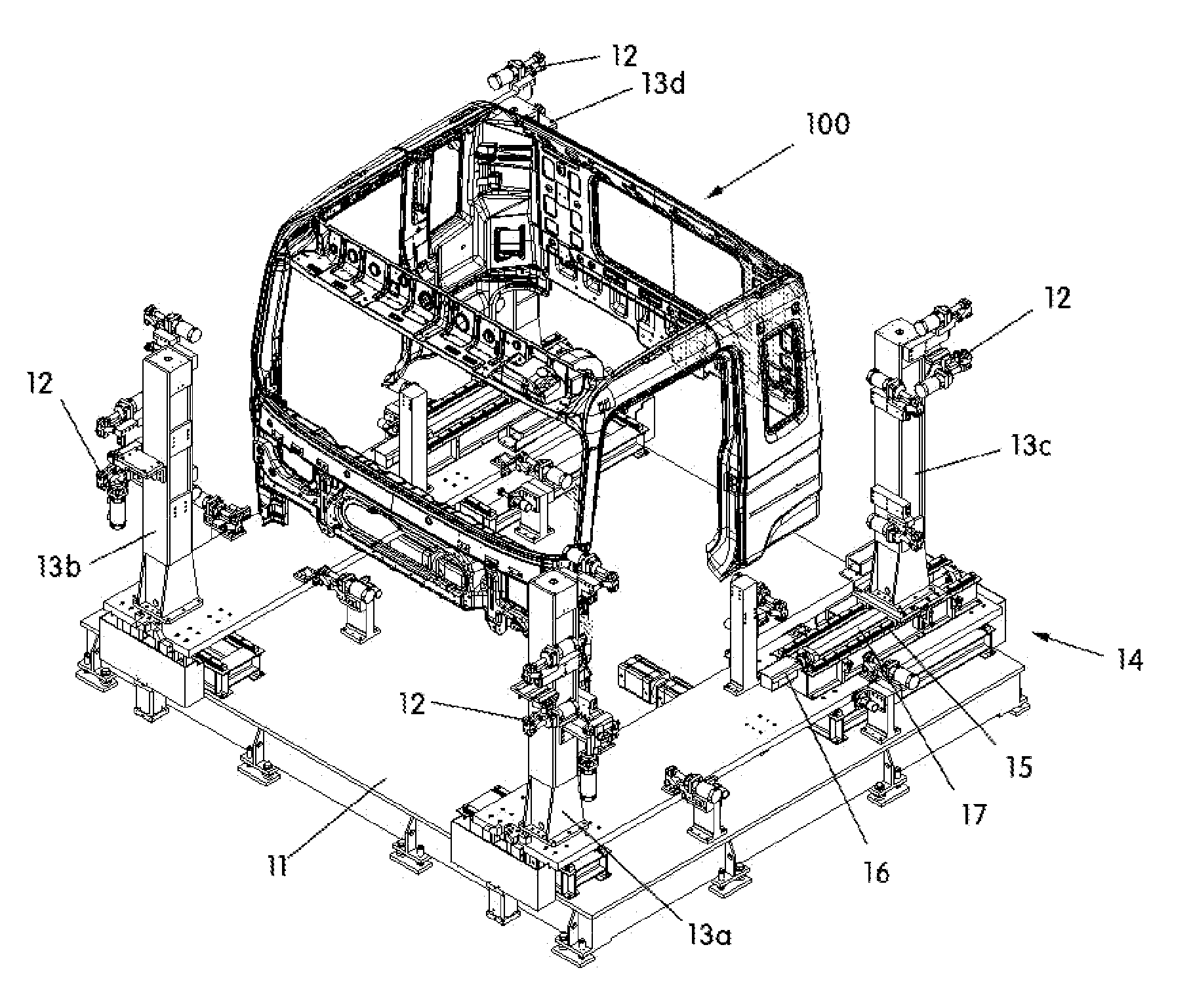

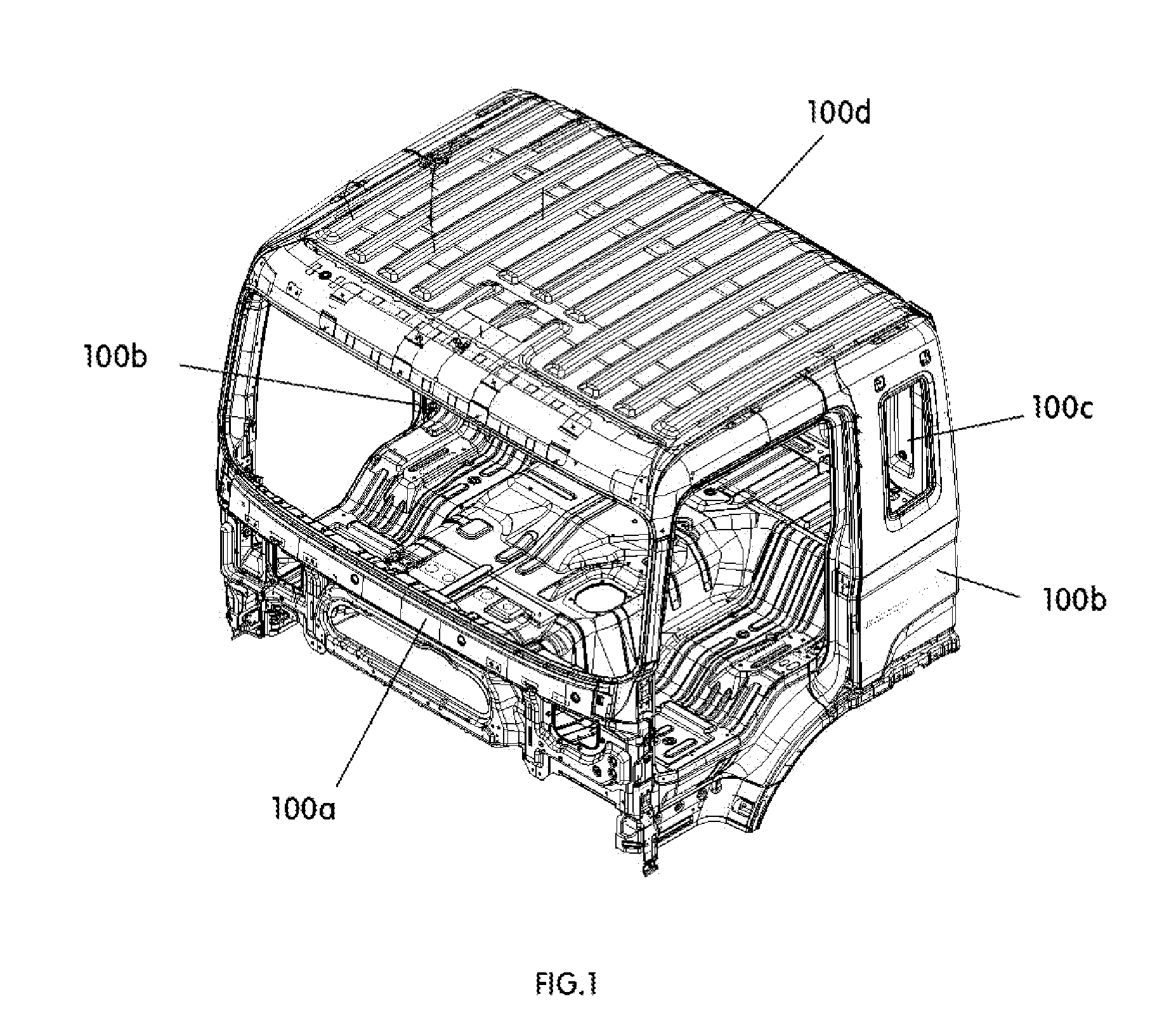

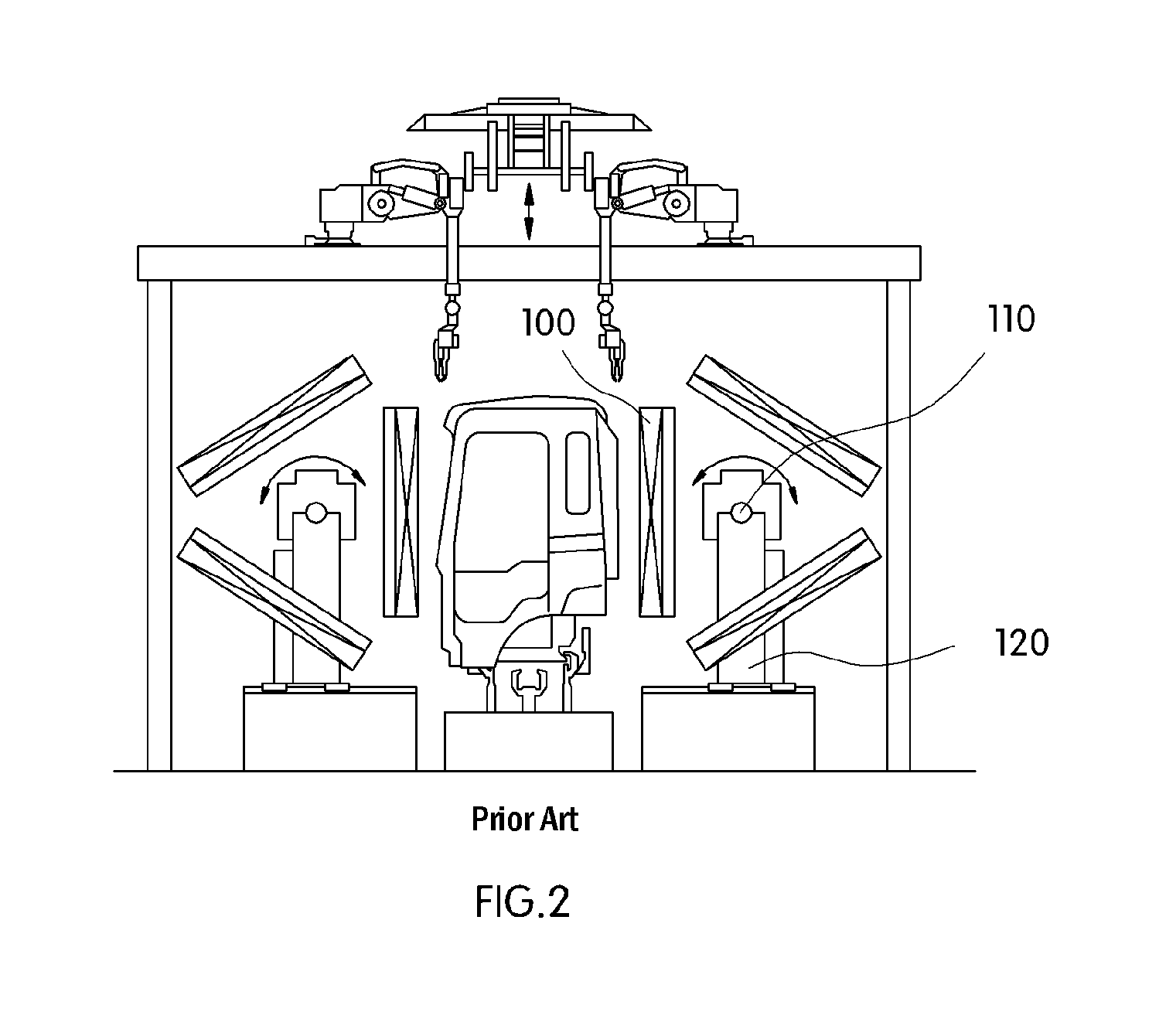

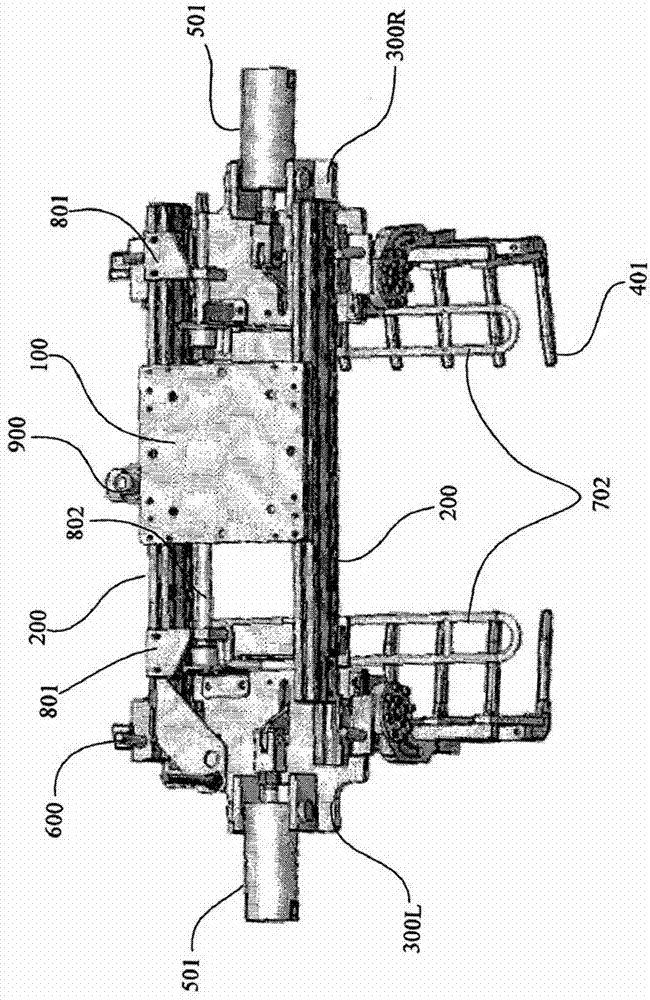

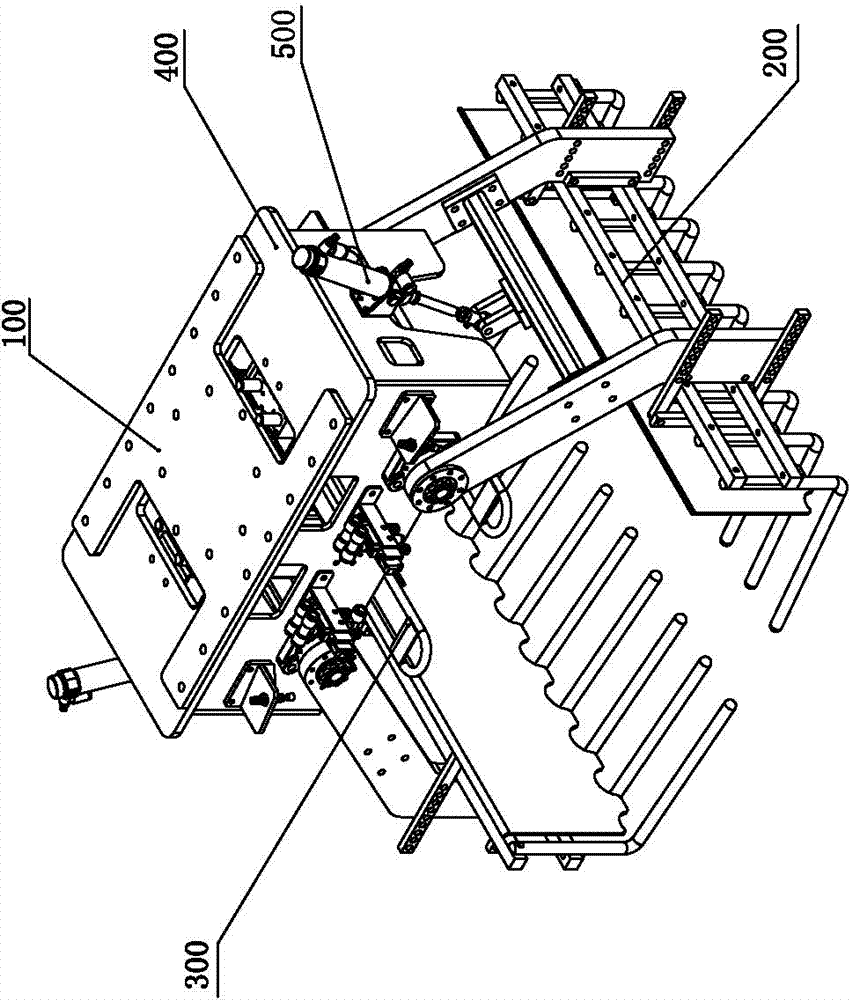

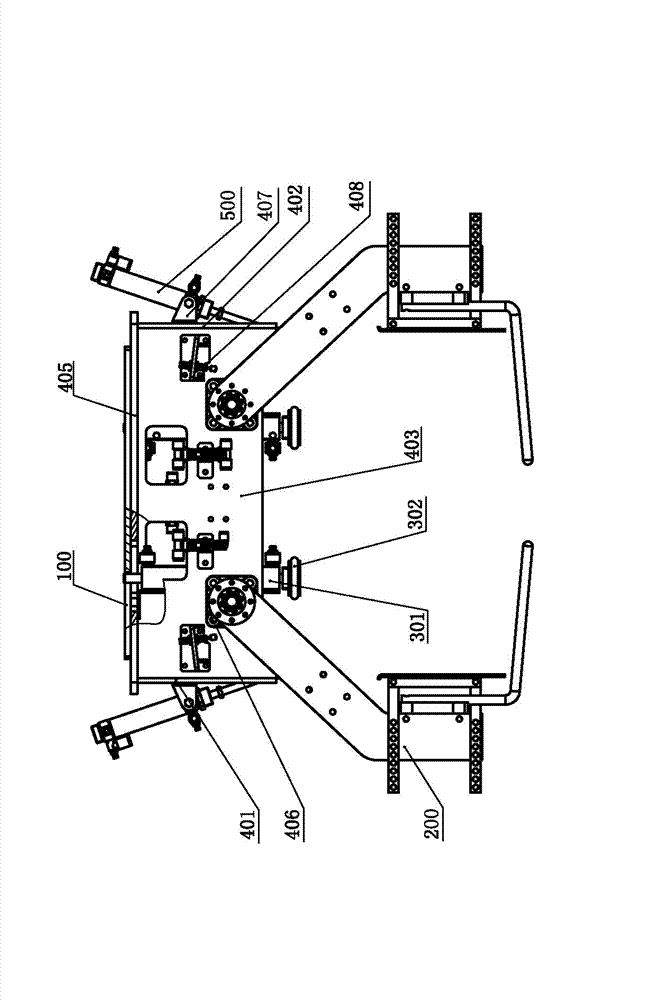

Complete body assembling apparatus for various vehicle models

InactiveUS20120137490A1Improve efficiencyFlexiblyWelding/cutting auxillary devicesAuxillary welding devicesRear quarterSingle process

The present invention relates to an apparatus for assembling a front panel, a plurality of side panels, a back panel, and a roof panel in a complete body assembly line for various vehicles. The complete body assembling apparatus realizes a new type of a coupling apparatus by which hangers for vehicle models are held in a post buck in a complete body line for a vehicle and the post buck is flexibly movable depending on the changes in various vehicle models. This in turn, allows various vehicle models to be produced in a single process by flexibly coping with various vehicle models and enhancing the efficiency of an entire complete body assembling process.

Owner:HYUNDAI MOTOR CO LTD

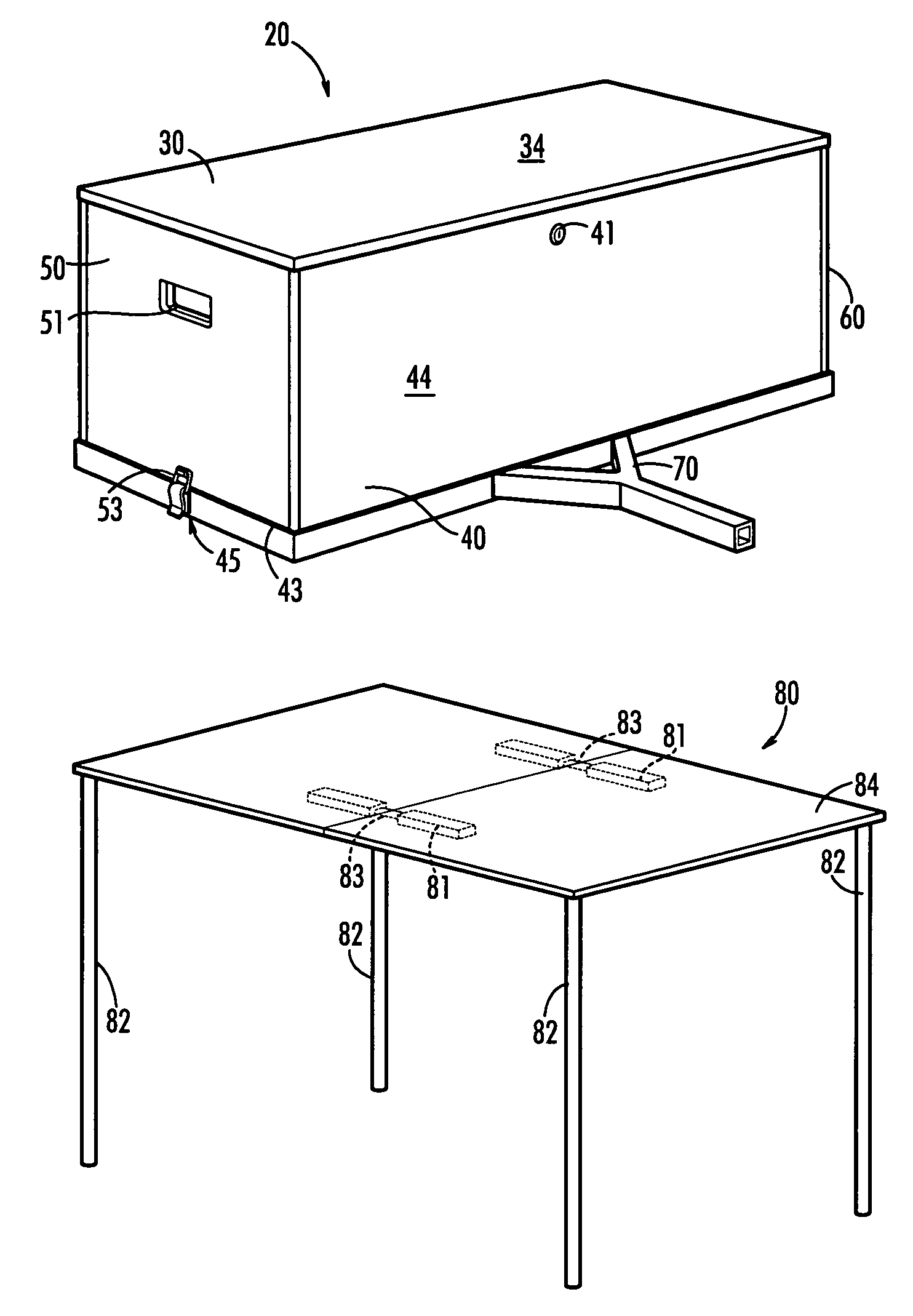

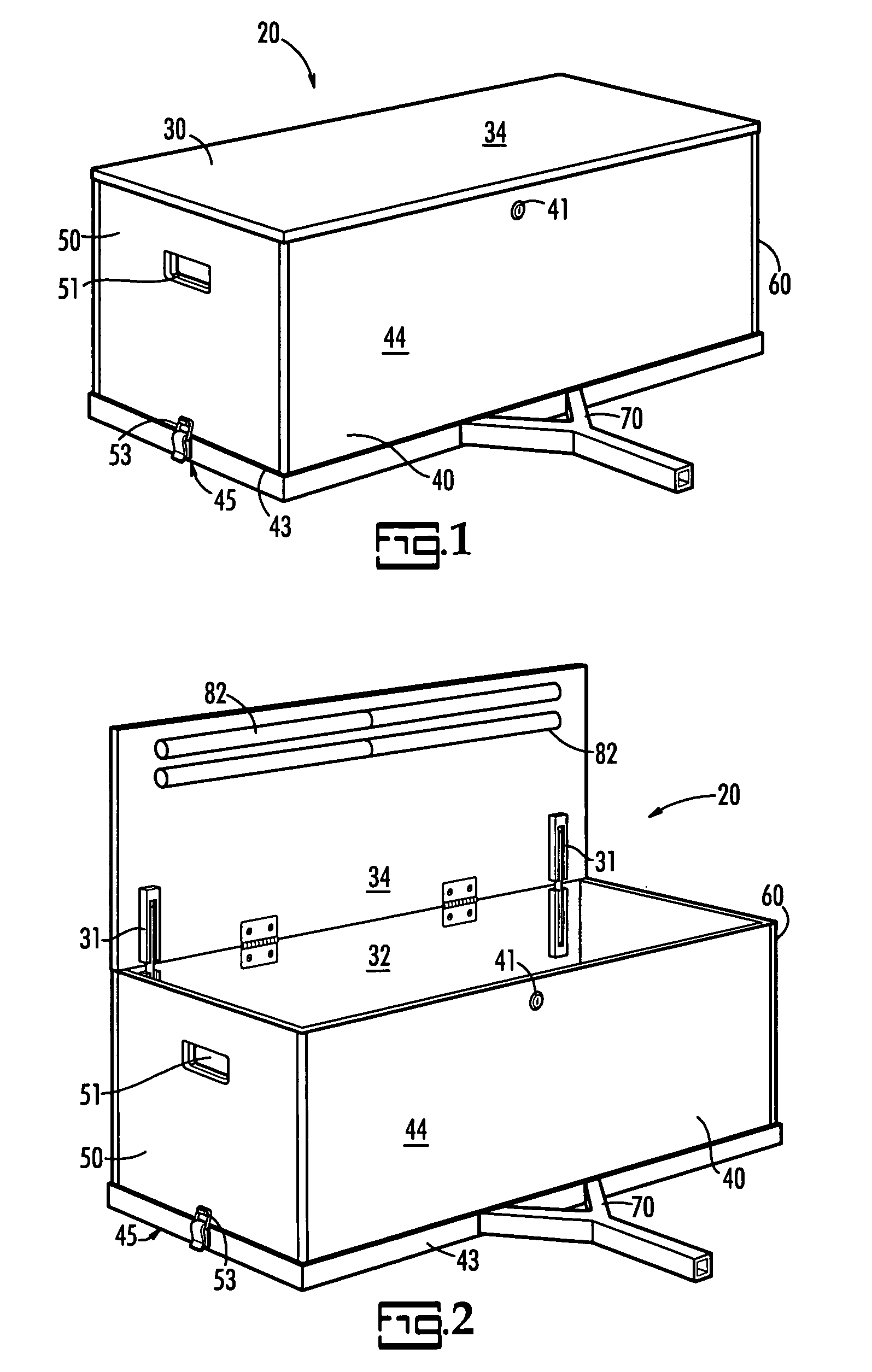

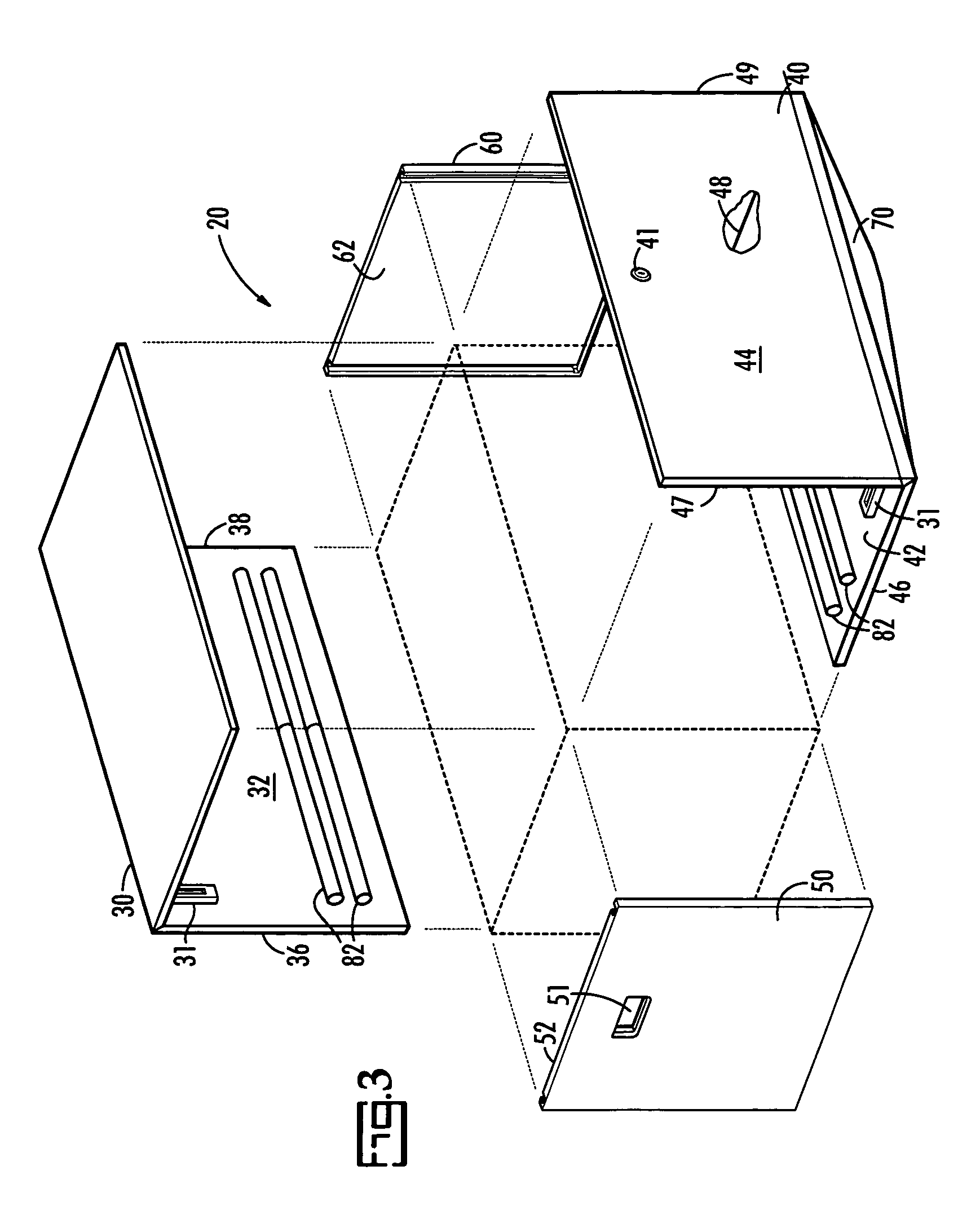

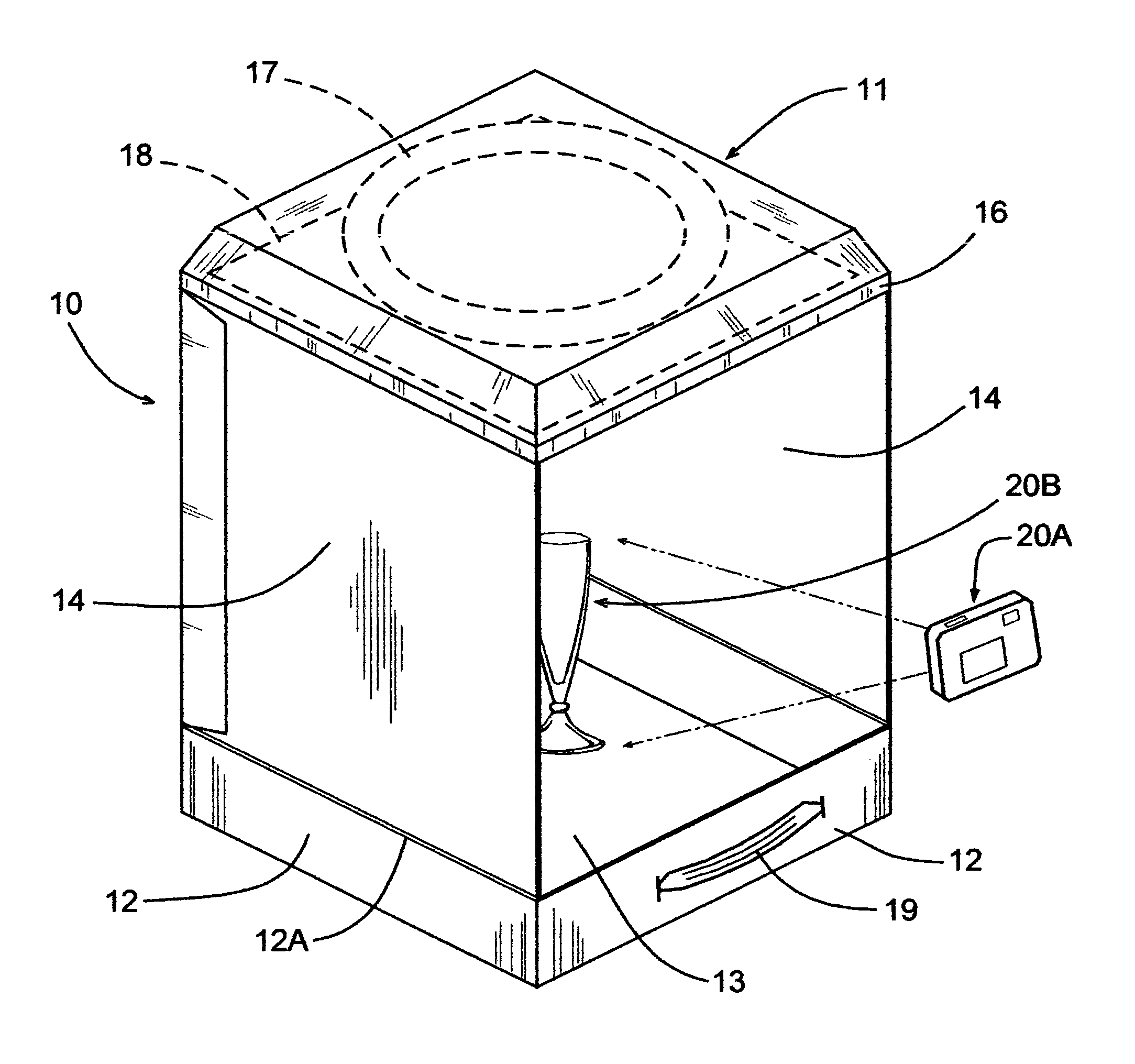

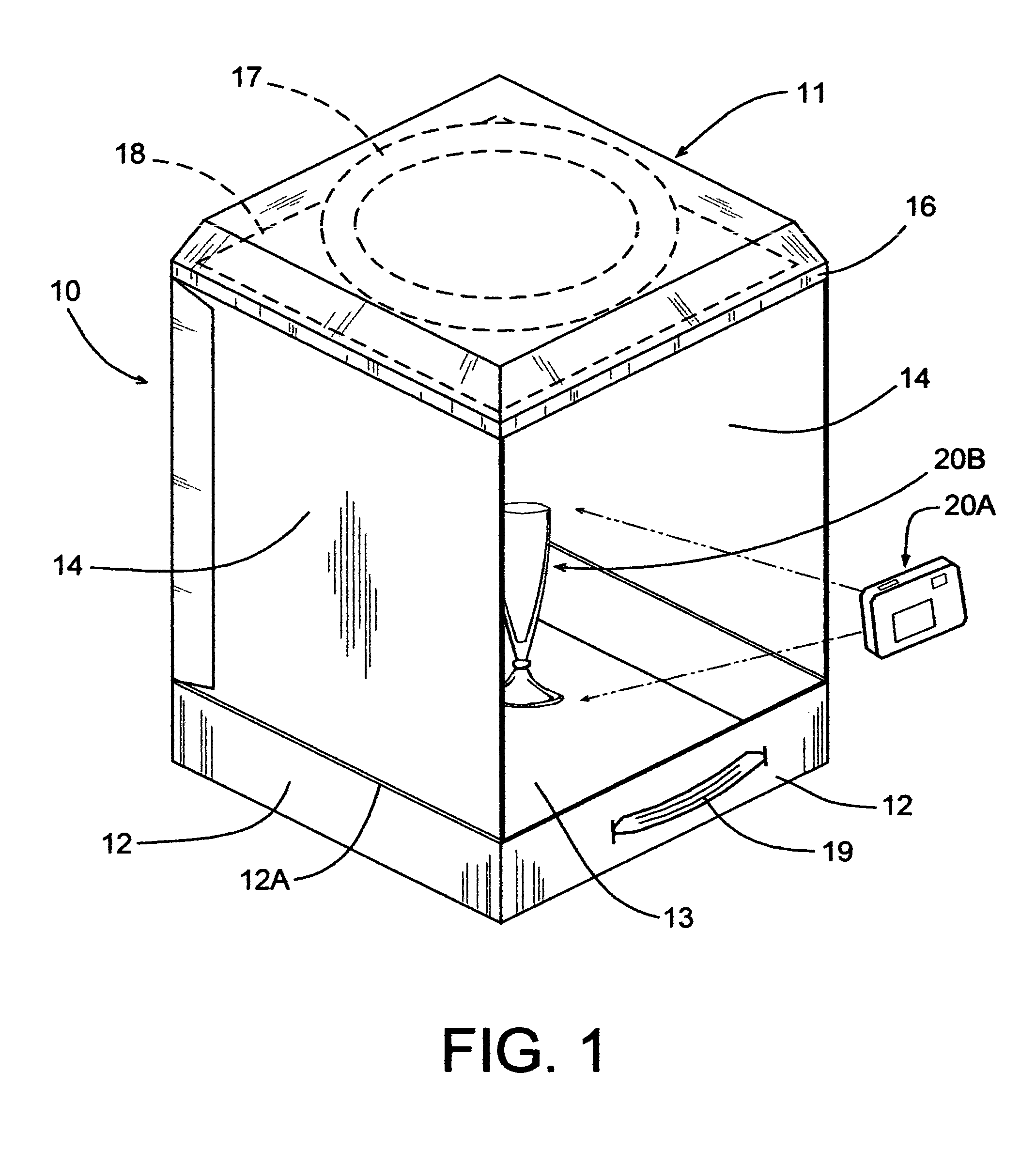

Convertible cargo container system

A convertible cargo container system having individual components that provide a table or work surface. The container system includes a pair of foldable side panels and a pair of rigid end panels coupled to the ends of each side panel to form an enclosed container. A back panel is hingeably connected to a top panel to form one side panel, and a bottom panel is hingeably connected to a front panel to form the other side panel. Each of the front, back, and bottom panels has opposing coupling ends. The interior surface of each end panel has a coupling track that receives the coupling ends of the front, back, and bottom panels. Each of the side panels may be unfolded to provide a table or work surface. Additionally, each of the side panels have retracting or folding legs attached to the interior surface of the side panel that may be extended or unfolded to support the table or work surface. A vehicle hitch coupling support is attached to the bottom of the container.

Owner:MORRIS DANIEL W

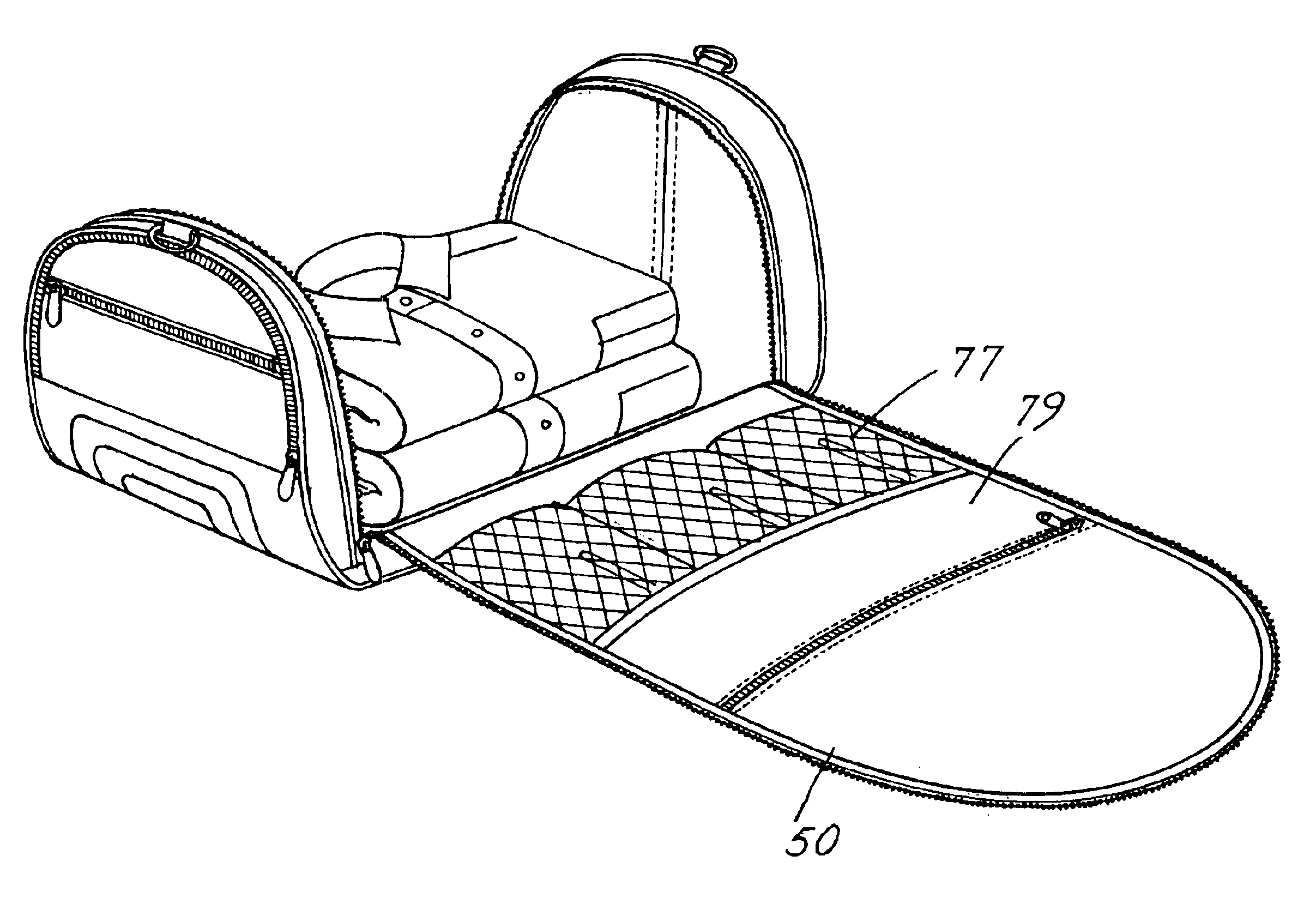

Luggage with cover

Travel luggage includes a reinforced bottom panel and opposite end panels with a telescoping handle and wheels attached to the bottom panel and arranged to stiffen the end panels to provide for a semi-rigid configuration of the luggage. The luggage further includes a flexible fold over flap that folds over the contents of the luggage and is connected by a single fastening mechanism extending from the back panel of the luggage along the side panels and front panel. The cover flap includes interior pouches or other storage features which may be removable from the fold over cover or flap.

Owner:TRAVEL CADDY

Collapsible tabletop lighting apparatus

Owner:BLANFORD THOMAS CHARLES

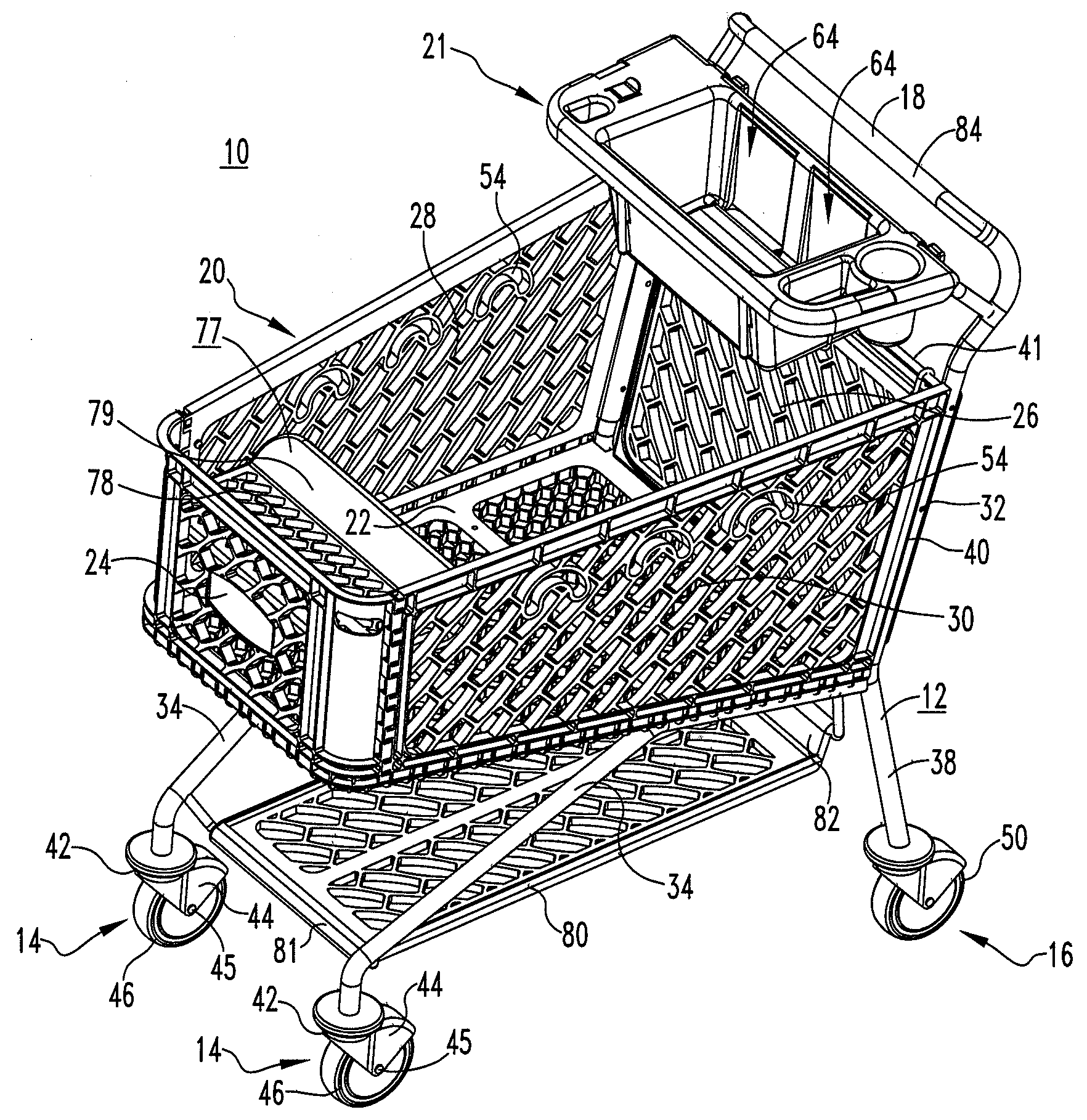

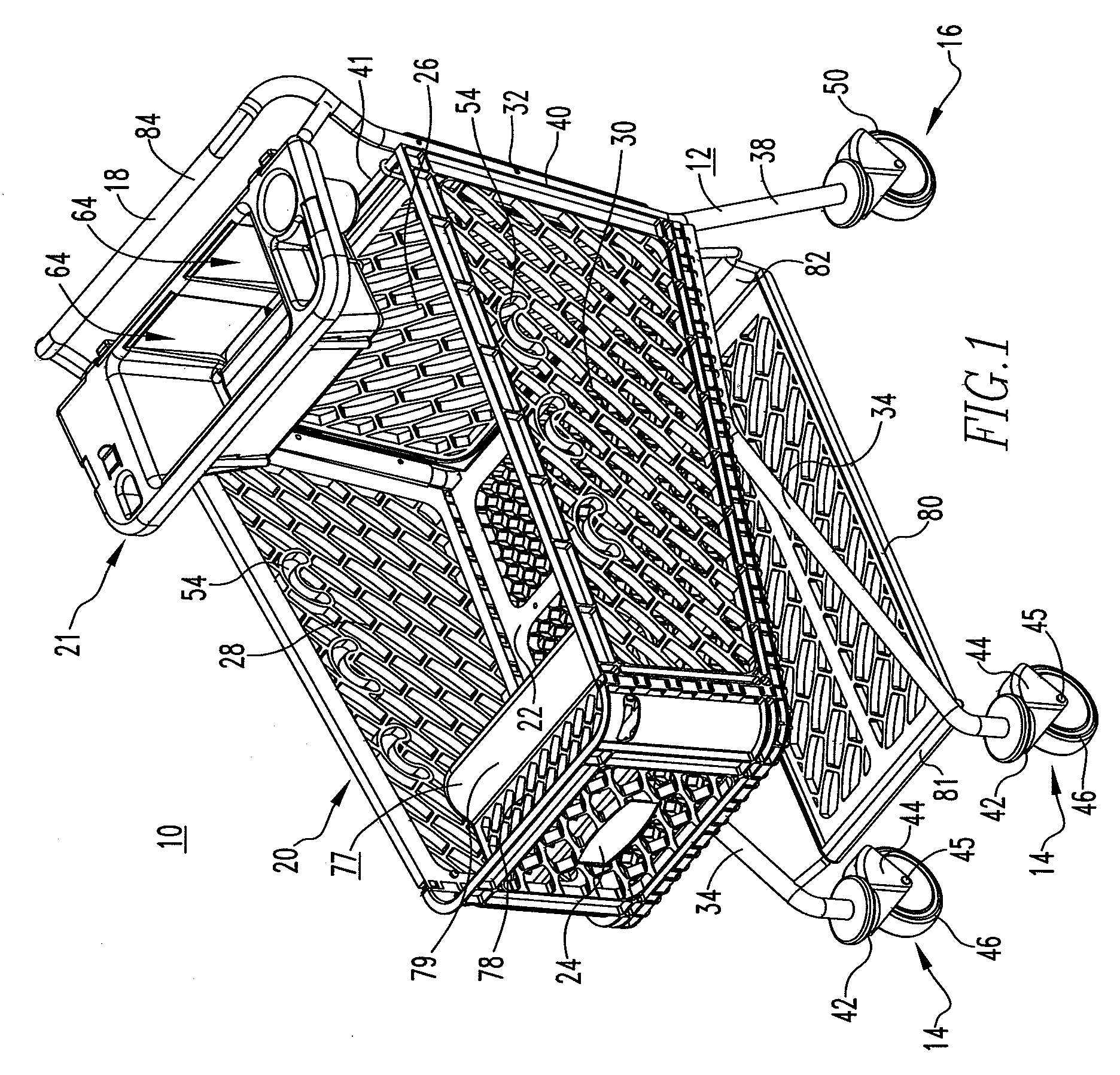

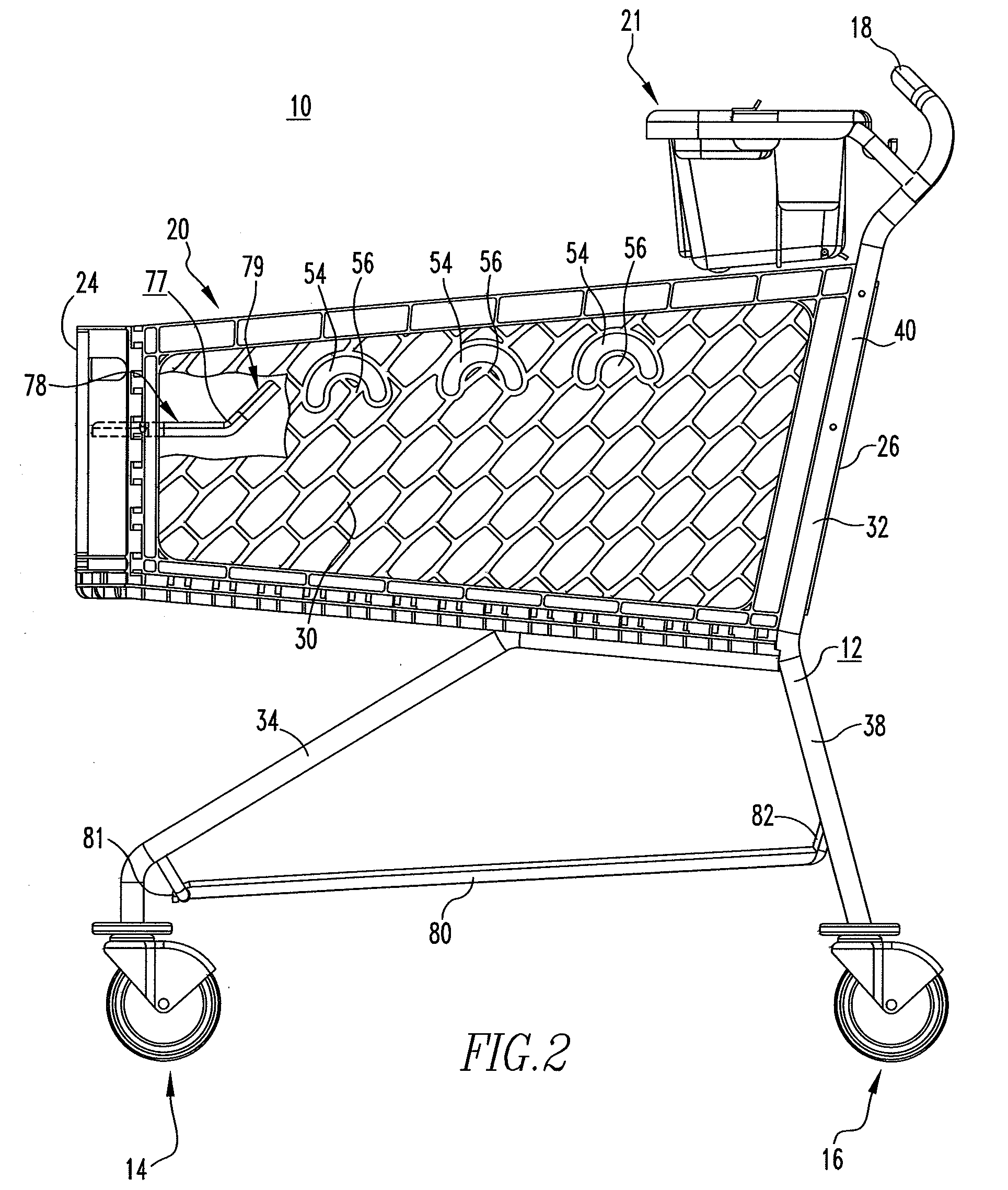

Shopping Cart

A shopping cart includes a frame, a number of front wheel assemblies and a number of rear wheel assemblies that are coupled to and support the frame, and a main container coupled to the frame. The main container includes a base, a front panel, a rear panel, and a pair of opposing side panels each having a tope edge. The front panel and the pair of opposing side panels are coupled together and extend upward from the base. The rear panel is pivotally coupled to the frame. A portion of the main container is structured to engage each of the corresponding top edges of the opposing side panels of another similarly constructed cart as the other cart is nested into the shopping cart. The engagement causes the number of rear wheel assemblies of the shopping cart to be moved from a first position to a second position generally above the first position.

Owner:PHOENIX INTANGIBLES HLDG

Stacking robot gripper

ActiveCN102729242ACrawl fastEasy to holdProgramme-controlled manipulatorGripping headsRear quarterRotational axis

The invention relates to a stacking robot gripper in the field of robots for stacking during package and transportation. The stacking robot gripper comprises a main frame mechanism, a connecting plate and two groups of symmetrical tooth gripping mechanisms and also comprises light-type cylinders, wherein the main frame mechanism mainly comprises a front side plate, a rear side plate, a left side plate, a right side plate and a top plate; the connecting plate is fixed on the top plate; the tooth gripping mechanisms are rotatably supported at the front side plate and the lower side plate of the main frame mechanism; the light-type cylinders are symmetrically and obliquely arranged at the left side and the right side of the main frame mechanism and are used for driving the tooth gripping mechanisms to rotate; each group of tooth gripping mechanisms comprise a plurality of L-shaped gripping teeth which are fixedly connected by a plurality of connecting rods, are uniformly distributed and point to the same side; the gripping teeth are fixedly connected with two rows of parallel rotating arms by the connecting rods; rotating shafts are connected at the end parts of the two rotating arms; the front side plate and the rear side plate are correspondingly provided with mounted bearings for supporting and installing the rotating shafts; and the corresponding inner sides of the two groups of tooth gripping mechanisms are also provided with pressing plates with adjustable distance, and the pressing plates are used for clamping the two sides of a gripped object. The stacking robot gripper has the advantages of simple and compact structure, flexible operation, fast gripping speed, stable gripping and wide application range.

Owner:扬州牧羊唯美自动化控制有限公司

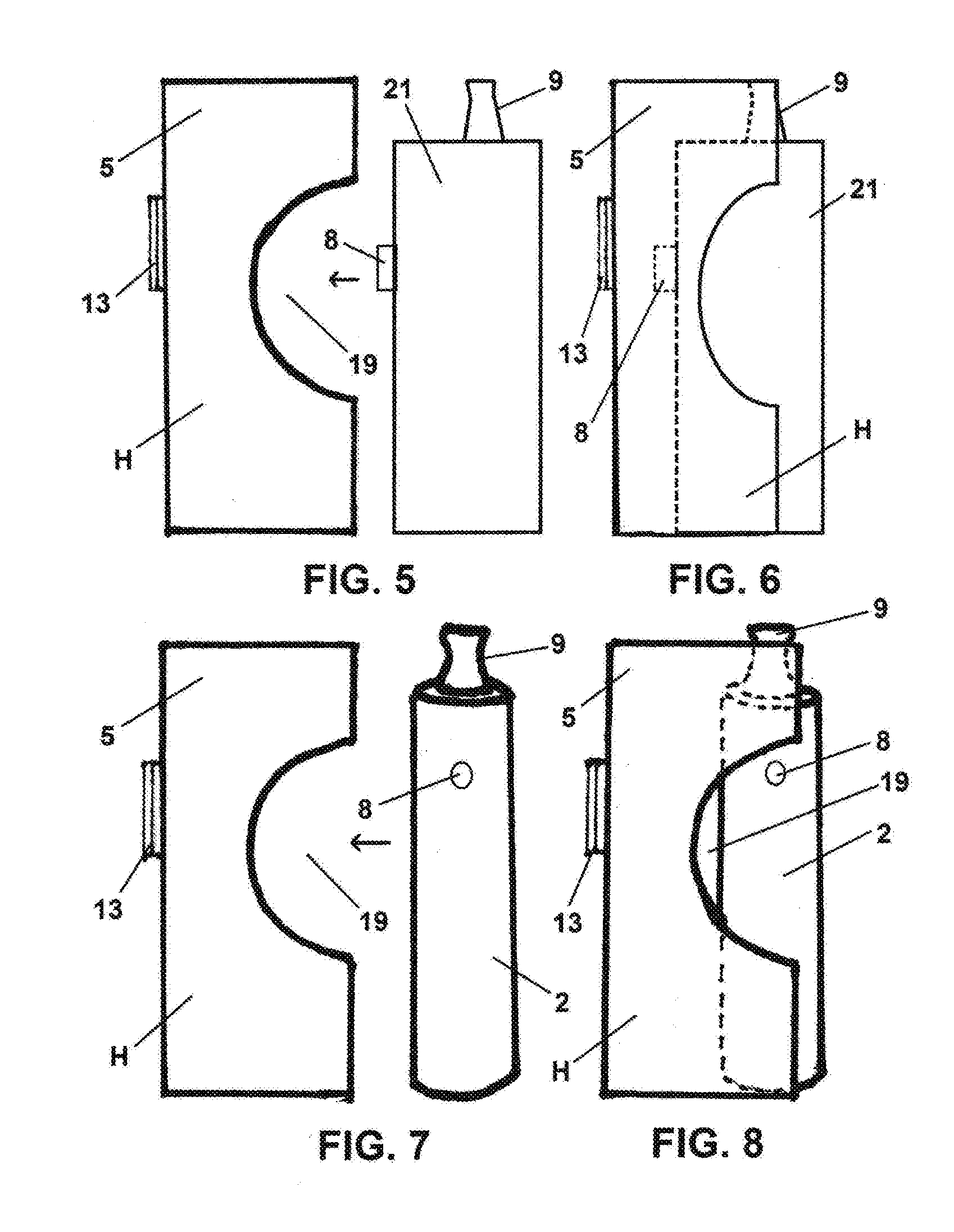

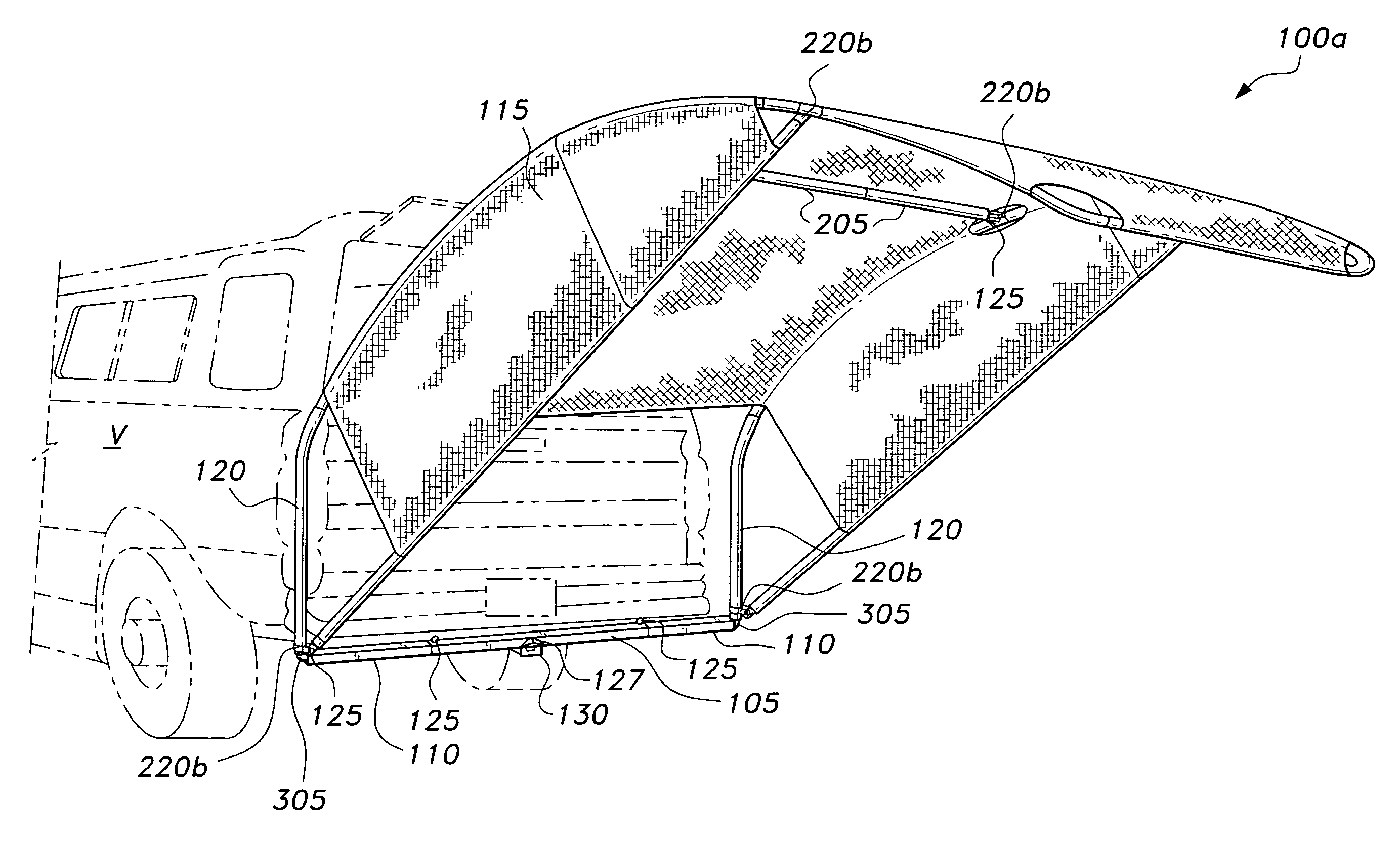

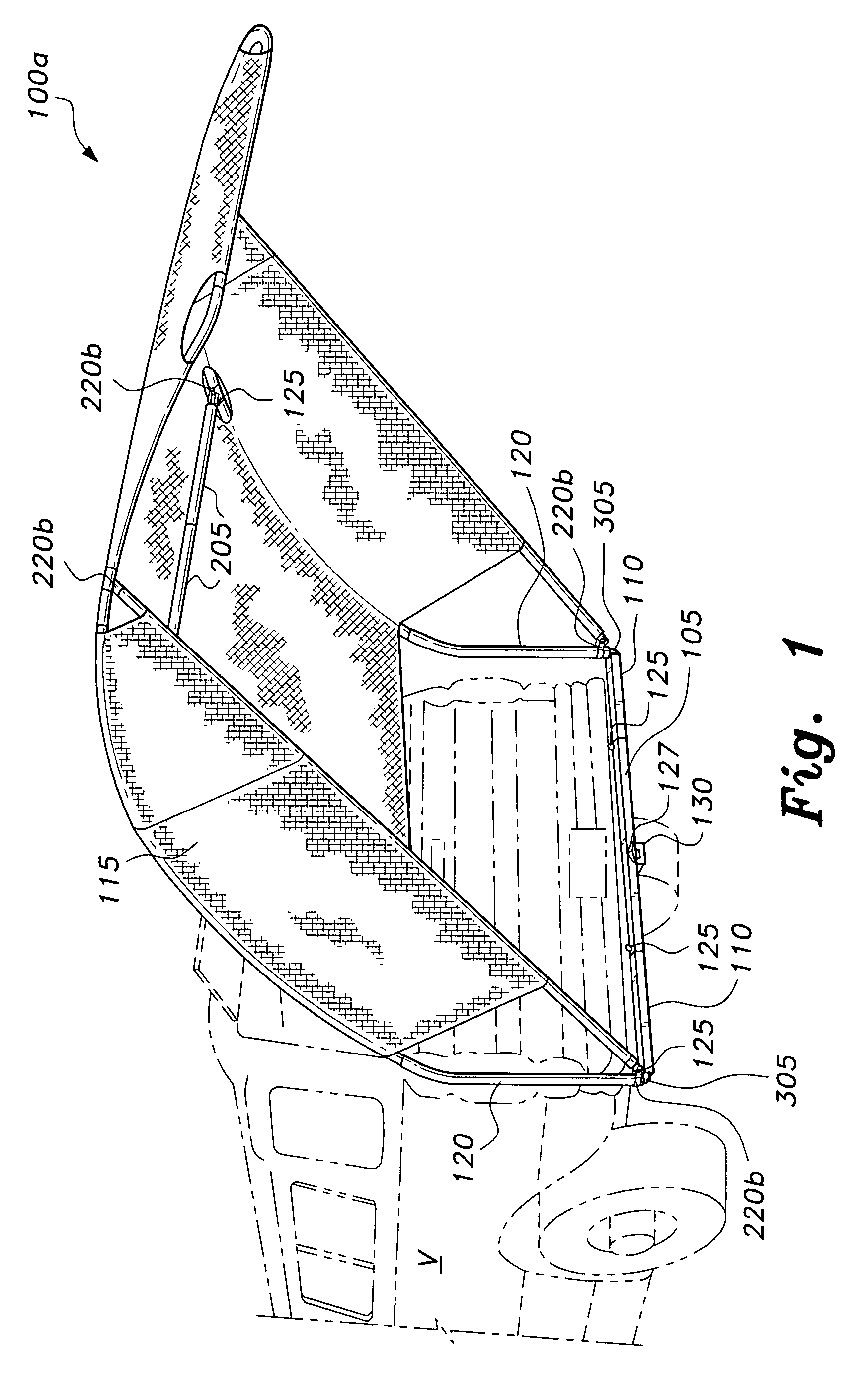

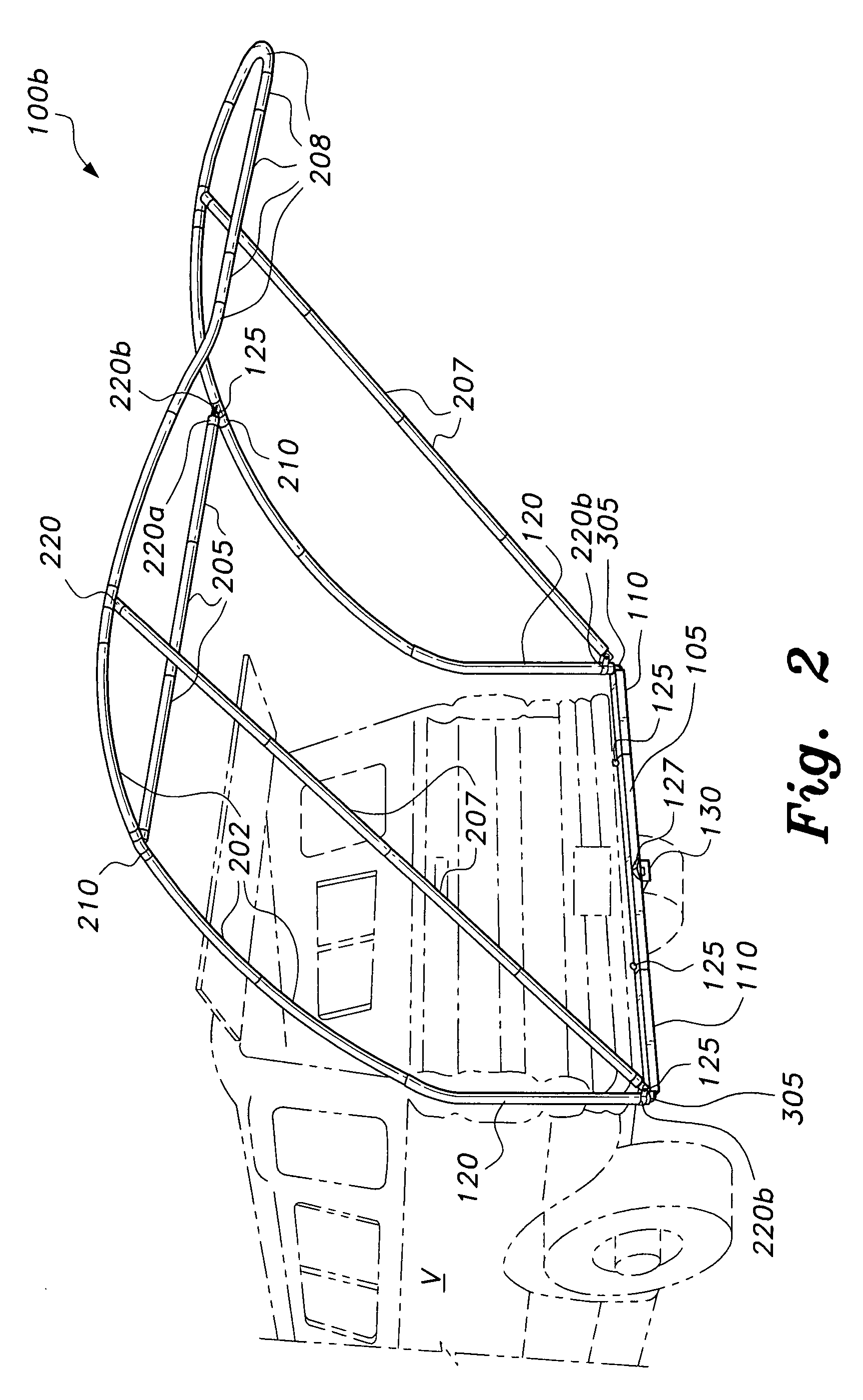

Tailgator/sunshade protective cover

Owner:SOTIRKYS CHARLES PETER +1

Device for holding and securing Electronic Cigarettes in a motor vehicle

Device for holding and securing Electronic Cigarettes within a motor vehicle comprising a box-like structure having side panels, a rear panel, and a bottom panel, accessible from the top and the front. The device contains a plurality of upper and lower flexible constructs within the interior of the device acting as securing means to secure either cylindrical or box-type Electronic Cigarettes of varying dimensions. The device holds and secures, alternately, cylindrical or box-type Electronic Cigarettes, in the same space within the holder, as opposed to having separate compartments for each type of Electronic Cigarette. The invention also introduces a multi-bracket vehicle door panel mounting system where different size brackets are employed to conform to vehicle door panels of varying depths.

Owner:WALLACE MICHAEL W +1

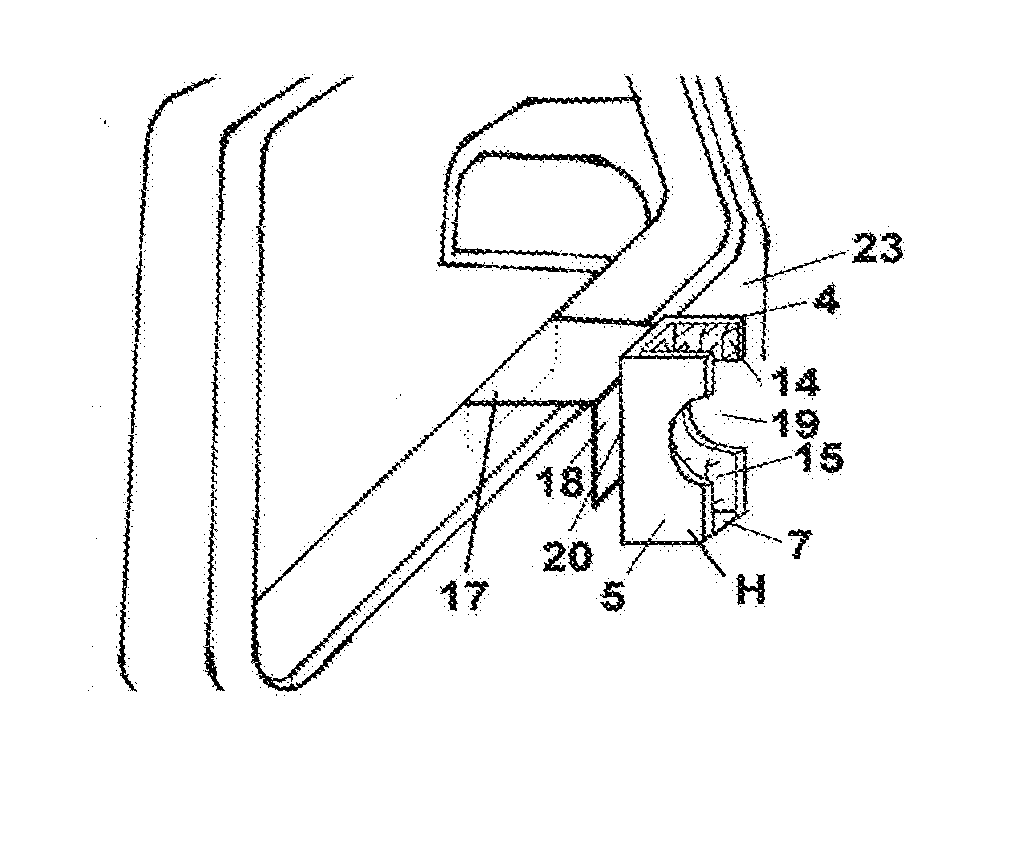

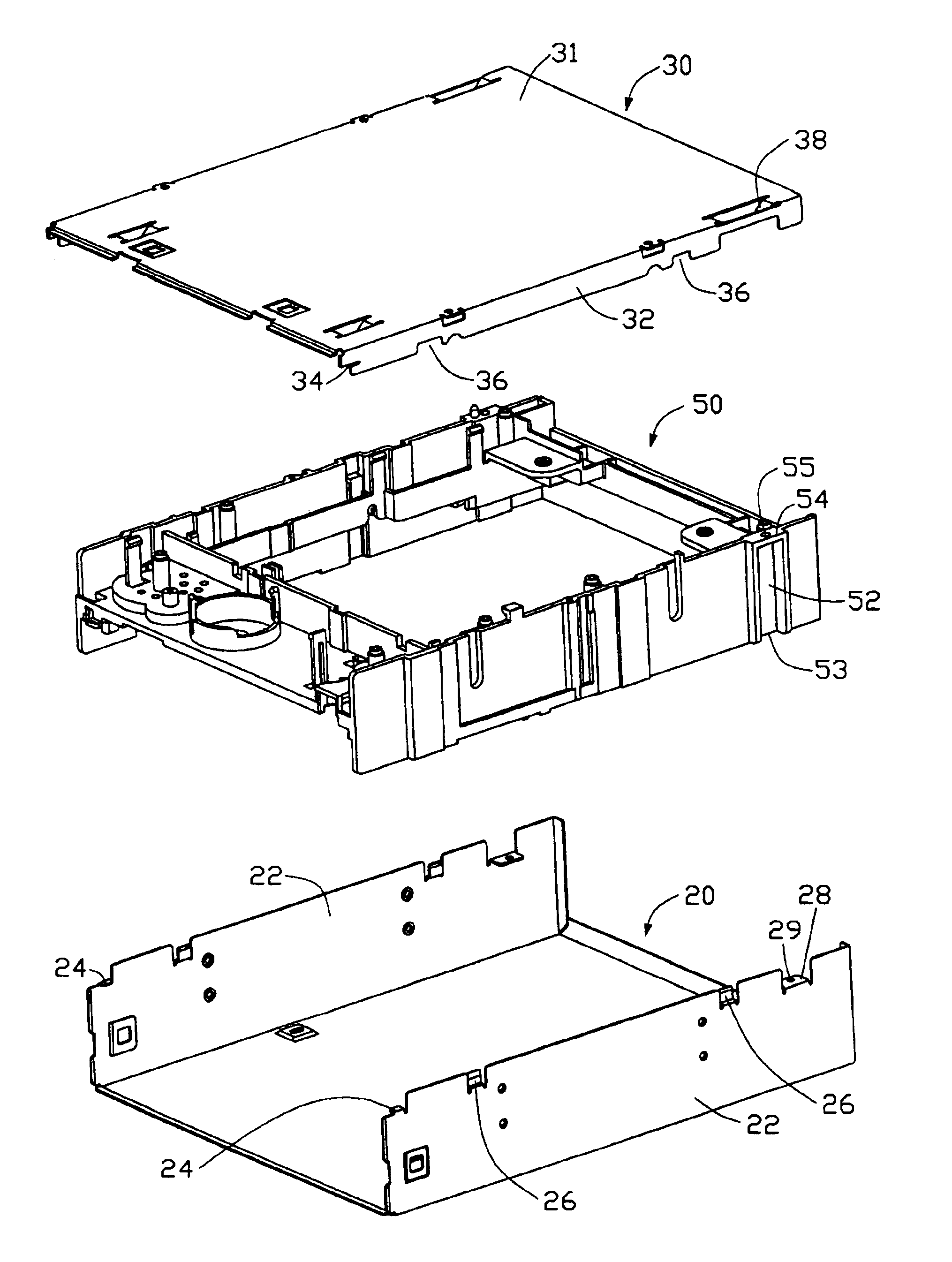

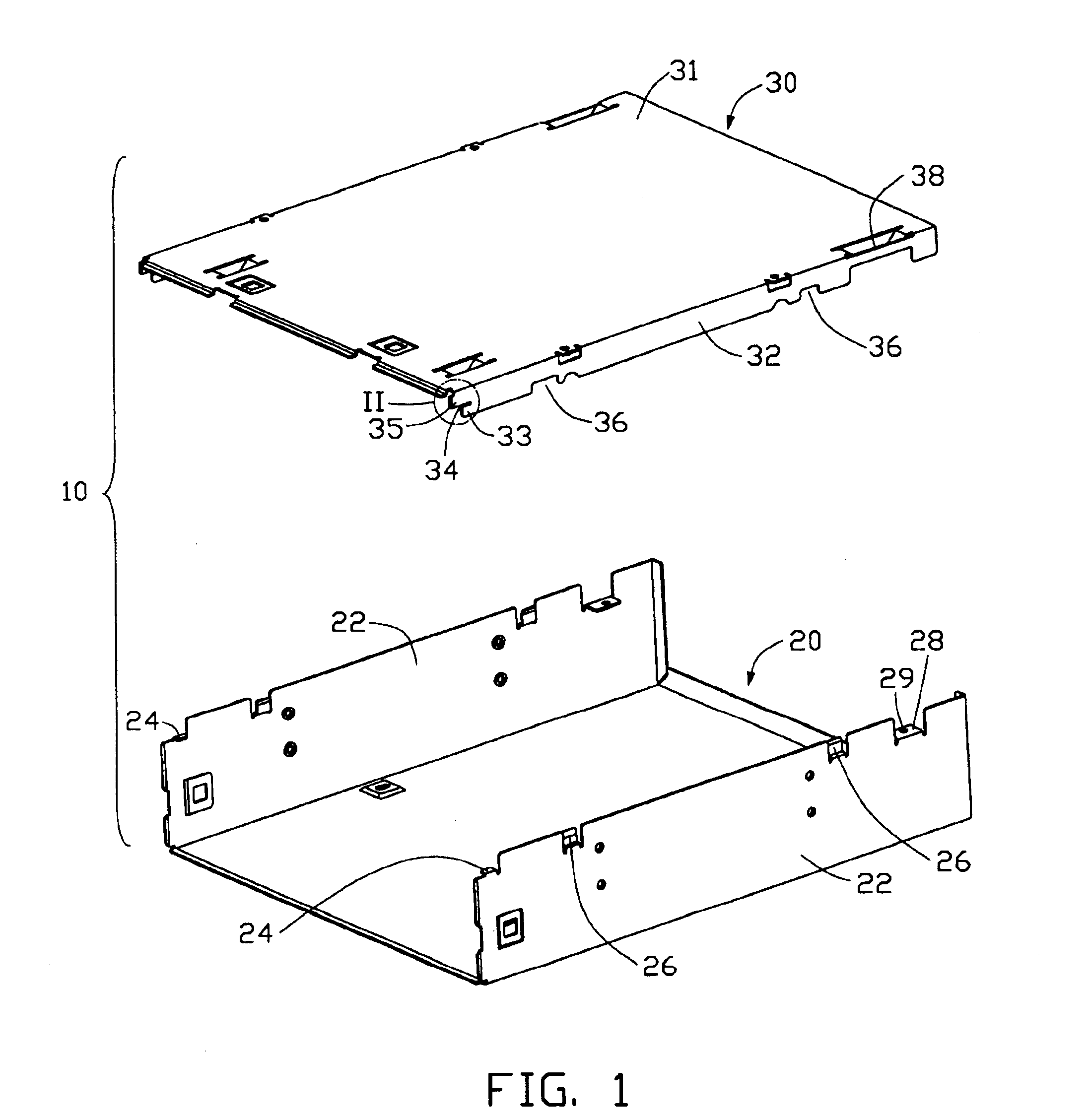

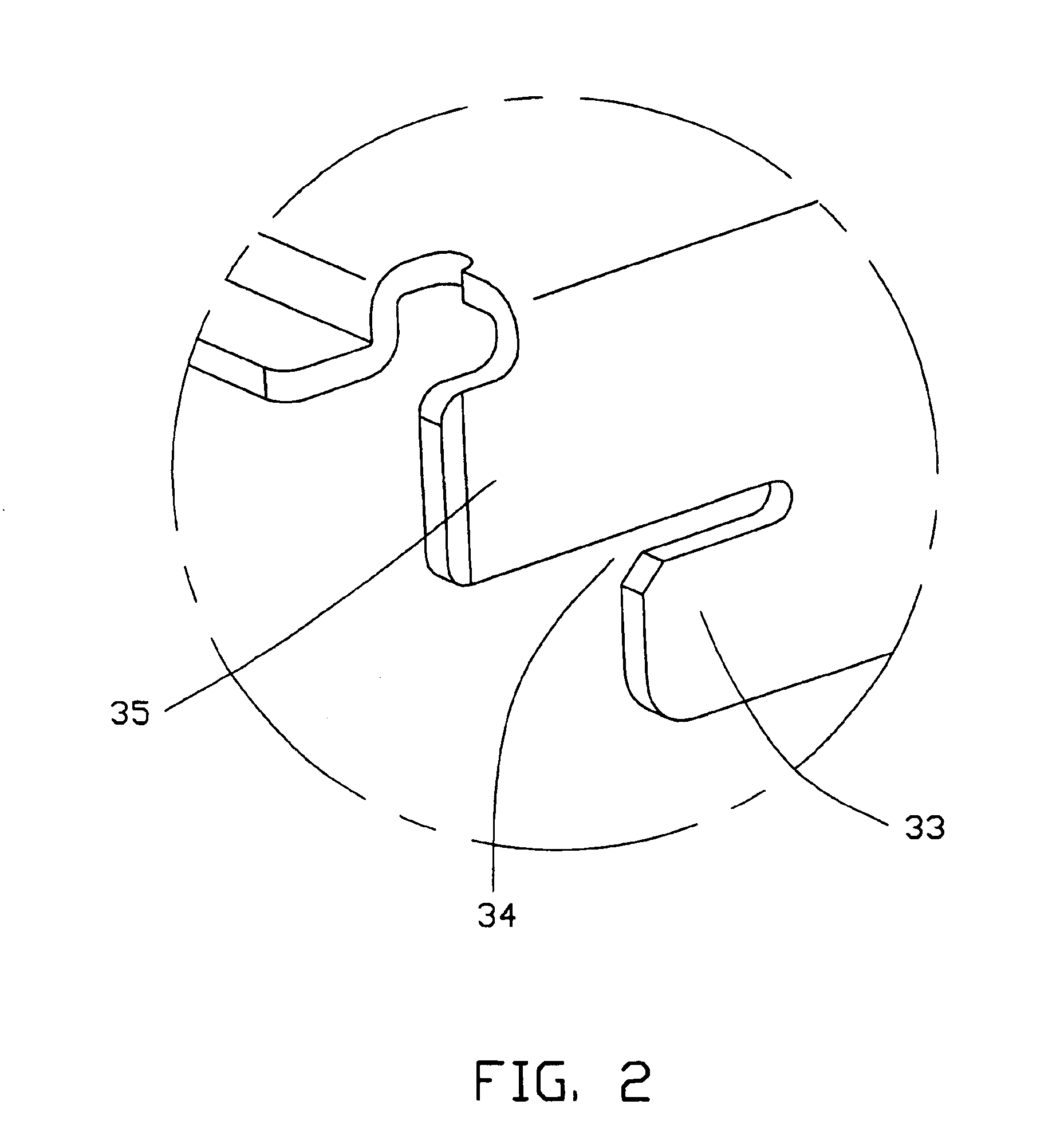

Optical disc driver enclosure

InactiveUS6909047B2Easy to disassembleCarrier constructional parts dispositionInstallation of lighting conductorsRear quarterEngineering

An optical disc drive enclosure (10) includes a first cover (20) and a second cover (30). The first cover has a bottom plate and two first side plates (22). A locating plate (24) extends inwardly from a front upper edge of each first side plate, and two protrusion plates (26) are formed on an upper edge of each first side plate. The second cover has a top plate (31) and two second side plates (32). A locating slot (34) is formed at a front end of each second side plate, and can engage with the corresponding locating plate. Two cutouts (36) are defined in each second side plate. During assembly, the locating slots engage with the locating plates, with the second cover at an angle to the first cover. The second cover is then rotated downwardly so that the cutouts engage with the protrusion plates and the second side plates are clipped between the first side plates and the protrusion plates. The first cover and the second cover can then be fixed together by a pair of screws (59).

Owner:HON HAI PRECISION IND CO LTD

Vehicle-mounted awning

Owner:BANFILL JEFFREY A +1

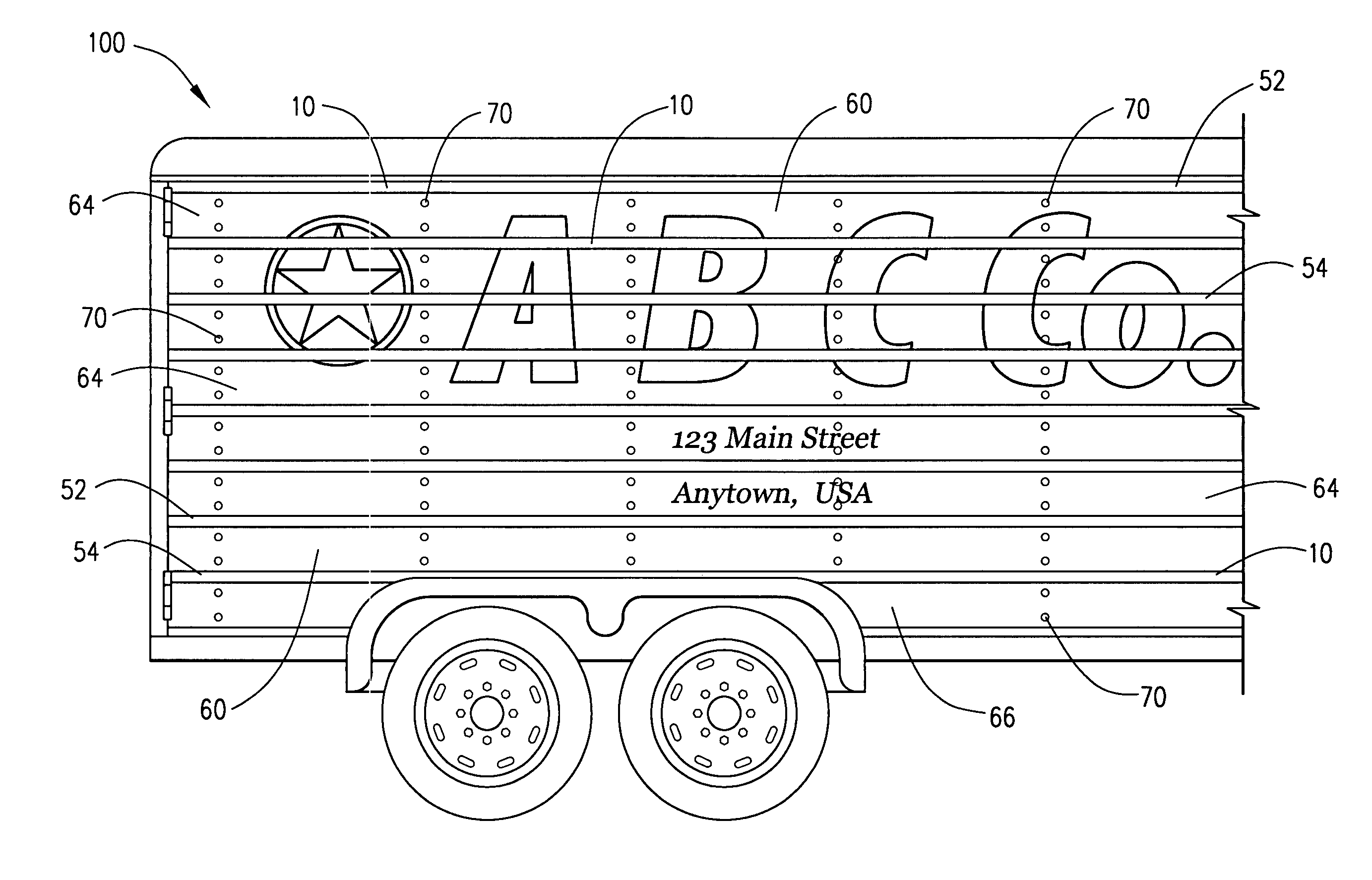

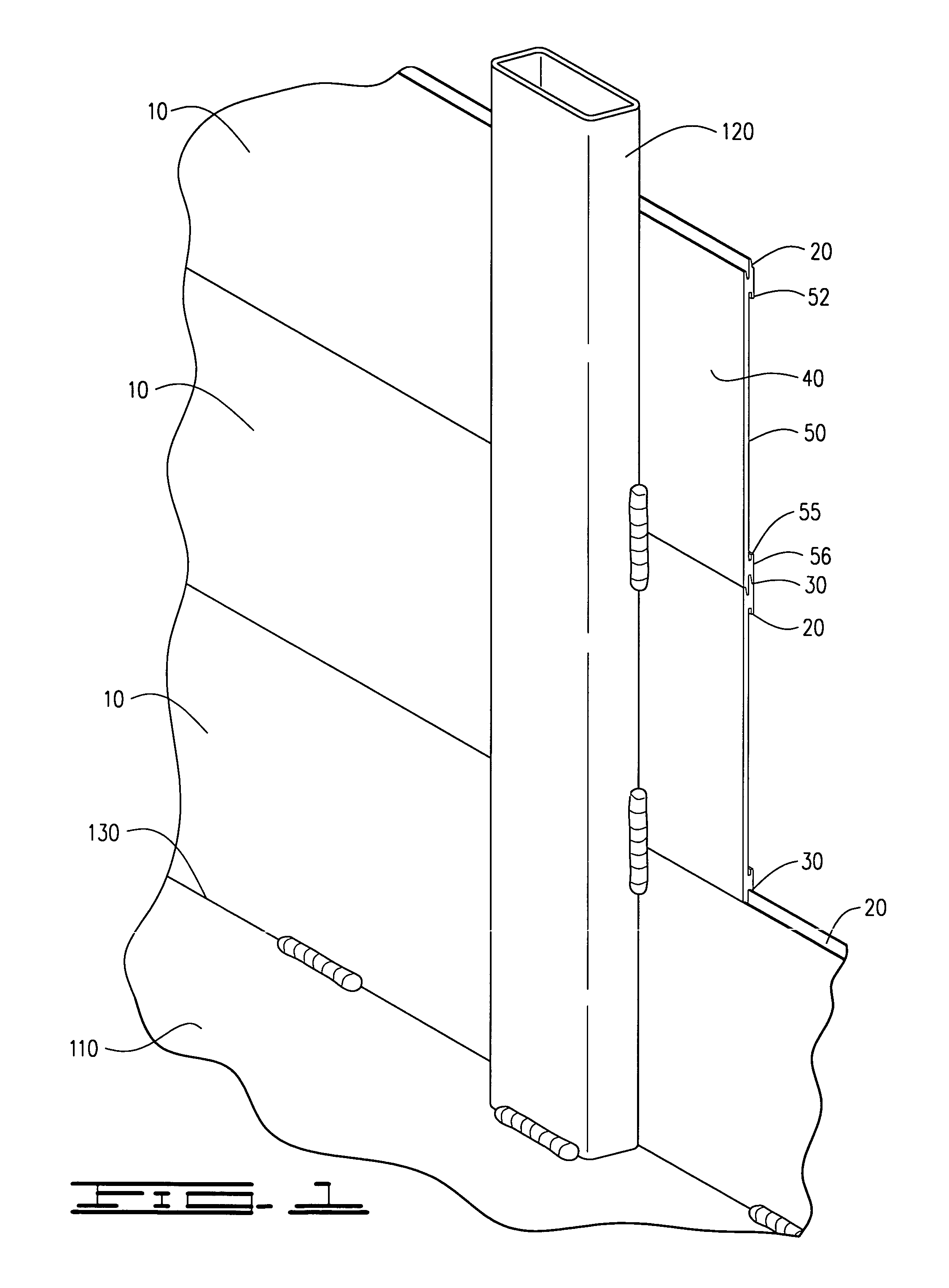

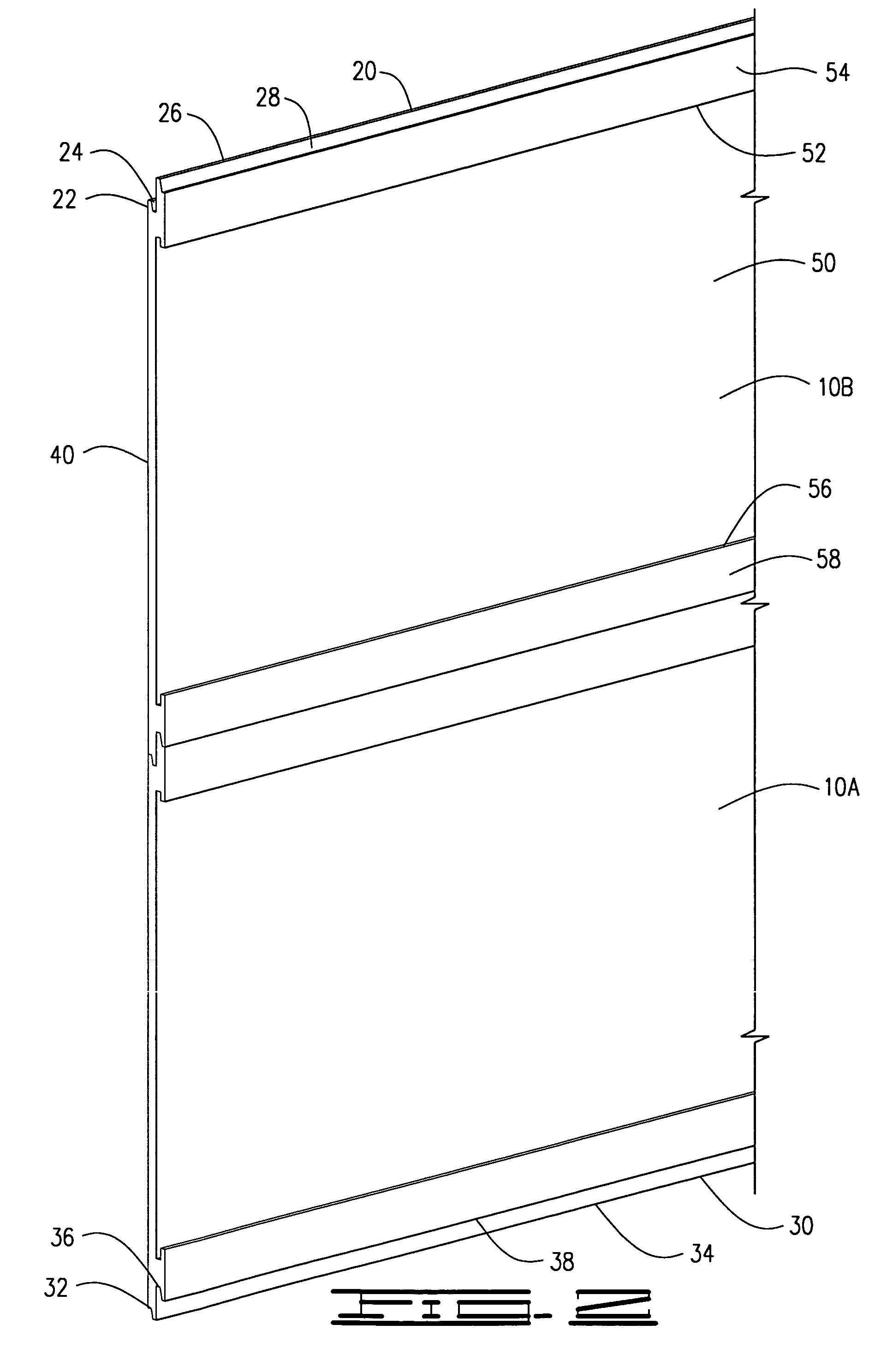

Interlocking channeled trailer side panels with integrated sliding outer panel inserts

A metal trailer interlocking panel attached to a trailer frame used in the construction of an enclosed or paneled trailer, preferably in a horizontal and stacked orientation, includes an upper groove assembly and a conforming and interlocking lower groove assembly, an inner surface welded to a vertical trailer frame member and an outer surface having a lower slot member and an upper slot member forming a sliding channel within which is slid a horizontal outer panel insert riveted to the panel. In the event the panel insert is damaged by hail, road debris, branches or other accidental means, or a simple change in aesthetics or display medium is desired, the panel insert may be exchanged without requiring replacement ofthe panel. The panel insert may also have an ornamental design or graphic applied to an outer surface, which enables the trailer owner to apply a variety of panel inserts and exchange graphics without having to repaint the entire trailer, and also to allow for change of information which may be applied to the panel inserts for advertising or other textual information.

Owner:STIDHAM BRIAN +1

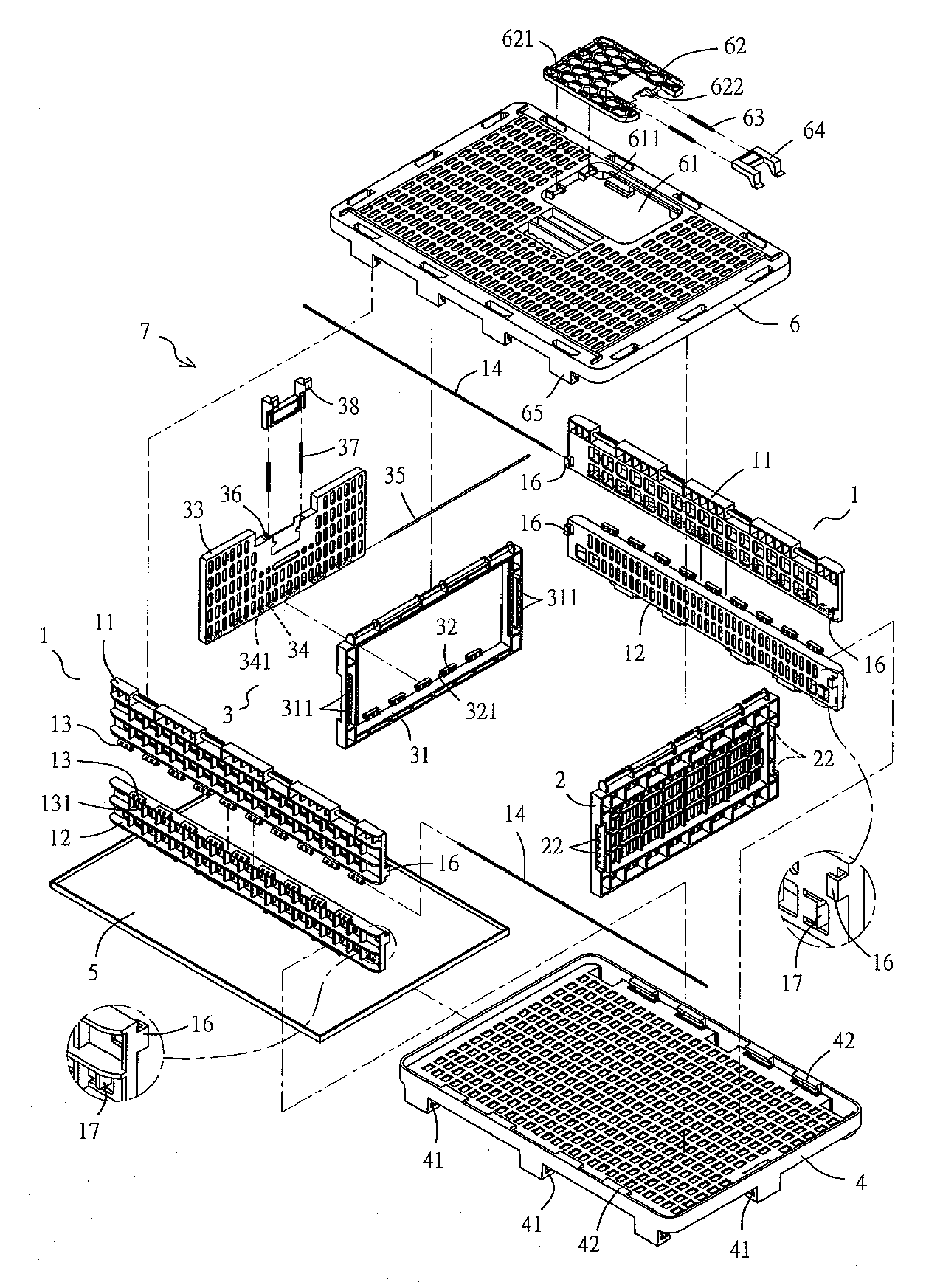

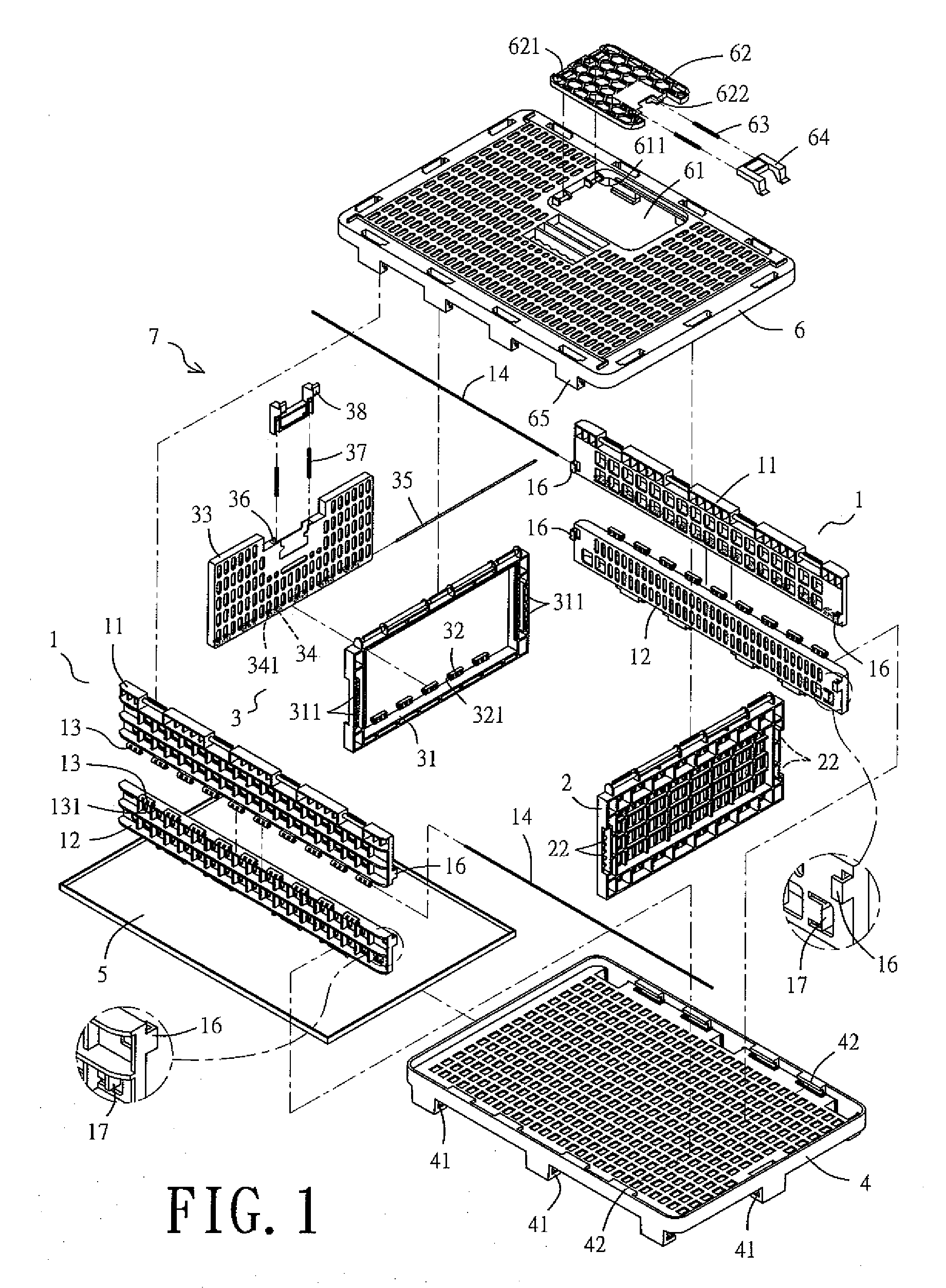

Pet Cage Assembly

InactiveUS20090288613A1Improve existing pet cage assemblyAssembly safetyAnimal housingBird housingsRear quarterBack door

A pet cage assembly comprises two lateral panels, a front panel, a rear panel, a bottom panel and a top panel. Each of the lateral panels comprises an upper and a lower sub-panel, each formed with fasteners extending inwards from two ends thereof for engaging with cavities formed on corresponding edges of the front and rear panels. Each of the lower sub-panels is formed with an extended, engaging portion adjacent to a section thereof to which the front panel is assembled, so that the front panel can be retained bilaterally by the engaging portions. The lateral, front and rear panels are fastened to a bottom side of the top panel, which is formed with an opening for receiving an upper door resiliently engaged therein. The rear panel comprises a frame pivotally attached by a rear door, which is resiliently engaged at an edge thereof with the frame.

Owner:YING YEEH ENTERPRISE

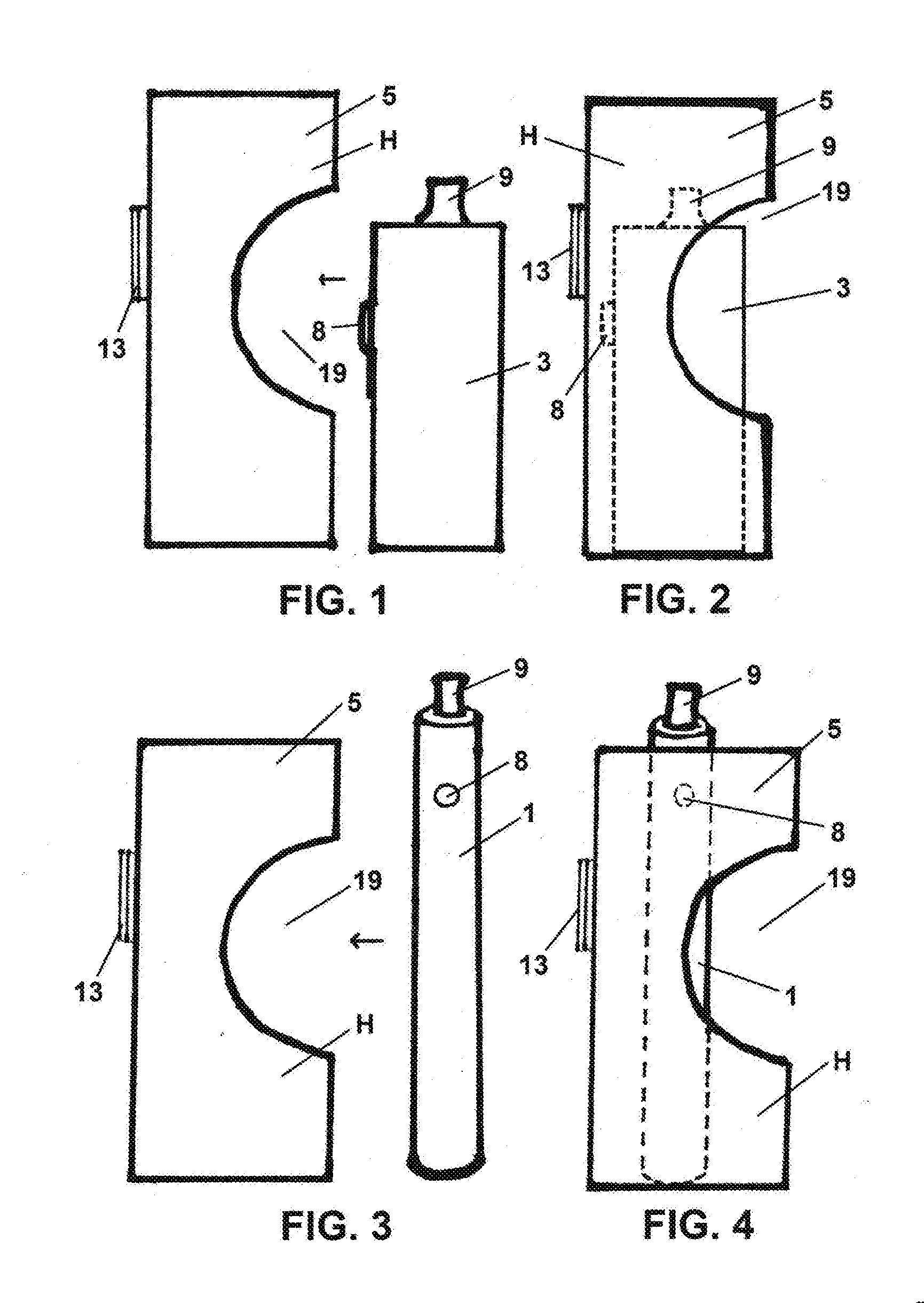

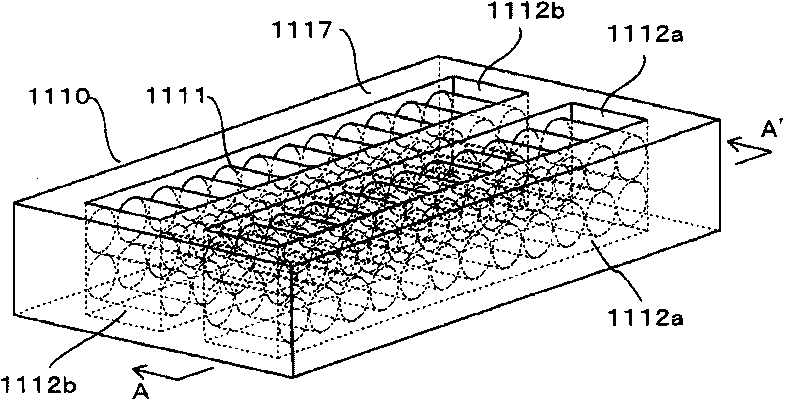

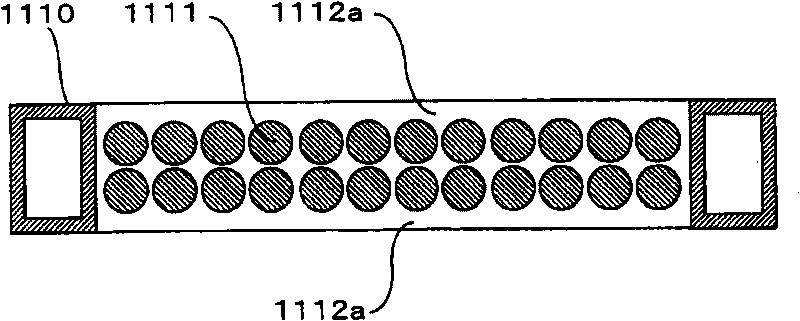

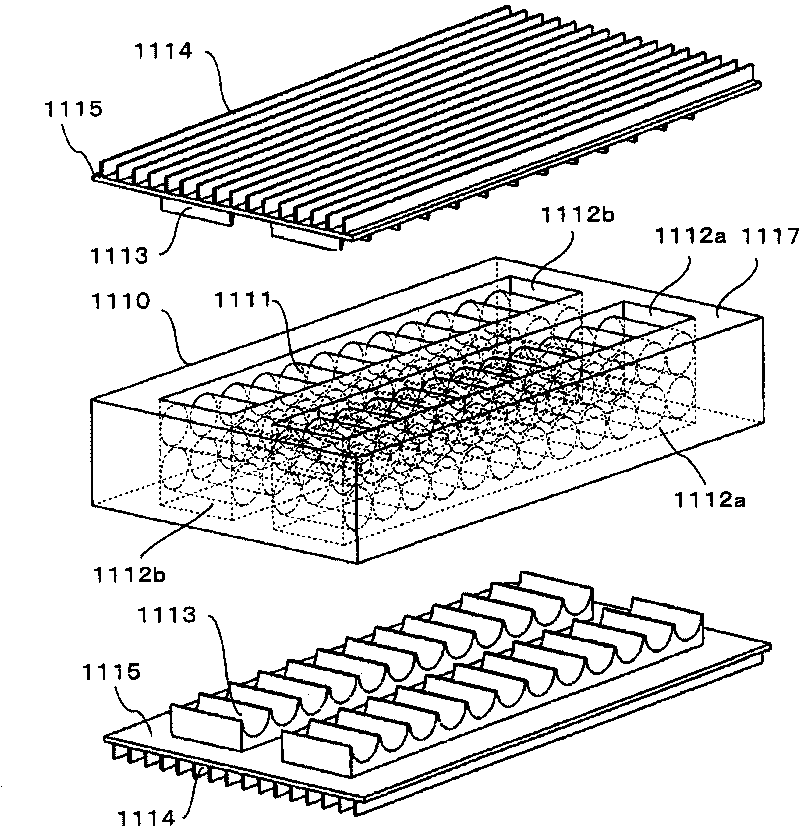

Battery module, and battery box holding battery module and railway vehicle equipped with battery box

InactiveCN101740802AEasy to changeImprove performanceCell temperature controlElectric locomotivesRear quarterComputer module

The invention provides a battery module and a railway vehicle, wherein the structure of the battery module (1110) can be switched easily between a draft structure and an enclosed structure in response to the specifications of a system, and a high-performance cooling structure making use of the respective structures is enabled regardless of which cooling structure is selected. A package of batterymodules (1110) in which multiple battery cells (1111) are arranged in parallel has openings (1112) formed on a pair of side panels of the package throughwhich the side walls of the battery cells 1111are exposed. Further, either cooling ducts (1118) for letting ambient cooling air flow therethrough or cover plates (1115) for sealing the package of the battery modules (1110) are selectively attached to openings (1112). The cover plates (1115) have heat absorbing blocks (1113) disposed on the inner side thereof for thermally coming into contact with the side walls of the battery cells (1111), and radiating fins (1114) disposed on the outer side thereof.

Owner:HITACHI LTD

Notched Tie Plate Insulator

A notched tie plate insulator adapted to be received within a recessed area of a tie plate of a railroad rail system. The insulator includes a bottom plate having a first side and a second side and a pair of side plates attached to the bottom plate. Each side of the bottom plate defines a notch therein. The side plate includes a longitudinal extending body having an upper surface and a lower surface and defining a recess on the upper surface and a protrusion on the lower surface, wherein the protrusion of each of the side plates is received within the notches of the bottom plate.

Owner:KOPPERS DELAWARE INC

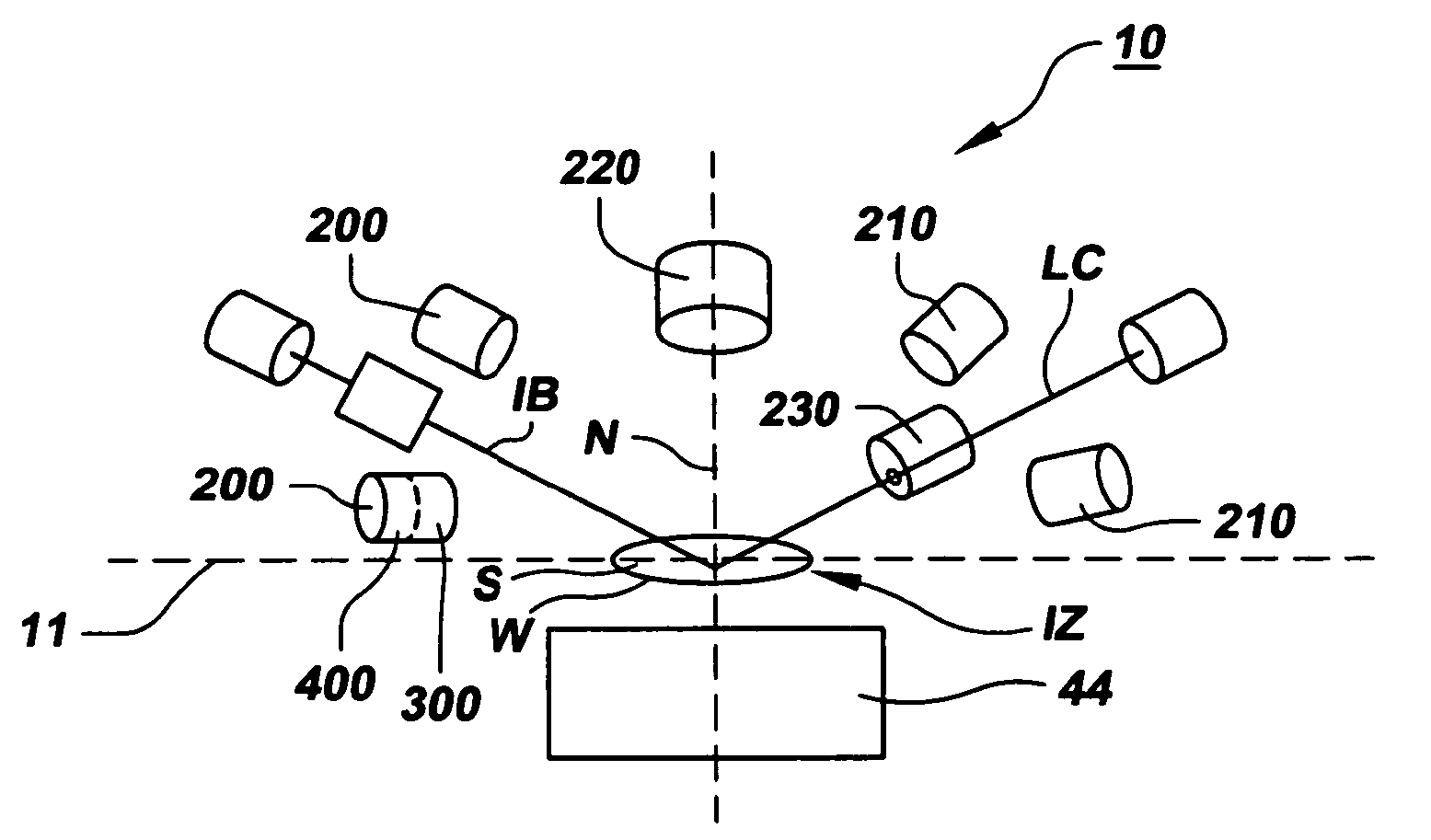

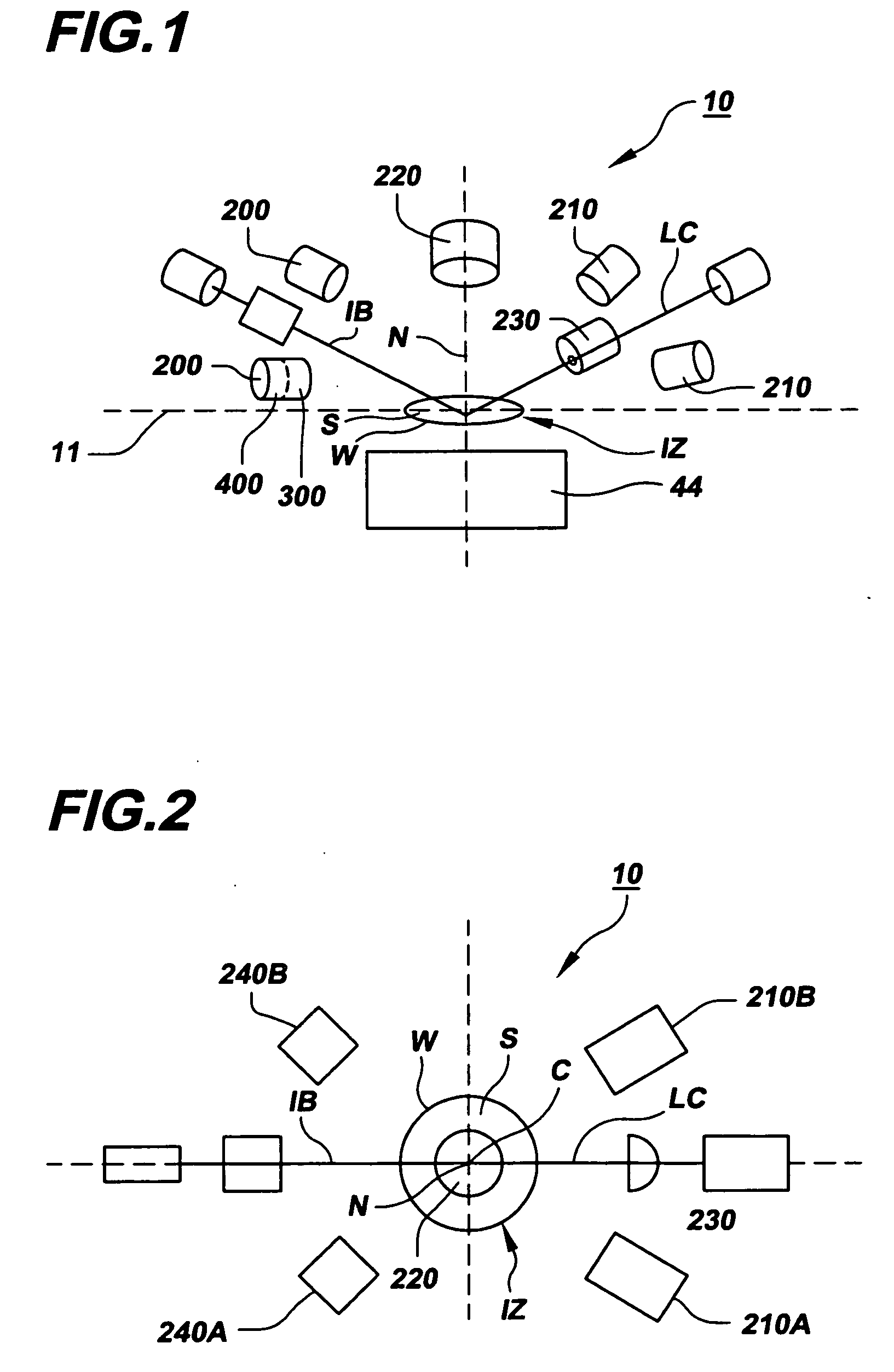

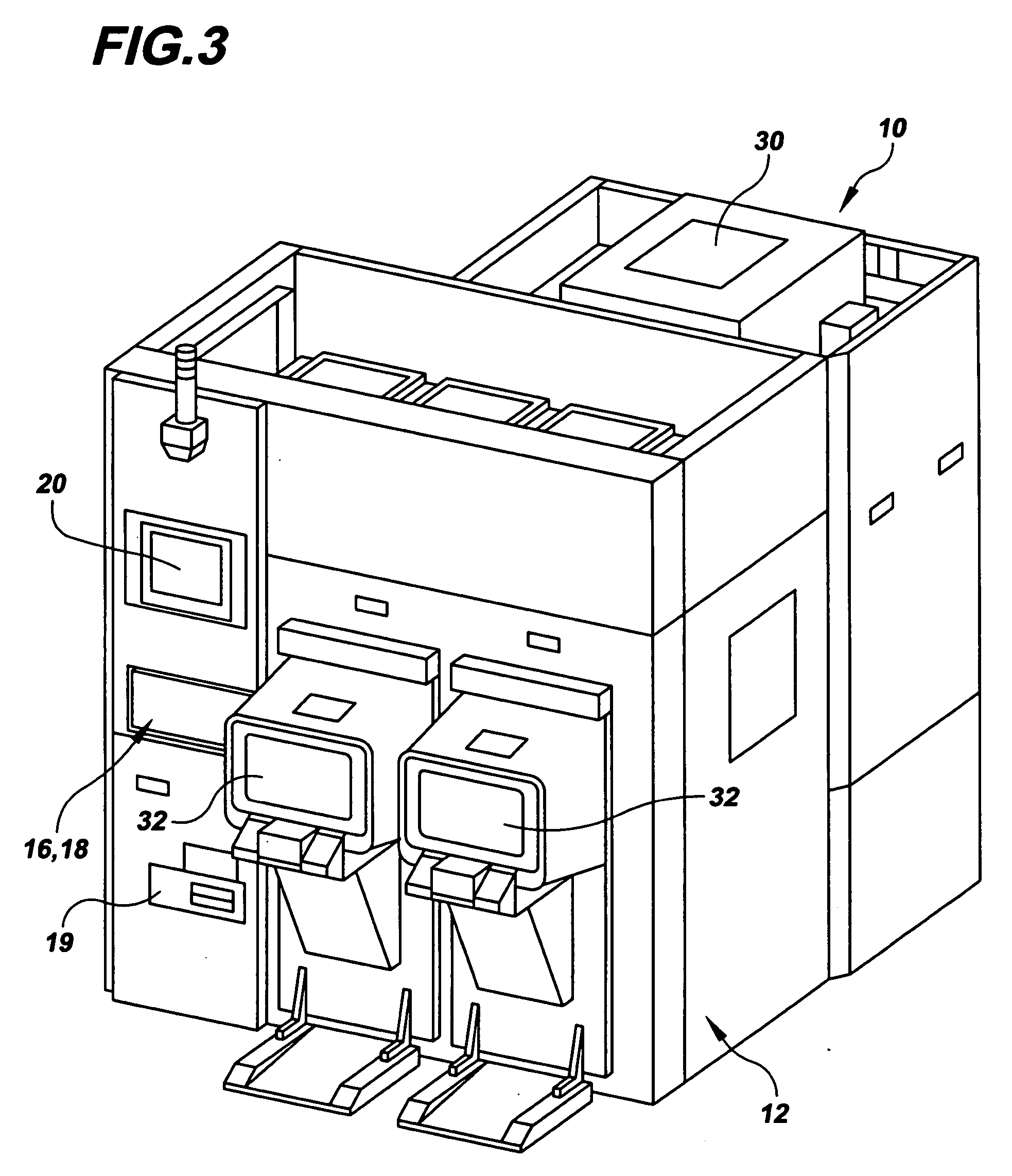

System and method for inspecting a workpiece surface by analyzing scattered light in a back quartersphere region above the workpiece

InactiveUS20060192949A1High sensitivity and reliabilityExpand the scope of detectionImage enhancementImage analysisRayleigh scatteringRear quarter

A surface inspection system includes a beam source subsystem, a beam scanning subsystem, a workpiece movement subsystem, an optical collection and detection subsystem, and a processing subsystem. The optical collection and detection system features back collectors disposed in the back quartersphere, outside the incident plane, for collecting light scattered from the surface of the workpiece. The back collectors are disposed at a relative minimum in the portion of scattered light attributable to haze relative to the portion of scattered light attributable to defect scatter portion, or, alternatively, at a relative minimum in the Rayleigh scatter.

Owner:ADE CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com