Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

164results about How to "Reduce flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

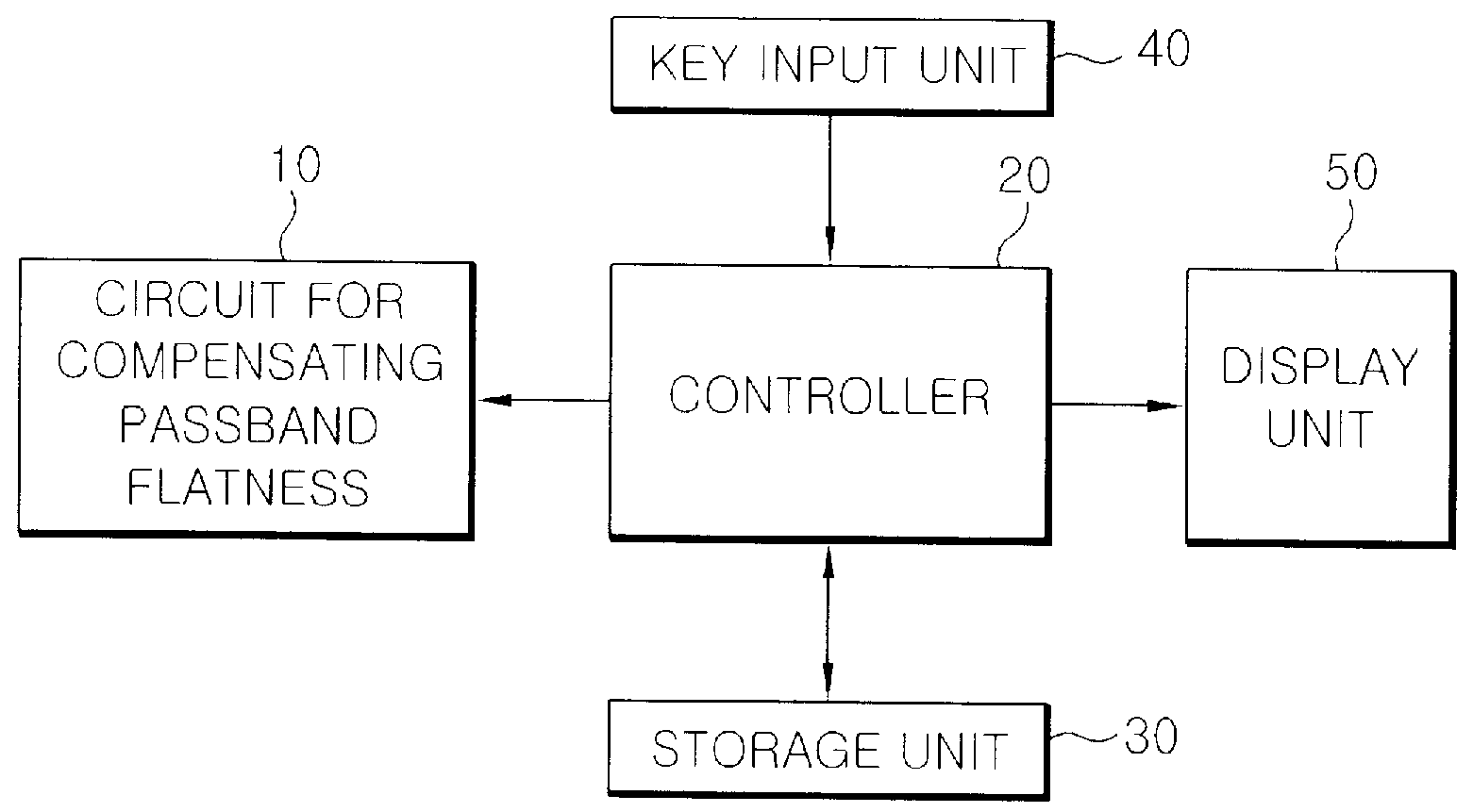

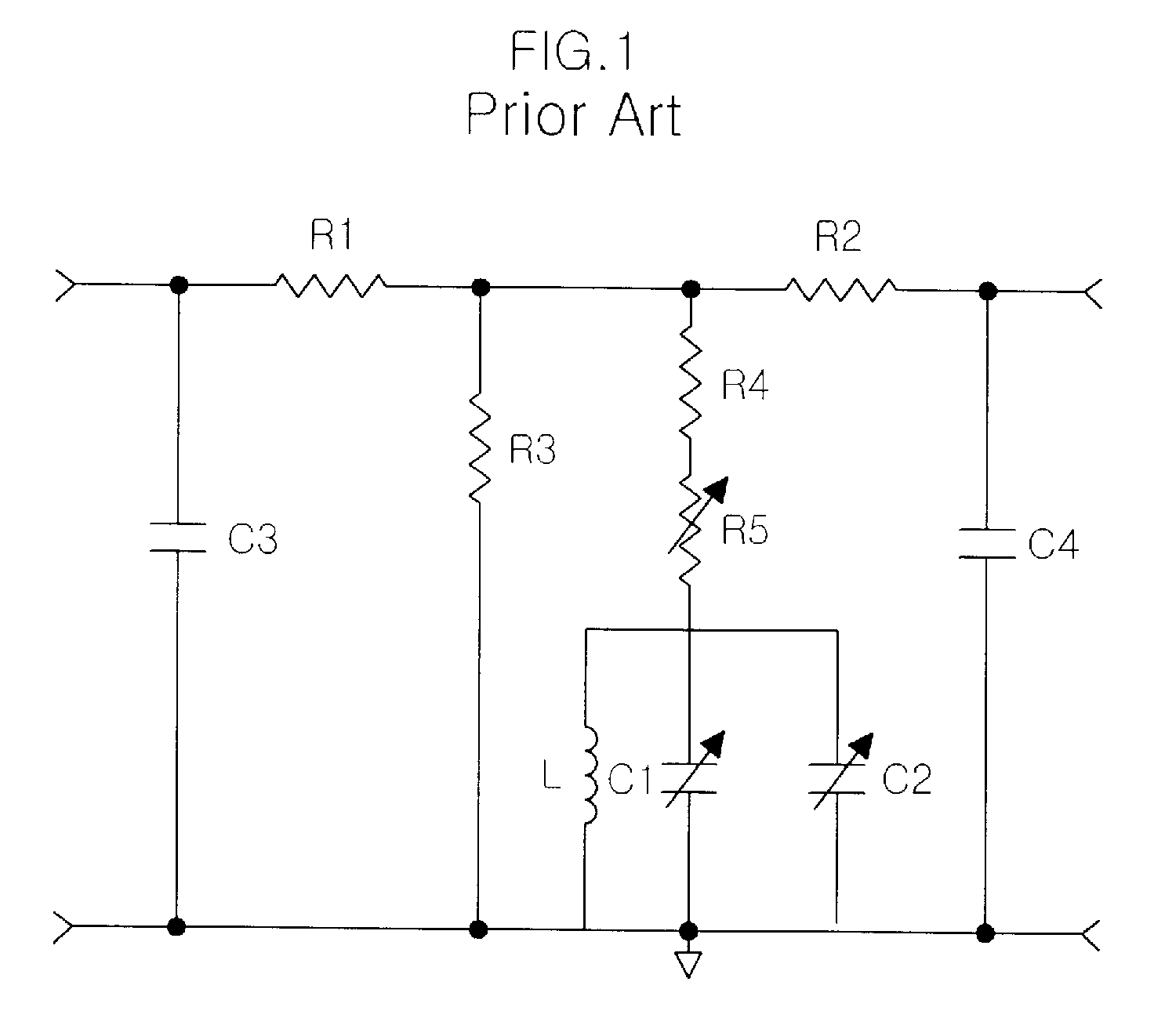

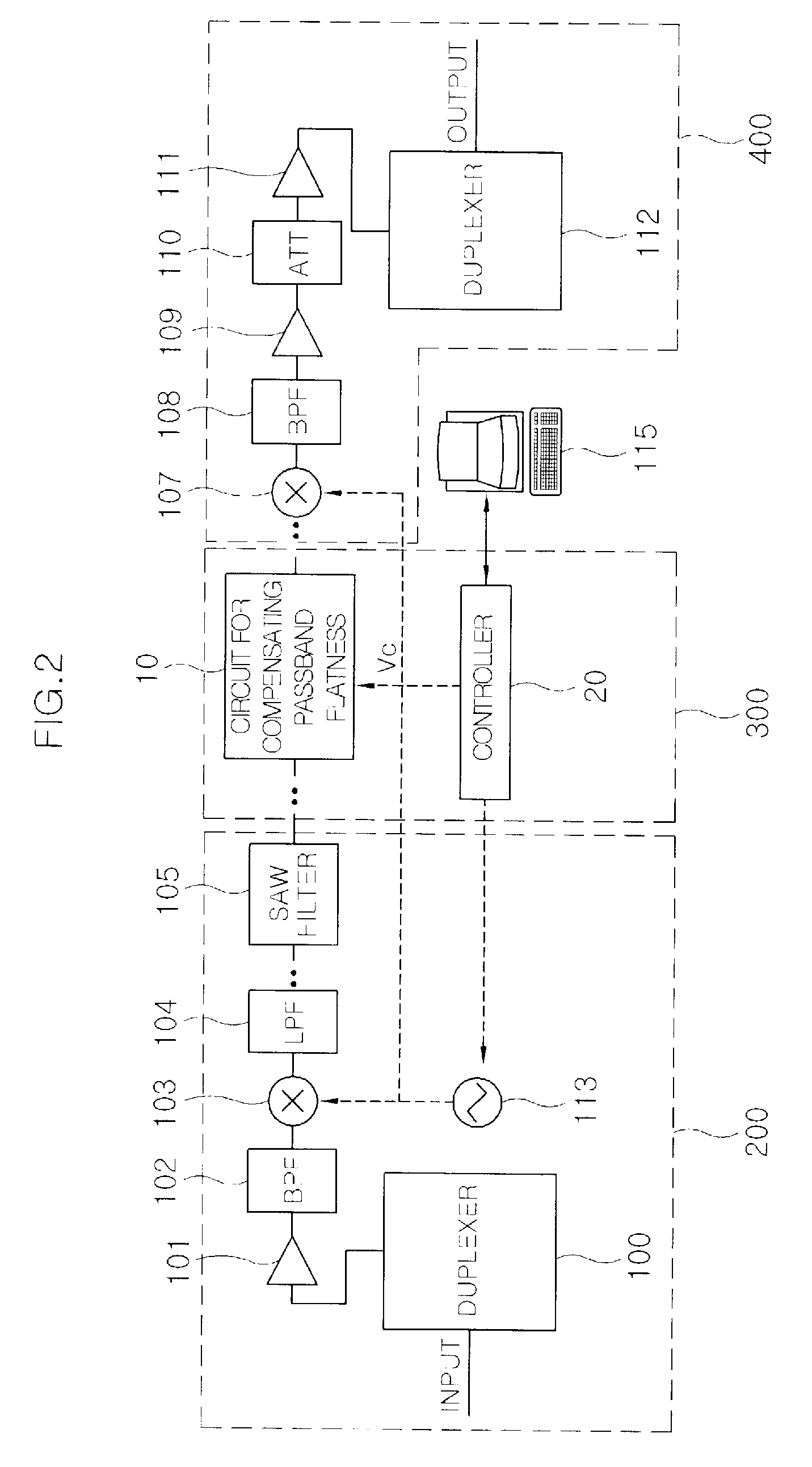

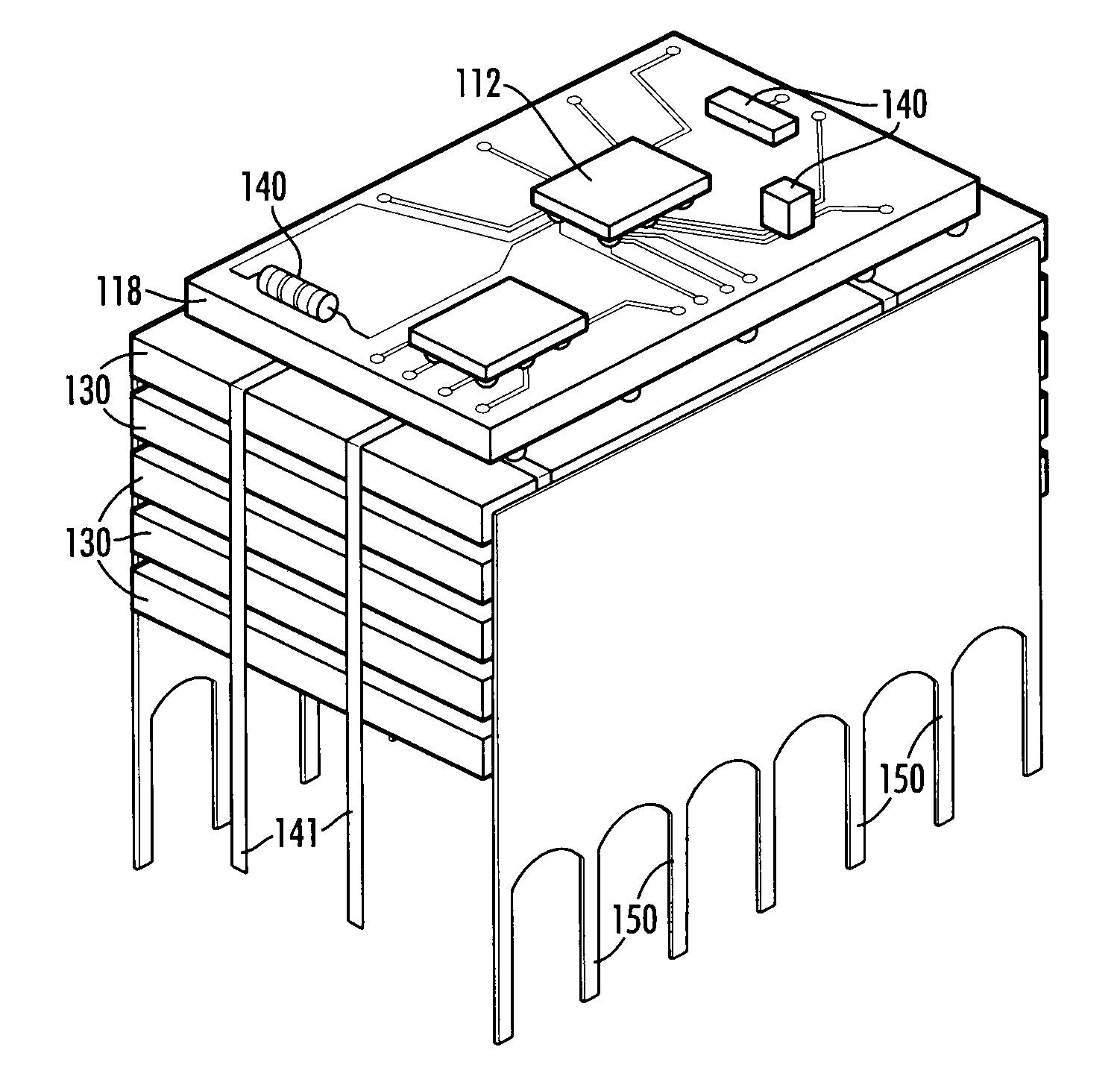

Circuit for compensating passband flatness, apparatus and method for compensating passband flatness

InactiveUS20090264065A1Flatness defectReduce inconvenienceRepeater circuitsRadio relay systemsFrequency bandVaricap

Disclosed is an apparatus for compensating passband flatness according to the present invention. The apparatus for compensating passband flatness for a mobile communication repeater to compensate passband flatness of band passed input signals comprises: a circuit for compensating passband flatness that includes a varactor diode formed to be connected to an inductance element to correct micro resonance frequencies for passbands of input signals according to voltages applied from the outside; and a controller that controls voltages input to the circuit for compensating passband flatness and varies the voltages applied to the varactor diode of the circuit for compensating passband flatness based on preset voltage values applied to the varactor diode so that passband flatness characteristics are compensated according to the corresponding frequency bands.

Owner:ECTELECOM

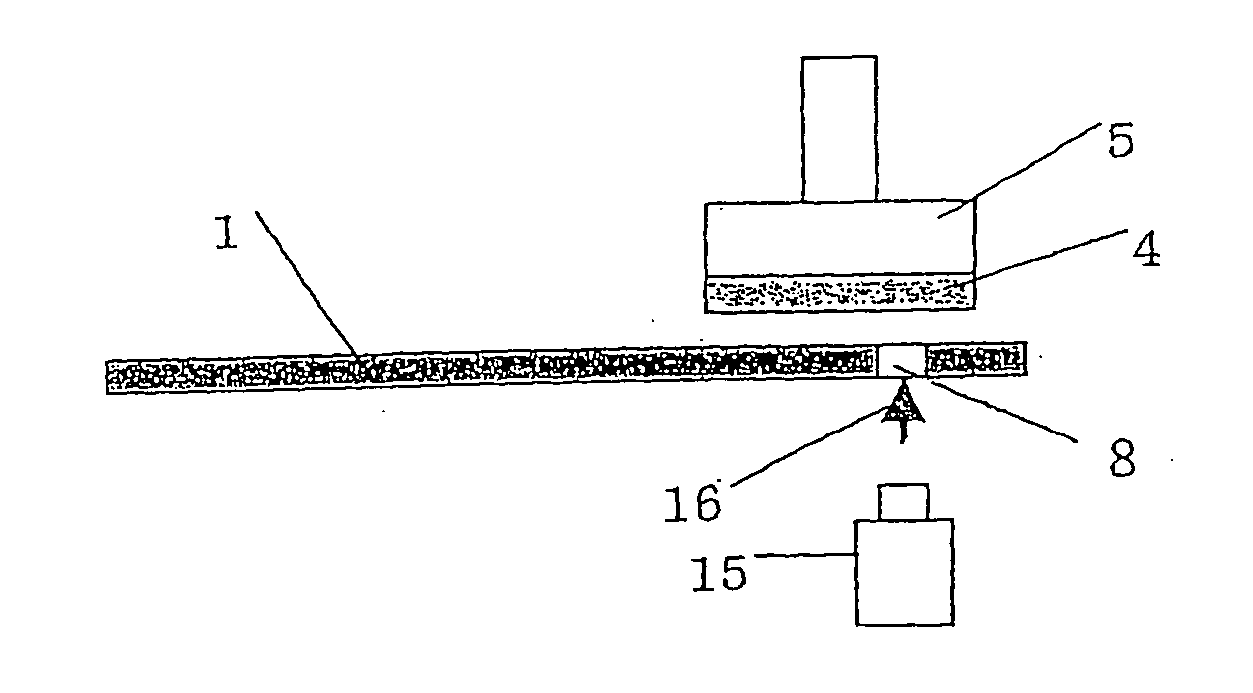

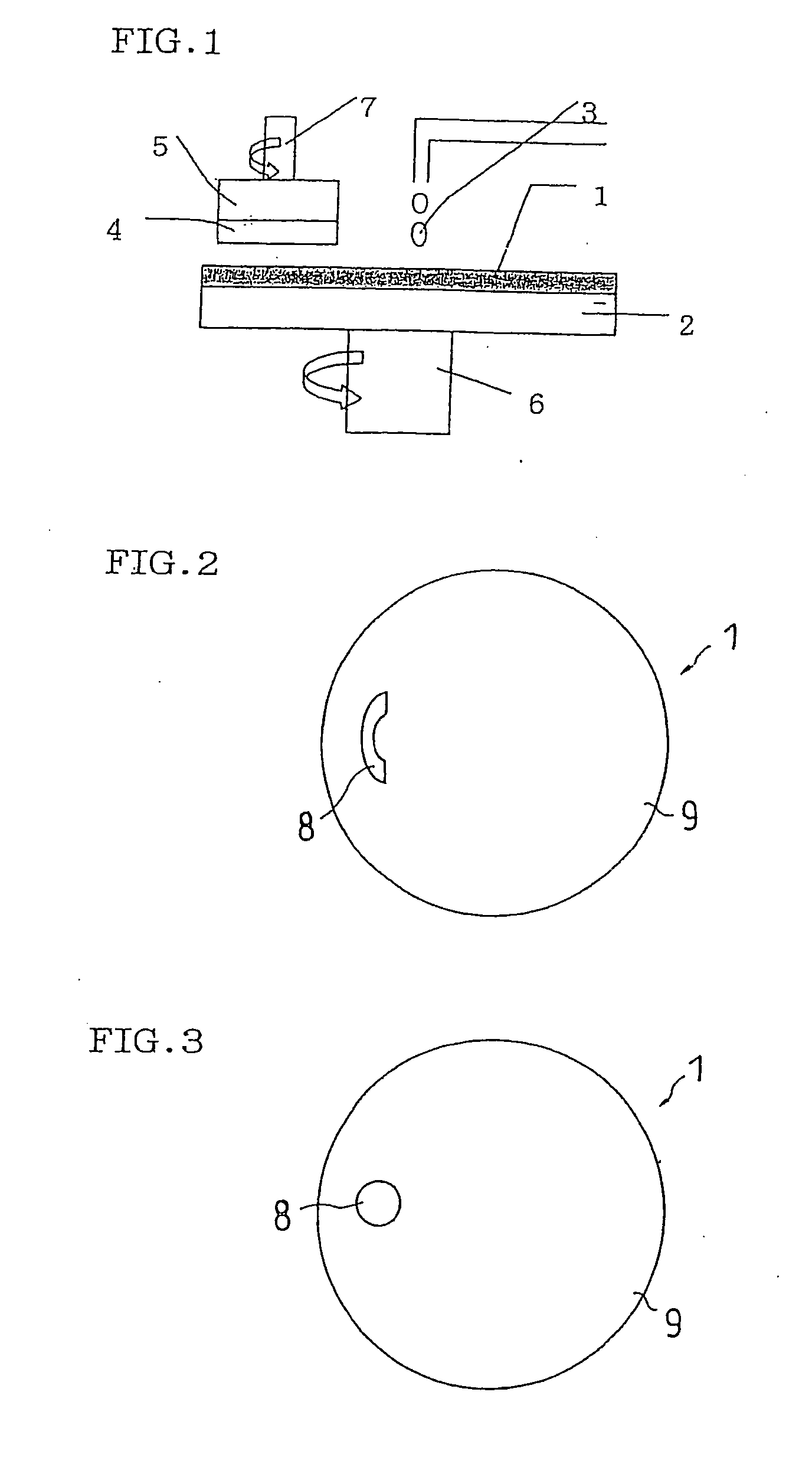

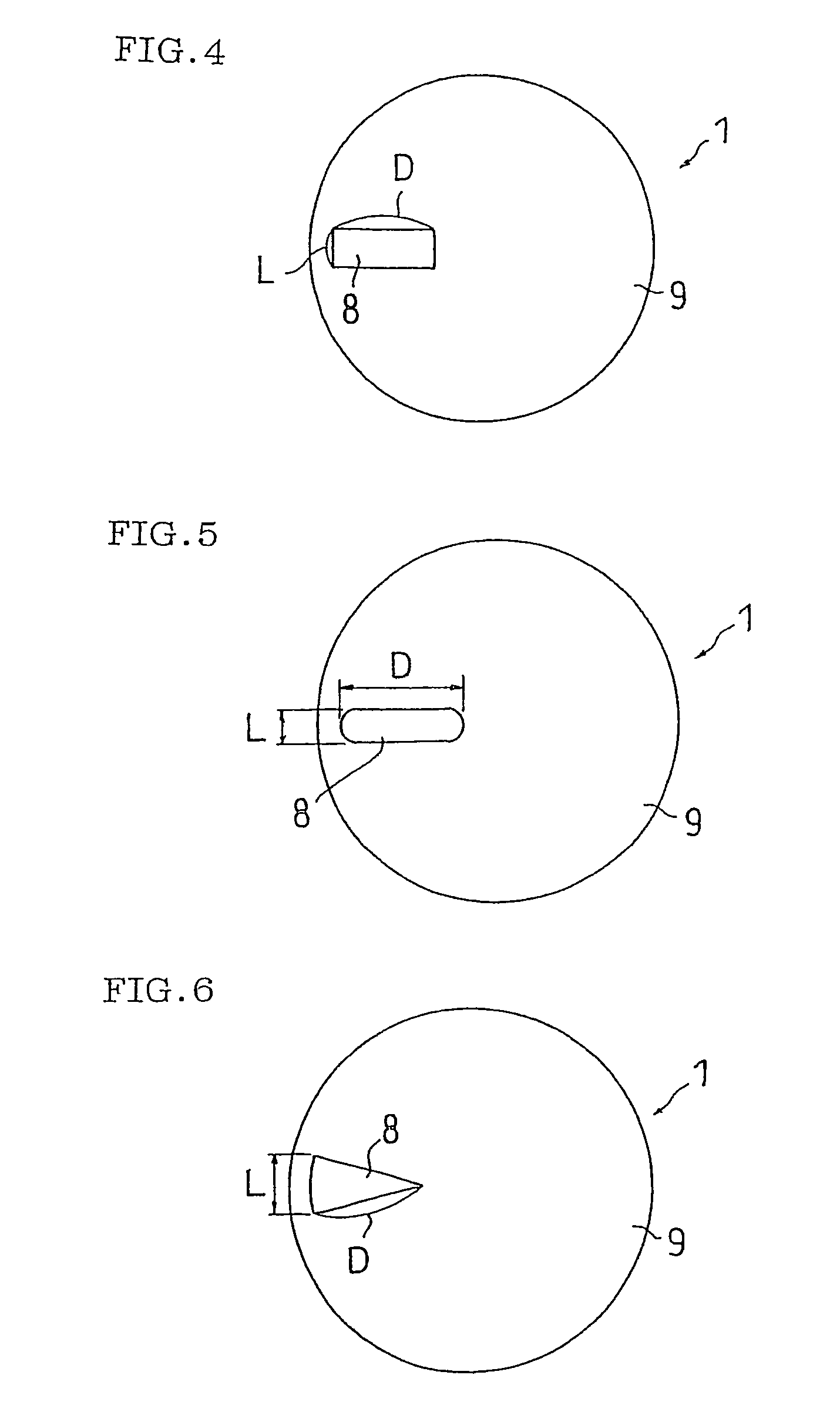

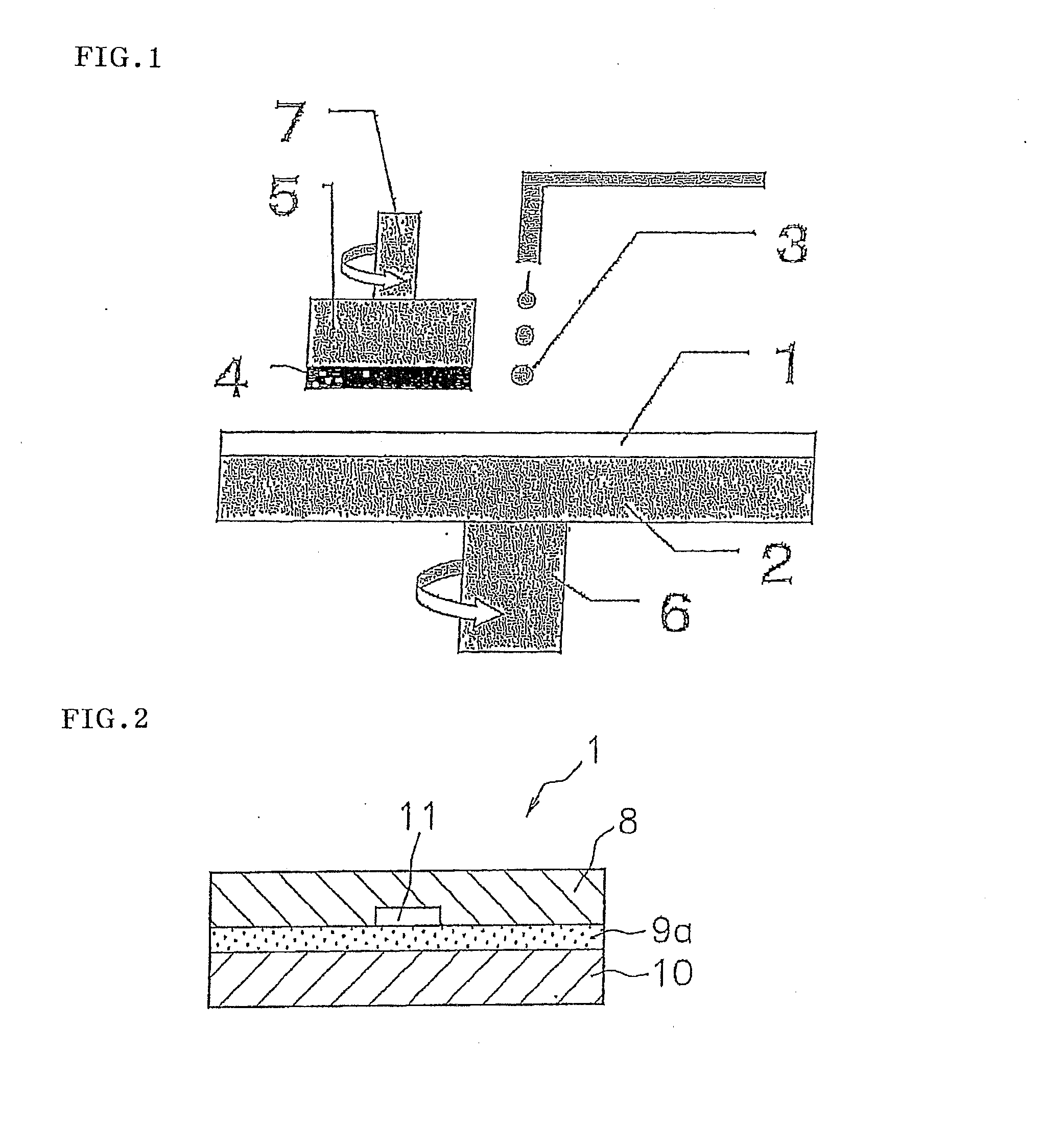

Polishing pad and method for manufacturing semiconductor device

InactiveUS20060037699A1Detection accuracy meetsHigh measurement accuracySemiconductor/solid-state device manufacturingLapping machinesWaferingDevice material

A polishing pad enabling a highly precise optical endpoint sensing during the polishing process and thus having excellent polishing characteristics (such as surface uniformity and in-plane uniformity) is disclosed. A polishing pad enabling to obtain the polishing profile of a large area of a wafer is also disclosed. A polishing pad of a first invention comprises a light-transmitting region having a transmittance of not less than 50% over the wavelength range of 400 to 700 nm. A polishing pad of a second invention comprises a light-transmitting region having a thickness of 0.5 to 4 mm and a transmittance of not less than 80% over the wavelength range of 600 to 700 nm. A polishing pad of a third invention comprises a light-transmitting region arranged between the central portion and the peripheral portion of the polishing pad and having a length (D) in the diametrical direction which is three times or more longer than the length (L) in the circumferential direction.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

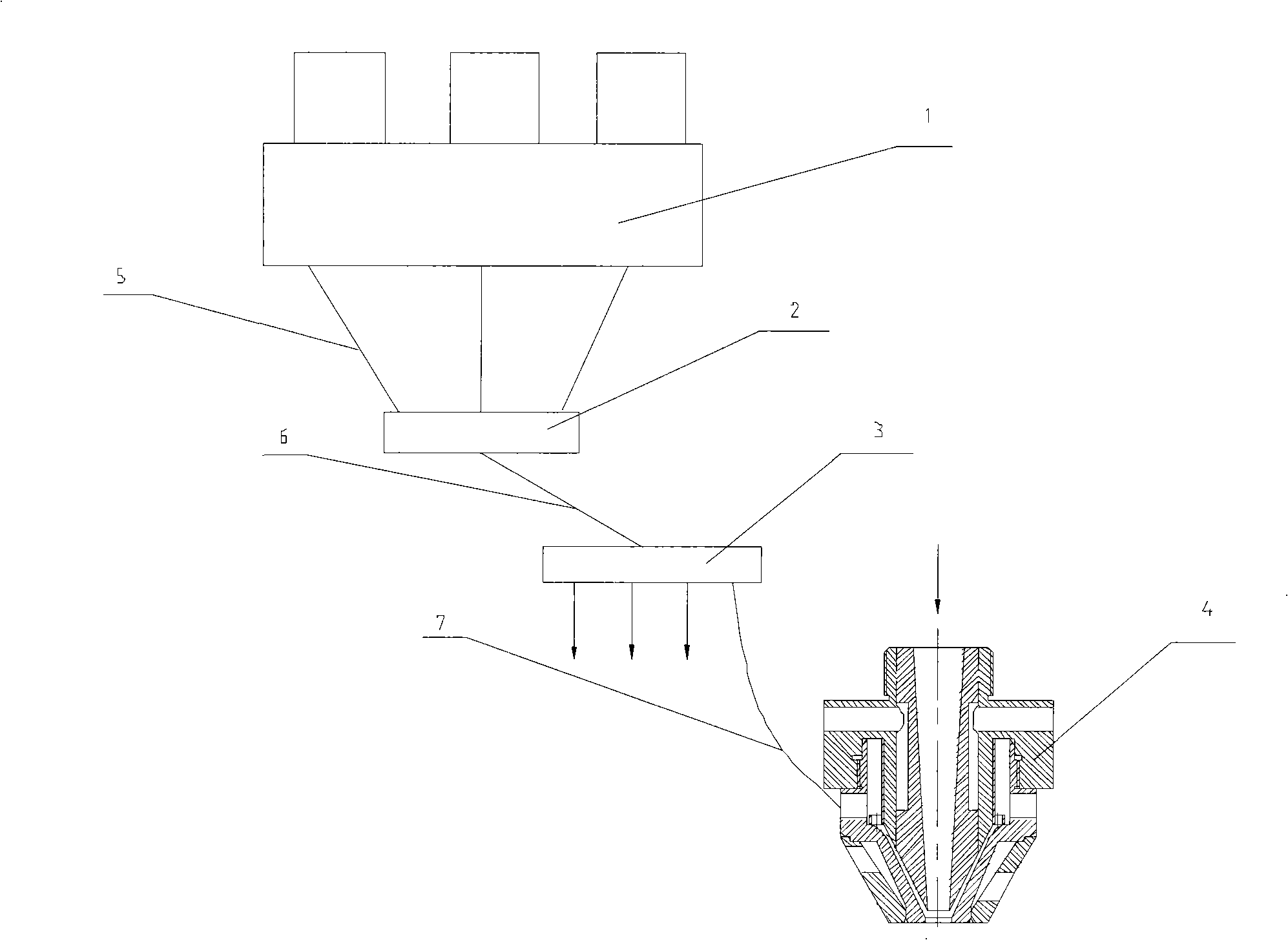

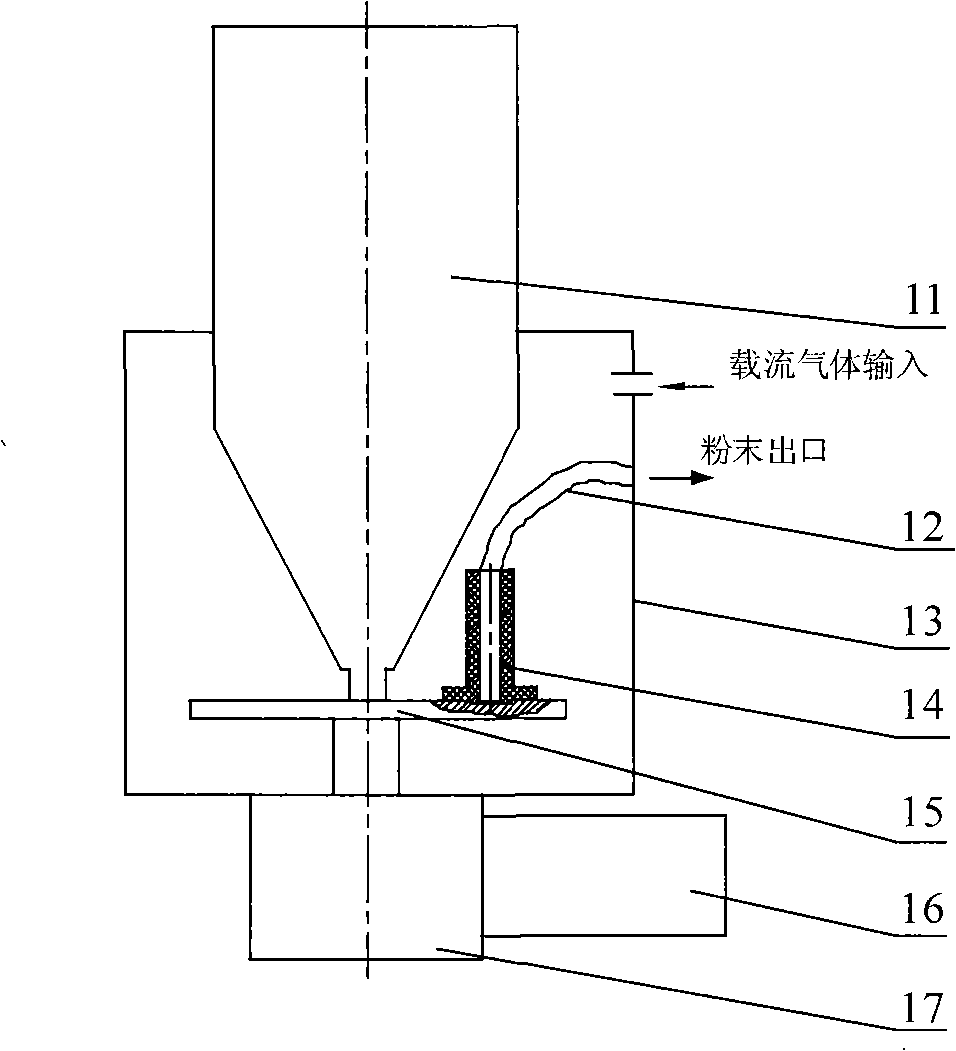

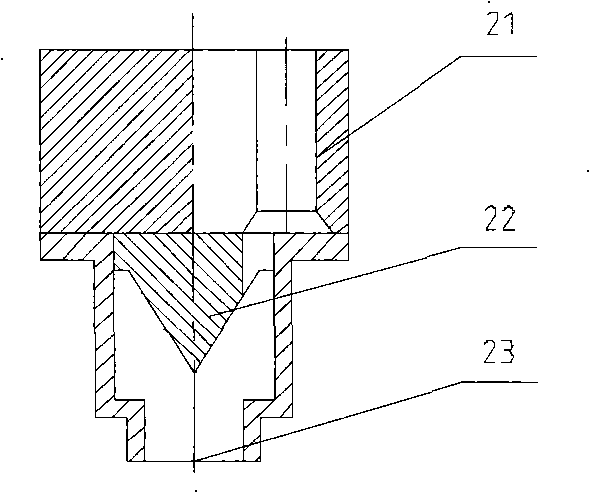

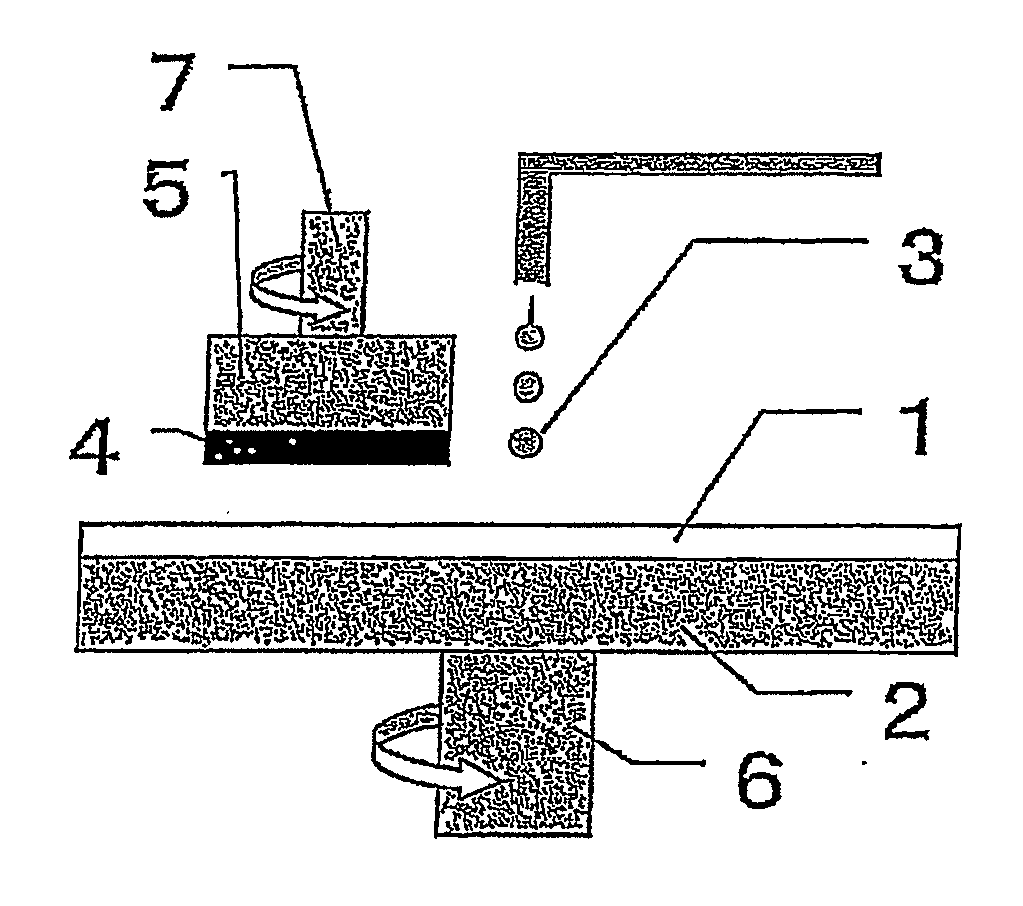

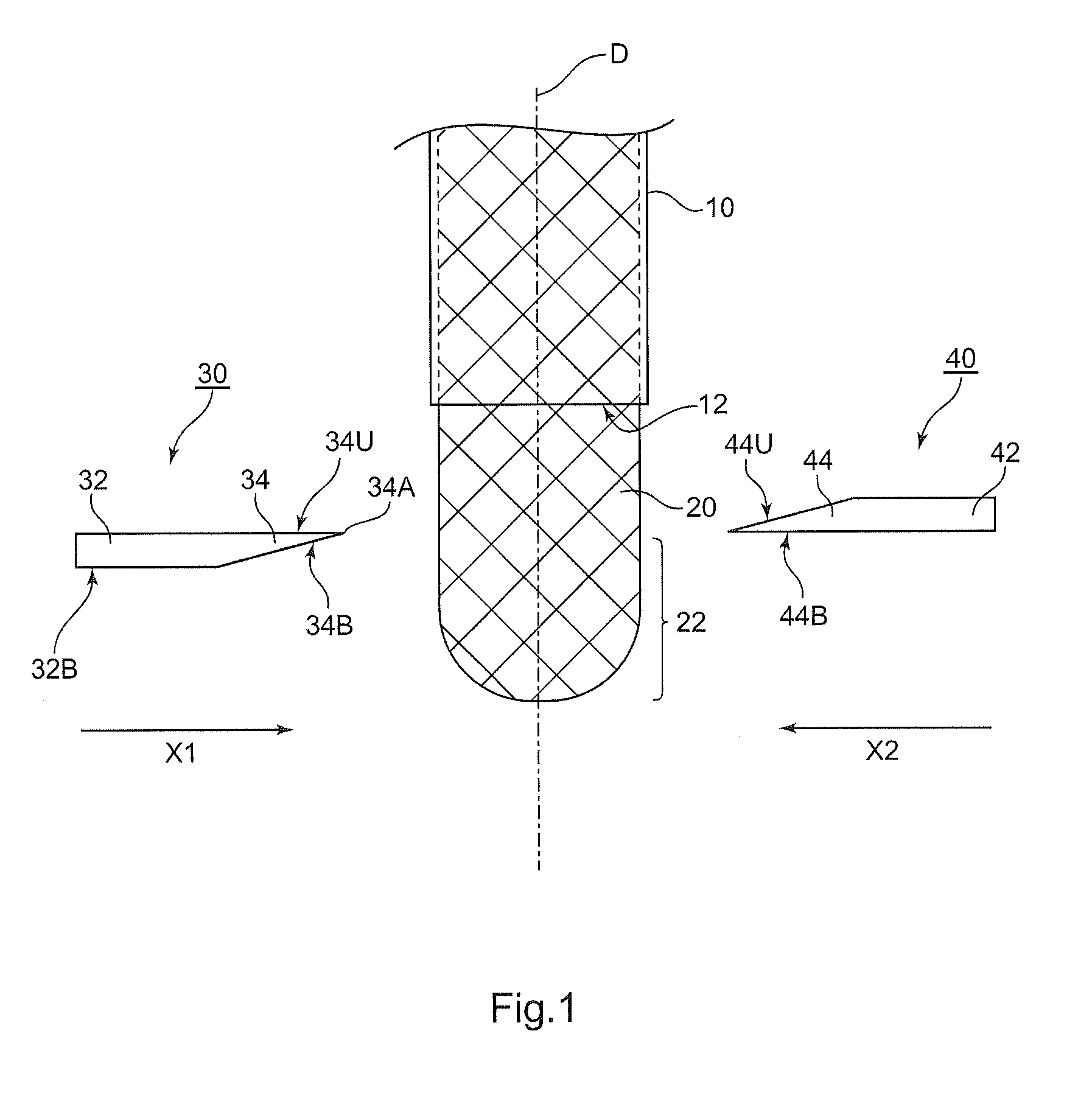

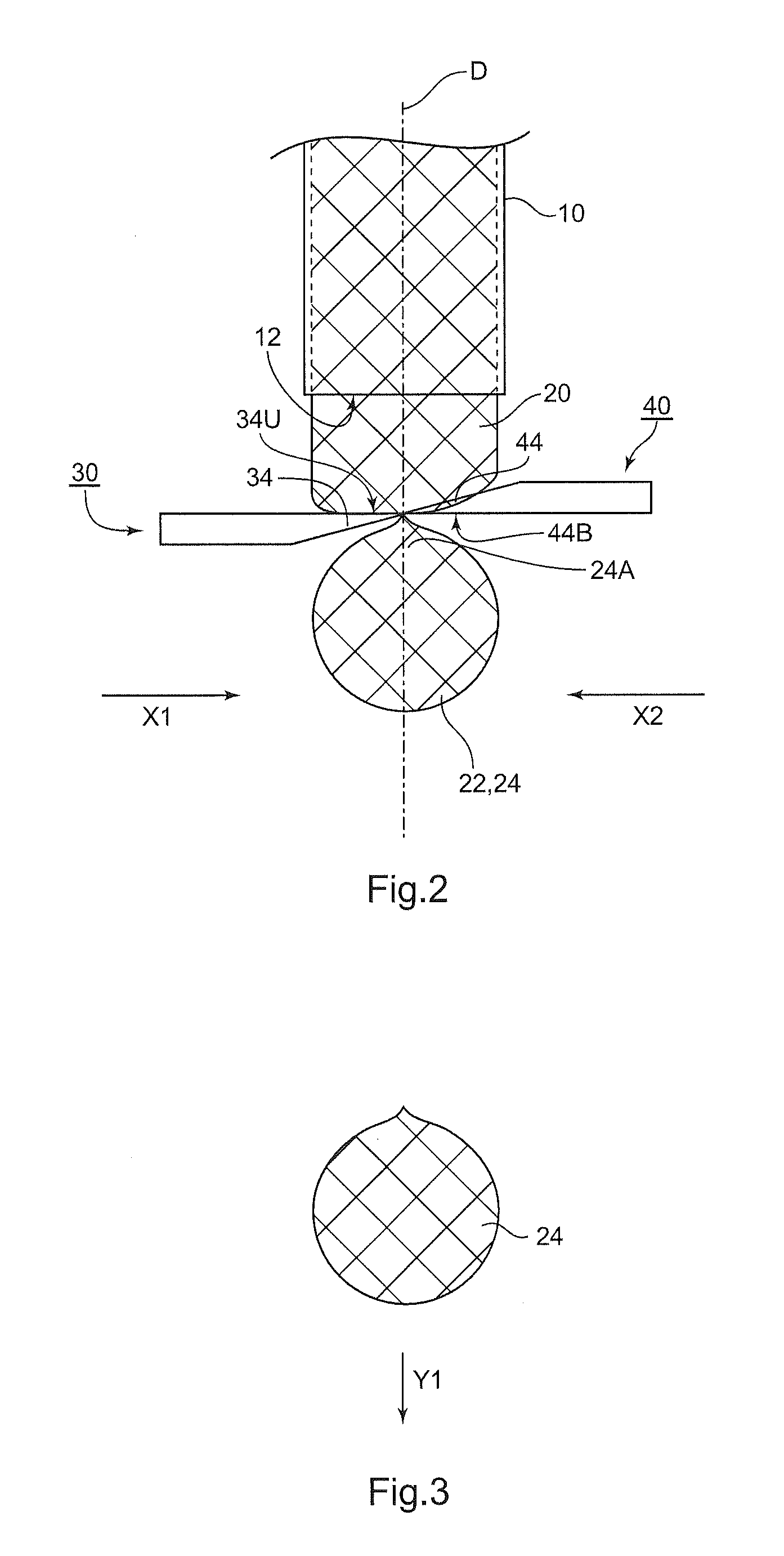

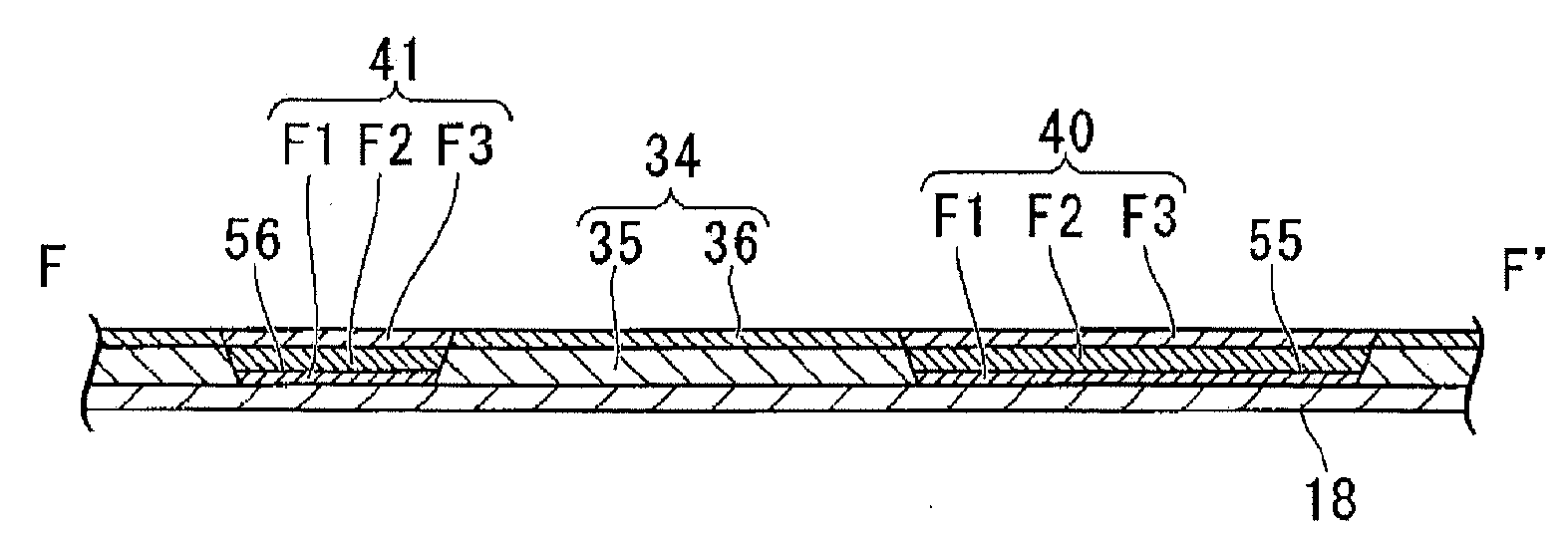

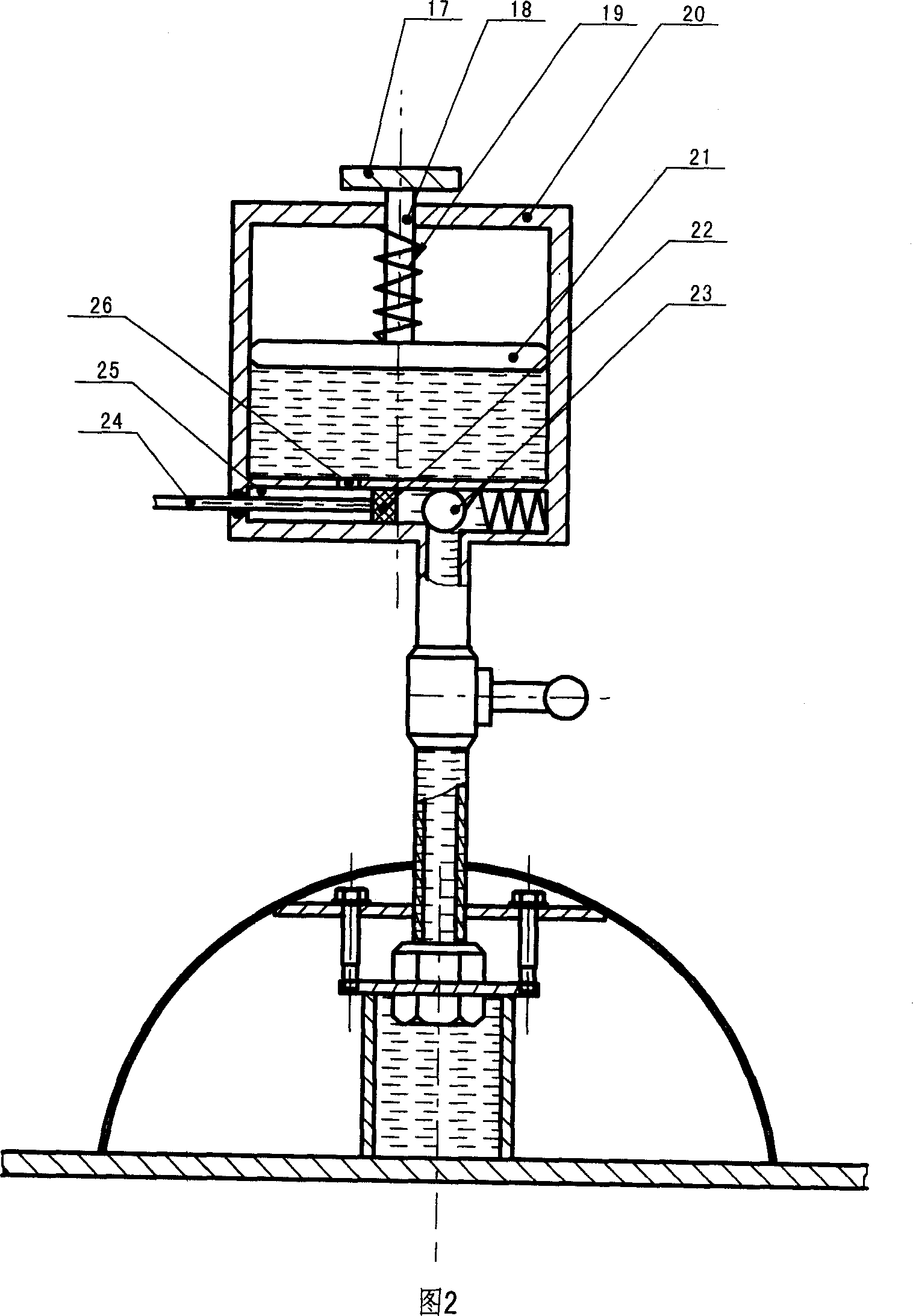

Coaxial powder feeding system for quickly molding and producing functional gradient material with laser

InactiveCN101342640AWell mixedImprove uniformityIncreasing energy efficiencyLaser beam welding apparatusNozzleRapid prototyping

The invention relates to a coaxial powder feeding system of laser rapid prototyping preparation function gradient material, comprising a powder inlet device, and the powder is absorbed and conveyed by carrier gas. The powder inlet device is communicated with a powder mixer through a first conveying pipe. The powder mixer is used for mixing the powder which has been conveyed. The mixed powder enters into a powder separate device through a second conveying pie. The powder separate device is used for separating the mixed powder into multi-path. The powder separate device is communicated with the powder inlet of a nozzle through a third conveying pipe. The nozzle makes the multi-path powder flock together in a molten pool formed by laser. The function gradient material is prepared under the cladding action of laser and powder. The mix of the powder is uniform. The coaxial powder feeding system has good power feeding property, which can realize the optimum processing, and at the same time, can be suitable for different processing distances. The powder utilization rate is high. The manufacturing accuracy is good. At the same time, the powder conveying distance can be adjusted with a certain scope, and so the coaxial powder feeding system can not be limited to the manufacturing space.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Polishing pad

ActiveUS20100048102A1Improve the level ofHigh polishing rateAbrasion apparatusSemiconductor/solid-state device manufacturingEndcappingPolyol

A polishing pad capable of maintaining a high level of dimensional stability upon moisture absorption or water absorption and providing high polishing rate includes a polishing layer of a polyurethane foam having fine cells, wherein the polyurethane foam includes a cured product of a reaction of (1) an isocyanate-terminated prepolymer (A) that includes an isocyanate monomer, a high molecular weight polyol (a), and a low molecular weight polyol, (2) an isocyanate-terminated prepolymer (B) that includes a polymerized diisocyanate and a polyethylene glycol with a number average molecular weight of 200 to 1,000, and (3) a chain extender.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Cleaning composition for removing impurities and method of removing impurities using the same

InactiveUS20070203041A1Efficient removalImprove etch selectivityDetergent mixture composition preparationSemiconductor/solid-state device manufacturingHydrofluoric acidCitrate salt

In a cleaning composition for removing residual impurities from a substrate or an apparatus for forming an integrated circuit, and a method of removing the impurities using the cleaning composition, the cleaning composition includes about 4 to about 50 percent by weight of at least two compounds selected from the group consisting of citric acid, a citrate salt, a fluoride salt, hydrofluoric acid, hydrogen peroxide and ammonium persulfate, and a remainder of water. The cleaning composition may effectively remove residual impurities from the substrate or the apparatus, and may prevent the substrate or the apparatus from being recontaminated by the impurities.

Owner:LEE GI WON

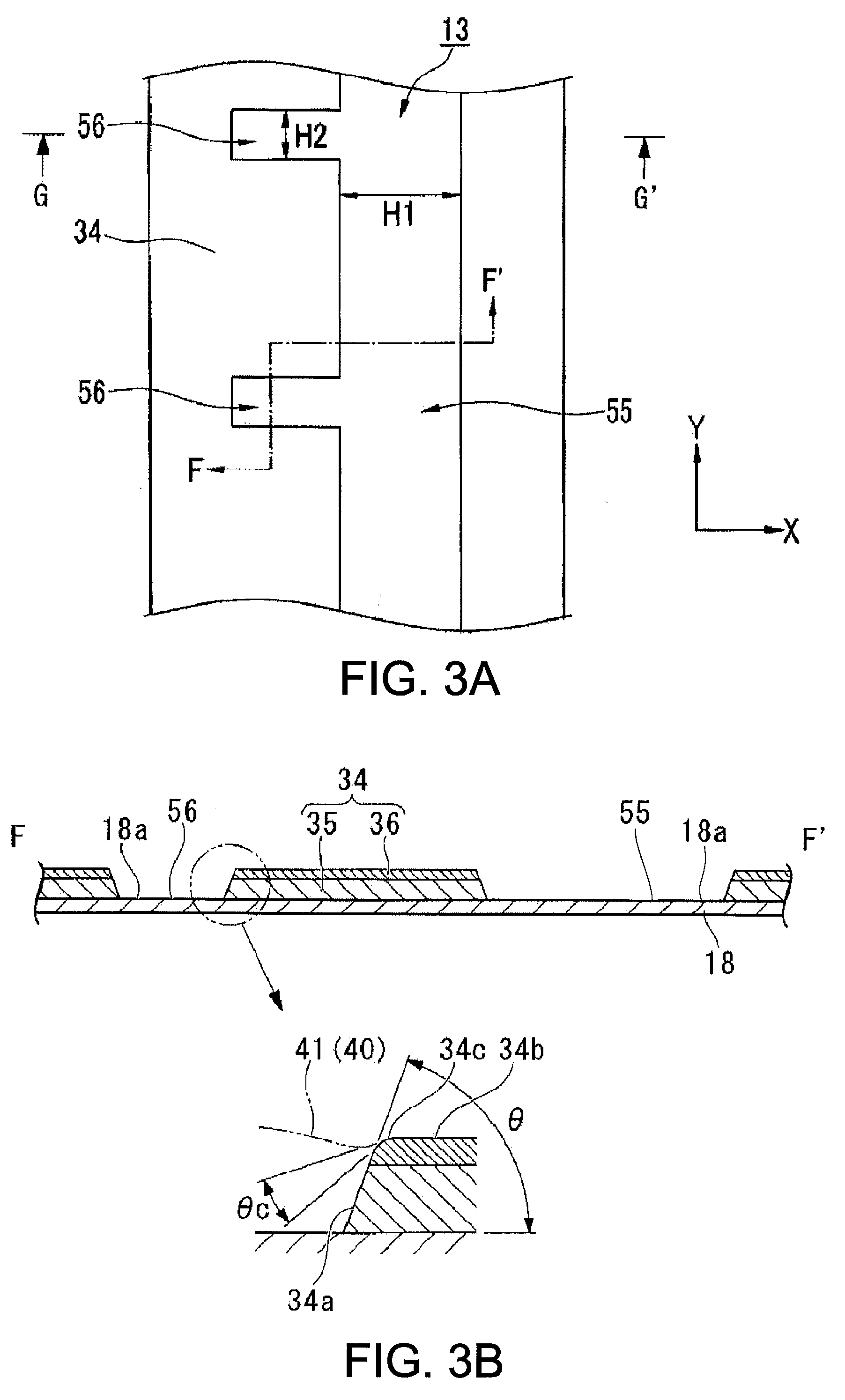

Manufacturing method of glass blank for magnetic recording glass substrate, manufacturing method of magnetic recording glass substrate and manufacturing method of magnetic recording medium

InactiveUS20110277508A1Improve flatnessLittle crack defectGlass drawing apparatusGlass forming apparatusVitrificationFlat glass

Provided is a method of manufacturing a glass blank for a magnetic recording medium glass substrate, including: manufacturing a glass blank by at least press molding a falling molten glass gob with a pair of press molds both so as to face each other in a direction perpendicular to a direction in which the molten glass gob falls, in which: the molten glass gob is formed of a glass material having a glass transition temperature of 600° C. or more; and when the press molding is carried out so that the molten glass gob is completely extended by pressure and molded into a flat glass between press-molding surfaces of the pair of press molds, at least a region in contact with the flat glass in each of the press-molding surfaces of the pair of press molds forms a substantially flat surface. Also provided are a method of manufacturing a magnetic recording medium glass substrate and a method of manufacturing a magnetic recording medium each using the method of manufacturing a glass blank for a magnetic recording medium glass substrate.

Owner:HOYA CORP

Method for manufacturing soi substrate

InactiveUS20100087045A1Improve flatnessDeficiency region is reducedSolid-state devicesSemiconductor/solid-state device manufacturingLower limitHydrogen

An SOI substrate is manufactured by forming an embrittled layer in a bond substrate by increasing the dose of hydrogen ions in the formation of the embrittled layer to a value more than the dose of hydrogen ions of the lower limit for separation of the bond substrate, separating the bond substrate attached to the base substrate, forming an SOI substrate in which a single crystal semiconductor film is formed over the base substrate, and irradiating a surface of the single crystal semiconductor film with laser light.

Owner:SEMICON ENERGY LAB CO LTD

Method for forming metal wiring line, method for manufacturing active matrix substrate, device, electro-optical device, and electronic apparatus

InactiveUS20070264814A1Improve flatnessReduce flatnessElectroluminescent light sourcesPrinted circuit aspectsActive matrixEngineering

A method for forming a metal wiring line, comprises: (a) forming a bank including a first opening corresponding to a first film pattern and a second opening corresponding to a second film pattern that is coupled to the first film pattern and has a width narrower than a width of the first film pattern; (b) disposing a droplet of a functional liquid in the first opening so as to dispose the functional liquid in the second opening by an autonomous flow of the functional liquid; (c) hardening the functional liquid disposed in the first opening and the second opening; and (d) forming the first film pattern and the second film pattern by alternately repeating step (b) and step (c) at least one time.

Owner:SEIKO EPSON CORP

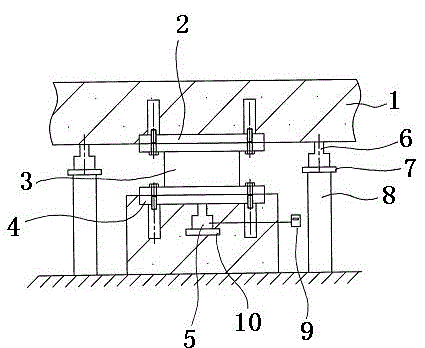

Method for replacing building shock insulation rubber support

ActiveCN104018434AGuaranteed StrengthAvoid uneven forceBuilding repairsBridge structural detailsDesign loadStructural stress

The invention belongs to the technical field of methods for replacing rubber supports, and discloses a method for replacing a building shock insulation rubber support. The method is mainly technically characterized in that supporting force generated when temporary support bodies are arranged is the same as the design load of the building shock insulation rubber support, then the support is demounted, concrete on the top of a pier column is removed at the same time, a new shock insulation rubber support is jacked through force measurement jacks, the design load is reached, a pier top and pre-buried boards are connected, concrete is poured to the pier top and the pre-buried boards, and finally the temporary support bodies are demounted. By the adoption of the mode of combining column top descending with support jacking, space is provided for replacement of the support, stress evenness of supports for supporting a building is guaranteed, the situation that the structural stress changes due to the fact that one support does not bear force is avoided, needed jacking force of the jacks is small, replacement is quick and safe, and construction cost is low.

Owner:丰泽智能装备股份有限公司

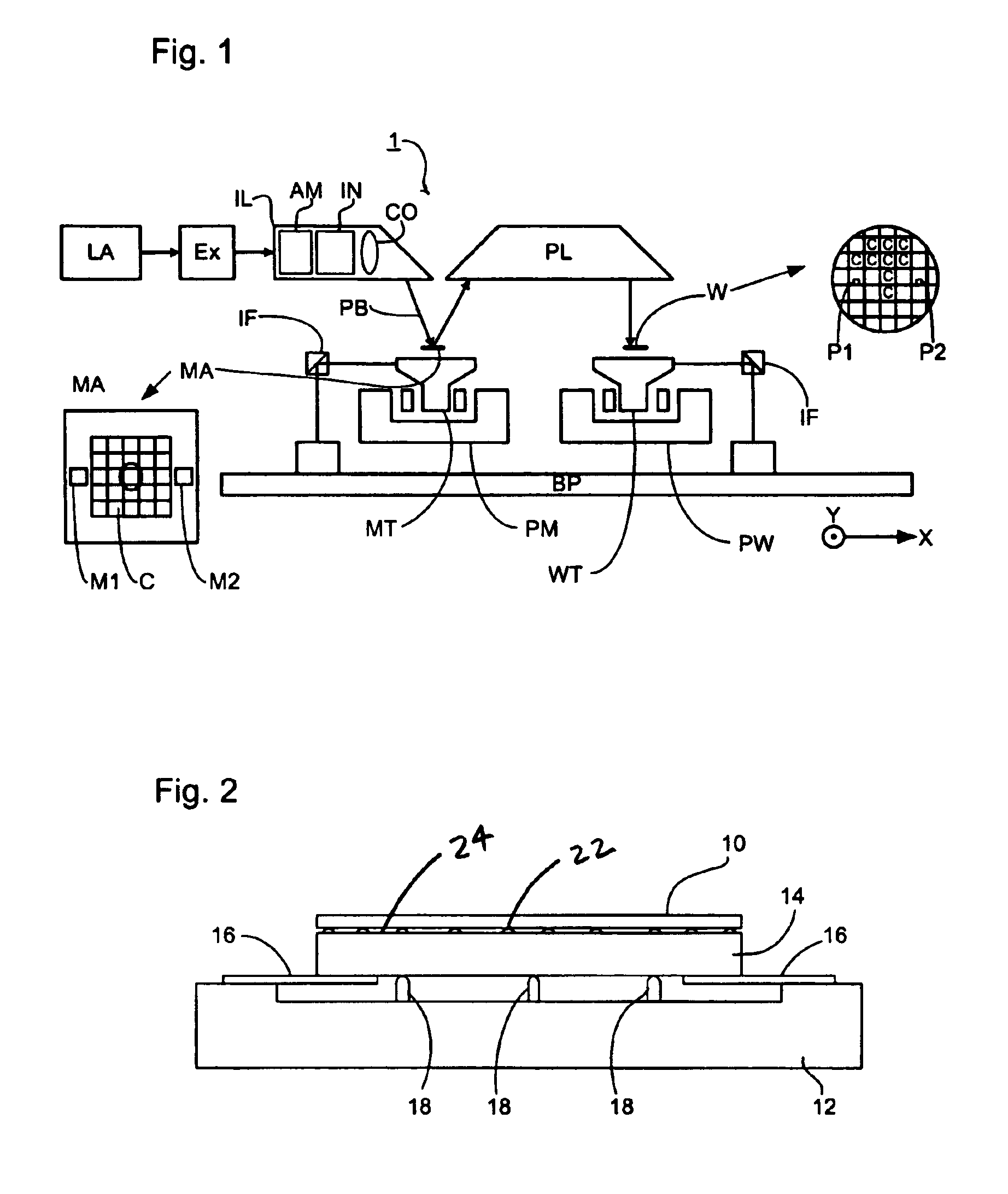

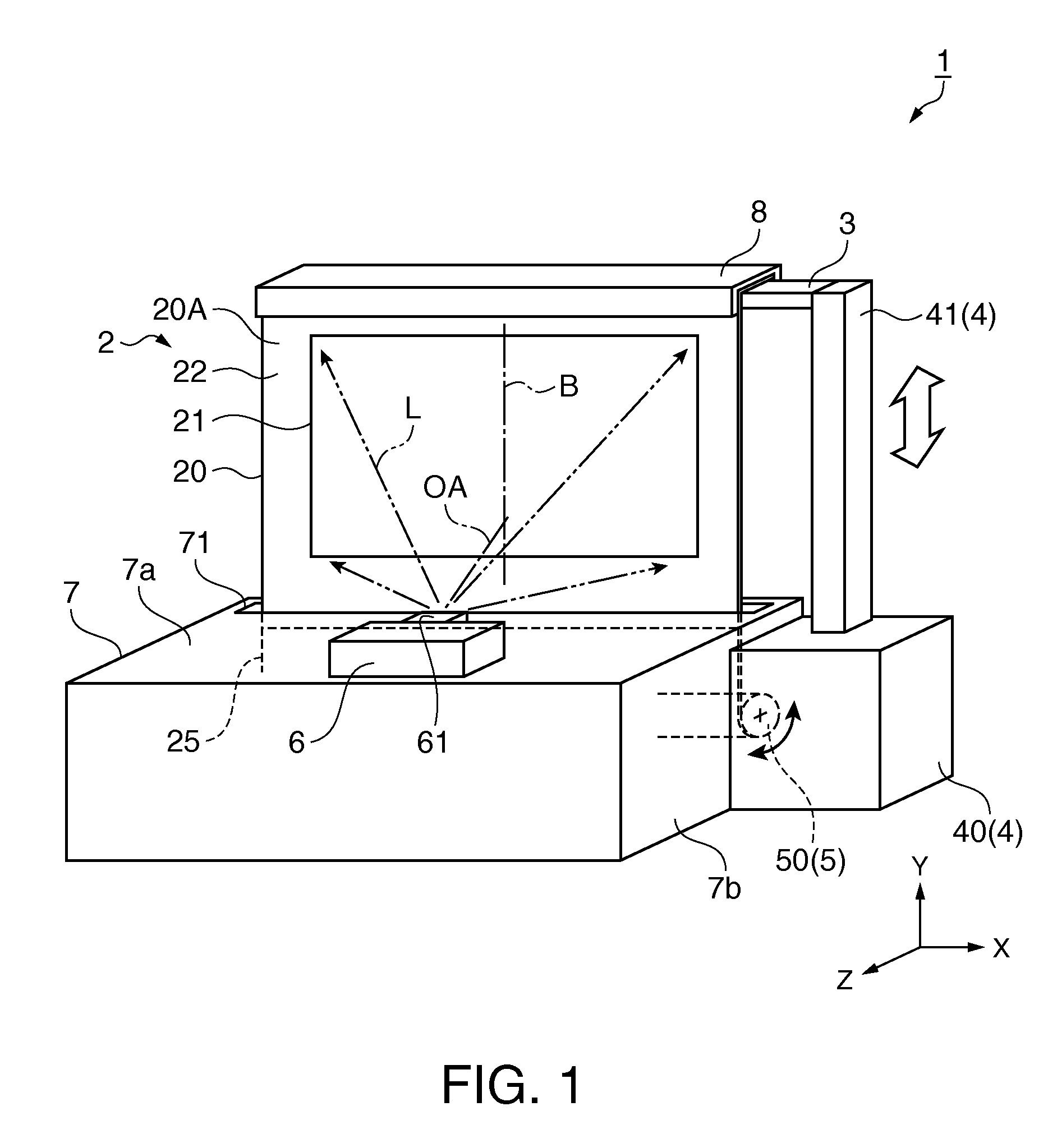

Lithographic apparatus and method of manufacturing a device

InactiveUS6956222B2Reduce sensitivityReduce flatnessSemiconductor/solid-state device manufacturingMachines/enginesLight beamProjection system

A lithographic projection apparatus includes a radiation system for providing a beam of radiation and a support structure for supporting a patterning device. The patterning device serves to pattern the beam according to a desired pattern. The lithographic projection apparatus includes a substrate table for holding a substrate and a projection system for projecting the patterned beam onto a target portion of the substrate. At least one holding structure includes at least one compliant member holding a pimple plate for holding a removable item for the apparatus.

Owner:ASML NETHERLANDS BV

Method for manufacturing semiconductor light emitting element, semiconductor light emitting element, lamp, electronic device and mechanical apparatus

ActiveUS20120326169A1High crystallinityImprove crystallinitySolid-state devicesSemiconductor/solid-state device manufacturingDopantSemiconductor

Provided is a method for manufacturing a semiconductor light emitting element (1) in which a defect is less likely to occur in a light emitting layer and a p-type semiconductor layer due to the surface of a second n-type semiconductor layer and which is capable of obtaining a high output. The method for manufacturing a semiconductor light emitting element includes a first step of forming a first n-type semiconductor layer (12c) on a substrate (11) and a second step of sequentially forming a regrowth layer (12d) of the first n-type semiconductor layer (12c), a second n-type semiconductor layer (12b), a light emitting layer (13), and a p-type semiconductor layer (14) on the first n-type semiconductor layer (12c). In the step of forming the second n-type semiconductor layer (12b), a step (1) of supplying Si less than that forming the regrowth layer (12d) as a dopant to form a first layer of the second n-type semiconductor layer and a step (2) of supplying the Si more than that in the step (1) to form a second layer of the second n-type semiconductor layer are performed in this order.

Owner:TOYODA GOSEI CO LTD

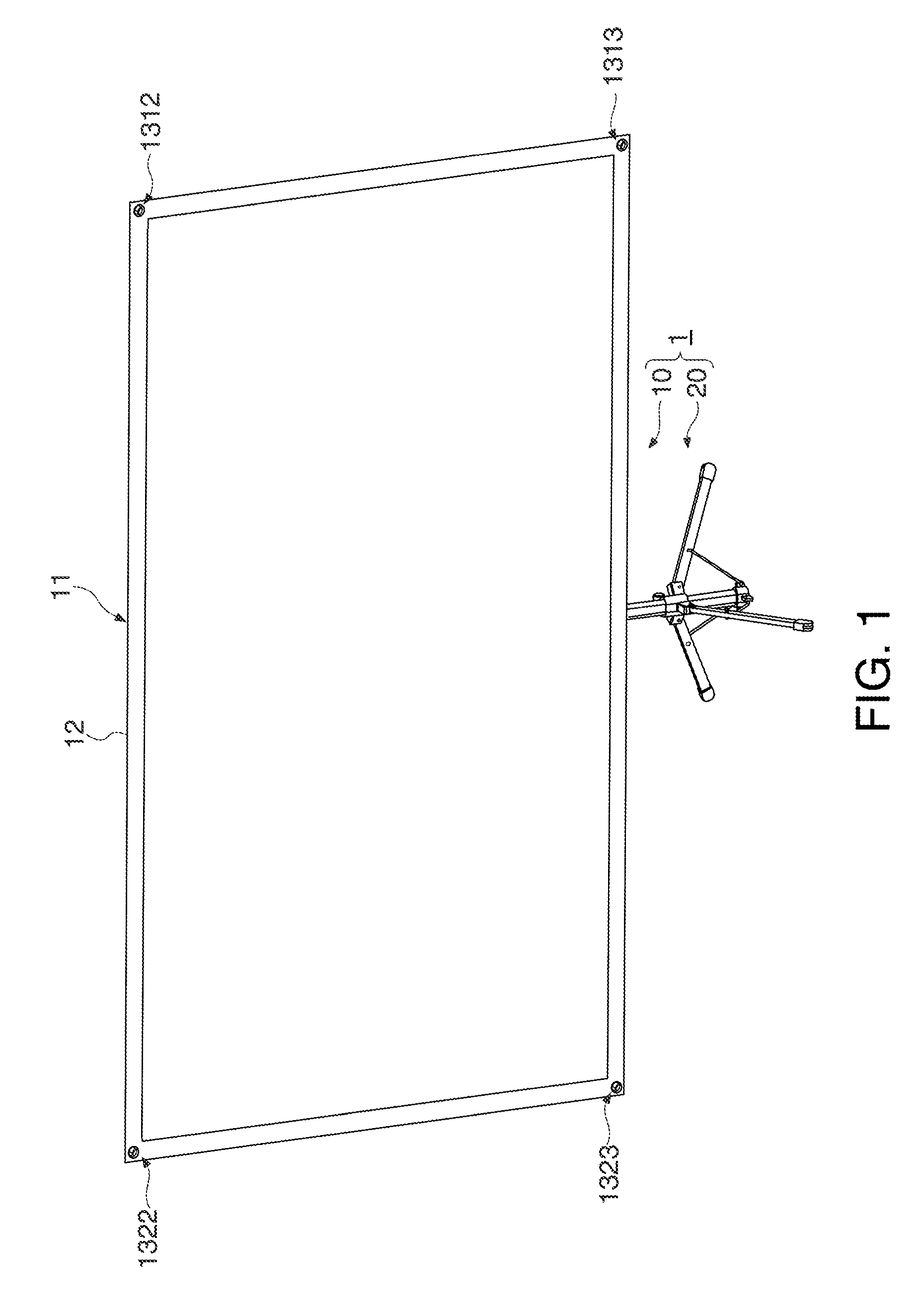

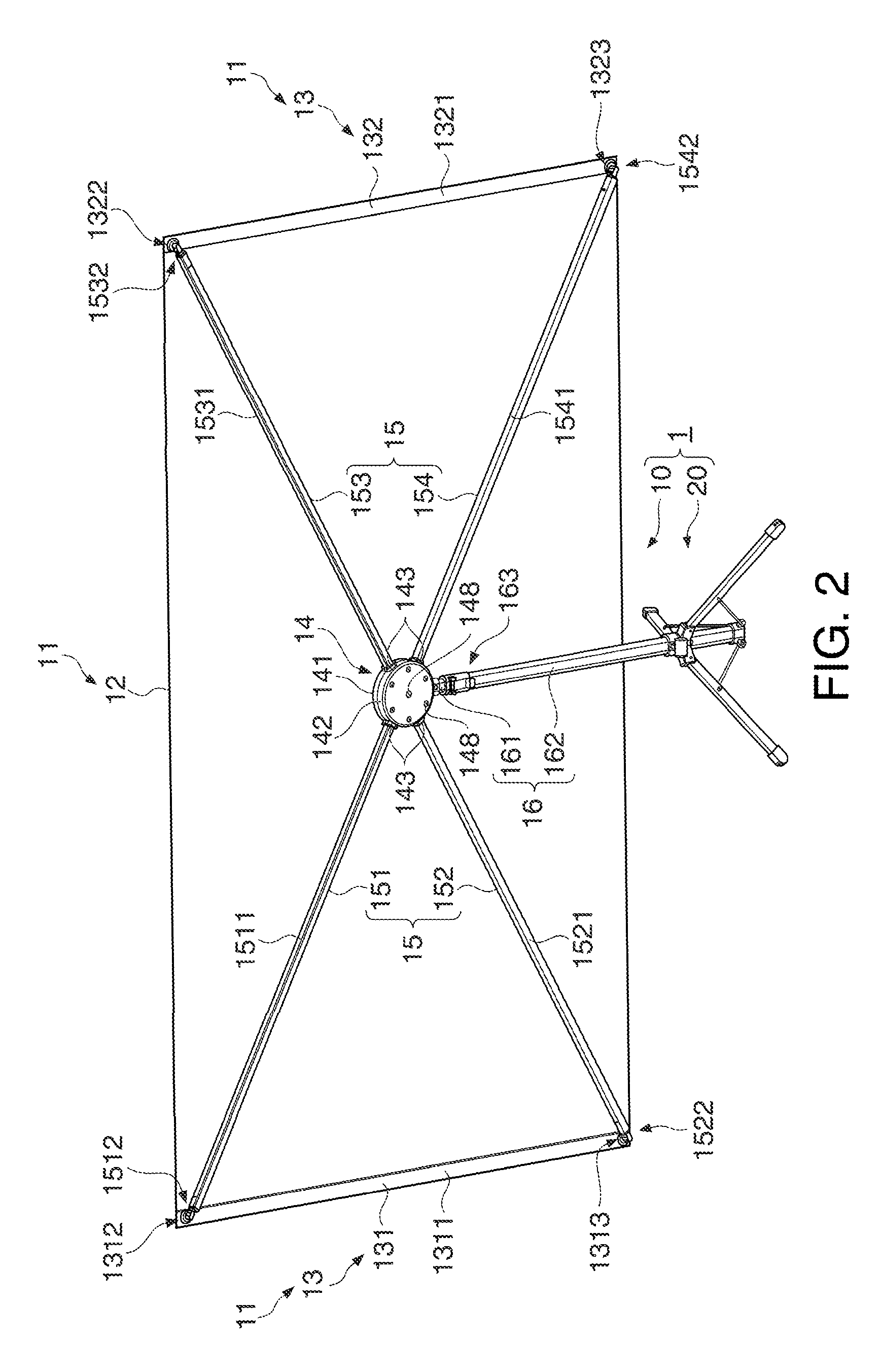

Screen

Owner:SEIKO EPSON CORP

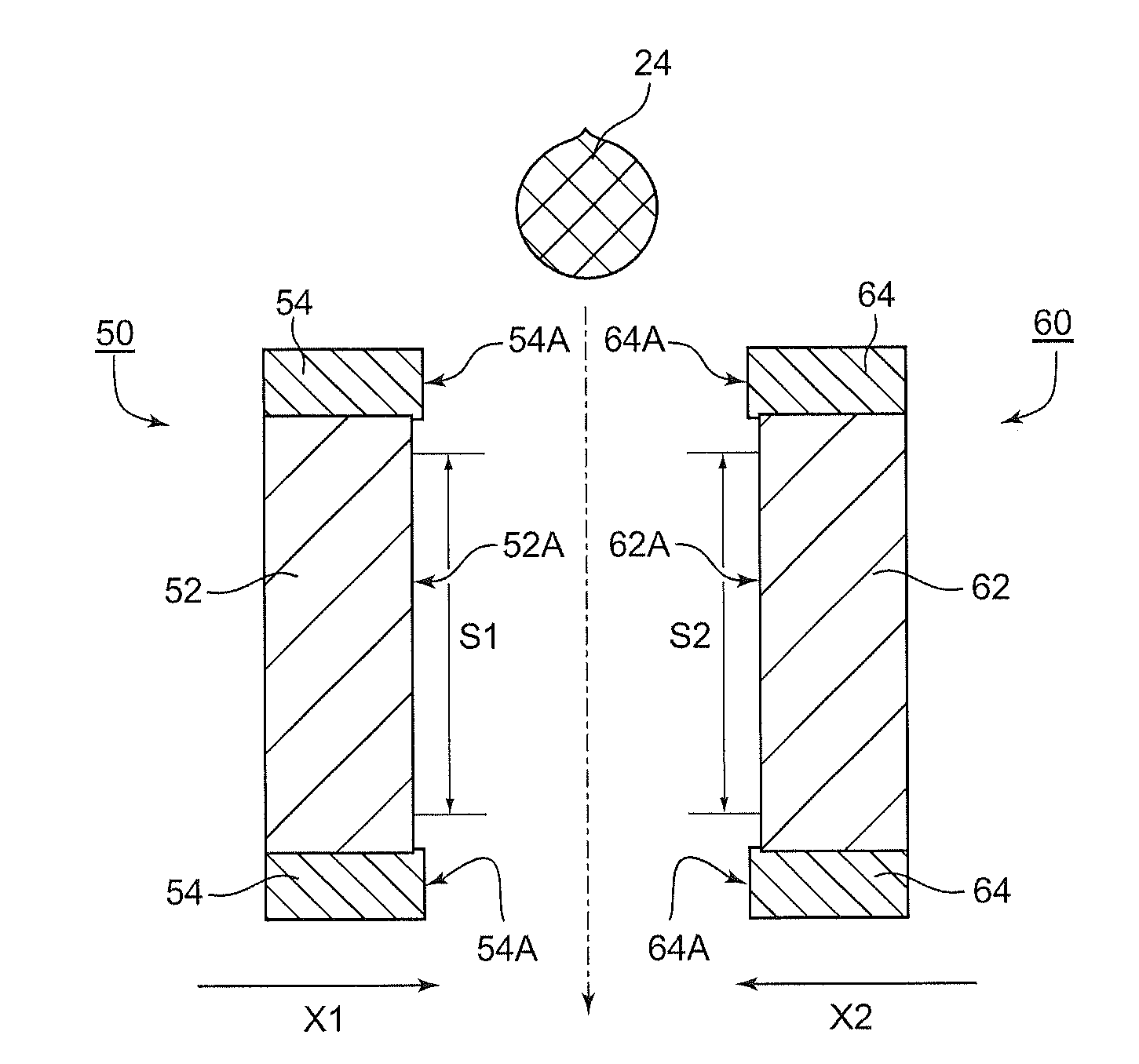

Method of attaching an electronic device to an mlcc having a curved surface

ActiveUS20090077800A1Reduce flatnessPrinted circuit assemblingLine/current collector detailsIntegrated circuitElectronic equipment

A method of forming an electrical component is provided. The method comprises preparing a subassembly by electrically connecting an integrated circuit to a flexible circuit; and attaching the subassembly to a multilayer ceramic capacitor having a mounting surface with a curvature deviation exceeding 0.008 inches per inch.

Owner:KEMET ELECTRONICS

Aeroplane oil box leakage source checking device

InactiveCN1991325ASimple structureLow manufacturing costMeasurement of fluid loss/gain rateAirplaneLiquid pressure

The invention belongs to leak detection equipment of airplane tank. The main characteristics of technique are that: the oil pipe passes through the negative pressure cover and the edges of oil pipe are mounted on the sealed cover, the sealed cover seals the leak detection box along the axial direction, the outer edges of the sealed cover fix the pressure regulation annular plate in the negative pressure cover along the supporting pole direction, the oil pipe connects with the oil cylinder. The invention can detect the inner missing dots according to the outer missing dots quickly and efficiently (the reverse is true), it has advantages of simplicity, intuitionistic, high efficiency and nicety, and the liquid pressure can be adjusted according to the requirement.

Owner:中国民用航空学院

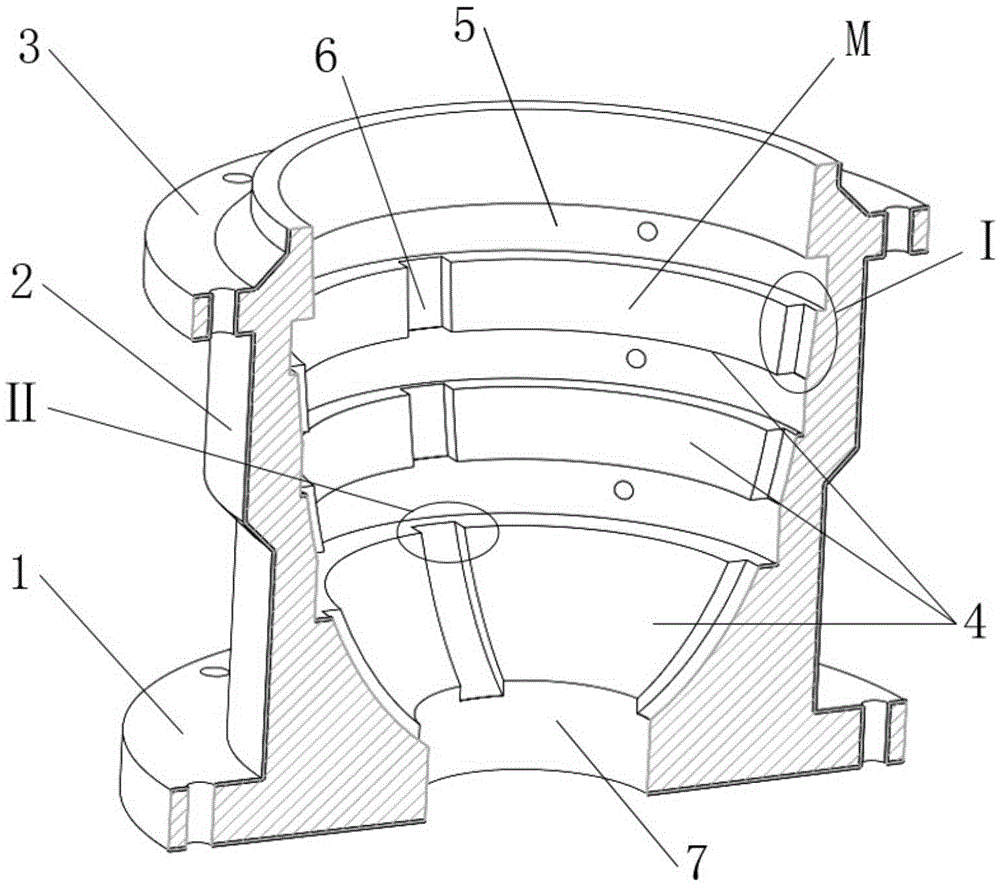

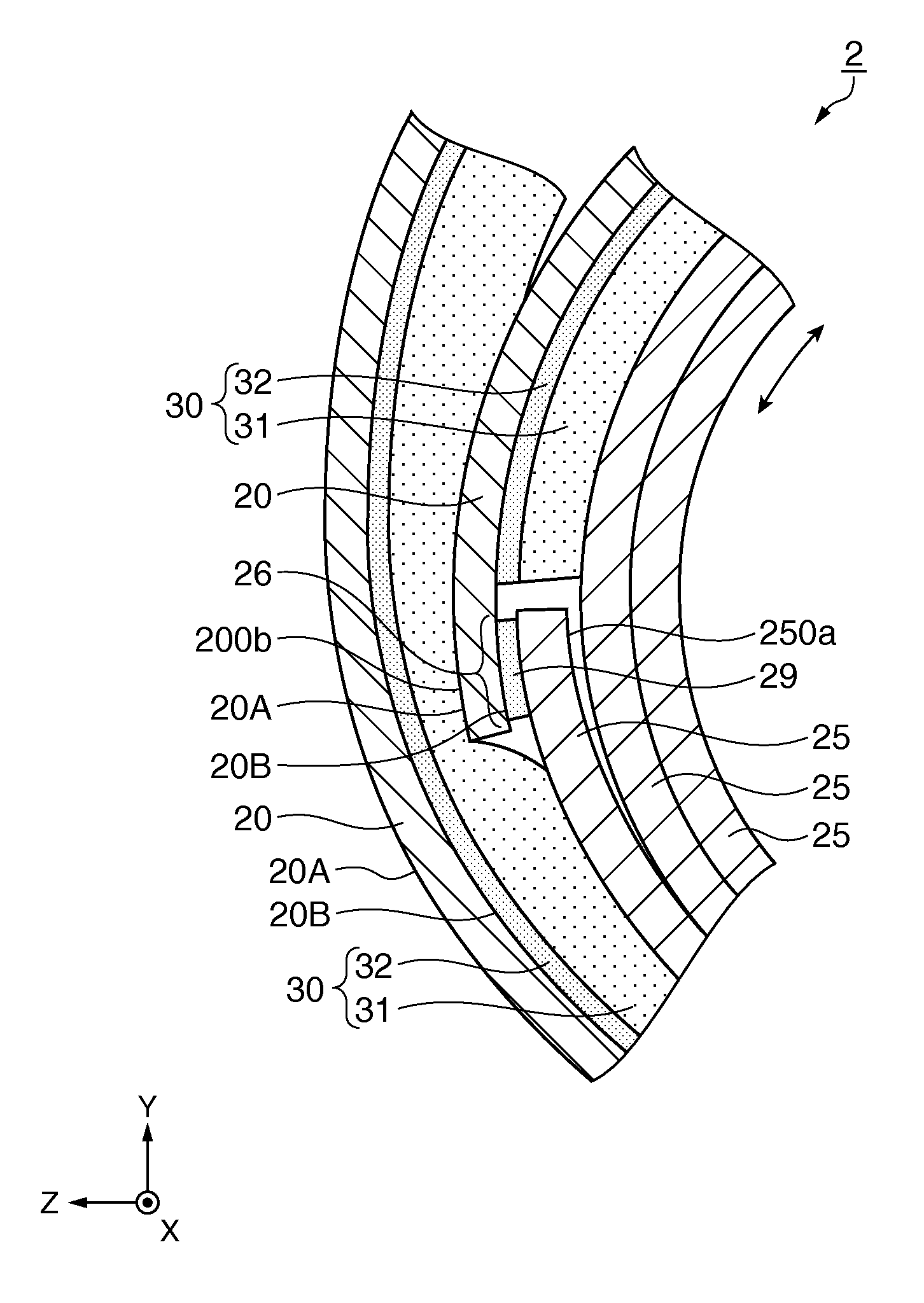

Clamping device for precisely machining inner surface of conformal optical cowling

ActiveCN105643303AFit tightlyAvoid the influence of machining accuracyWork clamping meansPositioning apparatusJoint surfaceRadian

The invention relates to a clamping device for precisely machining an inner surface of a conformal optical cowling, which relates to a machining clamping device, and aims at solving the problem that unpredictable total deformation can be produced because a joint surface of the existing clamping device for precisely machining the inner surface of the conformal optical cowling is in a local contact and even in a point contact, the cowling is difficult to completely fix and the machining precision is difficult to guarantee. The upper end of a basal body is provided with a flange, the lower end of the basal body is provided with a base, an inner cavity of the basal body is a curved inner cavity, the cross section of the curved inner cavity is a variable cross section which is gradually narrowed from top to bottom, a plurality of annular positioning bosses are arranged on the inner wall of the curved inner cavity, the curved radian of each annular positioning boss is consistent with that of the outer surface of the cowling, a transverse groove is formed between two adjacent annular positioning bosses, longitudinal grooves are formed in the plurality of annular positioning bosses, and a through hole which is communicated with the curved inner cavity is formed in the center of the bottom of the basal body. The clamping device is used for precisely machining the inner surface of the conformal optical cowling.

Owner:HARBIN INST OF TECH

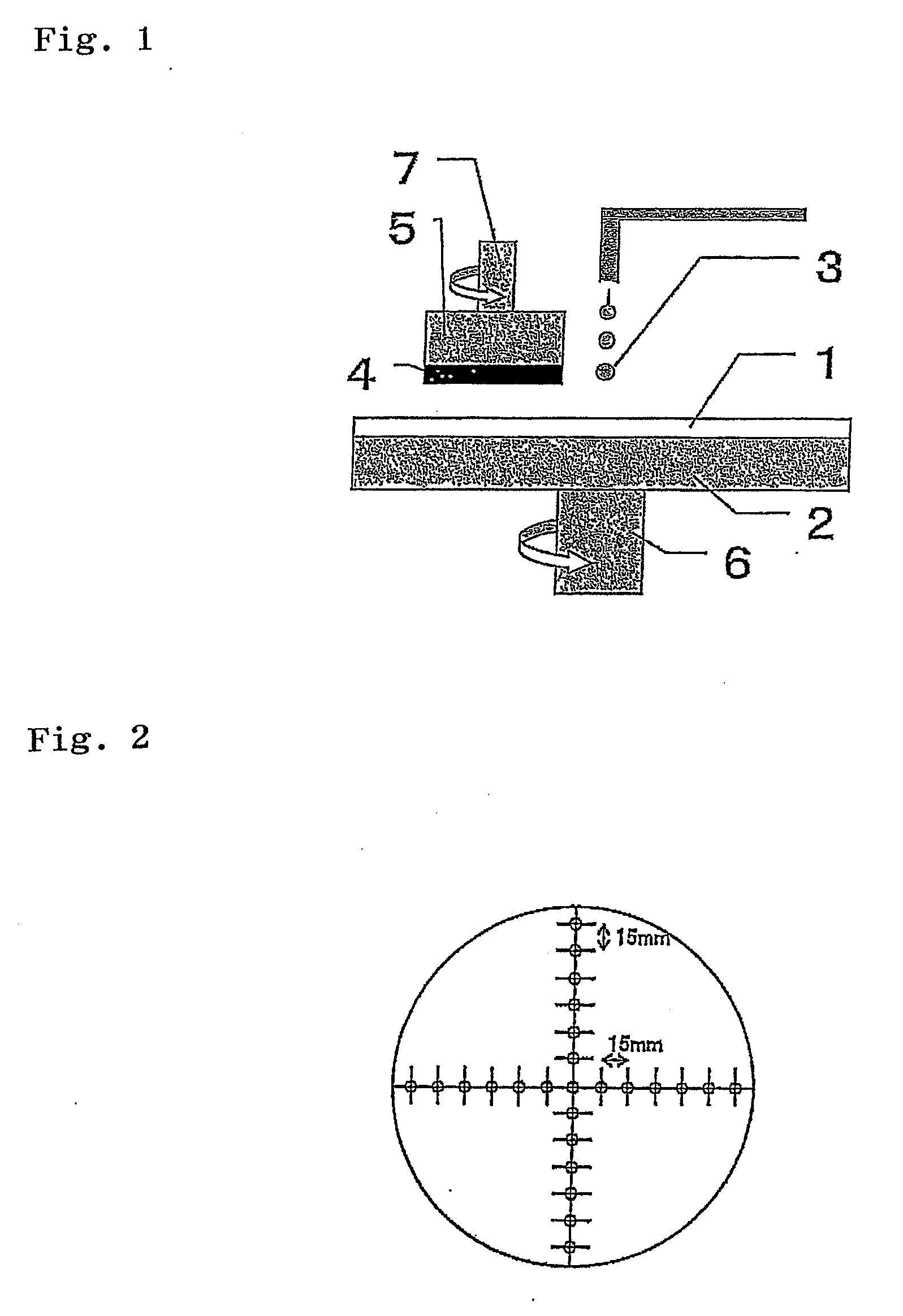

Polishing pad and method of producing semiconductor device

InactiveUS8845852B2Detection accuracy meetsHigh measurement accuracySemiconductor/solid-state device manufacturingFlexible-parts wheelsIn planeTransmittance

A polishing pad enabling a highly precise optical endpoint sensing during the polishing process and thus having excellent polishing characteristics (such as surface uniformity and in-plane uniformity) is disclosed. A polishing pad enabling to obtain the polishing profile of a large area of a wafer is also disclosed. A polishing pad of a first invention comprises a light-transmitting region having a transmittance of not less than 50% over the wavelength range of 400 to 700 nm. A polishing pad of a second invention comprises a light-transmitting region having a thickness of 0.5 to 4 mm and a transmittance of not less than 80% over the wavelength range of 600 to 700 nm. A polishing pad of a third invention comprises a light-transmitting region arranged between the central portion and the peripheral portion of the polishing pad and having a length (D) in the diametrical direction which is three times or more longer than the length (L) in the circumferential direction.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Screen

Owner:SEIKO EPSON CORP

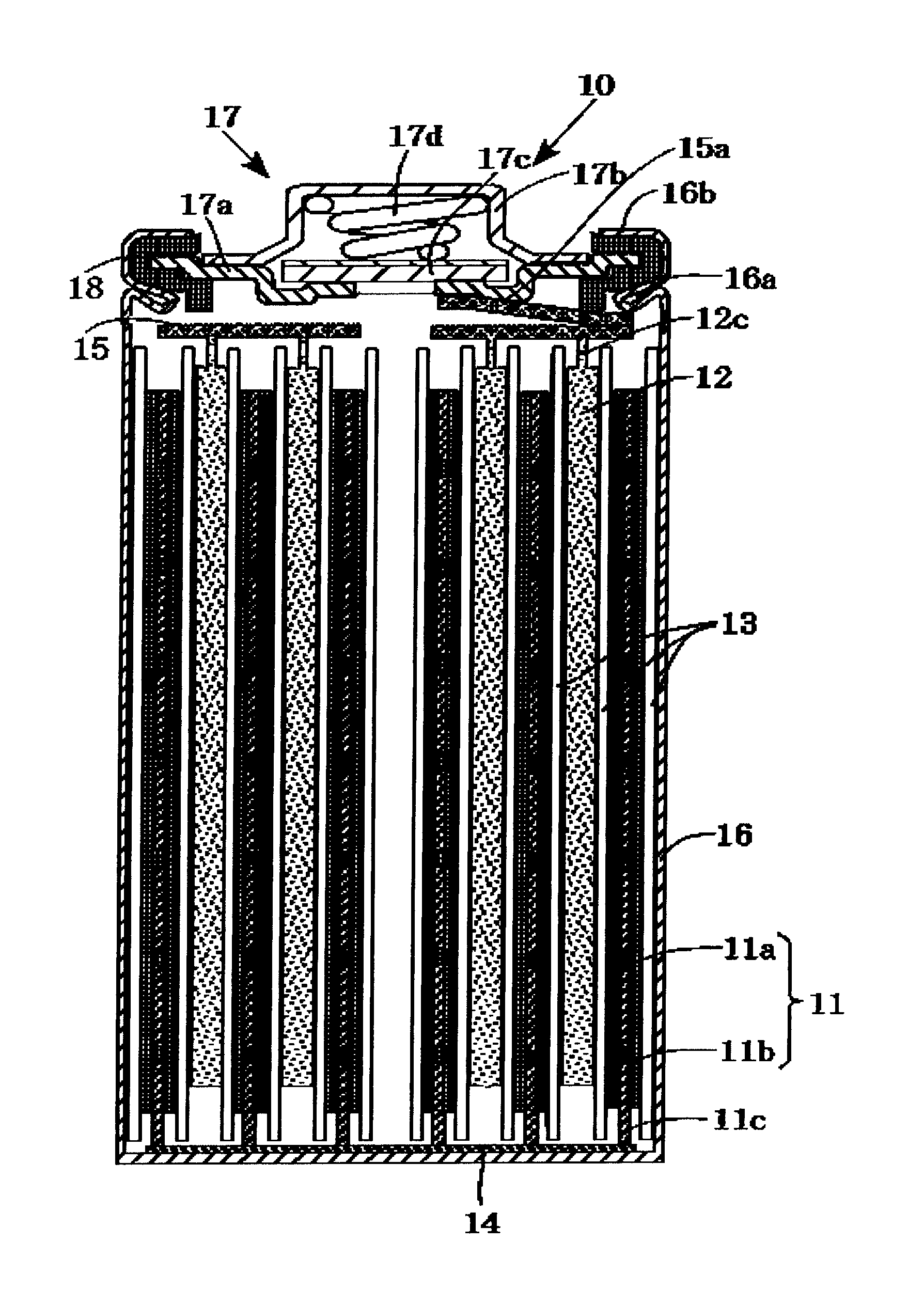

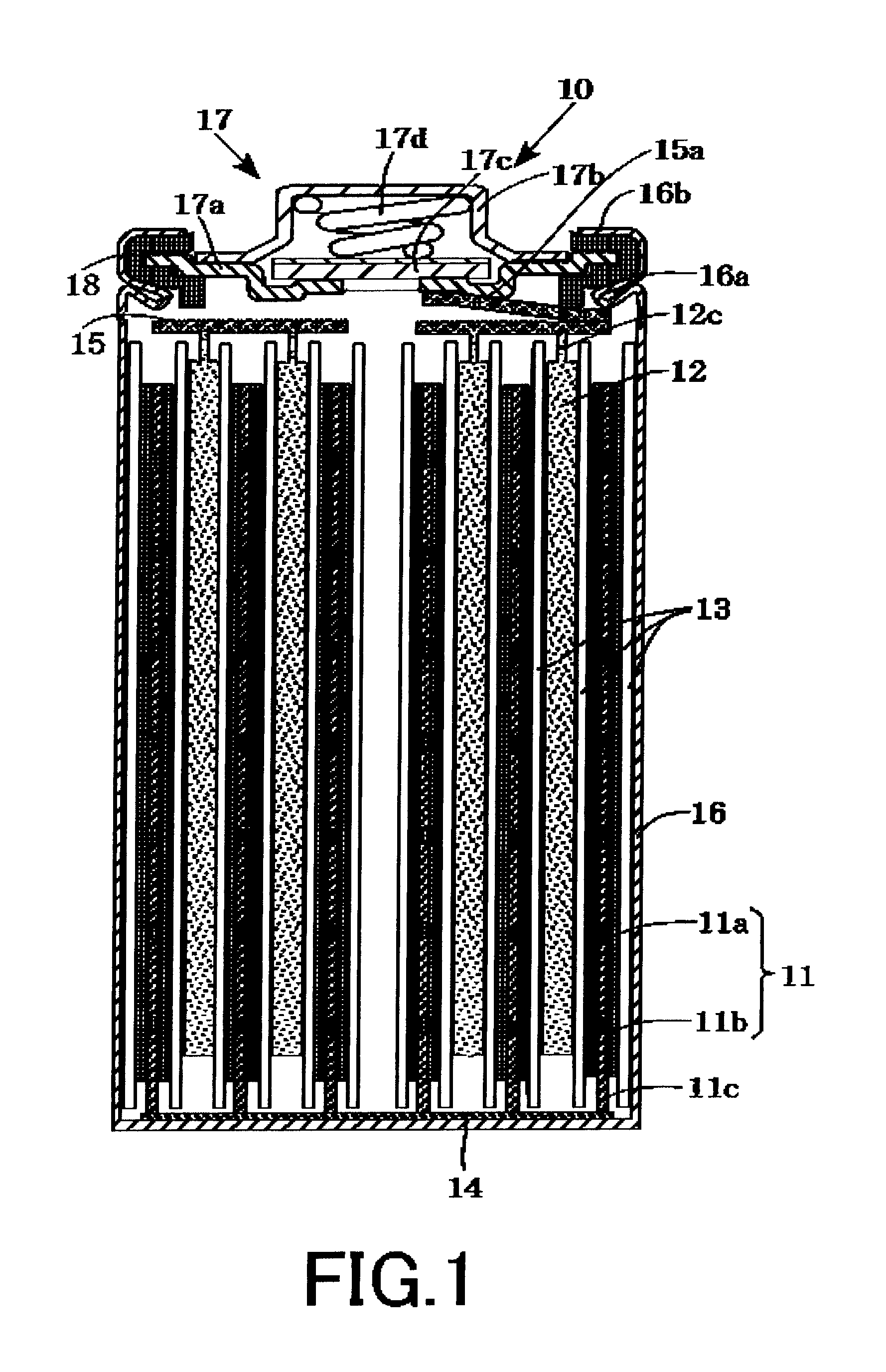

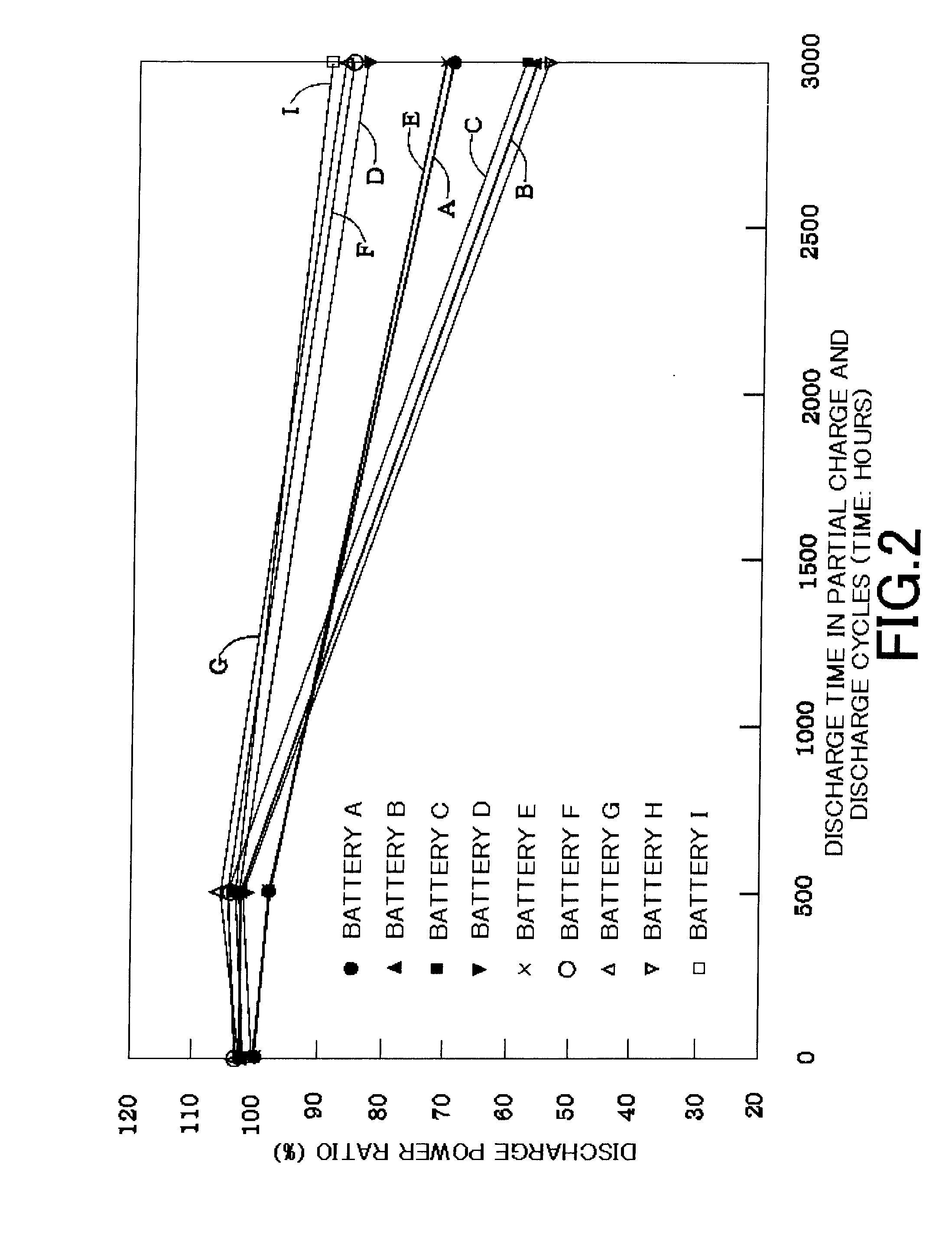

Hydrogen storage alloy for alkaline storage battery, and alkaline storage battery and alkaline storage battery system each including negative electrode having the alloy

ActiveUS20110229755A1Improve output powerIncrease output powerHydrogenMultiple metal hydridesRare-earth elementSurface layer

To provide a hydrogen storage alloy for an alkaline storage battery that improves output power by pulverization of the alloy in the initial stage of partial charge and discharge cycles and that maintains its surface condition to improve the amount of lifetime work (Wh), and an alkaline storage battery and battery system. A hydrogen storage alloy for an alkaline storage battery includes a composition expressed by LaxReyMg1-x-yNin-m-vAlmTv (Re; rare earth element(s) including Y; T: Co, Mn, Zn; 0.17≦x≦0.64, 3.5≦n≦3.8, 0.06≦m≦0.22, v≧0), and a main phase of an A5B19 type crystal structure. A ratio of X / Y of the concentration ratio X of Al to Ni in a surface layer and the concentration ratio Y of Al to Ni in a bulk layer is 0.36≦X / Y≦0.85. An alkaline storage battery includes the hydrogen storage alloy in its negative electrode. An alkaline storage battery system performs partial charge and discharge control.

Owner:SANYO ELECTRIC CO LTD

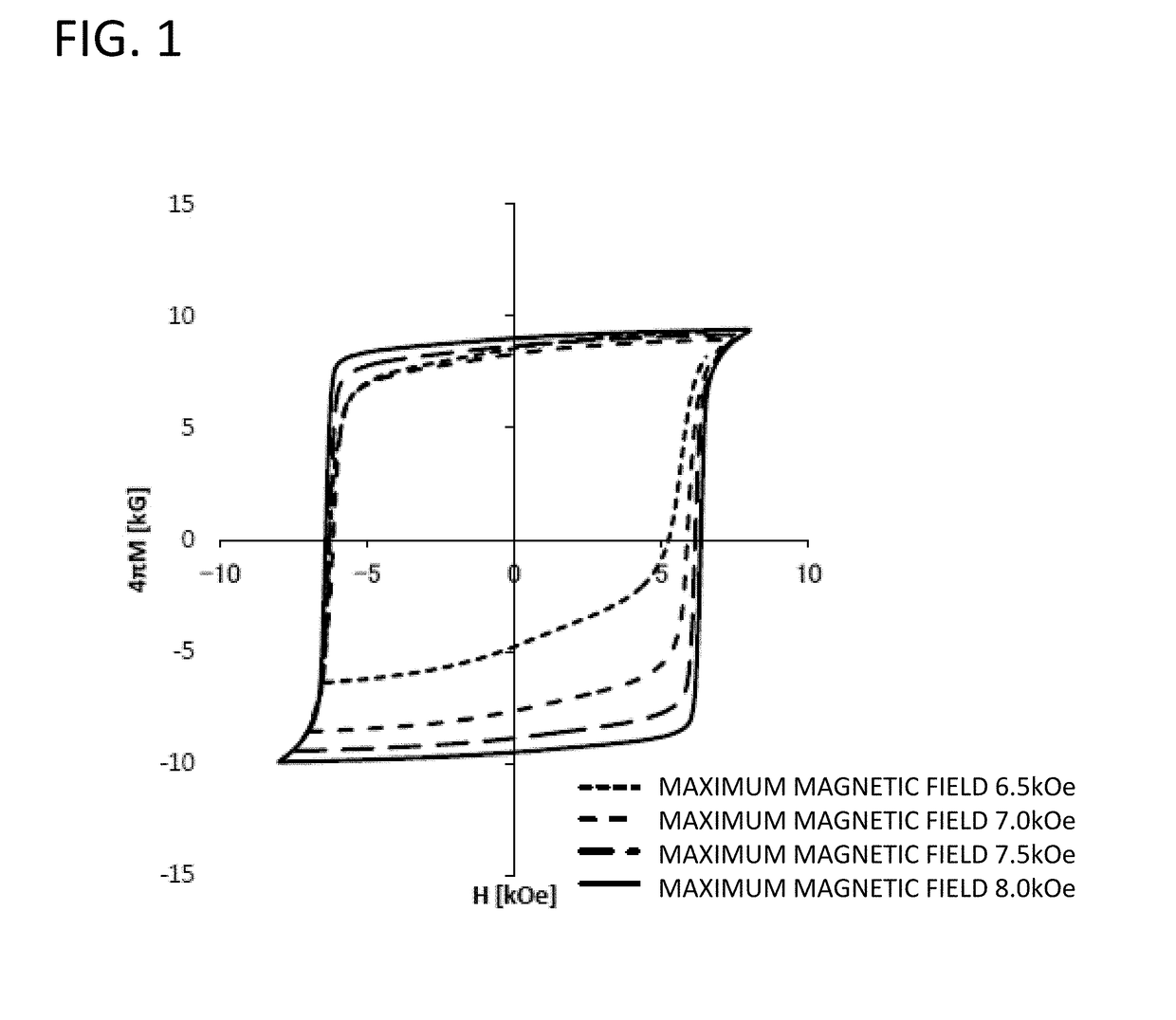

R-t-b based rare earth permanent magnet

ActiveUS20180040399A1Demagnetization field is reducedReduce probabilityMagnetic materialsRare-earth elementArea ratio

An R-T-B based rare earth permanent magnet is expressed by formula: (R11-x(Y1-y-z Cey Laz)x)aTbBcMd in which, R1 is one or more kinds of rare earth element not including Y, Ce and La. “T” is one or more kinds of transition metal, and includes Fe or Fe and Co as an essential component, “M” is an element having Ga or Ga and one or more of Sn, Bi and Si, 0.4≦x≦0.7, 0.00≦y+z≦0.20, 0.16≦a / b≦0.28, 0.050≦c / b≦0.070, 0.005≦d / b≦0.028, 0.25≦(a-2c) / (b-14c)≦2.00 and 0.025≦d / (b-14c)≦0.500. The magnet has a structure having a main phase, having a compound having a R2T14B type tetragonal structure, and a grain boundary phase, on an arbitrary cross sectional area, an area ratio of R-T-M, T-rich and R-rich phases, with respect to a total grain boundary phase area is 10.0% or more, 60.0% or less and 70.0% or less, respectively, and the coating rate of the grain boundary phase is 70.0% or more.

Owner:TDK CORPARATION

Laminate polishing pad

InactiveUS20130012107A1Prevent peelingEfficient dischargeAbrasion apparatusSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

An object of the invention is to provide a laminate polishing pad having a polishing layer and a cushion layer, which resist peeling. A laminate polishing pad including: a polishing layer with no region passing therethrough; an adhesive member; and a cushion layer placed on the polishing layer with the adhesive member interposed therebetween, wherein the back side of the polishing layer has at least one non-adhering region X continuously extending from a central region of the polishing layer to a peripheral end of the polishing layer, and / or the adhesive member has at least one non-adhering region Y continuously extending from a central region of the adhesive member to a peripheral end of the adhesive member.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Lithographic apparatus and method of manufacturing a device

InactiveUS20040178362A1Reduce sensitivityReduce flatnessSemiconductor/solid-state device manufacturingMachines/enginesLight beamProjection system

A lithographic projection apparatus includes a radiation system for providing a beam of radiation and a support structure for supporting a patterning device. The patterning device serves to pattern the beam according to a desired pattern. The lithographic projection apparatus includes a substrate table for holding a substrate and a projection system for projecting the patterned beam onto a target portion of the substrate. At least one holding structure includes at least one compliant member holding a pimple plate for holding a removable item for the apparatus.

Owner:ASML NETHERLANDS BV

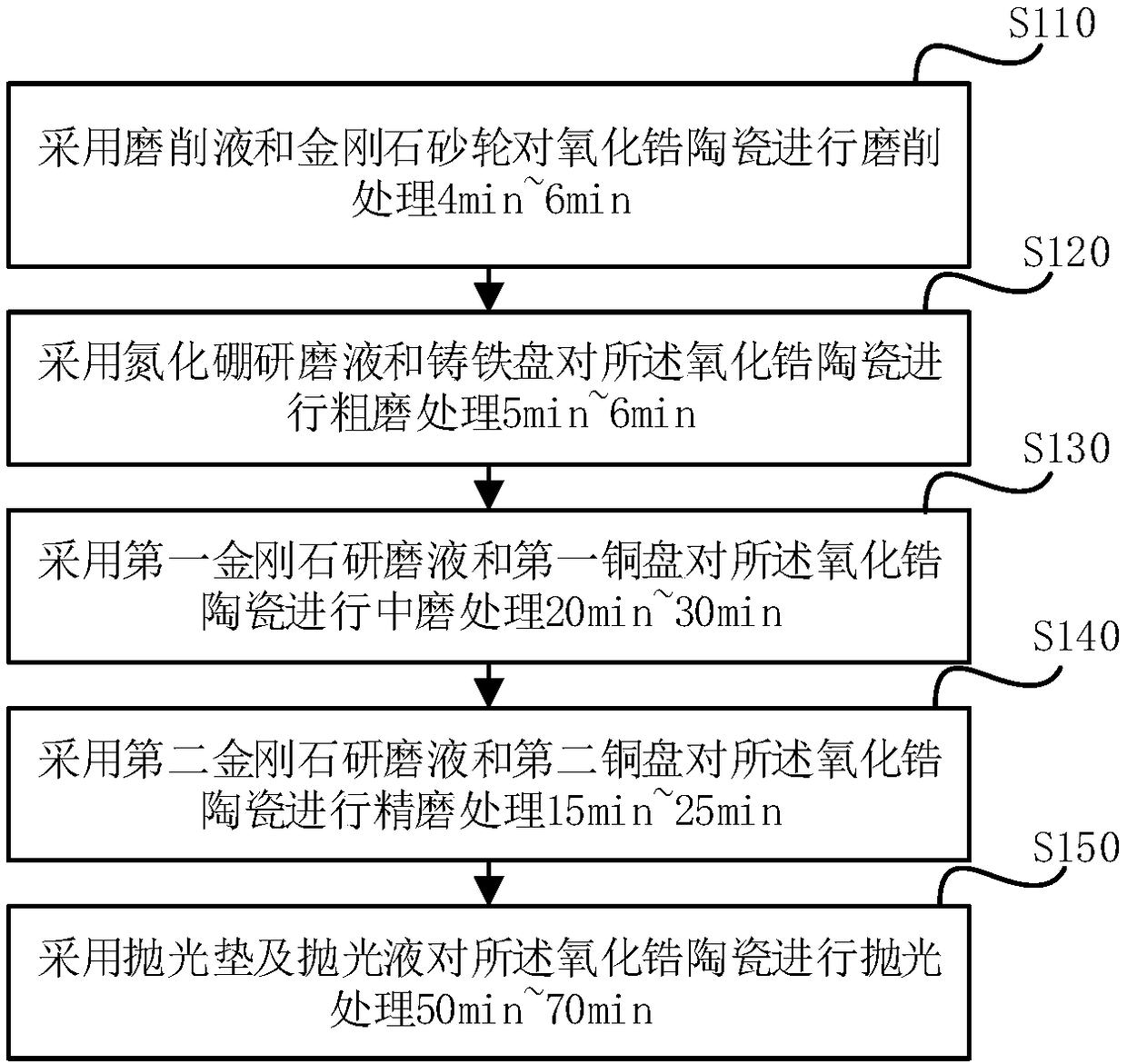

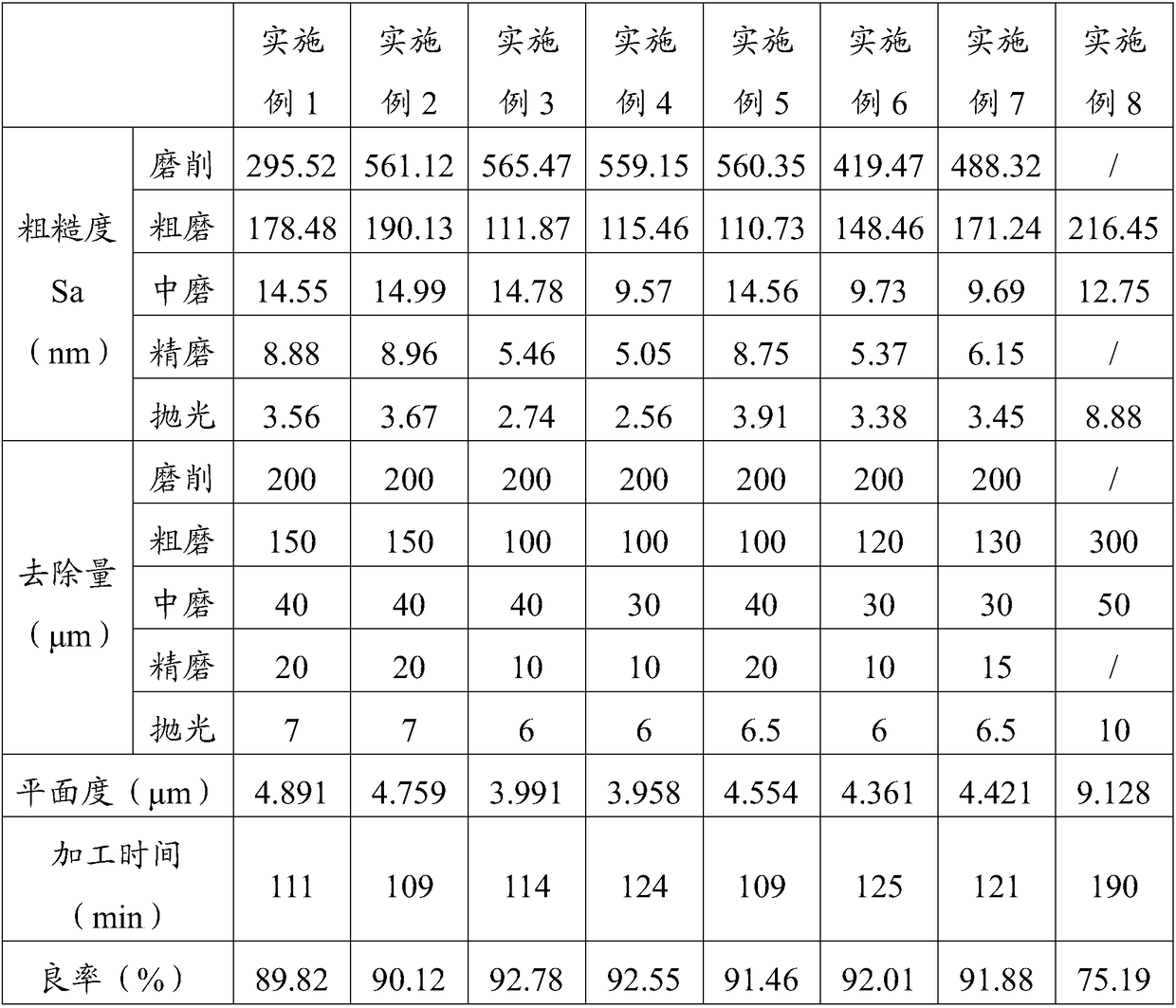

Method for grinding zirconia ceramics

ActiveCN109262373AReduce surface roughnessReduce flatnessPolishing machinesOther chemical processesSurface roughnessBoron nitride

The invention relates to a method for grinding zirconia ceramics, which comprises the following steps of: grinding the zirconia ceramics by using grinding liquid and a diamond grinding wheel for 4 minutes to 6 minutes; carrying out coarse grinding treatment on the zirconia ceramics for 5 minutes to 6 minutes by adopting boron nitride grinding liquid and a cast iron disc, carrying out medium grinding treatment on the zirconia ceramics for 20 minutes to 30 minutes by adopting a first diamond grinding liquid and a first copper disc, carrying out fine grinding treatment on the zirconia ceramics for 15 minutes to 25 minutes by adopting a second diamond grinding liquid and a second copper disc, and polishing the zirconia ceramics for 50 minutes to 70 minutes by adopting a polishing pad and a polishing solution. According to the method for grinding zirconia ceramics, grinding treatment is firstly carried out, then rough grinding treatment is carried out to reduce surface roughness and flatness, middle grinding treatment and fine grinding treatment are further carried out to reduce crack depth, surface roughness and flatness, so the processing difficulty during polishing treatment is reduced, the total processing time is less than 130 minutes, the processing time is obviously reduced, the processing efficiency is improved, and the yield of processed products is improved.

Owner:DONGGUAN HUAJING POWDER METALLURGY

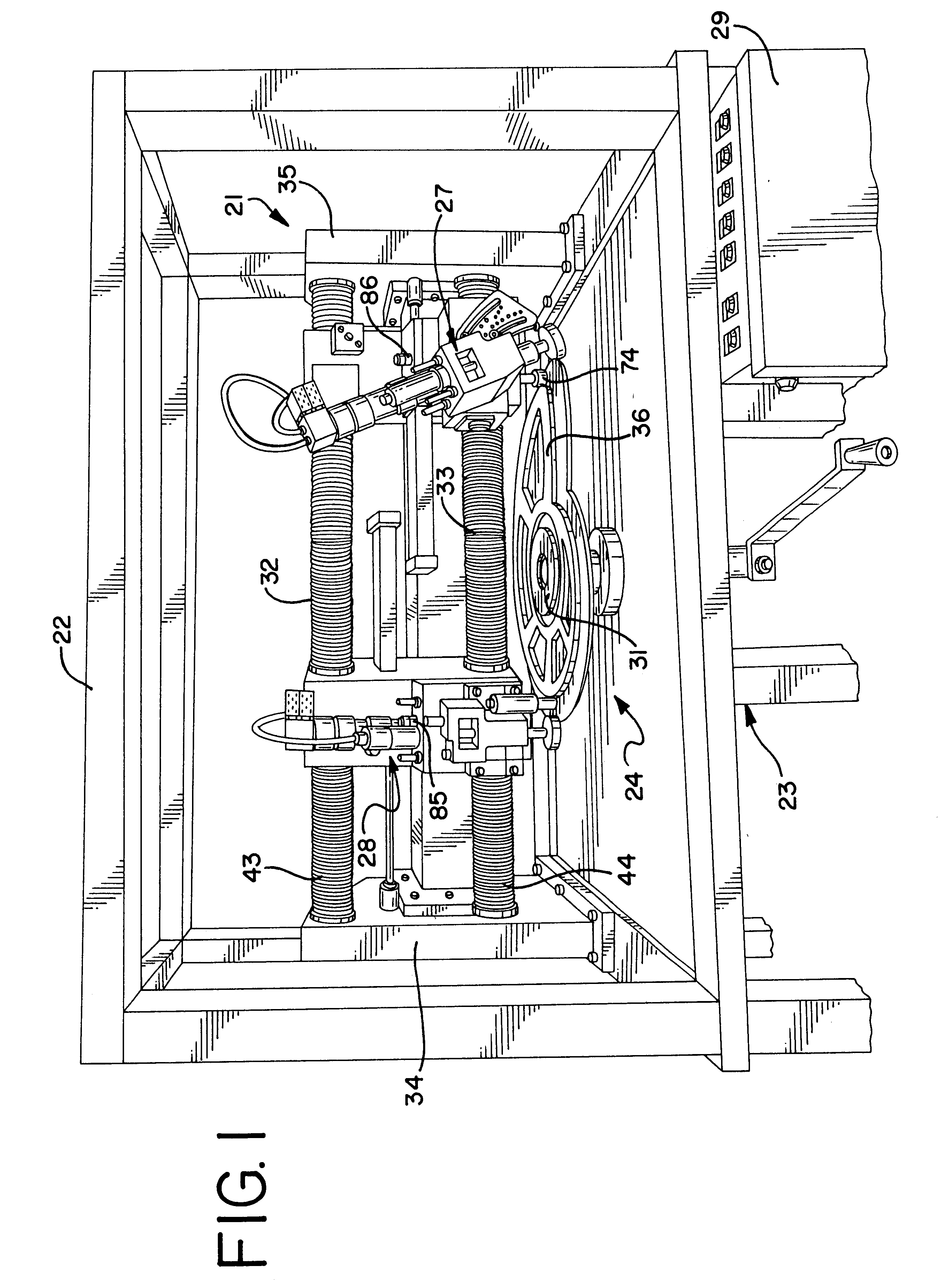

Off-line honing of slicer blades

InactiveUS6371835B1Minimize the numberClose tolerances with respect to blade flatnessOther manufacturing equipments/toolsPlane surface grinding machinesEngineeringGrinding wheel

An apparatus and method for honing, sharpening or grinding a curved peripheral cutting surface of a slicer blade are provided. Included is the use of one of a set of interchangeable cams that generally follows the curved shape of the blade cutting surface, whether same has a constant radius or varying radii. The honing is accomplished off-line of the slicer equipment, and the movement of two honing or grinding wheels is closely controlled so as to provide honed or ground cutting edges which are of substantially uniform width throughout their respective peripheries. The two honing or grinding wheels operate independently of each other on opposing edges of the blade, a large blade load area is provided therebetween, precision gib adjustments are provided between the wheel and the cam follower, and a single tool is needed to make adjustments of the apparatus.

Owner:KRAFT FOODS GRP BRANDS LLC

Screen and screen unit

Owner:SEIKO EPSON CORP

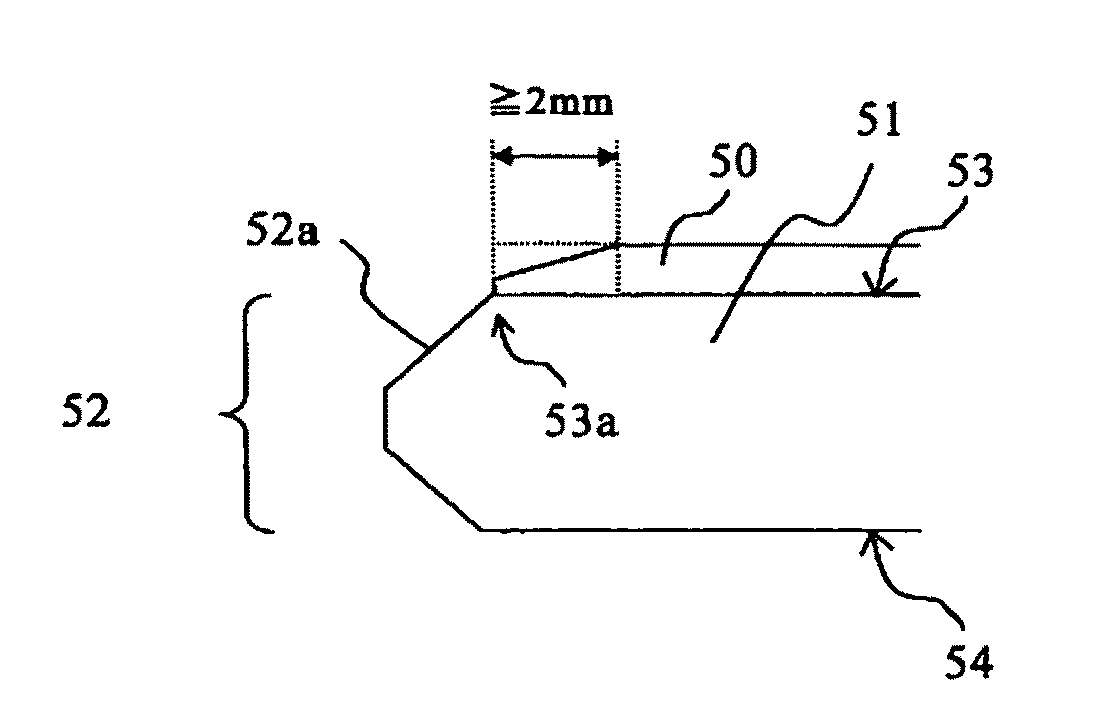

Method for polishing silicon wafer, method for producing silicon wafer, apparatus for polishing disk-shaped workpiece, and silicon wafer

InactiveUS20110256815A1Reduce thicknessLow resistivityEdge grinding machinesSemiconductor/solid-state device manufacturingProduction rateWafering

The present invention is a method for polishing a silicon wafer, in which an oxide film is formed on a back surface side of the wafer, wherein the oxide film on a chamfered portion of the silicon wafer is removed, and the oxide film on a peripheral portion of the back surface of the wafer is polished over at least 2 mm from the outermost peripheral portion of the back surface of the wafer so that a thickness of the polished oxide film decreases from inside to outside of the wafer, a method for producing such a silicon wafer, and a silicon wafer. Thereby, there are provided a method for polishing a silicon wafer in which particles' attaching to a wafer surface after handling can be prevented, decrease of resistivity due to autodoping is not brought about, and moreover, productivity does not decrease; a method for producing such a silicon wafer; an apparatus for polishing a disk-shaped workpiece suitable for performing the methods; and a silicon wafer in which particles do not attach to a surface after handling even if an oxide film is formed on a back surface of the wafer and decrease of resistivity due to autodoping is not brought about.

Owner:SHIN-ETSU HANDOTAI CO LTD

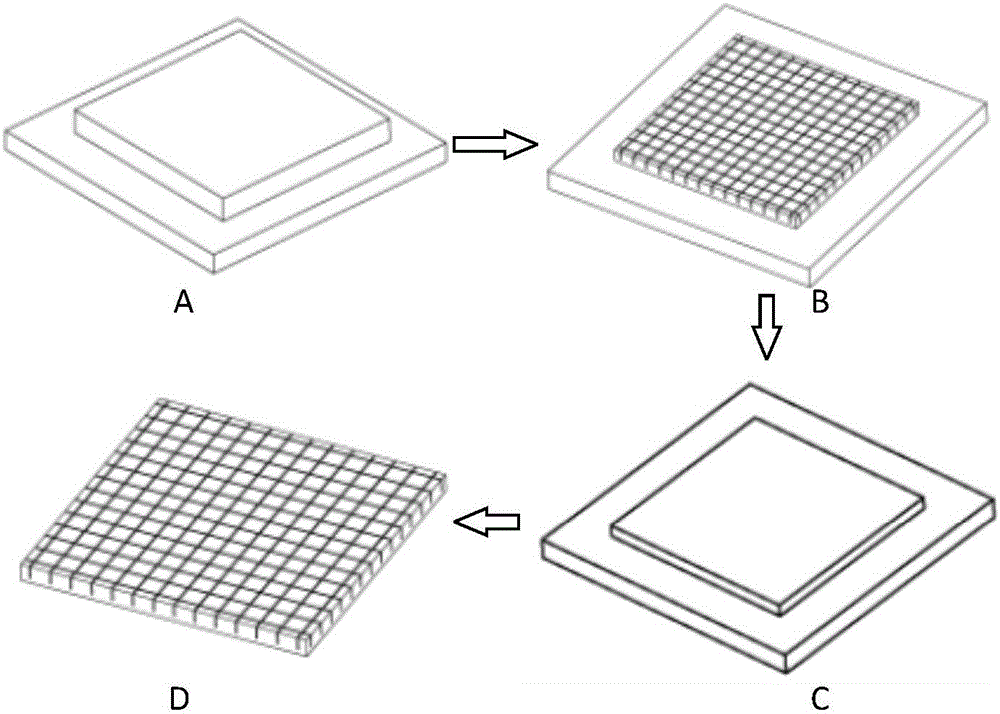

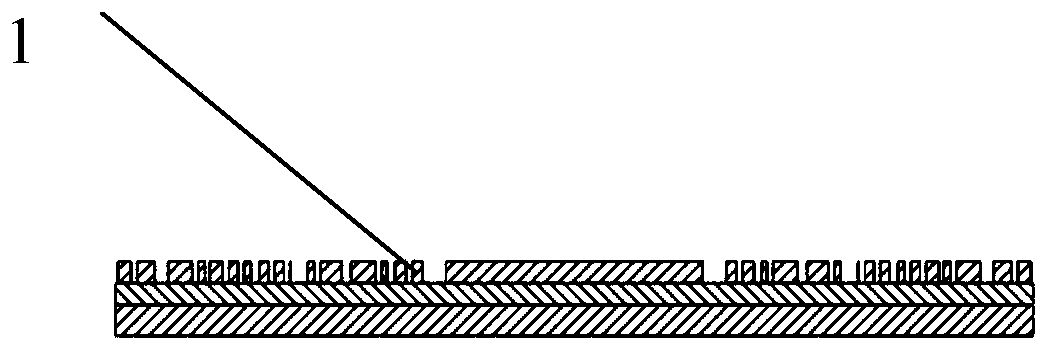

Making method of piezoelectric composite materials

ActiveCN106622924AReduce flatnessAvoid misalignmentMechanical vibrations separationMetallurgyPiezoelectric composite

The invention relates to a making method of piezoelectric composite materials. The making method of the piezoelectric composite materials comprises the following steps of bonding piezoelectric materials to a plate; cutting the piezoelectric materials bonded to the plate, wherein the depth of cutting cracks of the piezoelectric materials is less than the thickness of the piezoelectric materials; filling the cutting cracks of the piezoelectric materials with decoupling materials; using the plate as a standard, and grinding the upper surfaces of the solidified piezoelectric materials filled with the decoupling materials; then taking down the piezoelectric materials, and grinding the lower surfaces of the piezoelectric materials; and arranging electrodes on the surfaces of the ground piezoelectric materials, so as to obtain the piezoelectric composite materials. According to the making method disclosed by the invention, in the processing process, the situation that the piezoelectric materials are curved can be avoided, the right order and the regularity of the shape of microlite elements are effectively guaranteed, and reliable guarantee is provided for the consistency of plane array probes.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

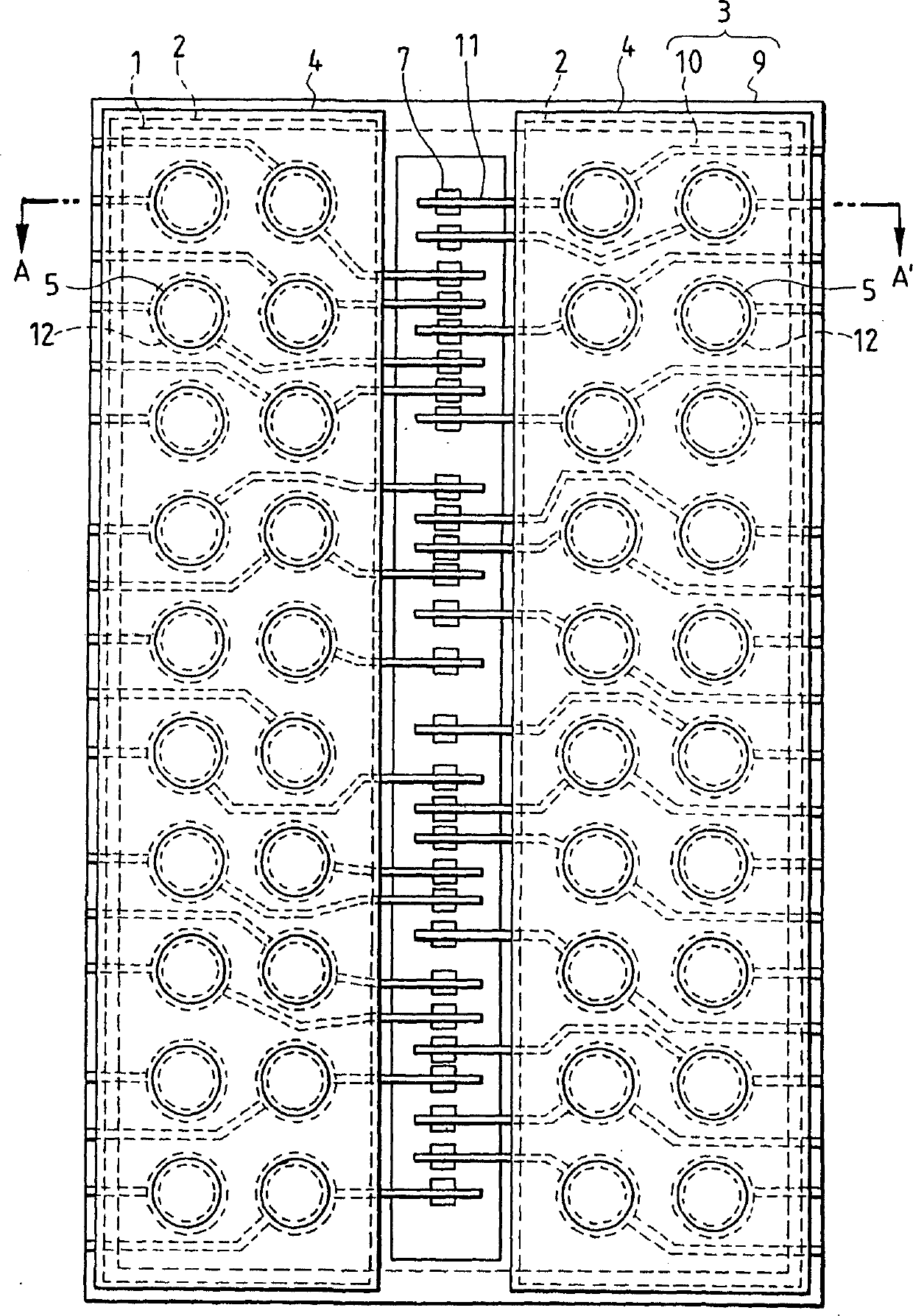

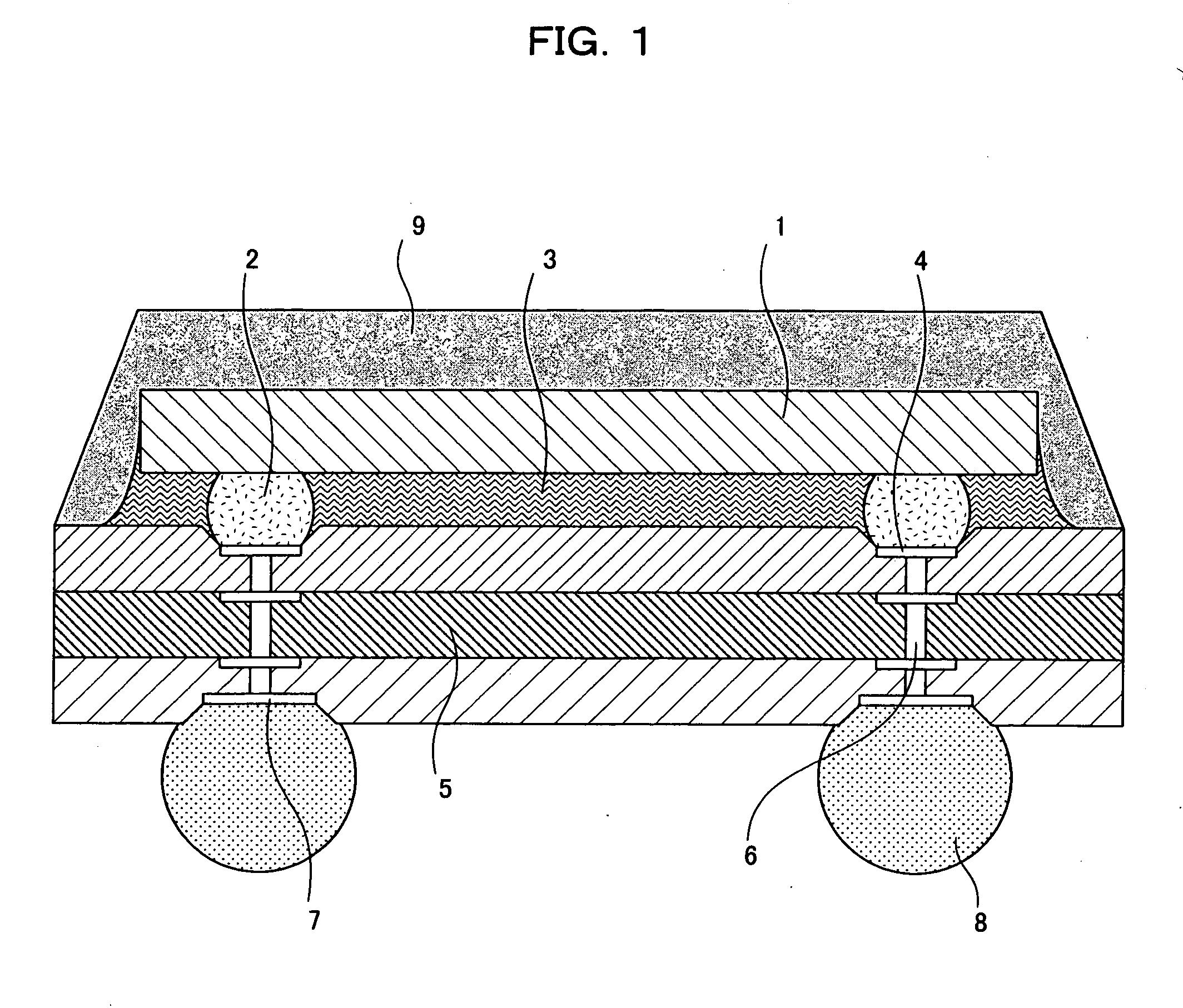

Semiconductor device

InactiveCN1728372AReduce flatnessReduce crackingSemiconductor/solid-state device detailsSolid-state devicesResistElastomer

A ball grid array type semiconductor package includes a semiconductor chip formed with bonding pads, an elastomer bonded to the semiconductor chip, a flexible wiring substrate bonded to the elastomer and formed with wirings connected at one end of the bonding pads of the semiconductor chip, a solder resist formed on the main surface of the flexible wiring substrate and solder bump electrodes connected to the other ends of the wirings. The elastomer is bonded to the flexible wiring substrate on the side of the tape, the solder resist is formed on the side of the wirings, and the solder bump electrodes are connected with the wirings by way of through holes formed in the solder resist.

Owner:HITACHI LTD +1

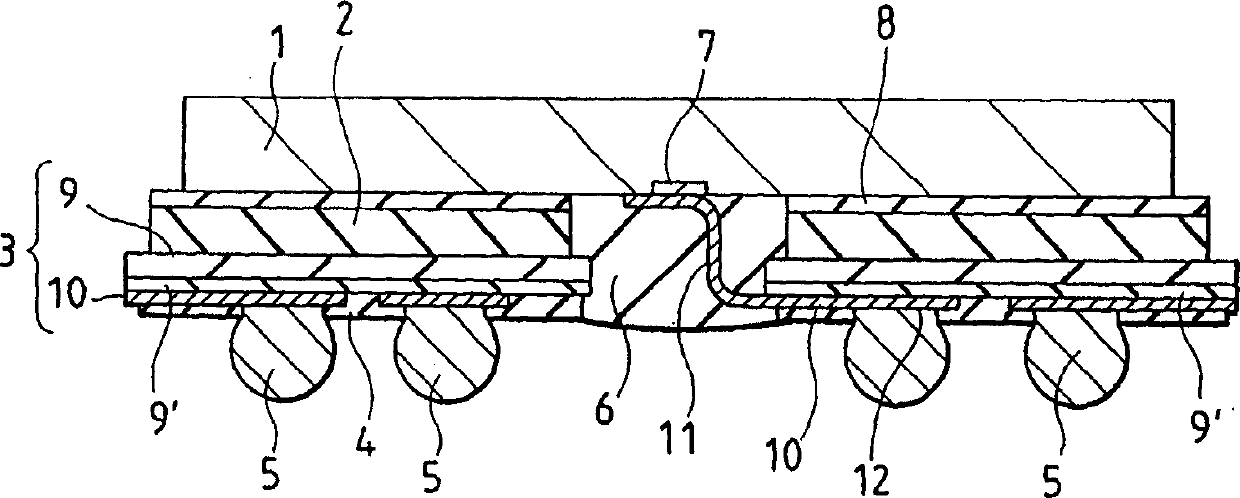

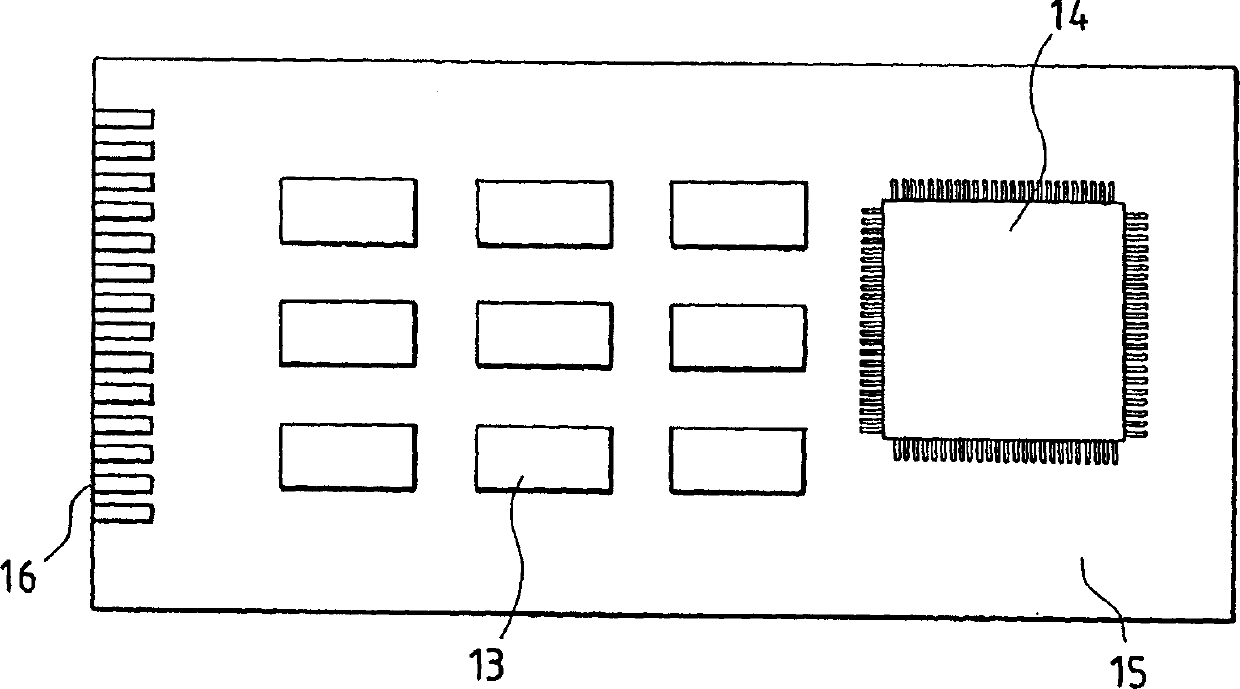

Semiconductor device and semiconductor device production method

InactiveUS20070075415A1Improve flatnessReduce flatnessSemiconductor/solid-state device detailsPrinted circuit aspectsResistDevice material

The present invention provides a semiconductor device in which the warp of a board is suppressed without the need for provision of a solder resist on opposite surfaces of the board and semiconductor element connection characteristics are improved by reducing stress exerted on a connection portion, and increases flexibility in assembly process.

Owner:PANASONIC CORP

Integrated gasket

InactiveCN101733602AReduce flatnessReduce processing difficultyWelding/cutting auxillary devicesAuxillary welding devicesCooling effectProcessing cost

The invention relates to an integrated gasket, which is formed by connecting a plurality of gasket bodies in series, the upper end faces of the gasket bodies are on the same plane after the gasket bodies are connected in series, the side ends of two adjacent gasket bodies are fixedly connected through a locating connecting block, two side end faces connected in the two adjacent gasket bodies are tightly matched with each other, and each of the gasket bodies is internally provided with a cooling water way used for leading out the heat on the gasket bodies. The integrated gasket greatly reduces the processing difficulty and the processing cost caused by overlong integrated gaskets, and synchronously, the embedded cooling protection is adopted, and the cooling effect is increased.

Owner:KUSN HUAHENG ENG TECH CENT

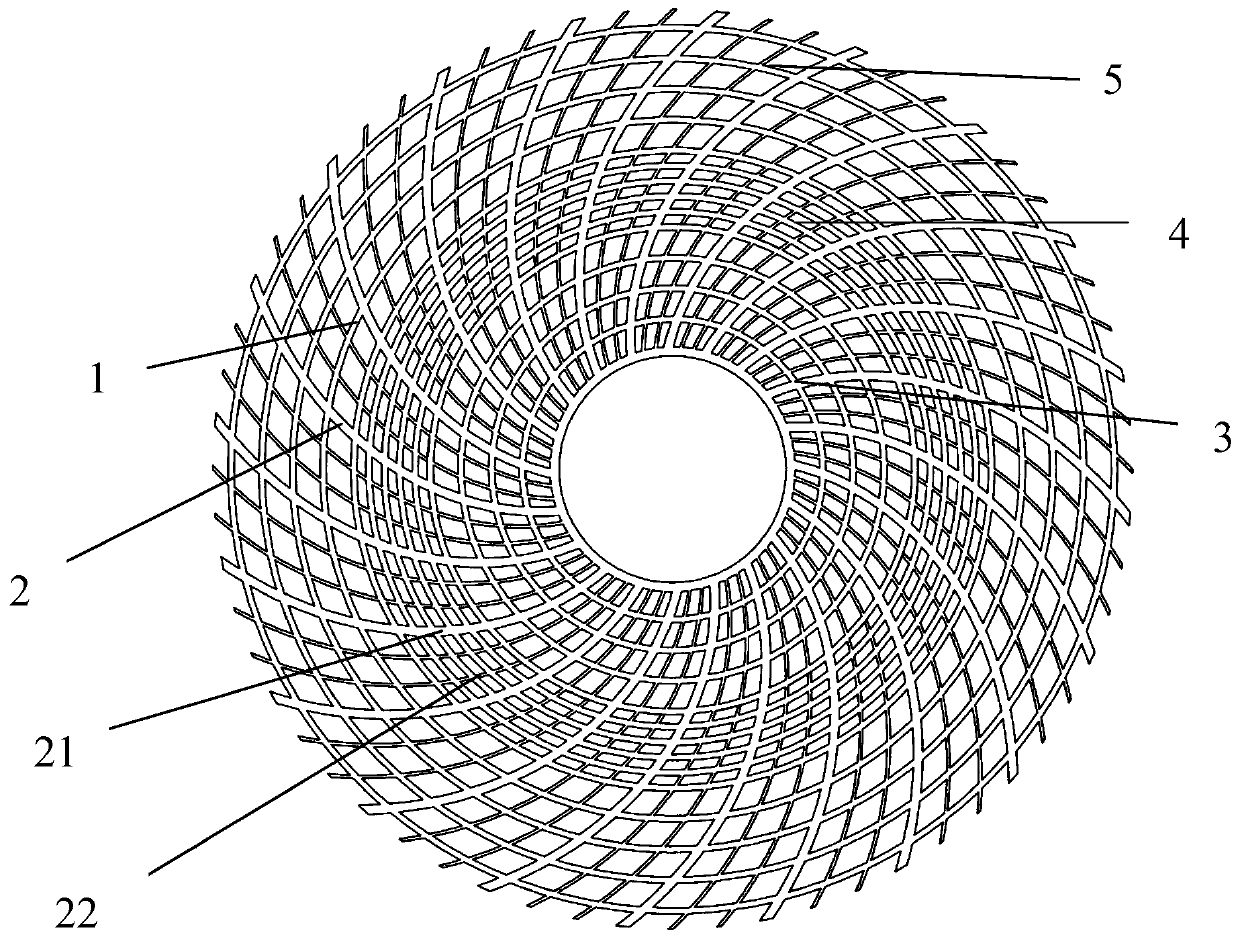

Groove grinding disc and method for manufacturing groove grinding disc

PendingCN110948381AReduce resistanceGood for chip evacuationGrinding devicesLapping toolsGrindingEngineering

The invention provides a groove grinding disc and a method for manufacturing the groove grinding disc. The grinding disc is provided with a groove; the groove is formed by coupling a plurality of concentric grooves with radii gradually increasing and a plurality of spiral line grooves which are arranged at equal intervals; the centers of the spiral line grooves are concentric with the centers of the concentric grooves; the grinding disc is divided into a first area, a second area and a third area from inside to outside in the radial direction; and the distance between the concentric grooves ofthe first area and the distance between the concentric grooves of the third area are greater than the distance between the concentric grooves of the second area. The application of the technical scheme can realize the improvement of the flow performance of grinding liquid in the grinding and polishing process, and the problems of blockage and wear of the grinding disc are obviously improved.

Owner:HUAQIAO UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com