Integrated gasket

A one-piece, liner technology, applied in the field of parts, can solve the problems that affect the quality of welding, the difficulty of processing, and the high processing cost, and achieve the effect of reducing welding deformation, reducing processing difficulty and processing cost, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below by means of embodiments in conjunction with the accompanying drawings.

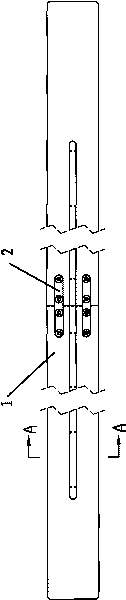

[0016] as attached figure 1 , attached figure 2 As shown, a one-piece liner, the structure is composed of a plurality of liner bodies 1 connected in series, the connection end faces of two adjacent liner bodies 1 are closely matched, and the connection end faces are precisely machined to eliminate the need for installation. The gap between the connecting positions of two adjacent pad bodies 1 is used to prevent the protective atmosphere from escaping and affect the heat dissipation effect here. Two adjacent pad bodies 1 are connected together by positioning connection blocks 2 , and connection positions matching the positioning connection blocks 2 are processed at both ends of each pad body 1 .

[0017] Each of the cushion bodies 1 is provided with a cooling water channel for dissipating the heat on the cushion body 1. The cooling water chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com