Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Eliminate deflection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

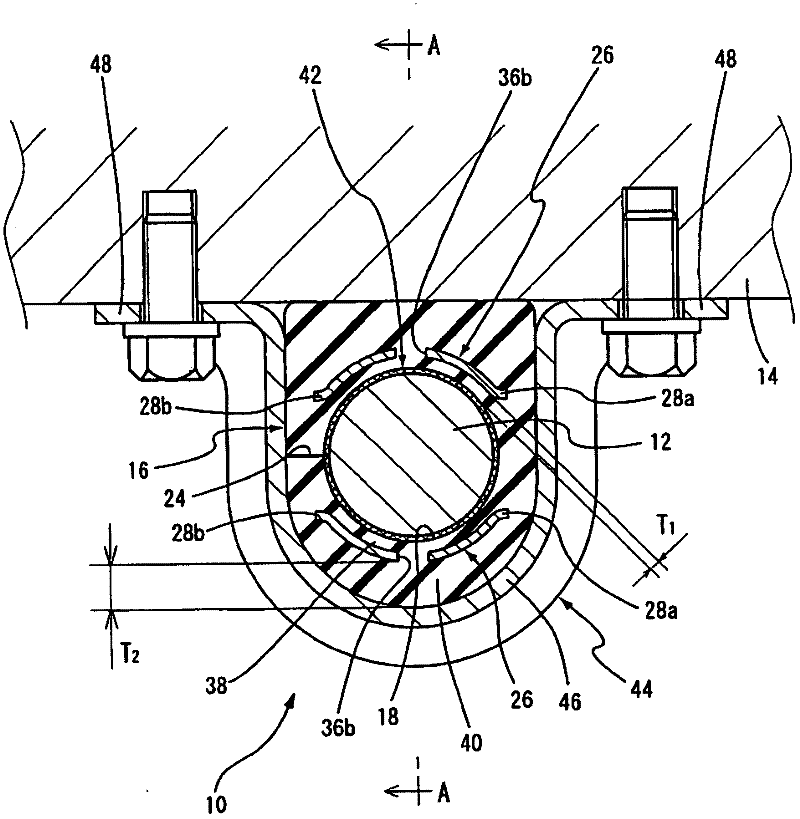

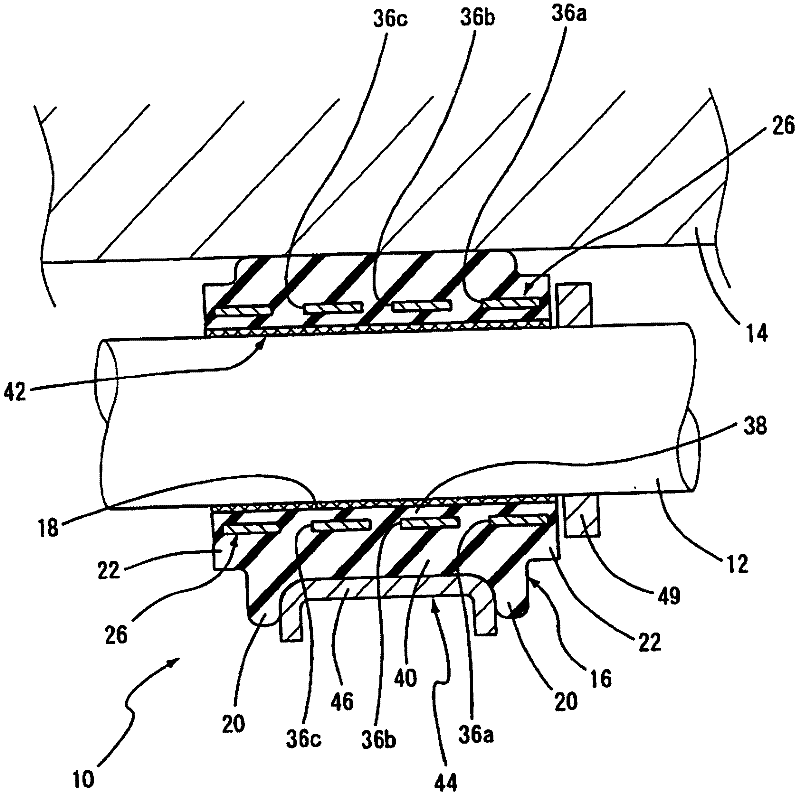

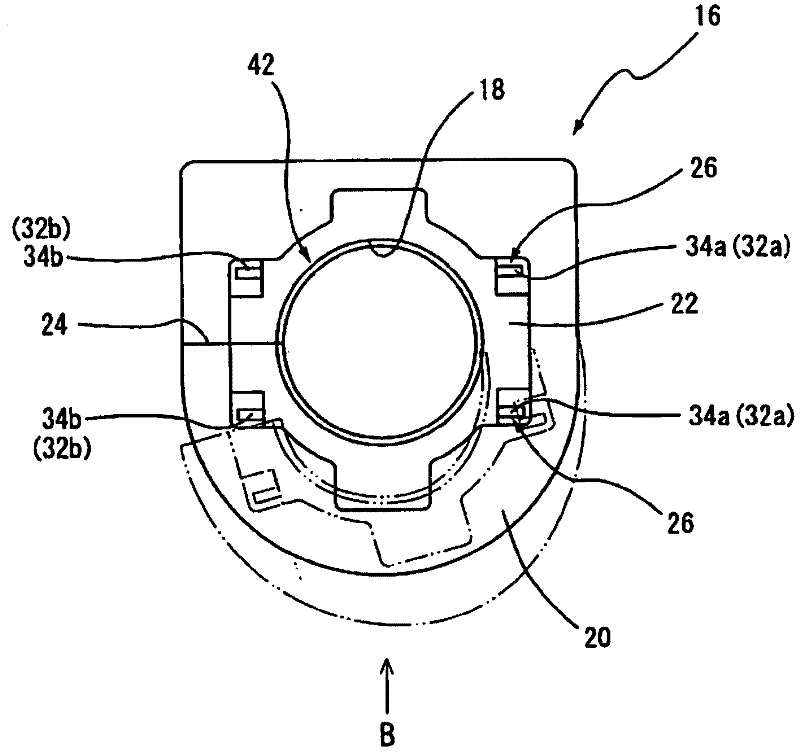

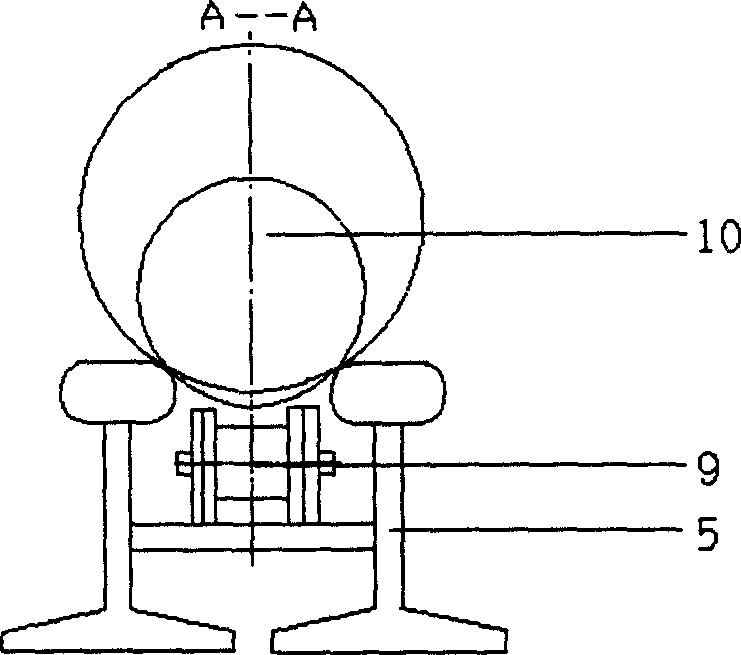

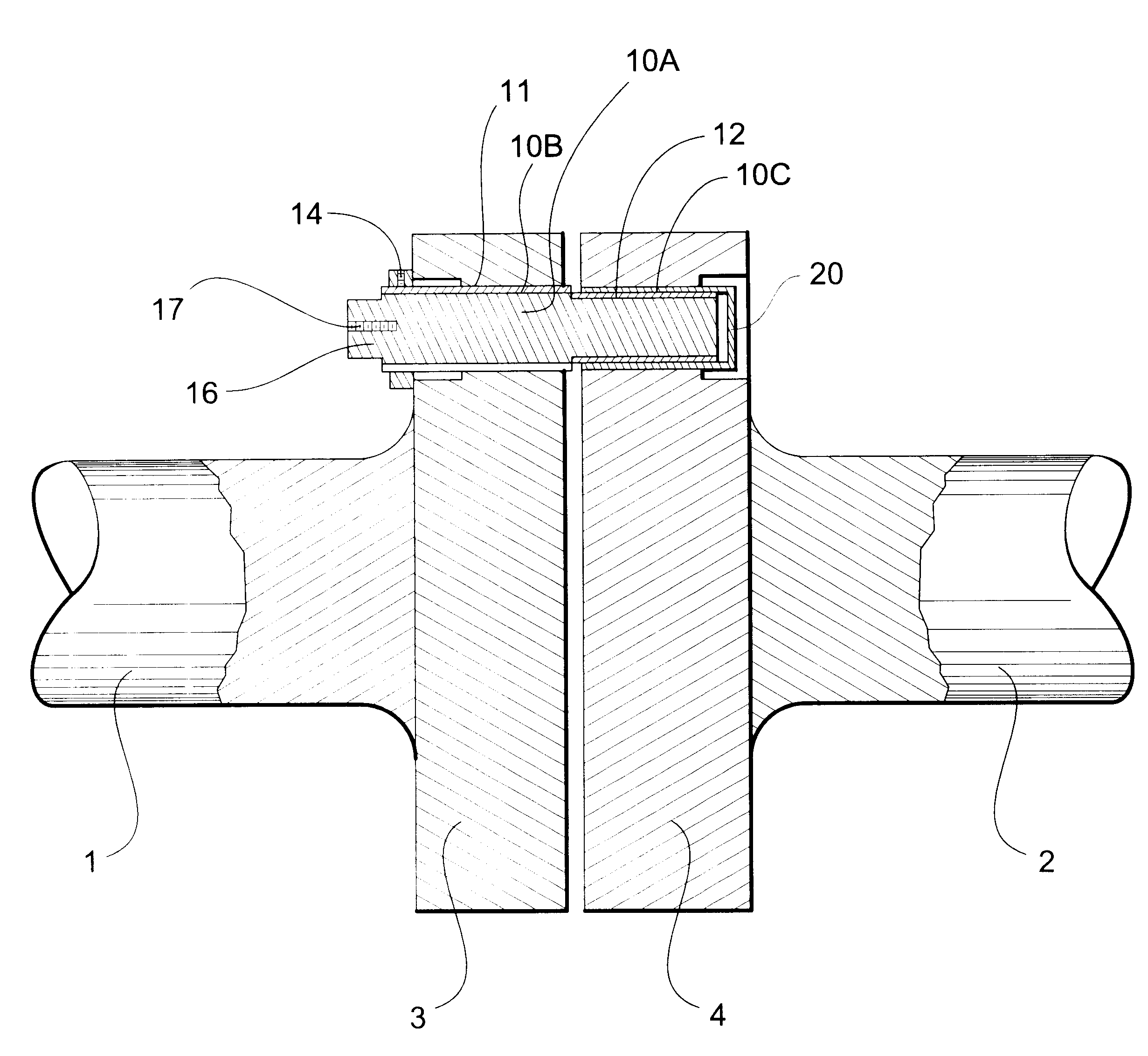

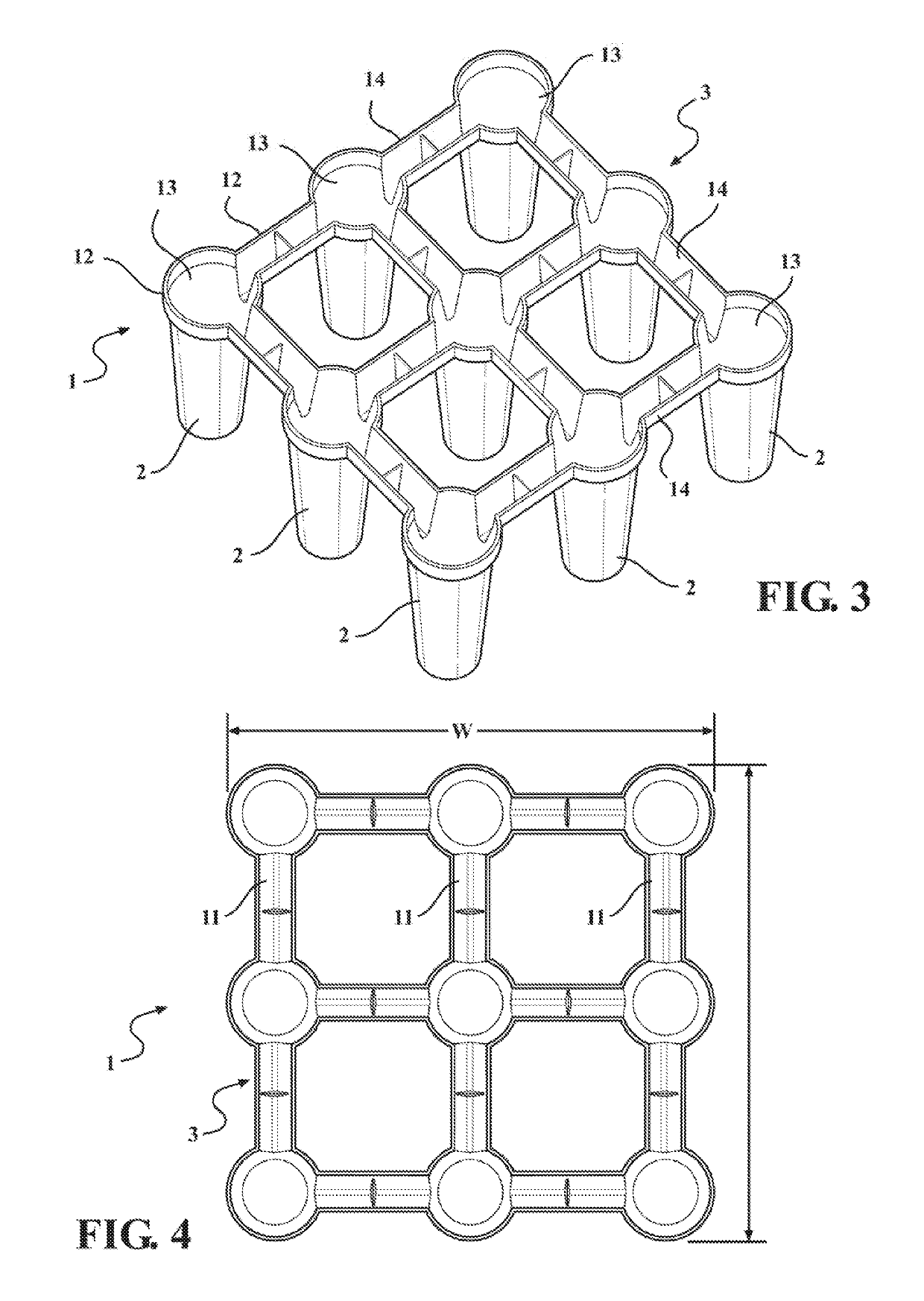

Vehicle stabilizer bushing

ActiveCN102470721AEliminate deflectionSmooth rotationSpringsNon-rotating vibration suppressionVulcanizationEngineering

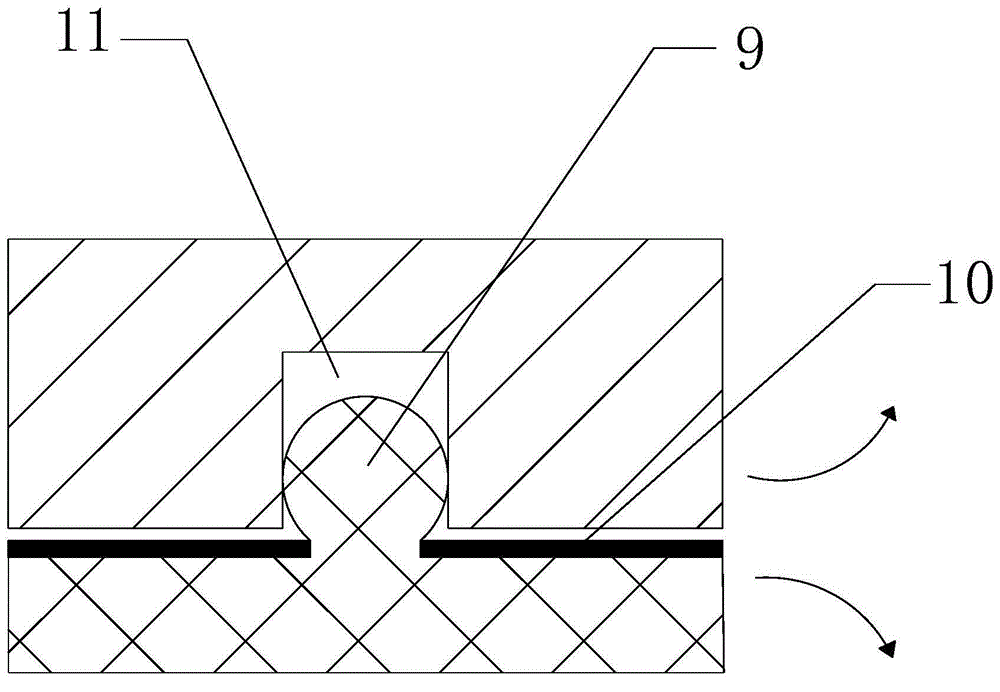

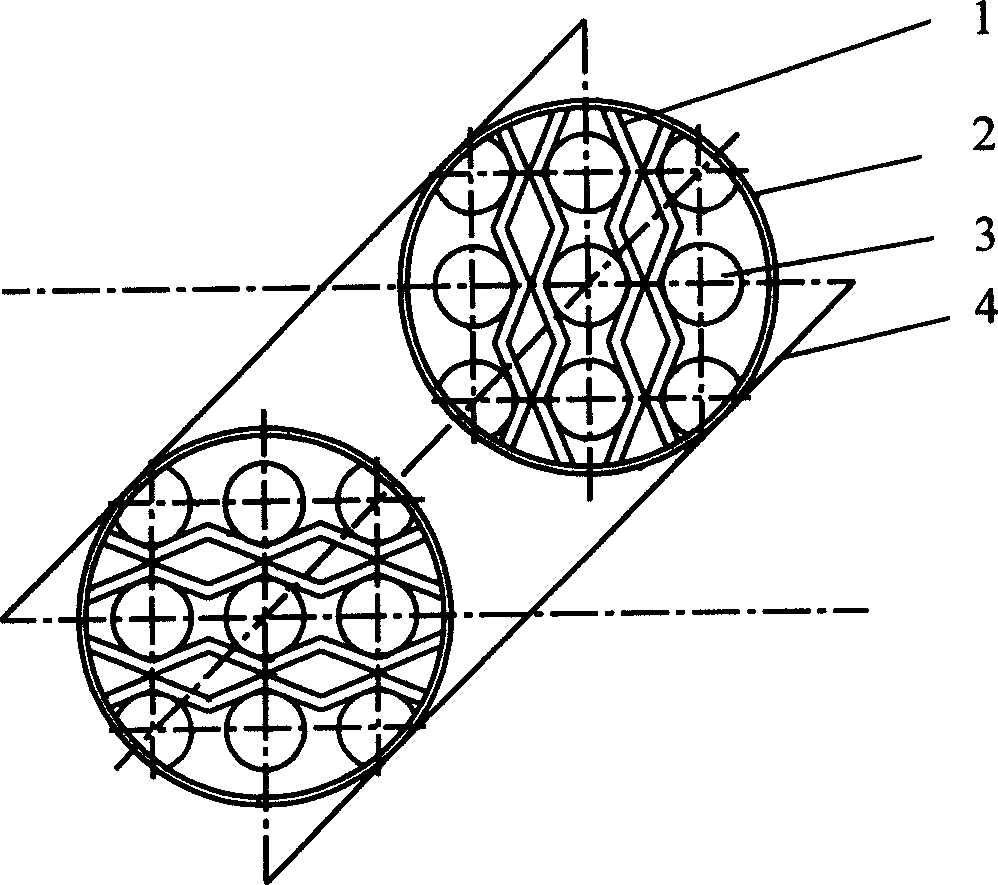

Disclosed is a stabilizer bushing which more efficiently reduces torsional friction between a bushing main body and a stabilizer bar. A bushing main body (16) is formed from a cylindrical rubber elastic body to which a sliding member (42) is fixed to a surface of the inner circumference. In a middle area of the bushing main body (16) perpendicular to the axis thereof, two partition members (26, 26) are embedded so as to be positioned vertically, and are adhered by vulcanization. The bushing main body (16) is constituted from an inner rubber part (38) of a thickness so as not to allow elastic deformation by an input load, and an outer rubber part (40) thicker than said inner rubber part. Meanwhile, through-holes (36a, 36b and 36c) are formed only in positions that equally divide the partition members (26, 26) in the circumferential and axial directions.

Owner:SUMITOMO RIKO CO LTD +1

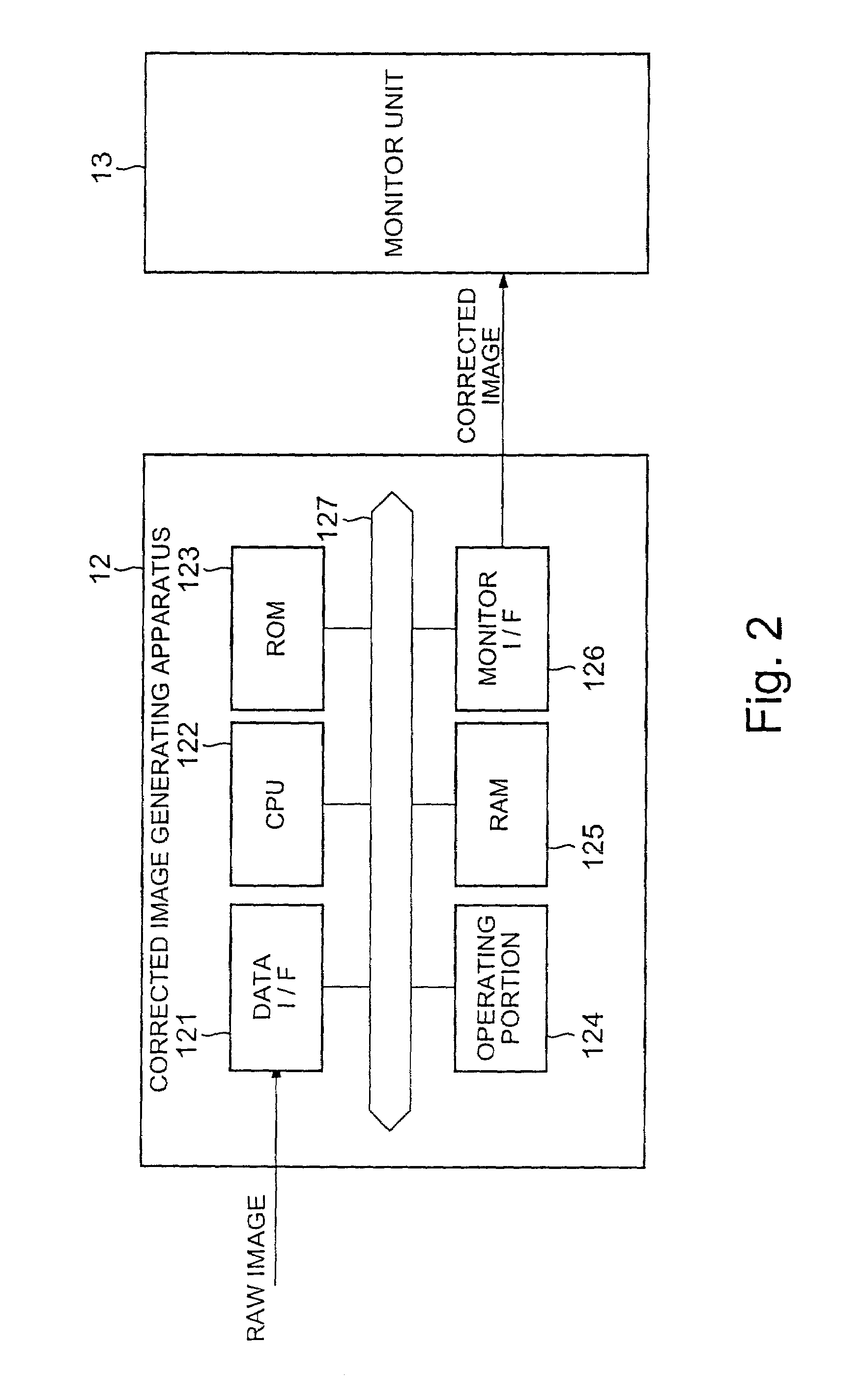

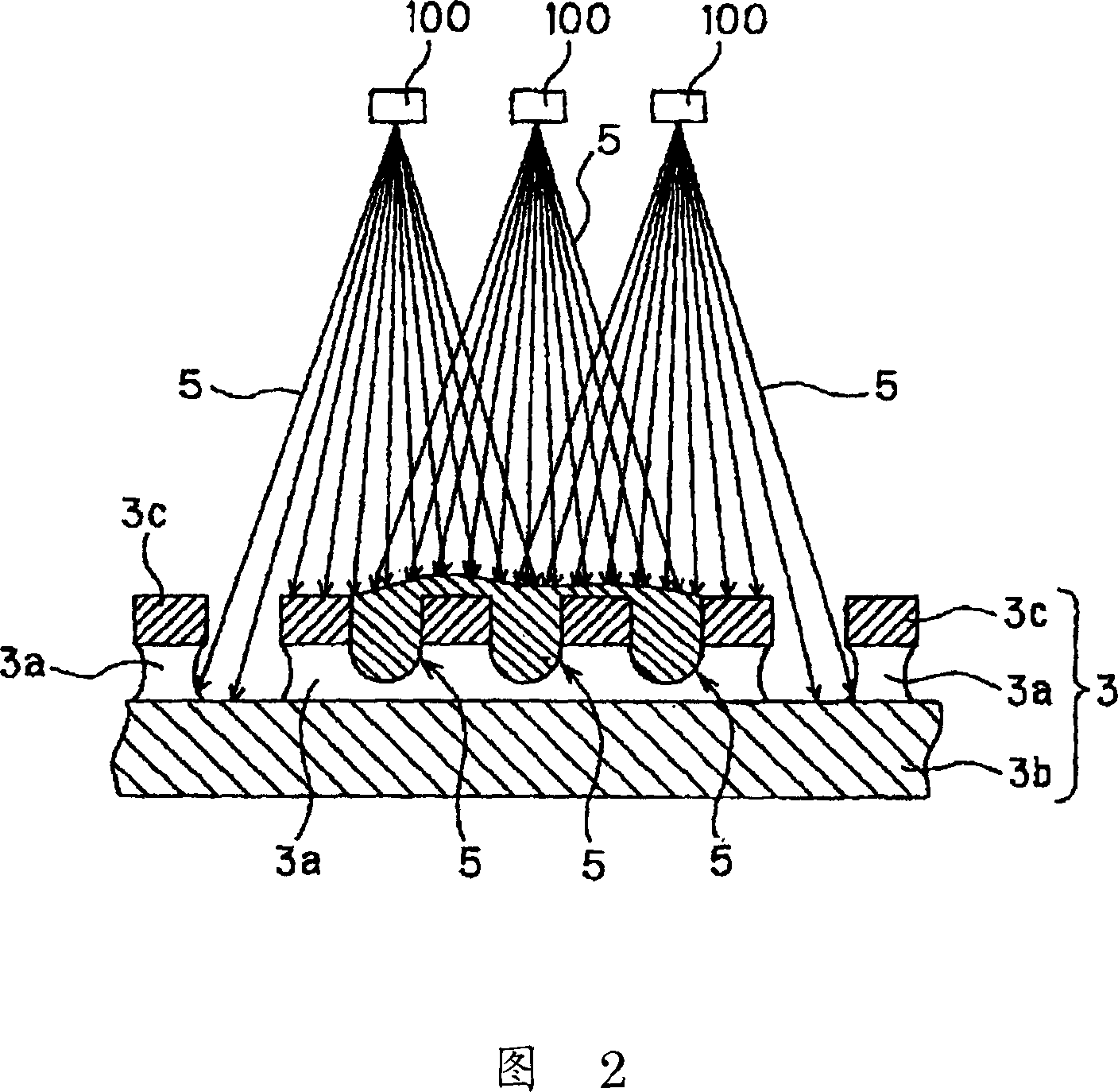

Corrected image generating apparatus and corrected image generating program storage medium

InactiveUS7333132B2High precision calibrationImprove accuracyTelevision system detailsImage analysisMotion vectorVisual perception

This invention provides a corrected image generating apparatus and the like for generating a corrected image by correcting a deflection due to the vibration of a camera in a raw image obtained by the camera which obtains the raw images of plural frames successively by scanning an object field of vision repeatedly in a scanning direction intersecting the arrangement direction of plural light receiving sensors composing the one-dimensional image pickup device in which the plural light receiving sensors are arranged one-dimensionally, in order to generate an image whose deflection is corrected. By obtaining a motion vector of each of short strips extending in the arrangement direction of the light receiving sensors of the one-dimensional image pickup device, the respective short strips are moved to obtain a corrected image.

Owner:FUJITSU LTD

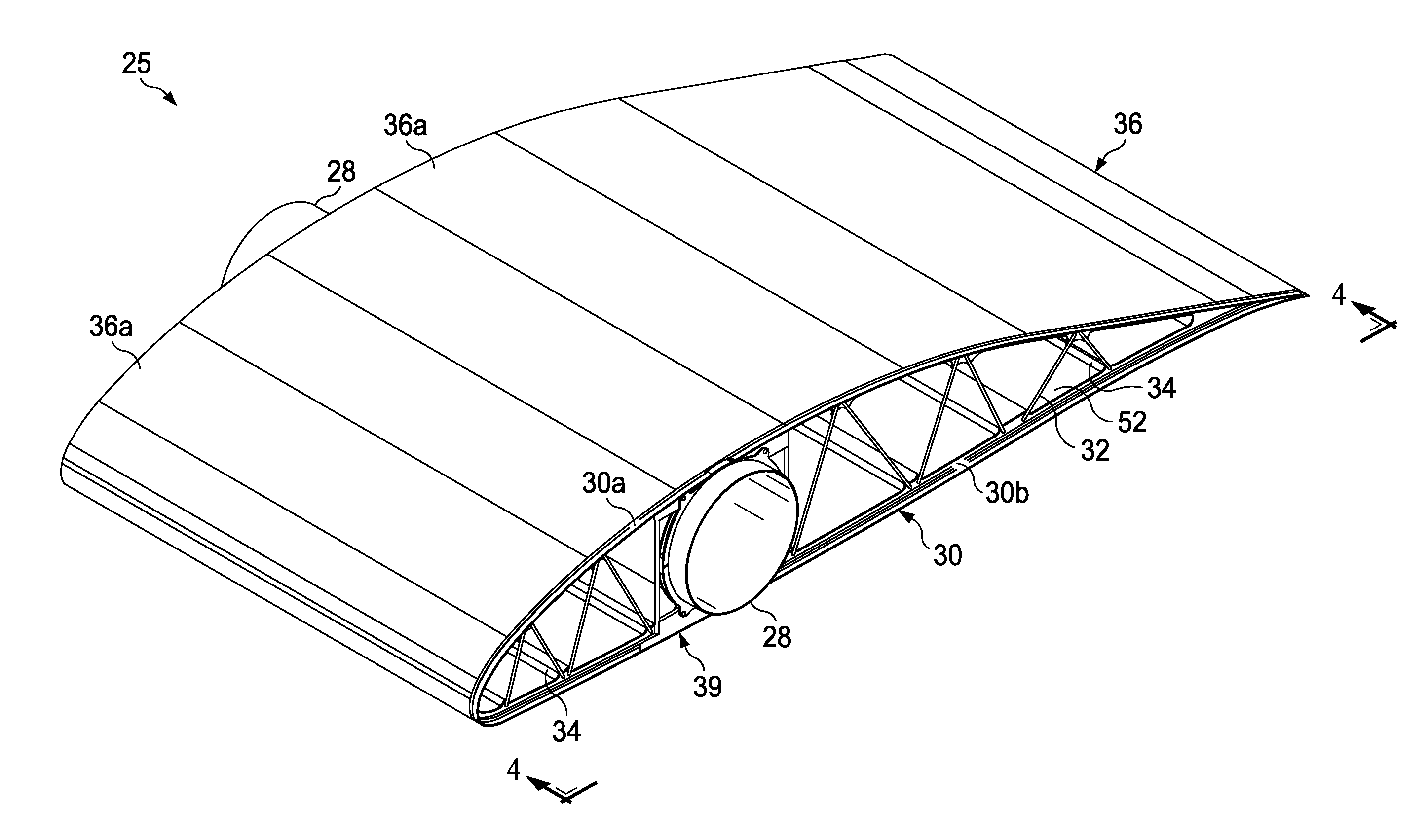

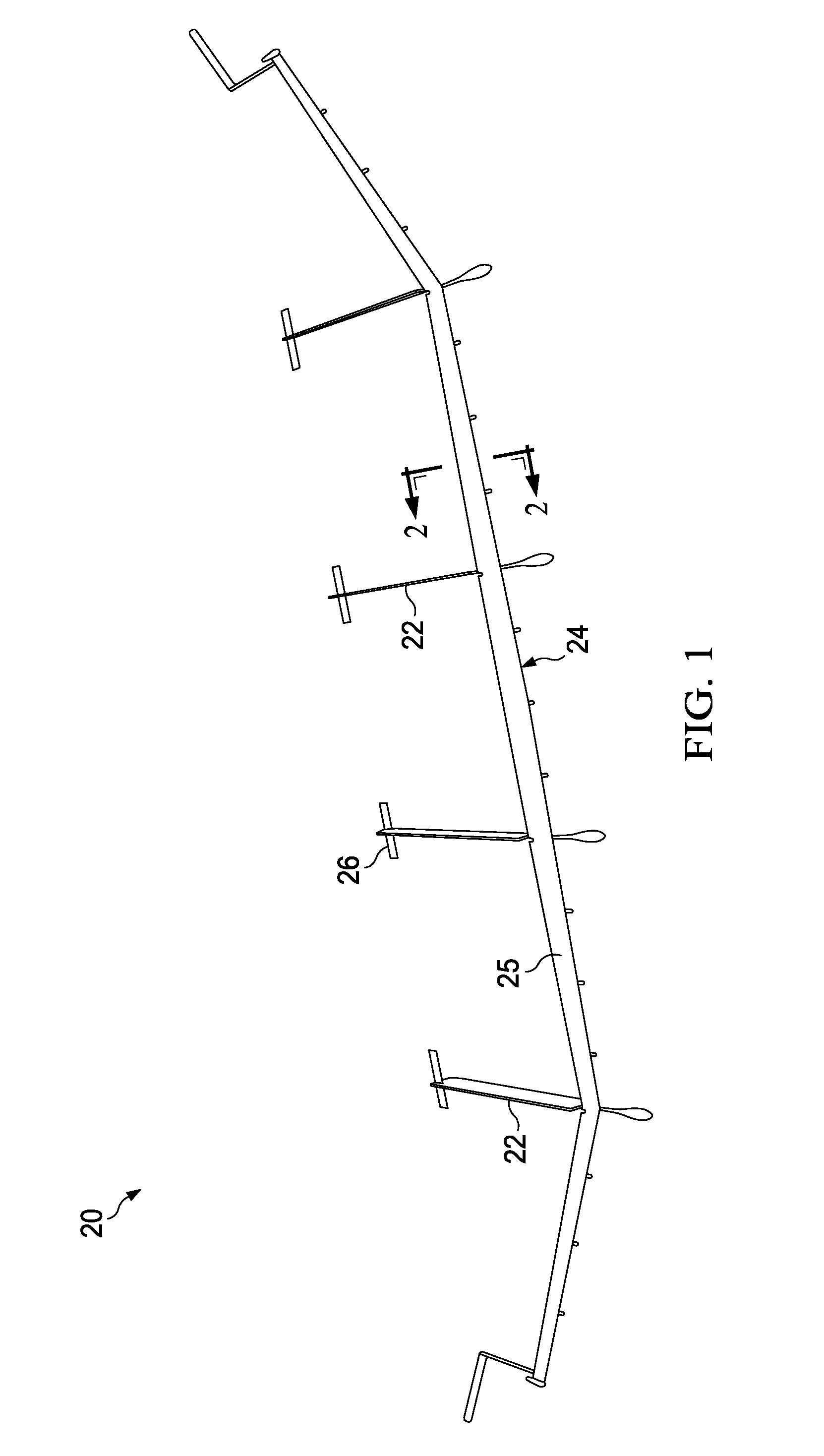

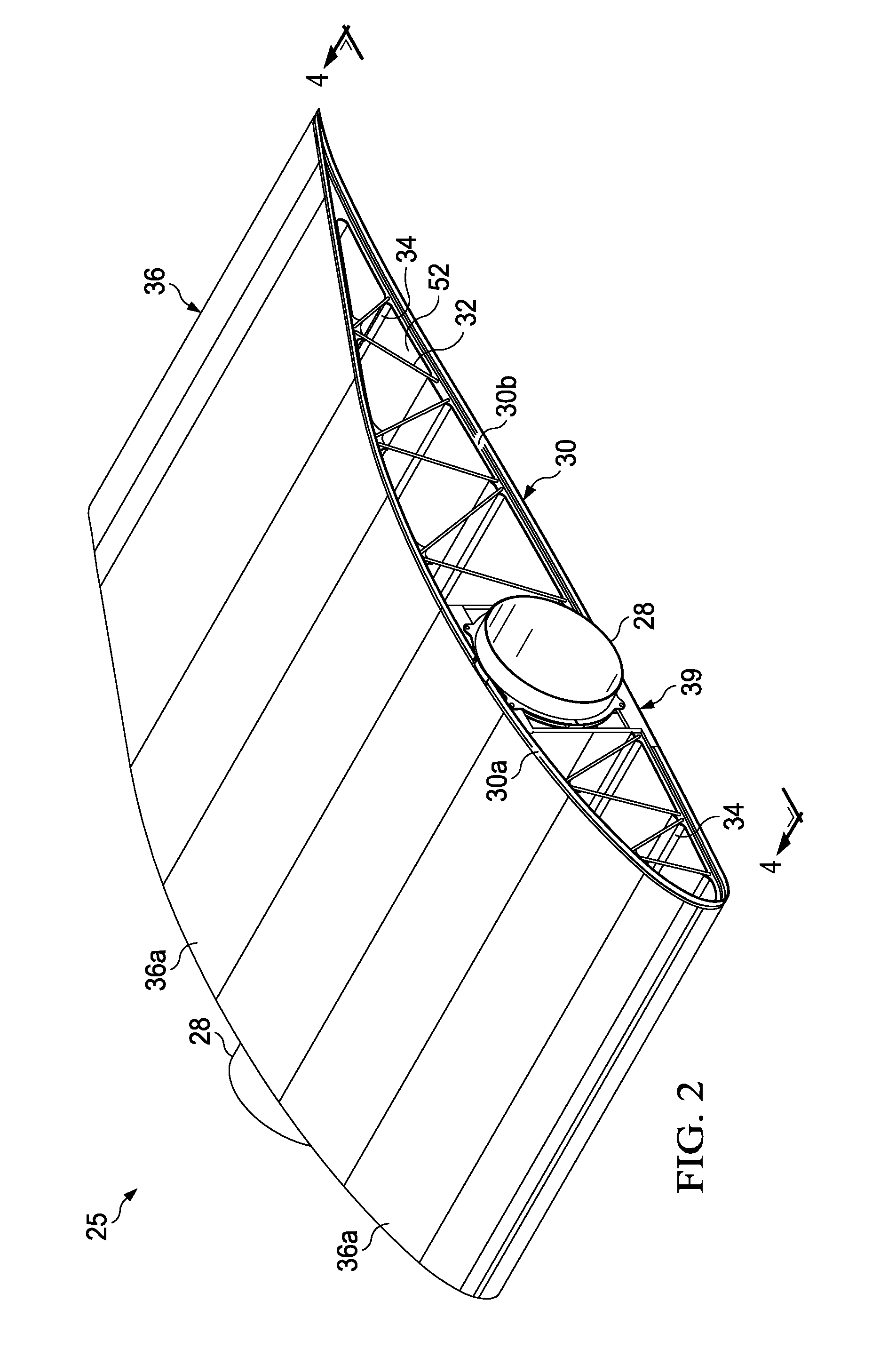

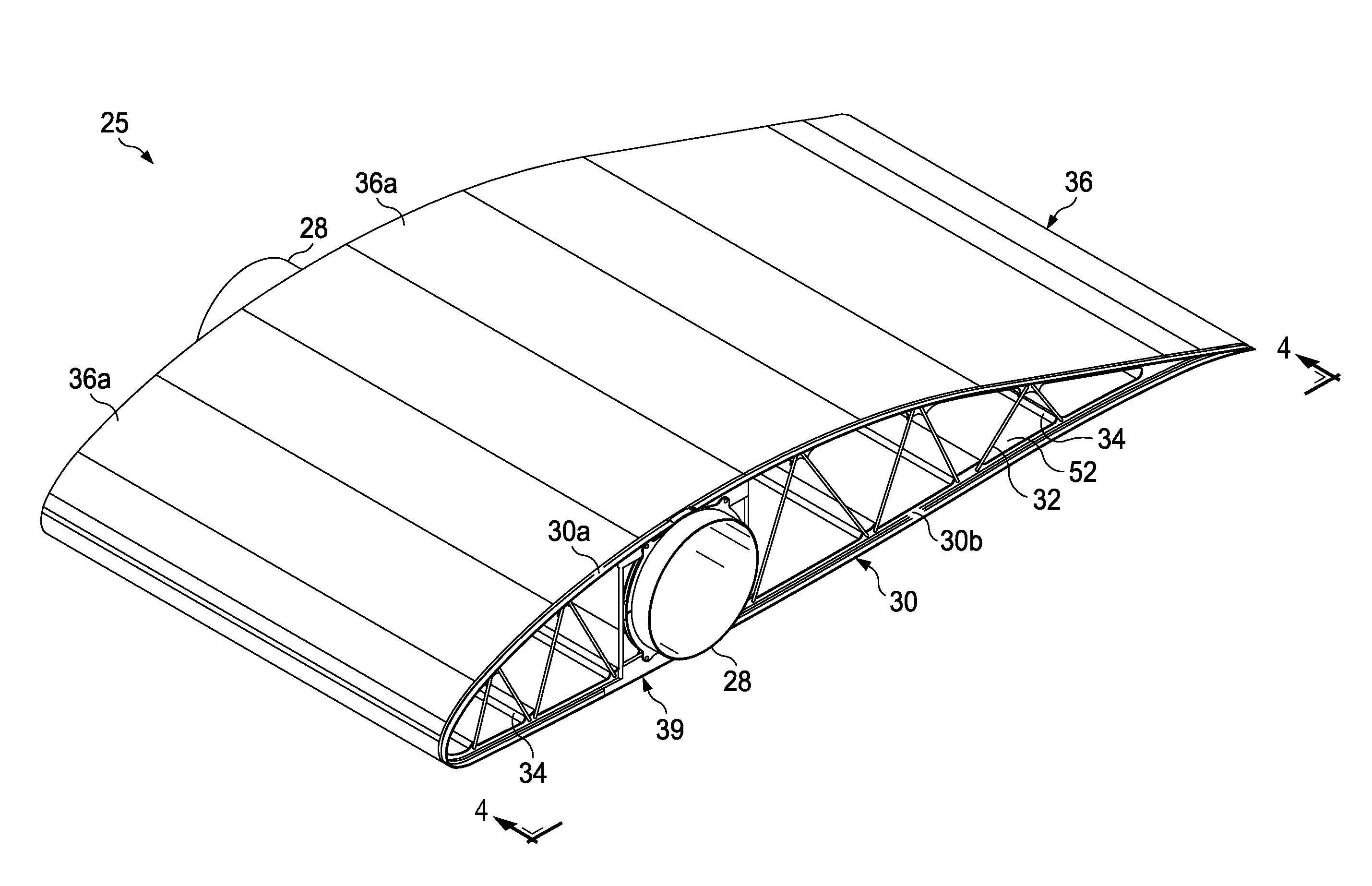

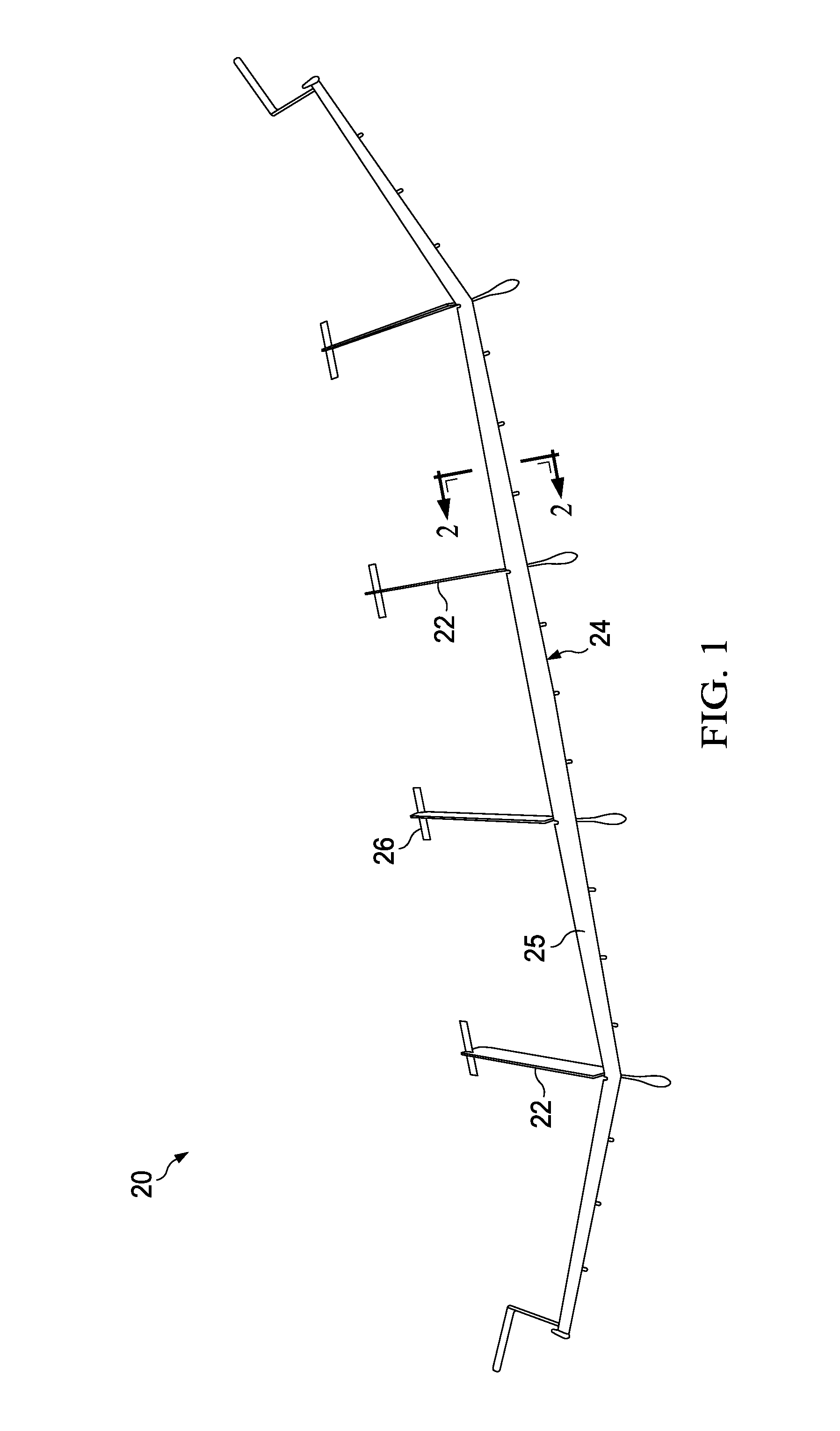

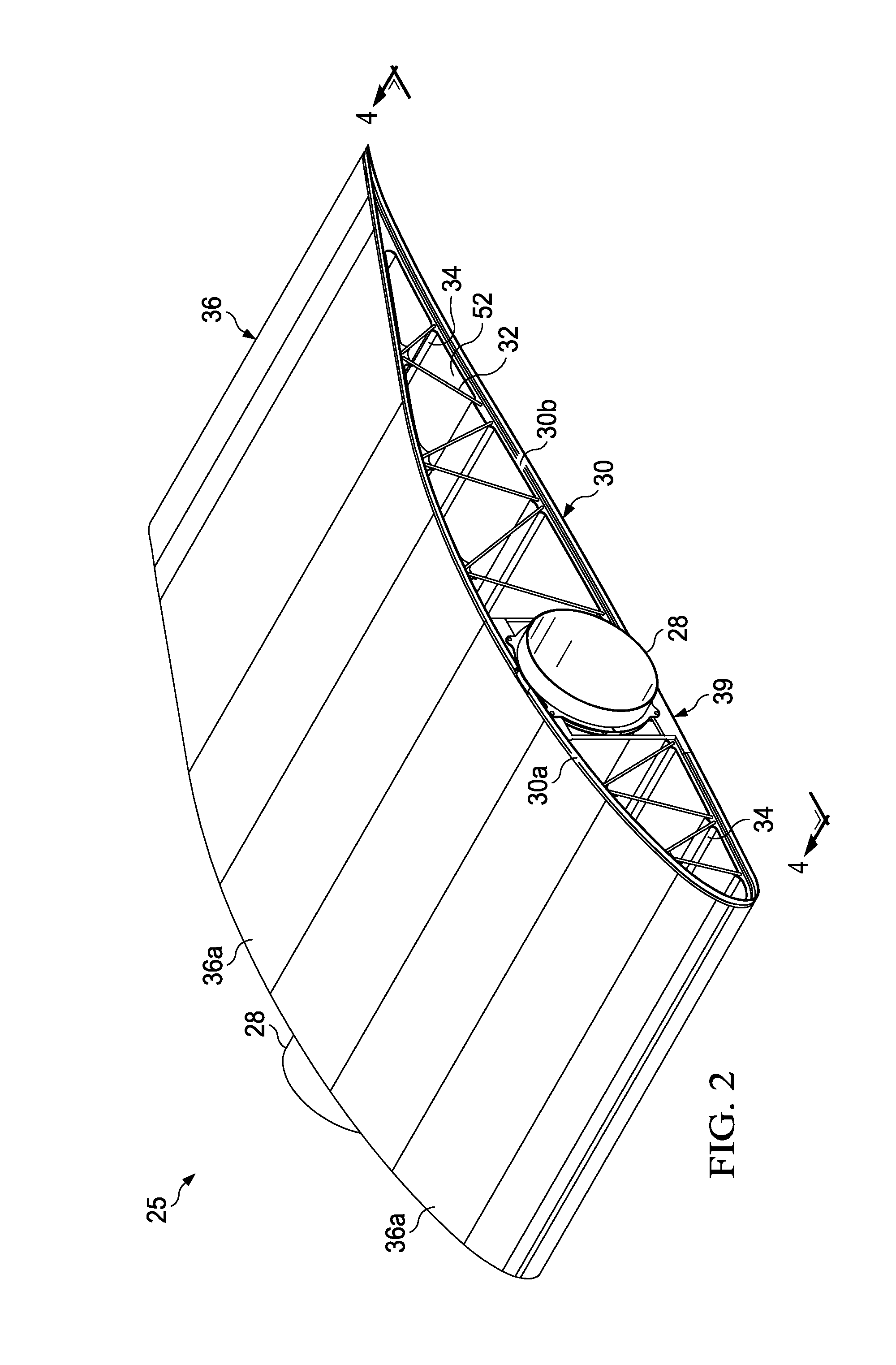

Attachment of Aircraft Ribs to Spars Having Variable Geometry

ActiveUS20130240671A1IsolatingEliminate radial deflectionPlungersSpars/stringersVariable geometryAirplane

Owner:THE BOEING CO

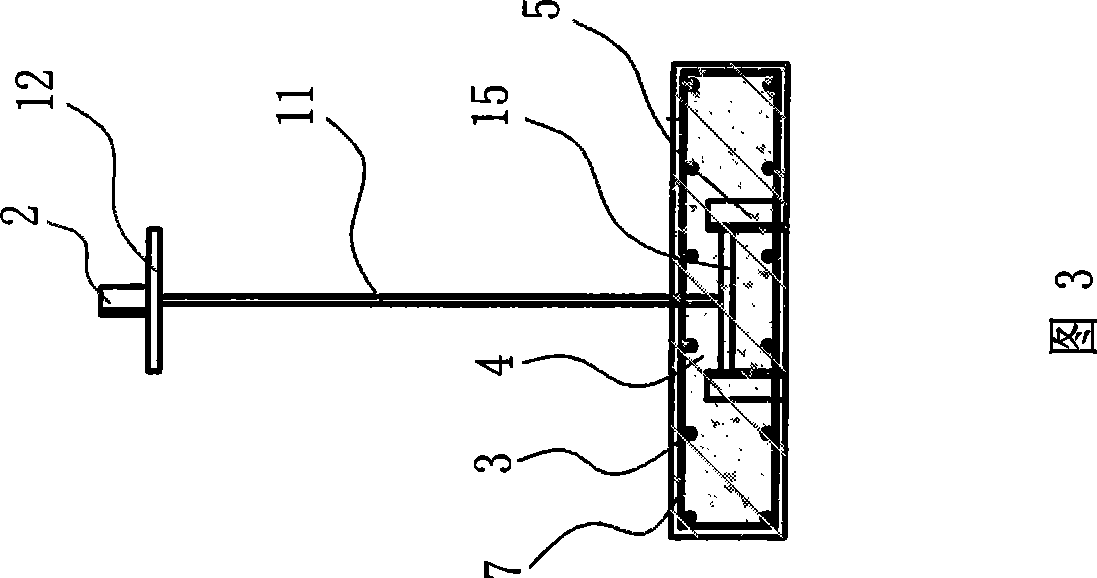

Windshield washer valve

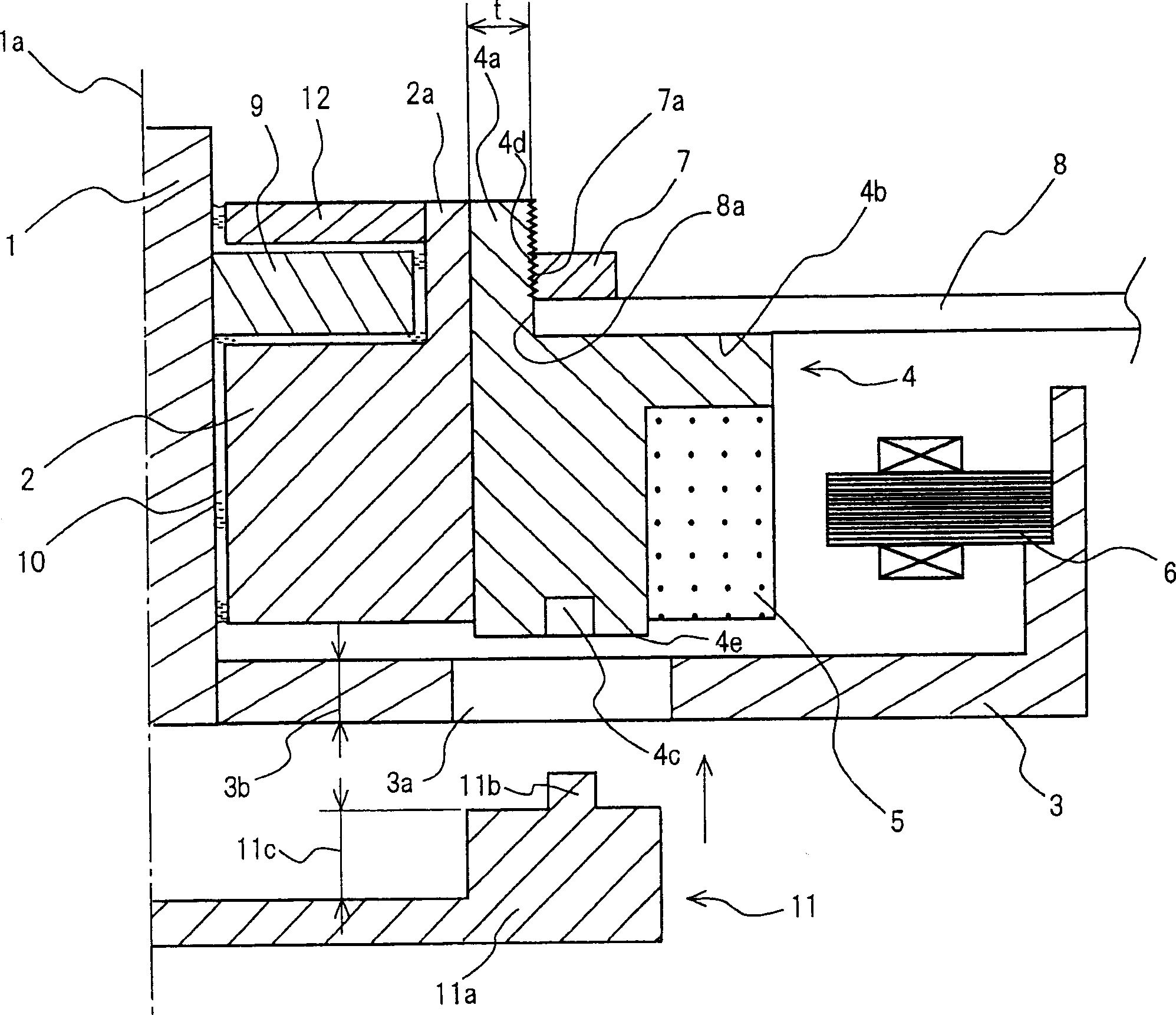

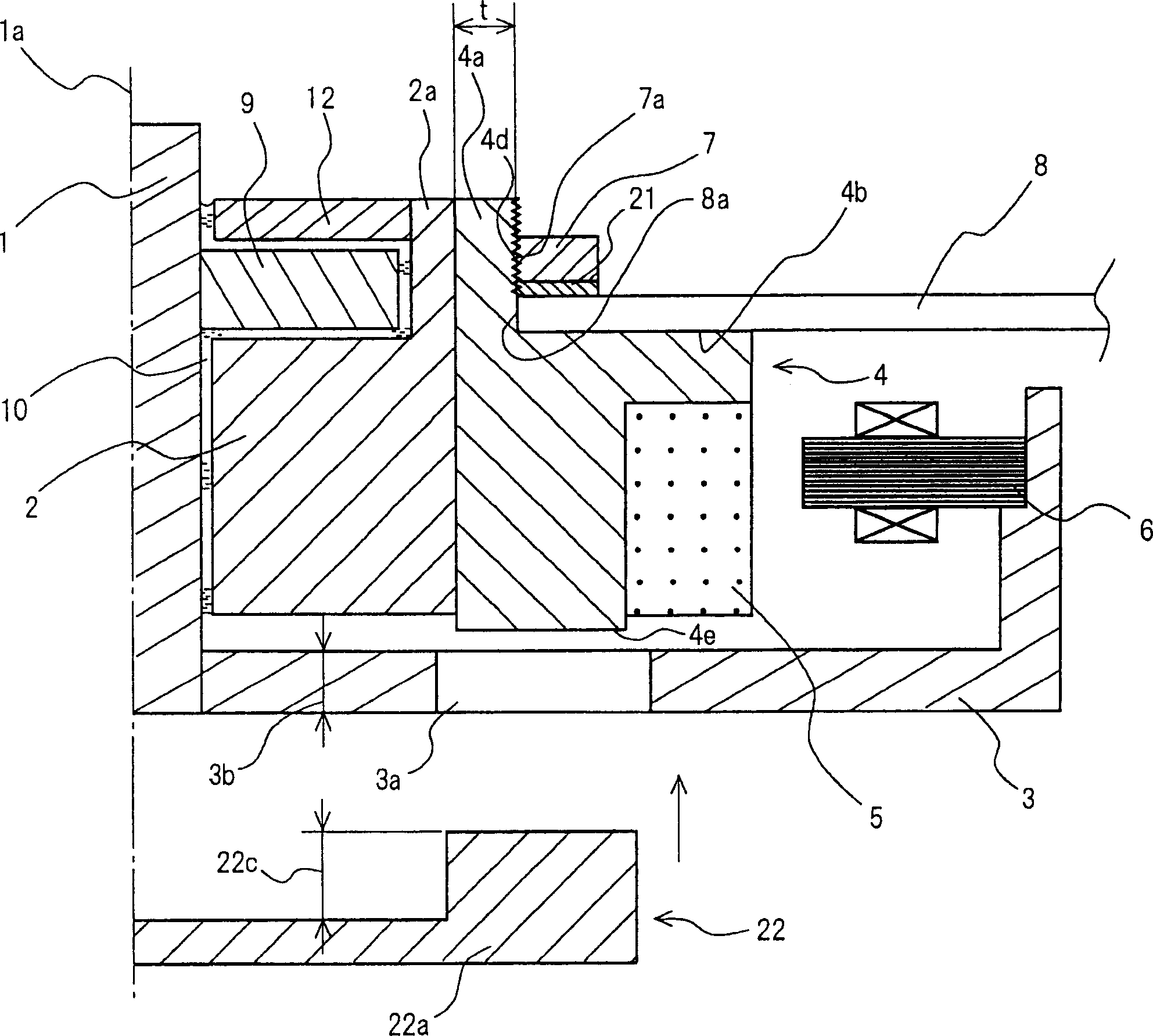

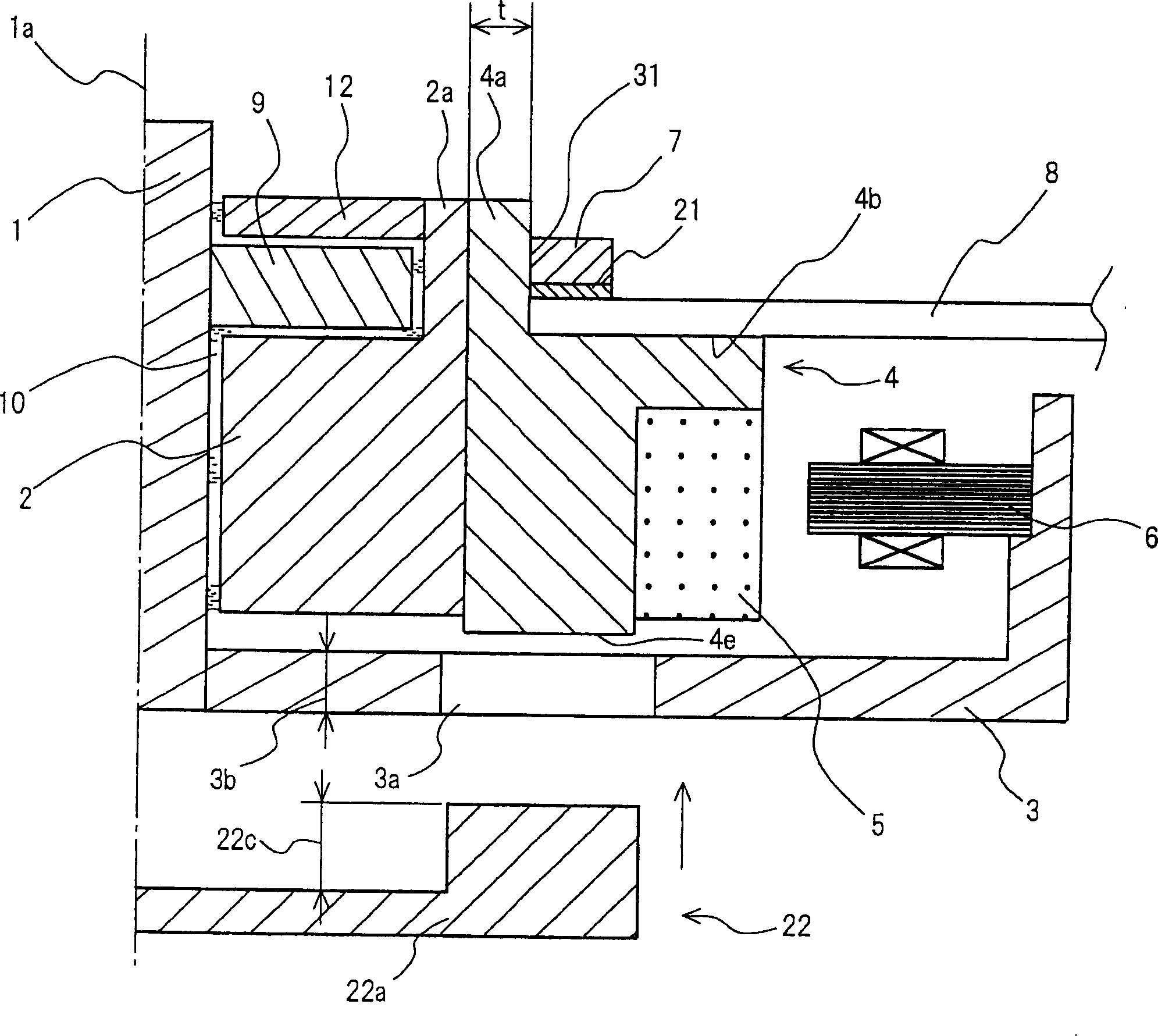

A valve device, in particular a window and lens cleaning device in motor vehicles, includes a housing (1) with a duct (2) and at least one nozzle (3), and also a tubular connecting piece (4) for feeding a pressurized fluid, in particular a cleaning liquid, into the duct and to the nozzle. The connecting piece (4) is provided at its nozzle-side end with a nonreturn valve which blocks a return flow from the nozzle to the connecting piece, wherein the connecting piece (4) is open at its nozzle-side end. The nonreturn valve comprises of an elastic shaped part (8) with a mouth which is normally closed and can be opened by the pressure of the cleaning liquid.

Owner:MANNESMANN VDO AG

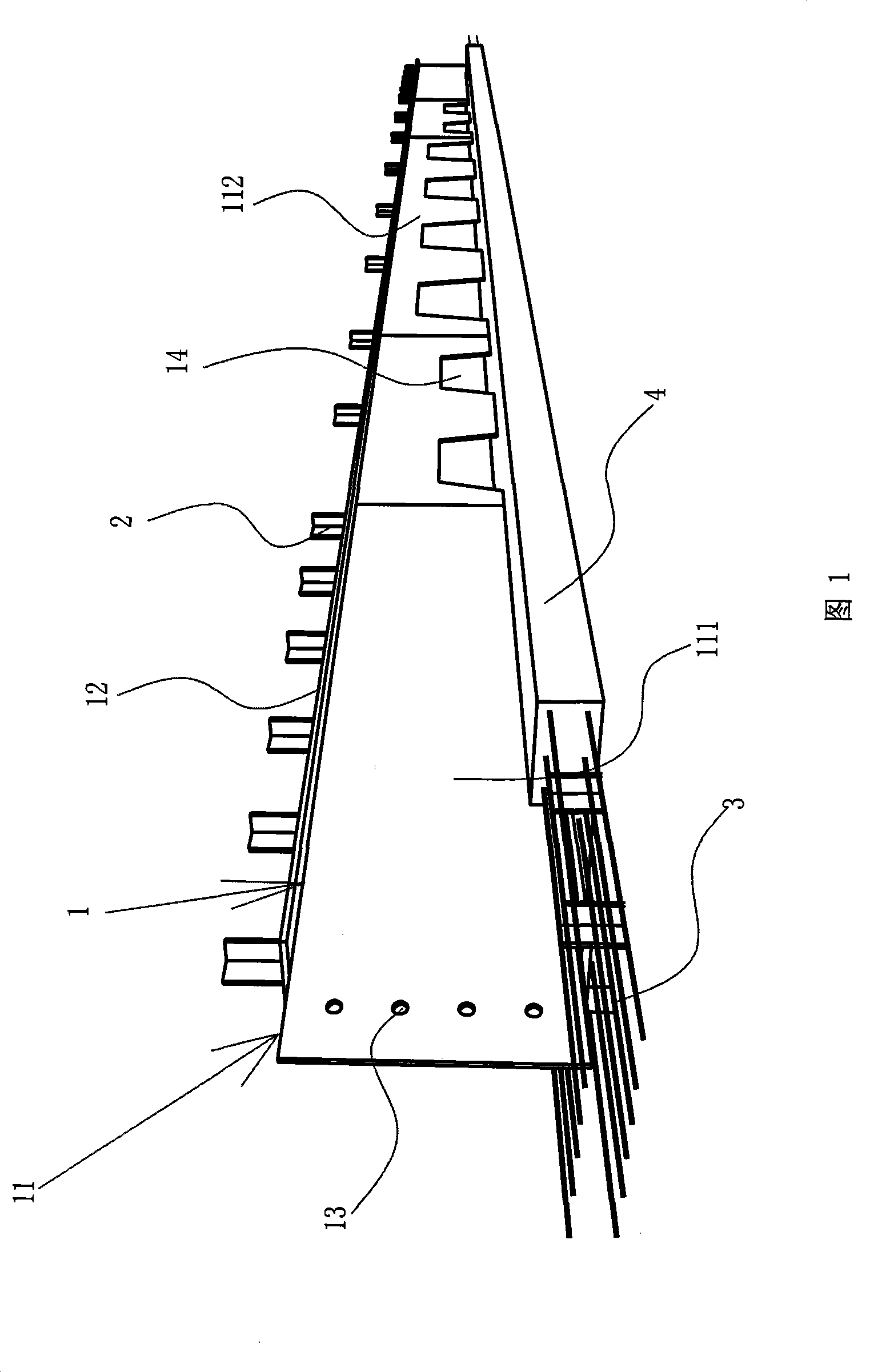

Pretensioned prestressing composite girder and method for producing the same

ActiveCN101418630ASmall beam heightReduce the overall heightLoad-supporting elementsBuilding material handlingShaped beamSheet steel

Provided is a pre-tensioned prestressed composite beam, which is an I-shaped beam composed of H-shaped steel and concrete, the web plate of the H-shaped steel is provided with trapezoidal holes (14) at intervals, the upper flange and the lower flange of the H-shaped steel are welded with shearing nails, the outer periphery of the lower flange is enclosed with concrete to form a steel-concrete lower flange (4), and the inside of the steel-concrete lower flange is embedded with prestressed steel twisted wire by pretensioning method. The manufacturing method of the composite beam is that: a steel plate is cut into two tooth-shaped plates along tooth-shaped line to be respectively as the trapezoidal hole plates of the H-shaped steel flange, the trapezoidal hole plates are welded with steel plates to form the web plate, the web plate is welded with the upper flange and the lower flange to form the H-shaped steel (1) having trapezoidal holes, the H-shaped steel is put on a base surface with the lower flange downward, the two sides of the lower flange are provided with side molds, a stirrup (7) is arranged and steel twisted wires (3) are longitudinally fastened between the two side molds, the steel twisted wire is tensioned to tensioning state, the concrete for enclosing the H-shaped lower flange is poured and tamped between the two side molds, the steel-concrete lower flange (4) is formed after demolding, and the steel twisted wire at tensioning state is loosened after the concrete reached to predetermined strength and is cut off at predetermined position. The invention is suitable for beams of buildings.

Owner:杨峰

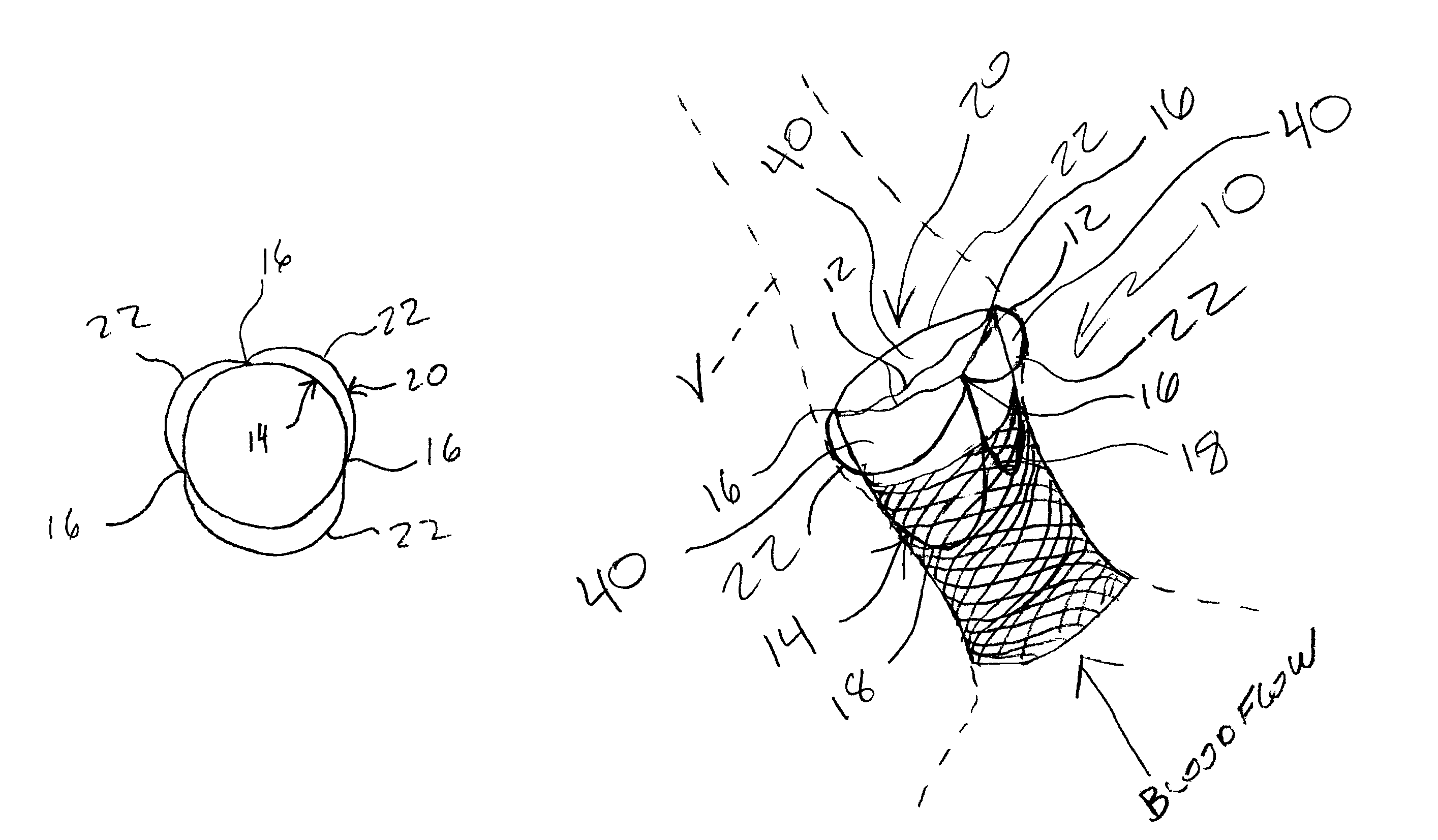

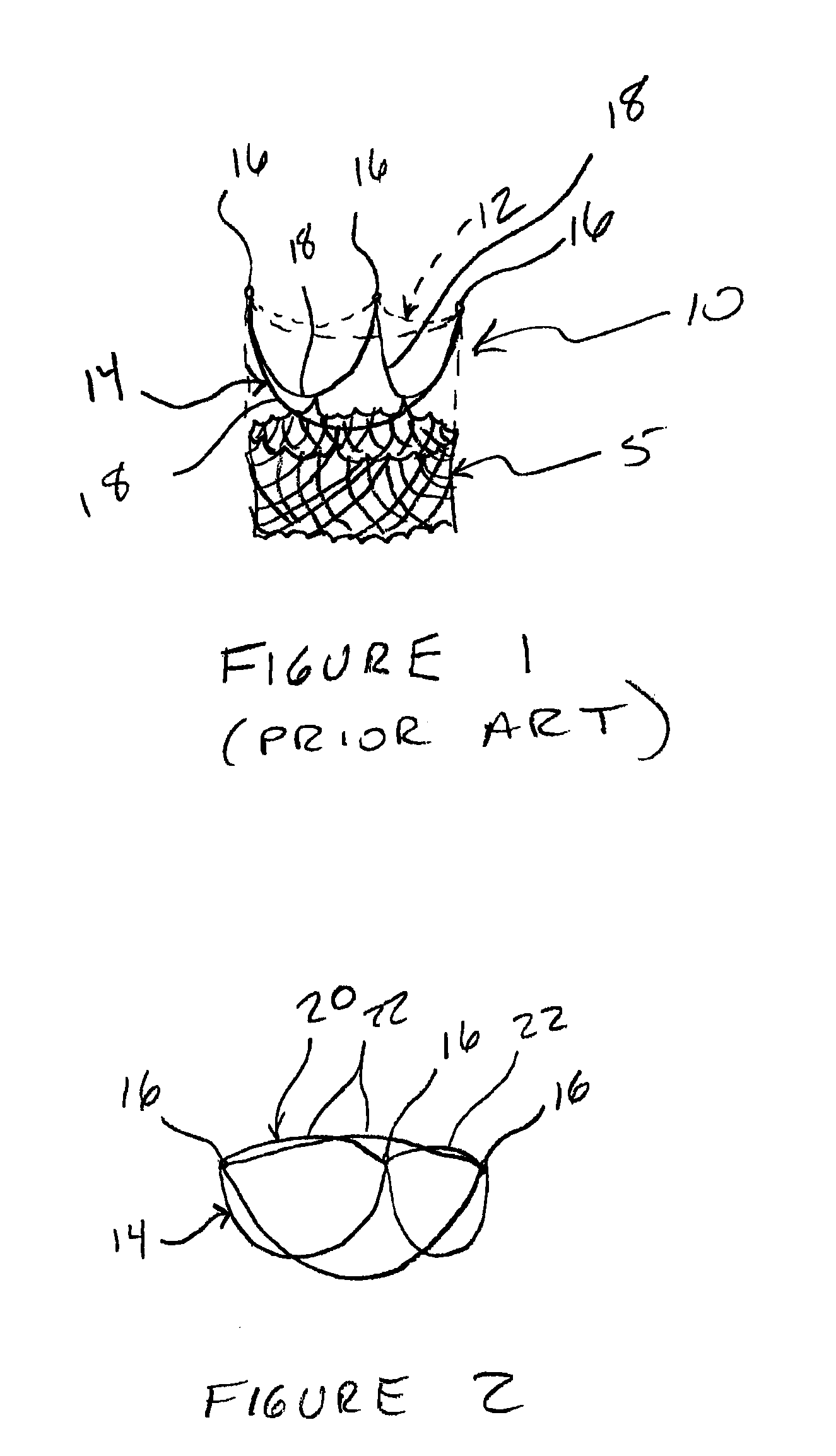

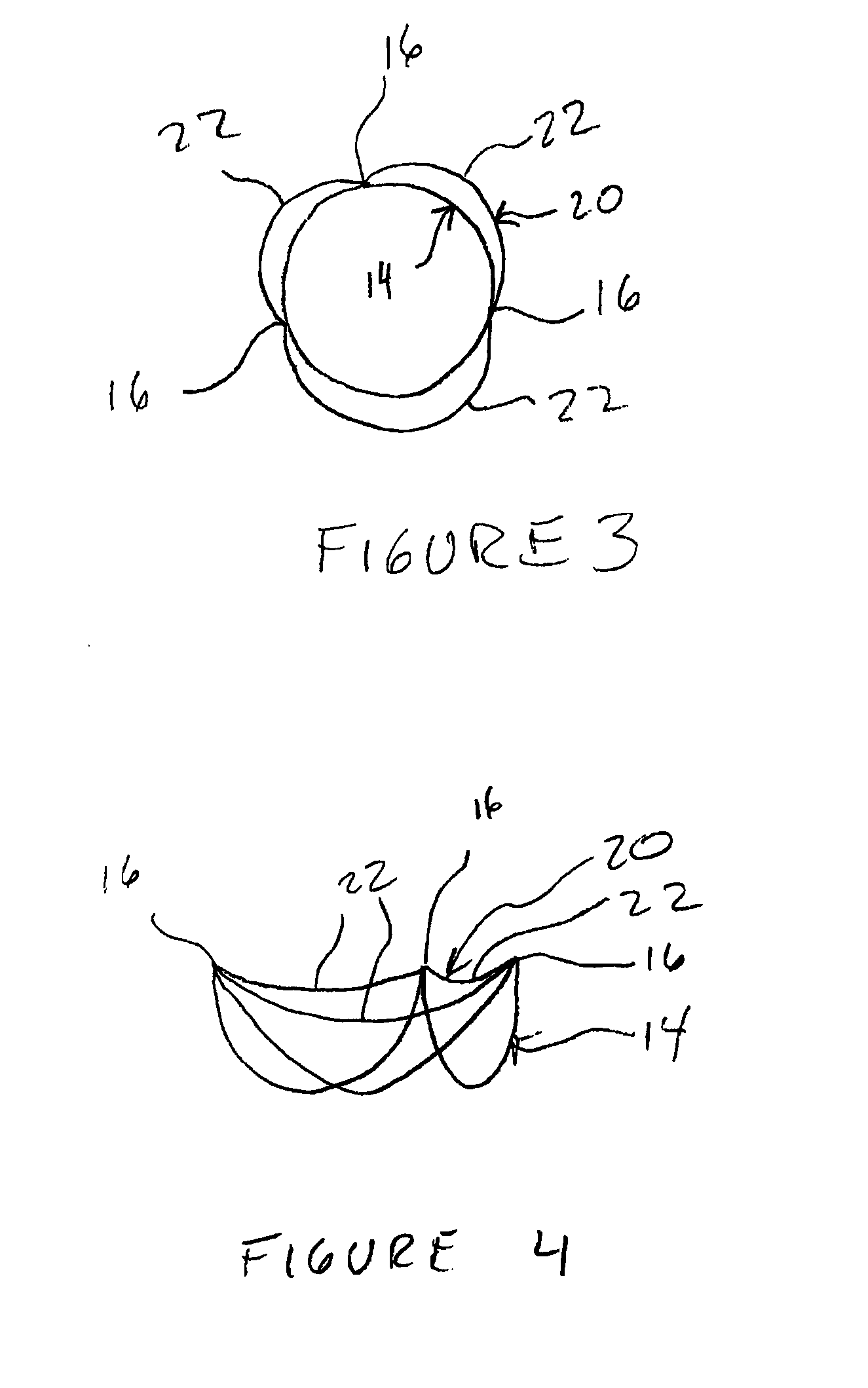

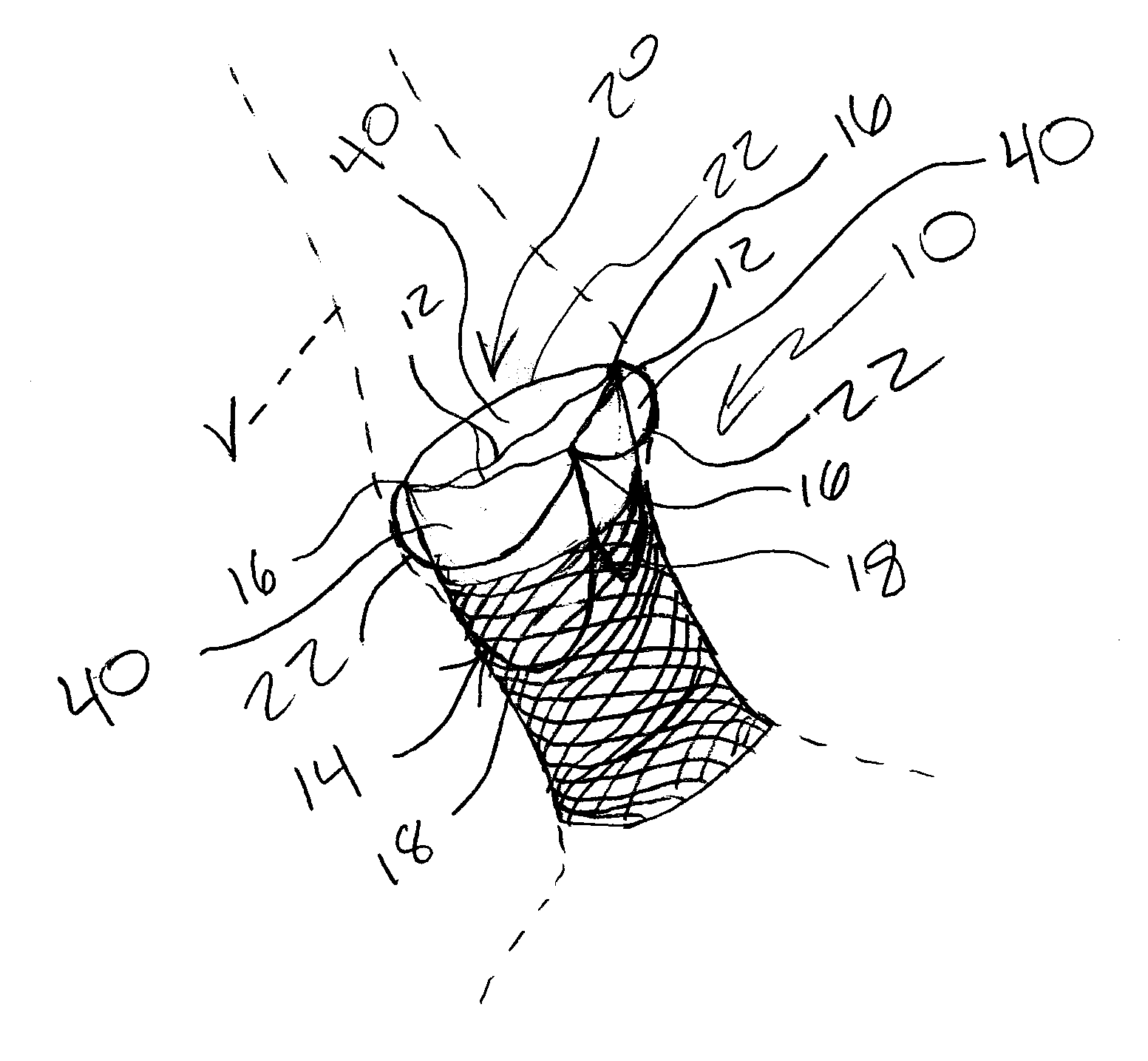

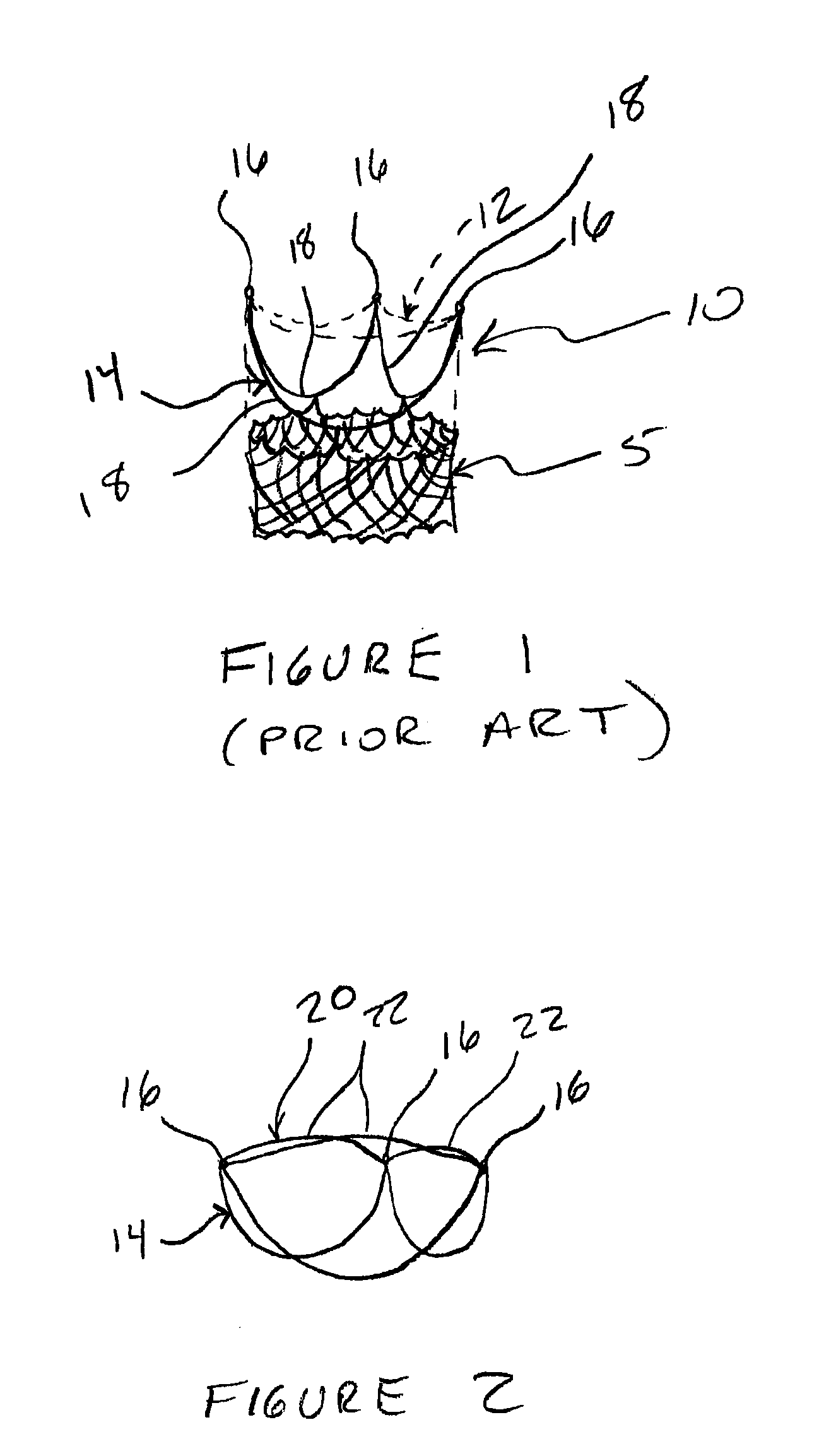

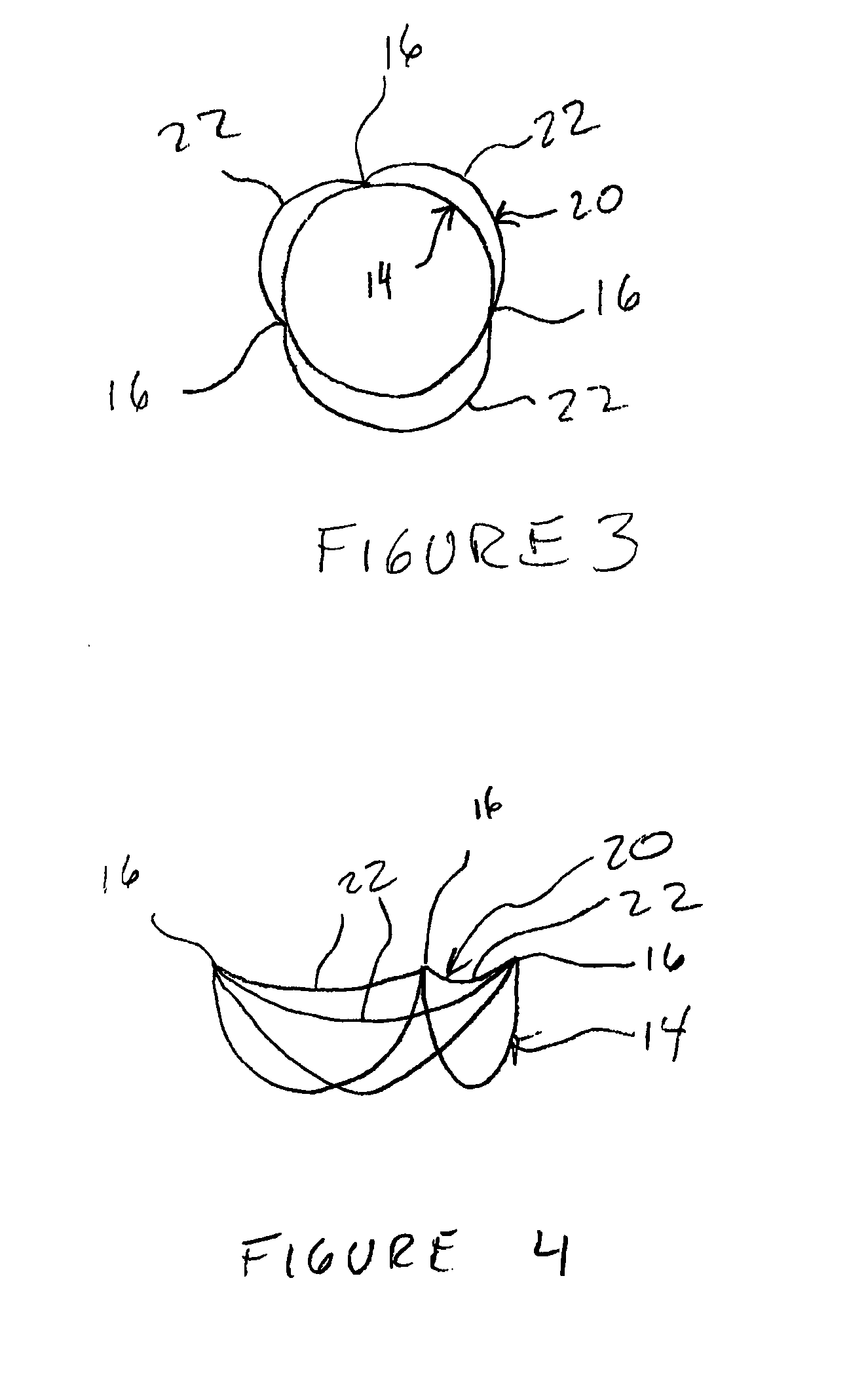

Reinforced commissural support structure

A device and method for controlling commissural tip deflection of a prosthetic valve, thereby both preventing failure due to repeated movement and / or uneven loading of the commissural points and also improving coaptation of the valve leaflets, including connecting reinforcing material between the commissural points so a spring-like span is created across the points. The spanning material may be in the form of a ring that is lashed, sewn or otherwise connected to the commissural points. The reinforcing material may form curved segments between the commissural points that extend outwardly to form sinuses behind the leaflets of the prosthetic valve. The reinforcing material may also extend in an upstream direction to avoid interfering with blood flowing out of the prosthetic valve.

Owner:EDWARDS LIFESCIENCES CORP

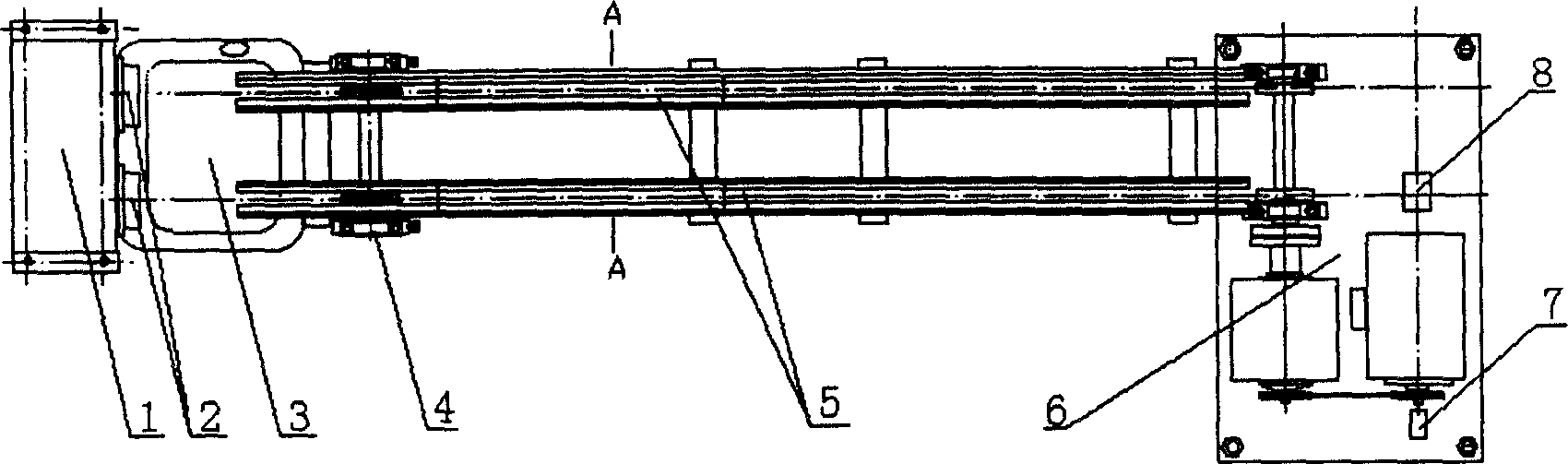

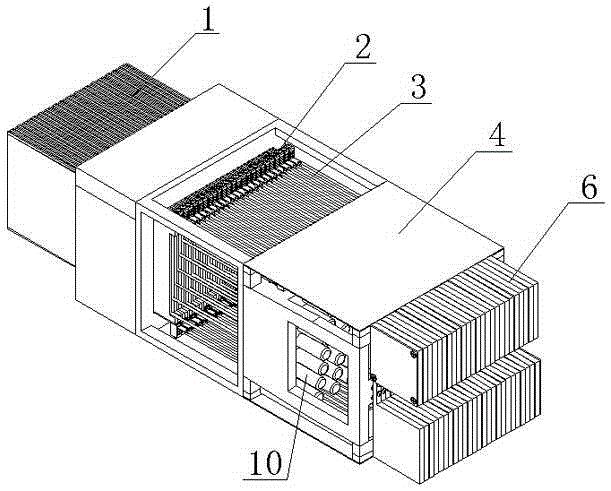

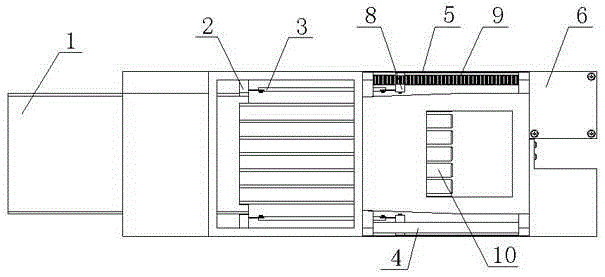

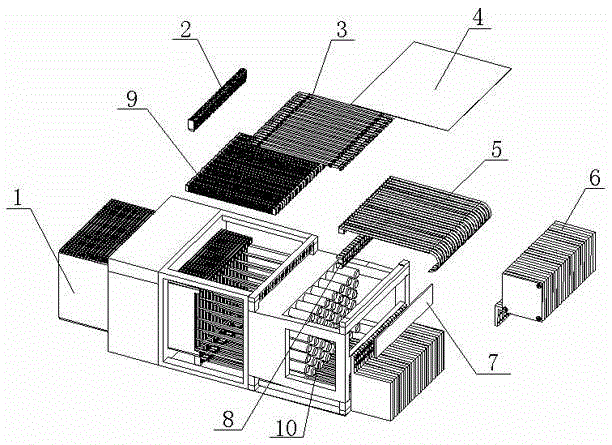

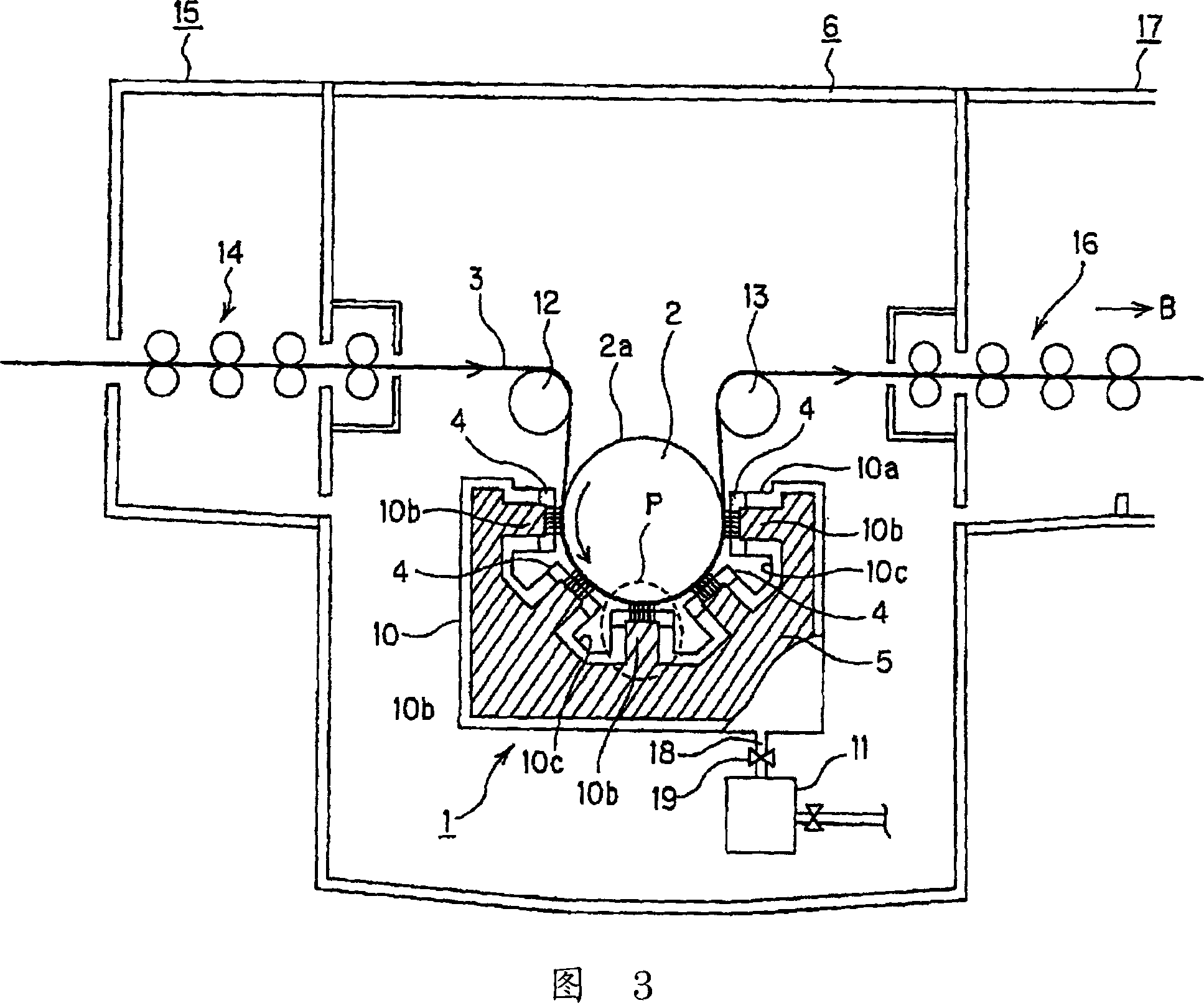

Low-frequency electromagnetic field horizontal continuous casting process and equipment for aluminum alloy and magnesium alloy

Owner:NORTHEASTERN UNIV

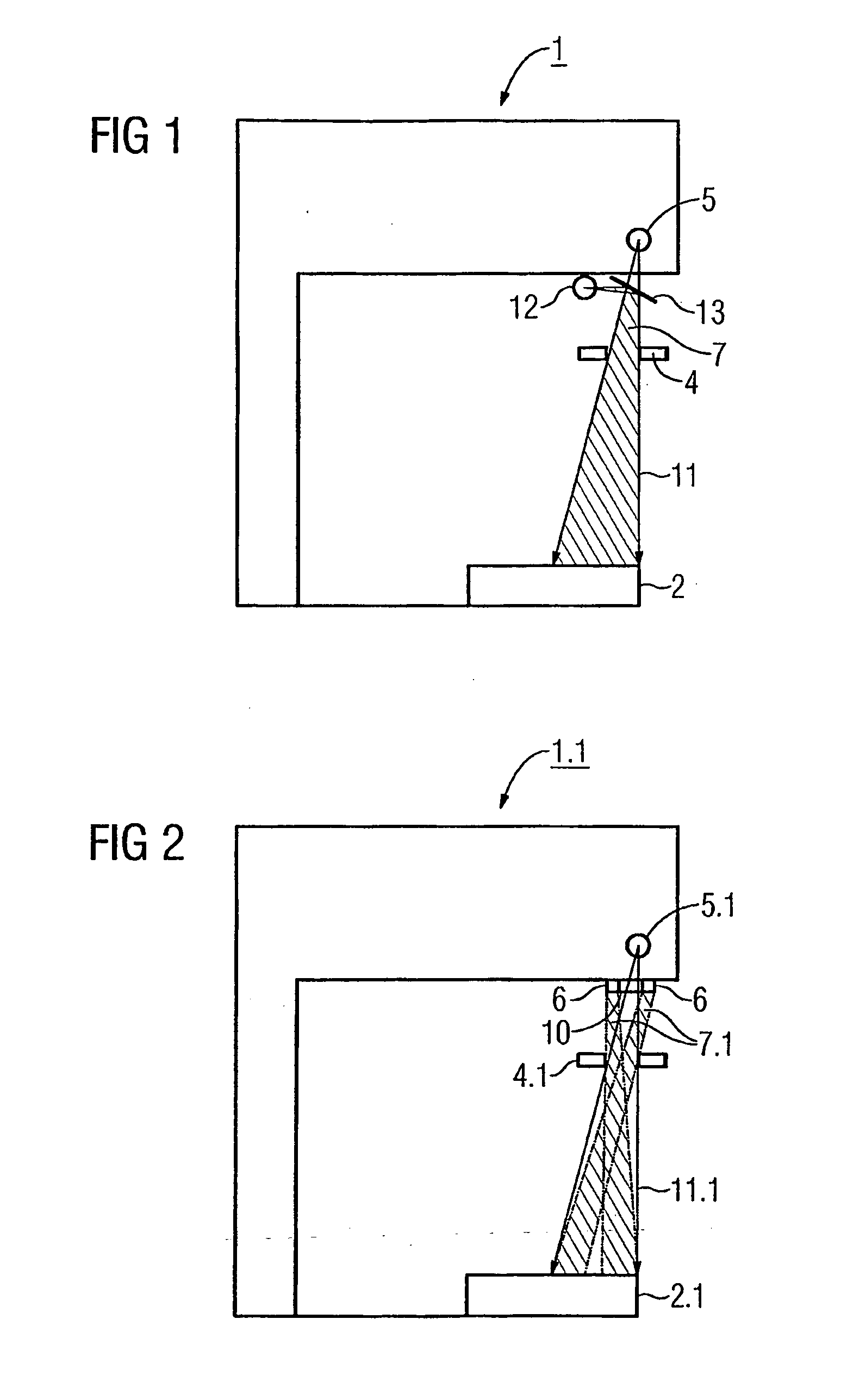

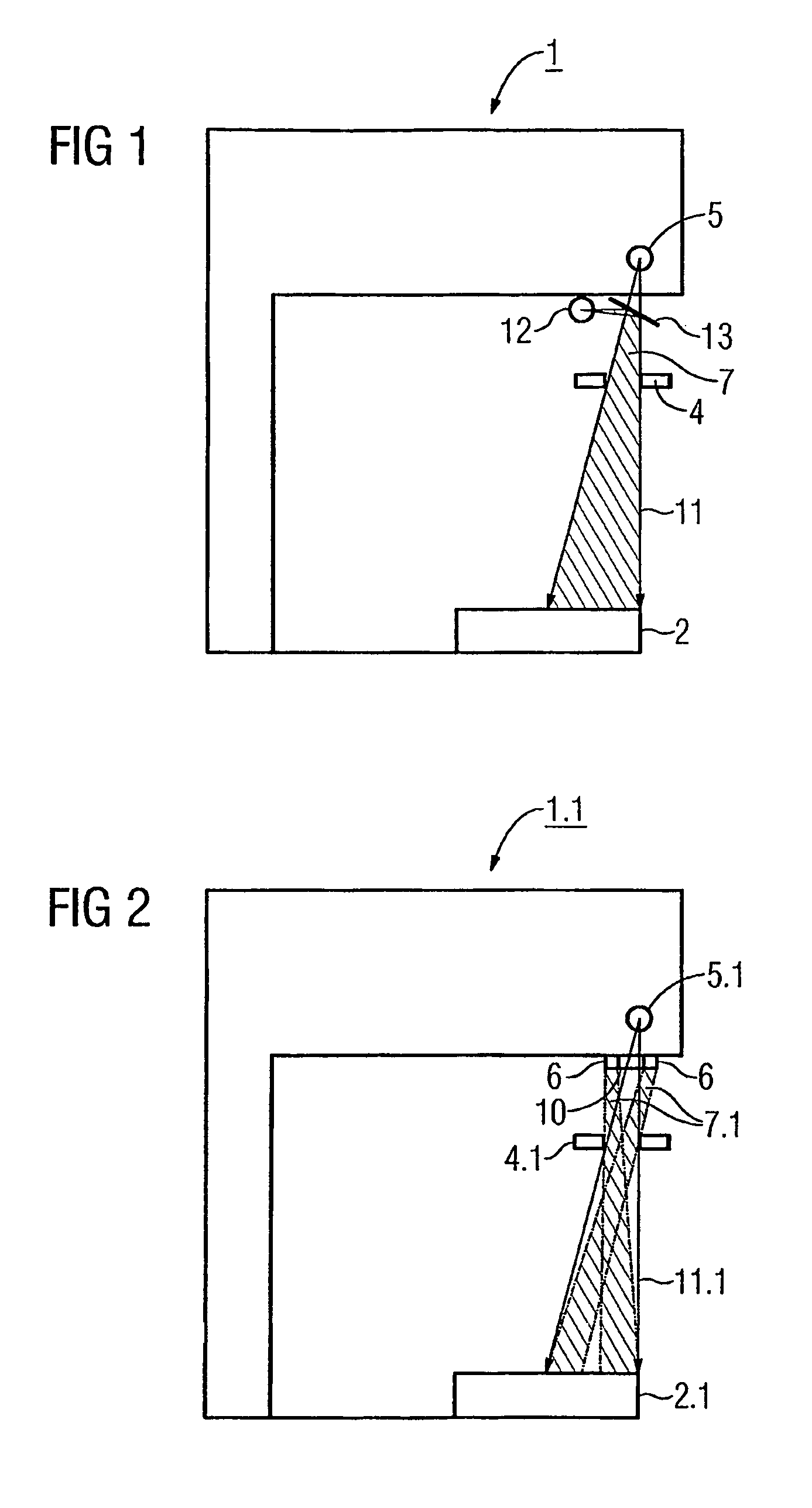

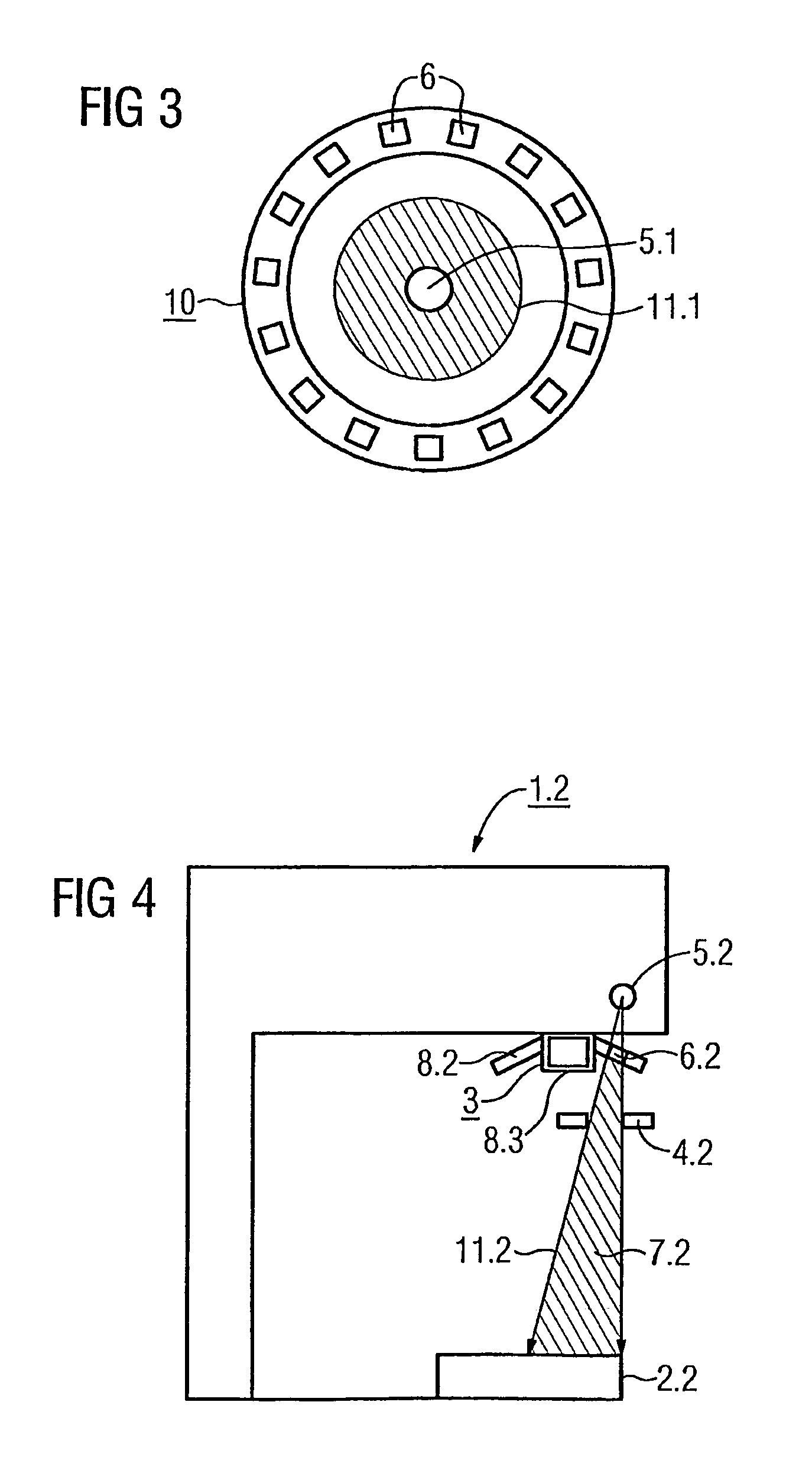

X-ray apparatus and mammographic x-ray apparatus with an indicator

InactiveUS20070183565A1Little effortEliminate deflectionPatient positioning for diagnosticsRadiation beam directing meansSoft x rayX-ray

An X-ray apparatus and a mammographic X-ray apparatus are provided. The X-ray apparatus includes an X-ray beam generated by an X-ray source and a diaphragm. At least one LED is disposed as an indicator means between the X-ray source and the diaphragm. The illuminating beam of the at least one LED is directed in an undeflected fashion onto the X-ray field. The at least one LED may be pivotable (swivable) out of the X-ray beam. The at least one LED is mounted on a filter array that is mounted between the X-ray source and the diaphragm.

Owner:SIEMENS AG

X-ray apparatus and mammographic x-ray apparatus with an indicator

InactiveUS7380986B2Little effortDeflecting the illuminating beam can be eliminatedPatient positioning for diagnosticsRadiation beam directing meansSoft x rayX-ray

Owner:SIEMENS AG

Reinforced Commissural Support Structure

A device and method for controlling commissural tip deflection of a prosthetic valve, thereby both preventing failure due to repeated movement and / or uneven loading of the commissural points and also improving coaptation of the valve leaflets, including connecting reinforcing material between the commissural points so a spring-like span is created across the points. The spanning material may be in the form of a ring that is lashed, sewn or otherwise connected to the commissural points. The reinforcing material may form curved segments between the commissural points that extend outwardly to form sinuses behind the leaflets of the prosthetic valve. The reinforcing material may also extend in an upstream direction to avoid interfering with blood flowing out of the prosthetic valve.

Owner:EDWARDS LIFESCIENCES CORP

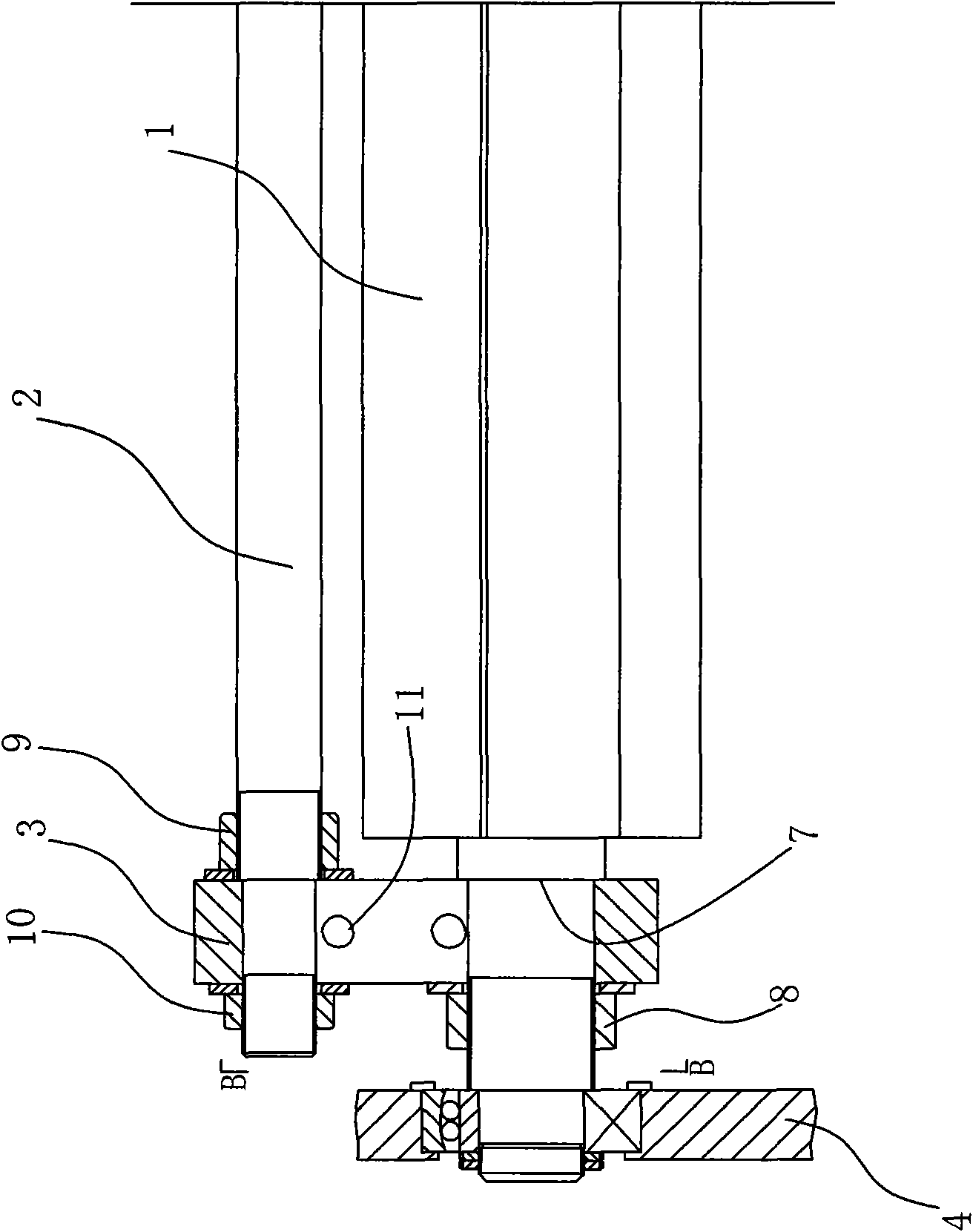

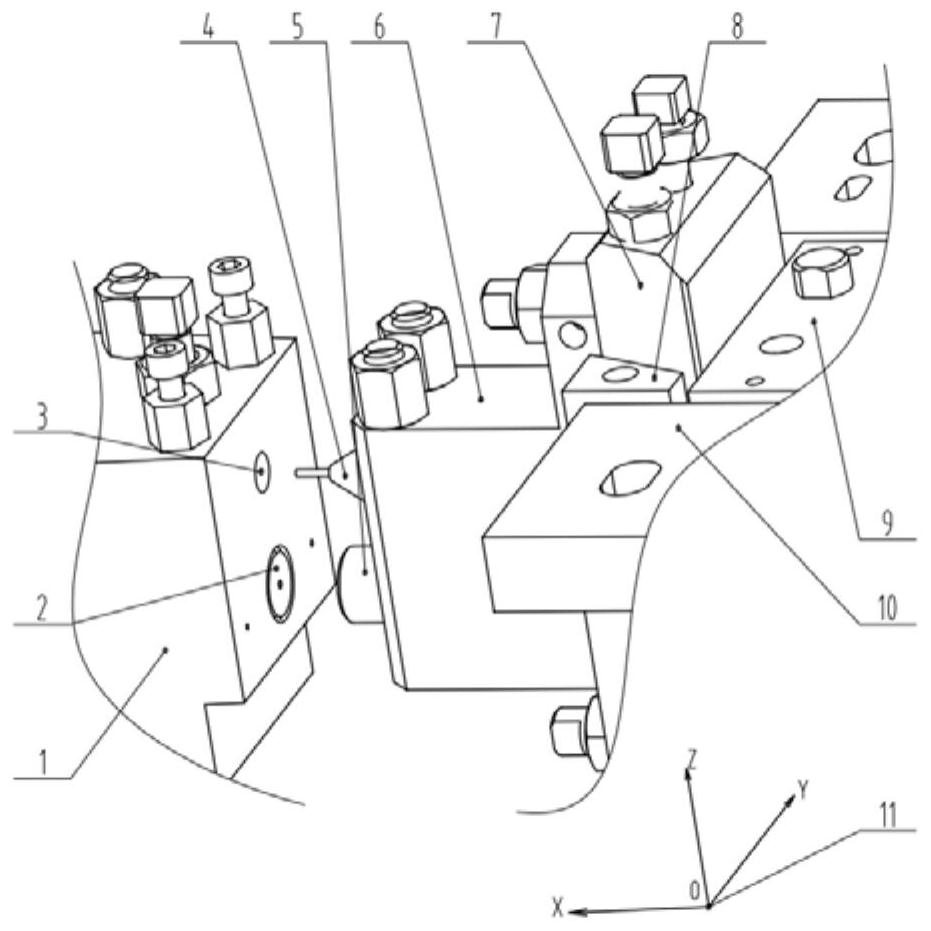

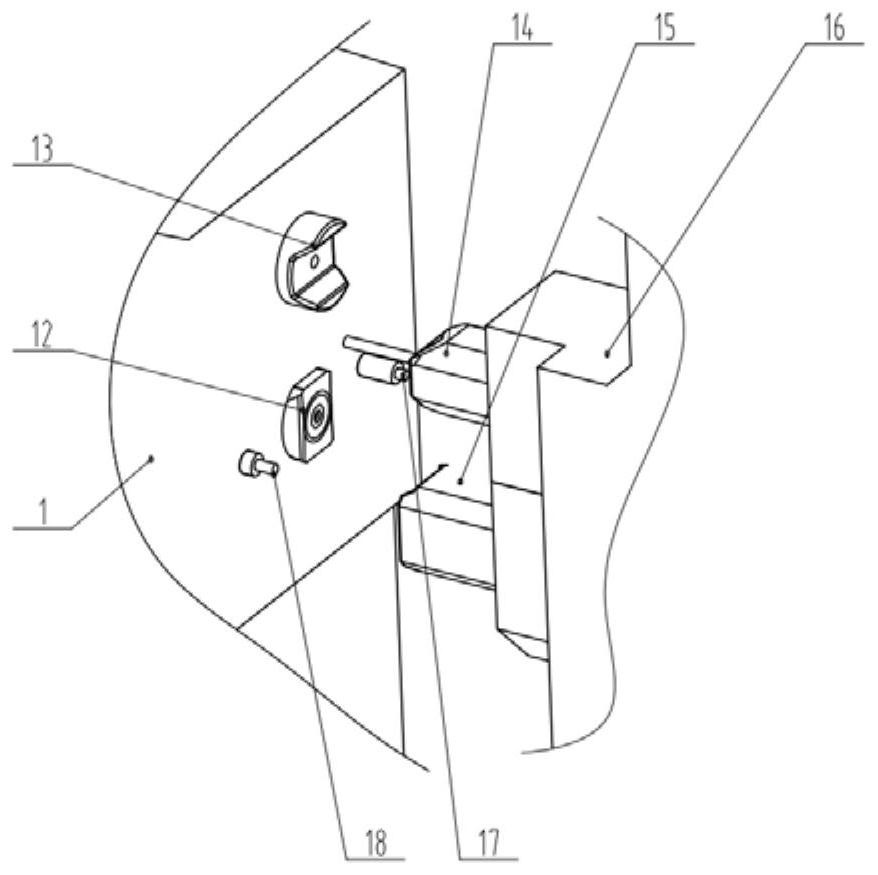

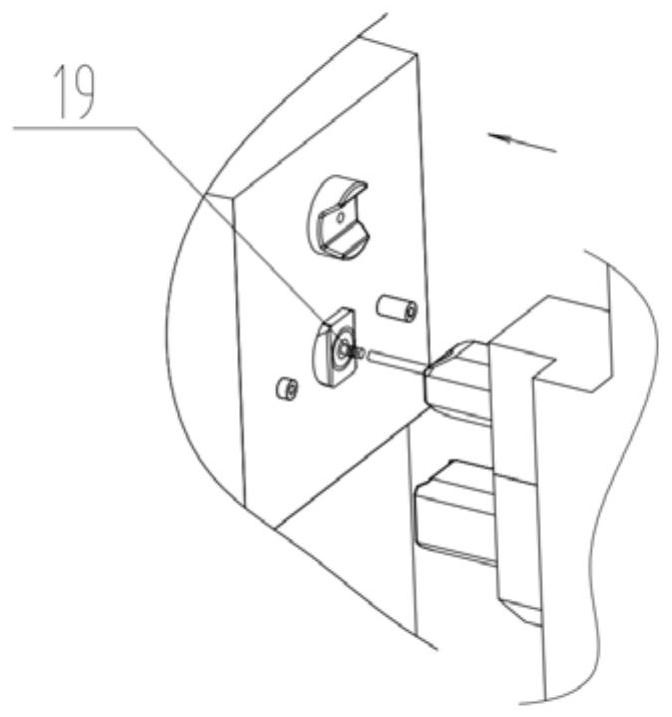

Combined device for improving working precision of comma scraper

InactiveCN101602039AIncrease stiffnessQuality improvementLiquid surface applicatorsCoatingsAxial displacementEngineering

The invention relates to a combined device for improving working precision of a comma scraper similar to a fine macroaxis. Two ends of an axis head of the comma scraper are supported by a bracket respectively; two ends of the axis head of the comma scraper positioned in the opposite inner sides of the two brackets are respectively and fixedly provided with a supporting arm vertical to the scraper axis; two supporting arms are provided with an auxiliary axis which has axial displacement along the scraper axis and is locked in the supporting arm; and a different position of the auxiliary axis is locked in the supporting arm to generate axial load with different sizes and directions on the supporting arm. The combined device can accurately and rapidly adjust tightening torques of nuts at two ends of the auxiliary axis according to the weight and working load born by the scraper, generates preset axial load, adds the needed torque to the comma scraper to balance bending moment which is generated by the weight and the working load born by the comma scraper or the fine macroaxis, removes the bending deformation generated by the weight and the working load and ensures that the edge linearity of the high-precision scraper still keeps high service precision in a working state.

Owner:HEFEI UNIV OF TECH

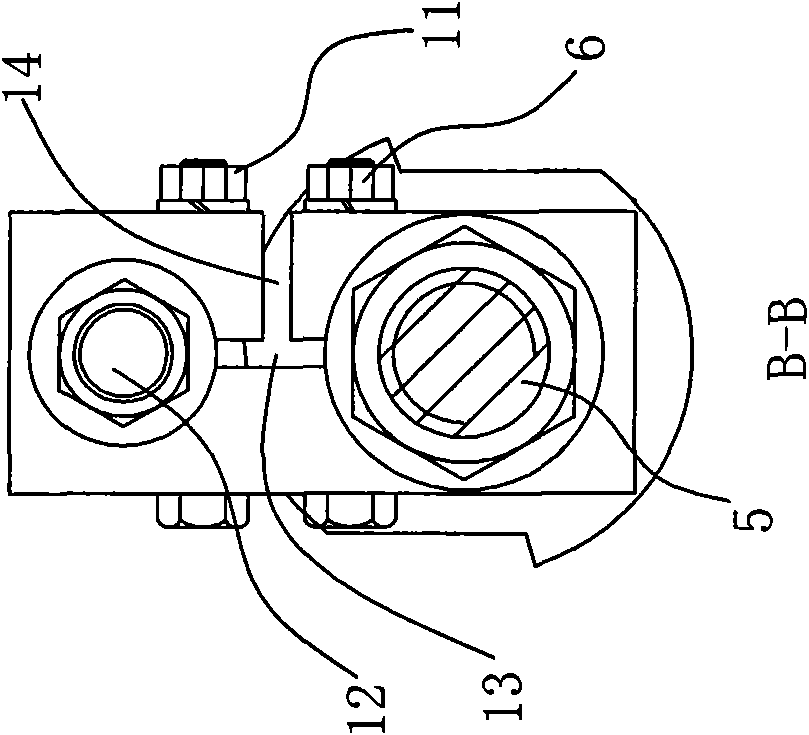

Apparatus and method for aligning shaft couplings

InactiveUS6171195B2Preventing damage to couplingPrecise alignmentYielding couplingFlanged jointsDrive shaftCoupling

An apparatus for precisely aligning bolt holes in first and second adjacent drive shaft couplings, including a cam pin for being positioned in the generally aligned bolt holes in the shaft couplings and rotated to bring the bolt holes in to more precise alignment. The cam pin includes a first, relatively large diameter segment having a cylindrical wall defining a first longitudinal axis for being positioned in a precisely fitting condition in the bolt hole of the first coupling, and a second, relatively small diameter segment having a cylindrical wall defining a second longitudinal axis offset from and eccentric to the longitudinal axis of the first segment for being relatively loosely positioned in the generally aligned bolt hole of the second coupling. A cam sleeve is provided for being positioned in axial and rotational sliding relation over the small diameter segment of the cam pin and within the bolt hole of the second coupling. The cam sleeve has an offset bore defining a progressively varying wall thickness whereby rotation of the cam pin and cam sleeve relative to each other and to the bolt holes within which they are positioned brings progressively varies the overall diameter of the cam pin to bring the bolt holes into precise alignment for installation of the connecting bolts.

Owner:FERGUSON LESLIE W

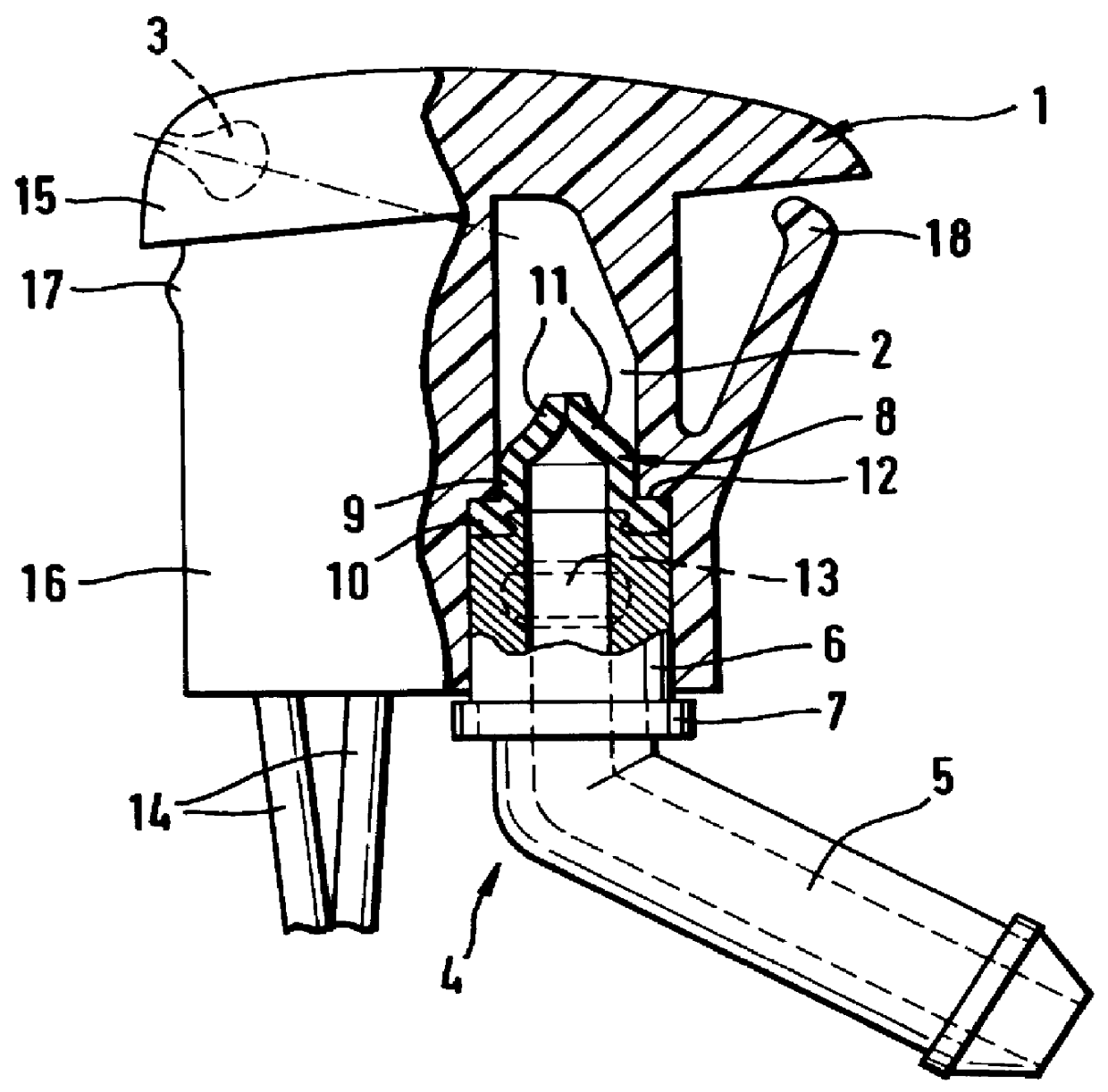

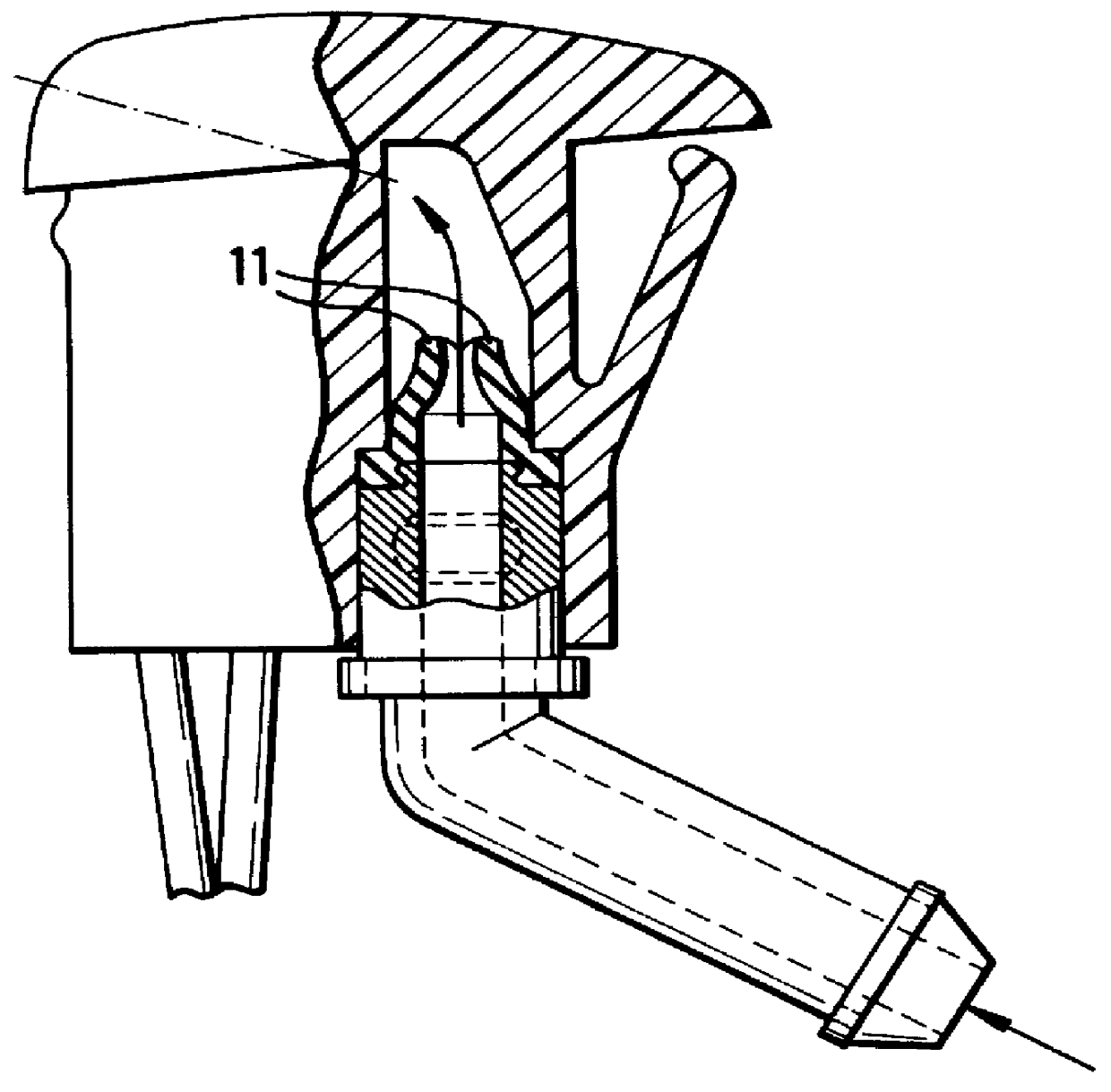

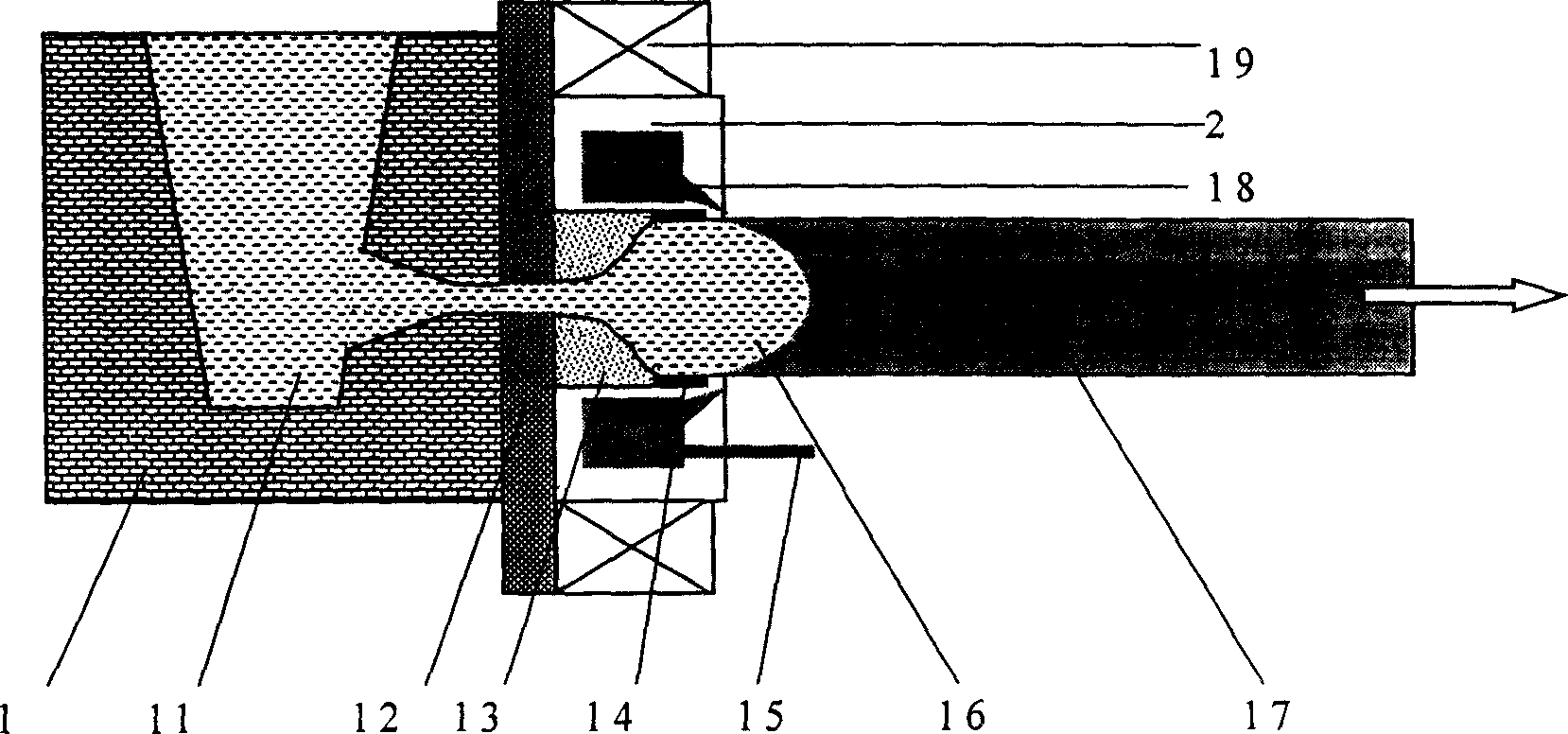

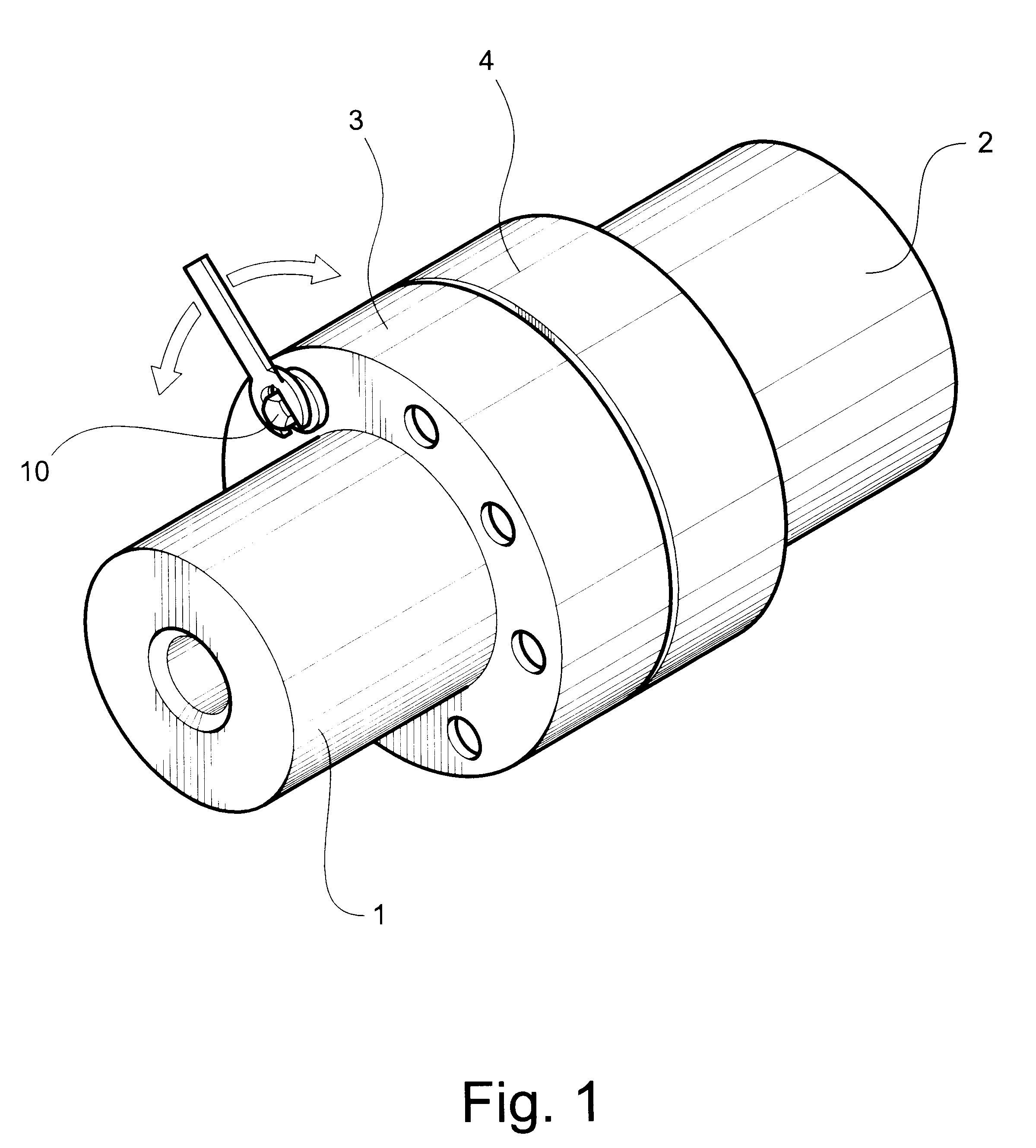

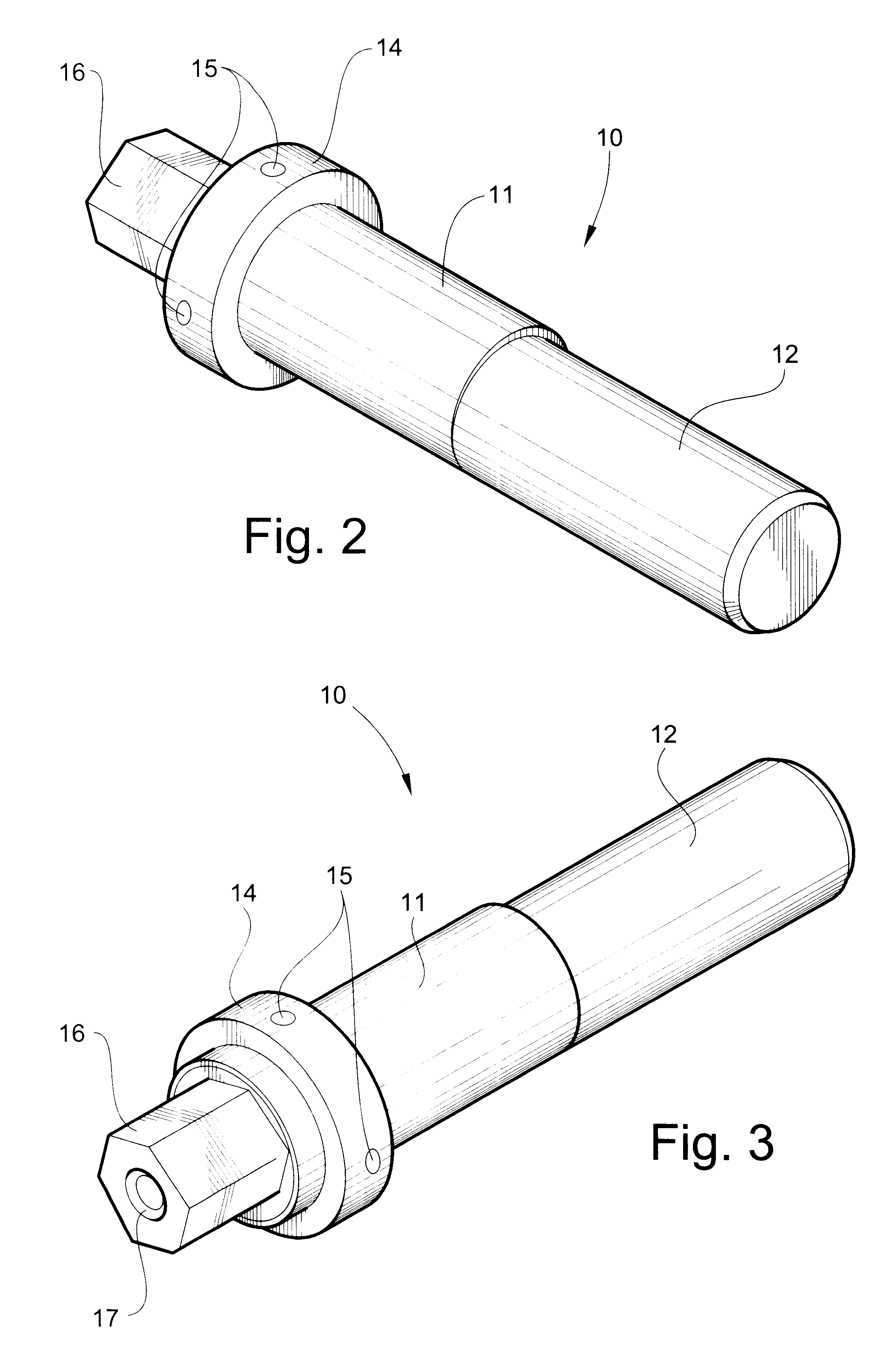

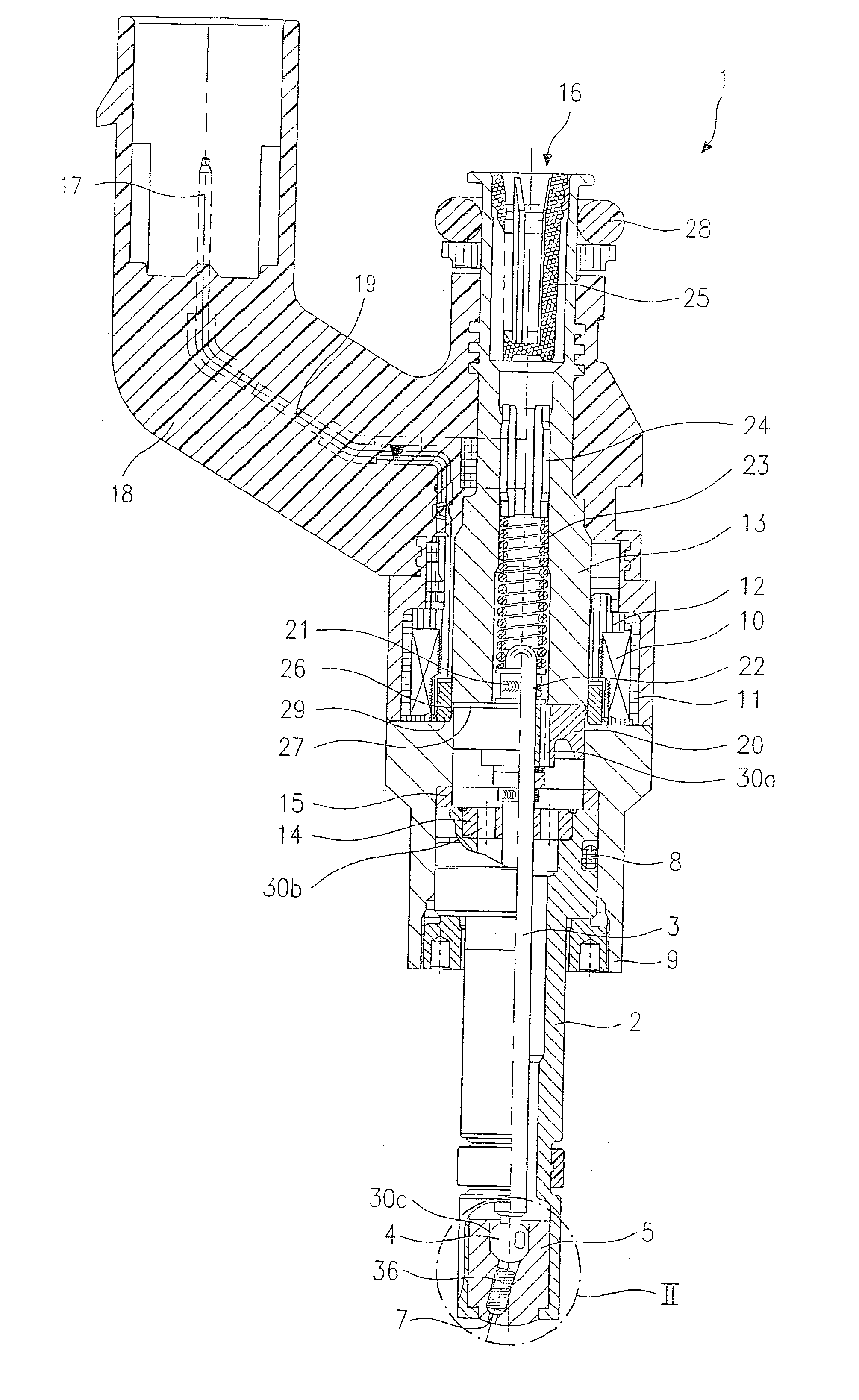

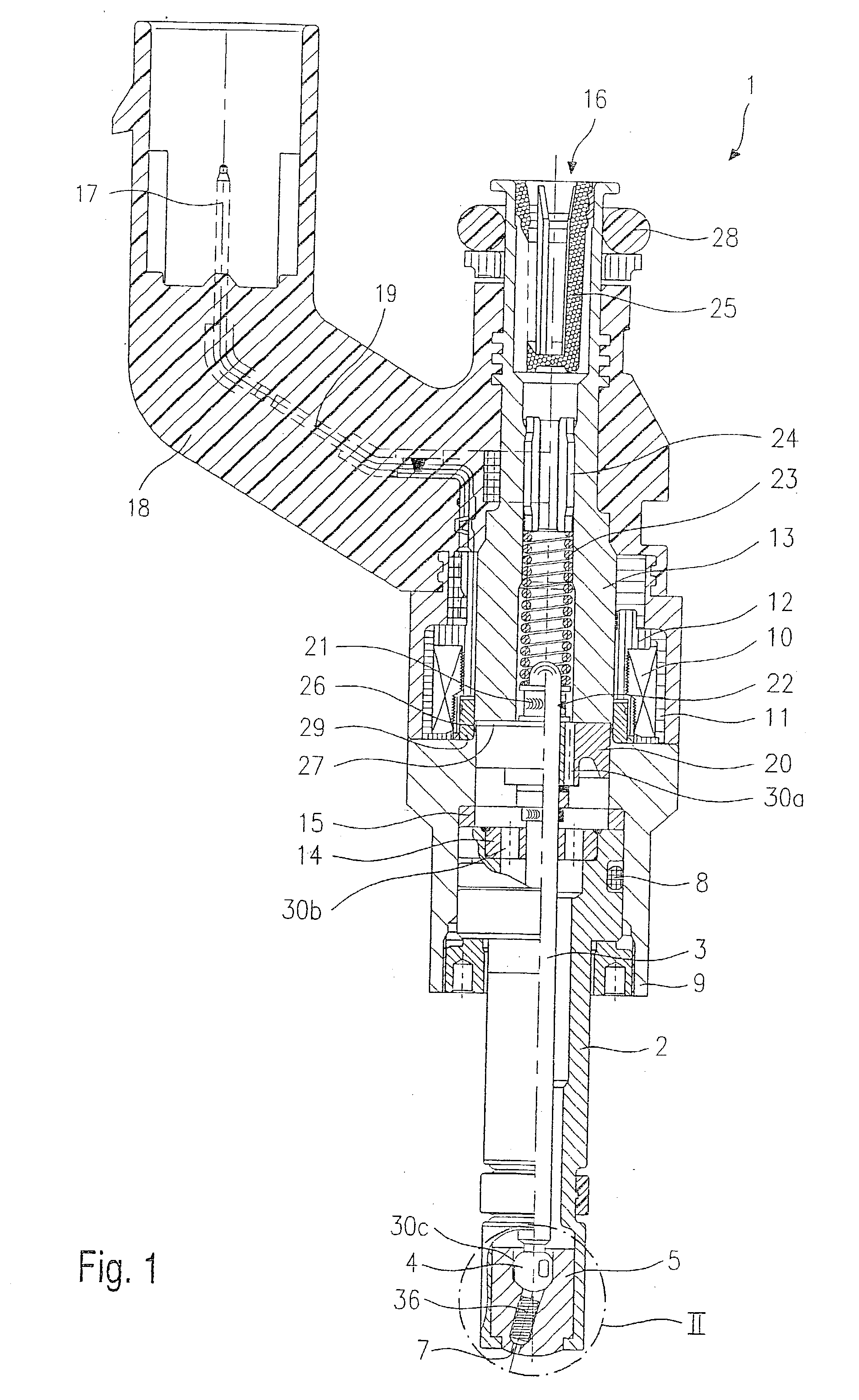

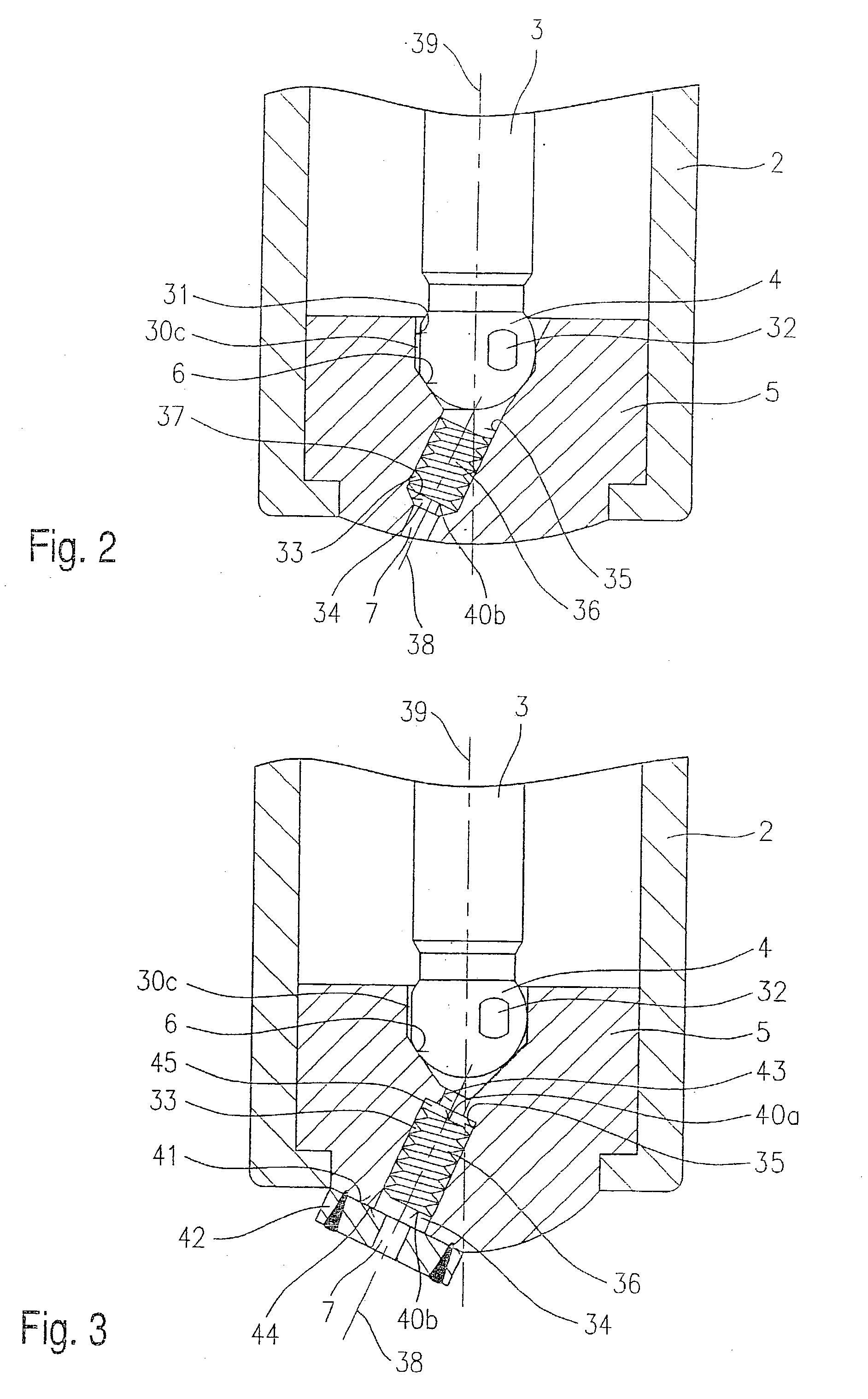

Fuel injection valve

InactiveUS20030111562A1Eliminate deflectionEliminates complicated remachining of the swirl insertSpray nozzlesMachines/enginesCombustionEngineering

A fuel injector (1) for fuel injector systems of internal combustion engines has a valve-closure member (4) which is mechanically linked to a valve needle (3) and cooperates with a valve-seat surface (6) of a valve-seat member (5) to form a sealing seat. A turbulence-producing element is provided in the valve-seat member (5), situated downstream from the sealing seat, and its center line (38) preferably forms an angle different from zero with the center line (39) of the fuel injector (1), a threaded rod (36) being pressed into the valve-seat member (5) as the turbulence-producing element.

Owner:ROBERT BOSCH GMBH

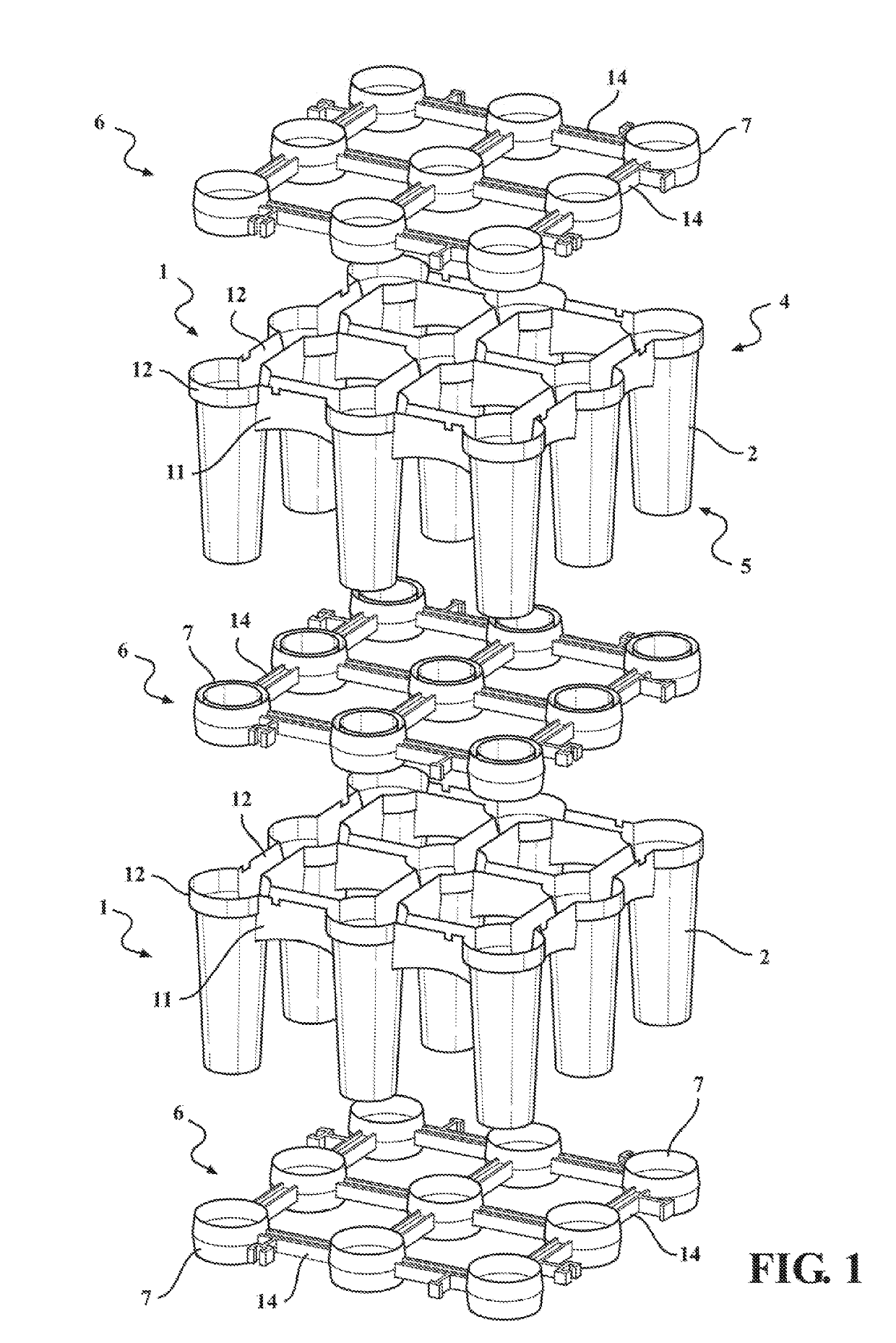

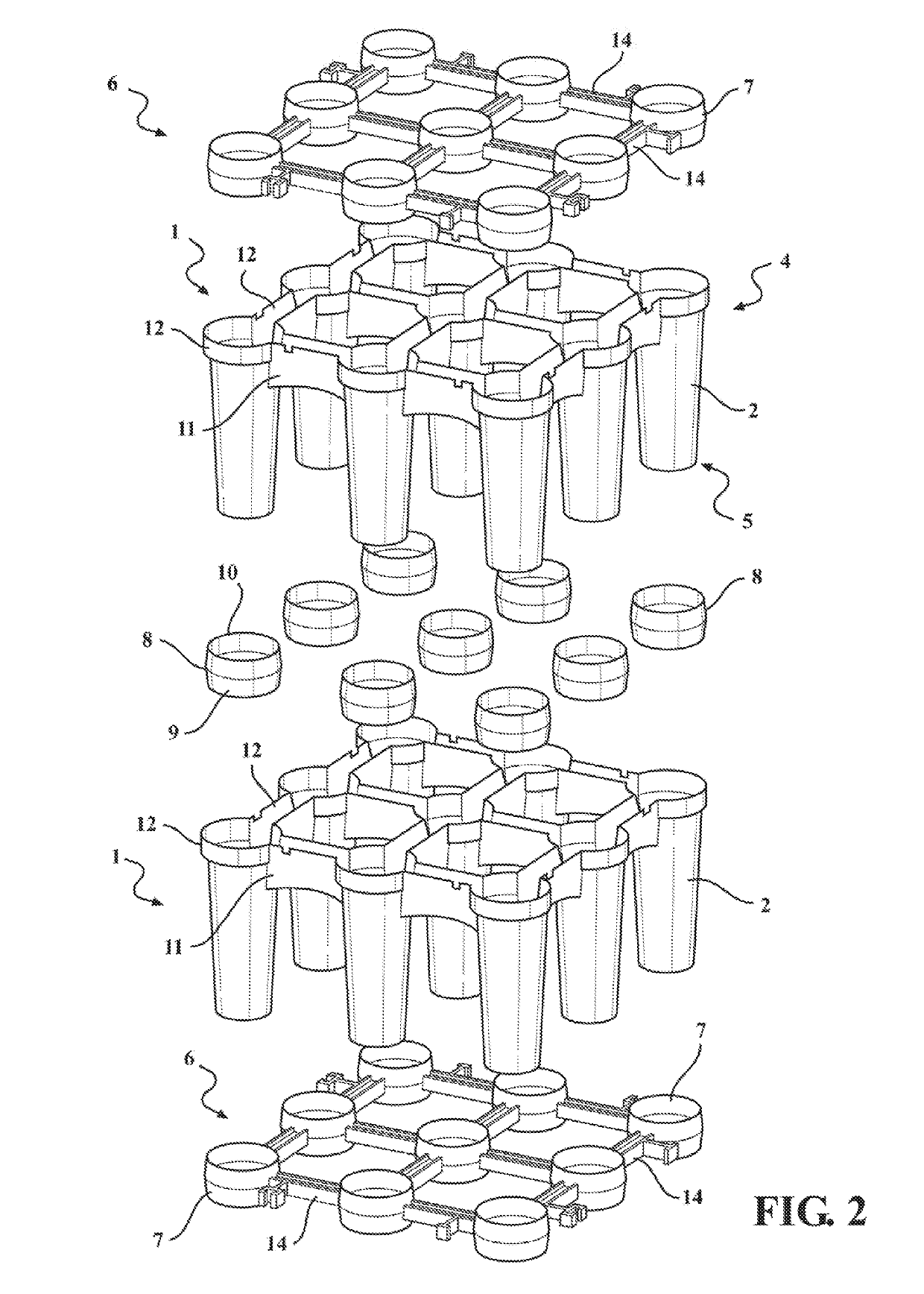

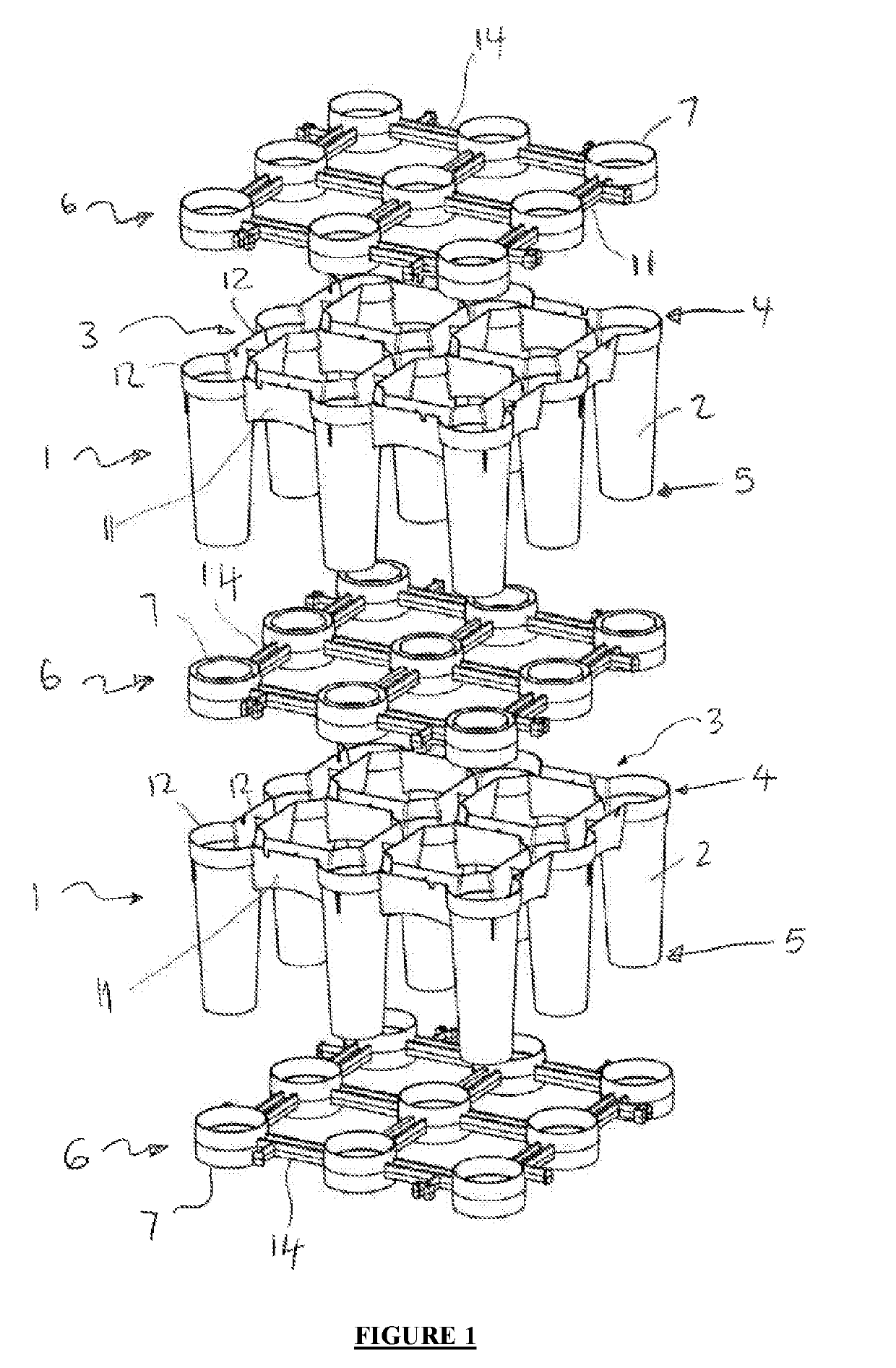

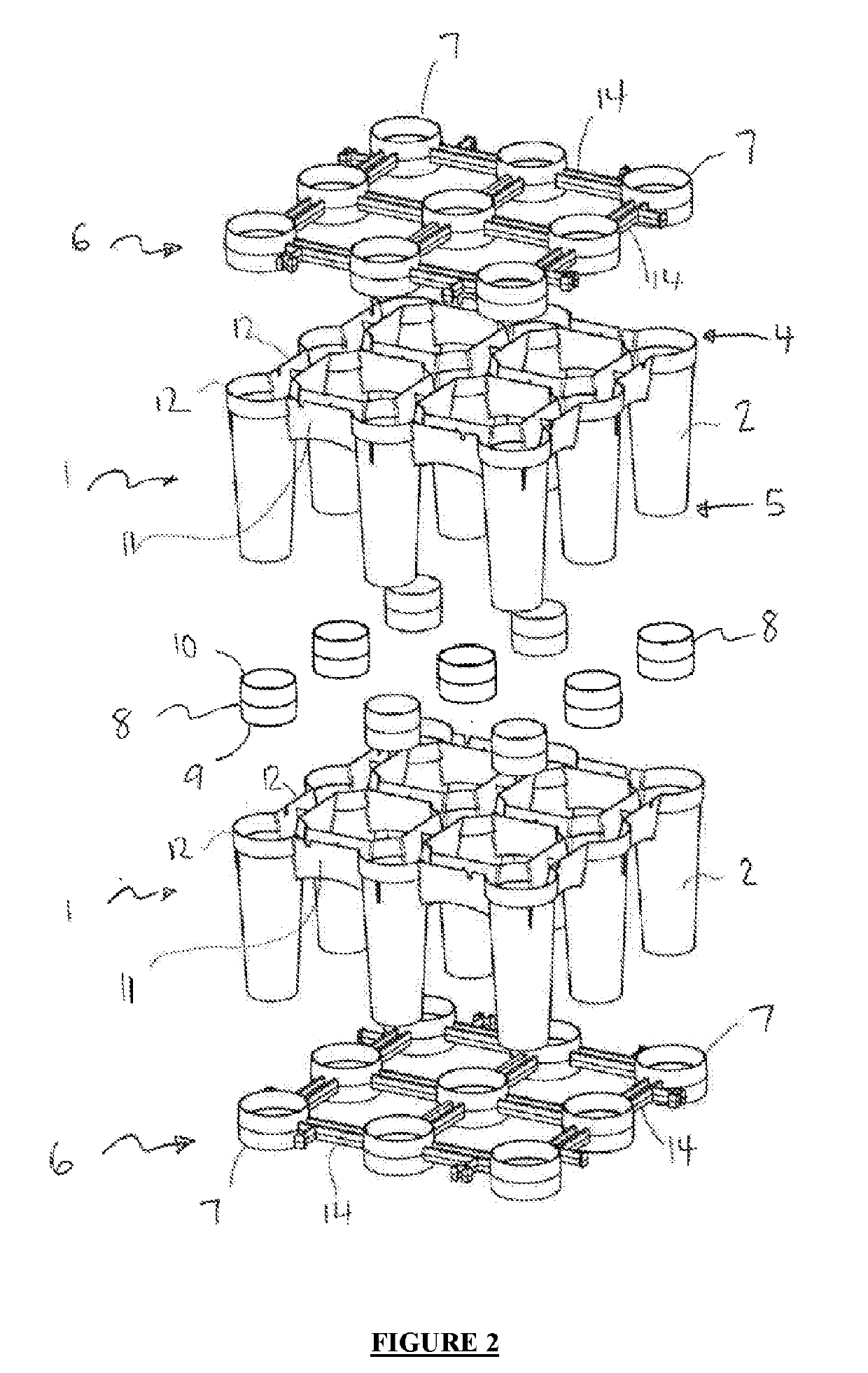

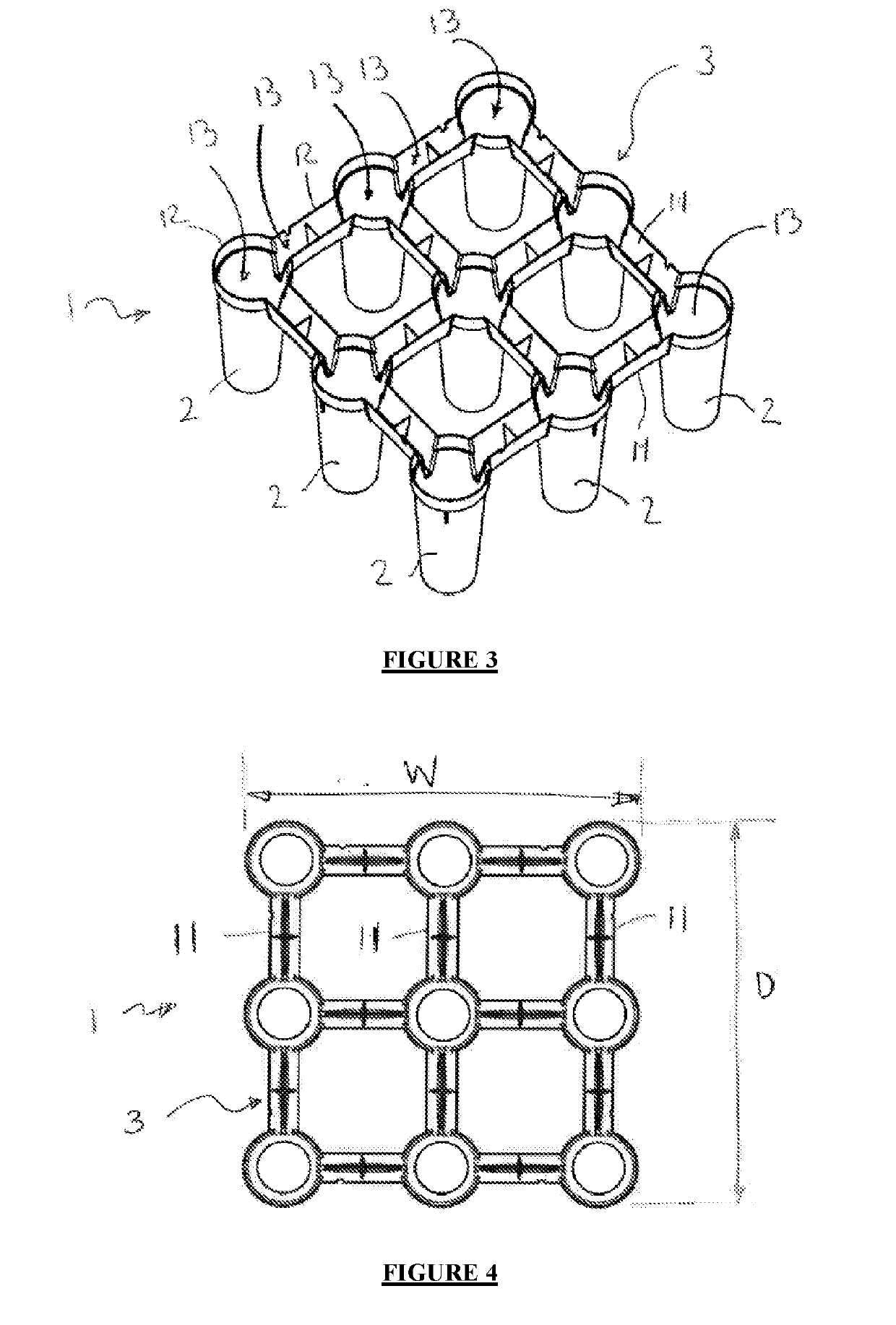

Structural cells, matrices and methods of assembly

ActiveUS10415260B2Eliminate deflectionWithstand compressive loadPaving reinforcementsGround-workEngineeringCell assembly

Structural cells and matrices using the structural cells for positioning below a hardscape that define a void space therein, the structural cells, matrices using the cells and methods of assembly allowing in one embodiment the introduction of a structural fluid such as concrete to provide an alternative structural cell and matrix product. In one embodiment a structural cell assembly is described comprising a structural cell with a plurality of legs integrally linked to a frame at a first frame end, the frame linking the legs together and the frame defining a generally flat plane with the legs extending substantially orthogonally away from the first frame end about the frame flat plane to a leg terminal end; and a separate plate engaging the legs, the separate plate comprising linked sockets, each socket engaging the leg terminal end; and / or linked sockets, each socket engaging the leg frame ends or a part thereof.

Owner:STRATA INNOVATIONS PTY

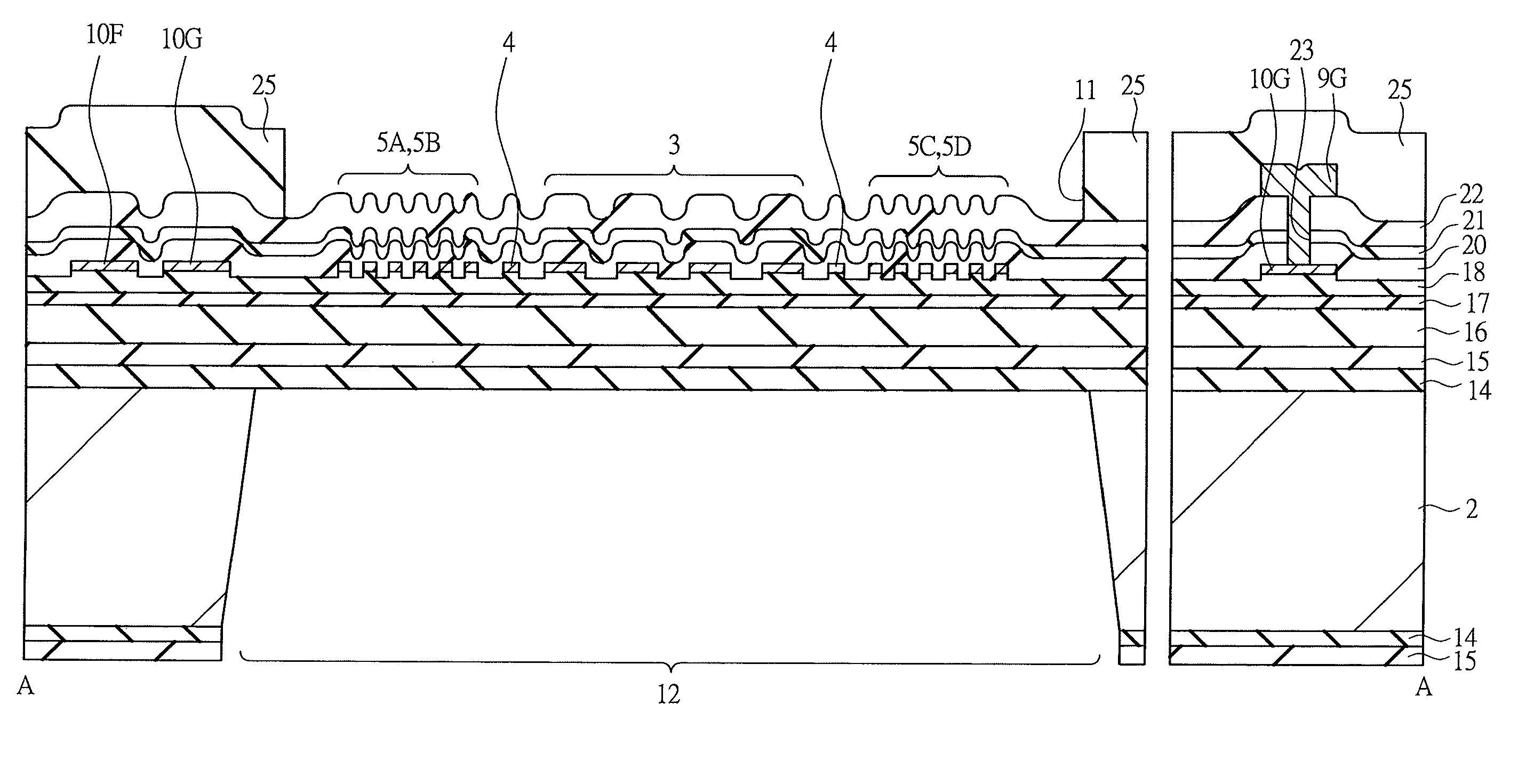

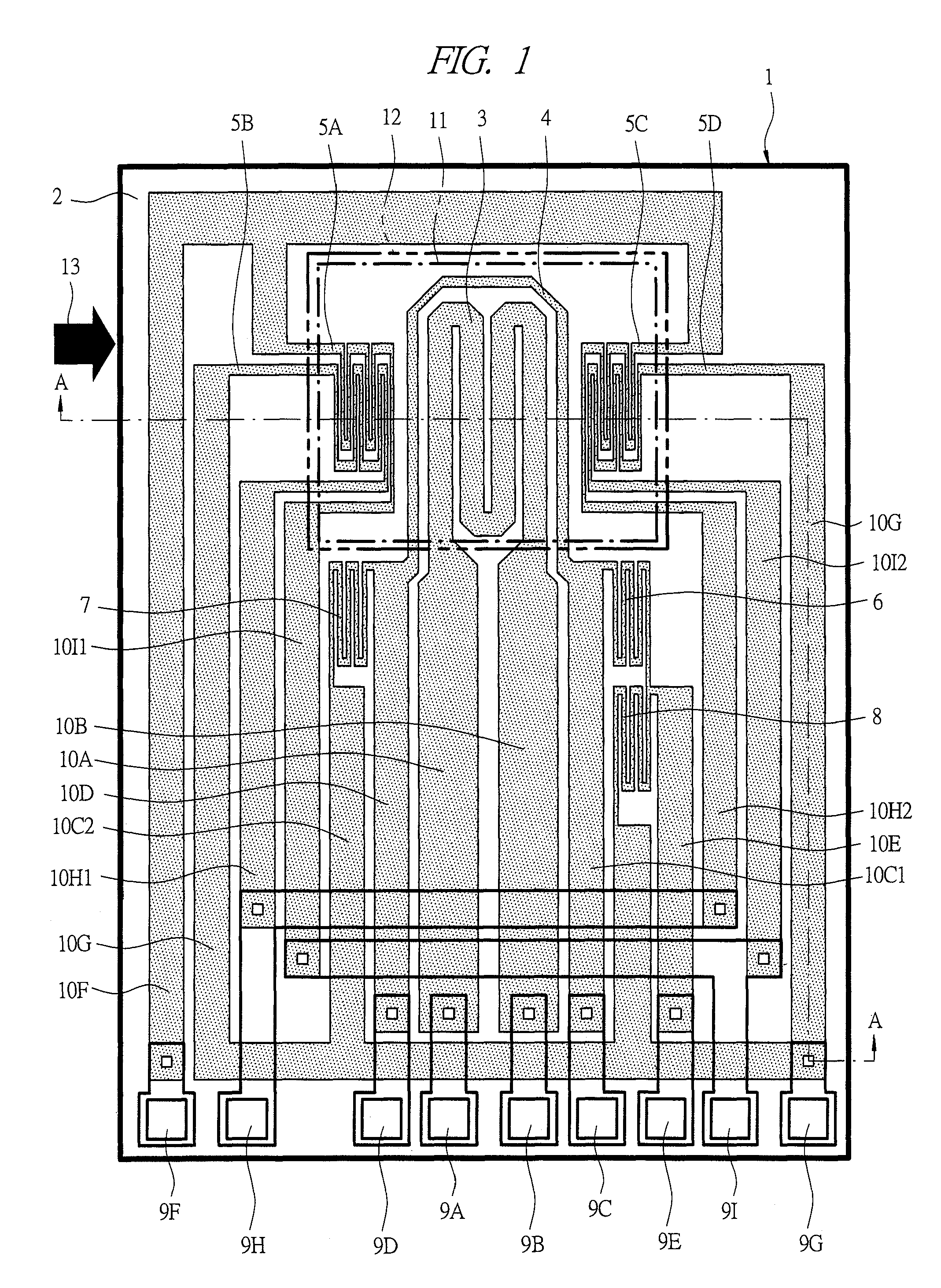

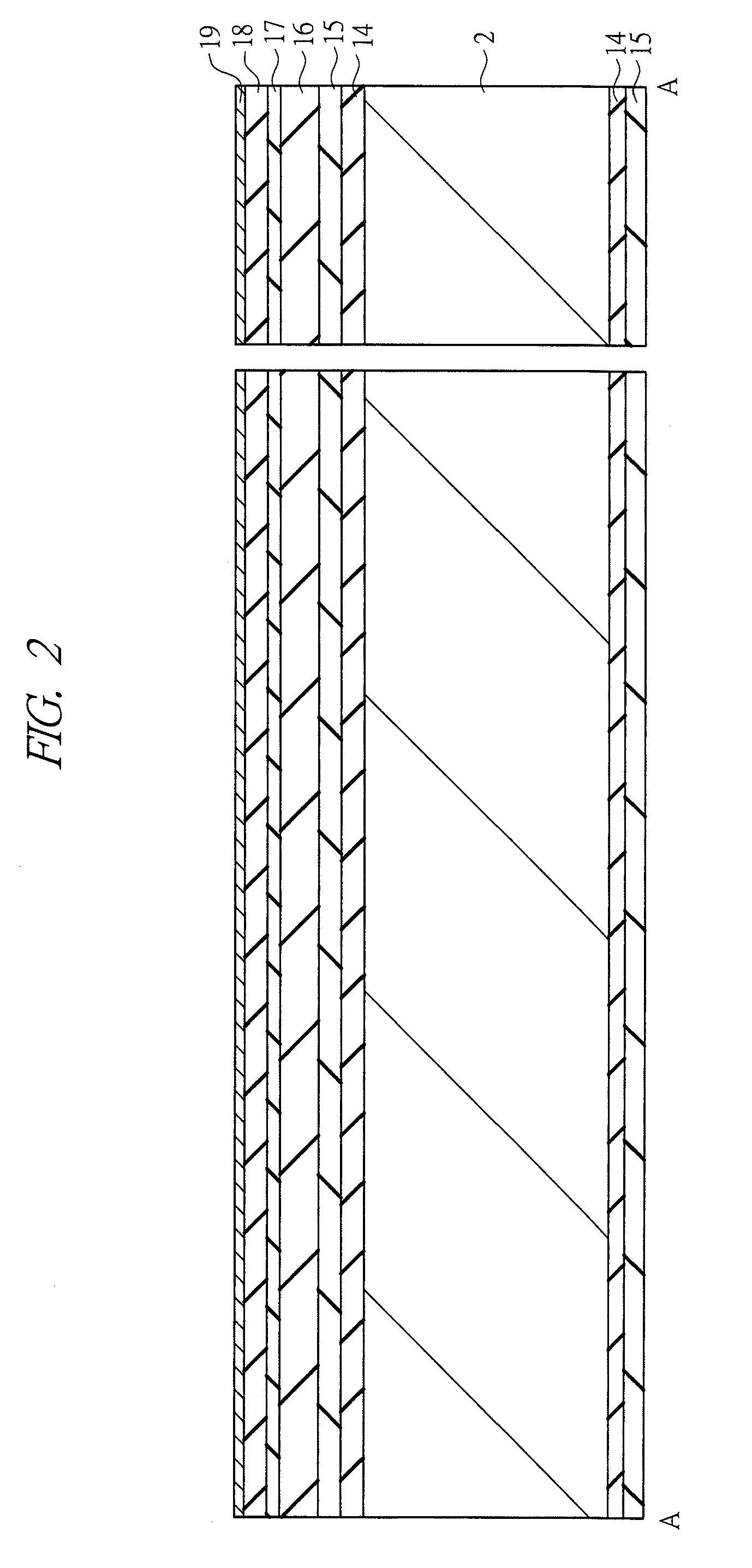

Thermal fluid flow sensor having stacked insulating films above and below heater and temperature-measuring resistive elements

ActiveUS8429964B2Reduce unevennessLarge roughnessVolume/mass flow by thermal effectsVolume flow proportion measurementElectrical resistance and conductanceDiaphragm structure

A thermal fluid flow sensor having a diaphragm structure body configured by an insulating film formed by stacking a film having compressive stress and a film having tensile stress on the top and bottom of a temperature-measuring resistive element and a heater resistive element which are processed by microprocessing is provided. The insulating film at a lower layer of the heater resistive element, a temperature-measuring resistive element for heater resistive element, upstream temperature-measuring resistive elements, and downstream temperature-measuring resistive elements, has films having compressive stress (a first insulating film, a third insulating film, and a fifth insulating film) and films having tensile stress (a second insulating film and a fourth insulating film) being alternately arranged, and two layers or more of the films having tensile stress are arranged.

Owner:HITACHI ASTEMO LTD

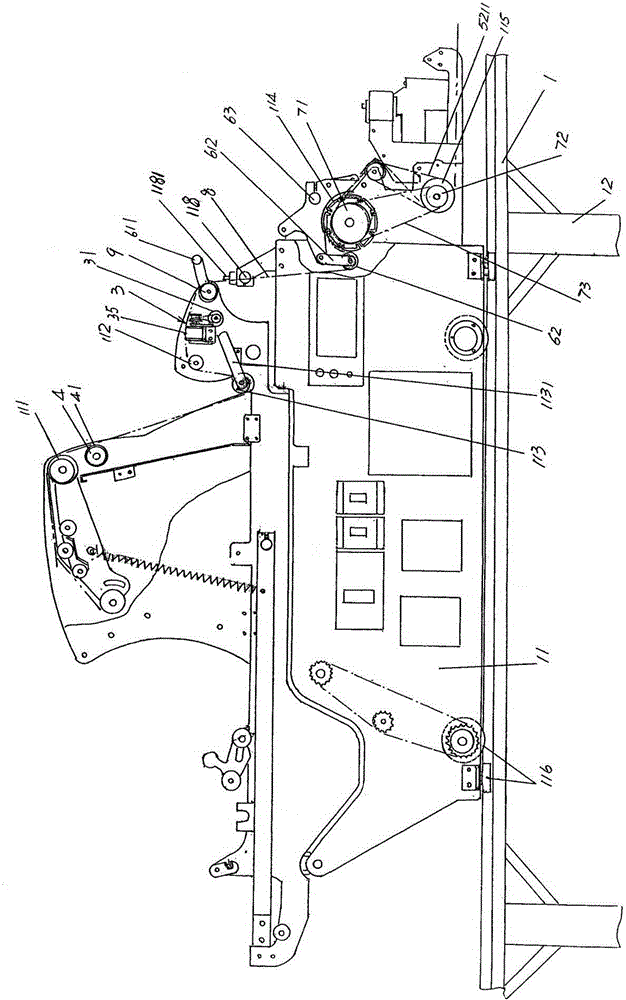

Stripping and fixing device of stretching machine

ActiveCN104003231BBlock replyPrevent swimmingUnfolding thin materialsWebs handlingScrew threadContact effects

An edge peeling and positioning device of a spreading machine belongs to the field of clothing machines. The spreading machine comprises a spreading table, a machine frame is arranged on the spreading table and provided with an upper cloth guiding roller, a lower cloth guiding roller, a cloth pressing roller, a large cloth spreading roller and a lower cloth spreading roller. The edge peeling and positioning device comprises a beam and a pair of toothed belt type edge peeling mechanisms and is characterized by further comprising a front cloth expanding roller, a rear cloth expanding roller and a peeled and expanded cloth edge maintaining roller, wherein the front cloth expanding roller is supported on the machine frame and provided with front cloth expanding threads, the rear cloth expanding roller is provided with rear cloth expanding threads, and the peeled and expanded cloth edge maintaining roller is provided with flanges; the beam is fixedly provided with a pair of belt supporting unit seats, which extend into an edge peeling toothed belt cavity and are fixedly provided with belt supporting units, and the belt supporting units are arranged inside the edge peeling toothed belt cavity and are in contact with the inner side of the edge peeling toothed belt. The edge peeling and positioning device of the spreading machine enables the cloth edges of both sides in the length direction of cloth spread on the spreading table to maintain a trim state, prevents both sides the cloth from moving towards the middle, eliminates the deflection of the edge peeling toothed belt and improves the integral contact effects of the edge peeling toothed belt with the cloth edges.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

Process for heating sleeve shaft through magnetic induction by large ring component

InactiveCN103170796AShorten the installation periodShorten round-trip shipping timesMetal working apparatusThermodynamicsThermal deformation

The invention relates to a process for heating a sleeve through magnetic induction by a large ring component. Finish machining is conducted on the ring component until certain size of the ring component is reached before shrinkage fit. In order to avoid thermal consumption after heating and prevent the surface of a ring from being burned due to the fact of partial overheat, asbestos cloth is coated and surrounds the outer surface of the ring, induction coils are wound on the outer surface of the ring, the ring is lifted above a rotating shaft through a crane, and after the ring is heated, when the minimum size of the ring is detected to meet requirements of a drawing through a measuring bar, the ring is smoothly dropped, and the shrinkage fit is conducted on the ring. After the ring is cooled to room temperature, size difference of an outer ring of the ring before the shrinkage fit and after the shrinkage fit is not larger than 0.02 millimeter. After the shrinkage fit is finished for the first time, the ring does not need machining a large equipment for the second time again after the shrinkage fit, the lowest heating temperature is controlled through intermediate-frequency electromagnetic induction heating, and deformation of the ring is small after the shrinkage fit after the ring is heated. The process for heating the sleeve shaft through magnetic induction by the large ring component has the advantages of being simple in operation, simple in required equipment, low in manufacturing cost, short in working period and the like, can save a large amount of cost from secondary machining to large-equipment machining, and is very high in application value.

Owner:HARBIN ELECTRIC MASCH CO LTD

Improvements in structural cells, matrices and methods of assembly

ActiveUS20190145112A1Low deflectionPrevent any vertical deflectionPaving reinforcementsGround-workStructural unitEngineering

Structural cells and matrices using the structural cells for positioning below a hardscape that define a void space therein, the structural cells, matrices using the cells and methods of assembly allowing in one embodiment the introduction of a structural fluid such as concrete to provide an alternative structural cell and matrix product. In one embodiment a structural cell assembly is described comprising a structural cell with a plurality of legs integrally linked to a frame at a first frame end, the frame linking the legs together and the frame defining a generally flat plane with the legs extending substantially orthogonally away from the first frame end about the frame flat plane to a leg terminal end; and a separate plate engaging the legs, the separate plate comprising linked sockets, each socket engaging the leg terminal end; and / or linked sockets, each socket engaging the leg frame ends or a part thereof.

Owner:STRATA INNOVATIONS PTY

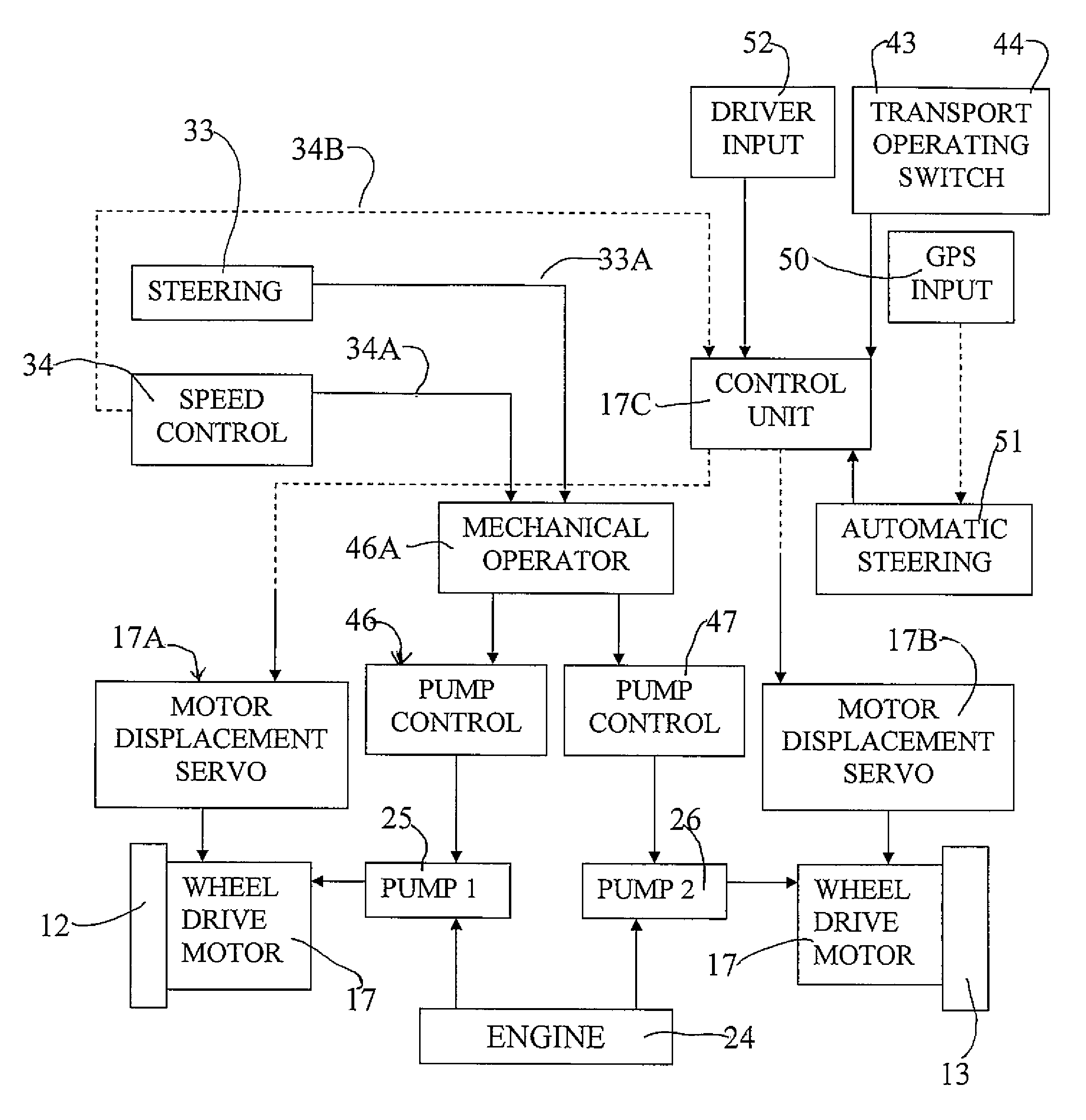

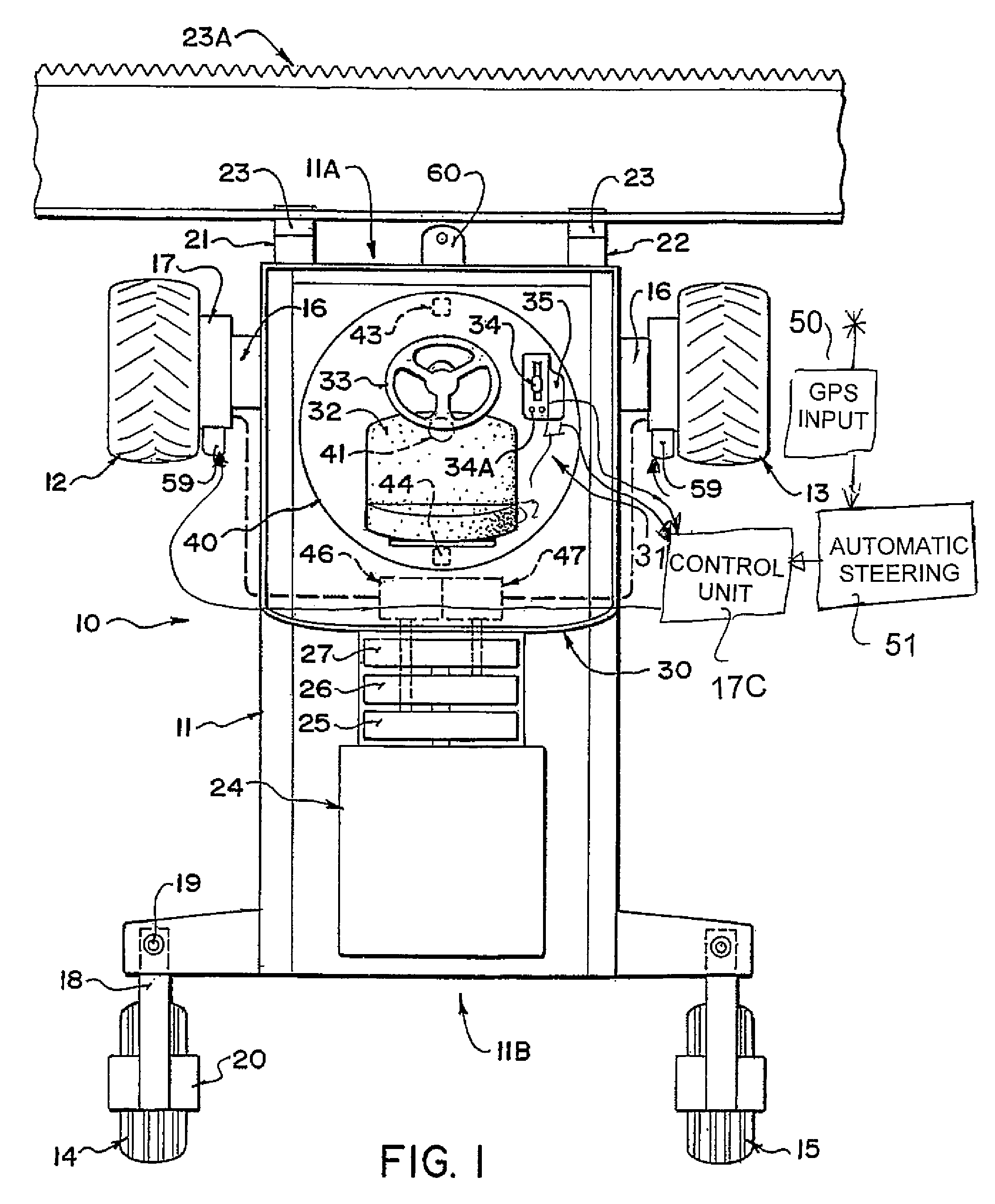

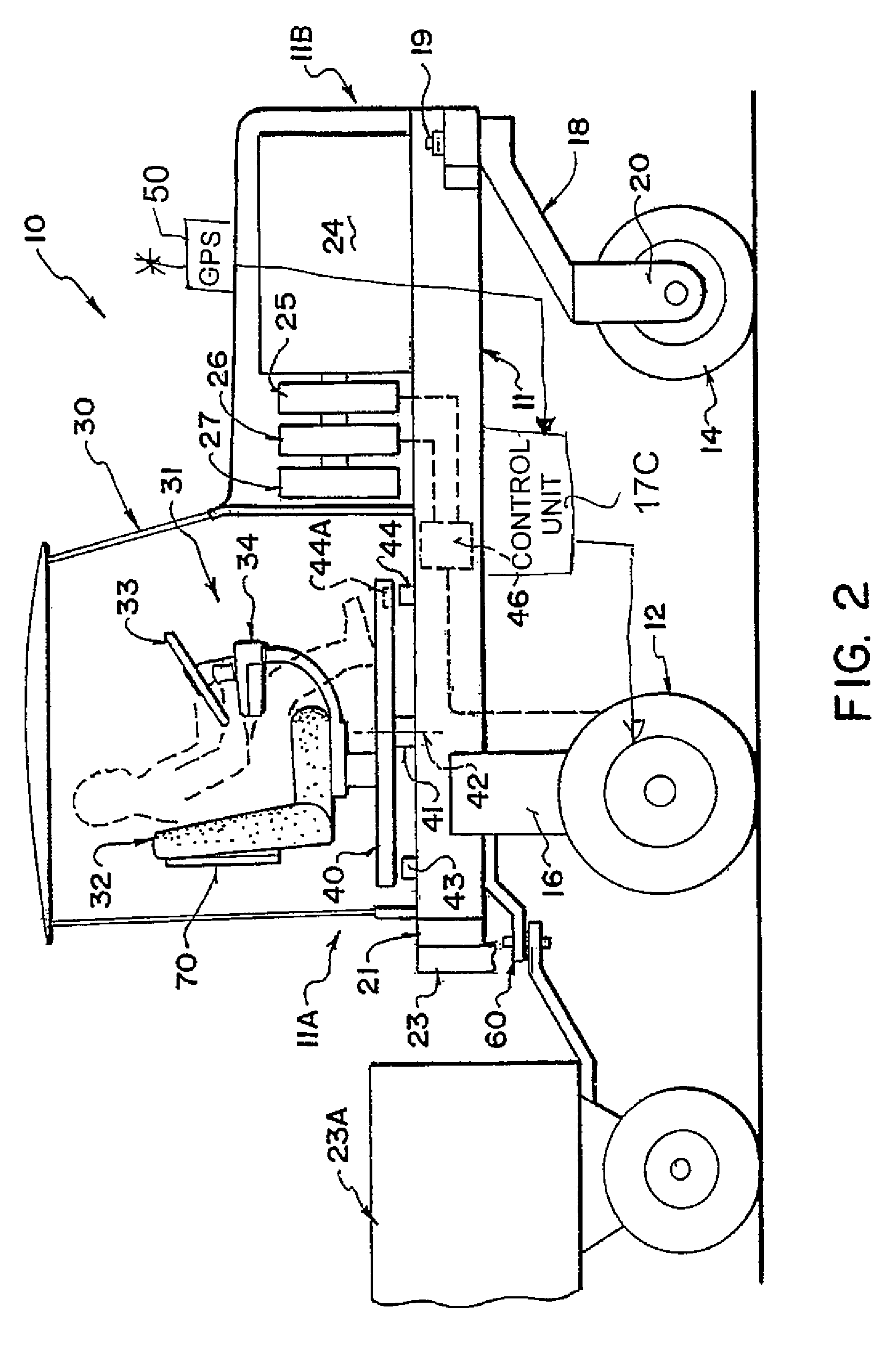

Speed and steering control of a hydraulically driven tractor

ActiveUS8985252B2Minimal displacementReduce in quantityAlternative steering controlGuiding agricultural machinesHydraulic motorAutomatic steering

A tractor has hydraulically driven wheels at a cab end and castor wheels at an engine end. Each driven wheels is driven by a hydraulic motor with a continuous adjustment of the motor displacement, with the motor being driven by a pump also having continuous displacement. The motor displacement is controlled by an electronic controller in response to stroking of the speed control lever to manage the displacement to provide required drive torques at different points in the stroke. There is provided an automatic steering system having a guidance controller arranged to receive GPS position information which controls the steering by differentially adjusting the displacement of the motors so that the automatic steering is independent of the manual steering which controls the pumps.

Owner:MACDON INDS

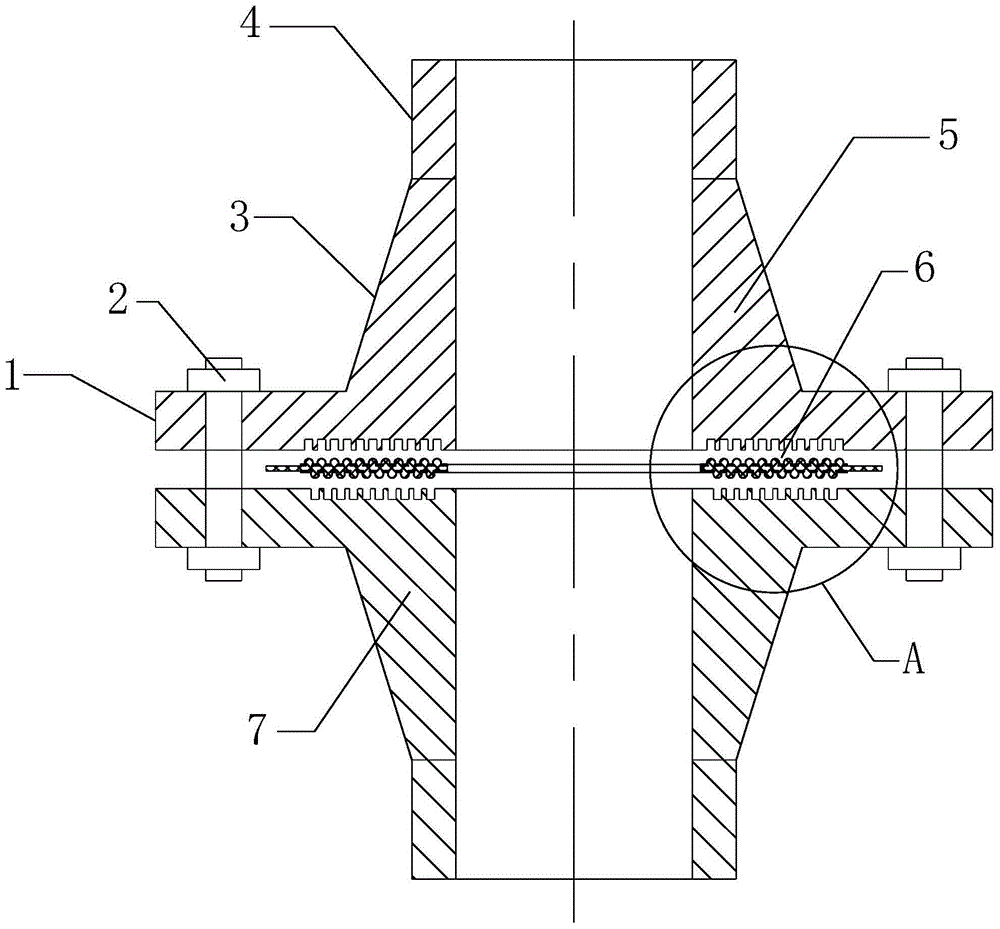

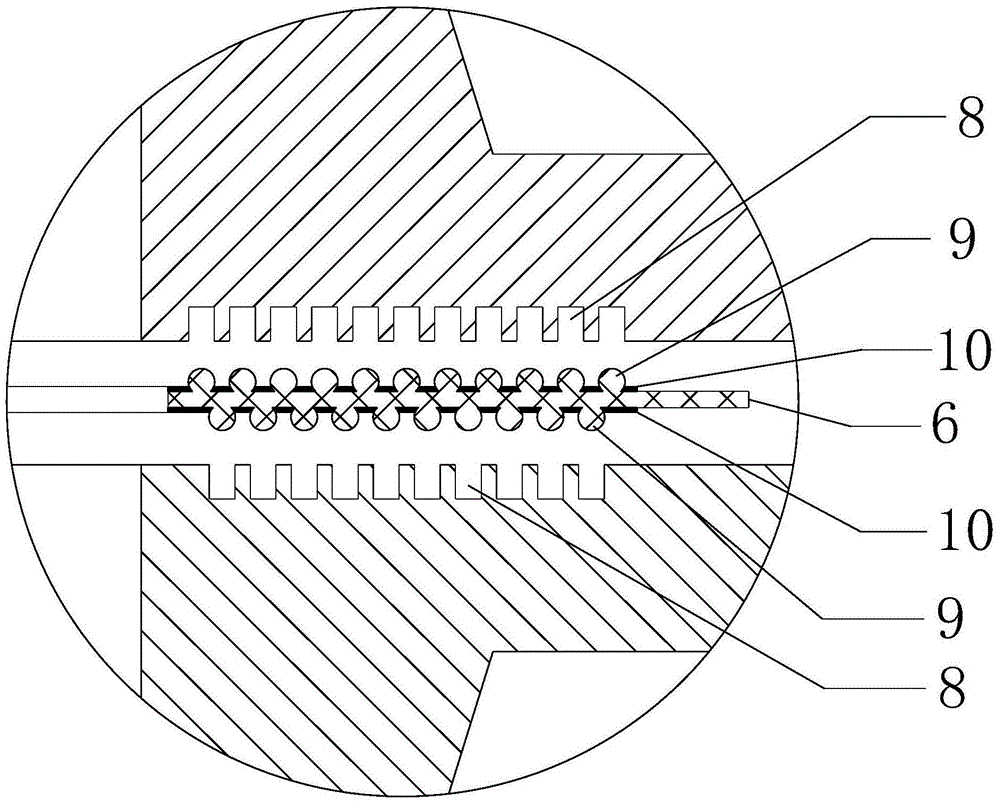

High-temperature flange sealing structure comprising flexible graphite metal omega-shaped tooth composite gasket

InactiveCN104565618APrevent leakageLeakage slowed or even eliminatedFlanged jointsInterference fitGraphite

The invention relates to the field of a pipeline flange sealing structure, in particular to a high-temperature flange sealing structure comprising a flexible graphite metal omega-shaped tooth composite gasket. The high-temperature flange sealing structure is characterized by comprising an upper flange, a lower flange and the flexible graphite metal omega-shaped tooth composite gasket. The upper surface and the lower surface of a metal frame of the flexible graphite metal omega-shaped tooth composite gasket are provided with annular boss in multiple circles respectively, the annular bosses are provided with omega-shaped sections and arranged at equal distance, the planar parts of the upper and lower surfaces of the flexible graphite metal omega-shaped tooth composite gasket are provided with flexible graphite layers, annular grooves matched with the annular bosses are arranged on the contact surfaces of the upper flange, the lower flange and the flexible graphite metal omega-shaped tooth composite gasket and provided with rectangular sections, the annular bosses are inserted into the annular grooves correspondingly and are in interference fit with the same. The high-temperature flange sealing structure can be applied to high-temperature and -pressure working conditions, excellent tightness can be kept for a long time, and leak of the flanges can be effectively prevented.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

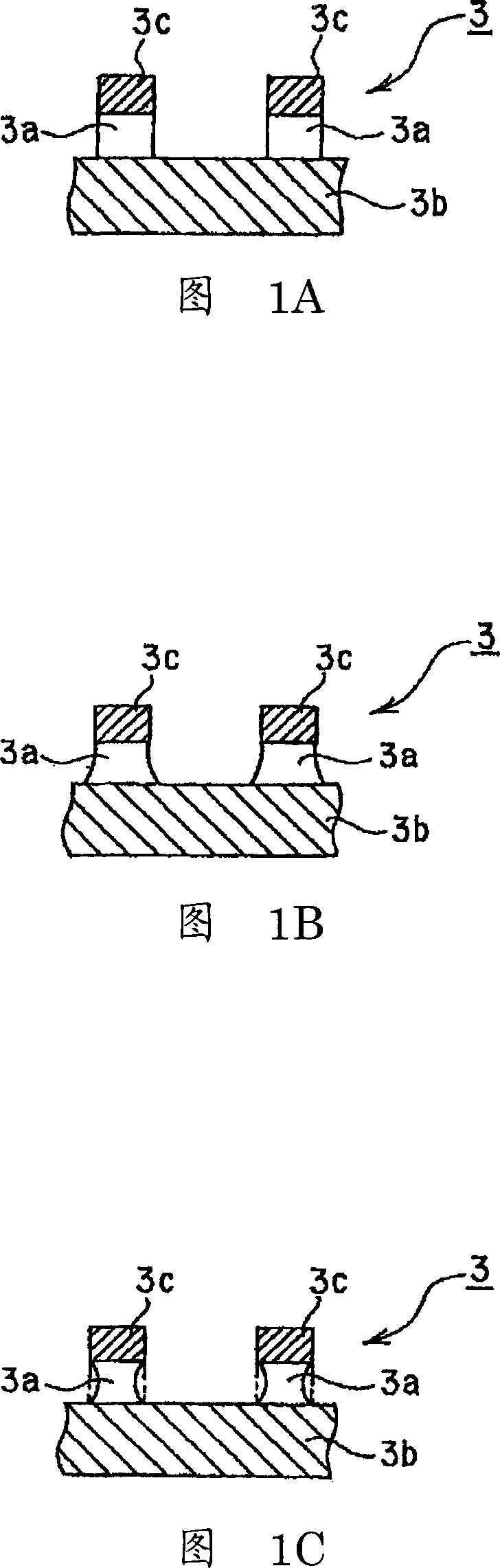

Masking material, piezoelectric vibrator, method of manufacturing piezoelectric vibrator, oscillator, electronic apparatus, and timepiece

InactiveCN102195588AUniform thicknessNo difference in thermal expansionImpedence networksVacuum evaporation coatingElectronMaterials science

Provided are a masking material capable of suppressing the occurrence of pattern blurring when forming a pattern on a substrate by a sputtering method, a piezoelectric vibrator using the masking material, a method of manufacturing the piezoelectric vibrator, and an oscillator, an electronic device, and a radio-controlled timepiece each having the piezoelectric vibrator. A masking material which is used when forming a pattern on a substrate by a sputtering method includes openings corresponding to the pattern, and portions where the openings are not formed have a uniform thickness.

Owner:SII CRYSTAL TECH

Grill bearing baffler of shell-and-tube heat exchanger

InactiveCN1834566AHigh strengthImprove rigidityHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

The present invention discloses a shell-and-tube heat exchanger grille support baffle device. It includes heat exchange tube and heat exchanger shell body, also includes grille and limited ring. The described grille is one which is formed from two gralled plates which are staggered at 90deg. and alternatively arranged and has four curved fasteners and eight supporting points. The described heat exchange tube is fastened and supported by said grille, so that the strength and rigidity of the heat exchange tube can be greatly raised, and the heat exchange efficiency of the heat exchanger also is raised.

Owner:SOUTH CHINA UNIV OF TECH

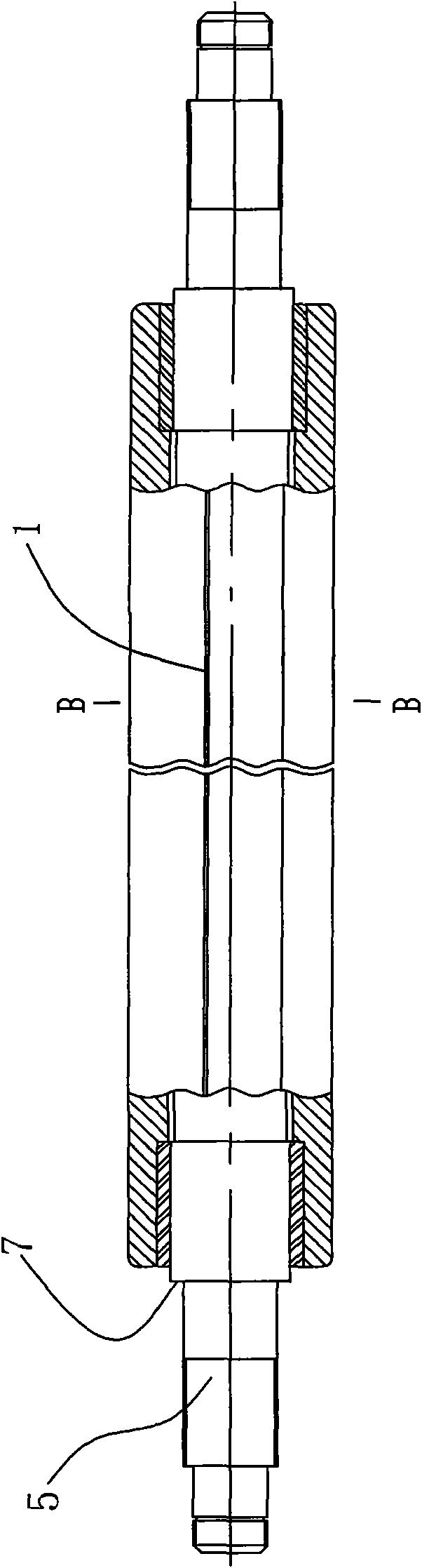

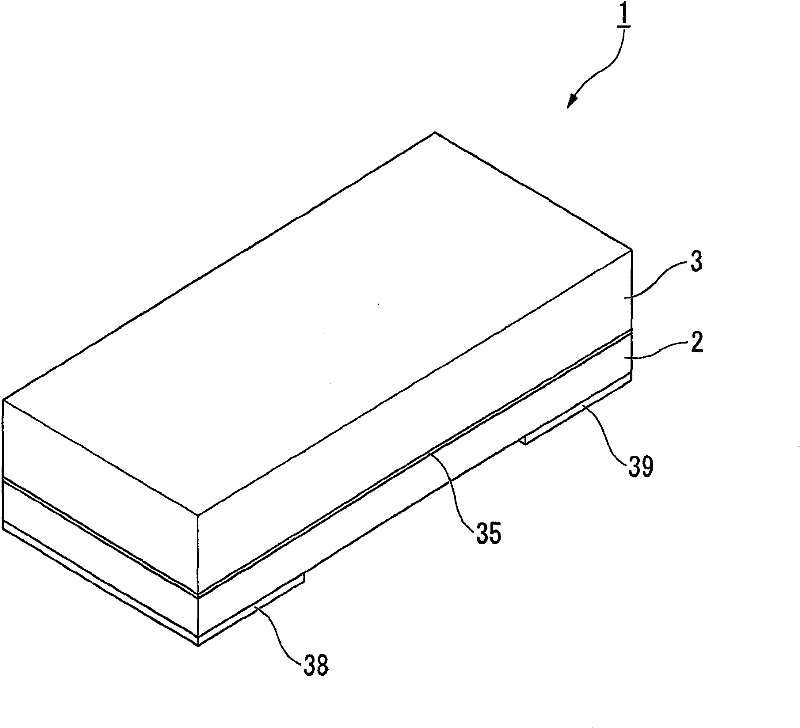

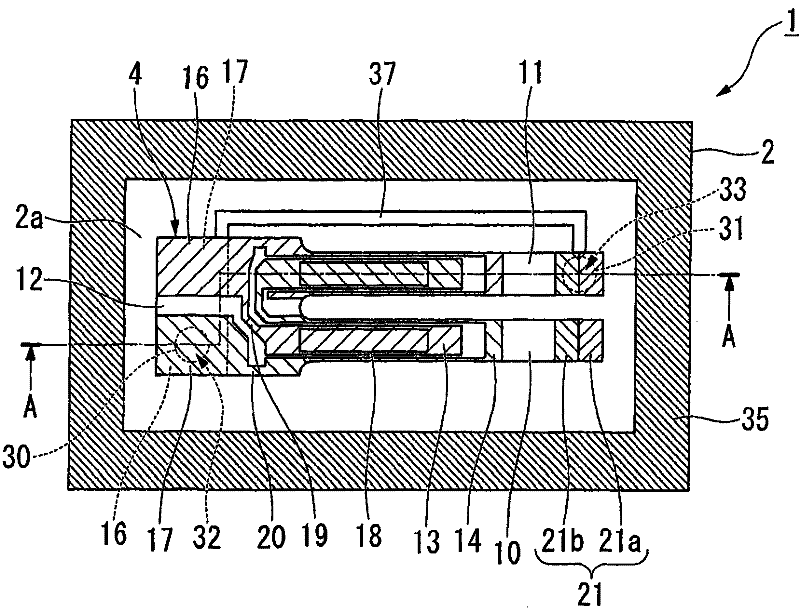

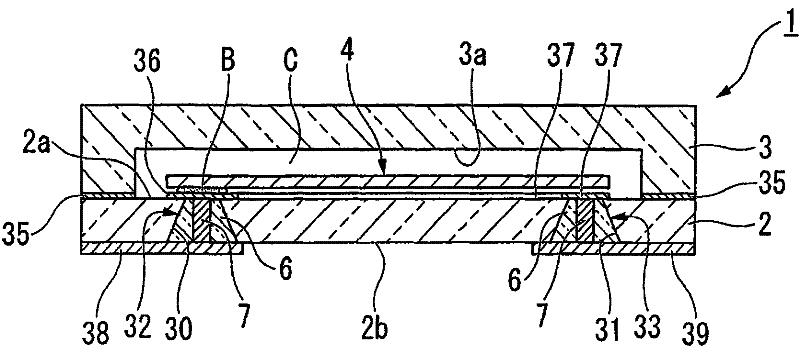

Spindle motor, disc driving apparatus having the same, and production method thereof

InactiveCN1734891AAvoid deformationStrain reliefRecord information storageSliding contact bearingsEngineeringScrew thread

The present invention provides a small and thin spindle motor in which no uneven pressure is applied to a recording medium when the recording medium is fixed to a hub, a disc driving apparatus having the spindle motor, and a production method thereof. The spindle motor comprises: a sleeve which is supported by a fixed shaft and rotates around a predetermined axis; and a hub provided on an outer peripheral portion of the sleeve, which includes: a tubular portion to be inserted into a central hole of a recording medium having a disc shape, which is coaxial with the sleeve and has a male thread formed on an outer peripheral surface; and a first receiving surface which is connected to the tubular portion and which holds the recording medium to the axis.

Owner:PANASONIC CORP

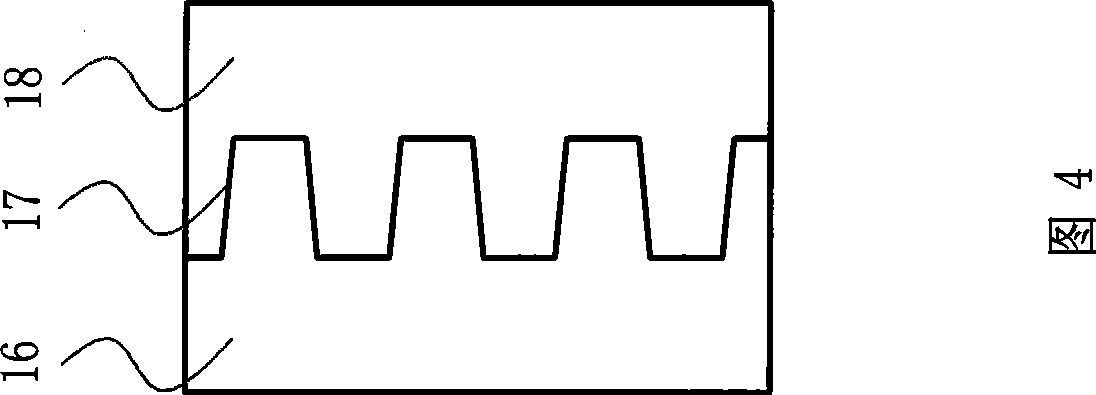

Multi-leaf collimator flexible regulating type encoder closed-loop control system

ActiveCN105425646AGuaranteed accuracyDoes not affect linear motionUsing optical meansProgramme control in sequence/logic controllersLoop controlGrating

The invention discloses a multi-leaf collimator flexible regulating type encoder closed-loop control system. The multi-leaf collimator flexible regulating type encoder closed-loop control system comprises leaves, a grating scale, a mobile slide block, a driving mechanism, a sensor and an integrated circuit board. The mobile slide block is connected with the leaves, and the mobile slide block is clamped on the grating scale and can freely slide along the grating scale. The sensor is fixed on the mobile slide block, and the sensor and the integrated circuit board are connected via electric signals. The driving mechanism is used for driving the leaves to perform linear reciprocating movement. Detection precision of the leaf position can be enhanced, installation is convenient, time of replacing consumables can be greatly reduced, equipment usage rate can be enhanced and equipment use cost can be reduced.

Owner:CHENGDU EBRIDGE TECH

Etching device and etching method

ActiveCN101002514AEliminate deflectionInjection pressure reliefPrinted circuit liquid treatmentConductive material chemical/electrolytical removalElectrical conductorWrap around

An etching device for forming a conductor pattern by applying etching to a wiring board. The etching device comprises a drum, a chamber, and nozzle heads. The drum is formed to be rotatingly run in such a state that a flexible wiring board is wrapped around the surface of the drum. The chamber is a room for storing an etching liquid under a specified pressure. The nozzle heads are disposed at the upper part of the chamber in proximity to the surface of the drum, and formed to linearly jet the etching liquid pressurized in the chamber from nozzle holes against the surface of the drum.

Owner:DEXERIALS CORP

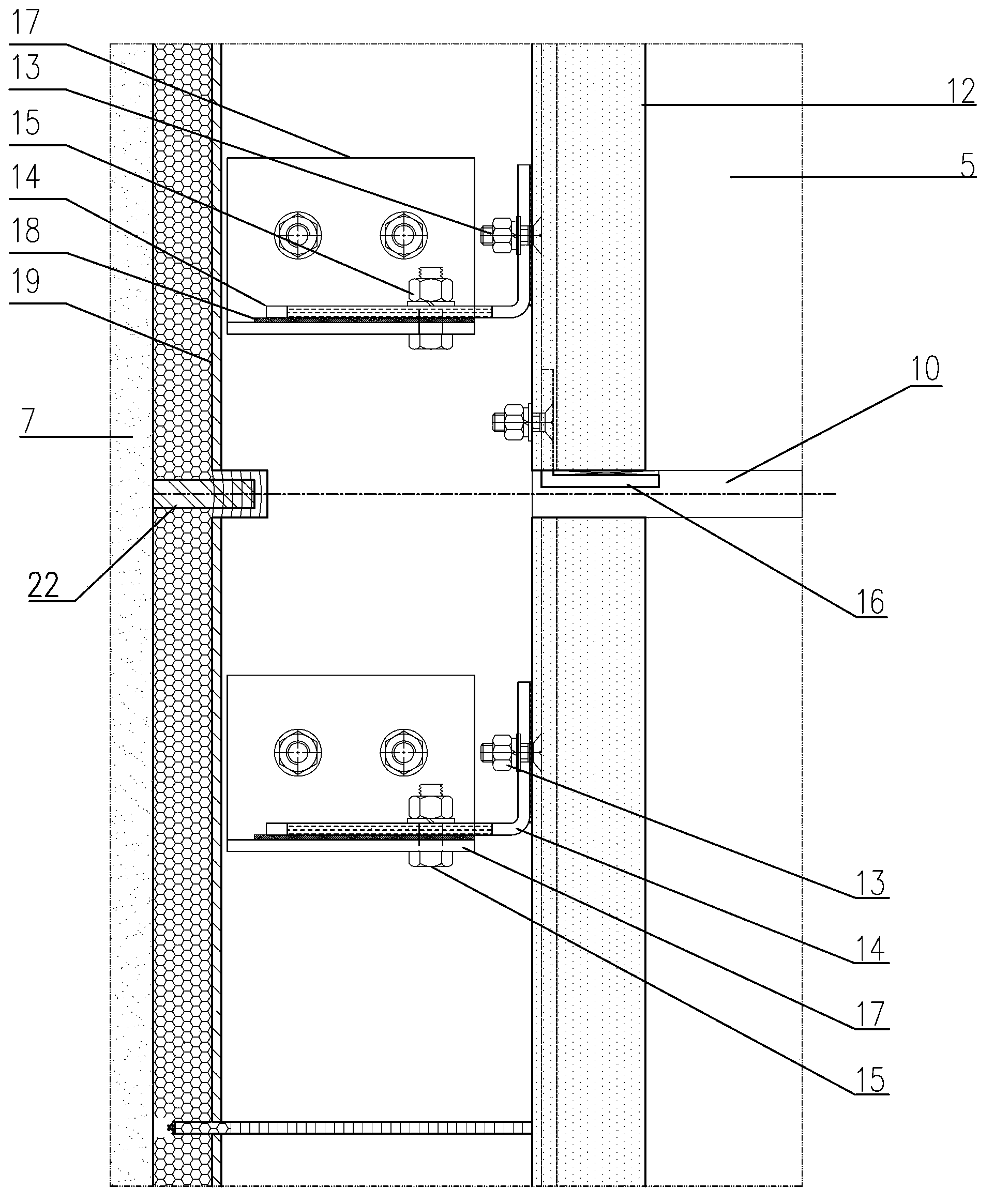

Corner and edge system of flexible structural system curtain wall

ActiveCN103437466ASolve the damageSolve the problem of surface material damageWallsVertical edgeStructural system

The invention provides a corner system of a flexible structural system curtain wall. A corner formed by end side vertical edges of curtain wall panels at both sides is provided with a rigid vertex angle pillar; the vertical edges, near the corner, of the curtain wall panels, are telescopically and fixedly arranged onto fixed connecting devices fixed to the vertex angle pillar; a seal structure of each vertical gap between the curtain wall panels and the fixed connecting devices is a telescopic seal structure; the end side vertical edges of the curtain wall panels are also provided with a corner supporting member; one end of the corner supporting member is hinged to the vertex angle pillar; the other end of the corner supporting member is hinged to a major structure. According to an edge system, the end side vertical edges, fixedly connected with the major structure, of curtain wall panels are telescopically and fixedly arranged onto the major structure, and the seal structure of each curtain wall panel is the telescopic seal structure. According to the corner and edge systems provided by the invention, the problem that the seal structure of the curtain wall is damaged or plane materials are damaged due to large-deflection deformation of the flexible structural system curtain wall can be well solved.

Owner:JANGHO GRP

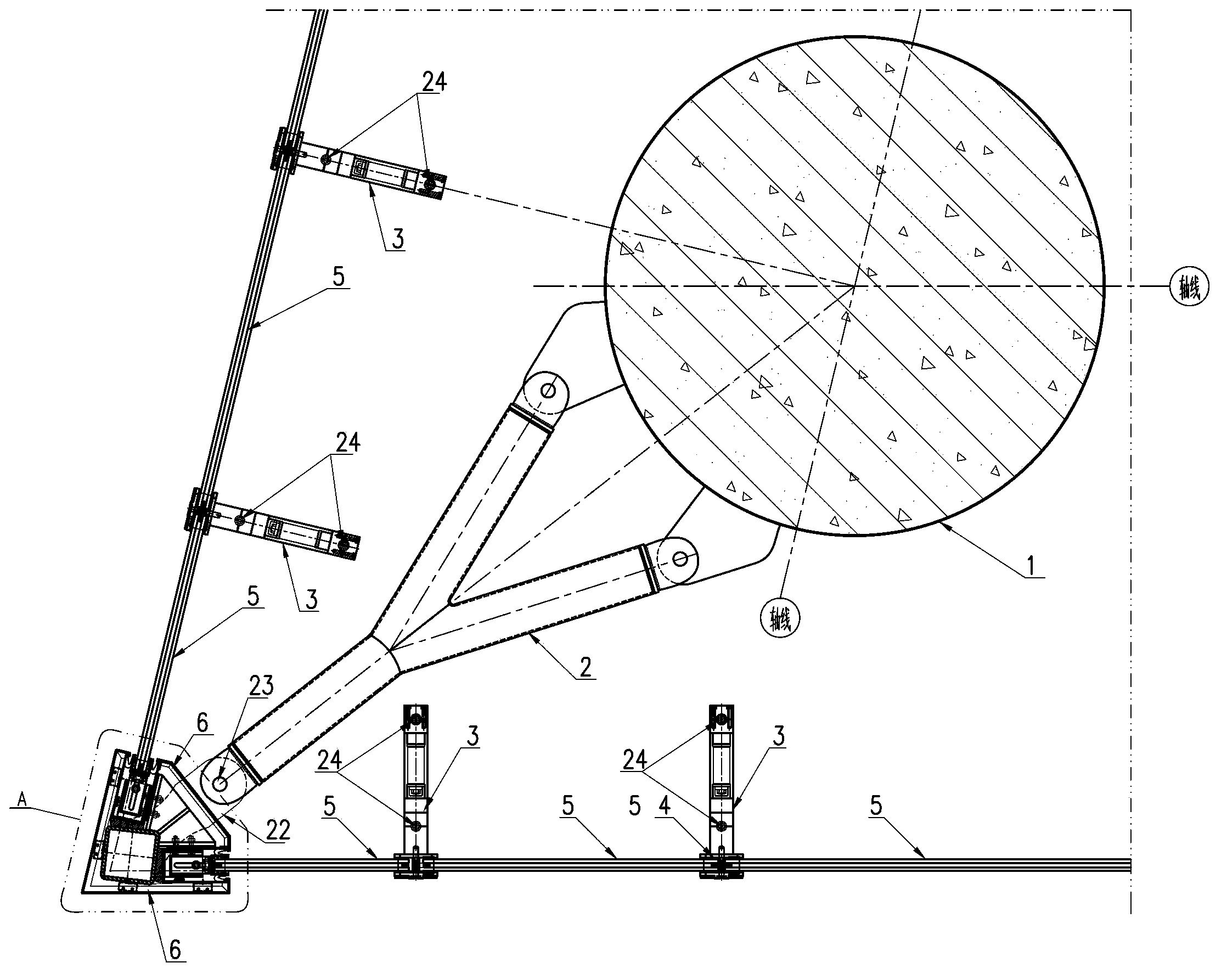

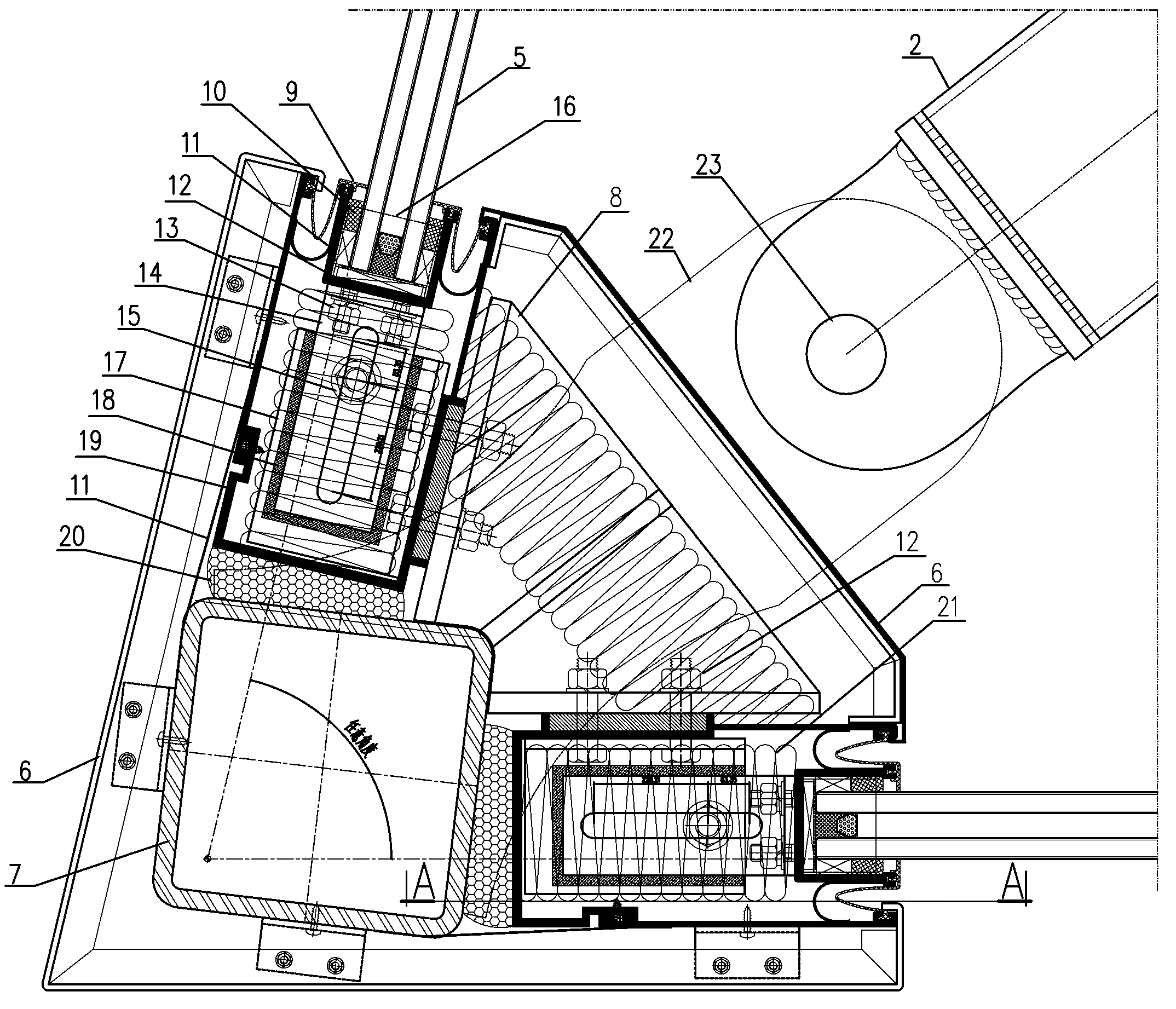

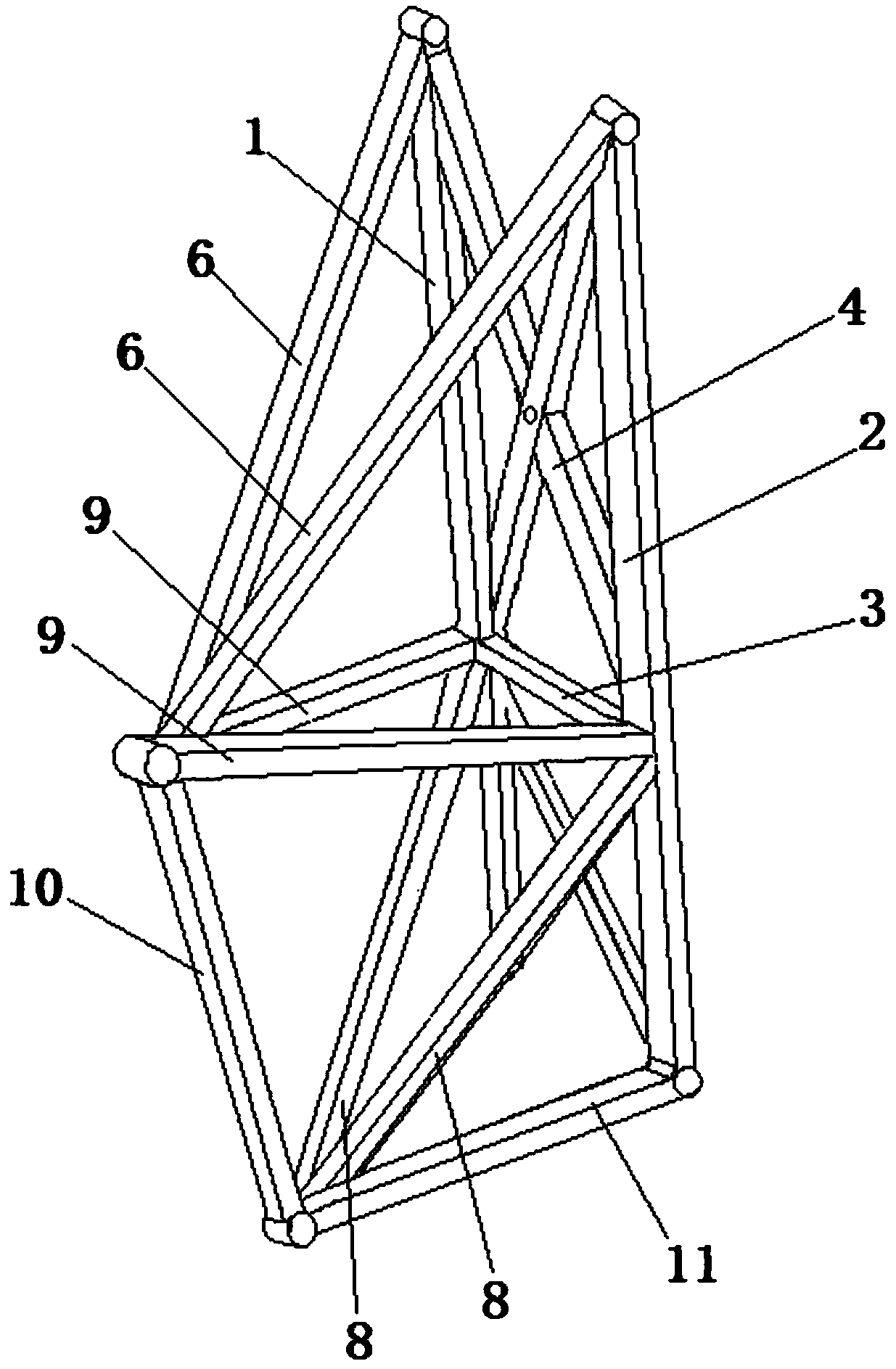

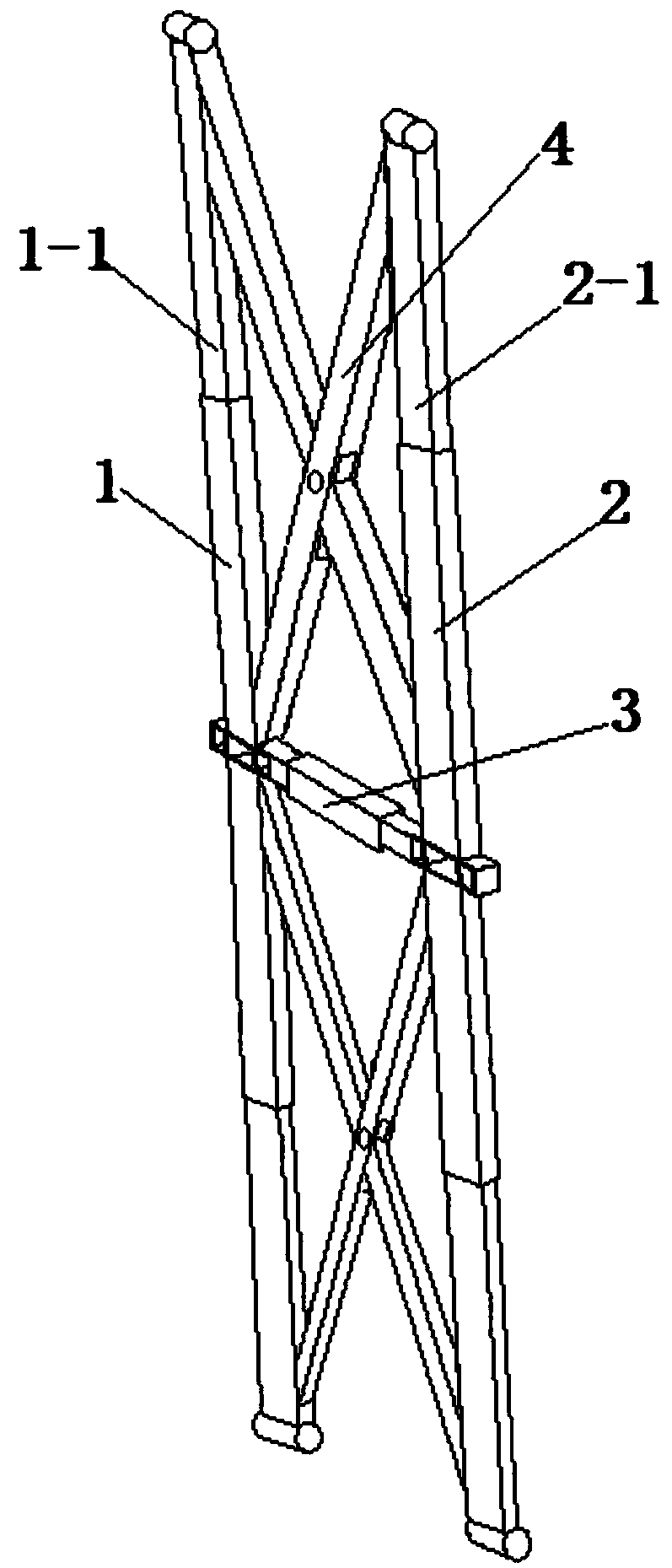

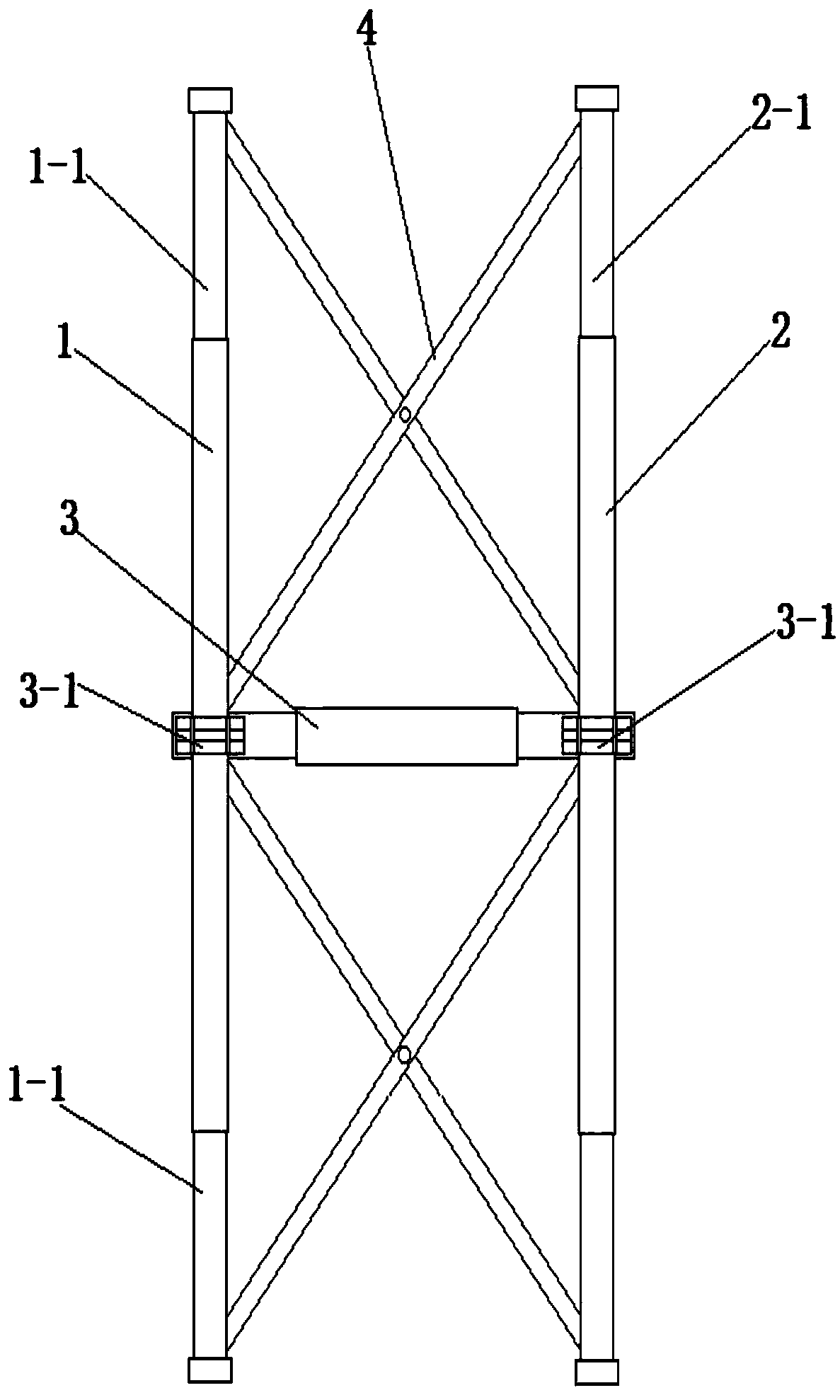

Foldable mechanical arm steel frame

The invention discloses a foldable mechanical arm steel frame. The foldable mechanical arm steel frame comprises a fixed steel frame, a first foldable steel frame and a second foldable steel frame. The fixed steel frame comprises a first stand rod, a second stand rod, an oblique support and a middle cross bar. The first foldable steel frame comprises two first top movable rods, a first middle movable rod and two first bottom movable rods. The second foldable steel frame comprises two second top movable rods, a second middle movable rod and two second bottom movable rods. The foldable mechanical arm steel frame is simple in structure and relatively small in weight; the foldable mechanical arm steel frame can be folded and retracted when not used, the space occupation is greatly reduced; thefoldable mechanical arm steel frame can be unfolded when used, the stress area is increased, the stress load is increased, and the situation that a mechanical arm is damaged due to too large stress of a local part is avoided; and the foldable mechanical arm steel frame can adapt to different working environments through multiple kinds of deformation and can be used on various engineering machines.

Owner:CHENGDU GENCHI TECH CO LTD

Attachment of aircraft ribs to spars having variable geometry

ActiveUS9346533B2Eliminate deflectionReduce or prevent a moment or twisting action of the tubular sparPlungersSpars/stringersVariable geometryAirplane

Owner:THE BOEING CO

Auxiliary forming positioning cold heading structure

PendingCN111687357AImprove positional accuracySimple structureForging/hammering/pressing machinesForging press detailsPhysicsEngineering

Owner:厦门金波贵金属制品有限公司

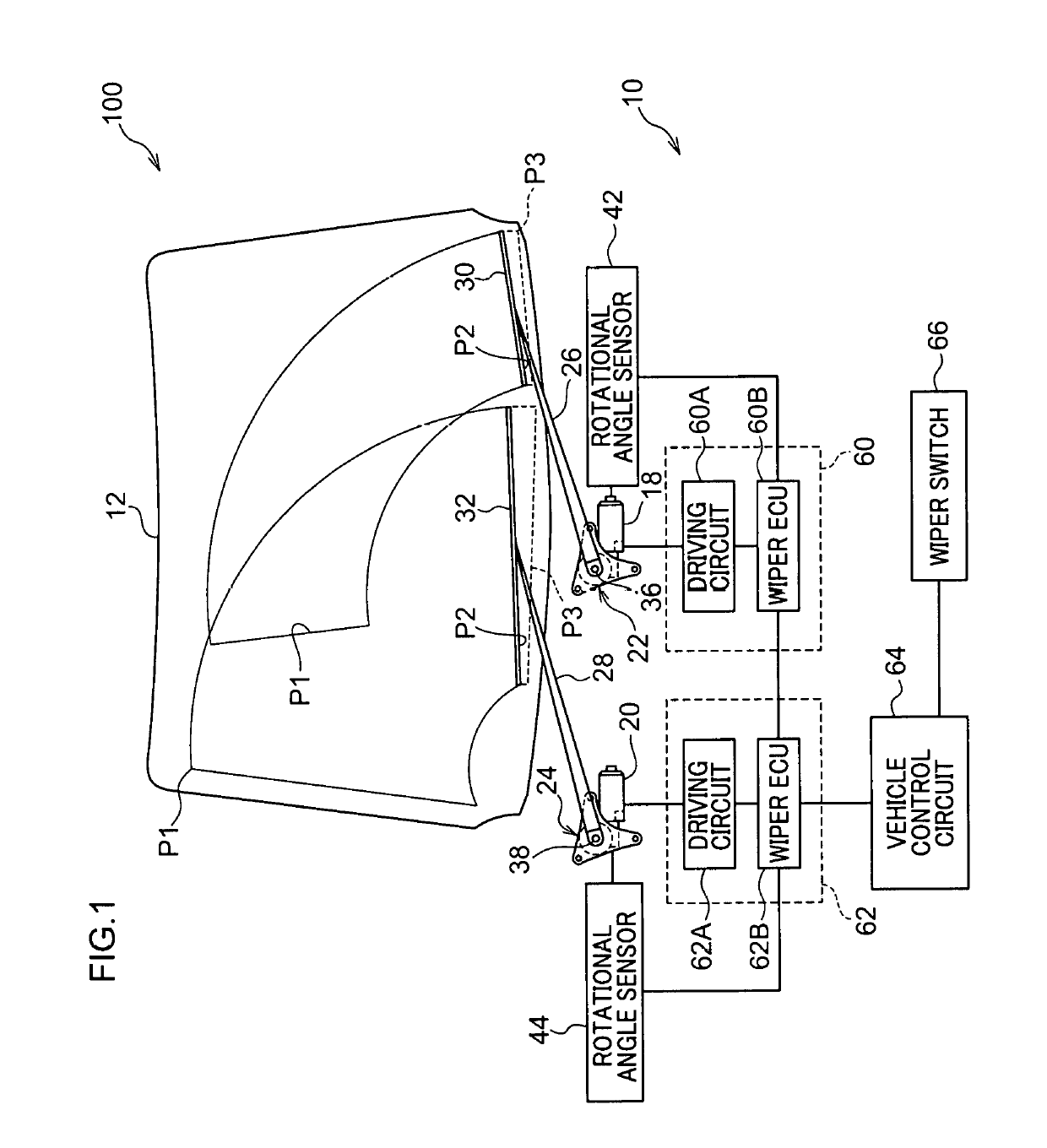

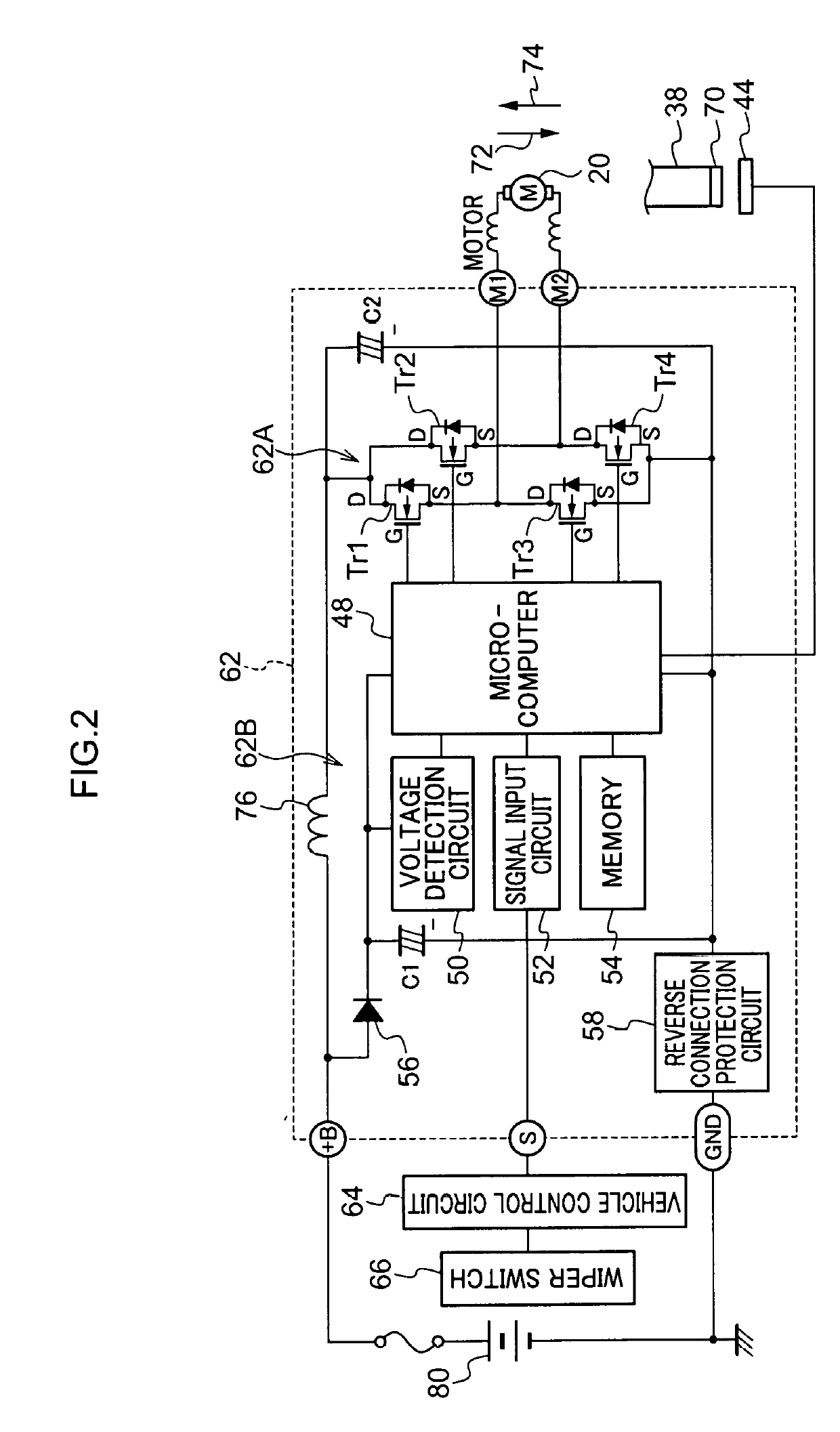

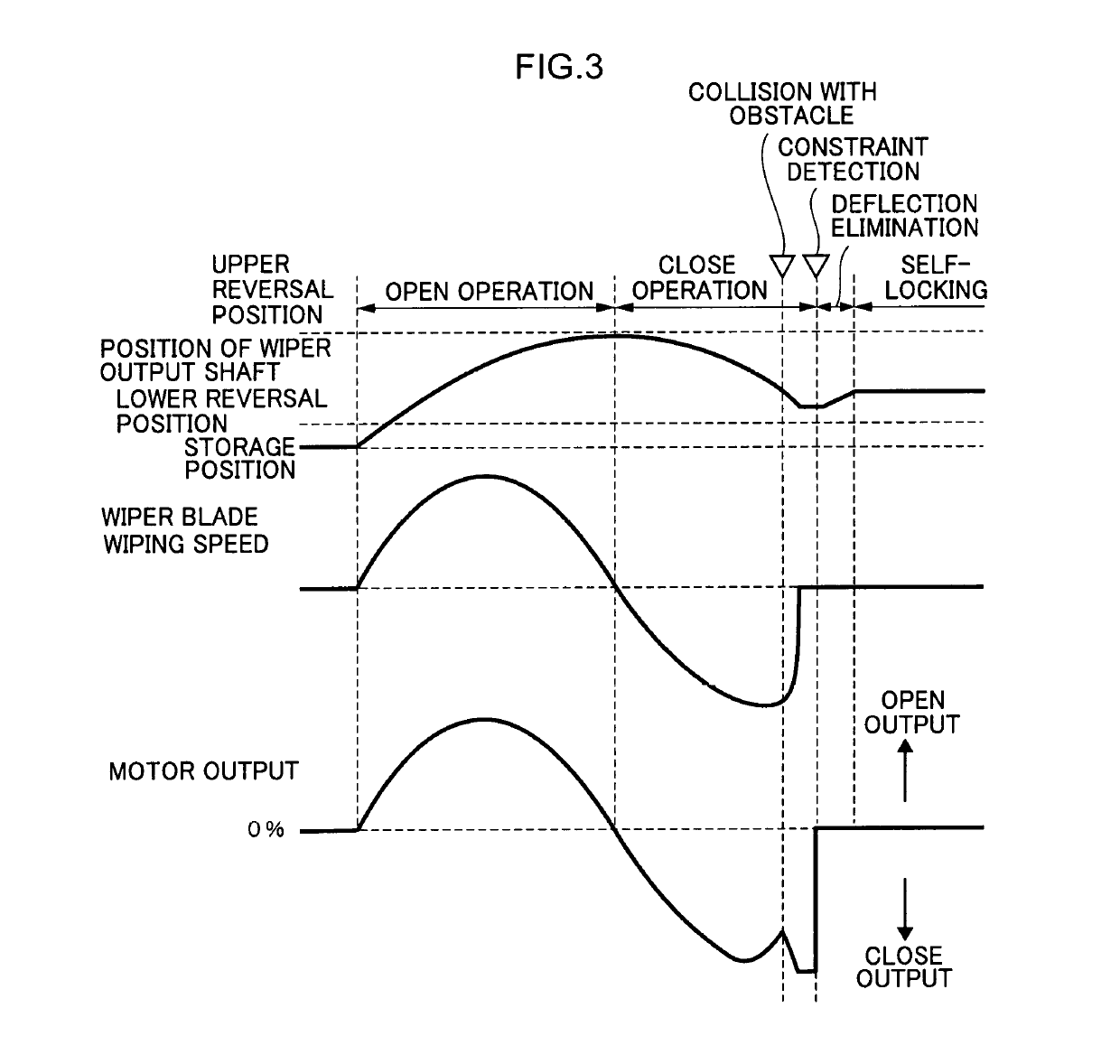

Wiper control device

ActiveUS20190263359A1Exclude influenceEliminate deflectionVehicle cleaningControl theoryControl circuit

A wiper control circuit stops the supply of power for rotating a wiper motor in a case in which a wiper blade is stopped before a storage position. In a case in which the amount of change in a rotational angle of an output shaft before and after stopping the supply of power for rotating the wiper motor, which is detected by a rotational angle sensor, has reached a predetermined range, the wiper control circuit performs self-locking to prevent the rotation of the output shaft in a state after the supply of power is stopped.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com