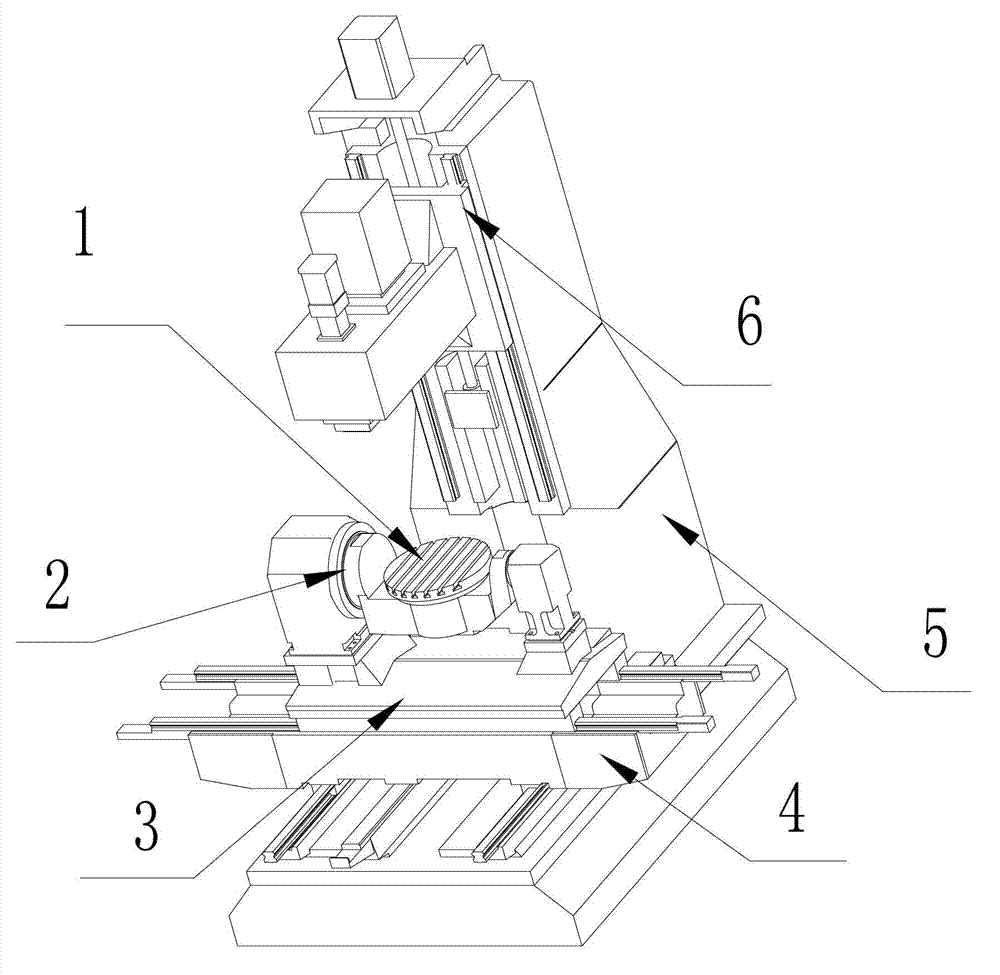

Double-turntable five-axis numerical control machine tool virtual assembling and numerical control machining simulation method

A technology of numerical control machine tools and virtual assembly, applied in simulators, general control systems, control/adjustment systems, etc., can solve the problems of incomplete guarantee of the correctness of numerical control simulation, high difficulty, and low simulation efficiency, so as to facilitate the discovery of machine tools Design problems, low accuracy of one-sided triangulation, and the effect of improving simulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] A virtual assembly and numerical control processing simulation method of a double turntable five-axis numerical control machine tool of the present invention comprises the following steps:

[0033] (1) Modeling: Under the environment of Pro / E, three-dimensional modeling is carried out for each moving part of the machine tool, the bed of the machine tool, blanks and fixtures required in NC machining. Complex fixtures and blank bodies can be modeled in Pro / E, and simple fixtures and blank bodies can be modeled in VERICUT.

[0034] Three-dimensional modeling of each moving part of the machine tool: first analyze the characteristics and hierarchical relationship of each part in each part, that is, analyze the parts that make up the part, clarify the required characteristics of the parts, the order of the characteristics, the intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com